Thermador PRD364WDGU/C, PRD364WIGU/C, PRD364WLGU/C, PRD366WGU/C, PRD484WCGU/C Installation Instruction

...

THERMADOR.COM

Installation

INSTRUCTIONS

Professional Series Pro Grand® Ranges

Installation

INSTRUCTIONS

Professional Series Pro Grand® Ranges

Table of contents (English) ................................................................ 2

Table de matières (Français)............................................................ 28

Índice de materias (Español) ........................................................... 55

Models |

Modèles |

Modelos:

PRD364WDGU/C

PRD364WIGU/C

PRD364WLGU/C

PRD366WGU/C

PRD484WCGU/C

PRD486WDGU/C

PRD486WIGU/C

PRD486WLGU/C

PRD48WCSGU/C

PRD48WDSGU/C

PRD48WISGU/C

PRD48WLSGU/C

PRD606WCG

PRD606WCSG

PRD606WEG

PRD606WESG

PRG364WDG

PRG364WLG

PRG366WG

PRG486WDG

PRG486WLG

THERMADOR.COM

Table of

Safety

CONTENTS

Safety ......................................................................................3

Important safety instructions........................................... 3

Installation instructions ..........................................................6

Planning information ....................................................... 6

Ventilation requirements ................................................6

Installation clearances...................................................... 7

Gas and electric locations ...............................................12

Unpacking and moving the range .................................. 13

Door removal and adjustment ........................................14

Installing the anti-tip bracket (required) ......................... 16

Gas requirements and connection .................................17

Electrical requirements and connection for

GAS models..................................................................... 18

Electrical requirements and connection for

DUAL FUEL models .........................................................19

Low backguard installation (optional) ............................. 22

DEFINITIONS

9 WARNING

This indicates that death or serious injuries may occur as a

result of non-observance of this warning.

9 CAUTION

This indicates that minor or moderate injuries may occur as a

result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or

property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

Placing and leveling the range........................................ 23

Data rating label.............................................................. 24

Burner test ...................................................................... 24

Installer checklist .................................................................... 27

Final check ....................................................................... 27

Support, accessories, and parts.................................back page

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page. 2

Safety

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Installer: Save these instructions for the local gas

inspector’s use. Please leave these Installation Instructions

with this unit for the owner.

Owner: Please retain these instructions for future

reference. Before using your appliance, be sure to read

this manual.

WARNING

If the information in this manual is

not followed exactly, a fire or

explosion may result causing

property damage, personal injury

or death.

-- DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

-- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING

RANGE TIPPING HAZARD:

• All ranges can tip and injury can result. To

prevent accidental tipping of the range,

attach it to the floor by installing the anti-tip

bracket supplied.

• A risk of tip-over may exist if the appliance

is not installed in accordance with these

instructions. For all ranges an anti-tip device

MUST be installed.

• A child or adult can tip the range and be killed.

• DO NOT operate the range without the anti-tip

device in place and engaged. Failure to do so can

result in death or serious burns to children or adults.

• If the range is pulled away from

the wall for cleaning, service or

for any other reason, ensure that

the anti-tip device is properly reengaged when the range is

pushed back against the wall. In

the event of abnormal usage

(such as a person standing,

sitting, or leaning on an open

door), failure to take this

precaution can result in tipping of

the range. Personal injury might result from spilled hot

liquids or from the range itself.

Local codes vary. Installer is responsible for ensuring that

the installation, gas connections, and grounding comply

with all applicable codes. Failure to follow appropriate

local codes and regulations may void the warranty.

WARNING

Page. 3

ELECTRICAL SHOCK HAZARD

• Disconnect power before installing or

servicing. Before turning power ON, be sure

that all controls are in the OFF position.

• DO NOT remove connections.

• DO NOT use an extension cord.

• Improper grounding can result in a risk of

electric shock.

• Failure to follow these instructions can result

in death, fire, or electrical shock.

The installation of appliances designed for manufactured

(mobile) home installation must conform with the

Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280 [formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD {Part

280}] or with local codes where applicable.

The installation of appliances designed for Recreational

Park Trailers must conform with state or other codes or, in

the absence of such codes, with the Standard for

Recreational Park Trailers, ANSI A119.5.

Examine the appliance after unpacking it. In the event of

transport damage, do not plug it in.

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Remove all tape and packaging before using the

appliance. Dispose of packaging in an environmentallyresponsible manner. Never allow children to play with

packaging material.

This appliance must be grounded. Grounding reduces the

risk of electric shock by providing a safe pathway for

electric current in the event of a short circuit.

Show the owner the location of the circuit breaker or fuse.

Mark it for easy reference.

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

NFPA 70 latest edition, or the Canadian Electric Code,

CSA C22.1-02.

DO NOT install this appliance outdoors.

For Massachusetts installations:

• Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified or

licensed by the state, province or region where this

appliance is being installed.

• Shut-off valve must be a “T” handle gas cock.

• Flexible gas connector must not be longer than 36''

(914 mm).

Verify the type of gas supplied to the location. Ensure that

the appliance is connected to the type of gas for which it

is certified.

This appliance is capable of being safely placed in

operation in the event of a power failure. Only the

standard top burners can be manually lit.

Always keep appliance area clear from combustible

materials, gasoline and other flammable vapors and

liquids.

Natural gas — 7 inch water column. (17.4 mb) min., 14

inch (34.9 mb) maximum

Propane gas — 11 inch water column. (27.4 mb) min., 14

inch (34.9 mb) maximum

This appliance is shipped from the manufacturer for use

with natural gas. For use with propane (LP) gas, a

conversion kit must be purchased separately. An

authorized servicer must do the LP conversion. See the

back cover for information about service, parts, and

accessories.

CAUTION

When connecting the unit to propane gas, make certain

the propane gas tank is equipped with its own highpressure regulator in addition to the pressure regulator

supplied with the appliance. The maximum gas pressure

to this appliance must not exceed 14.0'' water column

(34.9 mb) from the propane gas tank to the pressure

regulator.

This appliance complies with one or more of the

following Standards:

• UL 858, The Standard for the Safety of Household

Electric Ranges

• ANSI Z21.1, The American National Standard for

Household Cooking Gas Appliances

• CAN1-1.1-M81, Domestic Gas Ranges

• CSA C22.2 No. 61, Household Cooking Ranges

Check local building codes for the proper method of

appliance installation. Local codes vary; it is the

responsibility of the installer to ensure installation is in

accordance with these codes. Installation, electrical

connections, and grounding must comply with all

applicable codes.

In the absence of local codes the appliance should be

installed in accordance with the National Electric Code

NFPA 70 current issue and National Gas Code NFPA 54/

ANSI Z223.1 – current issue. In Canada, installation must

be in accordance with the Canadian Electric Code, CSA

C22.1-02 and the CAN 1-B149.1 and .2 – Installation

Codes for Gas Burning Appliances and/or local codes.

Proposition 65 Warning

This product may contain a chemical known to the State of

California, which can cause cancer or reproductive harm.

Therefore, the packaging of your product may bear the

following label as required by California:

State of California Proposition 65 Warning:

: WARNING

Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Page. 4

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Rear clearance requirements

• To avoid staining on the back wall, high temperature,

non-porous construction materials suitable for use in a

cooking environment are recommended.

• Models PCG305xx, PRG305xx, PRG304xx, PRD305xx,

PRD304, and PRD606xx are suitable for 0'' rear

clearance to combustible surfaces.

• All other models:

• When using the included island trim a minimum 6"

(152 mm)* rear clearance is required to a

combustible surface*.

• When installing against a combustible surface, a

Thermador

rear clearance to the combustible surface. A

Thermador low backguard must be purchased

separately.

• A rear clearance to a surface covered in a non-

combustible material (metal, ceramic tile, brick,

marble, or stone)

island trim.

*Clearances of less than 6'' (152 mm) should be approved by the

local codes and/or by the local authority having jurisdiction.

Clearances from non-combustible materials are not part of the

ANSI Z21.1 scope and are not certified by CSA.

®

low backguard is required for a 0''

*

is 0" when using the included

WARNING

To avoid possible burn or fire hazard, a backguard

designed specifically for this appliance should be installed

whenever the appliance is used.

WARNING

To eliminate risk of burns or fire caused by reaching over

heated surface units, cabinet storage located above the

surface units should be avoided.

CAUTION

This unit is designed as a cooking appliance. Based on

safety considerations, never use it for warming or heating

a room. Doing so may result in carbon monoxide

poisoning and overheating the appliance.

WARNING

Never Operate the Top Surface Cooking Section of this

Appliance Unattended

• Failure to follow this warning statement could result

in fire, explosion, or burn hazard that could cause

property damage, personal injury, or death.

• If a fire should occur, keep away from the appliance

and immediately call your fire department. DO NOT

ATTEMPT TO EXTINGUISH AN OIL/GREASE FIRE

WITH WATER.

Page. 5

Installation instructions

Planning information

9 CAUTION

To prevent possible damage to cabinets and cabinet

finishes, use only materials and finishes that will not

discolor or divide into layers. Materials should be able

to withstand temperatures up to 194 °F (90 °C). Heat

and moisture resistant adhesive must be used if the

product is to be installed in laminated cabinetry.

Check with the manufacturer to ensure materials meet

these requirements.

Before using your appliance, be sure to read this manual.

Pay special attention to the “Important safety

instructions” located at the beginning of the manual.

Tools needed

• 7/16'' box end wrench or ratchet

• 3/16'' (4.76 mm) drill bit

• Hand or electric drill

• 1/8'' (3.17 mm) drill bit

• 12'' Adjustable wrench

• T-20 screwdriver

• T-30 screwdriver

• Tape measure

• Furniture dolly or air sled

• Phillips screwdriver

• Level

• Marking instrument

• Protective gloves

• Safety glasses

Items not included

• Drywall / Concrete Anchors

•Rope/Twine

• 2 – NPT Flare Adapters

• Pipe Compound / Tape

• ¾'' (19 mm) Flex Line

Ventilation requirements

9 WARNING

This appliance should not be installed with a

ventilation system that directs air in a downward

direction toward the range. This type of ventilation

system may cause ignition and combustion problems

with the appliance resulting in personal injury,

property damage, or unintended operation.

Ventilating systems that direct the air upwards do not

have any restriction.

Refer to the “Ventilation planning guide” for approved

ventilation combinations.

It is strongly recommended that this appliance be installed

in conjunction with a Thermador

high heat capability of this unit, particular attention should

be paid to the hood and duct work installation to assure it

meets local building codes.

Downdraft ventilation should not be used. The

“Ventilation planning guide” indicates the ventilation

hood options and blower capacity guidelines that are

recommended for use.

Due to the high heat of the rangetop burners, installing a

microwave oven with a ventilation system over the

rangetop is not recommended.

Ventilation hoods and blowers are designed for use with

single wall ducting. However, some local building codes or

inspectors may require double wall ducting. Consult local

building codes and/or local agencies before starting to

assure that hood and duct installation will meet local

requirements.

NOTICE: Most range hoods contain combustible

components which must be considered when planning the

installation.

®

vent hood. Due to the

IMPORTANT: There is a possibility to discolor the back

wall under certain cooking conditions.

Page. 6

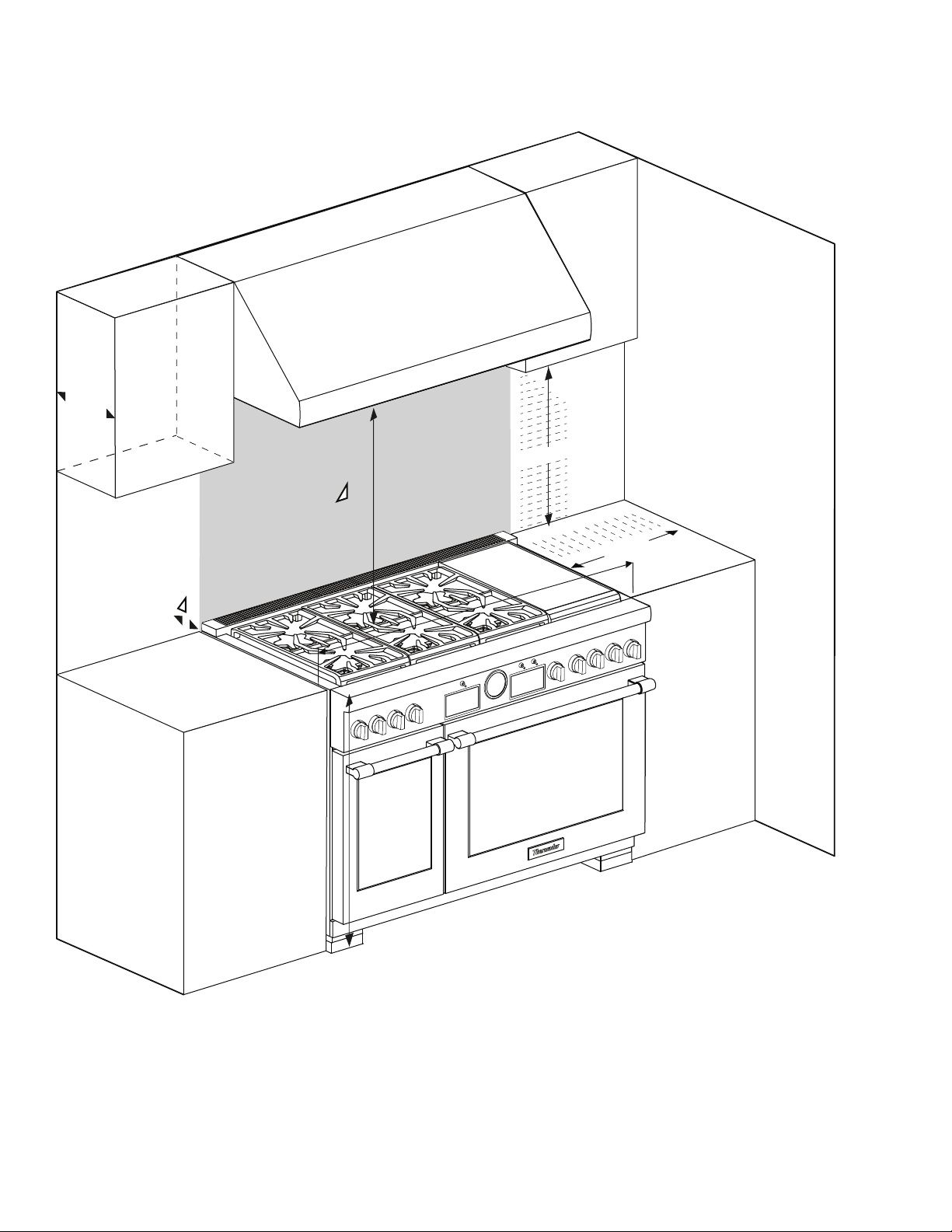

Ventilation preparation

To prepare for the ventilation

1. Select hood and blower models:

• For wall installations, the hood width must, at a

minimum, equal the width of the range/rangetop.

Where space permits, a hood larger in width than

the range/rangetop may be desirable for

improved ventilation performance.

• For island installations, the hood width should

overhang the width of the range/rangetop by a

minimum of 3'' (76 mm) on each side.

2. Hood placement:

• For best smoke elimination, the lower edge of the

hood should be installed 30'' (762 mm) above the

range cooking surface.

• If the hood contains any combustible materials

(i.e. a wood covering), it must be installed a

minimum of 36'' (914 mm) above the cooking

surface.

3. Consider make-up air:

• Due to the high volume of ventilation air, a source

of outside replacement air is recommended. This

is particularly important for tightly sealed and

insulated homes.

• A qualified heating and ventilating contractor

should be consulted.

Installation clearances

Cabinet requirements

The appliance is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown in this

section are required. The same clearances apply to island

installations, except for the overhead cabinets, which must

have a space wide enough to accept the island hood.

• See the “Ventilation planning guide” for

recommended hood options. Due to the high heat of

the burners, installing a microwave oven with a

ventilation system over the appliance is not

recommended on any model other than the 30'' 5–

burner. Refer to OTR manufacturer’s installation

manual for clearances.

• The gas and electrical supply should be within the

zones shown in the “Gas and electric locations”

section.

• The shaded area behind the appliance indicates an

opportunity to discolor the back wall under certain

cooking conditions.

• There must be a minimum of 5'' (127 mm) side

clearance from the appliance to combustible vertical

surfaces above the 36'' (914 mm) counter height.

• Within the 5'' (127 mm) side clearance to combustible

vertical surfaces above 36'' (91.4 cm), the maximum

wall cabinet depth must be 13” (330 mm).

• Wall cabinets within this 5'' (127 mm) side clearance

must be 18'' (457 mm) above the 36'' (914 mm) high

countertop.

• The maximum depth of the cabinets hanging on either

side of the hood is 13'' (330 mm).

• There is a 36'' (914 mm) minimum clearance required

between the top of the cooking surface and the

bottom of an unprotected cabinet. A 30'' (762 mm)

clearance can be used when the bottom of the wood

or metal cabinet is protected by not less than 1/4''

(6 mm) of a flame retardant material covered with not

less than No. 28 MSG sheet steel, 0.015'' (0.38 mm)

thick stainless steel, 0.024'' (0.61 mm) aluminum, or

0.02'' (0.51 mm) thick copper.

• DO NOT obstruct the flow of combustion and

ventilation air to the appliance.

• The appliance height is adjustable. The level of the

range top must be at the same level or above the

counter top level.

• To provide proper ventilation of the range DO NOT

remove range feet.

• Any openings in the wall behind the appliance and in

the floor under the appliance must be sealed.

Rear clearance requirements

• To avoid staining on the back wall, high temperature,

non-porous construction materials suitable for use in a

cooking environment are recommended.

• Model PCG305xx, PRG305xx, PRG304xx, PRD305xx,

PRD304, and PRD606xx are suitable for 0'' rear

clearance to combustible surfaces.

• All other models:

• When using the included island trim a minimum 6"

(152 mm)* rear clearance is required to a

combustible surface*.

• When installing against a combustible surface, a

Thermador

rear clearance to the combustible surface. A

Thermador low backguard must be purchased

separately.

• A rear clearance to a surface covered in a non-

combustible material (metal, ceramic tile, brick,

marble, or stone)

Island Trim.

*Clearances of less than 6'' (152 mm) should be approved by the

local codes and/or by the local authority having jurisdiction.

Clearances from non-combustible materials are not part of the

ANSI Z21.1 scope and are not certified by CSA.

®

low backguard is required for a 0''

*

is 0" when using the included

Page. 7

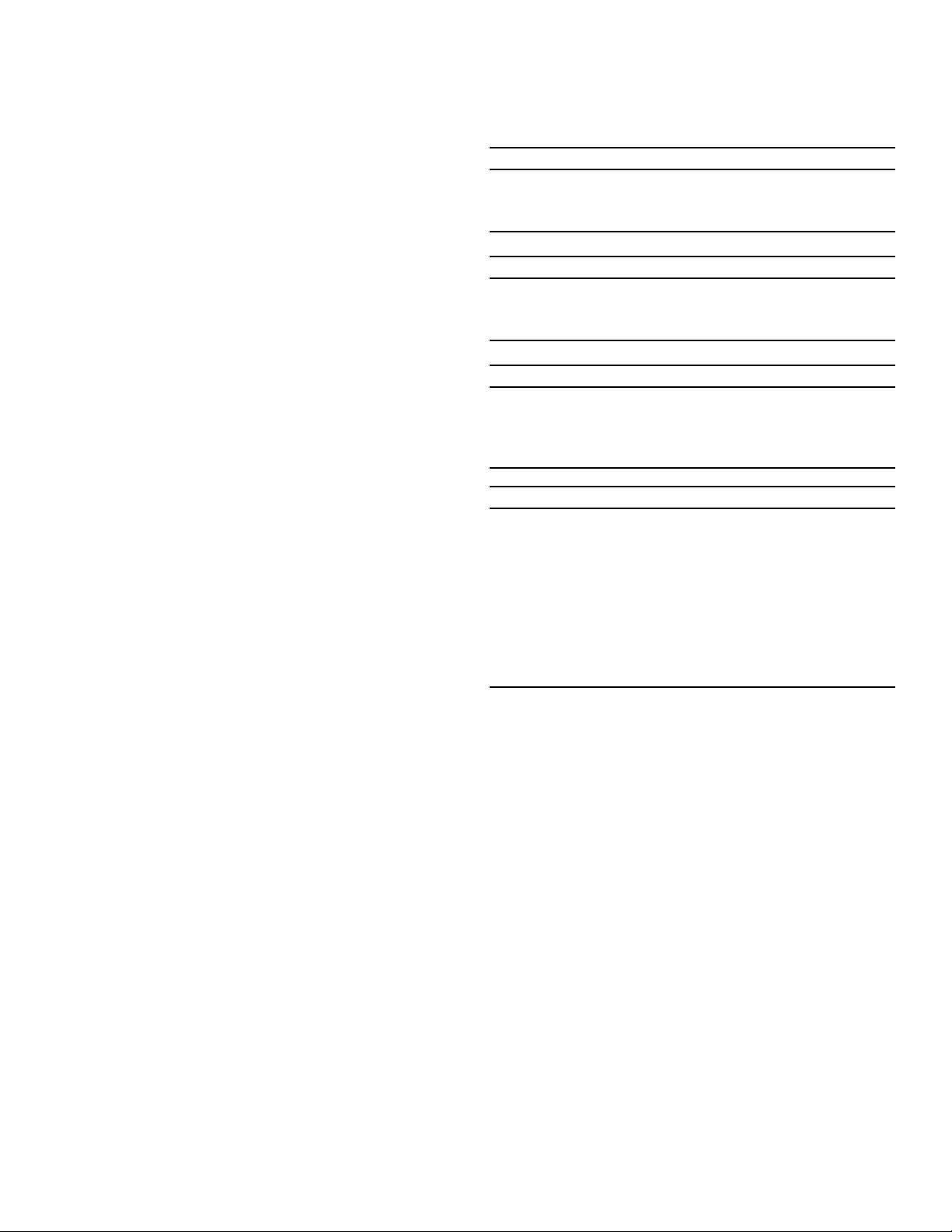

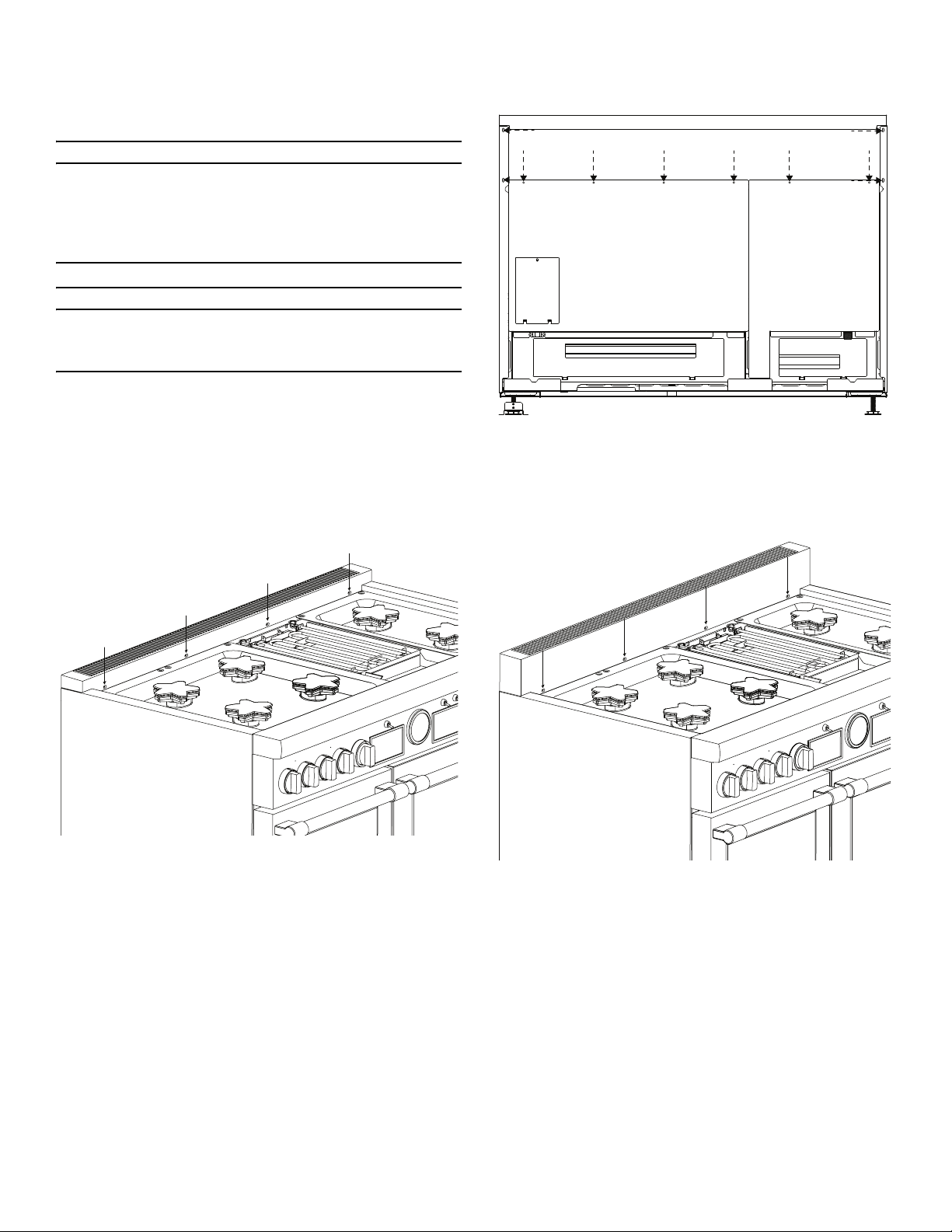

Cabinet clearance requirements with the

5

" (12

7

)

1

8

"

(457)

1

8

"

(

457)

1

8

"

(457)

30" (762) –

36" (914)

30" (762) –

36" (914)

30" (762) –

36" (914)

36" or 48"

(914 or 1219 )

36" or 48"

(914 or 1219 )

36" or 48"

(914 or 1219 )

13"

(330)

13"

(330)

13"

(330)

6" (152)6" (152)6" (152)

35 ⅞" (911) –

36 ¾" (933)

35 ⅞" (911) –

36 ¾" (933)

35 ⅞" (911) –

36 ¾" (933)

inches (mm)

included island trim

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition). Clearances from non-combustible materials are not part of the ANSI

Z21.1 scope and are not certified by CSA. Clearances of less than 6'' (152 mm) should be approved by the local codes and/or by the local authority

having jurisdiction.

Page. 8

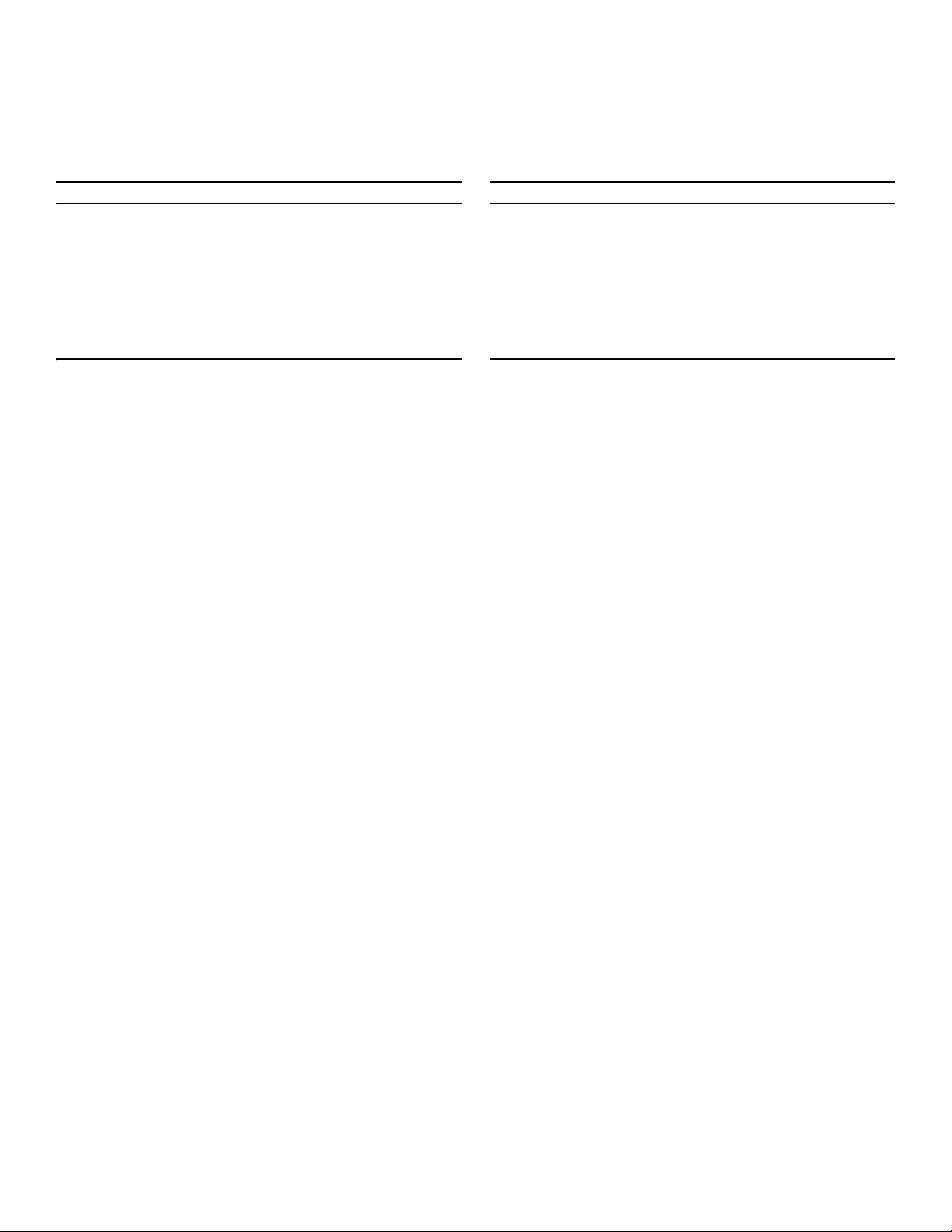

Cabinet clearance requirements with a

1

8"

(

457)

1

8"

(

457

)

1

8"

(

457)

36" or 48"

(914 or 1219 )

36" or 48"

(914 or 1219 )

36" or 48"

(914 or 1219 )

0"0"

5

" (12

7

)

30" (762) –

36" (914)

30" (762) –

36" (914)

30" (762) –

36" (914)

13"

(330)

13"

(330)

13"

(330)

35 ⅞" (911) –

36 ¾" (933)

35 ⅞" (911) –

36 ¾" (933)

35 ⅞" (911) –

36 ¾" (933)

inches (mm)

low backguard (purchased separately)

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition). Clearances from non-combustible materials are not part of the ANSI

Z21.1 scope and are not certified by CSA. Clearances of less than 6'' (152 mm) should be approved by the local codes and/or by the local authority

having jurisdiction.

Page. 9

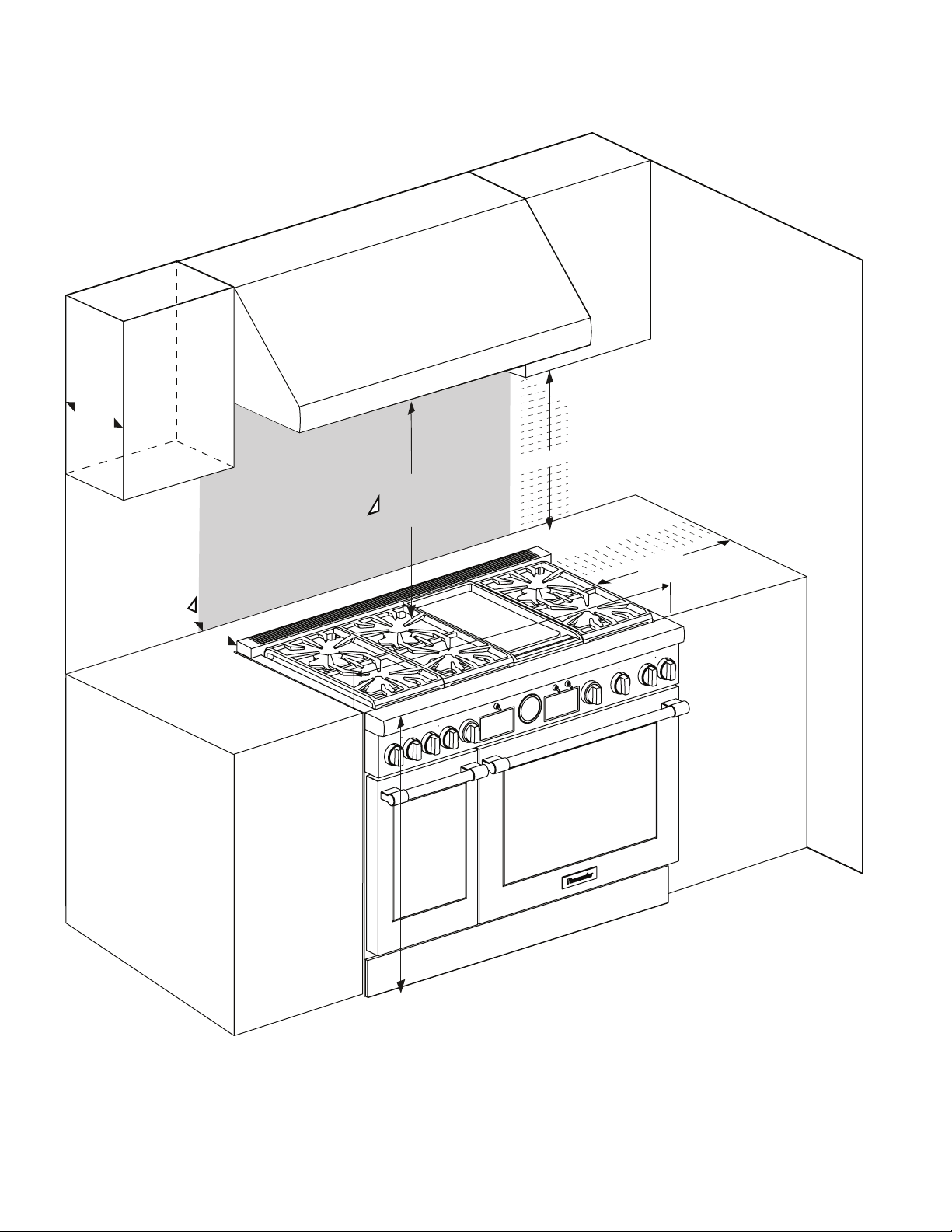

Cabinet clearance requirements for the

60" (1524) 60" (1524) 60" (1524)

1

8

"

(457)

1

8

"

(

457)

1

8

"

(457)

0"0"

5

" (12

7

)

30" (762) –

36" (914)

30" (762) –

36" (914)

30" (762) –

36" (914)

13"

(330)

13"

(330)

13"

(330)

35 ⅞" (911) –

36

¾" (933)

35

⅞" (911) –

36

¾" (933)

35

⅞" (911) –

36

¾" (933)

inches (mm)

60'' range with the included island trim

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition). Clearances from non-combustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less than 6'' (152 mm) must be approved by the local codes and/or by the local authority having

jurisdiction.

Page. 10

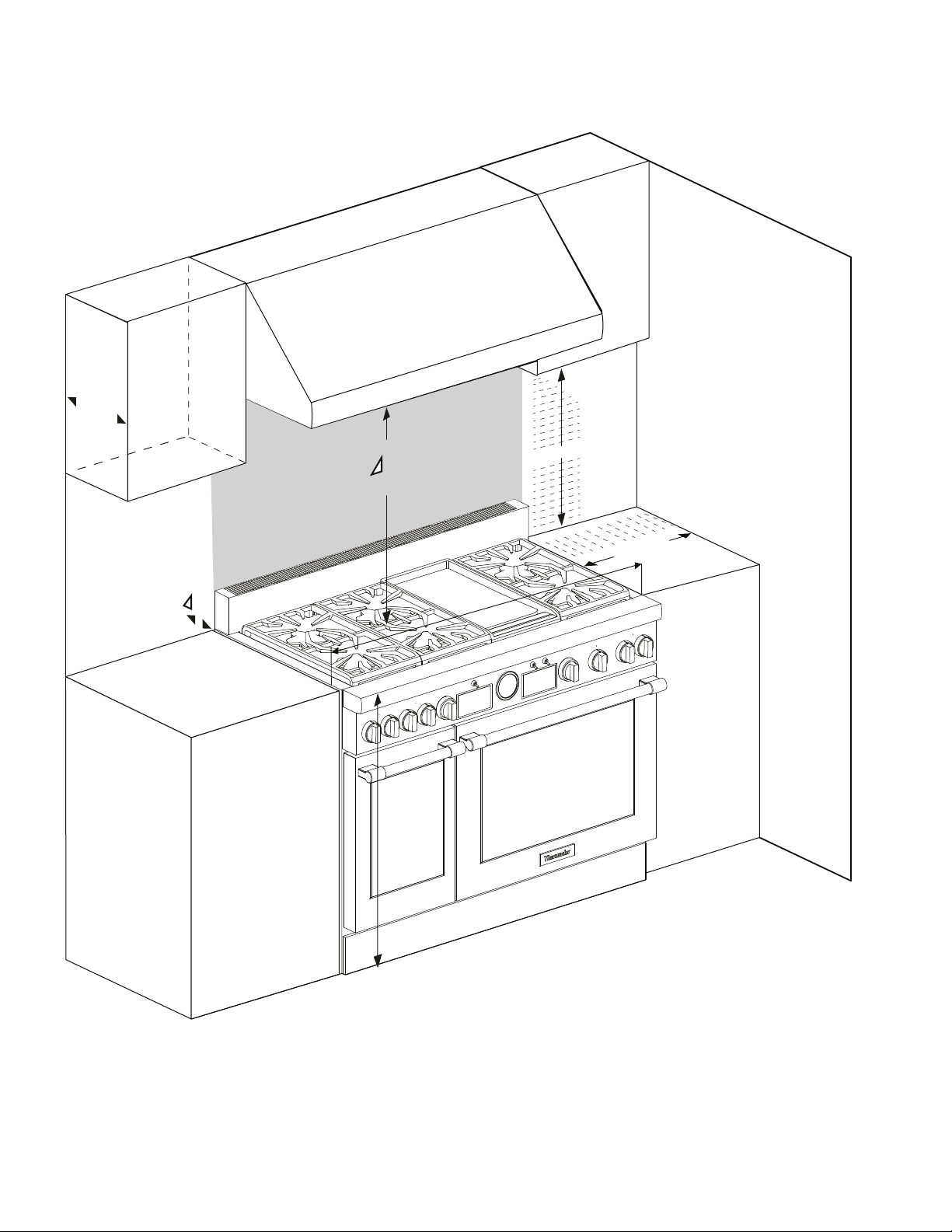

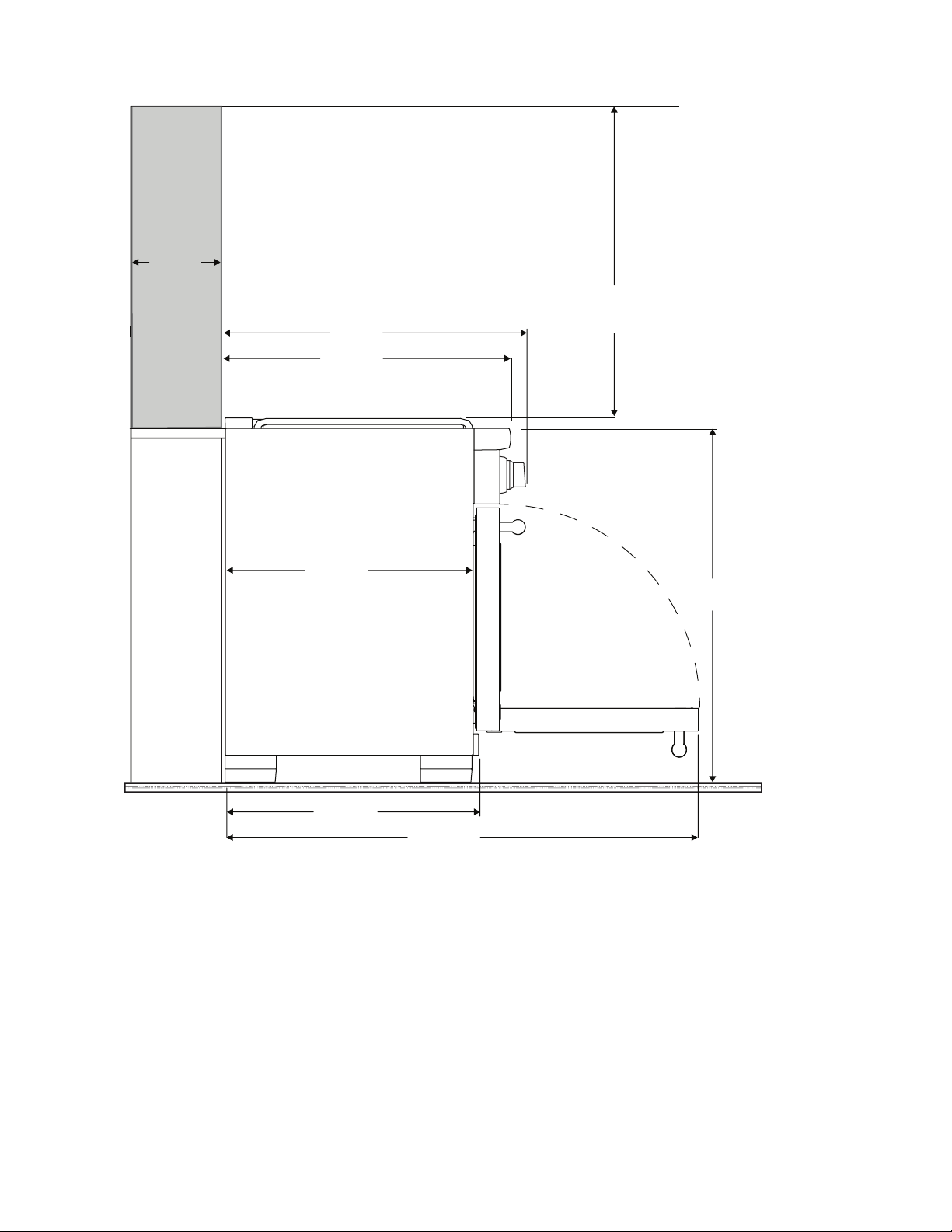

Side clearances

inches (mm)

28" (711)

27¼" (692)

30" (762) –

36" (914)

25⅛" (638)

35⅞" (911) –

36¾" (933)

26⅞" (683)

48¾" (1238)

6" (152) 6" (152) 6" (152)

• The model shown is with the included island trim. A

low backguard option is available (purchased

separately).

• For an island trim install, counter surface should have

a cantilever edge meeting the back section of the

island trim.

• If an inner wall is used under the cantilever counter

top there should be a 1/8'' (3 mm) gap from the rear

of the range.

• There is a 48-3/4'' (1,238 mm) total clearance.

• Shaded area behind range indicates minimum

clearance to combustible surfaces. Combustible

materials cannot be located within this area with the

island trim.

• There is a 25-1/8'' (638 mm) maximum recess depth.

Page. 11

Gas and electric locations

9"

(229)9"(229)9"(229)

36", 48", 60"

(914, 1219, 1524)

36", 48", 60"

(914, 1219, 1524)

36", 48", 60"

(914, 1219, 1524)

2"

(51)

2"

(51)2"(51)

8"

(203)

8"

(203)8"(203)

8"

(203)

8"

(203)8"(203)

CC

LL

CC

LL

6"

(152)

6"

(152)

6"

(152)

6"

(152)6"(152)6"(152)

Electric zoneElectric zoneElectric zone

Gas zoneGas zoneGas zone

inches (mm)

Gas and electrical requirements

• IMPORTANT: If not already present, install gas shut-

off valve in an easily accessible location. Make sure all

users know where and how to shut off the gas supply

to the range.

• A metal flex line or fixed metal pipe shall be used to

connect gas to the appliance. If a metal gas line

cannot be used, consult your local certified electrician

or local electric codes for proper grounding.

• Any opening in the wall behind the appliance and any

opening in the floor under the appliance must be

sealed.

• The range must be connected only to the type of gas

for which it is certified. If the range is to be connected

to propane gas, ensure that the propane gas supply

tank is equipped with its own high pressure regulator

in addition to the pressure regulator supplied with the

range.

• The gas and electrical supplies must be within the

zones as indicated in the image below.

• A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the

front, for the purpose of shutting off the gas supply.

The supply line must not interfere with the back of the

unit.

• The range is supplied with its own pressure regulator

that has been permanently mounted within the range

body.

• For nearly-flush installation to the back wall, the gas

supply line and electrical cord should not go above 9''

(229 mm) above the floor.

• When the power supply cord or conduit is connected

to the mating receptacle or terminal block cover, the

combined plug/receptacle or terminal block cover/

conduit connector should protrude no more than 2''

(51 mm) from the rear wall.

Page. 12

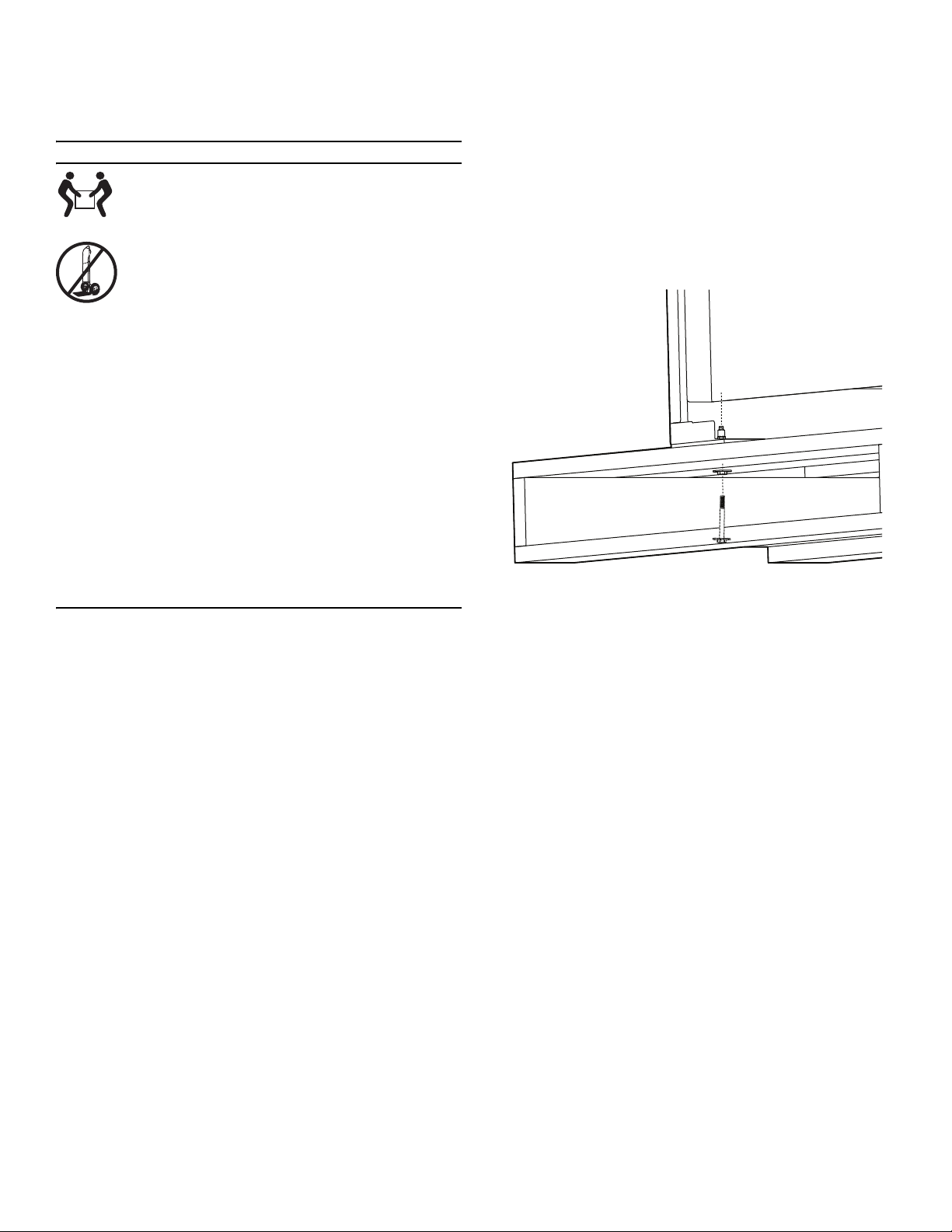

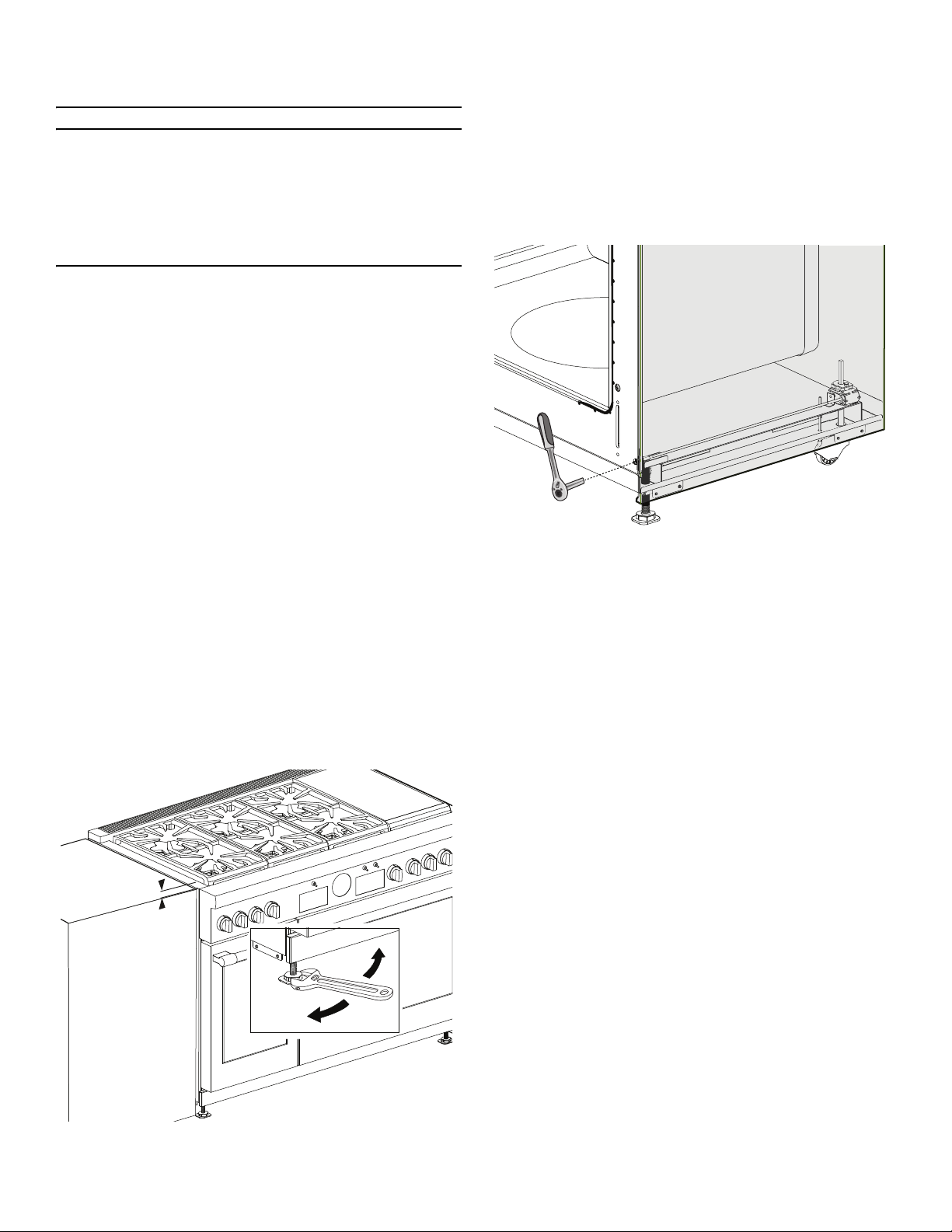

Unpacking and moving the

Moving the range

range

9 CAUTION

DO NOT lift the range by the oven door’s

handle, as this may damage the door hinges

and cause the door to fit incorrectly.

DO NOT lift the appliance by the range’s

control panel.

The unit is heavy and should be handled

accordingly. Proper safety equipment such as

gloves and adequate manpower of at least two

people must be used in moving the range to

avoid injury and to avoid damage to the unit or

the floor.

Rings, watches, and any other loose items that

may damage the unit or otherwise might

become entangled with the unit should be

removed.

Hidden surfaces may have sharp edges. Use

caution when reaching behind or under

appliance.

Due to the weight, a furniture dolly with soft wheels or an

air lift should be used to move this unit. The weight must

be supported uniformly across the bottom.

To remove the pallet bolts

1. To remove the pallet bolts in the front and in the back,

use a 7/16'' wrench or ratchet and socket to remove

the pallet bolt from the bottom of the pallet.

DO NOT use a hand truck or appliance dolly on

the back or front of the unit. Handle from the

side only.

Unpacking the range

NOTES:

• DO NOT remove control panel foam until unit is

completely installed.

• DO NOT lift on the control panel at any point during

the installation.

To unpack the appliance

1. Remove the outer carton and packing materials from

the shipping pallet.

2. Leave the protective film over brushed-metal surfaces,

to protect finish from scratches, until the range is

installed in its final position.

3. Remove the grates, burner caps and oven racks to

facilitate handling.

4. If desired, the oven doors may be removed (see “Door

removal and adjustment”).

2. Lift range and remove it from the pallet. Use

additional help as required to remove from pallet.

3. Transport the range by furniture dolly close to its final

location. Unit should not be dollied from the front. DO

NOT slide the range across an unprotected floor.

4. The range can then be tipped back and supported on

the rear legs while the dolly is carefully removed. THE

FLOOR UNDER THE LEGS SHOULD BE PROTECTED

BEFORE PUSHING THE UNIT INTO POSITION.

Page. 13

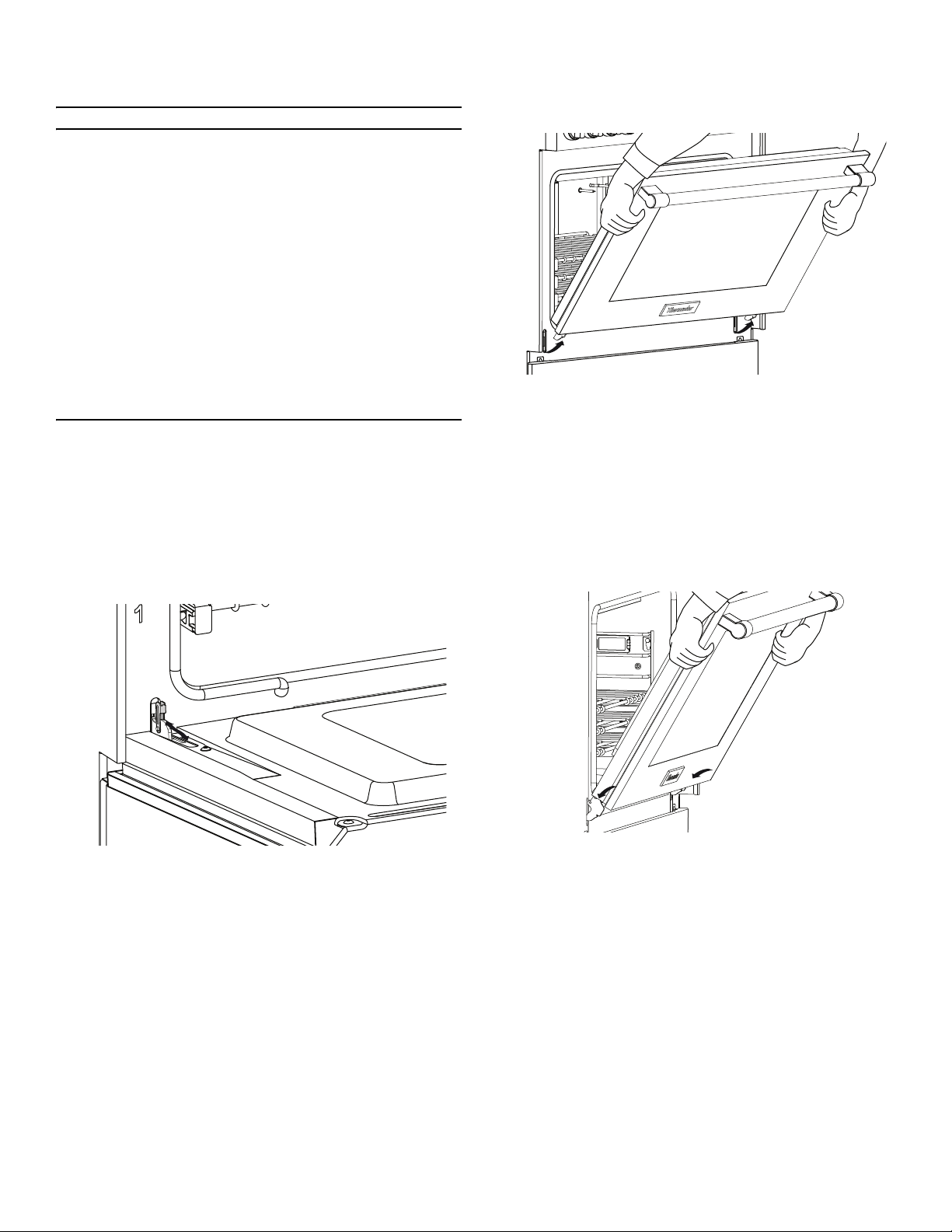

Door removal and adjustment

9 CAUTION

• USE CAUTION WHEN REMOVING THE DOOR.

THE DOOR IS VERY HEAVY.

• Make sure oven is cool and power to the oven has

been turned off before removing the door. Failure

to do so could result in electrical shock or burns.

• The oven door is heavy and fragile. Use both

hands to remove or replace the door.

• Failure to grasp the oven door firmly and properly

could result in personal injury and product

damage.

• With the door off, never release the levers and try

to close the hinges. Without the weight of the

door, the powerful springs will snap the hinges

closed with great force.

5. Grasp the door firmly on the ends of the door. Lift the

door up and out. There will be some spring resistance

to overcome.

6. Place the door in a safe and stable location.

To remove the oven door

1. Be sure to read the above CAUTION before

attempting to remove the door.

2. Open the door fully.

3. Flip the hinge clips for both sides of the door. A

screwdriver may be required to carefully pry the clip.

4. Close the door gently until it stops against the hinge

clips. The open hinge clips will hold the door open at

a slight angle, about 30°, from the closed position.

To reinstall the oven door

1. Hold the door firmly in both hands.

2. Hold the door at a 30° angle from the closed position.

Insert hinges centered evenly into the hinge slots. The

hinges will securely hook into the slots when properly

installed. DO NOT force, bend or twist the door.

3. Open door fully to expose hinges, levers, and slots.

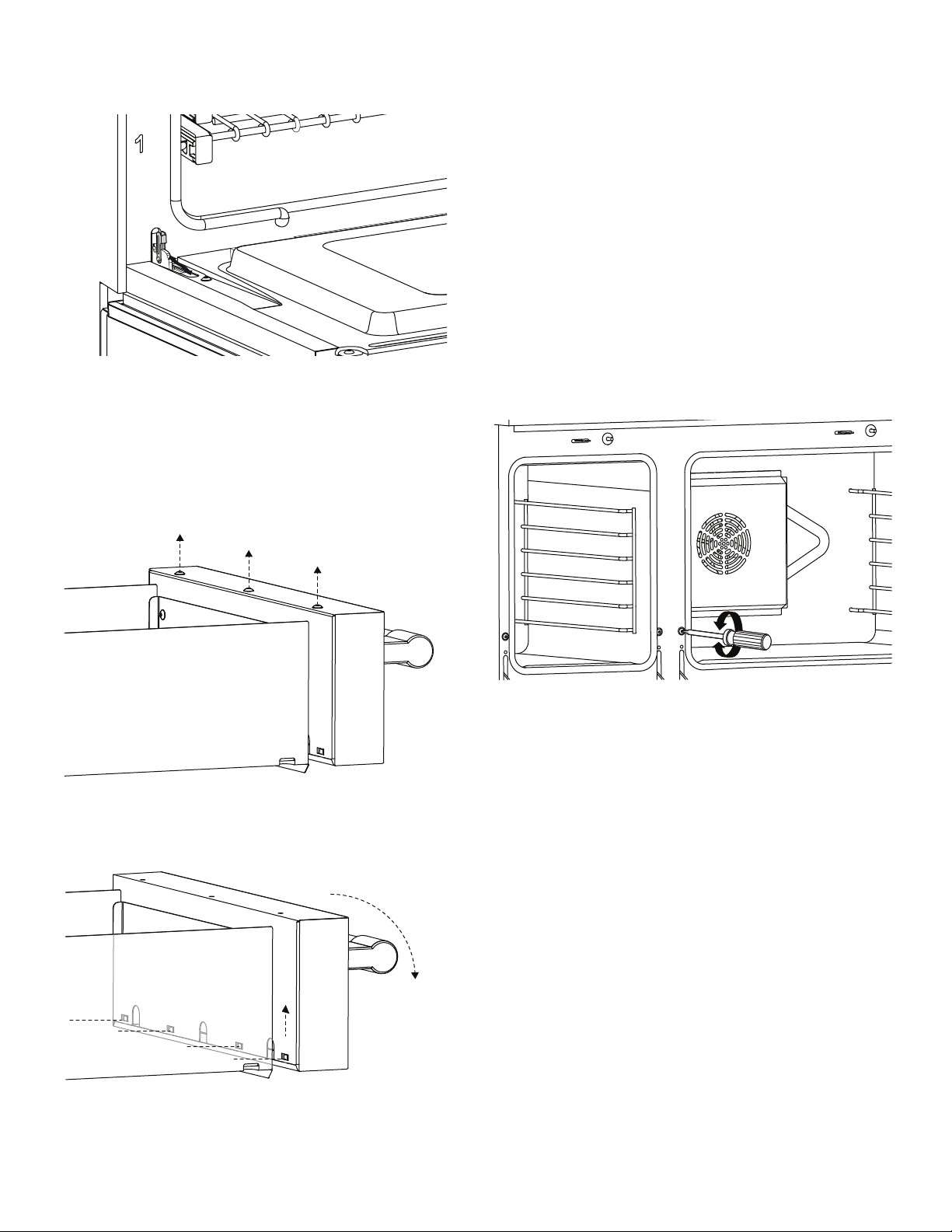

Page. 14

4. Flip the hinge until seated on the bracket. A

2

1

screwdriver may be required to carefully push the clip.

5. Close and open the door slowly to ensure it is

correctly and securely in place.

To remove the warming drawer

1. On the top of the warming drawer door, remove the

three (3) T-20 Torx screws.

To check door fit and adjustment

1. Open and close the door slowly to test the movement

and the fit of the door to the oven cavity. DO NOT

force the door to open or close. If the door is properly

installed, it should move smoothly and rest straight on

the front of the range when closed.

2. The range must be level for proper alignment of the

oven doors, see “Placing and leveling the range”.

3. Verify that the hinges are properly seated into the

hinge slots, and that the hinge clips are fully engaged

into the slots.

If door or handle appears slightly tilted

4. Rotate the large Torx head screw located directly

above the hinge receiver with a T-30 Torx driver.

Rotate each screw respective to its side and direction

the door needs to be adjusted.

2. Rotate the warming drawer door out and then pull

down to disengage from the retainer tabs.

NOTE: The steam oven door is not adjustable.

Page. 15

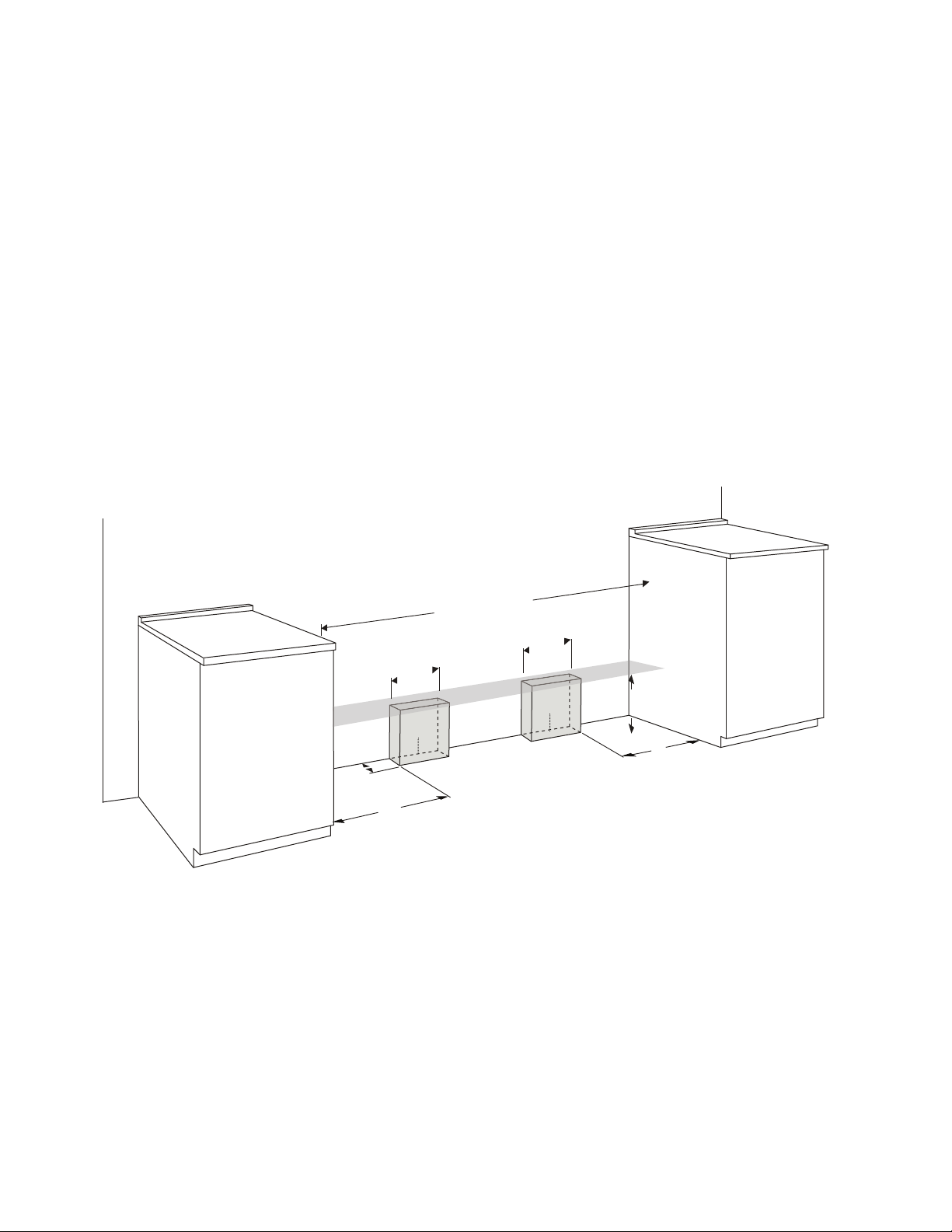

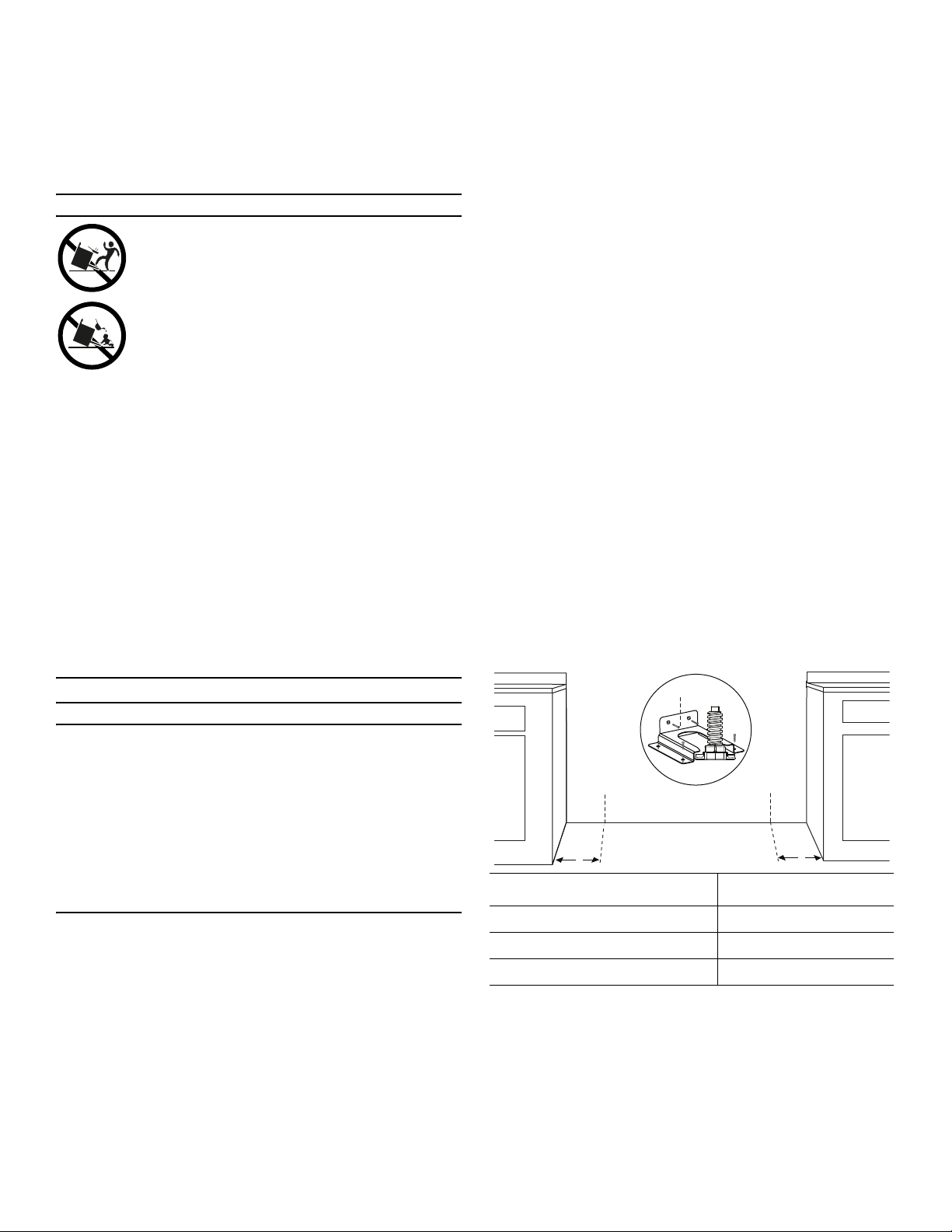

Installing the anti-tip bracket

C

L

C

L

xx

xx

C

L

(required)

For all ranges, an anti-tip device must be installed as per

these instructions.

9 WARNING

RANGE TIPPING HAZARD:

• All ranges can tip and injury can result. To

prevent accidental tipping of the range,

attach it to the floor by installing the anti-tip

bracket supplied.

• A risk of tip-over may exist if the appliance

is not installed in accordance with these

instructions. For all ranges an anti-tip device

MUST be installed.

• A child or adult can tip the range and be killed.

• DO NOT operate the range without the anti-tip

device in place and engaged. Failure to do so can

result in death or serious burns to children or

adults.

• If the range is pulled away from the wall for

cleaning, service or for any other reason, ensure

that the anti-tip device is properly re-engaged

when the range is pushed back against the wall. In

the event of abnormal usage (such as a person

standing, sitting, or leaning on an open door),

failure to take this precaution can result in tipping

of the range. Personal injury might result from

spilled hot liquids or from the range itself.

• Contact a qualified installer or contractor to

determine the proper method for drilling holes

through the wall or floor material (such as ceramic tile,

hardwood, etc.)

• The bracket may be attached to a solid wood surface

having a minimum wall thickness of ¾'' (19 mm).

• The thickness of the wall or floor may require use of

longer screws, available at your local hardware store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood surface.

• Use appropriate anchors when fastening the mounting

bracket to any material other than hard-wood or

metal.

• If the range is moved to a new location, the anti-tip

device must be removed and reinstalled.

Anti-tip bracket installation

Installing the anti-tip bracket for 36'' and 48'' models

1. Locate the anti-tip bracket in the literature packet,

inside the box that was on top of the appliance.

2. Place bracket on the floor in a position shown below.

The bracket may be placed on either the left or the

right side.

3. For walls, wall studs, or floors composed of solid

wood or metal, drill 1/8'' (3 mm) pilot holes.

4. Secure to floor and/or wall stud using the (4) 1 ½''

(38 mm) Phillips head screws provided.

9 WARNING

ELECTRICAL SHOCK HAZARD:

• Use extreme caution when drilling holes into the

wall or floor as there may be concealed electrical

wires.

• Identify the electrical circuits that could be

affected by the installation of the anti-tip bracket,

then turn off power to these circuits.

• Failure to follow these instructions may result in

electrical shock or other personal injury.

IMPORTANT:

• Hardware provided is for mounting through standard

thickness wood studs. Installers are responsible to

provide hardware for other types of mounting

situations.

Model Value for 'X'

36'' 3-7/8'' (98 mm)

48'' steam models only 1-5/8'' (41 mm)

48'' all other models 1-3/4'' (44 mm)

Later, when the unit is installed, the adjustable leg will

slide under the bracket.

Page. 16

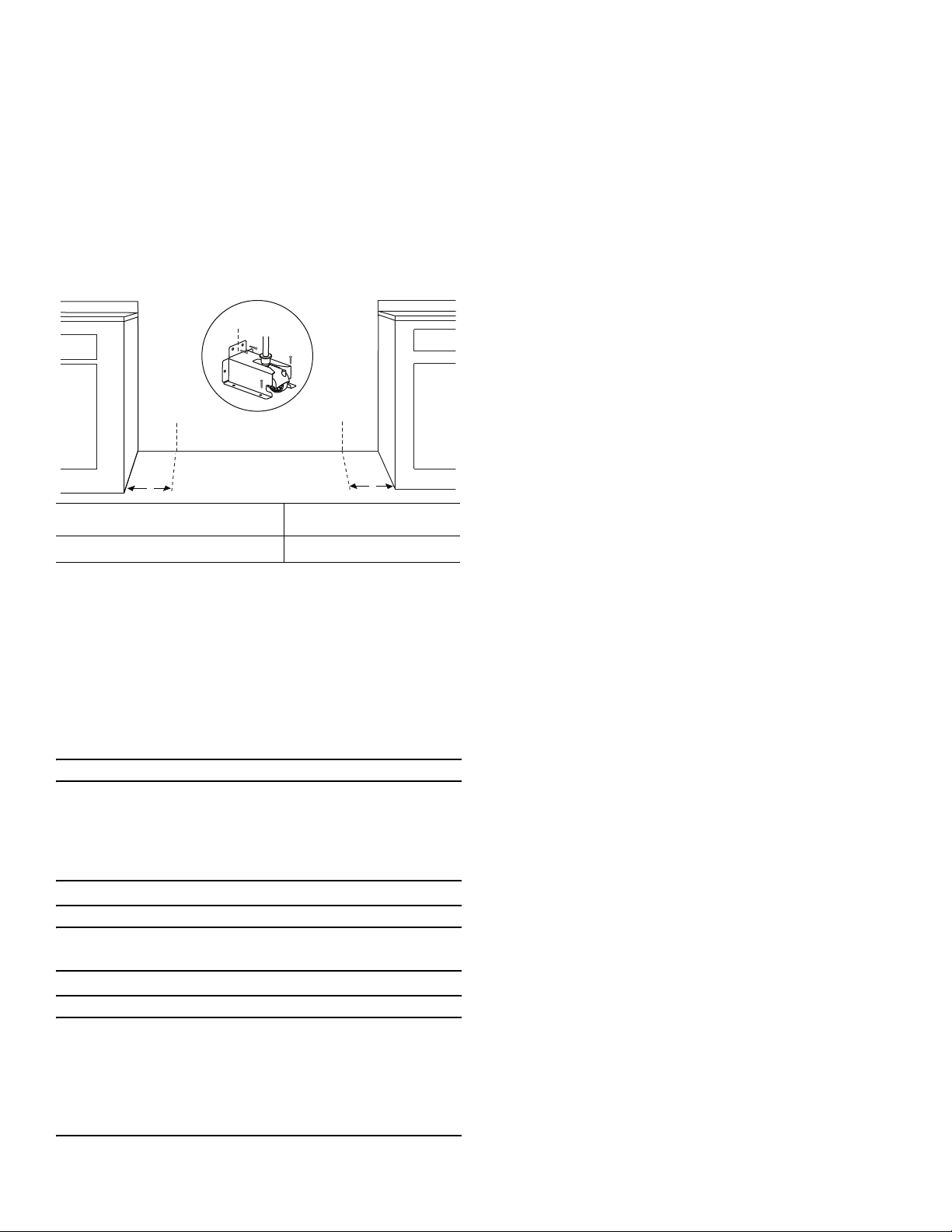

Installing the anti-tip bracket for 60'' models

C

L

C

L

xx

xx

C

L

1. Locate the anti-tip bracket in the literature packet,

inside the box that was on top of the appliance.

2. Place bracket on the floor in a position shown below.

The bracket may be placed on either the left or the

right side.

3. For walls, wall studs, or floors composed of solid

wood or metal, drill 1/8'' (3 mm) pilot holes.

4. Secure to floor and/or wall stud using the (4) 1 ½''

(38 mm) Phillips head screws provided.

Model Value for 'X'

Verify the type of gas being used at the installation site.

Make certain the range matches the type of gas available

at this location.

The gas supply connections shall be made by a competent

technician and in accordance with local codes or

ordinances. In the absence of local codes, the installation

must conform to the National Fuel Gas Code ANSI

Z223.1/NFPA54- current issue.

High altitude

This appliance has been tested for operation up to an

altitude of 10,100 ft (3,078 m) elevation above sea level.

A high altitude kit is required for natural gas above 5,400

feet (1,646 m) elevation above sea level, and for propane

(LP) above 10,000 feet (3048 m) elevation above sea level.

If desired, for altitudes above 2,000 feet (610 m) elevation

above sea level, adjustments can be made to the

rangetop burners with an adjustment kit. If flame

performance is satisfactory, adjustment will not be

required. It is required that a Certified Professional make

the high altitude adjustments during installation.

60'' 2'' (51 mm)

Later, when the unit is installed, the caster will slide under

the bracket. If the range is moved to a new location, the

anti-tip device must be removed and reinstalled.

Gas requirements and

connection

9 CAUTION

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/

2 psig (3.5kPa.).

9 WARNING

DO NOT use a flame of any kind to check for gas

leaks.

See the back cover for information about service, parts,

and accessories.

Gas requirements

Natural gas requirements:

• Inlet Connection: 1/2'' NPT internal (Minimum 3/4''

dia. flex line)

• Supply Pressure: 7'' min. to 14'' max. water column

(17.4 to 34.9 mb)

• Manifold Pressure: 5'' water column (12.5 mb)

Propane gas requirements:

• Inlet Connection: 1/2'' NPT internal (Minimum 3/4''

dia. flex line)

• Supply Pressure: 11'' min. to 14'' max. water column

(27.4 mb to 34.9 mb)

• Manifold Pressure: 10'' water column (24.9 mb)

9 CAUTION

When connecting unit to propane gas, make certain

the propane gas tank is equipped with its own high

pressure regulator in addition to the pressure

regulator supplied with the appliance. The pressure of

the gas supplied to the appliance regulator must not

exceed 14" water column (34.9 mb).

Page. 17

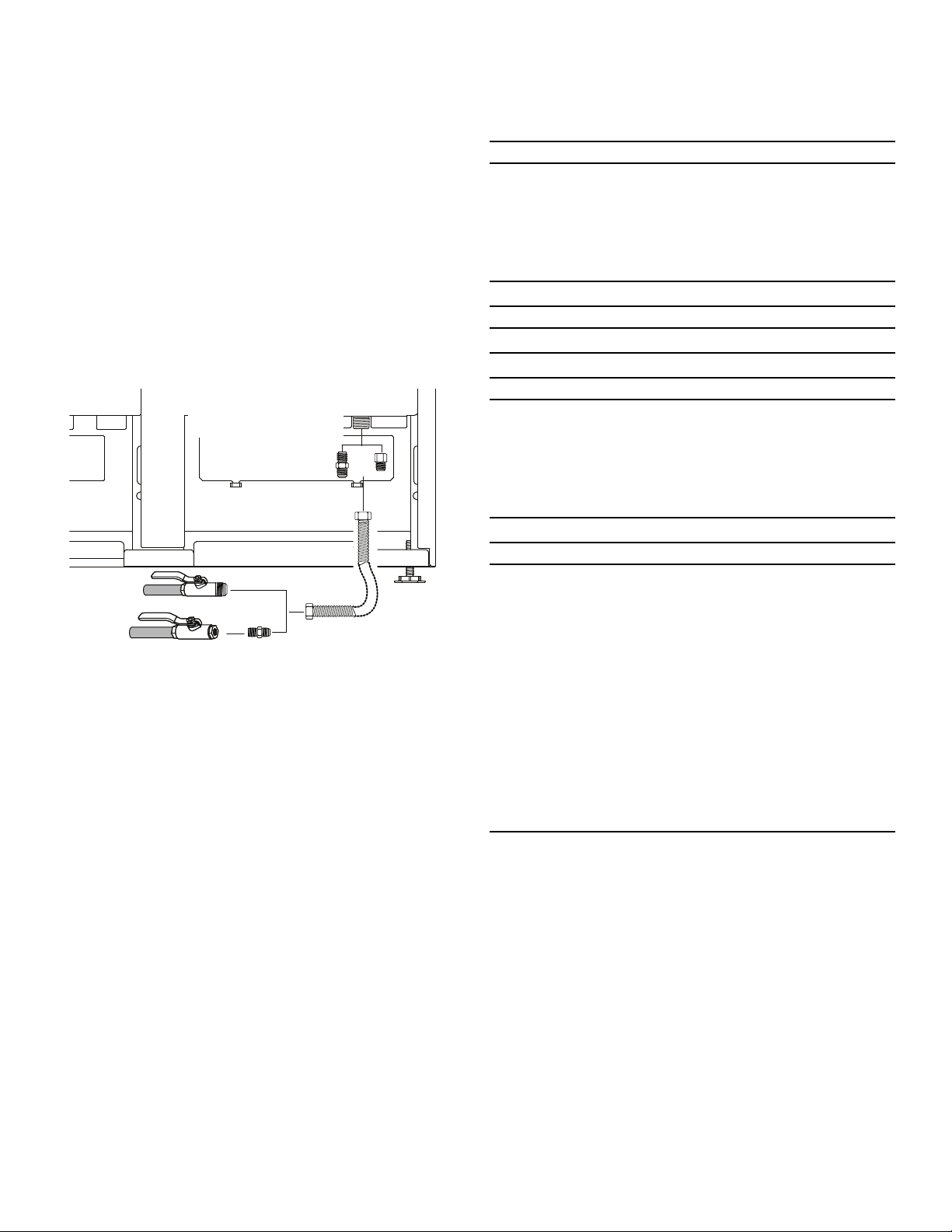

Gas connection

¾" (19) external threads¾" (19) external threads¾" (19) external threads

½" (12.7) internal threads½" (12.7) internal threads½" (12.7) internal threads

{

¾" (19)

Flex line

¾" (19)

Flex line

¾" (19)

Flex line

inches (mm)

Electrical requirements and

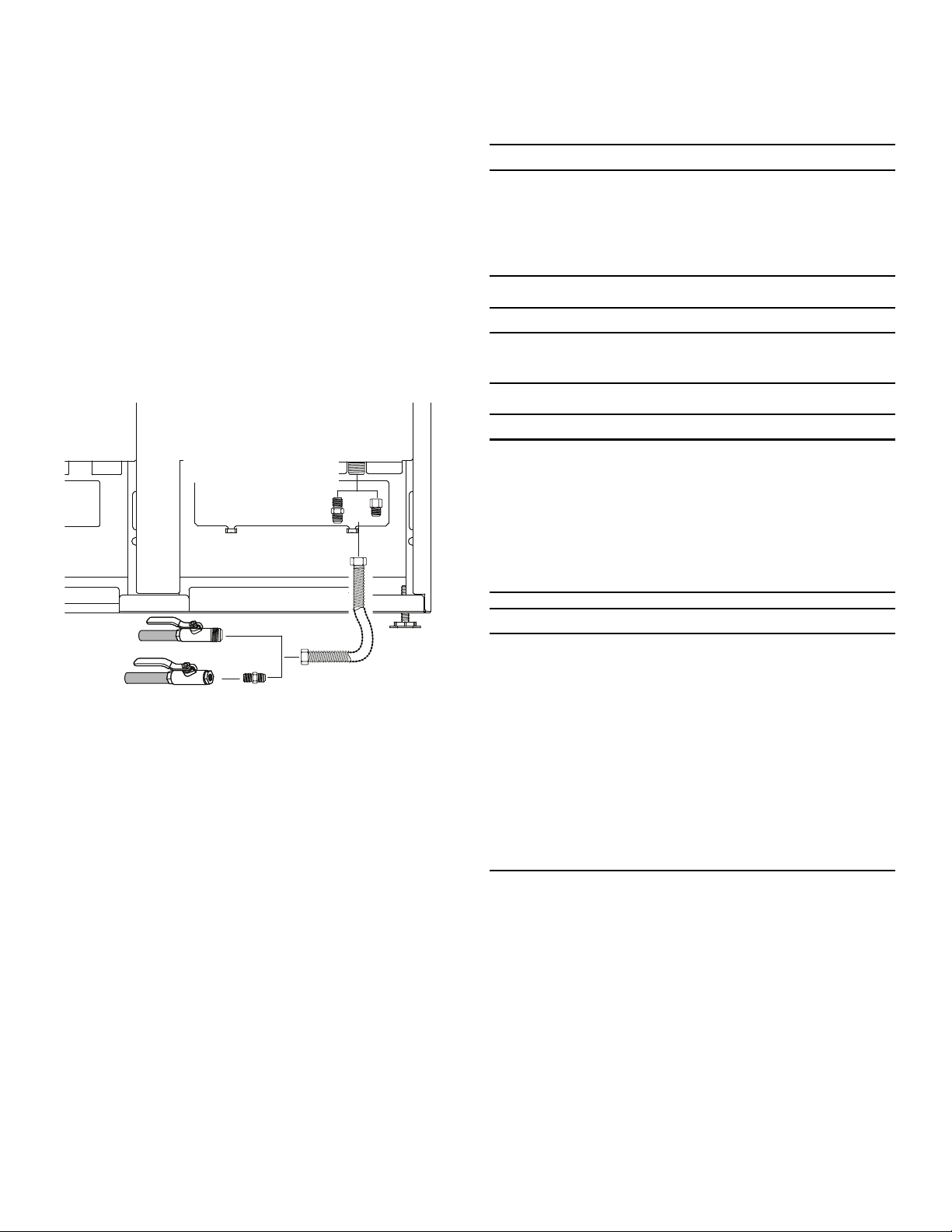

To connect the gas

1. Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

2. Use a ¾'' (19 mm) flex line to connect between the

gas supply and the appliance gas inlet. The gas supply

line connection is located at the lower right portion.

The appliance gas inlet connection is ½'' (12.7 mm)

NPT.

• Use caution to avoid crimping the ¾'' (19 mm) flex

line when making bends. Suggested length of flex

line is 48" (1219 mm); however, please check local

codes for your area's requirements before

installation.

®

3. Use pipe sealing compound or Teflon

pipe threads. DO NOT apply sealing compound or

tape to flare fittings. Take care not to apply excessive

pressure when tightening the fittings.

4. Leak testing of the appliance shall be in accordance

with the following instructions:

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

5. Bubbles forming indicate a gas leak. Repair all leaks

immediately.

tape on the

connection for GAS models

9 WARNING

Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being

turned ON accidentally. Always disconnect appliance

from the electric supply either by disconnecting

power cord or shutting off the breaker at the service

panel before servicing the appliance.

9 WARNING

This product must be properly grounded.

9 WARNING

Electrical grounding instructions

This appliance is equipped with a three-prong

grounding plug for your protection against shock

hazard and should be plugged directly into a properly

grounded receptacle. DO NOT cut or remove the

grounding prong from this plug.

9 CAUTION

Improper grounding or reverse polarization will cause

malfunction (such as continuous sparking of the

burner igniters). This can damage the appliance and

can create a condition of shock hazard. If the

dedicated circuit is not correctly grounded and

polarized, it is the responsibility and obligation of the

installer and user to have the existing receptacle

changed to a properly dedicated grounded and

polarized receptacle. This must be accomplished in

accordance with all applicable local codes and

ordinances by a qualified electrician. In the absence of

local codes and ordinances, the receptacle

replacement shall be in accordance with the National

Electric Code.

INSTALLER — show the owner the location of the circuit

breaker. Mark it for easy reference.

Page. 18

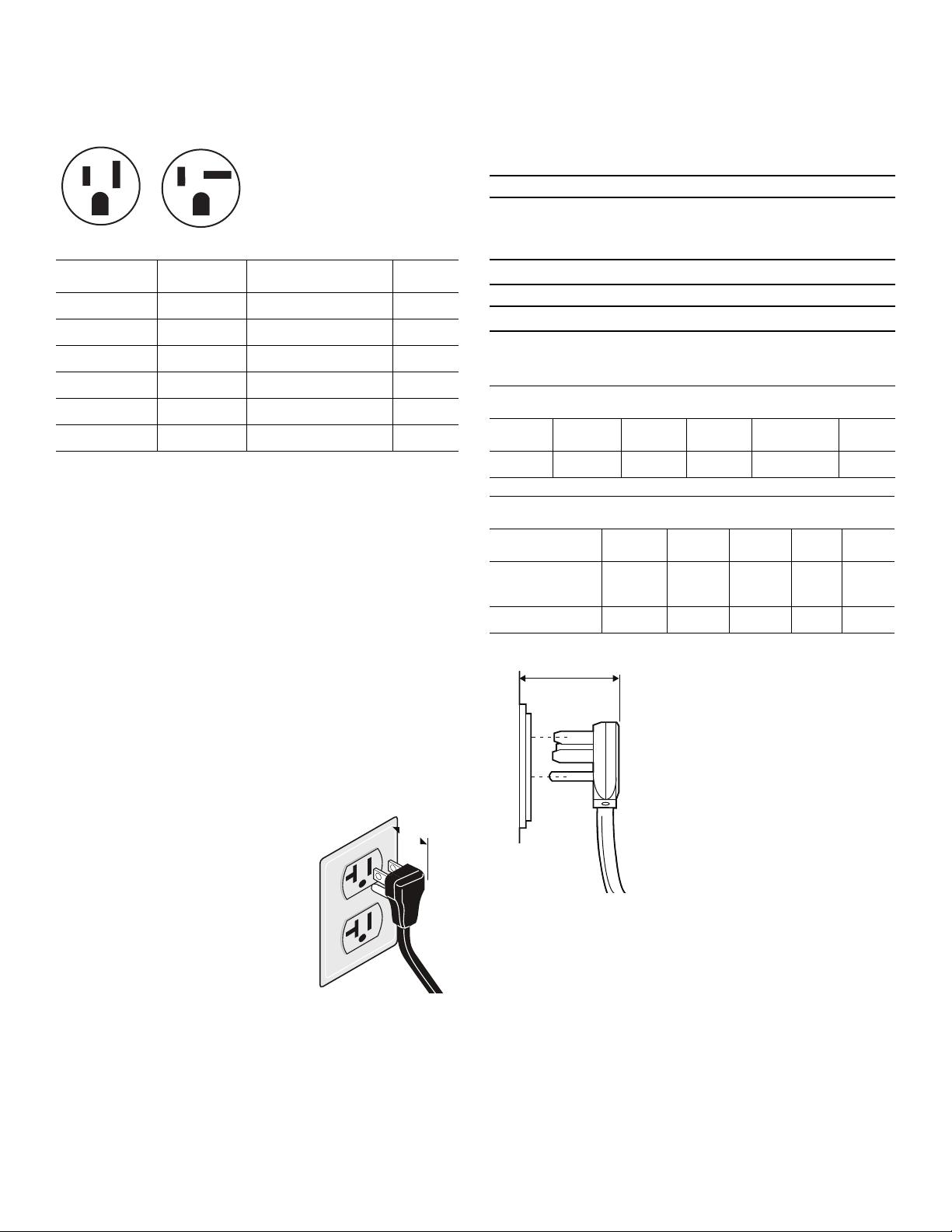

Gas unit electrical connection

NEMA 5-15 NEMA 5-20

G

G

N

N

2"

(51)

2" (51) max.

Electrical requirements and

Electrical supply circuit requirements

The cord supplied with the

gas ranges having an electric

griddle or grill requires a

NEMA 5-20 receptacle. All

other gas units require a

NEMA 5-15 receptacle.

Model Voltage Dedicated circuit Phase

Pxx305Wx 120 VAC 15 Amps Single

Pxx366Wx 120 VAC 15 Amps Single

Pxx364WDx 120 VAC 20 Amps Single

Pxx364WLx 120 VAC 20 Amps Single

Pxx486WDx 120 VAC 20 Amps Single

Pxx486WLx 120 VAC 20 Amps Single

• Before you plug in an electrical cord, be sure all

controls are in the OFF position.

• A neutral supply wire must be provided from the

power source (breaker) because critical range

components, including the surface burner spark

reignition modules, require it to operate safely and

properly.

• All 120 volt models must be plugged into a mating 3prong, grounding-type receptacle. The receptacle

must be connected to a properly dedicated grounded

and polarized electrical power supply rated at

120VAC, Single Phase, 60Hz.

• Observe all governing codes and ordinances when

grounding. In the absence of these codes or

ordinances observe National Electrical Code ANSI/

NFPA No. 70 current issue, or the relevant Canadian

Electric Code, CSA C22.1-02.

• Power cord and receptacle

should protrude no more than

2'' (51 mm) from the rear wall.

connection for DUAL FUEL

models

9 WARNING

An improper 240/208 VAC power supply will cause

malfunction, damage to this appliance, and possibly

create a condition of shock hazard.

9 WARNING

This product must be properly grounded.

Required dedicated circuit

Double oven ranges

Models Voltage US Canada Frequency Phase

All 240/208 50 AMP 50 AMP 60 Hz. Single

Single oven ranges

Models Voltage US Canada Freq. Phase

All except

PRD364WIGx

PRD364WIGx 240/208 40 AMP 40 AMP 60 Hz. Single

240/208 30 AMP 40 AMP 60 Hz. Single

When using a receptacle it may

be necessary to recess the

receptacle's housing into the rear

wall. Refer to Local Electrical

Code to determine the minimum

volume for all electrical / junction

boxes. Follow all local electrical

codes and ordinances, and/or the

National Electric Code, as

applicable.

NOTE: Plug styles may vary.

Page. 19

• Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being

turned ON accidentally.

• Prior to servicing appliance, always disconnect

appliance electrical supply cord, if so equipped, from

wall receptacle. If appliance is hard-wired to power

supply, disconnect power to unit by turning off the

proper circuit breaker. Lock service panel to prevent

power from being turned ON accidentally.

• A neutral supply wire must be provided from the

power source (breaker) because critical range

components, including the surface burner spark re-

ignition module, require it to operate safely and

d

c

b

a

properly.

• Mount the receptacle securely to a wall stud, then seal

around the receptacle's housing.

• If the correct power supply circuit is not provided, it is

the responsibility and obligation of the installer and

user to have proper power supply connected. This

must be accomplished in accordance with all

applicable local codes and ordinances by a qualified

electrician. It is the responsibility of the installer to

ensure compliance of local codes. In the absence of

local codes and ordinances, the power supply

connection shall be in accordance with the National

Electric Code.

• Observe all governing codes and ordinances when

grounding. In the absence of these codes or

ordinances observe National Electrical Code ANSI/

NFPA No. 70 current issue. See the following

information in this section for grounding method.

• Electrical wiring diagrams and schematics have been

placed in the kick panel area of the range for access

by a qualified service technician.

• The ranges are to be connected to a 240/208 VAC

power supply.

• Dual Fuel models must be connected to the power

supply utilizing one of the following methods. For all

methods of connection, the length of the cord or

conduit/wiring must allow the unit to be slid

completely out of the cabinet without having to

unplug or disconnect the unit from the power supply.

• Recommended minimum free length of cord or

conduit is 4ft (1.2 m). Electrical installations and

grounding must be in accordance with all local codes

and ordinances, and/or the National Electric Code, as

applicable.

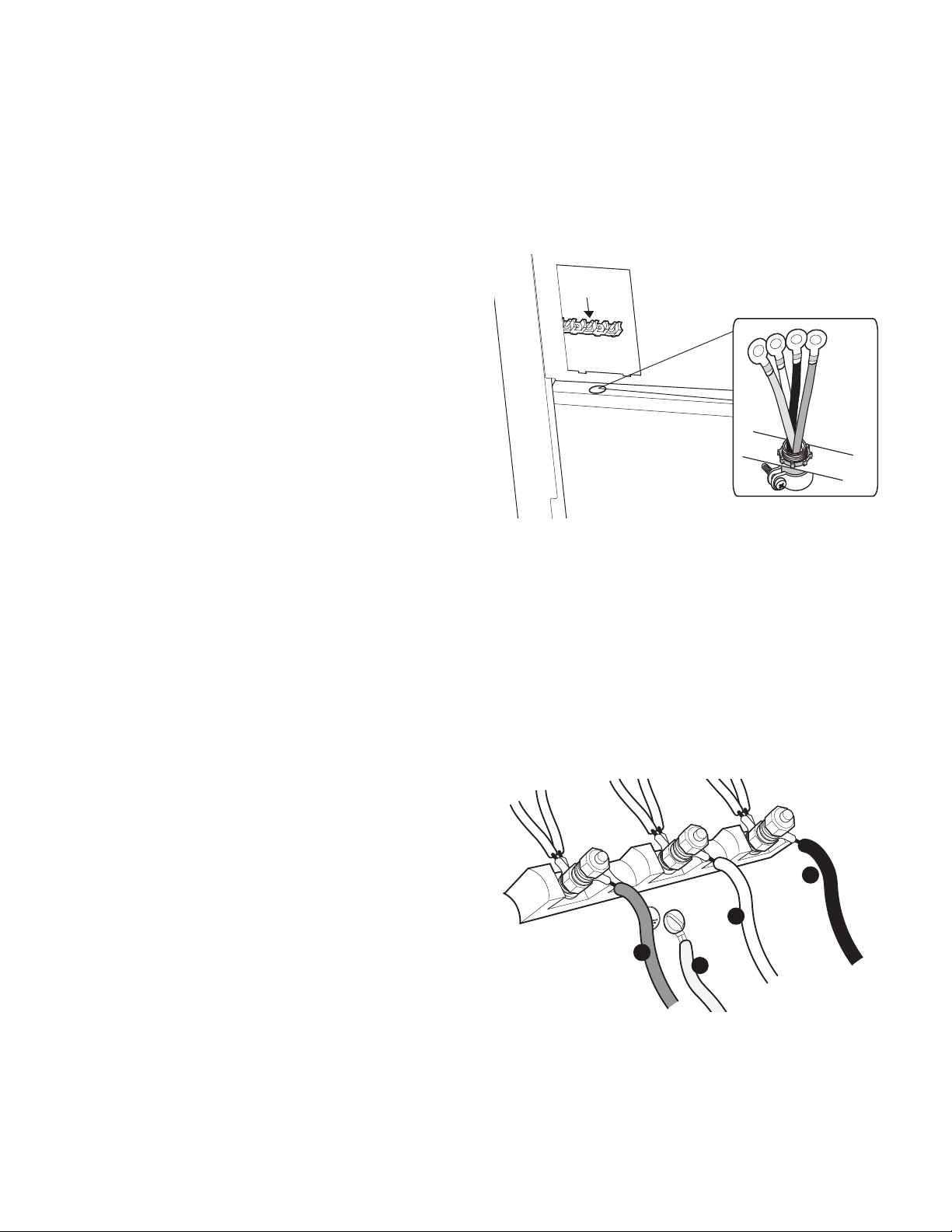

2. Remove upper nuts only from the terminal block

studs. DO NOT remove lower nuts which secure range

internal wiring leads.

3. If applicable, remove the 4-wire power cord from the

appliance.

4. Mount strain relief (not provided with range) into the

1'' (25.4 mm) diameter hole in the back panel located

below the terminal block. Route wires up through

strain relief.

5. Remove green ground screw and serrated washer

located beneath the terminal block.

6. Secure the neutral, grounded wire of the supply

circuit, to the center stud of the terminal block with

nut.

7. Secure the L1 (red) and L2 (black) power leads to the

outside terminal studs (brass colored) with nuts.

8. Secure the bare copper ground lead to the range

chassis using the ground screw and serrated washer.

Be sure that neutral and ground terminals do not

touch.

4-wire connection

This appliance must be connected to the power supply

with a listed (UL, CSA, ...) 3-POLE, 4-CONDUCTOR cord

kit rated 125/250 VOLTS, 50 AMPERES DEDICATED

CIRCUIT, and marked for use with ranges. It is the

responsibility of the installer to provide the proper wiring

components (cord, wires, etc.) and complete the electrical

connection as dictated by local codes and ordinances,

and/or the National Electrical Code.

The cord kit is required to be attached to the range

terminal block with a strain relief (not provided) which will

fit a 1'' (25.4 mm) diameter hole. If not already equipped,

the cord must also have 1/4'' (6 mm) faston closed-loop

lugs attached to the free ends of the individual

conductors, preferably soldered in place.

To wire a 4-wire connection

1. Locate the terminal block on the rear of the unit and

remove cover.

a – Red/L1 b – Green/ground

c – White/neutral d – Black/L2

9. Tighten all connections securely and

10. Reinstall the terminal block cover.

Page. 20

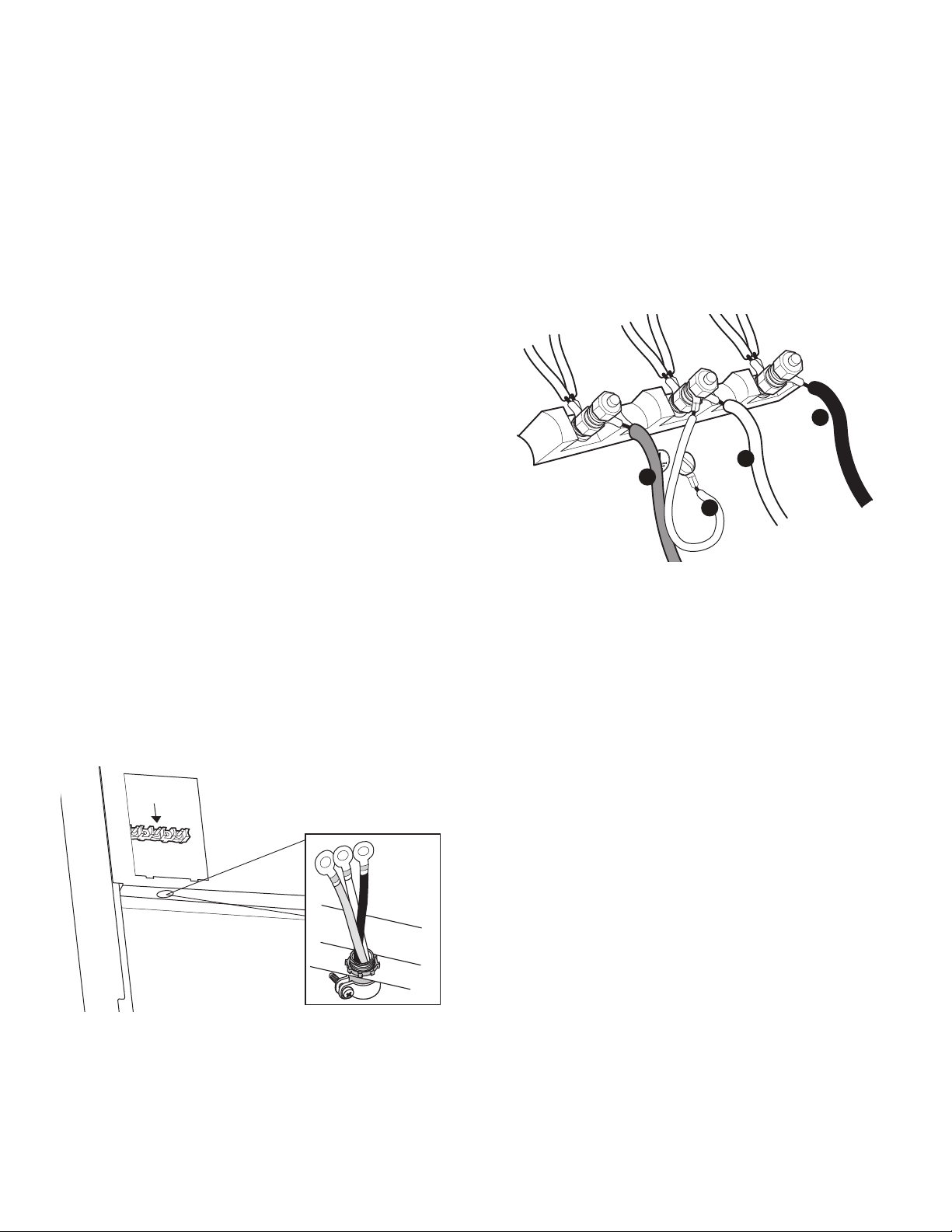

3-wire lead connection

d

c

a

b

Where local codes and ordinances permit grounding

through neutral, and conversion of supply to 4-wire is

impractical, the unit may be connected to the power

supply with a Listed (UL, CSA, ...) 3-POLE, 3CONDUCTOR cord kit rated 125/250 VOLTS, 50

AMPERES DEDICATED CIRCUIT, and marked for use with

ranges. It is the responsibility of the installer to provide

the proper wiring components (cord, wires, etc.) and

complete the electrical connection as dictated by local

codes and ordinances, and/or the National Electrical

Code.

The cord kit must be attached to the range back panel

with a strain relief which will fit a 1" (25.4 mm) diameter

hole. If not already equipped, the cord must also have

1/4'' (6 mm) faston closed-loop lugs attached to the free

ends of the individual conductors, preferably soldered in

place.

To wire a 3-wire connection

1. Locate the small bag with white jumper wire located in

the literature packet.

2. Locate the terminal block on the rear of the unit and

remove cover.

3. Remove upper nuts only from the terminal block

studs. DO NOT remove nuts which secure range

internal wiring leads.

4. If applicable, remove the 4-wire power cord from the

appliance.

5. Mount strain relief (not provided with range) into the

1'' (25.4 mm) diameter hole in the back panel located

below the terminal block. Route wires up through

strain relief.

6. Secure the neutral, grounded wire of the supply

circuit, to the center stud (silver colored) of the

terminal block.

7. Secure the L1 (red) and L2 (black) power leads to the

outside corresponding terminal block studs (brass

colored).

8. Remove the green ground screw and serrated washer

located beneath the terminal block. Screw one end of

the included white jumper wire to the chassis beneath

the terminal block with the green ground screw.

Secure the other end of the wire to the center stud of

the terminal block with nut.

a – Red/L1 b – Ground link wire provided

in small bag.

c – White/neutral d – Black/L2

9. Tighten nuts securely.

10. Reinstall the terminal block cover.

Page. 21

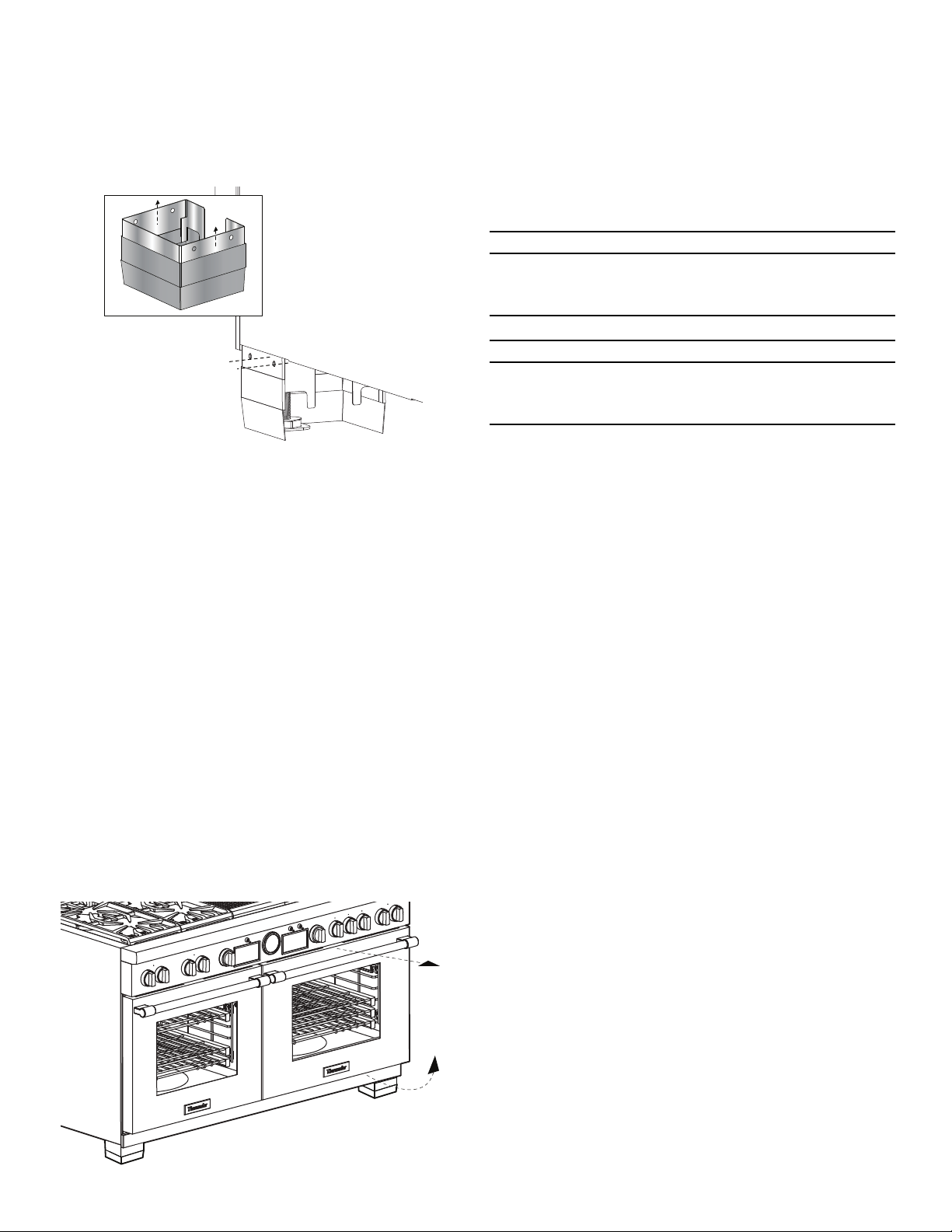

Low backguard installation

(optional)

9 WARNING

Fingers or hands could get pinched when installing

the backguard. Severe injury could result. Use

extreme caution and wear thick protective gloves to

avoid potential laceration to finger or hand while

sliding the backguard down onto the range.

9 WARNING

To reduce the risk of fire or injury to persons, ensure

all packaging has been removed from accessory

devices before use.

Installation methods will vary upon need. Before you

begin read these instructions carefully. Observe all local

codes and ordinances.

To install the low backguard

1. Remove the T-20 torx stainless screws in the front face

of the included island trim.

2. Remove the drill point screws securing the piece to

the back panel. Lift up to fully remove.

3. Align the back panel of the new accessory with the

flanges on the range side panels right and left rear

corners. Make sure the backguard front face is outside

the flange on the front side of the range.

4. Reinstall screws removed in Steps 1 and 2.

Page. 22

Placing and leveling the range

1/16''-1/8''

(2-3)

1/16''-1/8''

(2-3)

1/16''-1/8''

(2-3)

inches (mm)

9 CAUTION

The top edges of the range’s side panels must be on

the same or higher level as the adjacent countertop.

DO NOT operate range if sides are lower than the

adjacent cabinet. If the range is operated while at a

lower height relative to the adjacent cabinet, the

cabinet could be exposed to excessive temperatures,

causing damage to the cabinet and countertop.

Leveling leg adjustment

For proper performance, the range must be level. Priority

should be placed on ensuring that the oven cavities are

also level for optimum cooking performance.

To level 36'' and 48'' models

1. Measure the countertop heights first with a tape

measure and add an additional 1/16'' - 1/8'' (2-3 mm).

2. Rotate the legs using a 12'' (305 mm) adjustable

wrench on the flat sides of each foot.

• Leveling legs should be adjusted so that the range

sides are at the same or higher level as the

adjacent cabinet. Adjust the legs accordingly prior

to pushing the range back to its final location.

• It may be necessary to reposition the gas supply

line and the electrical cord as the range is pushed

back to its final position. This may be

accomplished by carefully pulling on a rope or

twine looped around the gas or electrical supply

line as the range is pushed back into its final

installed position.

3. As the range is moved into its final, installed position,

verify that the anti-tip bracket is in a position to

engage the appliance.

To level 60'' models

1. Height adjustments of the two rear caster legs are

made by turning the 5/16'' socket located behind the

front frame.

• Rotation direction will vary depending on which

side of the appliance is being adjusted.

• The oven doors must be removed in order to

access the leveling socket for the rear wheels (see

“Door removal and adjustment”. On models with

a warming drawer, the socket for the left caster

may be accessed by pulling the warming drawer

open.

2. With the range in the installed position, the final

height adjustments are made to the two front legs to

ensure proper alignment to the counter top.

3. Lower the center leveling foot of the unit to help

support the appliance weight.

4. Reinstall the oven doors (refer to “Door removal and

adjustment”).

Page. 23

Installing the leg covers

Electric wiring diagrams and schematics

To install the leg covers

1. Remove plastic coverings from the stainless steel

covers.

2. Beneath the range, wrap the cover assembly around

the leg.

3. Slide the outer cover up while the inner piece remains

on the floor. The mating part has dimples for which

the holes of the larger cover should seize. You should

feel a definitive click, letting you know that the cover

assembly has been mounted to the unit.

4. Repeat for all visible legs.

• If additional leg covers are required, they may be

ordered from the service center by calling

1-800-735-4328 at no charge for up to one year

after purchase date of the appliance.

Data rating label

Data rating label

The data rating label shows the model and serial number

of your appliance. Depending on your model, the data

rating labels are located above the main oven or behind

the kick plate.

The electric wiring diagrams and schematics are attached

behind the toe kick, and should not be removed except by

a service technician, then replaced after service.

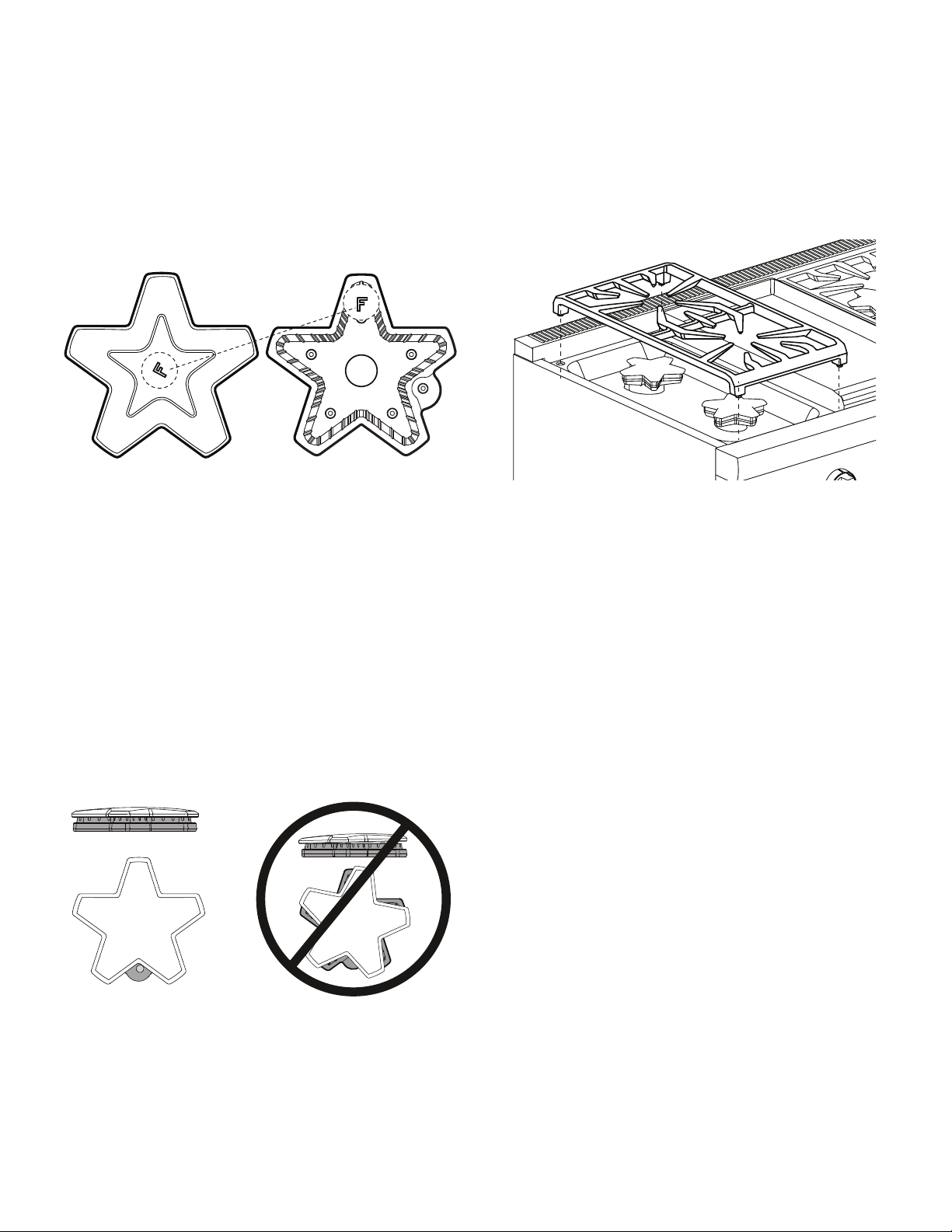

Burner test

9 WARNING

To prevent flare-ups and avoid the creation of harmful

by-products, do not use the cooktop without all

burner caps and all burner grates properly positioned.

9 WARNING

To prevent burns, do not touch burner caps or grates

while hot. Turn the cooktop off and allow the burners

to cool.

Install any loose components, such as burner caps and

grates that may have been removed earlier. Be certain that

burner caps seat properly into the burner bases. Before

testing operation of the appliance, verify that the unit and

the gas supply have been carefully checked for leaks and

that the unit has been connected to the electrical power

supply. Turn the manual gas shut-off valve to the open

position.

The burner caps must be properly placed on the burner

bases for the cooktop to function properly. If the burner

cap is not properly placed, one or more of the following

problems may occur:

• Burner flames are too high.

• Flames shoot out of burners.

• Burners do not ignite.

• Burner flames light unevenly.

• Burner emits gas odor.

Page. 24

Burner cap placement

Burner grate placement

Each cap has a letter (B, D, or F) cast in the underside of

the cap that corresponds to a letter (B, D, or F) cast in the

burner base that is attached to the appliance.

To place the burner caps

1. Place each burner cap on its correct burner base per

its corresponding letter designation.

2. Place burner cap gently on top of base so that the

prongs of the burner base fit snugly into the groove of

the burner cap.

To install the burner grates

1. Place grates flat-side down and align into the

rangetop recess.

2. Grates should rest flush against each other and

against the sides of the recess.

Test rangetop burners

Checking the burner cap placement

• Check each burner to make sure there is no gap

between the burner cap and burner base.

• You may gently try to move the burner caps from side

to side to check if the caps are properly placed on the

burner bases.

• When properly placed, each burner cap will rest flat

on top of its burner base, and completely cover the

star-shape of the burner base when viewed from the

top as shown below.

See figures below for appropriate flame characteristics. If

any of the rangetop burners continue to burn mostly or

completely yellow, verify that the burner cap is positioned

properly on the burner base, then re-test. If flame

characteristics do not improve, call Thermador service.

To test burner ignition

1. Select a rangetop burner knob. Push in and turn the

knob to HI.

• The igniter will produce a clicking sound. Once

the air has been purged from the supply lines, the

burner should light within four seconds.

2. Turn burner to LO. Verify that the flame completely

surrounds the burner.

• There should be a flame at each burner port and

there should be no air gap between the flame and

the burner. If any burners do not carry over, call

Thermador service.

Page. 25

3. Repeat the ignition and flame test for each rangetop

burner.

Flame characteristics

Yellow flames:

Further Adjustment is

required.

Yellow tips on outer cones:

Normal for LP Gas

Soft blue flames:

Normal for Natural Gas

If the flame is completely or mostly yellow, verify that

the regulator is set for the correct fuel. After

adjustment, retest.

Some orange-colored streaking is normal during the

initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

The burners that feature XLO

®

, cause the flame to cycle

on and off when the knob is set to the XLO function. This

is normal operation.

When flame is properly adjusted:

• There should be a flame at each burner port.

• There should be no air gap between the flame

and burner port.

Call Thermador service if:

• Any of the burners do not light.

• Any of the burners continue to burn yellow.

Page. 26

Installer checklist

Final check

Specified clearances maintained to cabinet

surfaces.

Unit level – front to back – side to side.

Burner caps positioned properly on burner bases.

All packaging material removed.

Kick panel in place and screws secure.

Verify flame at each burner. Flame may need to

burn for several minutes to remove impurities from

the gas lines.

Verify that the ExtraLow

around the entire burner.

INSTALLER: Leave the Home Connect™ instruction

leaflet with the owner of the appliance. In order to

utilize the full feature potential of the appliance, the

owner should download the Home Connect™ app

on their smart device and pair the appliance to the

home's Wi-Fi device.

Gas supply

Gas Connection: ¾'' (19 mm) N.P.T. with a min. ¾''

(19 mm) diameter flex line.

The appliance is connected only to the type of gas

for which it is certified for use.

Manual gas shut off valve installed in an accessible

location (without requiring removal of range).

Owner is aware of location of the gas shut-off valve.

Unit tested and free of gas leaks.

If used on propane gas, verify that the propane gas

supply is equipped with its own high pressure

regulator in addition to the pressure regulator

supplied with the appliance.

Gas supply pressure does not exceed 14'' W.C.

(34.9 mb).

®

feature works and relights

Operation

Bezels centered on burner knobs, and knobs turn

freely.

Each burner lights satisfactorily, both individually

and with other burners operating.

Oven door hinges seated and hinge locks in proper

position. Oven handle and door is level and

centered. Door opens and closes properly.

Burner grates correctly positioned, level, and do not

rock.

INSTALLER: Write the model number and serial

number in the Use and Care Guide. Leave the Use

and Care Guide and Installation Manual with the

owner of the appliance.

Clean and protect exterior surfaces

• Always wipe in the direction of the stainless steel

grain.

• To condition and protect stainless steel, use the

Thermador Stainless Steel Conditioner, which can be

purchased in the Thermador eShop (thermador.com/

customer-care).

• DO NOT allow deposits to remain for long periods of

time.

• DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

• DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe dry

with a clean cloth.

• Refer to the Use and Care Guide for additional

information.

Electrical

Receptacle with correct over-current protection is

provided for service cord connection.

Proper ground connection.

Owner is aware of location of the main circuit

breaker.

Page. 27

Troubleshooting

See Use and Care Guide for troubleshooting information.

Table des

Définitions de

MATIÈRES

Sécurité...................................................................................29

Instructions importants de sécurité................................. 29

Consignes d'installation.......................................................... 32

Renseignements de planification .................................... 32

Exigences en matière de ventilation............................... 32

Espaces libres pour l’Installation.....................................33

Alimentation de gaz et électrique................................... 39

Déballage et manutention de la cuisinière ..................... 40

Retrait et installation de la porte ....................................41

Installation du dispositif antibascule (requis) .................. 43

Exigences de l'alimentation du gaz et raccordement.....44

Exigences électriques et branchement........................... 45

Installation du dosseret...................................................49

Mise en place et nivelage de la cuisinière ......................50

Plaque signalétique......................................................... 51

Test des brûleurs............................................................. 51

SÉCURITÉ

9 AVERTISSEMENT

Ceci indique que le non respect de cet avertissement peut

entraîner des blessures graves, voire la mort.

9 ATTENTION

Ceci indique que le non respect de cet avertissement peut

entraîner des blessures légères ou modérées.

NOTICE : Ceci indique que la non-conformité à cet avis de

sécurité peut entraîner des dégâts à l'appareil ou à la propriété.

Note : Ceci vous avertit que d'importantes informations et/ou

conseils sont fournis.

Liste de vérification pour l'installateur.................................... 54

Liste de vérification ........................................................ 54

Soutien, pièces, et accessoires ................................. page verso

Cet appareil électroménager de THERMADORTM

est fait par BSH Home Appliances LtD

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

Des questions?

1-800-735-4328

www.thermador.ca

Nous attendons de vos nouvelles!

Page. 28

Sécurité

9 INSTRUCTIONS IMPORTANTS DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS AVANT DE PROCÉDER

Veuillez lire attentivement

Installateur : Laisser ces instructions avec l’appareil pour

le propriétaire.

Propriétaire : Conserver ces instructions à des fins de

références. Avant d'utiliser votre appareil, assurez-vous de

lire ce manuel.

AVERTISSEMENT

L’information fournie dans le présent

manuel doit être très rigoureusement

respectée, sous peine d’incendie ou

d’explosion entraînant des dommages,

des blessures ou la mort.

• Ne stockez pas et n’utilisez pas d’essence ou

autres ou la compagnie distributrice de gaz.

• SI VOUS SENTEZ UNE ODEUR DE GAZ :

• N’allumez aucun appareil.

• Ne touchez pas aux interrupteurs

électriques.

• N’utilisez pas les téléphones du bâtiment.

• Appelez immédiatement votre compagnie

de gaz de chez un voisin. Suivez les

instructions de la compagnie.

• Si vous n’arrivez pas à contacter la

compagnie de gaz, appelez les pompiers.

• L’installation et les réparations doivent être

réalisées par un installateur qualité, un

centre de réparation agréé ou la compagnie

de gaz.

AVERTISSEMENT

AVERTISSEMENT

DANGER DE BASCULEMENT :

• Toutes les cuisinières peuvent basculer et

causer une blessure. Pour éviter le

basculement accidentel de la cuisinière,

fixez-la au sol au moyen du dispositif antibascule fourni.

• L’appareil risque de basculer si le dispositif

n’est pas installé conformément aux

présentes instructions. Pour toutes les

cuisinières, un dispositif anti-bascule doit

être installé conformément aux présentes

instructions.

• Un enfant ou un adulte pourrait faire basculer

l’appareil et perdre la vie.

• Ne faites pas fonctionner l’appareil si le support antibascule n’est pas installé et qu’il ne retient pas

l’appareil. La non-observation de ces instructions peut

entraîner la mort ou causer de graves brûlures à des

enfants ou des adultes.

• En déplaçant la cuisinière pour la

nettoyer, la réparer ou pour toute

autre raison, assurez-vous qu’elle

s’est bien enclenchée dans le

dispositif anti-bascule lorsque

vous la remettez en place.

Autrement, si l’appareil est utilisé

de façon anormale (par exemple,

si quelqu’un monte, s’assoie ou

s’appuie sur une porte ouverte),

la cuisinière risque de basculer. Le basculement de la

cuisinière ou d’un liquide chaud se trouvant sur la

surface de cuisson pourrait causer des blessures

corporelles.

RISQUE D'ÉLECTROCUTION

• Coupez l’électricité avant d’installer l’appareil.

Avant de remettre (ON) l’électricité, assurezvous que toutes les commandes sont à la

position OFF.

• N’enlevez pas de connexion.

• N’utilisez pas une rallonge électrique.

• La mise à la terre inadéquate de l’appareil peut

entraîner un risque de décharge électrique.

• Le non-respect des présentes instructions peut

entraîner la mort, causer un incendie ou provoquer

une décharge électrique.

Page. 29

Les réglementations locales varient. L'installation, le

branchement au gaz et la mise à la terre doivent être

conformes à toutes les réglementations en vigueur. Le

non-respect des codes et règlements locaux appropriés

peut annuler la garantie.

Installation dans une maison préfabriquée (mobile) :

L’installation doit être conforme au Manufactured Home

Construction and Safety Standard, Titre 24 CFR, Partie

3280 (anciennement le Federal Standard for Mobile Home

Construction and Safety, Titre 24, HUD/Partie 280) ou,

lorsque cette norme n’est pas applicable, au Standard for

Manufactured Home Installations, ANSI/NCSBCS A225.1,

ou aux codes locaux, là où il y a lieu.

9 INSTRUCTIONS IMPORTANTS DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS AVANT DE PROCÉDER

L’installation de ces dispositifs conçus pour micro-maisons

préfabriquées doit se faire conformément aux

réglementations nationales ou autres ou, à défaut, à la

norme en matière de micro-maisons préfabriquées ANSI

A119.5.

Examinez l'appareil après l'avoir déballé. S'il a été

endommagé durant le transport, ne le branchez pas.

Enlevez tout le matériel d'emballage et le ruban adhésif

avant d'utiliser l'appareil. Jetez l'emballage selon les

consignes de tri sélectif. Ne laissez jamais des enfants

jouer avec le matériel d'emballage.

Montrez au propriétaire l’emplacement du disjoncteur ou

du fusible du circuit. Identifiez sa position pour pouvoir le

retrouver facilement.

Cet appareil doit être mis à la terre. La mise à la terre

réduit les risques de décharge électrique en fournissant au

courant électrique un fil d’échappement lors d’un courtcircuit.

L’appareil doit être mise à la terre en conformité aux

codes locaux, ou en l’absence de tels codes, à la dernière

version du National Electric Code NFPA 70 ou, au Canada,

au code canadien de l’électricité CSA C22.1-02.

Ne rangez pas cet appareil à l’extérieur.

Pour les installations au Massachusetts :

• L’installation doit être réalisée par un entrepreneur

qualifié ou agréé, un plombier ou un installateur de

gaz qualifié ou autorisé par l’État ou la région dans

laquelle cet appareil est installé.

• Le robinet d’arrêt de gaz doit être pourvu d’une

poignée en « T ».

• La longueur maximum autorisée du tuyau de gaz est

de 91,4 centimètres (36").

Vérifiez le type d'alimentation en gaz fourni sur le lieu

d’installation. L’appareil doit être raccordé au type de gaz

pour lequel il est certifié. Tous les modèles sont certifiés

pour une utilisation avec gaz naturel. Conversion sur place

pour utilisation au gaz propane exigeant le nécessaire de

conversion.

Ne pas conserver ou utiliser de l'essence ou d'autres

liquides ou vapeurs inflammables à proximité de cet

appareil ou de tout autre appareil.

L'appareil peut être utilisé en toute sécurité en cas de

panne de courant. Seuls les brûleurs normaux du haut

peuvent être allumés manuellement.

Gaz naturel — 7po (17,4 mb) min. à 14 po (34,9 mb) max.

de colonne d’eau

Gaz propane — 11 po (27,4 mb) min. à 14 po (34,9 mb)

L'appareil électroménager est livré de l'usine prêt à utiliser

avec du gaz naturel. Pour une utilisation avec du gaz

propane (pétrole liquéfié : PL), utilisez la trousse de

conversion vendue séparément. Un centre de réparation

autorisé doit procéder à la conversion au PL. Voir la

couverture arrière pour des renseignements sur les

réparations, les pièces et les accessoires.

ATTENTION

Lorsque vous branchez l'appareil au gaz propane, assurezvous que le réservoir de gaz propane est muni de son

propre mécanisme régulateur à haute pression en plus du

régulateur à haute pression fourni avec l'appareil. La

pression de gaz maximale de cet appareil ne devrait pas

excéder 14,0 pouces (34,9 mb) de colonne d'eau entre le

réservoir de propane et le régulateur à haute pression.

Cet appareil est conforme à une ou à plusieurs des

normes suivantes :

• UL 858 – norme visant la sécurité en matière de

cuisinières électriques domestiques

• ANSI Z21.1 – norme américaine régissant les appareils

électroménagers de cuisson au gaz

• CAN/CSA-C22.2 No 61-08 – cuisinières domestiques

• CAN/CGA1.1-M81 régissant les cuisinières à gaz

domestiques

Il est de la responsabilité du propriétaire et de

l’installateur de déterminer les exigences ou les normes

supplémentaires pouvant s’appliquer à des installations

particulières.

Vérifiez code de la construction locale en vigueur pour

connaître la bonne méthode d’installation de l’appareil.

L’installation, le branchement électrique et la mise à la

terre doivent respecter toutes les réglementations en

vigueur. Les réglementations locales varient et il est de la

responsabilité de l’installateur de s’assurer de la

conformité de l’installation avec ces réglementations. S’il

n’y a pas de réglementations locales, l’appareil doit être

installé conformément au code national américain actuel

sur les gaz combustibles ANSI Z223.1/ NFPA 54 et au

code national américain actuel de l’électricité ANSI/NFPA

No 70.

Page. 30

9 INSTRUCTIONS IMPORTANTS DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS AVANT DE PROCÉDER

Avertissement issu de la proposition 65 :

Ce produit pourrait contenir un produit chimique reconnu

par l'État de la Californie comme cancérigène ou ayant

des effets nocifs sur la reproduction. Par conséquent,

l’emballage de votre produit pourrait porter l’étiquette

suivante, comme requis par la Californie :

AVERTISSEMENT ISSU DE LA PROPOSITION 65 DE

L’ÉTAT DE LA CALIFORNIE :

: AVERTISSEMENT

Cancér et dommages à la reproduction –

www.P65Warnings.ca.gov.

Arrière exigences de dégagement

• Pour éviter de tacher le mur arrière, on recommande

des matériaux de construction non-poreux, résistants

à haute température qui conviennent à un

environnement propre à la cuisson.

• Le modèle PCG305xx, PRG305xx, PRG304xx,

PRD305xx, PRD304, et PRD606xx convient pour un

dégagement arrière de 0 '' pour alimenter les

surfaces.

• Tous les autres modèles:

• Lors de l'utilisation de la garniture pour l'îlot

comprise, le fabricant recommande un

dégagement arrière d'au moins 152 mm (6 po)

d'une surface combustible*.

• Lors de l'installation de l'appareil contre une

surface combustible, il faut un dosseret bas pour

un manque de dégagement (0 po). Il faudrait

acheter séparément un dosseret bas Thermador.

• Quand une surface est couverte d'une matière

non combustible (métal, céramique, brique,

marbre ou pierre)

dégagement (zéro pouce).

*Un dégagement de moins de 152 mm (6 po) doit être conforme