Models

Heat Pump Manual

Thermex Solutions

PRODUCT MANUAL

HEAT PUMPS

Document 001-D135

11 May 2015

THW20 THW40 THW60 THW80 THW100 THW150

THWW20 THWW40 THWW50 THWW60 THWW80 THWW100

THWP20 THWP40 THWP60

2

Heat Pump Manual

Terms and Conditions

Listed below are some basic operational and installation conditions that must be adhered to for

Thermex Solutions warranty to remain valid and more importantly for trouble free heat pump

operation

· If the heat pump is supplied without a pump then the minimum flow rate specified in the manual

must be maintained through the units at all times.

· The heat pump must be commissioned in accordance with the instruction in the manual and

the heat pump must be commissioned under normal operating conditions

· The operational settings on the controller must not be altered without first consulting Thermex

· The temperature cut out set point must never be set above 61°C without first consulting

Thermex Solutions

· The heat pump must be installed on level surface

· The heat pump must be powered up for at least 4 hours before starting the heat pump to allow

for the sump heater to warm the compressor oil.

· The pressure in the sealed refrigeration system must be checked by a refrigeration mechanic

before starting the heat pump to ensure that the pressure on the suction side is at least 200

kPa

· For any service work not carried out by Thermex Solutions, Thermex Solutions will only cover

costs of refrigerant to the value of the specified charge in the units.

· It is not Thermex Solutions’s responsibility to connect the heat pump to the BMS unless agreed

to before delivery of the heat pump

· The heat pump must not be installed too close to walls and other heat pumps with clearances

to be at least what is specified in the manual

· The heat pump must be installed with proper, neat access to facilitate servicing in a manner

that is compliant with safe work practices. Additional charges may apply for site where access

to the heat pump is unsafe or restricted

· Thermex Solutions will manufacture the heat pump to the specification provided to the sales

department. If the information supplied is incorrect Thermex Solutions takes no responsibility

for wear on the heat pump for short cycling in the case where the heat pump is over sized for

the heat load or the heat pump unable to maintain temperature when the heat pump is too

small for the heat load

· Thermex Solutions takes no responsibility for repairs carried out on the heat pump by un-

authorised service agents or if parts are installed that are not from Thermex Solutions’s

approved supplier list

· Costs for installations where a crane lift is required to undertake major repairs will not be

covered by Thermex Solutions

· All dimensions, technical specifications and software operation are correct at the time of

writing. However with constant development some of these specifications may change without

written notice

3

Heat Pump Manual

FOREWARD

This manual is designed to explain the installation, operation and the basic maintenance of

the product. It is recommended that for service issues Thermex Pty Ltd be contacted before

and work commences. A comprehensive service manual is available to be down loaded from

the website.

CONTACT DETAILS

Thermex Solutions Pty Ltd

161 Orchard Road

Chester Hill NSW 2162

Australia

Toll Free 1800649233 or +612 9721 9300

Fax + 612 9721 9344

www.thermex.com.au

CONTENTS

Safety 4

Marking 6

Certification 6

Warranty 7

General Information 7

Intended Use 7

Water Circuit 7

Technical Data 8

Heating System Schematic 16

Dimensions 17

Transport and Storage 19

Installation – electrical, water connection, water treatment, control circuit and final

checks

Operation 27

Control 29

Service and Maintenance 31

Wiring 37

Pump Curves N/A

Critical Spares 38

Trouble Shooting 39

Release Notes 40

Commissioning 41

Site Inspection 44

19

Heat Pump Manual

SAFETY

THE UNIT IS DESIGNED FOR OUTDOOR USE.

- This unit is designed to be safe in the use for which it was planned provided that it is

installed, started up and maintained in accordance with the instructions contained in

this manual.

- The unit contains electrical components that operate at line voltage and contains

moving parts. It therefore must be isolated from the electrical supply before being

worked on. All maintenance operations that require access to the unit must be carried

out by suitably qualified technicians who have a thorough understanding of all

necessary precautions associated with refrigeration and electrical machinery.

- The liquids to be heated must be compatible with the materials used in the

constructions of this unit. These liquids can be water or mixtures of glycol and water

for example. The liquids to be heated must not be flammable.

- All panels must be re-installed after carrying out any maintenance work.

- The unit is not to be used by the infirmed or children unless they are supervised by

responsible persons qualified to carry out the supervision.

- The unit should be secured to prevent it from toppling over.

WARNING

The unit is only to be installed, operated, maintained and serviced by

qualified persons only. Operation of units such as these can be hazardous

and should be serviced by persons with the proper training and

qualifications.

The unit and the Product Manual have markings, warning and instructions

on the safe operation of the unit and they must be adhered to.

WARNING

All wiring must be performed by qualified electricians. Improperly installed

wiring and grounding may result in electrocution and fire hazards

To avoid these hazards all wiring must be installed in accordance with all

the local relevant safety standards for wiring

WARNING

The heat pump contains refrigerants under high pressure. The system also

contains oils under high pressure. Before the refrigeration circuit can be

opened, the refrigerant should be reclaimed to reduce pressure in the

system.

Failure to recover the refrigerant to relieve pressure or the use of

refrigerants or refrigerant substitutes that are not specified for the unit may

result in system rupture and explosion.

- Where the above symbol is shown there are live electrical parts and the utmost care

should be taken. .

- Always isolate power from the unit when working on it.

- Maximum temperature setting is 60 degrees on the unit. Any higher than this may

cause problems with the condenser and/ or the water system over heating which may

become dangerous

Refrigerants have a narcotic effect when inhaled in high quantities. Should a leak occur of the

refrigerants then the room should be vacated and should only be re-entered after suitable

ventilation.

5

Heat Pump Manual

SAFETY

First Aid

- Eye Contact. Immediately flush with tepid water or sterile saline solution. Hold eyelids

apart for 15 minutes while irrigating. Seek medical attention.

- Inhalation. Remove from area of exposure immediately and if you are assisting a

victim avoid being exposed. Breathing apparatus must be worn in the presence of

high concentration of refrigerants. If victim is not breathing then apply artificial

respiration and seek urgent medical help. Give oxygen is available.

- Skin Contact. Cold Burns. Remove contaminated clothing and gently flush affected

area with warm water (30C) for 15 minutes. Apply sterile dressing and treat as for a

thermal burn. For large burns immerse in water for 15 minutes. DO NOT apply any

form if direct heat. Seek medical attention.

- Ingestion. For advice contact the poisons centre on 131126 in Australia. If swallowed

do not induce vomiting. Ingestion is considered unlikely due to product form.

- Advice to Doctor. Use of adrenaline and other catacholamines may be contraindicted

due to possible cardiac sensation. Treatment for asphyxia.

R134a HazChem code 2RE

R134a is non – flammable.

Disposal

The unit must be disposed of in a proper fashion. The refrigerants in the system must be

reclaimed by a qualified refrigeration mechanic and disposed of in accordance with the

statutory requirements. The compressor contains oil that must not be dumped.

Manual Handling

The unit weights approximately 650 kg. Do not try to move the unit manually. The unit can be

lifted with a crane (the centre of gravity is towards the front of the unit), a forklift or a pallet

jack.

6

All Thermex products are manufactured by Aqua Cooler in

Heat Pump Manual

MARKING

The units have various markings on them. There is a marking plate on the unit, an example is

shown below giving regulatory requirements. There will be a wiring diagram as shown in the

wiring diagram section of this document provided in a larger scale for ease of maintenance.

A four digit serial number sticker will also be placed under the marking plate. With this number

Thermex can trace the date of manufacture of the product and details on the unit.

The wiring diagram will show the model of the unit and the options installed.

CERTIFICATION

All the electrical components in the heat pump have certification for electrical safety. All the

exposed components are rated to IP66 against weather ingress.

Australia. Aqua Cooler is an accredited participant in the

WaterMark QA scheme and is audited annually by SAI Global

The Watermark scheme cover all products that are connected

to the town water supply.

7

Heat Pump Manual

WARRANTY

Thermex offers a full comprehensive 12 month parts warranty, 5 years on the compressor

and the condenser.

Any claim under this warranty must be made within 12 months of the date of purchase of the

product. To make a claim under the warranty, return the product (with proof of purchase) to

the supplier where you purchased the product or contact Thermex regarding warranty

conditions.

Thermex will pay your reasonable, direct expenses of claiming under this warranty. You may

submit details and proof of your expense claim to Thermex Pty Ltd for consideration.

This warranty is given by Thermex Pty Ltd, ABN 13 245 994 351, of 161 Orchard Rd, Chester

Hill, NSW 2162 – Ph 02 9721 9310.

This warranty is provided in addition to other rights and remedies you have under law: Our

goods come with guarantees which cannot be excluded under the Australian Consumer Law.

You are entitled to replacement or refund for a major failure and to compensation for other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a

major failure.

Attached to this document is a comprehensive commissioning procedure. This must be

carried out in accordance with the procedure and returned to Thermex or Thermex can do the

commissioning, otherwise the warranty will be voided.

GENERAL INFORMATION

The heat pump is designed to heat water to feed a central storage system. It has either an air

cooled copper and aluminium fin or a coaxial copper water sourced evaporator, a plate heat

condenser and a scroll compressor to circulate the refrigerant gas. Water is circulated out of

the unit via a pump which is not supplied with the unit. The unit has a microprocessor

controller to maintain temperature, control additional heat pumps and monitor flow through the

unit for safety reasons.

INTENDED USE

The heat pump is design to be installed outdoors and heat water to be storage in a remote

central storage location. The wetted parts in the heat pump are food grade however Thermex

takes no responsibility for the quality of the water being heated. Any other use of this water

heat pump is a not as it is intended.

8

Heat Pump Manual

HOT WATER CIRCUIT

The hot water circuit consists of

1. Condenser heat exchanger – this may be a plate heat exchanger, a coaxial heat

exchanger or shell and tube

2. Flow switch or flow meter

3. Copper pipe work

The heat pump will run whenever called unless the controller detects a drop in flow.

It is important to ensure that any water treatment is passive to the wetted parts of the system

which include

· Stainless Steel

· Copper

· High Density Polyethylene

· Brass

· ABS Plastic

· Nitrile Rubber

The water to water models have a water sourced evaporator that is connected to – typically –

the return condenser water from the installed chillers. This evaporator can have either a plate

heat exchanger or a coaxial heat exchanger. These heat exchangers have water flowing

through them that must be passive to the materials used. These include

· Stainless steel – 316

· Copper

· Brass

9

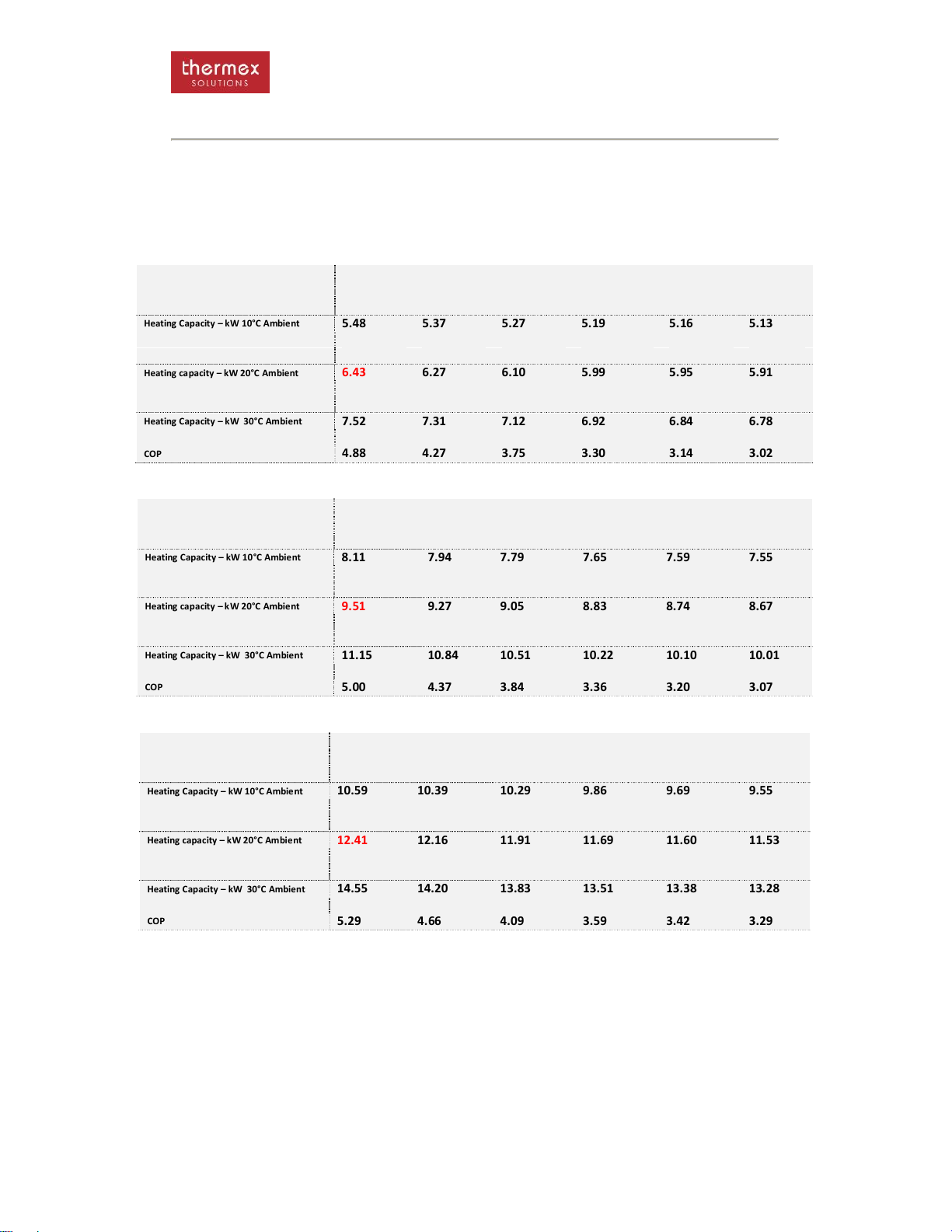

Model

THW07

Nomina

l heating capacity

– kW

7

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

5.48 5.37 5.27 5.19 5.16 5.13

1.51 1.67

1.85 2.05 2.13 2.19

3.63 3.22 2.85 2.53 2.42 2.34

6.43 6.27 6.10 5.99 5.95 5.91

1.53 1.69 1.88 2.08 2.16 2.22

4.20 3.71 3.24 2.88 2.75 2.66

7.52 7.31

7.12 6.92 6.84 6.78

1.54 1.71 1.90 2.10 2.18 2.24

4.88 4.27 3.75 3.30 3.14 3.02

Model

THW10 and THWDW10

Nominal heating capacity

– kW

10

Rated duty point

– in red

45°C

50°C 55°C 60°C 65°C 70°C

8.11 7.94 7.79 7.65 7.59 7.55

2.19 2.43 2.69 2.97 3.08 3.17

3.70 3.27 2.90 2.58 2.46 2.38

9.51 9.27 9.05 8.83 8.74 8.67

2.21 2.45 2.72 3.01 3.13 3.22

4.30 3.78 3.33 2.93 2.80 2.69

11.15 10.84 10.51 10.22 10.10 10.01

2.23 2.48 2.74 3.04 3.16 3.26

5.00 4.37 3.84 3.36 3.20 3.07

Mo

del

THW12 and THWDW12

Nominal heating capacity

– kW

12

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

10.59 10.39 10.29 9.86 9.69

9.55

2.69 2.99 3.34 3.71 3.86 3.98

3.94 3.47 3.08 2.66 2.51 2.40

12.41 12.16 11.91 11.69 11.60 11.53

2.71 3.01 3.35 3.74 3.90 4.02

4.58 4.04 3.56 3.13 2.98 2.87

14.55 14.20 13.83 13.51 13.38 13.28

2.75 3.05 3.38 3.76 3.91 4.03

5.29 4.66 4.09 3.59 3.42 3.29

Heat Pump Manual

TECHNICAL DATA

AIR TO WATER HEAT PUMPS

All units have a details data sheet available – the information supplied below is

intended as a guide only – please contact Thermex for a copy of the individual model

data sheets

20°C Ambient conditions 45°C Water supply 60% RH

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input – kW

COP

Heating capacity – kW 20°C Ambient

Power Input – kW

COP

Heating Capacity – kW 30°C Ambien t

Power Input – kW

COP

20°C Ambient conditions 45°C Water supply 60% RH

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input – kW

COP

Heating capacity – kW 20°C Ambient

Power Input – kW

COP

Heating Capacity – kW 30°C Ambien t

Power Input – kW

COP

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input – kW

COP

Heating capacity – kW 20°C Ambient

Power Input – kW

COP

Heating Capacity – kW 30°C Ambient

Power Input – kW

COP

20°C Ambient conditions 45°C Water suppl y 60% RH

10

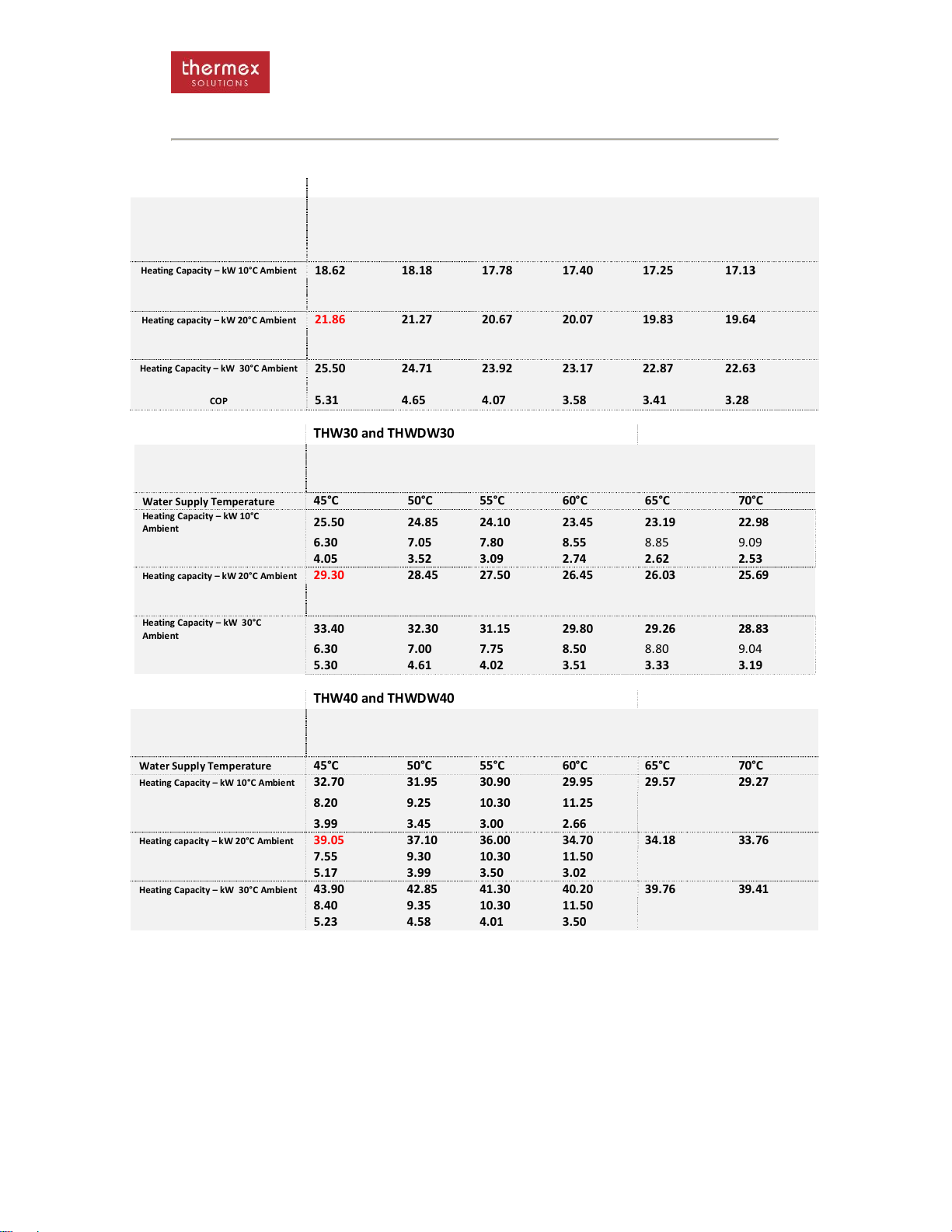

Model

Nominal heating capacity

–

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

18.62 18.18 17.78 17.40 17.25 17.13

4.77 5.28 5.83 6.40 6.63 6

.81

3.90 3.44 3.05 2.72 2.60 2.51

21.86 21.27 20.67 20.07 19.83 19.64

4.81 5.32 5.87 6.47 6.71 6.90

4.54 4.00 3.52 3.10 2.96 2.85

25.50 24.71 23.92 23.17 22.87 22.63

4.80 5.31 5.87 6.47 6.71 6.90

5.31 4.65 4.07 3.58 3.41 3.28

THW30 and THWDW30

THW30H and THWDW30

Nominal heating capacity

–

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

6.30 7.05 7.80 8.55 8.85 9.09

4.05 3.52 3.09 2.74 2.62 2.53

29.30 28.45 27

.50 26.45 26.03 25.69

6.30 7.05 7.80 8.55 8.85 9.09

4.65 4.04 3.53 3.09 2.94 2.83

Ambient

6.30 7.00 7.75 8.50 8.80 9.04

5.30 4.61 4.02 3.51 3.33 3.19

Model

THW40 and THWDW40

THW40H and THWDW40H

Nominal heating capacity

–

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

32

.70 31.95 30.90 29.95 29.57 29.27

3.99 3.45 3.00 2.66 2.54 2.45

39.05 37.10 36.00 34.70 34.18 33.76

7.55 9.30 10.30 11.50 11.98 12.36

5.17 3.99 3.50

3.02 2.85 2.73

43.90 42.85 41.30 40.20 39.76 39.41

8.40 9.35 10.30 11.50 11.98 12.36

5.23 4.58 4.01 3.50 3.32 3.19

Heat Pump Manual

TECHNICAL DATA

AIR TO WATER HEAT PUMPS

kW

20°C Ambient conditions 45°C Water suppl y 60% RH

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambient

Power Input

COP

Model

kW

Water Supply Temperature

Heating Capacity – kW 10°C

Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C

Power Input

COP

THW20 and THWDW20

20

30

20°C Ambient conditions 45°C Water suppl y 60% RH

25.50 24.85 24.10 23.45 23.19 22.98

33.40 32.30 31.15 29.80 29.26 28.83

kW

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambien t

Power Input

COP

40

20°C Ambient conditions 45°C Water suppl y 60% RH

8.20 9.25 10.30 11.25

11.63 11.93

11

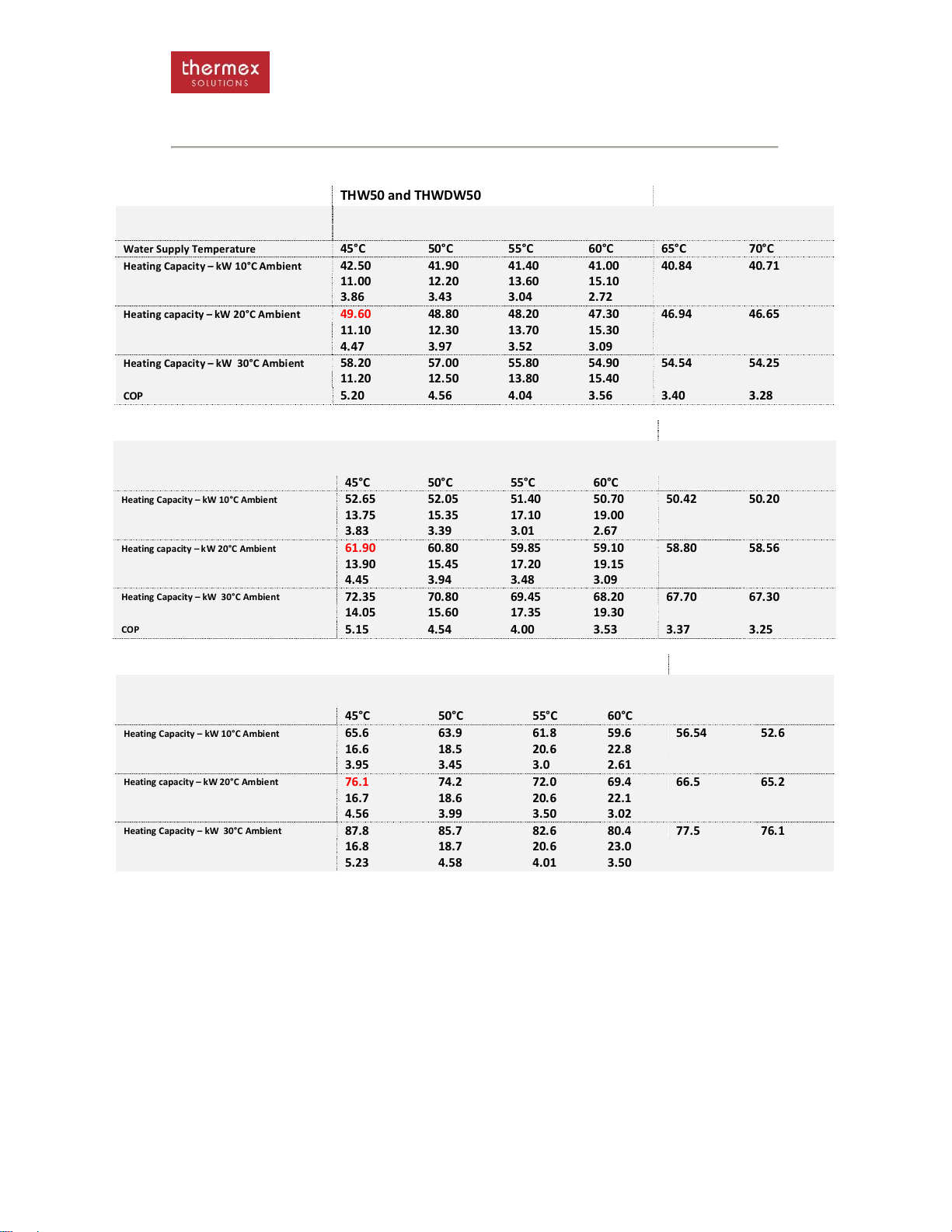

THW50 and THWDW50

THW50H* and THWDW50H

Nominal heating capacity

– kW

50

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

42.50 41.90 41.40 41.00 40.84

40.71

11.00 12.20 13.60 15.10 15.70 16.18

3.86 3.43 3.04 2.72 2.60 2.52

49.60 48.80 48.20 47.30 46.94 46.65

11.10 12.30 13.70 15.30 15.94 16.45

4.47 3.97 3.52 3.09 2.94 2.84

58.20 57.00 55.80 54.90 54.54 54.25

11.20 12.50 13.80 15.40 16.04 16.55

5.20 4.56 4.04 3.56 3.40 3.28

Model

THW60 and THWDW60

THW60H and THWDW60H*

Nominal heating capacity

– kW

60

Rated duty point

–

in red

45°C 50°C 55°C 60°C 65°C 70°C

52.65 52.05 51.40 50.70 50.42 50.20

13.75 15.35 17.10 19.00 19.76 20.37

3.83 3.39 3.01 2.67 2.55 2.46

61.90 60.80 59.85 59.10 58.80 58.56

13.90 15.45 17.20 19.15 19.93 20.55

4.45 3.94 3.48 3.09 2.95 2.85

72.35 70.80 69.45 68.20 67.70 67.30

14.05 15.60 17.35 19.30 20.08 20.70

5.15 4.54 4.00 3.53 3.37 3.25

Model

THW80 and THWDW80

THW80H and THWDW80H

Nominal heating capacity

– kW

80

Rated duty point

– in red

45°C 50°C 55°C 60°C 65°C 70°C

65.6 63.9 61.8 59.6 56.54 52.6

16.6 18.5 20.6 22.8 24.0 23.7

3.95 3.45 3.0 2.61 2.36 2.22

76.1 74.2 72.0 69.4 66.5 65.2

16.7 18.6 20.6 22.1 22.8 22.9

4.56 3.99 3.50 3.02 2.92 2.85

87.8 85.7 82.6 80.4 77.5 76.1

16.8 18.7 20.6 23.0 25.1 25.7

5.23 4.58 4.01 3.50 3.09 2.96

Heat Pump Manual

TECHNICAL DATA

AIR TO WATER HEAT PUMPS

Model

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambient

Power Input

COP

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambien t

Power Input

COP

20°C Ambient conditions 45°C Water supply 60% RH

20°C Ambient conditions 45°C Water supply 60% RH

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambient

Power Input

COP

20°C Ambient conditions 45°C Water supply 60% RH

12

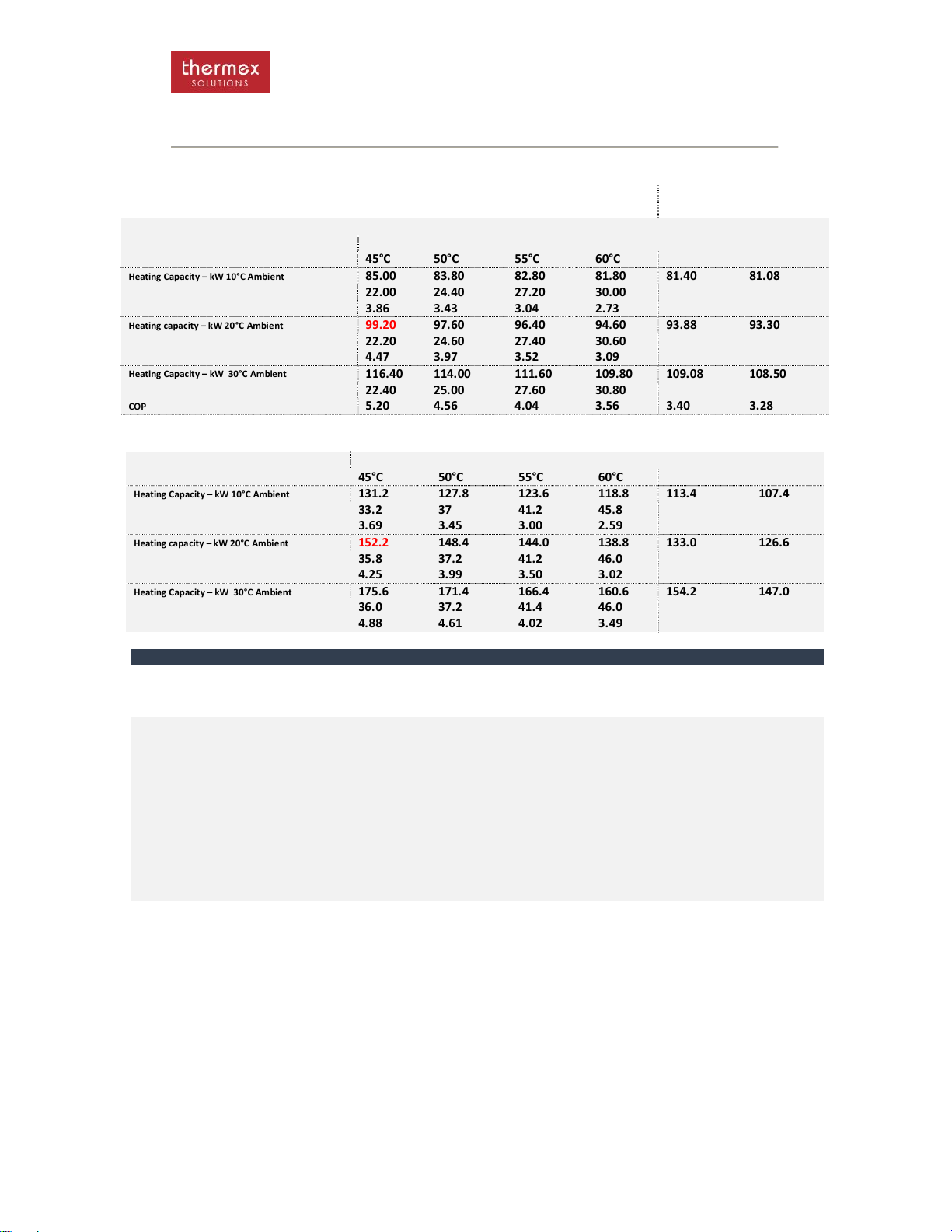

THW100 and THWDW100

THW100H and

Nominal heating capacity

– kW

100

Duty point in red

45°C 50°C 55°C 60°C 65°C 70°C

85.00 83.80 82.80 81.80 81.40 81.08

22.00 24.40 27.20 30.00 31.12 32.02

3.86 3.43 3.04 2.73 2.62 2.53

99.20 97.60 96.40 94.60 93.88 93.30

22.20 24.60 27.40 30.60 31.88 32.90

4.47 3.97 3.52 3.09 2.94 2.84

116.40

114.00

111.60

109.80

109.08

108.50

22.40 25.00 27.60 30.80 32.08 33.10

5.20 4.56 4.04 3.56 3.40 3.28

THW150 and THWDW150

Nominal

heating capacity

– kW

150

45°C 50°C 55°C 60°C 65°C 70°C

131.2 127.8 123.6 118.8 113.4 107.4

33.2 37 41.2 45.8 50.8 56.4

3.69 3.45 3.00 2.59 2.23 1.90

152.2 148.4 144.0 138.8 133.0 126.6

35.8 37.2 41.2 46.0 51.6 58.0

4.25 3.99 3.50 3.02 2.58 2.18

175.6 171.4 166.4 160.6 154.2 147.0

36.0 37.2 41.4 46.0 51.0 55.4

4.88 4.61 4.02 3.49 3.02 2.65

Minimum flow requirements across the unit

- litres/ second

7 and 10kW

1.0 2.4 0.8 20kW

1.0 2.4 0.8

30kW

1.5 3.6 1.2 40kW

2.0 4.8 1.6 50kW

2.4 6.0 1.9 60kW

2.9 7.2 2.3 80kW

3.8 9.5 3.0 100kW

4.8 11.8 3.8 130kW

6.2 15.5 5.0 150kW

7.2 18.0 5.8 200kW

9.6 23.5 7.7

TECHNICAL DATA

AIR TO WATER HEAT PUMPS

Model

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambient

Power Input

COP

Model

Water Supply Temperature

Heating Capacity – kW 10°C Ambient

Power Input

COP

Heating capacity – kW 20°C Ambient

Power Input

COP

Heating Capacity – kW 30°C Ambient

Power Input

COP

Heat Pump Manual

THWDW100H

20°C Ambient conditions 45°C Water supply 60% RH

Model Across condenser Across condenser high

water temperature units

>60C

Across evaporator – water to

water units

13

Electrical Data

– All units

10kW

13.1 19.4 105

20kW

15.7 22.0 111

17.5 24.5 118

27.1 38.0 173

33.6 47.0 225

38.0 49.0 272

51.2 76.0 173

56.6 94.3 225

130kW

86.2 98.2 272

150kW

103.0

144.0

173

142.0

181.5

225

380/415 V 3 Phase 50 hz + N and E

Delta Δ

Direct on line

Water Connections

– All units

- all female BSP brass fittings

Model

Supply/ Return

Evaporator water

– water to water units

20kW

1” 1” 30kW

1 ½”

1 ½”

40kW

1 ½”

1 ½”

50kW

1 ½”

1 ½”

60kW

2” 2”

80kW

2” 2”

100kW

2” 2”

130kW

2” 2”

150kW

2” 2”

200kW

2 ½”

2 ½”

Swimming pool heat pumps

2” PVC screwed connection

PERFORMANCE DATA

Model

THWW20 THWW40 THWW50 THWW60 THWW80

Nominal heating

Heating Capacity

4.8 4.8 9.5 9.5 12.2 12.2 15.1 15.1 17.9 17.9

4.6 3.5 4.0 3.1 4.1 3.2 4.1 3.2 4.3 3.2

8.1 7.1 7.3 7.3 7.5

TECHNICAL DATA

Heat Pump Manual

Model Maximum A/ Phase Maximum continuous

current

30kW

40kW

50kW

60kW

80kW

100kW

200kW

Power requirement

Compressor wiring

Compressor start method

Locked rotor amps per compressor

WATER TO WATER HEAT PUMPS

Performance Chart at 40/45°C Water Return/ Supply

50°C Condensing temperature – 20°C/ 15°C evaporator water

capacity – kW

– kW

Power Input

COP

Total unit COP

20 40 50 60 80

Heating

Capacity

Cooling

21.9 17.0 38.1 29.7 49.6 38.5 61.9 48 76.1 59.4

Side

Heating

Capacity

Cooling

Side

Heating

Capacity

Coolin

g Side

Heating

Capacity

Cooling

Side

Heating

Capacity

Cooling

Side

14

PERFORMANCE DATA

Pe

rformance Chart at 40/45

°C Water Return/ Supply

Model

THWW100

THWW1

50 THWW200

THWW250

Nominal

Heating

Cooling

Side Heating

Cooling

Side Heating

Cooling

Side Heating

Cooling

Side Heating

Power

4.1 3.2 3.9 3.3 4.0 3.1 4.1 3.2

Total Unit

GENERAL INFORMATION

Model

THWW20

THWW40

THWW50

THWW60

THWW80

kPa 50 50 50 50 50

kPa075

dB at 3m

60 60 60 61 62 GENERAL INFORMATION

Model

THWW100

THWW150

THWW200

THWW250

Pressure drop across

kPa 50 50 50 50

Pressure drop across

kPa 50 50 50 50

dB at

TECHNICAL DATA

50°C Condensing temperature – 20°C/ 15°C evaporator water

Heat Pump Manual

heating

capacity –

kW

Capacity –

kW

Input

COP

COP

100 150 200 250

Capacity

99.2 77 152.2 118.8 198.4 154 247.6 192

24.4 24.4 35.8 35.8 49.2 49.2 60.4 60.4

7.3 7.2 7.1 7.3

Pressure drop across condenser

Pressure drop across evaporator

condenser (heating side)

(cold side)

Noise rating at 3m

evaporator (cold side)

Noise rating at 3m

3m

Capacity

Capacity

Capacity

50 50 50 50 50

62 63 63 64

15

valve

Heat Pump Manual

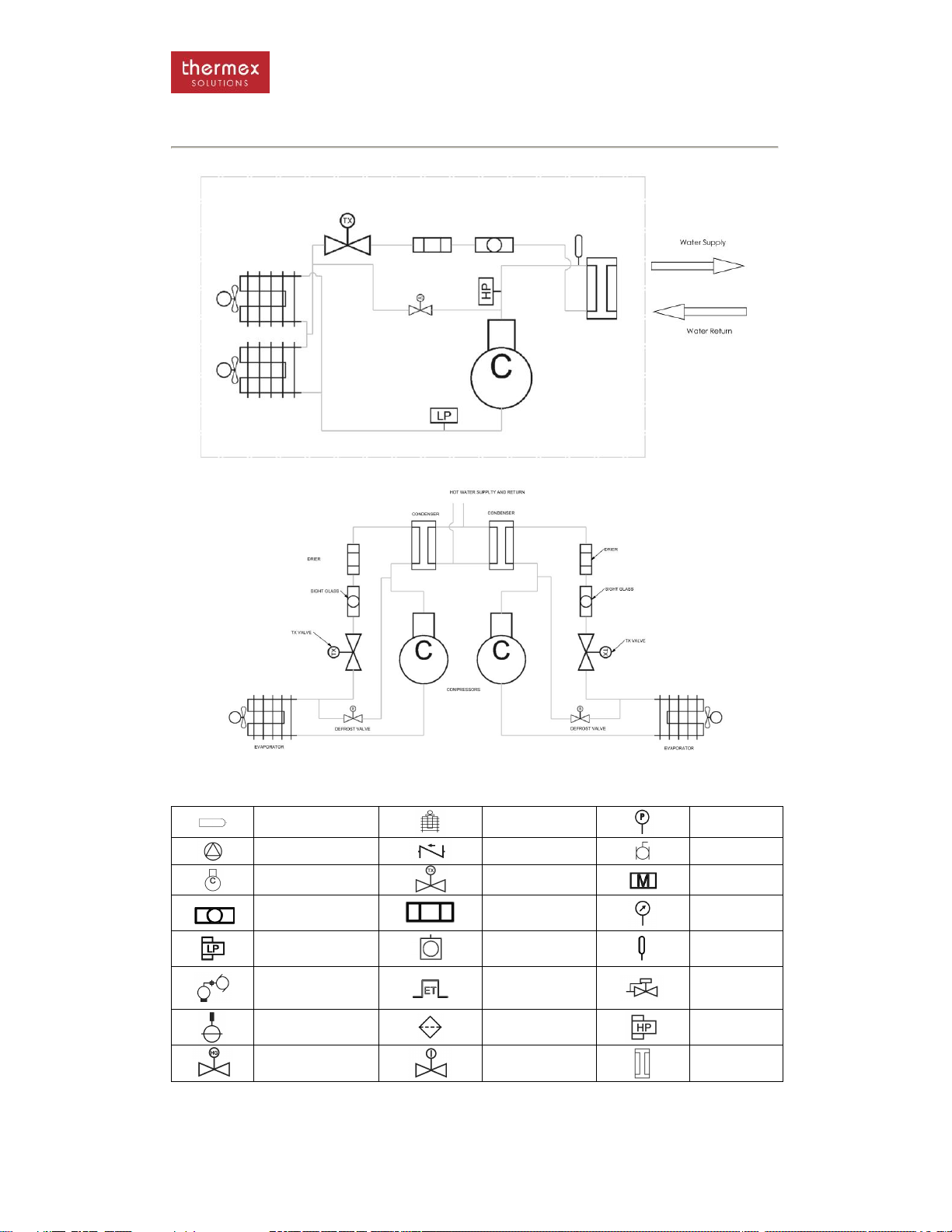

HEATING SYSTEM SCHEMATIC

THW20, THW40 and THW60

Heating System Schematic Symbols

Liquid receiver

Pump

Compressor

Sight glass

THW80 and THW120

Air Cooled

Evaporator

One way valve

TX valve

Drier

Pressure

transducer

Ball valve

Flow meter

Pressure

gauge

Low pressure switch

Motorised ball valve

Pressure relief valve

Hot gas bypass

valve

Drain

Expansion tank

Strainer

Isolation valve

Thermowell

Water

regulating

High pressure

switch

Plate heat

exchanger

16

Heat Pump Manual

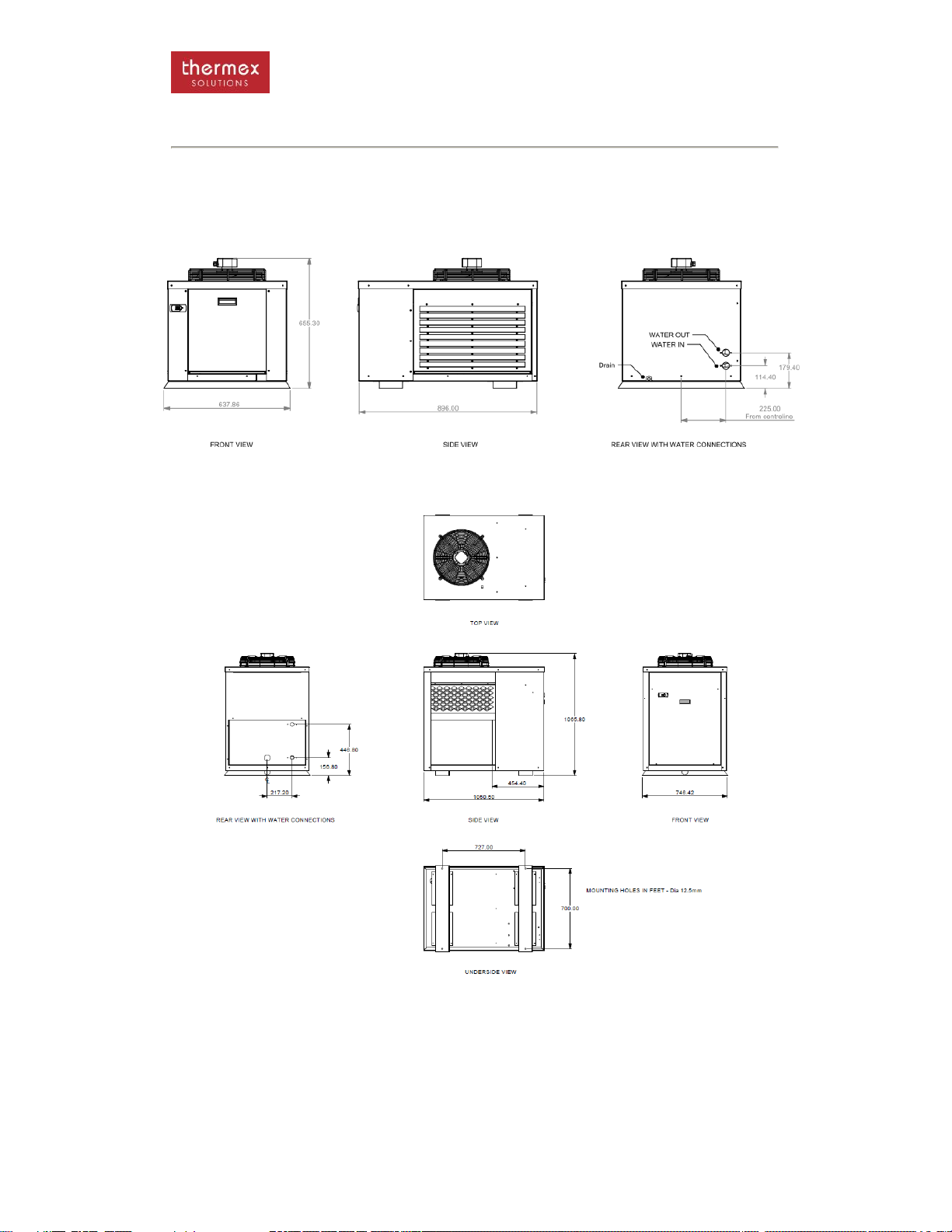

DIMENSIONS

.dxf and .dwg files are available for all models – please contact Thermex for details

THW07

THW20

17

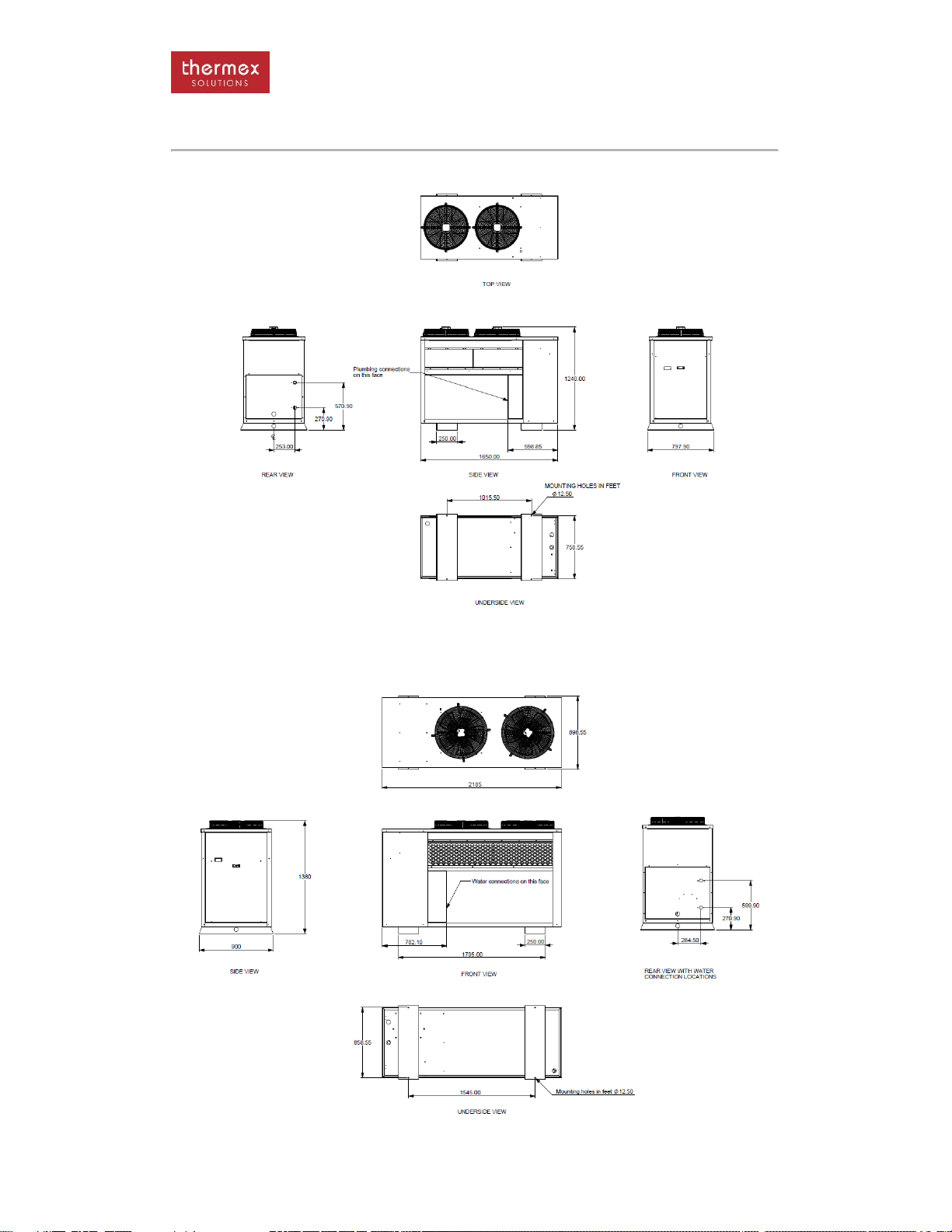

DIMENSIONS

Heat Pump Manual

THW30 and THW40

THW50 and THW60

18

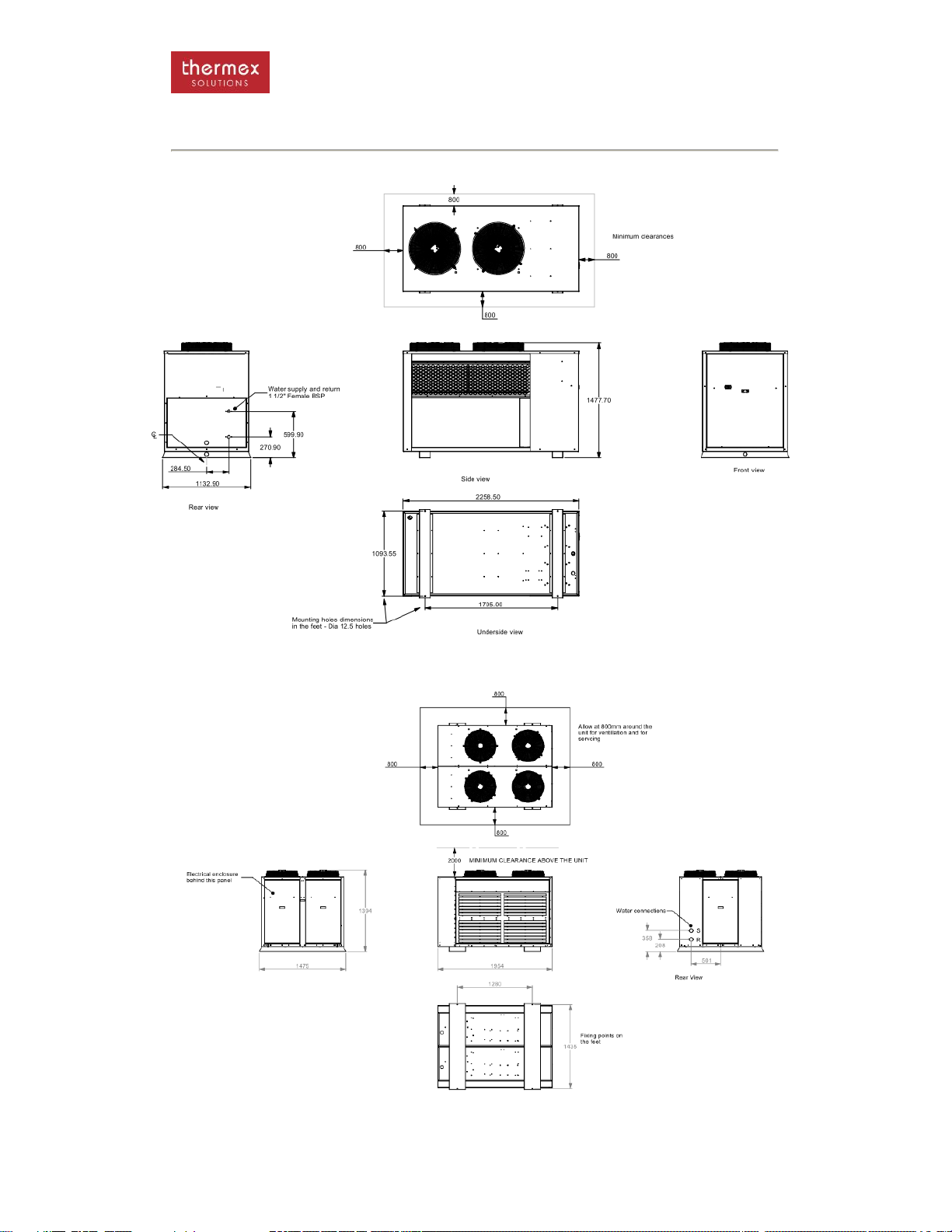

DIMENSIONS

Heat Pump Manual

THW80

THW100 AND THW130

Loading...

Loading...