Page 1

Maintenance Manual

CSR40-149 & -150

Power Saver

TK 50892-4-MM (Rev. 6/00)

Copyright ©2000, Thermo King Corporation, Minneapolis, MN, U.S.A.

Printed in U.S.A.

Page 2

This manual is published for informational purposes only and the information so provided should not be considered as all-inclusive

or covering all contingencies. If further information is required, Thermo King Corporation should be consulted.

Sale of product shown in this Manual is subject to Thermo King’s terms and conditions including, but not limited to, the THERMO

KING EXPRESS WARRANTY. Such terms and conditions are available upon request.

Thermo King’s warranty will not apply to any equipment which has been “so repaired or altered outside the manufacturer’s plants

as, in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular purpose or merchantability, or warranties arising

from course of dealing or usage of trade, are made regarding the information, recommendations, and descriptions contained herein.

Manufacturer is not responsible and will not be held liable in contract or in tort (including negligence) for any special, indirect or consequential damages, including injury or damage caused to vehicles, contents or persons, by reason of the installation of any

Thermo King product or its mechanical failure.

SmartSponge and Thermoguard are trademarks of Thermo King Corporation. All other trademarks are the property of their respective owners.

Page 3

Recover Refrigerant

At Thermo King we recognize the need to preserve the environment and limit

the potential harm to the ozone layer that can result from allowing refrigerant

to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and limits the loss

of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regulations concerning the use of refrigerants and the certification of technicians. For additional

information on regulations and technician certification programs, contact

your local THERMO KING dealer.

Page 4

Page 5

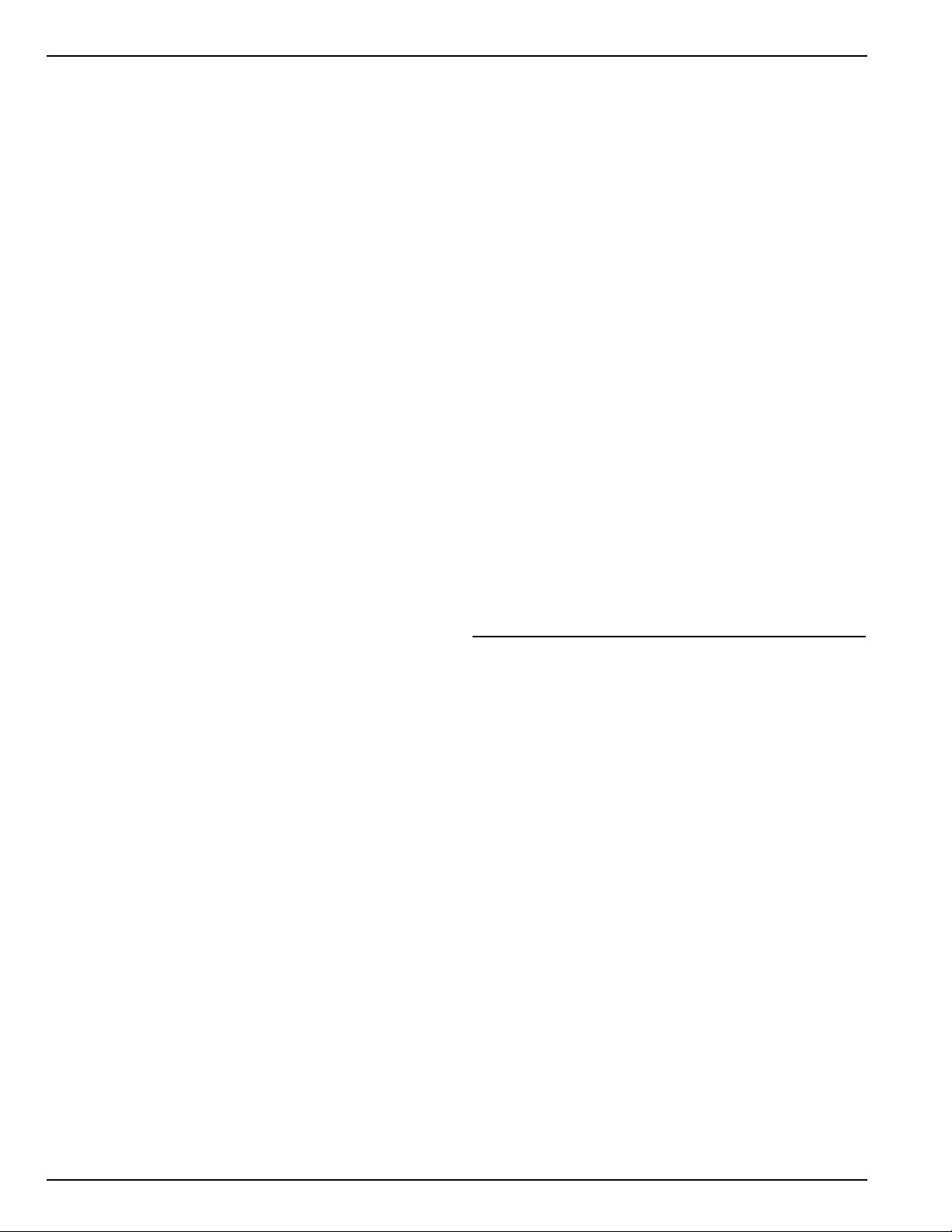

Table of Contents

Introduction v

About This Manual v

Other Reference Manuals v

CSR40-149 & -150 PS Model Features vi

Safety Precautions vii

General Practices vii

Refrigerant vii

Refrigerant Oil viii

Electrical viii

General Safety Practices for Servicing Units

(or Containers) Equipped with a

Microprocessor Controller ix

Unit Decals x

Serial Number Locations x

Service Guide xi

Specifications 1-1

System Net Cooling Capacity — Full Cool:

CSR40 PS Models — Air Cooled Condensing 1-1

System Net Heating Capacity 1-1

Evaporator Airflow:

CSR40 PS Models 1-1

Electrical System 1-2

Refrigeration System 1-3

MP-3000 Controller 1-4

Dehumidify and Humidify Systems (Options) 1-5

Physical Specifications 1-6

Metric Hardware Torque Charts 1-7

Unit Description 2-1

Unit Features 2-1

Unit Options 2-2

Operating Modes 2-3

Unit Illustrations 2-4

Typical Unit Front View 2-4

Unit Options Front View 2-5

CSR40 PS Evaporator Section – Front View 2-6

Hermetic Refrigeration System 2-7

MP-3000 Controller 2-8

Unit Control Box 2-9

Humidify System Option 2-10

Advanced Fresh Air Management Option 2-11

Typical Unit Back View 2-12

Operating Instructions 3-1

Unit Controls 3-1

Unit Instruments 3-1

Unit Protection Devices 3-1

Pretrip Inspection 3-3

Starting the Unit and Adjusting the Controller

Setpoint 3-4

Loading Procedure 3-5

Post Load Procedure 3-5

Post Trip Procedure 3-5

MP-3000 Controller 4-1

Controller Description 4-1

Status Indicator LEDs 4-3

Data Recording and Downloading Data 4-3

General Theory of Operation 4-4

Chill Loads 4-4

Frozen Loads 4-5

Modulation Display in Data Menu 4-5

Power Limit Mode 4-5

CSR40-149 & -150 PS Hermetic, June 2000

Page 6

ii Table of Contents

Compressor Liquid Injection 4-5

Warm Gas Bypass 4-5

Evaporator Fan Control 4-5

Condenser Fan Control 4-6

Economy Mode Operation 4-6

Probe Test 4-6

Dehumidify Mode (Option) 4-7

Sequence of Operation 4-7

Unit Start-up 4-7

Continuous Temperature Control Operation 4-8

Operating Mode Function Chart — Standard

Operation 4-9

Operating Mode Function Chart — Optional

Feature Operation 4-10

Defrost 4-11

Changing the Setpoint 4-12

Initiating a Manual Defrost 4-12

Displaying Alternate Controlling (Supply or

Return) Air Sensor Temperature 4-12

Displaying Alternate Fahrenheit (F) or

Celsius (C) Temperatures 4-13

Navigating the Controller Menu 4-13

General Operating Tips 4-13

Setpoint Menu 4-13

Changing the Setpoint Temperature 4-13

Changing the Economy Mode Setting 4-14

Changing the Humidity Mode Setting 4-14

Changing the Humidity Setpoint 4-14

Changing the Advanced Fresh Air

Management (AFAM) Mode Setting 4-14

Changing the AFAM Delay 4-15

Changing the AFAM Rate 4-15

Data Menu 4-16

Viewing the Data Menu 4-16

Alarms Menu 4-16

Alarm Types 4-16

Alarm Code States 4-17

Viewing the Alarm List Menu 4-17

Alarm List 4-17

Commands Menu 4-18

View the Commands Menu 4-18

Defrost 4-19

Function Test 4-19

CSR PS Function Test Procedure 4-21

Pretrip (PTI) Test 4-20

CSR PS Pretrip (PTI) Test Procedure 4-23

Manual Function Test 4-20

Power Management 4-28

Misc. Functions Menu 4-28

Viewing the Misc. Functions Menu 4-28

Setting the Date and Time 4-28

Changing the Temperature Display

Value (C/F) 4-29

Setting Cargo Data 4-29

Viewing or Setting Run Time 4-30

Configuration Menu 4-30

Viewing or Setting Functions 4-30

Datalogger Menu 4-31

Viewing the Datalogger Menu 4-32

Inspect Temp Log 4-32

Inspect Event Log 4-32

Set Log Time 4-33

Set a Trip Start 4-33

Inspect PTI Log 4-34

RMM State Menu 4-34

Viewing the RMM State Screen 4-34

Manual Emergency Mode Operation 4-34

Replacing the Controller 4-35

Automatic Configuration of Spare

Parts Controller 4-35

Controller Software Selection 4-36

Flash Loading Controller Software 4-36

Temperature Sensors 4-36

Diagnosis and Repair 4-38

Error Messages and Controller Actions 4-39

Alarm Codes, Descriptions and

Corrective Actions 4-42 to 4-61

Electrical Maintenance 5-1

Unit Wiring 5-1

High Pressure Cutout Switch 5-1

Low Pressure Cutout Switch 5-2

Condenser Fan and Evaporator Fan Rotation 5-2

Electric Heaters 5-3

CSR40-149 & -150 PS Hermetic, June 2000

Page 7

Table of Contents iii

Refrigeration System Diagnosis and Service 6-1

Hermetic Refrigeration System Diagnosis

Procedures 6-1

Hermetic Refrigeration System Visual Inspection

and Diagnosis Chart 6-3

Hermetic Refrigeration System Service

Procedures 6-4

Service Tools 6-4

Refrigerant Charge 6-5

Compressor Oil Charge 6-6

Installing and Removing Piercing Type Service

Valves and a Gauge Manifold Set 6-6

Gauge Manifold Valve Positions 6-8

Refrigerant Leak Test Procedure 6-9

Using Pressurized Nitrogen 6-9

Refrigerant Recovery from Hermetic

Refrigeration Systems 6-10

Evacuation and Cleanup of the

Refrigeration System 6-11

Charging the System with Refrigerant 6-15

Compressor Replacement 6-15

Compressor Discharge Temperature Sensor

Replacement 6-16

Stepper Motor Valve Replacement 6-17

Condenser Coil Replacement 6-17

Filter Drier/In-line Filter Replacement 6-18

Expansion Valve Replacement 6-18

Heat Exchanger Replacement 6-19

Receiver Tank Replacement 6-19

Low or High Pressure Cutout Switch Replacement 6-20

Warm Gas Bypass Solenoid Valve, Liquid

Injection Valve or Dehumidify Valve

(Option) Replacement 6-20

Structural/Accessory Maintenance 7-1

Mounting Bolts 7-1

Unit Inspection 7-1

Condenser Coil 7-1

Evaporator Coil 7-1

Defrost Drains 7-2

Condenser Fan Location 7-2

Evaporator Fan Location 7-2

Humidify System (Option) 7-2

Partlow (Model SR) Recording Thermometer

(Option) 7-3

Advanced Fresh Air Management (AFAM) System

(Option) 7-5

Mechanical Diagnosis 8-1

Mechanical Diagnosis 8-1

Electrical, Refrigeration and MP-3000 Menu Flow

Diagrams 9-1

Controller Diagram 9-3

Wiring Schematic 9-4

Main Relay Board Terminal Connections

(Page 1 of 3) 9-5

Main Relay Board Terminal Connections

(Page 2 of 3) 9-6

Main Relay Board Terminal Connections

(Page 3 of 3) 9-7

Refrigeration System Schematics:

Refrigeration System Components 9-8

Full Cool Flow and Pressure Diagram 9-9

Modulation Cool Flow and Pressure Diagram 9-10

Dehumidification Flow and Pressure Diagram 9-11

MP-3000 Menu Flow Diagram 9-12

CSR40-149 & -150 PS Hermetic, June 2000

Page 8

Page 9

Introduction

About This Manual

The information in this manual is provided to assist owners,

operators and service people in the proper upkeep and maintenance of Thermo King units. This manual includes maintenance and diagnosis information for both standard and optional unit features. Some optional features may not apply to your

unit. The maintenance information in this manual covers unit

models:

CSR PS Hermetic Models System Number

CSR40-149 Power Saver 917149

CSR40-150 Power Saver 917150

Other Reference Manuals

For detailed descriptions of our refrigeration systems or microprocessor controllers, see the appropriate manual. For further

information refer to:

Operation, Diagnosis and Refrigeration Maintenance

Manuals

Diagnosing Thermo King Container

Refrigeration Systems TK 41166

Electrostatic Discharge (ESD)

Training Guide TK 40282

Evacuation Station Operation and Field

Application TK 40612

Tool Catalog TK 5955

CSR40-149 & -150 PS Hermetic, June 2000

Page 10

vi CSR40-149 & -150 PS Model Features Introduction

CSR40-149 & -150 PS Model Features

MODEL

FEATURES

CSR40-149 PS

CSR40-150 PS

– – Slimline Frame

X X Top Air Discharge

X X 460-380V/3Ph/60-50 Hz, 18.3 m (60 ft) Power Cable and Plug

X X Dual Voltage Feature: 15 kVA Autotransformer with 460-380V Power Receptacle and 230-190V/3Ph/60-50 Hz, 18.3 m

(60 ft) Power Cable and Plug

X X 25 Amp Main Power Circuit Breaker

X X Automatic Phase Selection Control

X X Hermetic Scroll Compressor w/4.48 kW (6.0 Hp) Motor

X X Hermetic Refrigeration System

X X Refrigerant R-404A w/Polyol Ester Compressor Oil (TK P/N 203-433)

X X Stepper Valve Capacity Control System

X X Compressor Liquid Injection System

X X Warm Gas Bypass Valve System

X X MP-3000 Microprocessor Controller with Integral Datalogger

– – Three (3) Evaporator Fans with 2-Speed Motors

X X Two (2) Evaporator Fans with 2-Speed Motors

X X Condenser Fan with 1-Speed Motor

– – Fresh Air Exchange System

X X AFAM — Advanced Fresh Air Management

– – Data Retrieval Receptacle, Standard (5-Pin Deutsch)

X X Data Retrieval Receptacle, 5-Pin Threaded Cannon

– – Data Retrieval Receptacle, 15-Pin RS232

– X Dehumidify Control

– X Humidity System

– – Pressure Gauge, Discharge

– – Pressure Gauge, Suction

X X Recorder, Partlow

– – Recorder, Saginomiya

– – Remote Monitoring Plug (4-Pin)

®

– – TRANSFRESH

– – TRANSFRESH

– – TRANSFRESH

Provision

®

Purge Port

®

System, Complete

– – Thermistor Lead

– – USDA Cold Treatment Temperature Recording

– – Water-Cooled Condenser-Receiver Tank

X = Included

CSR40-149 & -150 PS Hermetic, June 2000

Page 11

Safety Precautions

General Practices

1. ALWAYS WEAR GOGGLES OR SAFETY GLASSES.

Refrigerant liquid and battery acid can permanently damage the eyes (see First Aid under Refrigerant Oil).

2. Never close the compressor discharge valve with the unit

in operation. Never operate the unit with the discharge

valve closed.

3. Keep your hands, clothing and tools clear of the fans

when the refrigeration unit is running. If it is necessary to

run the refrigeration unit with covers removed, be very

careful with tools or meters being used in the area.

4. Be sure the gauge manifold hoses are in good condition.

Never let them come in contact with a fan motor blade or

any hot surface.

5. Never apply heat to a sealed refrigeration system or container.

6. Fluorocarbon refrigerants, in the presence of an open

flame or electrical arc, produce toxic gases that are severe

respiratory irritants capable of causing death.

7. Be sure all mounting bolts are tight and are the correct

length for their particular application.

8. Use extreme caution when drilling holes in the unit. The

holes may weaken structural components. Holes drilled into

electrical wiring can cause fire or explosion. Holes drilled

into the refrigeration system may release refrigerant.

9. Use caution when working around exposed coil fins. The

fins can cause painful lacerations.

10. Use caution when working with a refrigerant or refrigeration system in any closed or confined area with a limited

air supply (for example, a trailer, container or in the hold

of a ship). Refrigerant tends to displace air and can cause

oxygen depletion, resulting in suffocation and possible

death.

11. Use caution and follow the manufacturer’s suggested

practices when using ladders or scaffolds.

Refrigerant

When removing any refrigerant from a unit, use a recovery

process that prevents or absolutely minimizes the refrigerant

that can escape to the atmosphere. Although fluorocarbon

refrigerants are classified as safe refrigerants when proper

tools and procedures are used, certain precautions must be

observed when handling them or servicing a unit in which they

are used. When exposed to the atmosphere in the liquid state,

fluorocarbon refrigerants evaporate rapidly, freezing anything

they contact.

First Aid

In the event of frost bite, the objectives of First Aid are to protect the frozen area from further injury, to warm the affected

area rapidly, and to maintain respiration.

• EYES: For contact with liquid, immediately flush eyes

with large amounts of water and get prompt medical attention.

• SKIN: Flush area with large amounts of lukewarm water.

Do not apply heat. Remove contaminated clothing and

shoes. Wrap burns with dry, sterile, bulky dressing to

protect from infection/injury. Get medical attention.

Wash contaminated clothing before reuse.

• INHALATION: Move victim to fresh air and use CPR or

mouth-to-mouth ventilation, if necessary. Stay with victim

until arrival of emergency medical personnel.

CSR40-149 & -150 PS Hermetic, June 2000

Page 12

viii Refrigerant Oil Safety Precautions

4. Do not make any rapid moves when working on high volt-

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

• Do not allow refrigerant oil to contact your eyes.

• Do not allow prolonged or repeated contact with skin or

clothing.

• To prevent irritation, you should wash thoroughly immediately after handling refrigerant oil. Rubber gloves are

recommended when handling Polyol Ester based refrigerant oil.

First Aid

• EYES: Immediately flush eyes with large amounts of

water for at least 15 minutes while holding the eyelids

open. Get prompt medical attention.

• SKIN: Remove contaminated clothing. Wash thoroughly

with soap and water. Get medical attention if irritation

persists.

• INHALATION: Move victim to fresh air and restore

breathing if necessary. Stay with victim until arrival of

emergency personnel.

• INGESTION: Do not induce vomiting. Contact a local

poison control center or physician immediately.

Electrical

High Voltage

When servicing or repairing a refrigeration unit, the possibility

of serious or even fatal injury from electrical shock exists.

Extreme care must be used when working with a refrigeration

unit that is connected to a source of operating power, even if

the unit is not running. Lethal voltage potentials can exist at

the unit power cord, inside the control box, inside any high

voltage junction box, at the motors and within the wiring harnesses.

Precautions

1. Be certain the unit On/Off switch is turned OFF before

connecting or disconnecting the unit power plug. Never

attempt to stop the unit by disconnecting the power plug.

2. Be certain the unit power plug is clean and dry before

connecting it to a power source.

3. Use tools with insulated handles that are in good condition. Never hold metal tools in your hand if exposed,

energized conductors are within reach.

age circuits. If a tool or other object falls, do not attempt

to grab it. People do not contact high voltage wires on

purpose. It occurs from an unplanned movement.

5. Treat all wires and connections as high voltage until a

meter and wiring diagram show otherwise.

6. Never work alone on high voltage circuits on the refrigeration unit. Another person should always be standing by

in the event of an accident to shut off the refrigeration unit

and to aid a victim.

7. Have electrically insulated gloves, cable cutters and safety

glasses available in the immediate vicinity in the event of

an accident.

First Aid

IMMEDIATE action must be initiated after a person has

received an electrical shock. Obtain immediate medical assistance if available.

The source of shock must be immediately removed by

either shutting down the power or removing the victim from

the source. If it is not possible to shut off the power, the wire

should be cut with either an insulated instrument (e.g., a wooden handled axe or cable cutters with heavy insulated handles)

or by a rescuer wearing electrically insulated gloves and safety

glasses. Whichever method is used, do not look at the wire

while it is being cut. The ensuing flash can cause burns and

blindness.

If the victim has to be removed from a live circuit, pull the

victim off with a non-conductive material. Use the victim’s

coat, a rope, wood, or loop your belt around the victim’s leg or

arm and pull the victim off. DO NOT TOUCH the victim.

You can receive a shock from current flowing through the victim’s body.

After separating the victim from power source, check

immediately for the presence of a pulse and respiration. If a

pulse is not present, start CPR (Cardio Pulmonary

Resuscitation) and call for emergency medical assistance. If a

pulse is present, respiration may be restored by using mouthto-mouth resuscitation, but call for emergency medical assistance.

Low Voltage

Control circuits are low voltage (24 Vac and 12 Vdc). This

voltage potential is not considered dangerous, but the large

amount of current available (over 30 amperes) can cause

severe burns if shorted to ground.

Do not wear jewelry, watch or rings. These items can short

out electrical circuits and cause severe burns to the wearer.

CSR40-149 & -150 PS Hermetic, June 2000

Page 13

Safety Precautions General Safety Precautions for Servicing Controllers ix

Welding of Units or Containers

General Safety Precautions for Servicing

Units (or Containers) Equipped with a

Microprocessor Controller

Precautions must be taken to prevent electrostatic discharge

when servicing the MP-3000 microprocessor and related components. If these precautionary measures are not followed, the

risk of significant damage to the electronic components of the

unit is possible.

The primary risk potential results from the failure to wear

adequate electrostatic discharge preventive equipment when

handling and servicing the controller. The second cause

results from electric welding on the unit and container chassis

without taking precautionary steps.

Controller Repair

When servicing the controller, it is necessary to ensure that

electrostatic discharges are avoided. Potential differences considerably lower than those which produce a small spark from a

finger to a door knob can severely damage or destroy solidstate integrated circuit components. The following procedures

must be rigidly adhered to when servicing these units to avoid

controller damage or destruction.

1. Disconnect all power to the unit.

2. Avoid wearing clothing that generates static electricity

(wool, nylon, polyester, etc.).

3. Do wear a static discharge wrist strap (TK P/N 204-622)

with the lead end connected to the controller's ground ter-

minal. These straps are available at most electronic equip-

ment distributors. DO NOT wear these straps with power

applied to the unit.

4. Avoid contacting the electronic components on the circuit

boards of the unit being serviced.

5. Leave the circuit boards in their static proof packing mate-

rials until ready for installation.

6. If a defective controller is to be returned for repair, it

should be returned in the same static protective packing

materials from which the replacement component was

removed.

7. After servicing the circuit board and any other circuits, the

wiring should be checked for possible errors before restor-

ing power.

Whenever electric welding is to be performed on any portion

of the refrigeration unit, container or container chassis with the

refrigeration unit attached, it is necessary to ensure that welding currents are NOT allowed to flow through the electronic

circuits of the unit. These procedures must be rigidly adhered

to when servicing these units to avoid damage or destruction.

1. Disconnect all power to the refrigeration unit.

2. Disconnect all quick-disconnect wire harnesses from the

back of the controller.

3. If the unit is equipped with an Remote Monitor Modem

(RMM), disconnect all wire harnesses from the RMM.

4. Switch all of the electrical circuit breakers in the control

box to the OFF position.

5. Weld unit and/or container per normal welding procedures. Keep ground return electrode as close to the area to

be welded as practical. This will reduce the likelihood of

stray welding currents passing through any electrical or

electronic circuits.

6. When the welding operation is completed, the unit power

cables, wiring and circuit breakers must be restored to

their normal condition.

CSR40-149 & -150 PS Hermetic, June 2000

Page 14

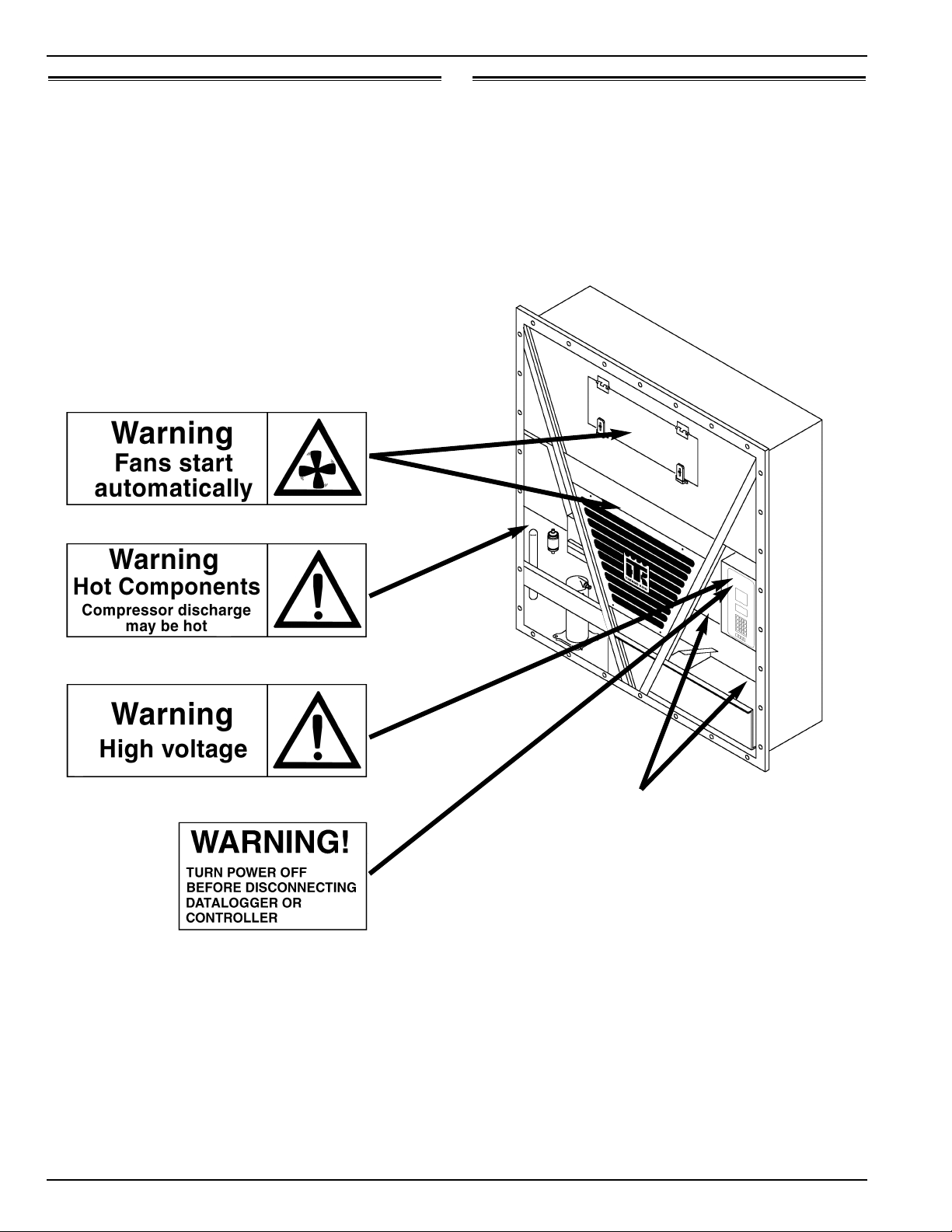

x Unit Decals Safety Precautions

Unit Decals

Serial number decals, refrigerant type decals and warning

decals appear on all Thermo King equipment. These decals

provide information that may be needed to service or repair the

unit. Service technicians should read and follow the instructions on all warning decals.

Serial Number Locations

Electric Motors: Nameplate attached to the motor housing.

Compressor: Nameplate on front of the compressor.

Unit: Nameplate on unit frame in power cord storage compart-

ment.

MP-3000 Controller: Nameplate on back of controller.

Unit Nameplate Location

CSR40-149 & -150 PS Hermetic, June 2000

Page 15

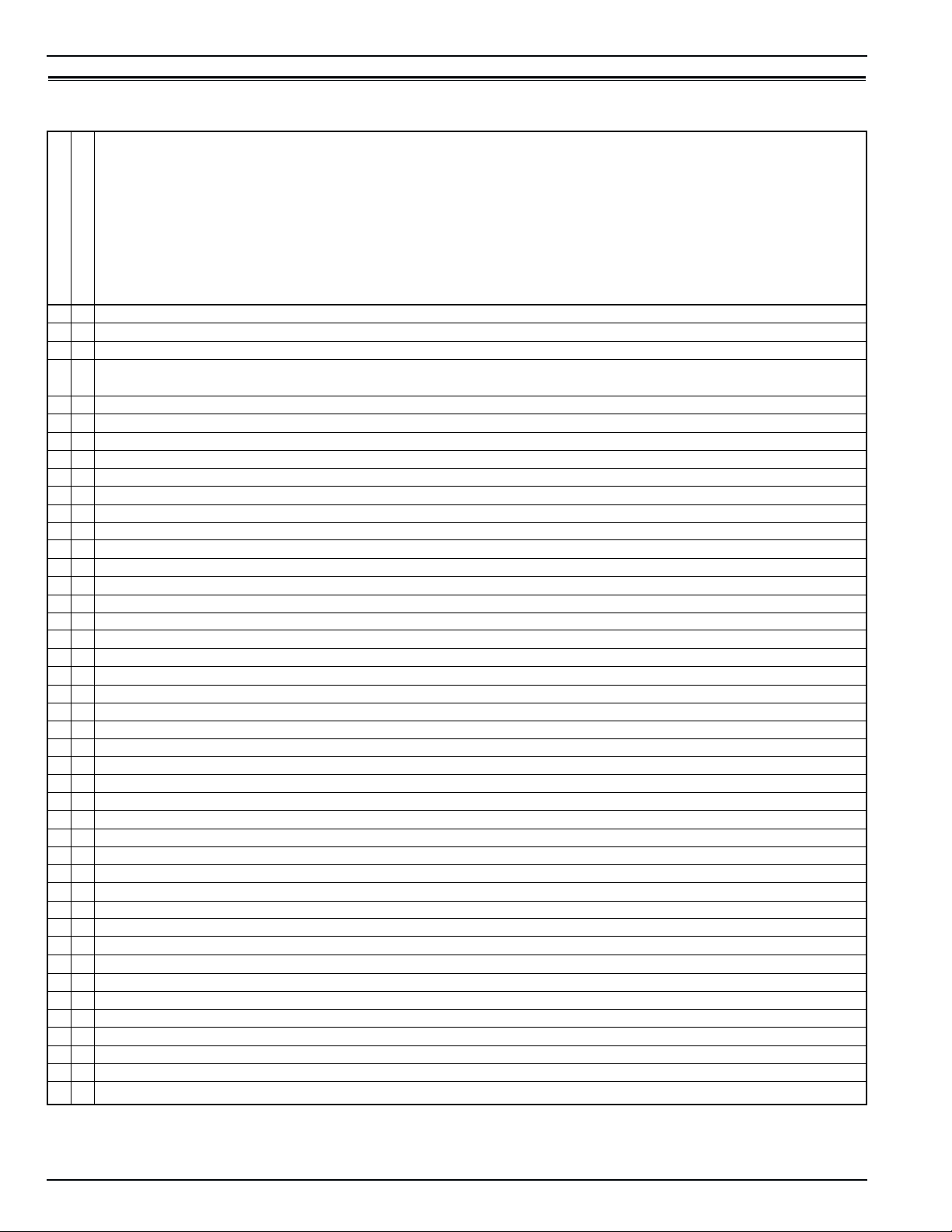

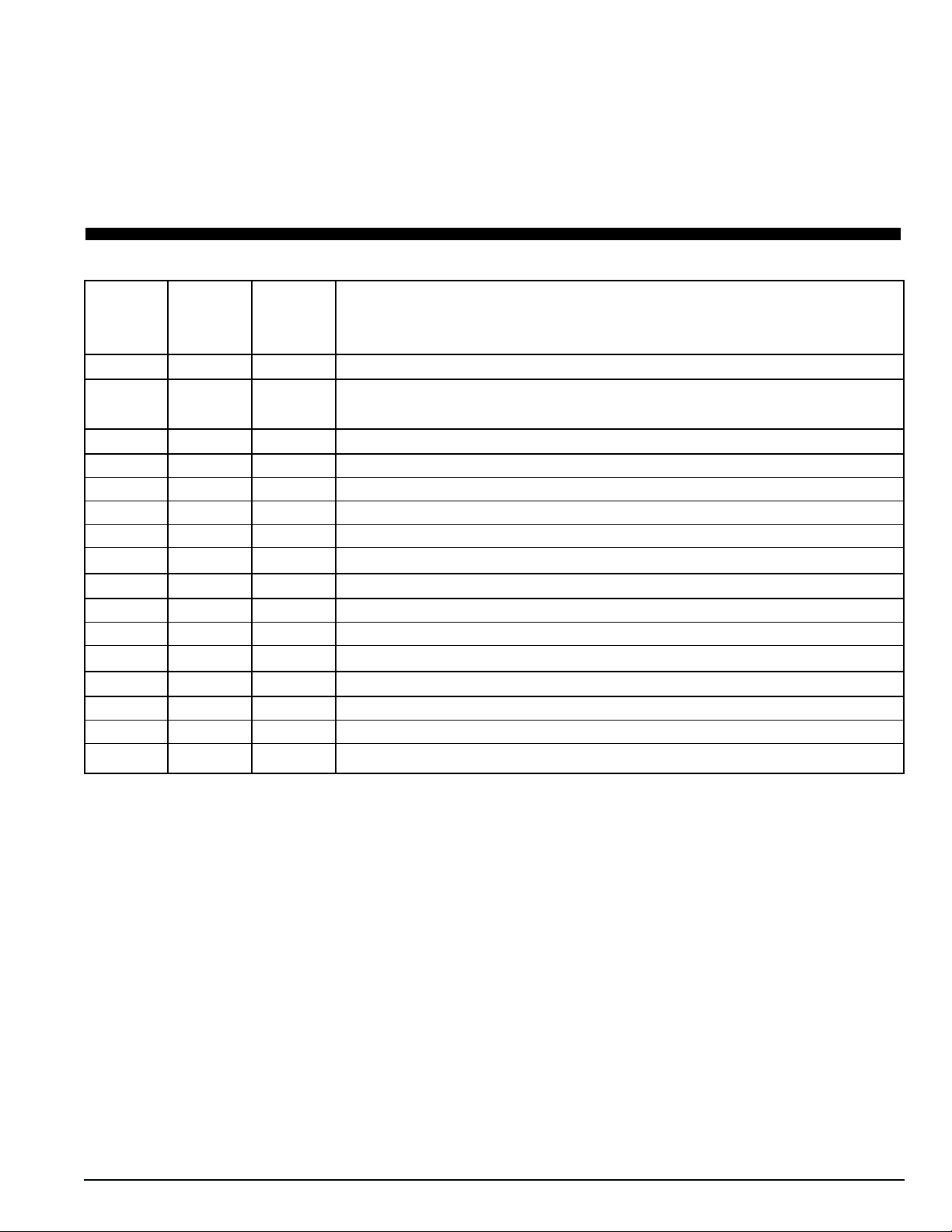

Service Guide

Every Annual/

1,000 Yearly

Pretrip Hours Inspect/Service These Items

Refrigeration

• Perform a controller Pretrip Inspection (PTI) test to check the refrigeration and electri-

cal systems.

Electrical

•••Visually inspect condenser fan and evaporator fan rotation.

•••Visually inspect electrical contacts for damage or loose connections.

•••Visually inspect wire harnesses for damaged wires or connections.

••

•

Download the data logger and check data for correct logging.

Check operation of protection shutdown circuits.

Structural

•••

•••

••

•

•••

••

Visually inspect unit for damaged, loose or broken parts.

Tighten unit, compressor and fan motor mounting bolts.

Clean entire unit including condenser and evaporator coils and defrost drains.

Humidify System (Option)

Check water level in water tank.

Check humidify system operation.

Clean water supply filter on water tank.

CSR40-149 & -150 PS Hermetic, June 2000

Page 16

Page 17

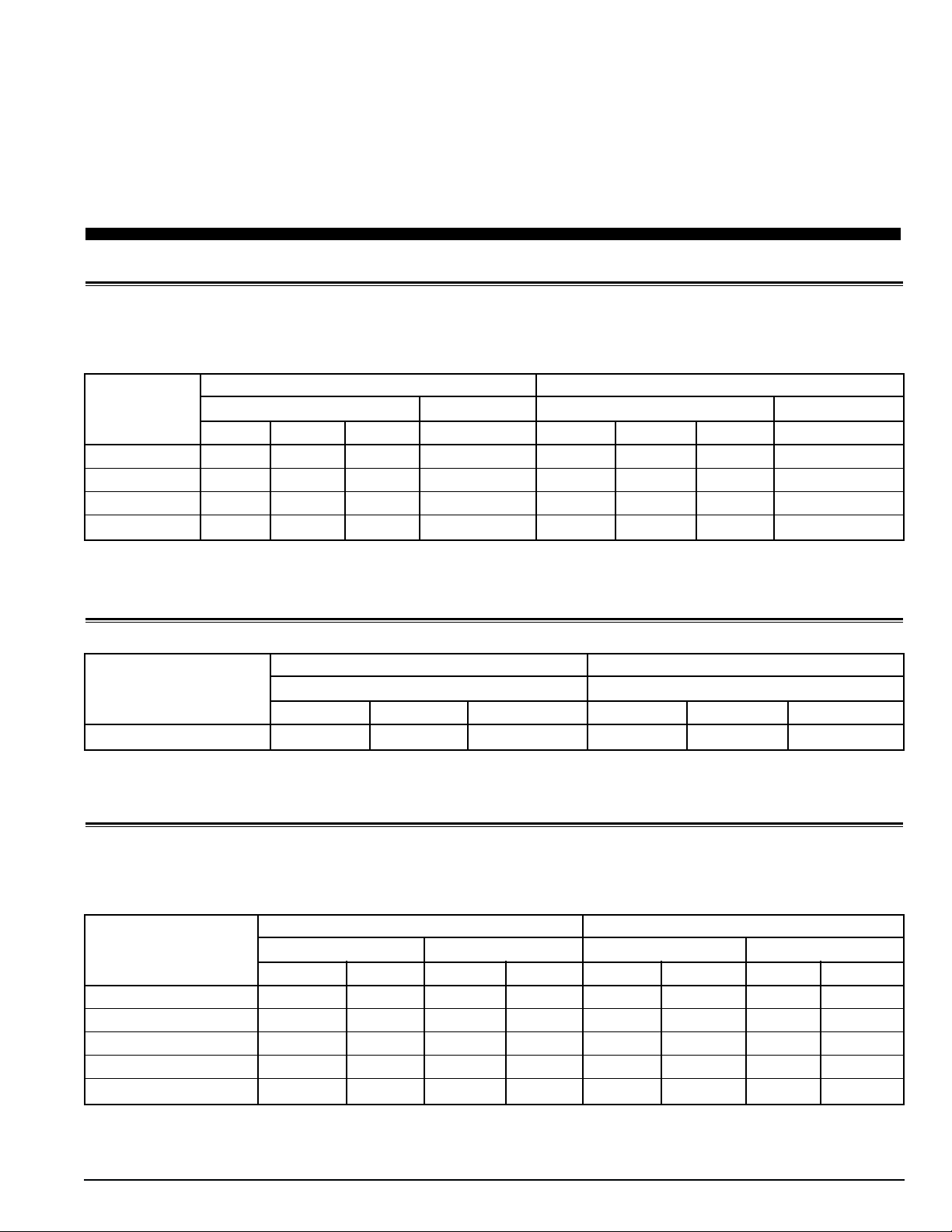

1 Specifications

System Net Cooling Capacity — Full Cool

CSR40 PS Models — Air Cooled Condensing*

Return air to 460/230V, 3 Phase, 60 Hz Power 380/190V, 3 Phase, 50 Hz Power

evaporator Net Cooling Capacity Power Consp Net Cooling Capacity Power Consp

coil inlet Watts Kcal/hr BTU/hr kW @460V Watts Kcal/hr BTU/hr kW @380V

21.1 C (70 F) 13,660 11,750 46,620 9.7 10,930 9,400 37,300 7.6

1.7 C (35 F) 10,090 8,680 34,440 8.9 8,070 6,940 27,545 6.9

-17.8 C (0 F) 5,945 5,115 20,290 6.0 4,755 4,090 16,230 5.4

-28.9 C (-20 F) 4,000 3,440 13,650 5.6 3,200 2,750 10,920 4.1

*System net cooling capacity with a 37.8 C (100 F) ambient air temperature and R-404A.

System Net Heating Capacity*

Heater Type 460/230V, 3 Phase, 60 Hz Power 380/190V, 3 Phase, 50 Hz Power

Heating Capacity Heating Capacity

Watts Kcal/hr BTU/hr Watts Kcal/hr BTU/hr

CSR40 PS 5,800 4,990 19,800 4,200 3,610 14,335

*System net heating capacity includes electric resistance rods and fan heat.

Evaporator Airflow

CSR40 PS Models

External Static 460/230V, 3 Phase, 60 Hz Power 380/190V, 3 Phase, 50 Hz Power

Pressure (water High Speed Low Speed High Speed Low Speed

column) m3/hr ft3/min m3/hr ft3/min m3/hr ft3/min m3/hr ft3/min

0 mm (0 in.) 6,560 3,860 3,170 1,865 5,480 3,225 2,710 1,595

10 mm (0.4 in.) 5,820 3,425 1,770 1,040 4,530 2,665 930 545

20 mm (0.8 in.) 5,000 2,940 — — 3,750 2,205 — —

30 mm (1.2 in.) 4,430 2,610 — — 2,930 1,725 — —

40 mm (1.6 in.) 3,520 2,070 — — 1,870 1,100 — —

CSR40-149 & -150 PS Hermetic, June 2000

Page 18

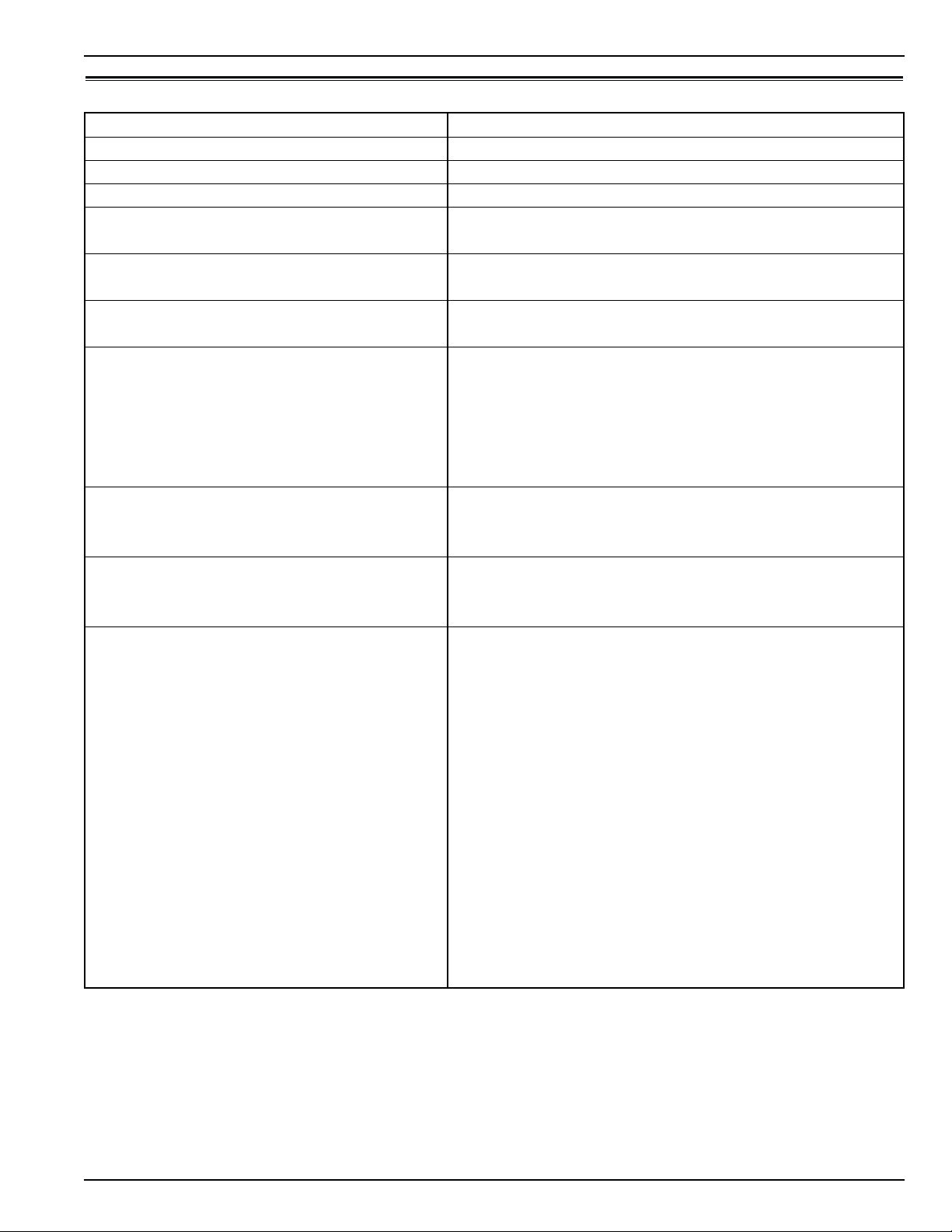

1-2 Electrical System Specifications

Electrical System

Compressor Motor: Type 460/380V, 60/50 Hz, 3 Phase

Kilowatts 4.48 kW @ 460V, 60 Hz

Horsepower 6.0 hp @ 460V, 60 Hz

RPM 3550 rpm @ 460V, 60 Hz

Locked Rotor Amps 70 amps @ 460V, 60 Hz

Condenser Fan Motor: Type 460/380V, 60/50 Hz, 3 Phase

Kilowatts 0.37 kW @ 460V, 60 Hz

Horsepower 0.50 hp @ 460V, 60 Hz

RPM 1140 rpm @ 460V, 60 Hz

Full Load Amps 1.0 amps @ 460V, 60 Hz; 1.0 amps @ 380V, 50 Hz

Locked Rotor Amps 4.0 amps @ 460V, 60 Hz; 4.0 amps @ 380V, 50 Hz

Evaporator Fan Motors: Type 460/380V, 60/50 Hz, 3 Phase

Number: CSR40 PS 2

Kilowatts 0.75 kW @ 460V, 60 Hz

Horsepower 1.0 hp @ 460V, 60 Hz

RPM (Each): High Speed 3450 rpm @ 460V, 60 Hz

Low Speed 1725 rpm @ 460V, 60 Hz

Full Load Amps (Each): High Speed 1.1 amps @ 460V, 60 Hz

Low Speed 0.55 amps @ 460V, 60 Hz

Locked Rotor Amps: High Speed 10.3 amps @ 460V, 60 Hz

Low Speed 2.9 amps @ 460V, 60 Hz

Electric Resistance Heater Rods: Type 460/380V, 60/50 Hz, 3 Phase

Number 6

Watts (Each) 680 Watts @ 460V, 60 Hz

Current Draw (Amps) 5 amps total @ 460V across each phase at heater contactor

Control Circuit Voltage: 29 Vac @ 60 Hz

24 Vac @ 50 Hz

Advanced Fresh Air Management (AFAM) Motor:

Voltage 24 Vdc

Evaporator Overheat Switch: Opens 54 +/- 3 C (130 +/- 5 F)

Closes 38 +/- 4.5 C (100 +/- 8 F)

CSR40-149 & -150 PS Hermetic, June 2000

Page 19

Specifications Refrigeration System 1-3

Refrigeration System

Compressor Model No.: ZM18K4E-TFD-279, Hermetic Scroll

Refrigerant Charge: CSR40 PS 3.6 Kg (8.0 lb) R-404A

Compressor Oil Capacity 1.77 liter (60 oz.)*

Compressor Oil Type Polyol Ester Based Type (required), TK Part No. 203-433**

High Pressure Cutout Switch: Cutout 3243 +/- 48 kPa, 32.43 +/- 0.48 bar, 470 +/- 7 psig

Cutin 2588 +/- 262 kPa, 25.88 +/- 2.62 bar, 375 +/- 38 psig

Low Pressure Cutout Switch: Cutout +21 to -20 kPa, +0.21 to -0.20 bar, 3 psig to 6” Hg vacuum

Cutin 48 to 90 kPa, 0.48 to 0.90 bar, 7 to 13 psig

High Pressure Relief Valve: Relief Pressure 3447 +520/-104 kPa, 34.47 +5.20/-1.04 bar, 500 +75/-15 psig

Reset 2758 kPa, 27.58 bar, 400 psig

Liquid Injection Control: Compressor Start Liquid injection valve opens for 5 minutes on each compressor start

Power Limit or Modulation Cool Liquid injection valve opens continuously during Power Limit and

Modulation Cool modes

Compressor Discharge Temperature Control Energizes (Opens) Liquid Injection Valve at 138 C (280 F)

De-energizes (Closes) Liquid Injection Valve at 132 C (270 F)

Compressor Shutdown (Auto Reset) at 148 C (298 F)

Liquid Injection Valve (Compressor): Voltage 24 Vac

Current 0.85 amps

Cold Resistance 5.6 ohms

Warm Gas Bypass Solenoid Valve: Voltage 24 Vac

Current 0.85 amps

Cold Resistance 5.6 ohms

Stepper Valve Regulating Motor: Voltage 12 Vdc

Current Draw 0.13 to 0.21 amperes per winding

0.26 to 0.44 amperes with 2 windings energized

Resistance 75 +/- 7.5 ohms across each winding at 24 C (75 F) ambient

*When the compressor is removed from the unit, oil level should be noted or the oil removed from the compressor should be mea-

sured so that the same amount of oil can be maintained in the replacement compressor.

**DO NOT use or add standard synthetic or mineral oils to the refrigeration system. If Ester based oil becomes contaminated with

moisture or with standard oils, dispose of properly — DO NOT USE!

CSR40-149 & -150 PS Hermetic, June 2000

Page 20

1-4 MP-3000 Controller Specifications

MP-3000 Controller

Temperature Controller: Type MP-3000 microprocessor with thermostat, digital thermometer, pro-

gramming keypad, mode indicators, LED display and LCD display

for displaying unit operating and cargo information

Setpoint Range -29.0 to +29.0 C (-20.2 to +84.2 F)

Digital Temperature Display -60.0 to +80.0 C (-76.0 to +176.0 F)

Controller Software (Original Equipment): Version See controller identification decal

Defrost Initiation Evaporator Coil Sensor - Manual Switch or Demand Defrost Initiation: Coil must be below

18 C (65 F). Defrost cycle starts when technician or controller

request defrost initiation.

- Timed Defrost Initiation: Coil must be below 10 C (50 F).

Defrost cycle starts 1 minute after the hour immediately following

a defrost timer request for defrost initiation. For example, if the

defrost timer requests a defrost cycle at 7:35, the defrost cycle will

start at 8:01. Datalogger will record a Defrost event for each inter-

val in which a Defrost cycle is pending or active (i.e. both the 8:00

and 9:00 data logs).

Demand Defrost Demand defrost function initiates defrost when:

- Temperature difference between the return air sensor and defrost

(evaporator coil) sensor is too large

- Temperature difference between the supply air sensor and return

air sensor is too large

Defrost Timer: Chilled mode - Supply Temperature at 5.1 C (41.2 F) or Above: Every 8 hours of

compressor operation.

- Supply Temperature at 5.0 C (41.0 F) or Below: Every 2.5 hours

of compressor operation. Defrost interval increases 0.5 hours each

timed defrost interval. Defrost synchronization creates step inter-

vals of 3, 4, 4, 5, 5, 6, 6 and 7 hours. Maximum time interval in

chilled mode is 7 hours.

Defrost Timer: Frozen mode Every 8 hours of compressor operation. Defrost interval increases 2

hours each timed defrost interval. Maximum time interval in frozen

mode is 24 hours.

Defrost Timer: Reset to Base Time Defrost timer resets if the unit is Off more than 12 hours, setpoint is

changed more than 5 C (9 F) or PTI Pretrip test occurs.

CSR40-149 & -150 PS Hermetic, June 2000

Page 21

Specifications Dehumidify and Humidify Systems 1-5

MP-3000 Controller (Continued)

Defrost Termination: Defrost (Coil) Sensor Chilled mode: Terminates defrost when coil sensor temperature

rises to 30 C (86 F); or exceeds 18 C (65 F) for 15

minutes

Frozen mode: Terminates defrost when coil sensor temperature

rises to 18 C (65 F); or exceeds 8 C (46 F) for 15

minutes

Termination Timer Terminates defrost after 90 minutes at 60 HZ operation if coil sen-

sor has not terminated defrost (120 minutes at 50 Hz operation)

Power Off Turning unit On/Off switch OFF terminates defrost

Compressor Shutdown Protection (Auto Reset):

Stops Compressor 130 C (266 F)

Allows Compressor Start 90 C (194 F)

Dehumidify and Humidify Systems (Options)

Dehumidify System (Option):

Turn Mode ON and OFF Set from CONTROL line of the Setpoint menu of the controller

Control Range (HUMSP) Setting 50% to 99% Relative Humidity

Humidify System (Option): Turn Mode ON and OFF Set from CONTROL line of the Setpoint menu of the controller

Operating Temperature Range 0 to 60 C (32 to 140 F)

Control Range (HUMSP) Setting 50% to 99% Relative Humidity

Air Compressor Output 2.5 m3/hr @ 0 kPa (1.5 CFM @ 0 psig)

Humidity Tank Heater: 240-600 Vac; 55 to 70 Watts at -17.8 C (0 F) Water Temperature

Humidity Sensor: Accuracy: +/- 1.5% between 55% and 75% Relative Humidity

+/- 3.0% between 75% and 95% Relative Humidity

Output Range: 4 to 20 milliamps

1% Relative Humidity = 0.2 milliamp

CSR40-149 & -150 PS Hermetic, June 2000

Page 22

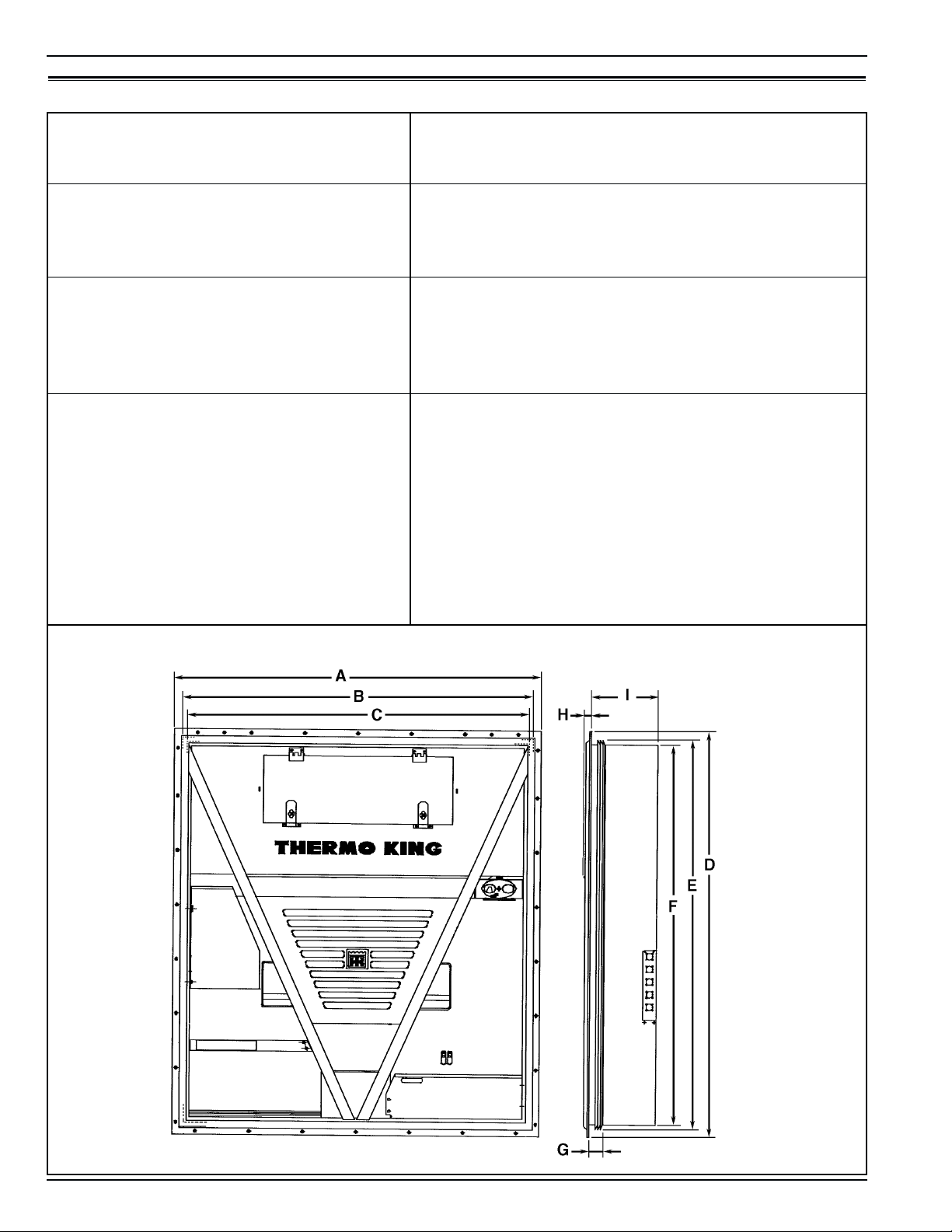

1-6 Physical Specifications Specifications

Physical Specifications

Advanced Fresh Air Management (AFAM)

Exchange Rate: CSR40 PS 0 to 285 m3/hr (0 to 168 ft3/min.) @ 60 Hz

0 to 236 m3/hr (0 to 139 ft3/min.) @ 50 Hz

Evaporator Fan Blade Specifications:

CSR40 PS Top Air Discharge: Diameter 355 mm (14.0 in.)

Pitch 25

Number 2

Weight (net): CSR40 PS Base Unit 413 Kg (910 lb)

Dual Voltage Option 45 Kg (99 lb)

Power Line Communications Option 3.6 Kg (8 lb)

Recorder (Partlow or Saginomiya) Option 5.9 Kg (13 lb)

Full TRANSFRESH®Option 13 Kg (28 lb)

Unit Dimensions: A = Flange Width 2025.5 mm (79.74 in.)

B = Gasket Width 1935 mm (76.18 in.)

C = Unit Width 1894 mm (74.57 in.)

D = Flange Height 2235.2 mm (88.00 in.)

E = Gasket Height 2140 mm (84.25 in.)

F = Unit Height 2094 mm (82.44 in.)

G = Gasket Depth 72 mm (2.83 in.) from back of flange

H = Maximum Protrusion 37 mm (1.46 in.) from back of flange

I = Unit Depth: CSR40 PS 420.0 mm (16.54 in.) from back of flange

o

CSR40-149 & -150 PS Hermetic, June 2000

Page 23

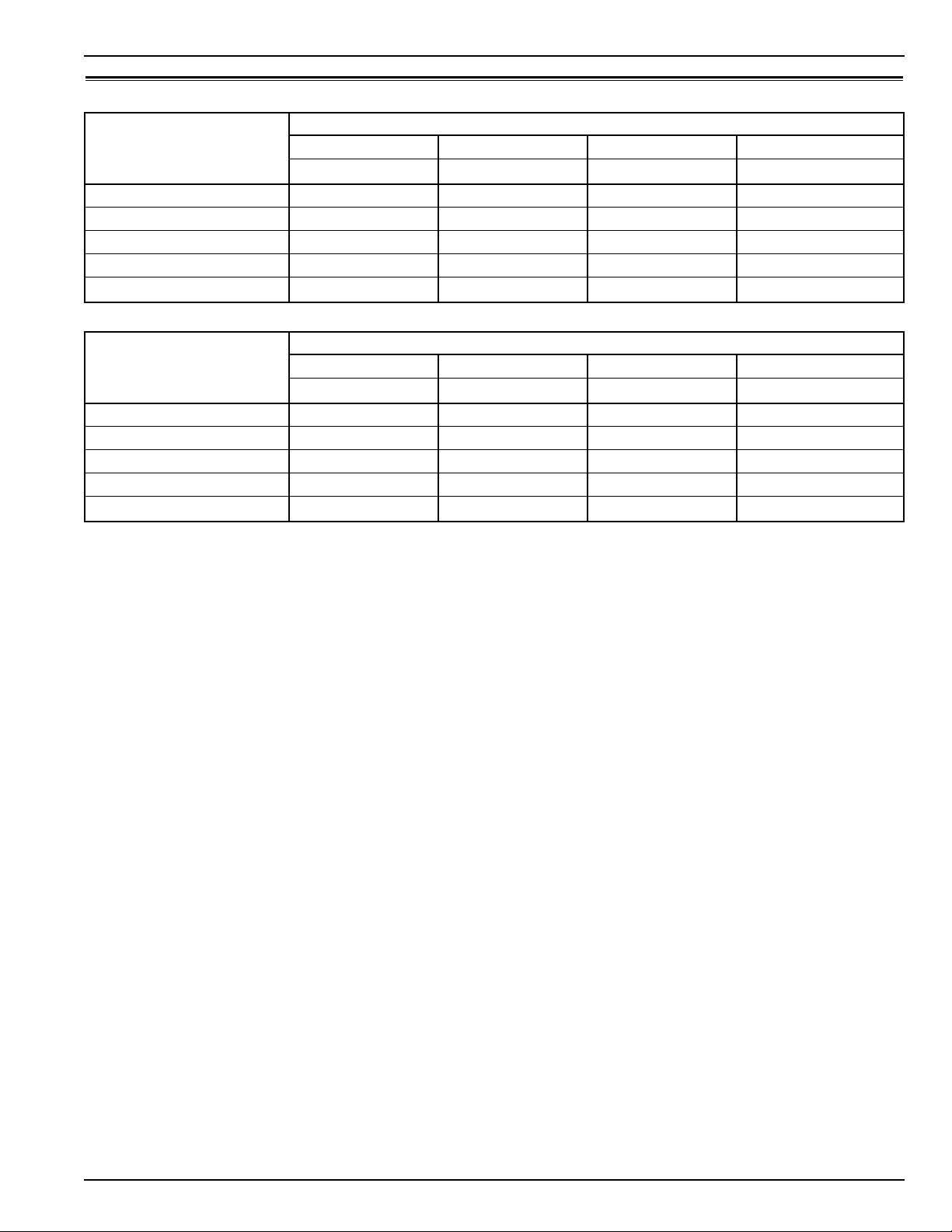

Specifications Metric Hardware Torque Charts 1-7

Metric Hardware Torque Charts

Bolt Size

Bolt Type M6 M8 M10 M12

and Class* N.m (Ft.-lb.) N.m (Ft.-lb.) N.m (Ft.-lb.) N.m (Ft.-lb.)

HH – CL 5.8 6-9 (4-7) 12-16 (9-12) 27-34 (20-25) 48-61 (35-40)

HH – CL 8.8 10-13 (7-10) 20-27 (15-20) 41-47 (30-35) 75-88 (55-65)

HH – CL 10.9 14-17 (10-13) 27-34 (20-25) 54-68 (40-50) 102-122 (75-90)

HH – CL 12.9 17-21 (12-16) 41-47 (30-35) 68-81 (50-60) 122-149 (90-110)

HH – SS (2) 10-13 (7-10) 20-27 (15-20) 41-47 (30-35) 75-88 (55-65)

Bolt Size

Bolt Type M14 M16 M18 M22

and Class* N.m (Ft.-lb.) N.m (Ft.-lb.) N.m (Ft.-lb.) N.m (Ft.-lb.)

HH – CL 5.8 75-88 (55-65) 115-135 (85-100) 177-216 (130-160) 339-406 (250-300)

HH – CL 8.8 115-135 (85-100) 177-216 (130-160) 271-339 (200-250) 475-610 (350-450)

HH – CL 10.9 136-176 (100-130) 224-298 (180-220) 393-474 (290-350) 678- 813 (500-600)

HH – CL 12.9 177-216 (130-160) 285-352 (210-260) 448-542 (330-400) 881-1016 (650-750)

HH – SS (2) 115-135 (85-100) 177-216 (130-160) 271-339 (200-250) 475-610 (350-450)

*HH = Hex Head, CL = Class.

CSR40-149 & -150 PS Hermetic, June 2000

Page 24

Page 25

2 Unit Description

Dual Speed Evaporator Fans

Unit Features

Model CSR40-149 & -150 PS units are all-electric, singlepiece, refrigeration units with top air supply. Each unit is

designed to cool and heat containers for shipboard or overland

transit. Each unit mounts in the front wall of the container.

Fork lift pockets are provided for installation and removal of

the unit.

The frame and bulkhead panels are constructed of aluminum and are treated to resist corrosion. A hinged, removable evaporator compartment door provides easy service

access. All operating components except the evaporator coil

and electric heaters can be replaced from the front of the unit.

A totally sealed, hermetic refrigeration system minimizes

maintenance and service.

Each unit is equipped with an 18.3 m (60 ft) power cable

for operation on 460-380V/3 Ph/60-50 Hz power. For operation on 460-380V/3 Ph/60-50 Hz power, plug the 460-380V

power cable into the proper power supply. The unit power

cable is stored below the control box in the condenser section.

Each unit is equipped with 460-380V/3 Ph/60-50 Hz electric motors. An automatic phase correction system provides

the proper electrical phase sequence for condenser fan, evaporator fan and compressor operation.

Unit features include a hermetic scroll compressor with a

liquid injection system; 2-speed evaporator fans; a fresh air

exchange system; and a MP-3000 controller with integral data

logger. For additional unit feature information, see “CSR40149 & -150 PS Model Features” on page vi of the

Introduction.

Hermetic Scroll Compressor with Liquid Injection

Cooling System

The refrigeration unit includes a hermetic scroll compressor

(one stationary and one orbiting member) with ambient compensated internal overload and high temperature protectors,

and a refrigerant injection system.

CSR PS models are equipped with either 2 or 3 evaporator fans.

All models feature 2-speed motors. The evaporator fans operate

continuously to circulate air inside the container. The fans operate on high speed for perishable cargo at setpoints of -9.9 C

(14.1 F) and above. At setpoints of -10 C (14 F) and below, the

evaporator fans operate on low speed for frozen cargo.

NOTE: If Economy Mode is ON:

• Fresh Loads: Evaporator fans operate on low

speed when container temperature is in-range.

• Frozen Loads: Evaporator fans stop during the

Null mode; controller operates fans on low speed

for 5 minutes every 45 minutes.

Fresh Air Exchange System

The fresh air exchange system removes harmful gases from

containers carrying sensitive perishable commodities. The

fresh air vent is located above the control box. The fresh air

vent is adjustable to accommodate a variety of cargo and

chilled load operating conditions. The fresh air vent should be

tightly closed when carrying frozen cargo.

MP-3000 Controller

The MP-3000 controller incorporates refrigeration system

component control, thermostat, digital thermometer, fault indication and data recording capabilities into one self-contained

package.

The controller mounts in a weather tight, corrosion resistance enclosure. A large-character LED display (top) provides

easy viewing of the control sensor temperature (return or supply air temperature). A 4-line, 20-character LCD display (bottom) display shows important data including the setpoint temperature, controller Main Menu tree and important unit operating data.

CSR40-149 & -150 PS Hermetic, June 2000

Page 26

2-2 Unit Options Unit Description

Sixteen general purpose keys are used to enter and scroll

through the controller menu tree and message text; initiate

Pretrip and Function tests; enter new setpoint temperature; and

enter trip information. The keyboard supports both numerical

and text input. Four special keys provide quick access to setpoint temperature change, manual defrost initiation, alternate

return/supply air temperature display, and alternate temperature scale (C/F) display.

Status indicator LEDs in the controller display signal

Compressor, Heat, Defrost, In-range, Alarm, Humidity,

Supply Temperature display and Return Temperature display.

A datalogger incorporated in the MP-3000 controller

records sensor temperatures as well as loss of power, alarms,

unit operating modes, sensor failure, setpoint change and unit

shutdown indications. All data recordings are stored in a

RAM memory that is backed by battery.

Logging intervals are selectable from 1 minute and 1/2, 1,

2 or 4 hours. When a 1 hour logging interval is selected, the

datalogger memory can store approximately 680 days of information. The logging of USDA sensors is fixed at 1 hour intervals to comply with USDA requirements.

The datalogger clock is factory set at UTC time. All data

logs include the time and date; setpoint temperature; and supply, return, USDA1, USDA2 and USDA3 sensor temperatures.

All temperature logs can be viewed from the controller’s LCD

message display.

A high speed serial communication port provides data

retrieval using a DRU-II hand-held data retriever or laptop

computer with SmartSponge software, or a REFCON power

line remote monitoring system.

Unit Options

Advanced Fresh Air Management (AFAM)

An advanced microprocessor controlled fresh air management

system provides programmable control of the air exchange

rate, programmable delayed vent opening, automatic air

exchange lock out for frozen cargo, automatic closure of the

air exchange vent when the ambient temperature decreases

below the cargo setpoint temperature, and data logging of the

air exchange rate and vent opening delay interval.

The AFAM system includes a door control module, vent

door, calibration decal and vent grille. The MP-3000 controller sends a communication signal to the door control module to position to vent door to the desired position. The controller can also be set to delay opening of the fresh air vent for

up to 72 hours, in 1-hour increments. This allows faster product temperature pulldown.

The system is precalibrated for air exchange rates of 0 to

285 m3/hr (0 to 168 ft3/min.). A calibrated decal located

inside the air exchange vent compartment can be used to visually verify the air exchange rate setting.

Dehumidification Control System

A dehumidification system lowers the relative humidity in the

container to the humidity setpoint. The control range is 50%

to 99% while the setpoint is adjustable between 0% and 99%.

Humidification Control System

An optional humidification system increases the relative

humidity in the container to the humidity setpoint. The control

range is 50% to 99% while the setpoint is adjustable between

0% and 99%.

Dual Voltage

A dual voltage system includes a 15 KVA auto transformer

and an 18.3 m (60 ft) power cable for operation on 230190V/3 Ph/60-50 Hz power. The power cable is stored below

the control box in the condenser section.

The 15 KVA auto transformer steps 230/190V power up

to 460/380V. The auto transformer includes a 460-380V/3

Ph/60-50 Hz power receptacle.

For operation on 230/190V power, plug the 460-380V

unit power cable into the receptacle on the auto transformer.

Then plug the 230/190V power cable into a 230-190V power

supply.

Recording Thermometer Option

Several models of temperature recorders are available for

mounting on the unit. Each temperature recorder is designed

to withstand widely varying environments including low and

high ambient temperatures, salt water, humidity, fungus,

industrial pollutants, dynamic loading, rain, sand and dust.

• The 31-day Partlow Recorder is mechanically driven by a

spring mechanism. On top air discharge units, the recording

thermometer records supply air temperature.

CSR40-149 & -150 PS Hermetic, June 2000

Page 27

Unit Description Operating Modes 2-3

Frozen Loads: Controller Setpoint at -10 C (14 F) or

Operating Modes

NOTE: See MP-3000 Controller chapter for complete

sequence of operation.

A sequence start of the required loads occurs during initial

start-up of the unit and when a control mode shift requires the

compressors to start. As the controller relays and unit loads

energize, the controller LCD display shows the setpoint temperature. The controller LED display shows the controlling air

sensor temperature. The controlling sensor is determined by

the setpoint temperature:

Setpoint Controlling Sensor

-9.9 C (14.1 F) and above Supply Air Temperature

-10 C (14 F) and below Return Air Temperature

The MP-3000 controller uses a proportional-integral

derivative (PID) algorithm to provide accurate temperature

control in direct response to load demand. Therefore it is difficult to predict which operating mode the unit should be in by

comparing the setpoint to the return or supply air temperature.

The unit operates in either the Fresh (Chill) or Frozen mode.

Chill to Frozen mode transition point is -10 C (14 F).

Temperature control by the controller is based on the return air

sensor temperature. The evaporator fans operate continuously

on low speed (except during defrost).

• Cool (down to 1 C [1.8 F] below setpoint)

• Null (compressor and condenser fan stops, evaporator

fans operate)

• Defrost (resistance heaters on, evaporator fans stop)

NOTE: If the Economy Mode is set to ON, the

evaporator fans stop when the unit shifts to Null.

The controller automatically starts and operates

the evaporator fans on low speed for 5 minutes

every 45 minutes while the unit remains in Null.

Below

Chill Loads: Controller Setpoint at -9.9 C (14.1 F) or

Above

Temperature control by the controller is based on the supply

air sensor temperature, the setpoint, the modulation temperature range and the pull-down rate. The evaporator fans operate

in high speed (except during defrost).

• Cool with Modulation (down to setpoint)

• Null (compressor and condenser fan stops, evaporator

fans operate)

• Heat (resistance heaters on, evaporator fans operate)

• Defrost (resistance heaters on, evaporator fans stop)

NOTE: If the Economy Mode is set to ON, the

evaporator fans operate on low speed at setpoints of -9.9 C (14.1 F) and above whenever the

container temperature is In-range.

CSR40-149 & -150 PS Hermetic, June 2000

Page 28

2-4 Unit Illustrations Unit Description

1

2

8

3

7

4

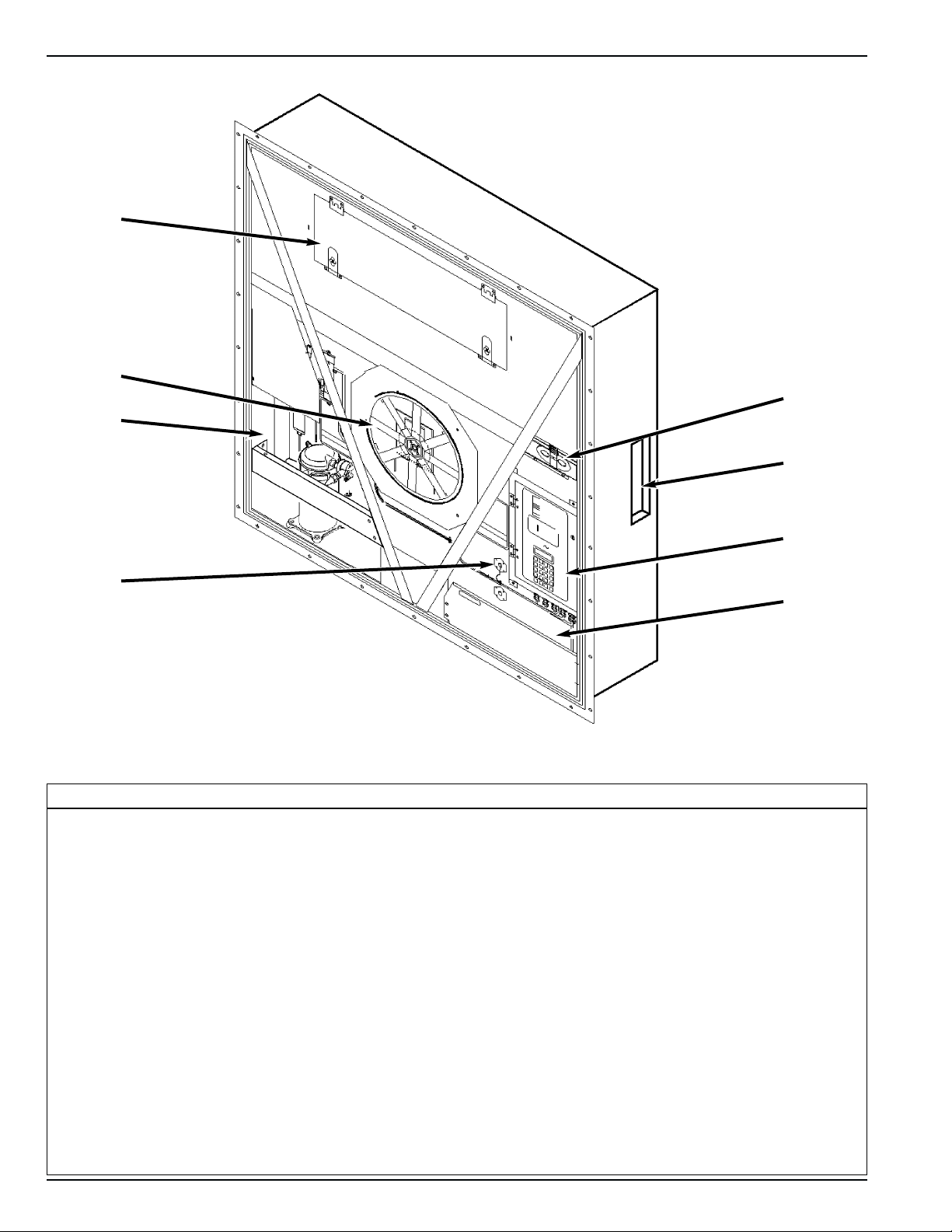

Typical Unit Front View

1. CSR40 PS: Evaporator Access Door, 1018 mm (40.08 in.) Wide with Two Latches

2. Condenser Fan

3. Compressor Compartment

4. Return Air Sensor Probe Holder

5. Power Cord Storage Compartment

6. Control Box

7. Rear Download and USDA Receptacle Panel (Access from Inside Container)

8. Fresh Air Exchange Vent

6

5

CSR40-149 & -150 PS Hermetic, June 2000

Page 29

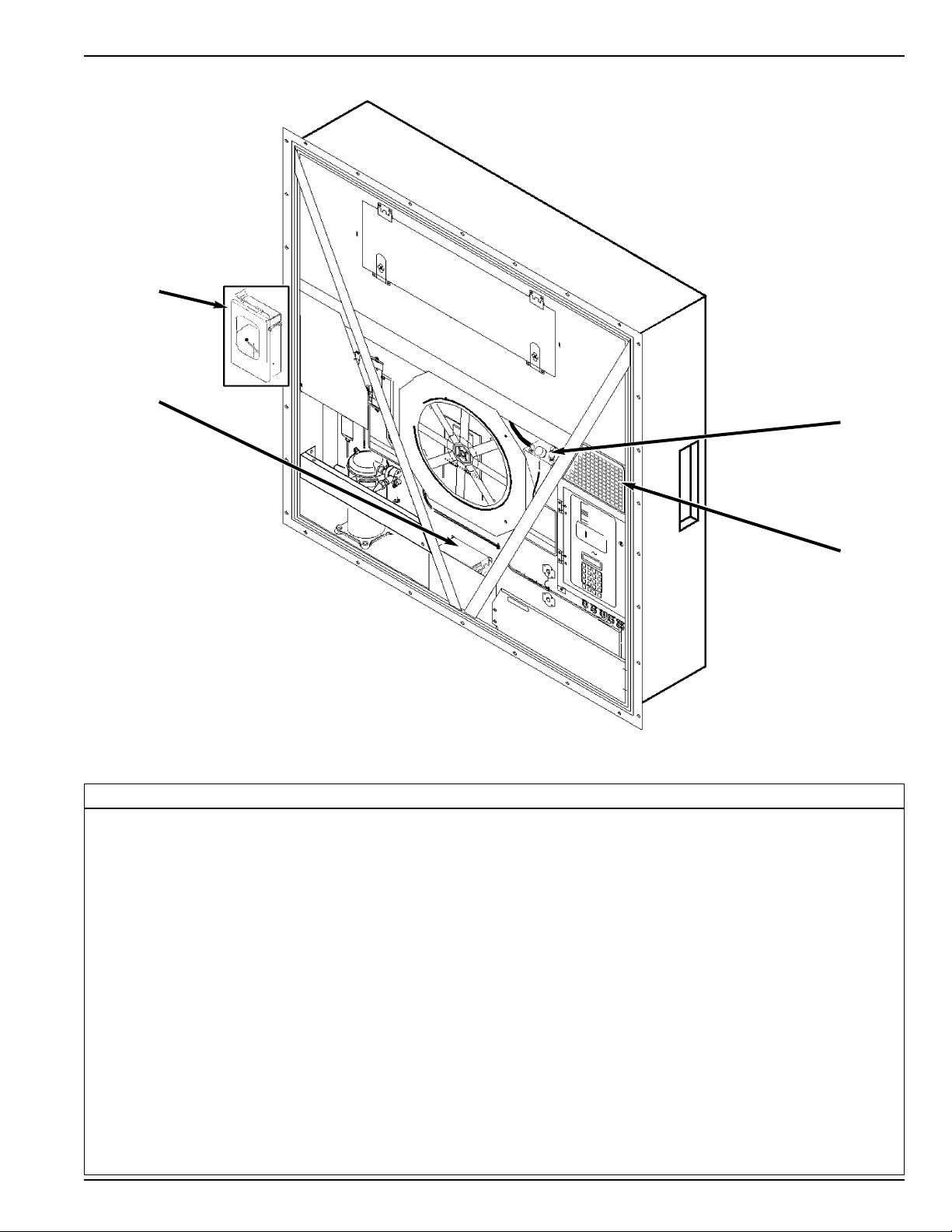

Unit Description Unit Illustrations 2-5

1

2

4

Unit Options Front View

1. Recording Thermometer Option

2. Dual Voltage Option

3. Advanced Fresh Air Management (AFAM) Option

4. Humidify System Option

3

CSR40-149 & -150 PS Hermetic, June 2000

Page 30

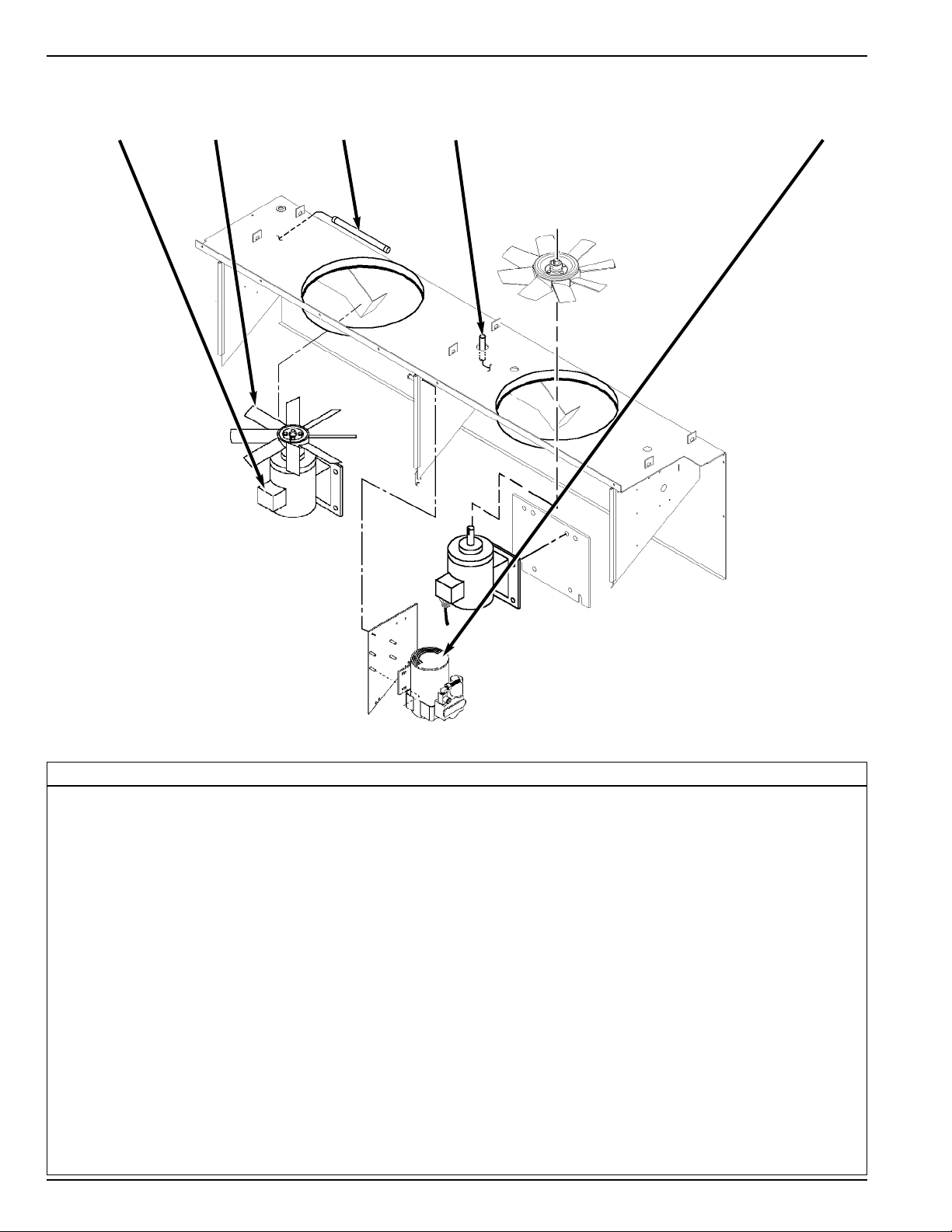

2-6 Unit Illustrations Unit Description

12 3 4 5

CSR40 PS Evaporator Section — Front View

1. Evaporator Fan Motor

2. Evaporator Fan Blade:

• CSR40 PS: 355 mm (14.0 in.) diameter, 25opitch

3. Supply Air Sensing Bulb for Recording Thermometer (Option)

4. Supply Air Sensor

5. Humidify System Compressor (Option), see page 2-10

CSR40-149 & -150 PS Hermetic, June 2000

Page 31

Unit Description Unit Illustrations 2-7

1

18

17

2

16

3

4

15

5

14

6

7

13

8

12

9

11

Hermetic Refrigeration System

1. Evaporator Coil 17. Warm Gas Bypass Solenoid Valve

2. Tube (Standard) 18. Dehumidify Valve (Option replaces standard tube)

3. Expansion Valve

4. Heat Exchanger

5. One-piece Filter Drier/In-line Filter

6. Stepper Motor Valve

7. Compressor Discharge Temperature Sensor

8. Liquid Injection Solenoid Valve

9. Scroll Compressor

10. Suction Line Process Tube

11. Low Pressure Cutout Switch

12. Discharge Line Process Tube

13. High Pressure Cutout Switch

14. Condenser Coil

15. High Pressure Relief Valve

16. Receiver Tank

CSR40-149 & -150 PS Hermetic, June 2000

10

Page 32

2-8 Unit Illustrations Unit Description

11

1

2

3

4

5

MP-3000 Controller

1. Battery Cable Connection to Controller

2. Cable No. 2 Connection to Controller

3. Download Cable Connection to Controller

4. Cable No. 3 Connection to Controller

5. Cable No. 1 Connection to Controller

6. Control Box Cover and Controller Keyboard Decal

7. Special Function Keypad

8. General Purpose Keypad

9. LCD Display (Setpoint Temperature, Message and Controller Main Menu Tree Display)

10. LED Display (Return or Supply Air Temperature Display and Status Indicator LEDs)

11. MP-3000 Controller

10

9

8

7

6

CSR40-149 & -150 PS Hermetic, June 2000

Page 33

Unit Description Unit Illustrations 2-9

8

7

6

1

2

3

Unit Control Box

1. Unit On/Off Switch

2. Communications Connector for Data Retrieval

3. Circuit Breaker

4. Main Relay Board

5. 12 Vdc Battery

6. Control Power Transformer

7. Compressor Contactors (2)

8. 25 Ampere Main Power Circuit Breaker

5

4

CSR40-149 & -150 PS Hermetic, June 2000

Page 34

2-10 Unit Illustrations Unit Description

10

9

8

1

2

3

4

5

Humidify System Option

1. Evaporator Drain Hose

2. Fill Cap

3. Water Tank Heater

4. Tank Overflow Hose

5. Drain Cock

6. Water Tank

7. Water Filter

8. Water Supply Hose

9. Air Compressor

10. Liquid Spray Nozzle

7

6

CSR40-149 & -150 PS Hermetic, June 2000

Page 35

Unit Description Unit Illustrations 2-11

1

2

8

3

4

5

Advanced Fresh Air Management (AFAM) Option

1. Gasket

2. Vent Door Assembly

3. Linkage Assembly

4. Damper Motor Housing

5. Damper Motor Assembly Mounting Bracket

6. Stop Bracket, Vent Door Full Open

7. Stop Bracket, Vent Door Closed

8. Grille

7

6

CSR40-149 & -150 PS Hermetic, June 2000

Page 36

2-12 Unit Illustrations Unit Description

1

2

3

4

5

6

Typical Unit Back View

1. Evaporator Grille

2. Unit Gasket

3. Humidity Sensor (Option)

4. Top Rear Plate

5. Bottom Rear Plate

6. Sensor Connector Assembly:

• Controller Communications and Data Download Port

• USDA1/Spare 1 Sensor Connection

• USDA2/Spare 2 Sensor Connection

• USDA3/Spare 3 Sensor Connection

• Cargo (Pulp) Sensor Connection

CSR40-149 & -150 PS Hermetic, June 2000

Page 37

3 Operating Instructions

The In-range LED illuminates when the controlling

Unit Controls

Unit Control Box

1. UNIT ON/OFF SWITCH.

a. ON position. Unit will operate on cool or heat

depending on the controller setpoint temperature and

the container air temperature.

b. OFF position. The unit will not operate.

MP-3000 Controller

The MP-3000 microprocessor controls all unit functions to

maintain the cargo at the proper temperature. The controller

also monitors and records system faults and performs pre-trip.

1. KEYPAD. Sixteen general purpose keys are used to display information, change the setpoint, change programmable features and initiate control tasks.

2.oC–oF KEY. Press this key to view temperatures in the

LED display in the alternate temperature value. Alternate

value (C or F) shows while the key is pressed.

3. RET/SUP KEY. Press this key to view the alternate sensor temperature in the LED display. Alternate sensor

(return or supply) shows while the key is pressed.

4. DEFROST KEY. Press this key to initiate a manual

defrost cycle. If the evaporator coil temperature is below

18 C (65 F), the unit will defrost. Otherwise the controller

will display “Defrost Not Activated” in the LCD display

and the unit will continue normal operation.

5. SETPOINT KEY. Press this key to change the setpoint.

Cursor in the LCD display automatically appears in the

“TEMP SETP” line of the Data menu. See “Changing the

Setpoint” in the MP-3000 Controller chapter for complete

instructions.

6. STATUS INDICATOR LEDs located in the large LED

display signal:

• Supply (Air Temperature)

• Return (Air Temperature)

• Humidity Mode (Humidification Option set to On in

Setpoint menu)

• Compressor (Cooling On)

• Heat (On)

• Defrost

• In-Range (Temperature)

• Alarm

air sensor temperature is less than 1.5 C (2.7 F) above setpoint (standard). The controller maintains the in-range

signal during defrost and after defrost for 60 minutes.

7. LED DISPLAY. Large red LED display shows current

control temperature during normal operation. LED display also shows current test state during a Pretrip (PTI) or

Function test.

8. LCD DISPLAY. A 4-line LCD message display shows

setpoint during normal operation. LCD display also

shows controller menu and unit operation information

when special keys are pressed.

Other Unit Controls

1. EVAPORATOR OVERHEAT SWITCH. A temperature

switch near the evaporator coil opens to de-energize the

heater contactor if the evaporator temperature reaches 54

+/- 3 C (130 +/- 5 F). The switch closes (resets) when the

evaporator temperature decreases to 38 +/- 4.5 C (100 +/8 F).

Unit Instruments

1. RECORDING THERMOMETER (OPTION). The

recording thermometer indicates and permanently records

the temperature of the supply air leaving the evaporator

section on a calibrated chart.

Unit Protection Devices

1. MAIN CIRCUIT BREAKER. A 25 ampere manual reset

circuit breaker protects the 460/380V power supply circuit

to the unit electric motors and control system transformer.

The main power circuit breaker is located in the control

box.

2. CONTROL SYSTEM CIRCUIT BREAKER. A 7 ampere

manual reset circuit breaker protects the 29 Vac control

circuit. This circuit breaker is located in the control box

beside the On/Off switch.

CSR40-149 & -150 PS Hermetic, June 2000

Page 38

3-2 Unit Protection Devices Operating Instructions

3. FUSES. A number of fuses are located on the main relay

board and controller plug to protect unit circuits and components.

• Three 20 amp fuses protect high voltage circuits on the

main relay board.

• A 2 amp fuse protects the controller’s 28 V system.

• A 2 amp fuse protects the controller’s battery charging

circuit.

4. COMPRESSOR DISCHARGE GAS TEMPERATURE

SENSOR. A refrigerant injection system uses the compressor discharge temperature to determine when cold

refrigerant will be injected into the center scroll of the

compressor to protect the compressor from excessively

high operating temperatures.

a. Chill Mode Liquid Injection:

• Controller energizes the liquid injection valve when

compressor discharge gas temperature increases to

138 C (280 F).

• Controller de-energizes the liquid injection valve to

stop liquid injection when the discharge gas temperature decreases to 132 C (270 F).

b. High Temperature Protection:

• The controller immediately stops unit operation if

the discharge gas temperature increases to 148 C

(298 F). The controller activates the Alarm LED

and records Alarm 56, Compressor Temperature

Too High. The controller restarts the unit when the

condition corrects itself.

5. HIGH PRESSURE CUTOUT (HPCO) SWITCH. If the

compressor discharge pressure rises above 3243 +/- 7 kPa,

32.43 +/- 0.48 bar, 470 +/- 7 psig, the high pressure cutout

opens to interrupt the ground circuit to the compressor

contactor:

• Compressor STOPS immediately.

• Evaporator and condenser fans continue normal opera-

tion. Controller determines that a high pressure cutout

switch is open when the unit current draw decreases by 7

amps for more than 3 seconds.

• The controller LCD display shows a High Pressure

Cutout message: “High Pressure Cutout Check

Condenser Probe” or “High Pressure Cutout Check

Condenser Fan”.

• After 1 minute, the controller energizes the compressor

contactor so the compressor will restart when the overload condition is corrected (switch resets) if power is

available. The high pressure switch resets (closes) when

the pressure drops to 1590 +/- 70 kPa, 15.9 +/- 0.7 bar,

230 +/- 10 psig.

• If the switch remains open for 5 minutes, controller also

activates Alarm LED and records Alarm 37, Total Power

Consumption Too Low.

6. LOW PRESSURE CUTOUT (LPCO) SWITCH. If the

compressor discharge pressure decreases to +21 to -21

kPa, +0.21 to -0.21 bar, 3 psig to 6 in. Hg vacuum; the

low pressure cutout opens:

• Compressor STOPS immediately.

• Evaporator and condenser fans continue normal opera-

tion.

• Compressor will restart if the low refrigerant condition is

corrected (switch closes) as long as power is available.

The low pressure switch resets (closes) when the pressure increases to 48 to 90 kPa, 0.48 to 0.90 bar, 7 to 13

psig.

NOTE: If the low pressure cutout switch remains

open, check for an obstruction or refrigerant leak

in the low or high pressure side of the refrigeration system.

7. HIGH PRESSURE RELIEF VALVE. A high pressure

relief valve is installed in the liquid line between the

receiver tank and filter drier. The relief valve protects

against excessive pressure build-up within the refrigeration system from extraordinary and unforeseen circumstances. The valve is a spring-loaded piston that lifts

when refrigerant pressure exceeds 3447 +520/-104 kPa,

34.47 +5.20/-1.04 bar, 500 +75/-15 psig. The valve is

located so that refrigerant pressure expelled from the

valve would be directed away from anyone servicing the

unit. The valve will reset when this pressure drops to 2758

kPa, 27.58 bar, 400 psig. The valve is non-repairable and

requires no adjustment. If the valve fails to reseat properly, recover the refrigerant charge and replace the valve.

8. OVERLOAD PROTECTION. The condenser fan motor,

evaporator fan motors and compressor motors include

internal overload protection with automatic reset.

9. PHASE SEQUENCE SELECTION. When the On/Off

switch is turned ON, phase sensors on the main relay

board determine the incoming power phase to ensure the

correct sure proper condenser fan and evaporator fan rotation. The controller then determines the correct phase

sequence for the compressor and energizes the correct

compressor contactor.

CSR40-149 & -150 PS Hermetic, June 2000

Page 39

Operating Instructions Pretrip Inspection 3-3

• If the controller calls for cooling, the compressor motor

Pretrip Inspection

Visual Inspection

The following inspections should be made before the container

is loaded:

1. Visually check the unit for physical damage.

2. Check the electrical connections in the unit control box,

making sure they are fastened securely.

3. Check the conditions of wires and terminals. Repair or

replace if necessary.

4. Check the refrigeration system for leaks. Inspect for evidence of oil leaks at all joints and connections.

5. Check the condenser and evaporator coils. Clean if necessary. Use an air or water spray jet directed against the coil

from the air discharge side. Also inspect the condenser

fan grille for damage. If the grille is damaged or missing,

abnormally high head pressure may result. Repair or

replace the grille if necessary.

CAUTION: Air or water spray jet pressure should

not be high enough to damage (bend) coil fins.

6. Check the mounting bolts on the unit, compressor and fan

motors. Tighten if necessary.

7. Clean the defrost drains.

8. Optional: Check water level in humidity system tank.

Add only demineralized or distilled water to prevent plugging of the atomizing nozzle.

9. Observe the unit for proper operation and functions during

Pre-load Operation.

10. Check to be sure the container ID that appears in the

Configuration menu is correct.

Functional Inspection

To properly perform a Full Pretrip Test on units equipped with

a MP-3000 controller, the container must be empty with the

rear doors closed.

1. Start the unit (see “Starting the Unit and Adjusting the

Controller Setpoint” on page 3-4). A second sequence

start of the required loads occurs during the Pretrip test:

• Controller LED display turns On and then Off.

• LED display briefly shows setpoint and then displays the

controlling (return) air sensor temperature.

• Controller senses the incoming power phase and selects

the correct power phase to unit components.

• Controller energizes unit loads, starting the evaporator

fans. The condenser fan may also start (if required).

starts. If the unit starts in Modulation Cool the stepper

motor valve opens or closes to the required setting.

• If the controller calls for heating, the electric heaters are

energized.

NOTE: If the compressor fails to start, turn the

On/Off switch OFF. Then repeat steps 1 through

3. If the unit still does not start, refer to “Alarm

Codes, Descriptions and Corrective Actions” in

the MP-3000 Controller chapter of this manual.

2. Check controller setpoint for proper setting. Adjust if

necessary.

NOTE: New setpoint must be between -29 C and

+29 C (-20.2 F and +84.2 F) or controller will

return to the previous setpoint display.

3. Check the direction of the condenser airflow (see

“Condenser Fan and Evaporator Fan Rotation” in the

Electrical Maintenance chapter of this manual).

4. Check direction of evaporator airflow (see “Condenser

Fan and Evaporator Fan Rotation” in Electrical

Maintenance chapter of this manual).

5. Perform a Pretrip (PTI) Test to check the unit refrigeration

and electrical systems for proper operation.

CAUTION: The PTI test should only be performed on an empty container!

NOTE: Correct all existing alarm conditions and

clear the alarm codes before performing a PTI

test. The controller will automatically clear all

existing alarms before beginning the PTI test.

To perform a PTI test:

• Press F2 key to enter Main Menu.

• Press F2 or F3 key to scroll up or down in menu to

“COMMANDS”.

• Press F4 key to access COMMANDS menu.

• Press F2 or F3 key to scroll up or down to “PTI”.

• Press F4 to start the PTI (Pretrip) Test.

• The controller then performs the Pretrip Test.

• Observe the unit for proper operation and functions dur-

ing pretrip test.

• LCD display shows PTI Test currently being performed.

PTI test ends automatically. Press any key on the controller to return the unit to normal operation.

CSR40-149 & -150 PS Hermetic, June 2000

Page 40

3-4 Starting the Unit Operating Instructions

• If an operating problem occurs during the Pretrip Test,

the Alarm LED will turn ON and FLASH. An “E” may

also appear in the right side of the LED display. View

and correct any alarm conditions. Then clear (acknowledge) the Alarm Code(s) and repeat the PTI Test.

NOTE: Clear the Alarm codes ONLY after the

alarm codes are documented and problems

repaired. A permanent record of the alarm codes

remains stored in the datalogger memory for

retrieval via DRU-II or SmartSponge retriever

Starting the Unit and Adjusting the

Controller Setpoint

CAUTION: Supply power connections from the unit

to the power source must always be made with the

refrigeration Unit On/Off switch and power supply

On/Off switch in the OFF positions. Never attempt to

start or stop the refrigeration unit with the unit power

cable.

software.

1. Verify that the Unit On/Off switch is in OFF position.

6. Enter trip ID information into the controller using the keypad.

7. Optional: Adjust the fresh air exchange rate to the desired

setting.

NOTE: The use of the Advanced Fresh Air

Management option should be established by the

shipper.

• AFAM System (Option): Set the AFAM Control screen

in the Setpoint Menu to ON. Then set the AFAM Delay

and AFAM Rate (see “Changing the Advanced Fresh

Air Management [AFAM] Mode Setting” on page 4-14).

2. Connect the unit power cord to proper power source:

• 460/380V power cord to 460/380V, 60-50 Hz power

source.

• Turn the power supply On/Off switch ON.

3. Switch the Unit On/Off switch to ON position. Check for

condenser fan and evaporator fan motor operation (see

“Condenser Fan and Evaporator Fan Rotation” in the

Electrical Maintenance chapter of this manual). If the unit

was properly pretripped, correct condenser fan rotation

will also indicate correct evaporator fan rotation.

4. Adjust controller setpoint to the desired temperature:

NOTE: The setpoint temperature can be set

between -29 C and +29 C (-20.2 F and +84.2 F) in

NOTE: If Dehumidification is turned ON, the

fresh air vent will close.

either oF or oC using the oC/oF key. Just press

and hold the F/C key (to display the alternate

temperature scale).

8. Optional: Operate the humidify system (see “Changing

the Humidity Mode Setting” on page 4-14).

NOTE: The use of the Humidify option should be

established by the shipper.

a. Verify that the air compressor operates and that water

is drawn into the atomizing nozzle and injected into

the return air stream (see “Humidify System” on page

7-2).

b. Adjust the humidity setpoint (see “Changing the

Humidity Setpoint” on page 4-14).

9. Install a new chart and prepare the recording thermometer

for temperature recording (if so equipped):

• Wind the chart drive on the recording thermometer

(Partlow recorders).

10. Stop the unit by moving the On/Off switch to the OFF

position.

• Press SETPOINT key to display cursor flashing in the

“TEMP SETP” line.

• Press F4 key to activate the setpoint change function.

An Enter Arrow appears in the menu line and the current

setpoint disappears.

• Enter minus sign (if required) first by pressing EXIT

key. Then press numeric keys to enter new setpoint.

• With correct setpoint in display, press and hold F4 key

until cursor stops flashing. Controller places new setpoint in controller memory and shows new setpoint in

LCD display.

NOTE: New setpoint must be between -29 C and

+29 C (-20.2 F and +84.2 F) or controller will

return to the previous setpoint display.

NOTE: If the setpoint is not entered within 30

seconds, the controller will default (return) to the

previous setpoint. If this occurs, repeat step 3.

CSR40-149 & -150 PS Hermetic, June 2000

Page 41

Operating Instructions Loading Procedure 3-5

Loading Procedure

1. Make sure the Unit On/Off switch is OFF before opening

the container doors. (The unit may be operating when

loading the container from a warehouse with door seals.)

2. Spot check and record load temperature while loading.

Especially note any off-temperature product.

Post Load Procedure

1. Make sure all doors are closed and locked.

2. Start unit if unit is OFF.

3. Check controller setpoint for proper setting.

4. Enter trip identification information into the controller

memory by selecting “Cargo Data” from the MISC

FUNCTIONS menu of the controller.

5. One-half hour after loading, initiate a manual defrost

cycle:

• Press the DEFROST key. The Defrost and Heat LEDs

turns ON as the unit enters Defrost. Defrost will stop

automatically.

NOTE: The evaporator coil temperature must be

below 18 C (65 F) to allow the unit the enter a

defrost cycle. If the evaporator coil temperature

is too high, the LCD display will read “Defrost

Not Activated”.

Post Trip Procedure

Trip data recorded by the MP-3000 datalogger may be down

loaded via the communications port on the control box using a

DRU-II hand-held data retriever, or laptop computer with

SmartSponge retriever software; or via the REFCON remote

monitor system.

CSR40-149 & -150 PS Hermetic, June 2000

Page 42

Page 43

4 MP-3000 Controller

Controller Description

The MP-3000 is an advanced microprocessor controller that

has been specially developed for control and monitoring of

refrigeration units. The controller contains the following basic

features:

1. LED display for TEMPERATURE:

• Five alpha numeric, 20.32 mm high characters:

Numerical hundreds, tens, ones and tenths position, a C

for Celsius or F for Fahrenheit for temperature display.

• LED display shows controlling (return or supply) sensor

temperature. Sensor temperature shown in LED display

is indicated by status indicator lights. If a sensor is out

of range the display shows “+Err” or “-Err”. The +/sign indicates whether the sensor temperature is out of

range high or low.

• The LED display also shows the test stage of a Pretrip

(PTI) or Function test.

2. LCD display for SETPOINT, MESSAGES and MENU:

• 4 line, 80 character LCD display shows setpoint temper-

ature during normal operation.

• Alarms, messages and the controller menu also appear in

the LCD display when special keys are pressed.

3. Sixteen general purpose keys are used to enter text and

scroll through the controller menu tree.

a. Text Input: The keyboard supports both numerical

and text input. Each key can have more than one meaning. Use the special text keys F1, F2, F3 and F4 to enter

text in an information screen:

• F1 key: Press the F1 key, then press another general

purpose key to enter the number shown on the key.

• F2 key: Press the F2 key, then press another general

purpose key to enter the first letter shown on the key.

• F3 key: Press the F3 key, then press another general

purpose key to enter the second letter shown on the key.

• F4 key: Press the F4 key, then press another general

purpose key to enter the third letter shown on the key.

MP3000 Controller

NOTE: When the F1, F2, F3 or F4 key is pressed

to enter a character in the display, the keypad

remains on that “character level” until another

“level” is selected by pressing the F1, F2, F3 or

F4 key.

1. LED display for TEMPERATURE. Status indicator

LEDs identify controlling sensor temperature (return

or supply) that appears in display.

2. LCD display for SETPOINT, MESSAGES and

MENU. Use the keypad to scroll through messages

and the controller menu.

3. General purpose keys are used to enter text and

scroll through menus.

4. Special function keys perform specific tasks.

CSR40-149 & -150 PS Hermetic, June 2000

Page 44

4-2 Controller Description MP-3000 Controller

Text Input Example: To enter THERMO in an information screen:

a. Enter “T” by pressing F3 key, then pressing STU key.

b. Enter “H” by pressing GHI key.

c. Enter “E” by pressing DEF key.

d. Enter “R” by pressing F4 key, then pressing PQR

key.

e. Enter “M” by pressing F2 key, then pressing MNO

key.

f. Enter “O” by pressing F4 key, then pressing MNO

key.

b. Menu Scrolling: General text keys F1, F2, F3 and

F4 also include directional arrows for entering and

scrolling through the controller Main Menu:

• F1 key: ESC indicates that pressing the F1 key moves

the cursor out of (exits) a menu list.

• F2 key: FORWARD/UP ARROWS indicate that pressing the F2 key scrolls the cursor forward and/or upward

through text boxes and menu lists.

• F3 key: BACKWARD/DOWN ARROWS indicate that

pressing the F3 key scrolls the cursor backward and/or

downward through text boxes and menu lists.

• F4 key: ENTER ARROW indicates that pressing the F4

key moves the cursor into the next menu level or into a

menu item text box.

4. Four special function keys (see illustration on page 4-1):

• C/F key: Press to view alternate temperature scale in

LED display.

• DEFROST key: Press to initiate defrost. Evaporator

coil temperature must be below 18 C (65 F).

• SUP/RET key: Press to view alternate return/supply

sensor temperature in LED display.

• SETPOINT key: Press to enter Setpoint Menu. The

first line of the Setpoint Menu is the setpoint temperature. Press F2 or F3 key to scroll up or down through

the menu list.

NOTE: Press the “5” key to increase the display

time of the current LCD data screen by 5 minutes. Maximum display time is 30 minutes for

data screens and 100 minutes for manual tests.

5. Status indicator LEDs (see “Status Indicator LEDs and

Alarm Codes” in this chapter).

6. Control Transformer: Low voltage control power and

ground is supplied to the MP-3000 controller and the main

relay board.

7. Main Relay Board: High voltage supply power and low

voltage control power and ground are supplied to the main

relay board. The main relay board contains:

• Relays to energize and de-energize unit contactors and

solenoids. Component relays include the heater, evaporator fan motor, condenser fan motor, and phase reversal

relays.

• Supply power circuit protection:

- 20 amp fuses (3) protect the high voltage circuits on the

main relay board.

• Control circuit fuse and circuit breaker protection:

- 7 amp manual reset circuit breaker protects the 24 Vdc

control circuit.

- 2 amp fuse protects the 28V ac control power circuit to

the controller.

- 2 amp fuse protects the battery charger output circuit to

the controller.

• Electronics for measuring phase sequence.

• Electronics for measuring amperage.

• Electronics for measuring voltage.

• Zero current transformer for earth leaking measurement

(option).

8. Replaceable sensors: Return air, supply air, evaporator

coil (defrost), condenser coil, ambient air and compressor

discharge (top cap) temperature sensors are field replaceable. Three (replaceable) spare sensor receptacles are also

provided for USDA temperature recording.

9. Probe Test (see “Probe Test” in this chapter).

10. Defrost cycle control (see “Defrost System” in this chapter).

11. Pretrip (PTI) test capability (see “PTI (Pretrip) Test” in

this chapter).