Page 1

Installation Manual

Truck Edition (TSA, EMEIA and AP)

Single Temperature Systems

T-580R, T-80 0M and T-1000M (with TSR Controller)

T-680S, T-88 0S, T-1080S (with SR-3 Controller)

T-600R, T-680R , T-800R, T-880R, T-1000R & T-1080R (with SR-3 Controller)

T-1200R (EMEIA Only with SR-3 Controller)

TK 55212-1-IM (Rev. 4, 01/15)

Page 2

Page 3

Installation Manual

Truck Edition (TSA, EMEIA and AP)

Single Temperature Systems

T-580R, T-800M and T-1000M (with TSR Controller)

T-680S, T-880S, T-1080S (with SR-3 Controller)

T-600R, T-680R, T-800R, T-880R, T-1000R and T-1080R (with SR-3 Controller)

T-1200R (EMEIA Only with SR-3 Controller)

TK 55212-1-IM (Rev. 4, 01/15)

Copyright

©

2011 Thermo King Corp., Minneapolis, MN, U.S.A.

Page 4

2

Installation Manual for T-Series Systems

Release History

Original (09/11) Released

Rev. 1 (02/13) Pages 20, 21, 23, 27 and 29 - Changed art to show revised lifting bar with forged clevis and pins, forged

connecting links and forged locking hooks used for lifting the unit.

Rev. 2 (03/13) Updated manual to include new Tier IV units.

Rev. 3 (10/14) Page 64: Added connection procedures for adding auxiliary power devices.

Rev. 4 (01/15) Page 46: Added important note about fuel tank air vent.

Page 5

3

Installation Manual for T-Series Systems

Page 6

4

Introduction

This manual was written to assist with the installation of Thermo King T-Series Systems onto truck bodies specifically designed and built for these

applications.

Due to its complexity, you should not attempt this installation unless you:

• Are an experienced mechanic.

• Can safely lift 34 kilos (75 lbs.).

• Are certified or trained in the repair and maintenance of dies el powered

refrigeration systems.

• Have a basic understanding of electricity and electrical wiring.

• Have the necessary tools and equipment to complete the installation.

This manual is published for informational purposes only. Thermo King makes no representations warranties express or implied, with respect to

the information recommendations and descriptions contained herein. Information provided should not be regarded as all-inclusive or covering

all contingencies. If further information is req uir ed, Thermo King Corporation Service Department should be consulted.

Thermo King’s warranty shall not apply to any equipment which has been “so installed, maintained, repaired or altered as, in the manufacturer’s

judgment, to affect its integrity.”

Manufacturer shall have no liability to any person or entity for any personal injury, property damage or any other direct, indirect,

special, or consequential damages whatsoever, arising out of the use of this manual or any info rmat i on, recommendations or

descriptions contained herein.

Page 7

5

Table of Contents

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Dimensions T-580R, T-600R, T-680R, T-680R, T-680S, T-800M,

T-800R, T-880R, T-880S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unit Dimensions T-1000M, T-1000R, T-1080R, T-1080S and T-1200R 9

Service Area - T-580R, T-600R, T-680R, T-680R, T-680S, T-800M,

T-800R, T-880R, T-880S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service Area - T-1000M, T-1000R, T-1080R, T-1080S and T-1200R . 11

Remote Power Receptacle Dimensions (OPTION) . . . . . . . . . . . . . . . . 12

Battery Box Dimensions (OPTION). . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remote Status Light Dimensions (OPTION) . . . . . . . . . . . . . . . . . . . . .14

HMI Controller Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Truck Body Opening Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Lifting Bar Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Installation Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Uncrating the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Installing the Hose Management Caps. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the Hose Management System (OPTION). . . . . . . . . . . . . . . 32

Securing the Oil Drain Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Securing the Evaporator Drain Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Installing the Fuel Pickup Tube Into a Steel or Aluminum Tank. . . . . . 38

Installing the Fuel Pickup Tube Into a Plastic Tank . . . . . . . . . . . . . . . . 40

Installing the Steel Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Installing the Aluminum Fuel Tank (OPTION) . . . . . . . . . . . . . . . . . . . 44

Installing the Fuel Pump and Fuel Lines . . . . . . . . . . . . . . . . . . . . . . . . 46

Installing the ServiceWatch™ Remote Download Port (OPTION). . . . 48

Installing the Remote Power Receptacle (OPTION) . . . . . . . . . . . . . . . . 50

Installing the Remote Status Light (OPTION) . . . . . . . . . . . . . . . . . . . .52

Installing the HMI Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Installing the Battery Box (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Battery Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Installing the Door Switch (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Auxiliary Electrical Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

UNIT CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Page 8

6

Safety Precautions

The symbol appears next to a point that is particularly important:

DANGER: Addresses a circumstance that, if encountered,

will lead to death or serious injury

WARNING: Add resses a c ircumsta nce that, if enco untered ,

might lead to death or serious injury.

CAUTION: Addresses a circumstance that, if enco untered,

may cause damage to eq uipment or minor injury.

DANGER: Never operate the unit with the discharge valve

closed because it could cause the compressor to explode,

causing death or serious in jury.

DANGER: Never apply heat to a sealed refriger ation system o r

container because it could explode, causing death or serious

injury

DANGER: Fluorocarbon refrigerants, in the pres ence of an

open flame or electrical short, produce toxic gases that are

severe respiratory irritants capable of causing death.

DANGER: Be careful when working with a refrigerant or

refrigeration system in any enclosed or confined area with a

limited air supply (i.e., a trailer, container or the hold of a

ship). Refrigerant tends to displace air and can cause oxygen

depletion which may re s ult in death by suffocation.

WARNING: Always wear goggles or safety glasses.

Refrigerant liquid, refrigeration oil, and battery acid can

permanently damage the eyes (see First Aid un der

Refrigeration Oil).

WARNING: Keep your hands away from fans and belts when

the unit is running. This should also be considered when

opening and closing the compressor service valves.

WARNING: Make sure gauge manifold hoses are in good

condition. Never let them come in contact with a belt, fan

motor pulley, or any hot surface.

WARNING: Make sure all mou nti ng bolts are tight and are of

correct length for their particular application

WARNING: Never drill holes in the unit unless absolutely

necessary. Holes dri ll ed into the unit may weaken structural

components. Holes drilled into electric al wiring can cau se fire

or explosion.

WARNING: When using ladders to install or service

refrigeration systems, always observe the ladder

manufacturer’s safety labels and warn ings. A w ork platform is

the recommended method for installations.

WARNING: Exposed coil fins are very sharp and can cause

painful lacerations.Wea r lea ther w ork gloves to prevent i njur y.

Page 9

7

Safety Precautions (continued)

Battery Installation and Cable Routing Refrigerant

First Aid

FROST BITE: In the event of frost bite, the objectives of First Aid are to

protect the frozen area from further injury, to warm the affected area

rapidly and to maintain respiration.

EYES: For contact with liquid, immediately flush eyes with large am ounts

of water and get prompt medical attention.

SKIN: Flush area with large amounts of lukewarm water. Do not apply

heat. Remove contaminated clothing and shoes. Wrap burns with dry,

sterile, bulky dressing to protect from infection/injury. Get medical

attention. Wash contaminated clothing before reuse.

INHALATION: Move victim to fresh air and use CPR or mouth-to-mouth

ventilation, if necessary. Stay with victim until arrival of emergency

medical personnel.

Refrigeration Oil

First Aid

NOTE: In case of eye contact, immediately flush with plen ty of water

for at least 15 minutes. CALL A PHYSICIAN. Wash skin with soap and

water.

WARNING: Im prop erly i ns talled battery cou ld result in a fire or

explosion! A Thermo King approved battery must be instal led

and properly secured to the battery tray.

WARNING: Improperly installed battery cables could result in

fire or explosion! Battery cables must be installed, routed and

secured properly to prevent them from rubbing, chaffing or

making contact with hot, sharp or rotating components.

WARNING: Do not attach fuel lines or any additional wiring

harnesses to the battery cables as this could caus e an

electrical fire!

CAUTION: Set all unit electrical controls to the OFF positio n

before connecting battery cables to the battery to prevent unit

from starting unexpectedly and causing personal injury.

CAUTION: Always wear protective clothing, gloves and eye

wear when handling and installing batteries. Battery acid can

cause serious burns when exposed to eyes or skin. If battery

acid contacts skin or clothing, wash imme diately with soap

and water. If acid enters your eye, immediately flood it with

running cold water for at least twen ty minutes and g et medi cal

attention immediately.

CAUTION: Always cover battery terminals to prevent them

from making contact with metal components during batter y

installation. Battery ter m inals grounding against metal could

cause the battery to explode.

WARNING: Al though fluorocarbon refrigerants are classified

as safe refrigerants, certain precautions must be observed

when handling them or servicing a unit in which they are

used. When released to the atmosphere in the liquid state,

fluorocarbon refrigerants evaporate rapidly , freezing anything

they contact.

WARNING: Av oid refrig eration o il contact with the eyes. Avo id

prolonged or repeated contact of refrigeration oil with skin or

clothing. Wash th oroughly after handling refrigeration oil to

prevent irritation.

Page 10

8

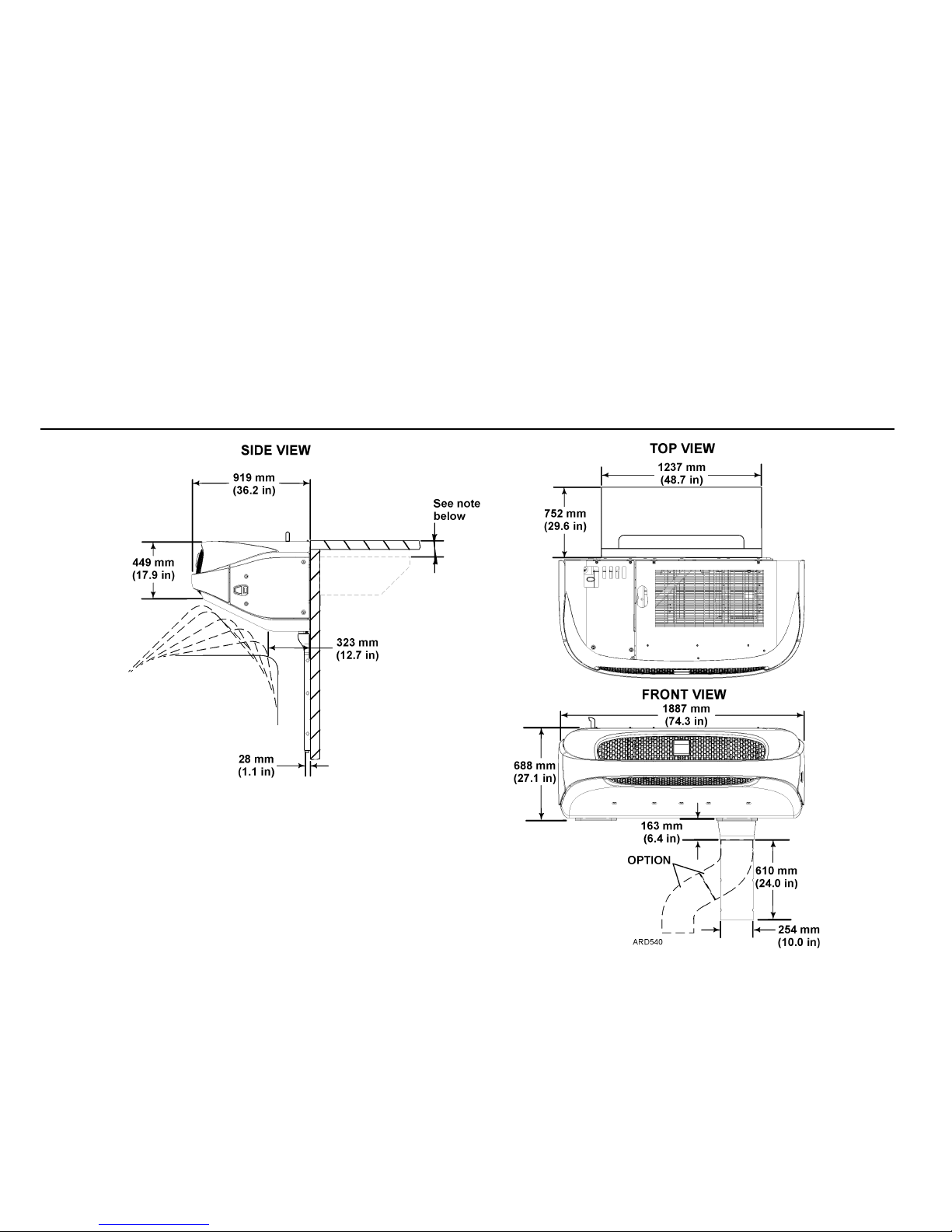

Unit Dimensions - T-580R, T-600R T-680R, T-680R, T-680S, T-800M, T-800R, T-880R, T-880S

NOTE: The top of the unit to be mounted flush with the top of the cargo box when

possible. The top of the evaporator to be positioned 25.4 mm (1.00 in.) below ceiling.

The dimension from the top of the cargo box to the evaporator cutout will vary

depending on the type of box, truck cab tilt clearance. etc.

T-580 th rough T-880 series units minimum dimension = 107 mm (4.2 5 in.)

Page 11

9

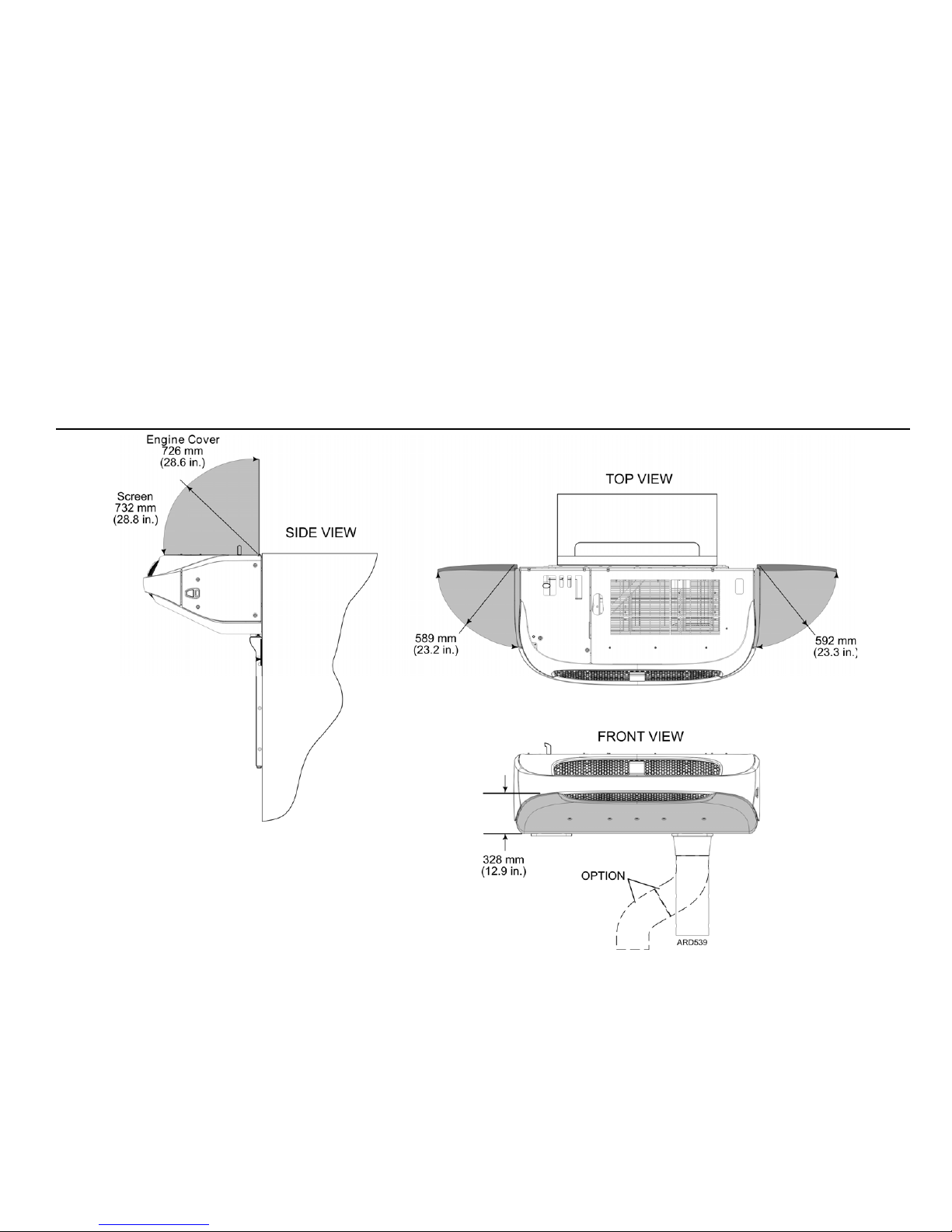

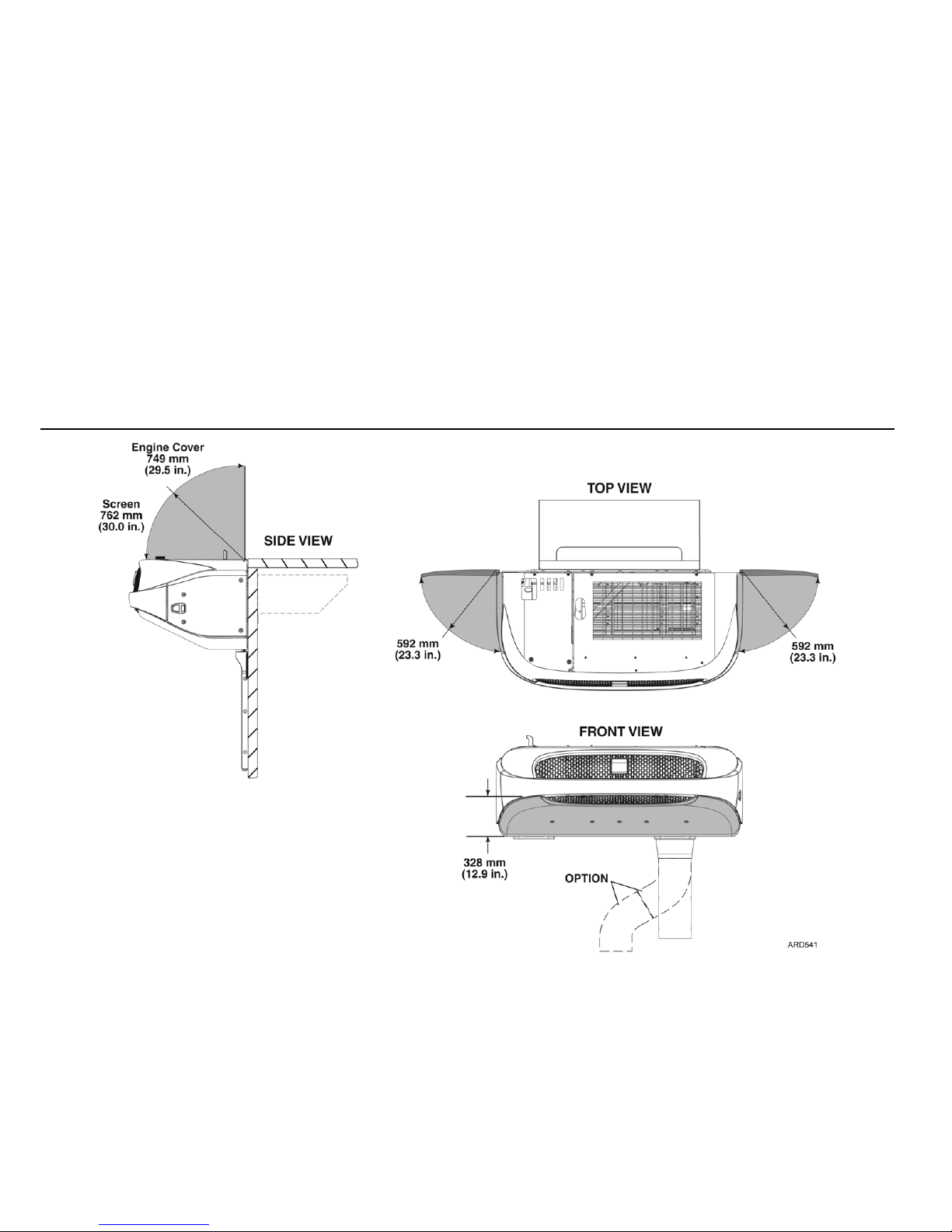

Unit Dimensions T-1000M, T-1000R, T-1080R, T-1080S and T-1200R

NOTE: The top of the unit to be mounted flush with the top of the cargo box when

possible. The top of the evaporator to be positioned 25.4 mm (1.00 in.) below ceiling.

The dimension from the top of the cargo box to the evaporator cutout will vary

depending on the type of box, truck cab tilt clearance. etc.

T-1000 through T-1200 series minimum dimension = 147 mm (5.75 in.)

Page 12

10

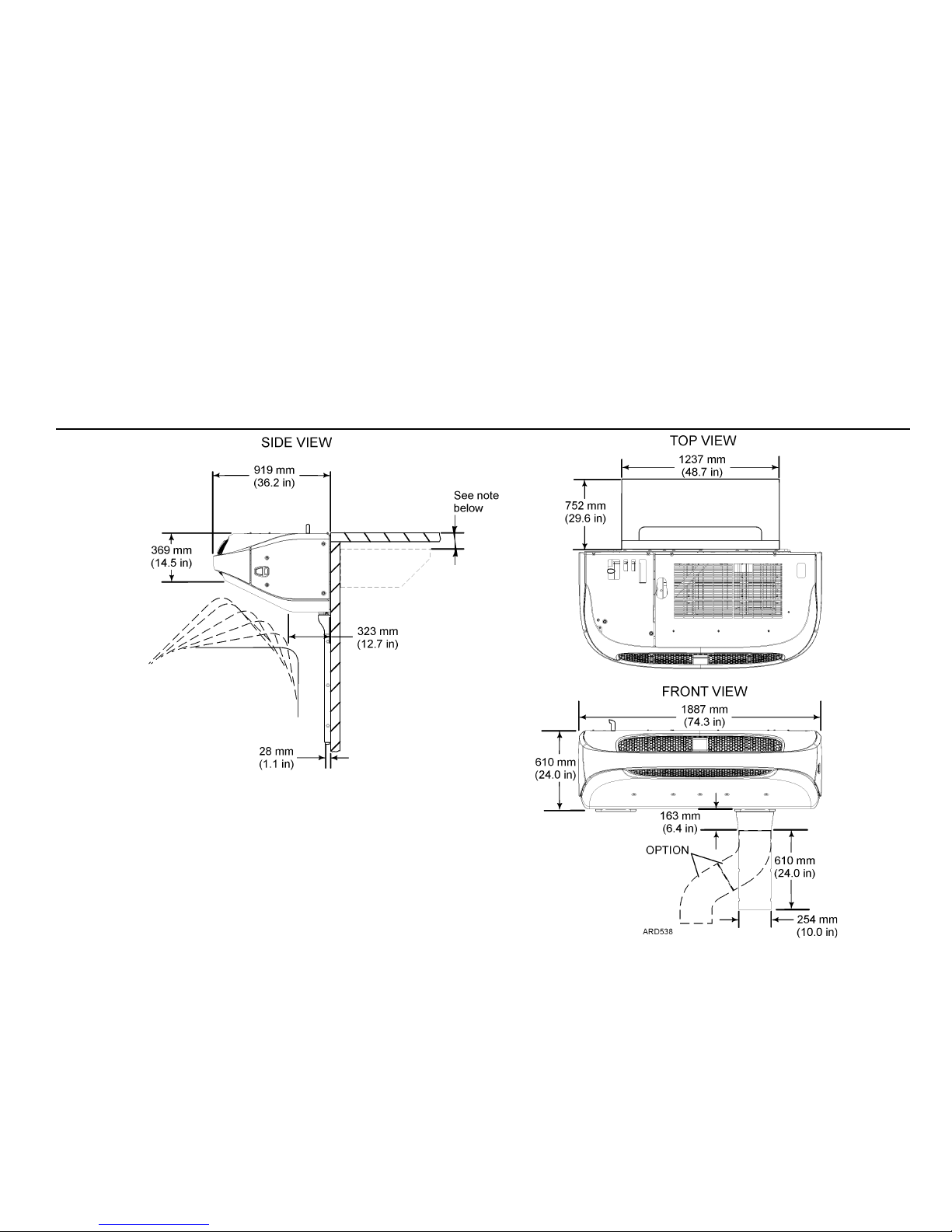

Service Area - T-580R, T-600R T-680R, T-680R, T-680S, T-800M, T-800R, T-880R, T-880S

Page 13

11

Service Area - T-1000M, T-1000R, T-1080R, T-1080S and T-1200R

Page 14

12

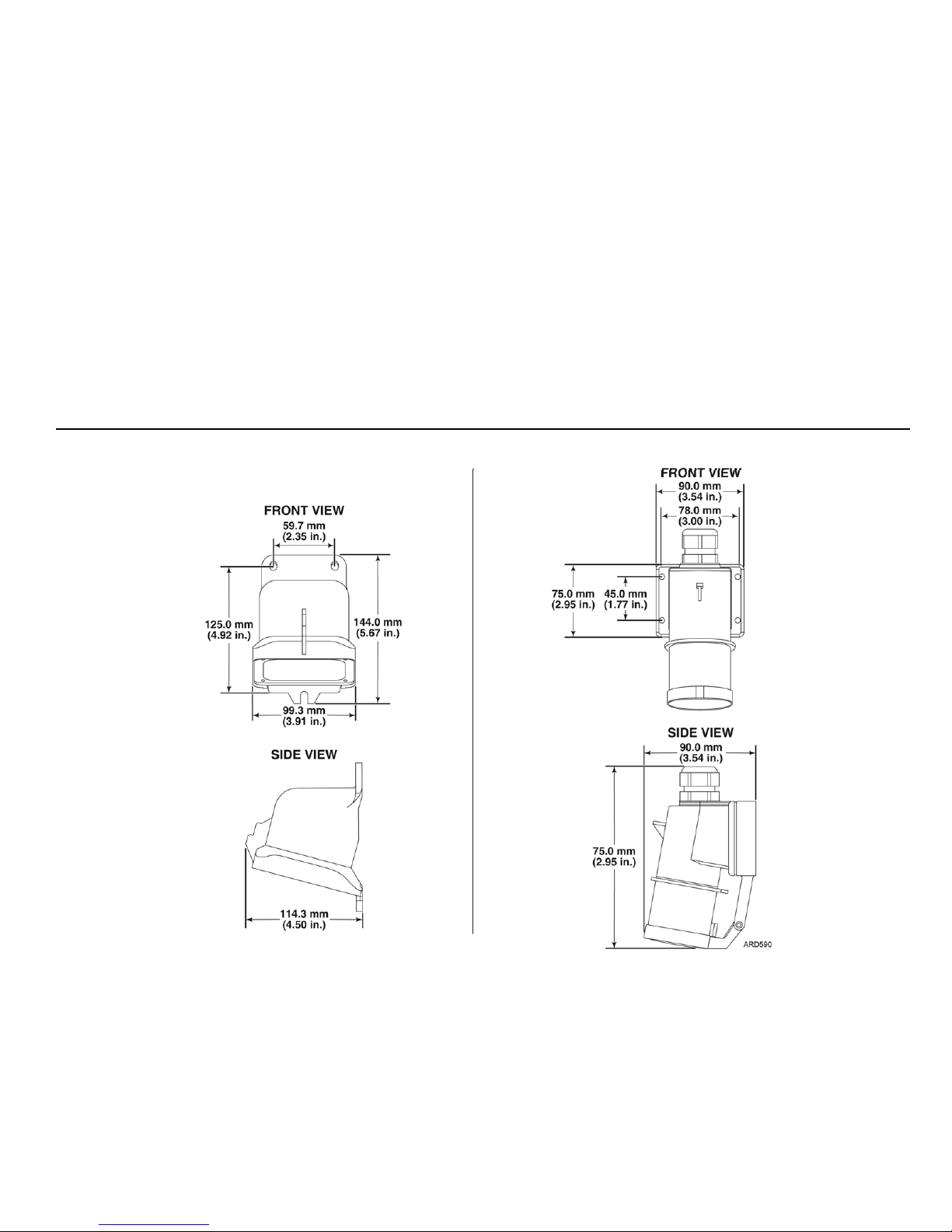

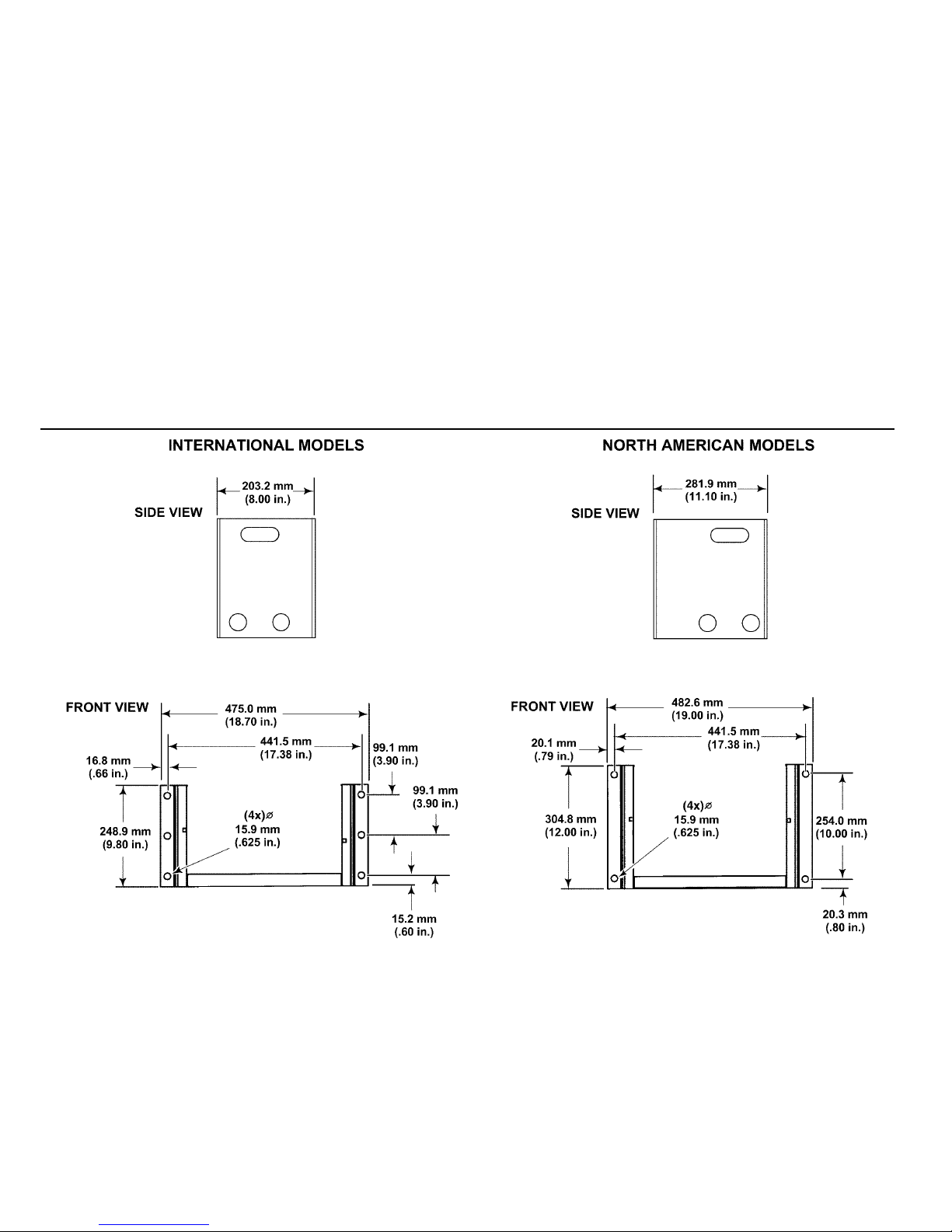

Remote Power Receptacle Dimensions (OPTION)

NORTH AMERICAN MODELS

INTERNATIONAL MODELS

Page 15

13

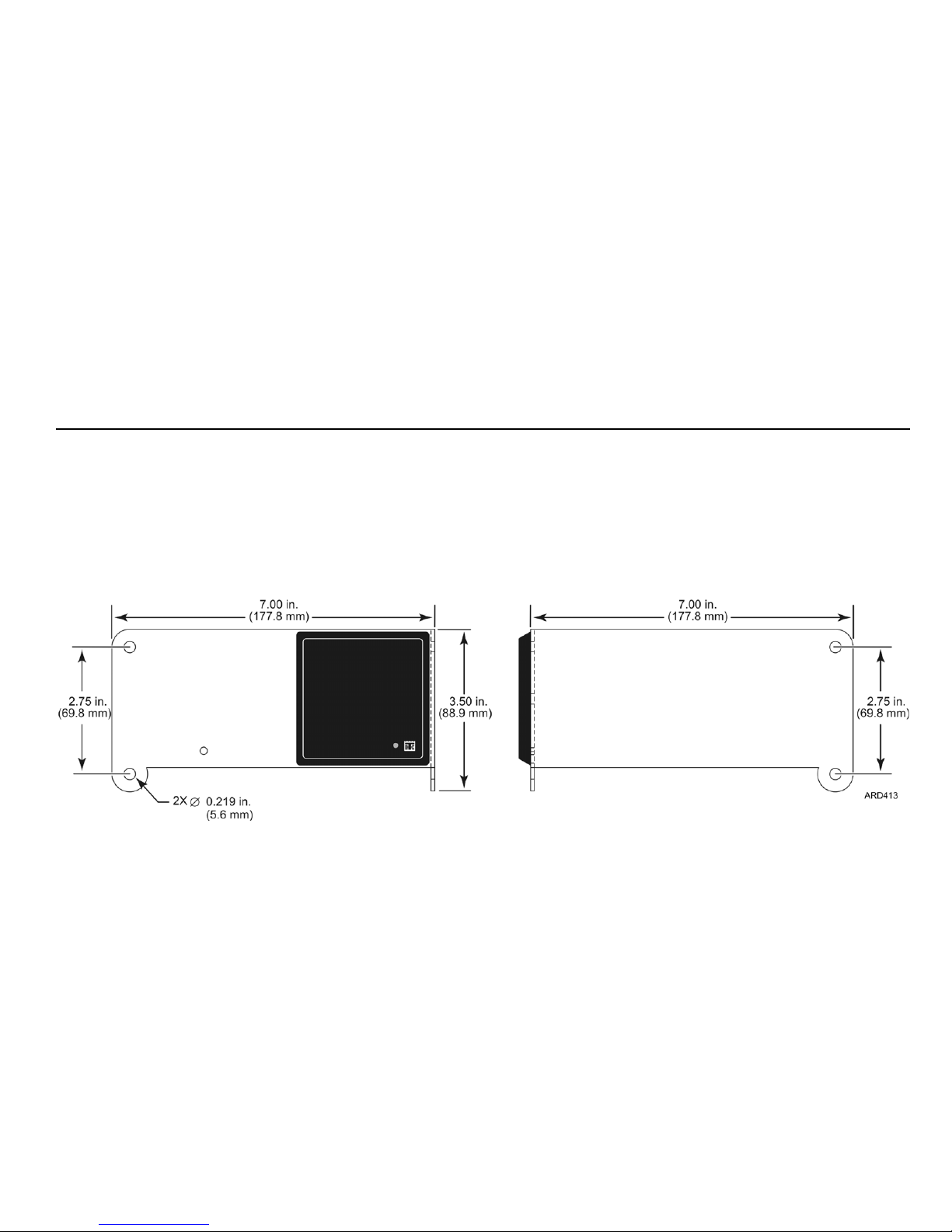

Battery Box Dimensions (OPTION)

Page 16

14

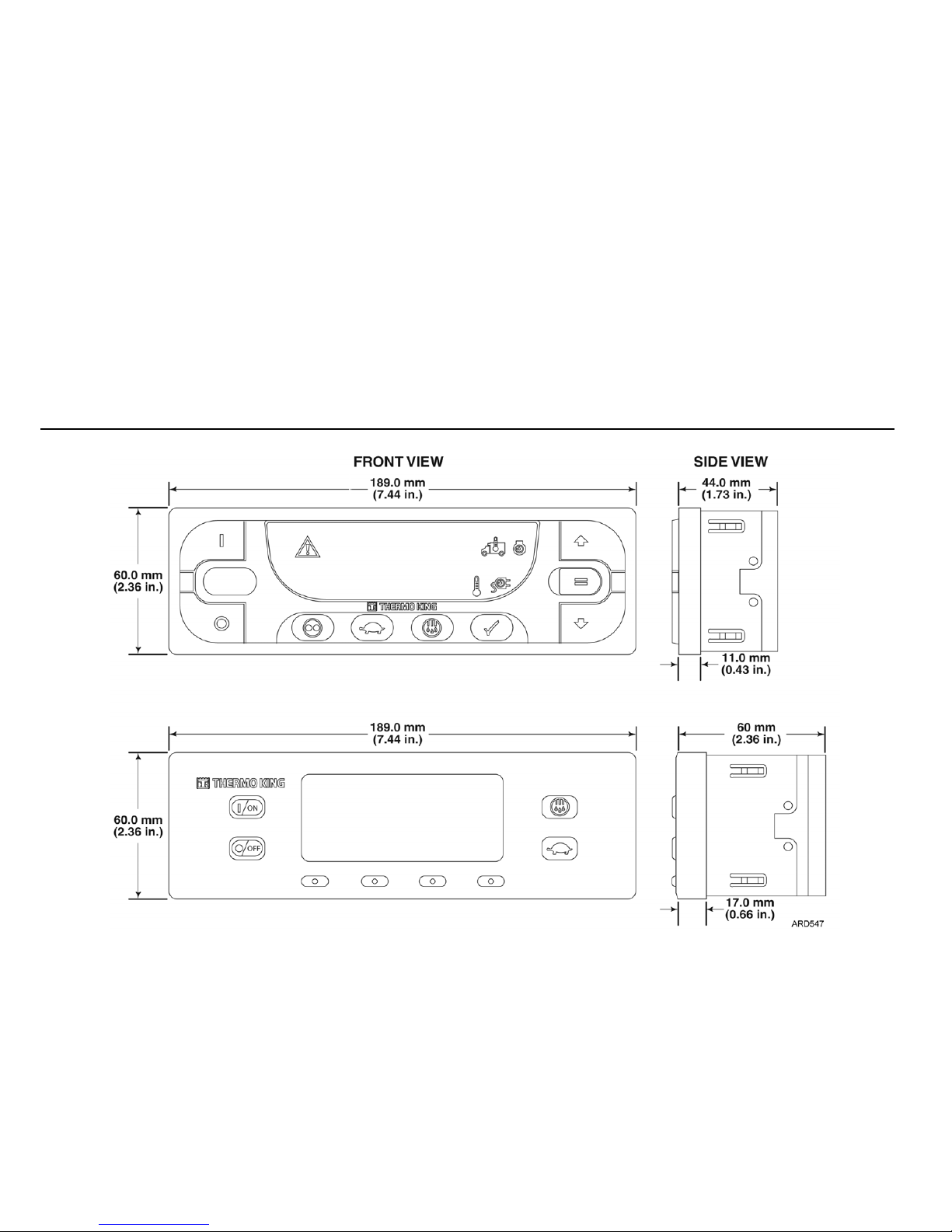

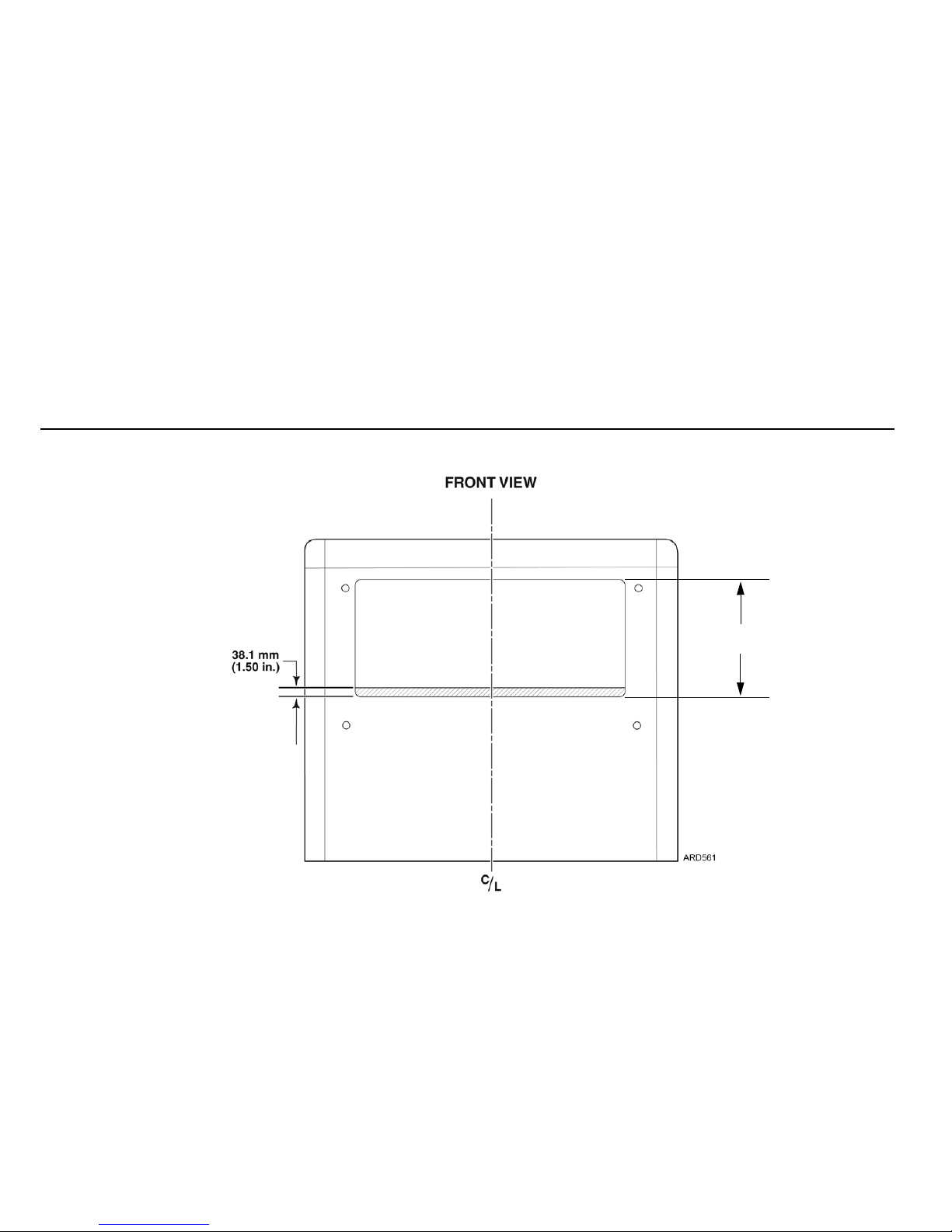

Remote Status Light Dimensions (OPTION)

Page 17

15

HMI Controller Dimensions

HMI Controller (LED Display)

HMI Controller (Graphics Display)

Page 18

16

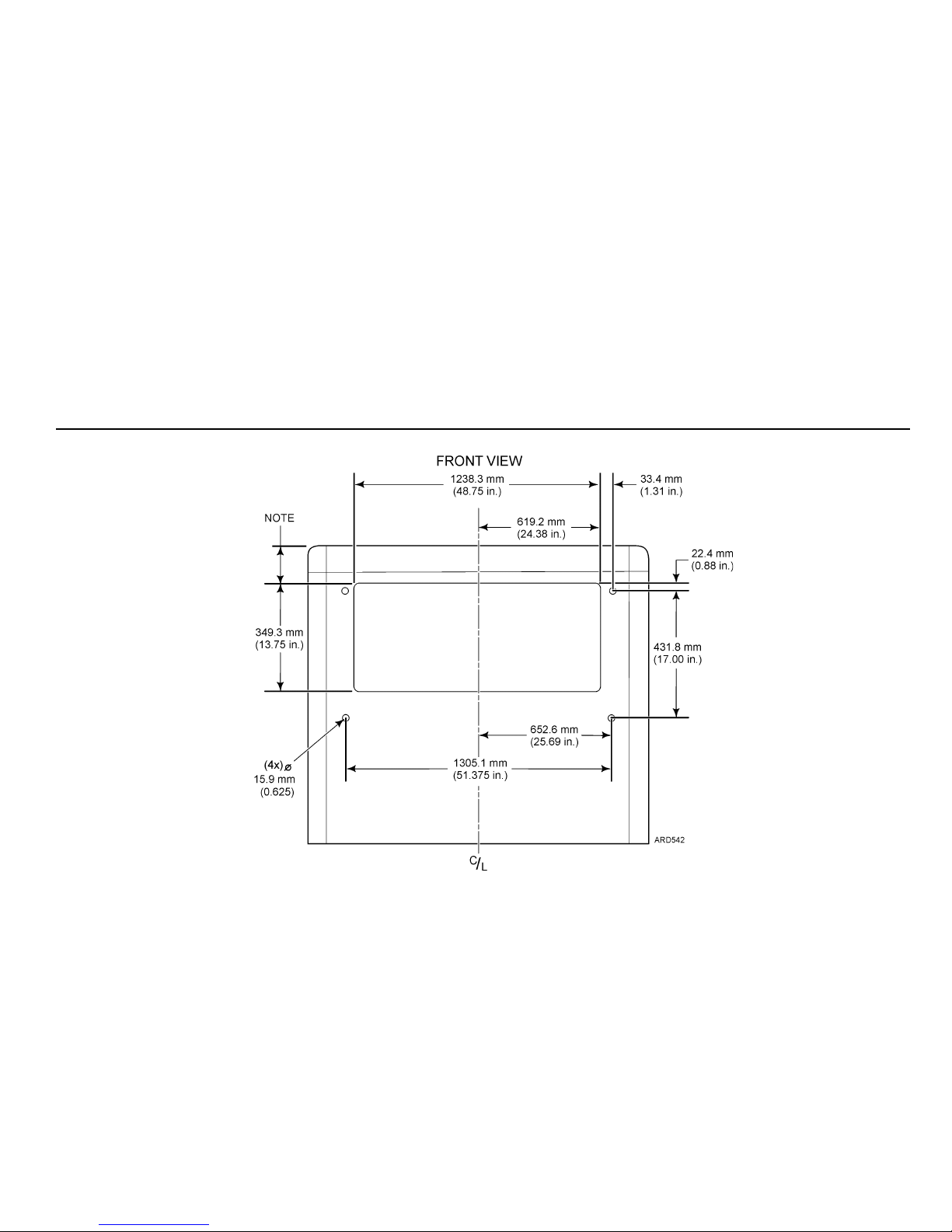

Truck Body Opening Dimensions

Installing a New Unit onto a New Truck Box

Important Installation Requirements:

• Gasket sealing surface of 50.8 mm (2.00 in.) wide is required around the unit opening. This surface must be flat within 6.4 mm (0.25 in.) and free of all rivets or head b o

proper gasket sealing.

• The top of the evaporator to be positioned 25.4 mm (1.00 in.) below ceiling.

• Unit mounting location must allow for adequate tilt clearance (see Unit Dimensions ).

NOTE: The top of the unit to be

mounted flush with the top of t he

cargo box when possible. The

top of the evaporator to be

positioned 25.4 mm (1.00 in.)

below ceiling.

The dimension from the top of

the cargo box to the evaporator

cutout will vary dependin g on the

type of box, truck cab tilt

clearance. etc.

T-580 through T-880 series

minimum dimension = 107 mm

(4.25 in.)

Page 19

17

Truck Body Opening Dimensions

Retrofitting a New Unit onto a Older Truck Box

Important Installation Requirements:

• Gasket sealing surface of 50.8 mm (2.00 in.) wide is required around the unit

opening. This surface must be flat within 6.4 mm (0.25 in.) and free of all rivets or head bolts for proper gasket se aling.

• Evaporator to be positioned 25.4 mm (1.00 in.) below ceiling.

• Unit mounting location must allow for adequate tilt clearance (see Unit Dimensions ).

NOTE:

Existing opening same as

RD-II, TS-500 and TS-600 units

and does not require

modifications.

Opening must only be enlarged

when changing from a TS-200,

TS-300, MD-100, MD-200,

MD-300, MD-II or KD-II

349.3 mm

(13.75 in.)

Enlarge Opening as shown (See

Page 20

18

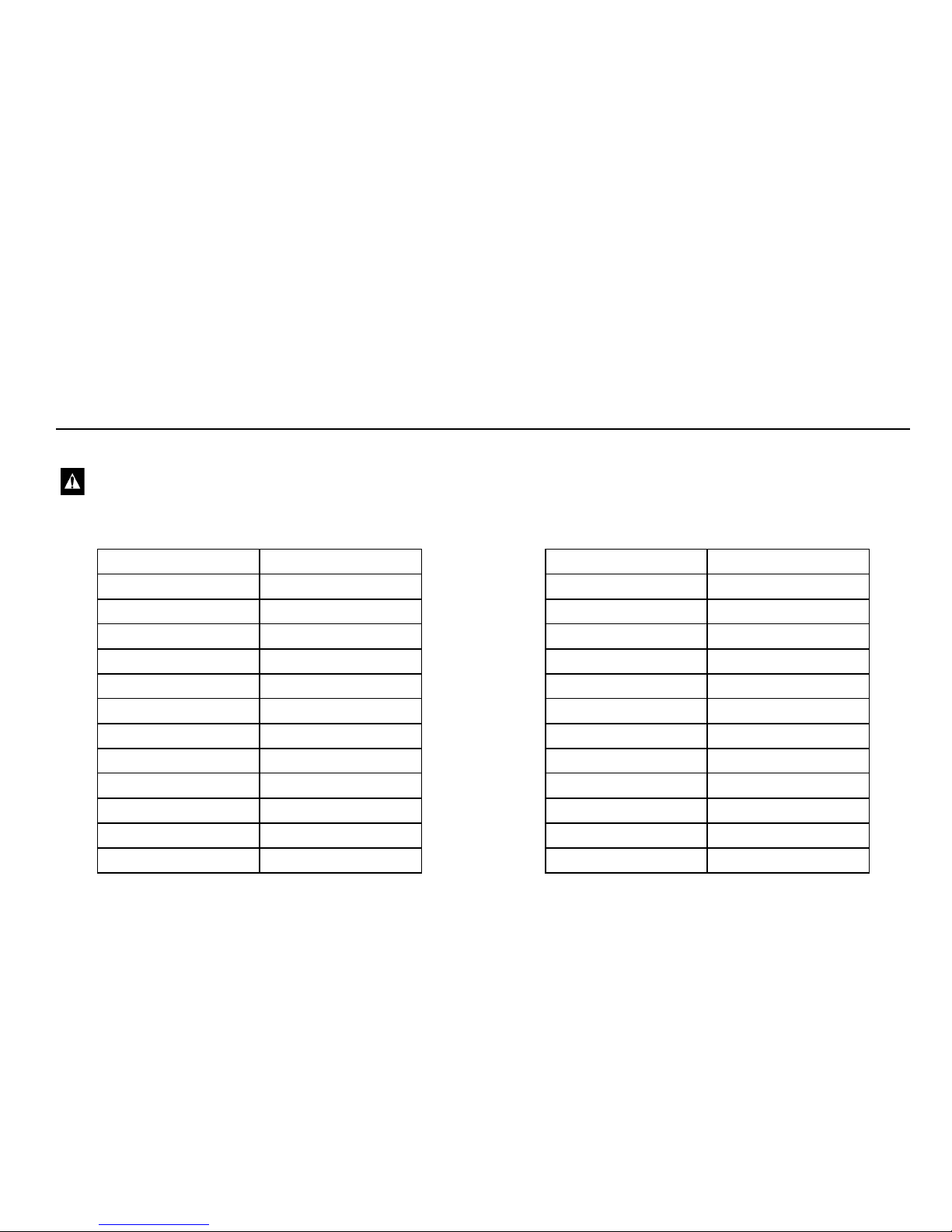

Unit Weights

Model 30 Units (approximate weight) Model 50 Units (approximate weight)

CAUTION: The truck wall must be structurally strong enough to support the weight of the refrigeration unit.

T-580R 434 kg (957 lbs.)

T-600R 443 kg (977 lbs.)

T-680R 437 kg (963 lbs.)

T-680S 447 kg (985 lbs.)

T-800R 443 kg (977 lbs.)

T-880R 437 kg (963 lbs.)

T-880S 447 kg (985 lbs.)

T-800M 443 kg (977 lbs.)

T-1000M 476 kg (1029 lbs.)

T-1000R 461 kg (1016 lbs.)

T-1080R 453 kg (999 lbs.)

T-1080S 459 kg (1012 lbs.)

T-1200R 475 kg (1046 lbs.)

T-580R 459 kg (1012 lbs.)

T-600R 468 kg (1032 lbs.)

T-680R 462 kg (1018 lbs.)

T-680S 472 kg (1040 lbs.)

T-800R 468 kg (1032 lbs.)

T-880R 462 kg (1018 lbs.)

T-880S 472 kg (1040 lbs.)

T-800M 468 kg (1032 lbs.)

T-1000M 516 kg (1138 lbs.)

T-1000R 510 kg (1125 lbs.)

T-1080R 502 kg (1108 lbs.)

T-1080S 508 kg (1121 lbs.)

T-1200R 524 kg (1155 lbs.)

Page 21

19

Lifting Bar Details

IMPORTANT: All T-580 through T-1200 series truck units require a new

lifting bar. This new bar must be used to safely lift and install these series

units. This new lifting bar can also be used to install earlier series truck

units.

WARNING: Thermo King requires a 3 point lifting bar to safely

lift and install units. A lifting bar can be made from the drawings

provided.

WA R NING : All h ard ware us ed to asse mble the li f t ing bar m ust be

DIN 931 class 10.9 (SAE Grade 8). The use of hardware other

than specified may cause personal injury, severe damage to the

equipment and void the warranty.

WARNING: Use forged clevis and pins, forged chain links and

forged locking hooks with strength equal to total lift capacity of

hoist mechanism and that meet all safety standards.

Page 22

20

Lifting Bar Details

A

B

C

D

A

B

C

D

87654321

87654321

SIZE DWG NO REV

TITLE

DRAWN DATE

THIRD ANGLE PROJECTION

D

REVISIONS

CHANGE ORDER

REV DESCRIPTION DATE APPROVED

CODE IDENT NO

CHECKED

APPROVED

ENG APPVLFINISH

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

UNLESS OTHERWISE SPECIFIED TOLERANCES

ON DIMENSIONS PER TKS09109

DIAGRAM-LIFTING BAR ASS'Y

FOR SELF-POWERED

LARGE TRUCK

-

--

6/15/90RL

6/15/90TB

1/20/88JO

NOTES:

2. USE TWO CHAIN LINKS WITH A CHAIN LINK MASTER AS SHOWN.

3. USE THREE FORGED CLEVIS AND PINS TO ATTACH LIFTING CHAINS.

4. EACH ASSEMBLY MUST HAVE STRENGTH EQUAL TO MINIMUM OF 1.5 TIMES

THE WEIGHT OF THE HOIST AND MEET ALL SAFETY STANDARDS.

2

1

4

3

5

ENTIRE UNIT

CLEVIS LIFTING

HOLES (1-5)

SCALE 0.250 SHEET 1 OF 2

J

9127C30

INGERSOLL-RAND IS THE SOLE OWNER OF THIS

DRAWING AND ALL INFORMATION IN IT, WHICH ARE

PROTECTED BY COPYRIGHT AND OTHER LAWS AND MAY

BE SUBJECT TO LAWS REGARDING EXPORTING

INFORMATION OUTSIDE OF THE U.S. THIS DRAWING

MAY BE USED ONLY BY ITS RECIPIENTS FOR THE

PURPOSE FOR WHICH IT IS PROVIDED AND ONLY BY

THE RECIPIENT, WHO AGREES THAT IT WILL NOT,

WITHOUT INGERSOLL-RAND'S PRIOR WRITTEN

PERMISSION: 1) DISCLOSE NOR USE THIS DRAWING

OR THE INFORMATION IN IT EXCEPT AS SPECIFIED

ABOVE; OR 2) MAKE ANY COPIES OF OR EXTRACTS,

REVISIONS, OR UPDATES FROM THE DRAWING. ALL

COPIES MUST BE RETURNED TO INGERSOLL-RAND

UPON COMPLETION OF THE WORK FOR WHICH THEY

HAVE BEEN PROVIDED OR UPON ANY EARLIER

REQUEST.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES.

INTERPRET DIM AND TOL PER

ASME Y14.5M - 1994

M GILMAN

18-Jun-08

MOVED LIFTING HOLES ALONG REAR BAR,

ADDED BRIDGING BAR FOR SPECTRUM TS

LIFTING POINT. ADDED WELD SYMBOLS,

RE-LABLED ALL LIFTING POINTS

F529536

M GILMAN

25-Mar-09

ADDED LIFTING HOLES FOR NEW UNITS,

ADDED BRIDGING BAR FOR MULTI-TEMPS.

G532334

E KIRBY

20-Jan-10

DIM 17.22 WAS 16.42. DIM 11.12 WAS

10.42. ADDED TSERIES SPECTRUM VIEW

H539147

M GILMAN

14-Jun-10

CHG DRAWING AND VIEWS, MOVED HOLES 1-6,

ADDED TABLE FOR ALL TRUCK UNITS.

I543699

J.DAVIES27-NOV-12

REMOVED CHAINS, BOLTS FROM VIEW SHT 1,

DEL NOTE 2.

J665985

Thermo King

UNIT

TYPE

FRONT

CHAIN LIFT

HOLE LOCATION

ENTIRE UNIT

CLEVIS LIFTING

HOLE LOCATION

TS 200/300/500/600 - 30 LEFT HOLE 1

TS 200/300/500/600 - 50 LEFT HOLE 2

SPECTRUM TS LEFT HOLE 4

MD II, MD 200, MD 300 - 30 RIGHT HOLE 1

MD II, MD 200, MD 300 - 50 RIGHT HOLE 2

KD II - 30 RIGHT HOLE 1

KD II - 50 RIGHT HOLE 2

RD II - 30 RIGHT HOLE 1

RD II - 50 RIGHT HOLE 2

T SERIES - 30/50 LEFT HOLE 3

T SERIES SPECTRUM LEFT HOLE 5

RELEASED 14/Jan/2013

Page 23

21

Lifting Bar Details

A

B

C

D

A

B

C

D

87654321

87654321

SIZE DWG NO REV

D

CODE IDENT NO

7.9

54.2

3.5

3.5

27.1

.50 THICK

3.5

1.75

2X .75

25.1

50.20

26.60

3X .875

1.75

23.50

28.70

.534

4.0

1.75

.534

4.0

2.4

1.75

2X .75

7.5

1.75

1.0

8.85

11.45

5.0

4X .534

1.75

1.0

8.85

11.45

5.0

4X .534

4.0

R1.25

(30.3)

.50 THICK

3.5

2X .75

1.75

4X .534

2X .8

2X 3.4

21.1

21.1

2X 58°

(2X )122°

2X 58°

23.6

11.2

17.2

2X 58°

31.7

2.1

2.1

9127C30

J

SHEET 2 OF 2SCALE 0.250

SCALE 0.250

REAR MEMBER

SCALE 0.250

FRONT MEMBER

SCALE 0.150

WELDING DETAIL

FRONT MEMBER

CENTER MEMBER

REAR MEMBER

SCALE 0.250

CENTER MEMBER

I

2X

2X

I

I

I

I

I

(1.6)

(1.4)

Page 24

22

Required Tools

1. Safety Glasses

2. Drill

3. Drill Bits

4. Tape Measure

5. Mechanics Tools

6. Lifting Bar (New Style Design Required) with forged clevis and pins,

forged connecting links and forged locking hooks.

7. Work Platform (Recommended)

Page 25

23

Required Tools

Page 26

24

Installation Components

1. Unit Mounting Washers 1.250 x 0.188 THK

2. Locking Nuts 1/2-13

3. Torx Head Screws

4. Hose Management Cap s

5. Hold Down Clamps

6. #14 Sheet Metal Screws

7. Drain Hose Check Valves

8. Fuel Pump

9. Fuel Pump Bracket

10. Screws HH 1/4-20 SS

11. Locking Nuts 1/4-20 SS

12. Fuel Pickup Tube

13. Fuel Line Fittings

14. Clamps

15. Self Tapping Screws #10 HWHSM

16. In-Line Fuse Holder

17. Fuse 60 amp

18. Terminal Connector Splice

19. Heat Shrink Sleeving 3.00''

20. Terminal Red 3/8''

21. Terminal Lug 3/8''

22. Cable Ties

23. Muffler Gasket

24. Exhaust Tube Extension

25. Nut-Blind

26. HMI Controller

27. HMI DIN Mount

28. Oil Drain Hose Retainer

Page 27

25

Installation Components

Page 28

26

Uncrating the Unit

Important Unit Lifting Information

NOTE: All T-580 through T-1200 series truck units require a new lifting

bar. This new bar mus t be used t o saf ely lift and install these series unit s.

See “Lifting Bar Details” on page 19.

Uncrating the Unit

Carefully remove the top and side crate member and remove the bottom

panel and installation kit components shipped with the unit.

1. Remove the top covers, top screen (if equipped) and the muffler from

the unit.

2. Install two M12 eyebolts and washers into the lifting holes in the rear

frame rails, and tighten securely. NOTE: M12 eyebolts must be used as

M12 nuts are factory installed inside the rear frame channel.

3. Install a third M12 eyebolt, washer and locking nut into the provided

hole in the support channel as shown and tighten hardware securely.

4. Attach the new three point lifting bar secu rely to t he t hree eyebolts a nd

slightly raise the unit.

5. Remove the eight skid bracket screws securing the unit to the of the

crate (Detail C).

6. Remove the two rear members of the crate and raise the unit from base

approximately 304.8 mm (12.0 in.) (Detail C).

7. Remove the four mounting bolts securing the two upright members to

the unit (Detail C).

The unit is now ready to install.

WARNING: Thermo King requires a 3 point lifting bar to safely

lift and install units. A lifting bar can be made from the drawings

provided. See “Lifting Bar Details” on page19 .

WARNING: Use forged clevis and pins, forged chain links and

forged locking hooks with strength equal to total lift capacity of

hoist mechanism and that meet all safety standards.

WARNING: Inst aller su pplied lifting eyebolts must be forged steel,

12 mm, 1.75 pitch, minimum 20.5 mm long. Substitutions are not

acceptable!

WARNING: Use only locking lifting hooks to attach to the lifting

eyebolts (Detail A).

WARNING: The point shown in Detail B below is not a major

lifting point. It is used only

to level and balance the unit during

installation (Detail B).

Page 29

27

Uncrating the Unit

Page 30

28

Installing the Unit

Important Unit Lifting Information

NOTE: All T-580 through T-1200 series truck units require a new lifting

bar. This new bar mus t be used t o saf ely lift and install these series unit s.

See “Lifting Bar Details” on page 19.

NOTE: The T-570R, T-600, T-600R, T-800, T-800R and T-1000 series

truck units have dual mounting hole patterns in the frame.

• T-570R, T-600, T-600R, T-600M, T-800 and T-800R use the lower

dual mounting hole patterns.

• T-1000, T-1000R and T-1000M use the upper mounting hole

patterns.

Installing the unit

NOTE: The muffler must not be installed before mounting the unit.

1. Use the new 3 point lifting bar to carefully lift the unit up to the truck

opening.

2. Install four M12 (1/2-13 in. Grade 5) mounting bolts through the wall

of the truck box.

NOTE: The mounting bolts should protrude 73.3 mm (2.90 in.) full

thread from the front wall of the cargo box (Detail B). Carefully sli de the

unit into the opening and over mounting bolts.

IMPORTANT: DO NOT INSTALL ANY COMPRESSIBLE WASHERS

OR OTHER MATERIALS BETWEEN THE UNIT AND THE TRUCK!

3. On the inside of the unit frame, install the four 4.8 mm (0.188 in.)

mounting washers and the locking nuts provided in the installation kit.

• Torque the mounting hardware to 81.4 N•m (60 ft. lbs.).

• Disconnect and remove the lifting bar.

NOTE: Depending on your particular installation, excess threads of the

upper roadside unit mounting bolt may need to be cut off to prevent

interference with the muffler.

4. Reinstall the muffler and the new gasket supplied in kit onto the engi ne.

• Torque the muffler mounting bolts to 18.4 N•m (13.6 ft. lbs).

• Install the exhaust pipe onto the muffler and tighten securely.

5. Remove and save the three M12 eyebolts installed earlier.

6. Reinstall the top cover or screen (if applicable) securely.

7. Install the bottom pan securely using the supplied M6 Torx head

mounting hardware.

WARNING: Thermo King requires a 3 point lifting bar to safely

lift and install units. A lifting bar can be made from the drawings

provided. See “Lifting Bar Details” on page19.

WARNING: Use forged clevis and pins, forged chain links and

forged locking hooks with strength equal to total lift capacity of

hoist mechanism and that meet all safety standards.

WARNING: Inst aller su pplied lifting eyebolts must be forged steel,

12 mm, 1.75 pitch, minimum 20.5 mm long. Substitutions are not

acceptable!

WARNING: Use only locking lifting hooks to attach to the lifting

eyebolts (Detail A).

WARNING: The point shown in Detail B below is not a major

lifting point. It is used only

to level and balance the unit during

installation (Detail B).

Page 31

29

Installing the Unit

Page 32

30

Installing the Hose Management Caps

Hose Management Caps (STANDARD)

Hose management caps provide a exit point under each side of the unit for

routing the individual drain hoses, fuel lines, electrical cables. The caps are

provided with cutout guide marks. Always remove any sharp edges after

cutting the caps.

Roadside Cap

1. Route the following items out of the roadside cutout of the bottom pan

and down the front exterior wall of the cargo box:

• Roadside Evaporator Drain Hose

• In-Cab Controller Harness

• Remote Receptacle Power Cable (Model 50 Units Only)

Curbside Cap

2. Route the following items out of the curbside cutout of the bottom pan

and down the front exterior wall of the cargo box:

• Curbside Evaporator Drain Hose

• Coolant Overflow Hoses (2)

• Fuel Supply and Return Lines (2)

• Positive and Negative Battery Cables (2)

• Unit Control Power Wire

• Fuel Pump Harness

• Oil Drain Hose (See “Securing the Oil Drain Hose” on page 34).

3. Trim the cutout areas on the caps as required.

4. Install each cap securely into the bottom pan.

Page 33

31

Installing the Hose Management Caps

Cutout Guide Marks

Front

of

Unit

Page 34

32

Installing the Hose Management System (OPTION)

Hose Management System (OPTION)

The hose management system organizes the routing of the drain hoses,

electrical cables and fuel lines down the truck wall. White plastic covers

protect these components from damage while providing a cleaner, finished

installation.

The kit consists of a funnel cap, clip assemblies, straight covers and

mounting hardware. Additional kits with offset covers are also available.

IMPORTANT: See “Securing the Oil Drain Hose” on page 34.

1. Route the following items out of the curbside cutout of the bottom pan

and down the front exterior wall of the cargo box:

• Curbside Evaporator Drain Hose

• Engine Overflow Hose

• Fuel Supply and Return Lines

• Positive Battery Cable

• Unit Control #2 Power Wire

• Fuel Pump Harness

• Negative Battery Cable

2. Install the funnel cap into the bottom pan securely.

3. Mark a line from the center of the funnel cap down the truck box wall.

4. Install two clip assemblies onto each cover with supplied hardware.

• Insure the surface area of the truck box is clean, flat and uniform.

• Clean the surface area thoroughly with 50:50 mixture of isopropyl

and water.

• Peel the backing off the adhesive strips. Using the center line,

position the covers and press firmly into position.

• Remove the covers from the clips.

NOTE: If adequate bond was not possible, attach the clips securely with

self-drilling screws.

5. Route and install the hoses and cables in the clips as shown.

6. Reinstall the covers securely.

7. Installation on the roadside is similar.

NOTE: For 50 Models ONLY. Route the standby power cable down the

center of the clip assemblies.

Page 35

33

Installing the Hose Management System (OPTION)

Front

of

Unit

Page 36

34

Securing the Oil Drain Hose

Oil Drain Hose

1. Secure the oil drain hose directly under the unit to the cargo box with

the two supplied retaining clips and self tapping screws as shown.

2. Ensure there is no contact and adequate clearance be tween the oil drain

hose and the hose management caps. The cutout in the hose

management cap should be as large as possible with no sharp edges.

3. Lower retaining clip should be positioned in an location easily

accessible for servicing the unit. Your actual location will depend on

the distance between the bottom of unit to top of cab, etc.

Page 37

35

Securing the Oil Drain Hose

The cutouts in the hose mana gemen t cap

should be as large as possible with no

sharp edges.

Page 38

36

Securing the Evaporator Drain Hoses

IMPORTANT: Evaporator drain hoses must be installed without any

sharp bends or kinks to allow for proper water drainage.

1. Route drain hoses from under the unit, through the Hose Management

Caps and down the front wall of the truck box.

2. Secure drain hoses with supplied self tapping screws and clamps.

3. Cut off excess drain hose and install a check valve onto each drain hose

securely with tie bands.

Page 39

37

Securing the Evaporator Drain Hoses

Page 40

38

Installing the Fuel Pickup Tube Into a Steel or Aluminum Tank

NOTE: The fuel pickup tube supplied in the installation kit will not be

needed when installing an optional Thermo King aluminum fuel tank.

The aluminum tank is already equipped with fuel inlet, fuel outlet and

vent fittings.

1. Tape the paper template (supplied with pickup tube) to the desired

location on the diesel fuel tank and center punch the three holes.

NOTE: Use a magnet, grease or special hole saws/drills that will

minimize metal or aluminum chips from entering the fuel tank.

Thoroughly clean and flush the tank to remove any chips.

2. Drill:

• 9.5 mm (0.375 in.) diameter holes first.

• 31.8 mm (1.250 in.) diameter hole next.

• Remove the template from the tank and remove any burrs from the

hole.

3. Cut the end of the pickup tube so approximately 25 mm (1.00 in.) is

above the bottom of the fuel tank.

4. Loosen the nut and slide all the parts to the top of the pickup tube

assembly.

5. Hold the parts in position and slide the assembly into the hole at a slight

angle until the bushing is inside the hole.

6. Tip the backup washer and sl ide it through t he hole and pos it ion it onto

the bushing. Thread the nut onto the bushing, position as needed to

facilitate fuel line connections and tighten to 54 Nm. (40 ft-lb.).

DANGER: Diesel fuel vapors are potentially explosive. Use

extreme caution when drilling in or around the diesel fuel tank.

Sparks from an electric drill or drill bit could cause an explosion.

Do not smoke while working near the diesel fuel tank. Drain all

diesel fuel from the tank and use nitrogen or an inert gas to purge

the diesel fuel vapors from the tank prior to drilling. Keep the

diesel tank filled with inert gas while drilling.

Page 41

39

Installing the Fuel Pickup Tube Into a Steel or Aluminum Tank

Page 42

40

Installing the Fuel Pickup Tube Into a Plastic Tank

1. Tape the paper template (supplied with pickup tube) to the desired

location on the diesel fuel tank and center punch the three holes.

NOTE: Use grease or special hole saws/drills that will minimize

plastic chips from entering the fuel tank Thoroughly clean and flush

the tank to remove any chips.

2. Drill:

• 9.5 mm (0.375 in.) diameter holes first.

• 31.8 mm (1.250 in.) diameter hole next.

• Remove the template from the tank and remove any burrs from the

hole.

3. Cut the end of the pickup tube so approximately 25 mm (1.00 in.) is

above the bottom of the fuel tank.

4. Loosen the nut and slide all the parts to the top of the pickup tube

assembly.

5. Hold the parts in position and slide the assembly into the hole at a slight

angle until the bushing is inside the hole.

6. Tip the backup washer and sl ide it through t he hole and pos it ion it onto

the bushing. Thread the nut onto the bushing, position as needed to

facilitate fuel line connections and tighten to 54 Nm. (40 ft-lb.).

DANGER: Diesel fuel vapors are potentially explosive. Use

extreme caution when drilling in or around the diesel fuel tank.

Sparks from an electric drill or drill bit could cause an explosion.

Do not smoke while working near the diesel fuel tank. Drain all

diesel fuel from the tank and use nitrogen or an inert gas to purge

the diesel fuel vapors from the tank prior to drilling. Keep the

diesel tank filled with inert gas while drilling.

Page 43

41

Installing the Fuel Pickup Tube Into a Plastic Tank

Page 44

42

Installing the Steel Fuel Tank

IMPORTAN T: Observe the positioning of existing OEM fasteners on the

vehicle frame. The four fasteners used to install the fuel tank brackets

must be located on the frame no

higher and no lower than any existing

OEM fasteners.

1. The fuel tank mounting brackets should be positioned 610 mm (24.00

in.) apart to properly support the combined weight of 118 kg (260 lbs.)

which includes the fuel tank, mounting brackets and 30 gallons of

diesel fuel.

• Measure and mark the location of the four mounting holes on the

frame.

• Use a 17 mm (11/16 in.) drill bit and drill four holes in the frame.

2. Install each fuel tank mounting bracket securely onto the truck’s frame

with two, 1/2 -13, Grade 5 bolts, flat washers and locking nuts.

Substitutions are not acceptable!

• Torque the bolts to 81-88 N•m (60-65 ft-lb.).

3. Install the mounting bands T-bolts onto the mounting brackets with flat

washers and locking nuts.

4. Install the fuel tank into the mounting bands.

• Torque the upper mounting band T-bolts to 47 N•m (35 ft-lb.).

IMPORTANT: Do not over tighten the mounting band bolts or damage to

the bands will result!

DANGER: An improperly installed fuel tank could l ead to seri ous

injury or death! Consult your truck’s chassis manufacturer for

specific details on proper fuel tank installation and

recommendations.

Page 45

43

Installing the Steel Fuel Tank

1

2

3

4

Page 46

44

Installing the Aluminum Fuel Tank (OPTION)

IMPORTANT: Observe the positioning of existing OEM fasteners on the

vehicle frame. The four fasteners used to install the fuel tank brackets

must be located on the frame no

higher and no lower than any existing

OEM fasteners.

1. The fuel tank mounting brackets should be positioned 610 mm (24.00

in.) apart to properly support the combined weight of 118 kg (260 lbs.)

which includes the fuel tank, mounting brackets and 30 gallons of

diesel fuel.

• Measure and mark the location of the four mounting holes on the

frame.

• Use a 17 mm (11/16 in.) drill bit and drill four holes in the frame.

2. Install each fuel tank mounting bracket securely onto the truck’s frame

with two, 1/2 -13, Grade 5 bolts, flat washers and locking nuts.

Substitutions are not acceptable!

• Torque the bolts to 81-88 N•m (60-65 ft-lb.).

3. Install the mounting bands onto the mounting brackets with flat

washers and locking nuts.

• Tighten only the lower T-bolt to 47 N•m (35 ft-lb.).

• Install the self-adhesive rubber strips onto each mounting bracket

as shown.

4. Install the fuel tank into the mounting bands.

• Confirm the rubber strips on both the mounting bands and the

mounting brackets are positioned correctly to prevent metal to

aluminum contact.

• Torque the upper mounting band T-bolts to 47 N•m (35 ft-lb.).

IMPORTANT: Do not over tighten the mounting band bolts or damage to

the bands will result!

DANGER: An improperly installed fuel tank could lead to ser ious

injury or death! Consult your truck’s chassis manufacturer for

specific details on proper fuel tank installation and

recommendations.

Page 47

45

Installing the Aluminum Fuel Tank (OPTION)

1

2

3

4

Page 48

46

Installing the Fuel Pump and Fuel Lines

NOTE: Do not connect unit fuel lines into any truck/trailer fuel lines.

1. The fuel pump must be installed as close to the fuel tank as possible

and not more than 762 mm (30.00 in.) above the fuel in the fuel tank.

2. Fuel lines should be routed in a protective housing with no kinks or

sharp bends.

3. Rubber grommets must be used when routing fuel lines through sheet

metal.

4. Secure all fuel lines with provided clamps.

5. Remove the protective plugs from each of the fuel pick up tubes on t he

fuel tank and install fuel line fittings.

6. From the unit, route and install the fuel supply line to the upper fuel

line fitting on the fuel pump. Tighten the fuel line fittings securely.

7. From the fuel pump, route the lower fuel supply line to the fuel tank.

• Cut the end of the nylon fuel supply line at a 45 degree angle and

insert into one of the fuel line fittings.

• Feed the fuel line down into the tank until it hits bottom, then pull it

back up 25 mm (1.00 in.) and tighten the fuel line fitting securely.

8. From the unit, route the fuel return line to the fuel tank.

• Insert the fuel return line into the other fuel line fitting and tighten

the fuel line fitting securely.

9. Remove the plastic cap from the fuel vent and point the outlet towards

the rear of the truck.

IMPORTANT: The factory installed fuel tank air vent must be in place

and functional for the Thermo King unit’s fuel system to operate

correctly and for the fuel tank to remain in compliance with Federal

Motor Carrier Safety Administration specifications (title 49, paragraph

393.67). A plugged or restricted fuel t ank air vent can result in premature

damage to the fuel pump and could also cause severe damage to the fuel

tank. NEVER

remove or install any other component in place of the fuel

tank air vent.

10. Operate the unit and check all fuel line fittings for fuel leaks.

DANGER: The Thermo King fuel pump should be installed onto

the supplied mounting bracket. The fuel pump and fuel lines

should be installed a safe distance away from the extreme heat

generated by the Diesel Particulate Filter (DPF) or exhaust system

components on the truck. Failure to do so could result in damage

to equipment or fire!

DANGER: Leaking fuel lines could cause a fire resulting in death

or serious injury All fuel lines must be tight and leak free!

DANGER: Do not route fuel lines with battery cables or electrical

wires, as this could cause a fire!

S=Supply R=Return

Page 49

47

Installing the Fuel Pump and Fuel Lines

Page 50

48

Installing the ServiceWatch™ Remote Download Port (OPTION)

Choose an appropriate location to mount the ServiceWatch port that

provides for safe and easy access for connecting the download cable. The

download port can be rotated to fit your particular installation.

1. Attach the download port securely to the truck box with four TEK

screws.

2. Provide a drip loop and secure the harness with supplied clamps and

screws.

Page 51

49

Installing the ServiceWatch™ Remote Download Port

Page 52

50

Installing the Remote Power Receptacle (OPTION)

Choose an appropriate location to mount the power receptacle that

provides for safe and easy access for connecting the power cord.

North American Units (Detail A)

1. Measure and drill three 13 mm (.500 in.) holes into truck body.

2. Insert the supplied rubber blind nuts into each hole in truck body.

3. Install the receptacle to the truck box with the supplied 1/4 x 20

mounting hardware and tighten securely.

4. Route and secure the harness with supplied clamps and screws.

International Units (Detail B)

1. Measure and drill four 9.5 mm (.375 in.) holes into truck body

2. Insert the supplied rubber blind nuts into each hole in truck body.

3. Install the receptacle to the truck box with the suppli ed 10-32 mounting

hardware and tighten securely.

4. Route and secure the harness with supplied clamps and screws.

DANGER: To prevent serious injury or death, the electric standby

power cord must not be connected to the unit during installation!

Page 53

51

Installing the Remote Power Receptacle (OPTION)

Page 54

52

Installing the Remote Status Light (OPTION)

Installation

1. Mount the Status Light in a location so that i s visible to the dri ver in the

truck’s mirror.

• Mark and drill the four mounting holes using a 3/16'' drill.

• Mount the status light securely with the supplied rivets.

2. Provide a “drip-loop” to prevent water from migrating into the Status

Light and route the harness towards the bottom of the unit.

3. Secure harness to the truck box using the supplied clamps and rivets.

4. Remove the bottom pan from the unit and locate the 6-pin connector

under the unit near the control box.

5. Remove the blank plug and attach the Status Light connector securely.

6. Secure excess harness up under the control box with band wraps.

7. Reinstall bottom pan.

Page 55

53

Installing the Remote Status Light (OPTION)

Page 56

54

Installing the HMI Controller

NOTE: Route and secure the controller harness to prevent rubbing,

chafing or making contact with sharp, moving or hot components. Allow

excess harness for tilt cab applications. The supplied rubber grommets

must be used when routing harness through sheet metal holes.

Inside Cab DIN Mounting

1. Install DIN (ISO 7736) mounting sleeve into driver panel DIN opening.

Bend the mounting sleeve tabs to secure.

2. Route the controller harness from the unit to insi de the cab and t hrough

the mounting sleeve.

HMI Controller (LED Display) - Insert the controller harness to the

mating connector at the rear of the HMI controller until it locks firmly in

position.

• Lightly pull on the harness to confirm the harness is locked

securely.

• Install the plug cover onto the rear of the controller with the two

supplied screws.

HMI Controller (Graphics Display) - Install the harness plug cover onto

the rear of the controller with the four supplied screws.

3. Install the HMI controller into mounting sleeve until it locks in

position.

Page 57

55

Installing the HMI Controller

NOTE: HMI with LED Display shown, HMI with Graphics Display installs the same.

Page 58

56

Installing the Battery Box (OPTION)

1. Secure battery in place with hold down bracket and rod.

2. Rubber grommets must be used where cables a nd fuse holder ent er box.

3. DO NOT install protective battery cover. This will be installed later.

CAUTION: Battery boxes and covers must be installed securely

with proper hardware to prevent them from falling off.

CAUTION: Battery cables must be properly routed and secure to

prevent rubbing, chafing or making contact with sharp, moving or

hot components.

Page 59

57

Installing the Battery Box (OPTION)

Page 60

58

Battery Connections

Important Battery Information

IMPORT ANT: See Safety Precautions - “Battery Installation and Cable

Routing” on page 7 for additional information.

NOTE: Thermo King units are designed for one 12 vol t , group 31

battery. The battery must be suitable for deep cycling, heavy duty

and rated with a minimum of 95 amp/hr.

Positive Cable

1. At the unit, locate the lar ge black cable ma rked POS+. Route this cable

to the battery, cut to the proper length and add battery cable lug from

installation kit (Detail A). This cable will be attached to the battery in

Step 2.

Unit Control Power Wire

2. At the unit, locate the large 8 AWG (#2) wire. Route this wire to the

battery, cut to the proper length and add fuse holder assembly.

• Use battery cable crimper to securely crimp 8 AWG (#2) wire and

fuse holder together and heat shrink the connection.

• Apply a liberal amount of Superlube to the 60 amp fuse and fuse

holder and then install fuse.

• Route the fuse holder terminal along with the positive cable

(POS+) into the battery box through the rubber grommet and

connect to the POSITIVE terminal of the battery (Detail A).

Fuel Pump Harness

3. Route and connect the fuel pump harness to the fuel pump.

Negative Cable

4. At the unit, locate the large black cable mar ked NEG -. Route this cable

to the battery, cut to the proper length and add the battery lug from

installation kit.

• Route the negative cable (NEG -) into the battery box through the

rubber grommet and connect to the NEGATIVE terminal of battery

(Detail B).

5. Install the battery box cover securely.

6. All harnesses and battery cables should be neatly routed and secured

with provided clamps.

Page 61

59

Battery Connections

Page 62

60

Installing the Door Switch (OPTION)

When installing CargoLink wireless door switches, see TK 55151 CargoLink Installation Manual.

NOTE: These instructions are intended as reference guide only to

assist with a typical door switch install ation. Y our ins tallation may be

different depending o n the cargo b ox, the amou nt and types o f doors

and the customers particular requirements.

Door Switch Components

The door switch consists of a magnet, a switch, non-magnetic mounting

hardware and a interface harness to connect to the host unit.

• The magnet is always mounted on the door.

• The switch (with harness) is always mounted to a stationary location.

Non-magnetic mounting hardware is included to install the switches. If

alternate hardware is used it must also be non-magnetic or the door switch

will not operate properly.

Installer is to supply and fabricate the harness connecting the interface

harness to the door switch per the table below. The harness should be 18

AWG or better, 3 wires, color coded RED, BLACK and WHITE

Mounting Locat ions

The door switch can be mounted on the inside or outside of either swing

out or roll-up doors and can be mounted in various positions to

accommodate particular applications.

IMPORTANT INSTALLATION NOTES:

• The door switch must be installed away from traffic (i.e. forklifts) or

protected from it.

• The door switch and magnet must be installed parallel to each other,

not perpendicular. Long cross hair aligns to long cross hair.

• It is important that a maximum gap of 19 mm (0.75 in.) is maintained

between the door switch and the magnet. Shims may be required and

must be a non-magnetic material (alumi num, wood, plas tic , etc.) or th e

door switch will not operate properly.

(Detail A) Ceiling Mounted

1. Mount the magnet flush with the top edge of the door and secure with

supplied hardware.

2. Close the door and mount the switch to the door sill parallel with the

magnet, being sure the “cross hairs” are aligned and that the maximum

gap of 19 mm (0.75 in.) is maintained.

(Detail B) Floor Mounted

1. Mount the magnet flush with the bottom edge of the door and secure

with supplied hardware.

2. Close the door and mount the switch to the floor parallel with the

magnet, being sure the “cross hairs” are aligned and that the maximum

gap of 19 mm (0.75 in.) is maintained.

(Detail C) Outside Door Installation

1. Mount the magnet flush with the top edge of the door and secure with

supplied hardware.

2. Close the door and mount the switch to the door sill parallel with the

magnet, being sure the “cross hairs” are aligned and that the maximum

gap of 19 mm (0.75 in.) is maintained.

Interface Harness Wiring Door Switch Wiring

RED = (DSP) POWER RED = (DSP) POWER

BLACK = (CH) GROUND BLACK = (CH) GROUND

WHITE = (DS) OUTPUT WHITE = (DS) OUTPUT

Page 63

61

Installing the Door Switch (OPTION)

Right Angle Mounting

Top x Top Mounting

Side x Side Mounting

Page 64

62

Installing the Door Switch (OPTION)

NOTE: The Door Switch Harness Connectors are located at the rear of the host unit.

1. Attach the interface harness to matching door switch connector located

at the rear of the host unit.

2. Route a 3 wire harness (INSTALLER SUPPLIED) from the interface

harness to a door switch. Connect matching wires per the table below

(RED/RED, WHITE/WHITE, BLACK/BLACK) to each door

switch using splice connectors. Crimp splice connectors securely and

apply heat with a heat gun.

3. All harnesses should be installed, routed and properly secured to

protect from damage.

4. Operate unit and verify door switch operation.

Interface Harness Wiring Door Switch Wiring

RED = (DSP) POWER RED = (DSP) POWER

BLACK = (CH) GROUND BLACK = (CH) GROUND

WHITE = (DS) OUTPUT WHITE = (DS) OUTPUT

Page 65

63

Installing the Door Switch (OPTION)

Interface Harness Wiri ng Door Switch Wiring

RED = (DSP) POWER RED = (DSP) POWER

BLACK = (CH) GROUND BLACK = (CH) GROUND

WHITE = (DS) OUTPUT WHITE = (DS) OUTPUT

Page 66

64

Auxiliary Electrical Accessories

NOTE: Thermo King does not recommend adding auxiliary electrical accessories to the electrical system of T-80 Series Self Powered Truck Units

equipped with SR-3 Controllers and Tier 4 Engines. However, if auxiliary accessories are connected to the electrical system, see the following guidelines

to ensure emission compliance for the Ti er 4 engines. The function and safety of the auxiliary access ory connected to t he Thermo K ing electrical syste m is

the customer’s responsibility.

Electrical Connection Guidelines

• Connect the 12 volt load to the 2 terminal (J24) on the Base

Controller.

•Use (J8) Pin 4 to control a 12 volt relay. The relay will be energized

when the unit is on.

• DO NOT connect ground wires for el ectrical acce ssories t o the CH

terminal (J23) on the Base Controller. Use independent ground

wires connected to the chassis ground or the negative battery

terminal.

Use (J8) Pin 4 to 12 Volt Relay Connection

DO NOT Connect Ground

Wires to CH Terminal (J23)

SR-3 Base Controller

J8 Pin 4

Location

4

2 T erminal (J24)

12 Volt Load

Connection

Page 67

65

UNIT CHECK LIST

UNIT CHECK LIST

Visually inspect the unit for transit and handling damage. File claim

with delivery carrier.

Install the unit as outlined in the Thermo King Installation Manual.

If the unit has a separate fuel tank add 10 gallons of fuel to the tank.

BEFORE STARTING THE UNIT

Check battery and battery cable installation.

Inspect fuel line routing checking for rubbing, chaffing or laying on

hot surfaces.

Visually inspect the unit for the following: Loose or improperly

fitting bolts, brackets, hardware, hose connections and hose routing.

Inspect all wiring connections and routing.

Check defrost drain hoses and kazoos.

Check unit mounting hardware for tightness.

Check compressor and engine mounts.

Check compressor clutch if equipped.

Install refrigeration gauge manifold. (Multi-Temp units only)

Check engine oil level.

Check condenser and evaporator section for cleanliness and signs of

refrigerant leaks.

Check front bulkhead and air chute if equipped.

Check damper door, bushings and springs.

MULTI-TEMP UNITS (REMOTE EVAPORATORS)

Check evaporator(s) sections for cleanliness.

Leak test interconnecting tubing.

Check for damage, loose or missing bolts and hardware on remote

evaporator(s).

Check for proper installation of drain tubes, drain kazoos and drain

tube heater wires.

Check for properly routed refrigerant lines wiring harnesses for

remote evaporator(s). Check for proper ly routed harnesses for remote

controller.

Check for proper installation of remote evaporator guards if

equipped.

Check remote harness wiring plugs in the host evaporator.

Check wiring, connections, and terminals in the remote

evaporator(s).

Check compartment bulk head(s) for proper fit if equipped.

START AND RUN UNIT

(ON MULTI-TEMP UNITS START ONLY THE HOST UNIT)

Check for proper oil pressure, coolant temperature, oil, fuel, or

coolant leaks.

Check alternator charge.

Cycle the unit and ensure the unit functions in the corr ect modes and

the mode indicators are working.

Set for continuous run with thermosta t set point a t 32 F (0 C) a nd run

the unit to 32 F (0 C).

Page 68

66

UNIT CHECK LIST (continued)

Observe and record refrigerant operating pressures in relation to

ambient and box temperatures.

Verify the readings above are correct for the conditions.

When box reaches 32 F (0 C) check calibration of thermostat,

thermometer and data logger.

Run unit for 30 minutes at 32 F (0 C). During this period check for

correct cycling.

Reset thermostat to 50 F (10 C).

Check throttling valve while in the heat cycle.

Check operation of Modulation system if equipped.

For Single Temp units perform a controlled check of the refrigerant

level. For Multi-temps check the charge per multi-temp unit

procedures.

MULTI-TEMP UNITS

Install the compartment bulk head(s) if equipped.

Check for correct rotation of remote evaporator fans.

Check for correct cycling and operation of remote evaporator fans.

ALL UNITS

Initiate and check defrost operation and terminat ion.Check operat ion

and adjustment of damper door and remote fans. Each zone on

multi-temps must be checked for proper operation.

Set the unit for Cycle Sentry Operation.

Check for proper operation of all door switches.

Remove the compartment bulk head(s) if equipped.

Set the unit for continuous run. Continue to run the unit with the back

doors open, alternating between high speed cool and heat until at

least 6 hours (10 hours preferred) are shown on the engine run time

hour meter to ensure complete break in of the engine, time for the

belts and other moving parts to take out the initial tension and

adjustment.

ELECTRIC STANDBY OPERATIONAL CHECKS

Test AC electrical contacts and connections by connecting to AC

power and running.

Check for correct electric motor rotation.

Cycle thermostat and check for correct modes of operation.

Power source not available to test AC.

STOP UNIT

On Multi-temp units leak test interconnecting tubing.

Check and readjust all belt tensions using TK belt gauge 204-427.

Check for oil, fuel, coolant, refrigerant and exhaust leaks.

Check engine oil and coolant level.

Check entire unit for loosened hardware and fittings.

Check and adjust all skin, door and panels for correct alignment and

operation.

Complete the commissioning registration process.

Release unit.

Page 69

67

Page 70

Loading...

Loading...