HT Heating Module

INSTALLATION PROCEDURES

HT Heating Module INSTALLATION PROCEDURES

Receiving, Storing and Handling . . .

1. Inspect materials for damage incurred during shipping.

2. Report damages to the carrier for settlement.

3. Identify parts against the packing list to ensure the proper

type and quantity has been received.

4. Store in a dry indoor location.

Contents . . .

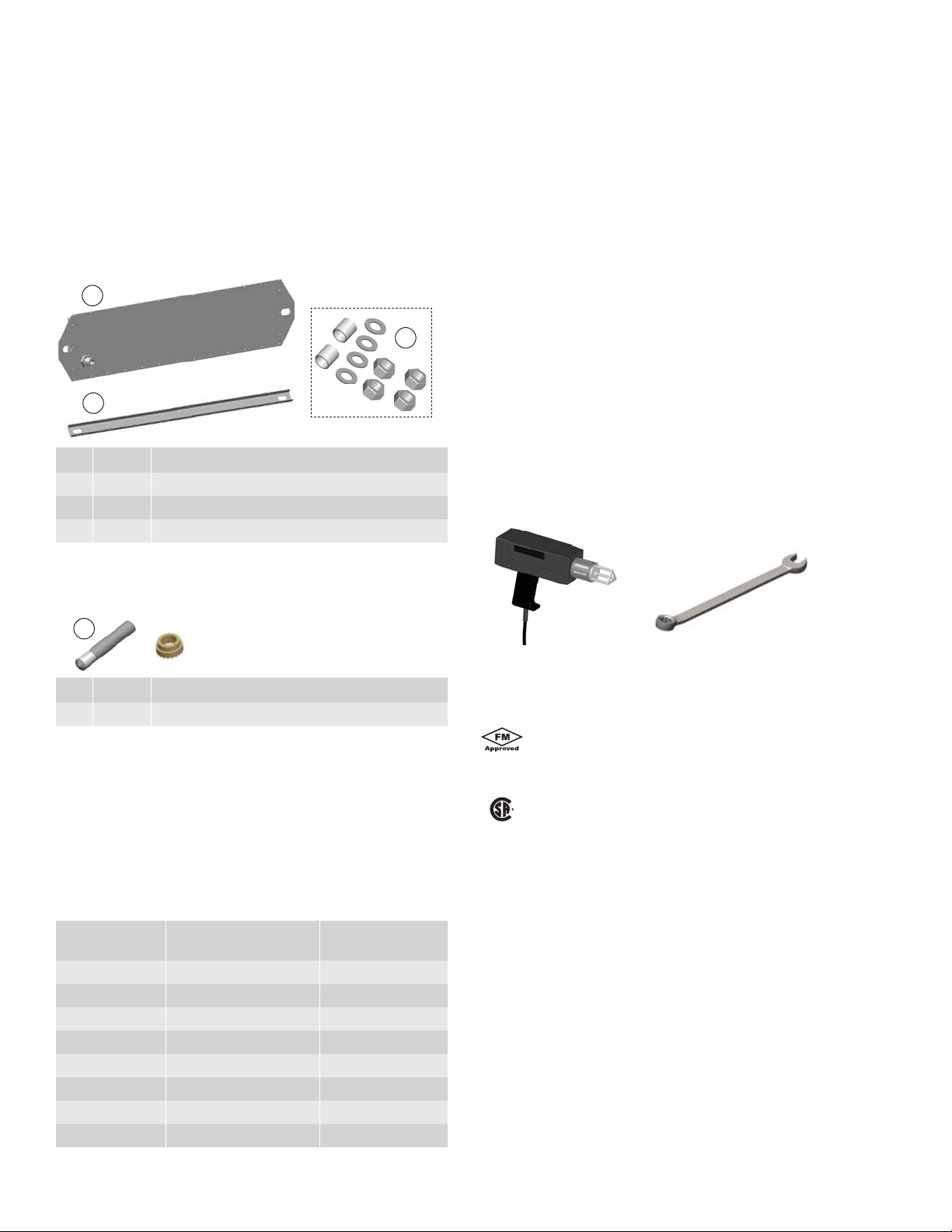

1

3

2

Item Quantity Description

1 1 Heating Module

2 1 Reinforcing Channel

3 1 Spacer Kit

Warnings . . .

• Multiple modules can be energized from the same circuit

breaker based on operating voltage and current draw. The

current draw and/or breaker sizing should be based on the

National Electrical Code, Canadian Electrical Code or any other

applicable code.

• To minimize the potential for arcing and ground-fault protection.

The National Electrical Code (NEC) and Canadian Electrical

Code (CEC) require ground-fault protection of equipment for

each branch circuit supplying electric heat tracing.

• Component approvals and performance ratings are based on

the use of Thermon specifi ed parts only.

• De-energize all power sources before connecting heaters.

• Individuals installing these products are responsible for

complying with all applicable safety and health guidelines.

Proper Personal Protective Equipment (PPE) should be utilized

during installation. Contact Thermon if you have any additional

questions.

Tools Required . . .

Mounting Studs:

(Order Separately for each Heating Module to be fabricated.)

4

Item Quantity Description

4 2 1/2" Stud with Ferrule

Standard Mounting Equipment . . .

Each HT Heating Module is shipped with a reinforcing channel,

spacers, 1/2" nuts and 1/2" washers. Mounting studs and

installation templates are supplied separately to facilitate

marking heater and mounting stud locations prior to installation

of heaters.

Available HT Module Sizes1 . . .

Catalog Number

Base Module

612 6 x 16.1 (15 x 40) 14.1 (36)

624 6 x 27.6 (15 x 70) 25.6 (65)

636

648 6 x 50.6 (15 x 129) 48.6 (123)

212 12 x 16.1 (30 x 40) 14.1 (36)

224 12 x 27.6 (30 x 70) 25.6 (65)

236

248 12 x 50.6 (30 x 129) 48.6 (123)

Module Dimensions

in (cm)

6 x 39.1 (15 x 99) 37.1 (94)

12 x 39.1 (30 x 99) 37.1 (94)

Stud Spacing

in (cm)

Stud Welder

19mm (0.75") Wrench

Certifi cations/Approvals . . .

Factory Mutual Research

Ordinary Locations

Hazardous (Classifi ed) Locations

Class II, Division 2, Groups F & G

Canadian Standards Association

Ordinary Locations

Hazardous (Classifi ed) Locations

Class II, Division 2, Groups E, F, & G

Notes:

1. Catalog numbers shown are partial numbers. Delivered product

will have prefi x and suffi x designations to identify complete

catalog number. Contact Thermon for design assistance.

2

HT Heating Module INSTALLATION PROCEDURES

Stud

Spacer

Installation Template

1. Have template and heating system layout

drawing available. Select the correct sized

template. Position installation template on

hopper wall per layout drawing and mark stud

locations. If two or more modules are to be

placed in one area, care should be taken to

insure proper fi t of all modules. By marking the

outline of each template with chalk or crayon

on the hopper wall, clearances can be verifi ed

prior to welding of studs.

Reinforcing Channel

Washer

Nuts

Washer

Stud Welder

(By Others)

2. Weld studs in place per the manufacturer's

recommendations.

Notes:

• Sandblasting of hopper surface or grinding

of welding beads or weld splatter is NOT

required for proper installation of the

HT Heating Modules. However, to provide

maximum heat transfer effi ciency, it is

recommended to install the HT Heating

Module on a fairly clean, smooth surface.

L1

L2/N

HT Heating Module

3. Place spacer on each stud and then place HT

Heating Module over studs.

2" Minimum Air Space

Heating Insulation

Heating Module

4. Assemble mounting components (supplied

with each module) in the following order:

• Place reinforcing channel over module and

studs.

• Place washer on each stud.

• Secure with one nut per stud and torque

down with 20-30 foot pounds.

• Add second nut to each stud and tighten.

Carefully route lead wires to junction box and

connect to the terminal strip according to the

layout drawing. See typical wiring schematic.

Typical Wiring Schematic for Heating Modules

IMPORTANT:

See Thermon project specifi c heater layout

and wiring drawings for actual heater wiring.

Hopper Insulation Design

IMPORTANT: The design of the hopper heating

system is based on the transfer of heat into the

hoppers via convection and conduction in the

air spaces between each stiffener to provide an

“oven” effect to ensure even distribution of heat.

It is important that the insulation be properly

sealed at each stiffener level to prevent drafts

or chimney effects. Allow 2 inch minimum

air space for heaters. (See project installation

manual for additional details).

Notes:

1. Route lead wires to junction box(es) according to project specifi c heater layout drawing. CAUTION: Do not rotate the feed through

fi tting which supports the heater wiring.

2. During heater installation, heaters should not be left exposed to rain, snow, moisture, etc..

3. Electrical insulation resistance test (megger) and resistance (Ohms) should be done on each heater per project installation manual.

3

THERMON . . . The Heat Tracing Specialists

®

100 Thermon Dr. • PO Box 609 • San Marcos, TX 78667-0609

Phone: 512-396-5801 • Facsimile: 512-396-3627 • 1-800-820-HEAT

www.thermon.com In Canada call 1-800-563-8461

Specifi cations and information are subject to change without notice. Form 50862-0712

For the Thermon offi ce nearest you

visit us at . . .

www.thermon.com

Loading...

Loading...