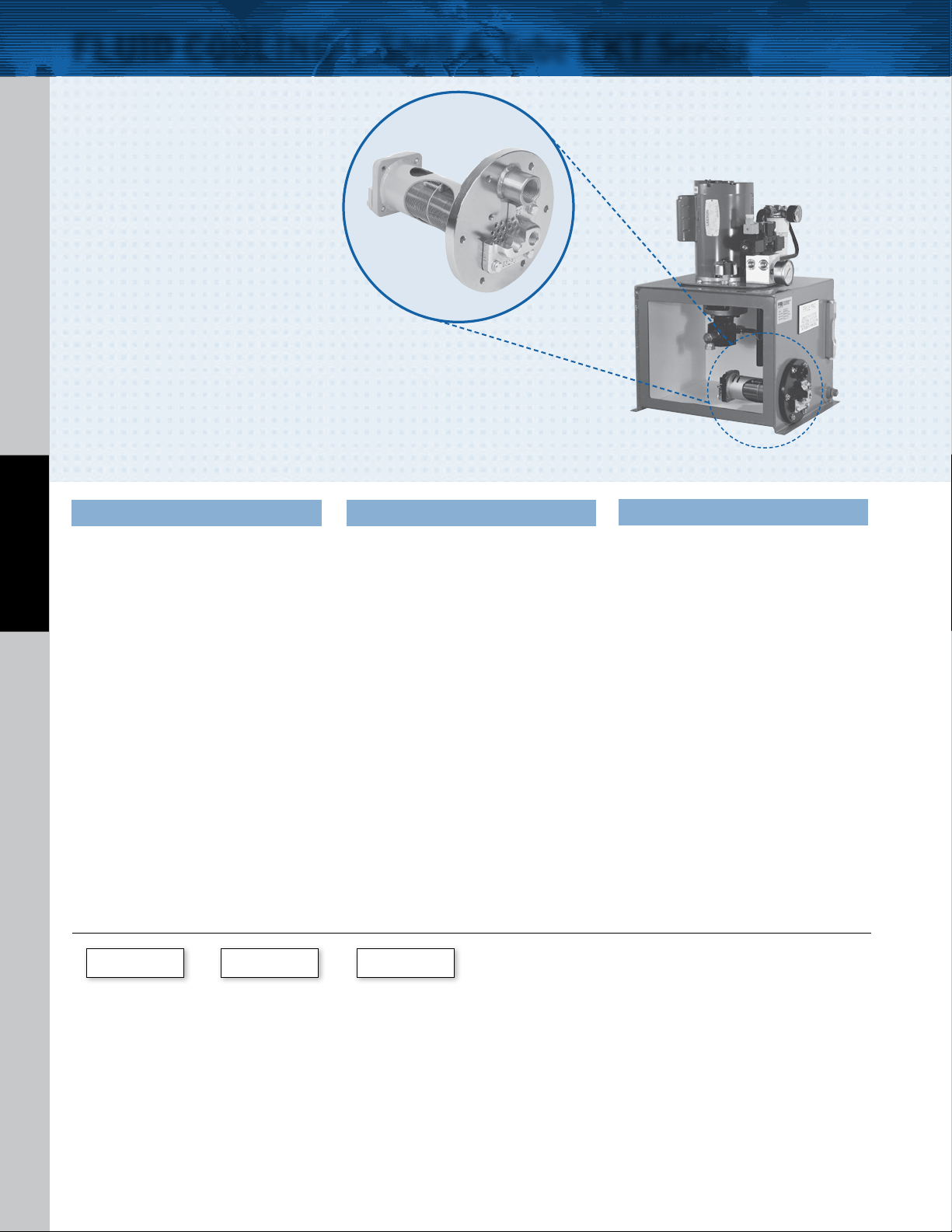

FLUID COOLING | Shell & Tube EKT Series

COPPER & STEEL CONSTRUCTION

Features

n

HPU, In-tank Cooler

n

Compact Size

n

EK Style & Size

n

High Efficiency Finned Bundle Design

n

Serviceable

n

Removable

n

In-tank Design Minimizes Space

Requirements and Reduces Plumbing

n

Internal Aluminum Fins Dramatically

Increase Performance

n

Removable End Bonnets Allow Water

Passage Servicing

n

WATER COOLED EKT

High Strength Steel Shell

OPTIONS

SAE or BSPP Connections Available

Internal Oil Flow Bypass Relief

(SURGE-CUSHION®)

Ratings

Operating Pressure:

Shellside 75 psi – Tub esi de 150 psi

Test Pressure:

Shellside 75 psi – Tub esi de 150 psi

Maximum Temperature 250° F

How to Order

EKT

Model

Series

EKT

EKTS

EKTM

–

Model Size Selected

Materials

Shell Steel

Tub es Copper

Fins Aluminum

Tubesheets S t e e l

B a f f l e s S t e e l

End Bonnets Cast Iron

Gaskets Nitrile Rubber/Cellulose Fiber

–

SURGE-CUSHION

Blank - No SURGE-CUSHION

R - SURGE-CUSHION

®

®

®

Surge-Cushion (Option)

The SURGE-CUSHION® is a protective device

(patented) designed to internally bypass

a portion of the oil flow during cold start

conditions, or when sudden flow surges

temporarily exceed the maximum flow allowed

for a given cooler. This device may replace an

external bypass valve, but it is not intended to

bypass the total oil flow.

EKT = NPT Connections.

EKTS = SAE Oil Conne ctions.

EKTM = All Met ric Connections.

TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

90

Dimensions

9.75

MODEL

A B

NPT or

BSPF

C D E F G H

J

Q R

EKT-508

EKT-518

EKT-708

EKT-718

EKT-1012

EKT-1024

8.87

18.87

8.72

18.72

12.55

24.55

6.79

Approx.

Ship Wt.

Net. Wt.

SAEJNPT or

BSPF

K

T1 T2 W

10.38

3.52

2.55

5.05

1.84

2.22

1.67

1.68

2.23

1.62

1.12

2.38

3.94

2.44

4.69

1.25

.50

1.19

1-1/2"

3/4"

#24

#12

3/4"

3/8"

1"

12

6

8.94

5.60

9.62

4.00

2.25

4.38

—

.79

1.12

.70

.62

11

14

23

30

42

58

14

16

27

34

46

63

Oil “Outlet”

“C” Dia.

A

D

Oil

“Inlet”

.34" Dia. Holes

“Q” Quantity

“R” Dia. Bolt Circle

T1 and T2 Radii

represent oil tank

cut out.

H

G

T1 Rad.

T2 Rad.

E

W

K (2 Places)

B

J

F

EKT-718

EKT-1024

EKT-1012

EKT-518

EKT-708

EKT-508

2

2.5

4

5

6

8 9

10

15

20 25 30 40 50 60

7

8

9

10

15

20

25

30

40

50

60

70

80

90

100

150

5

3

7

4

3

6

OIL FLOW - GAL/MIN

HP HEAT REMOVED IN COOLER

.34" Dia. Holes

“Q” Quantity

“R” Dia. Bolt Circle

T1 and T2 Radii

represent oil tank

cut out.

H

G

T1 Rad.

T2 Rad.

K (2 Places)

B

J

F

NOTE: We reserve the right to make reasonable design changes without notice. Certified drawings are available upon request. All dimensions in inches. Tank gasket is included.

BSPP threads are 55° full form whitworth.

Selection Procedure

Performance Curves are based on a 40°F approach temperature, a 2:1 oil

to water ratio and an average oil viscosity of 100 SSU. Example: oil leaving

cooler at 125°F with 85°F cooling water (125°F - 85°F = 40°F). The 2:1 oil

to water ratio means that for every GPM of oil circulated, a minimum of

1/2 GPM of water must must be circulated to obtain the curve results.

Step 1 Corrections for approach temperature and oil viscosity.

HP

Heat Removed in Cooler =

40°F

Actual x

Oil out and °F - Water in °F

HP

[ ]

Step 2 Oil Pressure Drop Coding: l = 5 PSI; n = 10 PSI. Curves

having no pressure drop symbol indicate that the oil pressure drop is less

than 5 PSI to the highest oil flow rate for that curve. Multiply curve oil

pressure drop by Correction B.

Viscosity Corrections

Average Oil SSU A B

50 0.84 0.6

100 1.0 1.0

200 1.14 2.0

300 1.24 3.1

400 1.31 4.1

500 1.37 5.1

Maximum Flow Rates

Unit Size Shell Side GPM) Tube Side(GPM)

500 20 6

700 60 12

1000 80 28

If maximum allowable flow rates are exceeded, premature failure may occur.

x Correction A

Performance Curves

www.thermaltransfer.com TTPSales@thermasys.com 262.554.8330

WATER COOLED EKT

91

EKT

Loading...

Loading...