Page 1

Operator’s Manual

SB-200TG

Operator’s Manual

SB-200TG

TK 53598-2-OP (Rev. 0, 02/07)

Page 2

Copyright© 2007 Thermo King Corp., Minneapolis, MN, USA

Printed in USA

SB-200TG

TK 53598-2-OP (Rev. 0, 02/07)

Copyright© 2007 Thermo King Corp., Minneapolis, MN, USA

Printed in USA

SB-200TG

TK 53598-2-OP (Rev. 0, 02/07)

Page 3

Disclaimer

This manual is published for informational purposes only. Thermo King Corporation makes no

representations or warranties, express or implied, with respect to the information, recommendations and

descriptions contained in this manual and such information, recommendations and descriptions should

not be regarded as all-inclusive or covering all contingencies. If you have questions or require further

information, please contact your local Thermo King dealer.

The procedures described herein should be undertaken only by qualified personnel. Failure to implement

these procedures correctly may cause damage to the Thermo King unit or other property or personal

injury.

Thermo King Corporation and its affiliates shall have no liability in contract or tort (including negligence

and/or strict liability) or otherwise, to any person or entity for any personal injury, property damage or any

other direct, indirect, special or consequential damage or liability whatsoever, arising out of or resulting

from any actions by any person that are contrary to this manual or any of the information,

recommendations or descriptions contained herein or the failure of any person to implement the

procedures described herein correctly or to follow caution and safety decals located on the Thermo King

unit.

Disclaimer

This manual is published for informational purposes only. Thermo King Corporation makes no

representations or warranties, express or implied, with respect to the information, recommendations and

descriptions contained in this manual and such information, recommendations and descriptions should

not be regarded as all-inclusive or covering all contingencies. If you have questions or require further

information, please contact your local Thermo King dealer.

The procedures described herein should be undertaken only by qualified personnel. Failure to implement

these procedures correctly may cause damage to the Thermo King unit or other property or personal

injury.

Thermo King Corporation and its affiliates shall have no liability in contract or tort (including negligence

and/or strict liability) or otherwise, to any person or entity for any personal injury, property damage or any

other direct, indirect, special or consequential damage or liability whatsoever, arising out of or resulting

from any actions by any person that are contrary to this manual or any of the information,

recommendations or descriptions contained herein or the failure of any person to implement the

procedures described herein correctly or to follow caution and safety decals located on the Thermo King

unit.

Page 4

3

Table of Contents

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . 11

Automatic Start/Stop Operation . . . . . . . . . . . . . . . . . 12

Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant Oil . . . . . . . . . . . . . . . . . . . . 13

Safety Decals And Locations . . . . . . . . . . . . . . . . . . . 14

EPA Emission Control System

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . .17

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Thermo King Corporation Responsibilities . . . . . .18

Owner Responsibilities . . . . . . . . . . . . . . . . . . . . .19

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

ELC (Extended Life Coolant) . . . . . . . . . . . . . . . . . . . .23

EMI 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Thermo King X430L Compressor . . . . . . . . . . . . . . . .24

3

Table of Contents

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . 11

Automatic Start/Stop Operation . . . . . . . . . . . . . . . . . 12

Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid–Refrigerant Oil . . . . . . . . . . . . . . . . . . . . 13

Safety Decals And Locations . . . . . . . . . . . . . . . . . . . 14

EPA Emission Control System

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . .17

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Thermo King Corporation Responsibilities . . . . . .18

Owner Responsibilities . . . . . . . . . . . . . . . . . . . . .19

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

ELC (Extended Life Coolant) . . . . . . . . . . . . . . . . . . . .23

EMI 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Thermo King X430L Compressor . . . . . . . . . . . . . . . .24

Page 5

Table of Contents

4

TG-VI Microprocessor Controller . . . . . . . . . . . . . . . . .25

CYCLE-SENTRY Start-Stop Controls . . . . . . . . . . 27

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DAS (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Opening the Front Doors . . . . . . . . . . . . . . . . . . . . . . . 29

Opening the Secondary Door Latch . . . . . . . . . . . 29

Closing the Front Doors . . . . . . . . . . . . . . . . . . . . . . . .30

Engine Compartment Components . . . . . . . . . . . . . . . 31

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . .32

TG-VI Controller Description . . . . . . . . . . . . . . . . . . 35

TG-VI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Upper and Lower Display . . . . . . . . . . . . . . . . . . . 37

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Remote Status Light (Optional) . . . . . . . . . . . . . . . . 43

Manual Pretrip Inspection

(Before Starting the Unit) . . . . . . . . . . . . . . . . . . . . .45

Unit Operation with TG-VI Controller . . . . . . . . . . . 47

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . 49

Starting the Unit with a Unit Self Check Test . . . . . . . 50

Displaying Operating Data During Normal Operation 52

Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 53

Selection of Operating Modes . . . . . . . . . . . . . . . . . . 54

Selecting CYCLE-SENTRY or Continuous Mode . . . 55

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . 56

Checking Software Revision . . . . . . . . . . . . . . . . . . . 57

Printing a Trip Report . . . . . . . . . . . . . . . . . . . . . . . . . 58

Initiating a Start of Trip . . . . . . . . . . . . . . . . . . . . . . . . 60

Displaying and Clearing Alarm Codes . . . . . . . . . . . . 61

Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Alarm Code 84 (Restart Null) . . . . . . . . . . . . . . . . . . . 65

Alarm Code 85 (Forced Unit Operation) . . . . . . . . . . . 65

Table of Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table of Contents

4

TG-VI Microprocessor Controller . . . . . . . . . . . . . . . . .25

CYCLE-SENTRY Start-Stop Controls . . . . . . . . . . 27

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DAS (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Opening the Front Doors . . . . . . . . . . . . . . . . . . . . . . . 29

Opening the Secondary Door Latch . . . . . . . . . . . 29

Closing the Front Doors . . . . . . . . . . . . . . . . . . . . . . . .30

Engine Compartment Components . . . . . . . . . . . . . . . 31

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . .32

TG-VI Controller Description . . . . . . . . . . . . . . . . . . 35

TG-VI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Upper and Lower Display . . . . . . . . . . . . . . . . . . . 37

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Remote Status Light (Optional) . . . . . . . . . . . . . . . . 43

Manual Pretrip Inspection

(Before Starting the Unit) . . . . . . . . . . . . . . . . . . . . .45

Unit Operation with TG-VI Controller . . . . . . . . . . . 47

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . 49

Starting the Unit with a Unit Self Check Test . . . . . . . 50

Displaying Operating Data During Normal Operation 52

Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 53

Selection of Operating Modes . . . . . . . . . . . . . . . . . . 54

Selecting CYCLE-SENTRY or Continuous Mode . . . 55

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . 56

Checking Software Revision . . . . . . . . . . . . . . . . . . . 57

Printing a Trip Report . . . . . . . . . . . . . . . . . . . . . . . . . 58

Initiating a Start of Trip . . . . . . . . . . . . . . . . . . . . . . . . 60

Displaying and Clearing Alarm Codes . . . . . . . . . . . . 61

Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Alarm Code 84 (Restart Null) . . . . . . . . . . . . . . . . . . . 65

Alarm Code 85 (Forced Unit Operation) . . . . . . . . . . . 65

Table of Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . 66

Page 6

Table of Contents

5

Loading and Enroute Inspections . . . . . . . . . . . . . . 83

Pre-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . . . 83

Post-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . . 85

Enroute Inspections . . . . . . . . . . . . . . . . . . . . . . . 86

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Electrical Control System . . . . . . . . . . . . . . . . . . . . . . 95

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . 96

Maintenance Inspection Schedule . . . . . . . . . . . . . 97

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Serial Number Locations . . . . . . . . . . . . . . . . . . . . .113

Emergency Cold Line . . . . . . . . . . . . . . . . . . . . . . .117

Recover Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . .118

California Proposition 65 Warning . . . . . . . . . . . . .119

Table of Contents

5

Loading and Enroute Inspections . . . . . . . . . . . . . . 83

Pre-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . . . 83

Post-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . . 85

Enroute Inspections . . . . . . . . . . . . . . . . . . . . . . . 86

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Electrical Control System . . . . . . . . . . . . . . . . . . . . . . 95

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . 96

Maintenance Inspection Schedule . . . . . . . . . . . . . 97

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Serial Number Locations . . . . . . . . . . . . . . . . . . . . .113

Emergency Cold Line . . . . . . . . . . . . . . . . . . . . . . .117

Recover Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . .118

California Proposition 65 Warning . . . . . . . . . . . . .119

Page 7

Table of Contents

6

Table of Contents

6

Page 8

7

List of Figures

Figure 1:Belt Warning

(Located on condenser housing) . . . . . . . . . . . . . . . . 14

Figure 2:Belt Replacement Caution

(Located on condenser housing) . . . . . . . . . . . . . . . . 14

Figure 3:Automatic Start Caution. . . . . . . . . . . . . . . . . 15

Figure 4:Fan Caution . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5:Door Latch Warning

(Located on curbside door) . . . . . . . . . . . . . . . . . . . . . 16

Figure 6:Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7:TK486V (Tier 2) . . . . . . . . . . . . . . . . . . . . . . 23

Figure 8:Control and Switch Panels . . . . . . . . . . . . . . 25

Figure 9:Door Latch Location . . . . . . . . . . . . . . . . . . . 29

Figure 10:Opening Secondary Door Latch . . . . . . . . . 29

Figure 11:Engine Compartment . . . . . . . . . . . . . . . . . 31

Figure 12:Relay Board . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 13:TG-VI Control Panel With all Possible

Icons and Characters Displayed . . . . . . . . . . . . . . . . . 35

Figure 14:Display Screen With all Possible Icons and

Characters Displayed . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 15:Upper and Lower Displays . . . . . . . . . . . . . .37

Figure 16:Standard Display . . . . . . . . . . . . . . . . . . . . .39

Figure 17:Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 18:Remote Status Light . . . . . . . . . . . . . . . . . .43

Figure 19:TG-VI Microprocessor Controller . . . . . . . . .47

Figure 20:Control and Switch Panels . . . . . . . . . . . . . .48

Figure 21:Unit Self Check . . . . . . . . . . . . . . . . . . . . . .50

Figure 22:Standard Display . . . . . . . . . . . . . . . . . . . . .52

Figure 23:Changing the Setpoint . . . . . . . . . . . . . . . . .53

Figure 24:Selecting CYCLE-SENTRY

or Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Figure 25:Initiating a Manual Defrost Cycle . . . . . . . . .56

Figure 26:Checking Software Revision . . . . . . . . . . . .57

Figure 27:Printing a Trip Report . . . . . . . . . . . . . . . . . .58

Figure 28:Initiating a Start of Trip . . . . . . . . . . . . . . . . .60

7

List of Figures

Figure 1:Belt Warning

(Located on condenser housing) . . . . . . . . . . . . . . . . 14

Figure 2:Belt Replacement Caution

(Located on condenser housing) . . . . . . . . . . . . . . . . 14

Figure 3:Automatic Start Caution. . . . . . . . . . . . . . . . . 15

Figure 4:Fan Caution . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5:Door Latch Warning

(Located on curbside door) . . . . . . . . . . . . . . . . . . . . . 16

Figure 6:Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7:TK486V (Tier 2) . . . . . . . . . . . . . . . . . . . . . . 23

Figure 8:Control and Switch Panels . . . . . . . . . . . . . . 25

Figure 9:Door Latch Location . . . . . . . . . . . . . . . . . . . 29

Figure 10:Opening Secondary Door Latch . . . . . . . . . 29

Figure 11:Engine Compartment . . . . . . . . . . . . . . . . . 31

Figure 12:Relay Board . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 13:TG-VI Control Panel With all Possible

Icons and Characters Displayed . . . . . . . . . . . . . . . . . 35

Figure 14:Display Screen With all Possible Icons and

Characters Displayed . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 15:Upper and Lower Displays . . . . . . . . . . . . . .37

Figure 16:Standard Display . . . . . . . . . . . . . . . . . . . . .39

Figure 17:Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 18:Remote Status Light . . . . . . . . . . . . . . . . . .43

Figure 19:TG-VI Microprocessor Controller . . . . . . . . .47

Figure 20:Control and Switch Panels . . . . . . . . . . . . . .48

Figure 21:Unit Self Check . . . . . . . . . . . . . . . . . . . . . .50

Figure 22:Standard Display . . . . . . . . . . . . . . . . . . . . .52

Figure 23:Changing the Setpoint . . . . . . . . . . . . . . . . .53

Figure 24:Selecting CYCLE-SENTRY

or Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Figure 25:Initiating a Manual Defrost Cycle . . . . . . . . .56

Figure 26:Checking Software Revision . . . . . . . . . . . .57

Figure 27:Printing a Trip Report . . . . . . . . . . . . . . . . . .58

Figure 28:Initiating a Start of Trip . . . . . . . . . . . . . . . . .60

Page 9

List of Figures

8

Figure 29:Alarm Symbol Location . . . . . . . . . . . . . . . .61

Figure 30:Loading Considerations . . . . . . . . . . . . . . . . 84

Figure 31:Unit Battery . . . . . . . . . . . . . . . . . . . . . . . . .90

Figure 32:Sequence for Connecting Jumper Cables . . 90

Figure 33:Unit Engine . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 34:Sequence for Disconnecting

Jumper Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Figure 35:Compressor Serial Number Location . . . . 113

Figure 36:Engine Serial Number Location . . . . . . . . 114

Figure 37:Unit Serial Number Plate Locations . . . . . 114

Figure 38:Unit Serial Number Plate . . . . . . . . . . . . . 115

List of Figures

8

Figure 29:Alarm Symbol Location . . . . . . . . . . . . . . . .61

Figure 30:Loading Considerations . . . . . . . . . . . . . . . . 84

Figure 31:Unit Battery . . . . . . . . . . . . . . . . . . . . . . . . .90

Figure 32:Sequence for Connecting Jumper Cables . . 90

Figure 33:Unit Engine . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 34:Sequence for Disconnecting

Jumper Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Figure 35:Compressor Serial Number Location . . . . 113

Figure 36:Engine Serial Number Location . . . . . . . . 114

Figure 37:Unit Serial Number Plate Locations . . . . . 114

Figure 38:Unit Serial Number Plate . . . . . . . . . . . . . 115

Page 10

9

Introduction

There is nothing complicated about operating and maintaining

your Thermo King unit, but a few minutes studying this

manual will be time well spent.

Performing pre-trip checks and enroute inspections on a

regular basis will m ini mi ze on -t he-r oad o perat ing problems. A

regular maintenance program will also help to keep your unit

in top operating condition. If factory reco mmended p rocedures

are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled

by a Thermo King dealer for four very important reasons:

• They are equipped with the factory recommended tools to

perform all service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the

repair and replacement of component parts is performed

by an authorized Thermo King dealer.

IMPORTANT: This manual is published for informational

purposes only and the information furnished herein should

not be considered as all-inclusive or meant to cover all

contingencies. If more information is re qu ired, consult your

Thermo King Service Directory for the location and

telephone number of the local dealer.

9

Introduction

There is nothing complicated about operating and maintaining

your Thermo King unit, but a few minutes studying this

manual will be time well spent.

Performing pre-trip checks and enroute inspections on a

regular basis will m ini mi ze on -t he-r oad o perat ing problems. A

regular maintenance program will also help to keep your unit

in top operating condition. If factory reco mmended p rocedures

are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled

by a Thermo King dealer for four very important reasons:

• They are equipped with the factory recommended tools to

perform all service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the

repair and replacement of component parts is performed

by an authorized Thermo King dealer.

IMPORTANT: This manual is published for informational

purposes only and the information furnished herein should

not be considered as all-inclusive or meant to cover all

contingencies. If more information is re qu ired, consult your

Thermo King Service Directory for the location and

telephone number of the local dealer.

Page 11

Introduction

10

Introduction

10

Page 12

11

Safety Precautions

Thermo King recommends t hat servicing be done only by a

Thermo King dealer. However, you should be aware of several

safety practices. This chapter gives basic safety precautions for

working with Thermo King units and describes the safety

stickers on your unit that you should be familiar with.

General Safety Practices

DANGER: NEVER operate the unit with the

compressor discharge valve closed. Doing so could

cause the compressor to explode, causing death or

serious injury.

WARNING: Always wear goggles or safety glasses

when working with or around the refrigeration system

or battery. Refrigerant or battery acid can cause

permanent damage if it comes in contact with your

eyes.

WARNING: Keep hands and loose clothing clear of

fans and belts at all times when the unit is operating

or when opening or closing compressor service

valves.

WARNING: Exposed coil fins can cause painful

lacerations. Service work on the evaporator or

condenser coils should be done by a certified Thermo

King technician.

WARNING: Do not apply heat to a closed cooling

system. Before applying heat to a cooling system,

drain it. Then flush it with water an d dr ai n t h e wa ter.

Antifreeze contains water and ethylene glycol. The

ethylene glycol is flammable and can ignite if the

antifreeze is heated enough to boil off the water.

11

Safety Precautions

Thermo King recommends t hat servicing be done only by a

Thermo King dealer. However, you should be aware of several

safety practices. This chapter gives basic safety precautions for

working with Thermo King units and describes the safety

stickers on your unit that you should be familiar with.

General Safety Practices

DANGER: NEVER operate the unit with the

compressor discharge valve closed. Doing so could

cause the compressor to explode, causing death or

serious injury.

WARNING: Always wear goggles or safety glasses

when working with or around the refrigeration system

or battery. Refrigerant or battery acid can cause

permanent damage if it comes in contact with your

eyes.

WARNING: Keep hands and loose clothing clear of

fans and belts at all times when the unit is operating

or when opening or closing compressor service

valves.

WARNING: Exposed coil fins can cause painful

lacerations. Service work on the evaporator or

condenser coils should be done by a certified Thermo

King technician.

WARNING: Do not apply heat to a closed cooling

system. Before applying heat to a cooling system,

drain it. Then flush it with water an d dr ai n t h e wa ter.

Antifreeze contains water and ethylene glycol. The

ethylene glycol is flammable and can ignite if the

antifreeze is heated enough to boil off the water.

Page 13

Safety Precautions

12

Automatic Start/Stop Operation

This unit is capable of automatic operation and could start at

any time without warning.

Electrical Hazard

Refrigerant

Although fluorocarbon refrigerants are classified as safe, use

caution when working with refrigerants or in areas where they

are being used.

CAUTION: Use extreme caution when drilling holes

in the unit. Drilling into electrical wiring or

refrigerant lines could cause a fire. Do not drill into

structural components.

WARNING: CYCLE-SENTRY Operation. The unit

can start at any time when the unit On/Off switch is

in the on position and the unit is operating in

CYCLE-SENTRY.

WARNING: Turn the unit On/Off switch to the Off

position before inspecting any part of the unit.

CAUTION: Turn off the high voltage power supply

and disconnect the electric cable before working on

the unit. Units with electric standby present a

potential electrical hazard.

DANGER: Fluorocarbon refrigerants can produce

toxic gases. In the presence of an open flame or

electrical short, these gases are severe respiratory

irritants CAPABLE OF CAUSING DEATH.

DANGER: Fluorocarbon refrigerants tend to

displace air and can cause oxygen depletion which

could result in DEATH BY SUFFOCA TION. Provide

adequate ventilation in enclosed or confined areas.

Safety Precautions

12

Automatic Start/Stop Operation

This unit is capable of automatic operation and could start at

any time without warning.

Electrical Hazard

Refrigerant

Although fluorocarbon refrigerants are classified as safe, use

caution when working with refrigerants or in areas where they

are being used.

CAUTION: Use extreme caution when drilling holes

in the unit. Drilling into electrical wiring or

refrigerant lines could cause a fire. Do not drill into

structural components.

WARNING: CYCLE-SENTRY Operation. The unit

can start at any time when the unit On/Off switch is

in the on position and the unit is operating in

CYCLE-SENTRY.

WARNING: Turn the unit On/Off switch to the Off

position before inspecting any part of the unit.

CAUTION: Turn off the high voltage power supply

and disconnect the electric cable before working on

the unit. Units with electric standby present a

potential electrical hazard.

DANGER: Fluorocarbon refrigerants can produce

toxic gases. In the presence of an open flame or

electrical short, these gases are severe respiratory

irritants CAPABLE OF CAUSING DEATH.

DANGER: Fluorocarbon refrigerants tend to

displace air and can cause oxygen depletion which

could result in DEATH BY SUFFOCA TION. Provide

adequate ventilation in enclosed or confined areas.

Page 14

Safety Precautions

13

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

First Aid

First Aid–Refrigerant

Eyes: For contact with liquid, immediately flush eyes with

large amounts of water. Get prompt medical attention.

Skin: Flush areas with large amounts of warm water. Do not

ap

ply heat. Wrap burns with dry, sterile, bulky dressing to

protect from infection or injury. Get prompt medical attention.

Inhalation: Move victim to fresh air and restore breathing if

ne

cessary. Stay with victim until emergency personnel arrive.

First Aid–Refrigerant Oil

Eyes: Immediately flush eyes with large amounts of water for

at least 15 minutes while holding the eyelids open. Get prompt

medical attention.

Skin: Remove contaminated clothing. Wash thoroughly with

so

ap and water. Get medical attention if irritation persists.

Inhalation:

Move victim to fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

WARNING: Fluorocarbon refrigerants evaporate

rapidly, freezing anything they contact if accidentally

released into the atmosphere from the liquid state.

W AR N ING : Al wa ys wear goggles or safety glasses to

protect eyes from refrigerant oil contact.

WARNING: Protect skin and clothing from

prolonged or repeated contact with refrigerant oil.

Rubber gloves are recommended.

WARNING: Wash thoroughly immediately after

handling refrigerant oil to prevent irritation.

Safety Precautions

13

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

First Aid

First Aid–Refrigerant

Eyes: For contact with liquid, immediately flush eyes with

large amounts of water. Get prompt medical attention.

Skin: Flush areas with large amounts of warm water. Do not

ap

ply heat. Wrap burns with dry, sterile, bulky dressing to

protect from infection or injury. Get prompt medical attention.

Inhalation: Move victim to fresh air and restore breathing if

ne

cessary. Stay with victim until emergency personnel arrive.

First Aid–Refrigerant Oil

Eyes: Immediately flush eyes with large amounts of water for

at least 15 minutes while holding the eyelids open. Get prompt

medical attention.

Skin: Remove contaminated clothing. Wash thoroughly with

so

ap and water. Get medical attention if irritation persists.

Inhalation:

Move victim to fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

WARNING: Fluorocarbon refrigerants evaporate

rapidly, freezing anything they contact if accidentally

released into the atmosphere from the liquid state.

W AR N ING : Al wa ys wear goggles or safety glasses to

protect eyes from refrigerant oil contact.

WARNING: Protect skin and clothing from

prolonged or repeated contact with refrigerant oil.

Rubber gloves are recommended.

WARNING: Wash thoroughly immediately after

handling refrigerant oil to prevent irritation.

Page 15

Safety Precautions

14

Ingestion: Do not induce vomiting. Immediately contact

local poison control center or physician.

Safety Decals And Locations

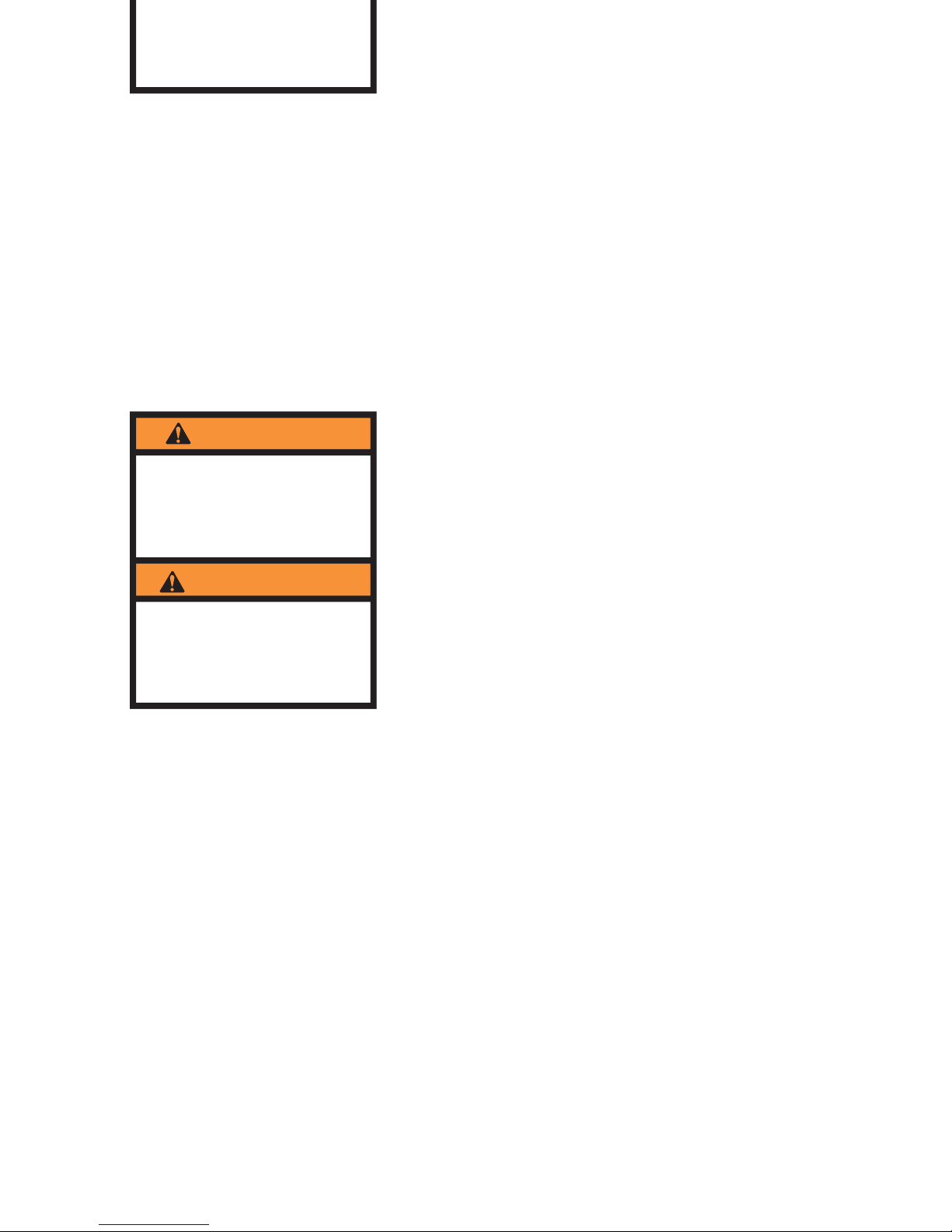

Figure 1: Belt Warning

(Located on condenser housing)

Figure 2: Belt Replacement Caution

(Located on condenser housing)

AKB65

AKB66

Safety Precautions

14

Ingestion: Do not induce vomiting. Immediately contact

local poison control center or physician.

Safety Decals And Locations

Figure 1: Belt Warning

(Located on condenser housing)

Figure 2: Belt Replacement Caution

(Located on condenser housing)

AKB65

AKB66

Page 16

Safety Precautions

15

Figure 3: Automatic Start Cauti on

(Locations vary depending on model. Decals are

located near areas that contain moving parts which

can cause severe injuries if hands or clothing become

tangled when unit automatically starts.)

Figure 4: Fan Caution

(Locations vary depending on model. Decals are

located near areas that contain fans which can cause

severe injuries when unit automatically starts.)

AKB67 AKB68

Safety Precautions

15

Figure 3: Automatic Start Cauti on

(Locations vary depending on model. Decals are

located near areas that contain moving parts which

can cause severe injuries if hands or clothing become

tangled when unit automatically starts.)

Figure 4: Fan Caution

(Locations vary depending on model. Decals are

located near areas that contain fans which can cause

severe injuries when unit automatically starts.)

AKB67 AKB68

Page 17

Safety Precautions

16

Figure 5: Door Latch Warning

(Located on curbside door)

WARNING

ATENCIÓN

NEW DOOR LATCH DESIGN

REQUIRES DOOR TO BE SLAMMED

SHUT BEFORE MOVING TRAILER.

FAILURE TO CLOSE DOOR FIRMLY

CAN ALLOW WIND TO TEAR DOOR

FROM REFRIGERATION UNIT AND

CAUSE INJURY TO OTHERS.

NUEVO DESEÑO DE CERRADURA

REQUIERE ASOTAR LA PUERTA ANTES

DE CONDUCIR EL TRAILER.

AL NO CERRAR LA PUERTA CON

FIRMEZA EL VIENTO PODRÍA

DESPRENDER LA PUERTA DE LA

UNIDAD DE REFRIGERACIÓN Y

CAUSAR DAÑOS A OTROS.

AEA2422

Safety Precautions

16

Figure 5: Door Latch Warning

(Located on curbside door)

WARNING

ATENCIÓN

NEW DOOR LATCH DESIGN

REQUIRES DOOR TO BE SLAMMED

SHUT BEFORE MOVING TRAILER.

FAILURE TO CLOSE DOOR FIRMLY

CAN ALLOW WIND TO TEAR DOOR

FROM REFRIGERATION UNIT AND

CAUSE INJURY TO OTHERS.

NUEVO DESEÑO DE CERRADURA

REQUIERE ASOTAR LA PUERTA ANTES

DE CONDUCIR EL TRAILER.

AL NO CERRAR LA PUERTA CON

FIRMEZA EL VIENTO PODRÍA

DESPRENDER LA PUERTA DE LA

UNIDAD DE REFRIGERACIÓN Y

CAUSAR DAÑOS A OTROS.

AEA2422

Page 18

17

EPA Emission Control System Warranty

Statement

Thermo King warrants to the initial owner and each subsequent

owner that the certified, non-road diesel engine in your unit is:

1. Designed, built and equipped so as to conform, at the time

of sale, with all applicable regulations adopted by the

United States Environmental Protection Agency (EPA).

2. Free from defects in materials and workmanship in

specific emission related parts for a period of five years or

3,000 hours of operation, whi chever comes first, after date

of delivery to the initial owner.

If an emission-related part or component fails during the

warranty period, it will be repaired or replaced. Any such part

or component repaired or replaced under warranty is warranted

for the warranty period.

During the term of this warranty, Thermo King will provide,

through a Thermo King authorized service dealer or other

establishment authorized by Thermo King, repair or

replacement of any warranted part at no char ge to the no n-road

engine owner.

In emergency, repairs may be performed at any service

establishment, or by the owner, using any replacement part.

Thermo King will reimburse the owner for their expenses,

including diagnostic charges for such emergency repair. These

expenses shall not exceed Thermo King’ s suggested retail price

for all warranted parts replaced, and labor changes based on

Thermo King’s reco mmend ed time allowance for the warranty

repair and the geographically appropriate hourly labor rate.

17

EPA Emission Control System Warranty

Statement

Thermo King warrants to the initial owner and each subsequent

owner that the certified, non-road diesel engine in your unit is:

1. Designed, built and equipped so as to conform, at the time

of sale, with all applicable regulations adopted by the

United States Environmental Protection Agency (EPA).

2. Free from defects in materials and workmanship in

specific emission related parts for a period of five years or

3,000 hours of operation, whi chever comes first, after date

of delivery to the initial owner.

If an emission-related part or component fails during the

warranty period, it will be repaired or replaced. Any such part

or component repaired or replaced under warranty is warranted

for the warranty period.

During the term of this warranty, Thermo King will provide,

through a Thermo King authorized service dealer or other

establishment authorized by Thermo King, repair or

replacement of any warranted part at no char ge to the no n-road

engine owner.

In emergency, repairs may be performed at any service

establishment, or by the owner, using any replacement part.

Thermo King will reimburse the owner for their expenses,

including diagnostic charges for such emergency repair. These

expenses shall not exceed Thermo King’ s suggested retail price

for all warranted parts replaced, and labor changes based on

Thermo King’s reco mmend ed time allowance for the warranty

repair and the geographically appropriate hourly labor rate.

Page 19

EPA Emission Control System Warranty Statement

18

Any replacement part can be used for maintenance or repairs.

The owner should ensure that such parts are equivalent in

design and durability to genuine Thermo King parts. However,

Thermo King is not liable for parts that are not genuine

Thermo King parts.

A part not being available within 30 days or repair not being

completed within 30 days constitutes an emergency.

As a condition of reimbursement, replaced parts and received

invoices must be presented at a place of business of a Thermo

King authorized service dealer or other establi shment

authorized by Thermo King.

This warranty covers the following emission-related parts and

components:

• Fuel Injection System

• Intake Manifold

•Exhaust Manifold

• Miscellaneous hoses, clamps, connectors and sealing

devices used in the above systems.

If failure of one of these parts or components results in failure

of another part or component, both will be covered by this

warranty.

Responsibilities

This warranty is subject to the following:

Thermo King Corporation

Responsibilities

During the emission warranty period, if a defect in material or

workmanship of a warranted part or component is found,

Thermo King will provide:

• New, remanufactured, or repaired parts or components

required to correct the defect.

NOTE: Items replaced under this warranty become the

property of Thermo King.

• Labor, dur ing normal working h ours, req uired to make t he

warranty repair. This includes diagnosis and labor to

remove and install the engine, if necessary.

EPA Emission Control System Warranty Statement

18

Any replacement part can be used for maintenance or repairs.

The owner should ensure that such parts are equivalent in

design and durability to genuine Thermo King parts. However,

Thermo King is not liable for parts that are not genuine

Thermo King parts.

A part not being available within 30 days or repair not being

completed within 30 days constitutes an emergency.

As a condition of reimbursement, replaced parts and received

invoices must be presented at a place of business of a Thermo

King authorized service dealer or other establi shment

authorized by Thermo King.

This warranty covers the following emission-related parts and

components:

• Fuel Injection System

• Intake Manifold

•Exhaust Manifold

• Miscellaneous hoses, clamps, connectors and sealing

devices used in the above systems.

If failure of one of these parts or components results in failure

of another part or component, both will be covered by this

warranty.

Responsibilities

This warranty is subject to the following:

Thermo King Corporation

Responsibilities

During the emission warranty period, if a defect in material or

workmanship of a warranted part or component is found,

Thermo King will provide:

• New, remanufactured, or repaired parts or components

required to correct the defect.

NOTE: Items replaced under this warranty become the

property of Thermo King.

• Labor, dur ing normal working h ours, req uired to make t he

warranty repair. This includes diagnosis and labor to

remove and install the engine, if necessary.

Page 20

EPA Emission Control System Warranty Statement

19

Owner Responsibilities

During the emission warranty period, the owner is responsible

for:

• The performance of all required maintenance. A warranty

claim will not be denied because the scheduled

maintenance was not performed. However, if the lack of

required maintenance was the reason for the repair, then

the claim will be denied.

• Premium of overtime cost.

• Cost to investigate complaints that are not caused by

defects in Thermo King material or workmanship.

• Providing timely notice of a warrantable failure and

promptly making the product available for re pair.

Limitations

Thermo King is not responsible for resultant damages to an

emission-related part or component resulting from:

• Any application or installation Thermo King deems

improper as explained in this Operator’s Manual, or any

other manuals provided for the unit.

• Attachments, accessory items, or parts not authorized for

use by Thermo King.

• Improper off-road engine maintenance, repair or abuse.

• Owner’s unreasonable delay in making the product

available after being notified of a potential product

problem.

This warranty is in addition to Thermo King’s standard

warranty applicable to the off-road engine product involved.

Remedies under this warranty are limited to the provision of

material and services as specified herein. Thermo King is not

responsible for incidental or consequential damages such as

downtime or loss of engi ne powered equipment .

EPA Emission Control System Warranty Statement

19

Owner Responsibilities

During the emission warranty period, the owner is responsible

for:

• The performance of all required maintenance. A warranty

claim will not be denied because the scheduled

maintenance was not performed. However, if the lack of

required maintenance was the reason for the repair, then

the claim will be denied.

• Premium of overtime cost.

• Cost to investigate complaints that are not caused by

defects in Thermo King material or workmanship.

• Providing timely notice of a warrantable failure and

promptly making the product available for re pair.

Limitations

Thermo King is not responsible for resultant damages to an

emission-related part or component resulting from:

• Any application or installation Thermo King deems

improper as explained in this Operator’s Manual, or any

other manuals provided for the unit.

• Attachments, accessory items, or parts not authorized for

use by Thermo King.

• Improper off-road engine maintenance, repair or abuse.

• Owner’s unreasonable delay in making the product

available after being notified of a potential product

problem.

This warranty is in addition to Thermo King’s standard

warranty applicable to the off-road engine product involved.

Remedies under this warranty are limited to the provision of

material and services as specified herein. Thermo King is not

responsible for incidental or consequential damages such as

downtime or loss of engi ne powered equipment .

Page 21

EPA Emission Control System Warranty Statement

20

EPA Emission Control System Warranty Statement

20

Page 22

21

Unit Description

Unit Overview

The Thermo King SB-200TG is a one piece, self-contained,

diesel powered, air cooling/heating unit operating under the

control of a TG-VI programmable microprocessor controller.

The unit mounts on the front of the trailer with the evaporator

extending through an opening in the front wall.

The unit is available as a Model 30 and features cooling and

heating using a quiet running Thermo King TK486V engine .

Figure 6: Front View

21

Unit Description

Unit Overview

The Thermo King SB-200TG is a one piece, self-contained,

diesel powered, air cooling/heating unit operating under the

control of a TG-VI programmable microprocessor controller.

The unit mounts on the front of the trailer with the evaporator

extending through an opening in the front wall.

The unit is available as a Model 30 and features cooling and

heating using a quiet running Thermo King TK486V engine .

Figure 6: Front View

Page 23

Unit Description

22

Design Features

The following chart lists key design features and options.

● Standard Features

❍ Option/Factory installed

❏ Option/Dealer Installed

Key Features & Options SB-200TG

EMI-3000

●

High-Capacity Condenser Coil ●

Easy-Access D oor Design ●

Composite Exterior Panels ●

Long-Life Coolant/Silicone Hoses ●

Standard Unit Color White ●

Standard Grille Color Black ●

Directional Air Delivery ●

Vibration Isolation System ●

Aluminum Undermount Fuel Tank 50 Gal.

(186 Liter)

●

DAS Data Logger ❍ / ❏

Remote Status Light ❏

Unit Description

22

Design Features

The following chart lists key design features and options.

● Standard Features

❍ Option/Factory installed

❏ Option/Dealer Installed

Key Features & Options SB-200TG

EMI-3000

●

High-Capacity Condenser Coil ●

Easy-Access D oor Design ●

Composite Exterior Panels ●

Long-Life Coolant/Silicone Hoses ●

Standard Unit Color White ●

Standard Grille Color Black ●

Directional Air Delivery ●

Vibration Isolation System ●

Aluminum Undermount Fuel Tank 50 Gal.

(186 Liter)

●

DAS Data Logger ❍ / ❏

Remote Status Light ❏

Page 24

Unit Description

23

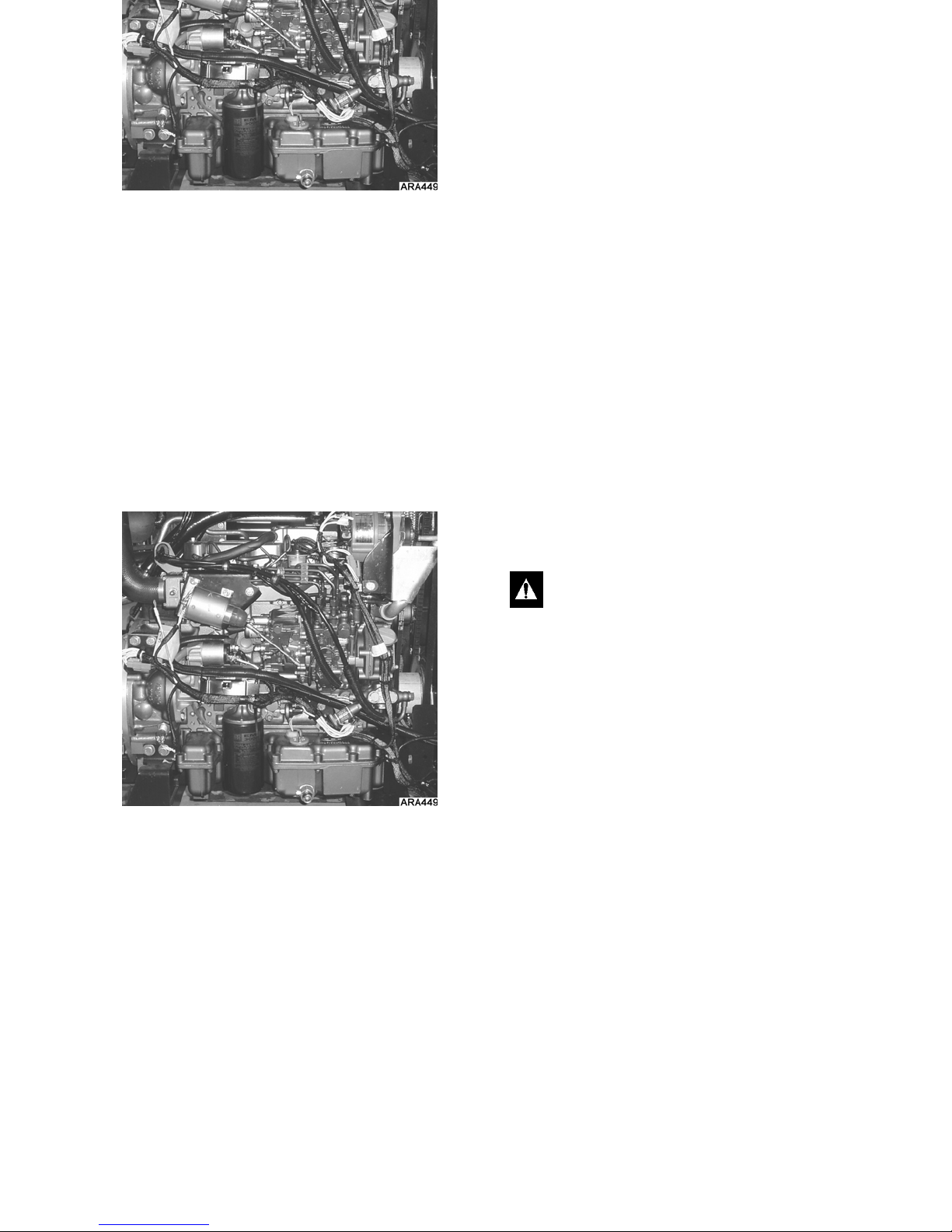

Diesel Engine

The unit uses a quiet running TK486V (Tier 2), which is a

4-cylinder, water cooled, direct injection diesel engine. The

engine is coupled directly to the compressor. Belts transmit

power to the unit fans, alternator and water pump.

Figure 7: T K486 V (Tier 2)

ELC (Extended Life Coolant)

ELC (Extended Life Coolant) is standard equipment. The

maintenance interval for ELC is five years or 12,000 hours. A

nameplate on the coolant expansion tank identifies units with

ELC (see “Safety Decals and Locations”). The new engine

coolant, Chevron Extended Life Coolant, is RED in color

instead of the previous GREEN or BLUE-GREEN colored

conventional coolants.

NOTE: The use of 50/50% pre-mixed ELC is recommended

to assure that de-ionized water is being used. If 100% full

strength concentrate is used, de-ionized or distilled water is

recommended instead of tap water to insure the integrity of

the cooling system is maintained.

CAUTION: Do not add “GREEN” or

“BLUE-GREEN” conventional coolant to cooling

systems using “RED” Extended Life Coolant, except

in an emergency. If conventional coolant is added to

Extended Life Coolant, the coolant must be changed

after 2 years instead of 5 years.

Unit Description

23

Diesel Engine

The unit uses a quiet running TK486V (Tier 2), which is a

4-cylinder, water cooled, direct injection diesel engine. The

engine is coupled directly to the compressor. Belts transmit

power to the unit fans, alternator and water pump.

Figure 7: T K486 V (Tier 2)

ELC (Extended Life Coolant)

ELC (Extended Life Coolant) is standard equipment. The

maintenance interval for ELC is five years or 12,000 hours. A

nameplate on the coolant expansion tank identifies units with

ELC (see “Safety Decals and Locations”). The new engine

coolant, Chevron Extended Life Coolant, is RED in color

instead of the previous GREEN or BLUE-GREEN colored

conventional coolants.

NOTE: The use of 50/50% pre-mixed ELC is recommended

to assure that de-ionized water is being used. If 100% full

strength concentrate is used, de-ionized or distilled water is

recommended instead of tap water to insure the integrity of

the cooling system is maintained.

CAUTION: Do not add “GREEN” or

“BLUE-GREEN” conventional coolant to cooling

systems using “RED” Extended Life Coolant, except

in an emergency. If conventional coolant is added to

Extended Life Coolant, the coolant must be changed

after 2 years instead of 5 years.

Page 25

Unit Description

24

EMI 3000

EMI 3000 is an extended maintenance interval package. It is

standard equipment. The EMI 3000 package consists of the

following key components:

• New EMI 3000-Hour Cyclonic Air Cleaner Assembly an d

Air Cleaner Element

• New EMI 3000-Hour Fuel Filter (black with gold

lettering)

• New EMI 3000-Hour Dual Element Oil Filter (black with

gold lettering)

• API Rating CI-4 Mineral Oil

• Five Year or 12,000 Hour ELC (Extended Life Coolant)

The EMI package allows standard maintenance intervals to be

extended to 3,000 hours, or 2 years, whichever occurs first.

NOTE: Units equipped with the EMI 3000 package do

require regular inspection in accordance with Thermo King's

maintenance recommendations.

NOTE: The new EMI 3000 oil filters and new EMI 3000 air

cleaners are NOT interchangeable with the older style oil

filters and air cl eaners.

Thermo King X430L Compressor

The unit is equipped with a Ther mo King X430L, four -cylinder

compressor with 30 cu. in. (492 cm

3

) displacement. The unit is

also equipped with a compressor oil filter.

Unit Description

24

EMI 3000

EMI 3000 is an extended maintenance interval package. It is

standard equipment. The EMI 3000 package consists of the

following key components:

• New EMI 3000-Hour Cyclonic Air Cleaner Assembly an d

Air Cleaner Element

• New EMI 3000-Hour Fuel Filter (black with gold

lettering)

• New EMI 3000-Hour Dual Element Oil Filter (black with

gold lettering)

• API Rating CI-4 Mineral Oil

• Five Year or 12,000 Hour ELC (Extended Life Coolant)

The EMI package allows standard maintenance intervals to be

extended to 3,000 hours, or 2 years, whichever occurs first.

NOTE: Units equipped with the EMI 3000 package do

require regular inspection in accordance with Thermo King's

maintenance recommendations.

NOTE: The new EMI 3000 oil filters and new EMI 3000 air

cleaners are NOT interchangeable with the older style oil

filters and air cl eaners.

Thermo King X430L Compressor

The unit is equipped with a Ther mo King X430L, four -cylinder

compressor with 30 cu. in. (492 cm

3

) displacement. The unit is

also equipped with a compressor oil filter.

Page 26

Unit Description

25

TG-VI Microprocessor Controller

Thermo King has applied the newest technological advances to

develop a programmable microprocessor controller that

controls unit functioning and displays operating information

quickly and accurately .

Features include:

Thermometer: Displays return air temperature with 0.1

degree accuracy.

Thermostat: Provides temperature control from -20 to 80 F

(- 28 to 27 C) in 1.0 degree increments.

Defrost Control: The controller is programmed to

automatically initiate timed or demand defrost cycles. The

operator can also manually initiate a defrost cycle. See

“Defrost” on page 27.

Alarm: Can detect and display alarm conditions. Refer to the

Operating and Alarm Codes Sections later in this manual.

1. Control Panel 4. Computer Port (Optional)

2. Display 5. Printer Port (Optional)

3. Keypad 6. On/Off Switch

Figure 8: Control and Switch Panels

ANA03

AJA1070

4

1

2

3

5

6

COMPUTER PRINTER

Unit Description

25

TG-VI Microprocessor Controller

Thermo King has applied the newest technological advances to

develop a programmable microprocessor controller that

controls unit functioning and displays operating information

quickly and accurately .

Features include:

Thermometer: Displays return air temperature with 0.1

degree accuracy.

Thermostat: Provides temperature control from -20 to 80 F

(- 28 to 27 C) in 1.0 degree increments.

Defrost Control: The controller is programmed to

automatically initiate timed or demand defrost cycles. The

operator can also manually initiate a defrost cycle. See

“Defrost” on page 27.

Alarm: Can detect and display alarm conditions. Refer to the

Operating and Alarm Codes Sections later in this manual.

1. Control Panel 4. Computer Port (Optional)

2. Display 5. Printer Port (Optional)

3. Keypad 6. On/Off Switch

Figure 8: Control and Switch Panels

ANA03

AJA1070

4

1

2

3

5

6

COMPUTER PRINTER

Page 27

Unit Description

26

Depending on the air temperature in the trailer sensed by the

TG-VI Microprocessor Controller, the unit will operate in one

of the following modes:

In Continuous Run Operation Mode:

• High Speed Co ol

• Low Speed Cool

• Low Speed Heat

• High Speed Heat

•Defrost.

In CYCLE-SENTRY Operation Mode:

• High Speed Cool

• Low Speed Cool

• Null (Engine Off)

• Low Speed Heat

• High Speed Heat

•Defrost.

Generally, the unit will operate in low speed switching back

and forth from cooling to heating as necessary, thus controlling

the temperature in the trailer.

On very hot days, with the setpoint at a low temperature, the

unit may cycle between high speed cool and low speed cool

without switching into a heating cycle.

On very cold days, the unit may cycle between high speed heat

and low speed heat. The unit may switch into cooling for short

periods of time.

CAUTION: Firmly close the controller access door

after operating the microprocessor controller or

before starting a trip. The control panel might be

damaged in transit if the door is not firmly closed.

Unit Description

26

Depending on the air temperature in the trailer sensed by the

TG-VI Microprocessor Controller, the unit will operate in one

of the following modes:

In Continuous Run Operation Mode:

• High Speed Co ol

• Low Speed Cool

• Low Speed Heat

• High Speed Heat

•Defrost.

In CYCLE-SENTRY Operation Mode:

• High Speed Cool

• Low Speed Cool

• Null (Engine Off)

• Low Speed Heat

• High Speed Heat

•Defrost.

Generally, the unit will operate in low speed switching back

and forth from cooling to heating as necessary, thus controlling

the temperature in the trailer.

On very hot days, with the setpoint at a low temperature, the

unit may cycle between high speed cool and low speed cool

without switching into a heating cycle.

On very cold days, the unit may cycle between high speed heat

and low speed heat. The unit may switch into cooling for short

periods of time.

CAUTION: Firmly close the controller access door

after operating the microprocessor controller or

before starting a trip. The control panel might be

damaged in transit if the door is not firmly closed.

Page 28

Unit Description

27

CYCLE-SENTRY Start-Stop Controls

The CYCLE-SENTRY Start-Stop fuel saving system provides

optimum operating economy.

CYCLE-SENTRY automatically starts the unit on

microprocessor demand, and shuts down the unit when all

demands are satisfied.

The system automatically monitors and maintains

compartment temperatures, the engine block temperature and

battery charge levels at a point where quick, easy starts are

possible.

Defrost

Frost gradually builds-up on evaporator coils as a result o f

normal operation. The unit uses hot refrigerant to defrost the

evaporator coils. Hot refrigerant gas passes through the

evaporator coil and melts the frost. The water flows through

collection drain tubes onto the ground. The methods of defrost

initiation are Manual and Automatic.

Automatic Defrost: The controller is programmed to

automatically initiate timed or demand defrost cycles. Defrost

intervals are set at the factory at 2, 4 6, 8, 10, or 12 hours. The

unit can enter a demand defrost cycle as often as every 30

minutes if required.

Manual Defrost: The operator manually initiates a defrost

cycle.

NOTE: The unit will not perform a Manual Defrost cycle

unless the O

N/OFF switch is set to ON, the unit is running in

Continuous or CYCLE -SENTRY mode, (or shut down in

CYCLE-SENTRY Null mode), and the coil temperature is

below 45 F (7.2 C).

WARNING: Set the unit ON/OFF switch to OFF

before opening doors or inspecting any part of the

unit. With the unit O

N/OFF switch in the ON position,

the unit may start at any time without warnin g.

Unit Description

27

CYCLE-SENTRY Start-Stop Controls

The CYCLE-SENTRY Start-Stop fuel saving system provides

optimum operating economy.

CYCLE-SENTRY automatically starts the unit on

microprocessor demand, and shuts down the unit when all

demands are satisfied.

The system automatically monitors and maintains

compartment temperatures, the engine block temperature and

battery charge levels at a point where quick, easy starts are

possible.

Defrost

Frost gradually builds-up on evaporator coils as a result o f

normal operation. The unit uses hot refrigerant to defrost the

evaporator coils. Hot refrigerant gas passes through the

evaporator coil and melts the frost. The water flows through

collection drain tubes onto the ground. The methods of defrost

initiation are Manual and Automatic.

Automatic Defrost: The controller is programmed to

automatically initiate timed or demand defrost cycles. Defrost

intervals are set at the factory at 2, 4 6, 8, 10, or 12 hours. The

unit can enter a demand defrost cycle as often as every 30

minutes if required.

Manual Defrost: The operator manually initiates a defrost

cycle.

NOTE: The unit will not perform a Manual Defrost cycle

unless the O

N/OFF switch is set to ON, the unit is running in

Continuous or CYCLE -SENTRY mode, (or shut down in

CYCLE-SENTRY Null mode), and the coil temperature is

below 45 F (7.2 C).

WARNING: Set the unit ON/OFF switch to OFF

before opening doors or inspecting any part of the

unit. With the unit O

N/OFF switch in the ON position,

the unit may start at any time without warnin g.

Page 29

Unit Description

28

DAS (Optional)

The DAS (Data Acquisition System) is an independent data

logger that logs information from dedicated external DAS

sensors and inputs. The DAS features (up to six) directly

connected sensors. The DAS is also connected through a serial

port to the unit microprocessor. Sensor readings can be viewed

on the microprocessor keyboard panel using the S

ELECT key.

See “Figure 8: Control and Switch Panels,” on page 25. The

DAS allows unit operating information, operating events,

alarm codes and compartment temperatures to be logged as

well. The data can be retrieved using an IBM

®

PC compatible

laptop or desktop comp uter and Thermo King WinTrac 4.1 (or

higher) software. The computer is connected to the computer

port on the front of t he control box . See “Figur e 8: Control and

Switch Panels,” on pag e 25. Detaile d graph or ta ble trip repo rts

can then be created.

A hand-held printer can be connected to the printe r por t on th e

front of the control box to print out the DAS sensor readings.

Refer to the DAS Data Acquisition System Manual TK 50565

for more information.

Unit Description

28

DAS (Optional)

The DAS (Data Acquisition System) is an independent data

logger that logs information from dedicated external DAS

sensors and inputs. The DAS features (up to six) directly

connected sensors. The DAS is also connected through a serial

port to the unit microprocessor. Sensor readings can be viewed

on the microprocessor keyboard panel using the S

ELECT key.

See “Figure 8: Control and Switch Panels,” on page 25. The

DAS allows unit operating information, operating events,

alarm codes and compartment temperatures to be logged as

well. The data can be retrieved using an IBM

®

PC compatible

laptop or desktop comp uter and Thermo King WinTrac 4.1 (or

higher) software. The computer is connected to the computer

port on the front of t he control box . See “Figur e 8: Control and

Switch Panels,” on pag e 25. Detaile d graph or ta ble trip repo rts

can then be created.

A hand-held printer can be connected to the printe r por t on th e

front of the control box to print out the DAS sensor readings.

Refer to the DAS Data Acquisition System Manual TK 50565

for more information.

Page 30

Unit Description

29

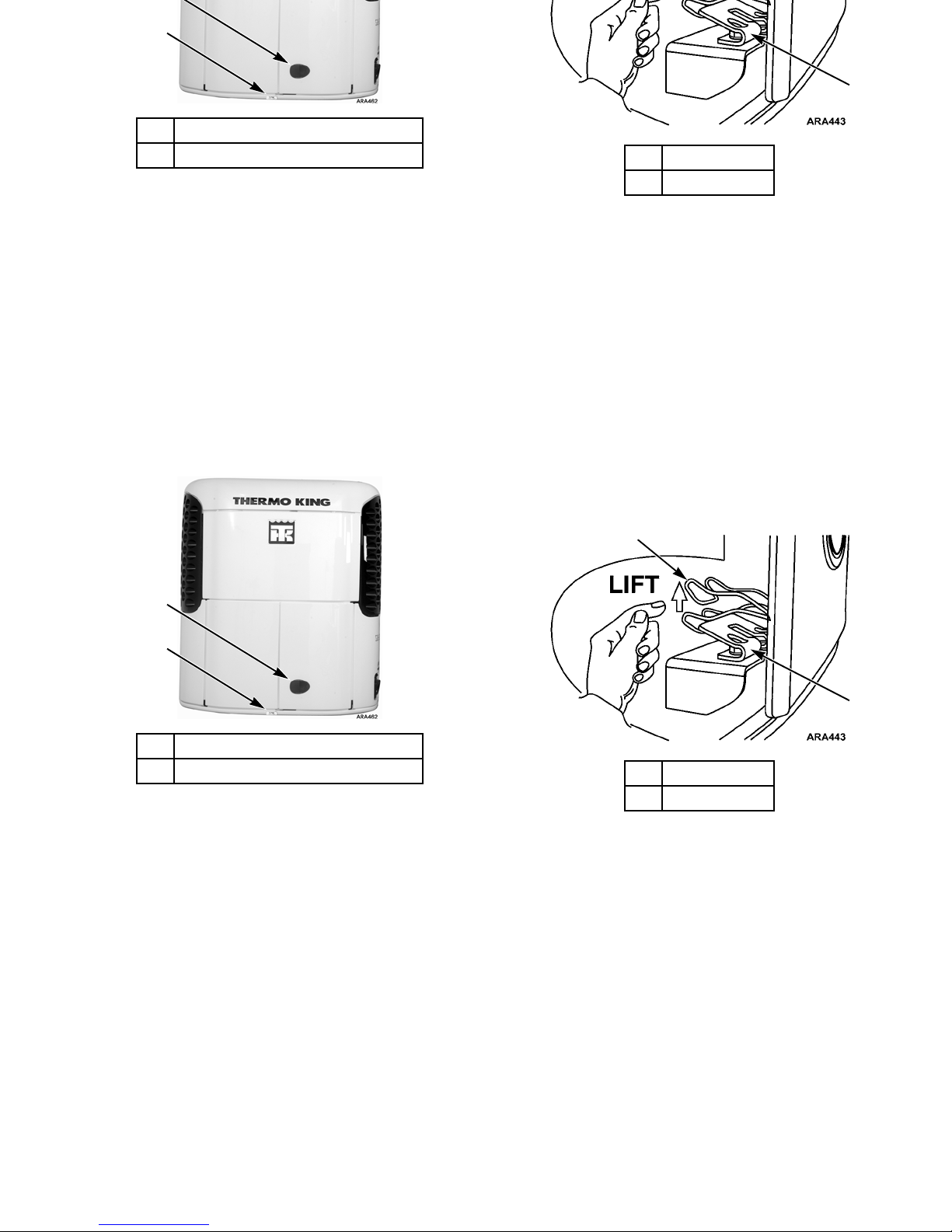

Opening the Front Doors

Pull the door latch handle to open the door and access the

engine compartment.

Opening the Secondary Door Latch

These units are also equipped with a secondary door latch. A

secondary door latch nameplate is located below the front

doors. After opening the door latch, reach between the front

doors and lift the spring latch over the spring catch while

opening the door.

1. Door Latch

2. Secondary Door Latch Nameplate

Figure 9: Door Latch Location

1

2

1. Spring Latch

2. Spring Catch

Figure 10: Opening Secondary Door Latch

1

2

Unit Description

29

Opening the Front Doors

Pull the door latch handle to open the door and access the

engine compartment.

Opening the Secondary Door Latch

These units are also equipped with a secondary door latch. A

secondary door latch nameplate is located below the front

doors. After opening the door latch, reach between the front

doors and lift the spring latch over the spring catch while

opening the door.

1. Door Latch

2. Secondary Door Latch Nameplate

Figure 9: Door Latch Location

1

2

1. Spring Latch

2. Spring Catch

Figure 10: Opening Secondary Door Latch

1

2

Page 31

Unit Description

30

Closing the Front Doors

Slam the door to close it. Do not push the door closed while

holding the door latch handle open or the door will not close

properly.

Unit Description

30

Closing the Front Doors

Slam the door to close it. Do not push the door closed while

holding the door latch handle open or the door will not close

properly.

Page 32

Unit Description

31

Engine Compartment Components

The following maintenance items can be checked visually.

Air Filter Restriction Indicator: The air filter restriction

indicator is attached to the engine intake manifold. When the

diaphragm indicates 25, service the air filter. Press the button

on the top of the restriction indicator to reset after servicing the

air cleaner.

Compressor Oil Sight Glass: Use this sight glass to check

the compressor oil level. Check the compressor oil when there

is evidence of oil loss (leaks). Refer to the unit Maintenance

Manual for the correct procedure.

Engine Oil Dipstick: Use the engine oil dipstick to check

the engine oil level.

1. Air Filter Restriction Indicator

2. Receiver Tank Sight Glass

3. Engine Oil Dipstick

4. Compressor Oil Sight Glass

Figure 11: Engine Compartment

21

34

WARNING: The unit can start at any time without

warning. Place the On/Off switch in the Off position

before inspecting any part of the unit.

CAUTION: Make sure the engi ne is turned of f before

attempting to check the engine oil.

Unit Description

31

Engine Compartment Components

The following maintenance items can be checked visually.

Air Filter Restriction Indicator: The air filter restriction

indicator is attached to the engine intake manifold. When the

diaphragm indicates 25, service the air filter. Press the button

on the top of the restriction indicator to reset after servicing the

air cleaner.

Compressor Oil Sight Glass: Use this sight glass to check

the compressor oil level. Check the compressor oil when there

is evidence of oil loss (leaks). Refer to the unit Maintenance

Manual for the correct procedure.

Engine Oil Dipstick: Use the engine oil dipstick to check

the engine oil level.

1. Air Filter Restriction Indicator

2. Receiver Tank Sight Glass

3. Engine Oil Dipstick

4. Compressor Oil Sight Glass

Figure 11: Engine Compartment

21

34

WARNING: The unit can start at any time without

warning. Place the On/Off switch in the Off position

before inspecting any part of the unit.

CAUTION: Make sure the engi ne is turned of f before

attempting to check the engine oil.

Page 33

Unit Description

32

Receiver Tank Sight Glass: This sight glass indicates the

level of refrigerant in the receiver tank.

Operate the unit in high speed cool for approximately 15

minutes to stabilize operating conditions and temperature

before attempting to check the refrigerant.

NOTE: If the ball floats, there is sufficient refrigerant in the

unit for that load at that particular trailer temperat ure. This

test does not determine if the unit contains a full charge or an

overcharge of refrigerant.

Unit Protection Devices

Fuse Link (Current Limiter): The fuse link is located in the

positive battery cable. The fuse link protects the electric

system from a short. If the fuse link burns out, replace it by

replacing the positive battery cable.

High Pressure Cutout Switch: The high pressur e cutout

switch (HPCO) is located on the compressor discharge

manifold. If the compressor discharge pressure becomes

excessive, the switch opens the circuit to the run relay to stop

the unit. The microprocessor will record Alarm Code 10.

High Pressure Relief Valve: This valve is designed to

relieve excessive pressure in the refrigeration system. It is

located on the receiver tank. If the high pressure relief valve

opens, much of the refrigerant will be lost. Take the unit to a

Thermo King dealer if this occurs.

Low Oil Level Switch: The low oil level switch closes if the

oil drops below an acceptable level. If it stays closed for a

specified time, the microprocessor shuts the unit down and

records Alarm Code 66.

Low Oil Pressure Switch: The low oil pressure switch

closes if the oil pressure drops below an acceptable level. If it

stays closed for a specified time, the microprocessor shuts the

unit down and records alarm code 19.

Preheat Buzzer: The preheat buzzer sounds when the

controller energizes the preheat relay. This warns anyone near

the unit that the controller is about to start the engine.

Unit Description

32

Receiver Tank Sight Glass: This sight glass indicates the

level of refrigerant in the receiver tank.

Operate the unit in high speed cool for approximately 15

minutes to stabilize operating conditions and temperature

before attempting to check the refrigerant.

NOTE: If the ball floats, there is sufficient refrigerant in the

unit for that load at that particular trailer temperat ure. This

test does not determine if the unit contains a full charge or an

overcharge of refrigerant.

Unit Protection Devices

Fuse Link (Current Limiter): The fuse link is located in the

positive battery cable. The fuse link protects the electric

system from a short. If the fuse link burns out, replace it by

replacing the positive battery cable.

High Pressure Cutout Switch: The high pressur e cutout

switch (HPCO) is located on the compressor discharge

manifold. If the compressor discharge pressure becomes

excessive, the switch opens the circuit to the run relay to stop

the unit. The microprocessor will record Alarm Code 10.

High Pressure Relief Valve: This valve is designed to

relieve excessive pressure in the refrigeration system. It is

located on the receiver tank. If the high pressure relief valve

opens, much of the refrigerant will be lost. Take the unit to a

Thermo King dealer if this occurs.

Low Oil Level Switch: The low oil level switch closes if the

oil drops below an acceptable level. If it stays closed for a

specified time, the microprocessor shuts the unit down and

records Alarm Code 66.

Low Oil Pressure Switch: The low oil pressure switch

closes if the oil pressure drops below an acceptable level. If it

stays closed for a specified time, the microprocessor shuts the

unit down and records alarm code 19.

Preheat Buzzer: The preheat buzzer sounds when the

controller energizes the preheat relay. This warns anyone near

the unit that the controller is about to start the engine.

Page 34

Unit Description

33

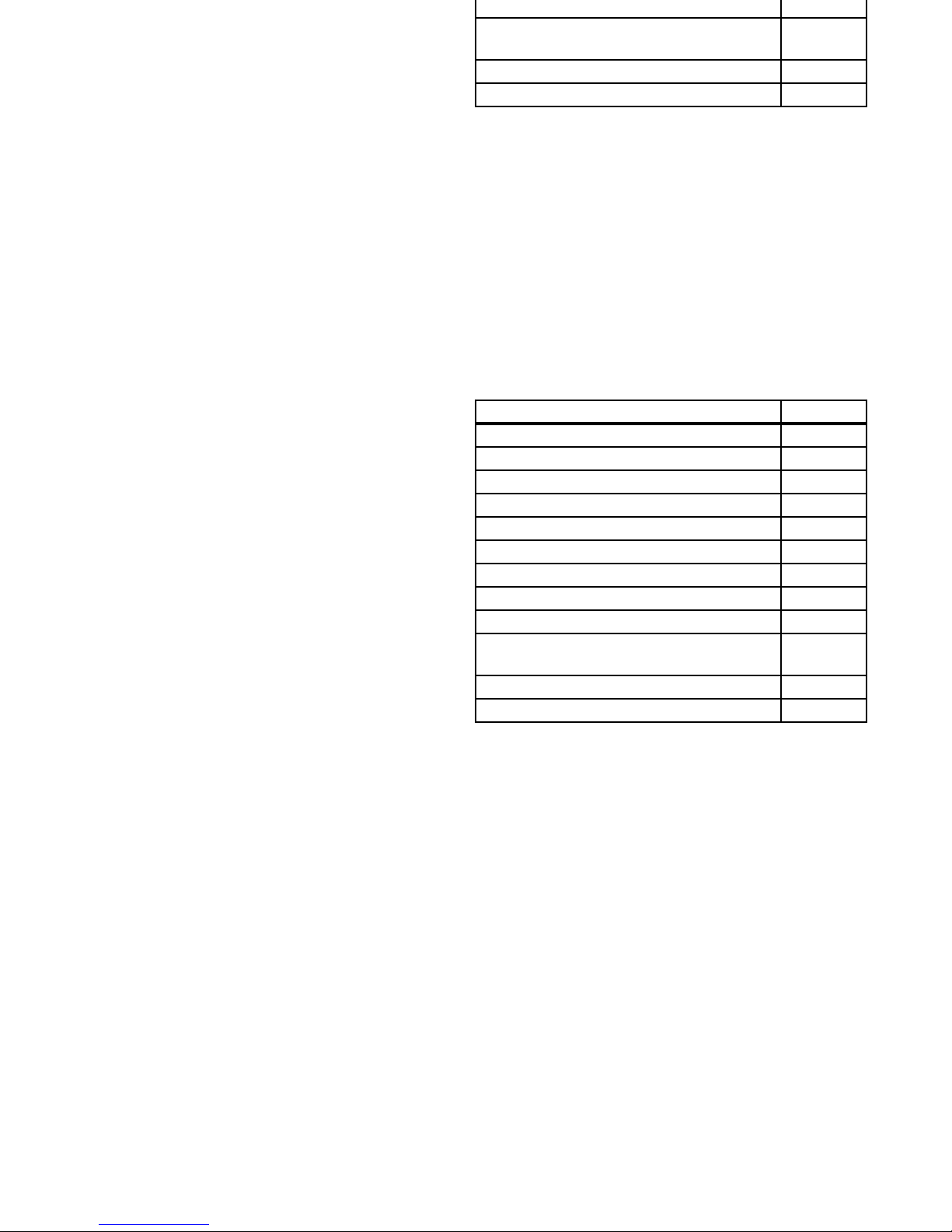

Fuses: A number of fuses, located on the relay boar d, p rotect

various circuits and components. Not all of the fused circuits

and components are used in this system. The relay board (see

Figure 12 on page 34) is located inside the control box. Refer

to TK 53687 the TG-VIc Diagnostic Manual for more

information about the fuses.

Fuse Size Function

F1 2A High Speed Relay

F2 2A Defrost Relay

F3 15A Damper Solenoid/Motor

F4 2A Run Relay

F5 2A Hot Gas Solenoid

F6 2A Pilot Solenoid

F7 2A Starter Relay

F8 2A Preheat Relay

F9 40A #2 Circuit

F10 2A Cool Light/Damper Motor Heater

F11 2A VHN (Ammeter Shunt)

F12 2A Data Logger

F13 2A VHP (Ammeter Shunt)

F14 2A High Speed Light

F15

None2ANo Fuse - All Thermo King and Bosch

Alternators

2A Fuse - All Prestolite Alternators

F16 2A Electric Motor Contactor

F17 2A Defrost Light

F18 15A High Speed Solenoid

F21 15A #8F Circuit

F22 2A Electric Heater Contactor

F25 2A Cycle-Sentry Light

F26 2A Emergency Heat

F27 2A Spare Fuse

F28 15A Spare Fuse

F29 30A Spare Fuse

F30 40A Spare Fuse

Fuse Size Function

Unit Description

33

Fuses: A number of fuses, located on the relay boar d, p rotect

various circuits and components. Not all of the fused circuits

and components are used in this system. The relay board (see

Figure 12 on page 34) is located inside the control box. Refer

to TK 53687 the TG-VIc Diagnostic Manual for more

information about the fuses.

Fuse Size Function

F1 2A High Speed Relay

F2 2A Defrost Relay

F3 15A Damper Solenoid/Motor

F4 2A Run Relay

F5 2A Hot Gas Solenoid

F6 2A Pilot Solenoid

F7 2A Starter Relay

F8 2A Preheat Relay

F9 40A #2 Circuit

F10 2A Cool Light/Damper Motor Heater

F11 2A VHN (Ammeter Shunt)

F12 2A Data Logger

F13 2A VHP (Ammeter Shunt)

F14 2A High Speed Light

F15

None2ANo Fuse - All Thermo King and Bosch

Alternators

2A Fuse - All Prestolite Alternators

F16 2A Electric Motor Contactor

F17 2A Defrost Light

F18 15A High Speed Solenoid

F21 15A #8F Circuit

F22 2A Electric Heater Contactor

F25 2A Cycle-Sentry Light

F26 2A Emergency Heat

F27 2A Spare Fuse

F28 15A Spare Fuse

F29 30A Spare Fuse

F30 40A Spare Fuse

Fuse Size Function

Page 35

Unit Description

34

Figure 12: Relay Board

F31 2A Modulation

F32 2A Remote Lights

F33 2A Oil Level Switch/ Door Switch

F34 2A Emergency Run

F35 2A Pilot Solenoid

F36 30A Main Power Fuse

F37 30A Main Power Fuse

Fuse Size Function

AJA106

9

Unit Description

34

Figure 12: Relay Board

F31 2A Modulation

F32 2A Remote Lights

F33 2A Oil Level Switch/ Door Switch

F34 2A Emergency Run

F35 2A Pilot Solenoid

F36 30A Main Power Fuse

F37 30A Main Power Fuse

Fuse Size Function

AJA106

9

Page 36

001 35

TG-VI Controller Description

TG-VI Overview

This unit is controlled by a ThermoGuard TG-VI

microprocessor. The TG-VI control panel consists of a display