Page 1

Simple to Start:

ON

OFF

1

ON

OFF

CONFIGURING SYSTEM

PLEASE WAIT

3

ON

OFF

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

1

2 & 6

ON

OFF

NEW SYSTEM MODE IS

CONTINUOUS

ON

OFF

PROGRAMMING CONT MODE

PLEASE WAIT

3

5

MENU

35

°F

35

PRODUCT/ SENSORSGAUGES

SETPOINT

.8

ON

OFF

2

ON

OFF

NEW SETPOINT IS

40 F

-

NO

NEW SETPOINT WILL BE

40 F

+

+/- TO CHANGE OK?

YES

ON

OFF

ON

OFF

-

NO

NEW SETPOINT WILL BE

40 F

+

+/- TO CHANGE OK?

YES

4

3

5

ON

OFF

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

1

2

ON

OFF

BATTERY VOLTAGE

13.

8

NEXTEXIT LOCK BACK

v

3

ON

OFF

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

2

DEFROST STARTED

ON

OFF

3

35

MENUSET SENSORSGAUGES

POINT

ON

OFF

4

ON

OFF

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

2

1

CONTROL DISCHARGE AIR TEMPERATURE

48.

NEXTEXIT LOCK

3

°F

BACK

ON

OFF

3

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

ON

OFF

3

2

ON

OFF

MAIN MENU

DOWNEXIT SELECT UP

PRETRIP

LANGUAGE

ALARMS

GAUGES

4

4

5

EXIT

PRETRIP

PASS

ON

OFF

7

MENU

35

°F

35

SET SENSORSGAUGES

POINT

.8

ON

OFF

2

1

ON

OFF

MAIN MENU

DOWNEXIT SELECT UP

SENSORS

DATA LOGGER

HOURMETERS

MODE

4

Simple to Set:

Setpoint Temperature

Simple to Defrost:

Initiate Manual Defrost

Simple to Check:

Pretrip Test

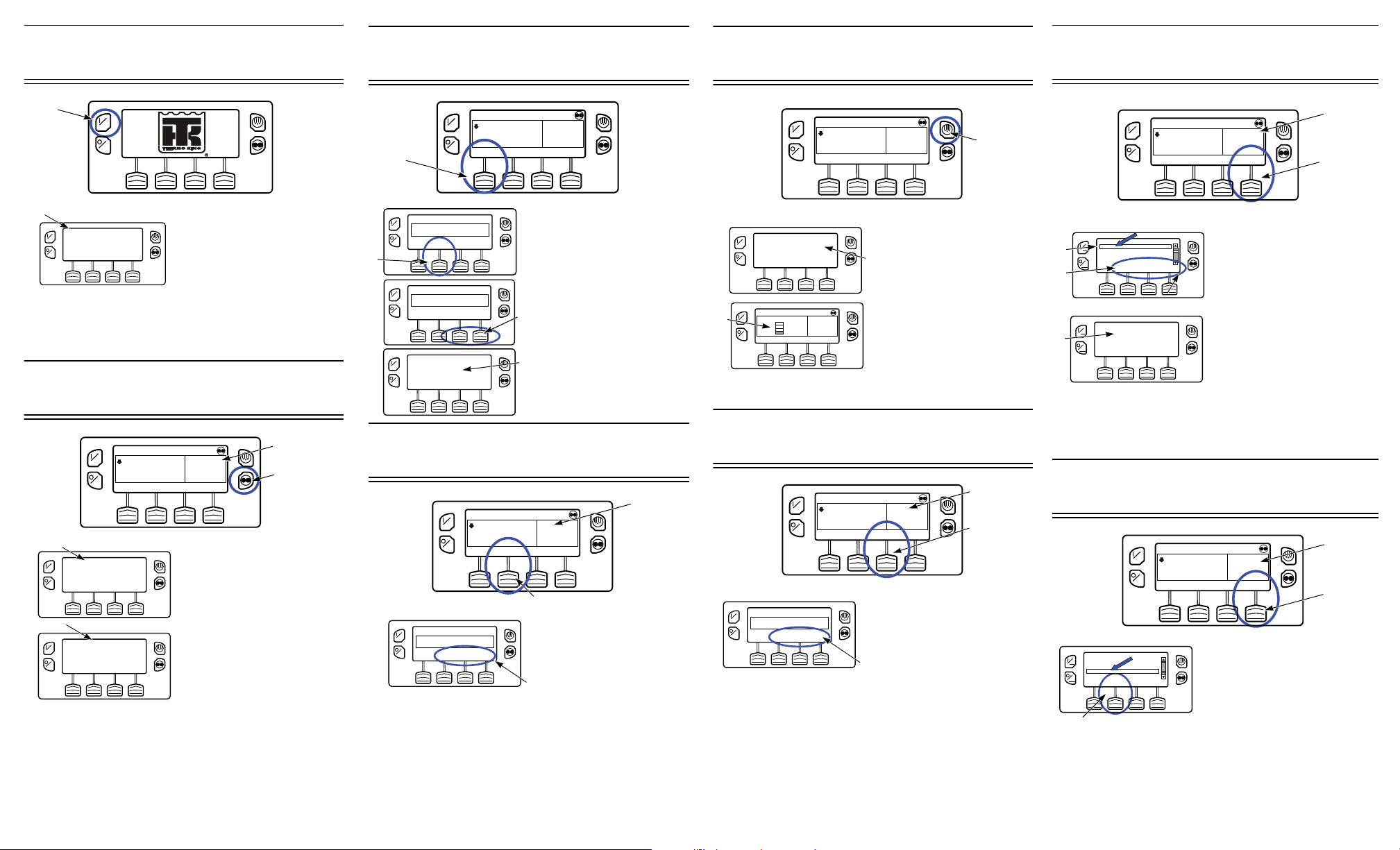

1. Press the ON Key.

2. The THERMO KING Logo appears

briefly.

3. The startup screen appears while

communications are established and

the unit prepares for operation.

4. The Standard Display defaults to the “TemperatureWatch” screen after

2-1/2 minutes. The TemperatureWat ch Display will remain on until any key

is pressed or a check, prevent or shutdown alarm occurs.

NOTE: For more detailed information, see the Operation chapter in

the appropriate unit operating manual.

Simple to Set:

CYCLE-SENTRY or Continuous Mode

Simple to Check:

Gauges

1. Press any key to return to the

Standard Display.

2. Press the SETPOINT Key on

the Standard Display.

3. Press the + or - Keys to change

the setpoint reading.

4. Press the YES or NO Key

accordingly.

5. The Standard Display appears

with setpoint changed to the new

setpoint.

NOTE: For more detailed

information, see the Operation

chapter in the appropriate unit

operating manual.

1. Return to the Standard Display.

2. Press the DEFROST Key.

3. The display will show

“Programming Defrost Please

Wait.”

4. The display then shows the

Defrost Display. The bar indicator

will fill in showing the time

remaining to complete the Defrost

cycle. When the Defrost cycle is

complete the display returns to

Standard Display screen.

NOTE: For more detailed information, see the Operation chapter in

the appropriate unit operating manual.

Simple to Access:

Sensors

1. Clear all alarm codes.

2. Return to the Standard Display.

3. Press the MENU Key.

4. Press the UP or DOWN Key as to

choose the Pretrip Menu.

5. Press the SELECT Key to start a

Pretrip Test.

6. If the unit is not running, a Full

Pretrip will be initiated. If the unit is

running in either diesel or electric

mode, a Running Pretrip will be

performed.

7. When all t est s ar e com pl ete, the re sul ts are repo rte d as PASS , CHEC K or

FAIL. If the results are CHECK or FAIL, the accompanying alarm codes will

direct the technician to the cause of the problem.

NOTE: For more de tai le d i nf orm at i on, se e th e Op er at i on ch ap ter in the

appropriate unit operating manual.

Simple to Check:

Hourmeters

1. Return to the Standard Display.

2. Press the CYCLE-SENTRY/

Continuous Key.

3. The “Programming Continuous

Mode” or “Programming CYCLESENTRY Mode” screen briefly

appears.

4. The “New System Mode is

Continuous” screen or the “New

System Mode CYCLE-SENTRY”

6. Pressing the CYCLE-SENTRY/Continuous Key again will change the

unit back to the previous mode.

NOTE: For more detailed information, see the Operation chapter in

the appropriate unit operating manual.

screen briefly appears.

5. The Standard Display appears

and the heading on top of screen

reads the new mode.

1. Return to the Standard Display.

Press the MENUKey.

2. Use UP and DOWN soft keys

to scroll to the gauges option.

Press the SELECT Key when

gauges option is highlighted.

scroll through following gauges: Coolant Temperature, Coolant Level,

3. Press BACK or NEXT Keys to

Engine Oil Pressure, Engine Oil Level, Amps, Battery Voltage, Accessory

Battery Voltage, Engine RPM, Fuel Level Sensor, Discharge Pressure,

Suction Pressure, ETV Position, Fresh Air Exchange, I/O. If no keys are

pressed within 30 seconds, the screen will return to the Standard Display.

4. Press the LOCK Key to display any gauge screen for an indefinite

period. Press the key again to unlock the screen.

5. Press the EXIT Key to return to the Standard Display.

NOTE: For more detailed information, see the Operation chapter in

the appropriate unit operating manual.

1. Return to the Standard

Display.

2. Press the SENSORS Key.

3. Press the BACK or NEXT

Keys to scroll through the

following sensor screens:

ControlReturn Air

Temperature, Control Discharge Air Temperature, Display Discharge Air

Temperature, Display Return Air

Temperature, Temperature Differential, Evaporator Coil Temperature,

Ambient Air Temperature, Spare 1 Temperature, Datalogger Temperature

Sensors 1-6 and the Board Temperature Sensor. If no keys are pressed

within 30 seconds, the screen will return to the Standard Display.

4. Press the LOCK Key to display any sensor screen for an indefinite

period. Press the key again to unlock the screen.

5. Press the EXIT Key to return to the Standard Display.

NOTE: For more detailed information, see the Operation chapter in

the appropriate unit operating manual.

1. Return to the Standard Display

screen.

2. Press the MENU Key.

3. Scroll through Main Menu by

repeatedly pressing the UP and

DOWN Keys until the hourmeters

Main Menu Screen appears.

4. Press the SELECT Key to enter the Hourmeters Menu.

5. Press the NEXT and BACK Keys to view the Hourmeter Displays.

NOTE: For more de tai le d i nf orm at i on, se e th e Op er at i on ch ap ter in the

appropriate unit operating manual.

Page 2

Simple to View:

MENU

35

35

SET SENSORSGAUGES

POINT

ON

OFF

2

1

MENU

35

35

SET SENSORSGAUGES

POINT

ON

OFF

1 OF 2 ALARMS

DOWNEXIT CLEAR HELP

5

64

x

PRETRIP REMINDER

64

CHECK AMBIENT TEMP SENSOR

ON

OFF

ON

OFF

MAIN MENU

DOWNEXIT SELECT UP

PRETRIP

LANGUAGE

ALARMS

GAUGES

7

4

3

5

6

ON

OFF

1 OF 1 ALARMS

DOWNEXIT CLEAR HELP

66

x

64

LOW ENGINE OIL LEVEL

1 OF 2 ALARMS

DOWNEXIT CLEAR HELP

5

64

x

PRETRIP REMINDER

64

CHECK AMBIENT TEMP SENSOR

ON

OFF

1

3

Cause of Alarm

mation, see the Operation chapter in the appropriate unit operating

manual.

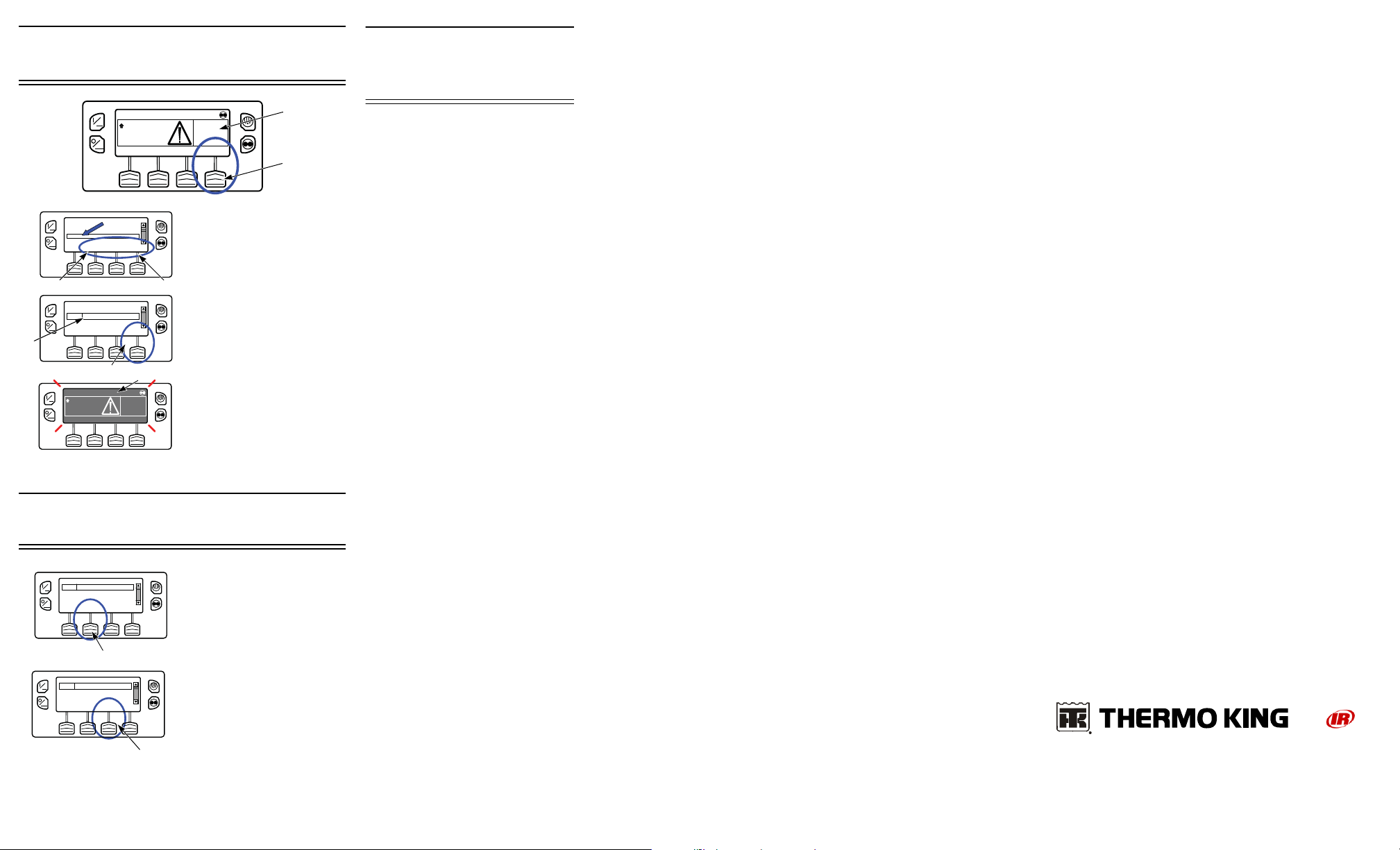

1. Return to the Standard Display

Screen.

2. Press the MENU Key.

3. Press the UP or DOWN Key until

the Alarm Menu appears.

4. Press the SELECT Key.

The Alarm Display will appear.

5. If alarms are present, the quantity

of alarms and the most recent alarm

code number will be shown.

6. If necessary to view all alarms,

scroll down using the DOWN Key.

7. If a serious condition occurs, the

unit will be shut down to prevent

damage to the unit or the load. If

this occurs, the Alarm Icon will

appear, the display and backlight

will flash on and off.

NOTE: For more detailed infor-

Simple to View:

Clearing Alarm Codes

1.If the alarm situation has been

resolved press the CLEAR Key to

clear the alarm.

2. The display will briefly show

CLEARING ALARMS – PLEASE

WAIT. Then the Alarm Menu will

reappear.

3. Press the HELP Key for

NOTE: For more detailed information, see the Operation chapter in the

appropriate unit operating manual.

additional information regarding the

alarm shown on the display. Also

see the complete Alarm Code list in

the next column.

4. T o return to the Main Menu press

the EXIT Key. To return to the

Standard Display press the EXIT

Key again.

Simple to

Determine:

Cause of Alarm

0No Alarms Exist

2 Evaporator Coil Sensor

3 Control Return Air Sensor

4 Control D ischarge Air Sensor

5 Ambient Air Sensor

6 Coolant Temp Sensor

7 Engine RPM Sensor

9 High Evaporator Temperature

10 High Discharge Pressure

11 Unit Controlling on Alternate Sensor

12 Sensor or Digital Input Shutdown

13 Sensor Calibration Check

17 Engine Failed to Crank

18 High Engine Coolant Temperature

19 Low Engine Oil Pressure

20 Engine Failed to Start

21 Cooling Cycle Check

22 Heating Cycle Check

23 Cooling Cycle Fault

24 Heating Cycle Fault

25 Alternator Chec k

26 Refrigeration Capacity

28 Pretrip Abort

29 Defrost Damper Circuit

30 Defrost Damper Stuck

31 Oil Pressure Switch

32 Refrigeration Capacity Low

33 Check Engine RPM

35 Run Relay Circuit

36 Electric Motor Failed to Run

37 Engine Coolant Level

38 Electric Phase Reversed

39 Water Valve Circuit

40 High Speed Circuit

41 Check Engine Coolant Temperature

42 Unit Forced to Low Speed

43 Unit Forced to Low Speed Modu lation

44 Check Fuel System

45 Hot Gas Bypass or Hot Gas Bypass

Circuit

46 Check Air Flow

48 Check Belts/Clutch

50 Reset Clock

52 Heat Circuit

54 Test Mode Time-out

56 Host Evap Fan Low Speed

57 Host Evap Fan High Speed

61 Low Battery Voltage

62 Ammeter Out of Calibration

63 Engine Stopped

64 Pretrip Reminder

65 Abnormal Temperature Differential

66 Low Engine Oil Level

67 Liquid Line Solenoid Circuit

68 Internal Controller Fault

70 Hourmeter Failure

74 Controller Reset to Defaults

79 Internal Data Logger Overflow

80 Compressor Temp Sensor

81 High Compressor Temp

82 High Compressor Temperature Shutdown

83 Low Engine Coolant Temperature

84 Restart Null

85 Forced Unit Operation

86 Discharge Pressure Sensor

87 Suction Pressure Sensor

89 Check Electronic Throttling Valve Circuit

90 Electric Overload

91 Electric Ready Input

92 Sensor Grades Not Set

93 Low Compressor Suction Pressure

96 Low Fuel Level

98 Fuel Level Sensor

99 High Compressor Pressure Ratio

105 Receiver Tank Pressure Solenoid C ircuit

106 Purge Valve Circuit

107 Condenser Inlet Solenoid Circuit

108 Door Open Time-out

110 Suction Line Solenoid Circuit

111 Unit Not Configured Correctly

113 Electric Heat Circuit

114 Multiple Ala rm s - Cannot R un

117 Auto switch from Diesel to Electric

118 Auto switch from Electric to Diesel

120 Alternat or Exc iter C ircu it

121 Liquid Injection Circuit

122 Diesel/Electric Relay Circuit

127 Setpoint Not Entered

128 Engine Run Time Maintenance Reminder #1

129 Engine Run Time Maintenance Reminder #2

130 Electric Run Time Maintenance Reminder #1

131 Electric Run Time Maintenance Reminder #2

132 Total Unit Run Time Maintenance Reminder #1

133 Total Unit Run Time Maintenance Reminder #2

134 Controller Power On Hours

141 Autoswitch Diesel to Electric Disabled

143 Remote Zone Drain Hose Heater Output

144 Lost Expansion Module CAN Communication

145 Loss of Controller "On" Feedback Signal

146 Software Version Mismatch

148 Autoswit ch Electric to Diesel Disabled

149 Alarm Not Identified

150 Out of Range Low

151 Out of Range High

153 Expansion Module Flash Load Failure

157 OptiSet Plus Mismatch

158 Primary So ftwa re Fail ed to Load

203 Display Return Air Sensor

204 Display Discharge Air Sensor

252 Check Fresh Air Exchange Circuit

500 Host Evaporator Fan Low Speed

501 Host Evaporator Fan High Speed

502 Host Evaporator Fan RPM Sensor

503 Host Condenser Fan 1 RPM Sensor

504 Host Condenser Fan 2 RPM Sensor

505 Roadside Condenser Fan Motor Speed Circuit

506 Curbside Condenser Fan Motor Speed Circuit

507 Digital Scroll Output Circuit

508 Speed Request Communication Error

509 Engine Control Unit (ECU) Failed to Enable

510 Engine Control Unit (ECU) Run Signal Failed

511 Engine Wait to Start Time Delay Expired

512 High Compressor Suction Pressure

513 Low Compressor Suction Ratio

514 Minimum ETV Discharge Superheat

Temperature

515 Minimum ETV Discharge Superheat

Temperature

516 I/O Controller to Application Controller

Communication Failure

517 Check for Water in Fuel System

518 Generator Ground Fault

519 Check Battery Charger Input Power

520 Check Battery Charger Output Power

521 Battery Charger External/Environmental Fault

522 Battery Temperature Sensor Alarm

523 Battery Temperature Sensor Alarm

524 Generator Operational Limit V out to

Frequency Ratio

525 Generator Frequency Range Fault

526 Generator Operational Limit Output Current

527 Reserved

528 Controller Not Receiving Messages From

Battery Charger

529 Check Fuel Pump Circuit

530 Low Pressure Differential

531 Check Economizer Pressure Sensor

538 Engine J1939 CAN Datalink Degraded

539 Engine J1939 CAN Datalink Failed

599 Engin e Ser vic e Tool Connected

600 Check Crankshaft Speed Sensor

601 Check Camshaft Speed Sensor

602 Check Intake Throttle Position Sensor

603 Check Exhaust Pressure Sensor

604 Check Coolant Temperature Sensor

605 Check Fresh Air Temperature Sensor

606 Reserved

607 Check Fuel Temperature Sensor

608 Check Rail Pressure Sensor

609 Check Intake Pressure Sensor

610 Check Atmospheric Pressure Sensor

611 Check Glow Plug Circuit

612 Check Intake Throttle Circuit

613 Check Injector(s)

614 Check High Pressure Fuel Pump

615 Rail Pressure Fault

616 Engine Overspeed

617 Internal ECU Fault

618 Check EGR System

619 ECU Main Relay Fault

620 Reserved

621 Reserved

622 Reserved

623 TRU CAN Message Timeout

624 Check Intake Air Temperature Sensor

625 Check Intake Air Temperature Sensor

626 Che ck Exhaust Temperature Sensor

699 Unknown ECU Fault

SR-4

Smart Reefer™ 4

Microprocessor

Driver Guide to

Simple

Operation

TK 55771-2-PC (Rev. 0, 01/14) ©Thermo King Corporation

Loading...

Loading...