Page 1

LP GAS CONVERSION

INSTRUCTIONS

For THERMADOR PROFESSIONAL® Pro Grand

Dual Fuel Ranges

INSTRUCTIONS DE CONVERSION

AU GPL

Pour les cuisinières mixtes au gaz PROFESSIONALmc

Pro Grand de THERMADOR

INSTRUCCIONES DE

Models/

Modèles/

Modelos:

PRD364JDGC

PRD364JDGU

PRD366JGC

PRD366JGU

PRD486JDGC

PRD486JDGU

PRD48JDSGC

PRD48JDSGU

PRD364NLGC

PRD364NLGU

PRD484NCGC

PRD484NCGU

PRD486NLGC

PRD486NLGU

PRD48NCSGC

PRD48NCSGU

PRD48NLSGC

PRD48NLSGU

CONVERSION AL GLP

Para las estufas mixtas PROFESSIONAL® Pro Grand

Page 2

Table of Contents

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conversion Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disassembling the Cooktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Regulator Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Replacing the Burner Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reassemble the Cooktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setting Valve Screws for the Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Check for Gas Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Checking manifold pressure (if necessary) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Check Flame Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conversion Label Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Customer Support, Accessories & Parts. . . . . . . back page

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

This kit is used to convert THERMADOR

PROFESSIONAL

natural gas to propane (LP) gas operation. This kit cannot

be used to convert older models of THERMADOR

PROFESSIONAL rangetops or ranges other than those

identified in these instructions (see applicable models on

the front cover). This kit cannot be used to convert all-gas

ranges, oven burners, or any other brand of appliance.

IMPORTANT: Only a qualified service technician or

installer should make this conversion.

INSTALLER: Please leave these conversion instructions

with this unit for the owner.

®

PRO GRAND® dual fuel ranges, from

To the Service Agent:

It is important that you know the following BEFORE you

begin the gas conversion of the appliance.

• Confirm that the Propane (LP) Gas supply system is

available and ready to use. This is particularly

important for new construction.

• You must plan for sufficient time and resources to

perform the LP conversion process properly and

completely before leaving the job site. Every step

described in these instructions must be performed to

safely convert the appliance for proper operation on

Propane Gas. INCOMPLETE OR INADEQUATE GAS

CONVERSION OF THE APPLIANCE CAN CREATE

A SAFETY HAZARD.

OWNER: Please retain these instructions for future

reference.

CAUTION

Disconnect gas and electric power before making

conversion. Before turning power ON, be sure that all

controls are in the OFF position.

WARNING

This conversion kit shall be installed by a

qualified service agency in accordance with

the manufacturer’s instructions and all

applicable codes and requirements of the

authority having jurisdiction. If the information

in these instructions is not followed exactly, a

fire, explosion or production of carbon

monoxide may result causing property

damage, personal injury or loss of life. The

qualified service agency is responsible for

the proper installation of this kit. The

installation is not proper and complete until

the operation of the converted appliance is

checked as specified in the manufacturer’s

instructions supplied with the kit.

WARNING

State of California Proposition 65 Warnings:

This product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

WARNING

If the Natural Gas orifices are left in place while

attempting to operate the appliance using Propane (LP)

Gas, at the higher pressure setting for LP Gas, the

burners will produce large flames which may emit high

levels of carbon monoxide into the room, or a fire or

explosion may occur.

WARNING

NEVER leave the gas conversion partially completed. If

the appliance is operated while the gas conversion is

incomplete, high levels of carbon monoxide may be

emitted, or a fire or explosion may occur.

Save the natural gas parts for possible conversion from LP

back to the natural gas in the future.

English 1

Page 4

Conversion Instructions

Before You Begin Conversion Preparation

1. Shut off the gas supply to the appliance prior to

CAUTION!

BEFORE PROCEEDING WITH THE CONVERSION,

SHUT OFF THE GAS SUPPLY TO THE APPLIANCE

PRIOR TO DISCONNECTING THE ELECTRICAL

POWER.

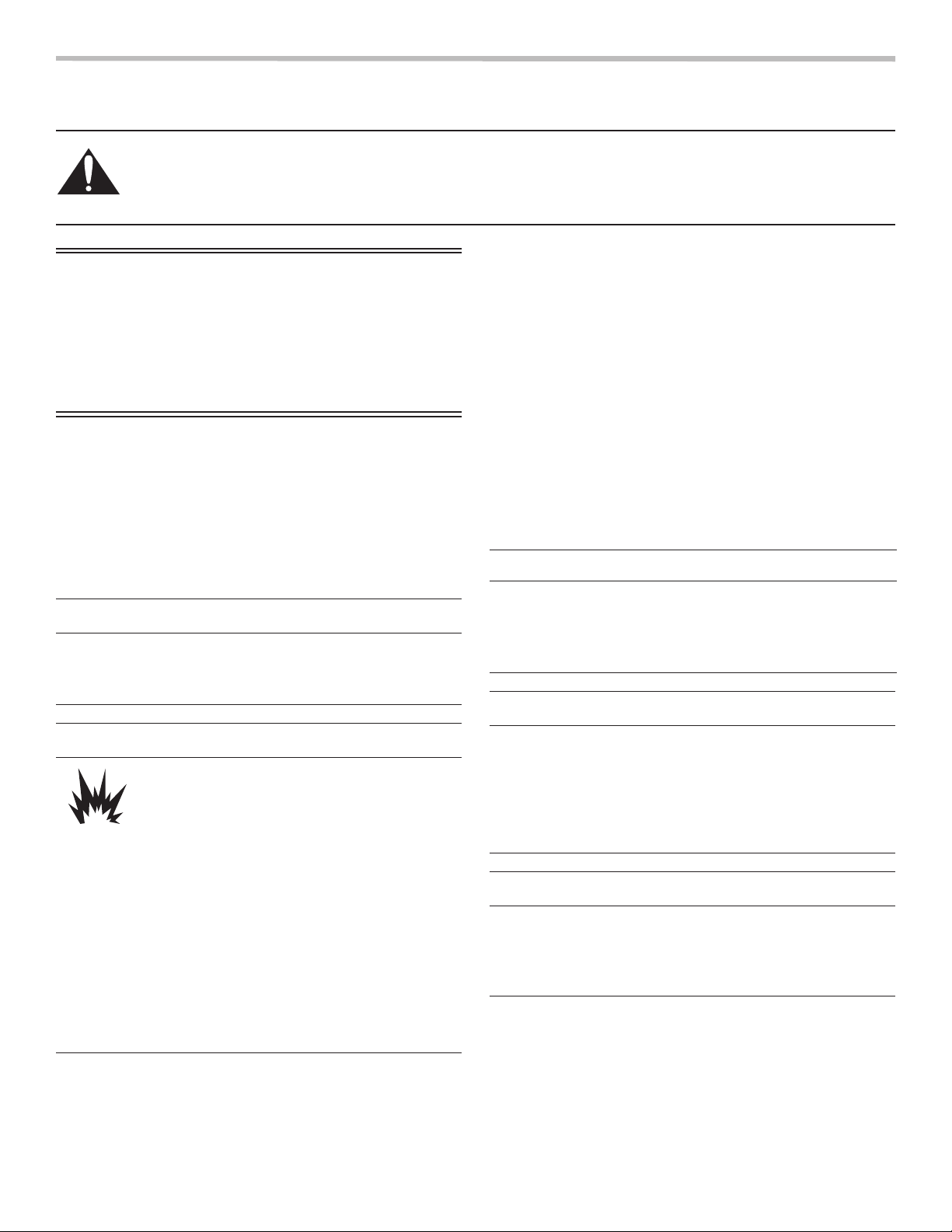

TOOLS NEEDED

Scissors

T-30 Torx screwdriver

T-20 Torx screwdriver

1/4" nut driver

7/8" socket or adjustable wrench

Flat-head screwdriver, 1/8" X .020" blade (included)

ITEMS INCLUDED

disconnecting the electrical power.

2. Cut a 3/8" long piece of the adhesive foam tape. Place

foam tape over the edge of the nut driver used to

replace the burner orifices, as shown.

• The foam tape helps to retain the orifice in the end

of the nut driver so it will not fall inside the

appliance during orifice removal or installation.

DESCRIPTION QUANTITY

Instructions 1

Foam Tape, 1" piece 1

Propane Conversion Label 1

®

STAR

STAR

When connecting the unit to propane gas, make certain

the propane gas tank is equipped with its own high

pressure regulator. The maximum gas pressure to this

appliance is not to exceed 14.0 inches water column from

the propane gas tank regulator.

Burner Jet Orifice (1.15 mm) 5

®

Burner Jet Orifice (1.25 mm) 1

CAUTION

Disassembling the Cooktop

IMPORTANT: Ensure that the power is turned OFF at

the breaker and the gas supply is turned OFF.

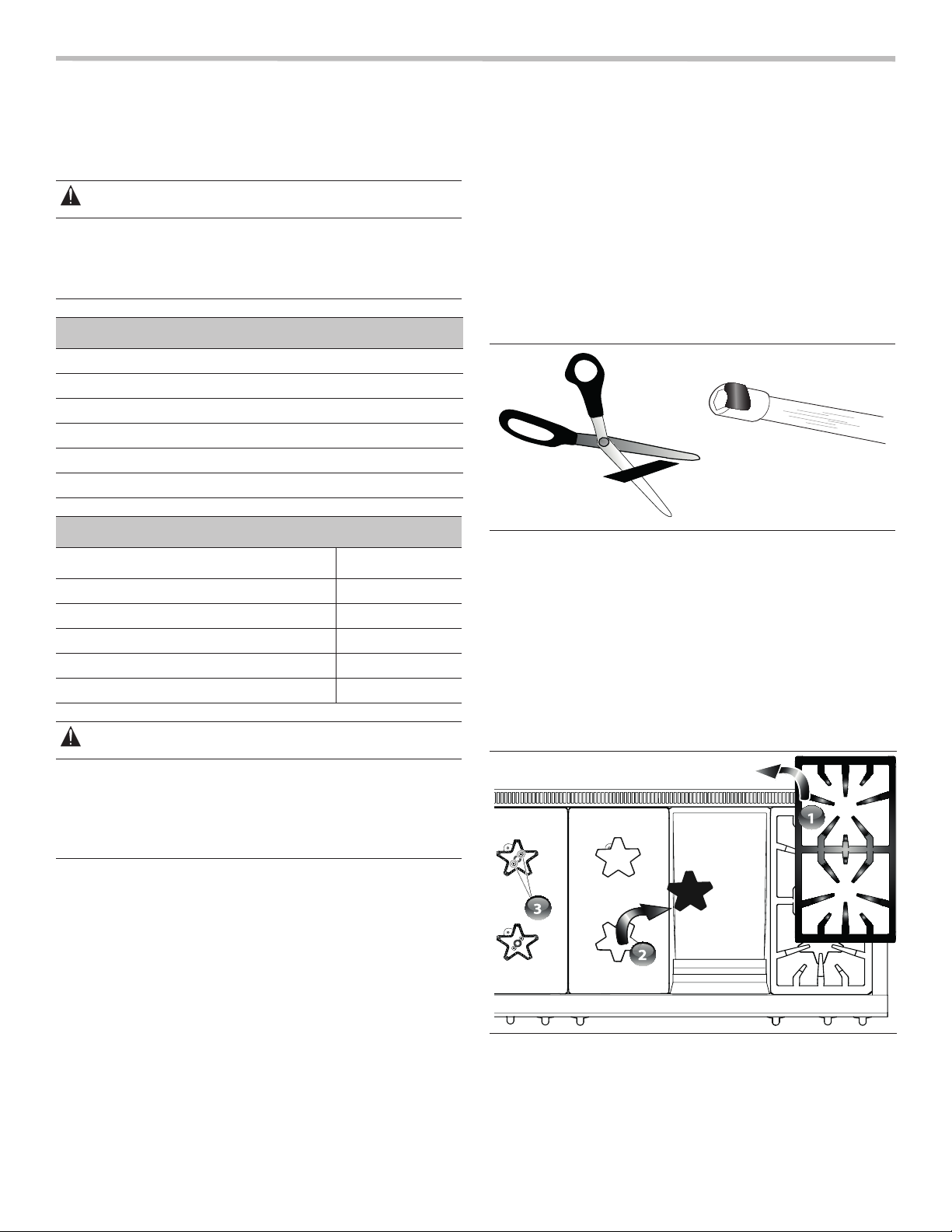

1. Remove the cooktop grates.

2. Remove the burner caps.

3. From each burner base, remove the two burner base

screws with a T-30 Torx screwdriver.

English 2

Page 5

4. To facilitate the removal of the spill trays, depending on

Burner Pedestal

model, remove the (3) or (4) T-20 Torx stainless screws

in the front face of the included Flush Island Trim.

5. Disconnect the igniter.

A.) Disconnecting a Two Piece Igniter

1) Carefully pull up on the burner base.

Burner Base

Electrode

6. From each burner pedestal, remove the burner

pedestal screws with a T-30 Torx screwdriver.

Burner Pedestal

Burner Pedestal

Venturi

7. Carefully remove the burner pedestal and the venturi.

8. Remove the spill trays by rotating the trays up and out

the back.

Ignitor Housing

Ignitor Wire

B.) Disconnecting a Single Piece Igniter

1) Carefully pull up on the burner base.

2) Disconnect the female terminal on the spark wire

from the male terminal on the electrode for each

burner.

IMPORTANT: The locking tab on the female

connector must be depressed to release from the

terminal on the electrode.

Burner Base

Electrode

Ignitor Wire

9. Remove the heat shield, on some models. Some

models have a double-width shield that extends under

adjacent spill tray.

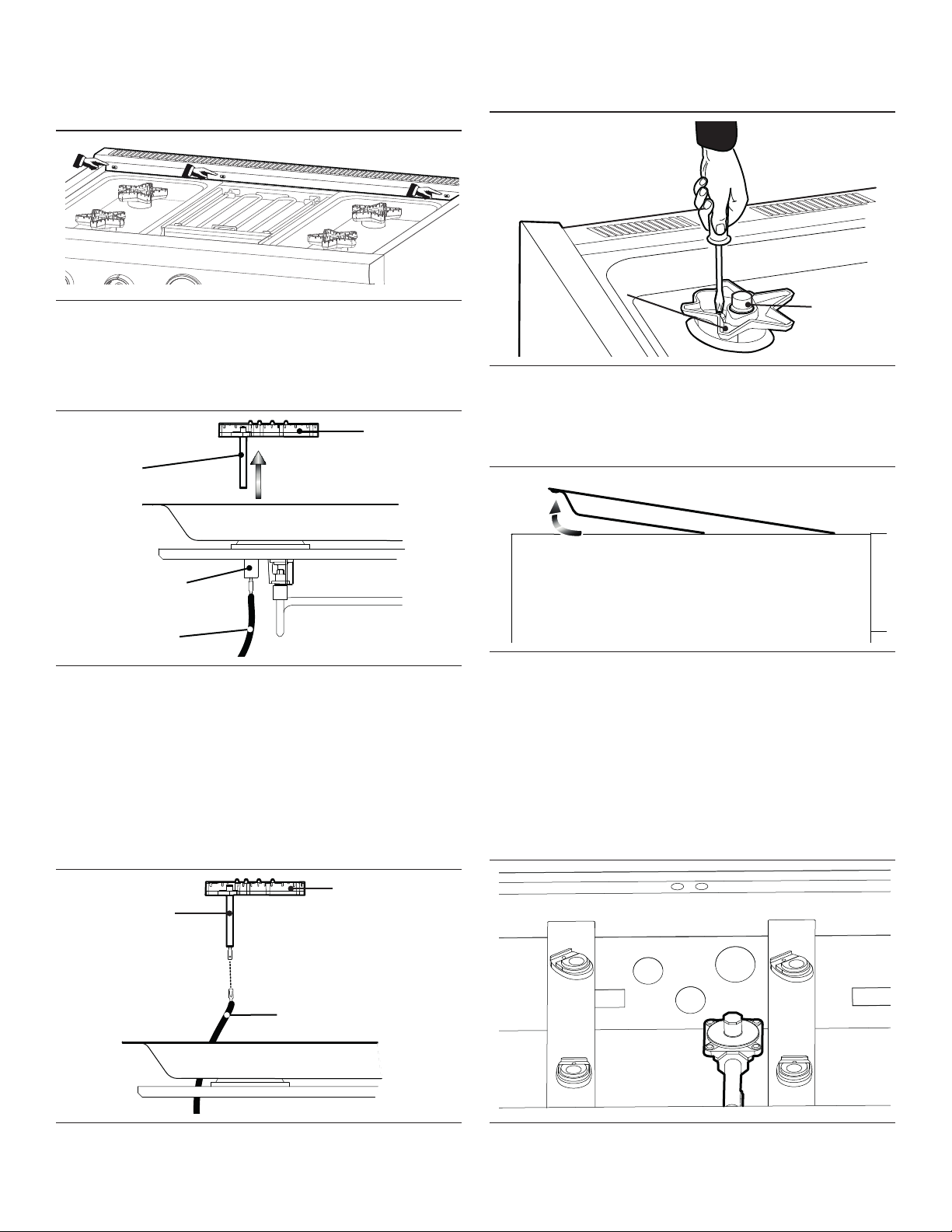

Regulator Conversion

The gas regulator is located in the cooktop, left side of

appliance. Exact location will vary per model.

English 3

Page 6

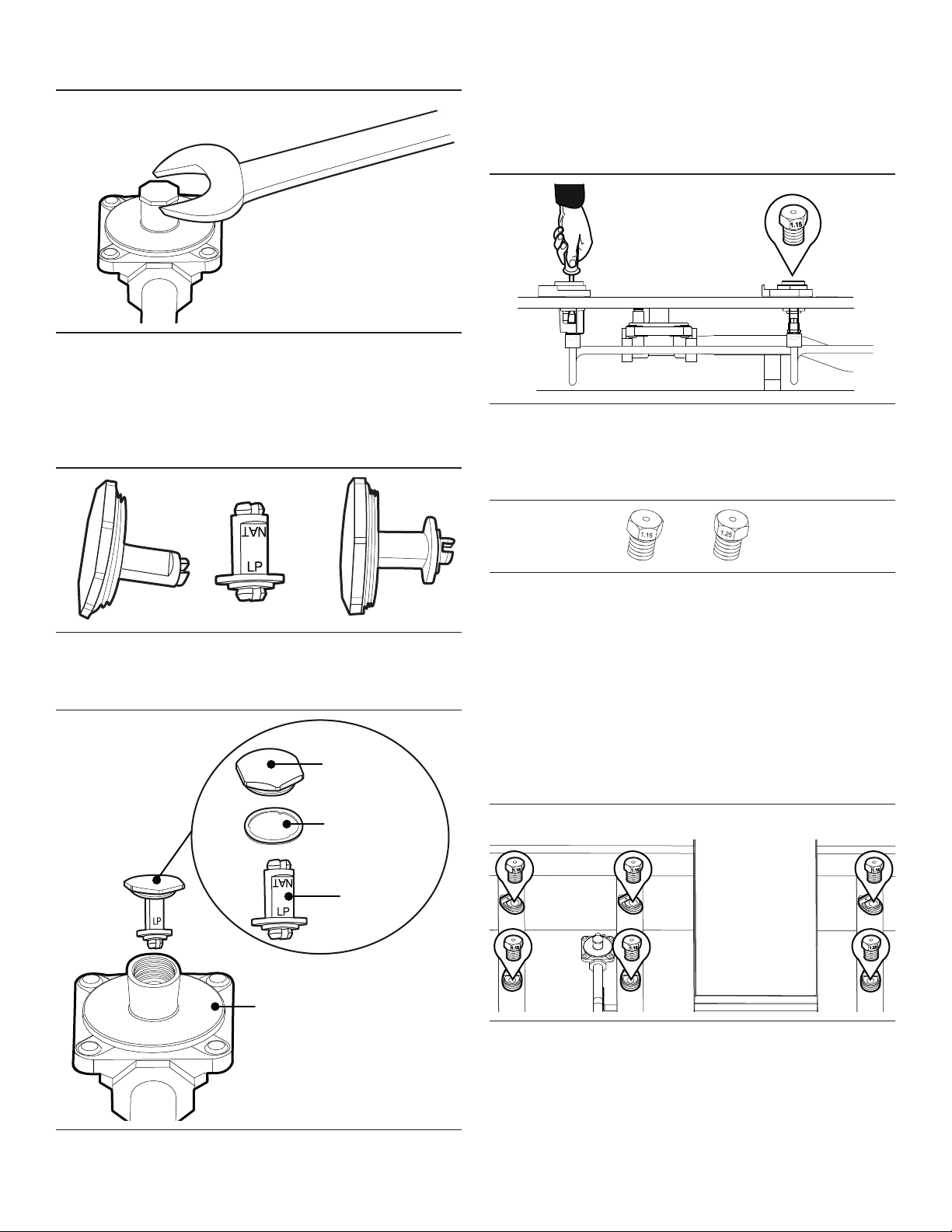

1. Remove conversion cap with a 7/8" socket or wrench.

1.15

1.15

1.15

1.15

1.15

1.25

2. Read the letters on the stem. You will see “NAT” at the

bottom of the stem. Snap-out the plunger from bottom

of the conversion cap.

3. Flip the stem over to the "LP" end, and snap the

plunger back into the cap, as shown.

Replace the Burner Orifices

1. Use a 7 mm or a 9/32” socket with 1/4” nut driver to

reach down through the jet holders and remove the

Natural Gas orifice from the burner’s jet holder.

2. Five orifices are stamped “1.15” (1.15 mm orifice

diameter) and one orifice is stamped “1.25” (1.25 mm

orifice diameter).

LP

NAT

4. Re-install conversion cap, configured for LP gas, back

into top of the regulator.

Brass Cap

Sealing Washer

Plunger

1.15 x 5 1.25 x 1

Replace the right-front burner orifice (XHI) with the

1.25 mm LP burner orifice. Replace the remaining

®

STAR

jet orifices.

• All of the replacement orifices in the conversion kit

IMPORTANT: DO NOT install the 1.25 mm LP orifice at

any other burner location than the right-front position.

1.15

1.15 1.15

burner jet orifices with one of the 1.15 mm LP

have straight threads (not pipe threads) and do not

require thread sealing compound.

1.15

1.15

1.15

English 4

Regulator Body

1.15 1.15

1.15

3. Perform a gas leakage test of each orifice and

associated supply tube fittings. See “Check for Gas

Leaks” on page 6.

• Leak-checking should occur after the orifice

conversion is complete, and before the burner is

reassembled and tested.

1.15

1.25

1.25

Page 7

Reassemble the Cooktop

1. For the single piece ignitor, carefully feed the wires

through the heat shields, if applicable. Ensure that the

ignitor wires do not crimp.

For the two piece ignitor, reinstall the heat shield, if

applicable (wire feed not necessary).

2. For the single piece ignitor, carefully feed the wires

through the spill trays. Ensure that the ignitor wires do

not crimp.

For the two piece ignitor, reinstall the spill trays (wire

feed not necessary).

3. Reinstall the Flush Island Trim with T-20 Torx screws.

4. For the single piece ignitor, carefully feed the ignitor

wires through the burner pedestals.

For the two piece ignitor, reinstall the burner pedestals

(wire feed not necessary).

5. Insert the venturi into the burner pedestals. Secure with

the black T-30 Torx screws, starting both before fully

securing either screw. Ensure that the venturi does not

‘lock down’. The venturi should be pulled out smoothly

and easily once the pedestals have been secured.

6. For the single piece ignitor, reconnect the ignitor wire to

the electrode on the burner base. Carefully feed the

ignitor wires back through their burner pedestals while

setting the burner bases back into place. Ensure that

the wires do not crimp or bunch.

For the two piece ignitor, set the burner bases back on

the burner pedestals (wire feed not necessary).

7. Secure with the burner bases with T-30 Torx screws,

starting both before fully securing either screw.

8. Replace burner caps and grates.

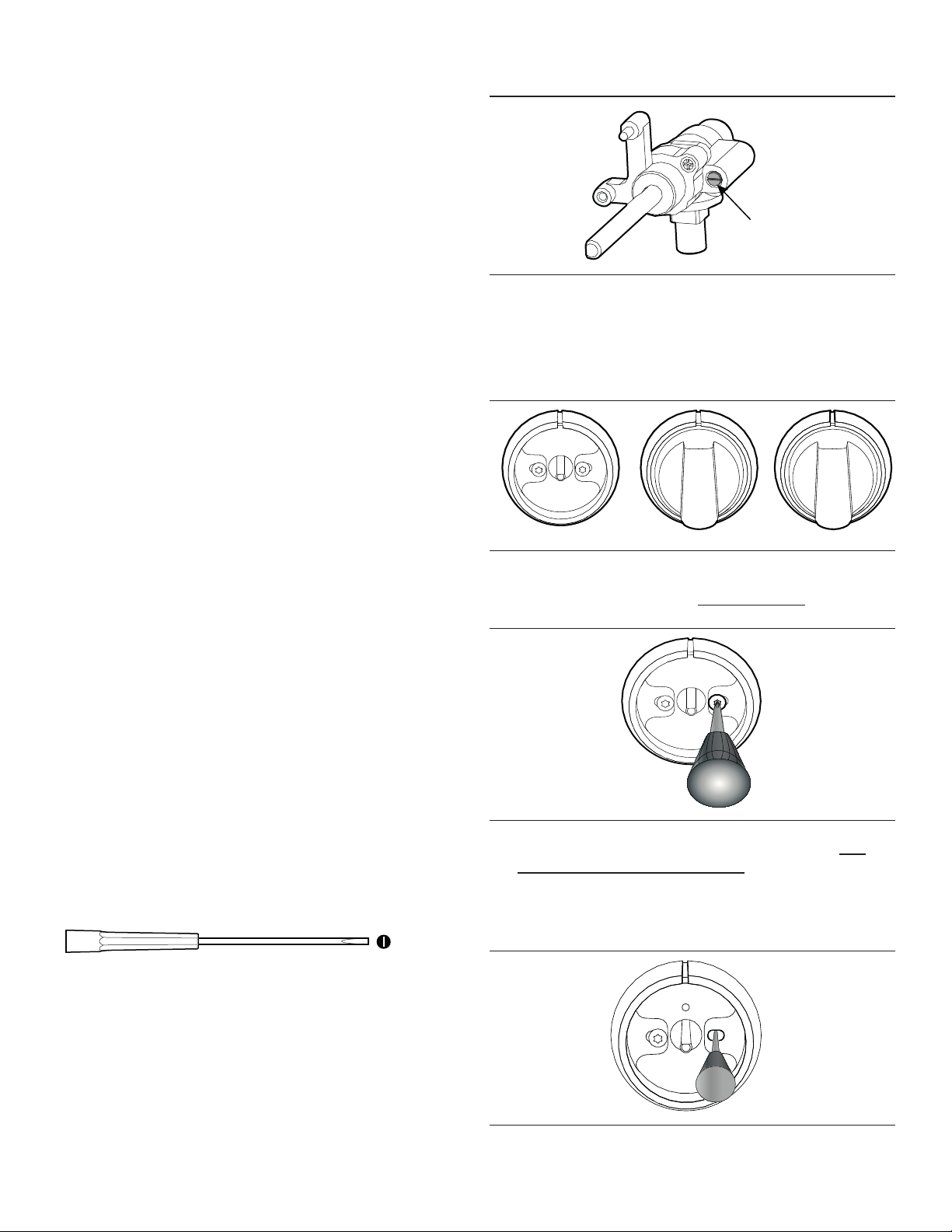

Setting valve screws

Valve Screw

1. Shut off the gas supply to the appliance.

2. Disconnect the electrical power.

3. Remove knob from the valve stem by slowly pulling

knob straight out, away from the control panel.

4. Remove the bezel-mounting screw located to the right

of the valve stem, using a

T-20 Torx driver.

Setting Valve Screws for the

Burners

Screw driver for valve screw setting

A flat-head screwdriver with an 1/8" [3.0 mm] wide, .020"

[0.50 mm] thickness tip (included) is used to reposition the

valve screws for minimum flow settings on manual valves.

Remove the protective cap before use.

5. To engage the valve screw, insert the included

blade screwdriver with 1/8” blade into the hole in the

bezel created by removal of the mounting screw. You

should feel the engagement of the screwdriver and the

valve screw.

flat-

English 5

Page 8

6. FOR STANDARD BURNERS, adjust the valve screw

By-pass screw access

hole with valve in OFF

position.

By-pass screw access

hole with valve in LOW

position.

by turning the valve screw clockwise about an

1/8 turn. Adjust the valve screw as little as required to

reach satisfactory simmer results. Due to normal

fluctuations in gas pressure, over-adjustment of valve

screw may affect flame stability.

7. FOR EXTRALOW BURNERS, auto-cycling of the

®

burners allows for exceptional simmer results

XLO

and adjustment is not required. However, adjustment

to the valve screw may be performed to suit individual

preference. Always turn OFF the power to the

appliance before adjusting flame settings. Turn the

valve stem to the LOW position for proper access to

the valve screws through clearance holes in the

potentiometers.

By-pass screw access

By-pass screw access

hole with valve in OFF

hole with valve in OFF

position.

position.

By-pass screw access

By-pass screw access

hole with valve in LOW

hole with valve in LOW

position.

position.

5. Monitor the base of the orifice junction to see if bubbles

are forming anywhere around the threaded connection.

• Bubbles forming are indications of gas leaks. The

amount and sizes of the bubbles are indications of

the severity of the leakage.

6. Repair all gas leaks immediately after their discovery;

this can often be accomplished by re-tightening the

orifice.

7. Since considerable torque is sometimes used during

orifice replacement, leak-check other fitting junctions

leading up to the orifice as well.

8. Turn off the gas and electrical supplies.

9. Reassemble the appliance in preparation for testing

the newly-converted burner systems.

Checking manifold pressure

(if necessary)

Checking the appliance manifold pressure is NOT

REQUIRED for the Propane Gas conversion; however, if

the outlet pressure of the gas regulator or the inlet pressure

to the appliance is suspect, the following procedure can be

used to check the manifold pressure.

Check for Gas Leaks

WARNING!

DO NOT use a flame of any kind to check for gas leaks.

Gas leakage checking using a liquid

solution

Leak-checking should occur after the orifice conversion is

complete, and before the burner is reassembled and

tested.

1. Make sure that all of the LP orifices have been

tightened and that all valves and controls are in the

OFF position.

2. Turn on electrical and gas supplies.

3. Spray a generous amount of soap and water mixture—

or other solution designed for checking gas leaks—on

the threaded junction at the base of the orifice. Avoid

spraying electrical devices. (A 25% dishwashing liquid

to water mixture is effective for this.)

4. Briefly turn on the valve or control while blocking the

orifice hole with a soft pencil eraser, your finger, or

something similar. It is normal to hear spark ignition

noise during this process.

1. Attach a portable or hand-held manometer, that reads

pressure in inches water column (WC), using a piece of

PVC or vinyl tubing.

2. Turn on the electrical and gas supplies to the

appliance.

3. Turn one of the cooktop burners to HI position. This is

important to acquire a true pressure reading under gas

flow conditions.

4. Turn the manual valve for the burner being monitored

to HI position. (Spark ignition noise will be heard

coming from this burner.)

English 6

Page 9

• The manifold pressure reading on the manometer

Star

®

Star

®

should be between 9.50" and 10.50" WC for an

appliance regulator converted to LP gas. If the

manifold pressure reading is below this range,

verify that the regulator has been properly

converted for use with LP gas, and that the inlet

pressure to the appliance is between 11.0" and

14.0" WC.

Check Flame Characteristics

To observe the burner flames, it may be necessary to turn

off lights or close window blinds to darken the room for

easier viewing of the flame.

1. Test STAR

knob and turn it to HI. The igniter electrode and spark

module will produce a clicking sound. Once the air has

been purged from the supply lines, the burner should

light within four seconds.

• The flames should be stable, with no excessive

NOTE: It is normal for slight yellow tipping of the flames to

appear after a few minutes of operation using Propane (LP)

Gas. Orange-colored streaks in the flame are produced

from burning airborne debris; this is normal during initial

start up and should dissipate within a few minutes of

operation.

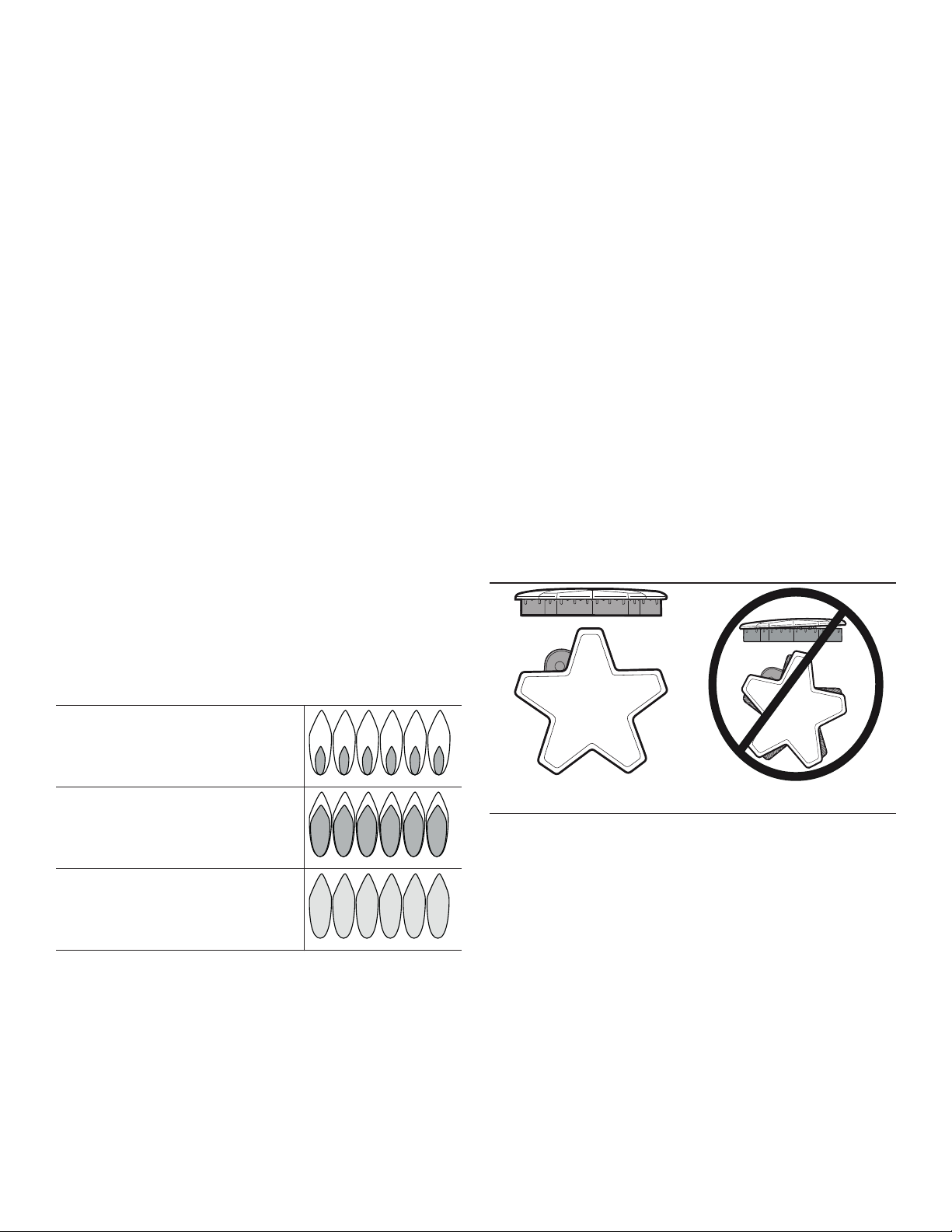

Yellow Flames:

Further adjustment is required.

®

burner ignition. Push in the burner control

noise. The inner cones of the individual flames

should be defined and separate from each other.

Portions of the flame, along the burner, should not

exhibit excessive or continuous indications of

“lifting” or “lazy flame”.

3. Test reignition of the XLO and observe the carry-over

of the small simmer flames as the XLO system cycles

the burners on and off.

• If the flame performance is not acceptable it may

be necessary to readjust the valve screw for a top

burner that does not have sufficient carry-over of

the flame. Turn the valve screw very slightly

counter-clockwise until carry-over of the flame is

acceptable. (See Setting Valve Screws for the

STAR Burners).

• If the burner flame is uneven, flutters, makes

excessive noise, or lifts, some of the slots in the

burner base may be blocked with food spillage or

other debris. Clogged slots can be cleared using a

straightened paper clip, needle, or similar object.

Hard-to-remove, encrusted food or debris can

sometimes be removed using a steel wool pad or

fine wire brush.

4. Burner flames that are “lazy”, with excessively-long

flames, can be created by an incorrectly fitted burner

cap—from which many of the outer mantles of the

individual flames will tend to “coalesce” or blend

together.

Verify that the burner cap is seated properly on its

burner base. The cap should fit reasonably flat when

correctly-positioned on the base and not rock

significantly.

Yellow Tips on Outer Cones:

Normal for LP Gas

Soft Blue Flames:

Normal for Natural Gas

2. Turn valve to SIM to see that the flame continues to

wrap around the burner. Blow out the flame, or use a

quick fan motion from a writing tablet or piece of

cardboard to extinguish the flame, and then observe

the burner’s ability to reignite and wrap around (also

called “carry-over”) the burner within several seconds.

This flame “carry-over” is essential for proper burner

ignition and reignition.

Correct burner cap Incorrect burner cap

5. Repeat the Ignition and Flame Test procedures for

each rangetop burner.

English 7

Page 10

Conversion Label Placement

1. For proper identification and evidence of the

appliance’s conversion for high-altitude operation, affix

the provided Conversion Label in a location next to the

Rating Labels on the appliance.

Data Rating

Label Location

2. After placing the Conversion Label, use a permanent

marker to fill-in the date, name, and address of your

service organization on the Conversion Label.

English 8

Page 11

Table des Matières

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Importantes Consignes de Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instructions de Conversion . . . . . . . . . . . . . . . . . . . . . . . . . 2

Avant de commencer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Préparation conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Comment démonter la surface de cuisson . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conversion d’un régulateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Remplacement des orifices des brûleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Comment remonter la surface de cuisson. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Réglage des vis de la soupape manuelle des brûleurs STAR . . . . . . . . . . . . 5

Inspection des fuites de gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Vérification de la pression d’admission (si nécessaire) . . . . . . . . . . . . . . . . . 7

Vérification des caractéristiques de la flamme . . . . . . . . . . . . . . . . . . . . . . . . 7

Pose de l’étiquette de conversion au LP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Entretien, pièces et accessoires. . . . . . . . . . . . . page verso

Cet appareil électroménager de

mc

THERMADOR

BSH Home Appliances Ltd.

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

est fait par

Questions?

1-800-735-4328

www.thermador.ca

Nous attendons de vos nouvelles!

Page 12

Sécurité

IMPORTANTES CONSIGNES DE SÉCURITÉ

LISEZ ET CONSERVEZ CES INSTRUCTIONS

Ce jeu sert à la conversion du gaz naturel au gaz propane

(LP) des cuisinières mixtes PROFESSIONAL PRO

GRAND de THERMADOR. Ce jeu ne peut pas servir à

convertir d’anciens modèles de surfaces de cuisson et de

cuisinières PROFESSIONAL de THERMADOR (voir la

page couverture pour connaître les modèles auxquels

s'appliquent ces instructions). Ce jeu ne peut pas être

utilisé pour convertir les cuisinières pour tout type de gaz

PROFESSIONAL de THERMADOR, ou tout autre type

d’électroménager.

IMPORTANT : Seuls un technicien en entretien et en

réparation ou un installateur qualifié devraient procéder à

la conversion de cet appareil.

INSTALLATEUR : Veuillez laisser les instructions de

conversion de cet appareil au propriétaire.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour

consultation ultérieure.

ATTENTION

Débranchez l’alimentation électrique et coupez

l’approvisionnement en gaz avant de procéder à la

conversion de cet appareil. Avant de mettre l’appareil

sous tension, assurez-vous que tous les boutons de

contrôle sont hors circuit.

AVERTISSEMENT

Conservez les pièces de gaz naturel pour une

reconversion potentielle de votre appareil à son ajustement

d'origine.

Au technicien responsable de l’installation :

Il est important que vous preniez connaissance de ce qui

suit AVANT de procéder à la conversion de l’appareil.

• Assurez-vous que le système d’approvisionnement en

gaz propane (LP) est disponible et prêt à être utilisé.

Cela s’avère particulièrement important pour les

nouvelles constructions.

• Vous devez prévoir suffisamment de temps et de

ressources pour procéder convenablement et

totalement à la conversion au LP avant de quitter

l’endroit où vous avez effectué le travail. Chaque étape

décrite dans les présentes instructions doit être suivie

pour convertir en toute sécurité l’appareil et assurer un

fonctionnement adéquat au gaz propane. LA

CONVERSION INADÉQUATE OU INCOMPLÈTE DE

L’APPAREIL PEUT PRÉSENTER UN RISQUE

D’ACCIDENT.

AVERTISSEMENT

Disposition de la proposition 65 de l'État de la

Californie

Ce produit contient ou facilite l'émission d'un ou de

plusieurs produits chimiques qui, selon l'État de la

Californie, peuvent causer le cancer, des anomalies

congénitales ou d'autres problèmes congénitaux.

Ce jeu de conversion doit être installé par

une entreprise d’entretien et de réparation

qualifiée conformément aux instructions du

fabricant ainsi qu’aux codes et exigences en

vigueur. Si les directives comprises dans les

présentes instructions ne sont pas suivies

avec exactitude, un incendie, une explosion

ou des émanations de monoxyde de carbone

pourraient survenir, ce qui pourrait causer

des dommages matériels, entraîner des

blessures ou causer la mort. L’entreprise d’entretien et

de réparation qualifiée est responsable de l’installation

adéquate de ce jeu de conversion. L’installation n’est

pas considérée comme adéquate et complète avant que

le fonctionnement de l’appareil converti n’ait été vérifié

en conformité avec les instructions fournies par le

fabricant du jeu de conversion.

AVERTISSEMENT

Si les orifices pour gaz naturel sont laissés en place

pendant que l’on tente de faire fonctionner l’appareil

avec le gaz propane, à un réglage de pression élevé

pour gaz LP, les brûleurs produiront une flamme plus

grosse ce qui peut émettre des niveaux élevés de

monoxyde de carbone dans la pièce, causer un incendie

ou une explosion.

AVERTISSEMENT

Ne laissez JAMAIS la conversion au gaz partiellement

terminée. Si l’appareil est utilisé alors que la conversion

n’est pas terminée, de hauts volumes de monoxyde de

carbone pourraient être relâchés, ou un incendie ou une

explosion pourrait survenir.

Française 1

Page 13

Instructions de Conversion

Avant de commencer

ATTENTION

Avant de procéder à la conversion, coupez

l’approvisionnement en gaz de l’appareil, puis

débranchez l’alimentation électrique.

PIÈCES FOURNIES

Ciseaux

Clé Torx T-30

Clé Torx T-32

Tourne-écrou 7 mm

Clé ou douille 7/8 po.

Tournevis d’horloger avec lame de 1/8 po x 0,020 po

PIÈCES ET OUTILS REQUIS

Description Quantité

Instructions 1

Ruban mousse, 1 po 1

Étiquette de conversion au propane 1

Orifice d’injection de brûleur STAR, 1,15 mm 5

Orifice d’injection de brûleur STAR, 1,25 mm 1

• La mousse aide à maintenir l’orifice dans

l’extrémité du tourne-écrou pour ne pas qu’il tombe

dans l’appareil pendant l’installation ou le retrait.

Comment démonter la surface

de cuisson

IMPORTANT : Assurez-vous que la source d'alimentation du disjoncteur est bloquée et que l'approvisionnement en gaz est fermé.

1. Enlevez les grilles de la surface de cuisson.

2. Enlevez les chapeaux des brûleurs STAR

3. puis enlevez les deux vis Torx à la base de chaque

brûleur à l’aide d’une clé T-30.

mc

.

ATTENTION

Lorsque vous branchez l’appareil au gaz propane,

assurez-vous que le réservoir de gaz propane est muni

de son propre mécanisme régulateur à haute pression. La

pression de gaz maximale de cet appareil ne devrait pas

excéder 14,0 pouces de colonne d’eau à partir du

régulateur du réservoir de gaz propane.

Préparation Conversion

1. Coupez l’alimentation électrique du disjoncteur

principal ou de la boîte de fusible.

2. Couper une pièce d’adhésif mousse de 3/8 po de long

fournie dans le nécessaire et placer sur le bord du

tourne-écrou utilisé pour remplacer les orifices de

brûleur Star, comme montré.

Française 2

Page 14

4. Pour faciliter le retrait des plateaux collecteurs,

Socle de brûleur

enlevez, selon le modèle, les trois (3) ou quatre (4) vis

Torx T-20 en acier inoxydable de la garniture avant

pour installation de type îlot.

5. Débranchez l'allumeur.

A.) Comment débrancher un allumeur à deux

pièces

1) Soulevez doucement la base du brûleur.

Base du

brûleur

Electrode

6. Retirez les vis du socle du brûleur à l'aide d'un

tournevis Torx T-30.

Socle de brûleur

Socle de brûleur

Venturi

7. Enlevez doucement la plaque du brûleur et le venturi.

8. Enlevez le plateau collecteur en les faisant tourner vers

le haut puis en le poussant vers l'arrière.

Boîtier de l’allumeur

Fil de l’allumeur

B.) Comment débrancher un allumeur à une pièce

1) Soulevez doucement la base du brûleur.

2) Sur l’électrode de chaque brûleur, débranchez le

pôle femelle du pôle mâle du câble d’allumage.

IMPORTANT : Vous devez enfoncer la languette de

verrouillage du connecteur femelle pour le retirer

du pôle de l’électrode.

Base du brûleur

Electrode

Fil de l’allumeur

9. Enlevez l'écran thermique, s'il y en a un. Certains

modèles sont munis d'un écran à largeur double qui se

prolonge sous le plateau collecteur adjacent.

Conversion d’un régulateur

Le régulateur de pression du gaz est situé près du coin

arrière gauche, à l’intérieur de la partie supérieure de

l’appareil. L'emplacement exact varie selon le modèle.

Française 3

Page 15

1. Enlevez la pièce de conversion avec une

1.15

1.15

1.15

une douille de 7/8 po.

2. Lisez les lettres apparaissant sur la tige. Les lettres

"NAT" sont écrites au bas de la tige. Retirez le piston

de la partie inférieure du bouchon de conversion.

3. Faites ressortir la tige de la base de la pièce, inversez

la tige de manière à ce que l’extrémité LP soit visible et

remettez la tige dans la pièce, comme illustré.

clé fixe ou

Remplacement des orifices

des brûleurs

1. Utilisez une douille de 7 mm (ou 9/32 po) avec une clé

de1/4 po et une rallonge pour atteindre l’orifice à gaz

naturel à travers le venturi et l’enlever du porte-

injecteur du brûleur.

2. Cinq orifices portent l’inscription « 115 » (diamètre de

l’orifice : 1,15 mm), comme illustré. Un orifice porte

l’inscription « 125 » (diamètre de l’orifice : 1,25 mm).

LP

NAT

4. Réinstallez la pièce de conversion – configurée pour le

gaz propane – sur le dessus du régulateur.

Chapeau

en laiton

Rondelle de

fermeture

Piston

1.15 x 5 1.25 x 1

Remplacez le avant droit (XHI) orifice d'injection des

brûleurs STAR par des orifices d'injection de 1,25 mm

pour GPL fournis avec la trousse. Remplacez autres

les orifices d'injection des brûleurs STAR par des

orifices d'injection de 1,15 mm pour GPL fournis avec

la trousse.

• Les orifices de remplacement du jeu de conversion

au LP ont un filetage cylindrique (et non un filetage

au pas de gaz) et ne requièrent pas l’utilisation de

mastic pour joints filetés.

IMPORTANT : N’installez PAS l’orifice LP de 1,25 mm à un

autre endroit qu’en avant à droite.

1.15

1.15 1.15

1.15

1.15

1.15

Française 4

Corps du détendeur

Page 16

3. Procédez à une brève inspection des fuites de gaz sur

chaque orifice et raccord selon les instructions

données à la section « Inspection des fuites de gaz ».

• L’inspection des fuites devrait se faire une fois que

la conversion des orifices est terminée et avant

que les brûleurs ne soient réassemblés et testés.

Comment remonter la surface

de cuisson

1. Pour les allumeurs à une pièce, faites passer les fils à

travers l'écran thermique, s'il y en a un. Assurez-vous

que les fils de l'allumeur ne s'enroulent pas.

Pour les allumeurs à deux pièces, réinstallez l'écran

thermique, s'il y en a un (il n'est pas nécessaire de faire

passer les fils).

2. Pour les allumeurs à une pièce, faites passer les fils à

travers le plateau collecteur. Assurez-vous que les fils

de l'allumeur ne s'enroulent pas.

Pour les allumeurs à deux pièces, réinstallez le plateau

collecteur (il n'est pas nécessaire de faire passer les

fils).

3. Réinstallez la garniture d'îlot avec des vis Torx T-20.

4. Pour les allumeurs à une pièce, faites passer les fils de

l'allumeur à travers le socle du brûleur.

Pour les allumeurs à deux pièces, réinstallez le socle

du brûleur (il n'est pas nécessaire de faire passer les

fils ils).

5. Insérez le venturi dans le socle du brûleur. Fixez-le en

place à l'aide de vis noires Torx T-30 en les insérant

partiellement avant de les visser jusqu'au fond.

Assurez-vous que le venturi n'est pas bloqué. Le

venturi doit être facile à enlever lorsque le socle est en

place.

6. Pour les allumeurs à une pièce, rebranchez le fil de

l'allumeur à l'électrode de la base du brûleur. Faites

doucement passer les fils de l'allumeur à travers la

plaque du brûleur et remettez la base du brûleur en

place. Assurez-vous que les fils de l'allumeur ne

s'enroulent pas.

Pour les allumeurs à deux pièces, réinstallez la base

du brûleur sur le socle (il n'est pas nécessaire de faire

passer les fils).

7. Fixez la base du brûleur à l'aide de vis Torx T-30 en les

insérant partiellement avant de les visser jusqu'au

fond.

8. Remettez les chapeaux des brûleurs et les grilles en

place.

Réglage des vis de la soupape

manuelle des brûleurs STAR

Tournevis pour le réglage de la vis de la

soupape

Un tournevis avec une pointe d’une largeur de 1/8 po

[3,0 mm] et d’une épaisseur de 0,020 po [0,50 mm],

apparaissant sur la photo ci-dessous, doit être utilisé pour

remettre en place les vis de dérivation et obtenir les

réglages minimaux de débit des soupapes manuelles.

Enlevez les bouchons de protection avant d'utiliser

l'appareil.

Réglage des vis de la soupape manuelle

Vis de la soupape

1. Coupez l’alimentation électrique du disjoncteur

principal ou de la boîte de fusible.

2. Coupez l’approvisionnement en gaz de la

cuisinière en fermant la vanne manuelle d’arrêt de

gaz.

3. Enlevez le bouton de la tige de la soupape en le tirant

lentement vers l’extérieur, en vous éloignant du tableau

de commande.

Française 5

Page 17

4. Enlevez la vis de montage de la collerette

Trou d’accès de la vis

de dérivation avec

soupape à la

position OFF.

Trou d’accès de la vis

de dérivation avec

soupape à la

position LOW.

d’encastrement située à la droite de la tige de la

soupape avec une clé Torx T-20.

Inspection des fuites de gaz

AVERTISSEMENT

N’utilisez PAS de flamme pour vérifier les fuites de gaz.

Inspection des fuites de gaz avec une

solution liquide

L’inspection des fuites devrait se faire une fois que la

conversion des orifices est terminée et avant que les

brûleurs ne soient réassemblés et testés.

5. Pour enclencher la vis de la soupape, insérez le

tournevis avec une lame de 1/8 po dans le trou de la

collerette d’encastrement créé par le retrait de la vis de

montage.

6. POUR LES BRÛLEURS STANDARDS, ajustez la vis

de la soupape en la tournant d'environ 1/8 de tour dans

le sens des aiguilles d'une montre. Ajustez la vis de la

soupape pour obtenir la puissance suffisante pour faire

mijoter des plats. Compte tenu des fluctuations

normales de pression du gaz, si vous serrez trop la vis

de la soupape, la stabilité de la flamme pourrait s'en

trouver affectée.

7. POUR LES BRÛLEURS EXTRALOW, le cycle

automatique des brûleurs XLOW permet l'utilisation

d'une fonction de mijotage exceptionnelle, sans aucun

ajustement. Toutefois, l'utilisateur peut ajuster la vis de

la soupape selon ses préférences. Éteignez toujours

l'alimentation électrique de l'appareil avant d'ajuster la

flamme. Ajustez la tige de la soupape à la position

LOW pour pouvoir accéder aux vis de la soupape à

travers les trous de passage des potentiomètres.

Trou d’accès de la vis

Trou d’accès de la vis

de dérivation avec

de dérivation avec

soupape à la

soupape à la

position OFF.

position OFF.

Trou d’accès de la vis

Trou d’accès de la vis

de dérivation avec

de dérivation avec

soupape à la

soupape à la

position LOW.

position LOW.

1. Assurez-vous que tous les orifices LP ont été serrés et

que toutes les soupapes et les commandes sont à la

position OFF.

2. Branchez l’alimentation électrique et

l’approvisionnement en gaz.

3. Vaporisez généreusement avec une solution d’eau

savonneuse – ou toute autre solution conçue pour

vérifier les fuites de gaz – la jonction filetée à la base

de l’orifice. Évitez de vaporiser les composantes

électriques. (Un mélange composé de 25 % de savon

à vaisselle dans de l’eau est efficace pour effectuer

cette vérification.)

4. Allumez brièvement la soupape ou la commande en

bloquant le trou de l’orifice avec la gomme à effacer

d’un crayon, votre doigt ou quelque chose de

semblable.

5. Surveillez la base de la jonction de l’orifice pour voir si

des bulles se forment autour du raccord fileté.

• Les bulles indiquent qu’il y a une fuite de gaz. La

quantité et la taille des bulles sont des indicateurs

de l’ampleur de la fuite.

6. Réparez les fuites de gaz immédiatement lorsque vous

les découvrez; pour ce faire, il suffit souvent de

resserrer l’orifice.

7. Puisque les pièces sont parfois serrées fort lors du

remplacement des orifices, vérifiez également les

fuites aux autres jonctions de raccords menant à

l’orifice.

8. Coupez l’alimentation électrique et fermez

l’approvisionnement en gaz.

9. Réassemblez l’appareil avant de tester les systèmes

des brûleurs nouvellement convertis.

Française 6

Page 18

Vérification de la pression

Vérification des

d’admission (si nécessaire)

Il n’est PAS NÉCESSAIRE de vérifier la pression

d’admission lors de la conversion d’un appareil au gaz

propane. Toutefois, si la pression de sortie du régulateur

de pression du gaz ou la pression d’entrée vers l’appareil

est suspecte, la procédure suivante peut être utilisée pour

vérifier la pression d’admission.

1. Fixez un manomètre portable ou à main qui lit la

pression en pouces de colonne d’eau (po de C.E.) en

utilisant un morceau de PVC ou un tube en vinyle.

caractéristiques de la flamme

Lorsque vous observez les flammes des brûleurs, enlevez

aussi peu de composantes que nécessaire pour en avoir

une vue non obstruée. Vous pourriez avoir à éteindre les

lumières ou fermer les stores pour assombrir la pièce et

ainsi mieux voir la flamme.

1. Testez l’allumage des brûleurs. Appuyez sur le bouton

de commande du brûleur et tournez-le dans le sens

antihoraire jusqu’à la position HI. L’électrode de

l’allumeur et le module d’étincelle produiront un bruit de

déclic. Une fois que l’air est sorti de la conduite

d’alimentation, le brûleur devrait s’allumer en moins de

quatre (4) secondes.

• Les flammes du propane doivent être stables et ne

pas être trop bruyantes. Les cônes intérieurs des

flammes doivent être bien définis et être

distinctement séparés l’une de l’autre.

NOTE : Il est normal que des pointes légèrement jaunes

apparaissent à l’extrémité des flammes après quelques

minutes de fonctionnement au gaz propane (LP). Les traits

orangés dans la flamme sont produits par la combustion de

débris flottant dans l’air. Ce phénomène est normal durant

les moments suivant l’allumage et devrait se dissiper après

quelques minutes de fonctionnement.

2. Branchez l’alimentation électrique et

l’approvisionnement en gaz de la cuisinière.

3. Allumez l’un des brûleurs à la position HI. Il est

important d’obtenir une vraie lecture de pression dans

ces conditions de circulation du gaz.

4. Tournez la soupape manuelle du brûleur testé à la

position HI. (Des bruits d’allumage par étincelle seront

émis par ce brûleur.)

5. La lecture de la pression d’admission sur le manomètre

devrait osciller entre 9,50 et 10,50 po de C.E. pour le

régulateur de tout appareil converti au gaz propane.

• Si la lecture de la pression d’admission est

inférieure, assurez-vous que la conversion du

régulateur a été bien effectuée pour une utilisation

au gaz propane et que la pression d’entrée vers

l’appareil oscille entre 11,0 et 14,0 po de C.E.

Flamme jaune :

Réglage nécessaire.

Pointe jaune sur cône extérieur :

Normal pour gaz LP.

Flamme bleue :

Normal pour gaz naturel.

2. Ajustez la soupape de commande du brûleur à SIM

pour vérifier si la flamme continue de brûler tout autour

du brûleur. Éteignez la flamme en soufflant dessus ou

en l’éventant à l’aide d’un bloc-notes ou d’un morceau

de carton, puis observez la capacité du brûleur à se

rallumer et à propager la flamme sur tout le brûleur en

quelques secondes. La propagation de la flamme est

essentielle pour l’allumage et le rallumage adéquats du

brûleur..

Française 7

Page 19

3. Testez la capacité de rallumage des deux brûleurs

Star

®

Star

®

Emplacement de la

plaque signalétique

STAR sur le côté gauche de l’appareil en positionnant

les boutons de commande à XLO et observez la

propagation des petites flammes de mijotage pendant

que le système XLO allume et éteint les deux brûleurs.

• Si le rendement de la flamme n’est pas

convenable, assurez-vous que des orifices de LP

aux dimensions adéquates sont installés et que le

régulateur a été convenablement converti pour une

utilisation au LP.

• Si la flamme d’un brûleur est inégale, scintille,

produit des sons excessifs ou s’élève, certaines

des fentes de la base du brûleur sont possiblement

obstruées par des débordements d’aliments ou par

d’autres débris. Les fentes bloquées peuvent être

nettoyées à l’aide d’un trombone, d’une épingle ou

d’un objet semblable. Les aliments ou les débris

incrustés et difficiles à enlever peuvent parfois être

retirés en utilisant une laine d’acier ou une brosse

métallique.

4. Une flamme « paresseuse », avec de longues

flammes, peut se créer en raison d’un chapeau de

brûleur mal placé. Plusieurs des manteaux supérieurs

des flammes individuelles auront tendance à fusionner

ou à confluer.

Assurez-vous que le chapeau du brûleur est

convenablement installé sur la base du brûleur.

Lorsque positionné correctement, le chapeau devrait

être assez à plat sur la base et ne pas trop se balancer.

Pose de l’étiquette de

conversion au LP

1. Pour une identification et une preuve adéquates de la

conversion de l’appareil au gaz propane (LP), apposez

l’étiquette de conversion fournie près des étiquettes de

classification de l’appareil. Cela est particulièrement

important si l’appareil converti est réinstallé dans une

maison différente.

Emplacement de la

Emplacement de la

plaque signalétique

plaque signalétique

2. Une fois que l'étiquette de conversion est apposée,

utilisez un marqueur indélébile pour y inscrire la date,

le nom et l'adresse de l'entreprise responsable de la

conversion.

Correct de la cuvette du

brûleur

Positionnement incorrect de

la cuvette du brûleur

5. Répétez la procédure d'essai de flamme et d'allumage

pour chaque brûleur de la surface de cuisson.

Française 8

Page 20

Índice de materias

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones Importantes de Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones de conversión . . . . . . . . . . . . . . . . . . . . . . . . 2

Antes de comenzar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preparación de conversión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cómo desmontar la placa de cocción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conversión del regulador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Reemplazo de los orificios de los quemadores . . . . . . . . . . . . . . . . . . . . . . . . 4

Cómo volver a ensamblar la placa de cocción . . . . . . . . . . . . . . . . . . . . . . . . 5

Ajuste de los tornillos de la válvula manual de los quemadores . . . . . . . . . . . 5

Prueba de los escapes de gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Verificación de la presión de admisión (si hace falta) . . . . . . . . . . . . . . . . . . . 7

Características de la llama . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Colocar la etiqueta de conversión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Servicio, piezas y accesorios . . . . . . . . . . . . . contraportada

Este electrodoméstico de THERMADOR® está

hecho por BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

¿Preguntas?

1-800-735-4328

www.thermador.com

¡Esperamos oír de usted!

Page 21

Seguridad

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

Este kit es utilizado para Planchas THERMADOR

PROFESSIONAL PRO GRAND

dual, y PRO HARMONY® estufas de combustible dual, de

operación con gas natural a Gas (LP). Este kit no puede

ser utilizado para convertir modelos anteriores de parrillas

o estufas THERMADOR PROFESSIONAL distintas a los

indicados en estas instrucciones (en la portada puede

encontrar los modelos a los que se aplican estas

instrucciones). Este kit no puede ser utilizado para

convertir estufas de todo gas THERMADOR

PROFESSIONAL

unidad de otra marca.

IMPORTANTE: Solo técnicos de servicio o instaladores

calificados o deben realizar la conversión.

INSTALADOR: Por favor deje estas Instrucciones de

Conversión junto a la unidad con el dueño.

DUEÑO: Por favor conserve estas instrucciones para

referencia futura.

®

, quemadores de horno, o cualquier otra

®

estufas de combustible

Guarde las piezas del gas natural para poder devolver su

aparato a su ajuste original.

Al Agente de Servicio:

Es importante que conozca lo siguiente ANTES de

comenzar la conversión de gas de la unidad.

• Confirme que el sistema de suministro de Gas

Propano (LP) está disponible y listo para utilizarse.

Esto es particularmente importante para

construcciones nuevas.

• Debe planear para tener suficiente tiempo y recursos

para realizar el proceso de conversión a LP

apropiadamente y completamente antes de abandonar

el sitio de trabajo. Cada paso descrito en estas

instrucciones debe ser realizado para convertir con

seguridad la unidad para una operación apropiada con

Gas Propano. LA CONVERSIÓN A GAS

INCOMPLETA O INADECUADA DE LA UNIDAD

PUEDE CREAR RIESGOS A LA SEGURIDAD.

ADVERTENCIA

PRECAUCIÓN

Desconecte el gas y corriente eléctrica antes de realizar

la conversión. Antes de encender la corriente,

asegúrese que todos los controles están en posición de

APAGADO.

ADVERTENCIA

Este kit de conversión debe ser instalado por

una agencia de servicio calificada de

acuerdo con las instrucciones del fabricante

y todos los códigos aplicables y

requerimientos de las autoridades que

tengan jurisdicción. Si la información de estas

instrucciones no es seguida exactamente puede surgir

fuego, explosión o producción de monóxido de carbono

causando daños a propiedad, lesiones personales o la

muerte. La agencia de servicio calificada es

responsable por la instalación apropiada de este kit. La

instalación no es apropiada o completa hasta la

operación de la unidad convertida es verificada como se

especifica en las instrucciones del fabricante proveídas

con el kit.

Advertencias en virtud de la Proposición 65 del

estado de California:

Este producto contiene una o más sustancias químicas

que el estado de California sabe que provocan cáncer,

defectos congénitos, u otro daño reproductivo.

ADVERTENCIA

Si los orificios de Gas Natural se dejan instalados

mientras se intenta operar la unidad utilizando Gas

Propano (LP), a la presión más alta establecida para

Gas LP, los quemadores producirán flamas largas que

pueden emitir altos niveles de monóxido de carbono a la

habitación, o un incendio o explosión pueden ocurrir.

ADVERTENCIA

NUNCA deje la conversión parcialmente terminada. Si

se opera la unidad con la conversión incompleta, altos

niveles de monóxido de carbono pueden ser emitidos, o

un incendio o explosión pueden ocurrir.

Español 1

Page 22

Instrucciones de conversión

Antes de comenzar Preparación de Conversión

1. Asegúrese de que la fuente de alimentación eléctrica

PRECAUCIÓN

Antes de proceder con la conversión, cierre el suministro

de gas a la unidad antes de desconectar la corriente

eléctrica.

HERRAMIENTAS REQUERIDAS

Tijeras

Llave Torx T-30

Llave Torx T-20

Aprietatuercas o llave de 1/4''

Llave o dado de 7/8''

Desarmador plano de con hoja 1/8'' X .020''

ARTÍCULOS INCLUIDOS

DESCRIPCIÓN CANTIDAD

del disyuntor esté bloqueada y que el suministro de

gas esté cerrado.

2. Corte una tira de espuma de 3/8” proveída en el kit y

colóquela sobre el borde del aprieta tuercas utilizado

para reemplazar los orificios de Quemador STAR,

según se muestra.

• La pieza de espuma ayuda a mantener el orificio al

final del aprieta tuercas, para que no se suelte y

caiga dentro de la unidad durante su remoción o

instalación.

Instrucciones 1

Cinta de Espuma, 1'' pieza 1

Etiqueta de conversión al propano 1

Orificio de inyección de quemador STAR

(1,15 mm)

Orificio de inyección de quemador STAR

(1,25 mm)

PRECAUCIÓN

Al conectar la unidad al gas propano, asegúrese que el

tanque de gas propano está equipado con su propio

regulador de alta presión. La máxima presión de gas a

esta unidad no debe exceder 14.0 pulgadas de columna

de agua desde el regulador del tanque de gas propano.

5

1

Cómo desmontar la placa de

cocción

IMPORTANTE: Asegúrese de que la fuente de alimentación eléctrica del disyuntor esté bloqueada y que el

suministro de gas esté cerrado.

1. Quite las rejillas del aparato.

2. Quite las tapas de los quemadores STAR.

3. luego quite los dos tornillos en la base de cada

quemador con una llave T-30.

Español 2

Page 23

4. Para quitar más fácilmente los colectores de grasa,

Pedestal de quemador

quite, según el modelo, los tres (3) o cuatro (4) tornillos

Torx T-20 de acero inoxidable que fijan el adorno a la

parte delantera del aparato, para las instalaciones de

tipo isla.

5. Desconecte el encendedor.

6. Quite los tornillos de cada uno de los pedestales con

un destornillador Torx T-30.

Pedestal de quemador

Pedestal de quemador

Venturi

A.) Cómo desconectar un encendedor de dos

piezas

1) Tire despacio de la base del quemador hacia

arriba.

Base del

quemador

Electrodo

Caja del encendedor

Cable del encendedor

B.) Cómo desconectar un encendedor de una pieza

1) Tire despacio de la base del quemador hacia

arriba.

2) En el electrodo de cada quemador, desconecte el

terminal hembra del terminal macho del cable de

chispas.

IMPORTANTE: Se debe pulsar sobre la lengüeta de cierre

del conector hembra para quitar el terminal del electrodo.

7. Quite cuidadosamente el pedestal del quemador y el

tubo Venturi.

8. Quite los colectores de grasa haciéndolos girar hacia

arriba luego empújelos hacia atrás.

9. Quite la pantalla térmica, si existe alguna. Algunos

modelos están equipados con una pantalla de anchura

doble que se prolonga bajo el colector de grasa

adyacente.

Conversión del regulador

El regulador de presión del gas se ubica cerca del rincón

trasero izquierdo, en el interior de la placa superior del

aparato. La ubicación exacta varía según el modelo.

Electrode

Base del quemador

Cable del encendedor

Español 3

Page 24

1. Quite la pieza de conversión con una llave fija o una

1.15

1.15

1.15

1.15

1.15

1.25

llave con boquilla de 7/8 pulg.

2. Lea las letras que están escritas sobre el eje. Las

letras NAT están escritas abajo del todo. Quite el

pistón de la parte inferior de la tapa de conversión.

3. Saque la varilla de la base de la pieza, inviértala para

que la extremidad LP se vea y vuelva a poner la varilla

en la pieza, como en la ilustración.

Reemplazo de los orificios de

los quemadores

1. Utilice una boquilla de 7 mm (o 9/32 pulg.) con una

llave de 1/4 pulg. y una extensión para alcanzar el

orificio de gas natural a través del tubo de venturi y

para quitarlo de la boquilla del inyector del quemador.

2. Cinco orificios llevan la inscripción “115” (diámetro del

orificio de 1,15 mm), como en la ilustración. Un orificio

lleva la inscripción “125” (diámetro del orificio de

1,25 mm).

LP

NAT

4. Reinstale la pieza de conversión – configurada para

gas propano – en la parte superior del regulador.

Tapa de

latón

Junta

Pistón

1.15 x 5 1.25 x 1

Reemplace el orificio del quemador delantero derecho

(XHI) con el 1,25 mm LP orificio del quemador.

Sustituya todos los orificios de inyección de los

quemadores STAR por orificios de inyección de 1,15

mm para GLP proporcionados con el juego de

conversión.

• Los orificios de reemplazo del juego de conversión

al LP tienen una rosca cilíndrica (no cónica) y no

necesitan la utilización de lacre para la junta

fileteada.

IMPORTANTE: NO instale el orificio LP en otro sitio que

no sea delante a la derecha.

1.15

1.15 1.15

1.15

1.15

1.15

Español 4

Caja del regulador

1.15

1.15 1.15

1.15

1.25

1.25

Page 25

3. Haga una breve prueba de escape de gas en cada

orificio y en los racores cercanos, conforme a las

instrucciones dadas en la sección “Prueba de los

escapes de gas”.

• La prueba de los escapes se debería hacer una

vez terminada la conversión de los orificios y antes

de que se vuelvan a ensamblar y testen los

quemadores.

Ajuste de los tornillos de la

válvula manual de los

quemadores

Destornillador para ajustar los tornillos de

la válvula

Cómo volver a ensamblar la

placa de cocción

1. Para los encendedores de una pieza, pase los cables

a través de la pantalla térmica, si existe alguna.

Asegúrese de que los cables no se enrollen.

Para los encendedores de dos piezas, reinstale la

pantalla térmica, si existe alguna (no hace falta pasar

los cables).

2. Para los encendedores de una pieza, pase los cables

a través del colector de grasa. Asegúrese de que los

cables del encendedor no se enrollen.

Para los encendedores de dos piezas, reinstale los

colectores de grasa (no hace falta pasar los cables).

3. Reinstale el adorno para las instalaciones de tipo isla

con tornillos Torx T-20.

4. Para los encendedores de una pieza, pase los cables

a través del pedestal del quemador.

Para los encendedores de dos piezas, reinstale el

pedestal del quemador (no hace falta pasar los

cables).

5. Inserte el tubo Venturi en el pedestal del quemador.

Fíjelo con tornillos negros Torx T-30 insertándolos

parcialmente antes de atornillarlos hasta el fondo.

Asegúrese de que el tubo Venturi no esté bloqueado.

El tubo Venturi debe ser fácil de quitar cuando el

pedestal está instalado.

6. Para los encendedores de una pieza, vuelva a

conectar el cable del encendedor al electrodo de la

base del quemador. Pase cuidadosamente los cables

del encendedor a través del pedestal al mismo tiempo

que reinstala la base del quemador en su sitio.

Asegúrese de que los cables del encendedor no se

enrollen.

Para los encendedores de dos piezas, reinstale la

base del quemador sobre el pedestal (no hace falta

pasar los cables).

7. Fije la base del quemador con tornillos Torx T-30

insertándolos parcialmente antes de atornillarlos hasta

el fondo.

8. Coloque las tapas de los quemadores y las rejillas en

su sitio.

Se debe utilizar un destornillador con una punta de una

anchura de 1/8 pulg. [3,0 mm] y de un grosor de 0,020

pulg. [0,50 mm], ilustrado en la foto aquí abajo, para poner

en su sitio los tornillos de derivación y obtener los ajustes

mínimos de flujo de las válvulas manuales.

Quite los tapones de protección antes de utilizar el aparato.

Ajuste de los tornillos de la válvula

Tornillo de la válvula

1. Corte la alimentación eléctrica del disyuntor

principal o de la caja de fusibles.

2. Corte el suministro de gas de la estufa cerrando la

válvula manual de cierre de gas.

3. Quite el botón de la varilla de la válvula tirando hacia el

exterior, alejándose del tablero.

Español 5

Page 26

4. Quite el tornillo de montaje con bisel ubicado a la

Agujero de acceso del

tornillo de derivación

con la válvula en

la posición OFF.

Agujero de acceso del

tornillo de derivación

con la válvula en

la posición LOW.

derecha de la varilla de la válvula con una llave Torx T-

20.

5. Para engranar el tornillo de la válvula, inserte el tornillo

de precisión con una hoja de 1/8 pulg. en el agujero del

bisel que quedó al quitar el tornillo de montaje.

6. PARA LOS QUEMADORES ESTANDARES, ajuste el

tornillo de la válvula girándola aproximadamente 1/8

de vuelta en el sentido de las agujas del reloj. Ajuste el

tornillo de la válvula para obtener la potencia suficiente

para cocer a fuego lento. Teniendo en cuenta las

fluctuaciones normales de presión del gas, la

estabilidad de la llama podría ser afectada si se aprieta

demasiado el tornillo de la válvula.

7. PARA LOS QUEMADORES EXTRALOW, el ciclo

automático de los quemadores XLOW permite utilizar

una función excepcional de cocción a fuego lento, sin

ningún ajuste. Sin embargo, el usuario puede ajustar el

tornillo de la válvula según sus preferencias. Apague

siempre la alimentación eléctrica del aparato antes de

ajustar la llama. Coloque el eje de la válvula en la

posición LOW para poder acceder a los tornillos de la

válvula a través de los agujeros de pasaje de los

potenciometros.

Prueba de los escapes de gas

ADVERTENCIA

NO utilice ningún tipo de llama para detectar los

escapes de gas.

Inspección de los escapes de gas con una

solución líquida

La prueba de los escapes se debería hacer una vez

terminada la conversión de los orificios y antes de que se

vuelvan a ensamblar y testeen los quemadores.

1. Asegúrese de que todos los orificios LP hayan sido

apretados y que todas las válvulas y las perillas estén

apagadas.

2. Conecte la alimentación eléctrica y el suministro de

gas.

3. Vaporice generosamente la parte enroscada del

orificio con una solución de agua jabonosa o con otra

solución concebida para detectar los escapes de gas.

Procure no vaporizar los componentes eléctricos. (Una

mezcla compuesta de 25% de jabón en agua es eficaz

para hacer esta inspección.)

4. Encienda brevemente la válvula o la perilla

bloqueando el agujero del orificio con la goma de un

lápiz, su dedo o algo semejante.

5. Fíjese en la base de la unión del orificio para ver si se

forman burbujas alrededor del racor enroscado.

• Las burbujas indican que hay un escape de gas.

La cantidad y las dimensiones de las burbujas son

indicadores de la amplitud del escape.

6. Repare todos los escapes inmediatamente cuando los

descubra. A menudo, sólo hace falta volver a apretar el

orificio para reparar el escape.

7. Ya que sucede que las piezas están apretadas

fuertemente durante el reemplazo de los orificios,

inspeccione también los escapes en las otras uniones

de los racores adyacentes al orificio.

8. Desconecte la alimentación eléctrica y el suministro de

gas.

9. Vuelva a ensamblar el aparato antes testear los

sistemas de los quemadores nuevamente convertidos.

Agujero de acceso del

Agujero de acceso del

tornillo de derivación

tornillo de derivación

con la válvula en

con la válvula en

la posición OFF.

la posición OFF.

Español 6

Agujero de acceso del

Agujero de acceso del

tornillo de derivación

tornillo de derivación

con la válvula en

con la válvula en

la posición LOW.

la posición LOW.

Page 27

Verificación de la presión de

Características de la llama

admisión (si hace falta)

La verificación de la presión de admisión NO ES

NECESARIA cuando se convierte un aparato a gas

propano. Sin embargo, si la presión de salida del regulador

de presión del gas o la presión de entrada hacia el aparato

parece sospechosa, se puede recurrir al proceso siguiente

para verificar la presión de admisión.

1. Ponga un manómetro portátil o de mano que lea la

presión en pulgadas de columna de agua utilizando un

pedazo de PVC o un tubo de vinilo.

2. Conecte la alimentación eléctrica y el suministro de

gas de la estufa.

3. Encienda uno de los quemadores en la posición HI. Es

importante obtener una lectura real de la presión bajo

esas condiciones de circulación de gas.

4. Gire la válvula manual del quemador en la posición HI.

(El quemador producirá ruidos de encendido por

chispas.)

5. La lectura de la presión de admisión del regulador de

cualquier aparato convertido a gas propano en el

manómetro debería oscilar entre 9,50 y 10,50

de pulgadas de columna de agua.

• Si la lectura de la presión de admisión es inferior a

esa cifra, asegúrese de que se haya hecho bien la

conversión del regulador para una utilización con

gas propano y que la presión de entrada hacia el

aparato oscile entre 11,0 y 14,0 pulgadas de

columna de agua.

Cuando observe las llamas de los quemadores, quite el

mínimo de componentes para ver las llamas directamente.

Es posible que tenga que apagar las luces o cerrar las

persianas de las ventanas para oscurecer la habitación y

así ver mejor las llamas.

1. Teste el encendido de los quemadores. Empuje la

perilla del quemador y gire en el sentido contrario a las

agujas del reloj hasta la posición HI. El electrodo del

encendedor y el módulo de chispas producirán un

chasquido. Una vez que haya salido el aire del

conducto de alimentación, el quemador debería

encenderse en menos de cuatro (4) segundos.

• Las llamas de LP deben ser estables y hacer poco

ruido. Los conos interiores de las llamas deben ser

bien definidos y estar visiblemente separados uno

de otro. La llama, alrededor del quemador, no

debe tener partes excesivamente elevadas o

llamas “vagas”.

NOTA: Es normal que de las puntas de las llamas estén

levemente amarillas después de unos minutos de

funcionamiento con gas propano (LP). Los trazos naranjas

en las llamas son producidos por la combustión de restos

en el aire. Este fenómeno es normal durante los momentos

que siguen el encendido y deberían disiparse después de

unos minutos de funcionamiento.

Flama amarilla:

Se requiere más ajuste.

Puntas amarillas sobre

conos:

Normal para Gas LP.

Flama azul suave:

Normal para Gas Natural.

Español 7

Page 28

2. Ponga la válvula de la perilla del quemador a SIM para

Star

®

Star

®

Ubicación de la

placa de señalización

verificar si la llama sigue difundiéndose alrededor del

quemador. Apague la llama soplándola o venteándola

con hojas o con un trozo de cartón. Luego, observe la

capacidad del quemador a encenderse de nuevo y a

propagar la llama en todo el quemador en pocos

segundos. La propagación de la llama es esencial para

que se encienda y vuelva a encender adecuadamente

el quemador.

3. Testee la capacidad de los dos quemadores STAR del

lado izquierdo del aparato para volver a encenderse

colocando los mandos en XLO y observe la

propagación de la pequeñas llamas de fuego lento

mientras el sistema XLO enciende y apaga los dos

quemadores.

• Si el rendimiento de la llama no es adecuado,

asegúrese de que los orificios de LP de

dimensiones adecuadas estén instalados y que el

regulador haya sido convenientemente convertido

para una utilización con LP.

• Si la llama de un quemador es irregular, centellea,

produce ruidos excesivos o cambia de tamaño,

algunos de los agujeros de la base del quemador

están posiblemente obstruidos por derrames de

alimentos o por otras partículas. Los agujeros

bloqueados se pueden limpiar con un clip, una

aguja o un objeto semejante. A veces, los

alimentos y los restos incrustados y difíciles de

limpiar se pueden quitar con un estropajo de acero

o un cepillo metálico.

4. Una llama “vaga”, con largas llamas, se puede crear

porque la tapa de un quemador está mal colocada.

Varias de las puntas de las llamas individuales tendrán

tendencia a fusionarse o a confluir.

Asegúrese de que la tapa del quemador esté

adecuadamente colocada sobre la base del quemador.

Cuando esté posicionada convenientemente, la tapa

debería estar plana sobre la base y no debería

balancearse demasiado.

Colocar la etiqueta de

conversión

1. Para una identificación y una prueba adecuadas de la

conversión del aparato a gas propano (LP), ponga la

etiqueta de conversión proporcionada cerca de las

etiquetas de clasificación del aparato. Esto es

particularmente importante si se reinstala el aparato

convertido en un hogar distinto.

Ubicación de la

Ubicación de la

placa de señalización

placa de señalización

2. Una vez pegada la etiqueta de conversión, utilice un

rotulador indeleble para escribir la fecha, el nombre y

la dirección de la empresa que llevó a cabo la

conversión del aparato.

Correcto de la tapa del

quemador

Incorrecto de la tapa del

quemador

5. Repita el proceso de chequeo de la llama y del

encendido de cada quemador de la placa de cocción.

Español 8

Page 29

THERMADOR® Service/Entretien/Mantenimiento

Service

We realize that you have made a

considerable investment in your

kitchen. We are dedicated to

supporting you and your appliance so

that you have many years of creative

cooking.

Please don't hesitate to contact our

excellent STAR

Department if you have any

questions or in the unlikely event that

your THERMADOR

needs service. Our service team is

ready to assist you.

USA:

800-735-4328

www.thermador.com/support

Canada:

800-735-4328

www.thermador.ca

TM

Customer Support

®

appliance

Parts & Accessories

Parts, filters, descalers, stainless

steel cleaners and more can be

purchased in the THERMADOR

eShop or by phone.

USA:

www.thermador-eshop.com

Canada:

Marcone 800-287-1627

or

Reliable Parts 800-663-6060

Entretien

Nous savons bien que vous avez

investi une somme considérable dans

votre cuisine. Nous nous faisons un

devoir de vous soutenir pour que vous

puissiez profiter pleinement d’une

cuisine où vous pourrez exprimer toute

votre créativité de nombreuses années

durant.

N’hésitez pas à communiquer avec l’un

des membres chevronnés de notre

équipe de soutien au client si vous avez

des questions ou dans le cas plutôt

improbable où votre appareil

THERMADOR

d’entretien. Notre équipe sera prête à

vous aider.

É.-U. :

800-735-4328

www.thermador.com/support

Canada :

800-735-4328

www.thermador.ca

MC

aurait besoin

Pièces et Accessoires

Vous pouvez vous procurer par

téléphone ou à notre boutique

THERMADOR en ligne des pièces, des

filtres, des produits nettoyants pour

acier inoxydable et plus encore.

É.-U. :

www.thermador-eshop.com

Canada :

Marcone 800-287-1627

or

Reliable Parts 800-663-6060

Mantenimiento

Nos damos cuenta que Usted invirtió

una suma considerable en su cocina.

Nos dedicamos a atenderle para que

pueda sacar provecho de una cocina

donde podrá expresar toda su

creatividad durante muchos años.

Por favor, no dude en ponerse en

contacto con uno de nuestros

empleados ESTRELLAS

atención al cliente si tiene preguntas

o en el caso más bien improbable que

su aparato THERMADOR

mantenimiento. Nuestro equipo

estará listo para ayudarle.

EEUU:

800-735-4328

www.thermador.com/support

Canadá:

800-735-4328

www.thermador.ca

TM

de

®

necesite

Piezas y Accesorios

Usted puede comprar piezas, filtros,

productos de limpieza para acero

inoxidable por teléfono o en nuestra

tienda THERMADOR en línea.

EEUU:

www.thermador-eshop.com

Canadá:

Marcone 800-287-1627

or

Reliable Parts 800-663-6060

1901 Main Street, Suite 600, Irvine, CA 92614 • 800-735-4328 • www.thermador.com

9001014151 • Rev. B • 5U065Q • © BSH Home Appliances Corporation, 10/14

Loading...

Loading...