Operator’s Manual

Precedent

TM

C-600, S-600 and S-700

Single Temperature Units

TK 56218-2-OP (Rev. 1, 12/15)

Precedent

TM

C-600, S-600 and S-700

Single Temperature Units

TK 56218-2-OP (Rev. 1, 12/15)

Copyright© 2015 Thermo King Corp., Minneapolis, MN, USA

Printed in USA

Disclaimer

This manual is published for informational purposes only. Thermo King Corporation makes no

representations or warranties, express or implied, with respect to t he information, recommendations

and descriptions contained in this manual and such information, recommendations and description s

should not be regarded as all-inclusive or covering all contingencies. In the event you have any

questions or require further information, please contact your local Thermo King dealer.

The procedures described herein should only be undertaken by suitably qualified personnel. Failure to

implement these procedures correctly may cause dam age to the Th ermo King unit or o ther property or

personal injury.

Thermo King Corporation and its affiliates shall have no liability in contract or tort (including negligence

and/or strict liability) or otherwise, to any person or entity fo r any personal injury, property damage or

any other direct, indirect, special or consequential damage or liability whatsoever, arising out of or

resulting from any actions by any person that are contrary to this manual or any of the information ,

recommendations or descriptions contained herein or the failure of any person to implement the

procedures described herein correctly or to follow caution and safety decals located on the Thermo

King unit.

2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EPA Emission Control System Warranty Statement 7

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermo King Corporation Responsibilities . . . . . . . 8

Owner Responsibilities . . . . . . . . . . . . . . . . . . . . . . 8

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Start/Stop Operation . . . . . . . . . . . . . . . . . 10

Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Battery Installation and Cable Routing . . . . . . . . . . . . 11

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant Oil . . . . . . . . . . . . . . . . . . . . 13

Safety Decals and Locations . . . . . . . . . . . . . . . . . . . 13

Condenser and Evaporator Fans . . . . . . . . . . . . . 13

High Voltage Components . . . . . . . . . . . . . . . . . . 14

Do Not Use Ether Starting Aids . . . . . . . . . . . . . . 15

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

ELC (Extended Life Coolant) . . . . . . . . . . . . . . . . . . . .17

EMI 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Thermo King Reciprocating Compressor . . . . . . . . . . .18

Electronic Throttling Valve . . . . . . . . . . . . . . . . . . . . . .18

SMART REEFER 4 (SR-4) Control System . . . . . . . . .18

Diesel Operation . . . . . . . . . . . . . . . . . . . . . . . . . .19

Electric Operation . . . . . . . . . . . . . . . . . . . . . . . . .19

CYCLE-SENTRYTM Start-Stop Controls . . . . . . . . . .20

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

OptiSet Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

FreshSet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Opening the Front Doors . . . . . . . . . . . . . . . . . . . . . . .22

Engine Compartment . . . . . . . . . . . . . . . . . . . . . . . . . .23

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . .23

Manual Pretrip Inspection . . . . . . . . . . . . . . . . . . . . .25

3

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . 27

SMART REEFER 4 (SR-4) Controller Overview . . . . .27

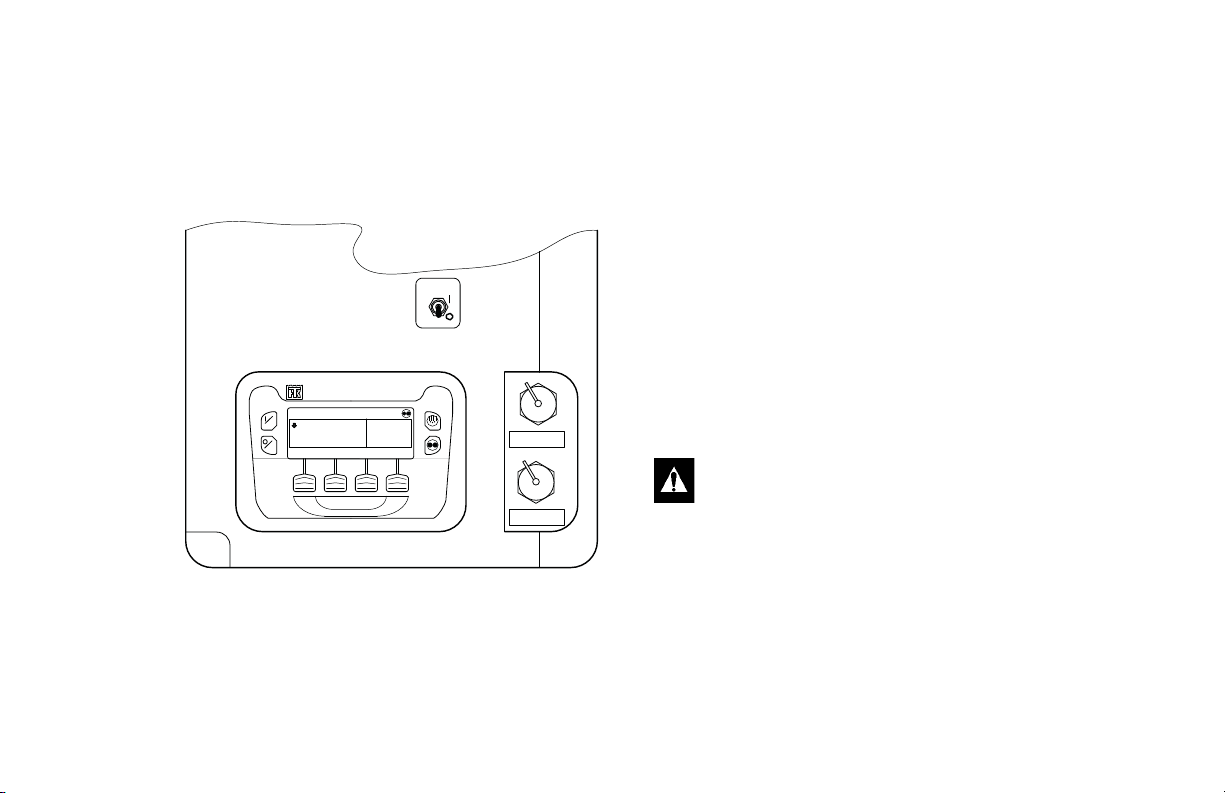

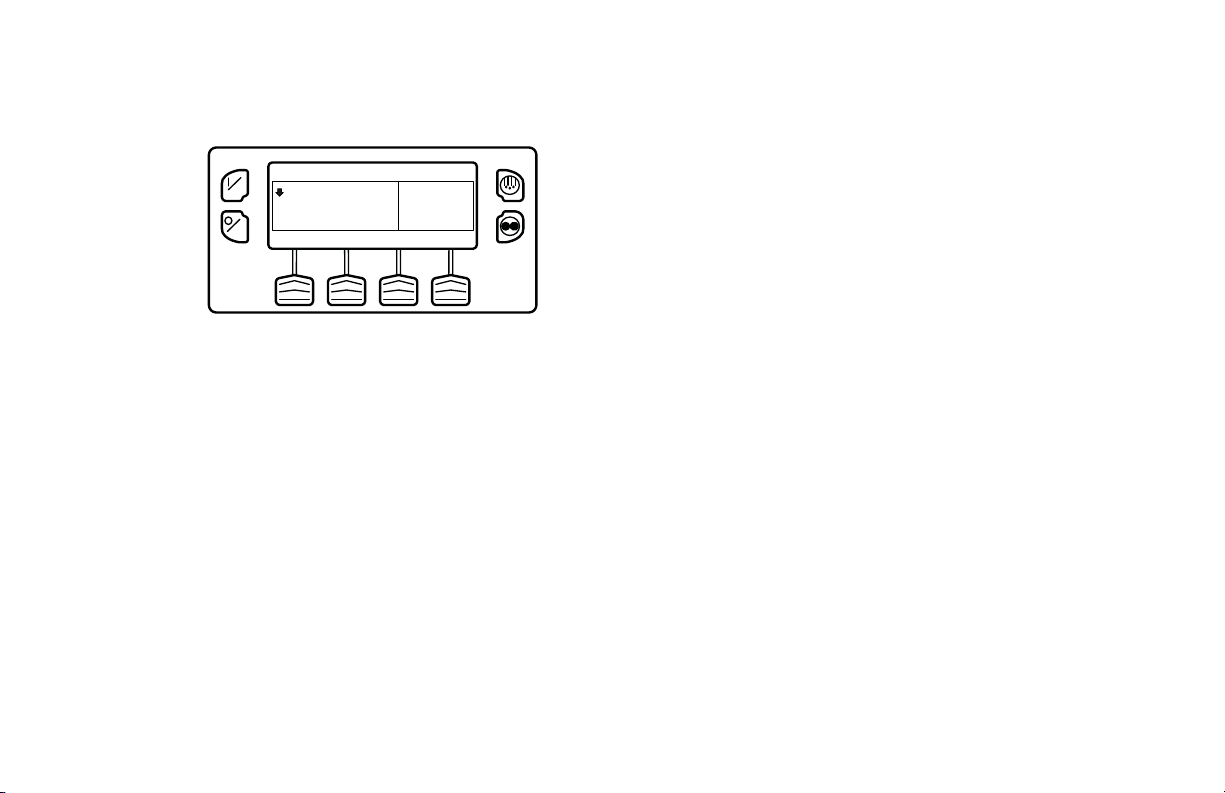

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Control Panel Display . . . . . . . . . . . . . . . . . . . . . .28

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Hard Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Turning Unit On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

If a Flash Drive is Connected: . . . . . . . . . . . . . . . .32

Configurable Soft Keys . . . . . . . . . . . . . . . . . . . . . 33

Display Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

If a Language is Enabled . . . . . . . . . . . . . . . . . . .34

If Log Alarms are Present . . . . . . . . . . . . . . . . . . . 36

Turning The Unit Off . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . 37

The TemperatureWatch Display . . . . . . . . . . . . . . . . .38

Changing The Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 39

Numerical Setpoints . . . . . . . . . . . . . . . . . . . . . . .39

Named Products - OptiSet Plus . . . . . . . . . . . . . . 40

Both Numerical Setpoints and Named Products . . 40

Changing the Setpoint - Numerical Setpoint . . . . .41

Changing the Setpoint - Named Product . . . . . . . 45

Changing the Setpoint - Both Numerical Setpoint

and Named Product Available . . . . . . . . . . . . . . .49

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . . 50

Starting the Electric Motor . . . . . . . . . . . . . . . . . . . . . 50

Switching from Diesel to Electric . . . . . . . . . . . . . . . . 51

Switching from Electric to Diesel . . . . . . . . . . . . . . . . 52

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . 53

Terminating a Defrost Cycle . . . . . . . . . . . . . . . . 56

Selecting Cycle Sentry or Continuous Mode . . . . . . . 56

Using the Gauges Key . . . . . . . . . . . . . . . . . . . . . 60

Using The Sensors Key . . . . . . . . . . . . . . . . . . . . . . . 62

Using the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . 64

Pretrip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Performing a Pretrip Test . . . . . . . . . . . . . . . . . . . 67

Flash Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Languages (If Enabled) . . . . . . . . . . . . . . . . . . . . 75

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Data Logger (CargoWatch) . . . . . . . . . . . . . . . . . 89

Hourmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

SmartPower Electric Standby Option . . . . . . . . . 102

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Clear All ECU Faults . . . . . . . . . . . . . . . . . . . . . 107

4

Loading and Enroute Inspections . . . . . . . . . . . . . 110

Pre-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . . 110

Post-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . 112

Enroute Inspections . . . . . . . . . . . . . . . . . . . . . . 113

Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . 119

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Maintenance Inspection Schedule . . . . . . . . . . . . .153

Serial Number Locations . . . . . . . . . . . . . . . . . . . . .159

Emergency Cold Line . . . . . . . . . . . . . . . . . . . . . . .160

Recover Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . .161

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . 148

Electrical Control System . . . . . . . . . . . . . . . . . . . . . 149

Electrical Standby (Smart Power Units Only) . . . . . . 150

Electric Motor and Overload Relay . . . . . . . . . . . 150

Standby Power Cord Requirements (Smart Power

Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

CALIFORNIA

Proposition 65 Warning . . . . . . . . . . . . . . . . . . . . . .161

5

Introduction

There is nothing complicated about operating and maintaining

your Thermo King unit, but a few minutes studying this

manual will be time well spent.

Performing pre-trip checks and enroute inspections on a

regular basis will minimize on-the-road operating problems. A

regular maintenance program will also help to keep your unit

in top operating condition. If factory recommended procedures

are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled

by a Thermo King dealer for four very important reasons:

• They are equipped with the factory recommended tools to

perform all service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the

repair and replacement of component parts is performed

by an authorized Thermo King dealer.

6

IMPORTANT: This manual is published for informational

purposes only and the information furnished herein should

not be considered as all-inclusive or meant to cover all

contingencies. If more information is required, consult your

Thermo King Service Directory for the location and

telephone number of the local dealer.

EPA Emission Control System Warranty

Statement

Thermo King warrants to the initial owner and each subsequent

owner that the certified, non-road diesel engine in your unit is:

1. Designed, built and equipped so as to conform, at the time

of sale, with all applicable regulations adopted by the

United States Environmental Protection Agency (EPA).

2. Free from defects in materials and workmanship in

specific emission related parts for a period of five years or

3,000 hours of opera tion , wh ich ever com es fi rst , af ter date

of delivery to the initial owner.

If an emission-related part or component fails during the

warranty period, it will be repaired or replaced. Any such part

or component repaired or replaced under warranty is warranted

for the warranty period.

During the term of this warranty, Thermo King will provide,

through a Thermo King authorized service dealer or other

establishment authorized by Thermo King, repair or

replacement of any warranted part at no charge to the non-road

engine owner.

In emergency, repairs may be performed at any service

establishment, or by the owner, using any replacement part.

Thermo King will reimburse the owner for their expenses,

including diagnostic charges for such emergency repair. These

expenses shall not exceed Thermo King’s suggested retail price

for all warranted parts replaced, and labor changes based on

Thermo King’s recommended time allowance for the warranty

repair and the geographically appropriate hourly labor rate.

7

EPA Emission Control System Warranty Statement

Any replacement part can be used for maintenance or repairs.

The owner should ensure that such parts are equivalent in

design and durability to genuine Thermo King parts. However,

Thermo King is not liable for parts that are not genuine

Thermo King parts.

A part not being available within 30 days or repair not being

completed within 30 days constitutes an emergency.

As a condition of reimbursement, replaced parts and received

invoices must be presented at a place of business of a Thermo

King authorized service dealer or other establishment

authorized by Thermo King.

This warranty covers the following emission-related parts and

components:

• Fuel Injection System

• Intake Manifold

• Exhaust Manifold

• Miscellaneous hoses, clamps, connectors and sealing

devices used in the above systems.

If failure of one of these parts or components results in failure

of another part or component, both will be covered by this

warranty.

Responsibilities

This warranty is subject to the following:

Thermo King Corporation

Responsibilities

During the emission warranty period, if a defect in material or

workmanship of a warranted part or component is found,

Thermo King will provide:

• New, remanufactured, or repaired parts or components

required to correct the defect.

NOTE: Items replaced under this warranty become the

property of Thermo King.

• Labor, dur ing n ormal worki ng ho urs, r equi red to make the

warranty repair. This includes diagnosis and labor to

remove and install the engine, if necessary.

Owner Responsibilities

During the emission warranty period, the owner is responsible

for:

8

EPA Emission Control System Warranty Statement

• The performance of all required maintenance. A warranty

claim will not be denied because the scheduled

maintenance was not performed. However, if the lack of

required maintenance was the reason for the repair, then

the claim will be denied.

• Premium of overtime cost.

• Cost to investigate complaints that are not caused by

defects in Thermo K ing material or workmanship.

• Providing timely notice of a warrantable failure and

promptly making the product available for repair.

Limitations

Thermo King is not responsible for resultant damages to an

emission-related part or component resulting from:

• Any application or installation Thermo King deems

improper as explained in this Operator’s Manual, or any

other manuals provided for the unit.

• Attachments, accessory items, or parts not authorized for

use by Thermo King.

• Improper off-road engine maintenance, repair or abuse.

• Owner’s unreasonable delay in making the product

available after being notified of a potential product

problem.

This warranty is in addition to Thermo King’s standard

warranty applicable to the off-road engine product involved.

Remedies under this warranty are limited to the provision of

material and services as specified herein. Thermo King is not

responsible for inc i dental or consequential dam age s suc h as

downtime or loss of engine powered equipment.

9

Safety Precautions

Thermo King recommends that se rvicing be done onl y by a

Thermo King dealer. However, you should be aware of several

safety practices. This chapter gives basic safety precautions for

working with Thermo King units and describes the safety

stickers on your unit that you should be familiar with.

General Safety Practices

WARNING: Keep hands and loose clothing clear of

fans and belts at all times when the unit is operating

with the doors open.

WARNING: Exposed coil fins can cause painful

lacerations. Service work on the evaporator or

condenser coils should be done by a certified Thermo

King technician.

WARNING: Do not apply heat to a closed cooling

system. Before applying heat to a cooling system,

drain it. Then flush it with water and drain the water.

Antifreeze contains water and ethylene glycol. The

ethylene glycol is flammable and can ignite if the

antifreeze is heated enough to boil off the water.

10

Automatic Start/Stop Operation

This unit is capable of automatic operation and could start at

any time without warning.

WARNING: The unit can start at any time without

warning. Press the O

place the microprocessor On/Off switch in the Off

position before inspecting or servicing any part of the

unit.

FF key on the control panel and

Electrical Hazard

DANGER: Dangerous three phase AC electric power

is present whenever the unit is operating in either

Diesel Mode or Electric Mode and whenever the unit

is connected to a source of external standby power.

Voltages of this magnitude can be lethal. Exercise

extreme caution when working on the unit.

Safety Precautions

Battery Installation and Cable

Routing

W ARNING: Improperly installed battery could result

in a fire or explosion. A Thermo Kin g approved

battery must be installed and properly secured to the

battery tray.

W ARNING: Improperly installed battery cables could

result in fire or explosion. Battery cables must be

installed, routed and secured properly to prevent

them from rubbing, chaffing or making contact with

hot, sharp or rotating components.

CAUTION: Do not connect other manufacturer’s

equipment or accessories to the Thermo King unit.

This could result in severe damage to equipment and

void the warranty.

CAUTION: Set all unit electrical controls to the OFF

position before connecting battery cables to the

battery to prevent unit from starting unexpectedly and

causing personal injury.

CAUTION: Always wear protective clothing, gloves

and eye wear when handling and installing batteries.

Battery acid can cause serious burns when exposed to

eyes or skin. If battery acid contacts skin or clothing,

wash immediately with soap and water. If acid enters

your eye, immediately flood it with running cold

water for at least twenty minutes and get medical

attention immediately.

CAUTION: Always cover battery terminals to prevent

them from making contact with metal components

during battery installation. Battery terminals

grounding against metal could cause the battery to

explode.

11

Safety Precautions

Refrigerant

Although fluorocarbon refrigerants are classified as safe, use

caution when working with refrigerants or in areas where they

are being used.

DANGER: Fluorocarbon refrigerants can produce

toxic gases. In the presence of an open flame or

electrical short, these gases are severe respiratory

irritants CAPABLE OF CAUSING DEATH.

DANGER: Fluorocarbon refrigerants tend to

displace air and can cause oxygen depletion which

could result in DEATH BY SUFFOCATION. Provide

adequate ventilation in enclosed or confined areas.

WARNING: Fluorocarbon refrigerants evaporate

rapidly, freezing anything they contact if accidentally

released into the atmosphere from the liquid state.

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

WARNING: Always wear goggles or safety gla sse s to

protect eyes from refrigerant oil contact.

WARNING: Protect skin and clothing from

prolonged or repeated contact wi th refrigerant oil.

Rubber gloves are recommended.

WARNING: Wash thoroughly immediately after

handling refrigerant oil to prevent irritation.

12

Safety Precautions

First Aid

First Aid–Refrigerant

Eyes: For contact with liquid, immediately flush eyes with

large amounts of water. Get prompt medical attention.

Skin: Flush areas with large amounts of warm water. Do not

apply heat. Wrap burns with dry, sterile, bulky dressing to

protect from infection or injury. Get prompt medical attention.

Inhalation: Move victim to fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

First Aid–Refrigerant Oil

Eyes: Immediately flush eyes with large amounts of water for

at least 15 minutes while holding the eyelids open. Get prompt

medical attention.

Skin: Remove contaminated clothing. Wash thoroughly with

soap and water. Get medical attention if irritation persists.

Inhalation: Move victim t o fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

Ingestion: Do not induce vomiting. Immediately contact

local poison control center or physician.

Safety Decals and Locations

Condenser and Evaporator Fans

Be aware of the warning nameplates near the condenser fans

and evaporator fans (example in Figure 1).

AMA1581

Figure 1: Fan Warning

13

Safety Precautions

AMA1580

AMA1579

1

2

3

4

5

6

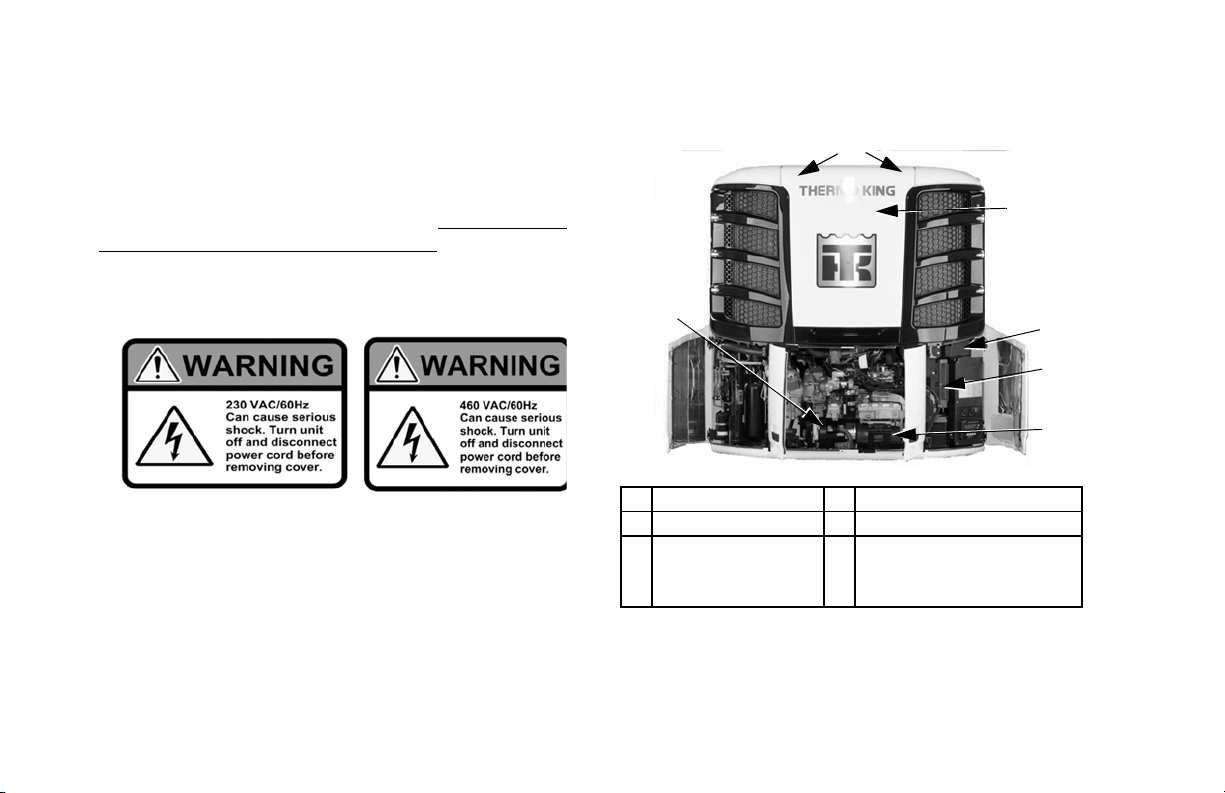

High Voltage Components

Var ious components on the Precedent unit operate using

220/3/60 or 460/3/60 high voltage and are identified by

warning nameplates (examples in Figure 2). All high voltage

wiring is identified by ORANGE conduiting. Be aware of the

locations of these components. Only certified, trained

technicians can service them.

Figure 2: High Voltage Warning

NOTE: See Figure 3 and Figure 4 for high voltage

component locations.

14

1. Condenser Motors 4. High Voltage Control Box

2. Evaporator Motor 5. AC Generator

3. High Voltage

Distribution Box

6. Electric Standby Motor &

Power Receptacle

(SmartPower Option)

Figure 3: High Voltage Component Locations (Front)

Safety Precautions

7

8

9

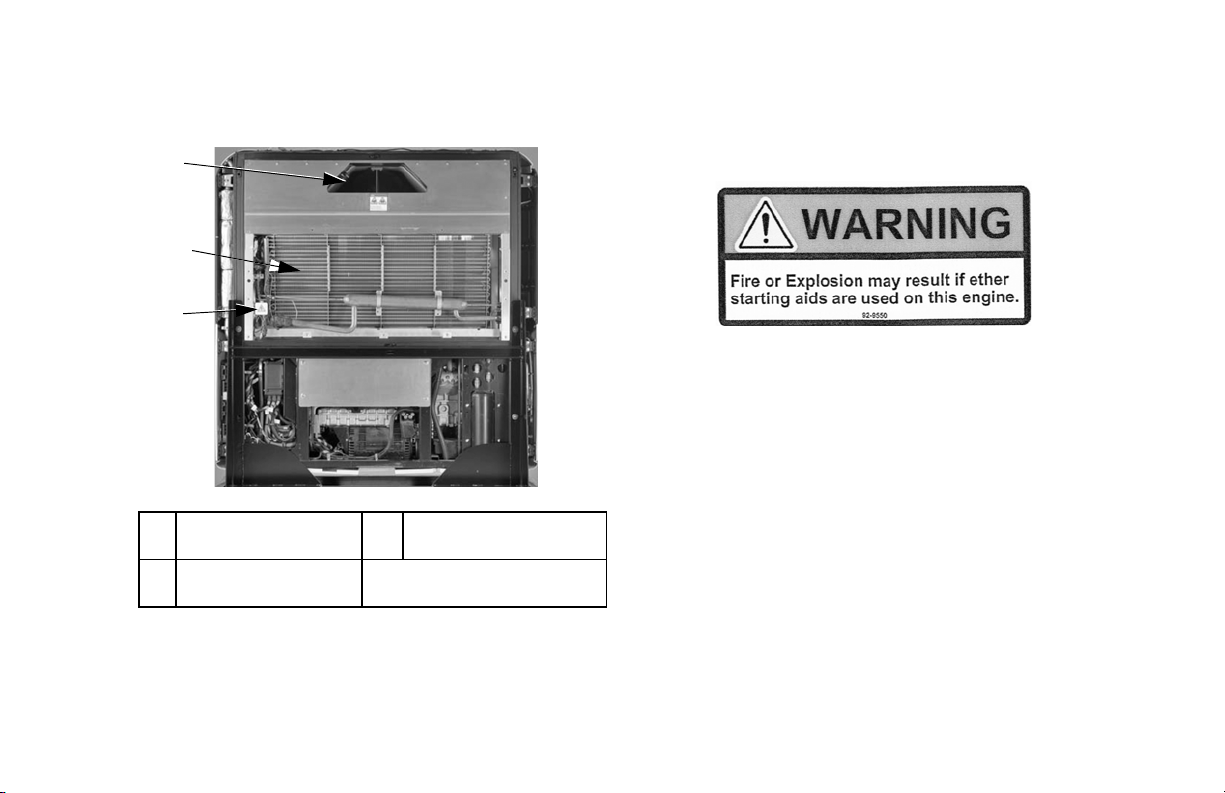

Do Not Use Ether Starting Aids

Figure 5: Do Not Use Ether Starting Aids

(Near Engine)

7. Evaporator Motor 9. High Voltage Junction

8. High Voltage Heater

Strips

Figure 4: High Voltage Component Locations (Rear)

Box

All ORANGE conduiting

contains High Voltage

15

Unit Description

Unit Overview

Thermo King Precedent C-600, S-600 and S-700 are one piece,

self-contained, diesel powered, air cooling/heating units

operating under the control of the SMART REEFER™ 4

(SR-4) programmable microprocessor controller. These units

mount on the front of the trailer with the evaporator extending

through an opening in the front wall. These single temperature

models are designed to maintain temperature in one

compartment or zone.

These units feature all-new DDE (Diesel Direct Electric)

architecture, quiet running Thermo King diesel engine and a

Thermo King reciprocating compressor.

The C-600, S-600 and S-700 are available in the following

models:

Standard : Cooling and heating on die sel engine operation.

SmartPower

engine operation and electric standby operation.

16

TM

Option: Cooli ng and heating on die sel

Figure 6: Front View

Unit Description

Diesel Engine

Precedent C-600, S-600 and S-700 use a 4-cylinder, water

cooled, direct injection diesel engine. The engine is coupled

directly to the compressor on standard units. SmartPower units

are equipped with a centrifugal clutch which transfers power

from the engine to the compressor. Belts transmit power to the

AC generator, water pump, and alternator on all models.

ELC (Extended Life Coolant)

ELC (Extended Life Coolant) is standard equipment. The

maintenance interval for ELC is five years or 12,000 hours. A

nameplate on the coolant expansion tank identifies units with

ELC. The new engine coolant, Chevron Extended Life

Coolant, is RED in color instead of the previous GREEN or

BLUE-GREEN colored conventional coolants.

CAUTION: Do not add “GREEN” or

“BLUE-GREEN” conventional coolant to cooling

systems using “RED” Extended Life Coolant, except

in an emergency. If conventional coolant is added to

Extended Life Coolant, the coolant must be ch anged

after 2 years instead of 5 years.

NOTE: The use of 50/50% pre-mixed ELC is recommended

to assure that de-ionized water is being used. If 100% full

strength concentrate is used, de-ionized or distilled water is

recommended instead of tap water to insure the integrity of

the cooling system is maintained.

EMI 3000

EMI 3000 is an extended maintenance interval package. It is

standard equipment. The EMI 3000 package consists of the

following key components:

• EMI 3000-Hour Cyclonic Air Cleaner Assembly and Air

Cleaner Element

• EMI 5-Micron 3000-Hour Fuel Filter

• EMI 3000-Hour Dual Element Oil Filter

• API Rating CI-4 Mineral Oil

• Five Year or 12,000 Hour ELC (Extended Life Coolant)

The EMI package allows standard maintenance intervals to be

extended to 3,000 hours, or 2 years, whichever occurs first.

NOTE: Units equipped with the EMI 3000 package do

require regular inspection in accordance with Thermo King's

maintenance recommendations.

17

Unit Description

Thermo King Reciprocating

Compressor

The Precedent C-600, S-600 and S-700 are equipped with a

4-cylinder 30.0 cu. in. (492 cm3) displacement Thermo King

X430 reciprocati n g compressor .

Electronic Throttling Valve

The ETV provides enhanced control of the refrigeration system

as follows:

• Allows the refrigeration system to fully utilize the power

capabilities of the engine under varying conditions

• Provides an additional measure of protection against high

discharge pressures

• Protects the engine from high coolant temperature

shutdowns

• Provides a means of precise temperature control.

SMART REEF ER 4 (SR-4) Control

System

The SR-4 is a microprocessor control system designed for

transport refrigeration. The SR-4 integrates the following

functions: changing setpoint and operating mode, viewing

gauge, sensor and hourmeter readings, initiating defrost cycles,

and viewing and clearing alarms.

The microprocessor components are located inside the control

box, which is located inside the lower roadside service door. It

is used to operate the unit. The control panel is mounted on the

face of the control box. It is clearly visible through an opening

in the lower roadside service door.

See “Operating Instructions” for mo re information about the

SR-4 Controller.

Depending on the air temperature in the trailer, as sensed by

the microprocessor Base Controller, the unit will typically

operate in on e of the following modes:

18

Unit Description

Diesel Operation

In diesel operation the microprocessor will select the operating

mode from the following:

• High Speed C ool

• Low Speed Cool

• Low Speed Modulated Cool

• Null (CYCLE-SENTRY operation only)

• Low Speed Modulated Heat

• Low Speed Heat

• High Speed Heat

• Defrost

Electric Operation

In electric operation the microprocessor will select the

operating mode from the following:

• Cool

• Modulated Cool

• Null (CYCLE-SENTRY operation only)

• Modulated Heat (Hot Gas only)

• Hot Gas Heat

• Full Heat (Hot Gas and Electric Heat)

• Defrost (Hot Gas and Electric Heat)

19

Unit Description

CYCLE-SENTRYTM Start-Stop

Controls

WARNING: The unit can start at any time without

warning. Press the O

place the microprocessor On/Off switch in the Off

position before inspecting or servicing any part of the

unit.

The CYCLE-SENTRY Start-Stop fuel saving system provides

optimum operating economy.

When CYCLE-SENTRY Mode is selected the unit will start

and stop automatically to maintain setpoint, keep the engine

warm and the battery charged. When Continuous Mode is

selected, the unit starts automatically and runs continuously to

maintain setpoint and provide constant airflow.

FF key on the control panel and

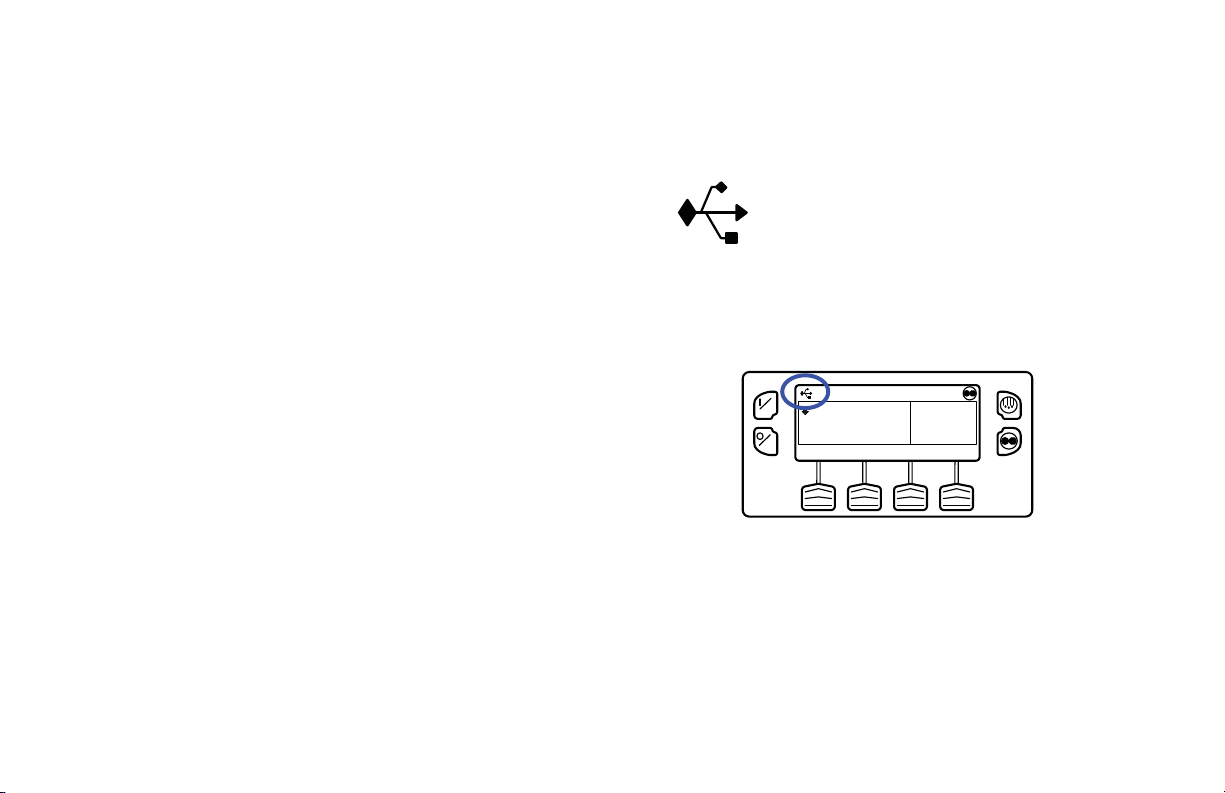

Data Logging

There are two separate data loggers. The data is downloaded

through the Flash Drive Only USB port on the front of the

control box using a flash drive and ThermoServ™ software.

ServiceWatch™: ServiceWatch is standard equipment. It

records operating events, alarm codes and compartment

temperatures as they occur and at preset intervals. This

information is typically used to analyze unit performance.

CargoWatch™: CargoWatch data logging requires the

installation of optional sensors. Up to six temperature

sensor/probes and four door switches can be installed.

CargoWatch also logs the setpoint. If optional temperature

sensors are installed, their readings are displayed as Datalogger

Sensor (1-6) Temperature in the sensor readings.

USB Ports: :

• The Flash Drive Only USB Port allows a USB Flash Drive

that has been pr operly conf igured us ing the T hermoServ ™

Service Tool to be connected to the unit.

• The optional PC Computer Only USB Port allows a PC

Computer to be connected to the unit via a standard USB

Cable.

20

MICRO

PROCESSOR

ON

OFF

THERMO KING

ON

OFF

POINT

35

SET SENSORSGAUGES

.8

SR4

Smart Reefer 4

°F

35

MENU

USB PORT

FLASH DRIVE ONLY

USB PORT

PC COMPUTER ONLY

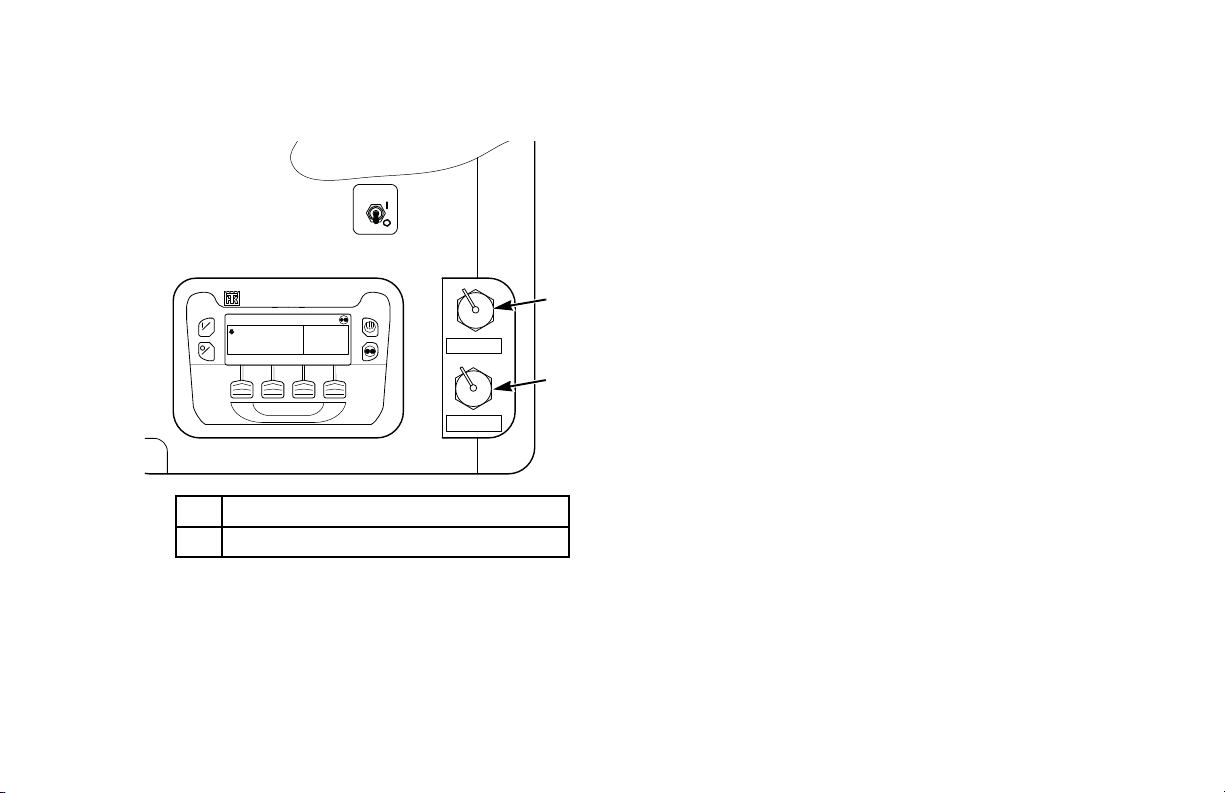

1. Flash Drive Only USB Port

2. PC Computer Only USB Port (option)

Unit Description

OptiSet Plus

OptiSet Plus is a grou p o f progr amm able funct io ns tha t cont ro l

how the unit will operate with specific setpoints or named

products. Thi s ass ur es tha t wh en a p art icu lar s etp oin t or n ame d

product is selected, the unit will always operate the same way.

This allows an entire fleet to be configured to match the

1

2

customers’ needs. Contact your Thermo King dealer for

information about programming OptiSet Plus.

FreshSet

FreshSet is included in OptiSet Plus. FreshSet is a demand

base temperature control for fresh products. FreshSet modifies

and adjusts unit airflow operation to control temperature and to

maximize protect ion of car go, whil e keepin g operati ng costs to

a minimum. Contact your Thermo King dealer for information

about programming FreshSet.

Figure 7: HMI Controller and USB Ports

Defrost

Frost gradually builds-up on evaporator coils as a result of

normal operation. Th e unit uses hot re f r ige ra n t to def ro s t th e

evaporator coil. Hot refrigerant gas passes through t he

21

Unit Description

evaporator coil and melts the frost. The water flows through

collection drain tubes onto the ground. The methods of defrost

initiation are Automatic, and Manual.

Automatic Defrost: The SR-4 automatically initiates timed

or demand defrost cycles. The SR-4 microprocessor can be

programmed to initiate timed defrost cycles at intervals of 2, 4,

6, 8, or 12 hours. Demand defrost cycles occur if the

differences between the return air temperature, discharge air

temperature, and coil temperature exceed certain limits. The

unit can enter defrost cycles as often as every 30 minutes if

required.

Manual Defrost: In Manual Defrost mode, the operator

initiates a defrost cycle. See “Initiating a Manual Defrost

Cycle.”

NOTE: The unit will not perform a Manual Defrost Cycle

unless the unit has been turned on with the O

is running in Continuous or CYCLE-SENTRY Mode (or s hut

down in CYCLE-SENTRY Null Mode), and the coil

temperature is below 45 F (7 C).

N key, the unit

Opening the Front Doors

Pull the right door latch handle out at a 45 degree angle and

turn it down (clockwise) 90 degrees to open the doors and

access the engine compartment. Push the door closed while

holding the door latch handle open and then turn it up

(counterclockwise) 90 degrees to close the door.

Figure 8: Door Latch Location

22

Unit Description

Engine Compartment

The following maintenance items can be checked visually.

WARNING: The unit can start at any time without

warning. Press the O

place the microprocessor On/Off switch in the Off

position before inspecting any part of the unit.

Engine Oil Dipstick: Use the engine oil dipstick to check

the engine oil level.

CAUTION: Make sure the engine is turned off before

attempting to check the engine oil.

FF key on the control panel and

Unit Protection Devices

Coolant Level Switch: The coolant level switch closes if

the coolant level drops below an acceptable level. If it stays

closed for a specified time, the microprocessor records alarm

code 37.

Engine Coolant Temperature Sensor:

The microprocessor uses the engine coolant temperature sensor

to monitor the engine coolant temperature. If the engine

coolant temperature rises above an acceptable level, the

microprocessor records alarm code 41 and possibly 18. The

microprocessor might also shut the unit down.

High Pressure Cutout Switch: The high pressure cutout

switch (HPCO) is located on the compressor discharge

manifold. If the compressor discharge pressure becomes

excessive, the switch opens the circuit to the run relay to stop

the unit. The microprocessor will record Alarm Code 10.

High Pressure Relief Valve: This valve is designed to

relieve excessive pressure in the refrigeration system. It is

located on the receiver tank. If the high pressure relief valve

opens, much of the refrigerant will be lost. Take the unit to a

Thermo King dealer if this occurs.

Low Oil Level Switch: The low oil level switch closes if the

oil drops below an acceptable level. If it stays closed for a

specified time, the microprocessor shuts the unit down and

records Alarm Code 66.

Low Oil Pressure Switch: The low oil pressure switch

closes if the oil pressure drops below an acceptable level. If it

stays closed for a specified time, the microprocessor shuts the

unit down and records alarm code 19.

23

Unit Description

Preheat Buzzer: The preheat buzzer sounds when the base

controller energizes the preheat relay. This warns anyone near

the unit that the controller is about to start the engine.

Overload Relay—Automatic Reset (SmartPower): An

overload relay protects the standby electric motor. The

overload relay opens the circuit to the electric motor if the

motor overloads for any reason (e.g., low line voltage or

improper power supply) while the unit is on electric standby

operation. The microprocessor will record Alarm Code 90.

Smart FETs: Smart FETs in the microprocessor protect some

circuits and components from an overcurrent condition.

Fuses: A number of fuses, located on the microprocessor,

protect various circuits and components. The microprocessor is

located inside the control box.

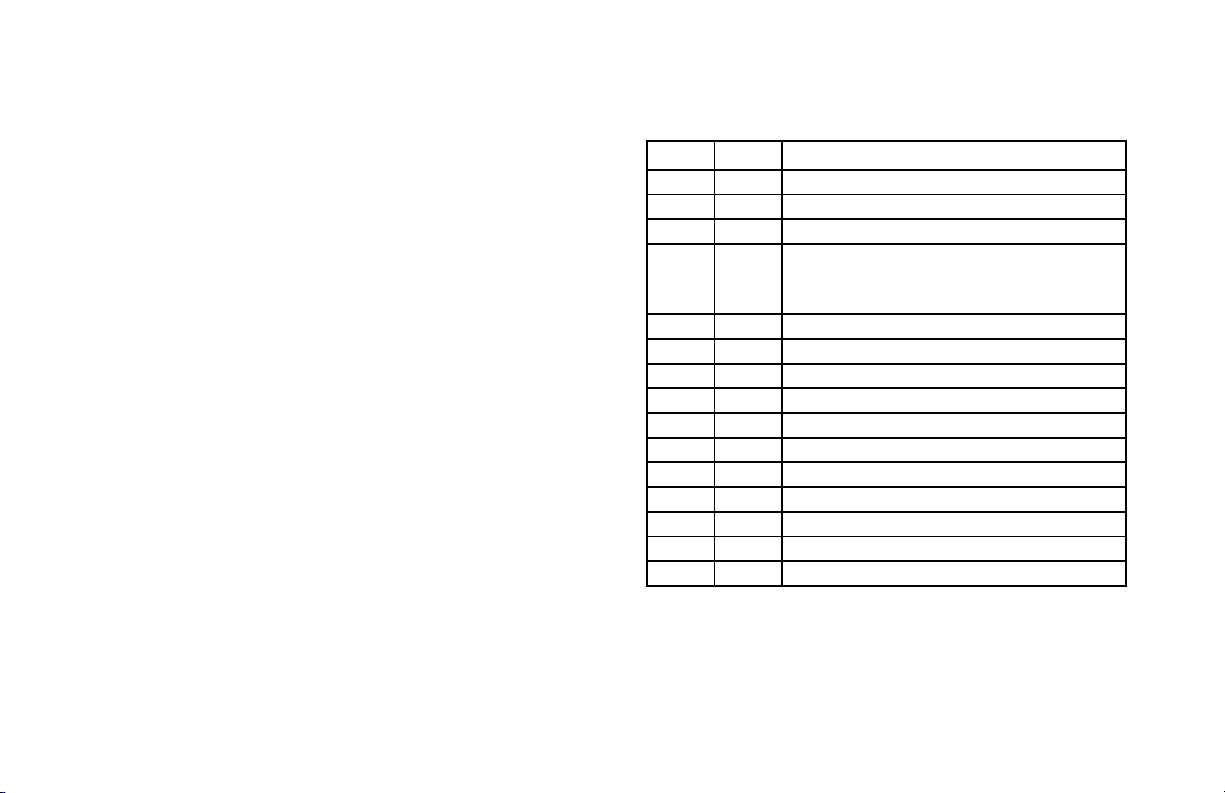

Fuse Size Function

F1 5A 2A Power for REB

F2 15A On/Off Switch Circuit

F3 40A Fuel Solenoid/Starter Circuit

F4 None2ANo Fuse - All Bosch and Thermo King

Alternators (Note 1)

2A Fuse - All Prestolite Alternators

F5 60A Preheat Circuit (Note 2)

F6 15A High Speed Solenoid Circuit

F7 2A 8X Power for CAN bus

F8 5A 2A Power for CAN bus J12

F10 15A On/Off Relay Circuit

F12 5A 2A Power for CAN bus J13

F13 2A Status Light Circuit

F15 2A SR-4 Power Supply Circuit

F20 2A Alternator Sense Circuit

F25 10A Fresh Air Door Circuit

F25 7.5A High Pressure Cutout Circuit

NOTE: The F5 preheat fuse is a “slow blow” type fuse. It is

designed for use with the Ya nmar trailer engine air

pre-heater. Always replace the fuse with the TK specified

fuse.

24

Manual Pretrip Inspection

Before Starting the Unit

Pretrip inspections are an important part of a preventative

maintenance program designed to minimize operating

problems and breakdowns. Perform this pretrip inspection

before every trip involving refrigerated cargo.

NOTE: Pretrip inspections are not intended to take the place

of regular maintenance inspections.

Fuel: Make sure the diesel fuel supply is adequate to

guarantee engine operation to the next check point. Allow for

maximum fuel consumption of one gallon per hour of engine

operation.

Engine Oil: Check the engine oil level. It should be at the

Full mark when the dipstick is threaded all the way into the oil

pan. Do not overfill.

CAUTION: Turn the engine off before checking the

engine oil level.

Engine Coolant: The engine coolant must have antifreeze

protection to -30 F (-34 C). Add coolant if Alarm Code 37 is

active. Check and add coolant to the expansion tank.

WARNING: Do not remove the expansion tank cap

while the coolant is hot.

Battery: Make sure the battery terminals are tight and free of

corrosion.

Belts: Make sure belts are in good condition and adjusted to

the proper tension. For more information about belt tension,

see the Specifications chapter.

Electrical: Check the electrical connections to make sure they

are securely fastened. Wires and terminals should be free of

corrosion, cracks, and moisture.

Structural: Visually inspect the unit for leaks, loose or

broken part s, and other damage .

25

Manual Pretrip Inspection

Coils: Make sure the condenser and evaporator coils are clean

and free of debris.

Cargo Box: Check the interior and exterior of the cargo box

for damage. Any damage to the walls or insulation must be

repaired.

Cargo Doors: Make sure that the cargo doors and weather

seals are in good condition. The doors should latch securely

and the weather seals should fit tightly.

Defrost Drains: Check the defrost drain hoses to make sure

they are open.

26

Operating Instructions

MICRO

PROCESSOR

ON

OFF

THERMO KING

ON

OFF

Figure 9: SR-4 Control Panel

(Optional PC USB Port Shown)

35

SET SENSORSGAUGES

POINT

.8

SR4

Smart Reefer 4

°F

35

MENU

USB PORT

FLASH DRIVE ONLY

USB PORT

PC COMPUTER ONLY

SMART REEFER 4 (SR-4)

Controller Overview

Thermo King has applied the latest advances in computer

technology to develop a device that controls temperature and

unit function, and displays operating information quickly and

accurately.

There is nothing complicated about learning to operate the

SR-4 Controller, but you will find that a few minutes studying

the contents of this manual will be time well spent.

WARNING: Do not operate the SR-4 until you are

completely familiar with the location and function of

each con t r o l.

27

Operating Instructions

The microprocessor components are located inside the control

box, which is located inside the lower roadside service door.

The microprocessor is connected to a Human Machine

Interface (HMI) Control Panel. It is used to operate the unit.

The USB ports are used to retrieve data from the data logging

system.

Microprocessor On/Off Switch: This switch supplies or

removes electrical power to the microprocessor. The

Microprocessor Power Switch is located above HMI Control

Panel. It is hidden when the lower roadside body panel

surrounding the Control Box is closed.

WARNING: The unit can start at any time without

warning. Press the O

place the microprocessor On/Off switch in the Off

position before inspecting or servicing any part of the

unit.

FF key on the control panel and

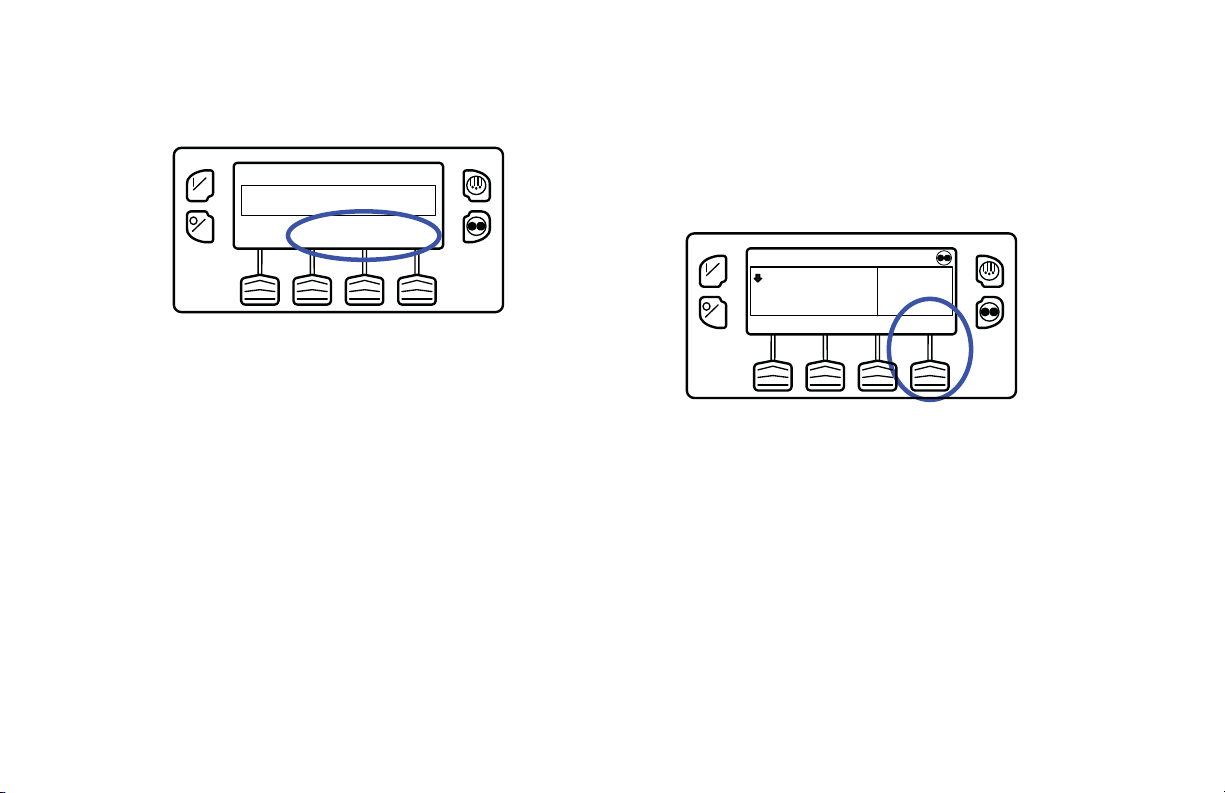

Control Panel

The control panel has a display and eight touch sensitive keys.

The display is capable of showing both text and graphics. The

four keys on the left and right sides of the display are “hard”

(dedicated) keys. The four keys under the display are “soft”

keys. The function of “soft” keys change depending on the

operation being performed. If a soft key is active, its function

will be shown in the display directly above the key.

Control Panel Display

The display is used to supply unit information to the operator.

This information includes setpoint, current box temperature

operating information, unit gauge readings, system

temperatures and other information as selected by the operator.

The default display is called the Standard Display. It is shown

in Figure 10 and will be described in detail later in this chapter.

28

THERMO KING

1

2

3

4

5

6

ON

OFF

35

SET SENSORSGAUGES

POINT

Operating Instructions

Display Icons

Display symbols or Icons are used to present additional unit

information

°F

35

.8

MENU

Down-Pointing Arrow: (At the left side of the

display) Shows the unit is cooling. If the arrow

were pointing upward the unit would be heating.

SR4

Smart Reefer 4

CYCLE SENTRY/Continuous Mode Key:

The unit is running in Cycle Sentry Mode as

shown by the C ycle Sent ry Ico n in t he uppe r rig ht

corner of the display. If the Cycle Sentry icon is

1. On Key (Hard Key)

2. Off Key (Hard Key)

3. Display

4. Defrost Key (Hard Key)

5. CYCLE-SENTRY/Continuous Mode Key

(Hard Key)

6. Soft Keys

Figure 10: Control Panel Display and Keys

not present, the unit is running in Continuous

Mode.

USB: The USB Icon in the upper left corner of

the display will appear when a USB device is

connected to either of the USB Ports on the Unit

Control Panel or inside the control box.

29

Operating Instructions

ON

OFF

Hard Keys

The keys on either side of the display are dedicated or “hard”

keys. Their function always remains the same.

On Key: Used to turn the unit on. First the

display will briefly show the Thermo King Logo

and then the statement “Configuring System Please Wait”. When the power-up sequence is

complete the display shows the Standard Display

of box temperature and setpoint.

Off Key: Used to turn the unit off. First the

display will briefly show “System is Powering

Down - Please Wait. Press On to Resume” and

then “Off” will appear momentarily. When the

power-down sequence is complete the display

will be blank. For more information see “Turning

the Unit On and Off” later in this section.

Defrost Key: Press this key to initiate a Manual

Defrost cycle.

CYCLE SENTRY: Used to select Cycle Sentry

Mode or Continuous Mode operation if allowed

by OptiSet Plus. For more information see

“Selecting Cycle Sentry or Continuous Mode”

later in this section.

Soft Keys

The four “soft” keys under the display are

multi-purpose keys. Their function changes

depending on the ope ratio n b eing p erf orme d. I f a

soft key is active the key function is shown in the

display directly above the key. The keys are

numbered from le ft to ri ght , wit h Key 1 on t he far

left and Key 4 on the far right.

Typical soft key applications:

•MENU •CLEAR • NO

• NEXT • HOURMETERS • SENSORS

• + OR - • GAUGES • EXIT

• SELECT • BACK • HELP

30

Operating Instructions

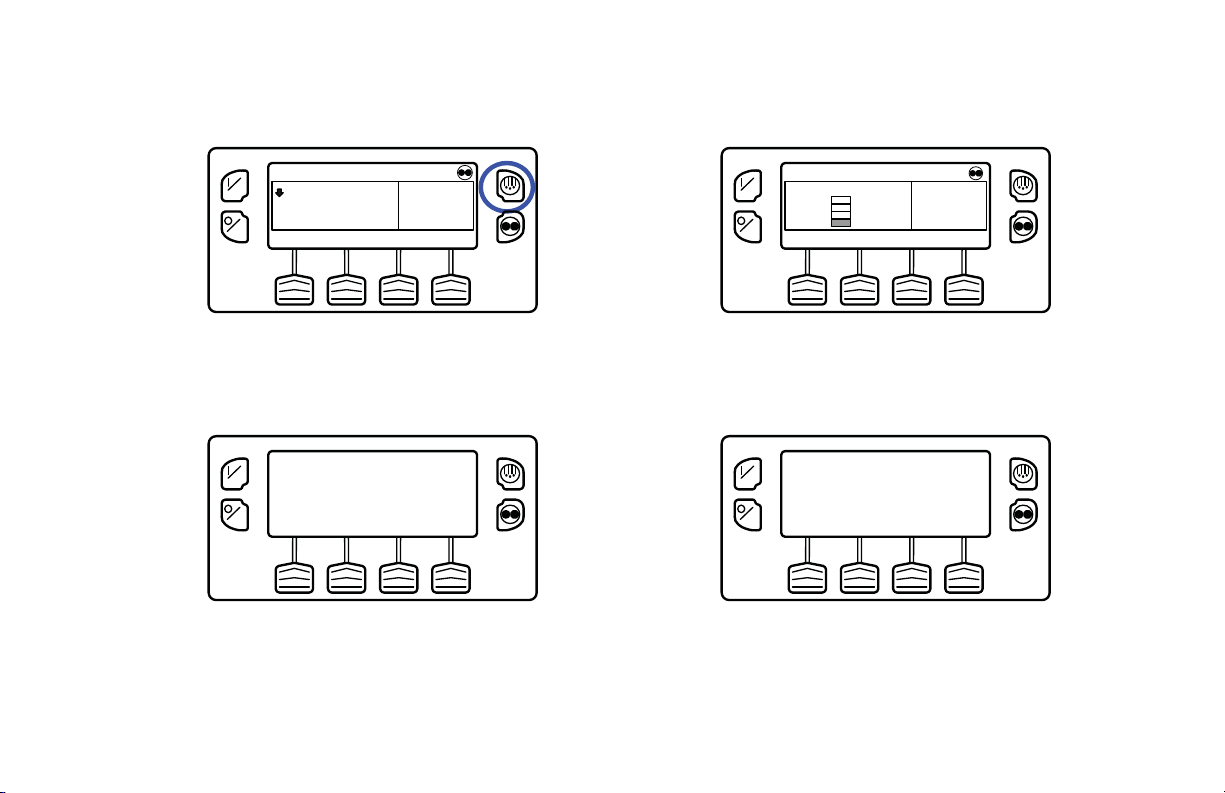

Turning Unit On

The unit is turned on by pressing the ON Key (Figure 11) and

off by pressing the OFF Key. When the On Key is pressed the

display briefly sh ows the T HERMO KING Log o as the d isplay

initializes.

IMPORTANT: The ON Key must be held down until the

Thermo King Logo appears. If the ON Key is not held down

long enough (approximately ½ second), the display may

flicker but the unit will not start up. If this occurs, hold the

ON Key down until the Thermo King logo appears.

NOTE: With extremely cold ambient temperatures it may

take up to 15 seconds for the display to appear on initial

startup.

ON

OFF

Figure 11: ON Key

Then the startup screen (Figure 12) appears while

communications are established and the unit prepares for

operation.

ON

OFF

CONFIGURING SYSTEM

PLEASE WAIT

Figure 12: Startup Screen

31

Operating Instructions

If a Flash Drive is Connected:

If a properly configured USB Flash Drive is inserted in the

Flash Drive Only USB Port on the Control Panel when the unit

is turned on, the display (Figure 13) will briefly show FLASH

DRIVE.

ON

OFF

FLASH DRIVE DETECTED

EXIT DOWN FLASH OPTISET

LOAD LOAD PLUS

ON

FLASH DRIVE

Figure 14: Flash Drive Menu

OFF

IMPORTANT: The engine start is not delayed by the Flash

Drive Menu shown above. The engine start prompt will

appear and the engine will start. After the engine is started

the display will return to the Flash Drive Menu or the

Figure 13: Flash Drive

Then FLASH DRIVE DETECTED and the Flash Drive Menu

will appear on the display (Figure 14). The display will be

shown for about 30 seconds and then the Standard Display will

appear. To go to the Standard Display immediately press the

EXIT Soft Key.

32

Standard Display.

If a properly configured USB Flash Drive is connected to the

USB Flash Drive connector, this feature allows the operator to

select the desired Flash Drive function. If enabled when the

Flash Drive was configured, the following functions may be

available:

Operating Instructions

• DOWNLOAD

• “Download the ServiceWatch Data Logger

• “Download the CargoWatch Data Logger

• FLASHLOAD

• “Flash load Base Controller Software

• “Flash load HMI Control Panel Software

• OPTISET PLUS

•SEND

• “Send OptiSet Plus files

• RETRIEVE

• “Retrieve OptiSet Plus files

The Flash Drive is also available from the Main Menu.

The Flash Drive Menu will time out about 30 seconds after the

engine starts. When the Flash Drive Menu times out, the

Standard Display will appear. To go to the Standard Display

immediately press the EXIT Key.

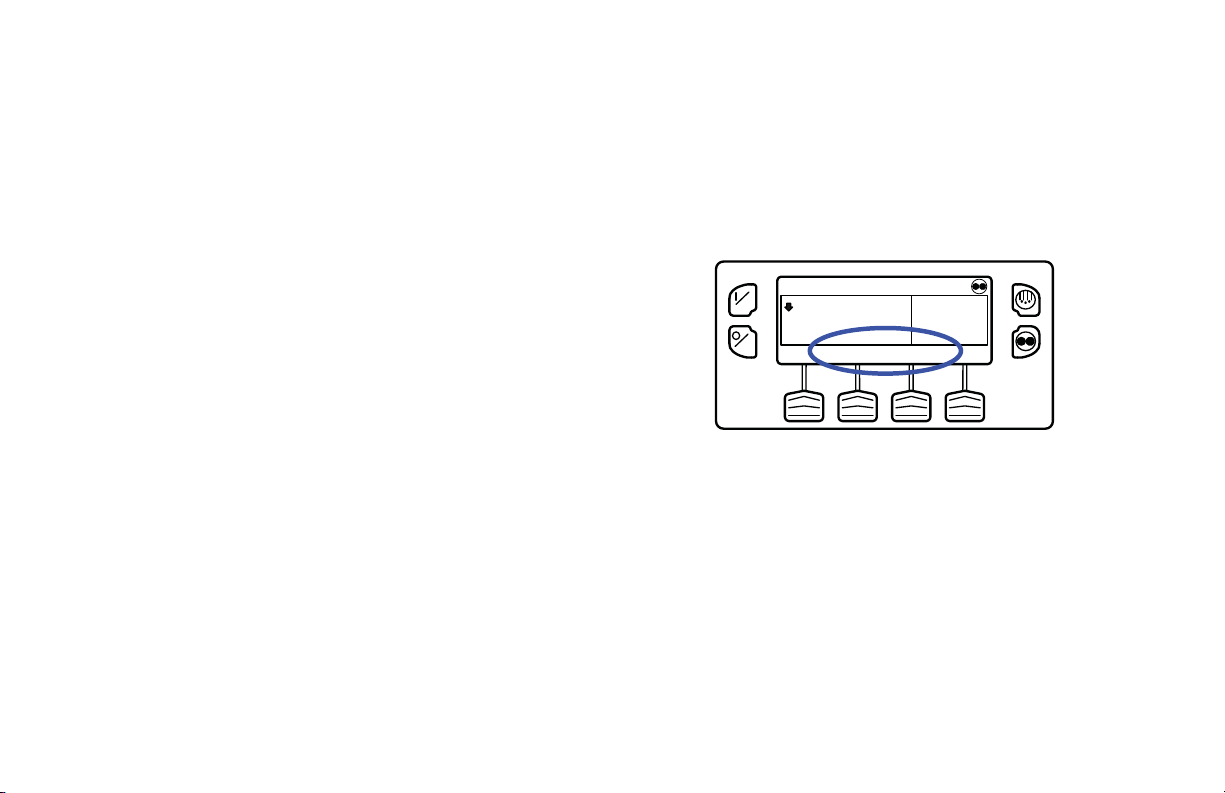

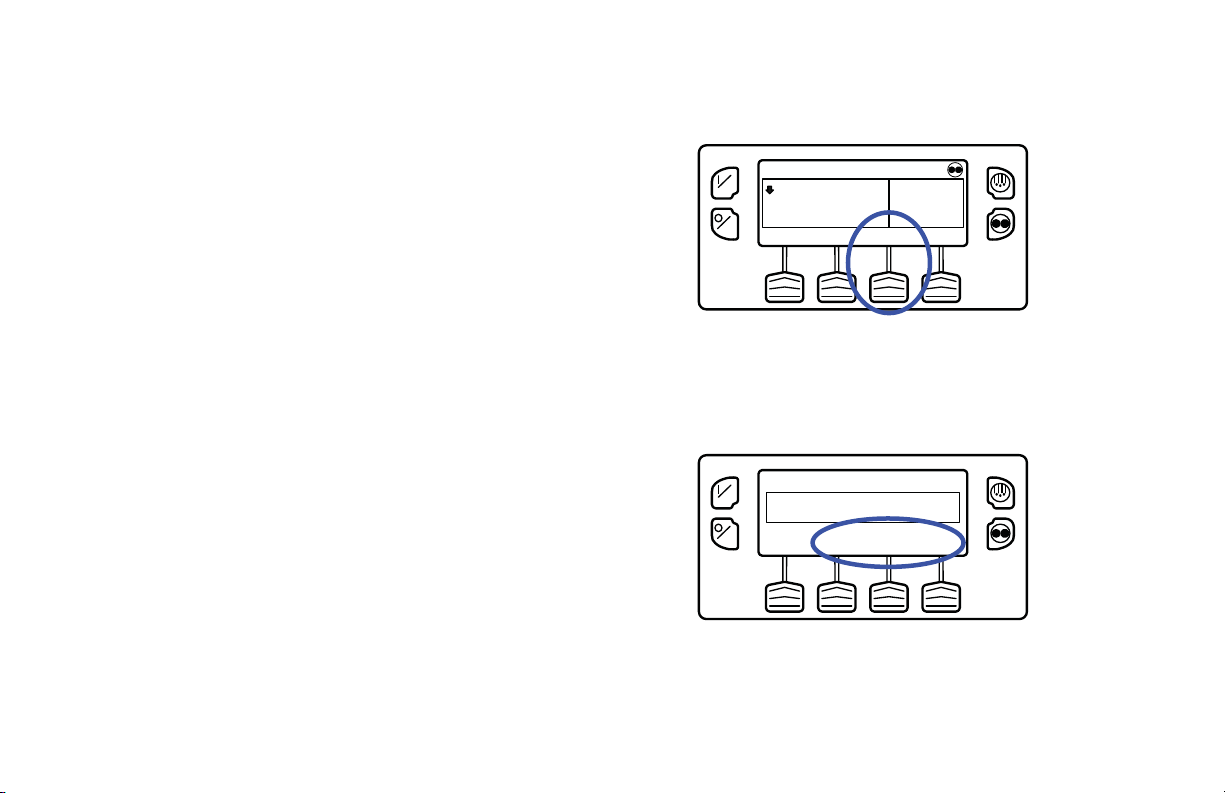

Configurable Soft Keys

When the Standard Display is shown, the default functions of

the two center soft keys are GAUGES and SENSORS.

(Figure 15)

ON

OFF

35

SET SENSORSGAUGES

POINT

Figure 15: Soft Keys

The functions of these two keys can be changed as required for

customer convenience. The functions of these two soft keys on

the Standard Display can be re-assigned to any of the following

functions using the Guarded Access > Main Menu

Configuration menu:

Gauges Pretrip SOT (start of trip)

Sensors Data Logger Hourmeters

°F

35

.8

MENU

33

Operating Instructions

The GAUGES and SENSORS functions are always available

from the Maintenance Menu.

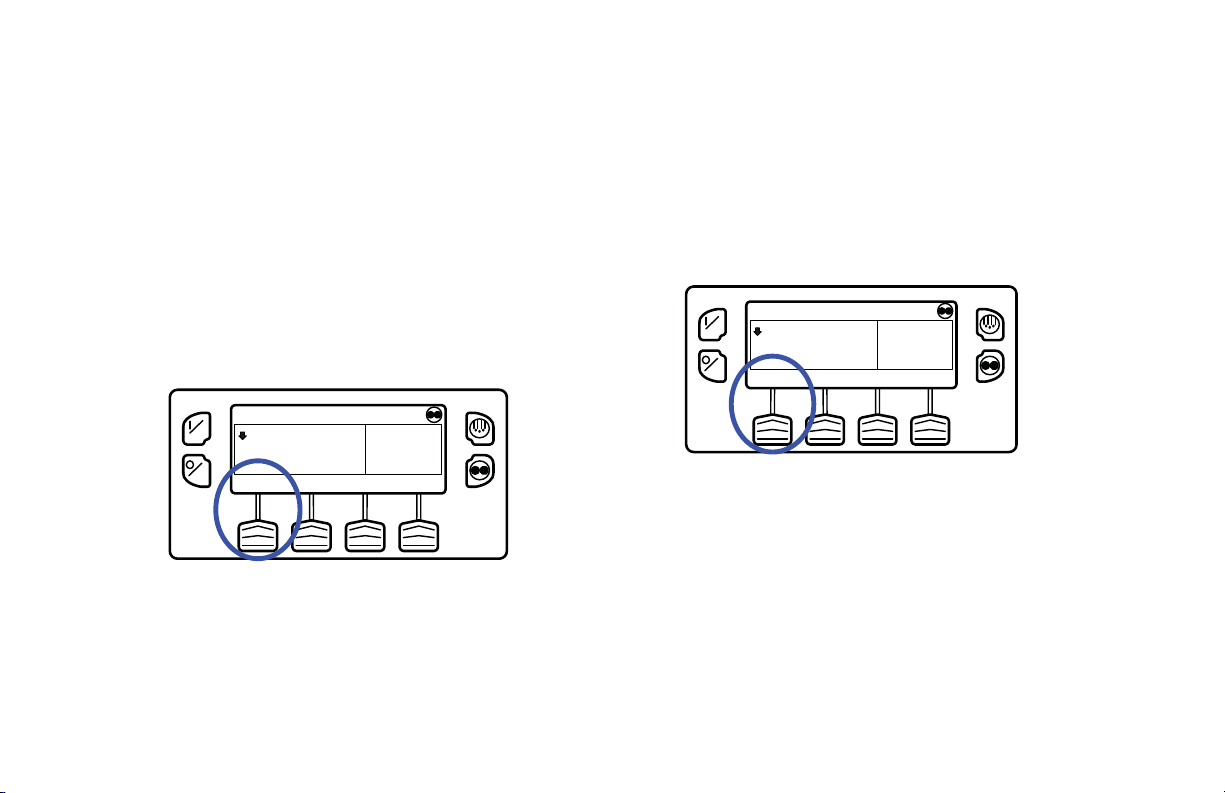

In the example show n in F igure 16 , t he so ft ke y fu ncti ons f rom

the Standard Display have been changed to PRETRIP and SOT

(Start of Trip marker). The GAUGES and SENSORS functions

are always available from the Maintenance Menu.

ON

OFF

35

SET SOTPRETRIP

POINT

°F

35

.8

MENU

Figure 16: PRETRIP and SOT

Display Heater

The HMI Control Panel is equipped with a display heater. This

heater is needed to make the display visible in very cold

ambient temperatures.

The HMI has its own internal temperature sensor for the

display heater. The heater is energized when the unit is turned

on and the ambient temperature is below 29.4 F (-2 C). The

heater turns off when the temperature sensed by the internal

sensor rises above 37.4 F (+3 C). The heater draws from 1.4 to

1.7 amps when energized.

The colder the ambient temperature the longer it will take for

the heater to make the display visible on a cold startup. It may

take 10-15 seconds for the display to appear with extremely

cold temperatures.

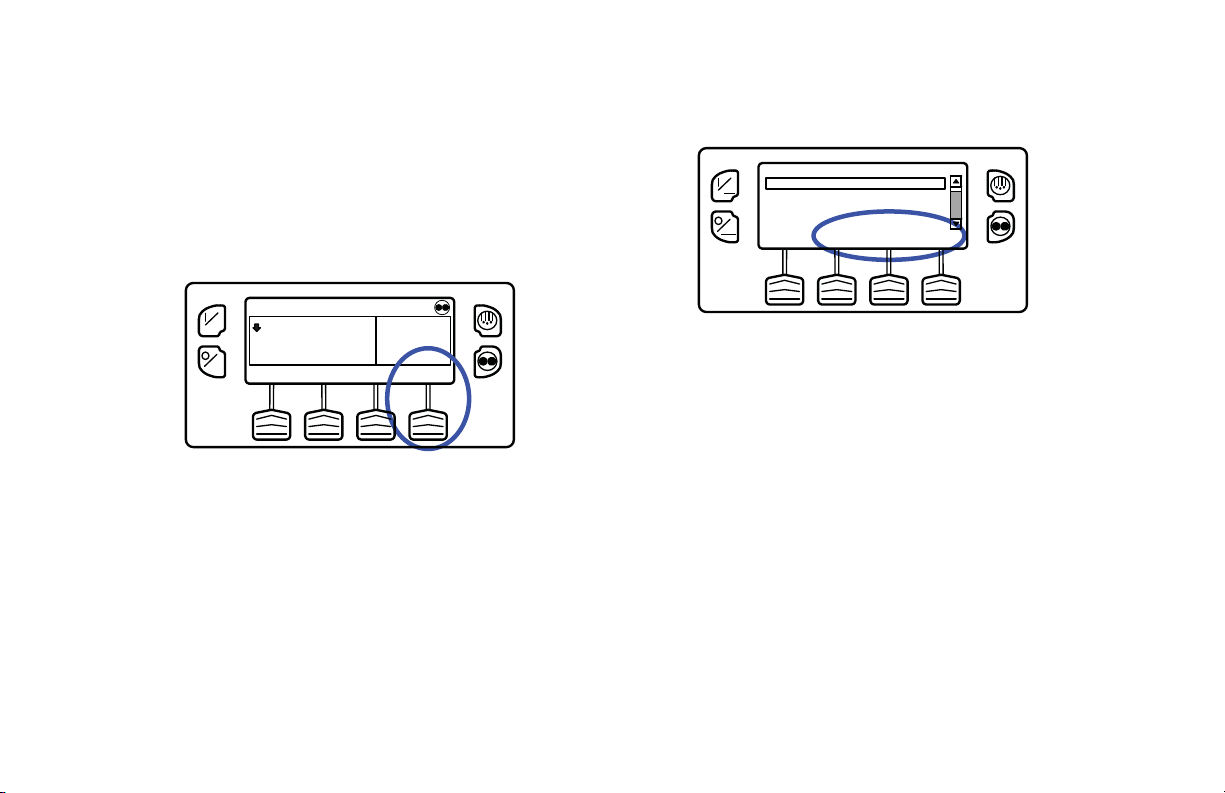

If a Language is Enabled

If more than one language has been enabled from the Guarded

Access Language Menu, a prompt will appear to allow the

desired langua ge to be c hosen as s hown be low. Only languages

specifically enabled from the Guarded Access Menu are

available. If a different language is desired, press the NO Key

(Figure 17).

IMPORTANT: The engine start is not delayed by the

language prompt shown below. The prompt will appear for 10

seconds and then the engine will start. After the engine is

started the display will return to the prompt shown.

34

Operating Instructions

The display will briefly show PROGRAMMING

ON

CURRENT LANGUAGE IS

ENGLISH

LANGUAGE - PLEASE WAIT in the new language as shown

in Figure 19.

OFF

OK?

YES NO

Figure 17: NO Key

The Language menu will appear as shown in Figure 18. Press

the + or - Keys to select the desired language. When the

desired language is shown press the YES Key to confirm the

choice.

Figure 18: + or -, then YES Key

Figure 19: New Language

The new language is conf irme d, and then t he S tan dar d Displ ay

will appear in the new language as shown in Figure 20. The

unit is ready to run.

Figure 20: Standard Display, New Language

35

Operating Instructions

If Log Alarms are Present

Log Alarms are indicated for 60 seconds each time the unit is

turned on. This level of alarm serves as a notice to take

corrective action before a problem becomes severe.

Maintenance items such as maintenance hourmeter time-outs

are log alarms. The Temperature Watch screen is not disabled

if only log alarm(s) are active.

If log alarm(s) are present the Log Alarm notice shown in

Figure 21 will appear on the display for 60 seconds. The

remote indicator alarm light (if installed) will also be on during

this period. After 60 seconds the Standard Display will appear

and the remote indicator alarm light will go off. Pressing the

EXIT soft key (Figure 21) will return to the Standard Display

immediately.

ON

OFF

Figure 21: Log Alarms Active

LOG ALARMS ACTIVE

GO TO MENU TO VIEW

EXIT

NOTE: The Alarm Icon does not app e ar on startup with log

alarms present.

When the unit is ready to run the Standard Display

appears(Figure 22).

ON

OFF

35

SET SENSORSGAUGES

POINT

°F

35

.8

MENU

Figure 22: Standard Display

36

Operating Instructions

Turning The Unit Off

Pressing the OFF Key stops unit operation. The unit shuts

down immedia tely and the displa y briefly shows the power

down message (Figur e 23).

SYSTEM IS POWERING DOWN

ON

OFF

Figure 23: Power Down Message

The Standard Display

The Standard Display is the default display that appears if no

other display function is selected. The Standard Display shows

the box temperature and setpoint. The box temperature is that

measured by the controlling sensor, usually the return air

sensor. The box temperature in Figure 25 is 35.8 F (2.1 C) with

a 35 F (1.7 C) setpoint.

ON

OFF

35

SET SENSORSGAUGES

POINT

°F

35

.8

MENU

The display briefly shows OFF (Fig ur e 24) and the n goes

blank. To start the unit again, press the ON Key.

Figure 25: Standard Display

ON

OFF

OFF

The down-pointing arrow at the left side of the

display shows the unit is cooling. If the arrow

were pointing upward the unit would be heating.

Figure 24: Display Shows OFF

37

Operating Instructions

The unit is running in Cycle Sentry Mode as

shown by the Cycle Sen try Ic on in t he uppe r r ight

corner of the display. If the Cycle Sentry icon is

not present, the unit would be running in

Continuous Mode.

The USB Icon in the upper left corner of the

display will appear when a USB Flash Drive is

connected to the Flash Drive Only USB Port on

the unit control panel or a PC computer is

connected to the PC Only USB Port on the Unit

Control Panel.

Pressing the left soft key allows the user to change the

SETPOINT, and pressing th e right soft key accesses the MAIN

MENU. The other two soft keys access the GAUGES menu

and the SENSORS menu.

NOTE: The functions of the GAUGES and SENSORS soft

keys may be re-assigned to better suit customer requirements.

The GAUGES and SENSORS functions are always available

from the Maintenance Menu.

The TemperatureWatch Display

The TemperatureWatch Display appears 2 ½ minutes after the

Standard Display appears so long as there is no key activity

and no check, prevent or shutdown alarms are present. The

TemperatureWatch Display will remain on until any key is

pressed or a check, prevent or shutdown alarm occurs.

The TemperatureWatch Display shows the box temperature

and setpoint. The large numbers allow unit conditions to be

checked from a distance. The box temperature is that measured

by the controlling sensor, usually the return air sensor . The box

temperature in Figure 26 is 35.8 F (2.1 C) with a 35 F (1.7 C)

setpoint. The Cy cle Se ntry i con in the uppe r righ t corn er of the

display shows that the unit is operating in Cycle Sentry mode.

If the Cycle Sentry icon is not present, the unit is running in

Continuous Mode. The down-pointing arrow indicates that the

unit is cooling. Pressing any soft key returns the display to the

Standard Display.

38

Operating Instructions

MENU

35

°F

35

TEMPERATURE SETPOINT

.8

ON

OFF

Changing The Setpoint

The Setpoint is changed from the Standard Display. If the

TemperatureWatch display is present, press any key to return to

the Standard Display.

IMPORTANT: If OptiSet Plus is in use there are several

possible options when changing the setpoint.

Figure 26: TemperatureWatch Display

If an alarm condition (other than a log alarm) is present, the

TemperatureWatch Display will not appear. If an alarm

condition occurs while the TemperatureWatch Display is

present the display will return to the Standard Display to

indicate that an alarm condition has occurred.

If the Defrost Key or Cycle Sentry Key is pressed, the display

will return to the TemperatureW atch Display immediately after

the defrost cycle is initiated or the operating mode is changed.

Numerical Setpoints

If OptiSet Plus is not in use or if only Numerical Setpoints are

enabled the left soft key will be labeled SETPOINT (Figure

27).

ON

OFF

35

SET SENSORSGAUGES

POINT

Figure 27: Setpoint

°F

35

.8

MENU

39

Operating Instructions

Named Products - OptiSet Plus

OptiSet Plus allows the use of Named Products such as

APPLES or BANANAS in place of a numerical setpoint. If

only named products are enabled the left soft key will be

labeled PRODUCT (Figure 28).

• A single setpoint temperature may be allowed for the

specific named product.

• A numerical setpoint range may be all owe d fo r t he

specific named product.

ON

OFF

35

PRODUCT SENSORSGAUGES

Figure 28: Left Soft Key Labeled “Product”

°F

35

.8

MENU

Both Numerical Setp oint s a nd Named

Products

OptiSet Plus can allow the use of both Numerical Setpoints and

Named Products. If both numerical setpoints and named

products are enabled the left soft key will be labeled

PRODUCT/SETPOINT (Figure 29).

ON

OFF

35

PRODUCT/ SENSORSGAUGES

SETPOINT

Figure 29: Left Soft Key Labeled

“PRODUCT/SETPOINT”

°F

35

.8

MENU

40

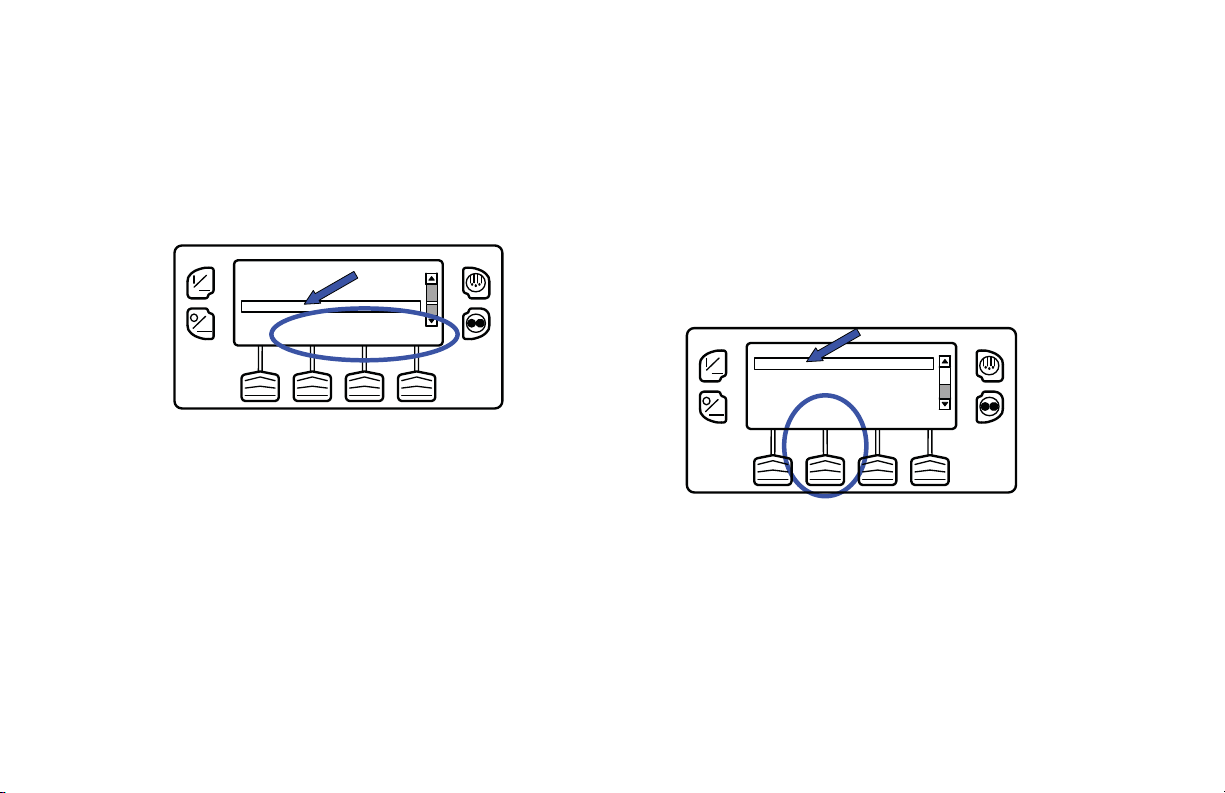

Changing the Setpoint - Numerical

-

NO

NEW SETPOINT WILL BE

40 F

+

+/- TO CHANGE OK?

YES

Setpoint

If the Temperature Watch display is shown, press any soft key

to return to the Standard Display. From the Standard Display,

press the SETPOINT Key (Setpoint Key

The setpoint display appears (Figure 30).

Operating Instructions

ON

OFF

+/- TO CHANGE

-

CURRENT SETPOINT

35 F

+

EXIT

ON

OFF

Figure 31: Setpoint Changed Using “+” Key

The YES and NO Keys (Figure 32) confirm the setpoint

change. When the desired setpoint has been selected using the

“+” and/or “-” Keys, press the YES Key to confirm and load

the new setpoint. If the setpoint is changed using the “+” or “-”

Keys, the change must be confirmed or rejected by pressing the

Figure 30: Setpoint Display

YES or NO Key wi th i n 10 seconds of cha ng ing t h e se tp oi nt. A

warning beep will sound for 5 seconds as a reminder.

The “-” and “+” Keys are used to increase or decrease the

setpoint until the desired setpoint is shown. In Figure 31 the

setpoint has been changed to 40 F using the “+” Key.

Failure to confirm the new setpoint by pressing Yes or No

within 10 seconds of changing the setpoint will result in no

setpoint change. In addition, Alarm Code 127 Setpoint Not

Entered is set, to indicate that a setpoint change was initiated

but not completed.

41

Operating Instructions

ON

OFF

NEW SETPOINT WILL BE

40 F

+/- TO CHANGE OK?

-

YES

+

NO

Figure 32: Yes and No Keys

After the YES K ey has been pressed, the display br i e fly shows

PROGRAMMING NEW SETPOINT - PLEASE WAIT. The

display then confirms the new setpoint for several seconds

(Figure 33):

ON

NEW SETPOINT IS

40 F

OFF

Figure 33: New Setpoint

If the NO Key is pressed the display will briefly show

SETPOINT NOT CHANGED and return to the Standard

Display. The Standard Display will show the old setpoint.

The display then returns to the Standard Display showing the

new setpoint. Notice in Figure 34 that the arrow now points up

to indicate that the unit is heating.

ON

OFF

35

SET SENSORSGAUGES

POINT

°F

40

.8

MENU

Figure 34: Up Arrow

IMPORT ANT: If the setpoint is changed using the “+” or “-”

Keys, the change must be confirmed or rejected by pressing

the YES or NO Key within 10 seconds of changing the

setpoint.

42

• If the YES Key is pressed, the setpoint change made with

the “+” or “-” Key is accepted, the setpoint changes, and

the display returns to the Standard Display.

• If the NO Key is pressed the setpoint change made with

the “+” or “-” Key is not accepted, the setpoint is not

changed, and the display returns to the Standard Display.

• If the YES or NO Key is not pressed within 10 seconds of

making a change with the “+” or “-” Key, the setpoint is

not changed and the display returns to the Standard

Display. The display briefly shows [SETPOINT NOT

CHANGED] and Alarm Code 127 Setpoint Not Entered is

set, to indicate that a setpoint change was initiated but not

completed.

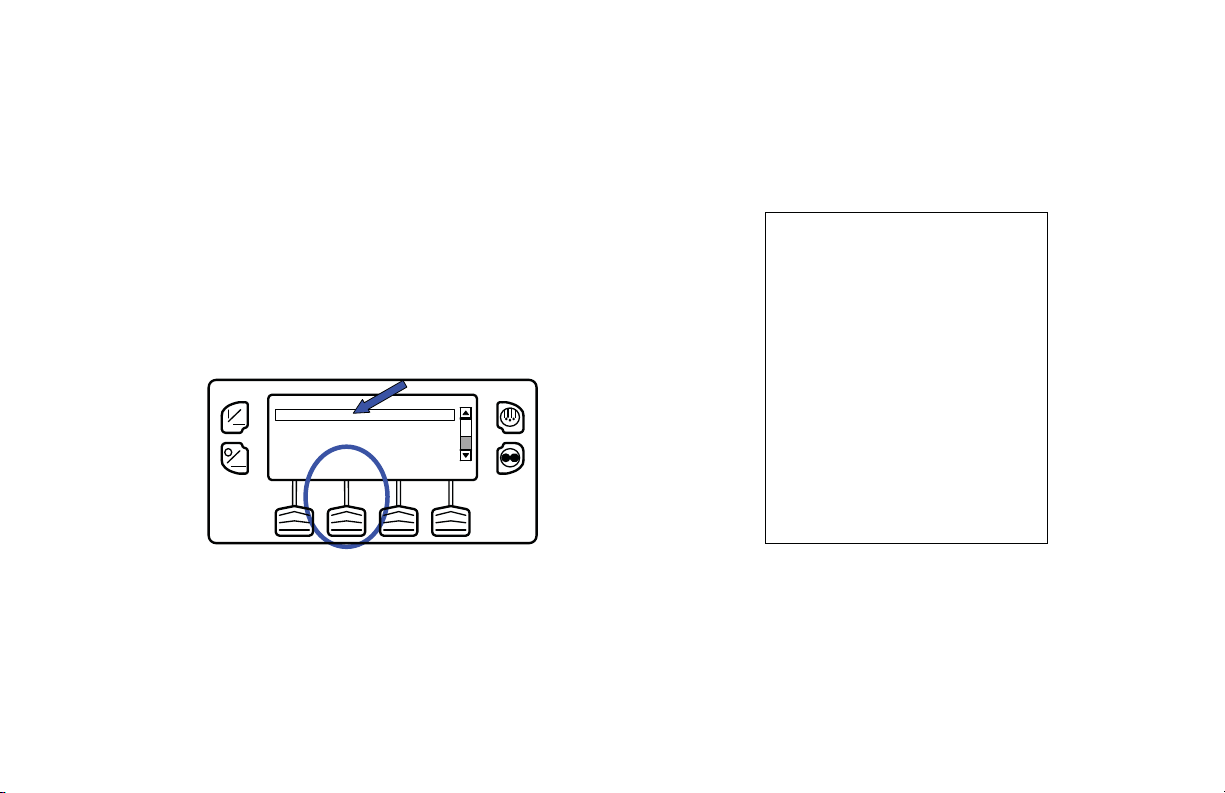

See Figur e 35 fo r a n overview of the Changing the Setpoint -

Numerical Setpoint procedure.

Operating Instructions

43

Operating Instructions

44

ON

OFF

Setpoint Key

ON

OFF

35

SET SENSORSGAUGES

POINT

+/- TO CHANGE

-

°F

.8

CURRENT SETPOINT

35 F

+

35

MENU

EXIT

ON

OFF

+ or - Keys

ON

OFF

NEW SETPOINT WILL BE

40 F

+/- TO CHANGE OK?

-

YES

+

NEW SETPOINT WILL BE

40 F

+/- TO CHANGE OK?

-

YES

+

NO

NO

ON

OFF

New Setpoint

ON

OFF

POINT

Yes or No Keys

Figure 35: Changing the Setpoint - Numerical Setpoint

NEW SETPOINT IS

35

SET SENSORSGAUGES

40 F

.8

°F

40

MENU

Operating Instructions

Changing the Setpoint - Named

Product

If the Temperature Watch display is shown, press any soft key

to return to the Standard Display. From the Standard Display,

press the PRODUCT Key.

Note that PRODUCT is displayed in place of SETPOINT

(Figure 36).

ON

OFF

Figure 36: Product Displayed

The display briefly shows PRODUCT and then the setpoint

display appears (Figure 37).

GRAPEFRUIT, ARIZONA

59

PRODUCT SENSORSGAUGES

°F

59

.8

MENU

ON

OFF

CURRENT PRODUCT IS

GRAPEFRUIT, ARIZONA

+/- TO CHANGE

-

+

EXIT

Figure 37: Setpoint Display

The “-” and “+” Keys are used to change the Named Product

until the desired product is shown. In Figure 38 the product has

been changed to Potato, Late Crop.

ON

OFF

NEW PRODUCT WILL BE

POTATO, LATE CROP

+/- TO CHANGE OK?

-

YES

+

NO

Figure 38: Named Product

45

Operating Instructions

The YES and NO Keys confirm the product change (Figure

39). When the desired product has been selected using the “+”

and/or “-” Keys, press the YES Key to confirm and load the

new product. If the product is changed using the “+” or “-”

Keys, the chan ge must be conf irmed or re jected b y pres sing th e

YES or NO Key within 10 secon ds of changing the product. A

warning beep will sound for 5 seconds as a reminder.

Failure to confirm the new product by pressing Yes or No

within 10 seconds of changing the product will result in no

product change. In addition, Alarm Code 127 Setpoint Not

Entered is set, to indicate that the product change was initiated

but not completed.

ON

OFF

NEW PRODUCT WILL BE

POTATO, LATE CROP

+/- TO CHANGE OK?

-

YES

+

NO

Figure 39: Yes and No Keys

After the YES Key has been pressed, the display briefly shows

PROGRAMMING NAMED PRODUCT - PLEASE WAIT.

The display then confirms the new setpoint for several

seconds.

ON

OFF

NEW NAMED PRODUCT IS

POTATO, LATE CROP

Figure 40: New Named Product

If the NO Key is pressed the display will briefly show

SETPOINT NOT CHANGED and return to the Standard

Display. The Standard Display will show the old setpoint.

The display then returns to the Standard Display showing the

new named product. Notice that the arrow points down, to

indicate that the unit is cooling (Figure 41).

46

ON

OFF

POTATO, LATE CROP

45

PRODUCT SENSORSGAUGES

°F

45

.8

MENU

Figure 41: Standard Display

IMPORTANT: If the named product is changed using the

“+” or “-” Keys, the change must be confirmed or rejected by

pressing the YES or NO Key within 10 seconds of changing

the named product.

• If the YES Key is pressed, the product change made with

the “+” or “-” Key is accepted, the product changes, and

the display returns to the Standard Display.

• If the NO Key is pressed the product change made with

the “+” or “-” Key is not accepted, the product is not

changed, and the display returns to the Standard Display.

Operating Instructions

• If the YES or NO Key is not pressed within 10 seconds of

making a change with the “+” or “-” Key, the product is

not changed and the display returns to the Standard

Display. The display briefly shows [SETPOINT NOT

CHANGED] and Alarm Code 127 Setpoint Not Entered is

set, to indicate that the product change was initiated but

not completed.

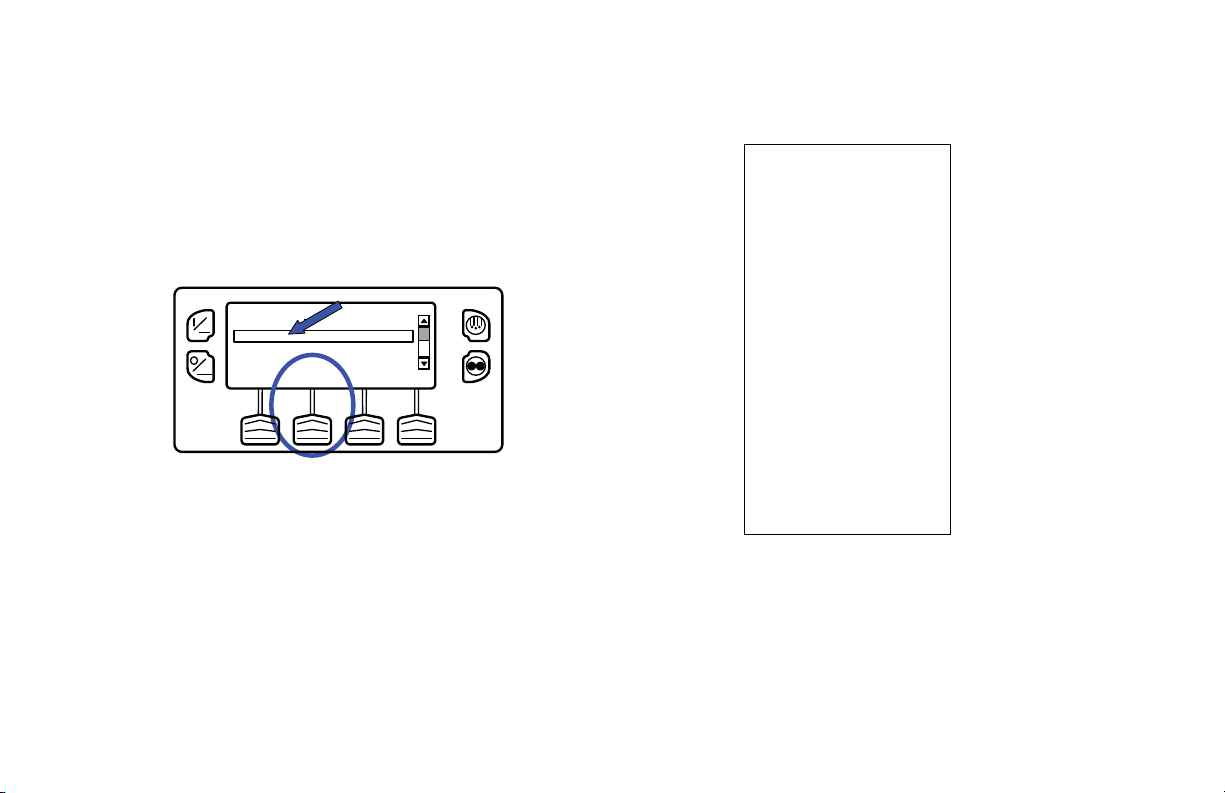

See Figure 42 for an overview of the Changing the Setpoint -

Named Product procedure.

47

Operating Instructions

48

ON

OFF

PRODUCT SENSORSGAUGES

Product Key

ON

+/- TO CHANGE

OFF

GRAPEFRUIT, ARIZONA

°F

.8

59

CURRENT PRODUCT IS

GRAPEFRUIT, ARIZONA

-

+

Setpoint Display

59

MENU

ON

OFF

NEW PRODUCT WILL BE

POTATO, LATE CROP

+/- TO CHANGE OK?

-

YES

+

NO

+ or - Keys

ON

EXIT

OFF

NEW PRODUCT WILL BE

POTATO, LATE CROP

+/- TO CHANGE OK?

-

YES

+

NO

If Yes Key Chosen,

Y es or No Keys

Figure 42: Changing the Setpoint, Named Product

ON

OFF

ON

OFF

NEW NAMED PRODUCT IS

POTATO, LATE CROP

POTATO, LATE CROP

45

PRODUCT SENSORSGAUGES

Standard Display

New Named Product

°F

45

.8

MENU

Operating Instructions

Changing the Setpoint - Both

Numerical Setpoint and Named

Product Available

If the Temperature Watch display is shown, press any soft key

to return to the Standard Display. From the Standard Display,

press the SETPOINT Key. Note that both PRODUCT and

SETPOINT are displayed as shown (Figure 43).

ON

OFF

35

PRODUCT/ SENSORSGAUGES

SETPOINT

Figure 43: PRODUCT and SETPOINT are displayed

The NAMED PRODUCT / NUMERIC SETPOINT prompt

will appear as shown (Figure 44).

°F

35

.8

MENU

.

ON

OFF

NAMED PRODUCT / NUMERIC

SETPOINT?

EXIT NAMED NUMERIC

Figure 44: NAMED PRODUCT / NUMERIC

SETPOINT Prompt

• Press the NUMERIC Soft Key to proceed with Changing

the Setpoint - Numeric Setpoint change as previously

shown.

• Press the NAMED Soft Key to proceed with Changing the

Setpoint - Named Product change as shown previously.

• Press the EXIT Soft Key to return to the Standard Display .

49

Operating Instructions

Starting the Diesel Engine

Diesel engine preheats and starts are automatic in both

Continuous Mode and Cycle Sentry Mode. The engine will

preheat and start as required when the unit is turned on. The

engine preheat and start will be delayed in Cycle Sentry mode

if there is no current need for the engine to run. If any keys are

being pressed on the HMI Control Panel the engine will not

preheat and start until 10 seconds after the last key is pressed.

NOTE: If the unit is equipped with optional Electric Standby

there may be some additional prompts before the engine will

start. See STARTING THE ELECTRIC MOTOR on the

following pages for details.

CAUTION: The engine may start automatically any time the

unit is turned on.

WARNING: Never use starting fluid.

When the engine is preparing to start the HMI Control Panel

will display the engine start screen (Figure 45). The preheat

buzzer sounds during the engine preheat and crank sequence.

ON

DIESEL ENGINE STARTING

OFF

Figure 45: Engine Start Screen

After the engine is started the display returns to the Standard

Display of temperature and setpoint.

Starting the Electric Motor

Units equipped with the SmartPower option only.

Electric Power Receptacle: The electric power receptacle

is used to connect the unit to an appropriate electric power

source for electric standby operation (Figure 46). The electric

power receptacle is usually mounted on the trailer below the

HMI Control Panel. Make sure the unit and the power supply

are turned off before connecting or disconnecting a power

cord.

50

Electric motor starting is automatic in both Continuous Mode

and Cycle Sentry Mode. The motor will start as required when

the unit is turned on. If any keys are being pr e ssed on the HMI

Control Panel prior to the motor start, the motor start will be

delayed until 10 seconds after the last key is pressed.

CAUTION: The motor may start automatically any time the

unit is turned on.

Figure 46: Electric Power Receptacle

When the motor is preparing to start the HMI Control Panel

will display the motor start screen (Figure 47). The preheat

buzzer sounds for 20 seconds before the electric motor starts.

Operating Instructions

ON

ELECTRIC MOTOR STARTING

OFF

Figure 47: Motor Start Screen

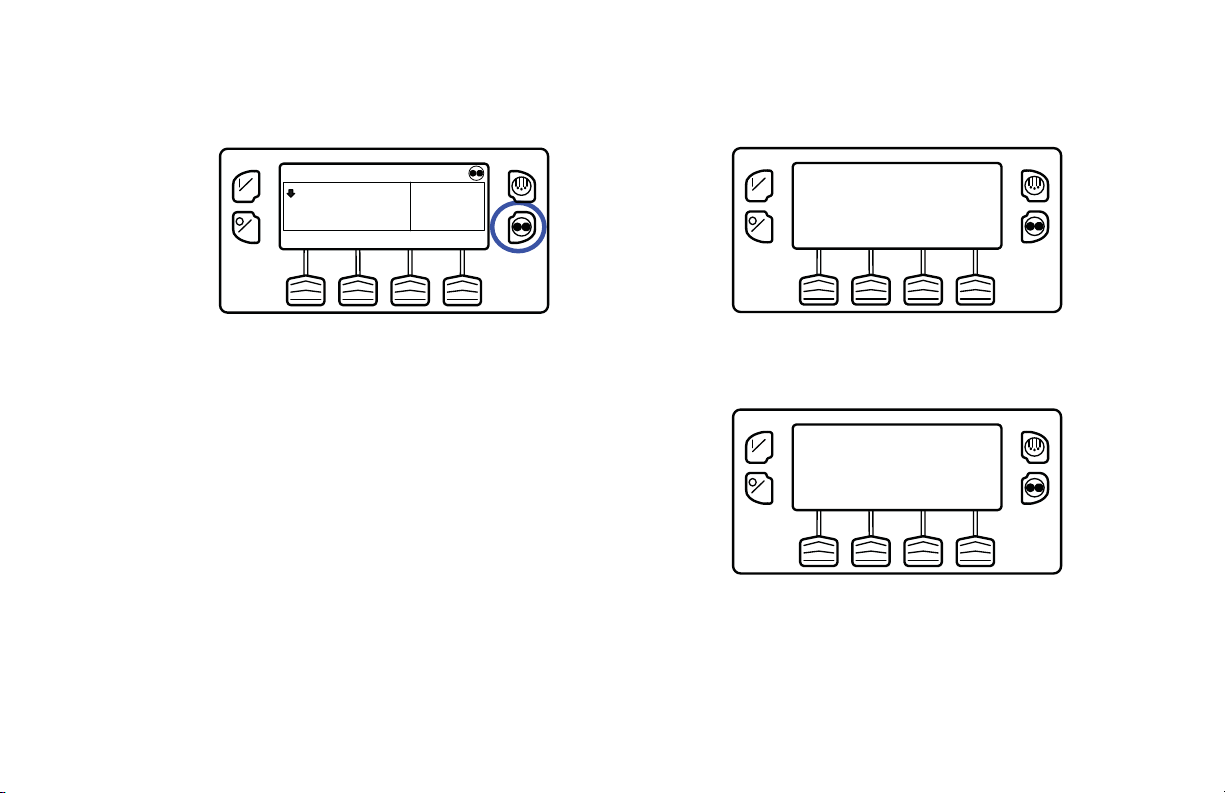

Switching from Diesel to Electric

Units equipped with the SmartPowerTM option only.

If the Diesel to Electric Auto-Switch Enabled feature in

Guarded Access is set YES then the unit will automatically

switch to Electric Mode operation when standby power is

connected and available.

If the Diesel to Electric Auto-Switch Enabled feature in

Guarded Access is set NO then the prompt screen (Figure 48)

will appear when standby power is connected and available.

51

Operating Instructions

ON

OFF

ELECTRIC STANDBY DETECTED

DO YOU WISH TO SWITCH TO

Figure 48: Standby Power Connected

ELECTRIC?

Electric Mode operation will briefly be confirmed. If unit

operation is required the electric motor will start as shown

previously under STARTING THE ELECTRIC MOTOR.

If the Diesel to Electric Auto-Switch Enabled feature in

NOYES

Guarded Access is set NO then the unit can also be switched

from Diesel mode to Electric mode operation using the Electric

Standby Selection from the Main Menu as shown later in this

section.

If NO is selected, then the unit will continue to operate in

Diesel Mode. If YES is selected then the display will briefly

show the screen in Figure 49.

ON

OFF

PROGRAMMING ELECTRIC

STANDBY

PLEASE WAIT

Figure 49: YES Selected

52

Switching from Electric to Diesel

Units equipped with the SMARTPOWER option only.

If the Electric to Diesel Auto-Switch Enabled feature in

Guarded Access is set YES then the unit will automatically

switch to Diesel Mode operation when standby power is turned

off or is no longer available.

If the Electric to Diesel Auto-Switch Enabled feature in

Guarded Access is set NO and standby power is discon nected

or fails, the unit will not automatically switch to Diesel mode.

This is primarily designed to prevent unauthorized diesel

engine starts when the truck is indoors or on a ferry where

engine operation is strictly prohibited. If the Electric to Diesel

Operating Instructions

Auto-Switch Enabled feature in Guarded Access is set NO then

the prompt screen (Figure 50) will appear when standby power

is turned off or is no longer available.

ON

OFF

ELECTRIC STANDBY NOT DETECTED

DO YOU WISH TO SWITCH TO

DIESEL?

YES NO

Figure 50: Standby Power is Off

If YES is selected then the display will briefly show the screen

in Figure 51.

PROGRAMMING DIESEL MODE

ON

OFF

PLEASE WAIT

Figure 51: Yes Selected

Diesel Mode operation will briefly be confirmed. If unit

operation is required the diesel engine will start as shown

previously under STARTING THE DIESEL ENGINE.

If the Electric to Diesel Auto-Switch Enabled feature in

Guarded Access is set NO then the unit can also be switched

from Diesel mode to Electric mode operation using the Diesel

Selection from the Main Menu as shown later in this section.

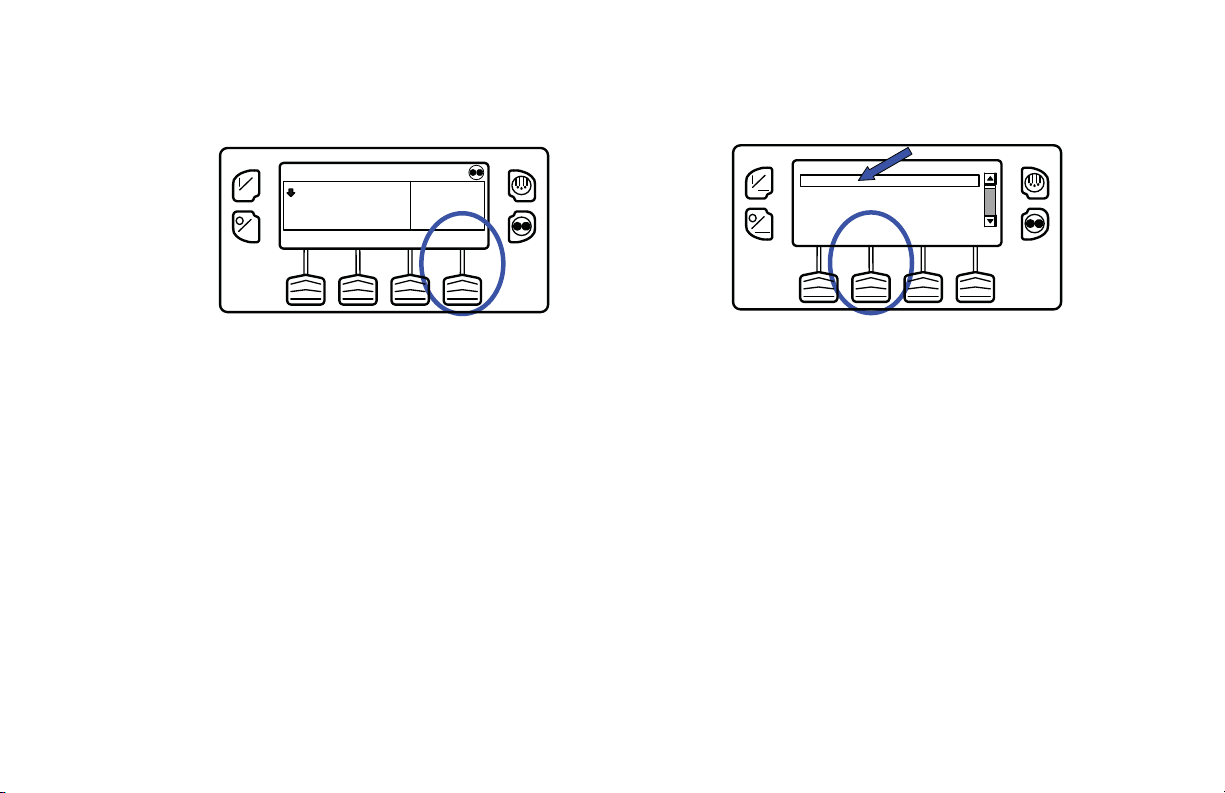

Initiating a Manual Defrost Cycle

Defrost cycles are usually initiated automatically based on time

or demand. Manual defrost is also available

Manual defrost is available if the unit is running and the

evaporator coil temperature is less than or equal to 45 F (7 C).

NOTE: If the Rail Alternate feature is set YES defrost is

allowed with an evaporator coil temperature less than or

equal to 55 F (13 C).

Other features such as door switch settings may not allow

manual defrost under some conditions. To initiate a manual

defrost cycle, press the Defrost Key (Figure 52).

53

Operating Instructions

ON

OFF

35

SET SENSORSGAUGES

POINT

°F

35

.8

MENU

Figure 52: Press Defrost Key

The display briefly shows [DEFROST], [PROGRAMMING

DEFROST - PLEASE WAIT] and then [DEFROST

STAR T E D ] ( F i g ur e 53).

ON

OFF

DEFROST STARTED

Figure 53: Defrost Started

The display then shows the Defrost display. The bar indicator

shows approximately how much time remains to complete the

defrost cycle. The bar indicator shows that the defrost cycle is

about 25% complete (Figure 54).

54

ON

35

OFF

POINT

Figure 54: Bar Indicator

If conditions do not allow a defrost cycle, the display shown in

Figure 55 will briefly appear. The display will then return to

the Standard Display.

ON

OFF

DEFROST NOT AVAILABLE

Figure 55: Defrost Not Available

See Figure 56 for an overview of the Initiating a Manual

Defrost Cycle procedure.

MENUSET SENSORSGAUGES

Operating Instructions

OFF

ON

SET SENSORSGAUGES

POINT

35

°F

35

.8

MENU

ON

OFF

DEFROST STARTED

Yes

ON

OFF

POINT

35

MENUSET SENSORSGAUGES

DEFROST NOT AVAILABLE

ON

OFF

No

Figure 56: Initiating a Manual Defrost Cycle

55

Operating Instructions

Terminating a Defrost Cycle

The defrost cycle terminates automatically when the coil

temperature is greater than or equal to 58 F (14 C) or the

defrost timer expires. Defrost can also be terminated by turning

the unit off and back on.

NOTE: If Rail Alternate is set YES the defrost cycle

terminates at 70 F (21 C) or if the defrost timer expires.

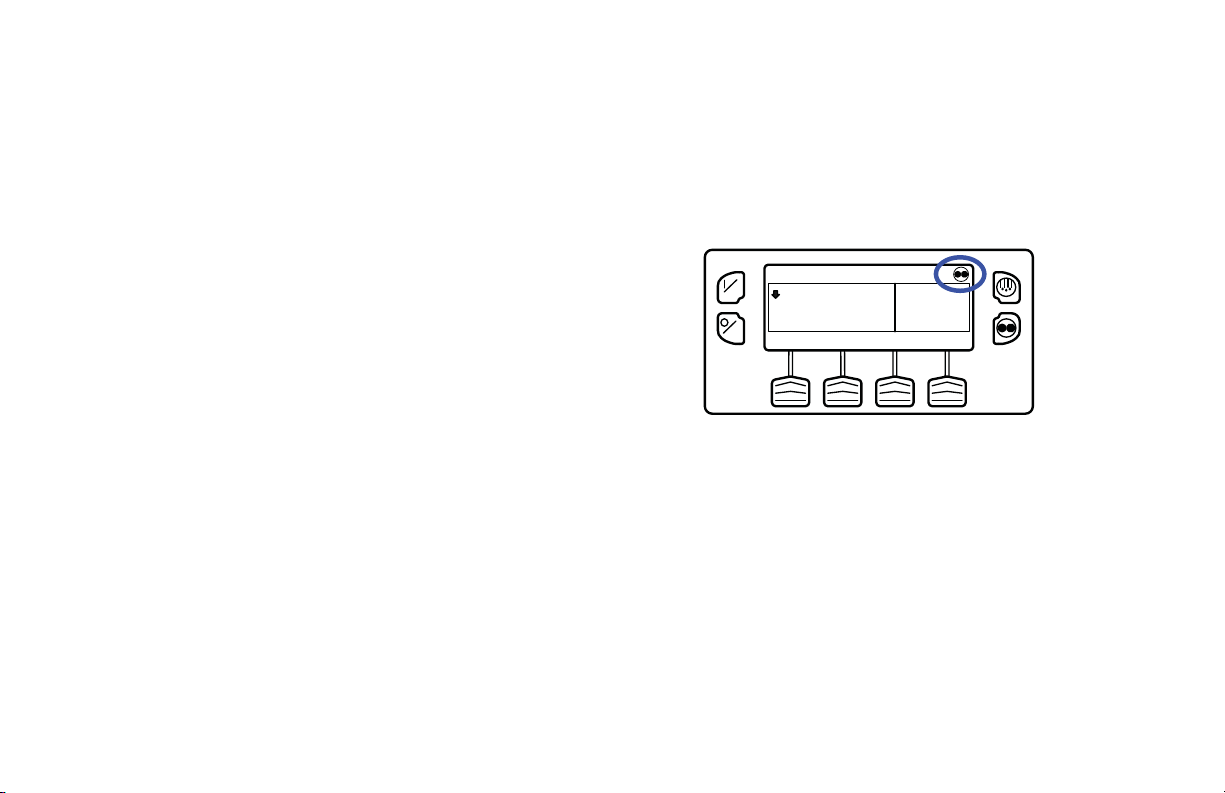

Selecting Cycle Sentry or

Continuous Mode

When Cycle Sentry Mode is selected the unit will start and stop

automatically to maintain setpoint, keep the engine warm and

the battery charged. When Continuous Mode is selected, the

unit starts automatically and runs continuously to maintain

setpoint and provide constant airflow.

IMPORTANT: Cycle Sentry or Continuous Mode may not be

selectable if OptiSet Plus is in use.

See Figure 62 for an overview of the Selecting Cycle Sentry

or Continuous Mode procedure.

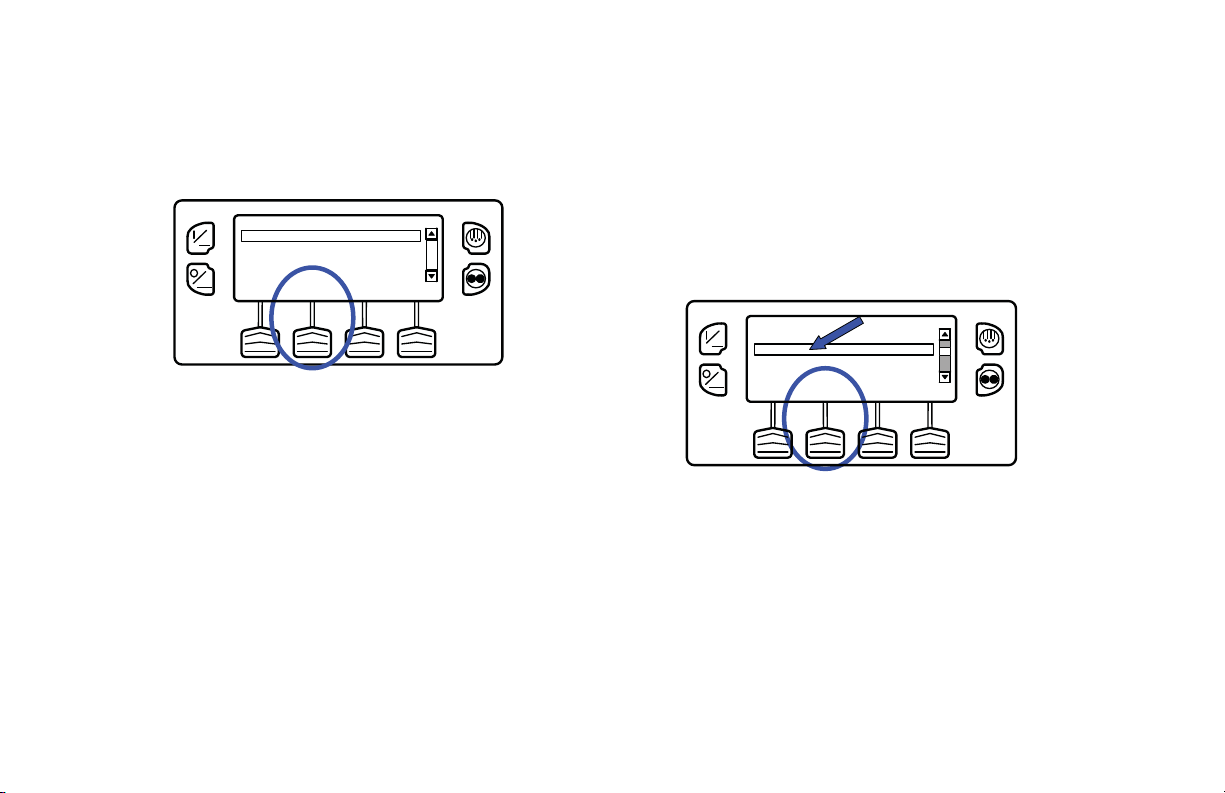

If the unit is operating in Cycle Sentry Mode, the Cycle Sentry

Icon will be present in the upper right corner of the display as

shown below. If the Cycle Sentry Icon (Figure 57) is not