Page 1

Model SCE

Separated-Combustion

Packaged Furnace/Blower

NOTE: Model SCE units are not certified for residential use.

INSTALLATION/OPERATION/MAINTENANCE

®

Form I-SCE (Version A)

Obsoletes Form RZ-NA I-SCE

TABLE OF CONTENTS Pages

Installation/Operation .............. 1-30

Check Installation & Startup 30-31

Optional Equipment ................ 32-33

Service/Maintenance ............... 33-36

INDEX by Page No.

Belts ......................................................... 24

Blower ...................................................... 24

Blower Rotation ....................................... 24

Adjusting Blower Speed .......................... 24

Burner Air Shutters .................................. 30

Burner Carryover Systems ........................ 29

Burner Orifices ... ........... .......... ................. 29

Burner Rack Removal .............................. 34

Burners ..................................................... 29

Check Installation & Startup ................... 30

Cleaning the Heat Exchanger ................... 35

Cleaning Pilot and Burners ..................... 34

Clearances .................................................. 4

Combustion Air .......................................... 7

Concentric Adapter Box ............................ 10

Optional Condensation Drain .................... 6

Optional Dampers & Controls .................. 32

Dimensions ................................................ 3

Dirty Filter Switch (Option) .................... 33

Drives ........................................................ 24

Duct Connections ...................................... 6

Ductstat (Optional) ................................... 25

Electrical Supply & Connections ............ 20

Optional Electronic Modulation .............. 26

Fan Control ............................................. 23

Filter Rack & Filters ................................ 32

Gas Piping and Pressures ......................... 18

Gas Valve ............................................ 24, 33

General ....................................................... 1

HAZARD INTENSITY LEVELS ............. 2

Horizontal Vent Terminal/

Combustion Air Inlet .......................... 12

Ignition System ....................................... 29

Installation Codes ...................................... 2

Limit Control .......................................... 23

Limit Control Check ............................... 35

MAINTENANCE .................................... 33

Manifold Pressure Setting ........................ 19

Motor ........................................................ 23

Mounting ................................................... 5

Optional Accessories ................................. 32

Pilot and Ignition Systems ...................... 29

SERVICE................................................. 33

Startup ..................................................... 30

Support ....................................................... 9

Suspension ................................................. 5

Thermostat ............................................... 20

Troubleshooting ...................................... 35

Optional Two-Stage Operation ................ 24

Uncrating ................................................... 3

Valve ........................................................ 24

Vent/Combustion Air System ............... 7, 33

Venting .................................................. 7-17

Vertical Vent Terminal/

Combustion Air Inlet .......................... 15

Warranty..................................................... 2

Wiring Diagram .................................. 21-22

REFERENCE

Replacement Parts ....................... Form P-SC

Gas Conversion .......................... Form P-GC

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in

open containers in the vicinity of this appliance is hazardous.

WARNING: Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury or death. Read the

installation, operation, and maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING: Gas-fired appliances are not designed for use in hazardous

atmospheres containing flammable vapors or combustible dust, in

atmospheres containing chlorinated or halogenated hydrocarbons, or in

applications with airborne silicone substances. See Hazard Levels, page

2.

GENERAL

The instructions in this manual apply to

Model SCE blower-type unit heater with

blower cabinet.

Installation should be done by a qualified

agency in accordance with the instructions

in this manual and in compliance with all

codes and requirements of authorities having jurisdiction.

Model SCE is design-certified by the Canadian Standards Association to ANSI Standards

and approved to CSA Standards. Model SCE is available for use with either natural or

propane gas. The type of gas, the firing rate, and the electrical characteristics are on the unit

rating plate.

This separated combustion unit is designed and manufactured in accordance with the ANSI

definition of separated combustion. That definition reads, "Separated Combustion System

Appliance: A system consisting of an appliance and a vent cap(s) supplied by the manufacturer, and (1) combustion air connections between the appliance and the outside atmosphere, and (2) flue gas connections between the appliance and vent cap, of a type(s)

specified by the manufacturer but supplied by the installer, constructed so that, when installed in accordance with the manufacturer's instructions, air for combustion is obtained

from the outside atmosphere and flue gases are discharged to the outside atmosphere."

Separated combustion units are designed to separate air for combustion and flue products

from the environment of the building in which the unit is installed. Separated combustion

Model Description

Separated-Combust ion, Blower-Ty pe

SCE

Unit Heater with Blower Cabinet

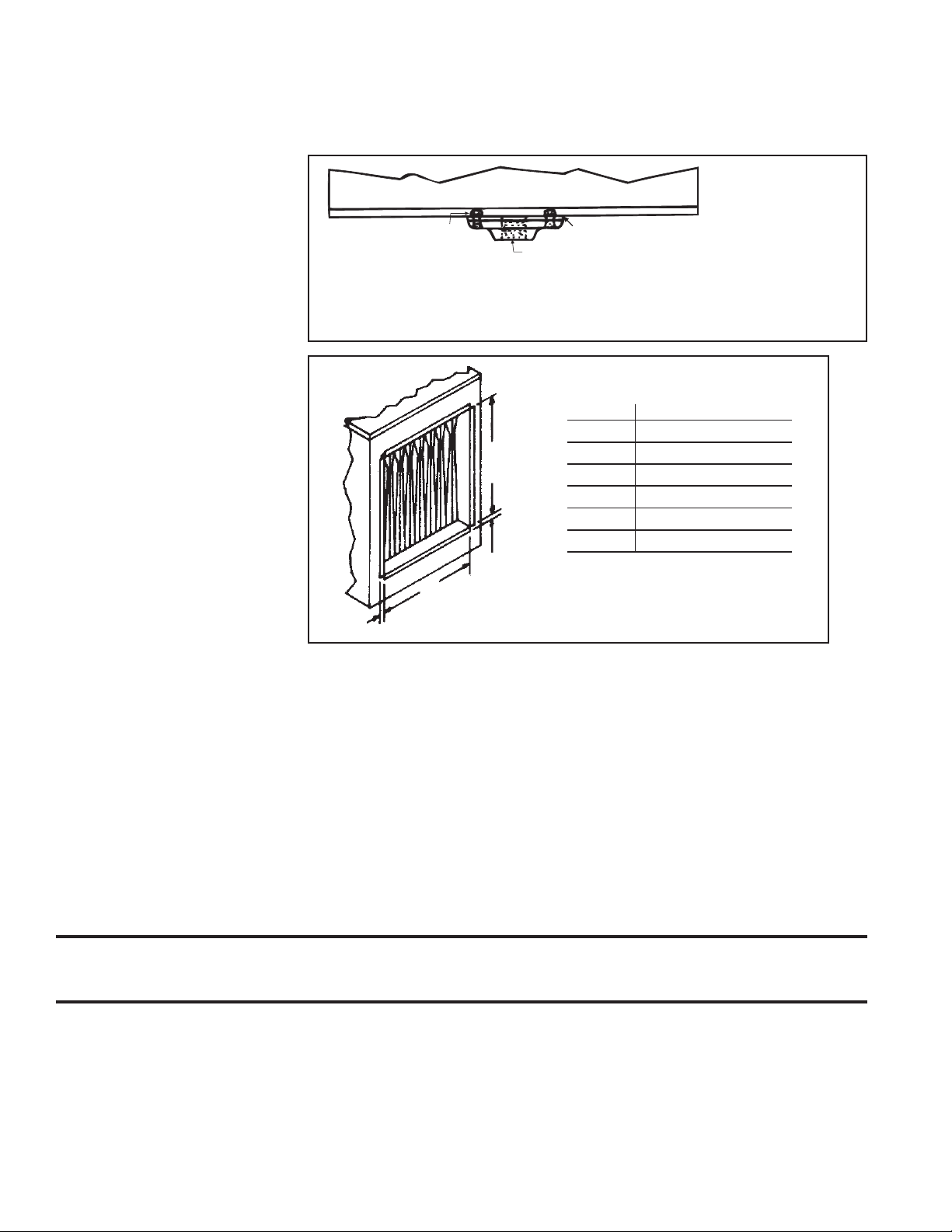

Front View

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 1

Rear View

Page 2

General (cont'd)

appliances are recommended for use in dust laden and some corrosive fume environments or

in buildings with negative pressure (up to .15" w.c.). As the definition states, all separated

combustion, power-vented equipment must be equipped with both combustion air and exhaust piping to the outdoors.

Definitions of

Hazard Levels

in this Manual

1. Installation Codes

Special Installations

(Aircraft Hangars/

Garages)

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or

death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or

death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury

and/or property damage.

These units must be installed in accordance with local building codes. In the absence of local

codes, in the United States, the unit must be installed in accordance with the National Fuel

Gas Code NFPA 54/ANSI Z223.1 (latest edition). A Canadian installation must be in accordance with the CSA B149. Natural Gas and Propane Installation Codes. Both codes are

available from CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction should be consulted before installation is made to verify local codes and installation

procedure requirements.

Installations in aircraft hangars should be in accordance with NFPA No. 409 (latest edition),

Standard for Aircraft Hangars; in public garages in accordance with NFPA No. 88A (latest

edition), Standard for Parking Structures; and for repair garages in accordance with NFPA

No. 88B (latest edition), Standard for Repair Garages. In Canada, installations in aircraft

hangars should be in accordance with the requirements of the enforcing authorities, and in

public garages in accordance with CSA B149 codes.

All Installations

2. Warranty

These gas-fired products are certified by ANSI Z83 family of standards governing the safe

usage of heating equipment in the industrial/commercial marketplace. This includes using

the heaters in makeup air applications to supply corridor pressurization in commercial buildings such as office structures and apartment complexes.

The heaters are not certified as residential heating equipment and should not be used as

such.

Clearances from the heater and vent to combustible construction or material in storage must

conform with the National Fuel Gas Code ANSI Z223.1a (latest edition) pertaining to gasburning devices, and such material must not attain a temperature over 160°F by continued

operation of the heater.

Refer to the limited warranty information on the Warranty Card in the "Owner's Envelope".

Warranty is void if ...

a. Separated-combustion heaters are used in atmospheres containing flammable vapors or

atmospheres containing chlorinated or halogenated hydrocarbons or any contaminant

(silicone, aluminum oxide, etc.) that adheres to the spark ignition flame sensing probe.

b. Wiring is not in accordance with the diagram furnished with the heater.

c. Unit is installed without proper clearance to combustible materials.

Form RZ-NA I-SCE, Page 2

Page 3

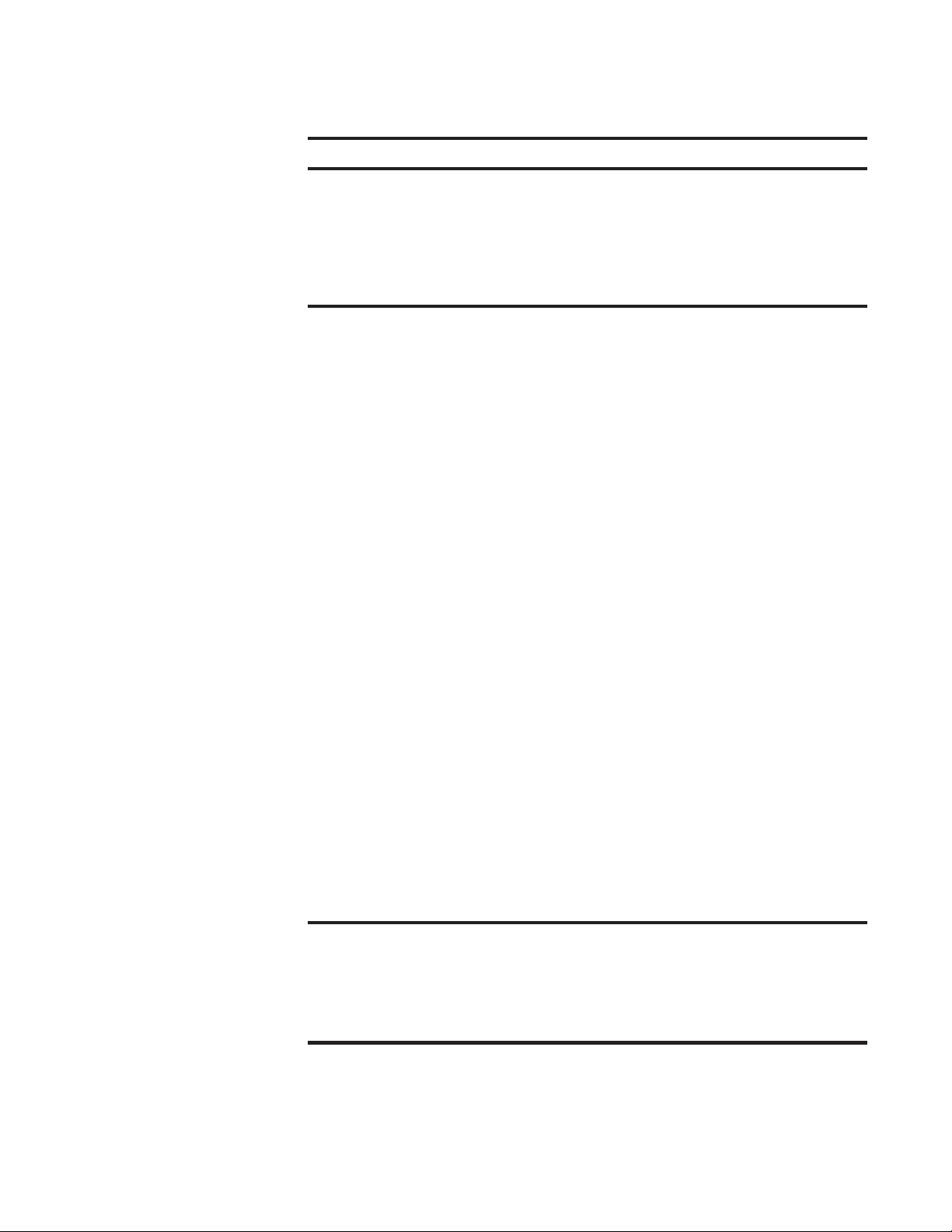

3. Dimensions

FIGURE 1 - Model SCE Dimensions - inches ±1/8 (mm ±3)

Standard

Model

SCE

A

Model SCE

with Optional

Horizontal

Inlet with

Duct Flanges

Size

Dim

ensions (inches ±1/8)

125

150, 175

200, 225

250

300

350

400

Dimensions (mm±3)

125

150, 175

200, 225

250

300

350

400

A BDE FGHJKLMN

32-1/4 25-1/4 15-1/ 4 8-1/8 16-1/4 7 17-3/4 17-3/8 17 1/2 40-1/ 4 27-3/ 4

32-1/4 30-3/4 20-3/ 4 8-1/8 21-3/4 7 23-1/4 22-7/8 18-3/8 1/2 39 27-3/4

35-1/4 36-1/4 26-1/ 4 10-3/ 4 27-1/ 4 10 28-3/4 28-3/8 17 1/2 40-1/4 30-3/4

35-1/4 43-1/2 33-1/ 2 9-3/4 34-1/2 9 36 35-5/ 8 16 1/2 39-1/4 30-3/4

35-1/4 44-1/2 4-1/5 10-3/4 35-1/2 10 37 38-5/8 17 3/4 40-1/ 4 30-3/ 4

35-1/4 50 40 10-3/4 41 10 42-1/2 42-1/8 18-3/ 8 3/ 4 39 30-3/4

35-1/4 55-1/2 45-1/ 2 10-3/ 4 46-1/ 2 10 48 47-5/ 8 17 3/ 4 40-1/4 30-3/4

819 641 387 206 413 178 451 441 432 13 1022 705

819 781 527 206 552 178 591 581 467 13 991 705

895 921 667 273 692 254 730 721 432 13 1022 781

895 1105 851 248 876 229 914 905 406 13 997 781

895 1130 876 273 902 254 940 930 432 19 1022 781

895 1270 1016 273 1041 254 1080 1070 467 19 991 781

895 1410 1156 273 1181 254 1219 1210 432 19 1022 781

2

51mm

18

457mm

7-7/32

183mm

6-31/32

177mm

19-1/2

495mm

2-1/4

57mm

6-3/32

155mm

3/4

19mm

F

3/4

19mm

3/4

19mm

D

B

Combustion Products

Discharge 6 (150mm) O.D.

Connections

19-1/2

495mm

34 (864mm) 24-1/8 (613mm)

2-13/16

71mm

3-5/16

84mm

M

Electrical

4-5/16

110mm

10

254mm

1-1/8

29mm

58-1/8 (1,476mm)

59-1/16 (1,500mm)

3/4

19mm

3/4

19mm

Combustion Products

3/4

Discharge 6 (150mm) O.D.

19mm

34 (864mm) 24-1/8 (613mm)

L (Gas

Connection)

Electrical

Connections

K

7-1/2

191mm

1-1/2

38mm

MK

7-1/2

191mm

4-5/16

110mm

10

254mm

1-1/8

29mm

58-1/8 (1,476mm)

59-1/16 (1,500mm)

4-9/16

116mm

Combustion

Air Inlet

6 (150mm) I.D.

GE

Combustion

Air Inlet

6 (150mm) I.D.

2-1/4

57mm

2-3/4

70mm

15/16

24mm

1-1/2

38mm

(4) Mounting Sockets

1 IPS free turning

female pipe thread

19-1/2

495mm

4-9/16

116mm

GE

2-3/4

70mm

L (Gas Connection)

15/16

24mm

3-1/4

83mm

J

(4) Mounting Sockets,

1 IPS free turning

female pipe thread

N

H

2-1/4

57mm

4. Uncrating

The furnace is shipped completely assembled. Immediately upon uncrating, check the gas specifications and electrical characteristics of the unit to be sure that they agree with the gas and

electric supply at the installation site.

Check the unit for any damage that may have been incurred during shipment. If damage is found,

document the damage with the transporting agency and immediately contact your Reznor distributor. If you are an authorized Distributor, follow the FOB freight policy procedures as published by Thomas & Betts for Reznor products.

The bottom corners are fastened to the crate with angle clips. Remove the lag screws from the

shipping clips. Remove the clips and return the bolts to the heater legs to support the corner leg

and the heater bottom. Putting the bolts back in the heater is required.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 3

Page 4

4. Uncrating (cont'd)

To protect the unit during shipping, blower models have special supports that must be

removed before installation. Follow these instructions to remove:

Blower Support Legs - Remove the blower support legs and screws.

Motor Shipping Block - Remove the wooden block located under the motor bracket. Find

the two rubber pads shipped in the instruction envelope. Place these pads on the ends

of the motor bracket bolts.

Motor Shipping Plate - Units that are equipped with motors of

1-1/2 HP or less have a metal shipping plate attached between the motor and the blower

housing. The shipping plate must be removed and the plate and screws discarded. On

units factory equipped with an optional belt guard, the belt guard must be removed to

reach the shipping plate.

Vent Terminal/Combustion Air Inlet

Kit with Concentric Adapter Box -

Required for All Installations

Options

Some gas control options have parts either shipped loose

with the heater or shipped separately. If your unit is

equipped with any of the gas control options in the table,

be sure these parts are available at the job site.

Before beginning installation, be sure that all other

shipped-separate options ordered are available at the

site, also. Shipped-separate options could include a

shutoff valve, a condensate drain kit, a thermostat, a

remote console, a disconnect switch, or high temperature vent sealing tape.

5. Clearances

and Location

For safety and convenience, provide clearances as shown in the following table. Clearance to

combustibles is defined as the minimum distance from the heater to a surface or object that is

necessary to ensure that a surface temperature of 90°F above the surrounding ambient temperature is not exceeded. Minimum clearances are also listed on the heater rating plate.

The concentric adapter assembly in the venting/combustion air kit (Option

CC2 or CC6) is required on all separated combustion models. Be sure that the

concentric adapter carton is at the installation site. (See parts lists in Paragraph 9.)

Application Option S hipped S eparate Components

Heati ng -- Gas

Control Option

Makeup Air -- Gas

Control Options AG9

AG7

AG3

AG15

AG16

AG39

Thermostat, P/N 48033

Control Switch, P/N 29054

Remot e Temperature Selector, P/N 48042

Control Switch, P/N 29054

Remot e Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Control Switch, P/N 29054

Remot e Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Remote Disp lay M odule, P/N 115852

Control Switch, P/N 29054

Remot e Temperature Selector, P/N 174849

Minimum

Clearances

- inches (mm)

Location

Form RZ-NA I-SCE, Page 4

Top

6"

(152mm)

For best results, the heater should be placed with certain rules in mind. In general, a unit should

be located from 8 to 12 ft (2.6 to 3.6M) above the floor. Units should always be arranged to blow

toward or along exposed wall surfaces, if possible. Where two or more units are installed in the

same room, a general scheme of air circulation should be maintained.

Suspended heaters are most effective when located as close to the working zone as possible, and

this fact should be kept in mind when determining the mounting heights to be used. However,

avoid directing the discharged air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken into consideration when

locating the unit heater so that a minimum quantity of airflow will be deflected by such obstacles.

When units are located in the center of the space to be heated, the air should be discharged

toward the exposed walls. In large areas, units should be located to discharge air along exposed

walls with extra units provided to discharge air in toward the center of the area.

At those points where infiltration of cold air is excessive, such as at entrance doors and shipping

doors, it is desirable to locate the unit so that it will discharge directly toward the source of cold

air from a distance of 15 to 20 feet (4.5 to 6 M).

Control Side Side Opposite Controls To Combus tibles To Non-Combustibles

6" (152mm) plus

width of unit

6" (152mm) 6" (152mm) 0" (0mm)

BottomSides

CAUTION: Do not locate the heater where it may be exposed to water

spray, rain, or dripping water.

Page 5

6. Suspension and

Mounting

Weights

Before installing, check the supporting structure to be sure that it has sufficient load-carrying capacity to support the weight.

Net Weight (lbs and kg)

Size 125 150-175 200-225 250-300 350 400

lbs 313 358 382 482 498 560

kg 142 162 173 219 226 254

Suspension

WARNING: Units must be

supported level for proper

operation. Do not place or add

additional weight to the

suspended unit. See Hazard

Levels, page 2.

FIGURE 2 - Suspension

Methods

Mounting Supports

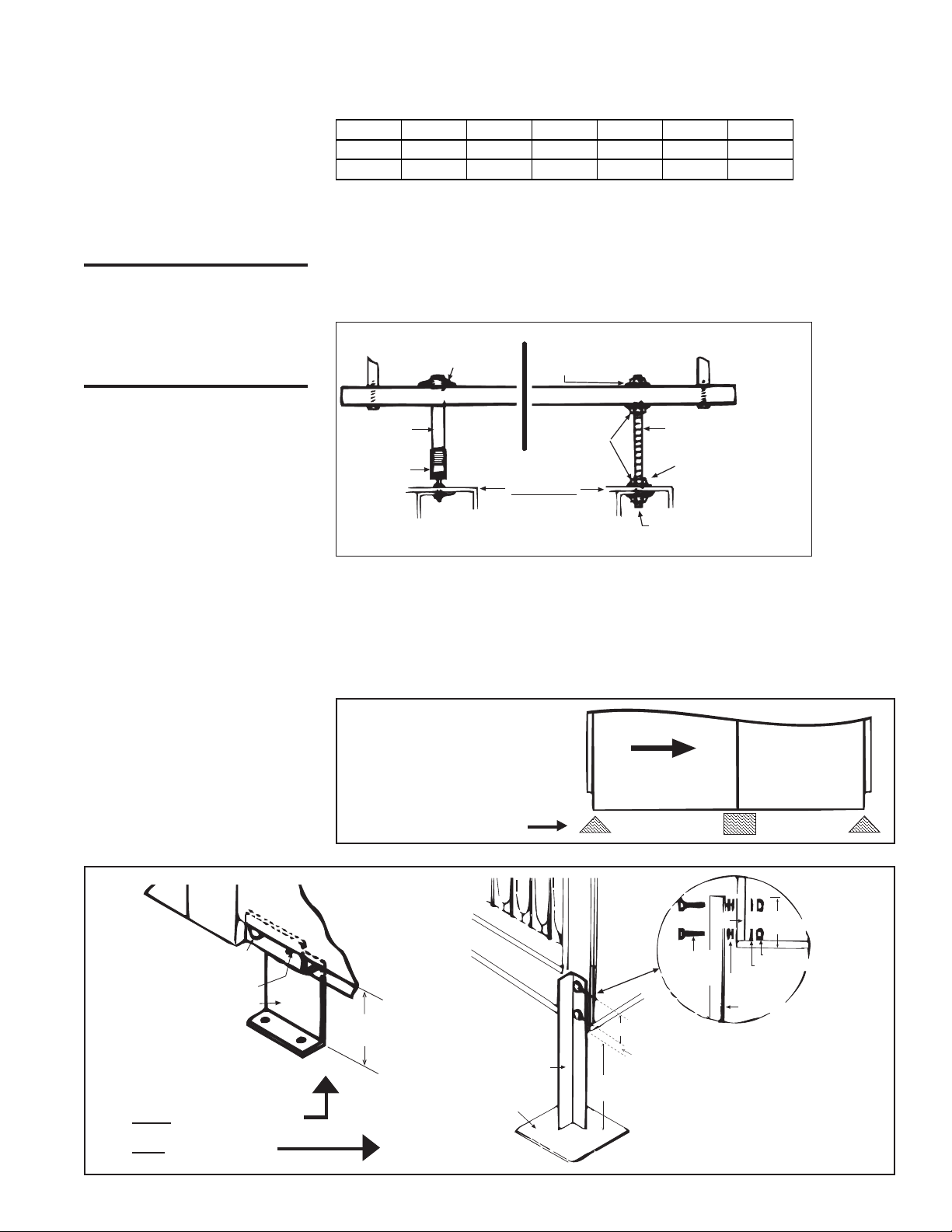

FIGURE 3 - Model SCE

Support Locations

FIGURE 4 - Corner Mounting Supports (NOTE: Support is also required where

furnace and blower cabinets

meet. See FIGURE 3.)

Model SCE has four-point suspension. See hanger centerline dimensions in FIGURE 1,

Paragraph 3.

At each suspension point, the unit is factory-equipped with a free-turning, female, 1" NPT

pipe hanger. Suspend by connecting the pipe hanger to a 1" threaded pipe. See suspension

method on the left in FIGURE 2. As an alternative method, the factory-installed pipe hanger

may be removed and the heater suspended as illustrated on the right in FIGURE 2.

Standard Assembly

1 Pipe Flange

1 Pipe

Threaded

Socket

Installer Replaced Assembly

Washer Nut Assembly

Washer Nut

Assembly

Heater Top

3/8 Rod

(Standard

threaded socket

assembly is removed.)

Access through

the side panel

Model SCE requires six support locations. See FIGURE 3.

Supports available from the manufacturer (P/N 74487) or field-fabricated legs as illustrated in

FIGURE 4 may be used at the four corner support locations. Do not use this type of support

at the center support locations (between the furnace and the blower section). At the center

locations, a field-fabricated, angle-iron brace support must extend horizontally, jointly supporting a portion of both the furnace and the blower cabinet. All supports must be noncombustible.

Field-supplied supports between

the blower cabinet and the furnace

Airflow

must extend horizontally supporting both sections.

Blower Section

Furnace Section

Support Locations

Furnace

Shipping Bolt Lug

Access Panel

Retaining Screw

P/N 74487 (4 required)

• above - available as a part

• right - field fabricated

6

(152mm)

2 x 2 x 1/4

Angle Iron Leg

6 x 6 x 1/4

Metal Plate

Cabinet Leg

Cabinet Leg

1/4 x 1-1/2

Hex Head

Bolts

Spacers

4 (102mm)

2-1/4

(57mm)

A = 6 (152mm) minimum height for

A

clearance to combustibles. The recommended

height is 8 (203mm) for plumbing and service

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 5

Drill 9/32 clearance holes in

angle iron leg and cabinet leg

7

(178mm)

1/4 Nuts

Lockwashers

Angle Iron Leg

Page 6

7. Optional

Condensation

Drain for Duct

Furnaces

Model SCE furnaces are certified for installation upstream or downstream from a cooling coil.

When installed downstream from a refrigeration system, condensation will form; and therefore, adequate provision must be made to dispose of condensate.

Periodic cleaning of the condensate collection and disposal system is required.

Install drain connection, Option CS1, on the furnace casing as illustrated in FIGURE 5.

FIGURE 5 - Option CS1,

P/N 31765, Optional

Condensate Drain

Connection

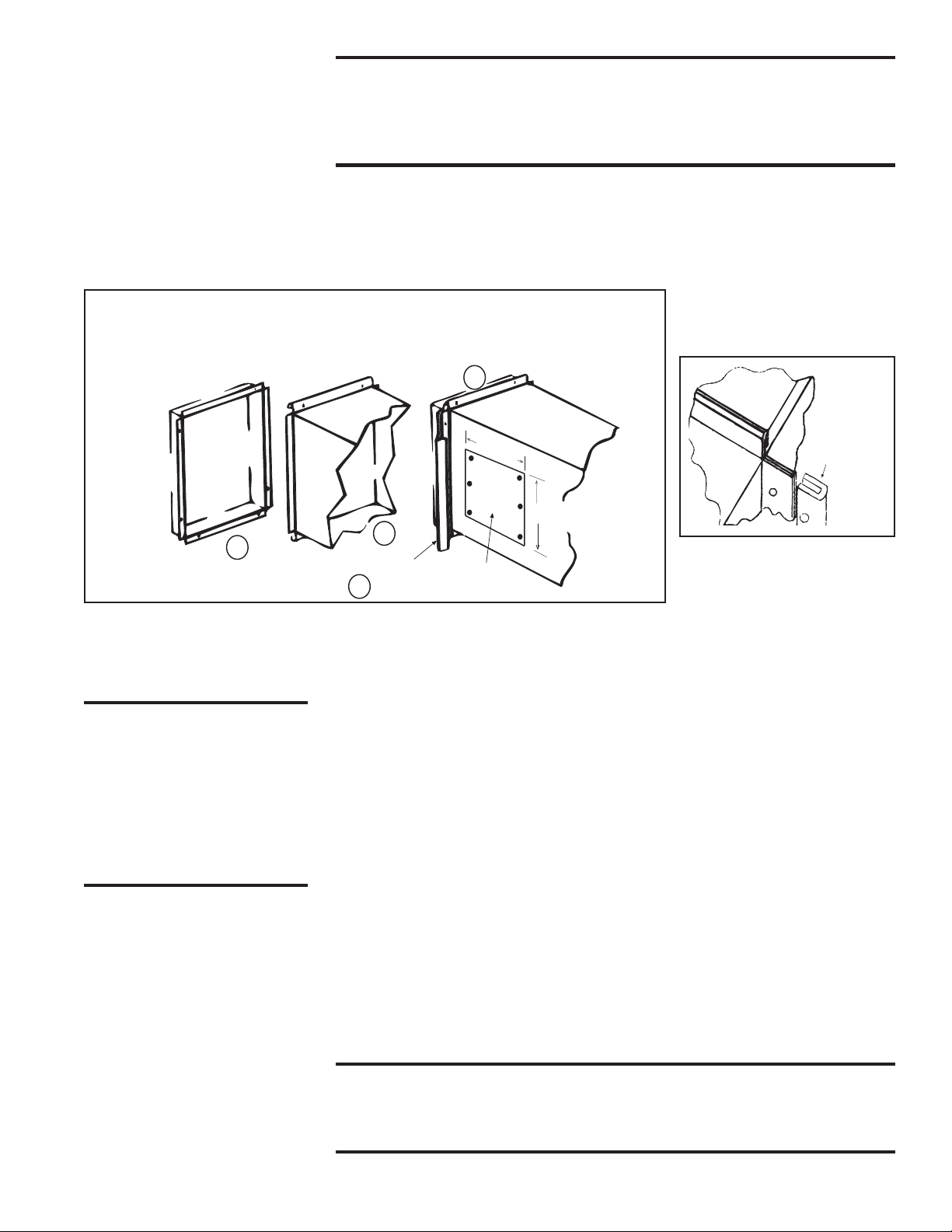

8. Duct Connections

FIGURE 6 - Duct

Connection Dimensions inches (mm)

Bottom of the Furnace Casing

#10 x 1-1/4 Bolt and Nut

3/4 Pipe Waste Nut

Terminate drain outside of the building. Provide a trap to prevent air from entering the

combustion zone. Periodic cleaning of the condensate collection and disposal system is

required. NOTE: Requires a four-inch (102mm) minimum clearance under the furnace if a

90° street elbow is used.

18

(457)

3/4 (19)

G

3/4

(19)

Gasket

Size G

125 15-1/4" (387mm)

150, 175 20-3/4" (527mm)

200, 225 26-1/4" (667mm)

250, 300 34-1/2" (876mm)

350 40" (1016mm)

400 45-1/2" (1156mm)

Requirements and Suggestions for Connecting and Installing Ducts

• Type of Ductwork - The type of duct installation to be used depends in part on the type of construction of the roof (whether

wood joist, steelbar joist, steel truss, pre-cast concrete) and the ceiling (whether hung, flush, etc.).

• Ductwork Material - Rectangular duct should be constructed of not lighter than No. 26 U.S. gauge galvanized iron or No. 24 B

& S gauge aluminum.

• Ductwork Structure - All duct sections 24 inches (610mm) or wider, and over 48 inches (1219mm) in length, should be cross

broken on top and bottom and should have standing seams or angle-iron braces. Joints should be S and drive strip, or locked.

• Through Masonry Walls - No warm air duct should come in contact with masonry walls. Insulate around all air duct through

masonry walls with not less than 1/2" (1" is recommended) of insulation.

• Through Unheated Space - Insulate all exposed warm air ducts passing through an unheated space with at least 1/2" (1" is

recommended) of insulation.

• Duct Supports - Suspend all ducts securely from adjacent buildings members. Do not support ducts from unit duct connections.

• Duct Sizing - Proper sizing of the supply air ductwork is necessary to ensure a satisfactory heating installation. The recognized

authority for such information is the Air Conditioning Contractors Association, 2800 Shirlington Road, Suite 300, Arlington, VA

22206 (www.acca.org). A manual covering duct sizing in detail may be purchased directly from them.

CAUTION: An external duct system static pressure not within the limits shown on the rating

plate, or improper motor pulley or belt adjustment, may overload the motor. See Hazard Levels,

page 2.

• Removable Panels - The ducts should have removable access panels on both upstream and downstream sides of the furnace.

These openings must be accessible when the furnace is in service and should be a minimum of 6" x 10" (152mm x 254mm) in size

so smoke or reflected light may be observed inside the casing to indicate the presence of leaks in the heat exchanger. The

covers for the openings must be attached in such a manner as to prevent leakage. See FIGURE 7A.

• Horizontal Discharge Duct Length - A minimum horizontal duct run of 24" (610mm) is recommended before turns or branches

are made in the duct system to reduce losses at the furnace outlet.

• Supply Air Duct/Furnace Horizontal Connection - The seal between the furnace and the duct must be mechanical. Duct

connection should be made with "U" type flanges on the top and bottom of the connecting duct. Slide the duct over the flanges

of the heater giving an airtight fit. Provide "U" type channels for the side flanges to ensure tight joints. Use sheetmetal screws

to fasten ducts and "U" channels to the furnace flange. See FIGURE 7B.

Form RZ-NA I-SCE, Page 6

Page 7

CAUTION: Joint where supply air duct attaches to the furnace must

be sealed securely to prevent air leakage into drafthood or burner

rack area. Leakage can cause poor combustion, pilot problems, shorten

heat exchanger life, and cause poor performance. See Hazard levels,

page 2.

• Return Air Duct/Furnace Connection - All return air ducts should be attached and

sealed to return air flanges to provide airtight connection.

• Return Air Duct/Grill Size - Make certain that return air ducting or grills have a free

area equal to the return duct size connection.

FIGURE 7A - Connecting

Ductwork to the Furnace

(1) Flanges on the furnace (heat exchanger) turn out as shown. (2) Shape duct connection as

shown -- "U" on top and bottom; "L" on sides. (3) Slide "U" channels over furnace top and

bottom flanges making connection. (4) Form "U" channels to seal sides. Drill and lock with

sheetmetal screws.

3

FIGURE 7B - Install "U"

Channel on Sides of Duct

Connection

Furnace

Heater

1

9. Venting and

Combustion Air

WARNING: Do not use an

existing venting system.

This heater requires

installation of the

combustion air/vent system

ordered with the unit (either

Option CC2 or Option

CC6).

6

Duct

2

U Channel

4

All separated combustion, power vented units MUST BE equipped with both combustion air

and exhaust piping to the outdoors. The unique concentric adapter box designed for use

with this heater allows for both combustion air and exhaust piping with only one horizontal

or vertical penetration hole in the building.

These instructions apply to installation and use of the concentric adapter and vent/combustion air kit (Option CC2 or CC6) designed for use with all Reznor separated-combustion

products. The systems illustrated in this manual are the only venting/combustion air systems approved for these separated combustion units. Do not use this concentric adapter box

with any other products.

Installation should be done by a qualified agency in accordance with these instructions. The

qualified service agency installing this separated-combustion system is responsible for the

installation.

Hazards of Chlorine - The presence of chlorine vapors in the combustion air of gas-fired

heating equipment presents a potential corrosion hazard. Chlorine found usually in the form

of freon or degreaser vapors, when exposed to flame, will precipitate from the compound, and

go into solution with any condensation that is present in the heat exchanger or associated

parts. The result is hydrochloric acid which readily attacks all metals including 300 grade

stainless steel. Care should be taken to separate these vapors from the combustion process.

This may be done by wise location of unit vent terminal and combustion air inlet with regard

to exhausters or prevailing wind directions. Remember, chlorine is heavier than air. This fact

should be kept in mind when determining installation location of these heaters and building

exhaust systems.

Access Panel

(152mm)

Duct

10 (254mm)

in Duct

U Channel

of Light

Gauge Metal

WARNING: SC Series separated combustion units are not designed or

approved for use in atmospheres containing flammable vapors or

atmospheres highly laden with chlorinated vapors. See Hazard Levels,

page 2.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 7

Page 8

9. Venting and

Combustion Air

(cont'd)

1) Type of Pipe

Vent Pipe

Specific Venting Requirements

All pipe is field supplied. Requirements are listed for both the vent pipe and the combustion

air inlet pipe.

• Vent pipe approved for a Category III appliance OR single-wall, 26-gauge or heavier

galvanized (or a material of equivalent durability and corrosion resistance) vent pipe is

required between the heater and the concentric adapter box.

• Double-wall (Type B) vent pipe is required for vent terminal section. The length of

vent pipe that extends through the box and runs concentric through the combustion air

pipe must be one-piece with no joints.

Combustion Air Pipe

2) Venter Outlet and

Combustion Air Inlet

• NOTE: If using 7" pipe on

Sizes 200-400 (see table

below), use a taper-type 6"

to 7" enlarger to attach the

vent pipe and a 7" to 6"

reducer to attach the

combustion air pipe.

3) Pipe Length

and Diameter

Pipe Diameter and

Maximum Pipe Length

Between the Heater and

the Concentric Adapter

Box

• Minimum length between the

heater and the concentric

adapter box is 5 feet (1.5M).

Diameters of Outdoor

Concentric Pipes

Model SCE - All Sizes

Inl et Ai r Pi pe

Diameter

Vent Pipe Diame ter

8"

203mm

5"

127mm

• Sealed, single-wall galvanized pipe is recommended for combustion air.

Model SCE heaters have both an inlet air and a venter outlet connection. Both are 6" diameter for all sizes.

Taper-type

Enlarger

Airflow

Taper-type

Reducer

Airflow

Pipe diameter and length requirements listed for the indoor sections of pipe (between the

heater and the concentric adapter box) are in the table below. Vent pipe diameters and

maximum indoor vent lengths apply to both horizontal and vertical vents. Add all straight

sections and equivalent lengths for elbows. The total length of the straight sections and

elbows must not exceed the Maximum Length.

Pipe Diameter and Maximum Pipe Length from Heater to Conc entr ic Adapter

Pipe Diameter

SCE

125

150

175

200

225

250

300

350

400

The diameters of the outside (terminal) concentric pipes are shown in the concentric box

connection illustrations in FIGURE 11, page 11. The outdoor lengths depend on the instal-

lation. Outdoor vent length requirements are listed in the installation instructions for the

horizontal and vertical vent/combustion air kits on pages 12-17.

Vent Pipe Inlet Air Pipe

inches mm inches mm feet M feet M feet M

6 152 6 152 50 15 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

6 152 6 152 50 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

6 152 6 152 30 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

6 152 6 152 30 15 8 2.4 4 1.2

7 178 7 178 70 21 8 2.4 4 1.2

Venter Outlet Connection (diameter)

SCE 125 150 175 200 225 250 300 350 400

inches666666666

mm 152 152 152 152 152 152 152 152 152

Combus tion Air Inlet Connection (diameter)

SCE 125 150 175 200 225 250 300 350 400

inches666666666

mm 152 152 152 152 152 152 152 152 152

Maxi mum

Length 90° Elbow

Equivalent Straight Length for a

45° Elbow

4) Joints and Sealing

Form RZ-NA I-SCE, Page 8

Provide pipes as specified in Requirement No. 1 and seal joints as follows:

• If using Category III

joining and sealing Category III vent pipe sections.

• If using single-wall vent pipe run, secure slip-fit pipe connections using sheetmetal

screws or rivets. Seal all joints with aluminum tape or silicone sealant.

vent pipe run, follow the pipe manufacturer’s instructions for

Page 9

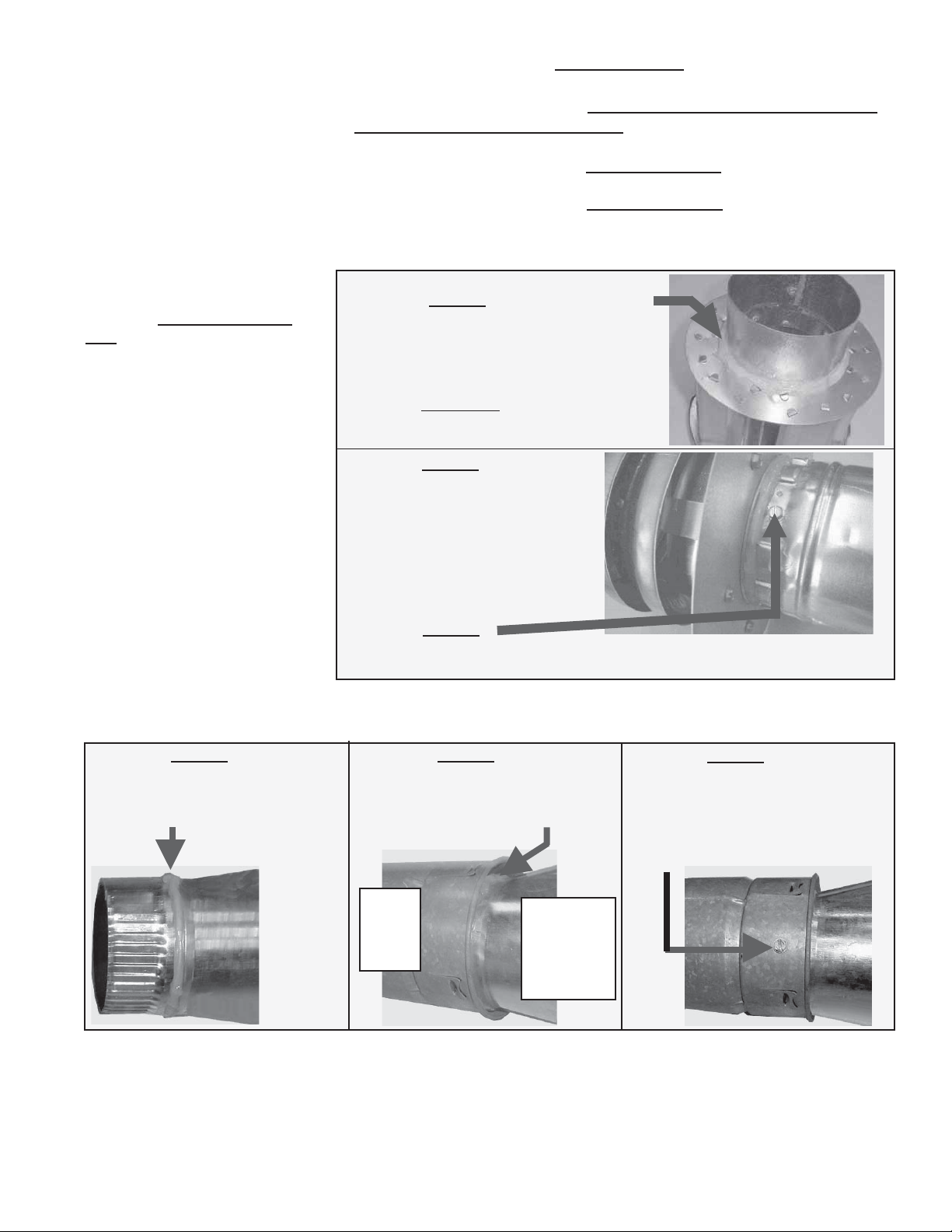

FIGURE 8 - Follow STEPS to

join Double-Wall (Type B)

Pipe and

the Vent Terminal

Cap (horizontal or vertical)

(NOTE: Pipes and vent caps may

not look exactly as shown in the

illustrations. Instructions apply to

both horizontal and vertical vent

kits.)

• To seal joints in the single-wall combustion air pipe, secure slip fit pipe connections

using sheetmetal screws or rivets. Seal all joints with aluminum tape or silicone sealant.

• To seal joint in the terminal section of double-wall vent pipe (allowed ONLY ABOVE

the concentric pipes on a VERTICAL vent, follow the pipe manufacturer’s instructions

for joining and sealing double-wall vent pipe sections.

• When joining the terminal section of

illustrated step-by-step instructions in FIGURE 8.

When joining the terminal section of double-wall vent pipe to a single-wall or Category III vent pipe run, follow the illustrated step-by-step instructions in FIGURE 9.

Figure 8 -

Place a continual 3/8” bead of silicone sealant

around the circumference of the vent cap collar. This will prevent any water inside the vent

cap from running down the double-wall pipe.

Do STEP 2 immediately following STEP 1.

STEP 1

Figure 8 - STEP 2

Insert the collar on the vent cap inside the

inner wall of the double-wall pipe. Insert

as far as possible. Add additional silicone

sealant to fully close any gaps between

the vent cap and the double wall pipe.

This is necessary to prevent water from

entering the double wall pipe.

double-wall vent pipe to the vent cap, follow the

FIGURE 9 - Follow STEPS

to join the Double-Wall (Type

B) Pipe to the Taper-type

Reducer that Joins it to the

Single-Wall or Category III

Vent Run

Figure 9 -

On the taper-type reducer, place a continual 1/4” bead of silicone sealant around

the circumference.

STEP 1

Do STEP 2

immediately

following

STEP 1.

5) Support

NOTE: The double-wall vent

terminal pipe does not attach to the

concentric adapter box and must be

supported during installation.

Figure 8 - STEP 3

Secure the vent cap to the double-wall pipe by drilling and inserting a 3/4” long sheetmetal

screw into the vent cap collar. Do not overtighten screw.

Make this connection a maximum of 6" (152mm) from the concentric adapter box.

Figure 9 - STEP 2

Insert the collar of the reducer into the

inner pipe of the double-wall pipe until the

bead of sealant contacts the inner

pipe creating a sealed joint.

5" I.D.

Double-

Wall

Pipe

6" to 5" or

7" to 5"

Taper-

Type

Figure 9 - STEP 3

Spaced equally around the double-wall

pipe, drill three small holes below the

sealant ring. Insert 3/4 inch long

sheetmetal screws to secure the joint. Do

not overtighten screws.

Reducer

Support horizontal runs every six feet (1.8M). Support vertical runs of type "B" double-wall

or Category III vent pipe in accordance with the requirements of the pipe manufacturer.

Support single-wall vertical pipe in accordance with accepted industry practices. Do not rely

on the heater or the adapter box for support of either horizontal or vertical pipes. Use noncombustible supports on vent pipe.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 9

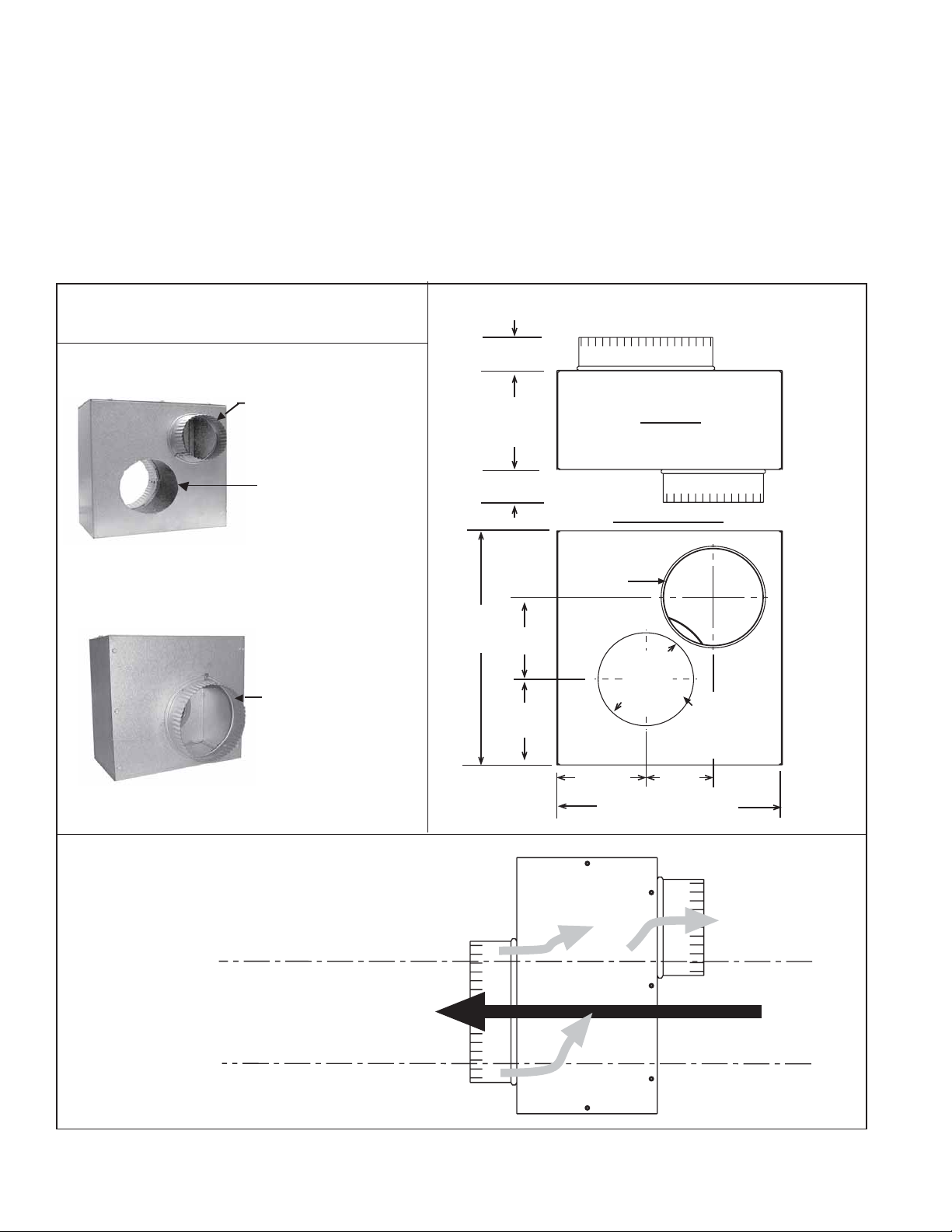

Page 10

9. Venting and Combustion Air (cont'd)

Specific Venting Requirements (cont'd)

6) Clearance

7) Concentric

Adapter Box

Do not enclose the vent pipe or place pipe closer than 6" (152mm) to combustible material.

All separated combustion installations require a concentric adapter box as illustrated in FIGURE 10.

The concentric adapter box is included in the vent/combustion air kit. Installation instructions depend

on whether the vent system is horizontal (Option CC6) or vertical (Option CC2).

FIGURE 10 - A Concentric Adapter Box is a

Required Part of all Model SCE Installations

View of Heater Connection Side

Collar for connecting

indoor portion of the

combustion air pipe

Opening for

double-wall vent

pipe to pass

through the box.

P/N 205885, Concentric Adapter Box

2 (51mm)

6-1/32

(153mm)

2 (51mm)

Top View

Heater Side View

6 Collar for

Combustion

Air Pipe

8 dia Collar for

Combustion Air Pipe

View of Vent Terminal Connection Side

Collar for

attaching outside

concentric portion

of the combustion

air pipe

Concentric Adapter Box Airflow

Vent (exhaust gas) flows through

field-supplied double-wall pipe

that extends straight through

the concentric adapter box.

14-1/4

(362mm)

End View

showing

Airflow

5

(127mm)

5-7/32

(133mm)

5-21/32

(144mm)

5-9/32

(134mm)

13-3/8 (340mm)

diameter

4

(102mm)

Opening for

vent pipe to

pass through

the box

Gray Arrows

show Flow of

Combustion Air

Form RZ-NA I-SCE, Page 10

Page 11

Pipe Connections at

the Concentric

Adapter Box

FIGURE 11 - Concentric

Adapter Box

Connections

When pipe diameters differ, depending on direction of airflow, join the pipes with either a tapertype reducer or enlarger. Refer to illustrations in FIGURE 11 for pipe connection requirements at

the concentric adapter box.

Do NOT make actual connections until after reading the instructions and length requirements for

installing the vent/combustion air kit. The connection requirements are the same for both verti-

cal and horizontal systems, but the length of the double-wall pipe will vary.

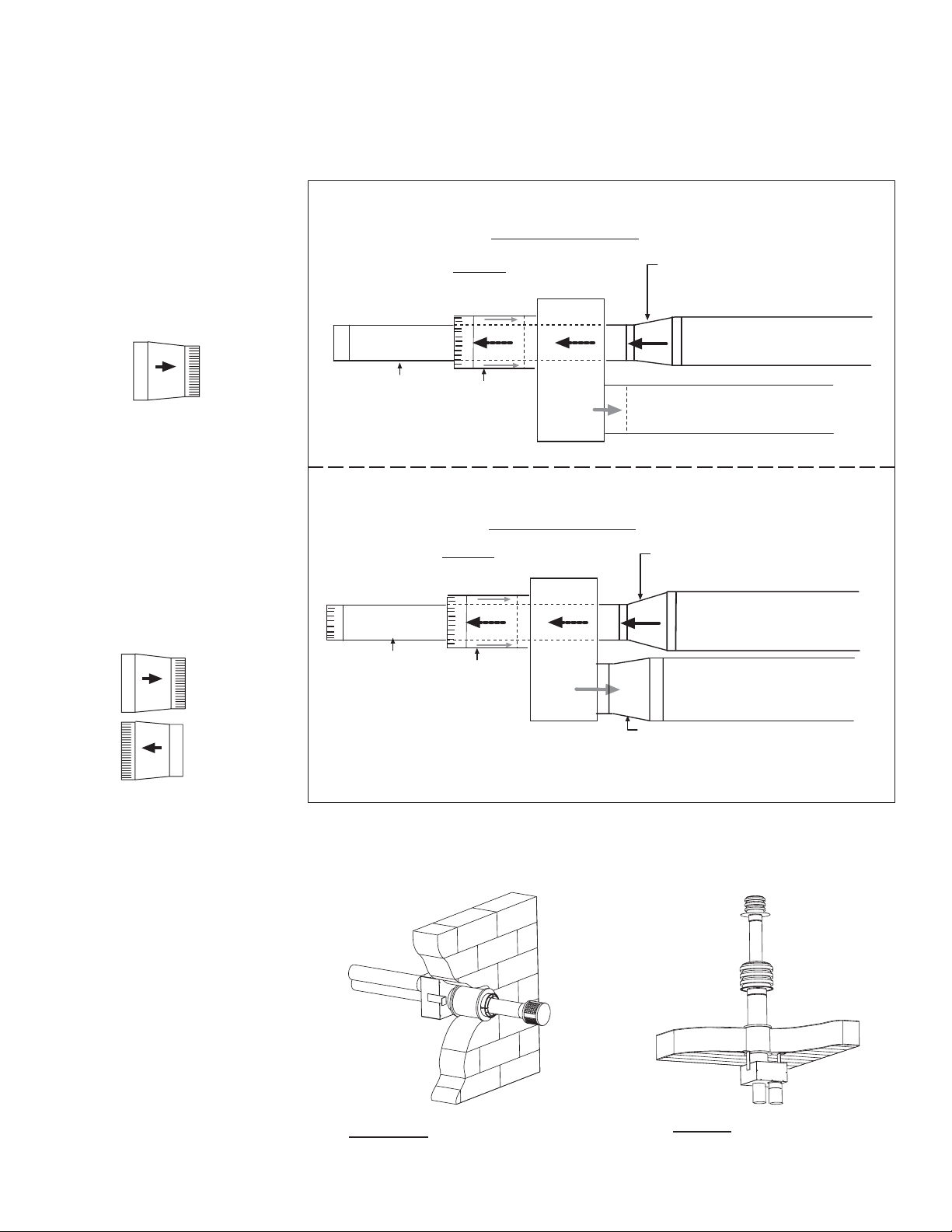

Model SCE 125-400 - Pipe diameters and connections required at the

concentric adapter box when using 6 pipes between the furnace and the box

• If using 6” diameter pipes,

Model SCE always require a

6” to 5” (152 to 127 mm)

reducer in the vent pipe.

Taper-type

Airflow

Reducer

• If using 7” diameter pipes

(allowed on Sizes 200-400),

Model SCE always requires

a 7” to 5” (178 to 127 mm)

reducer in the vent pipe and

a 6” to 7” (152 to 178 mm)

enlarger for attaching the

combustion air pipe.

Taper-type

Airflow

Airflow

Reducer

Taper-type

Enlarger

Requires a 6 to 5 inch (152 to 127mm)

taper-type reducer a maximum of 6

(152mm) from the concentric adapter

box.

6 (152mm) diameter single-wall

or Category III vent pipe attaches

to the heater

6 (152mm) diameter single-wall

inlet air pipe attaches to the heater

5 (127mm)

inside diameter

double-wall

vent pipe

Top View of Concentric Adapter

Box showing Pipe Connections

8 (203mm)

diameter

single-wall

inlet air pipe

Model SCE 200-400 - Pipe diameters and connections required at the

concentric adapter box when using 7 pipes between the furnace and the box

5 (127mm)

inside diameter

double-wall

vent pipe

Top View of Concentric Adapter

Box showing Pipe Connections

8 (203mm)

diameter

single-wall

inlet air pipe

Requires a 7 to 5 inch (178 to 127mm)

taper-type reducer a maximum of 6

(152mm) from the concentric adapter box.

7 (178mm) diameter single-wall

or Category III vent pipe attaches

to the heater

7 (178mm) diameter single-wall

inlet air pipe attaches tot he heater

Requires a 6 to 7 inch (152 to 178mm)

taper-type enlarger at the concentric

adapter box.

HORIZONTAL OR VERTICAL?

Is the Separated

Combustion Vent/

Combustion Air

System Horizontal or

Vertical?

Horizontal, Option CC6,

instructions begin on page 12.

Vertical, Option CC2,

instructions begin on page 15.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 11

Page 12

HORIZONTAL VENT

INSTRUCTIONS

Components Required Factory and Field

Parts in the Horizontal Vent

Terminal/Combustion Air

Package (Option CC6)

Qty P/N Des cription

1 205883 Comp let e Ho rizont al Ven t Kit (Sa me as Opt ion CC6)

1 205885 Concentric Ad ap ter Box A ssembly (See

1 53316 Screened Exhaust Assembly (illustrated below)

1 205894 Inlet Guard (illustrated below)

4 37661 #10-16 x 1/2" long Sc rews to attach th e in let gu ard

2 207232 Brackets for attaching Concentric Adapter Box (See

1 53335 Tube of High Temperature (450°F) Silicone Sealant

FIGURE 10

Screened

Exhaust

Assembly,

Inlet Guard,

P/N 205894

P/N 53316

, page 10.)

FIGURE 12,

page 13.)

Field-supplied installation

requirements:

Installation Instructions

for Horizontal Vent Kit

Option CC6

Clearances to Horizontal

Vent Terminal

WARNING: All vent

terminals must be

positioned or located

away from fresh air

intakes, doors and

windows to preclude

combustion products

from entering occupied

space. Failure to comply

could result in severe

personal injury or death

and/or property damage.

Form RZ-NA I-SCE, Page 12

• Vent pipes - see requirements, page 8.

• Combustion air pipes - see requirements, page 8.

• Taper-type vent pipe diameter reducers and/or increasers as required.

• Thimble (a thimble is not required if wall is of non-combustible construction).

• Flashing.

• Sheetmetal screws, tape, and sealant as required.

1. Determine the location on the outside wall for the vent terminal. Location must comply

with vent length requirements, Requirement No. 3 on page 8. In most applications, the

terminal would be on a level with the heater mounting height. Allow 1/4" per foot (6mm per

305mm) downward pitch for condensate drain.

The distance of the termination of the horizontal vent from adjacent public walkways, adjacent buildings, openable windows, and building openings must be in accordance with local

codes or, in the absence of local codes, must conform with National Fuel Gas Code Z223.2.

Local codes supersede all provisions in these instructions and in the National Fuel Gas

Code. Minimum clearances for the horizontal vent terminal are shown below. Also, select a

location that complies with adjoining building clearances as shown in FIGURE 13, page 14.

Products of combustion can cause discoloring of some building finishes and deterioration of

masonry materials. Applying a clear silicone sealant that is normally used to protect concrete

driveways can protect masonry materials. If discoloration is an esthetic problem re-locate the

vent or install a vertical vent.

Structure

Forced air inlet with in 10 ft (3.1M)* 3 ft (0.9M ) above

Combustion air inlet of another appliance 6 ft (1.8M)

Door, window, or gravity air inlet (any

building opening)

Electric meter, gas meter ** an d relief

equipment

Gas regu lato r ** U.S. - 3 ft (0.9M); Cana da - 6 ft (1.8M) horizo ntally)

Adjoining building or parapet 6 ft (1.8M)

Adjacent public walkways 7 ft (2.1M) above

Grade (gro un d level) 3 ft (.9M ) ab ov e***

*Does not apply to the inlet of a direct vent appliance. **Do not terminate the vent directly

above a gas meter or service regulator. *** Consider local snow depth conditions. The vent

must be at least 6” (152mm) higher than anticipated snow depth.

2. Install the Vent Pipe and Combustion Air Pipe Runs - Use the type of pipe specified in

Requirement No. 1, page 8. Comply with requirements in Requirement No. 2 and No. 4, page

8, when attaching pipes to the heater.

Seal all joints. Due to the high temperature, do not enclose the exhaust pipe or place pipe

closer than 6" (152 mm) to combustible material. Extend the runs close to the wall location

selected in Step 1. Support pipes as required in Requirement No. 5, page 10.

Minimum Cle arance s for Ve nt Terminal

Location (all dire ctio ns unless s pecified)

4 ft (1.2M ) ho rizontally

4 ft (1.2M ) below

1 ft (305mm) above

U.S. - 4 ft (1.2M) horizon tally ; Can ad a - 6 ft (1.8M)

Page 13

HORIZONTAL VENT

INSTRUCTIONS

(cont’d)

3. Prepare a hole through the outside wall for the 8" (203mm) diameter combustion air

pipe. Outside wall construction thickness should be between 1" (25mm) minimum and 48"

(1143mm) maximum. The larger diameter combustion air pipe serves as clearance for the

vent pipe on non-combustible construction. A thimble may be required depending on wall

construction and/or local codes.

4. Prepare the Concentric Adapter Box

a) Attach the brackets to the box. Follow the instructions in FIGURE 12.

FIGURE 12 - Brackets for

Attaching the Concentric

Adapter Box to the Wall

2) Attach the Box to the Wall (Step 5)

When the box is attached to the wall in Step 5,

use the 2-1/2 (64mm) portion of the brackets.

To adjust to construction each bracket has

three 7/32 diameter holes.

1) Attach the Brackets to the Box - The 6

(152mm) portion of each bracket is designed

with five 7/32 diameter holes so that attach ment to the box can be adjusted.

If the wall is combustible, position brackets to allow

for a 2 (51mm) clearance between the box and the

wall.

Adjust bracket attachment to allow for the slight

downward pitch of the terminal vent pipe.

After careful positioning, use sheetmetal screws to

attach the brackets. NOTE: If any holes are

made in the box in error, they must be sealed.

b) Attach the outside portion of the combustion air pipe to the box. Determine the length

by measuring the bracket length from box to wall, plus the wall thickness, plus 2" (51 mm).

(The inlet air pipe should extend beyond the outside wall approximately 2" (51mm).)

Attach the inlet air pipe to the collar of the concentric adapter with sheetmetal screws and

seal.

5. Attach the concentric adapter box to the wall. Insert the combustion air pipe through

the wall. Attach the brackets (FIGURE 12) to the wall. On the outside, caulk or flash the

inlet air pipe. Flashing is field-supplied.

6. Position the inlet guard over the end of the combustion air pipe. See FIGURE 13, page

14. Attach the guard to the inlet air pipe with the four 1/2" long screws provided.

7. Determine length and install the double-wall terminal vent pipe.

a) Determine length of pipe. The length of the vent pipe is determined by the installation

within the maximum and minimum requirements. The vent pipe extending through the box

and the inlet air pipe must be one piece of double-wall vent pipe without joints. See FIGURE

13, to determine lengths of each segment and calculate the total length required. The transition to the single-wall or Category III vent pipe run, must be made a maximum of 6” (152mm)

from the heater side of the box.

b) Install double-wall terminal vent pipe. Being sure the vent pipe is in the proper flow

direction, slide the end through the box. Position the vent pipe so that it will extend between

16" (406mm) and 24” (610mm) past the end of the combustion air pipe and no more than 6”

(152mm) out of the box toward the heater.

Use a taper-type reducer to attach the 5" double-wall vent pipe to the 6" or 7" single-wall or

Category III vent pipe run. Follow the instructions in FIGURE 9 , page 9.

8. Attach the exhaust (vent) cap to the end of the vent pipe. Align the cap so that its baffle

strips are positioned on the horizontal and vertical centerlines (See FIGURE 13). Follow

the instructions in FIGURE 8, page 9, to attach the exhaust cap. (NOTE: If vent pipe is

inserted from outside, cap may be attached before the double-wall vent pipe is installed. If

cap is attached first, be sure the baffle strips are positioned correctly when attaching the

vent terminal pipe to the vent run.)

9. Seal the vent pipe. Verify that the double-wall section of vent pipe has a slight downward

drop (1/4” per foot/6mm per 305mm) toward the vent terminal end. Use silicone sealant and

seal the circumference of the pipe and the opening of the box. Seal the area around the pipe

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 13

Page 14

HORIZONTAL VENT

INSTRUCTIONS

(cont’d)

FIGURE 13 - Installation

of a Typical SeparatedCombustion Unit with

Horizontal Vent and

Combustion Air Pipes

(Option CC6)

completely.

10. Attach the indoor combustion air pipe. If using 6" pipes, attach the single-wall combustion air pipe run to the collar on the concentric adapter box with sheetmetal screws. If using

7” pipe on Sizes 200-400, install a taper type enlarger as illustrated In FIGURE 11, page 11.

Seal joints with tape or sealant.

Installation of the horizontal vent and combustion air system on your separated-combustion unit is complete. Verify compliance with all venting installation requirements, pages

8-11, and FIGURE 13.

One piece of

Double-Wall

Vent Pipe

Screened

Exhaust

Cap

Top View

2 (51mm)

Inlet Air

Guard

16 (406mm)

minimum

24 (610mm)

maximum

Wall

1 (25mm)

minimum

48

(1219mm)

maximum

Building Overhang

2 (51mm) if wall is combustible

Attach box to wall with brackets.

Combustion Air to heater (seal joints)

Vent (Flue Exhaust) Pipe

from heater (seal joints)

Attach double-vent pipe to vent run no

6

(152

mm)

more than 6 (152mm) from the box. A

taper-type reducer is required.

Distance between the

Concentric Adapter Box

Box

and the Heater

For Maximum Length,

Adapter

Concentric

see Table on page 8.

Minimum length is 5 ft (1.5M).

Heater

Side View

6 ft (1.8M) minimum

Adjoining Building

Form RZ-NA I-SCE, Page 14

3 ft (1M)

minimum

6-15/16

(176mm)

3 ft (1M)

minimum

Building Projection

Exhaust (Vent) Cap

IMPORTANT: Install exhaust cap so the baffles

are positioned at 12:00, 3:00, 6:00, and 9:00 oclock.

Double-Wall

Vent Pipe -

Pitch to

Drain

Inlet Air

Guard

Wall

Combustion Air Pipe Pitch to Drain

Concentric

Adapter Box

Thimble

Page 15

VERTICAL VENT

INSTRUCTIONS

Components

Required - Factory

and Field

Parts in the Vertical Vent

Terminal/Combustion Air

Package (Option CC2)

Qty P/N De s cription

1 205896 Complete Vertical Vent Kit (Same as Option CC2)

1 205885 Concentric Adapter Box Assembly (See

1 53326 Exhau st (Vent) Terminal (illus trated below)

1 53330 Co mbu s tion Air (illus trat ed below)

2 207232 Brackets for attaching Concentric Adapter Box (See

1 53335 Tube of High Temperature Silicone Sealant

Exhaust

(Vent)

Terminal,

P/N 53326

Combustion

Air Inlet,

P/N 53330

FIGURE 1 0

, page 10)

FIGUR E 1 4

, belo w.)

Field-supplied installation

requirements:

Installation

Instructions

for Vertical Vent/

Combustion Air Kit

Option CC2

WARNING: All vent

terminals must be

positioned or located

away from fresh air

intakes, doors and

windows to preclude

combustion products

from entering

occupied space.

Failure to comply

could result in severe

personal injury or

death and/or property

damage.

• Vent pipes - see requirements, page 8.

• Combustion air pipes - see requirements, page 8.

• Taper-type pipe diameter reducers and/or increasers as required.

• Thimble (a thimble is not required if wall is of non-combustible construction).

• Flashing.

• Sheetmetal screws, tape, and sealant as required.

1. Determine the location of the vent terminal.

Select a location away from fresh air intakes, allowing space for the concentric adapter box inside.

Vent terminal must be located from adjacent buildings as shown in FIGURE 18, page 17.

If more than one vertical concentric vent/combustion air terminal (Option CC2) is being installed,

the minimum spacing between vent centerlines is determined by the minimum outdoor design

temperature (most extreme outdoor condition at the installation site).

Mi ni mum Ou tdo or Des i g n

Temperature

°F °C inches

31 or warmer 0 o r warmer 36 914

-10 to 30 -23 to -1 60 1524

less than -10 less than -23 84 2134

2. Install the Vent Pipe and Combustion Air Pipe Run - Use the type of pipe specified (Requirement No. 1, page 8), and comply with the attachment requirements in Requirement No. 2 and No.

4, page 8. Length must comply with Requirement No. 3, page 8.

Seal all joints. Due to the high temperature, do not enclose the exhaust pipe or place pipe closer

than 6" (152 mm) to combustible material. Provide supports for the pipes. Extend the runs to close

to the roof at the location selected in Step 1 above.

3. Prepare a hole through the roof for the 8" (203mm) diameter combustion air pipe. A

thimble may or may not be required depending on building construction and/or local codes.

The larger diameter combustion air pipe serves as clearance for the vent pipe on non-combustible construction.

4. Prepare the Concentric Adapter Box

a) Attach the brackets to the box. Follow the instructions in FIGURE 14.

2) Attach the Box to the Roof (Step 5)

When the box is attached to the roof in Step 5, use the

2-1/2 (64mm) portion of the brackets. To adjust to

construction each bracket has three 7/32 diameter holes.

Minimum S pacing between Centerlines of Vent Pipes in

Vertical Combustion Air/Vent Terminals (Option CC2)

mm

FIGURE 14 - Brackets

for Attaching the

Concentric Adapter Box

to the Roof

1) Attach the Brackets to the Box - The 6 (152mm)

portion of each bracket is designed with five

7/32 diameter holes so that attachment to the

box can be adjusted.

If the roof is combustible, position brackets to allow for

a 2 (51mm) clearance between the box and the roof.

After careful positioning, use sheetmetal screws to

attach the brackets. NOTE: If any holes are made in

the box in error, they must be sealed.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 15

Page 16

VERTICAL VENT

INSTRUCTIONS (cont’d)

FIGURE 15 - Assemble

Concentric Adapter Box,

Outdoor Combustion Air

Pipe, and Double-Wall Vent

Pipe

b). Attach the outside portion of the combustion air pipe to the box. Determine the length of

the combustion air pipe so that dimension ”X” in FIGURE 15 is equal to the bracket length,

plus the roof thickness, plus anticipated snow depth, but does not exceed 48“ (1219mm) or

have less than 18” (457mm) of pipe above the roof. Attach the inlet air pipe to the collar of the

concentric adapter box with sheetmetal screws.

A second section

of double-wall pipe

is permitted, joining

the long continuous

piece of vent pipe a

minimum of 3 (76mm)

above the top of the

combustion air pipe.

3 (76mm)

minimum

Vent pipe

extending

through the

box and the

combustion

air pipe MUST

be one continuous

piece of doublewall vent pipe.

pipe must not exceed 48 (1219mm).

Extend length of double-wall

22 (559mm) minimum

Cold Climate NOTE:

In geographic areas where

the design ambient is -10°F

or lower, this minimum

height is 34 (864mm).

X = length of

combustion air pipe required

through and above the roof.

Height from box to top of inlet air

Minimum height above the roof is

18 (457mm) and must be higher

than anticipated snow depth.

Double-Wall Vent Pipe -

vent pipe a maximum of 6

(152mm) below the box.

After box is installed, install Concentric Vent Pipe One piece of continuous double-wall pipe must extend

from a minimum of 3 (76mm) above the outer combustion air pipe to a maximum of 6 (152mm) below

the box. (NOTE: Vent pipe does not attach to the box;

it must be supported.)

Vent Flow

1) Calculate height (see requirements on the left).

2) Be sure vent flow marking on pipe is in the right

direction.

3) Slide pipe through the box and the outer inlet air pipe.

4) Attach to vent run no more than 6 (152mm) from the

adapter box. See instructions on page 9.

First, attach Combustion Air Pipe and install the

Concentric Box

1) Determine length (X) of pipe (see requirements

on the left).

2) Attach the pipe to the collar on the box.

3) Attach the brackets to the roof.

Mounting Brackets

Concentric

Adapter Box

Collar for Indoor Portion of

the Combustion Air Pipe

FIGURE 16 - Slide attached

Combustion Air Pipe up

through the Roof

Snow Clearance

18 (457mm) minimum

(NOTE: Maximum

from concentric adapter

box is 48 (1219mm)

Outside view with concentric

adapter box attached to underside of roof. Install field-supplied

flashing at roof opening.

Form RZ-NA I-SCE, Page 16

5. Attach the concentric adapter box to the roof. On the inside, insert the combustion air

pipe up through the opening and attach brackets to the roof. (See FIGURES 15 and 16.)

On the outside, flash the combustion air pipe to the roof. Flashing is field supplied.

6. Determine the length and install the double-wall vent pipe.

a) Determine the length. See FIGURE 15 to determine the required length of the vent pipe.

The vent pipe extending through the box and the inlet air pipe must be one piece of doublewall vent pipe without joints.

Determine the length by adding the requirements. Starting at the top, the vent pipe must

extend a minimum of 22” (559mm) beyond the top of the inlet air pipe; plus the width of the

roof; plus length of brackets; plus 6” (152mm) through the box; plus 6” (152mm) extending

out of the box on the heater side.

b) Install the pipe. Being sure the pipe is in the proper flow direction, slide the end into the

box and out through the combustion air pipe. Position the vent pipe to the lengths determined above. NOTE: The double-wall vent pipe does not attach to the box. The installer

must provide support.

Follow the instructions in FIGURE 9 , page 9, for connecting the double-wall pipe to the

single-wall pipe or Category III vent pipe run. A taper-type reducer is required.

Seal the circumference of the pipe and the opening of the box with silicone sealant. Seal the

area around the pipe completely.

Page 17

FIGURE 17 - Install Combustion Air Inlet and Vent Terminal

m

SECOND, Install the Exhaust (Vent) Terminal.

Follow the instructions in FIGURE 8, page 9.

12 (305mm) minimum

Cold Climate NOTE: In geographic areas where

the design ambient is -10°F or lower, this minimum

height is 24 (610mm)

5 Inside Diameter

Double-wall Vent Pipe

FIRST, Install Combustion Air Inlet.

1) Slide the combustion air inlet over the vent pipe.

2) Fasten bottom of inlet to the combustion air pipe with

sheetmetal screws. Be sure not to penetrate the vent pipe.

3) At the top, completely seal the space between the vent

pipe and the air inlet with silicone.

8 Diameter Single-wall Combustion Air Pipe

Installation of the vertical vent and combustion air system on your separated-

FIGURE 18 - Installation of Unit

with Vertical Vent Terminal/

combustion unit is complete. Verify compliance with all venting installation requirements, pages 8-11, and FIGURE 18 below.

Combustion Air Inlet (Option CC2)

7. On the outside, slide the combustion air inlet

over the vent pipe and fasten the collar to the

combustion air pipe with sheetmetal screws. See

FIGURE 17. Seal the opening at the top

between the vent pipe and the combustion air

inlet with silicone sealant to prevent water

leakage.

8. Attach the exhaust (vent) cap. Follow the

illustrated instructions in FIGURE 8 , page 9.

9. Attach the indoor combustion air pipe. Use

sheetmetal screws to attach the single-wall

combustion air pipe run to the collar on the

concentric adapter box.

If using 7” pipe on Sizes 200-400, install a taper

type enlarger as illustrated in FIGURE 11, page

11.

Seal joint with tape or sealant.

Rear

View

Flashing

(field-supplied)

Roof

Vent (flue

exhaust) Terminal

Double-wall Vent

(flue exhaust) Pipe

Seal with silicone

sealant supplied

with the kit.

Combustion

Air Inlet

Shaded area represents

required continuous (no

joints) section of doublewall vent pipe. Section of

pipe may extend higher.

Side View

6 ft (1.8M) minimum

Wall or

Adjoining

Building

Flashing

(field-supplied)

2 (51mm) if roof is combustible

Attach box to roof with brackets.

Roof

9-3/8 (238mm)

12 (305mm) minimum

Cold Climate NOTE:

In geographic areas where

the design ambient is -10°F

or lower, this minimum

height is 24 (610mm).

11 (279mm)

*18

(457mm)

minimum

(Top of Box)

Concentric

Adapter Box

4 ft (1.2M)

maximum

Combustion

Air Pipe

Concentric

Adapter

Box

One-piece of Double-Wall

Vent Pipe

Use taper-type reducer to

attach to vent run a maximu

*Inlet air cap must be at least 6

higher than anticipated snow depth.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 17

Page 18

10. Gas Piping and

Pressures

WARNING

This appliance is equipped for a maximum gas supply pressure of 1/2 psi, 3.5 kPa, or 14 inches

water column. NOTE: Supply pressures higher than 1/2 psi require installation of an additional service regulator external to the unit.

Pressure Testing Supply Piping

Test Pressure Above 1/2 PSI: Disconnect the heater and manual valve from the gas supply

which is to be pressure tested. Cap or plug the supply line.

Test Pressure Below 1/2 PSI: Before testing, close the manual valve on the heater.

WARNING: Manifold gas pressure must never exceed 3.5" w.c. for

natural gas or 10" w.c. for propane gas.

All piping must be in accordance with requirements outlined in the National Fuel Gas Code

ANSI/Z223.1 (latest edition) or CSA B149.1 and B149.2 (See Paragraph 1.) Gas supply piping

installation should conform with good practice and with local codes.

These separated-combustion units for natural gas are orificed for gas having a heating value

of 1000 (±50) BTUH per cubic ft. If the gas at the installation does not meet this specification,

consult the factory for proper orificing.

Seal the opening for the gas supply pipe with the grommet provided.

Pipe joint compounds (pipe dope) shall be resistant to the action of liquefied petroleum gas

or any other chemical constituents of the gas being supplied.

Install a ground joint union and manual shutoff valve upstream of the unit control system.

The 1/8" plugged tapping in the shutoff valve provides connection for supply line pressure

test gauge. The National Fuel Gas Code requires the installation of a trap with a minimum 3"

drip leg. Local codes may require a longer drip leg, typically 6" (See FIGURE 19.).

WARNING: All

components of a gas

supply system must be

leak tested prior to placing

the equipment in service.

NEVER TEST FOR

LEAKS WITH AN OPEN

FLAME. See Hazard

Levels, page 2.

FIGURE 19 - Gas

Connection

Form RZ-NA I-SCE, Page 18

Gas Connection (Standard Unit)

Model Size 125-250 300-400

Natural Gas 1/2" 3/4"

Propane Gas 1/2" 1/2"

NOTE: The above are gas connection sizes; not supply line sizes.

After all connections are made, disconnect the pilot supply at the control valve and bleed the

system of all air. Reconnect the pilot line and leak test all connections by brushing on a soap

solution.

6 I.D. Combustion

Air Inlet Collar

6O.D. Vent Connection

Control Side View

Seal with Grommet

1-1/2

(38)

Ground

Joint

Union

A manual shutoff

valve with 1/8 NPT

plugged tap, accessible

for test gauge connection, must be installed

immediately upstream

of the gas supply

connection.

2-3/4

(70)

Drip Leg

Page 19

Sizing Gas Supply Lines

Length Diameter of Pipe

of 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Pipe Natural Pro pane Natural Pro pane Natural Pro pane Natural Pro pane Natu ral Propane Natu ral Propane

20' 92 56 190 116 350 214 730 445 1100 671 2100 1281

30' 73 45 152 93 285 174 590 360 890 543 1650 1007

40' 63 38 130 79 245 149 500 305 760 464 1450 885

50' 56 34 115 70 215 131 440 268 670 409 1270 775

60' 50 31 105 64 195 119 400 244 610 372 1105 674

70' 46 28 96 59 180 110 370 226 560 342 1050 641

80' 43 26 90 55 170 104 350 214 530 323 990 604

90' 40 24 84 51 160 98 320 195 490 299 930 567

100' 38 23 79 48 150 92 305 186 460 281 870 531

125' 34 21 72 44 130 79 275 168 410 250 780 476

150' 31 19 64 39 120 73 250 153 380 232 710 433

175' 28 17 59 36 110 67 225 137 350 214 650 397

200' 26 16 55 34 100 61 210 128 320 195 610 372

Note: When sizing sup ply lines, consider pos sibilit ies of future exp ansion and increased requirements.

Capacity of Piping

Cubic Feet p er Hour based on 0.3" w .c. Pressure Drop

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Refer to National Fuel Gas Code for additional information on line siz ing.

Manifold or Orifice

(Valve Outlet) Pressure

Settings

Measuring manifold gas pressure cannot be done until the heater is in operation. It is

included in the steps of the "Check-Test-Start" procedure in Paragraph 25. The following

warnings and instructions apply.

For Natural Gas: When the heater leaves the factory, the combination valve is set so that the

outlet gas pressure of a single-stage valve or high fire of a two-stage valve is regulated to

3.5" w.c. Low fire on a two-stage valve is set to 1.8" w.c. Inlet supply pressure to the valve

must be a minimum of 5" w.c. or as noted on the rating plate and a maximum of 14" w.c. NOTE:

Always check the rating plate for minimum gas supply pressure. Minimum supply pressure

requirements vary based on size of burner and the gas control option. Most units require a

minimum of 5" w.c. of natural gas as stated above, but Sizes 350 and 400 with electronic

modulation require a minimum of 6" w.c. natural gas supply pressure. Sizes 300 and 350 with

mechanical modulation require 7" w.c.

For Propane Gas: When the heater leaves the factory, the combination valve is set so that

the outlet gas pressure of a single-stage valve or high fire of a two-stage valve is 10" w.c.

Low fire on a two-stage valve is set to 5" w.c. Inlet pressure to the valve must be a minimum

of 11" w.c. and a maximum of 14" w.c.

Before attempting to measure or adjust manifold gas pressure, the inlet (supply) pressure

must be within the specified range for the gas being used both when the heater is in operation and on standby. Incorrect inlet pressure could cause excessive manifold gas pressure

immediately or at some future time.

Instructions to Check Valve Outlet (Manifold) Pressure:

1) With the manual valve (on the combination valve) positioned to prevent flow to the main

burners, connect a manometer to the 1/8" pipe outlet pressure tap in the valve. NOTE: A

manometer (fluid-filled gauge) is recommended rather than a spring type gauge due to the

difficulty of maintaining calibration of a spring type gauge.

2) Open the valve and operate the heater. Measure the gas pressure to the manifold. To

measure the low stage pressure on units equipped with a two-stage valve, disconnect the

wire from the "HI" terminal on the valve. (Be sure to reconnect the wire.)

Normally adjustments should not be necessary to the factory preset regulator. If adjustment

is necessary, set pressure to correct settings by turning the regulator screw IN (clockwise) to

increase pressure. Turn regulator screw OUT (counterclockwise) to decrease pressure. Consult the valve manufacturer's literature provided with the furnace for more detailed information.

Form RZ-NA I-SCE, Mfg #207697 Rev 4, Page 19

Page 20

11. Electrical Supply

and Connections

All electrical wiring and connections including electrical grounding must be made in accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or, in Canada, the

Canadian Electrical Code, Part I-CSA. Standard C22.l. Check any local ordinances or gas

company requirements that apply.

Check the rating plate on the heater for the supply voltage and the current requirements. A

separate line voltage supply with fused disconnect switch should be run directly from the

main electrical panel to the unit, making connections in the junction box. Refer to FIGURE 1,

Paragraph 3. Seal all electrical entrance openings with field-supplied bushings.

Field-Supplied Wiring Size from Disconnect to Electrical Box for

Connection to Motor Contactor or Starter

Voltag e/ Phas e Motor HP Wire Gauge BX Cable

120/1 1/4 - 1/2 14 3/8"

1123/8"

208-230/ 1 1 - 1-1/ 2 14 3/8"

208-230/ 3 1/4 - 3 14 3/ 8"

5123/8"

460/3 1/4 - 5 14 3/8"

575/3 1/2 - 5 14 3/8"

CAUTION: If any of the

original wire as supplied

with the appliance must be

replaced, it must be

replaced with wiring

material having a

temperature rating of at

least 105°C, except for

sensor lead and optional

bypass damper combustion

air safety circuit (Option

AG39 or AG40) wires

which must be 150°C. See

Hazard Levels, page 2.

12. Control

Thermostat

A disconnect switch is available as optional equipment or may be supplied locally. When

installing the disconnect switch, be careful that the conduit and switch housing are clear of

all service panels. Allow at least four feet (1.2M) of service room between the disconnect

switch and any removable service panels. When providing or replacing fuses in a fusible

disconnect switch, use dual element time delay fuses and size 1.25 times the maximum total

input amps.

The heater is equipped with a low voltage (24V) control circuit. See the typical wiring diagrams on pages 21 and 22; a specific wiring diagram can be found in the heater junction box.

See separate instruction sheets for any optional equipment provided. Optional equipment is

identified on the wiring diagram supplied with the heater.

Field Control Wiri ng - Length and Gauge

Total Wire

Le n gt h

150ft (46M) 75ft (23M ) #18 ga uge

250ft (76M) 125ft (38M) # 16 gauge

350ft (107M) 175ft (53M ) # 14 gaug e

A thermostat is not supplied with the furnace. Use either an optional or a field-provided lowvoltage (24V) thermostat. Install the thermostat according to the manufacturer's instructions.

A low voltage thermostat is equipped with a heat anticipator which levels out unit cycling for

optimum temperature control. Set the anticipator at 1.0 amps for standard controls. See chart

below for amp ratings of optional controls.

Distance from

Unit to Control

Minimum Recommended

Wi re Gau ge

Form RZ-NA I-SCE, Page 20

CAUTION: Control circuit amps should be within the anticipator amp

rating of the thermostat used.

Ampere Rating of 24-Volt Controls

Fan Control ............................... .12 amps

Time Delay Heater ..................... .14 amps

RBM Relay Coil ......................... .12 amps

Contactor Coil ........................... .45 amps

Spark Ignition System ............... .1 amps

Maxitrol Gas Control System .... .51 amps

Honeywell Gas Valve ................ .5 amps

White-Rodgers Gas Valve ......... .6 amps

Page 21

Typical Wiring Diagrams

FIGURE 20 - W. D. 225711, Model SCE with Single-Stage Gas Control

DISCONNECT SWITCH

(SEE NOTE)

7

8

9

10

11

12

13

14

15

16

17

18

19

20

LINE

1/60 OR 3/60

GRD

G

TIME DELAY

BK BK BK BK

B C W

BL BR

8

BL

8

OPTIONAL SP/ST

S/W SWITCH

BK BK

8

RELAY CONTACTS

1 3

FAN TD

CONTACTS

1 3

BLOWER MOTOR

CONTACTOR

CONTACTS

T1

L1

L3

L2

BK

BL

R

RR

10

T3

T2

LINE VOLT

24V

R OR BK

R

R OR W

R

BK

Y

40 VA. CONTROL

TRANSFORMER

BR

INTERNALLY

PROTECTED

BLOWER

MOTOR

YBKBK

VENTER MOTOR

& CAPACITOR

WIRING CODE

BLACK - BK

BROWN - BR

RED - R

ORANGE - O

YELLOW - Y

GREEN - G

BLUE - BL

PURPLE - PR

WHITE - W

16

CR

W19

HTDH

BR

BR

BR

7

BLOWER MOTOR

CONTACTOR COIL

7

7 - 8 - 9

TIME DELAY

RELAY COIL

7

12 - 24

7

21

22

23

24

25

26

27

28

FIELD CONTROL WIRING

TOTAL WIRE MINIMUM RECOMMENDED

LENGTH WIRE SIZE

150 FEET #18 GA.

250 FEET #16 GA.

350 FEET #14 GA.

OPERATING SEQUENCE

1. SET THERMOSTAT AT LOWEST SETTING.

2. TURN ON POWER, MAIN AND MANUAL GAS VALVE.

3. SET THERMOSTAT AT DESIRED SETTING.

4. THERMOSTAT CALLS FOR HEAT.

(A) ENERGIZING THE VENTER MOTOR AFTER A 15 SECOND (APPROX.) TIME DELAY.

5. VENTER FLOW SWITCH SWITCHES TO N.O. POSITION AND POWERS THE IGNITION

CONTROLLER. WITH POWER SUPPLIED TO THE IGNITION CONTROLLER THE PILOT

GAS VALE IS ENERGIZED AND PILOT LIGHTS FROM IGNITOR, AFTER A TIME DELAY

PRE-PURGE (10-15 SECONDS ).

6. IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION THE SAFETY SWITCH

CLOSES THE MAIN VALVE AND RECYCLES THE SPARK GAP. ON UNIT EQUIPPED WITH

G770NGC-4 LOCKOUT CONTROL, IF PILOT IS NOT ESTABLISHED WITHIN 120 SEC. (APPROX.)