UL LISTED #157J FILE # E521958

INSTALLATION INSTRUCTIONS MANUAL

30" BUILT-IN RANGES WITH COOK'N'VENT

ELECTRIC MODEL RED30V

DUAL-FUEL MODEL RDDS30V

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these instructions for the local electrical inspector’s use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

WARNING: Before installing turn power OFF at the service panel. Lock service panel to prevent

power from being turned ON accidentally.

AVERTISSEMENT: Avant l’installation, COUPER au tableau de service, et fermer a clef le tableau de service

pour empecher l’alimination d’etre allumée per hasard.

■

IMPORTANT:

AND GROUNDING MUST COMPLY WITH ALL APPLICABLE CODES.

Check your local building codes for the proper method of

installation. In the U.S.A., if there are no applicable local codes,

this unit should be installed in accordance with the National Fuel

Gas Code #Z223.1-Current Issue, and the National Electrical

Code ANSI/NFPA No. 70 Current Issue. (In Canada, installation

must be in accordance with the CAN 1-B149.1 and .2 - Installation

Codes for Gas Burning Appliances and/ or local codes).

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

◆ Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

◆ WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

LOCAL CODES VARY. INSTALLATION, ELECTRICAL CONNECTIONS

MOBILE home installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

{formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD (Part 280)} or, when such standard is

not applicable, the Standard for Manufactured Home Installations,

ANSI A255.1 / NFPA501A, or with local codes.

AVERTISSEMENT: Si l'information dans ce

manuel n'est pas suivie exactement, un feu ou

une explosion peut résulter et causer des dégâts

matèriels et des risques d'accidents, ou la mort.

◆ Ne pas emmagasiner ou utiliser de l’essence

ou des autres vapeurs inflammables et liquides

aux endroits de celui-ci ou aucun autre

appareil.

◆ CE QUI FAIRE SI VOUS SENTEZ LE GAZ

• Ne pas essayer d’allumer aucun appareil

• Ne pas toucher aucun interrupteur

électrique; ne pas utiliser aucun téléphone

dans votre bâtiment.

• Appeler immédiatement votre fournisseur

de gaz du téléphone d’un voisin. Suivre

l’instruction du fournisseur de gaz.

• If you cannot reach your gas supplier, call

the fire department.

◆ Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

• Si vous ne pouvez pas contacter votre

fournisseur, téléphoner le service des

incendies.

◆ L’installation et le service doivent être

exécutés par un installateur qualifié, une agence

de service ou le fournisseur de gaz.

1

■

SAFETY WARNINGS

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside. Do not vent exhaust air

into spaces within walls or ceilings or into attics, crawl

spaces, or garages.

WARNING: TO REDUCE THE RISK OR FIRE,

ELECTRIC SHOCK. OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Installation Work And Electrical Wiring Must Be Done

By Qualified Person(s) In Accordance With All

Applicable Codes And Standards, Including Fire-Rated

Construction.

b) Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

ATTENTION: Pour réduire le risquie d'incendie et alfin

que l'air s'échappe bien, s'assurer de diriger l'air vers

l'extérieur – N'evacuez pas l'air vicié dans le vide intérieur

des murs, le vide des plafonds, les greniers, les vides sanitaires

ni le garages.

AVERTISSEMENT: – POUR RÉDUIRE LE RISQUE

D'INCENDIE, DE CHOC ÉLECTRIQUE, OU DE LA

BLESSURE AUX PERSONNES, OBSERVER LES

SUIVANTS:

a) Le Travail d’Installation et de Câblage Éectrique Doit

Être Fait Par les Personne(s) Qualifiées Conformément

à Tous les Codes & Normes Applicables, y Compris la

Construction Calculée à Feu.

b). Il faut suffisamment d'air pour permettre une bonne

combustion et une évacuation appropriée des gaz par

le conduit de fumée (cheminée) des appaeils à

combustible pour éviter le refoulement. Suivre la

directive des fabricants du matériel chauffant et les

normes de sécurité tel que ceux publiées par

l’Association du Protection de Feu National (NFPA),

et la Société Américaine pour les Ingénieurs de

Chauffage, de Réfrigération et de Climatisation

(ASHRAE), et les autorités des codes locales.

d) Ducted fans must always be vented to the outdoor.

WARNING: To Reduce the risk of fire, use only

metal ductwork.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional

information consult a qualified installer, service

agency, manufacturer (dealer) or the gas

supplier.

c) En coupant our en forant dans un mur ou dans un

plafond, ne pas endommager le câblage électrique et

des autres utilités cachées.

d) Les ventilateurs canalisé doivent être toujours

déchargés.

AVERTISSEMENT - Pour réduire le risque

d'incendie, utiliser seulement le travail du

conduit métallique.

AVERTISSEMENT: L'installation inexacte,

l'ajustment, la modification, le service ou

l'entretien peut causer la blessure ou la

propriété endommagée. Se référer â ce

manuel. Pour l'assistance ou l'information

additionnelle consulter un installateur qualifié,

une agence de service, le fabricant (le

marchand) ou le fournisseur de gaz.

2

SAFETY WARNINGS

■

WARNING: This unit is designed as a cooking

appliance. Based on safety consideration, never

use it for warming or heating a room.

WARNING: DO NOT LIFT RANGE BY

DOOR HANDLE. Remove the door before

removing the unit from the pallet to provide

more stability before installation. See 'Do-ItYourself Maintenance: Removing the Oven

Door' in the Care and Use Manual.

AVERTISSEMENT: L'appareil est pour la

cuisson. Basé sur les considérations de sécurité,

ne jamais utiliser le Cooktop pour chauffer une

chambre.

AVERTISSEMENT: NE PAS ÉLEVER LA

CUISINÈRE PAR LA POIGNÉE DE LA PORTE.

Énlever la porte avant d'énlever l'appareil du

plateforme de bois pouvoir plus de stabilité

avant d'installation. Lire ce manuel de Soin y

Utilisation.

TABLE OF CONTENTS ■

Safety Instructions and Applicable Codes...........................................................................................................1,2

Ventilation and Cabinet Considerations ............................................................................................................. 3,4

Gas Connections Model RDDS30VQ ................................................................................................................. 5,6

Electrical Connections ............................................................................................................................................6,7

Installing the Ventilation.......................................................................................................................................... 8-9

Ventilation ............................................................................................................................................................... 9-14

Blower Duct Sizing..............................................................................................................................................15-17

Anti-Tip Bracket Installation............................................................................................................................. 18-19

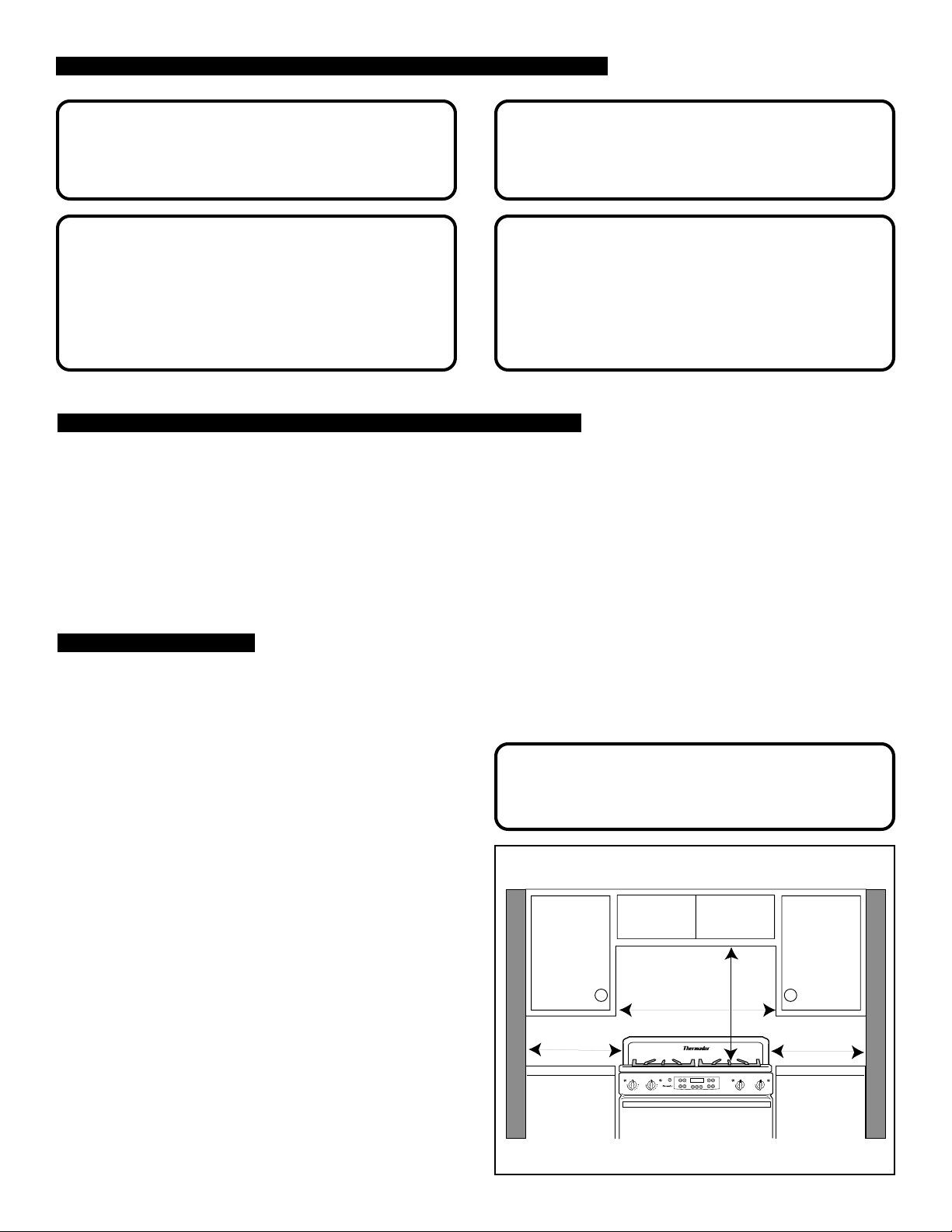

VENTILATION AND CABINET CONSIDERATIONS ■

COOK'N'VENT® VENTILATION SYSTEM

The range is equipped with a retractable rear ventilation

intake and integral plenum. The plenum outlet, located under

the range may be connected to an integral blower or a

remote blower (purchased separately). See Pages 8 – 17.

CABINET

This unit is designed for installation in a countertop near

adjacent walls and projecting surfaces constructed of

combustible materials. There must be a minimum clearance

of 30 inches between the top of the cooking surface and

the bottom of an unprotected wood or metal cabinet; or

24 inches when bottom of wood or metal cabinet is

protected by not less than 1/4" of flame retardant material

covered with not less than No. 28 MSG sheet metal, 0.015

inch stainless steel, or 0.024 inch aluminum or copper. (See

Figure 1). The minimum horizontal distance from the side

and back edge of the unit to adjacent vertical combustible

walls are as follows: Zero clearance is permitted on rear,

right and left walls.

Instructions are based on Standard American cabinets

measuring 36" high x 24" deep.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided.

Figure 1 Installation Guide

30" Min.

30" Minimum

No Clearance

to Wall

Required

Centered

OFF

OFF

XLOHI

No Clearance

to Wall

Required

OFF

LIGHT

TIMER

BAKE

+

CONVECT.

STOP

COOK

CLOCK

XLOHI

CANCEL

CLEAN BROIL

MIN/HR

TIME

OFF

HI

HI

LO

LO

For the cabinets over the cooking surface and the adjacent

cabinets, the maximum cabinet depth from back wall is 13".

3

VENTILATION AND CABINET CONSIDERATIONS

29-1/4"

Counter

Opening

Back Splash

Countertop

5/16 Flat

Min.

Wall

35-1/2" to 37"

High Counter

4" Toe Recess

Extend Across

Opening

30" Min.

Opening

29-15/16" Min

.

23 3/16"

Rear Edge

of Cutout

1-3/4"

Wall

24"

Face of

Cabinet

3/8"

23-3/16"

■

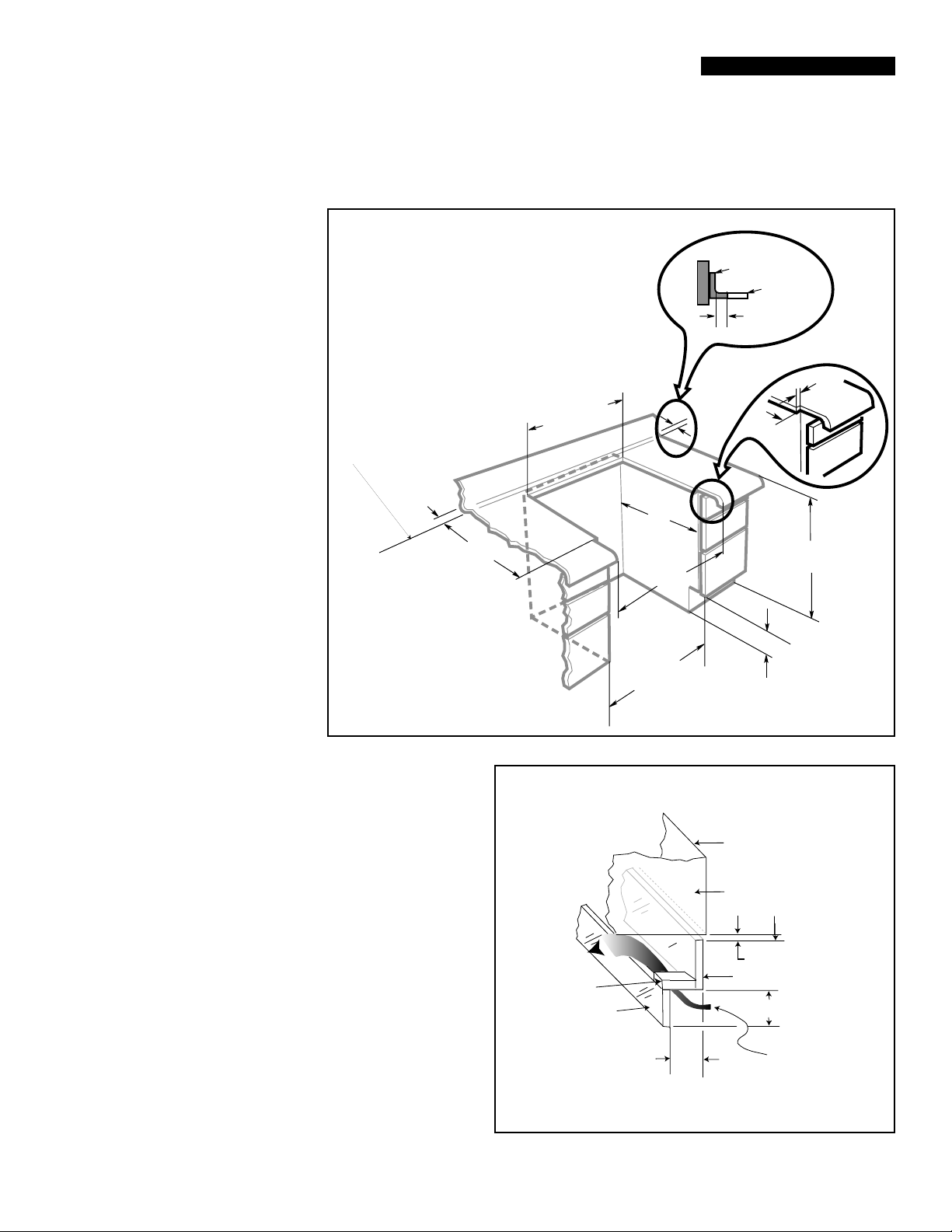

PREPARING CABINET

Use the dimensions in Figure 2 to make the countertop

cutout. The cutout center line must be the same as the

center line of the space between the cabinet side walls.

NOTICE. Some cabinet finishes

cannot survive the temperatures

allowed by U.L., particularly self–

Figure 2 – Preparing the

Cabinet

cleaning ovens; the cabinets may

discolor or stain. This is most

noticeable with laminated cabinets. If

your cabinet company does not

approve a temperature of 180°F., the

range should be installed such that the

oven front frame does NOT line up

BEHIND the plane of the front of the

cabinet doors. The cabinets and

countertop must be flush with the

kitchen wall. The rear edge of the

cutout must be between 1-3/4" and

1-7/8" from the wall. In an island or

peninsula installation, first layout a

notch in the countertop on each side,

so the back of the notches line up

with the front of the cabinet doors

(see Figure 2). Lay out the remaining

dimensions positioned from the back

of these notches. Recommended

locations for gas supply and electrical

outlet are on the floor. To get more

available space, remove the existing

back brace (see Figure 27, Page 18) and use floor mounted

anti-tip bracket (see Figure 30, Page 19).

If nonstandard cabinets are used, care should be taken to

alter dimensions accordingly.

If you don’t have the optional toe kick accessory for your

range, you’ll need to fabricate the toe space cover according

to the specifications shown in Figure 3. This toe space

cover must be mounted so that it may be easily removed

for servicing. There must be 25" minimum dimension

between the top of the countertop and the top of the under

range panel. A minimum of 25 square inches air inlet is

required in the toe kick area. Warranty is not valid without

gap and inlet.

NOTE: Follow all measurements precisely. If working with

nonstandard cabinets, take care to alter the dimensions to

maintain the minimum clearances.

Figure 3 – Toe Space Cover

Range Front

Face Frame

25 in Min.

Air Inlet

Supports

1/2" to 3/4"

Thick Wood

3-1/2"

Side View (Not to Scale)

Side of Range

25" From

Top of

Counter

1/4" Min. Clearance

Front Panel

4" to Desired

ToeKick Height

Air Inlet

Minimum

4

GAS CONNECTION (MODEL RDDS30V)

■

WARNING: Do not attempt any adjustment of the

pressure regulator except conversion to propane.

AVERTISSEMENT: Ne pas entreprener aucun

ajustement du régulateur de la pression excepte la

conversion à propane.

GAS PRESSURE (INCH WATER COLUMN)

GAS SUPPLY MANIFOLD

Natural 6 TO 14 5

Propane 11 to 14 10

Be sure the unit being installed is compatible with

the type of gas available. The range is shipped from the

factory for use with natural gas. Conversion for use with

propane gas can be made by using a kit, NLPKIT 6 P/N 3500-688. Only a qualified technician or installer can convert

the range. This kit includes instructions for adjusting valves

and pressure regulator and contains new burner jets. The

RDDS model is equipped with an intermittent/interrupted

ignition device (ExtraLow

NATURAL GAS

The cooktop is shipped from the factory for use with natural

gas only. The gas supply to the appliance regulator must be

a minimum of 6.0" water column. The maximum gas

pressure to the range regulator shall not exceed 14" W. C.

PROPANE GAS

®

).

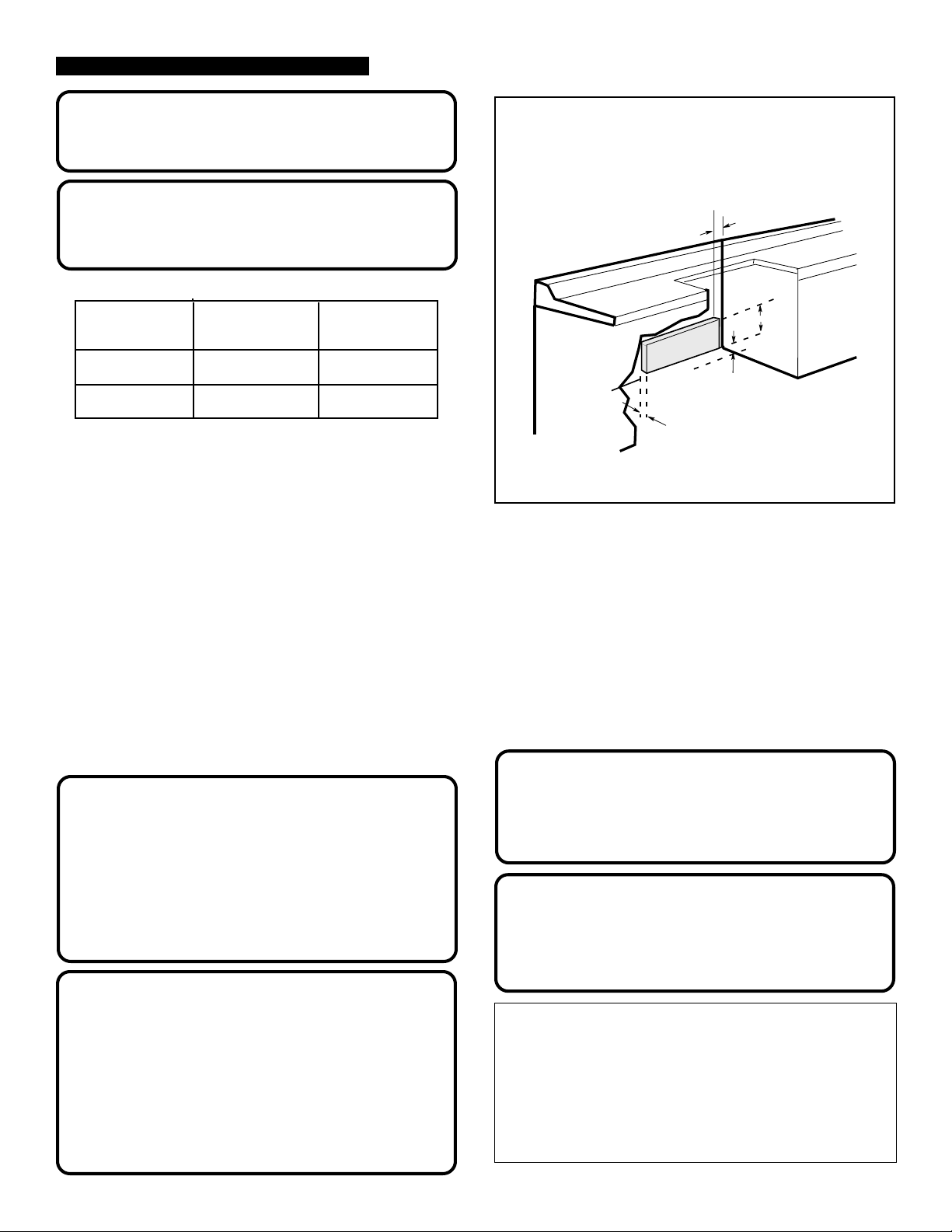

Figure 4 – Gas Supply Location

4-1/8" From

Cabinet Both

Sides

6"

3" From Floor

1-3/4" From Wall

IMPORTANT NOTES

(a) The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 1/2 psig (3.5kPa).

(b) The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig (3.5 kPa).

CAUTION: When connecting unit to propane gas,

make certain the propane gas tank is equipped with

its own high pressure regulator in addition to the

pressure regulator supplied with the appliance. The

gas supply to the appliance regulator must be a

minimum of 11.0" water column. The maximum gas

pressure to the appliance regulator is not to exceed

14.0" water column from the propane gas tank.

ATTENTION: En branchant l'appareil au gaz de

propane, soyez certain que le réservoir de gaz du

propane est équipé avec son régulateur de haute

pression en addition du régulateur de pression fourni

avec cet appareil. La founriture de gaz au régulateur

de l'appareil doit être un minimum de 11.0" colonne

d'eau. La pression de gaz maximale à cet appareil ne

doit pas excéder une colonne d'eau de 14.0 pounces

du régulateur du réservoir de gaz du propane.

Turn on gas and check supply line connections

for leaks using a soap solution. Do not use a

flame of any sort.

Always use pipe dope or Telflon® tape on the

pipe threads and be careful not to apply

excessive pressure when tightening the

fittings.

For Massachusetts Installations:

1. Shut-off valve must be a “T” handle gas cock.

2. Flexible gas connector must not be longer than

36 inches.

3. Not approved for installation in a bedroom or

a bathroom unless unit is direct vent.

5

GAS CONNECTION (MODEL RDDS30V)

■

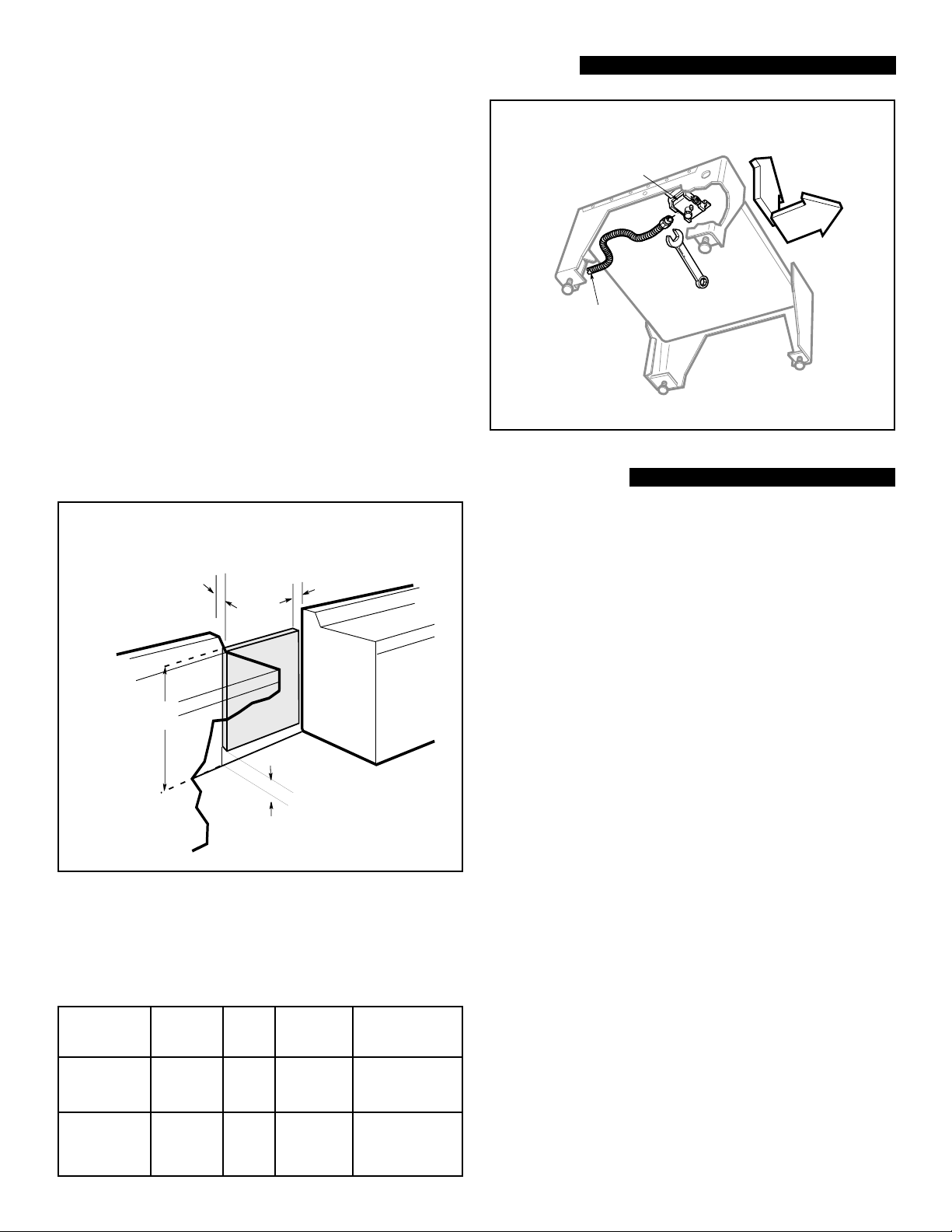

GAS CONNECTION

Figure 5 – Gas Supply Flexible

Connector Routing

For gas units, a 1/2" N.P.T. wall gas supply can lie anywhere

Regulator

within the shaded area. (See Figure 4). Attach a 1/2" N.P.T.

shut-off valve to the wall stub-out. The other end of the

valve should be connected to a 3/8" flexible gas connector (not supplied). The flexible connector shall be secured to

the pressure regulator located in the lower left area of the

range shown in Figure 5.

Flexible

Connector

To Shut Off

Valve

View of Bottum Side From Left Front of Range

■ ELECTRICAL CONNECTION (ALL MODELS)

Figure 6 – Electrical Location

1-3/4"

Max Protrusion

From Wall

4-1/8" From Cabinet

Both Sides

ELECTRICAL SUPPLY

(Electric and Gas models)

• The Range, provided with a 4' length of flex conduit and

conductors, shall be connected to a junction box

specified below.

Up

Front

32" From

Floor

3" From Floor

MODEL VOLTS HZ RATING CIRCUIT

KW REQUIRED

RDDS30V 120/240 60 5.1 30 Amps

120/208 60 4.0 20 Amps

• The electrical supply should be 3 wire, single phase, A.C.

with a grounded neutral.

• For electrical connection, a 4" x 4" junction box should

be placed within the shaded area. (See Figure 6). The

box has to be recessed into the wall. The maximum

protrusion of flex conduit and connector shall not

exceed 1-3/4" as shown in Figure 6.

GROUNDING

The unit is supplied with a flexible metallic conduit.

• If flexible metallic conduit is connected to a grounded

metallic conduit system, oven is grounded through the

metallic conduit.

• If local code permits grounding through the neutral,

connect both bare ground wire and white wire to white

wire neutral supply.

RED30V 120/240 60 12.0 50 Amps

120/208 60 9.8 50 Amps

• If local code requires separate ground, separate white

wire and bare gound wire, connect white to white and

ground bare wire separately.

6

Loading...

Loading...