Page 1

Bulletin 4390-974250

FluidConnectors

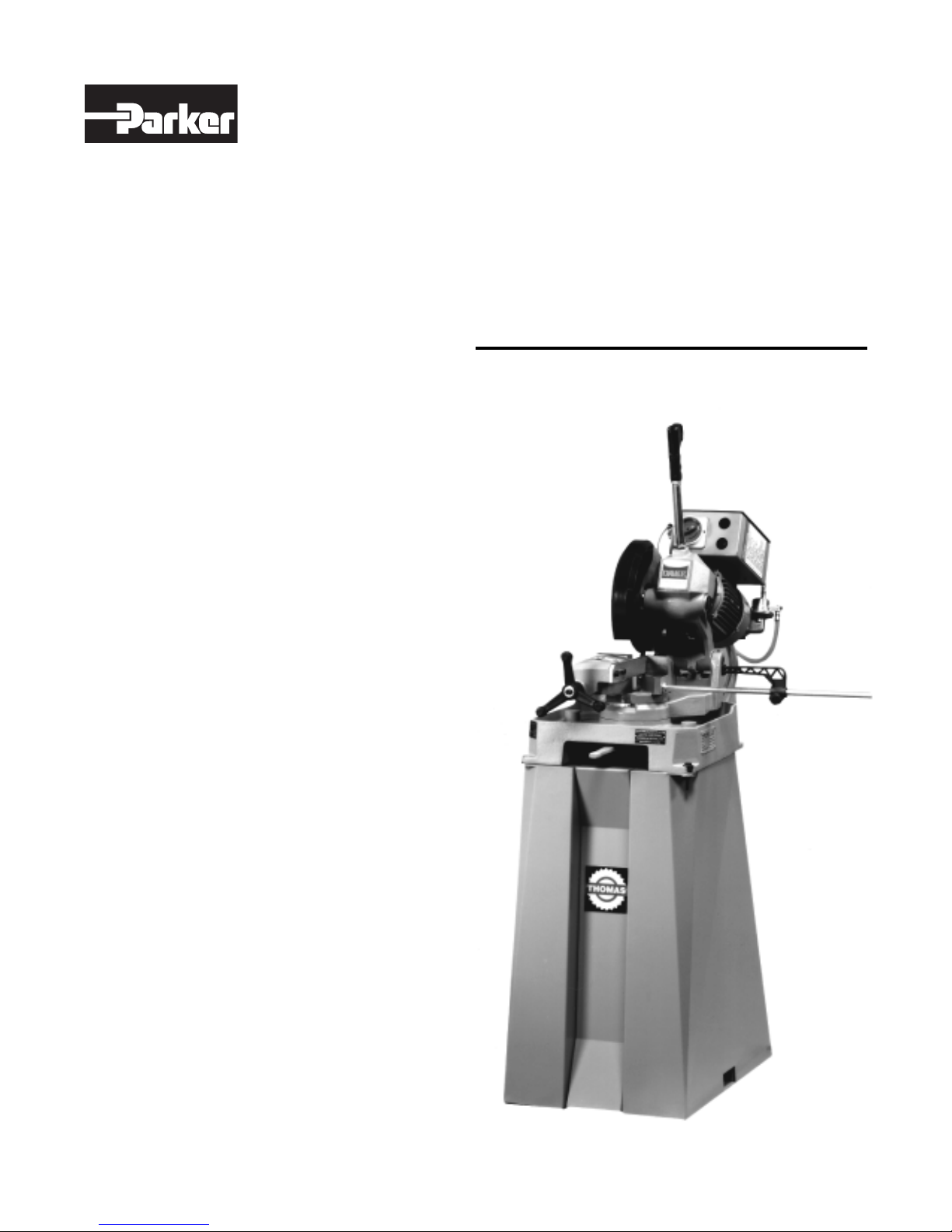

Cut 250 Saw Use and

Maintenance Manual

Part Number: 974250

Effective: September 1, 1999

Page 2

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

FAILURE OR IMPR OPER SELECTION OR IMPROPER USE OF THE PR ODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CA USE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE .

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by

users having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product

catalog. Due to the va riety of operating conditions and applications for these products or systems , the user, through its own analysis and testing, is solely responsible for making the

final selection of the products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation

and its subsidiaries at any time without notice.

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are

governed by the provisions stated in the "Offer of Sale".

FluidConnectors

WARNING

Offer of Sale

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 3

Bulletin 4390-974250

Contents

Cut 250 Saw Use and Maintenance Manual

Contents ............................................................................ 1

Ordering Spare Parts ....................................................... 1

Guarantee .......................................................................... 1

Machine Certification and Identification Marking ......... 2

CHAPTER 1______________________________________

Reference to Accident-Prevention Regulations ............ 3

1.1 – Advice for the operator ........................................... 3

1.2 – Location of shields against accidental contact with

the tool .................................................................... 3

1.3 – Electrical equipment according to European

Standard "CENELEC EN 60 204-1" (1992)............ 3

1.4 – Emergencies according to European Standard

CENELEC EN 60 204-1" (1992)............................. 3

CHAPTER 2______________________________________

Recommendations and Advice for Use .......................... 3

2.1 – Recommendations and advice

for using the machine ............................................. 3

CHAPTER 3______________________________________

Technical Characteristics ................................................ 4

3.1 – Table of cutting capacity and technical details ....... 4

CHAPTER 4______________________________________

Machine Dimensions – Transport –

Installation – Dismantling ................................................ 4

4.1 – Machine dimensions ............................................... 4

4.2 – Transpor t and handling of the machine .................. 4

4.3 – Minimum requirements for the premises

housing the machine .............................................. 5

4.4 – Anchoring the machine ........................................... 5

4.5 – Instructions for electrical connection ...................... 5

4.6 – Instructions for assembly of

the loose parts and accessories............................. 5

4.7 – Deactivating the machine ....................................... 5

CHAPTER 5______________________________________

Machine Functional Parts................................................ 5

5.1 – Operating head ....................................................... 5

5.2 – Vice ......................................................................... 6

5.3 – Bed .......................................................................... 6

CHAPTER 6______________________________________

Description of the Operating Cycle ................................ 6

6.1 – Starting up and cutting cycle .................................. 6

CHAPTER 7______________________________________

Regulating the Machine ................................................... 7

7.1 – Saw head ................................................................ 7

7.2 – Vice ......................................................................... 7

7.3 – Regulating arm blockage ........................................ 7

7.4 – Changing the blade................................................. 7

7.5 – Changing the lubricating coolant pump .................. 7

CHAPTER 8______________________________________

Routine and Special Maintenance .................................. 7

8.1 – Daily maintenance .................................................. 7

8.2 – Weekly maintenance .............................................. 7

8.3 – Monthly maintenance ............................................. 7

8.4 – Six-monthly maintenance ....................................... 8

8.5 – Oils for lubricating coolant ...................................... 8

8.6 – Special maintenance .............................................. 8

CHAPTER 9______________________________________

Material Classification and Choice of Tool ....................8

9.1 – Definition of materials ............................................. 8

9.2 – Choosing the blade................................................. 9

9.3 – Teeth pitch .............................................................. 9

9.4 – Cutting and advance speed.................................... 9

9.5 – Breaking in the blade .............................................. 9

9.6 – Type of blade ........................................................... 9

Tooth shape ............................................................ 9

Tooth cutting angle ................................................. 9

Sharpening circular saws ..................................... 10

9.6.1 – Table of recommended cutting parameters .......... 10

9.6.2 – Table of cutting speed according to

blade diameter ...................................................... 11

CHAPTER 10_____________________________________

Machine Components .................................................... 12

10.1 – List of spare parts ................................................. 12

CHAPTER 11_____________________________________

Wiring Diagrams ............................................................. 15

CHAPTER 12_____________________________________

Troubleshooting.............................................................. 17

12.1 – Blade and cut diagnosis ....................................... 17

12.2 – Electrical components diagnosis .......................... 19

CHAPTER 13_____________________________________

Noise T ests ...................................................................... 19

Plates and Labels ........................................................... 20

Offer of Sale .................................................................... 21

Ordering Spare Parts

• When ordering spare par ts you must state:

Machine model

Serial number

Part reference number

Without these references

See point 10.1 – List of spare parts.

we will not supply

FluidConnectors

the spare parts.

Guarantee

• The Company guarantees that the machine to which this

manual refers has been designed and built to comply with

safety regulations and that it has been tested for functionality in the factory.

• The machine is guaranteed for 12 months: the guarantee

does not cover the electric motors, electric components,

pneumatic components or any damage due to dropping or

machine misuse, the failure to observe maintenance standards or bad handling by the operator.

1

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 4

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

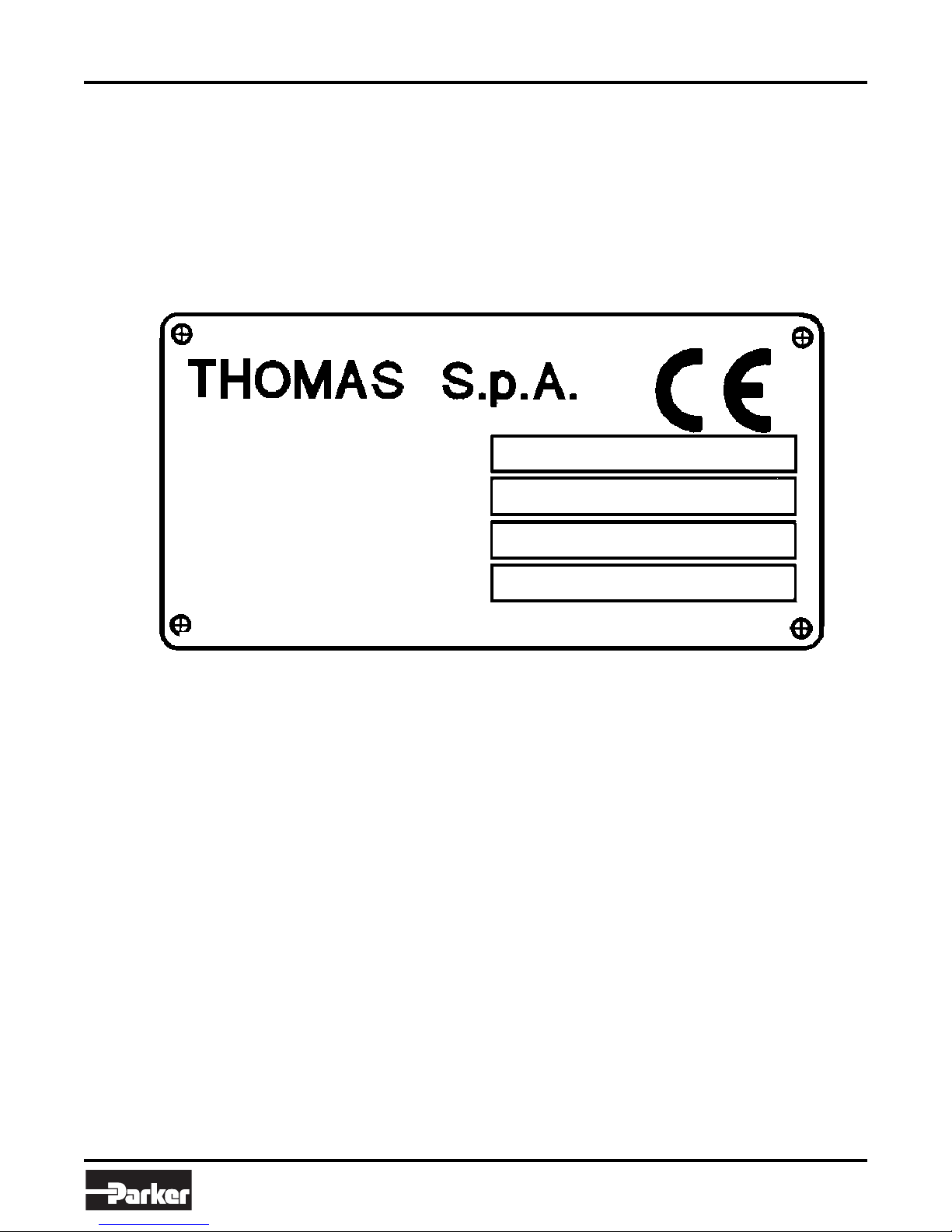

Machine Certificaton and Identification

Machine Certification and Identification Marking

MACHINE LABEL

via Pasubio, 32 36033 ISOLA VIC. - ITALIA

MODEL

TYP

SERIAL NUMBER

YEAR OF MANUFACTURE

CUT 250

FluidConnectors

2

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 5

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

Reference to Accident-

1

1.1 — Advice for the operator

•Check that the voltage indicated on the plate, normally fixed

•Check the efficiency of your electric supply and grounding

•When the tool head is in rest position (raised), the toothed

•It is not recommended to operate saw without its shields

•Always disconnect the power source before changing the

•It is not recommended to disconnect the “man present” de-

•Always wear eye protection.

•Never put your hands or arms into the cutting area while the

•Do not move the machine while it is cutting.

•Do not wear loose clothing , gloves that are too big, brace-

•Keep the area free of equipment, tools or any other object.

•Perform only one operation at a time and never have sev-

•All internal and/or external operations, maintenance or re-

1.2 — Location of shields against accidental

contact with the tool

Prevention Regulations

This machine has been built to comply with the national

and community accident-prevention regulations in force.

Improper use and/or tampering with the safety devices will

relieve the manufacturer of all responsibility.

to the machine motor, is the same as the line voltage.

system; connect the power cable of the machine to the socket

and the ground lead (yellow-green in color) to the ground

system.

blade must be stationary.

(these are all white, blue or grey in color).

blade or carrying out any maintenance job, even in the case

of abnormal machine operation.

vice, known more correctly in the EEC as the “safety switch

with hold-down action”.

machine is operating.

lets, chains or any other object that could get caught in the

machine during operation; tie back long hair.

eral objects in your hands at the same time.

pairs, should be performed in a well-lit area or where there

is sufficient light from extra sources so as to avoid the risk of

accidents.

1.3 — Electrical equipment according to

European Standard “CENELEC EN 60 204-1”

which assimilates, with some integrating

modifications, the publication “IEC 204-1

(1992)”

•The electrical equipment ensures protection against electric

shock as a result of direct or indirect contact. The active

parts of this equipment are housed in a box to which access

is limited by screws that can only be removed with a special

tool; the parts are fed with alternating current at low voltage

(24 V). The equipment is protected against splashes of water and dirt.

•Protection of the system against short circuits is ensured by

means of fuses and grounding; in the event of motor overload, protection is provided by a thermal probe.

•In the event of a power cut, the specific start-up button must

be reset.

•The machine has been tested in conformity with point 20 of

EN 60204.

1.4 — Emergencies according to European

Standard “CENELEC EN 60 204-1 (1992)”

•In the event of incorrect operation or of danger conditions,

the machine may be stopped immediately by pressing the

red mushroom button.

NOTE:Resetting of machine operation after each emergency

stop is achieved by reactivating the specific restart

button.

Recommendations

2

2.1 — Recommendations and advice for using

the machine

•The machine has been designed to cut tubing with different

•Only one operator is needed to use the machine.

and Advice for Use

shapes and profiles.

•Grey metal shield screwed onto the saw head.

•Self-regulating mobile blue plastic shield, fitted coaxially with

the fixed shield.

FluidConnectors

3

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 6

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

•To obtain break-in of the machine it is advisable to start using it at intervals of about half an hour. This operation should

be repeated two or three times, after which the machine

may be used continuously.

•Before starting each cutting operation, ensure that the part

is firmly gripped in the vice and that the end is suitably supported.

•Do not use blades of a different size from those stated in the

machine specifications.

•If the blade jams in the tube, release the running button

immediately, switch off the machine, open the vice slowly,

remove the part and check that the blade or its teeth are not

broken. If they are broken, change the blade.

•Before carrying out any repairs on the machine, consult the

dealer or call Parker Tube Fittings Division.

Technical

3

3.1 — Table of cutting capacity

and technical details

Characteristics

Machine Dimensions –

4

Transport – Installation –

Dismantling

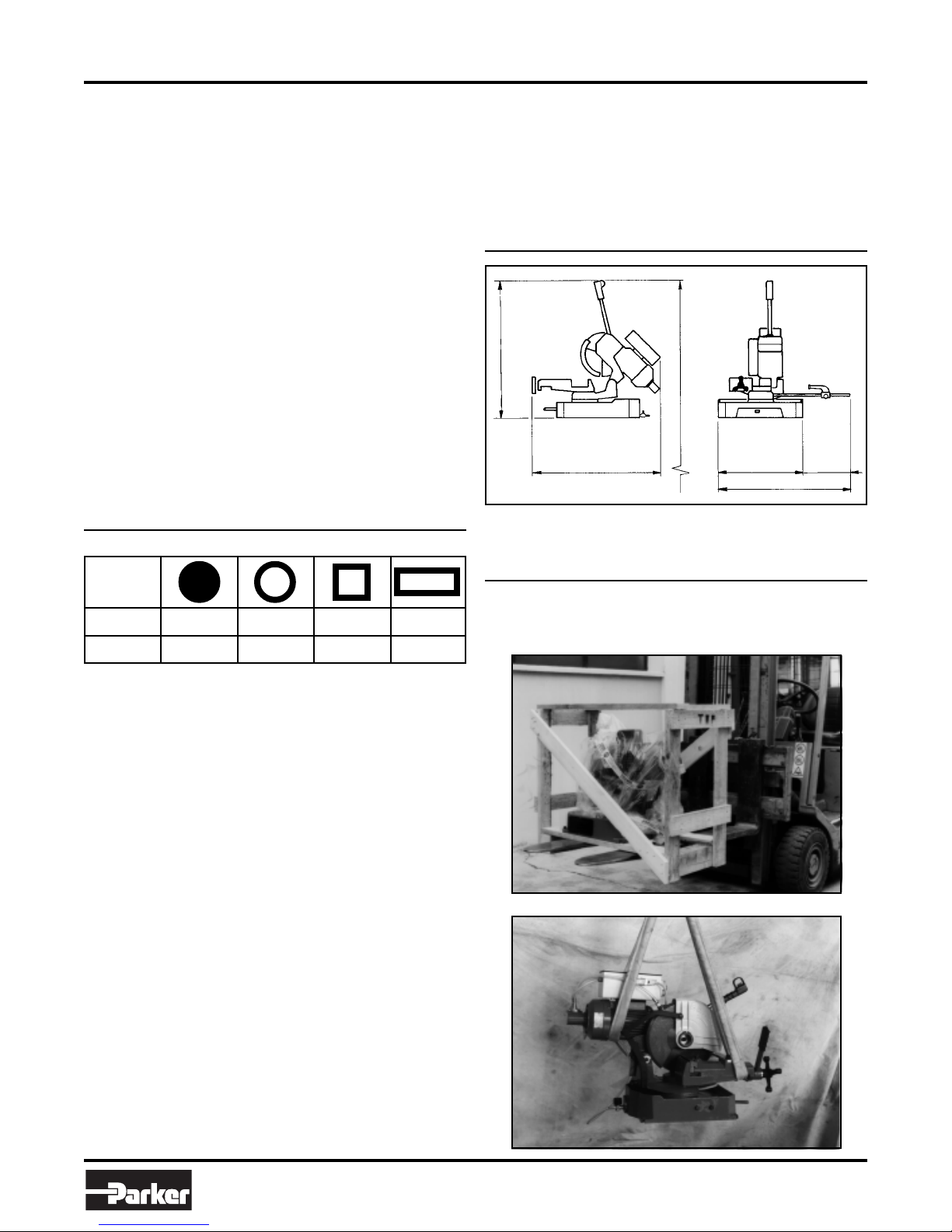

4.1 — Machine dimensions

800

1550 WITH PEDESTAL

940

410

770

360

Cutting

Capacity

90° 30 70 65 100 x 45

45° DX 25 60 55 65 x 150

•Three-phase el. motor for

2-speed blade rotation kW 0.75 ÷ 0.95

•Single-phase el. motor for

1-speed blade rotation kW 0.9

•Reduction gear in an oil bath Ratio=1:32

•Maximum blade diameter mm 250

•Blade rotation speed rpm 40 ÷ 80

•Vice opening mm 105

•Machine weight kg 80

4.2 — Transport and handling of the machine

If the machine has to be moved, use a fork-lift truck or sling it

with straps as illustrated.

FluidConnectors

4

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 7

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

4.3 — Minimum requirements for the premises

housing the machine

• Main voltage and frequency complying with the machine motor characteristics.

• Environment temperature from -10°C to +50°C.

• Relative humidity not over 90%.

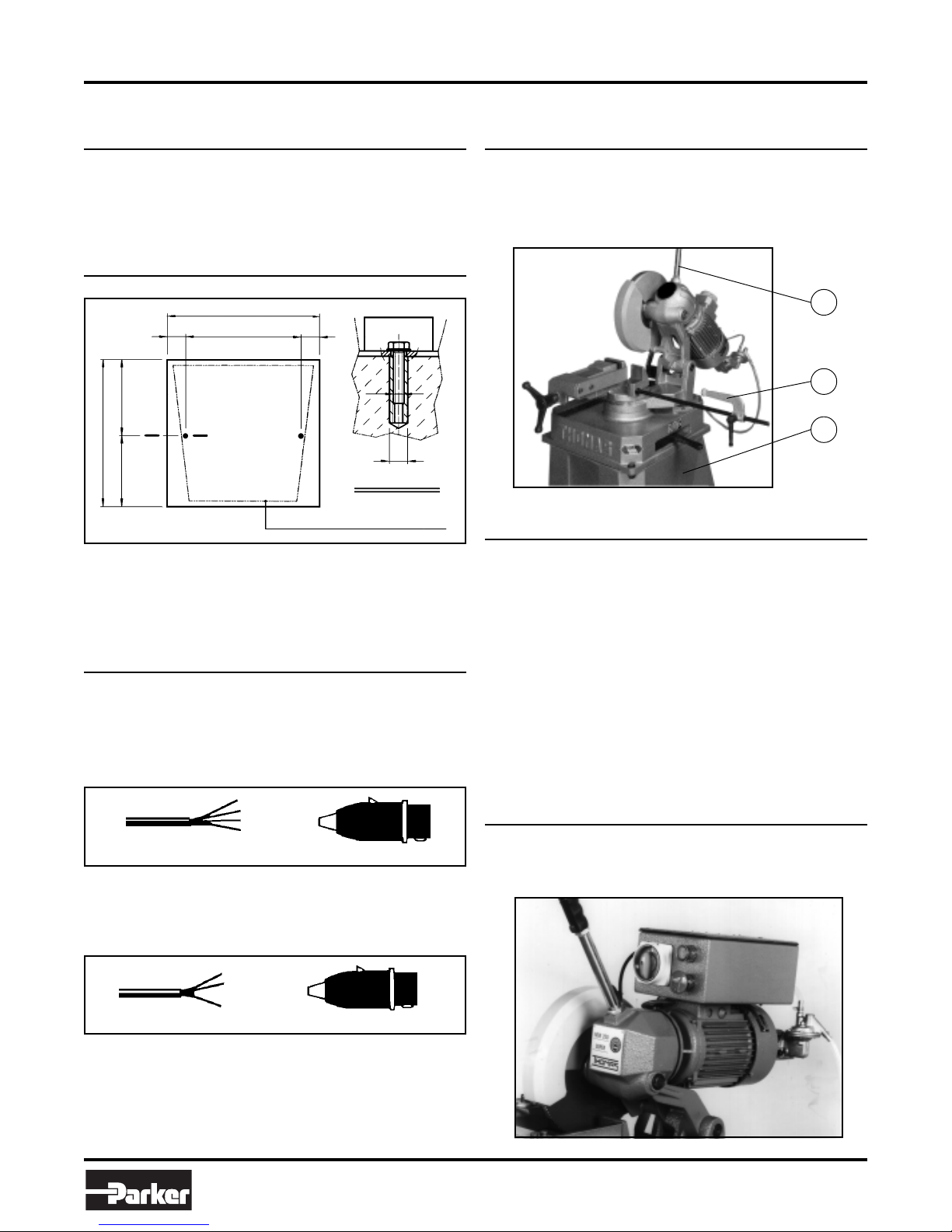

4.4 — Anchoring the machine

580

440

AA

560

270 290

• Position the machine base on a firm cement floor, maintaining, at the rear, a minimum distance of 800 mm from the

wall; anchor it to the ground as shown in the diagram, using

screws and expansion plugs or tie rods sunk in cement, ensuring that it is sitting level.

7070

M8

12

SEC. A - A

PEDEST AL PROFILE

4.5 — Instructions for electrical connection

• The machine may not be provided with an electric plug.

4.6 — Instructions for assembly of the loose

parts and accessories

Attach the components supplied as indicated in the photo:

• part. 1 Screw the lever onto the head

• part. 2 Attach the bar holding rod

• part. 3 Attach the pedestal fir mly onto the base

1

2

3

4.7 — Deactivating the machine

If the sawing machine is not to be used for a long period, it is

advisable to proceed as follows:

1) Detach the plug from the electric supply panel

2) Release the head return spr ing

3) Empty the coolant tank

4) Carefully clean and grease the machine

5) If necessar y, cover the machine.

1 – WIRING DIAGRAM FOR 5-WIRE SYSTEM WITH NEU-

TRAL FOR THREE-PHASE MACHINE - SOCKET FOR A

16A PLUG

R = L1

S = L2

T = L3

PE = GND

N = NEUTRAL

2 – WIRING DIAGRAM FOR THE SINGLE-PHASE SYSTEM

SOCKET FOR A 16A PLUG

= L1

= L2

= PE

FluidConnectors

Machine Functional Parts

5

5.1 — Operating head

• Machine part composed of the par ts that transmit movement (motor, reduction unit), the lubricating coolant pump

and the electrical components.

5

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 8

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

5.2 — Vice

• System for gripping material during the cutting operation,

operated with handwheel.

Provided with an anti-burr device for holding the part that is

to be cut.

5.3 — Bed

• Suppor t structure for the OPERATING HEAD (rotating ar m

for gradual cutting, with respective blocking system), the

VICE, the BAR STOP, and the housing for the cutting coolant TANK.

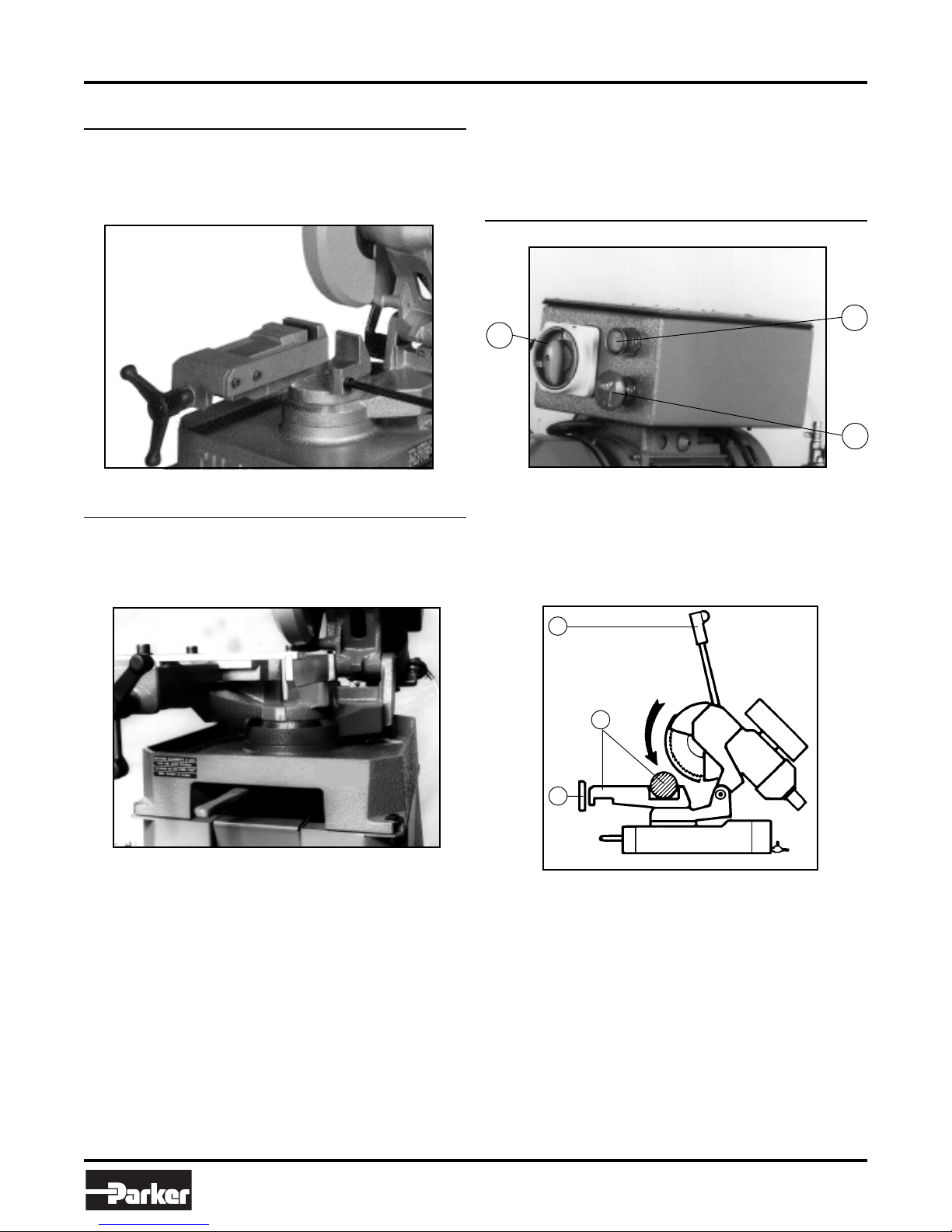

Description of the

6

6.1 — Starting up and cutting cycle

3

• Ensure that the machine is not in emergency stop condition;

• Select the cutting speed on the switch (3):

• Press the star t/reset button (2): green light will go on.

Operating Cycle

2

1

if it is, release the red mushroom button (1).

position 1 = 40 rpm

position 2 = 80 rpm

6

4

5

• Place material to be cut in the vice (4) and clamp the par t

into place by handwheel (5).

• Grip the handle (6) of the HEAD control ar m and press the

button, checking that the blade is turning in the direction

indicated (if not, invert the two phase leads) and that sufficient coolant is flowing.

• When starting to cut with a new blade, in order to safeguard its life and efficiency, the first two or three cuts

must be made while exerting a slight pressure on the

part, so that the time taken to cut is about double the

normal time (see below in the chapter on “Material classification and choice of blades” in the section on

in the blade

• Press the red emergency button (1) when there are conditions of danger or malfunctions in general, so as to stop

machine operation immediately.

).

Breaking

FluidConnectors

6

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 9

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

Regulating the Machine

7

7.1 — Saw head

• Does not require any adjustments.

7.2 — Vice

• Does not require any adjustments.

7.3 — Regulating arm blockage

• If there is blockage of the head arm in the desired position,

loosen the screw (1) on the lever, hold the bushing

(2) in position, turn the lever to the left and re-tighten the

screw.

2

• Attach the new blade, check the direction of the teeth, then

replace the flange, the screw and the guard.

7.5 — Changing the lubricating coolant pump

• Remove the lubrication tubing.

• Remove the fastening screws and replace the small pump,

being careful to keep the driving stem centred on the drive

shaft bearing.

Routine and Special

8

8.1 — Daily maintenance

Maintenance

The maintenance jobs are listed below, divided into

daily, weekly, monthl y

following operations are neglected, the result will be

premature wear of the machine and poor performance.

and

six-monthly

intervals. If the

1

Note: Before performing the following operations, the electric

power supply and the power cable must be completely

disconnected.

7.4 — Changing the blade

To change the blade:

• Release the guard and push it back.

• Place a piece of wood in the vice and lean the blade on it.

• Inser t the special spanner provided and remove the screw

( 1 ), loosening it in a clockwise direction, it has a

thread, then slip off the flange that holds the blade.

left-handed

1

• Clean the machine to remove accumulated shavings.

• Top off the level of lubricating coolant.

• Check the blade for wear.

• Lift the head into a high position to avoid yield stress on the

return spring.

• Check functionality of the guards and emergency stops.

8.2 — Weekly maintenance

• General cleaning of the machine to remove shavings, especially from the lubricant fluid tank.

• Clean the filter of the suction pump head and the suction

area.

• Clean and grease the screw and the sliding guide of the

vice.

• Clean the blade housing.

• Shar pen the blade.

8.3 — Monthly maintenance

• Check tightness of the screws on the motor, the pump, the

jaws and guards.

• Check that the guards are unbroken.

• Grease the head hinge pin.

FluidConnectors

7

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 10

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

8.4 — Six-monthly maintenance

• Change the oil in the reduction unit using oil type GEARCO

85W-140 by NATIONAL CHEMSERACH or MOBIL

GLYCOLE 30 or KLUBER SINTHESO 460 EP or an equivalent oil, proceed as follows:

• Remove the connecting plug

from the electric box and

12

un-screw the head moving

lever.

• Drain the old oil from the cap

at the side (1).

• Pour in new oil up to the

mark (1), through the lever

fixing hole, keeping the head

in a horizontal position (2).

• Reassemble all the parts.

• Check continuity of the equipotential protection circuit.

8.5 — Oils for lubricating coolant

Considering the vast range of products on the market, the

user can choose the one most suited to his own requirements,

using as reference the type SHELL LUTEM OIL ECO.

The minimum percentage of oil diluted in water is 8 - 10 %.

8.6 — Special maintenance

Special maintenance operations can be carried out by skilled

personnel, or contact Parker TFD or distribution personnel.

Material Classifiation and

9

Since the aim is to obtain excellent cutting quality, the various

parameters such as

ness, transverse cutting section

the type of cutting blade, cutting speed

descent

therefore be combined in a single operating condition according to practical considerations and common sense, so as to

achieve optimum conditions.

We therefore advise you always to choose original spare

blades that guarantee superior quality and performance.

9.1 — Definition of materials

The following table lists the characteristics of the materials to

be cut.

Choice of Tool

hardness of the material, shape and thick-

of the part to be cut,

and

, must be suitably combined.These specifications must

choice of

control of head

USE

Construction

steels

Carbon

steels

Spring steels

Alloyed steels for

hardening and

tempering and for

nitriding

Alloyed

casehardening

steels

Steel for

bearings

Tool steel

Stainless

steel

Copper all oys

Special brass

Bronze

Cast iron

TYPES OF STEEL CHARACTERISTICS

I

UNI

Fe360

Fe430

Fe510

C20

C40

C50

C60

50CrV4

60SiCr8

35CrMo4

39NiCrMo4

41CrAlMo7

18NiCrMo7

20NiCrMo2

100Cr6 100Cr6 100C6 534 A 99 52100 207 95 690÷980

52NiCrMoKU

C100KU

X210Cr13KU

58SiMo8KU

X12Cr13

X5CrNi1810

X8CrNi1910

X8CrNiMo1713

Aluminium cop per all oy G- C uAl 1 1Fe4Ni 4 UNI 5275

Special manganese/silicon bras s G-CuZn36Si1Pb1 UNI503 8

Manganese br onze SAE43 - SAE430

Phosphor bronze G-CuSn12 UNI 7013/2a

Gray pig iron G25

Spheroidal graphite cast iron GS600

Malleable cast iron W40-05

D

DIN

St37

St44

St52

CK20

CK40

CK50

CK60

50CrV4

60SiCr 7

34CrMo4

36CrNiMo4

41CrAlMo7

----

21NiCrMo2

56NiCrMoV7

C100W1

X210Cr12

----

4001

4301

----

4401

F

AF NOR

E24

E28

E36

XC20

XC42H1

----

XC55

50CV4

----

35CD4

39NCD4

40CADG12

20NCD7

20NCD2

----

----

Z200C12

Y60SC7

----

Z5CN18.09

----

Z6CDN17.12

GB

SB

---43

50

060 A 20

060 A 40

----

060 A 62

735 A 50

----

708 A 37

----

905 M 39

En 325

805 H 20

----

BS 1

BD2 - BD3

----

----

304 C 12

----

316 S 16

USA

AISI-SAE

----

----

---1020

1040

1050

1060

6150

9262

4135

9840

---4320

4315

----

S-1

D6 - D3

S5

410

304

----

316

Hardness

BRINELL

HB

116

148

180

198

198

202

202

207

224

220

228

232

232

224

244

212

252

244

202

202

202

202

220

140

120

100

212

232

222

Hardness

ROCKWELL

HRB

67

80

88

93

93

94

94

95

98

98

99

100

100

98

102

96

103

102

94

94

94

94

98

77

69

56,5

96

100

98

R=N/mm2

360÷480

430÷560

510÷660

540÷690

700÷840

760÷900

830÷980

1140÷1330

1220÷1400

780÷930

880÷1080

930÷1130

760÷1030

690÷980

800÷1030

710÷980

820÷1060

800÷1030

670÷885

590÷685

540÷685

490÷685

620÷685

375÷440

320÷410

265÷314

245

600

420

FluidConnectors

8

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 11

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

9.2 — Choosing the blade

First of all, the pitch of the teeth must be chosen, according to

these criteria:

• Parts with a thin and/or variable section such as profiles,

pipes and plate, need close teeth, so that the number of

teeth used simultaneously in cutting is from 3 to 6;

• Parts with large transverse sections and solid sections need

widely spaced teeth to allow for the greater volume of the

shavings and better tooth penetration;

• Parts made of soft material or plastic (light alloys, mild bronze,

teflon, wood, etc.) also require widely spaced teeth.

9.3 — Teeth pitch

As already stated, this depends on the following factors:

• Hardness of the material

• Dimensions of the section

• Thickness of the wall

S (MM) PICTH SHAPE SPEED

B

shaped

C

solid

C

solid

C

solid

C

solid

C

solid

2

2

1

1

1

1

S

SS

up to 2 4 - 6

2 ÷ 5 8

5 ÷ 10 8

over 10 8

up to 20 8

20 ÷ 50 10

9.6 — Type of blades

Blades differ in their constructive characteristics, such as:

• Tooth shape

• Tooth cutting angle

Tooth shape

The profile of the teeth depends on the size, shape and thickness of the section to be cut, either straight or at an angle. It

may also vary according to the pitch, but not so distinctly as to

make this an element for classification.

• Fine teeth are to be chosen for cutting small sections with a

profiled shape and tubular sections with thin walls (2-5 mm

depending on the material).

• Large teeth are suitable for cutting medium and large solid

sections or fairly thick profiled or tubular sections (over 5

mm).

“A” toothing: “AW” toothing:

Normal fine toothing Fine toothing with

alternate side rake

“B” toothing: “BW” toothing:

Normal large toothing with Large toothing with

or without shaving breaking alternate side rake

incision

9.4 — Cutting and advance speed

The cutting speed (m/min) and the advance speed (cm2/min =

area travelled b y the b lade teeth when remo ving shavings) are

limited by the heat build up at the tips of the teeth.

• The cutting speed is subordinate to the resistance of the

material (R = N/mm

mensions of the widest section.

• T oo high an advance speed (= b lade descent) tends to cause

the blade to deviate from the ideal cutting path, producing

non rectilinear cuts on both the vertical and the horizontal

plane.

2

), to its hardness (HRC) and to the di-

9.5 — Breaking in the blade

When cutting for the first time, it is good practice to break in

the tool making a series of cuts at a low advance speed

(= 30-35 cm2/min on material of average dimensions with respect to the cutting capacity and solid section of normal steel

with R = 410-510 N/mm

2

),

generously spraying the cutting area

with lubricating coolant.

FluidConnectors

“C (HZ)” toothing: Added toothing:

Large toothing with roughing Blades made in this way

tooth with rake on both sides, are used for cutting nonalternating with a finishing ferrous metals, such as

tooth without rake. The light alloys and plastics,

roughing tooth is 0.15- and in woodworking. The

0.30 mm higher. teeth are hard metal

Tooth cutting angle

Each tooth has two cutting angles:

αα

α : front rake angle

•

αα

γγ

γ : rear rake angle

•

γγ

9

(HM) plates brazed onto

the body of the blade;

there are various types

and shapes and, consid

ering the vastness of the

field.

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 12

Bulletin 4390-974250

Sharpening circular saws

The rake varies especially according to the type of material to

be cut.

9.7.1 — Recommended cutting parameters

2

2

2

2

2

2

Cut 250 Saw Use and Maintenance Manual

3 4 5 6 7 8 9 10 12 14 16

T

1,3 1,6 2,1 2,5 2,9 3,4 3,8 4,2 5,1 5,9 7,2

p

d 1,5 2 2,5 3 3,5 4 4,5 5 6 7 8

h = 0,2 mm h = 0,3 mm

2

2

2

2

2

2

2

2

2

2

2

Mild steel

R = 350-500 N/mm

Semi-hard steel

R = 500-700 N/mm

Extra-hard steel

Hard steel

R = 950-1000 N/mm

R = 750-950 N/mm

Austentic stainless

steel

R = 500-800 N/mm

Heat-treated steel

R = 950-1300 N/mm

Martensitic stainless

steel

R = 500-800 N/mm

Grey cast iron

Aluminium and alloys

Aluminium and alloys

R = 300-300 N/mm

R = 200-400 N/mm

Copper

R = 200-350 N/mm

Phosphor bronze

R = 400-600 N/mm

Hard bronze

R = 600-900 N/mm

Brass

R = 200-400 N/mm

Alloyed brass

R = 400-700 N/mm

Titanium and alloys

R = 300-800 N/mm

Tubes and beams

0,05. D

R = 300-600 N/mm

Tubes and beams

0,025. D

R = 300-600 N/mm

FluidConnectors

10

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 13

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

9.7.2 — Diagram of cutting speeds according to blade diameter

Vt m/min

KEY

n = g/min

T Tooth pitch in millimetres

Av mm/min Advance in millimetres per minute

Vt m/min Cutting speed in metres per minute

Az Tooth advance

Ng/min Number of revs per minute

Z Number of teeth on the blade

p Tooth depth

d Diameter of the tooth fillet cone distance

h Tooth protr usion

g Front rake

a Rear rake

N/mm Ultimate tensile stress

a-f Flat parts of the cutting edge

Ø Tube diameter or profile width

FluidConnectors

11

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 14

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

Machine Components

10

10.1 — List of spare parts

REFERENCE N° DESCRIPTION REFERENCE N° DESCRIPTION

1 Machine bed

2 Revolving arm

3 Revolving arm locking pin

4 Revolving arm locking bush

5 Revolving arm locking lever

6 Screw M8

7 Pin Ø 6

8 Countervice

9 Grain M6

10 Bar stop rod

11 Bar stop

12 Vice

13

14

15

16

17 Oiler Ø 5

18 Vice handwheel

19 Pin Ø 6

20 Vice thread

21

22

23 Burr-free plate

24 Seal filter support flange

25 Ring seeger Ø 42 I

26 Tank cover filter

27 Filter support flange

28 Screw M5

29 Washer

30 Coolant tap

31 Coolant tube

32 Screw M6

33 Tank filter

34 Screw M8

35 Nut M8

36 Hinge pin

37 Grain M6

38 Nut M6

39

40 Nut M16

41 Head lever

42 Head lever handgrip

43 Ring SM 30-40-7

44 Key 8x7x30

45 Blade shaft

46 Blade

47 Blade shaft flange stakes

48 Blade shaft flange

49 Screw M12

50 Fixed guard

51 Grain M16

52 Coolant tube

53 Mobile guard

54 Ring seeger Ø 60 E

55 Screw M6

57 Mobile guard rod

58 Ring seeger Ø 10 E

59 Tie rod support pin

60 Tie rod support

61 Screw M8

62 Pin Ø 4

63 Worm wheel

64 Grain M8

65 Worm wheel retaining washer

66 Screw M12

67 Ring nut M17

68 Worm screw

69 Ring DPSM 25-47-7

70 Front flange

71 Stud bolt

72 Washer

73 Nut M16

74 Bearing 6025 2rs

75 Motor shaft (rotor)

76 Key

77 Motor housing and stator

78

79 Head gasket

80

82 Motor head

83 Motor rear flange

84 Fan

85 Fan cover

86 Screw M4

87 Bearing 609

88 Pump connexion box

89 Screw M5

90 Coolant pump

91 Screw M6

92 Oil level-drain plug

93 Return spring connection

94 Head return spring

FluidConnectors

12

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 15

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

FluidConnectors

13

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 16

Bulletin 4390-974250

PARTS CALLOUT

95 Auxiliary relay

96 Remote control switch

97 Fuse carrier

98 Transformer

99 Socket connector

100 Plug Connector

Cut 250 Saw Use and Maintenance Manual

98

95

96

97

99

100

102

101

103

104

PARTS CALLOUT

101 Speed switch

102 Reset button

103 Emergency push button

104 Electric components box

105 Box cover

106 Box gasket

105 106

FluidConnectors

14

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 17

Bulletin 4390-974250

Wiring Diagrams

11

Cut 250 Saw Use and Maintenance Manual

CODE DESCRIPTION

KM Remote control s witch

ST1 Thermal probe

C Condenser

CODE DESCRIPTION

SB1 Mushroom button

SB2 Luminous button

HL Pilot lamp

KA Auxiliary relay

CODE DESCRIPTION

FU1 Fuse cartridge

FU2 Fuse cartridge

TC1 T ransformer

SQ1 Microswitch

FluidConnectors

15

CODE DESCRIPTION

M1 Disk motor

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

XP Soket

XS Plug

SA Switch

Page 18

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

CODE DESCRIPTION

KM Remote control s witch

ST1 Thermal probe

C Condenser

CODE DESCRIPTION

SB2 Luminous button

HL Pilot lamp

KA Auxiliary relay

CODE DESCRIPTION

TC1 T ransformer

SQ1 Microswitch

SB1 Mushroom button

CODE DESCRIPTION

SA Switch

FU1 Fuse cartridge

FU2 Fuse cartridge

FluidConnectors

16

CODE DESCRIPTION

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

M1 Blade motor

XP Soket

XS Plug

Page 19

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

Troubleshooting

12

This chapter lists the probable faults and malfunctions that could occur while the machine is being used and suggests possible

remedies for solving them.

The first paragraph provides diagnosis for TOOLS and CUTS, the second for ELECTRICAL COMPONENTS.

12.1 — Blade and cut diagnosis

FAULT PROBABLE CAUSE REMEDY

TOOTH BREAKAGE Advancing too fast

Improper cutting speed

Improper tooth pitch

Low quality blade

Ineffective gripping of the part in the vice.

Previously broken tooth left in the cut

Cutting resumed on a previously made cut.

Insufficient lubricant

Accumulation of excess material on

the blade.

PREMATURE WEAR Incorrect running in of the blade

Incorrect cutting speed

Unsuitable tooth profile

Wrong tooth pitch

Decrease advance, exert less cutting pressure

Change blade speed and/or diameter. See Chapter “Material

classification and choice of blades” and the

cutting speeds according to blade diameter .

suitable blade.

See Chapter “Material classification and choice of

blades”.

Use a better quality blade.

Check the gripping of the part.

Remove any excess pieces.

Make the cut elsewhere, turning the part.

Check the level of the liquid in the tank. Increase the flow of

lubricating coolant. Check that the hole and the outlet tubes

are not blocked.

Check the blend of lubricating coolant and choose a better

quality blade.

See Chapter “Material classification and choice of blades”

in the paragraph on

Change blade speed and/or diameter. See Chapter “Material

classification and choice of blades” and the

cutting speeds according to blade diameter .

Choose a suitable blade.

See Chapter “Material classification and choice of

blades” in the paragraph on

Choose a suitable blade.

See Chapter “Material classification and choice of blades”.

Running in the blade.

Type of blades.

T able of

Choose a

T able of

Low quality blade

Insufficient lubricating fluid

CHIPPED BLADE Hardness, shape or flaws in the material

(oxides, inclusions, lack of homogeneity,

etc.)

Incorrect cutting speed

Incorrect tooth pitch

Vibration

Blade incorrectly sharpened

Low quality blade

Incorrect emulsion of the lubricating

refrigerant

FluidConnectors

17

Use a better quality blade.

Check the lubrication level. Increase the flow of lubricate

fluid, check that the hole and the fluid outlet tube are not

blocked.

Reduce the cutting pressure and/or the advance.

Change blade speed and/or diameter. See Chapter “Material

classification and choice of blades” and the T able of

cutting speeds according to blade diameter.

Choose a suitable blade.

See Chapter “Material classification and choice of

blades”.

Check gripping of the part.

Replace the blade with one that is more suitable and correctly

sharpened.

Use a better quality blade.

Check the percentage of water and oil in the emulsion.

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 20

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

FAULT PROBABLE CAUSE REMEDY

BLADE VIBRA TION Incorrect tooth pitch

Unsuitable tooth profile

Ineffective gripping of the part in the vice

Dimensions of the solid section too large

with respect to the maximum admissible

cutting dimensions

Blade diameter incorrect and/or

too large

RIDGES ON THE Blade diamenter incorrect and/or too

CUTTING SURF ACE large

Ineffective gripping of the part in the vice

Fast advance

Blade teeth are worn

Insufficient lubricating fluid

T eeth do not disperse sha vings well

CRODICED CUTS Fast advance

Ineffective gripping of the part in the vice

Blade head not straight

Blade sides differently sharpened

Blade thinner than the commercial

standard

Dirt on the gripping device

Choose a suitable blade.

See Chapter “Material classification and choice of

blades”.

Choose a suitable blade.

See Chapter “Material classification and choice of

blades” in the paragraph on

Check the gripping of the part.

Refer to the instructions.

Decrease the blade diameter, adapting it to the dimensions of

the part to be cut. The cutting part of the blade must not be

too large for the shape of the part to be cut.

Decrease the blade diameter, adapting it to the dimensions of

the par to be cut. The cutting part of the blade must not be too

large for the shape of the part to be cut.

Check the gripping of the part.

Decrease advance. Exert less cutting pressure.

Sharpen the blade.

Check the lev el of the liquid in the tank. Increase the flow of

lubricant fluid. Check that the hole and the fluid outlet tube

are not blocked.

Choose a blade with a larger tooth pitch that allows better

unloading of shavings and that holds more lubricating fluid.

Decrease advance. Exert less cutting pressure.

Check the gripping of the part.

Adjust the head.

Choose tool quality carefully in every detail as regards type

and construction characteristics.

Carefully clean the laying and contact surfaces .

T ype of b lades

.

BLADE STICKS IN

THE CUT

Fast advance

Low cutting speed

Wrong tooth pitch

Accumulation of material on the blade

Insufficient lubricating fluid

FluidConnectors

18

Decrease advance. Exert less cutting pressure.

Increase speed.

Choose a suitable blade.

See Chapter “Material classification and choice of blades.”

Check the blend of lubricating coolant and choose a better

quality blade.

Check the lev el of the liquid in the tank. Increase the flow of

lubricating fluid. Check that the hole and the liquid outlet tube

are not blocked.

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 21

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

12.2 — Electrical components diagnosis

FAULT PROBABLE CAUSE REMEDY

THE GREEN PILOT

LIGHT “HL” DOES NOT

LIGHT UP

MOT OR STOPPED

WITH PILOT LIGHT

“HL” LIT

Fused lamp

Power supply

Fuses “FU 1”

Short circuits

Speed switch “SA” in position “0”

Emergency button “SB 1” on

Cycle reset or line button “SB 2”

Thermal probe built into the stator winding

has tripped due to motor overheating

T ransf ormer “TC 1”

Fuse “FU 2”

Auxilliary relay “KA”

Socket and plug connecting the electric

box/micros witch in the handle

Microswitch “SQ 1” in the handle

Remote-control switch “KM”

Motor “M 1”

Change it.

Check: • Phases

• Cables

• Socket

• Plug

V oltage must arrive upstream from the fuses.

Check for efficiency.

Identify and eliminate.

It must be turned to position 1 or 2.

Ensure that it is off and that its contacts are unbroken.

Check mechanical efficiency .

Check current continuity on the two wires in the prone after

letting the motor cool for about 10-15 minutes. If after this

time there is no current continuity in the two wires, the motor

must be changed or rewound.

Check that the supply voltage is the same as the line v oltage

and that it gives a value of 24 V at output.

Check fuse efficiency and ensure there are no short circuits

causing the protection to trip.

Check that 24 V reach the coil terminals when the button

“SB 2” is pressed. If this happens and the rela y is not self-f ed,

it must be changed.

Check that the plug is correctly inserted and look for any bad

connections inside the box.

Check operation and/or efficiency. Replace if broken.

Check that phases are present at both input and ouput.

Ensure that it is not blodked, that it closes when f ed, that it

does not cause short circuits. Otherwise change it.

Check that it is not burnt and that it turns freely .

It may be rewound or changed.

Noise T ests

13

In accordance with point 1.7.4.f of the Machines Directive EEC 89/392.

INTEGRATING PHONOMETER “DELTA OHM” mod. HD9019K1 serial n. 110996B295.

MICROPHONE mod. HD 9019S1.

SOUND GAUGER mod. HD 9101at 94dB/110dB a 1.000 Hz in class 1 according to IEC regulation n. 942 1988 and ANSI S1.40

1984.

3 measurements with the machine operating unloaded.

• The microphone was been located close to the operator’s head, at medium height.

• The weighted equivalent continuous acoustic pressure level was 77.6 dB (A).

• The maximum level of the WEIGHTED instantaneous acoustic pressure C was always less than 130 dB.

NOTE: With the machine operating, the noise level will vary according to the different materials being processed. The user must

therefore assess the intensity and if necessary provide the operators with the necessary personal protection, as required by

Law 277/1991.

FluidConnectors

19

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 22

Bulletin 4390-974250

Plates and Labels

Cut 250 Saw Use and Maintenance Manual

FluidConnectors

20

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 23

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

Offer of Sale

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized

distributors are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its authorized distributors. This

offer and its acceptance by any customer ("Buyer") shall be governed by all of the following Terms and Conditions. Buyer’s order for any such items,

when communicated to Parker Hannifin Corporation, its subsidiary or an authorized distributor ("Seller") verbally or in writing, shall constitute acceptance

of this offer.

1. Terms and Conditions of Sale: All descriptions, quotations, proposals,

offers, acknowledgments, acceptances and sales of Seller’s products are

subject to and shall be governed exclusively by the terms and conditions

stated herein. Buyer’s acceptance of any offer to sell is limited to these

terms and conditions. Any terms or conditions in addition to, or inconsistent

with those stated herein, proposed by Buyer in any acceptance of an offer

by Seller, are hereby objected to. No such additional, different or inconsistent terms and conditions shall become part of the contract between Buyer

and Seller unless expressly accepted in writing by Seller. Seller’s acceptance of any offer to purchase by Buyer is expressly conditional upon

Buyer’s assent to all the terms and conditions stated herein, including any

terms in addition to, or inconsistent with those contained in Buyer’s offer,

Acceptance of Seller’s products shall in all events constitute such assent.

2. Payment: Payment shall be made by Buyer net 30 days from the date

of delivery of the items purchased hereunder. Amounts not timely paid

shall bear interest at the maximum rate permitted by law for each month

or portion thereof that the Buyer is late in making payment. Any claims by

Buyer for omissions or shortages in a shipment shall be waived unless

Seller receives notice thereof within 30 days after Buyer’s receipt of the

shipment.

3. Delivery: Unless otherwise provided on the face hereof, delivery shall

be made F.O.B. Seller’s plant. Regardless of the method of delivery,

however, risk of loss shall pass to Buyer upon Seller’s delivery to a carrier.

Any delivery dates shown are approximate only and Seller shall have no

liability for any delays in delivery.

4. Warranty: Seller warrants that the items sold hereunder shall be free

from defects in material or workmanship for a period of 18 months from

date of shipment from Parker Hannifin Corporation. THIS WARRANTY

COMPRISES THE SOLE AND ENTIRE WARRANTY PERTAINING TO

ITEMS PROVIDED HEREUNDER. SELLER MAKES NO OTHER WARRANTY, GUARANTEE, OR REPRESENTATION OF ANY KIND WHATSOEVER. ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED

TO, MERCHANTABILITY AND FITNESS FOR PURPOSE, WHETHER

EXPRESS, IMPLIED, OR ARISING BY OPERATION OF LAW, TRADE

USAGE, OR COURSE OF DEALING ARE HEREBY DISCLAIMED.

NOTWITHSTANDING THE FOREGOING, THERE ARE NO WARRANTIES WHATSOEVER ON ITEMS BUILT OR ACQUIRED WHOLLY OR

PARTIALLY, TO BUYER’S DESIGNS OR SPECIFICATIONS.

5. Limitation Of Remedy: SELLER’S LIABILITY ARISING FROM OR IN

ANY WAY CONNECTED WITH THE ITEMS SOLD OR THIS CONTRACT

SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT

OF THE ITEMS SOLD OR REFUND OF THE PURCHASE PRICE PAID

BY BUYER, AT SELLER’S SOLE OPTION. IN NO EVENT SHALL

SELLER BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES OF ANY KIND OR NATURE WHATSOEVER, INC.

LUDING BUT NOT LIMITED TO LOST PROFITS ARISING FROM OR IN

ANY WAY CONNECTED WITH THIS AGREEMENT OR ITEMS SOLD

HEREUNDER, WHETHER ALLEGED TO ARISE FROM BREACH OF

CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE, FAILURE TO WARN

OR STRICT LIABILITY.

6. Changes, Reschedules and Cancellations: Buyer may request to

modify the designs or specifications for the items sold hereunder as well

as the quantities and delivery dates thereof, or may request to cancel all

or part of this order, however, no such requested modification or cancellation shall become part of the contract between Buyer and Seller unless

accepted by Seller in a written amendment to this Agreement. Acceptance

of any such requested modification or cancellation shall be at Seller’s

discretion, and shall be upon such terms and conditions as Seller may

require.

7. Special Tooling: A tooling charge may be imposed for any special

tooling, including without limitation, dies, fixtures, molds and patterns,

acquired to manufacture items sold pursuant to this contract. Such special

tooling shall be and remain Seller’s property notwithstanding payment of

any charges by Buyer. In no event will Buyer acquire any interest in

apparatus belonging to Seller which is utilized in the manufacture of the

items sold hereunder, even if such apparatus has been specially converted

or adapted for such manufacture and notwithstanding any charges paid by

Buyer. Unless otherwise agreed, Seller shall have the right to alter, discard

or otherwise dispose of any special tooling or other property in its sole

discretion at any time.

8. Buyer’s Property: Any designs, tools, patterns, materials, drawings,

confidential information or equipment furnished by Buyer or any other

items which become Buyer’s property, may be considered obsolete and

may be destroyed by Seller after two (2) consecutive years have elapsed

without Buyer placing an order for the items which are manufactured using

such property, Seller shall not be responsible for any loss or damage to

such property while it is in Seller’s possession or control.

9. Taxes: Unless otherwise indicated on the face hereof, all prices and

charges are exclusive of excise, sales, use, property, occupational or like

taxes which may be imposed by any taxing authority upon the manufacture, sale or delivery of the items sold hereunder. If any such taxes must

be paid by Seller or if Seller is liable for the collection of such tax, the amount

thereof shall be in addition to the amounts for the items sold. Buyer agrees

to pay all such taxes or to reimburse Seller therefore upon receipt of its

invoice. If Buyer claims exemption from any sales, use or other tax imposed

by any taxing authority, Buyer shall save Seller harmless from and against

any such tax, together with any interest or penalties thereon which may be

assessed if the items are held to be taxable.

10. Indemnity For Infringement of Intellectual Property Rights: Seller

shall have no liability for infringement of any patents, trademarks, copyrights, trade dress, trade secrets or similar rights except as provided in this

Part 10. Seller will defend and indemnify Buyer against allegations of

infringement of U.S. Patents, U.S. Trademarks, copyrights, trade dress

and trade secrets (hereinafter ‘Intellectual Property Rights’). Seller will

defend at its expense and will pay the cost of any settlement or damages

awarded in an action brought against Buyer based on an allegation that an

item sold pursuant to this contract infringes the Intellectual Property Rights

of a third party. Seller’s obligation to defend and indemnify Buyer is

contingent on Buyer notifying Seller within ten (10) days after Buyer

becomes aware of such allegations of infringement, and Seller having sole

control over the defense of any allegations or actions including all negotiations for settlement or compromise. If an item sold hereunder is subject to

a claim that it infringes the Intellectual Property Rights of a third party, Seller

may, at its sole expense and option, procure for Buyer the right to continue

using said item, replace or modify said item so as to make it noninfringing,

or offer to accept return of said item and return the purchase price less a

reasonable allowance for depreciation. Notwithstanding the foregoing,

Seller shall have no liability for claims of infringement based on information

provided by Buyer, or directed to items delivered hereunder for which the

designs are specified in whole or part by Buyer, or infringements resulting

from the modification, combination or use in a system of any item sold

hereunder. The foregoing provisions of this Part 10 shall constitute Seller’s

sole and exclusive liability and Buyer’s sole and exclusive remedy for

infringement of Intellectual Property Rights.

If a claim is based on information provided by Buyer or if the design for an

item delivered hereunder is specified in whole or in part by Buyer, Buyer

shall defend and indemnify Seller for all costs, expenses or judgments

resulting from any claim that such item infringes any patent, trademark,

copyright, trade dress, trade secret or any similar right.

11. Force Majeure: Seller does not assume the risk of and shall not be

liable for delay or failure to perform any of Seller’s obligations by reason of

circumstances beyond the reasonable control of Seller (hereinafter ‘Events

of Force Majeure’). Events of Force Majeure shall include without limitation, accidents, acts of God, strikes or labor disputes, acts, laws, rules or

regulations of any government or government agency, fires, floods, delays

or failures in delivery of carriers or suppliers, shortages of materials and

any other cause beyond Seller’s control.

12. Entire Agreement/Governing Law: The terms and conditions set

forth herein, together with any amendments, modifications and any different terms or conditions expressly accepted by Seller in writing, shall

constitute the entire Agreement concerning the items sold, and there are

no oral or other representations or agreements which pertain thereto. This

Agreement shall be governed in all respects by the law of the State of Ohio.

No actions arising out of the sale of the items sold hereunder or this

Agreement may be brought by either party more than two (2) years after

the cause of action accrues.

9/91-P

FluidConnectors

21

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Page 24

Fluid Connectors Group

Regional Sales Offices

& Service Centers

Your complete source

for

quality tube fittings, hose & hose

fittings, brass fittings & valves,

quick-disconnect couplings, and

assembly tools, locally-available

from a worldwide network of

authorized distributors.

Fittings & Couplings:

Available

in inch and metric sizes covering

SAE, BSP, DIN, GAZ, JIS and ISO

thread configurations, manufactured from steel, stainless steel,

brass, aluminum, nylon and

thermoplastic.

Hose, Tubing and Bundles:

Available in a wide variety of sizes

and materials including rubber,

wire-reinforced thermoplastic,

hybrid and custom compounds.

Worldwide Availability:

Parker operates Fluid Connectors

manufacturing locations and sales

offices throughout North America,

South America, Europe and AsiaPacific.

For information, contact the

nearest Regional Sales Office

listed, or call toll-free

1-800-C-PARKER

(1-800-272-7537).

Central Region

Sales Office & Service Center

Hiawatha, IA

(319) 393-1221

(319) 393-1224 FAX

Cleveland Region

Sales Office

Cleveland, OH

(216) 896-3000

(216) 896-4022 FAX

Service Center

Toledo, OH

(419) 878-7000

(419) 878-7001 FAX

Great Lakes Region

Sales Office & Service Center

Toledo, OH

(419) 878-7000

(419) 878-7001 FAX

Service Center

Ft. Wayne, IN

(219) 747-3111

(219) 747-3026 FAX

Minneapolis Region

Sales Office & Service Center

Minneapolis, MN

(612) 469-5000

(612) 469-5729 FAX

Service Center

Oshkosh, WI 54901

(414) 426-8471

(414) 426-8570 FAX

Northeast Region

Sales Office & Service Center

Trenton, NJ

(609) 586-5151

(609) 586-3149 FAX

Pacific Region

Sales Office & Service Center

Portland, OR

(503) 283-1020

(503) 283-2201 FAX

Service Center

Buena Park, CA

(714) 522-8840

(714) 994-1183 FAX

Southeast Region

Sales Office & Service Center

Greensboro, NC

(336) 373-1761

(336) 378-0913 FAX

Service Center

Conyers, GA

(770) 929-0330

(770) 929-0230 FAX

Southwest Region

Sales Office & Service Center

Mansfield, TX

(817) 473-4431

(817) 473-8078 FAX

Canada

Sales Office & Service Center

Grimsby, ON

(416) 945-2274

(416) 945-3946 FAX

(Contact Grimsby for other

Service Center locations.)

Parker Hannifin Corporation

Tube Fittings Division

3885 Gateway Blvd.

Columbus, OH 43228

FluidConnectors

Telephone: (614) 279-7070

Fax: (216) 279-7685

www.parker.com

Loading...

Loading...