Thermal Transfer Systems AlfaDisc 50 User Manual

All-welded Plate Heat Exchanger

AlfaDisc

Applications

AlfaDisc is suitable for most of the applications, such as

general cooling and heating duties, condensation, evapora

-

tion, reboiling and stream heating.

Standard design

AlfaDisc is built on the Plate & Shell concept. It is able to

withstand higher design pressure, is more compact, is better

developed for fatigue applications, has the possibility for

asymmetric flow and is cleanable on one side. These features in combination with an attractive price gives the range

competitive advantages over other welded concepts.

The AlfaDisc all-welded plate heat exchanger provides the

thermal efficiency and compactness of a plate and frame unit

under conditions that would normally call for a shell and tube

unit.

Designed for use with liquids, gases and two-phase mixtures

at pressure up to 100 bars (CE/PED) and 47 bars (ASME)

and at temperatures up to 538°C, the Plate&Shell unit works

well with aggressive media, such as organic solvents, steam

heaters and interchangers that are beyond the capability of a

gasketed unit. The unit is also available with removable core

design.

Typical capacities

Liquid flow rate

Up to 139 kg/s (2085 gpm), depending on media, permitted

pressure drop and temperature program.

Sizes

AlfaDisc 50

AlfaDisc 100

AlfaDisc 150

Working principle

The unit features a plate side and a shell side, which offer high

pressure ratings. It has alternating channels for hot and cold

media, and can offer true counter-current or co-current flow.

Number of passes could be up to 4 on each side.

Nozzle sizes up to DN 400 can be accommodated on

the shell side of the exchanger, offering higher steam

and liquid flow rates. Nozzles on the plate side can

be up to DN 150.

AlfaDisc 50

Turning plate port

Bypass restriction

diverters

Shell

divider

Flow principle of a multi-pass AlfaDisc.

The AlfaDisc unit can be fabricated from dissimilar

metals when only one side will be exposed to

corrosive conditions.

TECHNICAL DATA

Design pressure

CE/PED Vacuum to 100 bars

ASME Vacuum to 47 bars

Design temperature

Carbon steel Shell -29 - 538°C

Stainless steel Shell -160 - 538°C

Standard design pressure (g) / temperature

HS ASME/PED 10 bar / -29 - 300°C

US ASME/PED 25 bar / -29 - 300°C

SS ASME/PED 40 bar / -29 - 300°C.

Maximum heat transfer surface

AlfaDisc 50 22 m

2

(235 sq.ft.)

AlfaDisc 100 66 m

2

(706 sq.ft.)

AlfaDisc 150 162 m

2

(1733 sq.ft.)

STANDARD MATERIALS

Shell Material

Mild steel, Epoxy painted or stainless steel

Cover Material

Mild steel, Epoxy painted or stainless steel

Nozzles

Stainless steel and Titanium

Could be combined with carbon steel flanges

Plate material

316L & Titanium

STANDARD CONNECTIONS

Sizes mm (inch) Plateside Shellside

AlfaDisc50 50 (2”) 50-150 (2”-

6”)

AlfaDisc100 100 (4”) 100-300 (4”-12”)

AlfaDisc150 150 (6”) 150-400 (6”-16”)

Pressure ratings

CE/PED PN16, 25&40

ASME ASME cl. 150, 300 & 600

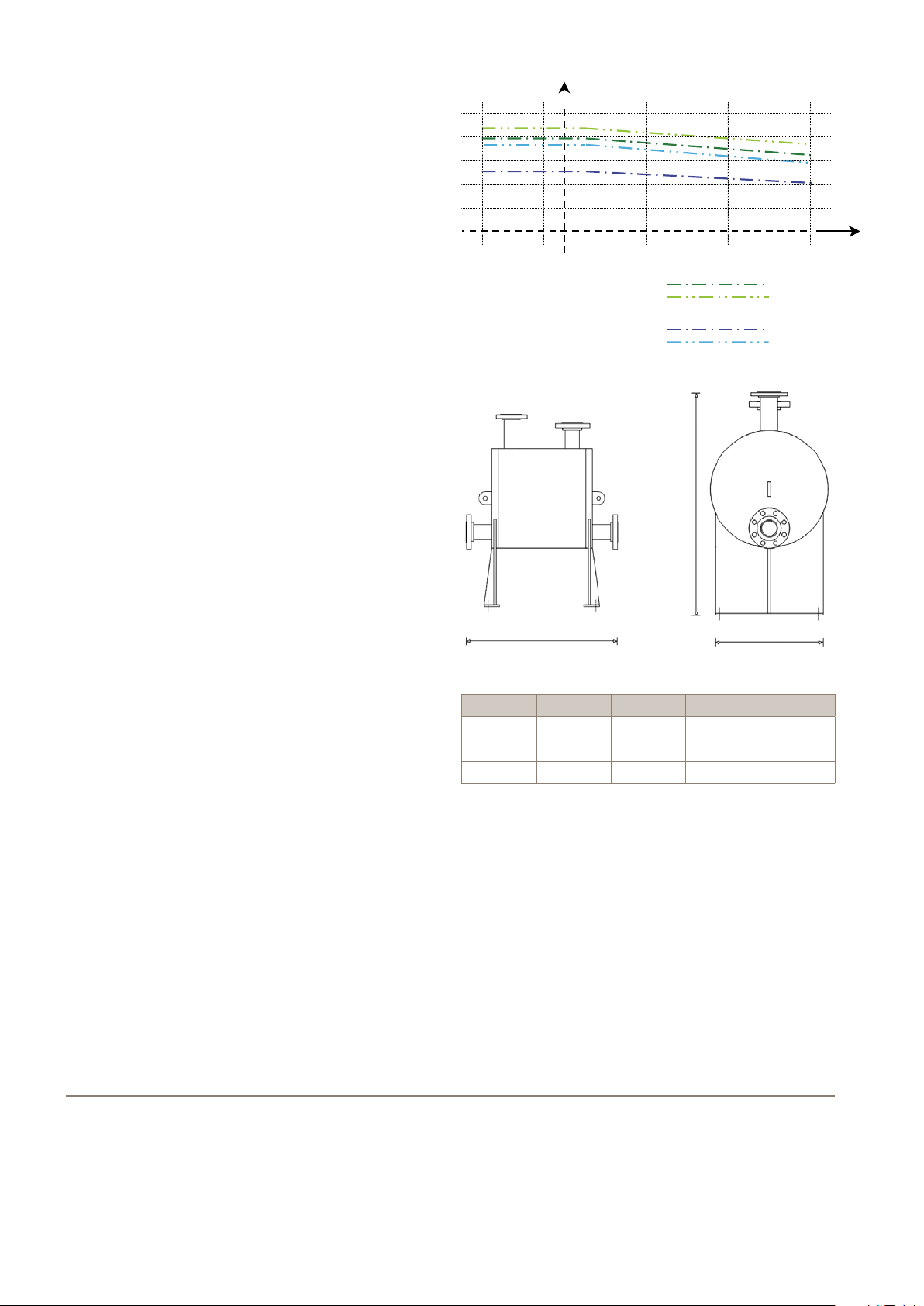

H D Lmin Lmax

AD50 686(27) 305(12) 483(19) 1219(48)

AD100 1117(44) 559(22) 635(25) 1448(57)

AD150 2032(80) 863(34) 965(38) 1880(74)

PCT00064EN 0708

How to contact Alfa Laval

Up-to-date Alfa Laval contact

details for all countries are

always available on our website

at www.alfalaval.com.

Alfa Laval reserves the right to change specifications without prior notification.

AlfaDisc – Plate pressure (g) / temperature

Measurements mm (inch)

Particulars required for quotation

- Flow rates or heat load

- Temperature program

- Physical properties of liquids in question (if not water)

- Desired working pressure

- Maximum permitted pressure drop

- Available steam pressure

H

D

L

AlfaDisc 50 plates

316L 0,6mm (63bar at 50°C to 47,9bar at 454°C)

316L 0,8mm (76bar at 50°C to 57,8bar at 454°C)

AlfaDisc 100 plates

316L 0,6mm (34bar at 50°C to 25,9bar at 454°C)

316L 0,8mm (53bar at 50°C to 40,3bar at 454°C)

Bar

-160°C -29°C 150°C 300°C 538°C

Temp°C

100

64

40

25

10

Loading...

Loading...