Thermador UCVM36XS, UCVP36XS, UCVM30XS Installation Manual

Installation

GUIDE

Masterpiece® Series Downdraft Hood

UCVM30XS, UCVM36XS, UCVP36XS

THERMADOR.COM

Table of

CONTENTS

ABOUT THIS MANUAL .................................................................... 3

Be sure to observe all listed warnings and cautions....................... 3

IMPORTANT SAFETY INSTRUCTIONS ........................................ 4-7

General notes .................................................................................... 4

Proper installation and maintenance ................................................ 5

Fire safety .......................................................................................... 6

Child safety ....................................................................................... 7

State of California Proposition 65 Warnings ..................................... 7

Protecting the environment .............................................................. 7

BEFORE YOU BEGIN ...................................................................... 8

Installation review ............................................................................. 8

Tools needed ................................................................................... 8

Parts supplied ................................................................................... 8

PLAN THE INSTALLATION ............................................................. 9

Select ducting option........................................................................ 9

Ductwork preparation ....................................................................... 9

Plan cabinetry ................................................................................... 9

DUCT EQUIVALENT CHART.......................................................... 10

SYSTEM DIMENSIONS .................................................................. 11

ACCESSORIES ................................................................................ 12

INSTALLATION ......................................................................... 13-21

Take measurements ....................................................................... 13

Cut coutertop opening .................................................................. 13

Installation with electric and induction cooktops ........................... 13

Installation with gas cooktops......................................................... 14

Prepare downdraft housing ............................................................ 14

Optional: Electrical panel can be mounted in a remote location .. 15

A - Installation using exible blower attached

to downdraft .................................................................................. 15

B - Installation using exible or remote blower mounted in a remote location - ducting through

front panel opening ....................................................................... 16

C - Installation using inline or remote blower - ducting

through left, right, below or rear ................................................... 16

Insert upper support bracket and attach support leg ................... 16

Cut out ductwork opening in cabinet ............................................ 17

Mounting downdraft with recirculation kit (UCVRECIRC) .............. 17

Mount downdraft in cabinet ..................................................... 17-18

Gas cooktops only: Install gas cooktop seal kit

(UCV30ST, UCV36ST) ................................................................18-19

Install roof cap, wall cap, inline or remote blower ......................... 19

Connect ductwork .......................................................................... 19

Install the electrical panel .............................................................. 19

Plan house wiring ........................................................................... 19

Install electrical wiring .................................................................... 20

Connect downdraft to power ........................................................ 21

Make-up air damper wiring ........................................................... 21

Install cooking appliance ............................................................... 21

Attach endcaps to downdraft ........................................................ 21

THERMADOR

Before calling service ...................................................................... 22

Data label ........................................................................................ 22

Service ............................................................................................. 22

Parts and accessories ...................................................................... 22

®

SUPPORT .............................................................. 22

This THERMADOR Appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 2

ABOUT THIS MANUAL

Be sure to observe all listed warnings and

cautions.

Look for the triangles with exclamation marks inside.

WARNING

This indicates that death or serious injuries may occur as a result

of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or property may

occur as a result of non-compliance with thisadvisory.

Note: This alerts you to important information and/or tips.

CAUTION

This indicates that minor or moderate injuries may occur as a

result of non-observance of this warning.

Pay special attention to the important safety instructions in the

“Safety” section.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

General notes

Note: Examine the appliance after unpacking it. In the event of

transport damage, do not plug it in.

Note: Do not remove any of the aluminum tape as it is needed for

sealing air leaks.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

Use this unit only in the manner intended by the manufacturer. If you

•

have questions, contact the manufacturer.

Before servicing or cleaning unit, switch power off at service panel

•

and lock the service disconnecting means to prevent power from

being switched on accidentally.

When the service disconnecting means cannot be locked,

•

securely fasten a prominent warning device, such as a tag, to the

servicepanel.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

Installation work and electrical wiring must be done by quali ed

•

person(s) in accordance with all applicable codes and standards,

including re-rated construction.

Suf cient air is needed for proper combustion and exhausting of

•

gases through the ue (chimney) of fuel burning equipment to

prevent back drafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

When cutting or drilling into wall or ceiling, do not damage

•

electrical wiring and other hidden utilities.

Ducted fans must always be vented to the outdoors.

•

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

AFTER INSTALLATION IS COMPLETE.

IMPORTANT: SAVE FOR THE LOCAL INSPECTOR’S USE.

WARNING

When properly cared for, your new appliance has been designed to

be safe and reliable. Read all instructions carefully before use. These

precautions will reduce the risk of burns, electric shock, re, and injury to

persons. When using kitchen appliances, basic safety precautions must

be followed, including those in the following pages.

Page 4

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Proper installation and maintenance

WARNING

Remove all tape and packaging before using the appliance. Destroy

the packaging after unpacking the appliance. Never allow children to

play with packaging material.

INSTALLER: Show the owner the location of the circuit breaker or fuse.

Mark it for easy reference.

This appliance must be properly installed and grounded by a quali ed

technician. Connect only to properly grounded outlet. Refer to

Installation Instructions for details.

This appliance is intended for normal family household use only. It is

not approved for outdoor use. See the Statement of Limited Product

Warranty in the Use and Care Guide. If you have any questions, contact

the manufacturer.

Do not store or use corrosive chemicals, vapors, ammables or nonfood

products in or near this appliance. It is speci cally designed for use when

heating or cooking food. The use of corrosive chemicals in heating or

cleaning will damage the appliance and could result in injury.

Do not operate this appliance if it is not working properly, or if it has

been damaged. Contact an authorized servicer.

Do not repair or replace any part of the appliance unless speci cally

recommended in this manual. Refer all servicing to a factory authorized

service center.

WARNING

Make sure the appliance and lights are cool and power to the

appliance has been turned off before replacing the LED (if equipped).

Failure to do so could result in electrical shock or burns.

WARNING

Do not use this unit in conjunction with a recirculation unit in gas cooking

application.

WARNING

Unit is heavy and requires at least two people or proper equipment to

move and install.

WARNING

When the hood is operated in exhaust-air mode simultaneously with

a different appliance which also makes use of the same chimney (such

as gas, oil or coal- red heaters, continuous- ow heaters, hot-water

boilers) care must be taken to ensure that there is an adequate supply

of fresh air which will be needed by the appliance for combustion.

This can be achieved if combustion air can ow through non-lockable

openings, e.g. in doors, windows and via the air-intake/exhaust-air wall

box or by other technical measures, such as reciprocal interlocking, etc.

WARNING

Avoid carbon monoxide poisoning – Provide adequate air intake so

combustion gases are not drawn back into the room.

An air-intake/exhaust-air wall box by itself is no guarantee that the

limiting value will not be exceeded.

Note: When assessing the overall requirement, the combined

ventilation system for the entire household must be taken into

consideration. This rule does not apply to the use of cooking

appliances, such as cooktops and ovens.

WARNING

To avoid electrical shock hazard, before installing, switch power off at

the service panel and lock the panel to prevent the power from being

switched on accidentally.

CAUTION

Grease left on lters can melt and move into the vent.

WARNING

Hidden surfaces may have sharp edges. Use caution when reaching

behind or under appliance.

WARNING

Tie long hair so that it does not hang loose, and do not wear loose

tting clothing or hanging garments, such as ties, scarves, jewelry, or

dangling sleeves.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Fire safety

WARNING

Use this appliance only for its intended use as described in this manual.

Always have a working smoke detector near the kitchen. In the event

that personal clothing or hair catches re, drop and roll immediately to

extinguish ames.

Have an appropriate re extinguisher available, nearby, highly visible

and easily accessible near the appliance.

Smother ames from food res other than grease res with baking

soda. Never use water on cooking res.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:

a. SMOTHER FLAMES with a close- tting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If

the ames do not go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

b. NEVER PICK UP A FLAMING PAN – You may be burned.

c. DO NOT USE WATER, including wet dishcloths or towels – a violent

steam explosion will result.

d. Use an extinguisher ONLY if:

- You know you have a Class ABC extinguisher, and

you already know how to operate it.

- The re is small and contained in the area where it started.

- The re department is being called.

- You can ght the re with your back to an exit.

a

Based on “Kitchen Fire Safety Tips” published by NFPPA.

a

WARNING

RISK OF FIRE

Hot oil and fat catch re fast. Never leave hot oil and fat unsupervised.

Never extinguish a re with water. Switch off the cooking position.

Suffocate ames carefully with a lid, a re blanket or similar.

WARNING

RISK OF FIRE

Grease deposits in the grease lters can ignite.

Clean the grease lters at least every two months or as frequently as

necessary.

Never operate the appliance without the grease lters.

WARNING

RISK OF FIRE

Grease deposits in the grease lters can catch re. Never work with a

naked ame near the appliance (e.g. ambéing). Install the unit near a

heat-producing appliance for solid fuels (e.g. wood or coal) only if there

is a closed, non-detachable cover. There must be no ying sparks.

WARNING

RISK OF FIRE

Use only metal ductwork.

WARNING

RISK OF BURNS

The accessible parts get hot during operation. Never touch hot parts.

Keep children away.

Whenever possible, do not operate the ventilation system during a

cooktop re. However, do not reach through re to turn it off.

WARNING

RISK OF FIRE

When gas burners are in operation without any cookware placed on

them, they can build up a lot of heat. A ventilation appliance installed

above the cooker may become damaged or catch re. Only operate

the gas burners with cookware on them.

CAUTION

It is recommended to wear gloves and long sleeves to protect hands

and forearms from abrasion and potential scratches during the

installation process.

Page 6

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Child safety

When children become old enough to use the appliance, it is the

responsibility of the parents or legal guardians to ensure that they are

instructed in safe practices by quali ed persons.

Do not allow anyone to climb, stand, lean, sit, or hang on any part of an

appliance. This can damage the appliance or cause injury.

WARNING

Be sure the entire appliance (including the grease lters and light bulbs,

if applicable) has cooled and grease has solidi ed before attempting to

clean any part of the appliance.

Do not use steam cleaners to clean the appliance.

State of California Proposition 65 Warnings

WARNING

This product may contain a chemical known to the State of California,

which can cause cancer or reproductive harm. Therefore, the packaging

of your product may bear the following label as required by California:

STATE OF CALIFORNIA PROPOSITION 65 WARNING:

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Protecting the environment

Unpack the appliance and dispose of the packaging in line with

environmental requirements.

NOTICE

Risk of damage due to corrosion. Always turn appliance on when

cooking to avoid condensation buildup. Condensation can lead

to corrosion damage.

Risk of damage due to moisture entering into the electronic circuitry.

Never clean operator controls with a wet cloth.

Surface damage due to incorrect cleaning. Clean stainless steel surfaces

in the grain direction only. Do not use any stainless steel cleaners on

operator controls. Never use strong or abrasive cleaning agents, since

they can cause surface damage.

Risk of damage from condensation back ow. Install exhaust vent at a

slight downward slope away from the appliance (1° slope).

Page 7

BEFORE YOU BEGIN

Installation review

This downdraft system can be used to exhaust cooking by-products

such as heat, steam, and smoke that may be created while cooking

using gas or electric cooktops. With its versatile design, there are six (6)

basic discharge options - left, right, rear, below, front and recirculation.

It is important to rst plan your installation. The purchase of additional

accessories to complete the installation may be necessary.

It can be mounted in an island, peninsula, or conventional wall location.

The blower (purchase separately) and electrical panel can be mounted to

the downdraft unit, inside the cabinet, or in a convenient remote location.

This unit can be easily installed following these basic steps:

Plan the installation.

•

Cut out the countertop opening.

•

Prepare the downdraft housing.

•

Cut out the cabinet opening for discharge.

•

Mount the downdraft in the cabinet.

•

Install gas cooktop seal kit accessory, if applicable.

•

Connect the ductwork and install the blower.

•

Install downdraft electrical panel, if in remote location.

•

Install the cooking appliance.

•

Install end caps to downdraft.

•

Check the operation.

•

Note: the high level of air ow of this appliance may effect the gas

ame on some types of gas cooktops. This is NORMAL and will cause

no harm, but can be corrected by lowering the speed of the blower.

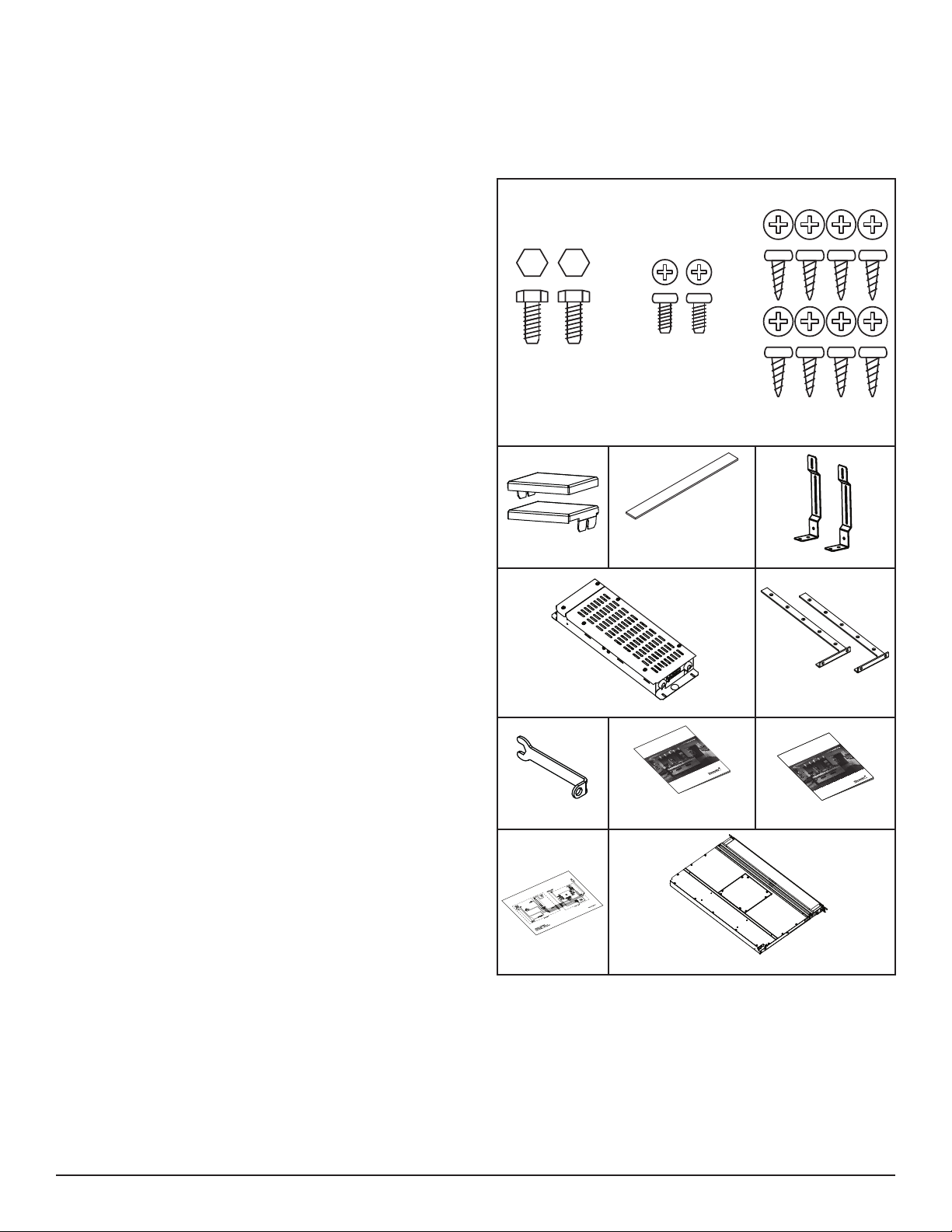

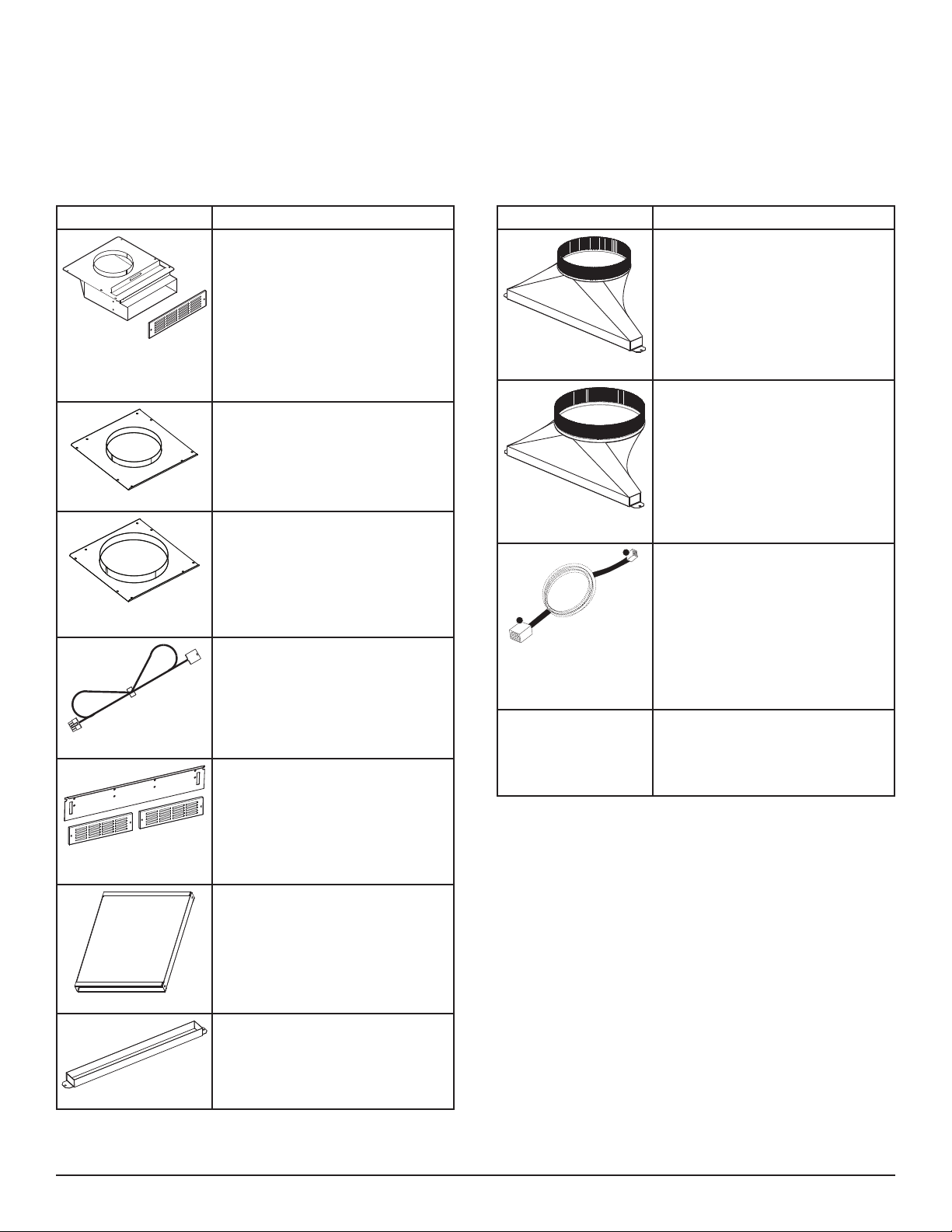

Parts supplied

2 - Screws,

1/4-20 x .50

(12.7 mm)

Hex Head

2 - End Cap Trim

1 Parts Bag containing:

2 - Screws,

No. 8-18 x .375

(9.5 mm)

Phillips

8 - Wood Screws,

No. 10 x .50 (12.7 mm)

Phillips Round Head

1 - Plastic installation

template

(see page 13) 2 - Support legs2 - Support legs

Tools needed

Measuring tape

•

Pencil

•

Phillips screwdriver no. 2

•

Nut drivers - 11/32” (8.7 mm), 3/8” (9.5 mm), 7/16” (11.1 mm)

•

Box-end wrench

•

Spirit-level

•

Aluminum tape (DO NOT use insulating tape)

•

Saw

•

Tin snips

•

Work gloves

•

2 - Upper Support 2 - Upper Support

1 - Electrical Panel1 - Electrical Panel

1 - Special key1 - Special key

MANUAL

TALLATION

TION

INSTALACIÓN

D'INS

ALLA

L

INST

MANUE

MANUAL DE

TEURS ENCASTRÉS SÉRIE MASTERPIECE

MASTERPIECE

VENTILA

VENTILADOR DE TIRO DESCENDENTE SERIE MASTERPIECE

InstallationInstallation

instructionsinstructions

®

SERIES DOWNDRAF

®

MD

OR

T

VENTILA

T

BracketsBrackets

DE

GUI

TION

N

CUI

AND CARE

RETIE

D'UTILISA

USE

E USO Y

D'ENT

D

GUIDE

ET

UÍA

G

MASTERPIECE

VENTILA

VENTILADOR DE TIRO DESCENDENTE SERIE MASTERPIECE

Use and Care guide

Wiring diagram Downdraft Ventilator Housing

O

DAD

®

SERIES DOWNDRAFT

TEURS ENCASTRÉS SÉRIE MASTERPIECE

®

MD

TOR

VENTILA

Page 8

PLAN THE INSTALLATION

Select ducting option

A

D

C

G

HD1101

The 6 basic discharge connections, left, right, rear, front, below and

recirculation can be achieved through A to G with the optional parts listed.

1. The downdraft blower system is designed for use with 8” (203 mm) round

ductwork using a exible blower or 6” (152 mm) or 10” (254mm) round

ductwork using an inline or remote blower. (Purchase blowers separately.)

Seven (7) different discharge connections are available:

A = 8” (203 mm) Round, Left Discharge out of Flex Blower

B = 8” (203 mm) Round, Right Discharge out of Flex Blower

C = 8” (203 mm) Round, Down Discharge out of Flex Blower (Electrical

Panel to be mounted remotely)

D = 1-7/8” x 19” (48 mm x 483 mm), Left Discharge out of Housing to

Remote Blower or Flex Blower in remote location.

Use 1-7/8” x 19” (48mm x 483mm) to 6”, 8”, or 10” (152 mm,

203mm, or 254 mm) round transition or 1-7/8“ x 19“ (48 mm x

483 mm) ductwork as appropriate.

E = 1-7/8” x 19” (48 mm x 483 mm), Right Discharge out of Housing

to Remote Blower or Flex Blower in remote location.

Use 1-7/8” x 19” (48 mm x 483 mm) to 6”, 8”, or 10” (152 mm,

203 mm, or 254 mm) round transition or 1-7/8“ x 19“ (48 mm x

483 mm) ductwork as appropriate.

F = 1-7/8” x 19” (48 mm x 483 mm), Rear Discharge out of Housing to

Remote Blower or Flex Blower in remote location.

Use 1-7/8” x 19” (48 mm x 483 mm) to 6”, 8”, or 10” (152 mm,

203 mm, or 254 mm) round transition or 1-7/8“ x 19“ (48 mm x

483 mm) ductwork as appropriate.

G = 1-7/8” x 19” (48 mm x 483 mm), Down Discharge out of Housing

to Remote Blower or Flex Blower in remote location.

Use 1-7/8” x 19” (48 mm x 483 mm) to 6”, 8”, or 10” (152 mm,

203 mm, or 254 mm) round transition or 1-7/8” x 19” (48 mm x

483 mm) ductwork as appropriate.

2. For best performance: Choose the ducting option which allows the

shortest length of ductwork and a minimum number of elbows and

transitions. Check location of oor joists, wall studs, electrical wiring

or plumbing for possible interference.

Note: The manufacturer is not responsible for performance complaints

attributable to the duct section.

The device achieves its optimum performance by means of a short,

•

straight exhaust air duct and as large a pipe diameter as possible.

The optimum extraction performance is not achieved and fan noise

•

is increased if exhaust air ducts are long and rough and if there is a

large number of duct bends or diameters less than 6” (152 mm).

The pipes or hoses for laying the exhaust air line must consist of

•

non-combustible material.

Seal the connection points of the ducts appropriately.

•

Ductwork must vent outside, not into attic spaces for example,

•

unless the available ’Non-duct Recirculation Kit’ is used.

F

B

E

Ductwork preparation

DUCTING RECOMMENDATIONS

Proper performance is dependent upon proper ducting.

MAKE-UP AIR: Local building codes may require the use of make-up air

systems when using ducted ventilation systems greater than speci ed

CFM of air movement. The speci ed CFM varies from locale to locale.

It is the responsibility of the owner and the installer to determine if

additional requirements and/or standards apply to speci c installations.

DO NOT USE FLEXIBLE DUCT; it creates back pressure/ air turbulence

and reduces performance.

Always install a metal vent cover where the ductwork exits the house.

COLD WEATHER installations should have an additional backdraft

damper installed to minimize backward cold air ow and a nonmetallic

thermal break to minimize conduction of outside temperatures as part

of the ductwork.

The damper should be on the cold air side of the thermal break. The

break should be as close as possible to where the ducting enters the

heated portion of the house.

For safety reasons, ducting should vent directly outdoors (not into

an attic, underneath the house, into the garage or into any enclosed

space). In gas cooking applications, the unit cannot be used in

conjunction with a recirculation unit.

THERMADOR® recommends not exceeding 50 ft. (15 m) of equivalent

duct.

Plan cabinetry

For left, right, or rear exhaust:

Allow at least 18” (457 mm) for transition and elbow or blower.

For left / right exhaust:

A 30” (762 mm) deep cabinet is recommended to align properly with

ex blower. Flex blower can be mounted to rear cabinet wall or to a

platform / frame (not provided) on the base of the cabinet oor. (See

ex blower instructions.)

Cabinet depths of 24” (610 mm) to 30” (762 mm) are required depending on the type of cooking appliance.

For some applications, gas or electrical connections will need to be

moved or routed around downdraft unit.

For gas cooktop installations make sure that a minimum 27 square inch

(174 cm²) opening is provided in the toe-kick and cabinet base. Inadequate

ventilation of the cabinet below the cooktop may result in ame outage

when operating the fan on higher speeds.

Note: A cooktop sealing kit must be purchased for gas applications.

The kit includes hole covers for the toe-kick and cabinet base, as well as

a trim seal for the cooktop.

Page 9

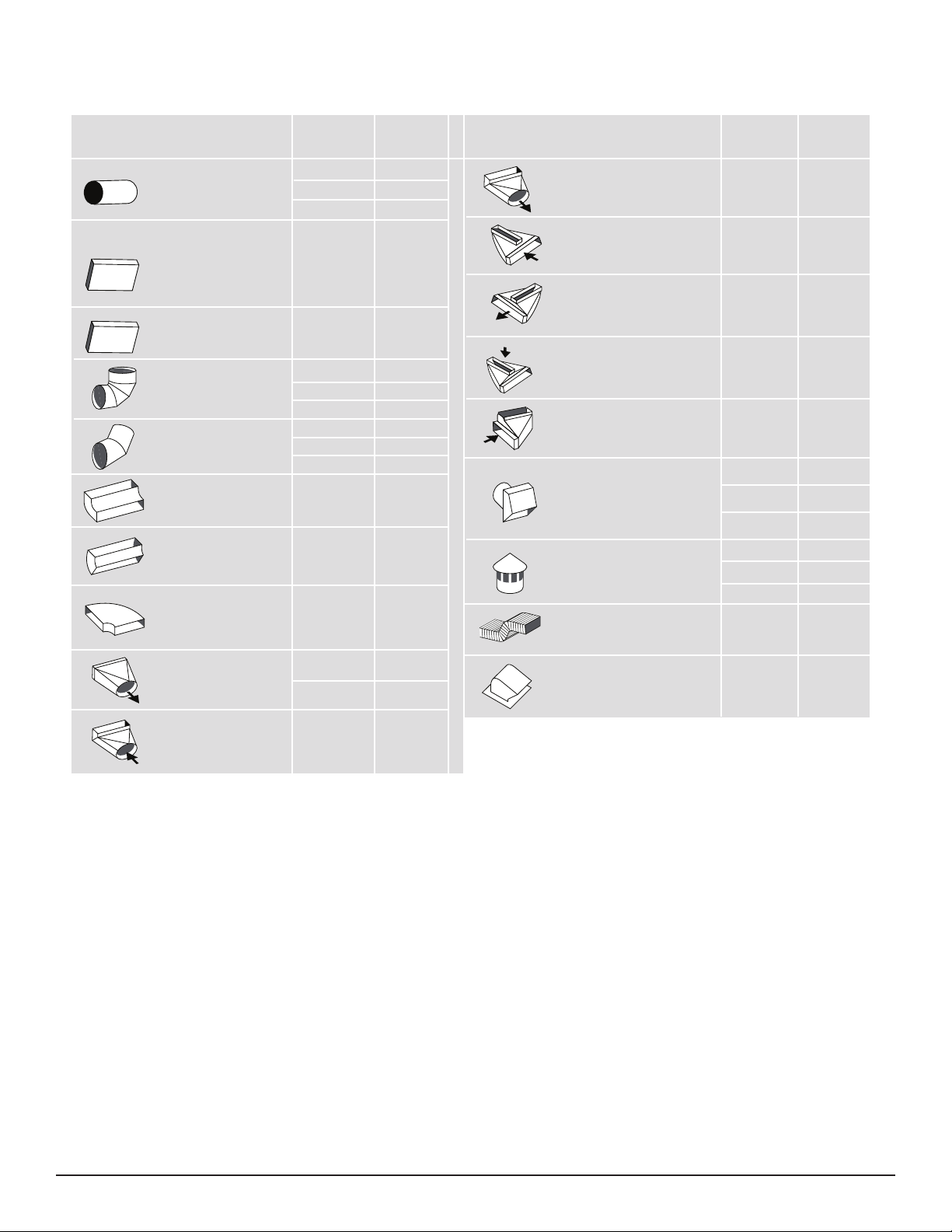

DUCT EQUIVALENT CHART

Duct Piece

Smooth, straight

3¼" x 10"

(83 mm x 254 mm)

straight

3¼" x 14"

(83 mm x 356 mm)

straight

90° Elbow , round

45° Elbow , round

3¼" x 10"

(83 mm x 254 mm),

90° Elbow , round

3¼" x 10"

(83 mm x 254 mm),

45° Elbow , round

3¼" x 10"

(83 mm x 254 mm),

Flat elb ow

Size

(in./mm)

6 (152) 1.2 (0.37)

8 (203) 0.7 (0.21)

10 (254) 0.6 (0.18)

N/A 1 (0.3)

N/A 0.7 (0.21)

6 (152) 12 (3.7)

8 (203) 6 (1.8)

10 (254) 5 (1.5)

6 (152) 5 (1.5)

8 (203) 3 (0.9)

10 (254) 2 (0.6)

N/A 5 (1.5)

N/A 15 (4.6)

N/A 20 (6.1)

Eq u i va l e n t

Length

(ft/m)

Duct P ie ce

3¼" x 10" (83 mm x 254 mm)

to round 90° Elbow

3¼" x 10" (83 mm x 254 mm)

Center reverse elbow , left

3¼" x 10" (83 mm x 254 mm),

Center reverse elbow , right

3¼" x 10" (83 mm x 254 mm),

Left reverse elbow

3¼" x 10" (83 mm x 254 mm),

Right reverse elbow

Round wall cap

Round roof c ap

2" (51 mm) long, 3¼" x 10"

(83 mm x 254 mm) flex

Size

(in./mm)

6 (152) 10 (3)

N/A 25 (7.6)

N/A 15 ( 4.6)

N/A 25 (7.6)

6 (152) 2 (0.6)

8 (203)

10 (254)

6 (152) 2 (0.6)

8 (203)

10 (254)

N/A 20 (6 .1)

Eq u i va l e n t

Length

(ft/m)

15 (4.6)N/A

2 (0.6)

2 (0.6)

2 (0.6)

2 (0.6)

3¼" x 10"

(83 mm x 254 mm)

to round

Round to 3¼" x 10"

(83 mm x 254 mm)

90° Elbow

6 (152) 5 (1.5)

8 (203) 2 (0.6)

6 (152) 10 (3)

3¼" x 10" (83 mm x 254 mm),

Roof jack and shutter

NOTE: These commonly used installation parts can be purchased at

a local hardware store. THERMADOR® does not manufacture

these parts.

Measurements in inches (mm).

N/A 2 ( 0. 6)

Page 10

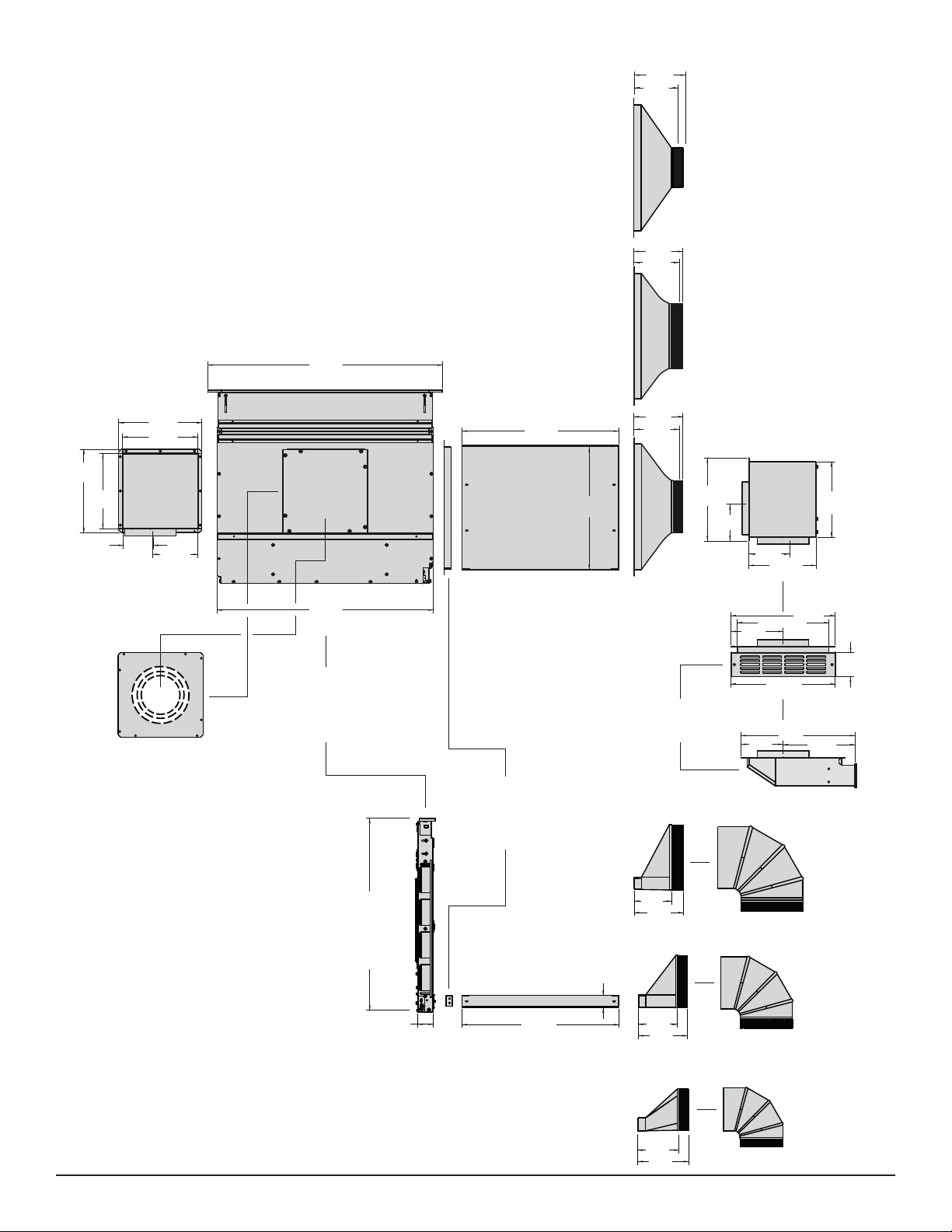

SYSTEM DIMENSIONS

7.500 in

191 mm

5.000 in

127 mm

7.500 in

191 mm

5.750 in

146 mm

CVTSIDE6

1-7/8” x 19” (48 mm x 483 mm)

TO 6” (152 mm) RD.

TRANSITION

VTD600P

FLEX BLOWER

12.750 in

324 mm

11.560 in

294 mm

12.750 in

324 mm

11.586 in

294 mm

OUTLET

4.240 in

108 mm

OUTLET

FRONT

7.320 in

186 mm

C

L

CVTFRONT6

6” (152 mm) RD. DUCT PLATE

CVTFRONT8

8” (203 mm) RD. DUCT PLATE

CVTFRONT10

10” (254 mm) RD. DUCT PLATE

30.000 in

762 mm

36.000 in

914 mm

FRONT

C

L

27.152 in

690 mm

33.152 in

842 mm

UCVM30XS

UCVM36XS

UCVP36XS

DOWNDRAFT

REAR

DUCTING

FRONT REAR

29.750 in

756 mm

(Chimney DOWN)

41.750 in

1060 mm

(Chimney UP)

2.410 in

61 mm

SIDE

DUCTING

24.000 in

610 mm

19.000 in

483 mm

CVDUCT2 1-7/8” x 19”

(48 mm x 483 mm)

RECTANGULAR DUCT

CVTRECT2

1-7/8” x 19” (48 mm x 483 mm)

RECTANGULAR DUCT

ADAPTER

CVDUCT2 1-7/8” x 19”

(48 mm x 483 mm)

RECTANGULAR DUCT

24.000 in

610 mm

1-7/8” x 19”

(48 mm x 483 mm)

TO 10” (254 mm) RD.

TRANSITION

CVTSIDE8 1-7/8” x 19” (48 mm x 483 mm)

CVTSIDE10

1-7/8” x 19” (48 mm x 483 mm)

TO 10” (254 mm) RD.

TRANSITION

7.500 in

191 mm

6.000 in

152 mm

12.750 in

324 mm

5.000 in

127 mm

CVTSIDE8

1-7/8” x 19”

(48 mm x 483 mm)

TO 8” (203 mm) RD.

TRANSITION

FRONT

UCVRECIRC NON-DUCT

RECIRCULATION KIT

CVTSIDE10

5.750 in

146 mm

7.500 in

191 mm

1.875 in

48 mm

6.000 in

152 mm

7.500 in

191 mm

TO 8” (203 mm) RD. TRANSITION

FLEX BLOWER

INLET

5.272 in

134 mm

14.048 in 357 mm

7.976 in

203 mm

6.478 in

165 mm

SIDE

VTD600P

SIDE

OUTLET

10.310 in

262 mm

15.952 in

405 mm

16.000 in

406 mm

17.478 in

444 mm

11.586 in

294 mm

3.750 in

95 mm

11.000 in

279 mm

10” (254 mm) RD.

ELBOW

*

8” (203 mm) RD.

ELBOW

*

Not available from Thermador.

*

Purchase locally.

CVTSIDE6

1-7/8” x 19”(48 mm x 483 mm)

TO 6” (152 mm) RD. TRANSITION

5.000 in

127 mm

7.500 in

191 mm

6” (152 mm) RD.

ELBOW

*

Page 11

ACCESSORIES (purchase separately)

1

2

Flexible Blower

Thermador Model VTD600P

MODEL DESCRIPTION

UCVRECIRC

UCVFILTER

(replacement lter)

CVTFRONT8

CVTFRONT6

CVTFRONT10

EXTNCE5

UCV30ST

UCV36ST

Inline and Remote Blowers

Thermador Models VTI610, VTR630, VTI1010, VTR1030, VTR1330

Non-Duct Recirculating Kit

Used in applications where ducting is not

feasible or available. Mount to toe kick

or base of a cabinet and attach directly

to VTD600P Flexible Blower using 8”

(203 mm) round duct. Kit can be rotated

so that the exhaust is not directly at your

feet. Includes decorative cover plate.

Rough-in Plate - 8” (203 mm) Round

Use for applications where 8” (203mm)

round duct or elbow attaches to front

of airbox (VTD600P inline blower

installation).

Rough-in Plate - 6” or 10” (152 mm or

254 mm) Round

Use for applications where 6” or 10”

(152 mm or 254 mm) round duct or

elbow attaches to front of airbox (inline

or remote blower installation).

Extension Cable - 5-ft. (1.5 m)

Used in applications where the electrical

panel is remotely mounted. If blower

discharge is down, electrical panel

must be relocated. Extends electrical

panel cable an additional 5-feet (1.5m)with the ability to connect up to two

extension cables.

Gas Cooktop Seal Kit - 30-in. (762 mm),

36-in. (914 mm)

Used to provide seal between gas

cooktop and downdraft. Also includes

cabinet hole cover plates. Two grilles are

provided in the kit, you may only need

one for your speci c installation.

Rectangular Duct - 2-ft. (0.6 m) sections

(1-7/8” x 19” /48 mm x 483 mm)

Galvanized steel construction.

2-ft. (0.6 m) sections can be connected

together.

B Connects to Hood

C Connects to Remote

or In-line Blower

EXTNCB25W

EXTNSET4

MODEL DESCRIPTION

1-7/8” X 19” (48 mm x 483 mm)

to 8” (203 mm) Round

Transition

Rectangular to 8” (203 mm) round

transition for left, right, below, or rear

exhaust- using Model VTD600P Flex

Blower. Can be attached to downdraft

unit or rectangular duct (CVDUCT2).

CVTSIDE8

1-7/8” X 19” (48 mm x 483 mm) to 6” or

10” (152 mm or 254 mm) Round

Transition

Rectangular to 6” or 10” (152 mm or

254 mm) round transition for left, right,

below, or rear exhaust using inline or

remote blower. Can be attached to

downdraft unit or rectangular duct

(CVDUCT2).

CVTSIDE6

CVTSID10

Extension Cable - 25-ft. (7.62 m)

The remote or inline blower harness

should be routed through the knockout

and secured with a 3/4” (19 mm) strain

relief. The 25 ft. Extension Cable can

then be connected to the Adapter Cable

included in EXTNSET4 Accessory Kit and

then to the hood electrical panel.

Extension Cable Connection Kit

Cable connection kit containing

(4) accessory cable adapters to

connect a variety of blower and hood

combinations.

Page 12

CVDUCT2

CVTRECT2

Rectangular Adapter for 1-7/8” x 19”

(48mm x 483 mm)

Use to connect 1-7/8” x 19” (48mm x

483 mm) rectangular duct directly to

downdraft when using side, below or

rearexhaust.

INSTALLATION

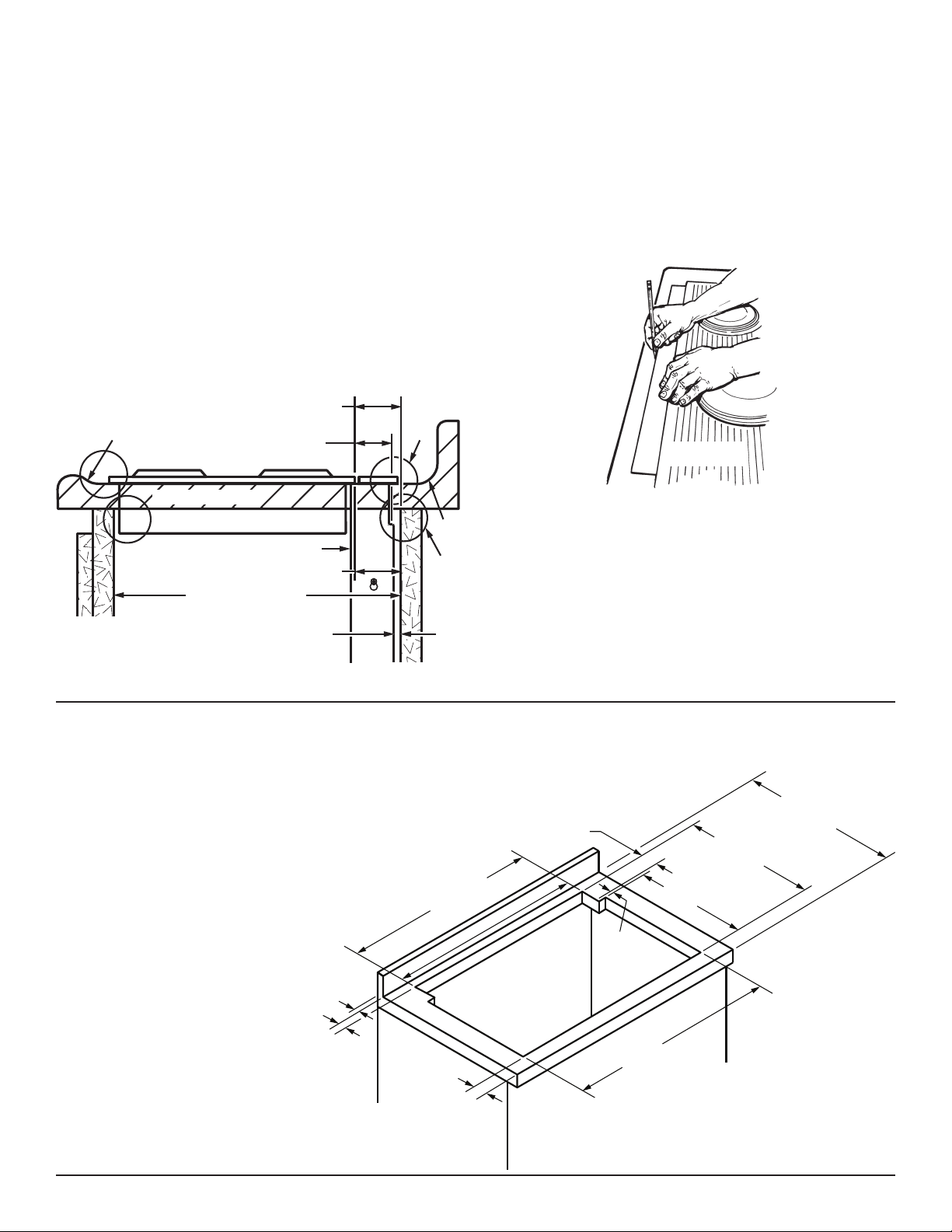

Take measurements

1. Refer to the cooktop installation instructions for dimensions of

cooktop, countertop cut-out, and cabinet requirements. However,

it is recommended that oversized cabinets be used for easier

installation. Custom island designs need to account for deeper

cabinets, especially when mounting the blower behind the

downdraft. You must also plan for an access door.

Pay special attention to the areas of potential interference highlighted

below. A countertop with (A) a raised lip and/or (B) a backsplash may

not allow enough at countertop for a proper installation. Note that

a minimum of 2-7/8” (73 mm) of at countertop is required behind

cooktop (C) and that a minimum of 2-7/8” (73 mm) is necessary between

the back edge of the cooktop and the inside of cabinet back (D).

FLAT COUNTERTOP (C)

A

2-7/8” (73 mm) MIN.

TEMPLATE

2-1/8” (54 mm) MIN.

COUNTERTOP

COOKTOP

DOWNDRAFT

2-7/8” (73 mm) MIN.

FRONT TO BACK

INSIDE CABINET DEPTH

5/8” (16 mm) MIN.

C

B

D

Cut countertop opening

1. Lay out and cut the cooktop cut-out far enough FORWARD so

downdraft will t behind it.

2. Set cooktop in place and slide it as far forward as possible without

exposing any gaps. Center and square it with edges of countertop.

COOKTOP

Template against back

edge of cooktop

3. Place the plastic template against the back ange of the cooktop.

Center the template. Trace around template to mark the

downdraftopening.

4. Remove cooktop from countertop.

5. Cut downdraft opening. Be careful not to chip edges of countertop.

Installation with electric and induction cooktops

Dimension “BT” is thickness of

the backsplash. Provide 1/2”

(13mm)clearance between the

vent cutout and the backsplash.

Any backsplash with a curved

radius where it meets the counter

will require additional clearance.

Thicker backsplashes may be used by

increasing the counter and cabinet

depths.

Set the cooktop into the coutertop

opening so that the back edge of the

cooktop overlaps the leading edge of

the downdraft.

Downdraft cutout width:

30” (762 mm) is 27-1/16” (687 mm)

36” (914 mm) is 33-1/16” (840 mm)

BT

MIN.

1/2”

(13 mm)

2-1/4” (57 mm)

Template

2-1/8” (54 mm)

25-7/16” - 25-9/16”

(646 mm - 649 mm)

22-11/16” - 22-13/16”

(576 mm - 579 mm)

19-7/8” - 20”

(505 mm - 508 mm)

11/16”

(17 mm)

Cooktop cutout width

Measurements in inches (mm).

Page 13

INSTALLATION

Installation with gas cooktops

Dimension “BT” is thickness of

the backsplash. Provide 1/2”

(13mm)clearance between the

vent cutout and the backsplash.

Any backsplash with a curved

radius where it meets the counter

will require additional clearance.

Thicker backsplashes may be used by

increasing the counter and cabinet

depths.

Set the cooktop into the coutertop

opening so that the back edge of the

cooktop overlaps the leading edge of

the downdraft.

Downdraft cutout width:

30” (762 mm) is 27-1/16” (687 mm)

36” (914 mm) is 33-1/16” (840 mm)

MIN.

1/2”

(13 mm)

Prepare downdraft housing

BT

1-7/8” (48 mm)

Template

2-1/8” (54 mm)

24-11/16” (627 mm)

22-5/16” (567 mm)

19-1/8” (486 mm)

1-1/16”

(27 mm)

Cooktop cutout width

Measurements in inches (mm).

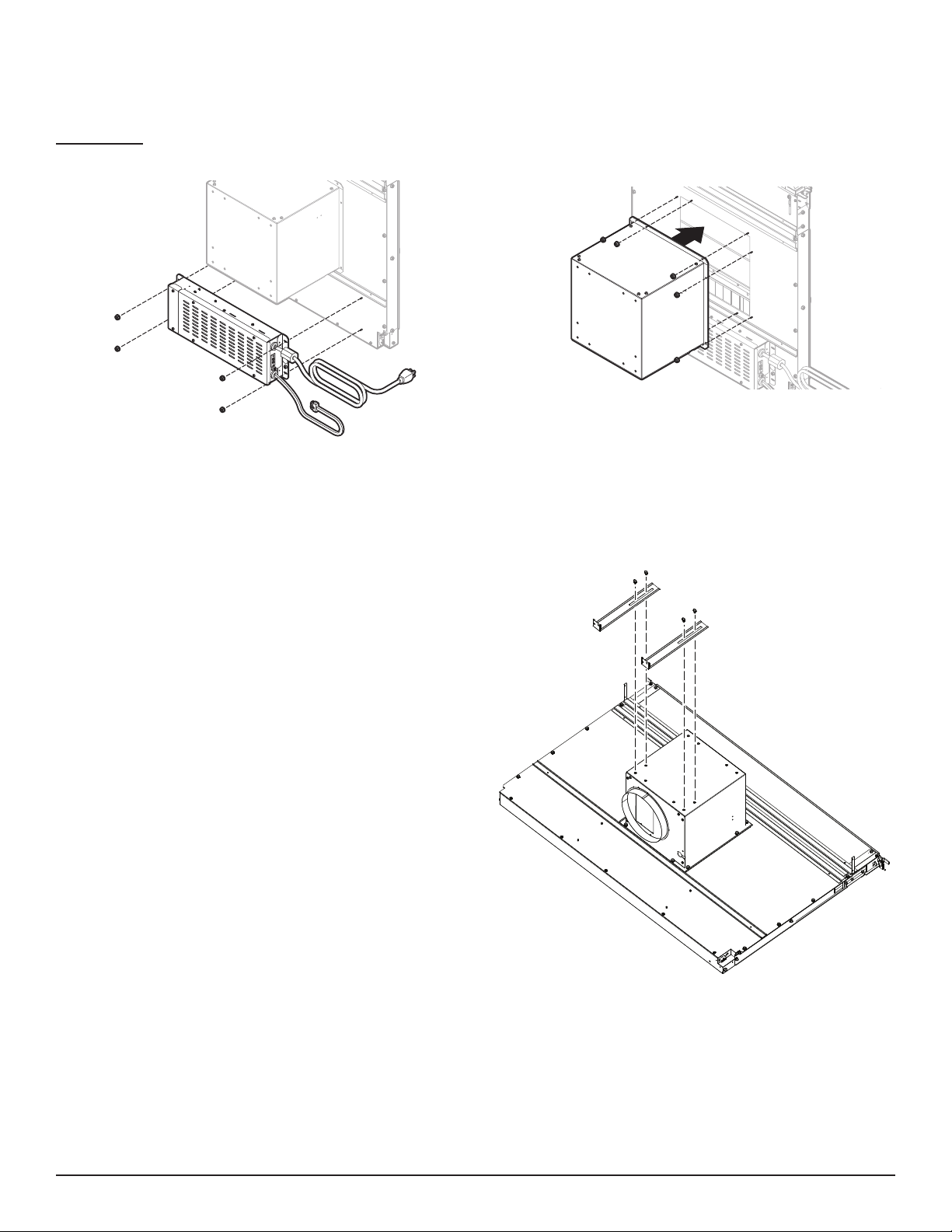

1. Place the downdraft on its back on a table or at work surface.

UPPER

SUPPORT

BRACKETS

DISCHARGE

COVERS

NUTS

(KEEP)

2. Detach the upper support brackets from the downdraft by cutting off

the tie wraps. Remove and set aside both support legs from sides of

the downdraft (one leg per side).

SUPPORT

LEG

NUT

(KEEP)

SCREWS

(DISCARD)

3. Cover the discharge openings that won’t be used for ducting.

Note: Use the nuts previously removed for side discharge covers.

Note: Discard the retaining screws, but KEEP THE NUTS.

Remove the bundle of 3 dischage covers from the bottom of the

downdraft.

Page 14

INSTALLATION

Optional: Electrical panel can be mounted in

a remote location.

No. 8-32

HEX NUTS

Example: There is a drawer at the bottom of the cabinet, in front of the

downdraft. This may require the electrical panel to be mounted in an

adjacent cabinet. If blower discharge is down, electrical panel must be

relocated.

1. Remove (4) no. 8-32 hex nuts and electrical panel. 5-ft. (1.5 m)

extension cables (purchase separately) may be needed to mount

electrical panel in a remote location. Do not use more than 2 extension

cables (EXTNCE5). Do not mount with electrical panel slots facing

downward.

2. Installation of a remotely located electrical panel may be completed

after connecting the ductwork and installing the blower. Install

electrical panel according to local codes.

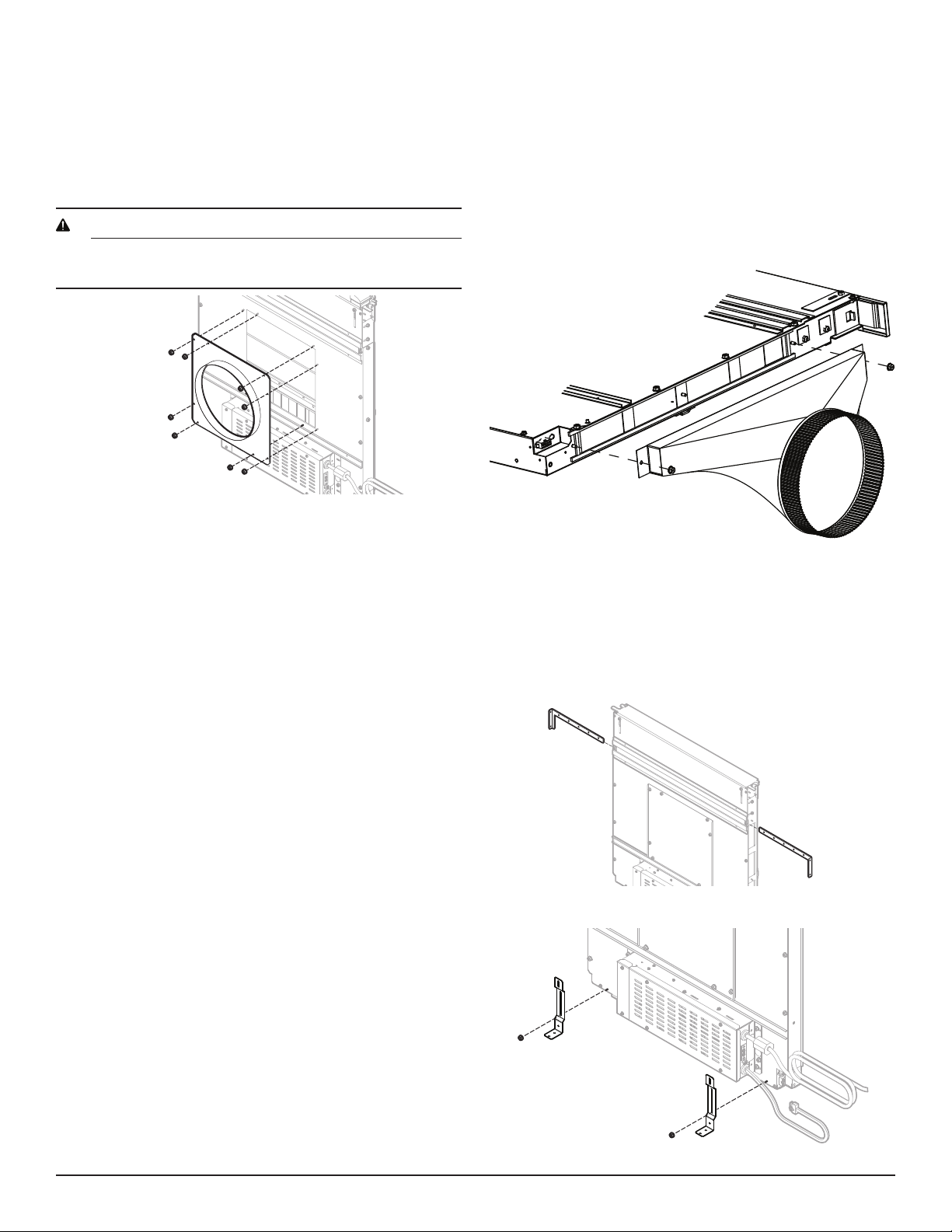

A - Installation using fl exible blower

attached to downdraft

(Purchase Model VTD600P Flexible Blower separately.)

1. Remove hex nuts to remove front panel cover.

2. Determine whether ex blower will discharge to the left, right,

ordown.

3. If blower discharge is down, remove (4) no. 8-32 hex nuts and

electricalpanel.

4. Place blower over studs around front panel opening.

5. Tighten hex nuts to secure blower in place.

(4) BOLTS

BLOWER

SUPPORT LEGS

Based on blower and ducting option selected,

go to the relevent section:

A - Installation using fl exible blower

attached to downdraft

B - Installation using fl exible or remote

blower - mounted in a remote location ducting through front panel opening

C - Installation using inline or remote blower

- mounted in a remote location - ducting

through left, right, below or rear

6. Remove bolts from ex blower housing. Attach blower support legs

to ex blower housing with these (4) bolts. Do not tighten bolts at

this time.

Page 15

INSTALLATION

B - Installation using fl exible or remote

blower - mounted in a remote location ducting through front panel opening

CAUTION

If exible blower is mounted as an inline blower: Do not use legs

alone for support. It may be necessary to add extra support for

the exible blower.

1. Remove hex nuts to remove front panel cover.

2. If blower discharge is down, remove (4) no. 8-32 hex nuts and

electricalpanel.

3. Place 6”, 8”, or 10” (152 mm, 203 mm, or 254 mm) round rough-in

plate (purchase separately) over studs around front panel opening.

4. Tighten hex nuts to secure remote discharge plate in place.

C - Installation using in-line or remote

blower - with ducting through left, right,

below or rear

(Requires purchase of 1-7/8” x 19” (48 mm x 483 mm) to 6”, 8”, or 10”

(152mm, 203 mm, or 254 mm) round transition. 1-7/8” x 19” (48 mm x 483 mm)

rectangular duct and connection adapters are also available.)

DUCTING OUT RIGHT SIDE OF

HOUSING SHOWN.

1. Use nuts to connect 1-7/8” x 19” (48 mm x 483 mm) rectangular ductwork

connection adapter or 1-7/8” x 19” (48 mm x 483 mm) to 6”, 8”, or

10” (152 mm, 203 mm, or 254 mm) round transition to housing when

installing ductwork.

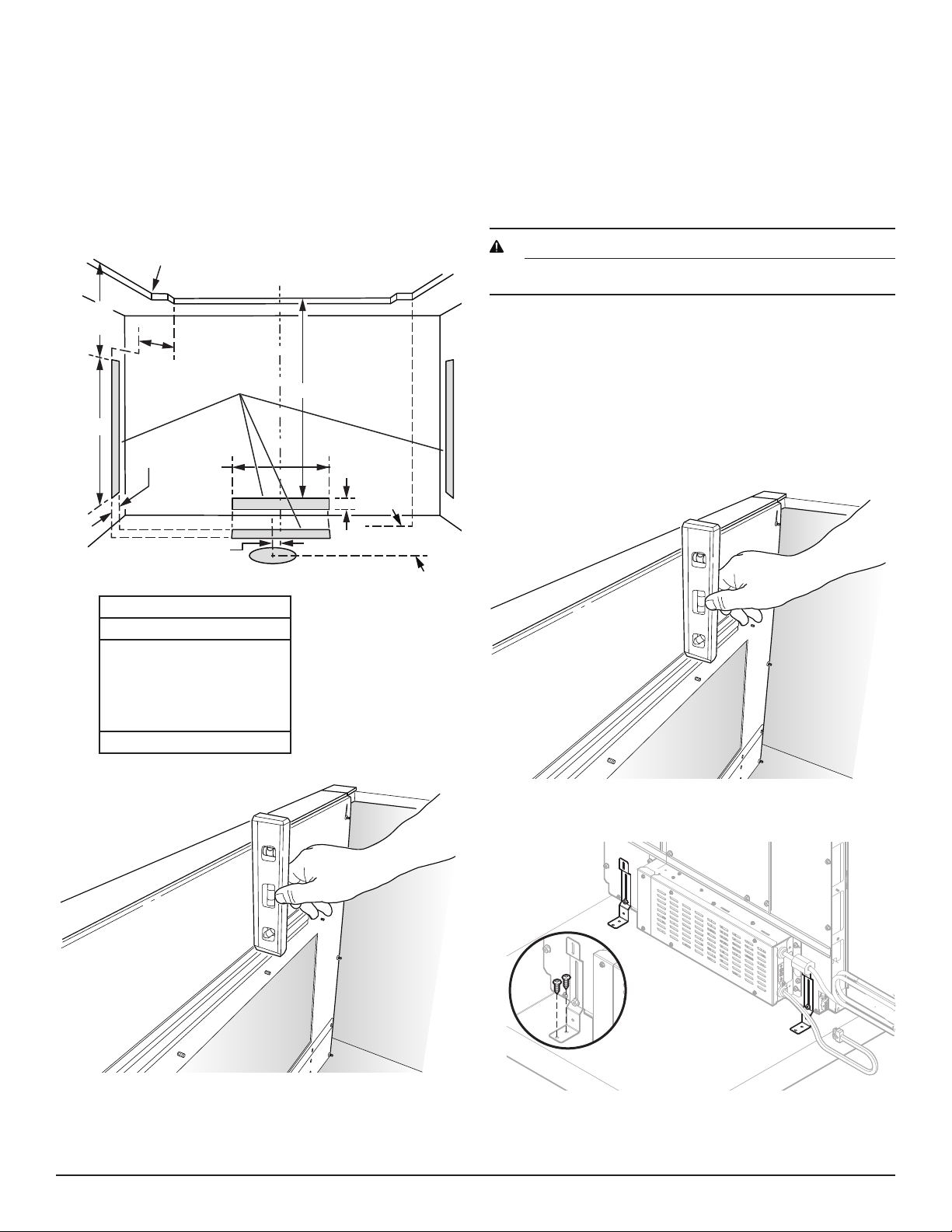

Insert upper support brackets and attach

support legs

1. Slide upper suport brackets into slide channel at top left and right of

unit.

Page 16

2.

Attach previously removed support legs to downdraft using one nut

for each leg. Do not tighten nut completely at this time.

INSTALLATION

Cut out ductwork opening in cabinet

1. Measure and mark where to cut the ductwork opening in the cabinet

based on the ducting option selected. Use the dimensions in the

illustration below to help plan how and where to provide duct access

through your cabinet.

REAR CORNER OF

COOKTOP CUT-OUT

7

/

5 ”

8

(149 mm)

21”

(533 mm)

CABINET FLOOR

1

/

(48 mm x 483 mm)

4 ”

8

(105 mm)

(102 mm)

INSIDE

Hole in Cabinet Floor

Using Flex Blower (Model

VTD600P & 8” (203 mm) round

duct straight down through

(1½"/ 38 mm left of installation

7¾ inches (197 mm)

TRANSITIONS

4”

(533 mm)

centered

Dimension A

cabinet oor.)

center line)

INSTALLATION

CENTER LINE

HOLE FOR

7

1

/

” x 19”

8

DUCT &

21”

1½”

(38 mm)

INSIDE

CABINET BACK

24¾” (629 mm)

4” (102 mm)

Measurements in

inches (mm).

A

3. Check that markings in cabinet line up with ducting coming from

downdraft.

4. Remove downdraft housing from cabinet.

CAUTION

Before cutting hole in cabinet for ductwork, check for interference

with oor joists, wall studs, electrical wiring or plumbing.

5. Cut ductwork hole in cabinet - as well as holes in wall or oor a necessary.

Mounting downdraft with recirculation kit

(UCVRECIRC)

If unit is to be installed using a recirculation kit, please follow the

installation instructions for the recirculation kit (UCVRECIRC) prior to

installing and mounting the downdraft in the cabinet.

Mount downdraft in cabinet

2. Set downdraft into cabinet/countertop opening as far back as possible

and make sure it is level.

1. Set downdraft into cabinet/countertop opening as far back as possible

and make sure it is level.

1

2 No. 10 x 0.500

WOOD SCREW

1

2. Extend support legs and attach to bottom of cabinet with (2) screws

through each leg. Tighten nuts.

If cabinet bottom is removed: Use blocks as spacers between oor and

support legs.

Page 17

INSTALLATION

2 No. 10 x 0.500

WOOD SCREW

3. Extend upper support brackets and attach to sides of cabinet with (2)

screws through each bracket.

Gas cooktops only:

Install gas cooktop seal kit (UCV30ST,

UCV36ST) (purchase separately)

Available for application with gas cooktops - where proper sealing is required

and holes are required in cabinet base. Kit includes trim seal, toe-kick cover

grille, and cabinet hole cover grille.

B

B

C

Installations using exible blower only:

(4)

BOLTS

FLEXIBLE

BLOWER

1

4. Extend blower support legs and secure them to bottom of cabinet with

a screw through each leg. Tighten (4) bolts to secure support legs to

ex blower.

C

B

A

B

B Cut one 18¼” x 2½” (464 mm x 64 mm) OPENING (A)* in the

cabinet toe kick.

-- or - Cut one 18¼” x 2½” (464 mm x 64 mm) OPENING (B) in the

cabinet side or back.

Mount one of the two metal grilles over this opening, using two

screws provided.

C If you chose to cut an opening in the toe kick - you must cut

another 18¼” x 2½” (464 mm x 64 mm) OPENING (C)* in the

cabinet oor.

Mount the second metal grille over this opening.

* IMPORTANT NOTE

When using toe kick opening (A) with opening (C) in cabinet oor:

Air must be able to ow freely between these two openings - and

not restricted by cabinet structure or any other obstruction.

A

B

Page 18

INSTALLATION

E

B

A

D

D Clean housing surface (B) with Isopropyl Alcohol or Rubbing

Alcohol. Remove TAPE STRIPS to reveal adhesive side of tape from

the back side of TRIM BRACKET (A).

E Center trim bracket left-to-right at TOP OF DOWNDRAFT

HOUSING (B). Stick trim bracket to downdraft housing so that

FLANGES (C) and (D) are ush with each other.

F Cut TRIM SEAL (E) to length: No shorter than downdraft countertop

cutout opening and no longer than cooktop width.

G Remove tape backing from TRIM SEAL (E). Center trim seal

left-to-right and stick trim seal across both FLANGES (C) and (D).

E

G

D

C

F

Plan house wiring

WARNING

RISK OF ELECTRIC SHOCK

Parts inside the appliance can have sharp edges. The connection

cable can be damaged. Do not bend or pinch connection cables

during installation.

Before connecting the appliance, check the house wiring to make sure

it has suf cient circuit protection. The voltage and frequency of the

appliance must match the electrical installation (see rating plate).

Only a quali ed electrician who takes the appropriate regulations into

account may lay or replace the connecting cable.

Follow all valid standards and laws.

Ensure that the electrical connection meets the requirements of the

latest version of all applicable standards and laws in the appropriate

country, especially the following standards:

National Electrical Code, ANSI/ NFPA 70, or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and C22.2 No.0-M91, UL 507.

Have a quali ed electrical technician check the grounding of the

appliance.

Do not ground to a gas line.

Keep these installation instructions for future reference.

Ensure that the wire diameter meets the requirements of the latest

version of all applicable standards and laws in the appropriate country,

especially the following standards:

Install roof cap, wall cap, inline or remote

blower

1. Follow instructions included with caps, inline and remote blower.

Connect ductwork

1. From roof cap, wall cap, or remote blower - work back towards the

cabinet, attaching all ductwork, elbows and transitions as previously

planned.

2. Connect ductwork (and transition, if required) to ex blower or downdraft.

If necessary, use (2) no. 8-18 x .375 (9.5 mm) Phillips screws for transition.

Note: Regardless of blower placement/exhaust, ensure that all seams are

properly taped - to make them secure and air-tight. This includes seams/

gaps between panels and/or on the blower.

Install the electrical panel

(if previously removed from downdraft housing)

1. If electrical panel was removed from the downdraft housing in order to

mount it in a remote location: Mount electrical panel in chosen location.

Note: Do not mount electrical panel with slots in cover facing downward.

National Electrical Code, ANSI/NFPA 70, or CSA Standards C22.1-

94, Canadian Electrical Code, Part 1 and C22.2 No.0-M91.

The downdraft with the Flex Blower (purchase separately) draws 3.0 Amps

and requires a 120 VAC, 60 Hz circuit.

The downdraft with Remote Blower (purchase separately) draws 9.0 Amps

(max.) and requires a 120 VAC, 60 Hz circuit.

The downdraft has a 30-in. (762 mm). long power cord with a 3-pronged

plug. Plan to provide a grounded outlet in a location which will allow the

power cord to reach.

Page 19

INSTALLATION

Install electrical wiring

CAUTION: Installation work and electrical wiring must be done

by quali ed person(s) in accordance with all applicable codes,

regulations, and standards, including re-rated construction.

CAUTION: Do not use an extension cord. If the product power

cord is too short, have a quali ed electrician install a three slot

receptacle.

From exterior or

in-line blower

1. Install a standard wiring box, with 3-pronged receptacle, within reach

of the downdraft’s power cord.

2. Remove electrical panel wiring box cover. Secure blower power cable

to electrical panel wiring box with U.L. approved strain relief.

B - Remote blower wiring

CAUTION: Installation work and electrical wiring must be done

by quali ed person(s) in accordance with all applicable codes,

regulations, and standards, including re-rated construction.

3. The following exterior or inline blowers can be used:

VTR630P - 600 cfm (17 m3/min) Remote Blower

VTI610P - 600 cfm (17 m3/min) Inline Blower

120 VAC • 60 Hz • 5.0 A (max.)

4. Install a standard wiring box, with 3-pronged receptacle, within reach

of the downdraft’s power cord.

ELECTRICAL PANEL

GROUND SCREW

WHITE (NEUTRAL)

BLUE (LOW 1, CAP OFF)

M

REMOTE

BLOWER

14/4 ROMEX

OR CONDUIT

GRAY (MED 2)

ORANGE (MED-HIGH 3)

BLACK (HIGH 4)

WIRING

BOX

Based on blower selected, go to the relevent

section:

A - Flex blower wiring

B - Remote blower wiring

A - Flex blower wiring

CAUTION: Installation work and electrical wiring must be done

by quali ed person(s) in accordance with all applicable codes and

standards, including re-rated construction.

ELECTRICAL PANEL

GROUND SCREW

WHITE (NEUTRAL)

BLUE (CAP OFF)

GRAY (MED 2)

ORANGE (MED-HIGH 3)

BLACK (HIGH 4)

WIRING

BOX

M

FLEXIBLE

BLOWER

GREEN

WHITE

BLUE (CAP OFF)

RED

ORANGE

BLACK

Note: Some blowers may come with plugs or connectors, these

should be removed and the 14/4 ROMEX or Conduit wiring should be

connected in an approved junction box. As an alternative, the BSH 25'

Extension Cable Kit (EXTNCB25W) and the Extension Cable Connection

Kit (EXTNSET4) can be used in place of the ROMEX or conduit wiring.

Please follow all required and recommended wiring instructions in this

manual and the extension cable kits.

5. Connect power wires to wires in electrical panel wiring box as shown.

Cap off Low (Speed 1) wire.

6. Replace wiring box cover.

3. Connect exible blower wires to wires in electrical panel wiring box

as shown. Cap off BLUE wire (LOW 1).

4. Replace wiring box cover.

Page 20

Loading...

Loading...