FLUID COOLING | Industrial AOL Series

BRAZED ALUMINUM CONSTRUCTION

HYDRAULIC OR

COMPRESSOR OIL COOLING

Features

n

Large Oil Flow

n

High Performance

n

Industrial Duty

n

AIR COOLED AOL

Brazed Aluminum Bar and Plate Core

n

Compact all aluminum core assembly

n

Ideal for converting water cooled

equipment to air cooled

n

Eliminates high water and sewer costs

n

Eliminates corrosion problems

associated with water cooled units

n

Vertical air flow works well for

heat recovery

n

State-of-the-art heat transfer

technology

n

Hydraulic motors available

n

Optional SAE Ports

n

Marine corrosion control coatings

available

n

High performance air side fin design

n

Detachable legs

Ratings

Maximum Operating Pressure

250 psi (17 BAR)

Maximum Operating Temperature

300° F (150° C)

Materials

Legs Steel with baked enamel finish

Shroud Steel

Standard Core Brazed Aluminum Bar and Plate

n

Tanks – 5052 Aluminum

n

Nose Bar & Little Bar – 3003-H Aluminum

n

Air Fin, Plate, Turbulator & End Plate –

3003-O Aluminum

Fan Aluminum Hub, Plastic Blades

Motor T E F C

AOL

How to Order

AOL

Model

Series

AOL - Standard

TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

50

– – –

Model Size Selected

400

725

950

1200

1600

2000

2500

3000

3500

Specify Mo tor

Required

0 - No Motor

2 - Single Phase

3 - Three Phase

6 - 575 Volt

9 - Hydraulic

18 - IEC Thr ee Phase

Connection

Type

Blank - NPT

S - SAE

–

Noise L evel

Blank - Standard

Noise Level

LN - Low

Noise Level

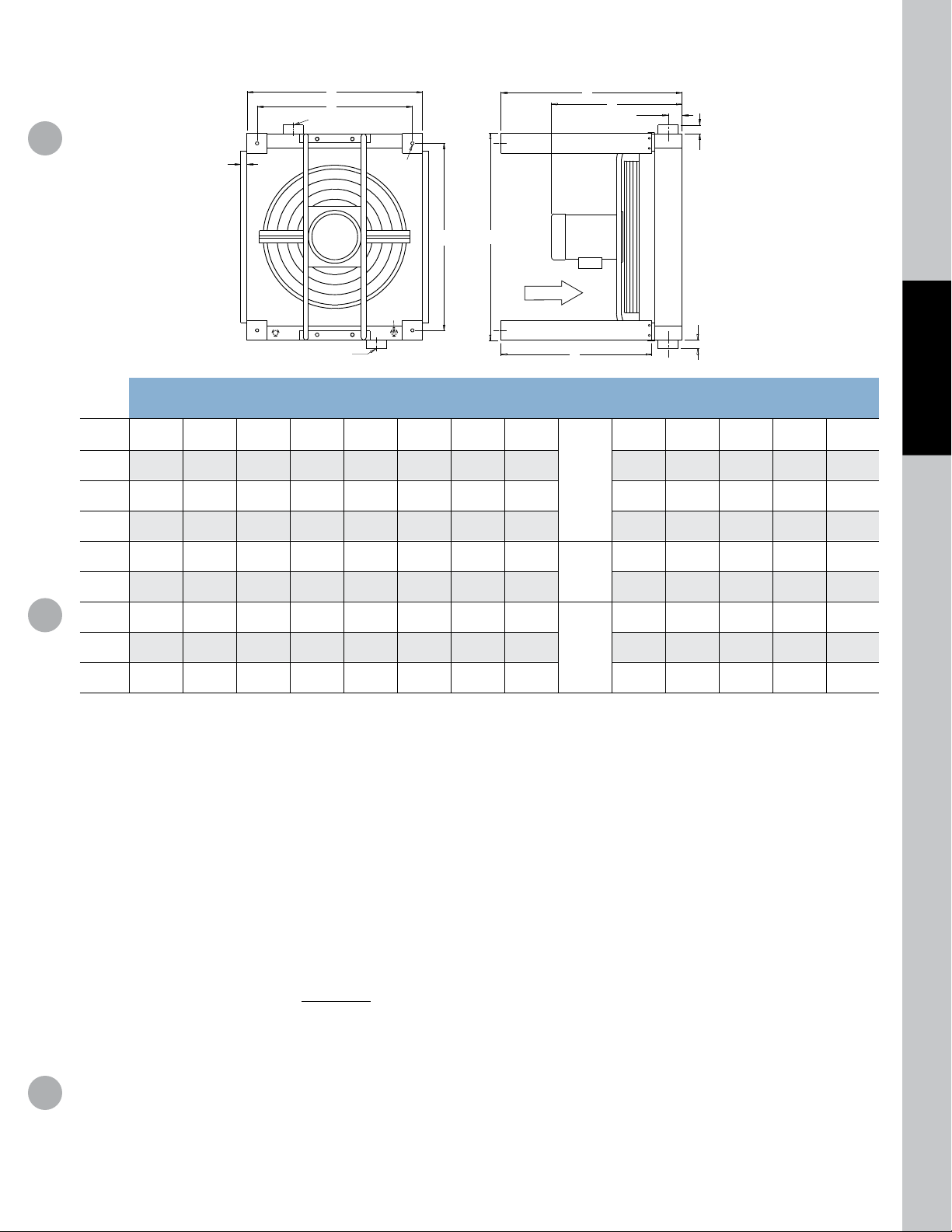

Dimensions

1.77

(44.96)

1.77

(44.96)

5/8 DIA.

4 PLACES

A

D

K

E

C

G

B

F

N TYP

“H” IN OR OUT OPTIONAL

VENT/DRAIN

PLUG

“H” IN OR OUT OPTIONAL

AIR FLOW

Net Shipping

D H H Weight Weight

Model A B C Approx. E F G NPT SAE J K L Lbs. Lbs.

AOL-400 34.20 17.96 22.69 20.86 30.00 13.96 18.69

(868.68) (456.18) (576.33) (529.84) (762.00) (354.58) (474.73) (150.62) (46.99) (31.75) (49.44) (67.13)

AOL-725 34.20 22.37 30.57 20.86 30.00 18.37 26.57

(868.68) (568.20) (776.48) (529.84) (762.00) (466.60) (674.88)

AOL-950 36.01 26.78 37.25 23.62 30.00 33.25

(914.65) (680.21) (946.15) (599.95) (762.00) 22.78 (844.55)

AOL-1200 36.01 26.78 41.20 25.51 30.00 (578.61) 37.20

(914.65) (680.21) (1046.48) (647.95) (762.00) (944.88) (152.40) (70.10) (31.75) (134.26) (195.04)

AOL-1600 36.01 34.89 41.20 27.51 30.00 30.89 37.20 8.00 2.76 1.25 355 515

(914.65) (886.21) (1046.48) (698.75) (762.00) (784.61) (944.88)

AOL-2000 36.01 37.88 51.05 26.25 30.00 33.88 47.05

(914.65) (962.15) (1296.67) (666.75) (762.00) (860.55) (1195.07)

AOL-2500 36.01 43.70 49.08 28.51 30.00 39.70 45.08

(914.65) (1109.98) (1246.63) (724.15) (762.00) (1008.38) (1145.03) (203.20) (70.10) (31.75) (251.74) (297.10)

AOL-3000 36.01 52.52 51.05 30.51 30.00 48.52 47.05

(914.65) (1334.01) (1296.95) (774.95) (762.00) (1232.41) (1206.50) 4 Bolt FLG. (203.20) (70.10) (31.75) (328.40) (374.21)

AOL-3500 36.01 56.30 51.05 30.51 30.00 52.30 47.05

(914.65) (1430.02) (1296.95) (774.95) (762.00) (13328.42 (1206.50) (203.20) (70.10) (31.75) (344.73) (390.09)

Note: We reserve the right to make reasonable design changes without notice. All dimensions are in inches and (millimeters).

5.93 1.85 1.25 109 148

2.00

5.88 1.85 1.25 151 170

2.00

2.00

6.00 2.76 1.25 296 430

2.00

2.50

2.50

(203.20) (70.10) (31.75) (218.63) (263.99)

8.00 2.76 1.25 555 655

3.00

3" SAE 8.00 2.76 1.25 724 825

3.00

8.00 2.76 1.25 760 860

3.00

(149.35) (46.99) (31.75) (68.49) (77.11)

#32 SAE

2-1/2-12

6.82 2.76 1.25 221 300

UN-2B

(173.23) (70.10) (31.75) (100.24) (136.08)

(203.20) (70.10) (31.75) (161.03) (233.60)

2-1/2 SAE

4 Bolt FLG

8.00 2.76 1.25 482 582

AIR COOLED AOL

Selection Procedure

Performance Curves based on 100°F (55.56°C) E.T.D. or Entering

Temperature Difference (E.T.D = Entering oil temperature minus ambient

air temperature). SAE #10 oil @ 200°F (93.33°C).

Oil pressure drop coding:

X = 5 PSI (.345 BAR)

l = 10 PSI (.689 BAR)

= 15 PSI (1.03 BAR)

s = 20 PSI (1.38 BAR)

n = 30 PSI (2.10 BAR)

E.T.D. temperature correction formula:

ENGLISH Version

100

HP

Curve = HP To Be Removed X Desired E.T.D

METRIC Version

KW = Heatload (KW)

—— — ———— ——

°C Desired E.T.D. (°C)

Conversion

Hp =

KW =

——

X .745 X E.T.D. (°F)

°C

Notes

1. A three-way thermostatic valve is recommended to bypass the cold oil

around the heat exchanger during start up.

2. Support piping as needed. Flexible connectors must be properly installed

to validate warranty.

3. Coolers should not operate in ambient temperatures below 35°F (1°C).

Consult factory for recommendations.

4. The fan cannot be cycled.

5. AOL coolers operated outdoors must be protected from weather.

Consult factory for recommendations.

6. If duct work or additional static resistance is added to the cooler

airstream, an auxiliary air mover may be required.

7. Can be mounted for horizontal air flow, with oil in at bottom port.

Maintenance

Periodic cleaning of the fins with compressed air is needed to remove the

accumulation of dirt and dust. If the inside of the tubes need to be cleaned of

oil and carbon, use a chlorinated solvent. Do not use strong solvents. Do not

use acids or caustic cleaners.

www.thermaltransfer.com TTPSales@thermasys.com 262.554.8330

51

AOL

Loading...

Loading...