EAP 110

ANNUNCIATOR

INSTALLATION, OPERATING &

SERVICE MANUAL

PM058 Rev 2 06/01/18

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

EAP 110 ANNUNCIATOR

CONTENTS

1. INTRODUCTION 4

1.1. PRODUCT REVISION HISTORY 4

1.2. GENERAL DESCRIPTION 4

2. INSTALLATION 6

2.1. GENERAL INFORMATION 6

2.2. BATTERY SUPPLY INPUT 6

2.3. EXTERNAL CONTACT INPUTS 7

2.4. REMOTE COMMUNICATION WIRING 7

2.5. ANNUNCIATOR CONTROL WIRING 8

2.6. ANNUNCIATOR LOCATION/INSTALLATION 8

3. DESCRIPTION 11

3.1. LEXAN FACEPLATE 11

3.2. PRINTED CIRCUIT BOARD 12

4. OPERATING INSTRUCTIONS 18

4.1. SEQUENCE OF OPERATION 18

4.2. CONTROL PUSH-BUTTONS 18

5. PROGRAMMING INSTRUCTIONS 19

6. SPECIFICATIONS 20

7. CONNECTION DIAGRAMS 21

PM058 Rev2 06/01/18 Thomson Technology

EAP 110 ANNUNCIATOR

8. ANNUNCIATOR LABELS 22

8.1. NFPA 110 LABELS 22

8.2. CSA 282 LABELS 23

8.3. MEC 20 (GROUP 2 FAULT) LABELS 24

8.4. MEC 2 (GROUP 2 FAULT) LABELS 25

9. TROUBLE SHOOTING 26

10. NOTES 27

PM058 Rev2 06/01/18 Thomson Technology

1. INTRODUCTION

1.1. PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to

this product since the original release.

Software Version

1.0 02/07/31 Original version.

1.1 06/01/17 Corrected phenomena of glowing LEDs. Enhanced operation under

extreme noise EMI/RFI environment

Operating & Service Manual Version

EAP 110 ANNUNCIATOR

Rev 2 06/01/17 Changed Software version. Added MEC 2 Group information &

misc. updates

Rev 1 05/05/18 Updated Annunciator labels - Section 8.

Rev 0 02/07/31 Original release.

Contact Thomson Technology, to obtain applicable instruction manuals. Soft

copy of most current version is available at www.thomsontechnology.com.

1.2. GENERAL DESCRIPTION

The EAP 110 annunciator is designed for remote fault annunciation of emergency

standby generator sets utilizing Thomson Technology MEC 2 & MEC 20 Engine

Controllers. The design uses an 8 conductor RS 422 communication data link to

provide the control & monitoring signals between the engine controller and remote

annunciator. The communication link allows a simple, cost effective system installation

at any building site. Up to 20 individual fault conditions are remotely monitored utilizing

both visual LED lights & audible alarm annunciation. Lamp test and alarm horn silence

front mounted pushbuttons are provided. Each fault is individually programmable for

audible horn operation and alarm labels are field configurable. Operation logic includes

a “auto-ringback” feature to annunciate subsequent alarm conditions. For applications

PM058 Rev 2 06/01/18 Thomson Technology

4

EAP 110 ANNUNCIATOR

requiring additional alarm annunciation from remote sensing contacts, the EAP 110 can

accept up to 4 hard wired contact inputs dependant upon the alarm configuration,

separate from the Annunciator communication data link. The EAP 110 is DC powered

from the same 12 or 24V engine starting battery as the engine controller is connected to.

Two EAP 110 annunciators can be interconnected together via the communication link

to allow up to 40 remote annunciator points from a single engine controller (consult

Thomson Technology for further details). The standard features of the EAP 110 meet

and exceed all requirements of NFPA 110, NFPA 99 & CSA 282-00 building code

standards for Emergency Standby Generator systems.

CAUTION

contents subject to damage by

STATIC ELECTRICITY

This equipment contains static-sensitive parts. Please observe the following anti-static

precautions at all times when handling this equipment. Failure to observe these

precautions may cause equipment failure and/or damage.

• Discharge body static charge

before handling the equipment (contact a

grounded surface and maintain contact while handling the equipment, a

grounded wrist strap can/should also be utilized).

• Do not touch any components on the printed circuit board with your hands

or any other conductive equipment.

• Do not place the equipment on or near materials such as Styrofoam,

plastic and vinyl. Place the equipment on grounded surfaces and only

use an anti-static bag for transporting the equipment.

PM058 Rev 2 06/01/18 Thomson Technology

5

2. INSTALLATION

2.1. GENERAL INFORMATION

The following installation guidelines are provided for general information only

pertaining to typical site installations. For specific site installation information,

consult Thomson Technology as required.

EAP 110 ANNUNCIATOR

NOTE:

Installations should be done according to all

applicable electrical regulation codes as

required.

CAUTION!!!

All installation and/or service work performed must be done by qualified

personnel only. Failure to do so may cause personal injury or death.

2.2. BATTERY SUPPLY INPUT

The EAP 110 can operate on any battery supply from 10 to 30 volts DC. The

battery DC negative or common conductor must be grounded to the main

generator-set frame ground. The EAP 110 is internally protected by a solid state

type fuse that protects it from inadvertent shorts. The solid state fuse will

automatically reset when the overcurrent condition is removed. Wiring from the

engine cranking battery to the annunciator should conform to the following

guidelines to avoid possible malfunction and/or damage.

2.2.1. Avoid wiring from the engine starter terminals - wiring should go

from the engine control panel.

directly

CAUTION!!!

The battery charger must be turned off before battery cables are

removed from the battery (i.e. for servicing). Failure to do so may

subject the annunciator to an overvoltage condition in which

damage may result.

PM058 Rev 2 06/01/18 Thomson Technology

6

EAP 110 ANNUNCIATOR

2.2.2. Wiring from the engine control panel to the annunciator should be two #14 AWG (2.5mm

2

) wires.

2.2.3. Under noisy environments (i.e. gas engines with high voltage ignitions,

etc.), wiring from battery should be a twisted pair of #14 AWG (2.5mm

wires.

2.3. EXTERNAL CONTACT INPUTS

All external contact inputs to the EAP 110 are optically isolated and filtered for

protection from noise spikes and transients. Wiring should conform to the

following guidelines to avoid possible Annunciator malfunction and/or damage

2.3.1. External contact wires (2 - #14 AWG (2.5mm

separate conduit.

2.3.2. Avoid wiring near AC power cables to prevent pick-up of induced

voltages.

2.3.3. An interposing relay may be required if field wiring distance is excessively

2

) should be run in a

2

)

long (i.e. greater than 100 feet (30m) and/or if a remote contact has a

resistance of greater than 5.0 ohms.

2.3.4. The external contacts (if used) must be voltage free (i.e. dry contact).

The use of a “powered” contact will damage the Annunciator.

2.4. REMOTE COMMUNICATION WIRING

All interconnecting wiring to/from the EAP 110 Annunciator communication port

shall utilize #22 AWG (min.) 8 conductor, twisted, shielded cable with RJ45

connectors. The drain (shield) wire must be connected at the Engine Controller

end only. Refer to connection diagram in Section 7 for further information.

Communication cable from the Annunciators’ com port must be suitably routed to

protect it from sources of electrical interference. Guidelines for protection against

possible electrical interference are as follows:

• Use high quality, 8 conductor shielded cable only with drain wire

grounded at the Engine Controller end only.

• Route the communication cable at least 3 M (10”) away from sources of

electrical noise such as variable speed motor drives, high voltage power

conductors, UPS systems, transformers, rectifiers etc.

• Use separate, dedicated conduit runs for all communication cables. Do

not tightly bundle communication cables together in the conduit. Conduit

PM058 Rev 2 06/01/18 Thomson Technology

7

EAP 110 ANNUNCIATOR

should be ferromagnetic type near sources of possible electrical

interference. The entire length of conduit should be grounded to building

earth ground.

• When communication cables must cross over low or high voltage AC

power conductors, the communication cables must cross at right angles

and not in parallel with the conductors.

For additional information on protection against electrical interference, contact

Thomson Technology factory.

2.5. ANNUNCIATOR CONTROL WIRING

As a minimum, all control wiring shall conform to the local regulatory authority on

electrical installations. Specific wire sizes for typical circuits (of distances up to

1000ft (300m)

2.5.1. Battery Control Power #14 AWG (2.5mm

2.5.2. External Fault Contacts #16 AWG (1.5mm

2.5.3. Remote Communication Wiring #22 AWG (0.34mm

Ê

) are as follows:

2

)

2

)

2

)

8 Conductor Shielded Cable

Ê

For distances exceeding 1000 Ft. (300m) consult THOMSON TECHNOLOGY.

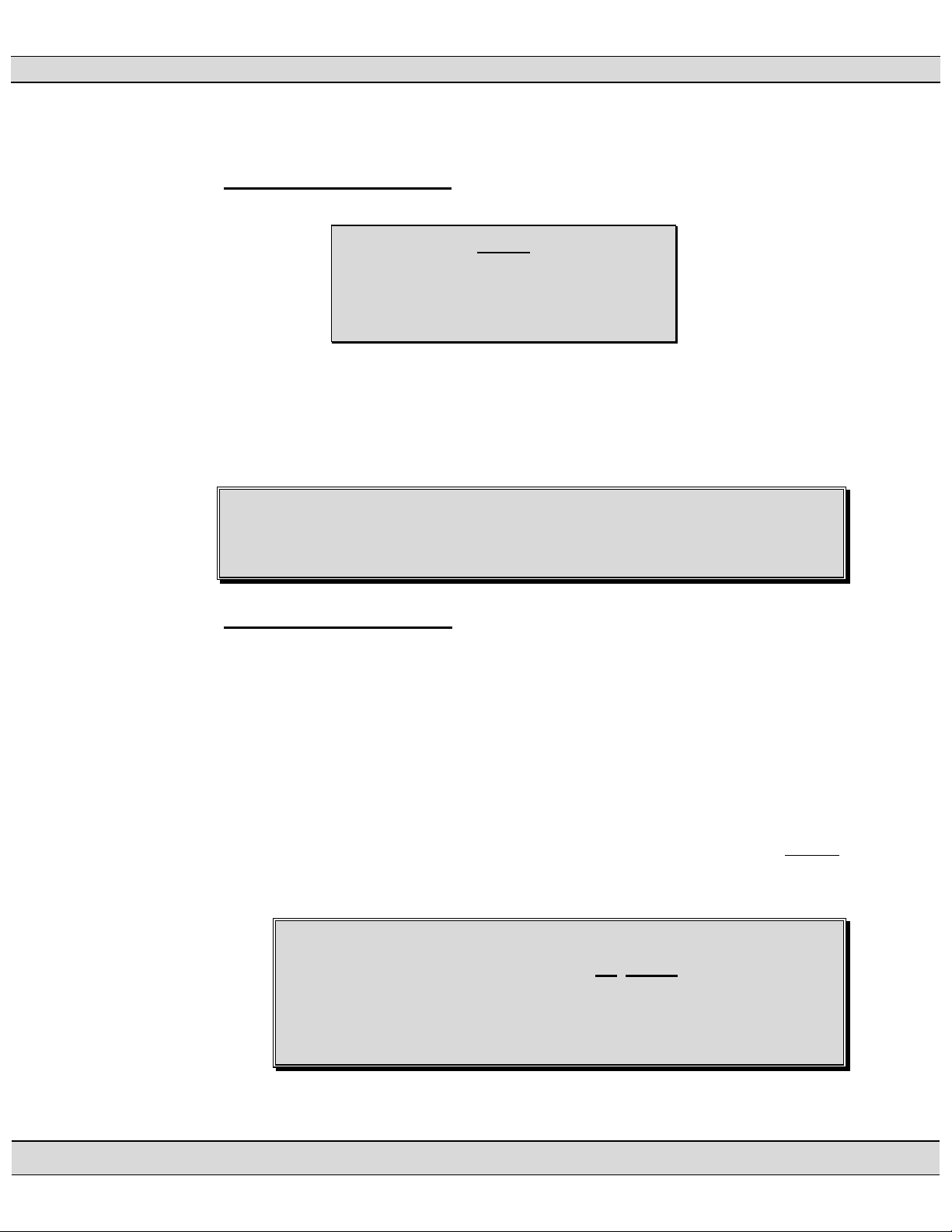

2.6. ANNUNCIATOR LOCATION/INSTALLATION

The annunciator is to be mounted indoors in a dirt free, dry location away from extreme

heat sources on a building wall at a suitable location for operating personnel. The

annunciator is to be mounted using four screws. The annunciator must be mounted

within 1000 feet wiring distance from the MEC 20/MEC 2 Engine controller using an 8

conductor shielded cable. The standard annunciator is suitable for surface mounting as

shown in FIGURE #1. The annunciator is available with an optional adapter plate for

flush mounting application as shown in FIGURE #2. Assembly details for the flush

mounting adapter are shown in FIGURE #3.

PM058 Rev 2 06/01/18 Thomson Technology

8

EAP 110 ANNUNCIATOR

EAP 110 Rear

Cover

6.0"

1.0"

6.0"

4.0"

1.0"

4.0"

4 Rear Cover

Mounting Holes

3/16"

DIAMETER

EAP 110 SURFACE MOUNTING

Enclosure Depth (from front faceplate)

= 3.0"

G:\ENGINEER\PRODUCTS\EAP110 Surface Mount.VSD

FIGURE #1

Flush Mount

Adapter Plate

7.0"

0.25"

EAP 110 Rear Cover

Cutout

(for 6" x 6" clearance)

7.0"

6.125"

6.125"

6.50"

6.50"

0.25"

4 Faceplate

Mounting Holes

3/16"

DIAMETER

EAP 110 FLUSH MOUNTING

Enclosure Depth (from front faceplate) = 3.0"

G:\ENGINEER\PRODUCTS\EAP110 Flush Mount.VSD

FIGURE #2

PM058 Rev 2 06/01/18 Thomson Technology

9

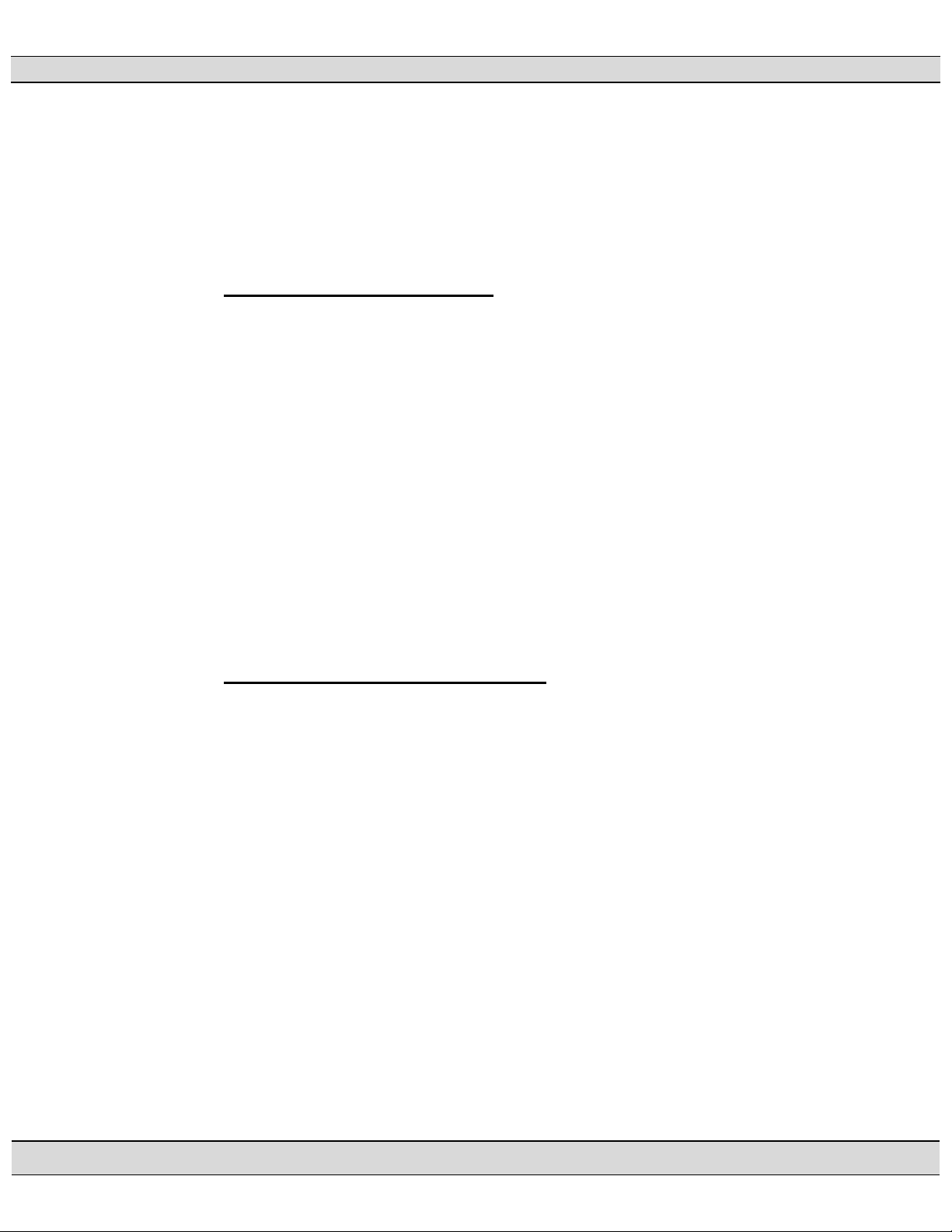

EAP 110 ANNUNCIATOR

Wall Edge

(Flush

Mounting)

6.0"

3.0"

EAP Flush Mounting

EAP Front

Faceplate

Plate (optional)

EAP 110 Assembly

(Side View)

Wall Edge

(Surface

Mounting)

EAP 110 Rear

Cover

FIGURE #3

G:\ENGINEER\PRODUCTS\EAP110 Assembly.VSD

PM058 Rev 2 06/01/18 Thomson Technology

10

EAP 110 ANNUNCIATOR

3. DESCRIPTION

The EAP 110 Annunciator consists of three parts: a Lexan/faceplate, a printed circuit board

(PCB) and a rear cover.

3.1. LEXAN FACEPLATE

The Lexan faceplate is shown as in FIGURE #4. The Lexan push-buttons and

LED’s are connected to the main PCB via plug-in ribbon cable.

EAP 110 Annunciator

Emergency

Stop

Overcrank

Shutdown

Overspeed

Shutdown

Low Oil

Pressure

Alarm

Low Oil

Pressure

Shutdown

Alarm

Silen ce

EPS

Supp ly ing

Load

Low Engine

Temperature

Alarm

Loss of

Speed Signal

Shutdown

High Engine

Temperature

Alarm

High Engine

Temperature

Shutdown

Lamp

Test

EPS Switch

Not in Auto

Weak B atte ry

Voltage

Low Battery

Voltage

High Battery

Voltage

Spare

(External Input #2)

Power On

Communication Fail

Spare

(Digita l Fault # 1 )

Spare

(Digita l Fault # 2 )

Battery

Charger

AC Fail

(Digita l Fault # 3 )

Low Fuel

Level

(Digita l Fault # 4 )

Spare

(External Input #1)

FIGURE #4

Alarm labels on the EAP 110 are removable through slots at the top edge of the

Lexan. The alarm labels are grouped in 4 rows of 5 labels each. Alarm Fault

circuits labels which are programmable in the MEC 2 or MEC 20 Engine

Controller can be relabeled on the EAP 110 Annuciator to correspond

accordingly. Alarm Fault circuits lights on the EAP which correspond to nonprogrammable MEC Engine Controller faults (e.g. Emergency Stop) cannot be

relabeled.

PM058 Rev 2 06/01/18 Thomson Technology

11

EAP 110 ANNUNCIATOR

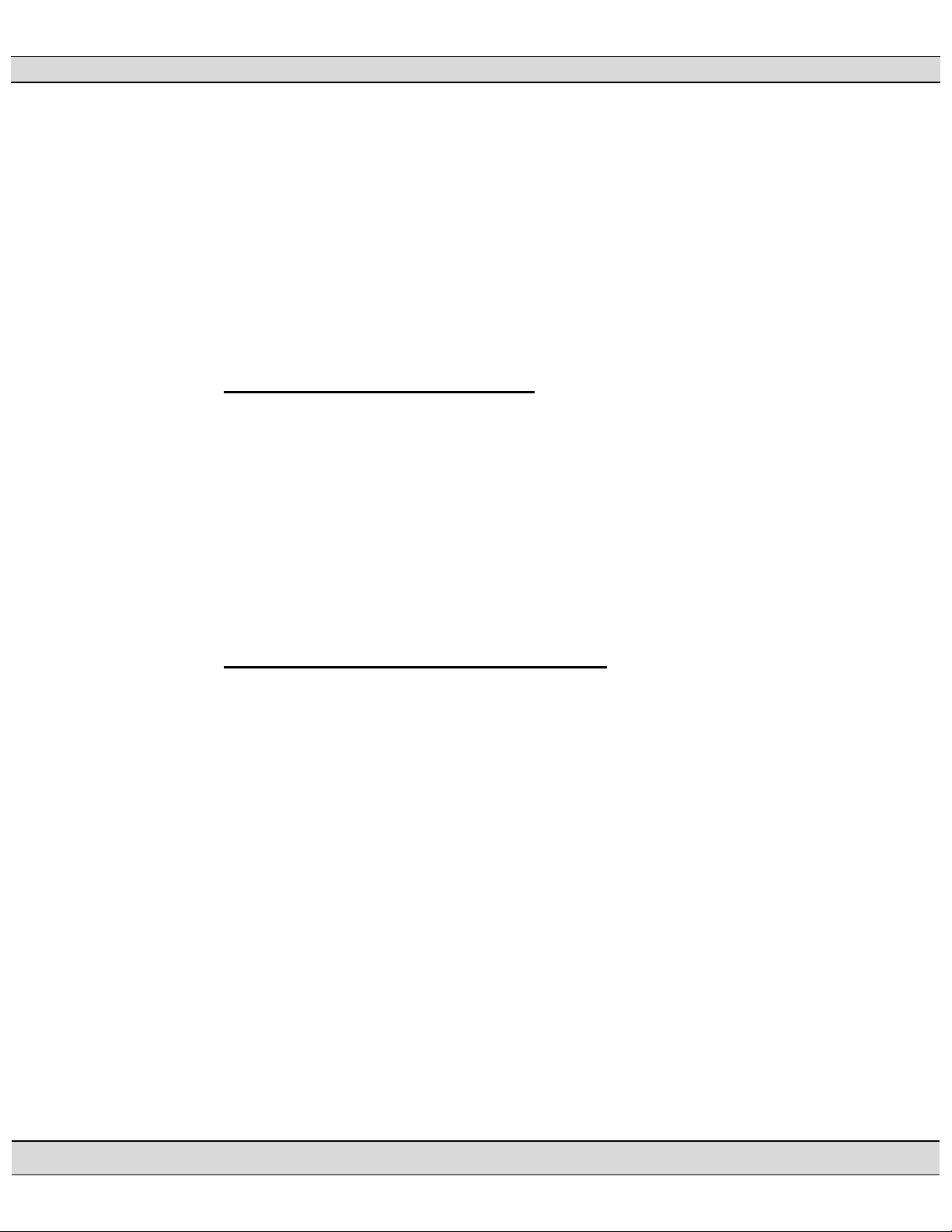

3.2. PRINTED CIRCUIT BOARD

The printed circuit board (PCB) is shown in FIGURE #5. The PCB contains the

following user interface items:

J1

Ext 4

Ext 3

Ext 2

Ext 1

GRD

B-

B+

EAP 110 PRINTED CIRCUIT BOARD LAYOUT

FIGURE #5

3.2.1. TERMINAL BLOCK

RJ45

JP3

JP2

Lexan Connector

One terminal block is provided for DC control power, ground and 4

external contact inputs. Refer to the connection diagram in section #7 for

further information.

3.2.2. COMMUNICATION PORT

One RJ45 communication port is provided on the circuit board for

interconnection to the MEC 2 or MEC 20 Engine controller. When two

EAP 110 annunciators are to be interconnected, a T-splitter RJ45 adapter

plug must be installed. Contact Thomson Technology for further details.

PM058 Rev 2 06/01/18 Thomson Technology

12

EAP 110 ANNUNCIATOR

3.2.3. ALARM ADDRESSING

Two jumpers (JP2 & JP3) are located on the PCB for programming the

specific alarm addressing on the EAP 110 as shown in FIGURE #5.

Note: Jumper JP1 is for Factory programming use. For normal operation,

JP1 must be On.

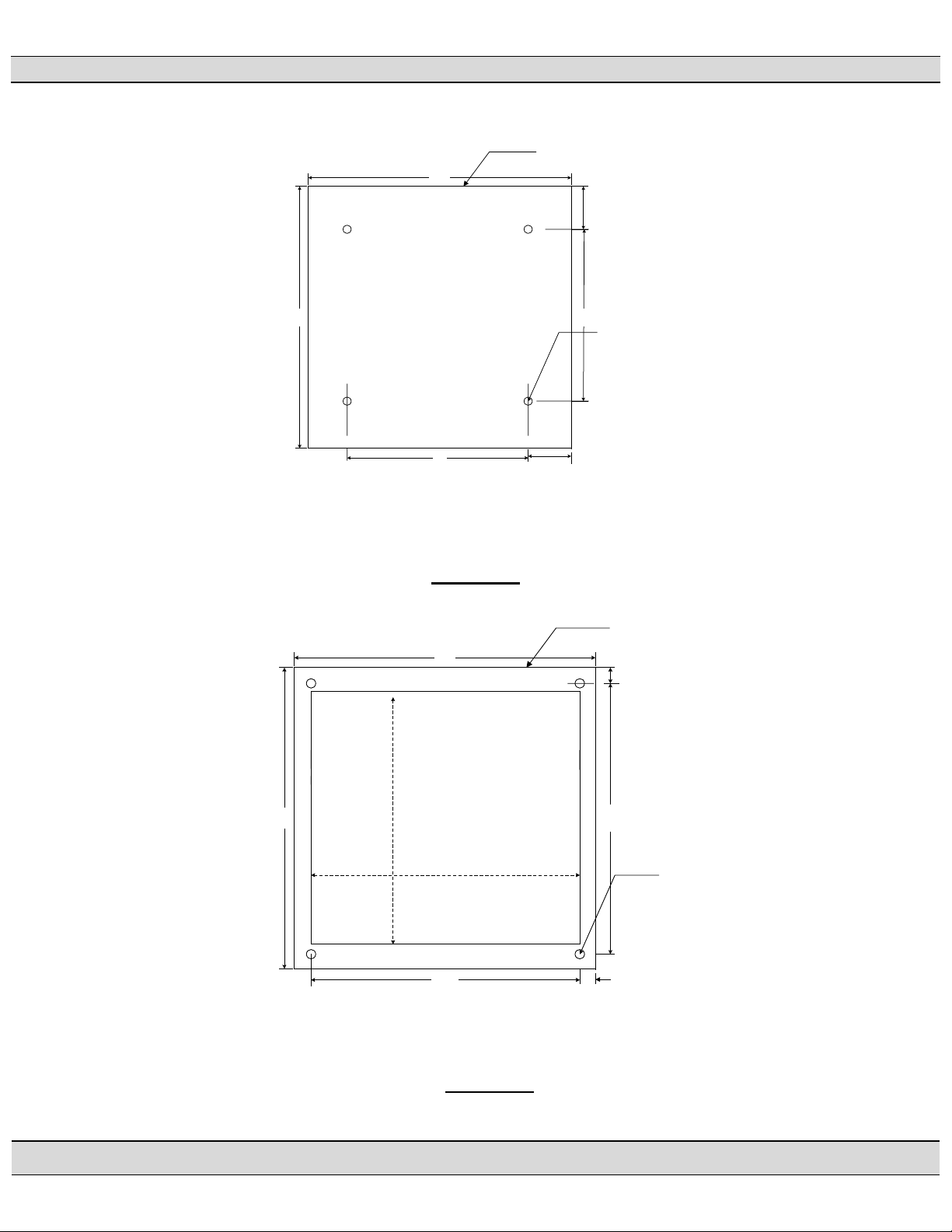

3.2.3.1. JP2 Alarm Group Addressing

Group 1 Faults: With jumper JP2 OFF, the EAP 110

addressing will be programmed to match the standard faults on

a MEC 2 or MEC 20 Engine controller as required NFPA 110

level 2 & CSA 282. FIGURE #6 Indicates the specific fault

addressing for Group 1 faults. The EAP 110 will be supplied

from the factory set for Group 1 addressing (i.e. JP2 OFF).

Note: LED Fault light “EPS SUPPLYING LOAD” is driven from

the MEC 2/MEC 20 engine controller

Programmable output #5.

Programmable Output #5 must therefore be programmed in the

MEC 2/MEC 20 engine controller for “ENGINE RUNNING” or

“EPS SUPPLYING LOAD” as is available. Refer to the

applicable MEC engine controller instruction manual for further

information.

PM058 Rev 2 06/01/18 Thomson Technology

13

EAP 110 ANNUNCIATOR

EAP 110 Annunciator

Emergency

Stop

Overcrank

Shutdown

Overspeed

Shutdown

Low Oil

Pressure

Alarm

Low Oil

Pressure

Shutdown

(or Extern al Input #4)

Alarm

Silence

EPS

Supplying

Load

Low Engine

Temperature

Alarm

Loss of

Speed Signal

Shutdown

High Engine

Temperature

Alarm

High Engine

Temperature

Shutdown

(or Extern al Input #3)

Lamp

Test

EPS Switch

Not in Auto

Weak Battery

Voltage

Low Battery

Voltage

High Battery

Voltage

Spare

(External Input #2)

Power On

Communication Fail

Group 1 Alarm Addressing

FIGURE #6

Spare

(Digita l Fault # 1 )

Spare

(Digita l Fault # 2 )

Battery

Charger

AC Fail

(Digita l Fault # 3 )

Low Fuel

Level

(Digita l Fault # 4 )

Spare

(External Input #1)

DATE

06/01/18 3:16 PM

G:\ENGINEER\PRODUCTS\EAP110\EAP110 LEXAN GROUP 1.VSD

PM058 Rev 2 06/01/18 Thomson Technology

14

EAP 110 ANNUNCIATOR

Group 2 Faults

With jumper JP2 ON, the EAP 110 addressing will be

programmed to match the 20 additional faults circuits as may

be programmed on a MEC 20 Engine controller. FIGURE #7

Indicates the specific fault addressing for Group 2 faults. Fault

names for digital faults #5-12 and programmable output #6 will

be dependent upon how the connected MEC 20 Engine

Controller is programmed.

Notes:

1) Group 2 addressing is not applicable for MEC 2 Engine

Controllers

2) Low Oil Pressure and High Engine temperature

Shutdowns are driven from the engine controllers Analog

engine sender input devices if programmed accordingly. Refer

to the engine controller instruction manual for further

information.

EAP 110 Annunciator

Under

Voltage

Shutdown

Over

Voltage

Shutdown

Under

Frequency

Shutdown

Spare

(Digital Fault #7)

Spare

(External Input #4)

Alarm

Silen c e

Progr. #6

Spare

(Digital Fa u lt #5 )

Over

Frequency

Shutdown

Spare

(Digital Fa u lt #6 )

Spare

(External Input #3)

Lamp

Test

Spare

(Digital Fa u lt # 1 2)

Over

Current

Alarm

High Engine

Temperature

Shutdown

Low Oil

Pressure

Shutdown

Spare

(External Input #2)

Power On

Commu n ic a tion Fail

Spare

(Digital Fault #8)

Spare

(Digital Fault #9)

Spare

(Digital Fa u lt # 1 0)

Spare

(Digital Fa u lt # 1 1)

Spare

(External Input #1)

Group 2 Alarm Addressing (MEC 20)

DATE

G:\ENGINEER \PR ODUCTS\EAP110\EAP 110 LEXAN GROUP 2.VSD

06/01/24

FIGURE #7

PM058 Rev 2 06/01/18 Thomson Technology

15

EAP 110 ANNUNCIATOR

EAP 110 Annunciator

Under

Voltage

Shutdown

Over

Voltage

Shutdown

Under

Frequency

Shutdown

Spare

(External Input #4)

Alarm

Silence

Progr. #6

Over

Current

Alarm

Over

Frequency

Shutdown

Spare

(External Input #3)

Lamp

Test

Group 2 Alarm Addressing (MEC 2)

High Engine

Temperature

Shutdown

Low Oil

Pressure

Shutdown

Spare

(External Input #2)

Power On

Commun ic atio n Fail

G:\ENGINEER\PROD UC TS\EAP110\EAP110 LEXAN GROUP 2 ME C 2..VSD

Spare

(External Input #1)

DATE

06/01/24

FIGURE #8

3.2.3.2. JP3 Low Oil Pressure & High Engine Temp Shutdown Fault Addressing (Group 1 Addressing):

Fault LED lights D19 & D20 as shown in FIGURE #8 may be

programmed for input from either two different alarm address inputs

when the annunciator is set for group 1 addressing.

With JP3 jumper ON, the EAP 110 Fault LED lights D19 & D20 will be

addressed to external input contacts #4 & #3 as connected to the EAP

110 terminal blocks.

With JP3 jumper OFF, the EAP 110 Fault LED lights D19 & D20 will be

addressed to the MEC 2 or MEC 20 Engine controller

circuits for Low Oil Pressure (LOP2) & High Engine Temperature

(HET2) respectively as programmed. If these faults are not

programmed on the MEC Engine Controllers, these fault LEDs will not

be active. Refer to the applicable engine controller instruction manual

for further information.

PM058 Rev 2 06/01/18 Thomson Technology

16

Analog Shutdown

EAP 110 ANNUNCIATOR

Notes:

1) If Low Oil Pressure & High Engine Temperature shutdowns are

driven by the standard Digital Fault contacts (Inputs #1 & #2) on

the MEC Engine controller, EAP 110 fault Lights D11 & D12 as per

FIGURE #8 will be activated when set for Group 1 addressing.

2) The EAP will be supplied from the factory with JP3 OFF (i.e. to

address to the analog LOP & HET faults)

D1

D2

D3

D10

D19

D16

D8

D4

D9

D20

S2S1

Alarm

Silence

EAP 110 LED Numbering

Lamp

Test

D15

D5

D6

D7

D18

D22

Power On

Communication Fail

D21

D11

D12

D13

D14

D17

FIGURE #9

PM058 Rev 2 06/01/18 Thomson Technology

17

EAP 110 ANNUNCIATOR

4. OPERATING INSTRUCTIONS

4.1. SEQUENCE OF OPERATION

When the EAP 110 is energized and is interconnected to an operating system, it

will display any faults which are currently active on the MEC 2 or MEC 20 Engine

controller. Any new faults will be displayed by a flashing LED light and the

internal alarm horn will sound. Once the alarm has been acknowledged via

“ALARM SILENCE” push-button, the horn will be silenced and the LED light will

remain on continuously. Any subsequent alarms will cause the horn to sound

again and new fault LED to flash. The activated LED lights will remain on until

the fault condition has been reset at the engine controller. If the EAP 110 is also

connected to the 4 possible external contact input circuits, these faults will be

activated in the same sequence by the remote contacts closing or opening upon

a fault. Remote contacts close to initiate an alarm fault.

4.2. CONTROL PUSH-BUTTONS

The following control push-buttons are located on the front faceplate keypad.

4.2.1. ALARM SILENCE FUNCTION

To initiate an alarm (horn) silence function, press the “ALARM SILENCE”

pushbutton. Should subsequent faults be activated, the alarm horn will resound which will require another alarm silence action.

4.2.2. LAMP TEST

A lamp test feature is provided to test all LED annuciator lights. To

activate the lamp test feature, press the “LAMP TEST” pushbutton.

PM058 Rev 2 06/01/18 Thomson Technology

18

EAP 110 ANNUNCIATOR

5. PROGRAMMING INSTRUCTIONS

The EAP 110’s audible horn may be programmed individually per alarm fault

circuit. The EAP 110 will be supplied from the factory with the horn “ENABLED”

for all alarm circuits.

To enter the programming mode, follow the procedure as shown:

NOTE:

The EAP 110 will not provide alarm

annunciation during the program mode.

1. Simultaneously press and hold both ALARM SILENCE & LAMP TEST pushbuttons down for 3 seconds, then release.

2. All LED’s illuminated will indicate that they are programmed as the Horn

Disabled. All LED’s which are not illuminated indicate that they are

programmed as the Horn-Enabled. The factory default setting is HornEnabled.

3. To program LED D1’s horn function, momentarily press the LAMP TEST

push-button. The flashing rate of the LED will change to reflect the different

settings. The two different flashing rates indicate the following operation:

Long Pulse On, Short Pulse Off = Horn Disabled

Short Pulse On, Long Pulse Off = Horn Enabled

4. Once the desired operation is selected for D1, momentarily press the ALARM

SILENCE push-button to advance the programming point to the next LED

and repeat process 3.

5. This process can be completed for all LED lights D2-D22. Once the last LED

is selected (D22), the programming mode will be terminated once the ALARM

SILENCE push-button is momentarily pressed. Note: the programming mode

will be automatically terminated following no key presses in approximately 30

seconds. Once the programming mode is terminated, the EAP 110 will

resume normal operation.

PM058 Rev 2 06/01/18 Thomson Technology

19

EAP 110 ANNUNCIATOR

6. SPECIFICATIONS

SUPPLY VOLTAGE 12V or 24V nominal (+- 20%), negative ground

SUPPLY CURRENT 100 ma (maximum), (+- 20%)

COMMUNICATION PORT RS 422, 4.8 KBaud, Thomson Technology T-Net Protocol

to MEC 2/MEC 20

8 conductor #22 AWG (min) Shielded/Twisted cable (1000 ft Max),

Plug-in RJ45 Connector

EXTERNAL CONTACT INPUT Close to DC Negative

TEMPERATURE RANGE -40 C to +50 Deg C

ENVIRONMENTAL Faceplate NEMA 12, Rear Enclosure NEMA 1

DIMENSIONS 6.0” W x 6.0” H x 3.0” D (Flush mount adapter option

(7.0” w x 7.0” H)

MOUNTING Surface Mount (Standard), Flush-mount (Optional)

Rear Enclosure conduit box c/w Qty 8 ½” knockouts

Specifications subject to change without notice.

PM058 Rev 2 06/01/18 Thomson Technology

20

EAP 110 ANNUNCIATOR

7. CONNECTION DIAGRAMS

EAP 110

Annunciator

Ext 1

Ext 2

Ext 3

Ext 4

J1

GRD

Communication

Cable**

1000' maximum cable

length

No

Connection

Expansion

Port

Com

Port

J6

J7

B+ B-B+ B-

External Alarm

Sensing contacts

(optional use as

required)

**8 conductor Shielded Twisted Cable c/w RJ45 connectors. Communication cable wiring must be

suitably routed to protect it from sources of electrical interference. Refer to section 2.4. of this manual

for further information.

EAP 110

Annunciator

J1

(Group 2)

MEC 2/20

Engine

Controller

+

-

12-24V Engine

Cranking Battery

B+ B-

J1

B+ B-

Communication

Cables**

Optional RJ45 Connector

Splitter

(required for 2 x

EAP 110)

leng th (total fr om

1000' maximum cabl e

GRD

No C onnection

control ler)

Com Port

J6

Expansion

Port

MEC 2/20

Engine

Controller

J7

B+ B-

+

Power and contacts to be connected as

shown below

External Alarm

Sensing contacts

(optional use as

required)

Ext 1

Ext 2

Ext 3

Ext 4

EAP 110

Annunciator

(G ro up 1 )

Ext 1

Ext 2

Ext 3

Ext 4

-

**8 conductor Shielded Tw isted Cable c/w RJ45 connectors. Communication cable w iring must be

suitably routed to protect it fr om sources of electric al interference. Refer to instruction manual f or

further information.

12-24V Engine

Cranking Battery

PM058 Rev 2 06/01/18 Thomson Technology

21

EAP 110 ANNUNCIATOR

8. ANNUNCIATOR LABELS

The EAP 110 will be supplied from the factory with Group 1 alarm labeling for NFPA 110

& CSA 282 applications. If new labels are required for any of the programmable faults or

for Group 2 faults, the following standard labels may be Photo copied, modified as

required and maybe inserted into the EAP 110 Lexan as required.

8.1. NFPA 110 LABELS

Using xacto knife and straight edge, cut into 4 vertical strips at crop marks.

Insert each strip into the correct lexan slot, centering text in windows.

Emergency

Stop

Overcrank

Shutdown

Overspeed

Shutdown

Low Oil

Pressure

Alarm

Low Oil

Pressure

Shutdown

EPS

Supplying

Load

Low Engine

Temperature

Alarm

Loss of

Speed Signal

Shutdown

High Engine

Temperature

Alarm

High Engine

Temperature

Shutdown

EPS Switch

Not In Auto

Weak Battery

Voltage

Low Battery

Voltage

High Battery

Voltage

(External 2)

(Digital Fault 1)

(Digital Fault 2)

Battery

Charger

AC Fail

Low Fuel

Level

(External 1)

PM058 Rev 2 06/01/18 Thomson Technology

22

EAP 110 ANNUNCIATOR

8.2. CSA 282 LABELS

Using xacto knife and straight edge, cut into 4 vertical strips at crop marks.

Insert each strip into the correct lexan slot, centering text in windows.

Emergency

Stop

Overcrank

Shutdown

Overspeed

Shutdown

Low Oil

Pressure

Alarm

Low Oil

Pressure

Shutdown

EPS

Supplying

Load

Low Engine

Temperature

Alarm

Loss of

Speed Signal

Shutdown

High Engine

Temperature

Alarm

High Engine

Temperature

Shutdown

EPS Switch

Not In Auto

Weak Battery

Voltage

Low Battery

Voltage

High Battery

Voltage

(External 2)

(Digital Fault 1)

(Digital Fault 2)

Low Coolant

Shutdown

Low Fuel

Level

Level

(External 1)

PM058 Rev 2 06/01/18 Thomson Technology

23

EAP 110 ANNUNCIATOR

8.3. MEC 20 (GROUP 2 FAULT) LABELS

Using xacto knife and straight edge, cut into 4 vertical strips at crop marks.

Insert each strip into the correct lexan slot, centering text in windows.

Under

Voltage

Shutdown

Over

Voltage

Shutdown

Under

Frequency

Shutdown

(Digital Fault7)

(Progr. #6)

(Digital Fault 5)

Over

Frequency

Shutdown

(Digital Fault 6)

(Digital Fault 12)

High Engine

Temperature

Shutdown

Pressure

Shutdown

Over

Current

Alarm

Low Oil

(Digital Fault 8)

(Digital Fault 9)

(Digital Fault 10)

(Digital Fault 11)

(External 4)

(External 3)

(External 2)

(External 1)

PM058 Rev 2 06/01/18 Thomson Technology

24

EAP 110 ANNUNCIATOR

8.4. MEC 2 (GROUP 2 FAULT) LABELS

Using xacto knife and straight edge, cut into 4 vertical strips at crop marks.

Insert each strip into the correct lexan slot, centering text in windows.

Under

Voltage

Shutdown

Over

Voltage

Shutdown

Under

Frequency

Shutdown

(Progr. #6)

Over

Frequency

Shutdown

High Engine

Temperature

Shutdown

Pressure

Shutdown

Over

Current

Alarm

Low Oil

(External 4)

(External 3)

(External 2)

(External 1)

PM058 Rev 2 06/01/18 Thomson Technology

25

EAP 110 ANNUNCIATOR

9. TROUBLE SHOOTING

A number of problems can cause the EAP 110 Annunciator not to function properly. Refer to

the following list of typical problems. Consult the factory for any detailed information or for any

problems not listed.

CAUTION!!!

Before opening the annunciator to perform any service task, it is imperative to isolate the

control system from any possible source of power. Failure to do so may result in serious

personal injury or death due to electrical shock.

Service procedures must be undertaken by

SYMPTOM CORRECTIVE ACTION

Annunciator does not power up even with correct

DC power applied

Lamp Test does not activate any LED lights on the

EAP Annunciator

DC Power On LED is illuminated and

Communication link is correct however EAP 110

does not respond to any activated fault conditions

qualified personnel only!

- Check that there are no wiring errors/short

circuits connected to the Annunciator. Note:

The EAP 110 contains an electronic fuse that

triggers upon an overload condition and does

not reset until the supply voltage is removed,

and overload condition is corrected.

- Check if adequate DC supply voltage is applied

to the EAP & the polarity is correct.

- Verify the Lexan ribbon cable is connected to

the EAP printed circuit board.

- Verify JP1 on the EAP 110 PCB has a jumper

connector on it (Jumper On = Run Mode)

from the Engine controller.

PM058 Rev 2 06/01/18 Thomson Technology

26

EAP 110 ANNUNCIATOR

SYMPTOM CORRECTIVE ACTION

Communication Fail Light is on - Check the communication cable is connected

properly on both the EAP 110 end and at the

MEC 2/MEC 20 engine controller end.

Notes:

1) On MEC 20 applications, ensure

communication cable is connected to the

Annunciator fault lights do not correspond to same

faults on the MEC Engine Controller

10. NOTES

MEC Expansion Port (J6) and

communication port (J7)

2) MEC 2 applications require software version

1.2 (or greater) software version for correct

EAP 110 operation.

- Verify the EAP 110 has the correct alarm group

addressing jumpers installed. Refer to section

3.2.3 for further information.

not the

PM058 Rev 2 06/01/18 Thomson Technology

27

Loading...

Loading...