Page 1

FLUID COOLING | Industrial AOC Series

FEATURES

n

AC Motors

n

Core Filter

n

3/4” Tubes

n

Low Cost

n

Industrial Duty

n

Quiet Operation

AIR COOLED AOC

n

For Low Flow Rates

n

Oil Flows to 150 GPM

n

Mounting Brackets Included

n

SAE Connections

n

Single or Three-Phase 60/50 Hz

Motors

n

Filter Standard

OPTIONS

Built-in Serviceable Bypass Valve;

NPT or BSPP Oil Connections

Ratings

Operating Pressure - 300 psi

Test Pressure - 300 psi

Operating Temperature - 350° F

Materials

Tub es Copper

Fins Aluminum

Tur bul ato rs Aluminum

Fan Blade Aluminum with steel hub

Fan Guard Steel with black baked enamel finish

Cabinet Steel with baked enamel finish

Manifolds Copper: Model AOC-08

Steel: Models AOC-19 – AOC-70

Connections Brass: Model AOC-08

Steel: Models AOC-19 – AOC-70

Nameplate Aluminum

Filter Stainless frame with washable media

Relief Bypass Valve Option

MODEL DESCRIPTION

AOC-08 Available in one pass (30 and 60

AOC-19

thru

AOC-33

AOC-37

Thru

AOC-70

psi), two pass (60 psi), designs

only. Valves are built into tubes

and do not affect external

dimensions. All steel valves.

Non-serviceable.

Available in 30 psi or 60 psi

settings. 3/4”, external, all steel

valve. May be removed for

servicing.

Available in 30 psi or 60 psi

settings. 1-1/2”, external, all

steel valve. May be removed for

servicing.

How to Order (AOC-08 models only)

AOC 0 8

Model

Series

AOC - Standard

*Bypass not available in Four Pass

AOC

– – –

Model Size

Selected

Number of

Passes

1 - One Pass

2 - Two Pass

4 - Four Pass

Connection

Type

1 - NPT

2 - SAE

3 - BSPP

Relief Bypass*

Blank - No Byp ass

How to Order (Models AOC-19 through AOC-70)

AOC

Model

Series

AOC - Standard

TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

4

– – –

Model Size

Selected

Connection

Type

1 - NPT

2 - SAE

3 - BSPP

Relief Bypass

Blank - No Byp ass

30 - 30 psi

60 - 60 psi

–

Specify Mo tor

30 - 30 psi

60 - 60 psi

115/230 V Single Phase

–

Specify Mo tor

Required

115/230 V Single Phase

208 -230/460V Three P hase

575 Volt

No Motor

Required

No Motor

Page 2

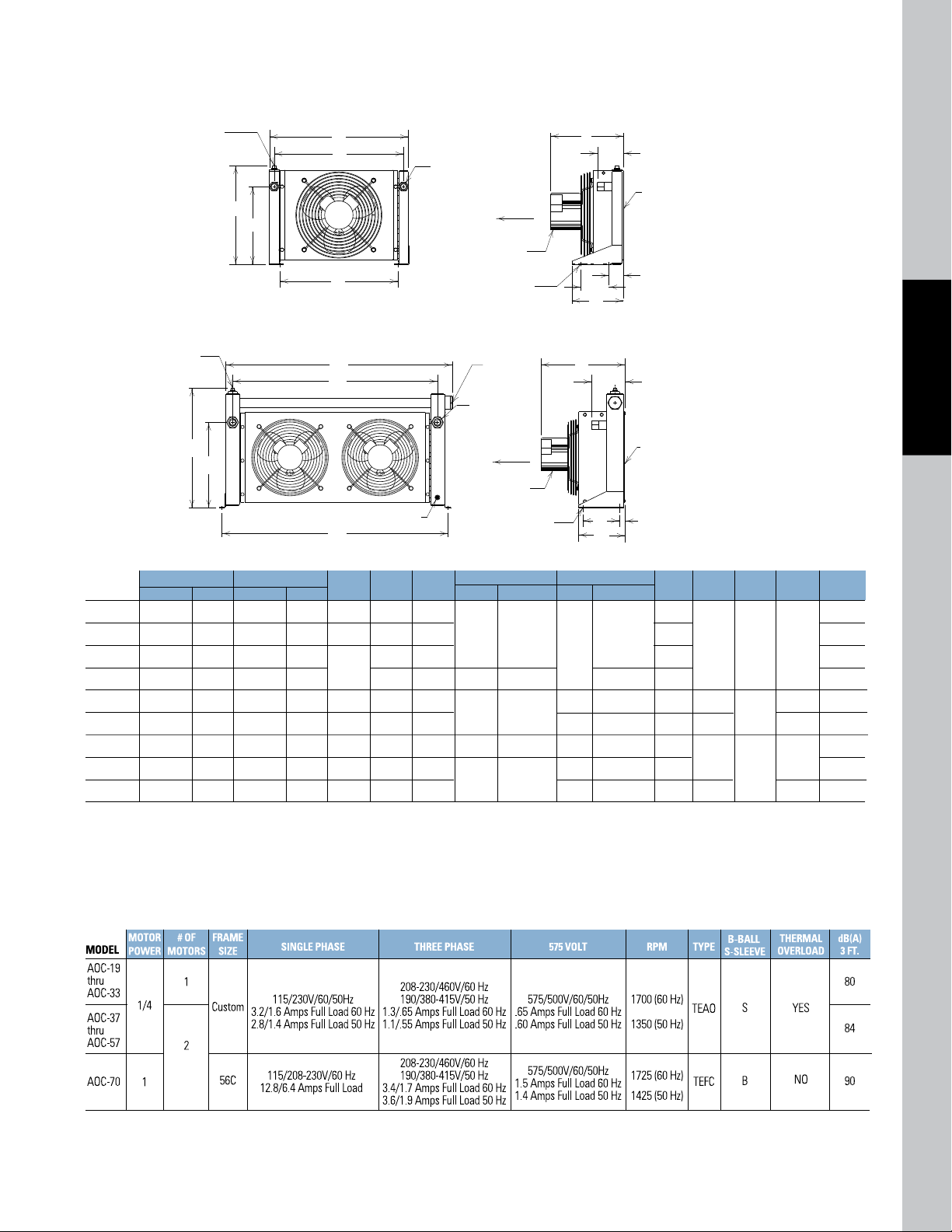

Dimensions

ELECTRIC

MOTOR

1/2 NPT

FOR OPTIONAL

TEMP. SENSOR

AIR

FILTER

SERVICEABLE

BYPASS VALVE

30 OR 60 PSI

3/8 NPT

DRAIN

.53 DIA HOLE

2 EACH BRACKET

AIR FLOW

J

M

P

F (2 PLACES)

B

E

H

A

D

C

G

MODELS AOC-37 THROUGH AOC-70

IN OUT

BypassNo Bypass

13.62

15.62

19.62

25.62

18.50

22.50

30.50

36.50

38.38

16.00

18.00

22.00

28.00

21.38

25.38

33.28

39.38

41.25

16.50

22.00

24.75

30.25

39.00

41.00

42.00

48.00

51.00

18.16

23.66

26.41

31.91

40.38

42.38

43.38

49.38

52.38

13.08

12.19

13.19

15.66

15.62

17.09

16.72

22.62

10.31

12.31

16.31

22.31

15.25

19.25

27.25

32.75

34.00

15.00

20.50

23.25

28.75

36.50

38.50

39.50

45.50

48.50

14.75

18.69

21.44

26.97

40.50

42.50

43.75

49.75

52.75

BypassNo Bypass

NPT & BSPP

SAE

MODEL

AOC-19

AOC-22

AOC-24

AOC-33

AOC-37

AOC-50

AOC-54

AOC-57

AOC-70

A B

C D E

G

#12

#16

#20

#24

#32

.75

1.00

1.25

1.50

2.00

NPT & BSPPSAE

3.05

4.62

4.68

4.89

6.68

8.44

2.61

1.06

1.12

1.87

1.62

5.00

6.50

9.00

8.18

8.31

8.37

12.37

12.12

4.12

4.34

5.97

6.03

6.30

8.15

9.91

F

H J M P

19

33

46

65

95

120

154

190

322

LBS

AIR FLOW

ELECTRIC

MOTOR

.41 X 1.19 SLOT

2 EACH BRACKET

1/2 NPT

FOR OPTIONAL

TEMP. SENSOR

C

G

AIR

FILTER

J

M

P

F (2 PLACES)*

B

E

H

A

D

MODELS AOC-19 THROUGH AOC-33

Models AOC-19 Through AOC-33

Models AOC-37 Through AOC-70

AIR COOLED AOC

NOTE: All dimensions in inches. We reserve the right to make reasonable design changes without notice.

*Inlet and outlet oil ports reversible if relief bypass option is not used.

Specifications

Electric Motor Data

NOTE: Amp ratings are per motor.

www.thermaltransfer.com TTPSales@thermasys.com 262.554.8330

5

AOC

Page 3

2.5

2

2.5

3

4

5

6

7

8

9

10

15

20

25

30

40

50

60

70

80

90

100

3 4 5 6 7 8 9 10 15 20 25 30 40 6050 100908070 200 250 300150

●

■

▲

✛

●

●

●

●

●

●

●

●

■

■

■

■

■

■

■

■

▲

▲

▲

▲

▲

▲

▲

▲

✛

✛

✛

✛

✛

OIL FLOW - G.P.M.

HORSEPOWER REMOVED IN COOLER

AOC-19

AOC-22

AOC-24

AOC-33

AOC-37

AOC-50

AOC-54

AOC-57

AOC-70

Oil ▲P

● = 5 PSI

■ = 10 PSI

▲ = 20 PSI

✛ = 40 PSI

50 60 80 100 150 300 400 500

3

2

1.5

1

.8

.6

OIL

P MULTIPLIER

OIL VISCOSITY - SSU

OIL

P CORRECTION CURVE

Selection Procedure

50 100 002 003 500

5

1

2

3

4

OIL P MULTIPLIER

OIL VISCOSITY - SSU

OIL

P CORRECTION CURVE

400

Performance Curves are based on 50SSU oil leaving the cooler 40°F higher

than the ambient air temperature used for cooling.This is also referred to as

a 40°F approach temperature.

STEP 1 Determine the Heat Load.This will vary with different systems,

but typically coolers are sized to remove 25 to 50% of the input

nameplate horsepower.

(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)

If BTU/Hr. is known: HP =

BTU/Hr

2545

STEP 2 Determine Approach Temperature. Desired oil leaving cooler

AIR COOLED AOC

STEP 3 Determine Curve Horsepower Heat Load. Enter the

°F – Ambient air temp. °F = Actual Approach

information from above:

Horsepower heat load x

40 x Cv

= Curve Horsepower

Actual Approach

STEP 4 Enter curves at oil flow through cooler and curve horsepower.

Any curve above the intersecting point will work.

STEP 5 Determine Oil Pressure Drop from Curves:

l = 5 PSI; n = 10 PSI; s = 20 PSI; ; = 40 PSI. Multiply

pressure drop from curve by correction factor found in oil

correction curve.

Desired Reservoir Temperature

Return Line Cooling: Desired temperature is the oil temperature leaving the

cooler. This will be the same temperature that will be found in the reservoir.

Off-Line Recirculation Cooling Loop: Desired temperature is the oil temperature entering the cooler. In this case, the oil temperature change must be

determined so that the actual oil leaving temperature can be found.

Calculate the oil temperature change (oil

Oil

T = (BTU’s/Hr.) / (GPM Oil Flow x 210).

T) with this formula:

To calculate the oil leaving temperature from the cooler, use this formula:

Oil Leaving Temp. = Oil Entering Temp – Oil

T.

This formula may also be used in any application where the only temperature

available is the entering oil temperature.

Oil Pressure Drop: Most systems can tolerate a pressure drop through the

heat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.

Care should be taken to limit pressure drop to 5 PSI or less for case drain

applications where high back pressure may damage the pump shaft seals.

Oil Temperature

P

Typical operating temperature ranges are:

Hydraulic Motor Oil 110° - 130°F

Hydrostatic Drive Oil 130° - 180°F

Bearing Lube Oil 120° - 160°F

Lube Oil Circuits 110° - 130°F

Performance Curves

AOC

TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

6

De-rate cooler performance by 10%

when used in 50Hz service.

Page 4

1.5

2

3

4

5

6

8

10

15

20

1.5

1

.8

.6

7

.7

2.5

.9

●

■

HORSEPOWER REMOVED IN COOLER

OIL FLOW - GPM

8.31

9.41

2.31

1.50

.34 DIA. HOLE (BOTH SIDES)

AIR

FLOW

3/4" NPT,

#12 SAE,

or BSPP (2-PLACES)

12.25

11.12

7.50

9.19

.9 1

1.5

2

3

4

5

6

8

7

9

2.5

1.5

1

.6

.7

.8

.9

●

■

▲

HORSEPOWER REMOVED IN COOLER

OIL FLOW - GPM

9.41

.34 DIA. HOLE (

BOTH SIDES

)

8.31

9.50

AIR

FLOW

1/2" NPT,

#8 SAE,

or BSPP

(2-PLACES)

4.00

3.80

7.50

13.12

2.31

1.50

.5.4 .6 .7 .8 .9 1 1.5 2 2.5 3 4 5

1.5

1

.9

.8

.7

.6

●

■

▲

HORSEPOWER REMOVED IN COOLER

OIL FLOW - GPM

9.41

2.31

1.50

1.50

13.50

9.50

8.31

2.83

6.00

7.50

.34 DIA. HOLE (BOTH SIDES)

AIR

FLOW

1/2" NPT,

#8 SAE,

or BSPP

(2-PLACES)

MODEL

AOC-08

MOTOR POWER

1/30

115/230 VOLT

115 VOLT

230 VOLT

50/60 Hz

1.1 Amps Full Load

.7 Amps Full Load

RPM

3000

dB(A) 3 FT.

70

TYPE

TEAO

BEARINGS

B-BALL S-SLEEVE

S

THERMAL

OVERLOAD

YES

SHIPPING

WEIGHT (lbs.)

12

CV Viscosity Correction

OIL

SAE 5 SAE 10 SAE 20 SAE 30 SAE 40

Average

110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°F

Oil Temp °F

40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F

100 1.14 1.2 2 1.3 5 1.5 8 1.7 7

150 1.01 1.05 1.11 1.2 1 1.3 1

200 .99 1.00 1.01 1.08 1.10

250 .95 .98 .99 1.00 1.00

AOC-08 Model Only

One Pass

AIR COOLED AOC

Two Pass

Four Pass

Specifications

Electric Motor Data

www.thermaltransfer.com TTPSales@thermasys.com 262.554.8330

7

AOC

Loading...

Loading...