Page 1

Operator’s Manual

T-1090 SPECTRUM

Multi-Temperature Unit with Premium HMI

September 2019

Revision A

TTKK 5566770044--11--OOPP--EENN

Page 2

Introduction

This manual is published for informational purposes only and the

information furnished herein should not be considered as all-inclusive or

meant to cover all contingencies. If more information is required, consult

your Thermo King Service Directory for the location and telephone number

of the local dealer.

TThheerrmmoo KKiinngg’’ss wwaarrrraannttyy sshhaallll nnoott aappppllyy ttoo aannyy eeqquuiippmmeenntt wwhhiicchh hhaass

bbeeeenn ““ssoo iinnssttaalllleedd,, mmaaiinnttaaiinneedd,, rreeppaaiirreedd oorr aalltteerreedd aass,, iinn tthhee

mmaannuuffaaccttuurreerr’’ss jjuuddggmmeenntt,, ttoo aaffffeecctt iittss iinntteeggrriittyy..””

MMaannuuffaaccttuurreerr sshhaallll hhaavvee nnoo lliiaabbiilliittyy ttoo aannyy ppeerrssoonn oorr eennttiittyy ffoorr aannyy

ppeerrssoonnaall iinnjjuurryy,, pprrooppeerrttyy ddaammaaggee oorr aannyy ootthheerr ddiirreecctt,, iinnddiirreecctt,, ssppeecciiaall,,

oorr ccoonnsseeqquueennttiiaall ddaammaaggeess wwhhaattssooeevveerr,, aarriissiinngg oouutt ooff tthhee uussee ooff tthhiiss

mmaannuuaall oorr aannyy iinnffoorrmmaattiioonn,, rreeccoommmmeennddaattiioonnss oorr ddeessccrriippttiioonnss

ccoonnttaaiinneedd hheerreeiinn.. TThhee pprroocceedduurreess ddeessccrriibbeedd hheerreeiinn sshhoouulldd oonnllyy bbee

uunnddeerrttaakkeenn bbyy ssuuiittaabbllyy qquuaalliiffiieedd ppeerrssoonnnneell.. FFaaiilluurree ttoo iimmpplleemmeenntt tthheessee

pprroocceedduurreess ccoorrrreeccttllyy mmaayy ccaauussee ddaammaaggee ttoo tthhee TThheerrmmoo KKiinngg uunniitt oorr

ootthheerr pprrooppeerrttyy oorr ppeerrssoonnaall iinnjjuurryy..

There is nothing complicated about operating and maintaining your Thermo

King unit, but a few minutes studying this manual will be time well spent.

Performing pre-trip checks and enroute inspections on a regular basis will

minimize operating problems. A regular maintenance program will also help

to keep your unit in top operating condition. If factory recommended

procedures are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled by a Thermo

King dealer for four very important reasons:

• They are equipped with the factory recommended tools to perform all

service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the repair and

replacement of component parts is performed by an authorized Thermo

King dealer

2

TK 56704-1-OP-EN

Page 3

IInnttrroodduuccttiioonn

Customer Satisfaction Survey

Let your voice be heard!

Your feedback will help improve our manuals. The survey is accessible

through any internet-connected device with a web browser.

Scan the Quick Response (QR) code or click or type the web address http://

irco.az1.qualtrics.com/SE/?SID=SV_2octfSHoUJxsk6x to complete the

survey.

TK 56704-1-OP-EN

3

Page 4

Table of Contents

SSaaffeettyy PPrreeccaauuttiioonnss .............................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ........................ 88

Danger, Warning, Caution, and Notice . . . . . . . . . . . . . . . . . . . . . . . . 8

General Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Automatic Start/Stop Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigeration System Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant Oil Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Welding Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety Nameplates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

UUnniitt DDeessccrriippttiioonn................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. ............................................1166

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ELC (Extended Life Coolant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reciprocating Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

HMI Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CYCLE-SENTRY™ Start/Stop System . . . . . . . . . . . . . . . . . . . . . . . . 20

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TracKing™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SmartPower Electric Standby (Model 50 Units Only) . . . . . . . . . . 21

SmartPower Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . 21

SmartPower Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4

TK 56704-1-OP-EN

Page 5

TTaabbllee ooff CCoonntteennttss

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Engine Compartment Components. . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll

PPaanneell........................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. ............................................2266

Truck Premium Display HMI Control Panel . . . . . . . . . . . . . . . . . . . 26

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hard Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Turning the Unit On and Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

If More Than One Language is Enabled . . . . . . . . . . . . . . . . . . . . 30

The Standard Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Starting the Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Switching from Diesel to Electric . . . . . . . . . . . . . . . . . . . . . . . . 38

Switching from Electric to Diesel . . . . . . . . . . . . . . . . . . . . . . . . 39

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . 41

Terminating a Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Selecting High Speed Lockout Mode (If Enabled) . . . . . . . . . 42

Using the Gauges Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Gauges Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using the Sensors Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Sensors Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Main Menu Choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Languages Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Log Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Check Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Shutdown Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Prevent Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

TK 56704-1-OP-EN

5

Page 6

TTaabbllee ooff CCoonntteennttss

Pretrip Alarm Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Alarm Codes When Switching Between Diesel and

Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Alarm Code Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Displaying and Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . 57

Table of Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Datalogger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hourmeters Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Hourmeter Names and Definitions. . . . . . . . . . . . . . . . . . . . . . . . 66

Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Selecting CYCLE-SENTRY or Continuous Mode. . . . . . . . . . . 70

Selecting Temperature Display Units . . . . . . . . . . . . . . . . . . . . 72

Keypad Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Selecting Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pretrip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Pretrip Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Conditions where Pretrip Tests are Not Allowed . . . . . . . . . . . . 81

Pretrip Test Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Pretrip Test Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Performing a Pretrip Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Diesel/Electric Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Adjust Brightness Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

LLooaaddiinngg aanndd EEnnrroouuttee IInnssppeeccttiioonnss .................................... .. .. .. .. .. .. .. 9900

Inspecting the Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Enroute Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

SSppeecciiffiiccaattiioonnss .. .. .. .. .. .. .. .. .. .. .. .. .. .. .......................................... .. .. .. .. .. .. .. .. .. .. .. 9933

Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Electrical Control System Specifications . . . . . . . . . . . . . . . . . . . . . 94

6

TK 56704-1-OP-EN

Page 7

TTaabbllee ooff CCoonntteennttss

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Electric Standby Specifications (SmartPower™ Model 50

Units). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Electric Motor and Overload Relay. . . . . . . . . . . . . . . . . . . . . . . 95

Standby Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

UUnniitt MMaaiinntteennaannccee ................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .......................... 9977

Maintenance Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Condenser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Remote Evaporators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

SSeerriiaall NNuummbbeerr LLooccaattiioonnss .. .. .. ........................................ .. .. .. .. .. .. .. .. .. ..110044

EEmmeerrggeennccyy CCoolldd LLiinnee .. .. .. .. .. .. .. .. .. ................................................ .. .. .. ..110077

UUnniitt WWaarrrraannttyy ........ .. .. .. .. .. .. .. .. .. .. .. .. ................................................ .. .. .. .. ..110088

EPA and ARB Supplemental Emissions Warranty

Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

TK 56704-1-OP-EN

7

Page 8

Safety Precautions

Danger, Warning, Caution, and Notice

Thermo King® recommends that all service be performed by a Thermo King

dealer and to be aware of several general safety practices.

Safety advisories appear throughout this manual as required. Your personal

safety and the proper operation of this unit depend upon the strict

observance of these precautions.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury and unsafe practices.

Indicates a situation that could result in equipment or propertydamage only accidents.

General Practices

DDAANNGGEERR

RRiisskk ooff IInnjjuurryy!!

Improper servicing can lead to fire, electrocution, or explosion. Never

service, repair, or troubleshoot a system unless you are a professional

service person.

DDAANNGGEERR

HHaazzaarrddoouuss GGaasseess!!

Refrigerant in the presence of an open flame, spark, or electrical short

produces toxic gases that are severe respiratory irritants which can cause

serious injury or possible death.

8

TK 56704-1-OP-EN

Page 9

SSaaffeettyy PPrreeccaauuttiioonnss

DDAANNGGEERR

CCoonnffiinneedd SSppaaccee HHaazzaarrddss!!

Avoid engine operation in confined spaces and areas or circumstances

where fumes from the engine could become trapped and cause serious

injury or death.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

When using ladders to install or service refrigeration systems, always

observe the ladder manufacturer’s safety labels and warnings. A work

platform or scaffolding is the recommended method for installations and

servicing.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

Never operate the unit unless you completely understand the controls;

otherwise serious injury may occur.

CCAAUUTTIIOONN

SSeerrvviiccee PPrroocceedduurreess!!

Turn the unit off before attempting to check the engine oil.

CCAAUUTTIIOONN

HHaazzaarrddoouuss PPrreessssuurreess!!

Do not remove expansion tank cap while coolant is hot.

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

Avoid direct contact with hot coolant.

Automatic Start/Stop Operation

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

The unit can start and run automatically any time the unit is turned on.

Units start automatically in both Cycle Sentry mode and Continuous mode.

Turn the unit Microprocessor On/Off switch Off before doing inspections or

working on any part of the unit.

TK 56704-1-OP-EN

9

Page 10

SSaaffeettyy PPrreeccaauuttiioonnss

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

Thermo King units may have options that allow for remote starting from a

fully off state. Turn the unit Microprocessor On/Off Switch Off before doing

inspections or working on any part of the unit.

Electrical Hazard

DDAANNGGEERR

HHaazzaarrddoouuss VVoollttaaggee!!

When servicing or repairing a temperature control unit, the possibility of

serious or even fatal injury from electrical shock exists. Extreme care must

be used when working with a refrigeration unit that is connected to a source

of operating power, even if the unit is not operating. Lethal voltage

potentials can exist at the unit power cord, inside the control box, at the

motors and within the wiring harnesses.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

On SmartPower electric standby equipped units, always turn off the

external standby power source before handling, connecting, or

disconnecting the power cable. Always disconnect the standby power cord

before servicing the unit.

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

The unit On/Off switch must be turned Off before connecting or

disconnecting the standby power plug. Never attempt to stop the unit by

disconnecting the power plug.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

The unit power plug must be clean and dry before connecting it to a power

source.

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

A certified electrician should verify that the proper standby power

requirements are being supplied before connecting to a new power source.

10

TK 56704-1-OP-EN

Page 11

SSaaffeettyy PPrreeccaauuttiioonnss

Low Voltage

IImmppoorrttaanntt:: Some SR-3 components are connected directly to un-switched

battery power. All connections and circuits labeled with a “2”

prefix are connected directly to battery power. Always

disconnect the battery before servicing the unit.

WWAARRNNIINNGG

LLiivvee EElleeccttrriiccaall CCoommppoonneennttss!!

Control circuits used in refrigeration units are low voltage (12 to 24 volts

dc). However, the large amount of amperage available can cause severe

burns if accidentally shorted to ground with metal objects, such as tools. Do

not wear jewelry, watches, or rings because they increase the risk of

shorting out electrical circuits and damaging equipment or causing severe

burns.

Refrigeration System Hazards

In the United States all technicians who maintain, service, repair, or dispose

of equipment that could release refrigerants into the atmosphere must be

EPA 608 certified. Thermo King recommends all service be performed by a

Thermo King dealer.

DDAANNGGEERR

HHaazzaarrddoouuss GGaasseess!!

Refrigerant in the presence of an open flame, spark, or electrical short

produces toxic gases that are severe respiratory irritants which can cause

serious injury or possible death.

DDAANNGGEERR

RReeffrriiggeerraanntt VVaappoorr HHaazzaarrdd!!

Do not inhale refrigerant. Use caution when working with refrigerant or a

refrigeration system in any confined area with a limited air supply.

Refrigerant displaces air and can cause oxygen depletion, resulting in

suffocation and possible death.

TK 56704-1-OP-EN

11

Page 12

SSaaffeettyy PPrreeccaauuttiioonnss

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) RReeqquuiirreedd!!

Refrigerant in a liquid state evaporates rapidly when exposed to the

atmosphere, freezing anything it contacts. Wear butyl lined gloves and

other clothing and eye wear when handling refrigerant to help prevent

frostbite.

Refrigerant Oil Hazards

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) RReeqquuiirreedd!!

Protect your eyes from contact with refrigerant oil. The oil can cause serious

eye injuries. Protect skin and clothing from prolonged or repeated contact

with refrigerant oil. To prevent irritation, wash your hands and clothing

thoroughly after handling the oil. Rubber gloves are recommended.

NNOOTTIICCEE

MMaatteerriiaall DDaammaaggee!!

Wipe up spills immediately. Refrigerant oil can damage paints and rubber

materials.

First Aid

RREEFFRRIIGGEERRAANNTT

• EEyyeess:: For contact with liquid, immediately flush eyes with large amounts

of water and get prompt medical attention.

• SSkkiinn:: Flush area with large amounts of warm water. Do not apply heat.

Remove contaminated clothing and shoes. Wrap burns with dry, sterile,

bulky dressing to protect from infection. Get prompt medical attention.

Wash contaminated clothing before reuse.

• IInnhhaallaattiioonn:: Move victim to fresh air and use Cardio Pulmonary

Resuscitation (CPR) or mouth-to-mouth resuscitation to restore

breathing, if necessary. Stay with victim until emergency personnel

arrive.

• FFrroosstt BBiittee:: In the event of frost bite , the objectives of First Aid are to

protect the frozen area from further injury, warm the affected area

rapidly, and to maintain respiration.

RREEFFRRIIGGEERRAANNTT OOIILL

12

TK 56704-1-OP-EN

Page 13

SSaaffeettyy PPrreeccaauuttiioonnss

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention.

• SSkkiinn:: Remove contaminated clothing. Wash thoroughly with soap and

water. Get medical attention if irritation persists.

• IInnhhaallaattiioonn:: Move victim to fresh air and use Cardio Pulmonary

Resuscitation (CPR) or mouth-to-mouth resuscitation to restore

breathing, if necessary. Stay with victim until emergency personnel

arrive.

• IInnggeessttiioonn:: Do not induce vomiting. Immediately contact local poison

control center or physician.

EENNGGIINNEE CCOOOOLLAANNTT

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention.

• SSkkiinn:: Remove contaminated clothing. Wash thoroughly with soap and

water. Get medical attention if irritation persists.

• IInnggeessttiioonn:: Do not induce vomiting. Immediately contact local poison

control center or physician.

BBAATTTTEERRYY AACCIIDD

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention. Wash skin with soap and water.

EELLEECCTTRRIICCAALL SSHHOOCCKK

Take IMMEDIATE action after a person has received an electrical shock. Get

quick medical assistance, if possible.

The source of the shock must be quickly stopped, by either shutting off the

power or removing the victim. If the power cannot be shut off, the wire

should be cut with an non-conductive tool, such as a wood-handle axe or

thickly insulated cable cutters. Rescuers should wear insulated gloves and

safety glasses, and avoid looking at wires being cut. The ensuing flash can

cause burns and blindness.

If the victim must be removed from a live circuit, pull the victim away with a

non-conductive material. Use wood, rope, a belt or coat to pull or push the

victim away from the current. DO NOT TOUCH the victim. You will receive a

shock from current flowing through the victim’s body. After separating the

victim from power source, immediately check for signs of a pulse and

respiration. If no pulse is present, start Cardio Pulmonary Resuscitation

(CPR). If a pulse is present, respiration might be restored by using mouth-tomouth resuscitation. Call for emergency medical assistance.

AASSPPHHYYXXIIAATTIIOONN

TK 56704-1-OP-EN

13

Page 14

SSaaffeettyy PPrreeccaauuttiioonnss

Move victim to fresh air and use Cardio Pulmonary Resuscitation (CPR) or

mouth-to-mouth resuscitation to restore breathing, if necessary. Stay with

victim until emergency personnel arrive.

Welding Precautions

Take precautions before electrically welding any portion of the unit or the

vehicle to which it is attached. Verify that welding currents are not allowed to

flow through the unit’s electronic circuits.

Observe the following precautions when welding to avoid damaging

electronic components.

• If the microprocessor has a power switch, turn it OFF before connecting

or disconnecting the battery.

• Disconnect power to the unit.

• Disconnect all wire harnesses from the microprocessor.

• If there are any electrical circuit breakers in the control box, switch them

OFF.

• Close the control box.

• Components that could be damaged by welding sparks should be

removed from the unit.

• Use normal welding procedures, but keep the ground return electrode as

close to the area being welded as practical. This will reduce the likelihood

of stray welding currents passing through any electronic circuits.

14

TK 56704-1-OP-EN

Page 15

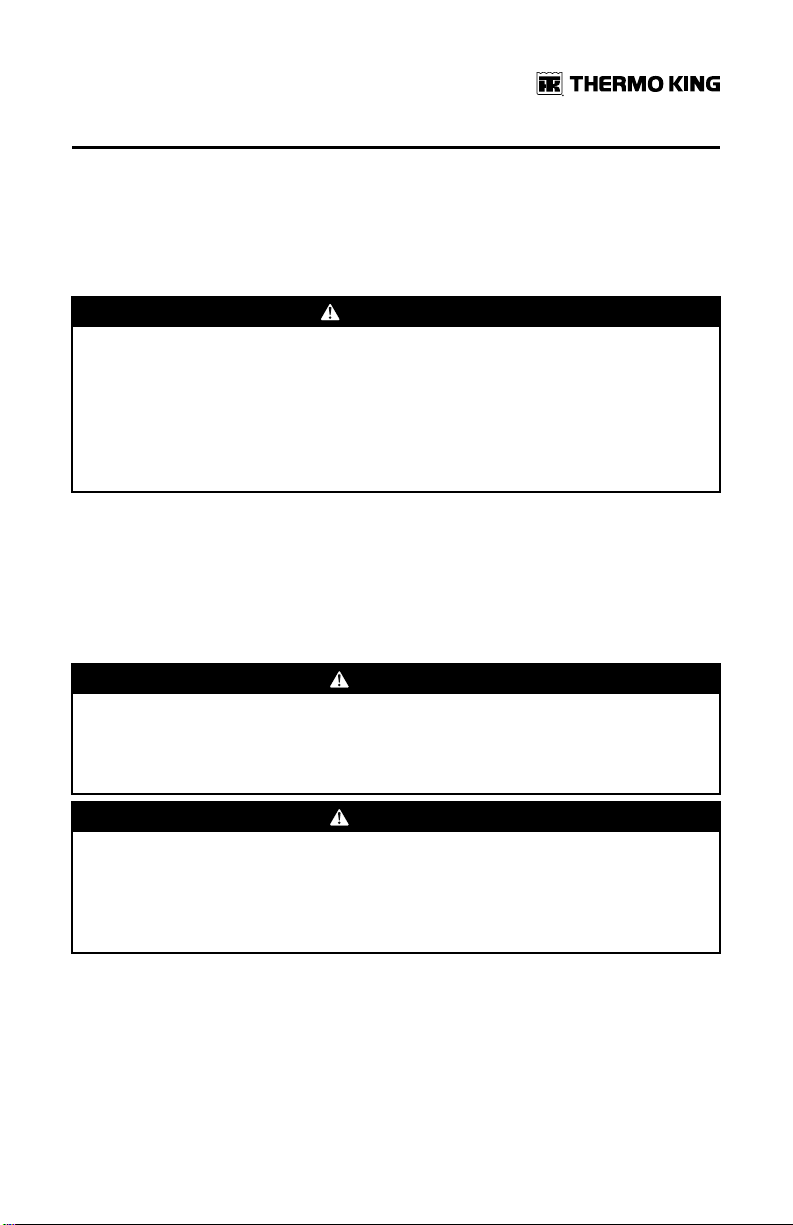

RCS1114

RCS1112

RCS1116

99-7834

RCS1125

SSaaffeettyy PPrreeccaauuttiioonnss

Safety Nameplates

Observe all safety nameplates placed in various locations on the unit.

Figure 1. Proposition 65 Nameplate

Figure 2. Automatic Start Warning Nameplate

Figure 3. Caution Lifting Nameplate

TK 56704-1-OP-EN

Figure 4. Caution No Grab No Step Nameplate

Figure 5. High Voltage Nameplate

15

Page 16

Unit Description

General Description

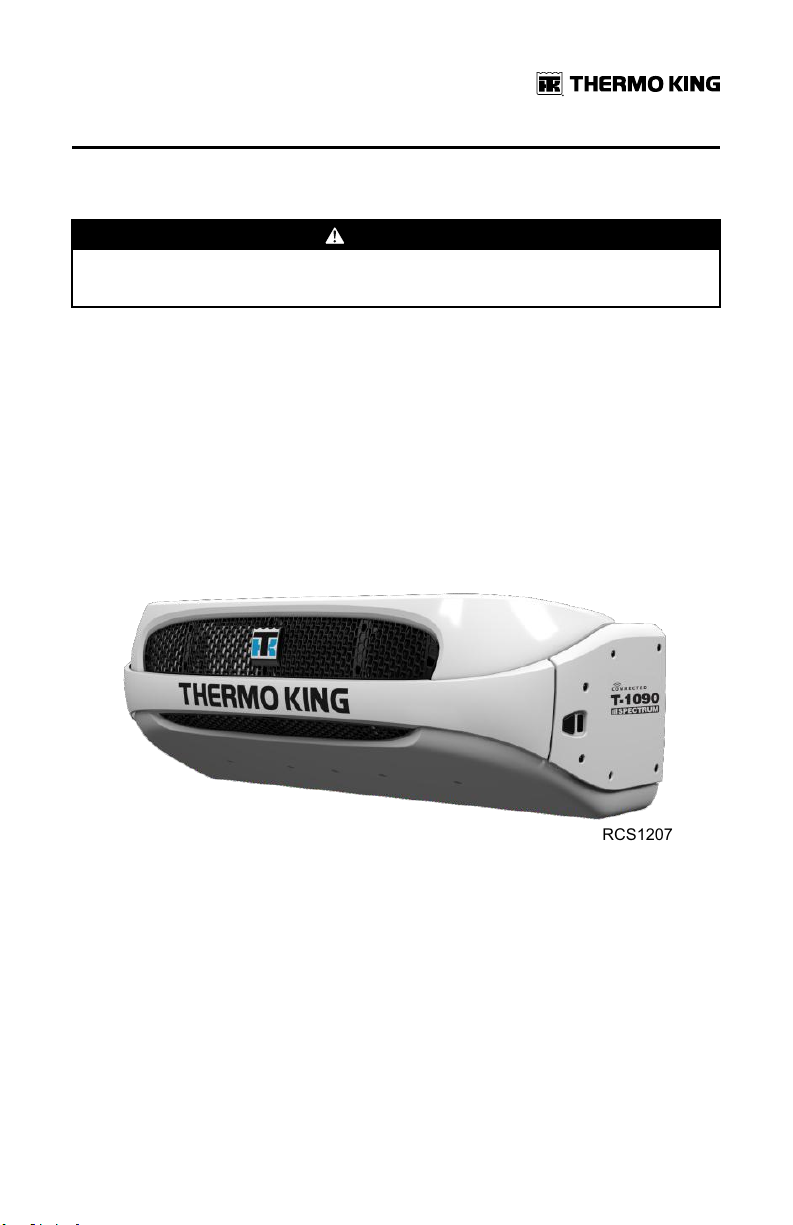

The T-1090 SPECTRUM™ is a self-powered multi-temperature cooling and

heating unit designed for straight trucks. The condensing unit is mounted on

the front of the truck cargo box. The remote evaporators are located in up to

three individual compartments inside the cargo box. The unit uses Chlorine

free R-404A refrigerant.

The basic models provide the following:

SSttaannddaarrdd UUnniitt ((MMooddeell 3300)):: Cooling and hot gas heating on engine

operation.

SSmmaarrttPPoowweerr™™ UUnniitt ((MMooddeell 5500)):: Cooling and hot gas heating on engine

operation and electric standby operation.

A three cylinder, EPA Tier 4, special clean and quiet diesel engine powers the

unit when in the truck is in route. SmartPower (Model 50) units are also

equipped with an electric motor for standby power operation while the truck

is stationary.

The SR-3 microprocessor based temperature control system and in-cab HMI

controller manage unit functions. CYCLE-SENTRY™, an exclusive Thermo

King feature, automatically starts and stops the unit according to

temperature demands. This continuous monitoring function optimizing the

unit’s performance and reduces fuel consumption while maintaining

temperature in multiple compartments.

The on-board Pretrip unit self check feature can be run before beginning the

daily distribution route to identify any possible unit malfunctions and help

prevent down time.

16

TK 56704-1-OP-EN

Page 17

UUnniitt DDeessccrriippttiioonn

Design Features

• Microprocessor Controlled

• Continuous System Monitoring

• In-Cab HMI Controller

• Alarm Code Display

• Battery Voltage Display

• Coolant Temperature Display

• CYCLE-SENTRY Start/Stop Controls

• Engine and Electric SmartPower (Model 50) Hour Meter

• OptiSet Plus Temperature Profiles

• Smart Defrost

• Unit Self Check-pretripping

• Aerodynamic Thermo Plastic Injection Molded Skins with In-mold Color

• Air Cleaner, Dry Type

• Alternator, 12 Volt, 37 Amp

• Bypass Oil Filter

• Coolant Expansion Tank

• Economy Mode

• Fahrenheit and Celsius Display

• Fuel Filter, Spin On

• Oil Filter, Full Flow

• Serpentine Belt with Manual Tensioner

• R-404A Chlorine-free Refrigerant

• Robotic Welded Steel Frame

• X214 Compressor (T-590 and T-690)

• X430P Compressor (T890, T-1090 and T-1090 SPECTRUM)

• ETV (Electronic Throttling Valve) (T-690, T-890, T-1090 and T-1090

SPECTRUM)

• TK374F Tier 4 Diesel Engine (T-590, T-690, and T-890)

• TK380F Tier 4 Diesel Engine (T-1090 and T-1090 SPECTRUM)

• USB Diagnostic Port

• TracKing™

TK 56704-1-OP-EN

17

Page 18

UUnniitt DDeessccrriippttiioonn

Unit Options

• Body Mount HMI Enclosure

• Door Switch

• MAX Cooling System

• Electric Evaporator Heaters

• SmartPower Electric Standby (Model 50)

• SmartPower Automatic Phase Correction (Model 50)

• SmartPower Diesel/Electric Autoswitching (Model 50)

• Engine Block Heater

• Fuel Tank (30 gallon aluminum, 18” and 22”)

• Quick Oil Drain Kit

• Rear Remote Control (flushmount)

• Remote Indicator Light

• Snow Cover

• Whisper™ Sound Kit

• Top Cover System

• Precision Temperature Control (all except T–590)

• TouchPrint

• Bluetooth

• Solar Panels

• Battery Box

• Evaporator Side Screens

18

TK 56704-1-OP-EN

Page 19

RCS1161

UUnniitt DDeessccrriippttiioonn

Engine

Engine power for the T-1090 SPECTRUM is provided by the TK380F, a three

cylinder, EPA Tier 4, special clean and quiet diesel engine rated at 19.3

continuous horsepower (14.4 kW) at 2425 RPM. A belt drive system transfers

energy to the compressor and alternator.

ELC (Extended Life Coolant)

The maintenance interval for ELC is eight years or 15,000 hours. A nameplate

near the coolant expansion tank identifies units with ELC. This coolant is Red

instead of the previous Green or Blue-Green coolants.

Figure 6. ELC (Extended Life Coolant) Nameplate

IImmppoorrttaanntt:: Only OAT extended life coolants (Chevron Delo® XLC or

equivalent) should be added to Thermo King systems.

Conventional coolants should not be used (Typically identified

by green or blue-green color). If a conventional coolant is

combined with the Thermo King factory fill up to 25% by volume,

the coolant must be changed at the next service opportunity.

Above 25%, the coolant must be changed immediately.

Conventional coolants dilute/interact with the additive packages

of extended life coolant which significantly reduces the service

life of the coolant.

NNoottee:: The use of 55/45% pre-mixed ELC is recommended to ensure that

deionized water is being used. If 100% full strength concentrate is

used, deionized or distilled water is recommended instead of tap

water to ensure the integrity of the cooling system is maintained.

Clutch

The centrifugal clutch engages fully at 600 ± 100 RPM on engine operation,

constantly turning the compressor, alternator, and fans at both high and low

TK 56704-1-OP-EN

19

Page 20

UUnniitt DDeessccrriippttiioonn

speed. The clutch isolates the engine from the belt drive system during

electric standby operation on Model 50 units.

Reciprocating Compressor

The T-1090 SPECTRUM features the X430P, 4 cylinder reciprocating

compressor with 30.0 cu in (492 cc) displacement.

HMI Controller

The HMI Controller communicates with the Base Controller (located inside

the control box) and is used operate the unit and display unit information. It

also provides access to all the controller functions and menus.

CYCLE-SENTRY™™ Start/Stop System

The CYCLE-SENTRY Start/Stop fuel saving system provides optimum

operating economy.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

The unit can start at any time without warning. Press the OFF key on the

HMI control panel and place the microprocessor On/Off switch in the Off

position before inspecting or servicing any part of the unit.

The CYCLE-SENTRY system automatically starts the unit on microprocessor

demand and shuts down the unit when all demands are satisfied.

The system monitors and maintains the compartment temperature, the

engine block temperature, and battery charge levels at a point where quick,

easy starts are possible.

Defrost

Frost will gradually build up on the evaporator coils as a result of normal

operation. Periodically this frost must be melted to prevent a loss of cooling

and airflow.

Defrost is accomplished by passing hot refrigerant gas through the

evaporator coil, thus melting the frost (or ice). Melted frost drains out of the

unit onto the ground through the drain tubes.

Defrost can be initiated at any time the evaporator coil temperature is below

42 F (5.5 C).

20

TK 56704-1-OP-EN

Page 21

UUnniitt DDeessccrriippttiioonn

There are two methods of defrost initiation:

SSRR--22//SSRR--33 MMiiccrroopprroocceessssoorr CCoonnttrroolllleerr:: The Microprocessor Controller is

programmed to automatically initiate timed and forced defrost cycles. The

SR-2/SR-3 uses temperature sensors to determine if forced defrost is

required.

MMaannuuaall DDeeffrroosstt:: Manual Defrost allows the operator to initiate a defrost

cycle by pressing the Defrost key. See “Initiating a Manual Defrost Cycle.”

TracKing™

T-90 series units are equipped with a wireless communication platform that

offers fleet owners the ability to monitor their refrigerated units. Cellular,

GPS, and Bluetooth capabilities communicate with Thermo King’s webbased TracKing™ application, and Bluetooth with the Thermo King Reefer

App. A third party interface offers a gateway for telematics providers to

communicate with the Thermo King unit. To learn more about the TracKing

features, contact your Thermo King dealer.

SmartPower Electric Standby (Model 50 Units Only)

The SmartPower Electric Standby option allows the unit to be operated on

either the diesel engine or external electric power.

DDAANNGGEERR

HHaazzaarrddoouuss VVoollttaaggee!!

High voltage AC power is present whenever the unit is operating in the

Electric Standby mode and whenever the unit is connected to external

standby power. Voltages of this magnitude can be lethal. Exercise extreme

caution when working on the unit.

SmartPower Standard Features

The following features are standard equipment on units equipped with

SmartPower Electric Standby.

AAuuttoommaattiicc DDiieesseell//EElleeccttrriicc SSeelleeccttiioonn:: The unit will automatically switch to

electric operation when a power cord is connected and the standby power is

switched On.

OOvveerrllooaadd RReellaayy:: The overload relay is self-resetting.

HHoott GGaass HHeeaatt:: Hot gas heat is utilized on all units.

TK 56704-1-OP-EN

21

Page 22

UUnniitt DDeessccrriippttiioonn

AAuuttoommaattiicc PPhhaassee CCoorrrreeccttiioonn:: The control system features two motor

contactors. This allows correct motor rotation regardless of phase rotation

on the incoming power.

SmartPower Optional Features

The following features are available as options on units equipped with

Electric Standby.

• Auto Switching

Unit Protection Devices

HHiigghh PPrreessssuurree CCuuttoouutt SSwwiittcchh ((HHPPCCOO)):: This normally closed switch

monitors the discharge pressure at the compressor. It opens on high

discharge pressure to shut the unit down to prevent damage.

EElleeccttrroonniicc TThhrroottttlliinngg VVaallvvee ((EETTVV)):: This component is an electromechanical

control device used to limit the suction pressure to the compressor. The

valve is controlled by the microprocessor controller.

EEnnggiinnee OOiill PPrreessssuurree SSwwiittcchh//SSeennssoorr:: The engine oil pressure switch/sensor

is located on the filter head above the bypass oil filter. Engine oil pressure

should rise immediately on starting. If engine oil pressure drops below 10 ±

2 psig (69 ± 14 kPa), the switch/sensor signals the microprocessor to stop the

engine.

PPrreehheeaatt BBuuzzzzeerr:: The preheat buzzer sounds when the CYCLE-SENTRY

system energizes the glow plugs. This should warn anyone near the unit that

the CYCLE-SENTRY system is about to start the diesel engine.

CCoooollaanntt TTeemmppeerraattuurree SSeennssoorr:: This sensor provides an engine coolant

temperature input to the microprocessor. If the engine coolant temperature

is too high, the controller stops the unit and records an alarm.

EElleeccttrriicc MMoottoorr OOvveerrllooaadd RReellaayy ((MMooddeell 5500)):: The overload relay protects the

electric standby motor. The overload relay opens the circuit from the

contactor to the electric motor if the motor overloads for any reason and an

alarm will occur. The relay resets when the alarm code is cleared.

FFuusseess:: Sizes and functions are described in the Specifications chapter of this

manual.

Engine Compartment Components

CCoooollaanntt EExxppaannssiioonn TTaannkk:: The coolant level and temperature are monitored

by the base controller. If the coolant temperature becomes too high or the

level becomes too low, an alarm will occur.

22

TK 56704-1-OP-EN

Page 23

RCS1207

UUnniitt DDeessccrriippttiioonn

The engine must have antifreeze protection to –30 F (–34 C). Check and add

coolant in the expansion tank as needed.

CCAAUUTTIIOONN

HHaazzaarrddoouuss PPrreessssuurreess!!

Do not remove expansion tank cap while coolant is hot.

EEnnggiinnee OOiill DDiippssttiicckk:: Use the engine oil dipstick to check the engine oil level.

RReecceeiivveerr TTaannkk SSiigghhtt GGllaassss:: The receiver tank sight glass is used to assist in

checking the amount of refrigerant in the system.

CCoommpprreessssoorr OOiill SSiigghhtt GGllaassss:: The compressor oil sight glass is used to

check the relative level of compressor oil in the compressor sump.

Unit Components

Figure 7. Front View of Unit

TK 56704-1-OP-EN

23

Page 24

1

2

3

4

5

6

7

8

9

RCS1141

UUnniitt DDeessccrriippttiioonn

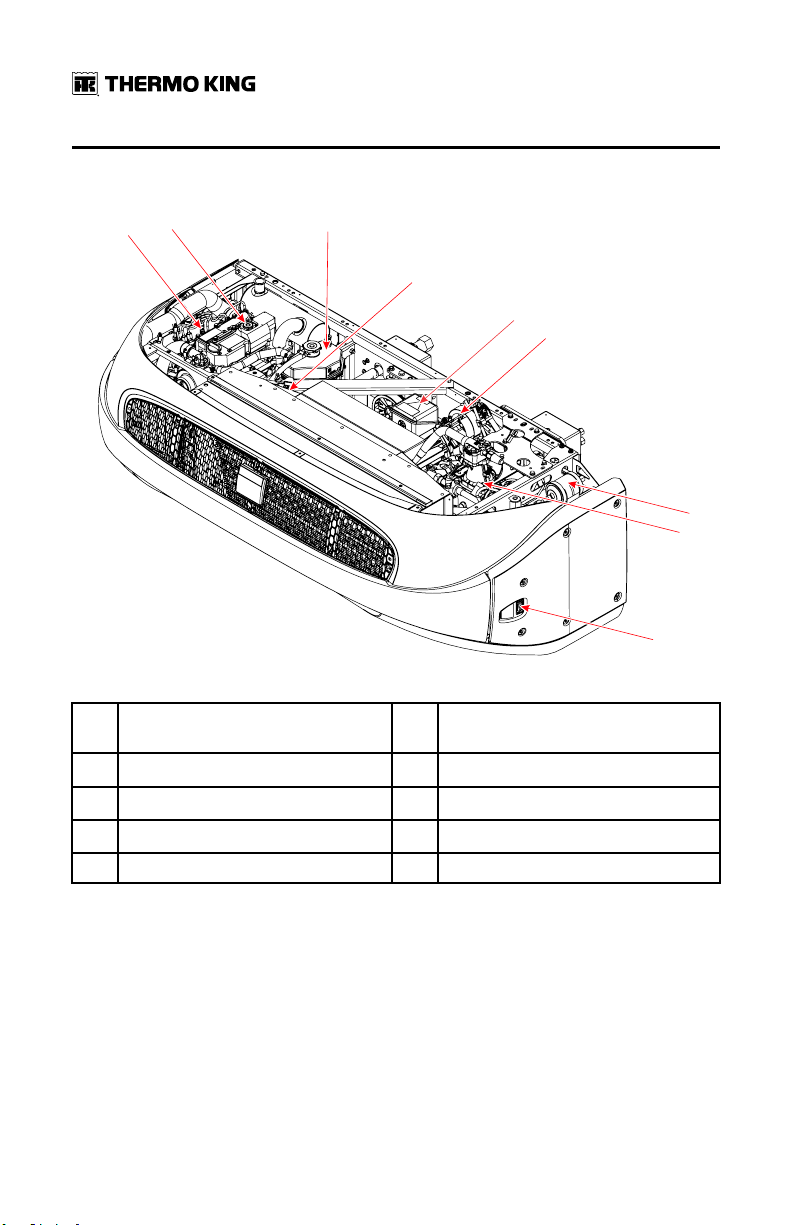

Figure 8. Engine Compartment Components

1. Engine Oil Dipstick (on side of

engine)

2. Engine 7. Dehydrator (Filter-Drier)

3. Coolant Expansion Tank 8. Compressor

4.

Coolant Overflow Bottle

5. Electric Motor

24

6. Alternator

9.

Base Controller On/Off Switch

TK 56704-1-OP-EN

Page 25

UUnniitt DDeessccrriippttiioonn

Figure 9. S-2 Remote Evaporator – Front View

Figure 10. S-3 Remote Evaporator – Front View

TK 56704-1-OP-EN

25

Page 26

Operating Instructions for Premium HMI Control Panel

Truck Premium Display HMI Control Panel

The Truck Premium Display is used to operate the unit, display unit

information, and access all Maintenance and Guarded Access Menus. The

Truck Premium Display communicates with the Base Controller via the

Controller Area Network (CAN) bus. It is connected to the Base Controller via

CAN Connector J14 on the interface board. The Truck Premium Display is

typically located in the vehicle driver’s compartment. It may be installed in

the truck instrument panel using a DIN mounting ring or under the

instrument panel using an under dash mounting kit.

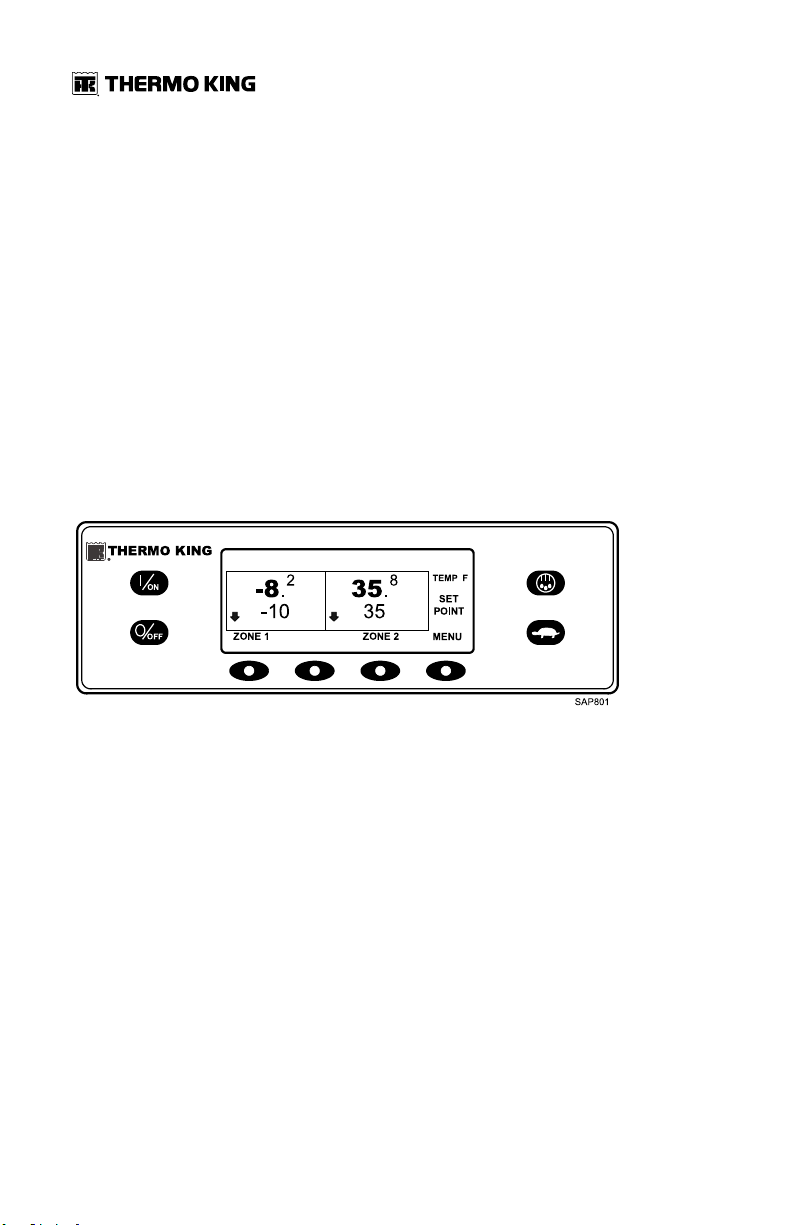

Figure 11. Truck Premium HMI Control Panel

The HMI control panel consists of a display and 8 touch-sensitive keys.

The display is capable of showing both text and graphics.

The keys on the left and right sides of the display are dedicated single

function “hard” keys.

The four keys under the display are “soft” keys. The functions of these soft

keys change depending on the operation being performed. If a soft key is

active the current key function is shown in the display directly above the key.

Display

The display presents information to the operator. This information includes

setpoint and temperature for each zone, unit or zone operating information,

gauge readings, temperatures, and other information as selected by the

operator.

26

TK 56704-1-OP-EN

Page 27

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

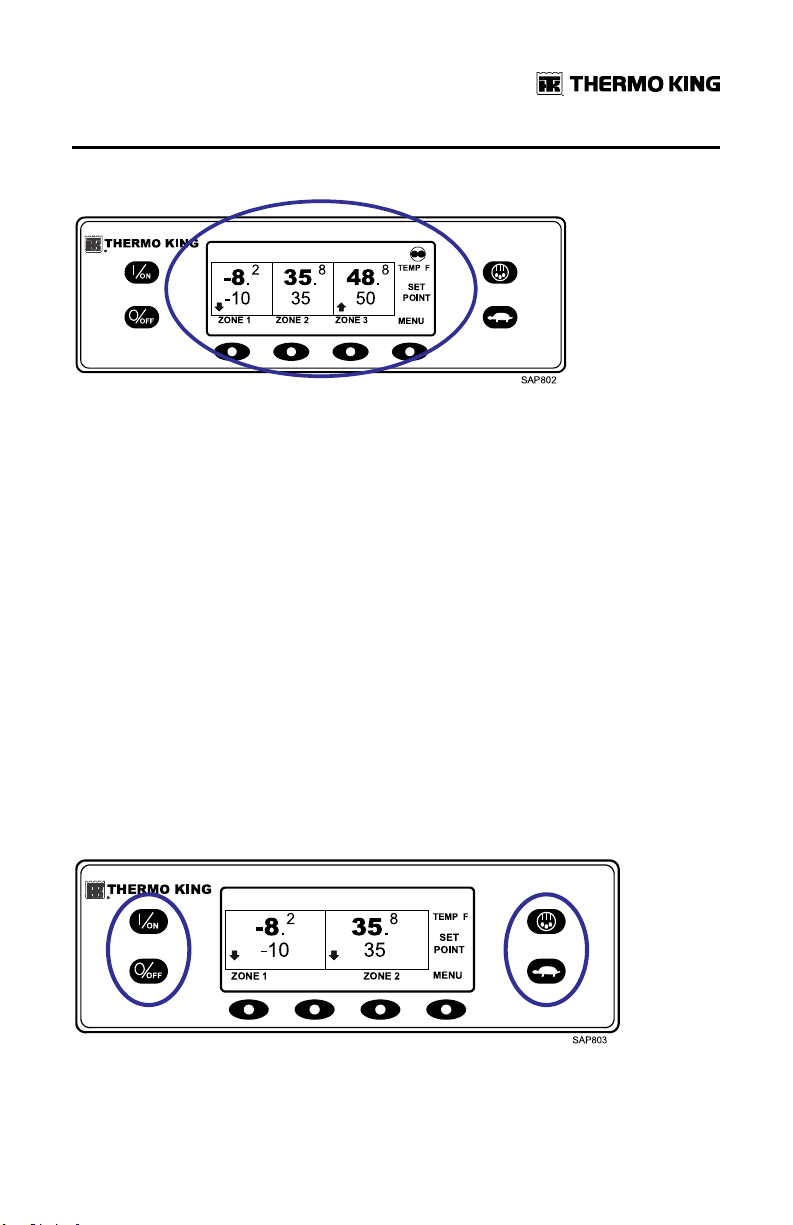

Figure 12. Display

The Standard Display of box temperature and setpoint for three zones is

shown (Figure 12, p. 27). The Cycle Sentry Icon in the upper right of the

display shows the unit is running in Cycle Sentry Mode. Zone 1 has a

setpoint of -10°F, and a return air temperature of -8.2°F. The downward

pointing arrow shows this zone is cooling. Zone 2 has a setpoint of 35°F, and

a return air temperature of 35.8°F. The absence of an arrow indicates that

this zone is in null. Zone 3 has a setpoint of 50°F, and a return air

temperature of 48.8°F. The upward pointing arrow shows this zone is

heating.

NNoottee:: The zone temperature shown is always return air temperature.

The four keys under the display are termed “soft” keys. The functions of

these keys change depending on the operation being performed. The

function of each soft key is shown by labels in the display located directly

above each soft key. The soft key under each zone is used to turn that zone

on and off and allows the Setpoint for that zone to be changed. Pressing the

soft key under MENU accesses the MAIN MENU.

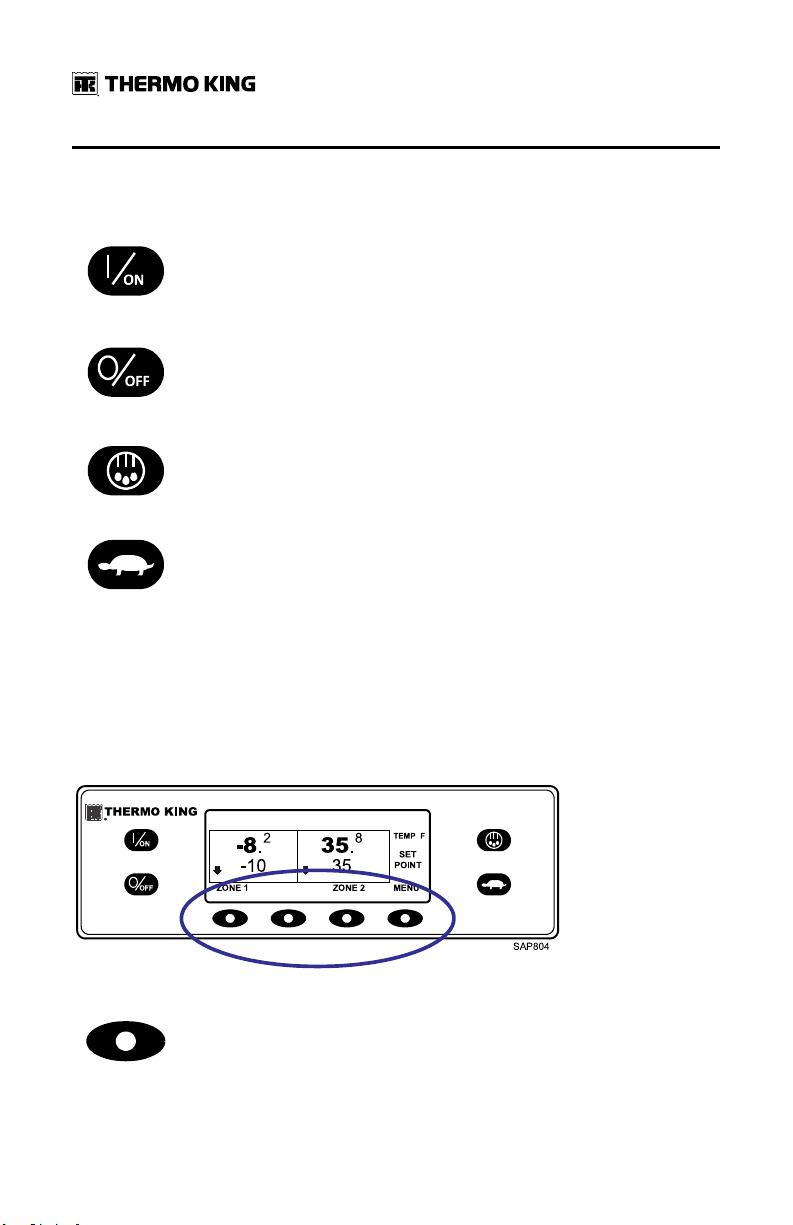

Hard Keys

Figure 13. Hard Keys

TK 56704-1-OP-EN

27

Page 28

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The keys on either side of the display are dedicated or "hard" keys. Their

function always remains the same.

This key is used to turn the unit on. First the display will briefly show the

Thermo King Logo and then the statement "Configuring System - Please

Wait". When the power-up sequence is complete the display shows the

Standard Display of box temperature and setpoint. For more information

see "Turning the Unit On and Off" later in this section.

This key is used to turn the unit off. First the display will briefly show

"System is Powering Down - Please Wait. Press On to Resume" and then

"Off" will appear momentarily. When the power-down sequence is

complete the display will be blank. For more information see "Turning the

Unit On and Off" later in this section.

This key is used to initiate a manual defrost cycle. For more information

see "Initiating a Manual Defrost Cycle" later in this section.

This key is used to lock out high speed operation in noise sensitive areas.

For more information see "Selecting High Speed Lockout" later in this

section.

Note: The Thermo King Premium Truck HMI Control Panel features a High

Speed Lock-Out key as shown here. The Thermo King Truck HMI

Control Panel features a Cycle Sentry key in this position. When

using the Thermo King Premium Truck HMI Control Panel, Cycle

Sentry Mode or Continuous Mode is selected from the Main Menu –

Mode Submenu as shown later in this section.

Soft Keys

Figure 14. Soft Keys

The four "soft" keys under the display are multi-purpose keys. Their

function changes depending on the operation being performed. If a soft

key is active the key function is shown in the display directly above the

key. The keys are numbered from left to right, with Key 1 on the far left

and Key 4 on the far right.

28

TK 56704-1-OP-EN

Page 29

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Typical soft key functions:

ZONE ON/OFF and SETPOINT CHANGE

MENU + or - HOURMETERS EXIT

NEXT SELECT GAUGES HELP

YES/NO CLEAR BACK SENSORS

Turning the Unit On and Off

IImmppoorrttaanntt:: Verify the Base Controller On/Off Switch is turned on before

turning on the HMI Control Panel. The Base Controller On/Off

switch is located on the outside of the control box side of the

unit.

If the HMI Control Panel is turned on and the Base Controller On/Off Switch

is turned off, the HMI display screen will briefly show LOST CONTROLLER

POWER. The HMI will then power down.

The unit is turned on by pressing the ON key and off by pressing the OFF

key. When the ON key is pressed, the display briefly shows the THERMO

KING Logo as the display initializes.

IImmppoorrttaanntt:: The ON key must be held down until the Thermo King Logo

appears as shown (Figure 15, p. 29). If the ON key is not held

down long enough (approximately ½ second), the display may

flicker but the unit will not start up. If this occurs, hold the ON key

down until the Thermo King logo appears.

NNoottee:: With extremely cold ambient temperatures, it may take up to 15

seconds for the display to appear on initial startup.

Figure 15. ON Key

The startup screen shown (Figure 16, p. 30) appears while communications

are established and the unit prepares for operation.

TK 56704-1-OP-EN

29

Page 30

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

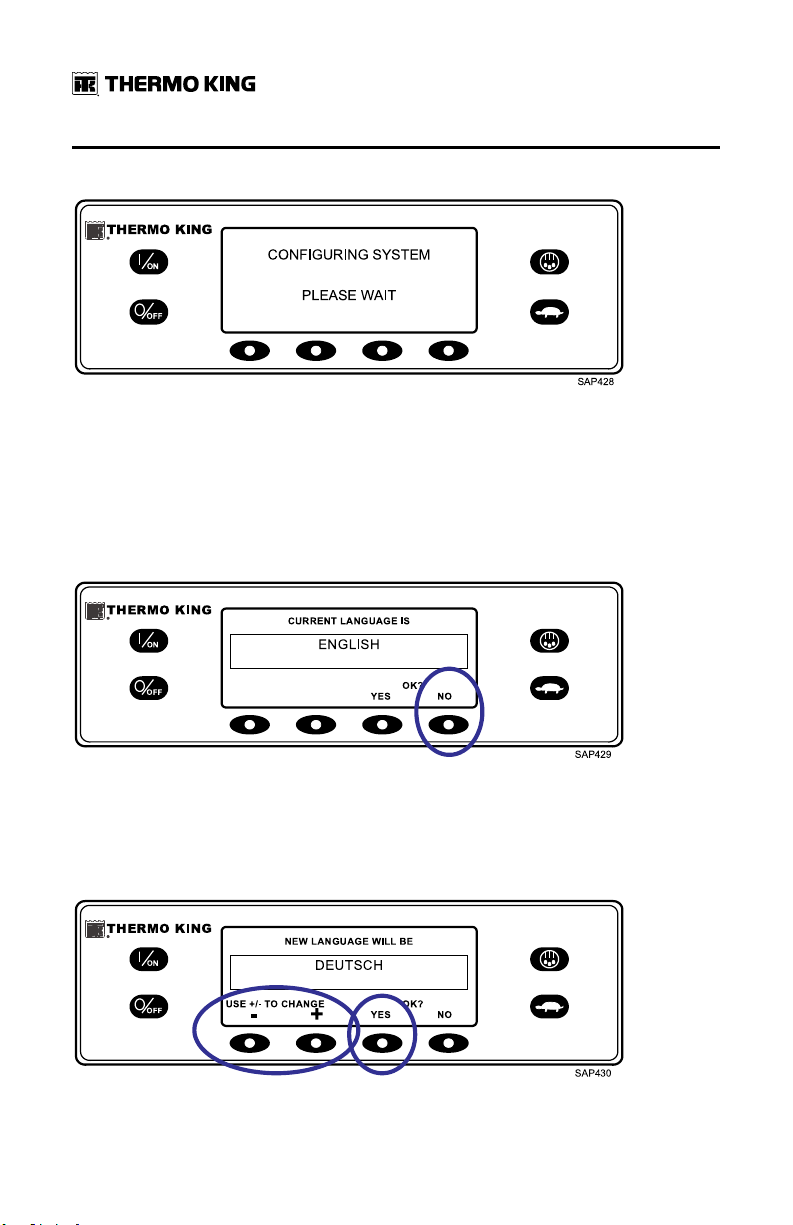

Figure 16. Startup Screen

If More Than One Language is Enabled

If more than one language has been enabled, a prompt will appear to allow

the desired language to be chosen as shown (Figure 17, p. 30). Only

languages enabled from the Guarded Access Menu are available. If a

different language is desired, press the NO key.

Figure 17. NO key

The Language menu will appear as shown (Figure 18, p. 30). Press the + or keys to select the desired language. When the desired language is shown,

press the YES key to confirm the choice.

Figure 18. YES Key

30

TK 56704-1-OP-EN

Page 31

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The display will briefly show PROGRAMMING LANGUAGE - PLEASE WAIT

in the new language as shown (Figure 19, p. 31).

Figure 19. Programming Language

The new language is confirmed, and the Standard Display will appear in the

new language as shown (Figure 20, p. 31). The unit is ready to run.

Figure 20. Truck Premium HMI Control Panel

Should it be necessary to change to another language at any time, return to

the Standard Display and then press and hold the first and last soft keys for

five seconds as shown (Figure 21, p. 31). The Standard Display below is

shown in Deutsch (German).

Figure 21. First and Last Soft Keys

TK 56704-1-OP-EN

31

Page 32

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The Language menu will appear in the current language as shown (Figure

22, p. 32). Press the + or - keys to select the desired language. When the

desired language is shown, press the YES key to confirm the choice. All

languages in the installed software can be selected using this method.

Figure 22. Language Menu

When the unit is ready to run, the Standard Display appears.

Figure 23. Standard Display

Pressing the OFF key stops unit operation. The unit shuts down immediately

and the display briefly shows the power down message.

Figure 24. Power Down Message

32

TK 56704-1-OP-EN

Page 33

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The display briefly shows OFF and then goes blank. To start the unit again,

press the ON key.

Figure 25. Off Display

The Standard Display

The Standard Display is the default display that appears if no other display

function is selected. The Standard Display shows the box temperature and

setpoint. The box temperature is that measured by the controlling sensor,

usually the return air sensor. The box temperature shown is 35.8°F with a 35°

F setpoint.

Figure 26. Standard Display

The CYCLE-SENTRY Icon in the upper right corner of the display shows that

the unit is operating in CYCLE-SENTRY Mode. If the CYCLE-SENTRY Icon is

not present, the unit is operating in Continuous Mode.

The down-pointing arrow indicates that the unit is cooling. If the unit was

heating, the arrow would be pointing upward.

Pressing the left soft key allows the user to change the SETPOINT, and

pressing the right soft key accesses the MAIN MENU. The other two soft

keys access the GAUGES menu and the SENSORS menu.

TK 56704-1-OP-EN

33

Page 34

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Changing the Setpoint

From the Standard Display, press the ZONE soft key for the desired zone.

ZONE 2 is shown (Figure 27, p. 34).

Figure 27. Zone Key

The setpoint display appears as shown (Figure 28, p. 34).

Figure 28. Setpoint Display

The - and + soft keys are used to increase or decrease the setpoint until the

desire setpoint is shown. The setpoint has been changed to 40°F using the +

key (Figure 29, p. 34).

Figure 29. Increase Setpoint

34

TK 56704-1-OP-EN

Page 35

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The YES and NO soft keys confirm the setpoint change. When the desired

setpoint has been selected using the + and/or - keys, press the YES soft key

to confirm and load the new setpoint. If the setpoint is changed using the +

or - keys, the change must be confirmed or rejected by pressing the YES or

NO soft key within 10 seconds of changing the setpoint.

Failure to confirm the new setpoint by pressing YES or NO within 10 seconds

of changing the setpoint will result in no setpoint change. In addition, Alarm

Code 127 Setpoint Not Entered is set, to indicate that the setpoint change

was not completed.

Figure 30. YES/NO Soft Keys

After the YES soft key has been pressed, the display briefly shows

PROGRAMMING NEW SETPOINT - PLEASE WAIT. The display then confirms

the new setpoint for several seconds.

Figure 31. New Setpoint

If the NO soft key is pressed, the display will briefly show SETPOINT NOT

CHANGED and return to the Standard Display. The Standard Display will

show the old setpoint. The display then returns to the Standard Display

showing the new setpoint. The arrow now points up to indicate that the unit

is heating (Figure 32, p. 36). The Zone 2 arrow now points up, to indicate that

Zone 2 is heating.

TK 56704-1-OP-EN

35

Page 36

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

IImmppoorrttaanntt:: If the setpoint is changed using the + or - keys, the change must

be confirmed or rejected by pressing the YES or NO soft key

within 10 seconds of changing the setpoint.

• If the YES key is pressed, the setpoint change made with the + or - key is

accepted, the setpoint changes, and the display returns to the Standard

Display.

• If the NO key is pressed, the setpoint change made with the + or - key is

not accepted, the setpoint is not changed, and the display returns to the

Standard Display.

• If either the YES or NO key is not pressed within 10 seconds of making a

change with the + or - key, the setpoint is not changed, and the display

returns to the Setpoint Display. The display briefly shows [SETPOINT

NOT CHANGED] and Alarm Code 127 Setpoint Not Entered is set, to

indicate that a setpoint change was started but not completed.

Figure 32. Standard Display, New Setpoint

Starting the Diesel Engine

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

The engine may start automatically any time the unit is turned on.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

Never use starting fluid. Damage to the engine can occur.

Diesel engine preheats and starts are automatic in both Continuous Mode

and CYCLE-SENTRY Mode. The engine will preheat and start as required

when the unit is turned on. The engine preheat and start will be delayed in

CYCLE-SENTRY mode if there is no current need for the engine to run. If any

36

TK 56704-1-OP-EN

Page 37

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

keys are being pressed on the HMI Control Panel, the engine will not preheat

and start until 10 seconds after the last key is pressed.

NNoottee:: If the unit is equipped with optional Electric Standby, there may be

some additional prompts before the engine will start. Refer to Starting

the Electric Motor for details.

When the engine is preparing to start, the HMI Control Panel will display the

engine start screen (Figure 33, p. 37). The preheat buzzer sounds during the

engine preheat and crank sequence.

Figure 33. Engine Start Screen

After the engine is started, the display returns to the Standard Display of

temperature and setpoint.

Starting the Electric Motor

NNoottee:: Units equipped with the Electric Standby option only.

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

The motor may start automatically any time the unit is turned on.

TK 56704-1-OP-EN

37

Page 38

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Electric motor starting is automatic in both Continuous Mode and CYCLESENTRY Mode. The motor will start as required when the unit is turned on. If

any keys are being pressed on the HMI Control Panel prior to the motor start,

the motor start will be delayed until 10 seconds after the last key is pressed.

When the motor is preparing to start, the HMI Control Panel will display the

motor start screen (Figure 34, p. 38). The preheat buzzer sounds for 20

seconds before the electric motor starts.

Figure 34. Motor Start Screen

After the motor is running, the display returns to the Standard Display of

temperature and setpoint.

Switching from Diesel to Electric

NNoottee:: Units equipped with the Electric Standby option only.

If the Diesel to Electric Autoswitch Enabled feature in Guarded Access is set

YES, the unit will automatically switch to Electric Mode operation when

standby power is connected and available.

If the Diesel to Electric Autoswitch Enabled feature in Guarded Access is set

NO, the prompt screen shown (Figure 35, p. 39) will appear when standby

power is connected and available.

38

TK 56704-1-OP-EN

Page 39

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 35. Prompt Screen

If YES is selected, the display will briefly show the screen below (Figure 36,

p. 39).

Figure 36. Programming Screen

Electric Mode operation will briefly be confirmed. If unit operation is

required, the electric motor will start as shown in Starting The Electric Motor.

Switching from Electric to Diesel

NNoottee:: Units equipped with the Electric Standby option only.

If the Electric to Diesel Autoswitch Enabled feature in Guarded Access is set

YES, the unit will automatically switch to Diesel Mode operation when

standby power is turned off or is no longer available.

If the Electric to Diesel Autoswitch Enabled feature in Guarded Access is set

NO, the prompt screen (Figure 37, p. 40) will appear when standby power is

turned off or is no longer available. Alarm Code 91 Check Electric Ready

Input and Alarm Code 84 Restart Null will both be set.

TK 56704-1-OP-EN

39

Page 40

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 37. Prompt Screen

Turn the unit off and back on using the OFF and ON Keys. This will clear

Alarm Code 91 Check Electric Ready Input and Alarm Code 84 Restart Null.

NNoottee:: The CLEAR Soft Key will not clear these two alarms. The prompt

screen shown (Figure 38, p. 40) will appear.

Figure 38. Prompt Screen

If YES is selected, the display will briefly show the programming screen

(Figure 39, p. 40). Diesel Mode operation will briefly be confirmed.

Figure 39. Programming Screen

40

TK 56704-1-OP-EN

Page 41

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

If unit operation is required, the diesel engine will start as shown previously

in Starting The Diesel Engine.

Initiating a Manual Defrost Cycle

Defrost cycles are usually initiated automatically based on time or demand.

Manual defrost is only available if the zone is running and the zone

evaporator coil temperature is less than or equal to 45°F (7°C). Other features

such as door switch settings may not allow manual defrost under some

conditions.

To initiate a manual defrost cycle, press the Defrost Key as shown (Figure

40, p. 41).

Figure 40. Defrost Key

The display will briefly show [DEFROST]. The Zone Select display will

appear. Zone 1 has been selected (Figure 41, p. 41).

Figure 41. Select Zone

The display briefly shows [DEFROST], [PROGRAMMING DEFROST - PLEASE

WAIT] and then [DEFROST STARTED].

TK 56704-1-OP-EN

41

Page 42

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 42. Defrost Started

The display then shows the Defrost display. The bar indicator shows

approximately the percentage of time remaining to complete the defrost

cycle. The bar indicator (Figure 43, p. 42) shows that the Zone 1 defrost cycle

is approximately 25% complete.

Figure 43. Defrost Display

Terminating a Defrost Cycle

The defrost cycle terminates automatically when the coil temperature is

greater than or equal to 52°F (11°C) or the defrost timer expires. Defrost can

also be terminated by turning the unit off and back on.

Selecting High Speed Lockout Mode (If Enabled)

High speed operation can be locked out in noise sensitive areas if required.

NNoottee:: High Speed Lockout Enable must be set to [Enabled] in the Guarded

Access/Programmable Features Menu or this feature will not be

available.

42

TK 56704-1-OP-EN

Page 43

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

IImmppoorrttaanntt:: HIGH SPEED LOCKOUT TIMEOUT: If High Speed Lockout Mode

is selected, the High Speed Inhibit Timeout feature may be set to

return the unit to normal operation after a set time period has

expired. This prevents extended operation with high speed

operation locked out. The time period may be from 15 minutes to

2 hours. If the time period is set and is exceeded, the unit will

return to normal operation, with high speed operation allowed. If

this occurs, the message HIGH SPEED LOCKOUT ACTIVE at the

top of the display will disappear. If necessary to return to High

Speed Lockout Mode, press the High Speed Lockout Key again.

The High Speed Lockout Key is a toggle. If high speed is currently allowed,

pressing the High Speed Lockout Key will disable high speed operation.

Pressing the High Speed Lockout Key again will allow high speed operation.

To change the setting, press the High Speed Lockout key as shown (Figure

44, p. 43).

Figure 44. High Speed Lockout Key

The display will briefly show [PROGRAMMING HIGH SPEED LOCKOUT PLEASE WAIT].

Figure 45. Programming Screen

TK 56704-1-OP-EN

43

Page 44

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

The change is confirmed by briefly displaying [HIGH SPEED LOCKOUT

ACTIVE] or [HIGH SPEED LOCKOUT INACTIVE].

Figure 46. High Speed Lockout Display

The display will then return to the Standard Display. If High Speed Lockout is

turned on, the message HIGH SPEED LOCKOUT ACTIVE will be shown at the

top of the display.

Figure 47. High Speed Lockout Active

Pressing the High Speed Lockout key again will turn the feature off.

Using the Gauges Key

The GAUGES key allows the operator to view the unit gauges. To access the

GAUGES menu press the GAUGES key.

44

TK 56704-1-OP-EN

Page 45

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 48. Gauges Key

The first gauge display will appear. Press the NEXT and BACK keys to scroll

through the gauges. The Battery Voltage Gauge is shown (Figure 49, p. 45).

Press the LOCK key to lock the selected gauge on the display.

Figure 49. Next, Back, Lock Keys

The gauges and I/O conditions available are shown below. The order in

which the gauges appear may vary slightly based on software revision. Not

all gauges may appear, depending on unit configuration and software

revision.

To return to the Standard Display press the EXIT key.

Gauges Available

CCoooollaanntt TTeemmppeerraattuurree:: Displays the temperature of the engine coolant.

CCoooollaanntt LLeevveell:: Displays the coolant level in the overflow tank as OK or

LOW.

EEnnggiinnee OOiill PPrreessssuurree:: Displays the engine oil pressure as OK or LOW.

EEnnggiinnee OOiill LLeevveell:: Displays the engine oil level as OK or LOW.

AAmmppss:: Displays the current flow in amps flowing to or from the unit battery.

BBaatttteerryy VVoollttaaggee:: Displays the voltage of the unit battery.

TK 56704-1-OP-EN

45

Page 46

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

EEnnggiinnee RRPPMM:: Displays the engine speed in RPMs.

DDiisscchhaarrggee PPrreessssuurree:: Displays the unit discharge pressure.

SSuuccttiioonn PPrreessssuurree:: Displays the unit suction pressure.

EETTVV PPoossiittiioonn:: Displays the current position of the ETV valve. ETV units only.

CCoommpprreessssoorr TTeemmppeerraattuurree:: Displays the temperature sensed by the

compressor temperature sensor. Scroll compressor only.

II//OO ((IInnppuutt//OOuuttppuutt SSttaattee)):: Displays the current state of the input/output

devices (ON or OFF) listed here:

High Speed Relay/Electric

Heat

Run Relay Alternator Frequency Drain Hose Heater

Run Relay Feedback Diesel/Electric Relay (Model 50

Alternator Excite Output Electric Ready Input (Model 50

Defrost Damper Electric Overload (Model 50 units

Hot Gas Solenoid Condenser Inlet

Solenoid

Purge Valve

units only)

units only)

only)

Using the Sensors Key

The SENSORS key allows the operator to view the temperatures read by the

unit temperature sensors. To access the SENSORS menu press the

SENSORS key.

Figure 50. Sensors Key

The first sensor display will appear. Press the NEXT and BACK keys to scroll

through the sensors. The Discharge Air Temperature sensor is shown

(Figure 51, p. 47). Press the LOCK key to lock the current sensor on the

display.

46

TK 56704-1-OP-EN

Page 47

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 51. Next, Back, Lock Keys

The sensors available are shown below. To return to the Standard Display

press the EXIT key.

Sensors Available

RReettuurrnn AAiirr TTeemmppeerraattuurree:: Displays the temperature of the control return air

sensor.

DDiisscchhaarrggee AAiirr TTeemmppeerraattuurree:: Displays the temperature of the control

discharge air sensor.

TTeemmppeerraattuurree DDiiffffeerreennttiiaall:: Displays the calculated difference between the

control return air sensor and the control discharge air sensor.

EEvvaappoorraattoorr CCooiill TTeemmppeerraattuurree:: Displays the temperature of the evaporator

coil sensor.

AAmmbbiieenntt AAiirr TTeemmppeerraattuurree:: Displays the temperature of the ambient air

sensor.

SSppaarree 11 TTeemmppeerraattuurree:: Displays the temperature of the spare 1 temperature

sensor.

DDaattaa LLooggggeerr SSeennssoorr 11 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 1.

DDaattaa LLooggggeerr SSeennssoorr 22 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 2.

DDaattaa LLooggggeerr SSeennssoorr 33 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 3.

DDaattaa LLooggggeerr SSeennssoorr 44 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 4.

DDaattaa LLooggggeerr SSeennssoorr 55 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 5.

TK 56704-1-OP-EN

47

Page 48

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

DDaattaa LLooggggeerr SSeennssoorr 66 TTeemmppeerraattuurree:: Displays the temperature of the Data

Logger sensor 6.

Using The Main Menu

The Main Menu contains several additional submenus that allow the

operator to view information and modify unit operation. To access the Main

Menu press the MENU key.

Figure 52. Menu Key

The first Main Menu choice will appear. Press the NEXT and BACK keys to

scroll through the menu choices. When the desired selection is shown on the

display, press the SELECT key to access it. The Pretrip submenu is shown

(Figure 53, p. 48). To return to the Standard Display press the EXIT key.

Figure 53. Pretrip Submenu

Main Menu Choices

LLaanngguuaaggee MMeennuu:: If more than one language is enabled, this will be the first

menu item to appear. If only one language is enabled, this menu will not

appear. The Language Menu allows the operator to select a language from a

list of up to 11 languages at one time. All subsequent displays are shown in

the selected language. Three different language packages with a total of 23

48

TK 56704-1-OP-EN

Page 49

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

languages are available. English is the default language and is provided in

each of the packages.

AAllaarrmmss MMeennuu:: Allows the operator to view all alarms, and allows most

alarms to be cleared. If only one language is enabled, this will be the first

menu item to appear.

GGaauuggeess MMeennuu:: Allows the operator to view the unit gauges and the state of

the Inputs and Outputs on both the Interface Board and the Expansion

Module.

SSeennssoorrss MMeennuu:: Allows the operator to view the unit temperature sensors. If

a DAS Data Logger is installed, the data logger sensors may also be viewed.

DDaattaa LLooggggeerr MMeennuu:: Allows the operator to send a Start of Trip marker to the

ServiceWatch Data Logger and the optional DAS Data Logger (if installed). A

Print request can also be sent to the optional DAS Data Logger (if installed)

to print the most recent trip record.

HHoouurrmmeetteerrss MMeennuu:: Allows the operator to view the unit hourmeters that

have the view feature enabled in the Guarded Access Menu. If the view

feature for a particular hourmeter is not enabled, that hourmeter will

continue to accumulate time but cannot be viewed from the Main Menu.

However, all hourmeters can be viewed from the Maintenance Menu, even if

they are not enabled.

MMooddee MMeennuu:: Allows the operator to change the unit operating modes if

allowed. Not all modes may appear depending on the settings selected from

the Guarded Access menu and the HMI Control Panel software version.

• Turn Off CYCLE-SENTRY Mode/Turn On CYCLE-SENTRY Mode (If CYCLESENTRY is Off unit runs in Continuous).

• Allows Temperature Units to be selected as Fahrenheit or Celsius.

• Allows Single Zone Control or Multi Zone Control to be selected.

• Allow Keypad Lock-Out to be selected.

• Allows Sleep Mode to be entered.

PPrreettrriipp MMeennuu:: Allows the operator to start a Pretrip Test. If an alarm is

active, the Pretrip Test is not allowed and the operator is prompted to clear

the alarm(s).

EElleeccttrriicc SSttaannddbbyy MMeennuu:: If the Electric Standby option is present and the

Diesel to Electric Auto-switch feature is set NO, this feature allows the

operator to manually select electric mode operation. This feature does not

appear if the unit does not feature optional Electric Standby or if the Diesel to

Electric Auto-switch feature is set YES.

TK 56704-1-OP-EN

49

Page 50

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

DDiieesseell MMooddee MMeennuu:: If a unit equipped with electric standby is running in

electric mode and the Electric to Diesel Auto-switch feature is set NO, this

feature allows the operator to manually select diesel mode operation. This

feature does not appear if the unit does not feature optional Electric Standby

or if the Electric to Diesel Auto-switch feature is set YES.

AAddjjuusstt BBrriigghhttnneessss MMeennuu:: Allows the operator to adjust the HMI Control

Panel display backlight intensity as required by local conditions.

TTiimmee MMeennuu:: Allows the operator to view the unit time and date. The time

and date cannot be changed from this menu.

Languages Menu

If the Language feature is enabled, an alternate language can be selected

from the Language Menu. After a new language is chosen, all subsequent

displays will appear in that language. If the language feature is not enabled,

this menu does not appear. The default language is English. Only languages

that have been enabled in Guarded Access will appear. Exercise care when

changing languages, once changed, all HMI Control Panel displays will be in

the new language. If the user is not familiar with the new language,

problems may be experienced returning to the default language.

MMiixx aanndd MMaattcchh LLaanngguuaaggee FFeeaattuurree:: Software revision 68xx allows any five

languages from both the 65/75xx and 66/76xx to be enabled. Japanese and

Chinese are not available for use with this feature.

NNoottee:: WinTrac 4.8.1 or later is required to use the Mix and Match Language

Feature.

To select an alternate language, press the MENU key.

Figure 54. Menu Key

If enabled, the Language Menu is the first menu item to appear as shown

(Figure 55, p. 51). Press the SELECT key to choose the Language menu.

50

TK 56704-1-OP-EN

Page 51

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 55. Select Key

The Language menu will appear as shown (Figure 56, p. 51). Press the + or keys to select the desired language. When the desired language is shown,

press the YES key to confirm the choice.

Figure 56. + or - Keys, Yes Key

The display will briefly show PROGRAMMING LANGUAGE - PLEASE WAIT

in the new language as shown (Figure 57, p. 51).

Figure 57. New Language

The new language is confirmed, and then the Standard Display will appear in

the new language as shown (Figure 58, p. 52).

TK 56704-1-OP-EN

51

Page 52

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

NNoottee:: The Standard Display in Deutsch (German) is the same as in English.

The unit is ready to run.

Figure 58. Standard Display

Repeat the process to select a different language. To select a different Main

Menu item, press the NEXT key. To return to the Standard Display press the

EXIT key.

IImmppoorrttaanntt:: If necessary, English and all other languages in the installed HMI

Control Panel software revision may be accessed from the

Standard Display.

Should it be necessary to change to another language at any time, return to

the Standard Display and press and hold the first and last soft keys for five

seconds as shown (Figure 59, p. 52).

Figure 59. Standard Display

After five seconds, the Language Menu will appear in the current language

as shown (Figure 60, p. 53). Press the + or - keys to select the desired

language. When the desired language is shown, press the YES key to

confirm the choice. All languages in the installed HMI Control Panel software

can be selected using this method.

52

TK 56704-1-OP-EN

Page 53

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Figure 60. Language Menu

Alarms

Alarms may be one of four types as shown.

Log Alarms

Log Alarms are indicated for 60 seconds each time the unit is turned on. This

level of alarm serves as a notice to take corrective action before the

condition impacts unit performance. Maintenance items such as

maintenance hourmeter time-outs are Log Alarms.

When the unit is turned on, the display will show the Thermo King Logo and

the "Configuring System" message. If Log Alarm(s) are present, the Log

Alarm notice will appear on the display for 60 seconds as shown (Figure 61,

p. 53). The amber K symbol of the remote indicator alarm light (if installed)

will also be on during this period. The Standard Display will appear and the

remote indicator alarm light will go to the white T symbol after 60 seconds.

NNoottee:: The Alarm Icon does not appear on startup with log alarms present.

Figure 61. Log Alarm Notice

NNoottee:: If required, an engine start may occur while the Log Alarm Notice is

shown (Figure 61, p. 53). This is normal operation.

TK 56704-1-OP-EN

53

Page 54

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

Check Alarms

Check Alarms are indicated by an Alarm Icon in the display. The amber K

symbol of the remote indicator alarm light (if installed) will be on. This level

of alarm serves as a notice to take corrective action before a problem

becomes severe. The unit will run with check alarms but some features and

functions may be inhibited.

Shutdown Alarms

Shutdown Alarms will be set if continued operation could cause damage to

the unit or the load. Shutdown Alarms are indicated by the following:

• The Alarm Icon will appear in the display.

• The display and backlight will flash on and off.

• The display will switch from normal to inverted and back to normal (light

areas become dark and dark areas become light).

• The remote indicator alarm light (if installed) will display only a row of

LEDs at the bottom.

Figure 62. Shutdown Alarm

Shutdown Alarms will force the unit into shutdown to prevent potential

damage to the unit or load. The unit will remain in shutdown until the

Shutdown Alarm is manually cleared. Exceptions are some engine and

electric Shutdown Alarms that become Log Alarms when switched to the

alternate operating mode (diesel to electric or electric to diesel).

Prevent Alarms

Prevent Alarms are also indicated by a steady Alarm Icon in the display. The

remote indicator alarm light (if installed) will be on. The unit will attempt to

resolve the situation as shown below:

• The unit will be temporarily shut down if a Prevent Alarm is active.

54

TK 56704-1-OP-EN

Page 55

OOppeerraattiinngg IInnssttrruuccttiioonnss ffoorr PPrreemmiiuumm HHMMII CCoonnttrrooll PPaanneell

• The unit will remain shut down for a timed restart interval or until the

fault conditions are corrected.