50 L HyPerforma DynaDrive Single-Use

Bioreactor Quick Start Guide

This Guide provides a brief overview of setting up the Thermo Scientific™ HyPerforma™ DynaDrive Single-Use Bioreactor (S.U.B.)

system. For more detailed information about the DynaDrive S.U.B., refer to the 50 L HyPerforma DynaDrive S.U.B. User’s Guide

(DOC0090).

Warnings and safety

Hazardous voltage inside—risk of electrical

shock. Service should be provided by certified

personnel only.

Hot surface—do not touch.

The heating jacket is designed to heat the inner

vessel wall. Contact with surfaces may cause

burns.

Pinch hazard. Use caution when opening/

closing the door, securing the BPC to the

top and bottom ports in the tank, and during

operation of the DynaDrive S.U.B.

Burst hazard—air under pressure. Do not

exceed 30 mbar (0.5 psi) BPC pressure. Do

not exceed 34 mbar (5 psi) inlet pressure.

Ensure that the vent filter is correctly positioned

and working properly.

Tipping hazard. The vessel should only

be moved by pushing using the provided

handles or at the mid-point of the vessel.

If pulled or moved too quickly, the vessel can

tip, potentially leading to damage to equipment

or injury to personnel. To reduce the risk of

tipping, the vessel should only be moved

slowly over smooth, flat surfaces by at least

two qualified personnel. During movement, any

locking feet should be retracted, and casters

should be in the unlocked position. The vessel

should not be moved by pulling of any kind.

The Thermo Scientific HyPerforma

DynaDrive S.U.B. may not be installed in

a potentially explosive atmosphere as set

forth in the applicable EU ATEX Directive.

It is the responsibility of the end user to review

and understand the potential dangers listed in

the ATEX 2014/34/EU guidelines.

Static electricity may build up in BPCs.

• BioProcess Containers (BPCs) may act

as insulators for electrostatic charge. If

electrostatic charge is transferred to a BPC,

the charge may be stored in the BPC and/or

the product inside. This phenomena varies

by product and use; therefore, it is the sole

responsibility of the end user to ensure a

hazard assessment is conducted and the

risk of electrostatic shock is eliminated.

• Where applicable, a product contact

stainless steel coupler may be grounded

to the frame to dissipate electrostatic

buildup from the material within a BPC. It

is good practice to dissipate electrostatic

buildup by grounding all BPCs prior to

coming in contact with them. When working

with BPCs, the use of nonconductive

materials, such as nonconductive gloves, is

recommended.

Rotating parts—entanglement hazard.

Rotating and moving parts can cause injury.

Keep hands away from moving parts during

operation. Do not operate this equipment unless

the supplied guarding is in place and properly

functioning. It is the responsibility of the end

user to assess this equipment and ensure that

equipment and safeguards are in good working

condition, and that all operators are trained and

aware of entanglement hazards and associated

protective devices, such as hazard signs and

guarding.

Follow lockout/tagout procedures. To

prevent injury, when servicing equipment, use

your company’s lockout/tagout procedures

to isolate electrical, mechanical, pneumatic,

hydraulic, chemical, thermal, gravitational, or

any other potential energy and protect workers

from the release of hazardous energy.

Use caution with hazardous chemicals or

materials. Personnel servicing equipment

need to know the hazards of any chemicals

or materials that may be present on or in the

equipment. Use general hazard communication

techniques such as Safety Data Sheets, labels,

and pictograms to communicate any hazards.

Note that this machine does not produce or

process any toxic, corrosive, flammable, and

explosive substances, nor uses any additives,

compounds of mercury, cadmium, chromium,

asbestos, CFC, or HCFC for machine

maintenance purposes.

Use a properly configured and approved

power cord for voltage supply in your

facility.

Read and understand the user’s guide

before operating the equipment. The

HyPerforma DynaDrive S.U.B. is designed to

be operated under traditional eukaryotic cell

culture conditions. A general understanding

of bioreactor systems and their operation is

important prior to using the system for the first

time. Read and understand this user’s guide

before operating; failure to do so could result

in injury and potential loss of product. Only

trained operators should be allowed to operate

the equipment.

For complete warnings, safety, and warranty information,

refer to the 50 L HyPerforma DynaDrive S.U.B. User’s

Guide.

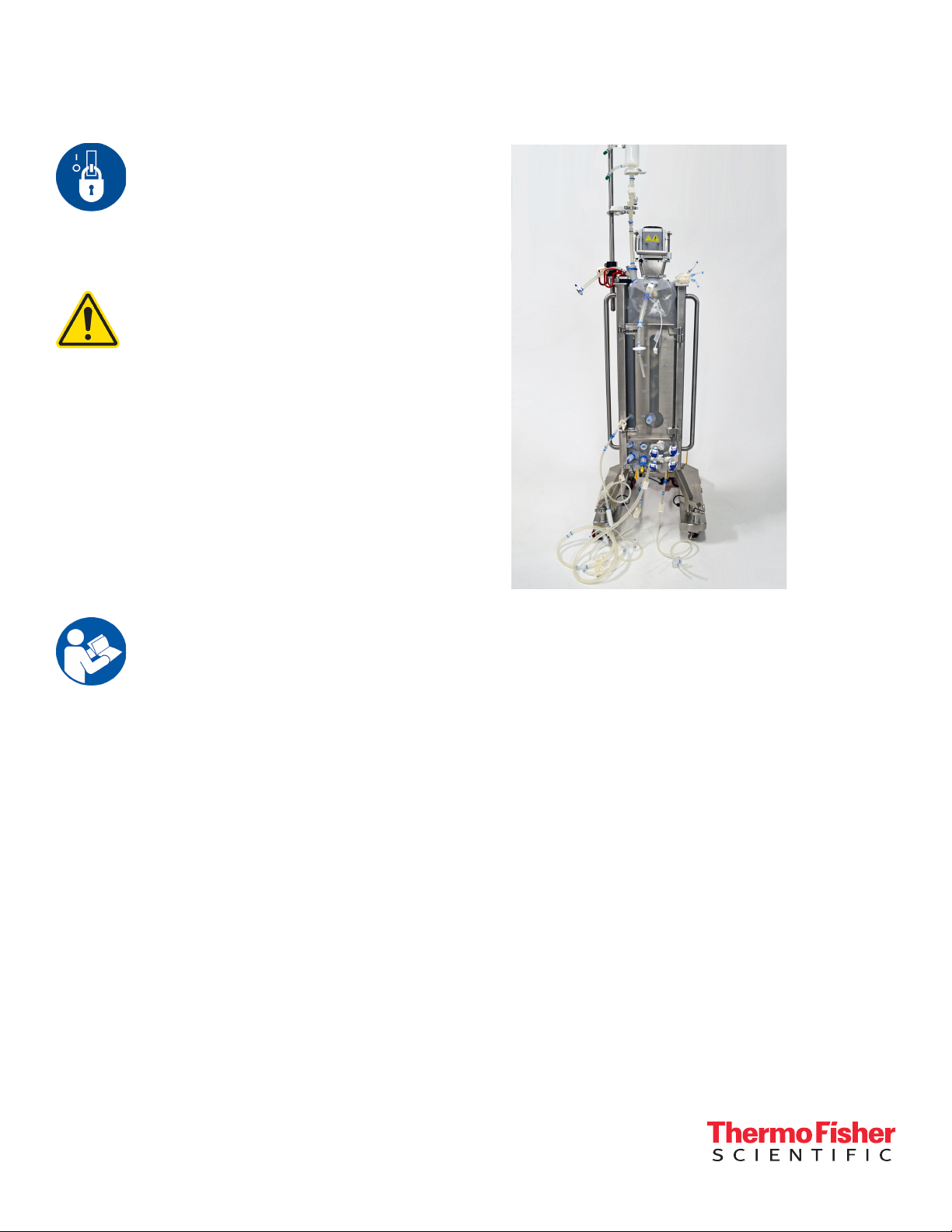

Figure 1. Front view of the 50 L DynaDrive S.U.B.

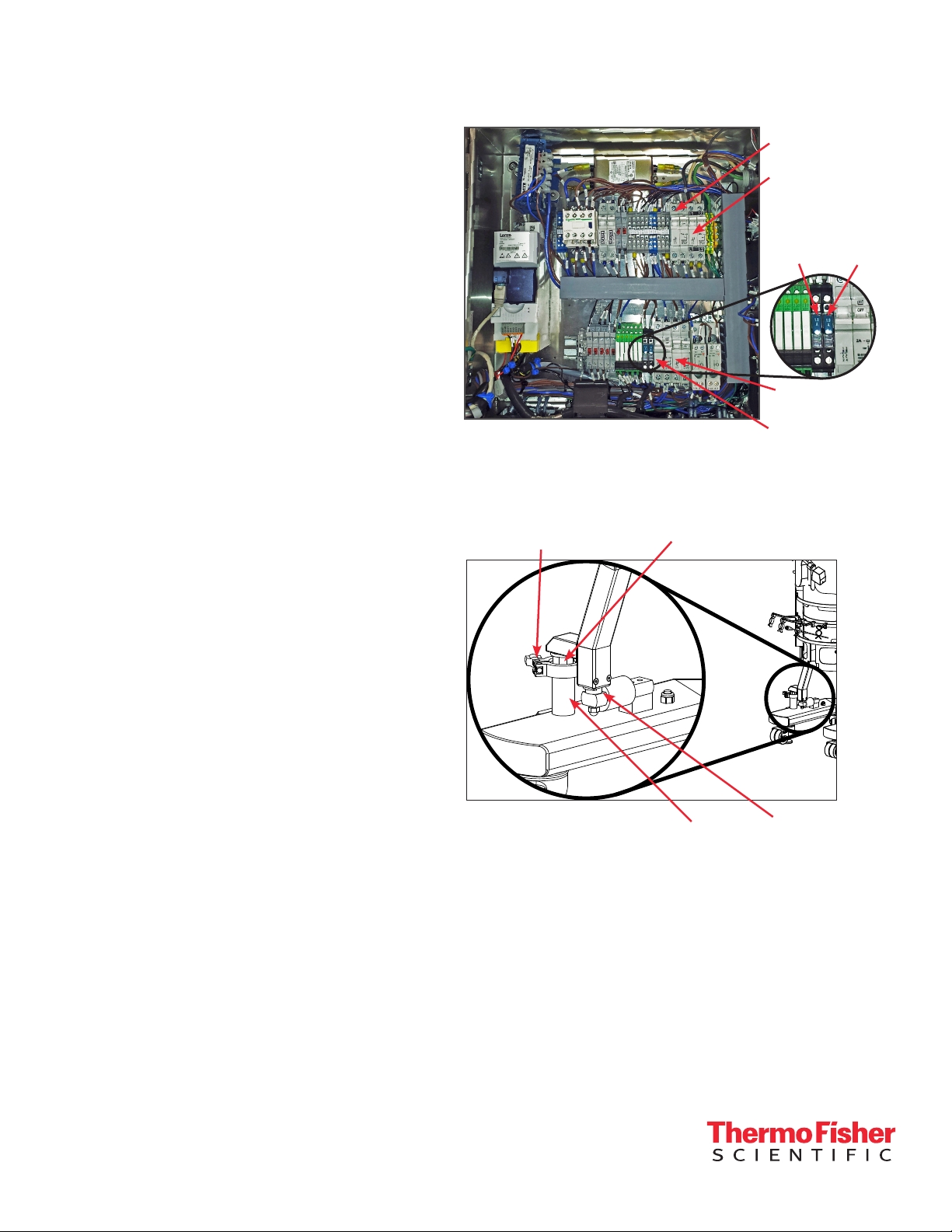

Electrical preparation (for systems with the

optional Thermo Scientific E-Box)

1. Using a flat-head screwdriver, open the E-Box

and locate the breakers for the pressure sensor,

continuous power outlets non E-stoppable (2), and

continuous power outlets E-stoppable (2) (Figure

2 on the following page). These breakers should

be in the “on” position (“up” position or pressed in,

depending on the breaker type) during operation.

For electrical schematics, please refer to the ETP,

which is provided on a USB drive.

Unpacking the system

First, inspect the packaging for damage. Call your Thermo

Scientific sales representative if any damage is present.

Use the instructions provided in the 50 L HyPerforma

DynaDrive S.U.B. Unpacking Guide (DOC0149) to unpack

your S.U.B. unit from the shipping crate.

2

2. Close the E-Box and lock the panel using a

A

flat-head screwdriver before continuing.

3. Connect all electrical plugs to facility power. Refer

to hardware/electrical labels and schematics to

ensure proper electrical voltage is connected to

the DynaDrive S.U.B. Note: The yellow plug and

receptacle are for 120 VAC, and the blue plug and

receptacle are for 240 VAC S.U.B.s.

Unlocking load cells

Figure 3 illustrates the location and components of load

cells on a 50 L DynaDrive S.U.B.

All load cells must be fully locked down in order to

move the DynaDrive S.U.B. For DynaDrive S.U.B.

hardware units purchased with factory-installed load

cells, the load cells are shipped in the locked position

(threaded up) for equipment protection.

1. To unlock the load cells (after the system is in its

final location), remove and discard the delrin slip

ring if it is present. Remove the tri-clamp.

Figure 2. DynaDrive S.U.B. E-Box interior.

38.1 mm (1.5 in.)

Tri-clamp

Lockout nut

VFD breaker

Main power

breaker

Temp.

display

breaker

E-Stop power

breaker

Continuous power

breaker

Pressure

sensor

breaker

2. Loosen the lockout nut, using an adjustable or

1.25 in. wrench (not supplied), until the nut is tight

against the base or leg of the S.U.B. Repeat this

process for each load cell until all of the lockout

nuts are disengaged from the lockout posts. Do

not reinstall the tri-clamp.

3. At this point, the DynaDrive S.U.B. hardware is

ready to be prepared for BPC loading.

Leveling and connecting the system

All manual movements of the DynaDrive S.U.B.

hardware should be over smooth surfaces, with the

S.U.B. empty and disconnected from all power and

gas/feed sources. All load cells must be fully locked

down in order to move a S.U.B.

1. Verify that the facility electrical supplies are

sufficient to support the power requirements of the

DynaDrive S.U.B. and ancillary components, such

as controllers or pumps.

Figure 3. Load cell schematic.

Lockout

post

Delrin slip

ring

3

2. Locate the outer support container in the area for the

cell culture run.

Note: Refer to the TCU manufacturer’s guidelines for

detailed TCU setup information.

3. When monitoring the batch volume, the unit may be

placed on a weight scale if load cells are not part of

the system. Other methods may be used to measure

all incoming and outgoing liquids.

4. Level the platform by disabling the swivel casters on

the bottom of the outer support container. This is

accomplished by threading the leveling feet (at the

center of each caster) to the floor.

5. Verify the location of the pH/DO controllers and

ensure that the cable and tubing lengths are

sufficient.

6. Verify that the main power is off and the emergency

stop (E-Stop) is pulled out. Note: The E-Stop

disconnects all power to the system. An alarm buzzer

will sound when the E-Stop is activated.

7. Verify that the main motor power switch is in the “off”

position.

8. Connect all electrical plugs to facility power. Refer to

hardware/electrical labels and schematics to ensure

proper electrical voltage is connected to the S.U.B.

The main power switch can now be turned on.

9. Connect the inlet and outlet lines from the

temperature control unit (TCU) quick-connects to

the jacket (Figure 4). The inlet is typically on the right

side if you are facing the connectors; refer to the

permanent labels on the inlet and outlet lines.

10. Use the tri-clamp fitting to attach the water jacket

inlet/outlet ports to the bottom of the outer support

container (Figure 5).

Figure 5. Removing the tri-clamp and attaching the fitting.

Note: Figure 5 shows the tri-clamp fitting and inlet/outlet

ports on a standard HyPerforma S.U.B. The location and

process is the same for DynaDrive S.U.B.s.

Loading the BPC

Use the following information to install and set up the BPC.

Checkpoints prior to BPC loading

9 A 50 L DynaDrive BPC is being used for the

50 L outer support container.

9 The outer support container is stationary, with the

casters locked in place.

9 Two operators are available for BPC loading.

9 The Thermo Scientific BPC Unpacking and Inspection

Guide (DOC0021) has been reviewed for information on

handling, transporting, and storing BPCs.

Figure 4. Attaching water jacket port using a

tri-clamp.

4

1. Open the door on the bioreactor outer support

container.

2. Use a safety cutter to slit the taped sides/ends of the

cardboard box in which the BPC is shipped.

3. Lift the lid off the top of the box, then lift the

cardboard tray out of the box and set it on a flat,

raised surface (Figure 6).

6. Hold the exposed end of the BPC in place and use your

other hand to pull the outer polybag away from the BPC

(Figure 9).

Figure 6. Removing lid and setting the tray on a flat sur face.

4. Use a safety cutter to cut the plastic cling wrap

securing the BPC to the cardboard tray. Remove the

cling wrap and undo the flaps that are folded on the

underside of the tray (Figure 7).

Figure 7. Undoing flaps on bottom of tray.

5. Use a safety cutter to carefully open the outer

polybag (Figure 8). Take care to not damage the

BPC.

Figure 9. Pulling the outer polybag away

from the BPC.

7. The BPC is also protected by an inner polybag. Use a

safety cutter to open the inner polybag, taking care to

not damage the BPC, and remove the polybag while

holding the BPC in place.

8. Push the blue and black button on the hub cover located

at the top of the S.U.B. to unlock it (Figure 10). Swing the

cover open (Figure 11).

9. Raise the BPC lift mechanism lever fully, which will

simultaneously lower the bearing hub port (Figure 12).

Figure 8. Cutting open the outer

polybag.

5

Figure 10. Pushing button on hub

cover.

Figure 12. Raising BPC lift lever.

Figure 11. Hub cover opened.

10. Do not allow the BPC or line sets to touch the floor as

you carefully unfold the BPC and locate the top bearing

hub and front line sets. Do not remove the polybags

from the line sets at this stage, as the BPC may

become difficult to manage.

11. Align the bearing hub with the purple bearing

(Figure 13). Pull down on the black hub locking

mechanism as you insert the top bearing hub into

the bearing. Ensure that the locking mechanism fully

engages; the lip at the bottom should be completely

hidden from view when the locking mechanism

retracts.

Figure 13. Aligning hub with the bearing.

Figure 14. Pulling down on BPC lift

lever and locking mechanism.

14. Begin slowly filling the BPC with air to allow the drive

train to separate from the inside of the BPC. This also

aids in the proper alignment of the BPC in the outer

support container.

• Attach the air supply to one of the sparging gas

inlet lines after removing the bubble wrap from the

line set. Note: Air pressure to the overlay gas line

on the DynaDrive S.U.B. BPC should not exceed

34 mbar (0.5 psi).

• Begin air inflation through one of the sparging gas

lines. Times will vary based upon flow rate and inlet

pressure.

12. Pull down on the BPC lift mechanism lever (Figure 14).

The lever will not move all the way down until the black

bearing hub locking mechanism is pulled down, as

well. After the hub mechanism has been lowered and

subsequently raised, the purple bearing hub will lock

into place. Note: Ensure the hub and lift mechanism

lever are fully engaged by attempting to push the lever

back up. If the hub is not locked, the hub will fall out

and the arm will raise.

13. Once the hub is locked into place, close and lock the

hub cover. The blue and black button must be pressed

again to lock the cover. The BPC should be hanging

freely.

6

WARNING: The BPC is not rated as a

pressure vessel. DO NOT EXCEED 34 mbar

(0.5 psi) within the BPC or the system could

fail, causing personal injury or damage

to equipment. DO NOT leave the BPC unattended

while inflating. Consult your sales representative for

recommended air flow rates. The operating pressures

at the level of the DynaDrive S.U.B. are of primary

importance, and these values must be adhered to.

15. While the BPC continues filling with air, remove all

bubble wrap and polybags from the line sets. Guide

any top line sets through the opening at the top of the

unit.

16. Remove all bubble wrap from the exhaust vent filter.

Secure the exhaust vent filter to the top-mounted

holder on the rim of the tank (Figure 15). Use the red

handles shown in Figure 15 to adjust the height of the

exhaust vent filter holder.

Figure 15. Securing the exhaust

vent filter to the holder.

Figure 16. Pulling a top hanging

tab on the BPC towards the pin.

Figure 18. Top front tab attached.

Figure 17. Placing the black top

tab holders on top front of tank.

20. Gently pull at the bottom corners of the BPC

(Figure 19) until the sides of the BPC are straight.

Note: You may need to wait for the BPC to fill with

more air before this is possible.

17. Attach the two hanging tabs at the top back side of the

BPC to the pins on the top back of the outer support

container (Figure 16). Check the BPC to ensure that the

foam probe is hanging freely, and is not entangled in

the drive train.

18. Clip (or slide on, from the front) the black top tab

holders on both sides of the outer support container

(Figure 17).

19. Attach the two hanging tabs at the top front side of

the BPC to the pins on the black top tab holder, which

was installed in the previous step. Note: Attaching

the top tabs will help keep the BPC properly oriented

inside the tank. Figure 18 shows the top front BPC tab

attached to the tab holder.

7

Figure 19. Pulling the bottom corners of

the BPC to straighten out the sides.

21. Locate the yellow positioning loop at the bottom

center of the BPC. Pull the loop toward the center

cutout at the bottom front of the outer support

container (Figure 20). Once the loop is aligned with

the correct cutout, slide it toward the back of the

DynaDrive S.U.B. until you feel it shift into place.

Yell o w

positioning

loop

Figure 20. Positioning loop aligned with

the center cutout.

22. Use the following steps to lock the positioning loop in

place:

• Pull down the white-topped pin to open the gate

(Figure 21).

• Swing the gate connected to the pin forward

and to the right until the pin aligns with the drilled

hole on the right side of the bottom tab cutout

(Figure 22).

• Push the pin back up to lock the gate. Figure 23

shows the positioning loop locked into place.

Figure 23. Positioning loop locked in place.

23. Guide all line sets on the bottom front of the BPC

through the bottom cutouts in the outer support

container (Figure 24). Note: Verify that all line clamps

are closed and located as close as possible to the

body of the BPC.

Figure 24. All line sets placed in

proper cutouts.

24. Attach the hanging tabs on the bottom of the BPC

to the pins at the bottom back of the outer support

container.

Figure 21. Pulling down on the

white pin.

8

25. Carefully close the door on the front of the outer

support container (Figure 25). Before latching the door

shut, ensure that the cross flow sparger line is aligned

through the left-most cutout in the door, the perfusion

port (if present) is aligned in the center cutout of the

door, and both rows of probe ports are aligned just

below the bottom front of the door.

Figure 22. Swinging the gate to

the right.

Cross flow

sparger line

Perfusion

port

Rows of probe

ports aligned

below the door

Figure 25. Door shut, with lines

and por ts aligned in cutouts.

26. Close and secure the latches at the top and bottom of

the door.

27. Remove the polybag from the drain line set, position

the line clamp as close as possible to the BPC port,

and close.

28. Remove the plastic insert located in the thermowell, if

present.

Figure 26. Inserting the RTD. Figure 27. RTD placed in a

double probe clip.

30. Clamp the black foam probe holder to the outer

support container, behind the top left tab holder, if

facing the front of the S.U.B. Insert the foam probe

into the foam probe holder on the outer support

container (Figure 28).

29. Insert the resistance temperature detector (RTD) into

the thermowell (Figure 26) using the steps below. Note:

Due to the shorter thermowell on DynaDrive BPCs, the

Figure 28. Foam probe in holder.

15.24 cm (6 in.) RTD is the ONLY compatible size. DO

NOT use larger RTDs, which will damage the BPC.

• Place a small amount of glycerol (0.5 mL) in the

thermowell to aid in heat transfer. The glycerol also

31. Optional: Connect a pressure sensor at the top of

the BPC. Then connect the appropriate pressure

transducer cable to the third-party controller.

serves as a lubricant and aids in insertion.

• The sensor should be inserted until the base of the

RTD meets the mouth of the thermowell.

• Secure by twisting the luer lock collar, if provided.

• Place a double probe clip on the probe support

hanger and place the RTD so it is resting in the

hook (Figure 27).

Find out more at thermofisher.com/dynadrive

For Research or Further Manufacturing. Not for diagnostic use or direct administ ration into humans or animals.

© 2020 Thermo Fisher Scientifi c Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its

subsidiaries unless otherwise specified. DOC0148 Revision A 092 0

Loading...

Loading...