Thermo King 098223, 098580, 098218, 098581, 098582 Maintenance Manual

...

Additional text information

Maintenance Manual

SB-210+

SB-210+

MAGNUM +

Additional text information

Additional text information

to be placed here

to be placed here

TK 60275-4-MM (Rev. 3, 08/15)

TK 5XXXX-X-PL

TK 5XXXX-X-PL

MAGNUM+

TK 60275-4-MM (Rev. 3, 08/15)

Copyright© 2012 Ingersoll Rand - EMEIA Printed in Ireland

The maintenance information in this manual covers unit models:

Base Units

MAGNUM+ 098212 098216 098218 098203

098219 098223 098580

098581 098582 098583

098585 098586 098587

098588 098589 098590

098591 098592 098593

098594

For further information, refer to:

Parts Manuals

MAGNUM Parts List TK 54356

Operation, Diagnosis and Refrigeration Maintenance Manuals

Diagnosing Thermo King Container Refrigeration Systems TK 41166

Electrostatic Discharge (ESD) Training Guide TK 40282

Evacuation Station Operation and Field Application TK 40612

Tool Catalog TK 5955

The information in this manual is provided to assist owners, operators and service people in the proper

upkeep and maintenance of Thermo King units.

Revision History

Rev. 3 – TK 60275-4-MM (Rev. 3, 08/15) Add information per Service and Software Bulletins

since previous revision.

This manual is published strictly for informational purposes. The informa tion so provided sh ould

not be considered as all-inclusive or covering all contingencies. Thermo King Corporation

should be consulted if further information is required.

Sale of product shown in this manual is subject to Thermo King’s terms and conditions.

This includes, but not limited to, the Thermo King Limited Express Warranty. Such terms

and conditions are available upon request. Thermo King’s warranty will not apply to any

equipment which has been “so repaired or altered outside the manufacturer’s plants as,

in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, are made regarding the information,

recommendations, and descriptions contained herein. This includes warranties of

fitness for a particular purpose or merchantability, or warranties arising from course of

dealing or usage of trade. The manufacturer is not responsible and will not be held liable

in contract or in tort (including negligence) for any special, indirect or consequential

damages. This includes injury or damage caused to vehicles, contents or persons, by

reason of the installation of any Thermo King product or its mechanical failure.

2

Recover Refrigerant

At Thermo King, we recognize the need to preserve the environment

and limit the potential harm to the ozone layer that can result from

allowing refrigerant to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and limits

the loss of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regulations

concerning the use of refrigerants and the certification of technicians.

For additional information on regulations and technician certification

programs, contact your local Thermo King dealer.

R-404A

WARNING: Use only Polyol Ester-based refrigeration compressor oil in

R-404A. See Thermo King Parts Manual for part number.

Do not mix Polyol Ester and standard synthetic compressor oils. Keep Polyol

Ester compressor oil in tightly sealed containers. If Polyol Ester oil becomes

contaminated with moisture or standard oils, dispose of properly–DO NOT USE.

When servicing Thermo King R-404A unit, use only those service tools certified

for and dedicated to R-404A refrigerant and Polyol Ester compressor oils.

Residual non-HFX refrigerants or oils will contaminate R-404A systems.

3

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Refrigerant Oil Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electrostatic Discharge and the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Welding of Units or Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Removing Refrigerant Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Identifying Unit Safety and Warning Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Locating Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Component Serial Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Service Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Service Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Evaporator Airflow Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Electrical System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Refrigeration System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Unit Description, Features & Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Scroll Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

MP-4000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Power Module Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Compressor Digital Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Economizer Heat Exchange System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Fresh Air Exchange System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Receiver Tank Sight Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Evaporator Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Condenser Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

USDA Cold Treatment Temperature Recording (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Electronic Chart Recorder (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Remote Monitoring Modem (RMM, RMM+) (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Suction and Discharge Pressure Sensors (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

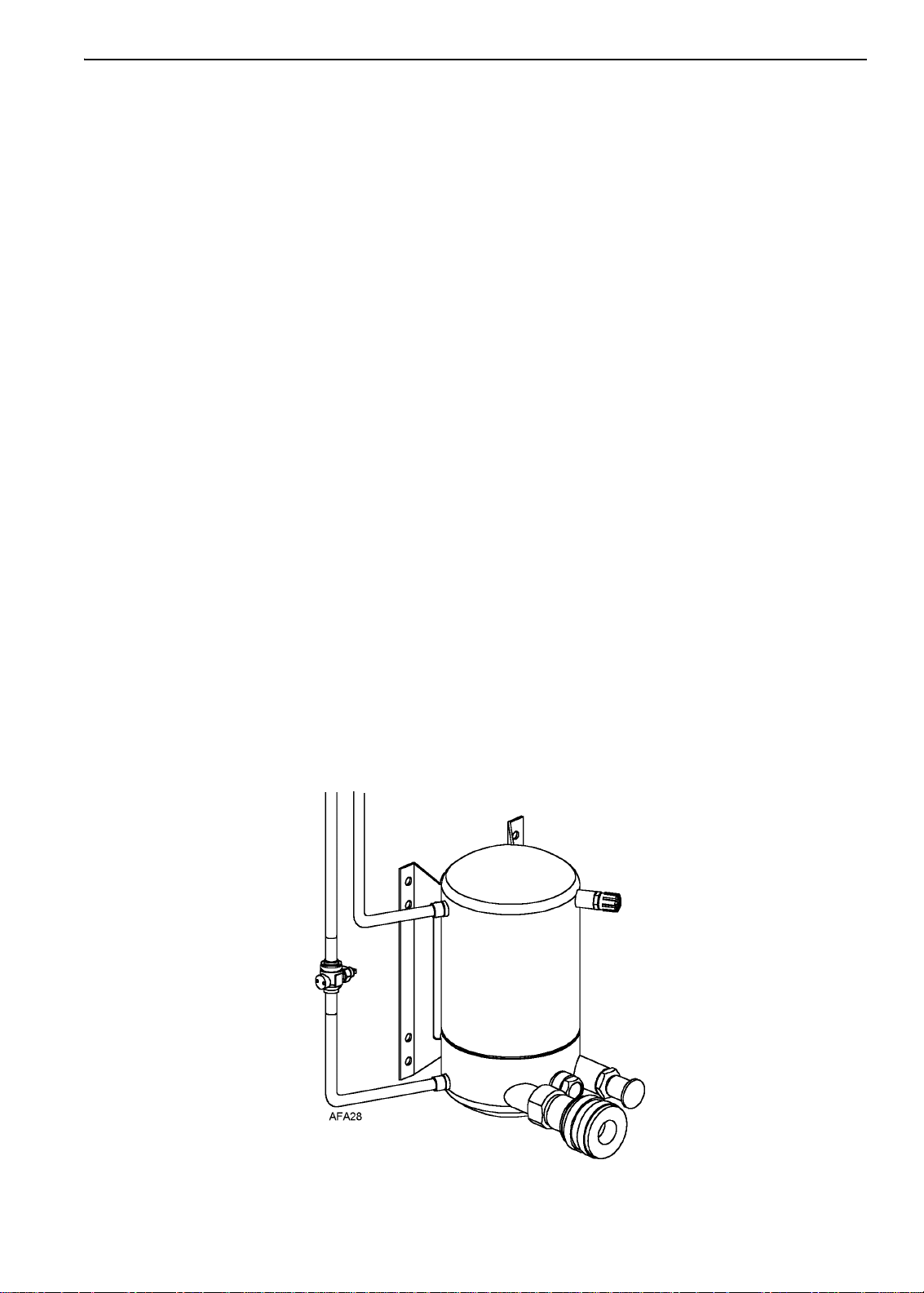

Water-Cooled Condenser/Receiver Tank (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Air Ventilation Logging (AVL - Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Advanced Fresh Air Management (AFAM) System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Advanced Fresh Air Management Plus (AFAM+) System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Controller Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Controller Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Controller Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Controller Input and Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Idle Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Glossary of Mode Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Three Special Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

MP-4000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Software Version 2.3.4 100927 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Version 2.3.6 110301

Software Version 2.3.7.0 110608 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Software Version 2.3.8.0 110628 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Software Version 2.4.0.0 111220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

. . . . . . .44

4

Table of Contents

Software Version 2.4.2.0 120313 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Software Version 2.4.3.0 120628 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Software Version 2.5.0.0 121121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Software Version 2.5.1.0 130213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Software Version 2.5.3.0 130424 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Software Version 3.1.0.0 140612 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Software Version 3.2.0.0 140822 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unit On/Off Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Unit Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Initiating a Manual Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Viewing Alarms/Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Display Alternate Fahrenheit (F) or Celsius (C) Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Changing Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Controller Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Controller Lockup Issue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Emergency Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Rotation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FULL COOL Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DEFROST Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

High or Low Speed Fans Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Navigating the Controller Operating Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Navigating the Controller Operating Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Icon Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Menu Scrolling Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Changing Screen Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Data/Values Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

MP4000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Data/Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Setpoint/Control Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cold Treatment (CT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Multiple Temperature Set (MTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

OPTISET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Controlling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Pull Down Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Watercool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Humidity Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

AVL (Air Ventilation Logging) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Fresh Air Vent Man - AFAM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Fresh Air Vent Man - AFAM+ Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

AFAM Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

AFAM Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

AFAM+ CO2 Max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFAM+ O2 Min

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 77

. . . . . . . . . . 77

Smart PTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Alarm List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Warning List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Unit Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Unit Configuration (Configuration Depends on Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5

Table of Contents

Miscellaneous Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Datalogger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

States Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Special Function Keys - User Activated Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

PTI Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Defrost Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

PTI (Pretrip) Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Automated Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Manual Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Alarms/Warnings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Alarm Code States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Alarm/Warning List Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

View the Alarm/Warning List Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Warning List Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Alarm List Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Viewing or Setting Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Set Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Datalogger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Viewing the Datalogger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Inspect Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Trip Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Set Log Time Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

States Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Air Ventilation Logging (AVL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Starting the AFAM System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Change the AFAM Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Change the AFAM Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Advanced Fresh Air Management Plus (AFAM+) System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Set AFAM+ System Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Change the AFAM Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Change the CO

Minimum and Maximum Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

2

Changing the AFAM+ Settings Using ‘OPTISET’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Modify Optiset Product Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Testing AFAM+ / AFAM System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

AFAM+ Option Alarm Codes (see manual for further descriptions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Pulsating Vent Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

AFAM+ Door Closes Automatically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Pulsating AFAM+ Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

AFAM+ Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Operating Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Chill Loads: (Setpoint at -9.9 C [14.1 F] and Above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Frozen Loads: (Setpoint at -10 C [14 F] and Below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Compressor Vapor Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

High Temperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Power Limit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Evaporator Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Condenser Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Probe Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Dehumidify Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Continuous Temperature Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Frozen Loads (Controller Setpoint at -10 C [14 F] and Below): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Compressor Digital Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Economizer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Data Recording and Downloading Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Cold Treatment (CT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Multiple Temperature Setpoint (MTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

6

Table of Contents

Controller Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Controller Door Open and Close Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Flash Loading Controller Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

MP-4000 Test System Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Controller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Electrical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Main Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Evaporator Overheat Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

High Pressure Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

High Pressure Cutout Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

High Pressure Cutout Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

High Pressure Cutout Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Low Pressure Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Low Pressure Cutout Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Low Pressure Cutout Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Low Pressure Cutout Switch or Suction Transducer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Discharge and Low Pressure Sensors (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Discharge and Low Pressure Sensors Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Discharge and Low Pressure Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Condenser Fan and Evaporator Fan Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Check Condenser Fan Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Check Evaporator Fan Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Reversing Power Phase on MAGNUM Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Evaporator Heater Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Extended Capacity Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Electric Heaters Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Compressor Discharge Gas Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Compressor Discharge Temperature Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Installing Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Testing the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Resistance Values for Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Refrigeration Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Use the Correct Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Use the Correct Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Use Filters and Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Use the Correct Refrigerant Recovery Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Detecting Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Locating Special Service Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Perform an Oil Acid Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Isolate the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Working with a Gauge Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Using a New Gauge Manifold Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Gauge Manifold Valve Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Gauge Manifold Set Installation & Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Gauge Manifold Set Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Removing the Gauge Manifold Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Checking Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Receiver Tank Sight Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing the Refrigeration System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

. . . . . . . . . 176

Using Pressurized Nitrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Purge High Side to Low Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Maximum Gas Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Recovering Refrigerant from the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Evacuation and Cleanup of the Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

7

Table of Contents

Unit Preparation and Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Unit Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Pressure Rise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Factors Affecting the Speed of System Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Heat Saves Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Charging the System with Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Unit Charging by weight (from an Evacuated Condition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Compressor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Compressor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Condenser Coil Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Filter Drier/In-line Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Evaporator Expansion Valve (TXV) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Economizer Expansion Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Economizer Heat Exchanger Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Economizer Heat Exchanger Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Economizer Heat Exchanger installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

Receiver Tank/ Water-Cooled Condenser Tank Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Vapor Injection Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Compressor Digital Control Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Servicing The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Taking Care of the Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Inspecting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Checking the Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Cleaning the Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Cleaning the Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Cleaning the Defrost Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Positioning the Condenser Fan Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Positioning the Evaporator Fan Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Servicing the Fresh Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Adjusting the Fresh Air Exchange System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Diagnosis: Troubleshooting, Warnings and Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Controller Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Warnings and Controller Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Wiring and Schematic Diagrams Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Controller Menu Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

8

Safety Instructions

General Precautions

• Always wear goggles or safety glasses. Refrigerant liquid and battery acid can permanently damage

the eyes.

• Never operate the unit with the discharge valve closed. Never close the compressor discharge valve

with the unit in operation.

• Keep your hands, clothing and tools clear of the fans when the refrigeration unit is running. If it is

necessary to run the refrigeration unit with covers removed, be very careful with tools or meters being

used in the area.

• Check the condition of the gauge manifold hoses. Never let the hoses come in contact with a fan

motor blade or any hot surface.

• Never apply heat to a sealed refrigeration system or container.

• Fluorocarbon refrigerants produce toxic gases in the presence of an open flame or electrical arc. The

gases are severe respiratory irritants capable of causing death.

• Firmly tighten all mounting bolts. Check each bolt for correct length for their particular application.

• Use extreme caution when drilling holes in the unit. The holes may weaken structural components.

Holes drilled into electrical wiring can cause fire or explosion. Holes drilled into the refrigeration

system may release refrigerant.

• Use caution when working around exposed coil fins. The fins can cause painful lacerations.

• Use caution when working with a refrigerant or refrigeration system in any closed or confined area

with a limited air supply (for example, a trailer , container or in the hold of a ship). Refrigerant tends to

displace air and can cause oxygen depletion. This can result in suffocation and possible death.

• Use caution and follow the manufacturer’s suggested practices when using ladders or scaffolds

.

Refrigerant Oil Precautions

Observe the following precautions when working with or around refrigerant oil:

• Do not allow refrigerant oil to contact your eyes.

• Rubber gloves are recommended when handling Polyol Ester based refrigerant oil.

• Do not allow prolonged or repeated contact with skin or clothing.

• Immediately wash all exposed skin after handling refrigerant oil.

Use the following First Aid practices if needed.

Eyes: Immediately flush eyes with large amounts of water. Continue flushing for at least 15 minutes

while holding the eyelids open. Get prompt medical attention.

Skin: Remove contaminated clothing. Wash thoroughly with soap and water. Get medical attention if

irritation persists.

Inhalation: Move victim to fresh air. Restore breathing if necessary. Stay with victim until arrival of

emergency personnel.

Ingestion: Do not induce vomiting. Contact a local poison control center or physician immediately.

9

Safety Instructions

Electrical Precautions

The possibility of serious or fatal injury from electrical shock exists when servicing a refrigeration unit.

Extreme care must be used when working with a refrigeration unit that is connected to its power source.

Extreme care must be used even if the unit is not running. Lethal voltage potentials can exist at the unit

power cord, inside the control box, inside any high voltage junction box, at the motors and within the

wiring harnesses.

Precautions

In general disconnect the units power cord before repairi ng or changing any electrical

components.

Note that even though the controller is turned off, one of the phases is still live and represents

a potential danger of electrocution

Where turning of the unit is not possible (for example at voltage measuring or troubleshooting), follow

safety precautions below.

• Turn the unit On/Off switch to Off before connecting or disconnecting the unit power plug. Never

attempt to stop the unit by disconnecting the power plug.

• Be certain the unit power plug is clean and dry before connecting it to a power source.

• Use tools with insulated handles. Use tools that are in good condition. Never hold metal tools in your

hand if exposed, energized conductors are within reach.

• Do not make any rapid moves when working with high voltage circuits. Do not grab a falling tool or

other object. People do not contact high voltage wires on purpose. It occurs from an unplanned

movement.

• Treat all wires and connections as high voltage until ammeter and wiring diagram show otherwise.

• Never work alone on high voltage circuits on the refrigeration unit. Another person should always be

standing by in the event of an accident to shut off the refrigeration unit and to aid a victim.

• Have electrically insulated gloves, cable cutters and safety glasses available in the immediate vicinity

in the event of an accident.

First Aid

IMMEDIATE action must be initiated after a person has received an electrical shock. Obtain immediate

medical assistance.

The source of shock must be immediately removed. Shut down the power or remove the victim from the

source. If it is not possible to shut off the power , the wire should be cut with either an insulated instrument

(e.g., a wooden handled axe or cable cutters with heavy insulated handles). A rescuer wearing electrically

insulated gloves and safety glasses could also cut the wire. Do not look at the wire while it is being cut.

The ensuing flash can cause burns and blindness.

Pull the victim off with a non-conductive material if the victim has to be removed from a live circuit. Use

the victim’s coat, a rope, wood, or loop your belt around the victim’s leg or arm and pull the victim off.

Do not touch the victim. You can receive a shock from current flowing through the victim’s body.

Check immediately for the presence of a pulse and respiration after separating the victim from power

source. If a pulse is not present, start CPR (Cardio Pulmonary Resuscitation) and call for emergency

medical assistance. Respiration may also be restored by using mouth-to-mouth resuscitation.

10

Safety Instructions

Low Voltage

Control circuits are low voltage (24 Vac and 12 Vdc). This voltage potential is not considered dangerous.

Large amount of current available (over 30 amperes) can cause severe burns if shorted to ground. Do not

wear jewelry, watch or rings. These items can shortcut electrical circuits and cause severe burns to the

wearer.

Electrostatic Discharge Precautions

Precautions must be taken to prevent electrostatic discharge while servicing the MP-3000a

microprocessor and related components. The risk of significant damage to the electronic components of

the unit is possible if these precautionary measures are not followed. The primary risk potential results

from the failure to wear adequate electrostatic discharge preventive equipment when handling and

servicing the controller. Th e second cause results from electric welding on the unit and container chassis

without taking precautionary steps.

Electrostatic Discharge and the Controller

You must avoid electrostatic discharges when servicing the controller. Solid-state integrated circuit

components can be severely damaged or destroyed with less than a small spark from a finger to metal

object. You must rigidly adhere to the following statements when servicing these units. This will avoid

controller damage or destruction.

• Disconnect all power to the unit.

• Avoid wearing clothing that generates static electricity (wool, nylon, polyester, etc.).

• Do wear a static discharge wrist strap (refer to Tool Catalog) with the lead end connected to the

controller's ground terminal. These straps are available at most electronic equipment distributors. Do

not wear these straps with power applied to the unit.

• Avoid contacting the electronic components on the circuit boards of the unit being serviced.

• Leave the circuit boards in their static proof packing materials until ready for installation.

• Return a defective controller for repair in the same static protective packing materials from which the

replacement component was removed.

• Check the wiring after servicing the unit for possible errors. Complete this task before restoring

power.

11

Safety Instructions

Welding of Units or Containers

Electric welding can cause serious damage to electronic circuits when performed on any portion of the

refrigeration unit, container or container chassis with the refrigeration unit attached. It is necessary to

ensure that welding currents are not allowed to flow through the electronic circuits of the unit. The

following statements must be rigidly adhered to when servicing these units to avoid damage or

destruction.

• Disconnect all power to the refrigeration unit.

• Disconnect all quick-disconnect wire harnesses from the back of the controller.

• Disconnect all wire harnesses from the Remote Monitor Modem (RMM).

• Switch all of the electrical circuit breakers in the control box to the Off position.

• Weld unit and/or container per normal welding procedures. Keep ground return electrode as close to

the area to be welded as practical. This will reduce the likelihood of stray welding currents passing

through any electrical or electronic circuits.

• The unit power cables, wiring and circuit breakers must be restored to their normal condition when

the welding operation is completed.

Removing Refrigerant Properly

Use a refrigerant recovery process that prevents or absolutely minimizes refrigerant escaping to the

atmosphere. Fluorocarbon refrigerants are classified as safe refrigerants when proper tools and

procedures are used. Certain precautions must be observed when handling them or servicing a unit in

which they are used.

Fluorocarbon refrigerants evaporate rapidly, freezing anything they contact when exposed to the

atmosphere in the liquid state. In the event of frost bite, attempt to protect the frozen area from further

injury, warm the affected area rapidly, and maintain respiration.

• Eyes: For contact with liquid, immediately flush eyes with large amounts of water and get prompt

medical attention.

• Skin: Flush area with large amounts of lukewarm water. Do not apply heat. Remove contaminated

clothing and shoes. Wrap burns with dry, sterile, bulky dressing to protect from infection/injury. Get

medical attention. Wash contaminated clothing before reuse.

• Inhalation: Move victim to fresh air and use CPR or mouth-to-mouth ventilation, if necessary. Stay

with victim until arrival of emergency medical personnel.

12

Safety Instructions

2

BEN074

AXA0214

AXA0215

AXA0218

AXA0217

AXA0216

1

3

1. Controller Nameplate

2. Unit Nameplate

3. Compressor Nameplate

Nameplate and Warning Locations

13

Safety Instructions

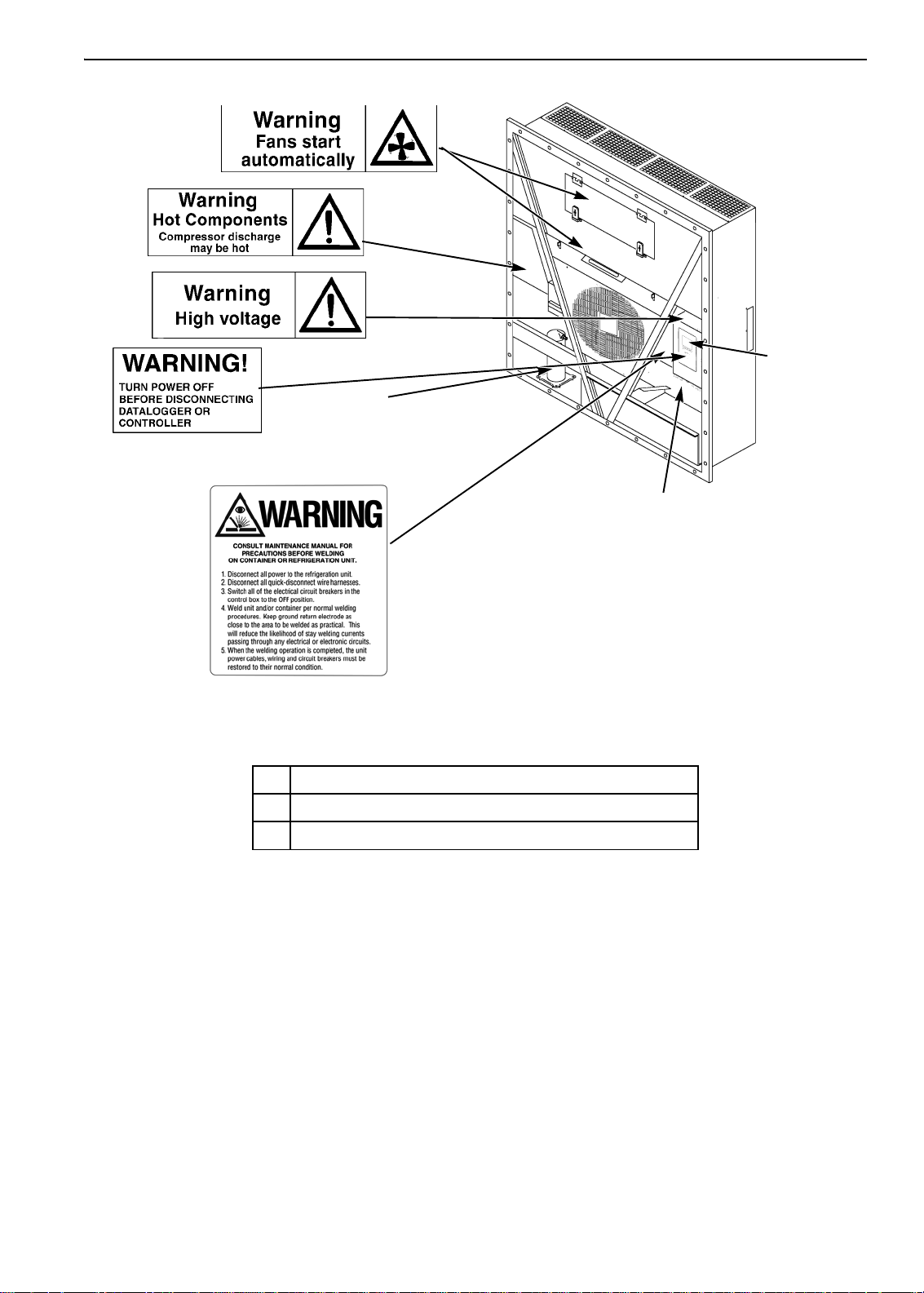

Identifying Unit Safety and Warning Decals

Serial number decals, refrigerant type decals and warning decals appear on all Thermo King® equipment.

These decals provide information that may be needed to service or repair the unit. Service technicians

should read and follow the instructions on all warning decals. See Figure .

Locating Serial Numbers

Serial numbers can be found on the component’s nameplate.

• Electric Motor Nameplate: Attached to the motor housing.

• Compressor Nameplate: On front of the compressor.

• Unit Nameplate: On unit frame in power cord storage compartment.

• MP-4000 Controller Nameplate: On top of controller.

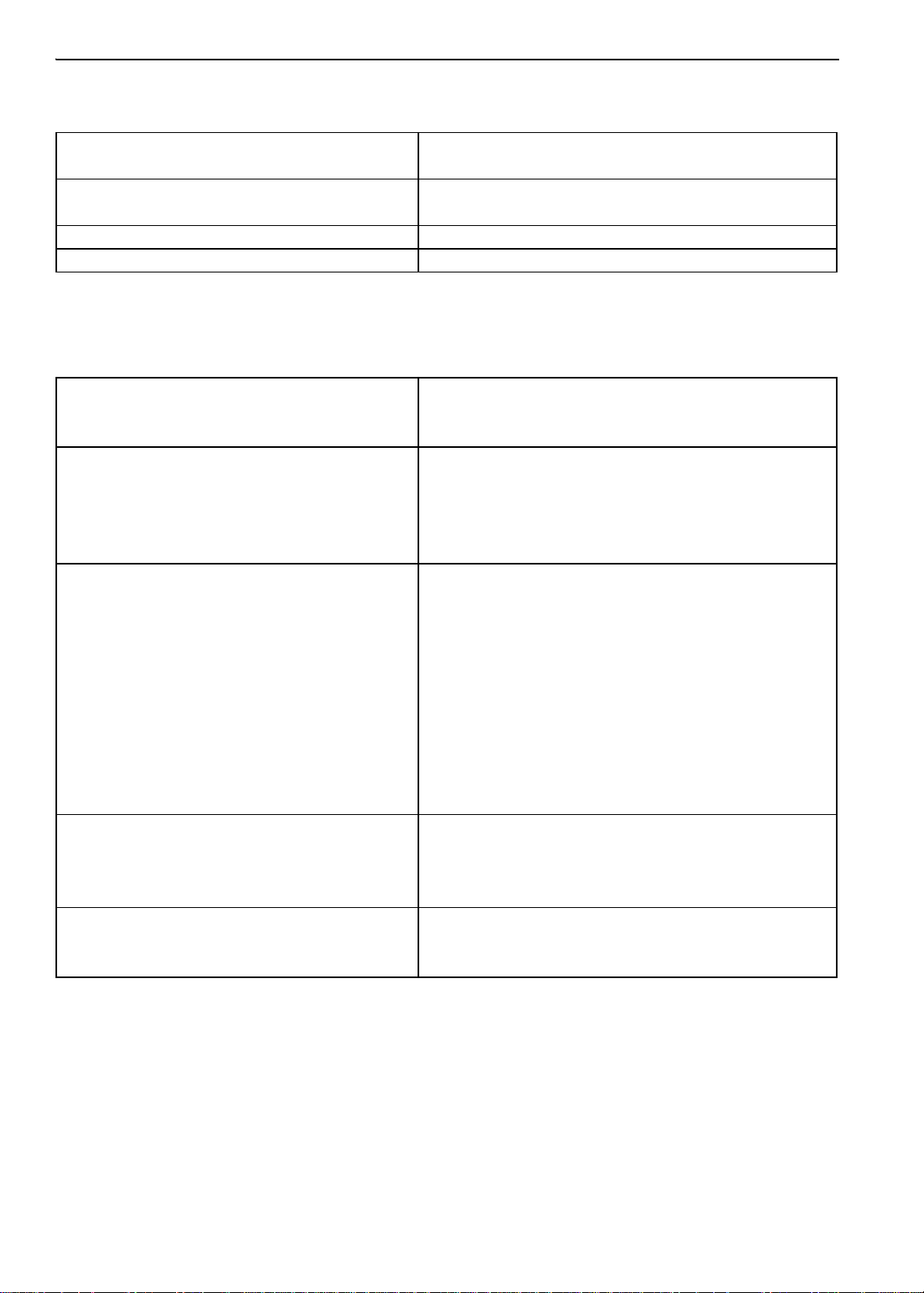

Component Serial Number Identification

To better identify the different electronic components, our supplier has changed their serial number

labeling on the MP-4000 controller and power module. The label will show part number, date, and

sequence.

MP4000 Controller

New label shows controller ID ABS782800212245390

Part number Date 2012 24 wk Sequence

ABS7828002 1224 5390

ID in controller would show 1224-5390

Figure 1: Label on Controller Figure 2: ID in Controller

14

Figure 3: Controller ID Shown in Datalogger

Service Guide

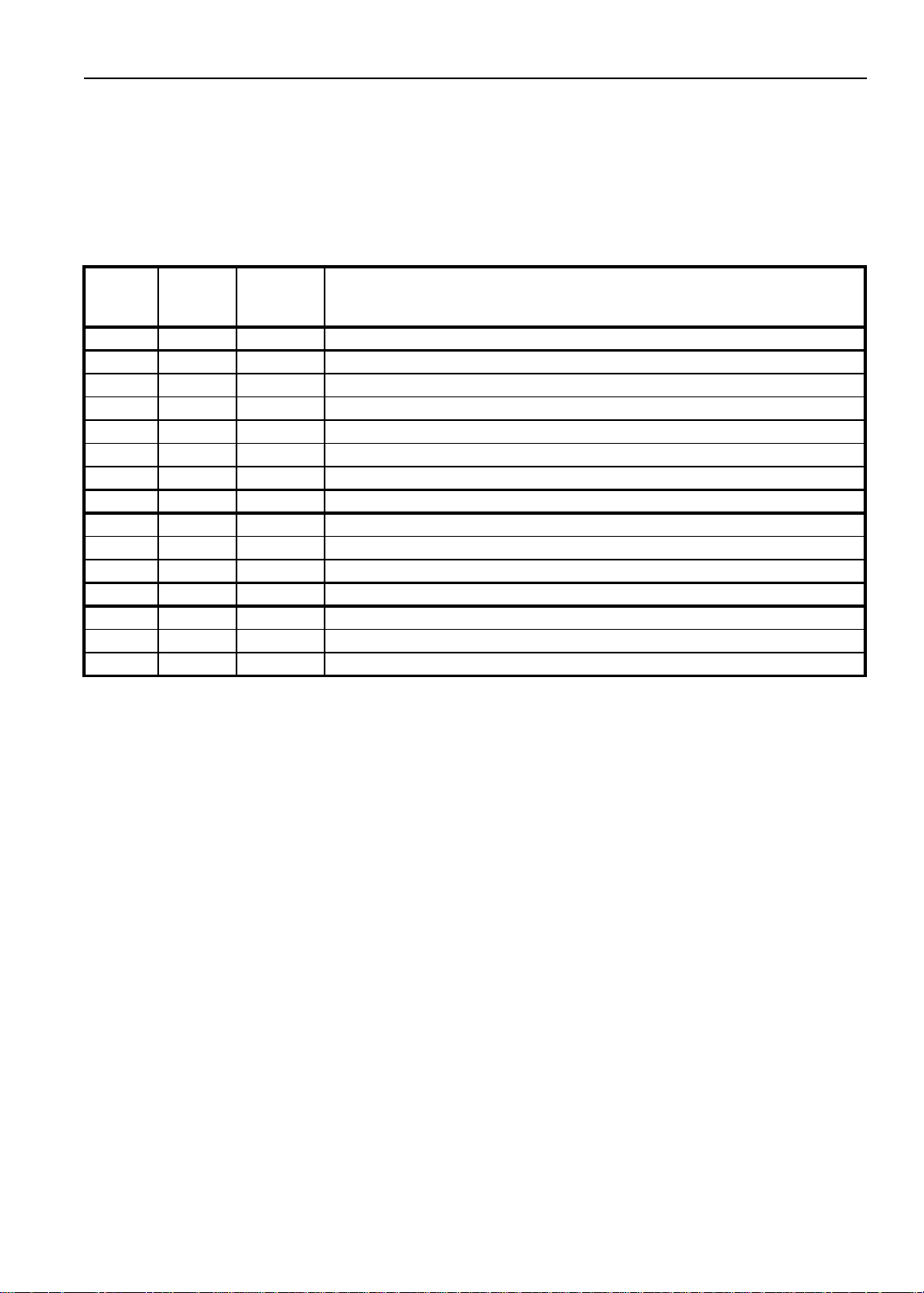

Service Guide

A closely followed maintenance program will help to keep your Thermo King unit in top operating

condition.

The following service guide table should be used as a guide when inspecting or servicing components on

this unit.

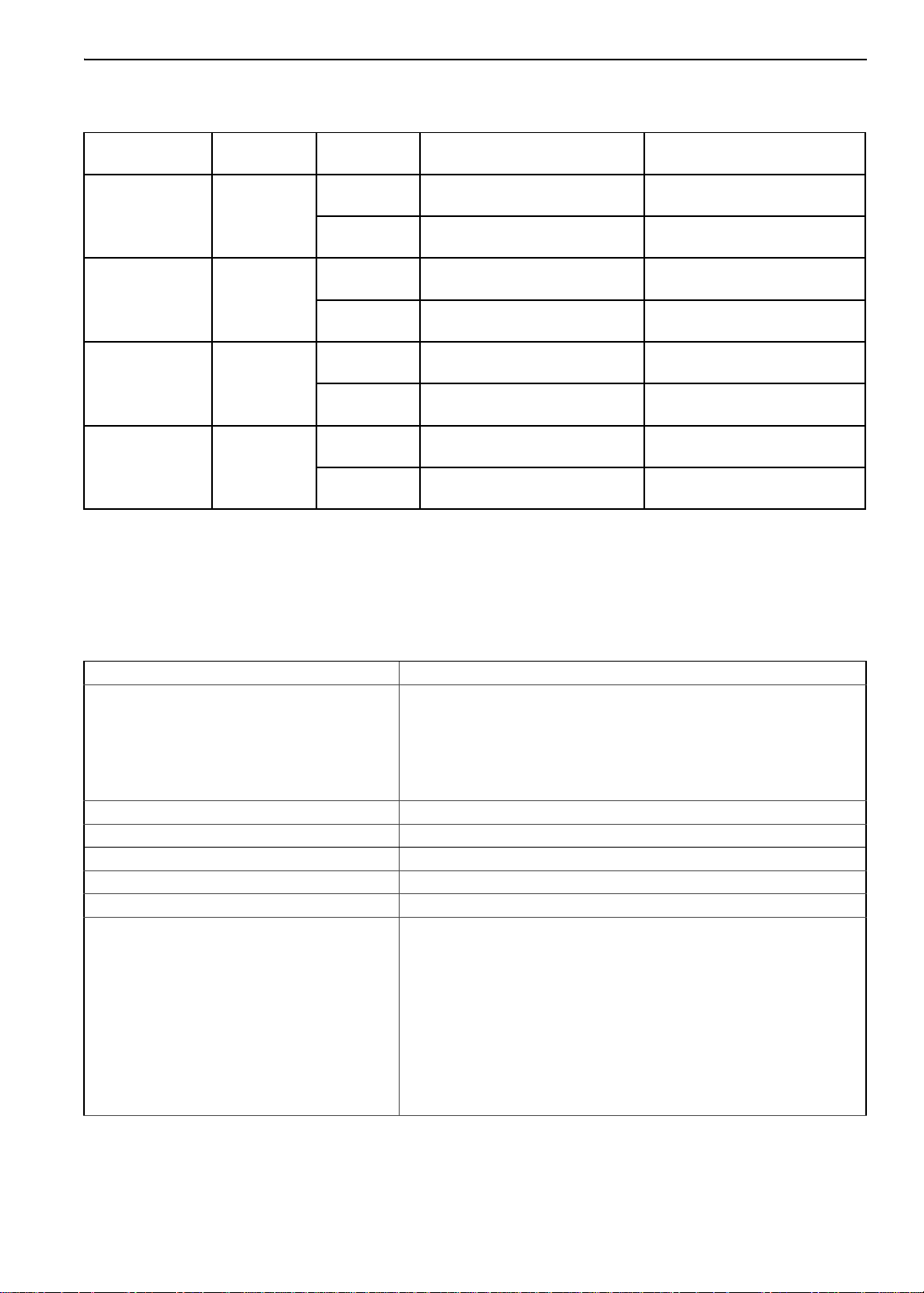

Every

Pretrip

• Perform a controller pretrip inspection (PTI) check.

• • • Visually check condenser fan and evaporator fan.

• • • Visually inspect electrical contacts for damage or loose connections.

• • • Visually inspect wire harnesses for damage or loose connections.

• • • Check refrigerant charge.

• • • Visually inspect unit for damaged, loose or broken parts.

• • • Tighten unit, compressor and fan motor mounting bolts.

1,000

Hours

• • Download the data logger and check data for correct logging.

• • Check for proper discharge and suction pressures.

• • Clean entire unit including condenser and evaporator coils, and defrost drains.

Annual/

Yearly

Electrical

• Check operation of protection shutdown circuits.

Refrigeration

• Check filter drier/in-line filter for a restriction pressures.

Structural

Inspect/Service These Items

NOTE: If a unit has been carrying cargo which contains a high level of sulphor or phosphorous (e.g.

garlic, salted fish etc.), it is recommended that clean evaporator coil after each trip.

15

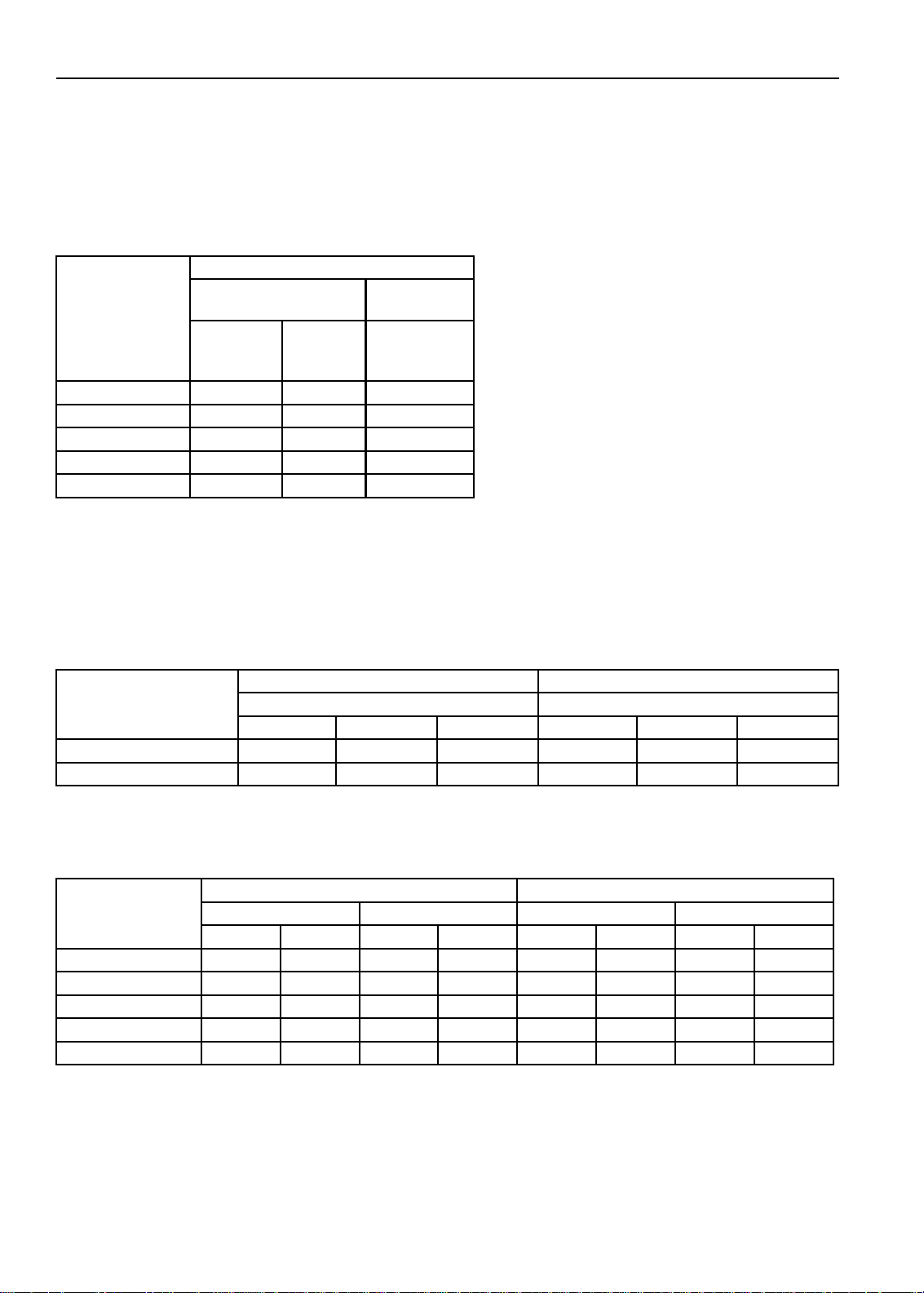

Specifications

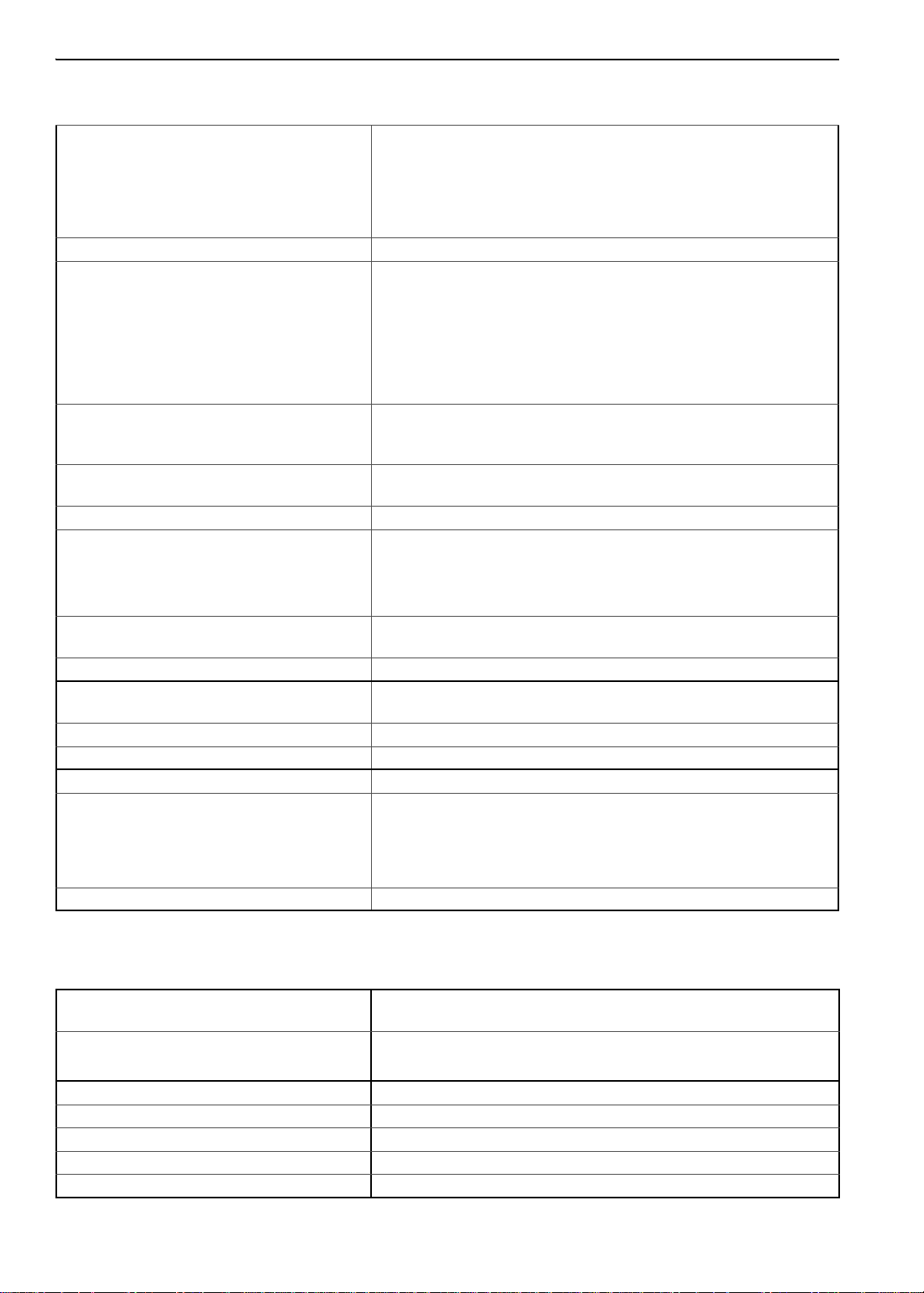

System Net Cooling Capacity— Full Cool

MAGNUM+ Model — Air Cooled

Condensing*

460/230V, 3 Phase, 60 Hz Power

Return air to

evaporator coil

inlet

21.1 C (70 F) 56,700 16.603 11.55

1.7 C (35 F) 40, 945 11.990 11.03

-17.8 C (0 F) 24,785 7.258 7.57

-29 C (-20 F) 17, 215 5,041 6.6

-35 C (-31 F) 14,000 4.104 6.03

*System net cooling capacity with a 38 C (100 F) ambient air

Net Cooling Capacity Power

Consump

60 Hz

Capacity

B/hr

temperature and R-404A.

60 Hz

Capacity

kW

60 Hz Power

kW

Evaporator Airflow Specifications

System Net Heating Capacity*

460/230V, 3 Phase, 60 Hz Power 380/190V, 3 Phase, 50 Hz Power

Heating Capacity Heating Capacity

Watts Kcal/hr BTU/hr Watts Kcal/hr BTU/hr

MAGNUM+ normal 5,250 4,515 17,914 3,900 3,353 13,300

MAGNUM+ extended 7,250 6,234 24,738 5,550 4,772 18,937

*System net heating capacity includes electric resistance rods and fan heat.

MAGNUM+

External Static

Pressure (water

column)

0 mm (0 in.) 6,560 3,860 3,170 1,865 5,480 3,225 2,710 1,595

10 mm (0.4 in.) 5,820 3,425 1,770 1,040 4,530 2,665 930 545

20 mm (0.8 in.) 5,000 2,940 — — 3,750 2,205 — —

30 mm (1.2 in.) 4,430 2,610 — — 2,930 1,725 — —

40 mm (1.6 in.) 3,520 2,070 — — 1,870 1,100 — —

460/230V, 3 Phase, 60 Hz Power 380/190V, 3 Phase, 50 Hz Power

High Speed Low Speed High Speed Low Speed

3

m

/hr ft3/min m3/hr ft3/min m3/hr ft3/min m3/hr ft3/min

16

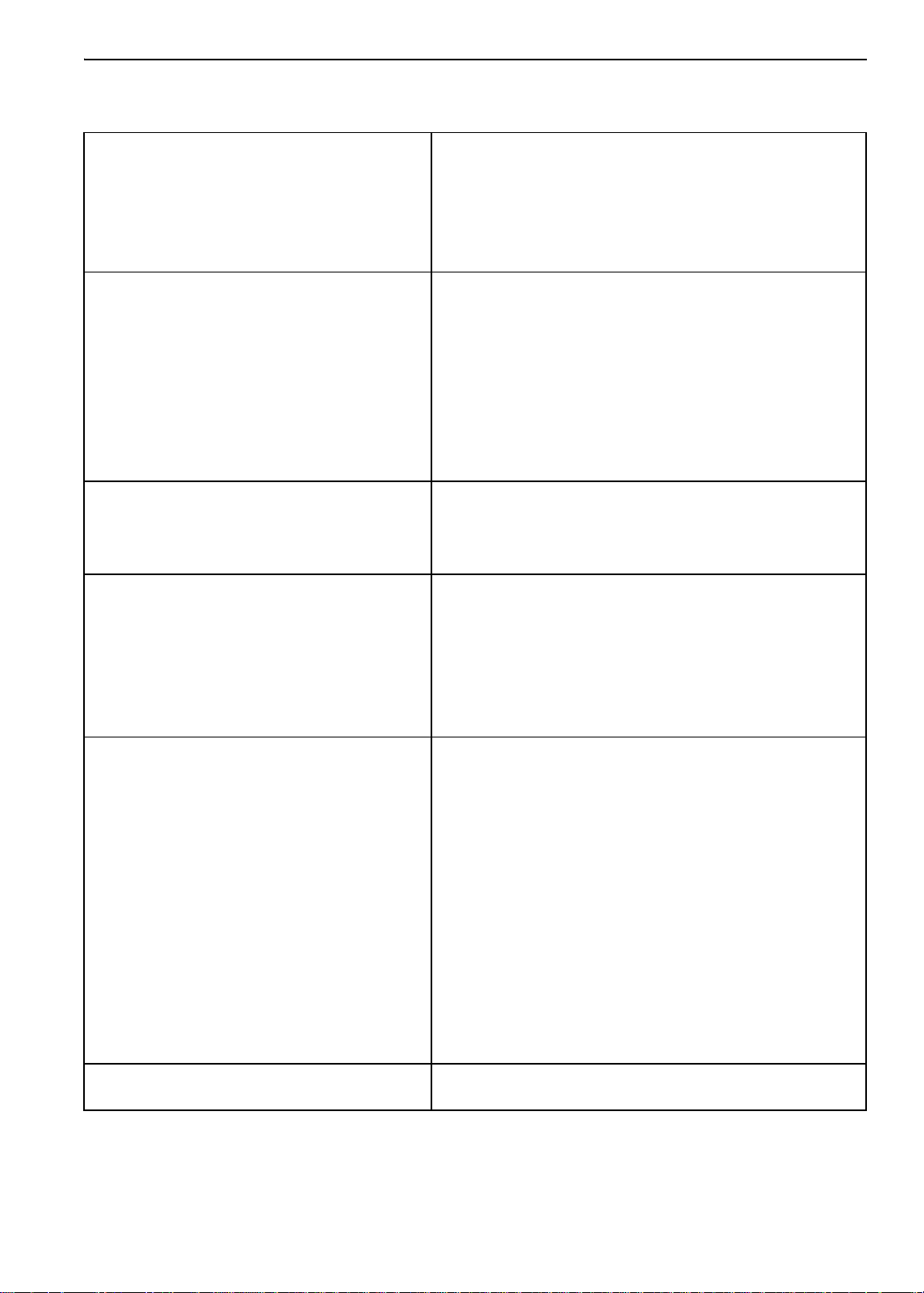

Electrical System Specifications

Compressor Motor:

Type 460/380V, 60/50 Hz, 3 Phase

Kilowatts 4.48 kW @ 460V, 60 Hz

Horsepower 6.0 hp @ 460V, 60 Hz

RPM 3550 RPM @ 460V, 60 Hz

Locked Rotor Amps 70 amps @ 460V, 60 Hz

Condenser Fan Motor:

Type 460/380V, 60/50 Hz, 3 Phase

Kilowatts 0.55 kW @ 460V, 60 Hz

Horsepower 0.75 hp @ 460V, 60 Hz

Number: All Models 1

Motor:

RPM 1725 RPM @ 460V, 60 Hz

Full Load Amps 1.0 amps @ 460V, 60 Hz; 1.0 amps @ 380V, 50 Hz

Locked Rotor Amps 3.9 amps @ 460V, 60 Hz; 3.7 amps @ 380V, 50 Hz

Evaporator Fan Motors:

Type 460/380V, 60/50 Hz, 3 Phase

Kilowatts 0.75 kW @ 460V, 60 Hz

Horsepower 1.0 hp @ 460V, 60 Hz

Motor:

RPM (Each): High Speed 3450 RPM @ 460V, 60 Hz

Low Speed 1725 RPM @ 460V, 60 Hz

Full Load Amps (Each): High Speed 1.6 amps @ 460V, 60 Hz

Low Speed 0.8 amps @ 460V, 60 Hz

Locked Rotor Amps: High Speed 10.5 amps @ 460V, 60 Hz

Low Speed 9.0 amps @ 460V, 60 Hz

Electrical Resistance Heater Rods:

Type 460/380V, 60/50 Hz, 3 Phase

Number:

Normal Capacity

Normal Capacity

Extended Capacity

Watts (Each):

Normal Capacity

Normal Capacity

Extended Capacity

Current Draw (Amps):

Normal Capacity

Extended Capacity

Control Circuit Voltage:

6 (18 ga wire)

3 (18 ga wire)

3 (16 ga wire)

680 Watts @ 460V, 60 Hz

1360 Watts @ 460V, 60 Hz

2000 Watts @ 460V, 60 Hz

5 amps total @ 460V across each phase at heater contractor

4.5 amps total @ 460V across each phase at heater contractor

29 Vac @ 60 Hz

Specifications

17

Specifications

Refrigeration System Specifications

Compressor:

Model No.: ZMD18KVE-TFD-277, Scroll

Refrigerant Charge:

MAGNUM+ 4.0 Kg (8.0 lb.) R-404A

Compressor Oil Capacity 1.77 liter (60 oz.)*

Compressor Oil Type: Polyol Ester Based Type (required), (refer to Tool Catalog)**

*When the compressor is removed from the unit, oil level should be noted or the oil removed from the compressor should be

measured so that the same amount of oil can be maintained in the replacement compressor.

**Do not use or add standard synthetic or mineral oils to the refrigeration system. If Ester based oil becomes contaminated

with moisture or with standard oils, dispose of properly — Do Not Use!

High Pressure Cutout Switch:

Cutout 3240 ± 48 kPa, 32.4 ± 0.5 bar, 470 ± 7 psig

Cutin 2586 ± 262 kPa, 25.9 ± 2.6 bar, 375 ± 38 psig

Low Pressure Cutout Switch:

Cutout -17 to -37 kPa, -0.17 to -0.37 bar, 5 to 11 in. Hg vacuum

Cutin 28 to 48 kPa, 0.28 to 0.48 bar, 4 to 7 psig

High Pressure Relief Valve:

Relief Temperature 99 C, 210 F

Vapor Injection Control:

V apor injection valve is energized (open) continuously when

the compressor duty cycle (ON time) is 100 percent (Full

Modulation Cool or Power Limit

Compressor Discharge Temperature Control:

Vapor Injection Valve Energizes (Opens) 138 C (280 F)

Vapor Injection Valve De-energizes (Closes)

Compressor Shutdown (Auto Reset) 148 C (298 F)

Vapor Injection Valve (Compressor):

Voltage 24 Vac

Current 0.85 amps

Cold Resistance 5.6 ohms

Compressor Digital Control Valve:

Voltage 24 Vac

Current Draw 0.85 amps

Cool). High compressor discharge temperature may cause

the vapor injection valve to energize (open) but only while

the Compressor Digital Control valve is not energized

(closed).

6 C (10.7 F) below energize temperature

(132 C [123 F])

18

Specifications

Normal R-404A System Operating Pressures (Scroll Compressor)

Container T emp.

21 C (70 F) Cool

2 C (35 F) Cool

-18 C (0 F) Cool

-29 C (-20 F) Cool

Suction and discharge pressures vary too greatly during Modulation Cool to use for evaluating or diagnosing refrigeration

system performance. During the Modulation Cool mode, the suction pressure will vary between 100 and 450 kPa, 1.0 and 4.5

bar, 15 and 65 psig depending upon the percent (percent) cooling capacity.

**Discharge pressure is determined by condenser fan cycling.

Operating

Mode

Ambient

Temp.

27 to 38 C, 80

to 100 F

16 to 27 C, 60

to 80 F

27 to 38 C, 80

to 100 F

16 to 27 C, 60

to 80 F

27 to 38 C, 80

to 100 F

16 to 27 C, 60

to 80 F

27 to 38 C, 80

to 100 F

16 to 27 C, 60

to 80 F

Suction Pressure Discharge Pressure

410 to 670 kPa, 4.10 to 6.70

bar, 59 to 97 psig

400 to 600 kPa, 4.00 to 6.00

bar, 58 to 87 psig

385 to 425 kPa, 3.85 to 4.25

bar, 56 to 62 psig

345 to 385 kPa, 3.45 to 3.85

bar, 50 to 56 psig

214 to 228 kPa, 2.14 to 2.28

bar, 31 to 33 psig

200 to 215 kPa, 2.00 to 2.15

bar, 29 to 31 psig

145 to 160 kPa, 1.45 to 1.60

bar, 21 to 23 psig

130 to 145 kPa, 1.30 to 1.45

bar, 19 to 21 psig

2140 to 2650 kPa, 21.40 to

26.50 bar, 310 to 385 psig

1725 to 2140 kPa, 17.25 to

21.40 bar, 250 to 310 psig

1860 to 2380 kPa, 18.60 to

23.80 bar, 270 to 345 psig

1450 to 1860 kPa, 14.50 to

18.60 bar, 210 to 270 psig**

1515 to 2035 kPa, 15.15 to

20.35 bar, 220 to 295 psig**

1100 to 1515 kPa, 11.00 to

15.15 bar, 160 to 220 psig**

1450 to 1965 kPa, 14.50 to

19.65 bar, 210 to 285 psig**

1035 to 1450 kPa, 10.35 to

14.50 bar, 150 to 210 psig**

MP-4000 Controller Specifications

Temperature Controller:

MP-4000 is a controller module for the Thermo King Magnum+

Unit. Additional requirements can be met by means of expansion

Type

Setpoint Range -40.0 to +30.0 C (-31.0 to +86.0 F)

Digital Temperature Display -60.0 to +80.0 C (-76.0 to +176.0 F)

Controller Software (Original Equipment):

Version See controller identification decal

Defrost Initiation:

Evaporator Coil Sensor

modules. The MP4000 is solely responsible for temperature

regulation of the reefer container, but other monitoring equipment

can be used in conjunction with the MP 4000 - such as a chart

recorder.

• Manual Switch or Demand Defrost Initiation: Coil must be

• Timed Defrost Initiation: Coil must be below 4 C (41 F). Defrost

v

below 18 C (65 F). Defrost cycle starts when technician or

controller requests defrost initiation.

cycle starts 1 minute after the hour immediately following a

defrost timer request for defrost initiation. For example, if the

defrost timer requests a defrost cycle at 7:35, the defrost cycle

will start at 8:01. Datalogger will record a Defrost event for each

interval in which a Defrost cycle is pending or active (i.e. both the

8:00 and 9:00 data logs).

19

Specifications

MP-4000 Controller Specifications (Continued)

Demand defrost function initiates defrost when:

• Temperature difference between the return air sensor and

Demand Defrost

Defrost Timer:

Chilled mode

Frozen mode

Reset to Base Time

Defrost Termination:

Defrost (Coil) Sensor

Termination Timer

Power Off Turning Unit On/Off switch Off terminates defrost

Compressor Shutdown Protection

(Auto Reset):

Stops Compressor 148 C (298 F)

Allows Compressor Start 90 C (194 F)

Bulb Mode:

Evaporator Fan Speed Settings

Defrost Termination Temperature Setting 4 to 30 C (40 to 86 F)

defrost (evaporator coil) sensor is too large for 90 minutes

• Temperature difference between the supply air sensors and

return air sensor is too large

Evaporator Coil Temperature must be below 5C (41 F) to activate

the defrost compressor hour timer.

There is an interval set for defrosting, however, the defrost timer is

built intelligent - it detects whether or not there is ice building up on

the coil. If there is no ice building up on the coil, it extends the

defrost interval, and if there is Ice building up earlier on the coil it

reduces the defrost interval. The maximum interval is 48 hours.

Every 8 hours of compressor operation. Defrost interval increases 2

hours each timed defrost interval. Maximum time interval in Frozen

mode is 24 hours.

Defrost timer resets if the unit is off more than 12 hours, setpoint is

changed more than 5 C (9 F) or PTI pretrip test occurs.

Chilled mode: Terminates defrost when coil sensor temperature

rises to 18 C (65 F).

Frozen mode: Terminates defrost when coil sensor temperature

rises to 18 C (65 F).

Terminates defrost after 90 minutes at 60 HZ operation if coil

sensor has not terminated defrost (120 minutes at 50 Hz operation)

Flow High: High speed only

Flow Low: Low speed only

Flow Cycle: Fans will cycle between low and high speed every 60

minutes

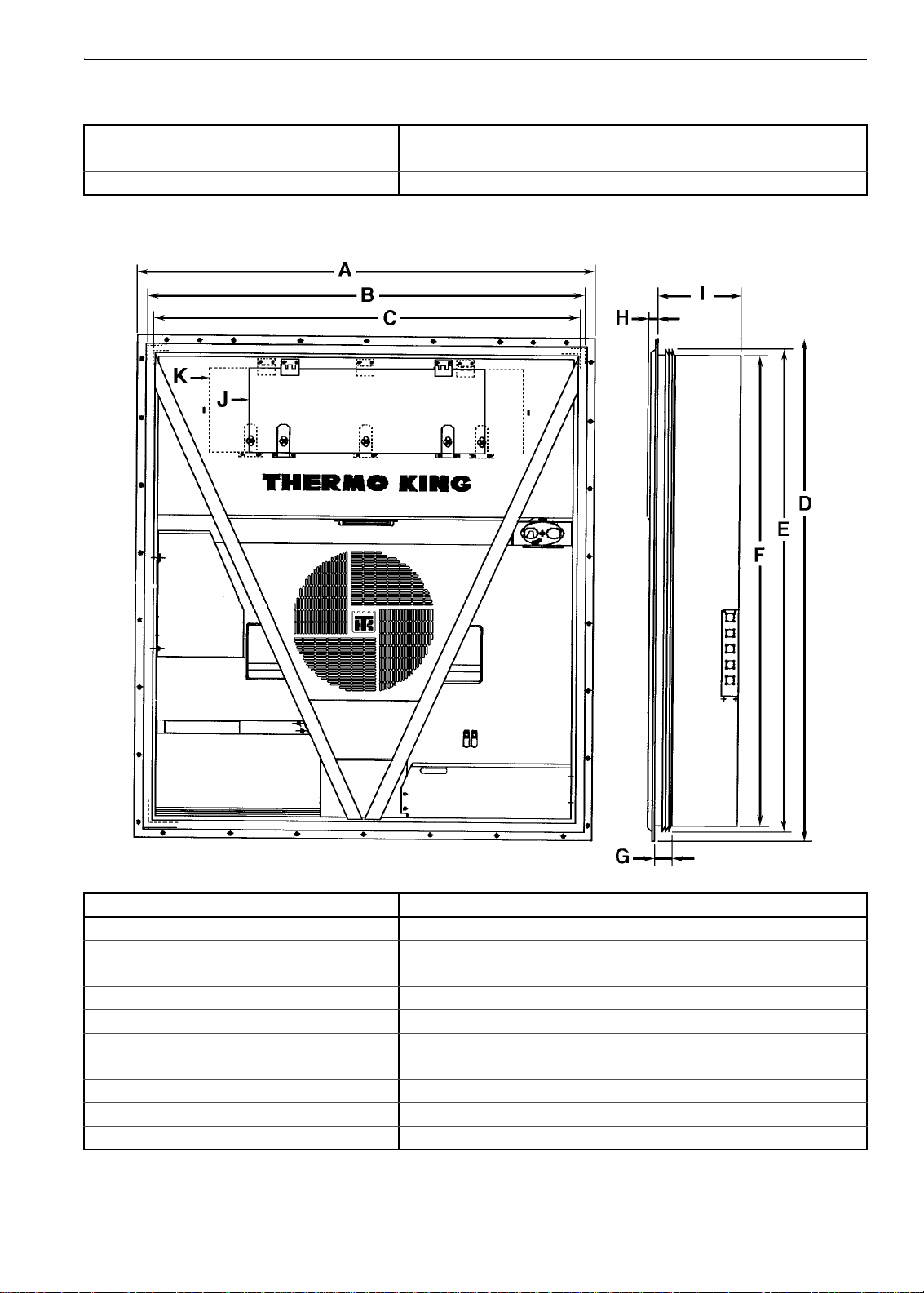

Physical Specifications

Fresh Air Exchange Venting System

(Adjustable):

3

MAGNUM+

0 to 225 m

0 to 185 m

Evaporator Fan Blade Specifications:

MAGNUM+:

Diameter 355 mm (14.0 in.)

Pitch 25°

Number of Fans 2

20

/hr (0 to 168 ft3/min.) @ 60 Hz

3

/hr (0 to 139 ft3/min.) @ 50 Hz

Physical Specifications (Continued)

AMA313

Weight (net):

MAGNUM+ Base Unit 380 Kg (875 lb.)

Water-cooled Condenser-Receiver Option 13.6 Kg (30 lb.)

Specifications

Unit Dimensions:

A = Flange Width 2025.5 mm (79.74 in.)

B = Gasket Width 1935 mm (76.18 in.)

C = Unit Width 1894 mm (74.57 in.)

D = Flange Height 2235.2 mm (88.00 in.)

E = Gasket Height 2140 mm (84.25 in.)

F = Unit Height 2094 mm (82.44 in.)

G = Gasket Depth 72 mm (2.83 in.) from back of flange

H = Maximum Protrusion 37 mm (1.46 in.) from back of flange

I = MAGNUM+ 420.0 mm (16.54 in.) from back of flange

J = MANGUM+ Evaporator Access Door

Figure 1: Physical Specifications

21

Unit Description, Features & Options

BEN074

Introduction

This chapter will briefly describe the following items:

• General Unit Description.

• Standard Component Descriptions.

• Optional Component Descriptions.

General Description

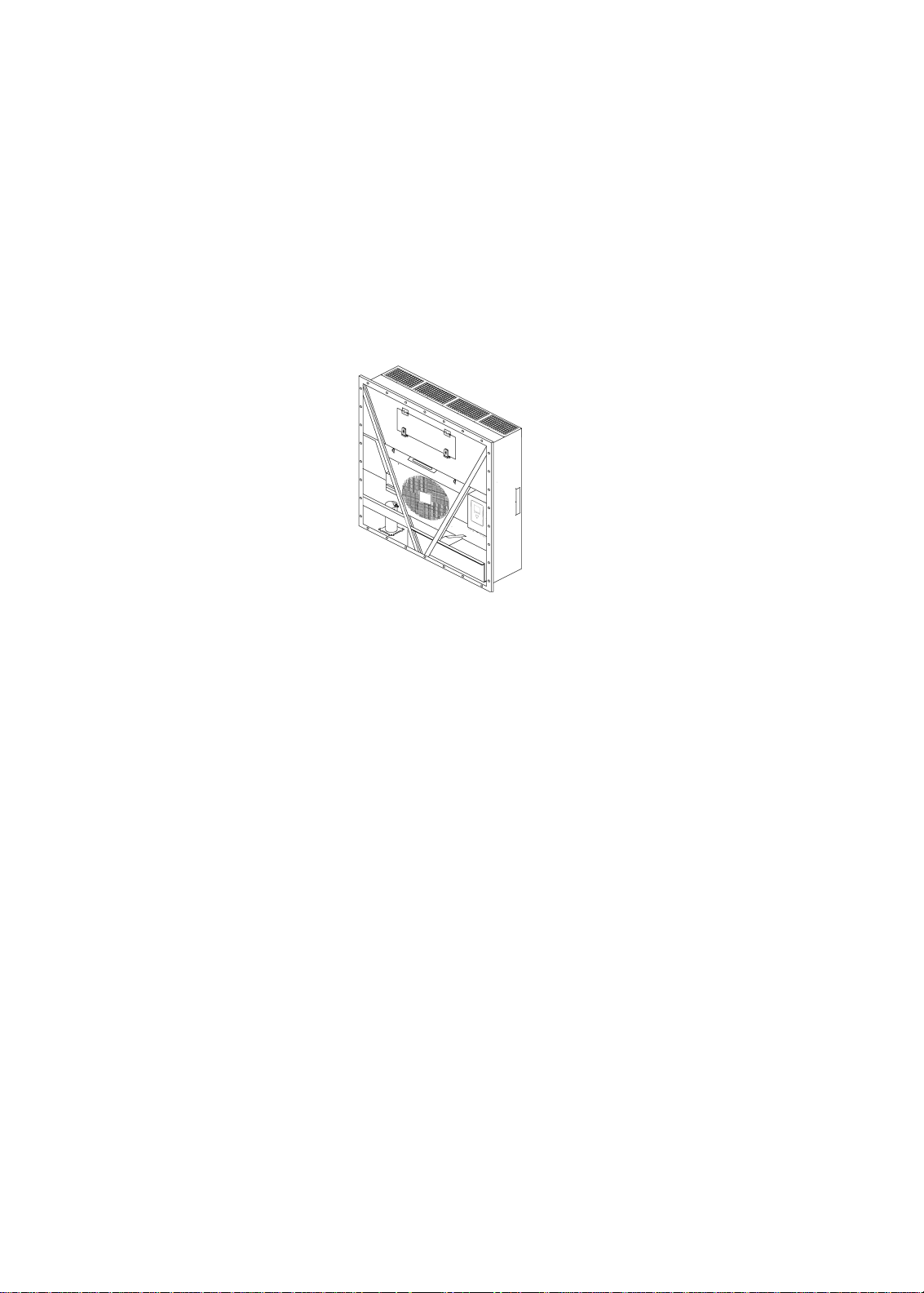

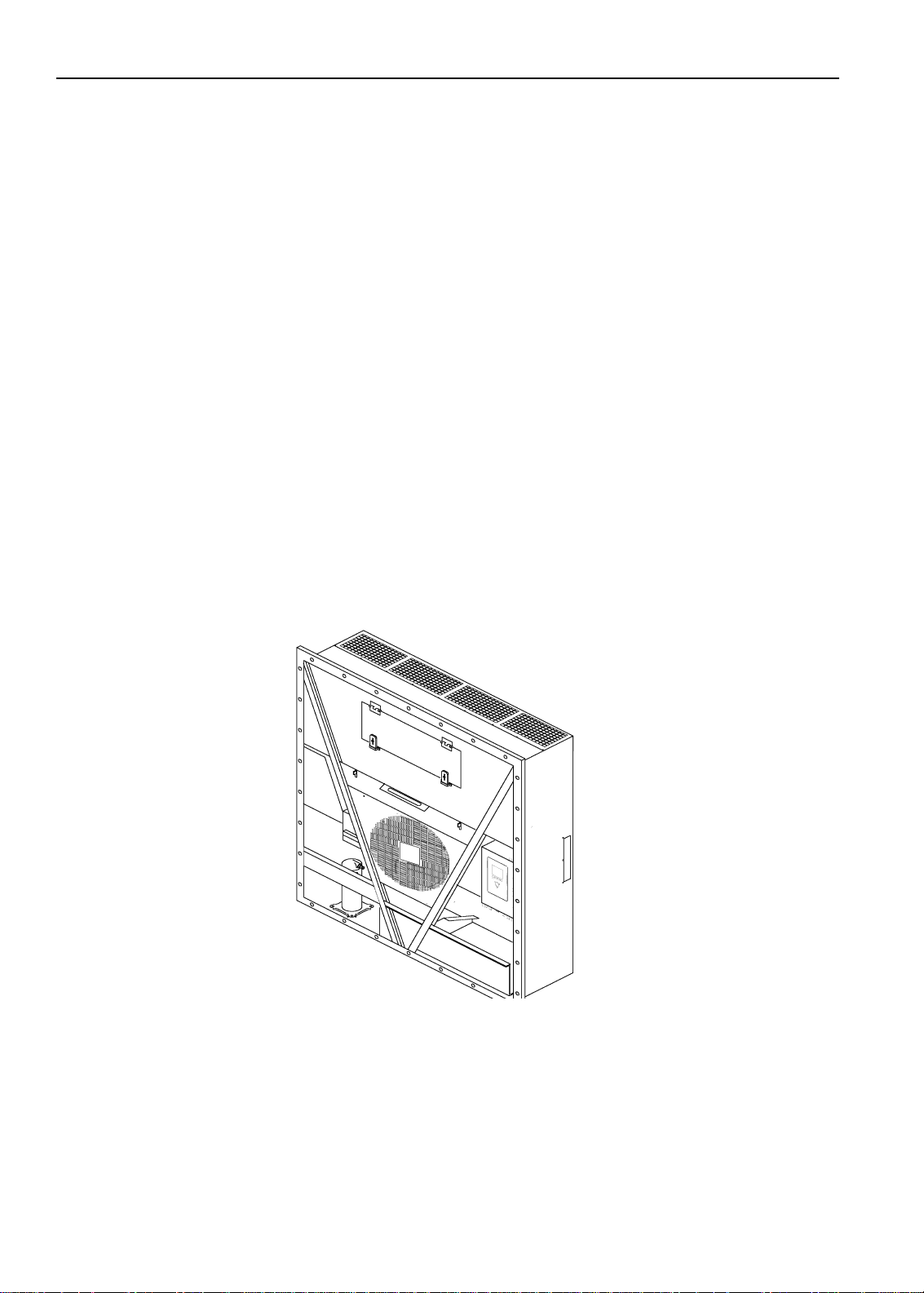

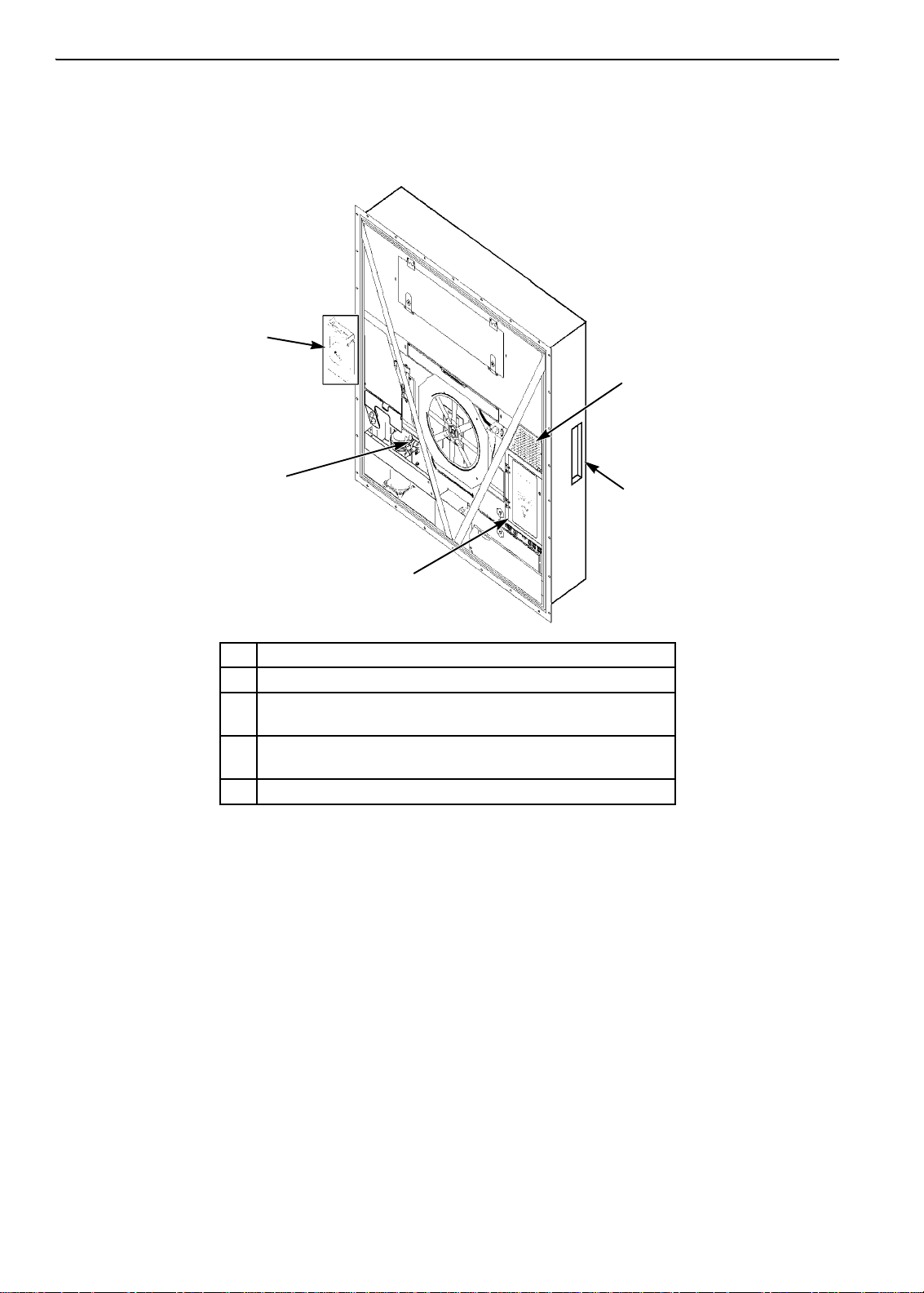

MAGNUM units are all-electric, single-piece, refrigeration units with bottom air supply. The unit is

designed to cool and heat containers for shipboard or overland transit. The unit mounts in the front wall of

the container. Fork lift pockets are provided for installation and removal of the unit.

The frame and bulkhead panels are constructed of aluminum and are treated to resist corrosion. A

removable evaporator compartment door provides service access. All components except the evaporator

coil and electric heaters can be replaced from the front of the unit.

Each unit is equipped with an 18.3 m (60 ft.) power cable for operation on 460-380V/3 Ph/60-50 Hz

power. The unit power cable is stored below the control box in the condenser section.

Each unit is equipped with 460-380V/3 Ph/60-50 Hz electric motors. An automatic phase correction

system provides the proper electrical phase sequence for condenser fan, evaporator fan and compressor

operation.

Figure 2: MAGNUM+ Unit

The MAGNUM+ container unit features the following components. Each component will be described

briefly on the following pages.:

• Scroll Compressor

• Compressor Digital Control Valve

• Economizer Heat Exchange System

• Temperature Sensors

22

Unit Description, Features & Options

• Fresh Air Exchange System

• Receiver Tank Sight Glass

• Evaporator Fans

• Condenser Fan Control

• Suction/Discharge Pressure Sensor (Optional)

• Remote Monitoring Receptacle Option (4-pin) (optional)

• Remote Monitoring Modem (RMM, RMM+) (Optional)

• USDA Cold Treatment Temperature Recording (Optional)

•

Advanced Fresh Air Management (AFAM) and Advanced Fresh Air Management Plus (AFAM+)

(Optional)

Scroll Compressor

The scroll compressor features a digital port and an intermediate suction port.

Digital Port

The digital port provides cooling capacity control. The digital port is located at the top of the scroll

assembly on the compressor body. When energized, the Digital Control valve disengages the scroll set.

This reduces pumping capacity to zero.

Intermediate Suction Port

The intermediate suction port draws suction gas from the economizer heat exchanger into the scroll

assembly of the compressor. The scroll seals of f the suction port . This prevents economizer gas from

leaking back to the main suction port. It also prevents the economizer gas pressure from influencing the

cooling capacity of the unit evaporator (main suction gas pressure).

Figure 3: Scroll Compressor

23

Unit Description, Features & Options

1

BEN074

MP 3000 MRB

Red Holder

F 20 amp Fuse

PM 4000 Power Module

Black Holder

FF 20 amp Fuse

MP-4000 Controller

The MP-4000 is an advanced microprocessor controller that has been specially developed for the control

and monitoring of refrigeration units. See “Controller Description and Operating Chapter” for more

detailed information.

1. MP-4000 Controller

Figure 4: MP-4000 Controller

Power Module Fuses

The PM-4000 Power Module in the MAGNUM Plus unit uses Ultra Fast 20 amp fuses to protect the

power module and are not interchangeable with the MP3000 MRB fuses. The fuses from the MP3000

MRB must never be used in the PM 4000 Power Module.

Part number for a PM 4000 Power Module fuse (FF 20 amp 500v and black fuse holder) is:

P/N 419286 Fuse & Holder Blk MP4000

Part number for the MP3000 MRB fuse (F 20 amp 500V and red fuse holder) is:

P/N 419318 Fuse & Holder Red MP3000

Fuse and fuse holder will be sold together as a kit. Individual fuse and holder part number for the MP3000

will supersedes to the kit number once inventory is used up.

Figure 5: Power Module Fuses

24

Unit Description, Features & Options

AXA0428

AXA0427

Compressor Digital Control Valve

The MP-4000 controller pulses the Compressor Digital Control solenoid valve between open and closed

positions. This provides precise cooling capacity control. No pump down function or warm gas bypass

control is used in conjunction with the Compressor Digital Control valve. See the “General Theory of

Operation Chapter” for more detailed information.

Figure 6: Compressor Digital Control Solenoid Valve

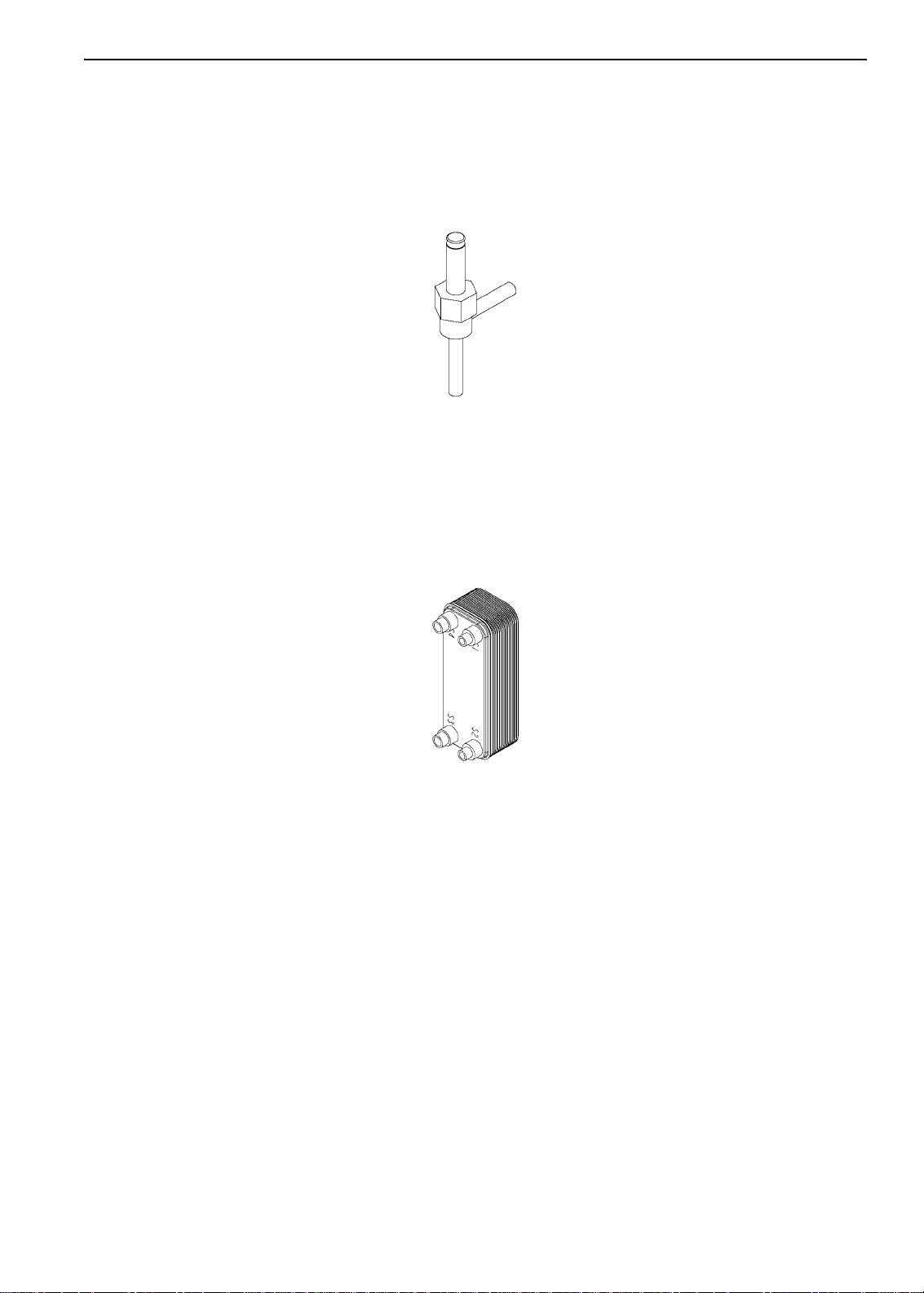

Economizer Heat Exchange System

An economizer heat exchange system replaces the conventional heat exchanger. The economizer Heat

Exchange system subcools the liquid refrigerant before it reaches the evaporator expansion valve.

Subcooling liquid refrigerant increases the cooling efficiency and capacity of the evaporator. See the

“General Theory of Operation Chapter” for more detailed information.

Figure 7: Economizer Heat Exchanger

Temperature Sensors

Each sensor element is connected to a cable and packaged in a sealed stainless steel tube. The temperature

signal from the sensor is transmitted through the cable. PT.1000 type temperature sensors are used to

sense temperatures for the:

• Supply Air

• Return Air

• Evaporator Coil

• Condenser Coil

• Ambient Air

The compressor sensor is of Thermistor type and is located in the top cap of the compressor.

These sensors are field replaceable. Five sensor receptacles are provided; three USDA and one cargo

temperature.

25

Unit Description, Features & Options

1

BEN075

AXA0371

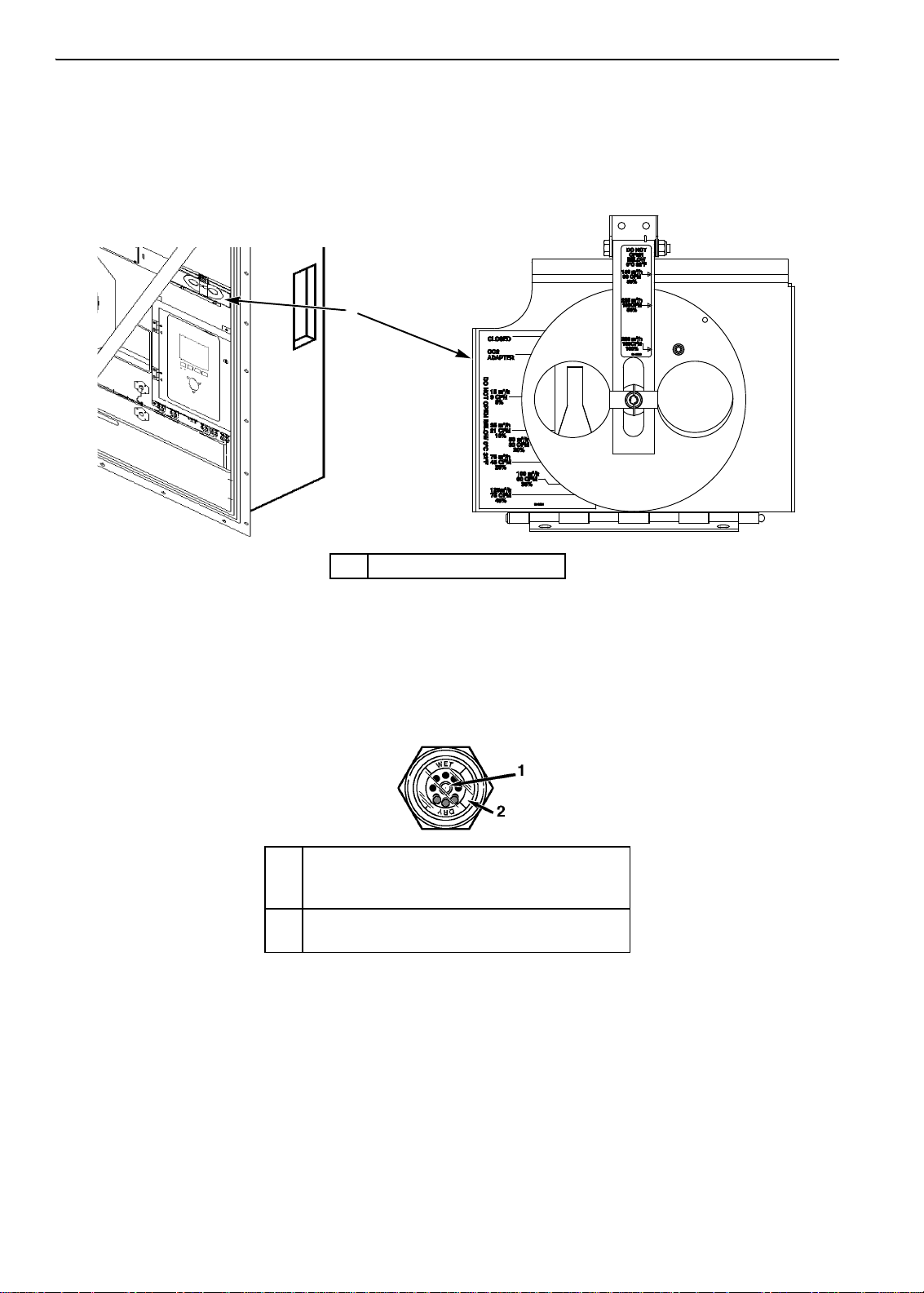

Fresh Air Exchange System

The fresh air exchange system removes harmful gases from containers carrying sensitive perishable