Page 1

INSTALLATION INSTRUCTIONS

ROOF OR WALL VENTILATOR

MODEL VTR1400Q, VTR1000Q & VTR600R

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

IMPORTANT SAFETY INSTRUCTIONS

SAFETY WARNING: Before servicing or cleaning unit, switch

power off at the service panel and

lock service disconnecting means to

prevent power from being switched

on accidentally. When the service

disconnecting means cannot be

locked, attach a tag to the service

panel to indicate power has been

switched off for maintenance.

WARNING - TO REDUCE

THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wir-

ing must be done by qualified

person(s) in accordance with all

applicable codes & standards, including fire-rated construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent back

drafting. Follow the heating equipment manufacturers guideline and

safety standards such as those published by the National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air Conditioning En-

gineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. To properly exhaust air, be sure to

duct air out side. Do not vent

exhaust air into spaces within walls,

ceilings, attics, crawl spaces, or garages.

WARNING: To reduce the risk of

fire, use only metal ductwork.

CAUTION - For General Ventilating Use Only. Do Not Use To

Exhaust Hazardous Or Explosive

Materials And Vapors.

READ AND SAVE THESE INSTRUCTIONS

Recommended for use only over conventional domestic gas and electric ranges, and

use with an approved Thermador Hood.

I. INSTALLATION:

1. Remove and discard shipping bracket (attached to motor mounts and inlet collar). Check to see if blower

wheel turns freely. Do not replace top until installation

is complete.

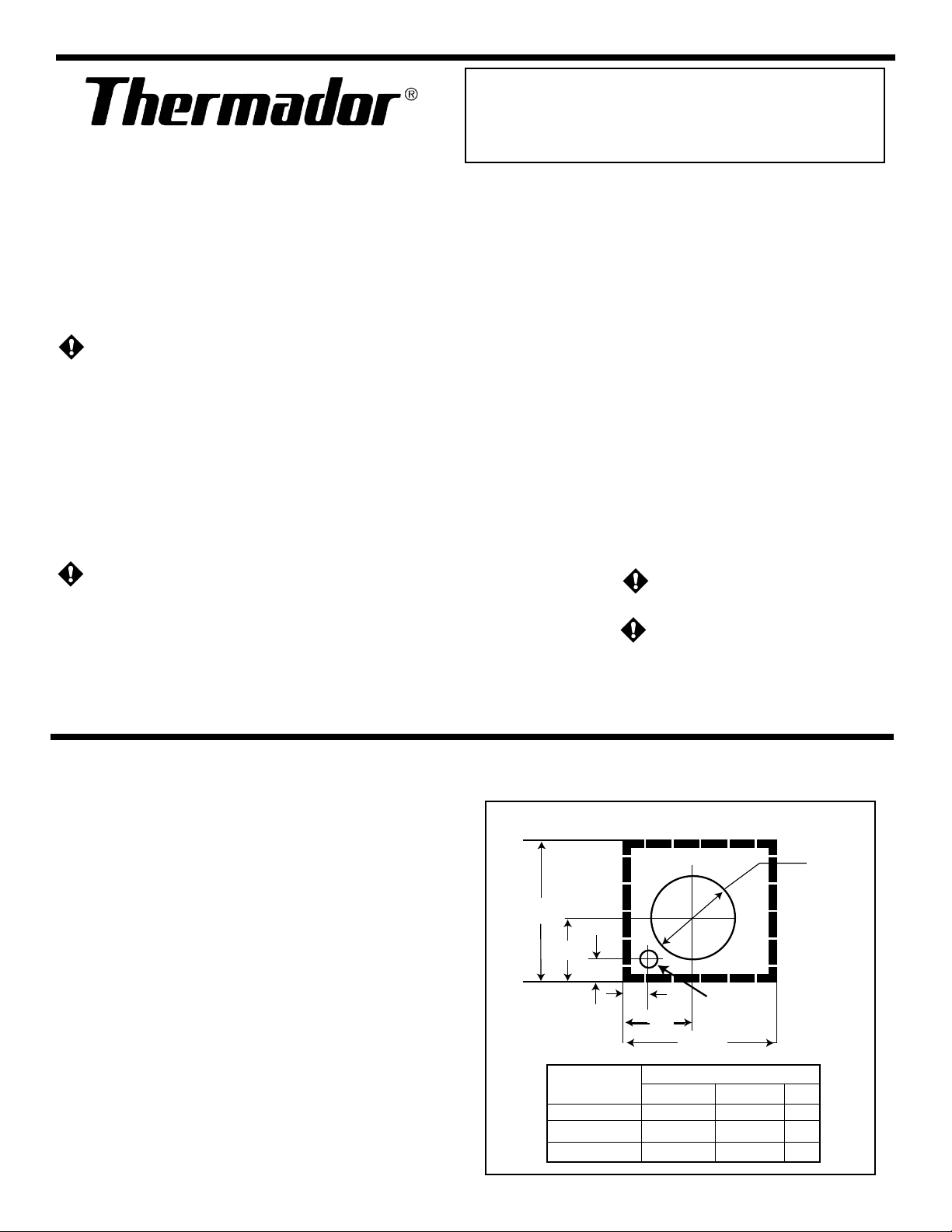

2. Provide a square cutout through the roof (or wall) as

shown by the dashed lines, or cut a round hole to fit duct

with a separate hole for electrical conduit as shown by

solid lines in Fig. 1.

3. Install the remote ventilator with the discharge pointing

down slope as shown in Figures 3 and 4. Follow standard

roofing procedures. Install the ventilator so the discharge edge is on top of the shingles and the rear edge

is underneath the shingles.

Fig. 1 TOP VIEW Down Slope of Roof or Wall

14"

B

1"

1"

A

Model A B C

VTR600R 5-11/16" 6-1/8" 9"

VTR1000Q 7-1/4" 6-15/16" 11"

VTR1400Q 7-1/4" 6-15/16" 11"

1

1-1/4 "

Hole

14"

Dim.

C Dia.

Page 2

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

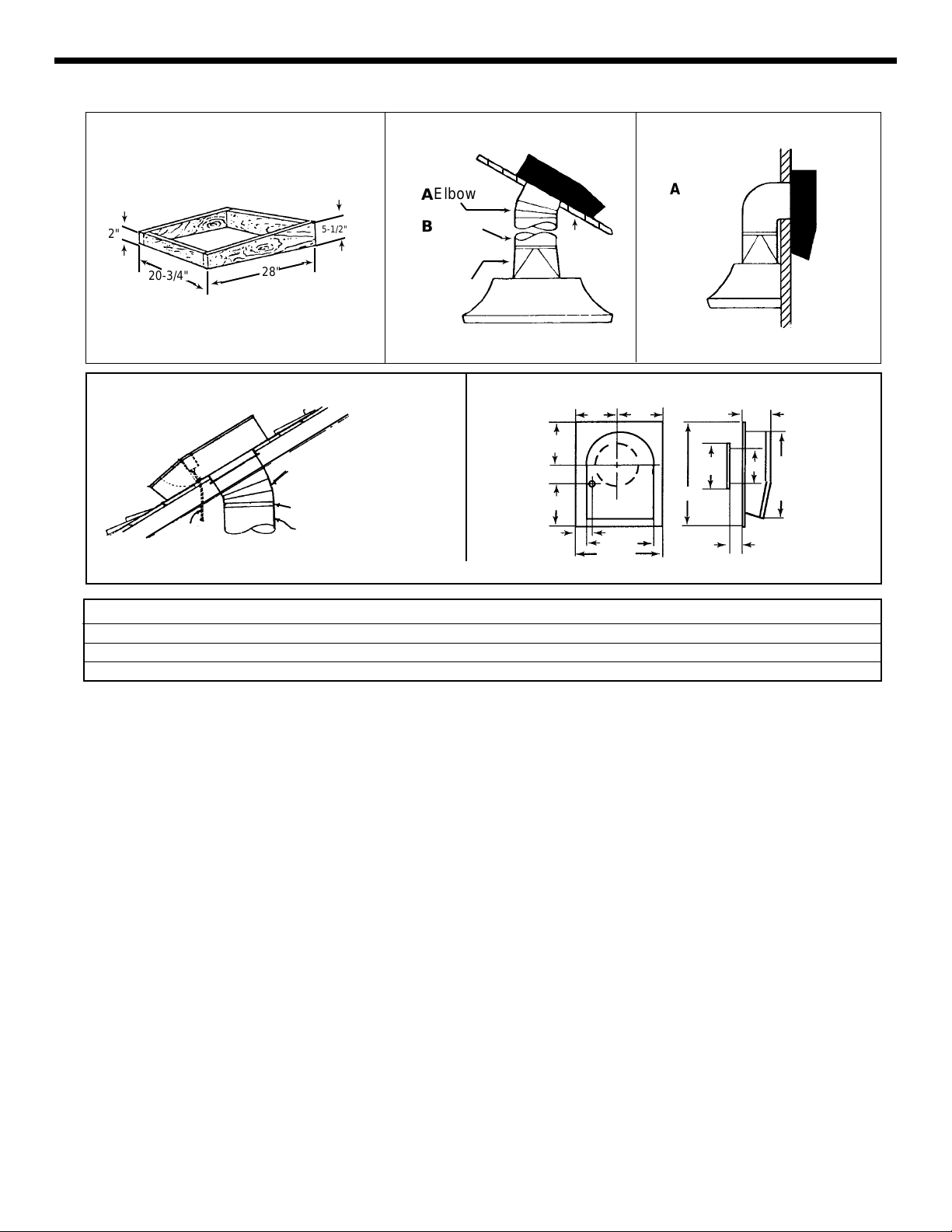

Figure 2 CURB FOR ROOF

➛

2"

➛

➛

20-3/4"

➛

➛

28"

➛

➛

5-1/2"

➛

Figure 3 Figure 4

Elbow

Elbow

A

A

➛

Round

B

Duct

Roof

➛

➛

➛

Roof

Transition

Transition

➛

➛

➛

Outside

Wall

Figure 5

Figure 6 – Remote Blower Dimensions

11-3/8"

9-3/8"

5-7/8"

C

G

H

I

J

Conduit

(Not Provided)

A Adjustable Elbow

Tape Joints

B Dia. Duct Conduit

D

E

F

20-3/4"

28"

TYPICAL INSTALLATION USING THERMADOR HOODS

MODEL A B C D E F G H I J

VTR1000Q 10" Dia. 10" Dia. 10-3/4 10-1/4 3-1/8 17-5/8 10-3/4 10 26-1/4 4

VTR1400Q 10" Dia. 10" Dia. 10-3/4 10-1/4 3-1/8 17-5/8 10-3/4 10 26-1/4 4

VTR600R 8" Dia. 8" Dia. 10-3/8 11-1/2 4-5/8 14-7/8 8-3/4 8 24 3-1/2

NOTE: The unit must be sealed between the roof (or

wall) and the underside of the flange with roofing mastic

to prevent leaks. For installation on a flat roof, or roofs

with a pitch less than 1-1/2" in 12", install ventilator on

the curb as shown in Fig. 2. Position the curb on flat roofs

so that the discharge (low) end points away from

prevailing wind.

3. Connect ventilator to the exhaust system with 8 inch

dia. duct for VTR600R and 10" dia. duct for VTR1000Q

and VTR1400Q. Use adjustable elbow to adjust to roof

angle. Tape all joints to prevent air leaks.

4. Connect ducting in the inlet to the ventilator with duct

tape.

5. Clearance to combustible material is 0".

II. FOR WIRING TO ALL APPROVED

®

THERMADOR

PRODUCTS, USE INSTALLATION INSTRUCTIONS PROVIDED WITH

THAT PRODUCT.

III. WIRING TO A WALL MOUNT 4 POSITION

VENTILATOR SPEED CONTROL SWITCH:

1. Use Thermador 4 position ventilator speed control

model CTR3Q (purchased separately).

2. Power supply required for these ventilators is

15 amps. @120V. AC, 60 Hz. connected per local

codes.

3. Run three (3) #14 AWG. wires (black, white and

green) from the power supply at the electrical

circuit panel to the wall box. See Figure 8.

4. Run electrical conduit per local code to conduit

outlet in bottom of ventilator as shown in Fig. 5.

Other end of conduit will connect to wall box with

4 position switch. See Figure 8.

5. Run five (5) #14 AWG. wires in conduit between

Ventilator J-box and 4 position switch. Use color

coded wire corresponding to colors shown in

Figure 8.

6. Use wire nuts to connect wires as shown in

Figure 8.

2

Page 3

IV. FOR WIRING TO A WALL MOUNT INFINITE

VENTILATOR SPEED CONTROL SWITCH

MODEL VTR600R ONLY:

1. Use Thermador infinite speed control switch model

#SSC1C (Purchase separately).

2. Power supply required for these ventilators is

15 amps. @120V. AC, 60 Hz. connected per local codes.

3. Run three (3) #14 AWG. wires (black, white and green)

from the power supply at the electrical circuit panel to

the wall box. See Figure 9.

4. Run electrical conduit per local code to conduit outlet

in the bottom of ventilator as shown in Figure 5.

Connect other end of conduit to wall box with speed

control switch as shown in Figure 9.

5. Run three (3) #14 AWG wires in conduit between

VTR600R and the infinite ventilator speed control switch.

Use color coded wire corresponding to wire colors

shown in Figure 9.

6. Use wire nuts to connect wires per Fig. 9 wiring diagram.

NOTE: There should be two (2) excess wires (blue and red)

from the motor. These wires are not needed for

wiring to this infinite ventilator speed control switch.

These wires should be individually capped with wire

nuts and pushed back inside the wiring compartment

on the remote ventilator VTR600R.

Fig. 7

WARNING:

Disconnect power before installing switch. Before turning

power on, be sure that all controls are in the OFF position.

1/2" Thin Wall Conduit

Ventilator Wall Switch

Model CTR3Q or SSC1C (VTR600R Only)

(Not Provided)

Fig. 8

Power Supply

120 V. 60 Hz.

Fig. 9

VTR600R/VTR1000Q/VTR1400Q: WIRING DIAGRAM FOR WALL MOUNT FOUR (4) POSITION

SWITCH MODEL # CTR3Q

White (Common)

Motor

Switch

3

2

1

CTR3Q

Black

VTR600R ONLY: WIRING DIAGRAM FOR WALL MOUNT INFINITE SWITCH MODEL #SSC1C

L1

White

Black

Blue

Red

Green

(Common)

(Hi)

(Med)

(Low)

(Ground)

in

Blower

Unit

VTR600R

VTR1000Q

VTR1400Q

White (Common)

Motor

in

Blower

Unit

VTR600R

ONLY

Power Supply

120 V. 60 Hz.

Black

Black

Switch

SSC1C

Black

White

Black

Green

(Common)

Blue

Red

(Ground)

3

Page 4

Installation must comply with all local codes

KITCHEN VENTILATION TIPS

6. WARNING - TO REDUCE THE RISK

OF A RANGE TOP GREASE FIRE:

1. Cooking Appliances such as Ranges, Cooktops, Barbecue Units, Grills, etc., require adequate ventilation. Hood

should be large enough and Cooking Appliances located

so that the Hood overhangs the Cooking Surface as much

as possible.

2. Consult a Competent Kitchen Designer or Ventilation

Engineer for proper Hood size and C.F.M. requirements.

3. Provide make-up air input to the kitchen so exhausted air

is not drawn through furnace unit or down fireplace

chimney.

4. Locate the Cooking Area for minimum cross drafts, away

from doors and windows, etc., when possible.

5. For best performance duct runs should be as short and

as straight as possible. Where turns are necessary, keep

turning radius as large and as smooth as possible.

a) Never leave surface units unattended at high set-

tings. Boil-overs cause smoking and greasy spillovers

that may ignite. Heat oils slowly on low or medium

settings.

b) Always turn hood ON when cooking at high heat or

when cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appro-

priate for the size of the surface element.

Thermador reserves the right to change specifications or design without notice. Some models are certified for use in Canada. Thermador is not responsible for products which are transported from the United

States for use in Canada. Check with your local Canadian distributor or dealer. Thermador , 5551 McFadden

Avenue, Huntington Beach, CA 92649.

For the most up to date critical installation dimensions by fax, use your fax handset and call 702/833-

3600. Use code #8030.

5551 McFadden Avenue, Huntington Beach CA, 92649 • 800/735-4328

UL LISTED #157J FILE # E521958

ECO 71566 19-12-182H • © Thermador Corporation, 1998 • Litho in U.S.A. 11/00

4

Loading...

Loading...