HyPerforma 5:1 Single-Use

Bioreactor (S.U.B.) User’s Guide

DOC0022 • Revision H

February 2021

Contents

Warnings, safety, and warranty information 1

How to use this guide 7

Chapter 1 HyPerforma Single‑Use Bioreactor (S.U.B.)

overview 11

1.1 Introduction to the S.U.B. 12

1.2 Hardware characteristics 16

1.2.1 S.U.B. hardware components 16

1.2.2 S.U.B. system features 18

1.2.3 Additional system components 19

1.3 End user and third-party supplied components 26

1.3.1 pH and DO probes 26

1.3.2 Controllers 27

1.4 BPC characteristics 28

1.4.1 S.U.B. BPC components 28

1.4.2 S.U.B. BPC features 29

Chapter 2 Hardware assembly and setup 31

2.1 Initial installation preparation 32

2.1.1 Hardware shipment and setup 32

2.1.2 Hardware uncrating 32

2.1.3 Site preparation 32

2.2 Installation and setup 34

2.2.1 Preparing load cells 34

2.2.2 Leveling and connecting the system 35

2.2.3 Verifying drive shaft segments for 2,000 L systems 38

2.2.4 Setting the air pressure rate for motor lift adjustment

(1,000 and 2,000 L systems only) 38

2.2.5 Using the handheld controller for motor lift (1,000 and

2,000 L systems only) 39

Chapter 3 Operating information 41

3.1 General system operating information 42

3.1.1 BPC preparation 42

3.1.2 BPC handling instructions 42

3.1.3 BPC operating information 42

Contents

3.1.4 Hardware operating information 44

3.1.5 External data logging and control 47

3.2 BPC and drive shaft loading instructions for 50, 100,

and 250 L systems 47

3.2.1 Initial BPC loading steps for 50, 100, and 250 L

systems

3.2.2 Drive shaft insertion for 50, 100, and 250 L

systems

3.2.3 Final installation steps for 50, 100, and 250 L

systems

47

53

57

3.3 BPC and drive shaft loading instructions for 500

and 1,000 L systems 60

3.3.1 Initial BPC loading steps for 500 and 1,000 L

systems 60

3.3.2 Drive shaft insertion for 500 and 1,000 L systems 66

3.3.3 Final installation steps for 500 and 1,000 L systems 71

3.4 BPC and drive shaft loading, and condenser system

setup instructions for 2,000 L systems 74

3.4.1 Initial BPC loading steps for 2,000 L systems 74

3.4.2 Condenser system setup for 2,000 L systems 82

3.4.3 Drive shaft insertion for 2,000 L systems 94

3.4.4 Final installation steps for 2,000 L systems 100

3.5 Probe preparation and insertion 103

3.5.1 Preparation and sterilization 103

3.5.2 Making CPC AseptiQuik connections 105

3.5.3 Probe insertion 107

3.5.4 Probe calibration 109

3.6 Cell culture operating instructions 110

3.6.1 Operating conditions for cell culture applications 110

3.6.2 Checkpoints prior to media fill 111

3.6.3 Media fill 111

3.6.4 Agitation for units with electrical control panels 112

3.6.5 Agitation rate calculations 114

3.6.6 Drive shaft rotation 119

3.6.7 Temperature control 119

3.6.8 Sparging strategy 120

3.6.9 pH probe calibration 122

Contents

3.6.10 DO probe calibration 122

3.6.11 Checkpoints prior to inoculation 123

3.6.12 Cell inoculation 123

3.6.13 Volume scale up 124

3.6.14 In-process checkpoints 124

3.6.15 BPC sampling 124

3.6.16 Dispense and harvest 127

3.6.17 BPC disposal 128

3.6.18 S.U.B. shutdown 128

3.6.19 Preparation for the next run 129

3.7 Verification procedures 129

3.7.1 Mixing speed verification 129

3.7.2 Temperature controller verification 129

3.7.3 Pressure monitor verification (when present) 129

3.7.4 Load cell verification

130

Chapter 4 System features and specifications 131

4.1 Hardware features 132

4.1.1 Design features for 50–250 L systems 132

4.1.2 Design features for 500 L systems 133

4.1.3 Design features for 1,000 L systems 134

4.1.4 Design features for 2,000 L systems 135

4.2 Hardware specifications 136

4.3 E-Box features 154

4.4 BPC specifications 155

4.5 Additional system component part numbers 167

Chapter 5 Maintenance and troubleshooting 171

5.1 Maintenance 172

5.1.1 Routine maintenance 172

5.1.2 Preventive maintenance 172

5.2 Troubleshooting and frequently asked questions 174

5.2.1 Hardware operation issues 174

5.2.2 Cell culture operation issues 176

5.2.3 Sparging issues 177

5.2.4 Probe and connector issues 178

5.2.5 Other issues 179

Contents

Chapter 6 General ordering information 181

6.1 Ordering instructions 182

6.2 Ordering/support contact information 182

6.3 Technical support 183

Appendices Appendix A—Installation of female electrical receptacle

for units with AC motors and electrical control panels 184

Appendix B—Mettler Toledo IND331 display load cell

calibration instructions 187

Appendix C—2,000 L S.U.B. agitator operation and

maintenance guidelines 189

Appendix D—Drive shaft use log 190

Warnings, safety, and warranty information

Warnings, safety, and warranty

information

Thank you for purchasing this high-quality Thermo Scientific

equipment. We have included safety information in this guide, based

on our knowledge and experience. It is important, however, for you

to work with your Safety Management personnel to ensure that this

equipment is integrated into your safety practices. Please take some

time to perform your own job safety analysis in order to identify and

control each potential hazard.

WARNING: Read and understand this user's guide before

operating the equipment.

The Thermo Scientific

is designed to be operated under traditional eukaryotic cell culture

conditions. A general understanding of bioreactor systems and their

operation is important prior to using the system for the first time. Read

and understand this user’s guide before operating; failure to do so

could result in injury and potential loss of product.

™

HyPerforma™ Single-Use Bioreactor (S.U.B.)

WARNING: Hazardous voltage inside.

The mixer motor, motor controller and control panel all have

electrical components. There is a risk of electrical shock and

injury. Disconnect power before opening electrical components.

Service should be performed by certified personnel only.

Thermo Fisher Scientific recommends using standard lockout

procedures when working on electrical components. The main breaker

on the electrical control panel (E-Box) may be locked out.

WARNING: Static electricity may build up in BPCs.

• BioProcess Containers (BPCs) may act as insulators for

electrostatic charge. If electrostatic charge is transferred to a BPC,

the charge may be stored in the BPC and/or the product inside.

This phenomena varies by product and use; therefore, it is the sole

responsibility of the end user to ensure a hazard assessment is

conducted and the risk of electrostatic shock is eliminated.

• Where applicable, a product contact stainless steel coupler may be

grounded to the frame to dissipate electrostatic build up from the

material within a BPC. It is good practice to dissipate electrostatic

buildup by grounding all BPCs prior to coming in contact with them.

When working with BPCs, the use of nonconductive materials, such

as nonconductive gloves, is recommended.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 1

Warnings, safety, and warranty information

WARNING: Rotating parts—entanglement hazard.

Rotating and moving parts, such as the motor mount for 1,000 L and

2,000 L systems, can cause injury. Keep hands away from moving

parts during operation.

• Do not operate this equipment unless the supplied guarding is in

place and properly functioning.

• It is the responsibility of the end user to assess this equipment

and ensure that equipment and safeguards are in good working

condition, and that all operators are trained and aware of

entanglement hazards and associated protective devices, such as

hazard signs and guarding.

WARNING: Use ladders and elevated platforms with caution.

A few operations, such as loading a BPC into a large S.U.B., may

require the use of a ladder or platform. Before use, ensure the ladder

has been inspected and weight-rated for its user. When using a ladder

or platform, be sure it is stable, maintain three points of contact, and

make sure the steps are clean.

WARNING: Follow lockout/tagout procedures.

To prevent injury, when servicing equipment, use your company's

lockout/tagout procedures to isolate electrical, mechanical, pneumatic,

hydraulic, chemical, thermal, gravitational, or any other potential energy

and protect workers from the release of hazardous energy.

WARNING: Use caution with hazardous chemicals or materials.

Personnel servicing equipment need to know the hazards of any

chemicals or materials that may be present on or in the equipment.

Use general hazard communication techniques such as Safety Data

Sheets, labels, and pictograms to communicate any hazards.

WARNING: Potential confined space.

Operators may enter larger S.U.B. systems. Evaluate this equipment

against your confined space standards and procedures.

WARNING: Burst hazard—air under pressure.

The S.U.B. BPC chamber is under slight pressure under normal

operating conditions. Normal passive venting prevents any excess of

pressure building up within the chamber. Chamber pressure and inlet

line pressure should be monitored for proper settings.

• Contents under pressure

• Do not exceed 0.03 bar (0.5 psi) BPC pressure

• Do not exceed 0.34 bar (5 psi) inlet pressure

• Ensure vent filter is properly positioned and working properly

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 2

Warnings, safety, and warranty information

WARNING: Hot surface. Do not touch.

The heating jacket is designed to heat the inner vessel wall. Under

normal operating conditions, the motor will generate heat and could

create hot surfaces.

• Hot surface inside

• Contact with surfaces may cause burns

• Do not touch while in operation

WARNING: Pinch hazard.

The motor lift on 1,000 L and 2,000 L S.U.B.s can be raised and

lowered using the handheld controller. Caution should be used when

changing the position of the motor to avoid pinching an operator or

causing damage to the equipment or the BPC.

WARNING: Tipping hazard. The vessel should only be moved by

pushing using the provided handles or at the mid-point of the

vessel.

If pulled or moved too quickly, the vessel can tip, potentially leading

to damage to equipment or injury to personnel. To reduce the risk

of tipping, the vessel should only be moved slowly over smooth, flat

surfaces by at least two qualified personnel. During movement, any

locking feet should be retracted, and casters should be in the unlocked

position. The vessel should not be moved by pulling of any kind.

WARNING: The Thermo Scientific HyPerforma Single-Use

Bioreactor may not be installed in a potentially explosive

atmosphere as set forth in the applicable EU ATEX Directive.

It is the responsibility of the end user to review and understand the

potential dangers listed in the ATEX 2014/34/EU guidelines.

Protective earth grounding

Protective earth grounding must be verified prior to plugging the

S.U.B. into any electrical outlet. Ensure the receptacle is properly earth

grounded.

Environmental conditions

• Operating: 17°C to 27°C; 20 to 80% relative humidity, noncondensing

• Storage: –25°C to 65°C

• Installation category II (over voltage) in accordance with IEC 664

• Altitude Limit: 2,000 meters

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 3

Warnings, safety, and warranty information

Electrical connections

Power should be supplied by a non-GFCI 15 amp circuit. Ground

faults occur when current is leaking somewhere, in effect, electricity is

escaping to the ground. Electrocution can occur when the human

body serves as the path for the leakage to the ground. A ground

fault circuit interrupter (GFCI) senses the current flowing to the ground

and switches off the power (trips the GFCI) in a fraction of a second at

currents well below those that are considered dangerous. Due to the

sensitivity of GFCIs to electrical leakage (a few mA), it is recommended

that the S.U.B. NOT be plugged into a GFCI outlet.

Water jacket vessel information

S.U.B. hardware units with water jackets have been designed to be

operated with water as the heat transfer medium, with temperatures

not exceeding 50°C (122°F) under less than 1 MPa (150 psig) operating

pressure. For the utmost safety it is recommended that the S.U.B. be

operated at 75 psig or less.

Note: The S.U.B. BPC operating limits for temperature are 5 to 40°C.

The internal pressure should not exceed 0.03 bar (0.5 psi). The water

jacket is not required to be registered, inspected and stamped with the

Code U symbol per section U-1(c)2(f) of the ASME Boiler and Pressure

Vessel Code and/or European Pressure Equipment Directive (PED)

97/23/EC. Upon request, a Declaration of Conformity, PED Sound

Engineering Practices can be made available.

Use of agitation speed governors and safety interlocks

Agitation speed governors set up on the bioreactor controller are used

to limit the maximum mixing speed, according to pre-defined liquid

volumes. Safety interlocks, which stop agitation when the volume in a

S.U.B. drops below defined limits, and speed-based governors prevent

damage to the drive shaft in the bioreactor. Agitation speed governors

and safety interlocks typically prevent the hazardous conditions listed

below.

• Operating the motor at any speed while loading the drive shaft

• Operating the agitator when volumes are less than 20% of a

system’s working volume

• Operating the agitator above recommended speeds based on

qualified power input to volume (P/V) thresholds

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 4

Warnings, safety, and warranty information

The hazardous conditions above must be avoided in order to ensure

qualified reliability. Using safety interlocks and agitation speed

governors eliminates the chance of human error, which could reduce

system reliability. Both the amount of liquid in the vessel and the

amount of power applied to the impeller have an impact on the applied

deflection on the shaft. Excess deflection and/or mixer speed may

damage the drive shaft.

For more information about using P/V and safety interlocks in

2,000 L bioreactor systems, see section 3.6.5 of this publication.

Warranty information

Any warranties, if applicable, covering this equipment exclude: (a)

normal wear and tear; (b) accident, disaster or event of force majeure;

(c) your misuse, fault or negligence; (d) use of the equipment in a

manner for which it was not designed; (e) causes external to the

equipment such as, but not limited to, external puncturing, power

failure or electrical power surges; (f) improper storage and handling of

the equipment; (g) use of the equipment in combination with equipment

or software that we did not supply; (h) equipment sold to you as ‘used’

products; (i) contact with improperly used or unapproved chemicals

or samples; (j) installation, removal, use, maintenance, storage, or

handling in an improper, inadequate, or unapproved manner, such as,

but not limited to, failure to follow the documentation or instructions in

the deliverables or related to the equipment, operation outside of stated

environmental or other operational specifications, or operation with

unapproved software, materials or other products; (k) manufacture in

accordance with requirements you gave us; (l) installation of software

or interfacing or use of the equipment in combination with software

or products we have not approved; (m) use of the deliverables

or any documentation to support regulatory approvals; (n) the

performance, efficacy or compatibility of specified components; and

(o) the performance of custom equipment or products or specified

components or achievement of any results from the equipment,

specified components or services within ranges desired by you

even if those ranges are communicated to us and are described in

specifications, a quote, or a statement of work. ADDITIONALLY, ANY

INSTALLATION, MAINTENANCE, REPAIR, SERVICE, RELOCATION

OR ALTERATION TO OR OF, OR OTHER TAMPERING WITH, THE

EQUIPMENT PERFORMED BY ANY PERSON OR ENTITY OTHER

THAN US WITHOUT OUR PRIOR WRITTEN APPROVAL, OR ANY

USE OF REPLACEMENT PARTS WE HAVE NOT SUPPLIED, WILL

IMMEDIATELY VOID AND CANCEL ALL WARRANTIES WITH

RESPECT TO THE AFFECTED EQUIPMENT. IF THE EQUIPMENT

IS TO BE USED IN THE UNITED STATES, WE MAY VOID YOUR

WARRANTY IF YOU SHIP THE EQUIPMENT OUTSIDE OF THE

UNITED STATES.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 5

Warnings, safety, and warranty information

Use restrictions

You must use this equipment in accordance with our documentation

and if applicable, with our other associated instructions, including

without limitation, a “research use only” product label or “limited use”

label license. This equipment is intended for research use or further

manufacturing in bioprocessing applications and not for diagnostic

use or direct administration into humans or animals, we do not submit

the equipment for regulatory review by any governmental body or

other organization, and we do not validate the equipment for clinical or

diagnostic use, for safety and effectiveness, or for any other specific

use or application.

Seismic guidance

The buyer of the equipment is responsible to ensure country specific

codes and seismic values are assessed for suitability of equipment

installation and safety at the designated site. In addition, it is the buyer’s

responsibility to assess the building structure for the designated

equipment to ensure correct seismic anchoring and tethering designs

for both the equipment and facility. It is highly recommended that

the buyer consult with a local, licensed third party architecture,

and engineering firm to provide the buyer with correct engineering

analysis and stamped documentation prior to equipment installation

at the facility. In addition, the buyer will be responsible for rigging and

anchoring of the equipment to a specified, fixed location. Thermo

Fisher can assist with establishing compliant seismic anchoring and

tethering designs for purchased equipment based on building and

country codes upon request at an agreed upon fee.

It is also noted that movable equipment (i.e. non-fixed or caster mount)

is exempt from seismic design requirements according to ASCE

7-16, Chapter 13, section 1.4. Although these units are exempt from

the seismic design requirements of ASCE 7, it should be noted that

such equipment is susceptible to overturning during a seismic event.

Therefore, it is the responsibility of the buyer to address seismic safety

for movable equipment at the designated facility.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 6

How to use this guide

How to use this guide

Scope of this publication

This user's guide contains information about the standard Thermo

™

Scientific

HyPerforma™ 5:1 S.U.B. systems, including hardware,

components, product design verification methods, installation,

operation, and specifications. It is intended for use by people who may

or may not have experience with Thermo Scientific systems, but who

have some knowledge of bioproduction processes and large-scale

mixing systems.

Document change information

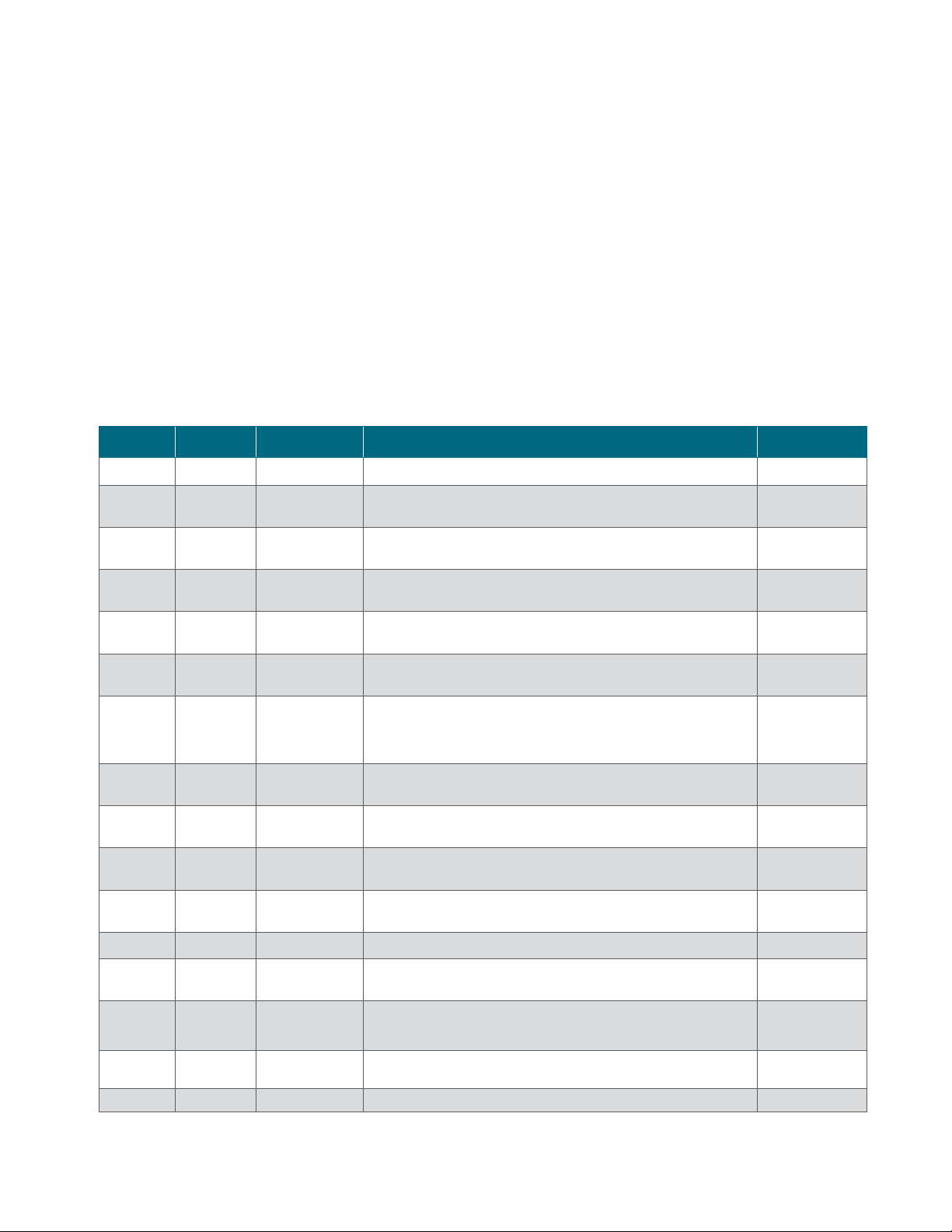

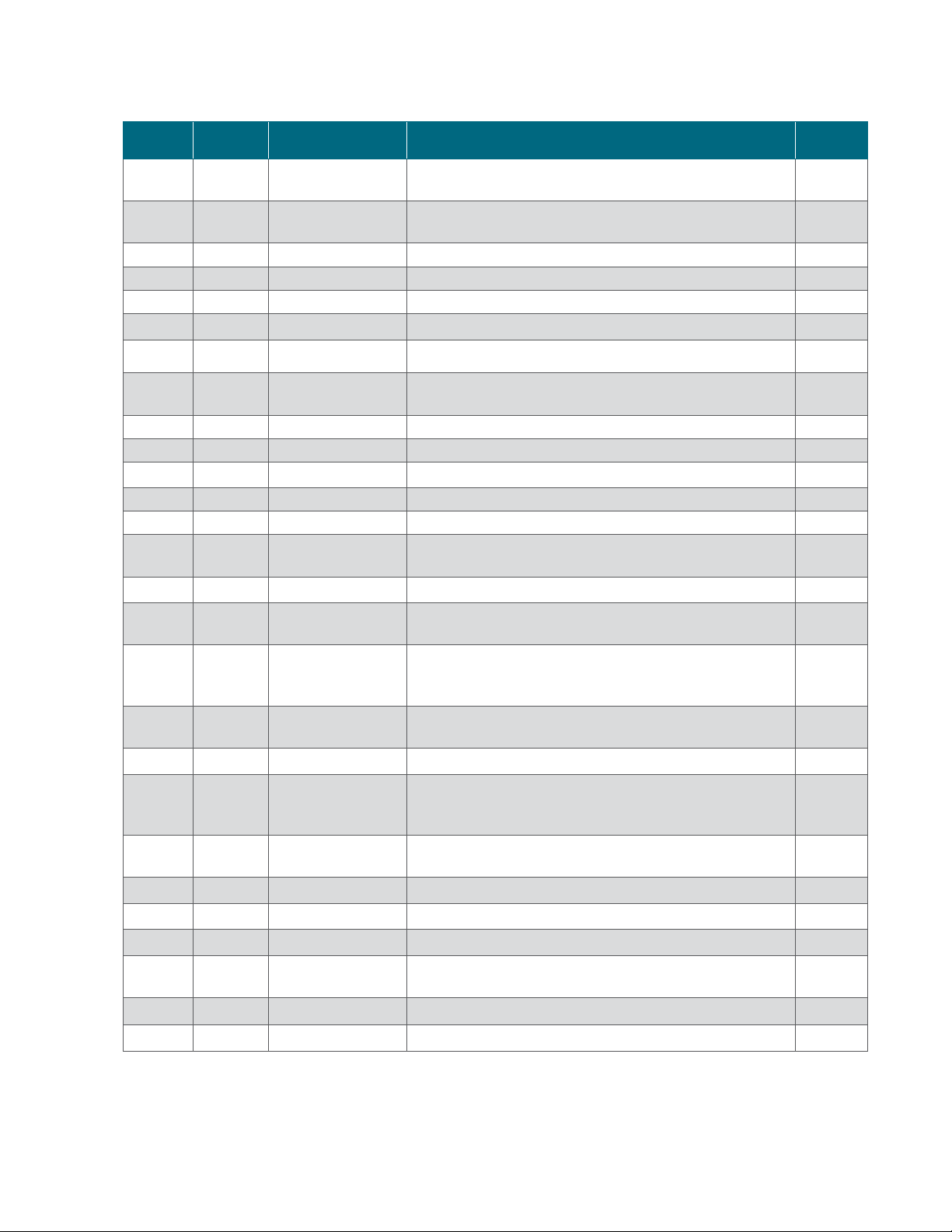

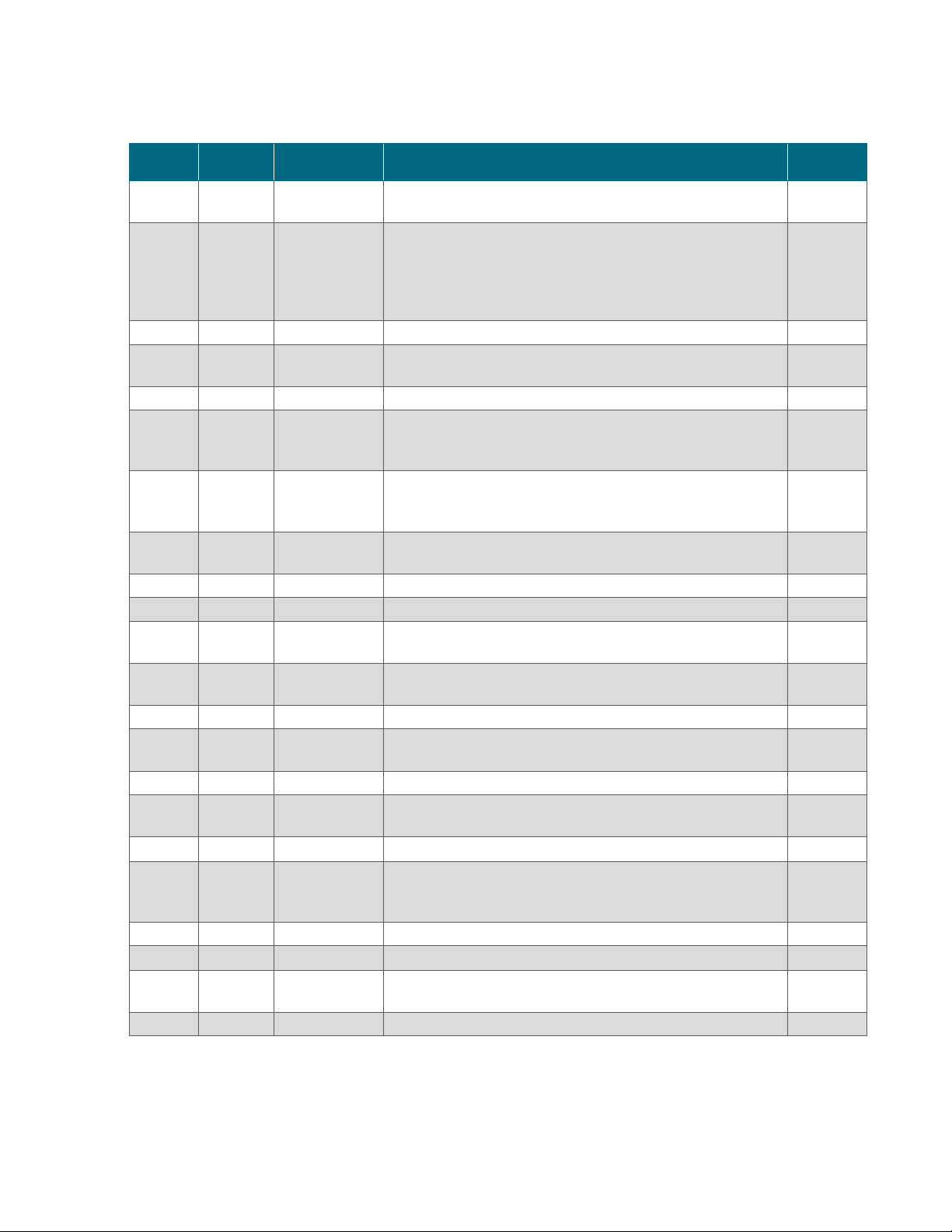

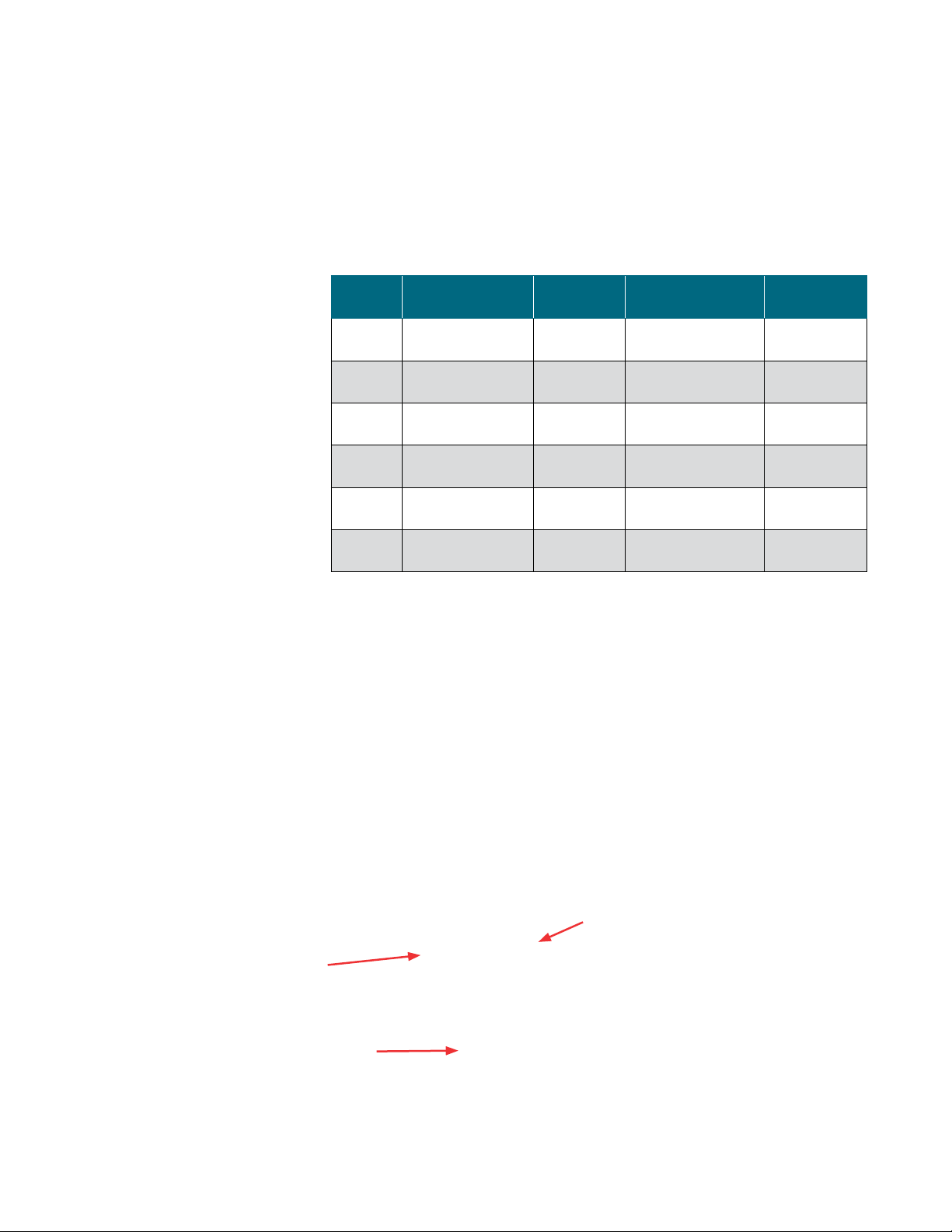

Revision Date Section Change made Author

A 10/2016 -- Initial release S. Jelus/E. Hale

B 02/2017

B 02/2017

B 02/2017 2.2.4

B 02/2017 3.6.4

B 02/2017 5.1. 2

Warnings and

Safety

Warnings and

Safety

Added pinch hazard and potential confined space warnings to

Warnings and Safety information

Added information about safety interlocks to Warnings and Safety

information

Added number information and photo of ends of mutiple-section

drive shaft

Added warning note about agitation rate and volume requirements,

and the use of safety interlocks

Added measurement to Table 5.1 for 2,000 L drive shafts and

cross-reference to Appendix D

E. Hale

S. Jelus

S. Jelus/E. Hale

S. Jelus/E. Hale

E. Hale

Added information about 2-piece drive shaft, a note about the

B 02/2017 3.4.3

B 02/2017 1.1

B 02/2017 3.4.3

B 02/2017 3.4.3

B 02/2017 3.4

B 02/2017 4.2 Added 1,000 L and 2,000 L hardware specifications E. Hale

B 02/2017 4.2

B 02/2017 4.2

B 02/2017 1.2.3 Added information about BPC lift for 2,000 L systems E. Hale

B 02/2017 4.3 Added drawing of 1,000 L electrical control panel E. Hale

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 7

position of impeller tubing inside the BPC, and serial number

information and a photo of ends of multiple-section drive shafts

Added information about and photo of the BPC bearing port cap

label

Added a note about not pushing drive shaft straight into the

assembly when loading

Added information and Figure 3.102 to illustrate proper insertion of

drive shaft

Added 2,000 L BPC and drive shaft loading, and condenser system

setup instructions

Added information about 2-piece drive shaft to 2,000 L

specifications

Added ceiling height requirements for 2-piece drive shaft and detail

about mixing speed to 2,000 L specifications

S. Jelus/E. Hale

E. Hale

S. Jelus/E. Hale

S. Jelus/E. Hale

E. Hale

S. Jelus/E. Hale

E. Hale

How to use this guide

Revision Date Section Change made Author

Document change information (continued)

B 02/2017

1.2.3 and

2.2.6

B 02/2017 2.2.5

Added information about motor lift and handheld controller for

1,000–2,000 L systems

Added information about setting the air pressure rate for motor

adjustment for 1,000–2,000 L systems

E. Hale

E. Hale

B 02/2017 3.6.5 Added Agitation Rate Calculations section to Chapter 3 E. Hale

B 02/2017 3.3 Added 1,000 L systems to 500 L BPC loading section E. Hale

B 02/2017 3.3.2 Added information about drive shaft serial numbers E. Hale

B 02/2017 1.2.1 Added drawing showing 2,000 L S.U.B. features E. Hale

B 02/2017 2.1.3 Added 1,000 L and 2,000 L electrical box preparation E. Hale

B 02/2017 Appendix C

Added Appendix C—2,000 L S.U.B. agitator operation and

maintenance guidelines

S. Jelus/

E. Hale

B 02/2017 Appendix D Added Appendix D—Drive shaft use log E. Hale

B 02/2017 Chapter 4 Removed 5:1 S.U.B. Made-to-order table E. Hale

B 03/2017 3.4.3 Added image of 2,000 L 5:1 BPC hanging tag E. Hale

B 03/2017 1.2.3 Added drive shaft specifications table E. Hale

B 04/2017 Warnings and Safety Added explosive atmosphere (ATEX) warning E. Hale

B 04/2017 4.2

Changed "Maximum Mixing Rate" to "Agitation Speed Range" in

hardware specifications

E. Hale

C 05/2017 Chapter 4 Corrected drive shaft diameter for 500 L S.U.B. E. Hale

D 09/2017 3.6

Added harmonics/cavitation graph and context about these

operating parameters to agitation information

E. Hale

Added a FAQ about excessive residue buildup in condenser bag

D 09/2017 5.2, 3.4

due to low TCU coolant levels, and provided more information in

E. Hale

the 2,000 L condenser system instructions

D 09/2017

Warnings, safety, and

warranty information

Added warranty and usage information E. Hale

D 09/2017 How to use this guide Added a section for abbreviations/acronyms E. Hale

Added noise level to specifications for all S.U.B. sizes, and

D 09/2017 Chapter 4

corrected 2,000 L ceiling height requirement for 4-piece drive

E. Hale

shaft loading

D 09/2017 Chapter 4

Added accessory part numbers, and BPC illustrations and

specifications

E. Hale

D 10 / 2017 3.4.3 Added note that all 2,000 L drive shaft heads are now black E. Hale

D 01/2018 -- Updated warning symbols and "Hot surface" warning E. Hale

D 01/2018 4.2 Corrected 500 L ceiling height requirement for drive shaft loading E. Hale

D 01/2018 3.6.5

D 01/2018 3.6.5

D 01/2018 3.6.5

Revised Graph 3.4 by changing 2,000 L line to 750 and 1,000 L

line to 375 L

Changed Table 3.4 footnote to "> 20 W/m

Changed first footnote in Table 3.6 to "> 20 W/m

3

"

3

"

E. Hale

E. Hale

E. Hale

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 8

How to use this guide

Revision Date Section Change made Author

D 01/2018 5.1. 2 Removed 2,000 L row from Table 5.1 E. Hale

D 01/2018 5.1. 2

D 01/2018 3.4.3 Updated Figure 3.102 to show the new deep impeller pocket E. Hale

D 03/ 2018 Chapter 4

D 04/ 2018 -- Removed references to 2,000 L S.U.B. four-piece drive shafts E. Hale

D 08/ 2018

E 11/2 0 18

E 11/2 0 18

E 11/2 0 18 2.1.3, 3.6.4, 4.3 Updated text and images of the E-Box E. Hale

E 11/2 0 18 3.5.3 Removed references to metal probe clips E. Hale

E 11/2 0 18 Appendices

E 11/2 0 18 2.2.3, Various

E 12/2018 3.1.4, 3.6.4 Edited sentence (3.1.4), reworded step #2 (3.6.4) E. Hale

E 12/2018 3 . 7.1

E 12/2018 4.2 Added tolerance to "Agitation speed range" in all specifications E. Hale

F 09/2019 4.2, Various

G 06/2020 -- Minor formatting revisions T. Golightly

G 06/2020

G 06/2020 3.2.1 Removed former Step 13, and removed former Figure 3.11 T. Golightly

G 06/2020 3.2.1 Updated image for Figure 3.10 T. Golightly

G 06/2020 3.2.1

G 06/2020 3.3.1, 3.4.1 Added a CAUTION note to the BPC loading instructions T. Golightly

Document change information (continued)

Under "Drive shaft longevity and replacement," added "of cumulative

use" after "replacing your drive shaft every 360 days." In the second

sentence of the second paragraph, changed to "every 180 days of

cumulative use." In the first sentence of the note, added "< 50%

working volume."

Changed "Operating temperature range" to specifications for all

S.U.B. sizes to "Ambient to 40 ± 0.5°C (104 ± 0.9°C)"

Warnings, safety,

and warranty

information

Warnings, safety,

and warranty

information

How to use this

guide

Warnings, safety,

and warranty

information

Added seismic guidance K. Leeman

Added emphasis to "Electrical connections" section, changed

"certified personnel" to "Thermo Fisher Scientific service personnel,"

and updated ATEX warning

Changed "Input into Thermo Scientific publications" section to

"Questions about this publication"

Removed Appendix B (AC-Tech variable speed drive settings) and

renamed Appendices B through D, accordingly

Removed section 2.2.3 (Attaching the cable management system

arm) and edited images showing the arm

Updated accuracy in "Mixing speed verification" to ± 1.5 rpm or 1%

of setpoint, whichever is greater

Minor formatting changes and updated cart length demension on

Figure 4.10

Added Warning for Tipping Hazard T.Golightly

Added a CAUTION note below Step 12 for the BPC loading

instructions

E. Hale

E. Hale

E. Hale

E. Hale

E. Hale

E. Hale

E. Hale

T. Golightly

T. Golightly

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 9

How to use this guide

Document change information (continued)

Revision Date Section Change made Author

H 10/2020 4.2

H 10/2020 4.2 Replaced Figures 4.7–4.10 with updated dimensions T. Golightly

H 10/2020 1.3.1

Corrected the overall width, length, and height in

Tables 4.2 and 4.4

Updated the "Finesse pH and DO" sensors to

"Hamilton pH and DO" sensors in Table 1.2

T. Golightly

T. Golightly

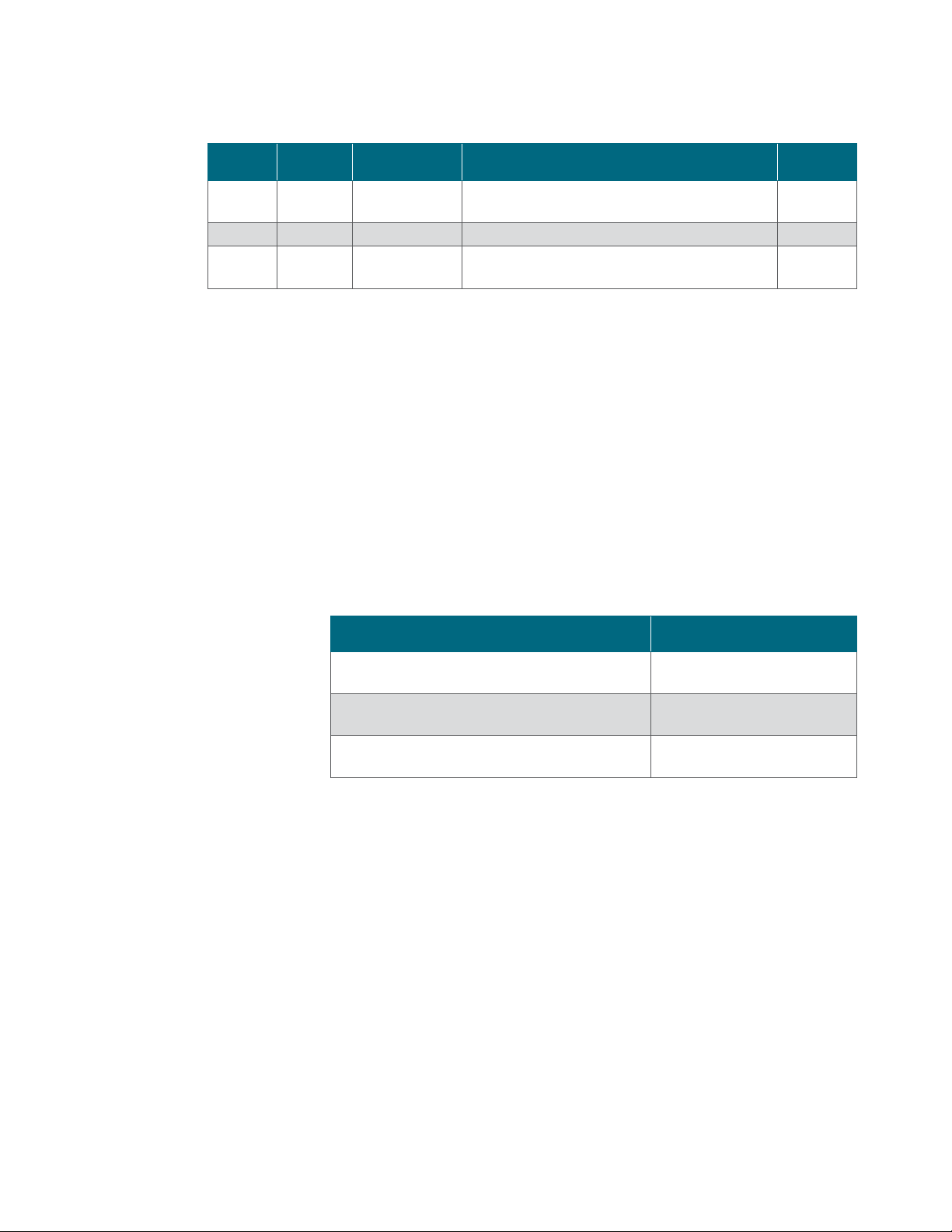

Questions about this publication

If you have any questions or concerns about the content of

this publication, please contact technicaldocumentation@

thermofisher.com and your Thermo Fisher Scientific sales team.

Related publications

Please contact your local sales representative for information about the

related publications listed below.

Publication Description

Thermo Scientific HyPerforma 5:1 S.U.B. Validation

Guide (DOC0023)

Thermo Scientific HyPerforma 5:1 S.U.B. Data Sheets

(for various sizes)

Thermo Scientific HyPerforma 5:1 S.U.B. Packing and

Unpacking Guide (DOC0033)

Information about validation

procedures

Product descriptions and ordering

information

Instructions for packing and

unpacking equipment

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 10

How to use this guide

Abbreviations/acronyms

Refer to the list below for definitions of the abbrieviations and acronyms

used in this publication.

BPC BioProcess Container

cGMP Current good manufacturing practices

DO Dissolved oxygen

ETP Equipment Turnover Package

GFCI Ground fault circuit interrupter

HMI Human machine interface

ID Inner diameter

IEC International Electrical Code

OD Outer diameter

PED Pressure Equipment Directive

PID Proportional integral derivative

P/V Power input to volume

RTD Resistance temperature detector

STR Stirred tank reactor

S.U.B. Single-Use Bioreactor

TCU Temperature control unit

VFD Variable frequency drive

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 11

1

HyPerforma Single-Use

Bioreactor (S.U.B.)

overview

Chapter contents

1.1 Introduction to the S.U.B.

1.2 Hardware characteristics

1.3 End user and third-party supplied components

1.4 BPC characteristics

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 12

Chapter 1 | S.U.B. overview

1.1 Introduction to the S.U.B.

The Thermo Scientific HyPerforma Single-Use Bioreactor (S.U.B.) has

been designed as a single-use alternative to conventional stirred tank

bioreactors currently utilized in eukaryotic cell culture. Based on years

of accepted stirred tank reactor (STR) design, the S.U.B. emulates STR

scalability and operating parameters, yet it has the unique advantage

of being a single-use device. Ease of setup with respect to system

operation, and integration into existing facilities makes the S.U.B. an

attractive alternative to its conventional STR counterpart.

The 5:1 S.U.B. allows users to take advantage of low volume mixing

in addition to half and full volume, providing greater flexibility all in

one system. Critical design parameters such as height-to-diameter

ratios, mixer design and location, and typical control system interfaces

have been maintained. A key element to the single-use design is the

plastic (polyethylene) impeller with a bearing/seal assembly linking to

an external mixer drive. Quick setup and changeover allows for faster

turnover in cell culture runs over traditional reusable systems.

The S.U.B. system consists of the following primary components:

1. Outer support container with water jacket heating system

2. S.U.B. BioProcess Container (BPC) that is supplied gamma

irradiated

3. Control system for units with AC motors for agitation

4. Direct drive agitation mixing assembly with an AC or DC motor

(DC motor not available for 1,000 and 2,000 L systems), drive shaft,

and impeller

Figure 1.1. 50–500 L S.U.B.s.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 13

Chapter 1 | S.U.B. overview

The outer support container is engineered and fabricated to fully

support each BPC and allow easy access for operation. It is a stainless

steel vessel that holds and supports the BPC. The outer support

container contains the mixing drive and water jacketed tank on casters

(2,000 L S.U.B.s are not on casters). The drive shaft is detachable and

reusable, and is inserted into the BPC through the mixing assembly

and into the bearing port. Load cells are standard for all 5:1 S.U.B.

systems.

The BPC includes the impeller assembly, sparger, vent filter inlet/

outlet ports, probe integration ports, filling, dispensing, and sampling

ports. Each BPC comes fully assembled and gamma irradiated. The

materials are fully qualified for biological product contact per USP

Class VI plastics. Each assembly is manufactured under current Good

Manufacturing Practices (cGMP) and is supported by qualification

and validation information. Innovative, proprietary technology allows

for the integration of the mixing shaft and pH/dissolved oxygen (DO)

probes, and the resistance temperature detector (RTD). The probe and

temperature interfaces are comparable to traditional systems with the

design allowing for simple aseptic connections. Integrated spargers

(drilled hole, overlay, and cross flow) are built into the BPC through

universal ports.

The Thermo Scientific S.U.B. utilizes an open architecture design for

the control system, allowing for integration with customer systems

or with third-party controllers for feed pumps, mass flow controls,

and human-machine interface (HMI) screens. Controls for agitation

are integrated into the S.U.B., with pH/DO probes and controls being

supplied by the user or a third-party integrator. HyPerforma S.U.B.

systems require a temperature control unit (TCU) selected and supplied

by the end user or by Thermo Fisher Scientific.

Figure 1.2. 2,000 L 5:1 S.U.B.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 14

Chapter 1 | S.U.B. overview

This user’s guide covers the setup, operation, maintenance, and

troubleshooting of all 5:1 S.U.B. systems in the following volumes: 50,

100, 250, 500, 1,000, and 2,000 L.

Figures 1.3–1.7 illustrate some of the standard labeling on 50,

100, 250, and 500 L 5:1 S.U.B. systems. Systems in these sizes

include the following:

• Hanging tag labeled for "5:1 Mixing" attached to the BPC bearing

port (Figures 1.3 and 1.4)

• Motor mount engraved with "5:1 Mixing" (Figures 1.5 and 1.6)

• "Usable by 5:1 drive shaft only" warning label on BPC bearing port

cap (Figure 1.7)

• Drive shaft with a black head that is engraved with "5:1 Mixing."

Figure 1.3. Hanging tag on 50–500 L 5:1 BPC bearing port.

Figure 1.5. Engraving on 50–500 L 5:1 motor mount.

Figure 1.4. Close‑

up view of 5:1 BPC

hanging tag.

Figure 1.6. Close‑up

view of engraving on

5:1 motor mount.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 15

Chapter 1 | S.U.B. overview

Figure 1.7. Label on 50–500 L 5:1 BPC

bearing port cap.

Important notes:

• If your 50, 100, 250, or 500 L system components are not labeled

for 5:1 mixing, consult your sales representative immediately.

• There are no 5:1 mixing labels for 1,000 and 2,000 L S.U.B.s and

BPCs.

• 5:1 S.U.B. mixing speeds should be reduced when operating at

lower volumes to avoid damaging the system. For recommended

agitation rates, see section 3.6.4 and the hardware specifications in

section 4.2 of this user's guide.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 16

Chapter 1 | S.U.B. overview

1.2 Hardware characteristics

1. 2.1 S.U.B. hardware components

Figures 1.8 and 1.9 below illustrate all available components of a

500 L S.U.B. system. Note: 50, 100, and 250 L systems do not have a

BPC loading door, and use a one-piece drive shaft.

1

4

2

5

3

7

8

9

Figure 1.8. Front view of 500 L S.U.B.

1. Exhaust vent filter holder

2. Mixing assembly with shield

3. Mixer motor

4. Bearing port receiver with clamp

5. BPC loading door (500 L only) and liquid sight

windows

6. Electrical control panel (E-

7. Probe hanger bracket

8. Probe access windows

9. Leveling casters

10. Load cells

Box

), optional

10

11

12

13

6

15

16

17

Figure 1.9. Back view of 500 L S.U.B.

11. Standard tool set: 10 mm (3/8 in.) x 16.9 Nm (150

in-lb.) square torque wrench, load cell and motor cap

lockout wrench

12. Cable management system

13. Drive shaft, stored (2-piece)

14. 304 Stainless steel outer support container

15. 0.95 cm (3/8 in.) Dimpled jacket

16. Bleed valve

17. Cart assembly

18. Bottom cutouts/pins for BPC attachment/alignment

19. Quick-connect water inlet/outlet ports

19

14

18

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 17

Chapter 1 | S.U.B. overview

Figures 1.10 and 1.11 below illustrate all available components of a

2,000 L S.U.B. system. Note: 1,000 L systems have a cutout instead of

a back access door, and do not include a BPC lift. See section 4.1.3 for

a complete illustration of a 1,000 L S.U.B.

1

2

3

4

10

11

12

15

11

19

5

6

7

13

8

9

14

16

20

21

17

22

18

Figure 1.10. Front/side view of 2,000 L S.U.B.

1. Motor lift

2. Mixer motor

3. Mixing assembly with motor safety shield

4. Handheld controller for motor adjustment (on bracket)

5. Emergency stop (E-Stop)

6. Drive shaft, stored

7. BPC loading door and liquid sight windows

8. Probe access window

9. Probe hanger bracket (with probe clips)

10. Exhaust vent filter holder

Figure 1.11. Back view of 2,000 L S.U.B.

13. Load cell display

14. Electrical control panel (E-Box), optional

15. 0.95 cm

(3/8 in.)

Dimpled jacket

16. BPC lift control

17. Bleed valve

18. Quick-connect water inlet/outlet ports

19. 304 Stainless steel outer support container

20. Rear access door

21. Bottom cutouts/pins for BPC attachment and alignment

22. Load cell (3)

11. BPC lift, for 2,000 L 5:1 S.U.B.s only (2)

12. Standard tool set: 10 mm (3/8 in.) x 16.9 Nm (150 in-lb.)

square torque wrench, load cell and motor cap lockout wrench

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 18

Chapter 1 | S.U.B. overview

1.2.2 S.U.B. system features

The S.U.B. is designed for system mobility and easy integration, and

utilizes a straightforward operator interface. The following sections give

general descriptions of S.U.B. hardware features.

Agitation

If your system uses an AC motor and a Thermo Scientific electrical

control panel (E-Box), the stirring speed is adjusted by using the E-Box

keypad interface. The agitation control interface utilizes a digital display

to indicate stirring speed in units of revolutions per minute (rpm). Power

is supplied to the motor by a two-position power switch. The up and

down arrows on the agitation keypad adjust the stirring speed. If

your 50, 100, 250, or 500 L system has a DC motor and is integrated

and managed by a third-party controller, agitation is managed by the

controller. Thermo Fisher Scientific does not provide electrical control

for units with DC motors.

Bioreactor control system

The S.U.B. is designed to integrate with existing bioreactor control

systems in their numerous configurations. The S.U.B. control system

supplied with the Thermo Scientific E-Box manages the agitation

process parameters. Parameters of pH and DO, gas management,

feed addition, and base addition control must be managed by an

external controller supplied by the end user or a third-party integrator.

Temperature

The S.U.B. can be operated within the temperature range from ambient

to 40°C. The process temperature is measured by means of a supplied

RTD (pt-100) that is inserted into the thermowell of the BPC. Water

jacket system temperature control is maintained through the TCU.

Condenser system

The condenser system is recommended for 2,000 L S.U.B. use, and

is available as optional hardware for smaller systems. It cools exhaust

gases and re-circulates condensate into the bioreactor.

Heating performance

Heating times for the S.U.B. systems vary based upon operating

liquid volume and temperature, ambient or heating fluid temperature,

sparger rate, and mixing rate. Users should adjust process liquid

staging and seeding strategies to the unique aspects of the S.U.B.

Process controllers are designed to provide optimum heat transfer

and to minimize heat-up times while maintaining the material integrity

of the polymer film construction of the BPC. Refer to section 3.1.4 for

expected heating times.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 19

Chapter 1 | S.U.B. overview

1.2.3 Additional system components

Drive shafts

The drive shaft couples the mixing impeller that is inside the BPC to

the motor. If you are using a 5:1 BPC, it is important to use the correct

drive shaft. See Table 1.1 for drive shaft specifications for each S.U.B.

size.

Table 1.1. Drive shaft specifications for 50–2,000 L systems.

System

size

50 L 85.09 cm (33.5 in.) 1-piece

100 L 100.58 cm (39.6 in.) 1-piece

250 L 120.90 cm (47.6 in.) 1-piece

500 L 155.7 cm (61.3 in.) 2-piece

1,000 L 167.6 cm (66 in.)

2,000 L 215.6 cm (84.9 in.) 2-piece

Overall shaft

length

Number of

pieces

3-piece or

4-piece

Head description Material

Black, engraved with

"5:1 Mixing"

Black, engraved with

"5:1 Mixing"

Black, engraved with

"5:1 Mixing"

Black, engraved with

"5:1 Mixing"

White Stainless steel

Black, engraved with

drive shaft length

Stainless steel

or aluminum

Stainless steel

or aluminum

Stainless steel

or aluminum

Stainless steel

or aluminum

Carbon fiber

Probe assembly

Autoclave tray

for probe kits

Probe integration

The autoclave tray (Figure 1.12) holds the electrochemical probes and

bellows in place during the autoclave sterilization process. Design

elements include the following.

• Fabricated from stainless steel

• Features a plastic handle for easy transport right out of the

autoclave

• Positions probes on 15% incline for greater probe/membrane

longevity

• Will restrain probe bellows from collapsing during sterilization

• Accommodates two probes

Handle

Figure 1.12. Autoclave tray and probe assembly.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 20

Chapter 1 | S.U.B. overview

The probe assembly (Figure 1.13) is an innovative design to package

user-supplied pH and DO probes for sterilization, and to aseptically

connect them to the BPC. The probe assembly includes an aseptic

connector, molded bellows cover, and threaded probe adapter.

Molded bellows cover

Aseptic

connector

Threaded probe

adapter

Figure 1.13. Probe assembly.

BPC lift (2,000 L systems only)

The BPC lift (Figure 1.14) helps users load the BPC into 2,000 L

S.U.B.s. Two hooks, on opposite sides of the S.U.B., attach to tabs on

the BPC. The BPC lift control (Figure 1.15) is used to raise and lower

the BPC. For instructions on using the BPC lift, see section 3.4 of this

publication.

Figure 1.14. BPC lift for 2,000 L systems.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 21

Chapter 1 | S.U.B. overview

Emergency stop

(E-Stop)

Motor enable switch

Vertical lift

switch

Main

disconnect

switch

Figure 1.15. BPC lift control for 2,000 L

systems.

Motor lift and handheld controller (1,000 and 2,000 L systems

only)

1,000 and 2,000 L 5:1 S.U.B. systems include a motor lift (Figure 1.16),

used to adjust the position of the motor. The motor lift is operated

by a handheld controller (Figure 1.17), which is located on a bracket

attached to the front of the S.U.B. For instructions on how to operate

the handheld controller, see section 2.2.5 of this guide—Using the

Handheld Controller for Motor Lifts (1,000 and 2,000 L systems only).

Figure 1.16. Motor lift for 1,000–2,000 L systems.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 22

Figure 1.17. Handheld controller

for motor lifts.

Chapter 1 | S.U.B. overview

Options and accessories

The following additional system components may or may not be

installed on your S.U.B. system. To order accessories for retro-fitting to

your unit, contact your sales representative.

Exhaust vent filter heaters

The exhaust vent filter heater system, which includes the heater, a

controller, and power cord (Figure 1.18), is available for increased

longevity of the exhaust filter on the BPC. The heating element is fully

insulated with molded silicone and secured around the filter by use

of snap retainers, fully encapsulating the exhaust filters for consistent

temperature regulation. Heating the filter sufficiently to eliminate

the formation of condensation reduces the risk of fouling the filter

membrane.

The heater is factory preset to operate between 40°C–50°C, but can

easily be adjusted to the demand of the application. Temperature

settings above 60°C are not recommended.

Figure 1.18. Vent filter heater.

Load cells

Load cells, which are used to determine the weight of the contents of a

S.U.B., are installed on all standard 5:1 S.U.B. systems. Load cell retrofit kits can also be added to existing S.U.B. units by a certified service

technician. Load cells arrive uncalibrated. The load cell manufacturer or

a qualified technician should calibrate these systems onsite.

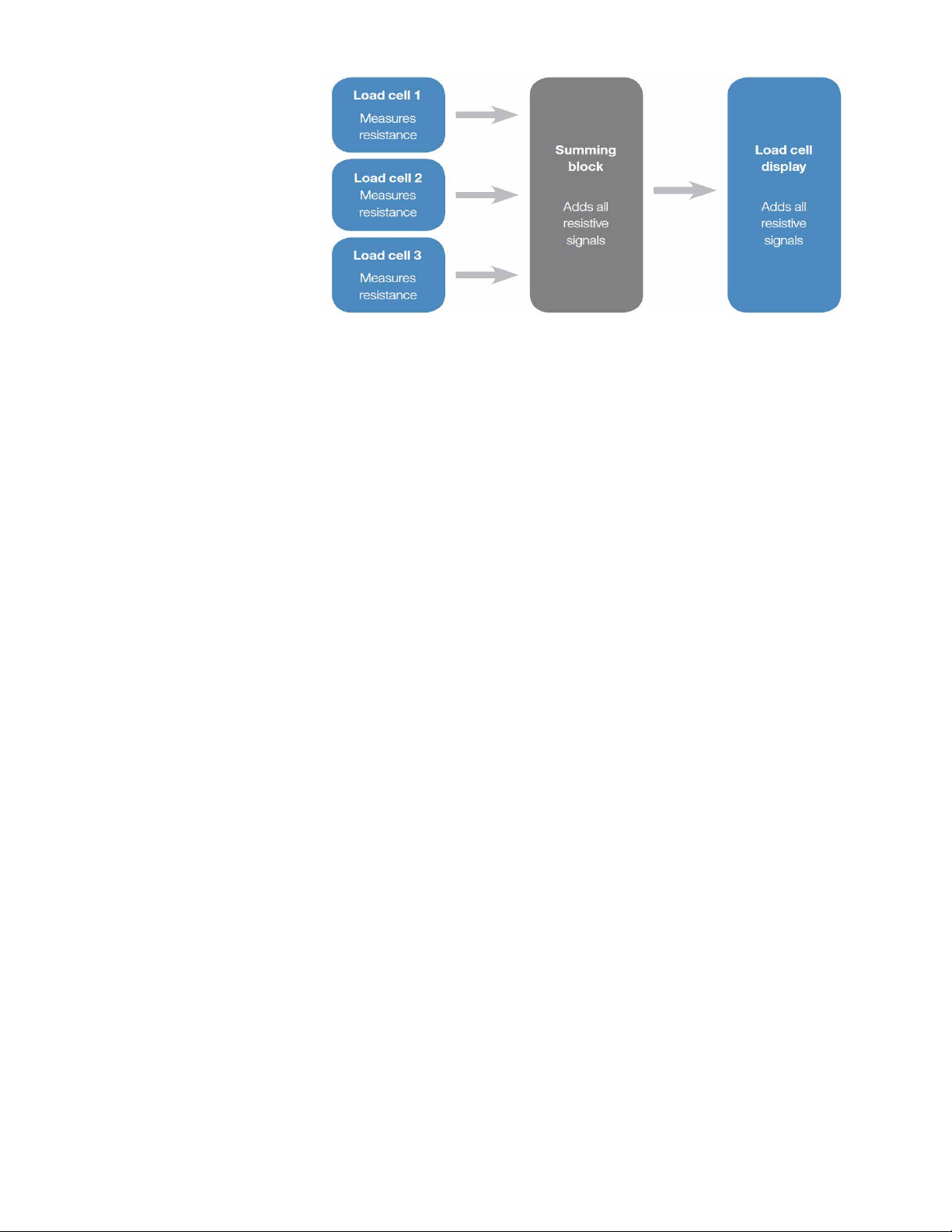

The load cell kit comes with three load cells, summing block,

wiring, and a display screen with a choice of several data interfaces

(Figure 1.19).

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 23

Chapter 1 | S.U.B. overview

Figure 1.19. Load cell system overview.

Load cells are typically radial-mounted in sets of three. The mounting

location (Figure 1.20) varies slightly for each size in order to allow easy

access to the bottom drain or sparging mechanisms and tubing.

Figure 1.20. Load cell location.

AC and DC motors

AC and DC motor options are available to help tailor the S.U.B. system

to your specific needs. Note: DC motors are only available for 50, 100,

250, or 500 L systems.

DC motors operate at a lower voltage and, when integrated with a

controller system that receives sensor feedback, provide more accurate

speed control through a digital program transmitter. The DC motor

comes with an encoder, but does not come with a motor control

option from Thermo Scientific. For DC motors, a control option must be

specified by the end user.

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 24

Chapter 1 | S.U.B. overview

AC motors may be used with the Thermo Scientific E-Box. AC motors

include a variable frequency drive, and are controlled using either the

provided keypad or a controller specified by the end user.

Cable management systems

The cable management system is available as an option on 50, 100,

250, 500, and 1,000 L units. It is used to organize various lines and

includes the following components (Figure 1.21).

• Internal channel for sparge lines

• External channels for feed and base addition lines

• Harvest line hook

Channels for

sparge lines

Channels for

feed and base

addition lines

Harvest line

hook

Figure 1.21. 500 L S.U.B. with

cable management system.

Miscellaneous items

The miscellaneous items listed below are ancillary components

that support the operation of the HyPerforma S.U.B. for cell culture

production, and enhance the overall performance of the complete

system.

• Sampling manifold with luer lock

• S.U.B. temperature sample port—For RTD calibration/validation

Thermo Scientific HyPerforma 5:1 Single‑Use Bioreactor User's Guide | 25

Loading...

Loading...