Thermador PD304 User Manual

INSTALLATION

INSTRUCTIONS

For Thermador Professional® Duel Fuel Ranges

Models

PD304

PD36

PD48

Please Read Entire Instructions

Before Proceeding

IMPORTANT: Save these instructions for the Local Gas Inspector’s use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

WARNING

Disconnect power before installing. Before

turning power ON, be sure that all controls

are in the OFF position.

IMPORTANT

Local codes vary. Installation, gas

connections and grounding must

comply with all applicable codes.

WARNING:

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

■ Do not try to light any appliance.

■ Do not touch any electrical switch.

■ Do not use any phone in your building.

■ Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

For Massachusetts Installations:

1. Installation must be performed by a qualified

or licensed contractor, plumber or gas fitter

qualified or licensed by the state, province or

region where this appliance is being installed.

2. Shut-off valve must be a “T” handle gas

cock.

3. Flexible gas connector must not be longer

than 36 inches.

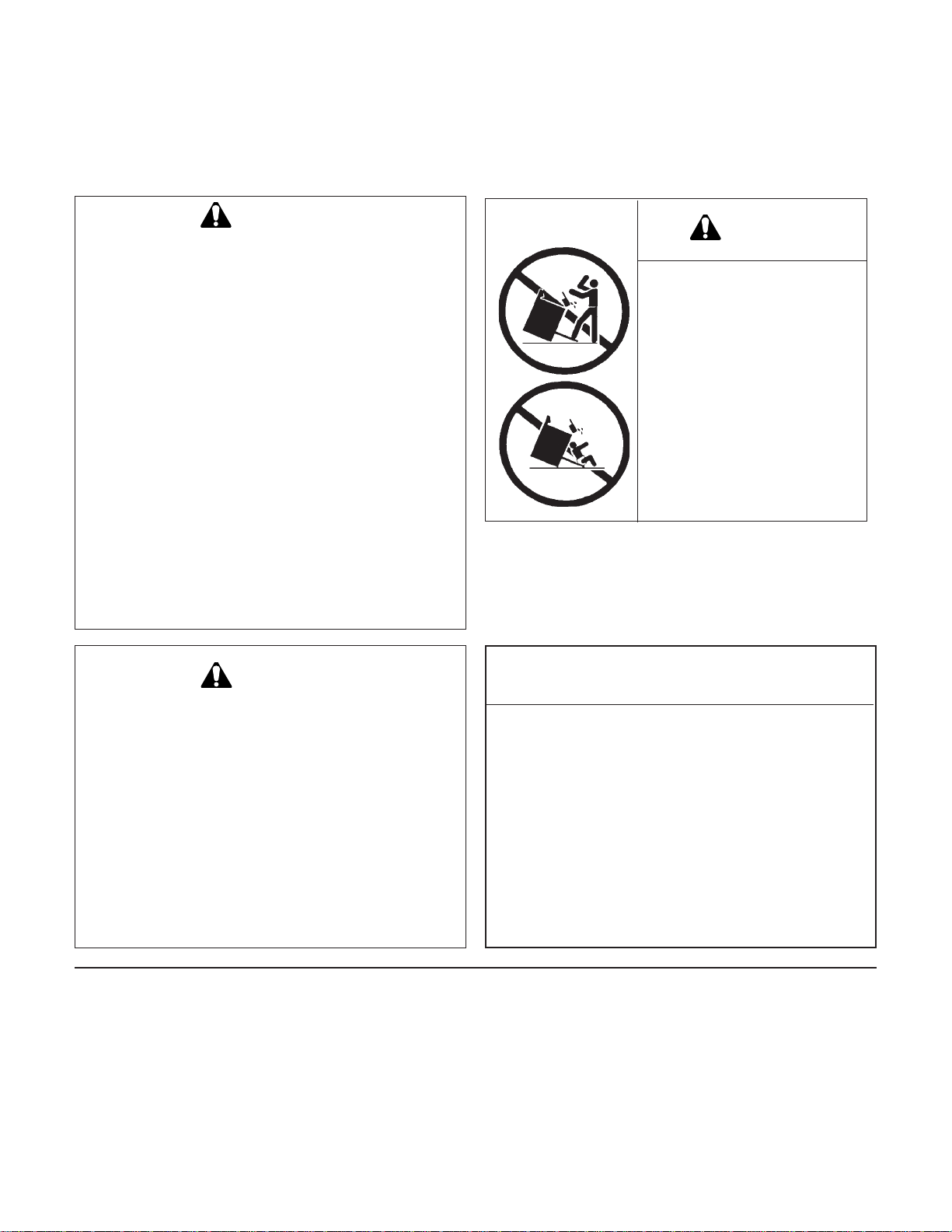

WARNING

■

ALL RANGES CAN TIP

■ ■

■ INJURY TO PERSONS

■ ■

COULD RESULT

■

INSTALL ANTI-TIP

DEVICE

■ SEE INSTALLATION

INSTRUCTIONS

TO REDUCE THE RISK OF TIPPING OF THE

APPLIANCE, IT MUST BE SECURED BY A

PROPERLY INSTALLED ANTI-TIP DEVICE.

VERIFY THAT THE ANTI-TIP DEVICE IS

ENGAGED PER INSTALLATION IN

STRUCTIONS. (NOTE: ANTI-TIP DEVICE IS

REQUIRED ON ALL 30" AND 36" RANGES)

■ If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed

by a qualified installer, service agency or the

gas suppler.

Note: This Range is NOT designed for installation in manufactured (mobile) homes or for installation in Recreational Park Trailers.

DO NOT install this range outdoors.

Model PD304 Model PD364GL

Low Back Model LB36R

Contents

Introduction............................................................................ 1-2

Important Installation Information ............................................... 2

Step 1: Ventilation Requirements ............................................. 3

Step 2: Cabinet Preparation............................................... 4 – 8

Step 3: Unpacking, Moving

and Placing the Range........................................... 9 – 10

Step 4: Installing Anti-Tip Device .................................... 11 – 12

Step 5: Gas Requirements and Hookup.................................. 13

Step 6: Electrical Requirements,

Connection and Grounding ................................ 14 – 16

Model PD484GGE

Low Back Model LB48R

Step 7: Backguard Installation ................................................ 17

Step 8: Door Installation.......................................................... 18

Step 9: Test and Adjustment................................................... 19

To Clean and Protect Exterior Surfaces.................................. 19

Installer Checklist.................................................................... 20

1

Important Installation Information

Introduction

The Thermador Professional® Ranges are free standing units available in a number of configurations.

Model PD304 is equipped with four sealed gas surface

burners and a 30-inch

ing oven with broil capability. Models PD364GE,

PD364GL, and PD366 feature a gas cooking surface

with four sealed gas surface burners with either an

electric griddle or gas grill or six sealed gas surface

burners plus a 36-inch

ing oven with broil capability. Models PD484GGE,

PD486GE, and PD486GL feature a gas cooking surface with four sealed burners, electric griddle and gas

grill, six sealed burners and an electric griddle, or six

sealed burners and a gas grill. PD48 Ranges provide

a large

same as used in the PD36 Ranges) and a small electric

oven with bread proofing and warming features as well

as bake and broil capability.

electric convection, self-cleaning oven (the

GAS TYPE VERIFICATION

Verify the type of gas supplied to the location. Ensure

that the appliance is connected to the type of gas for

which it is certified. All models are certified for use with

natural gas. Field conversion of the appliance for use

with propane gas supply will require a conversion kit.

IMPORTANT

• A backguard must be utilized when there is less

than a 12” horizontal clearance between combustible materials and the back edge of the range. The

Thermador Low Back backguard must be ordered separately and installed at the rear of the

range. For island installations and other installations with more than 12” clearance, an optional

stainless steel Island Trim is available to cover the

backguard mounting flanges.

electric convection self-clean-

electric convection, self-clean-

This appliance has been tested in accordance with

ANSI Z21.1, Standard for Household Cooking Appliances (USA) and in accordance with CAN 1.1-M81

Domestic Gas Ranges (Canadian).

strongly recommended that this appliance be

It is

installed in conjunction with a suitable overhead

vent hood. (See Step 1 for Ventilation Requirements.) Due to the high heat capability of this unit,

particular attention should be paid to the hood and

duct work installation to assure it meets local building

codes.

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units

should be avoided.

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply

with all applicable codes. In the absence of local codes

the appliance should be installed in accordance with

the National Fuel Gas Code ANSI Z223.1/FNPA 54

current issue and National Electrical Code ANSI/

NFPA 70-current issue. In Canada, installation must

be in accordance with the CAN 1-B149.1 and .2 –

Installation Codes for Gas Burning Appliances and/or

local codes.

CAUTION:

When connecting the unit to propane gas,

make certain the propane gas tank is equipped

with its own high pressure regulator in addition

to the pressure regulator supplied with the

range. The maximum gas pressure to this

appliance is not to exceed 14.0 inches

water column (34.9 mb) from the propane

gas tank to the regulator.

• Verify that the appliance is correct for the type of

gas being provided. Refer to Step 5 on Page 13

before proceeding with the installation.

Gas Supply :

Natural Gas - 6 inch water column, (14.9 mb) min.,

8 inch (20 mb) nominal

Propane Gas - 11 inch water column, (27.4 mb),

14 inch (34.9 mb) maximum

CAUTION

This unit is designed as a cooking appliance.

z

2

Based on safety considerations, never use it for

warming or heating a room

This appliance is equipped with an intermittent/interrupted ignition device that cycles the two far left

surface burners on and off when in the ExtraLow

setting.

.

®

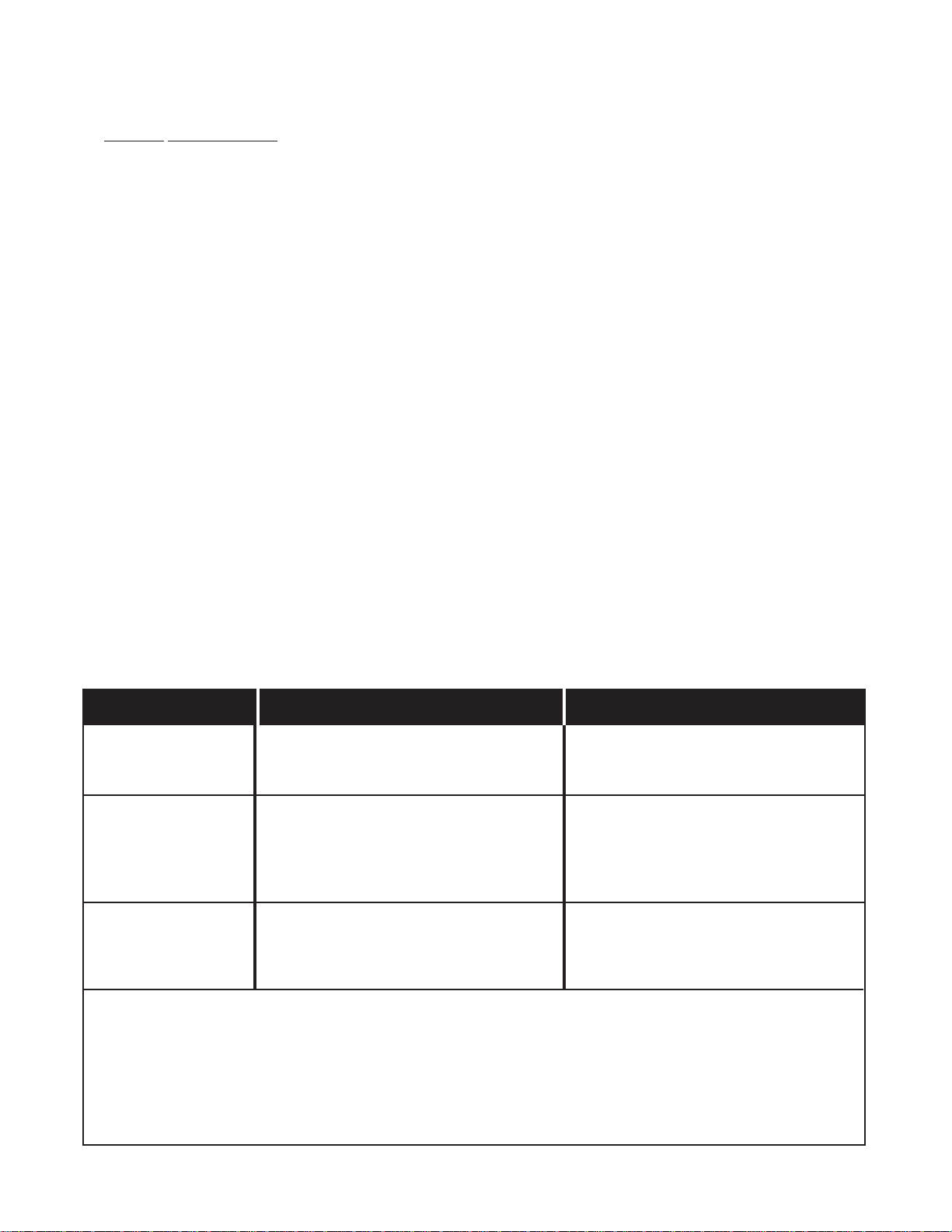

Step 1: Ventilation Requirements

It is strongly recommended that a

suitable exhaust hood be installed

above the range. Downdraft

ventilation should not be used. The

table below indicates the

Thermador hoods, by model

number, that are recommended

for use with all ranges.

1. Select Hood and

Blower Models:

• For wall installations, the hood

width must, at a minimum,

equal the width of the range

cooking surface. Where

space permits, a hood larger

in width than the cooking surface may be desirable for improved ventilation performance.

• For island installations, the

hood width should, at a minimum, overhang the range

cooking surface by 6" on each

side.

IMPORTANT:

Ventilation hoods and blowers are

designed for use with single wall

ducting. However, some local

building codes or inspectors may

require double wall ducting. Consult local building codes and/or

local agencies, before starting, to

assure that hood and duct installation will meet local requirements.

• Hood blower speeds should

be variable to reduce noise

and loss of heated or air conditioned household air when

maximum ventilation is not

required. Normally, the maximum blower speed is only

required when using the grill.

2. Hood Placement:

• For best smoke elimination, the

lower edge of the hood should

be installed a minimum of 30" to

a maximum of 36" above the

range cooking surface. (See

Fig. 1).

• If the hood contains any combustible materials (i.e. a wood

covering), it must be a minimum of 36" above the cooking

surface.

3. Consider Make-Up Air:

• Due to the high volume of ventilation air, a source of outside

replacement air is recommended. This is particularly important for tightly sealed and

insulated homes.

• A qualified heating and ventilating contractor should be consulted.

RANGE WIDTH

30" RANGE PH30ZS

36" RANGE

48" RANGE

Notes: * For wall installations where adequate space is available, the installer or user may elect to

PH36ZS, 42ZS

WALL INSTALLATION ISLAND INSTALLATION

HOOD* BLOWER** HOOD* BLOWER**

PH30HQS

PHE30,36

PHE36,42

HNW36YS

HNW42 YS

PH48ZS

PH48HQS

PHE48,60

VTR1000Q,

VTR1400Q

OR VTN 1000Q

VTR1000Q, VTR1400Q

or VTN 1000Q

VTR1000Q, VTR1400Q

VTR1000Q, VTR1400Q

VTR1000Q

VTR1400Q

or VTN 1000Q

HTNI42YS

HNI42YS

PHI48ZS

HTNI42YS

HNI42YS

PHI48ZS

HTNI48YS

HNI48YS

HTNI54YS

HNI54YS

PHI60ZS

VTR1000Q,

VTR1400Q

VTR1000Q

VTR1400Q

VTR1400Q

use a hood that is wider than the range cooking surface. This may be particularly beneficial

for those cases, such as a long duct run or heavy usage of the grill, in which improved

capturing of the cooking exhaust is desired.

** Thermador offers a choice of remote (VTR1000Q or VTR1400Q) or in-hood

(VTN1000Q) blowers for use in wall installations.

3

Step 2: Cabinet Preparation

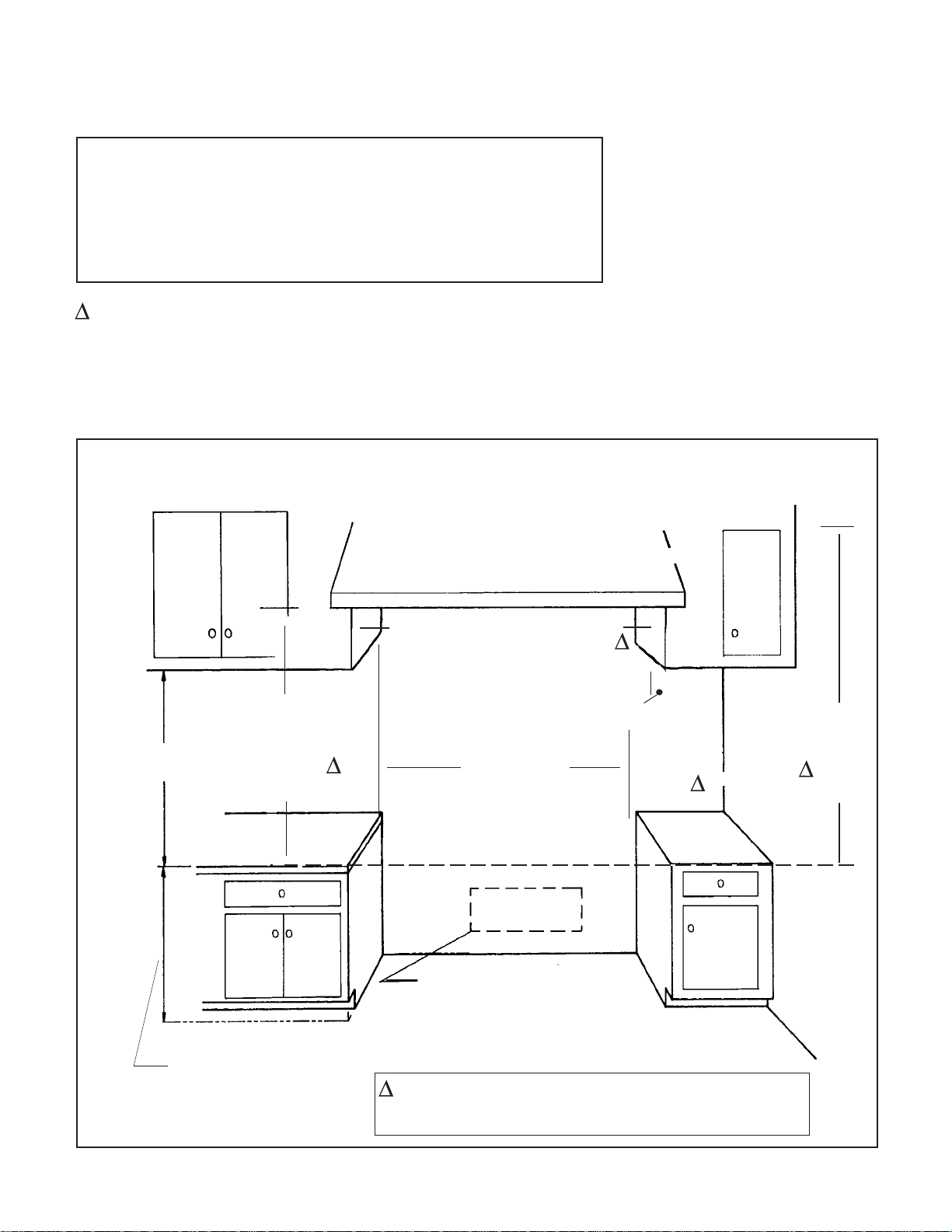

1. The range is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown

in Fig. 1 are required. The same clearances apply

to island installations, except for the overhead

cabinets, which must have a space wide enough

to accept the flared island hood, as indicated in

Fig. 1.

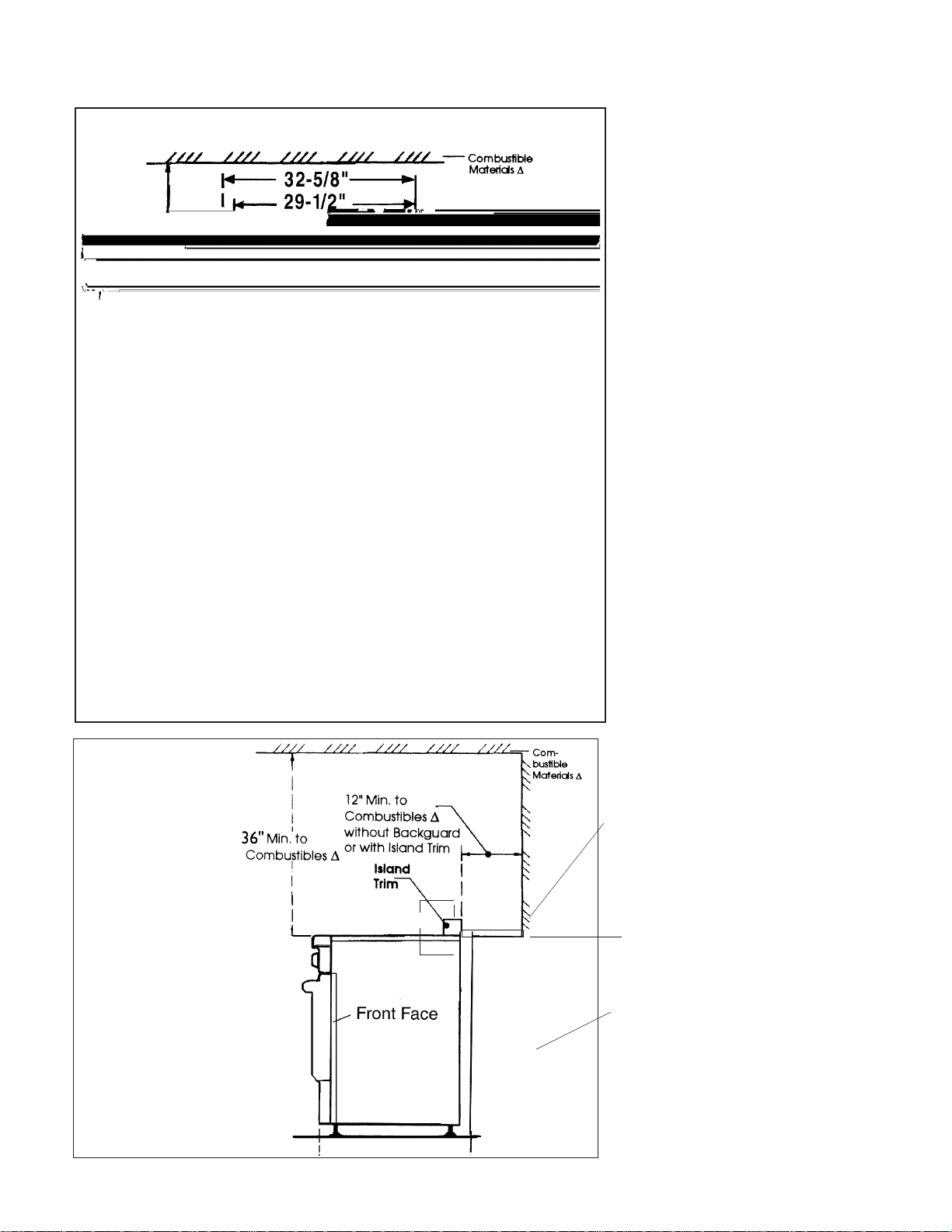

2. The 36" ranges may be recessed into the cabinets beyond the edge of the front face of the oven

(See Figures 2A and 2B). The 30" and 48" ranges

are not approved to be installed flush with the

cabinets.

CAUTION

In these installations, the door and cabinet on

36-inch models can cause a pinching hazard.

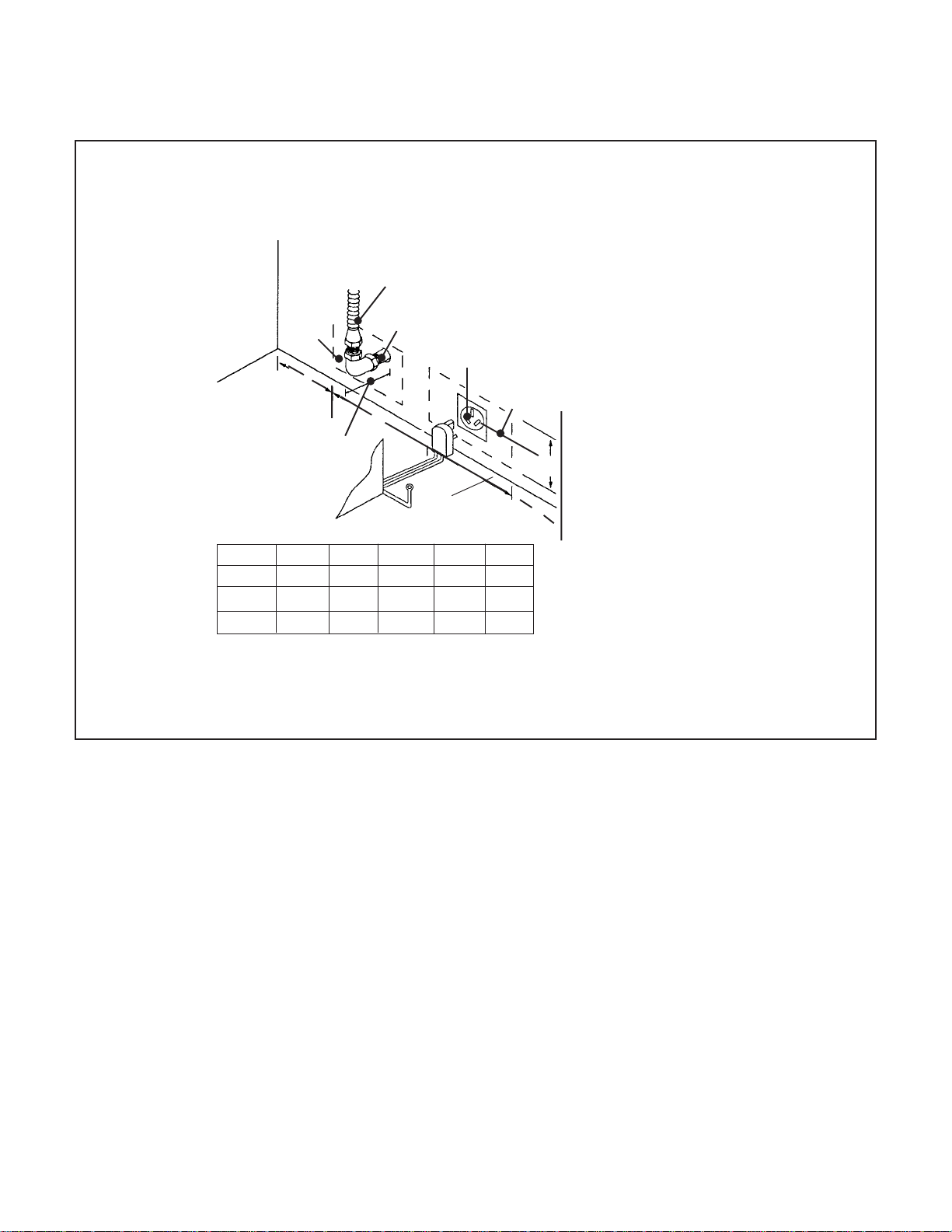

3. The gas and electrical supply should be within the

zones shown in Fig. 3A.

4. Any openings in the wall behind the range and in

the floor under the range must be sealed.

5. When there is less than a 12" horizontal clearance between combustible material and the

back edge of the range above the cooking surface, a Thermador Low Back or High Shelf

backguard must be installed. (See Fig. 2A). When

clearance to combustible material is over 12",

a Thermador Island Trim may be used. (See Fig.

2B). Figures 2A and 2B indicate the space

required for each type of backguard.

6. Always keep appliance area clear and free from

combustible materials, gasoline and other flammable vapors and liquids.

7. Do not obstruct the flow of combustion and

ventilation air to the unit.

NOTE: The maximum depth of over head cabinets

installed on either side of the hood is 13".

A 36-inch minimum clearance is required between

the top of the range and the bottom of an unprotected

cabinet. A 30-inch minimum distance is necessary

when the bottom of the wood or metal cabinet is

protected by not less than 1/4 inch of a flame

retardant material covered with not less than No. 28

MSG sheet steel, 0.015 inch (0.4 mm) thick stainless

steel, 0.024 inch (0.6 mm) aluminum, or 0.020 inch

(0.5 mm) thick copper. Flame retardant materials

bear the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

Followed by the flame spread and smoke ratings.

These designations are shown as “FHC (FIame

Spread/Smoke Developed).” Materials with “O”

flame spread ratings are flame retardant. Local codes

may allow other flame spread ratings.

4

Step 2: Cabinet Preparation

CAUTION:

Do not install the Models PD304 and PD48 ranges such that the

oven door is flush with the cabinet face.

result in damage to the cabinets due to exposure to high heat.

As defined in the “National

Fuel Gas Code” (ANSI

Z223.1, Latest Edition).

FIG. 1 Cabinet Clearances

A flush installation could

For 30" Ranges

For 36" Ranges

For 48" Ranges

30" or 36" Wide Hood

}

42" or 48" for Island

36" or 42" Wide Hood

}

42" or 48" for Island

48" or 60" Wide Hood

}

48", 54" or 60" for Island

³

18" Min.

³

•

³

³

³

30" Min. to 36" Max. bottom of

overhead Hood to cooking

surface (36" if hood contains

combustible materials )

³

³

*35-3/8" Min. Range Height

with Leveling Legs fully

retracted

*36-3/4" Max. Range Height

with Leveling Legs fully

extended.

³

Min. Distance Between Overhead

Cabinets of Combustible Materia

30" Range – 30"

36" Range – 36"

48" Range – 48"

³

For Electrical and Gas Supply Zone,

see Figure 3A. Zone size and position

differ according to the model.

as defined in the “National Fuel Gas Code” (ANSI Z223.1,

Latest Edition). *The range height is adjustable. The level of the

range top must be at the same level or above the countertop level.

Range width

30", 36" or 48"

13" Max.

Cabinet

Depth

Cooking

Surface

³

l

}

3" Min. to

combustible

³

³

side wall

material ,

(both sides)

³

³

CAUTION: See Figs.

2A, and 2B. 36"

Min. to combustible

³

material ,

from cooking

surface

³

5

FIG. 2A - Side View

Step 2: Cabinet Preparation

3/8"

FIG. 2B - Side View

4"

³

³

NOTE:

For Island trim installations,

counter surface should have a

cantilever edge meeting the back

section of the island trim

accessory.

Cantilever Countertop

NOTE:

If an inner wall is used under the

1/8"

6

cantilever counter top, there

should be a 1/8" gap from the rear

of the range to the inner wall.

Step 2: Cabinet Preparation

GAS AND ELECTRIC SUPPLY ZONES:

FIG. 3A Gas & Electrical Supply Zone for Dual Fuel Ranges

Typical placement shown.

Other placement of Gas

Supply and Electrical

Receptacle within the

Electrical and Gas Supply

Zone is acceptable.

NOTE:

A Manual Gas

Shut-Off Valve

(not shown)

must be easily

accessible

through an

adjacent cabinet

without moving

the range.

2" Maximum Protru-

sion from Wall for

Model A B C D E

PD30 8" 12" 10" 6-1/2" 5-1/4"

PD36 10-1/2" 15" 10-1/2" 6-1/2" 5-1/4"

PD48 16-1/2" 16" 15-1/2" 6-1/2" 5-1/4"

Gas

Supply

Zone

³

A

³

Gas Supply

3/4" Flex Line to

Appliance

³

B

1/2"

N.P.T.

240 VAC Receptacle

(Shown) or Junction

Box

Centerline of

Electrical

Supply Zone

E

³

Floor

³

³

³

C

³

D

³

³

The Dual Fuel ranges may be connected to the power supply with a

range supply cord kit or by hardwiring to the power supply. It is the

responsibility of the installer to provide the proper wiring components

(cord or conduit and wires) and complete the electrical connection as dictated by local codes and ordinances,

and/or the National Electric Code.

The units must be properly grounded.

Refer to Step 6 for details.

The range must be connected only

to the type of gas for which it is

certified. If the range is to be con-

nected to propane gas, ensure that the

propane gas supply tank is equipped

with its own high pressure regulator in

addition to the pressure regulator supplied with the range. (See STEP 5.)

NOTE: Any opening in the wall behind the appliance and

any opening in the floor under the appliance must be

sealed.

7

Step 2: Cabinet Preparation

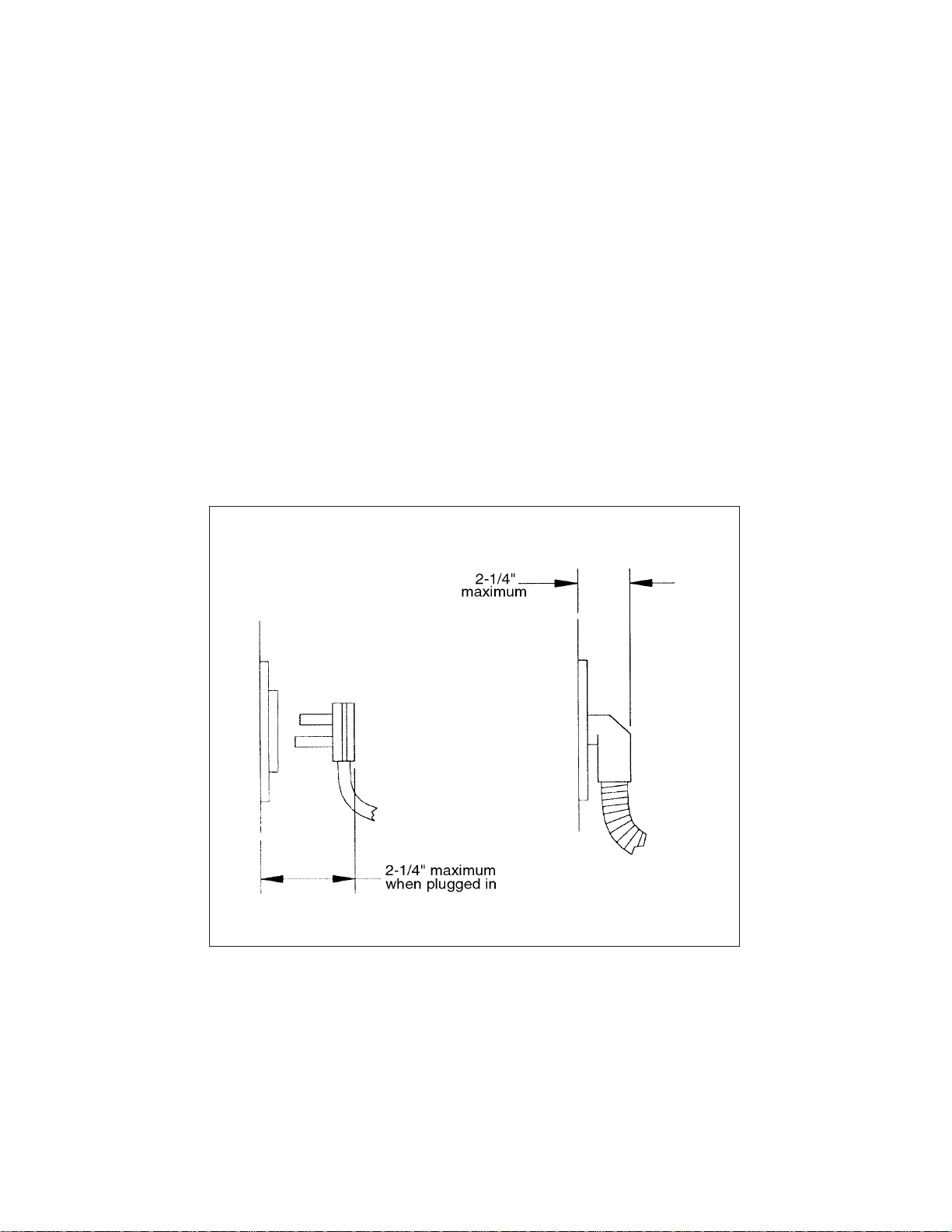

ELECTRICAL SUPPLY, DUAL FUEL RANGES

Installation of Dual Fuel ranges

must be planned so that the roughin of the junction box for the receptacle or conduit connection will allow maximum clearance to the rear

of the unit.

When the power supply cord (not

supplied) or conduit is connected

FIG. 3B WALL CONNECTION

to the mating receptacle or junction

box cover, the combined plug/receptacle or junction box cover/conduit connector should protrude no

more than 2-1/4" from the rear wall.

See Figure 3B.

This is especially critical if the junction box in the wall will be directly

behind the junction box on the unit

when the unit is installed. Refer to

Figure 9 on Page 15 for location of

junction box on unit. To minimize

binding when the unit is connected

to the receptacle or junction box,

orient the receptacle or conduit

connector, and slide back into position.

Power Cord & Receptacle

Junction Box & Conduit

8

Step 3: Unpacking, Moving and Placing The Range

CAUTION

Proper equipment and adequate manpower must be

used in moving the range

to avoid injury, and to avoid

damage to the unit or the

floor. The unit is heavy

and should be handled

accordingly.

• The range has an approximate

shipping weight as shown in

Chart A. It is recommended that

the grates, griddle plate and

frame, burner caps, front kick

panel and oven racks be removed to facilitate handling.

This will reduce the weight as

shown in Chart A and allow the

range to pass through 30" doorways. See Figs. 2A and 2B on

Page 6. Do not remove the

grill or griddle assemblies.

Chart A 30" Range 36" Range 48" Range

Shipping Weight 335 lbs. 444 lbs. 584 lbs.

Weight without 285 lbs. 390 lbs. 524 lbs.

packing materials

Without door(s), 215 lbs. 295 lbs. 395 lbs.

burner caps, front kick

panel and oven racks

FIG. 4 – Removal of Two

Front Shipping Bolts

FIG. 5 – Removal of Two Rear

Shipping Bolts

Left Rear

Shipping

Bolt

³

• Remove the outer carton and

packing material from the shipping base. The dual fuel ranges

are held to the skid by four (4)

bolts (see Fig. 4 and 5). After

removing the bolts the range

must be lifted and removed from

the skid.

• Remove angle-mounting brackets from range. This requires

the installer to remove two

screws holding each bracket

then remove bracket and reinstall screws.

9

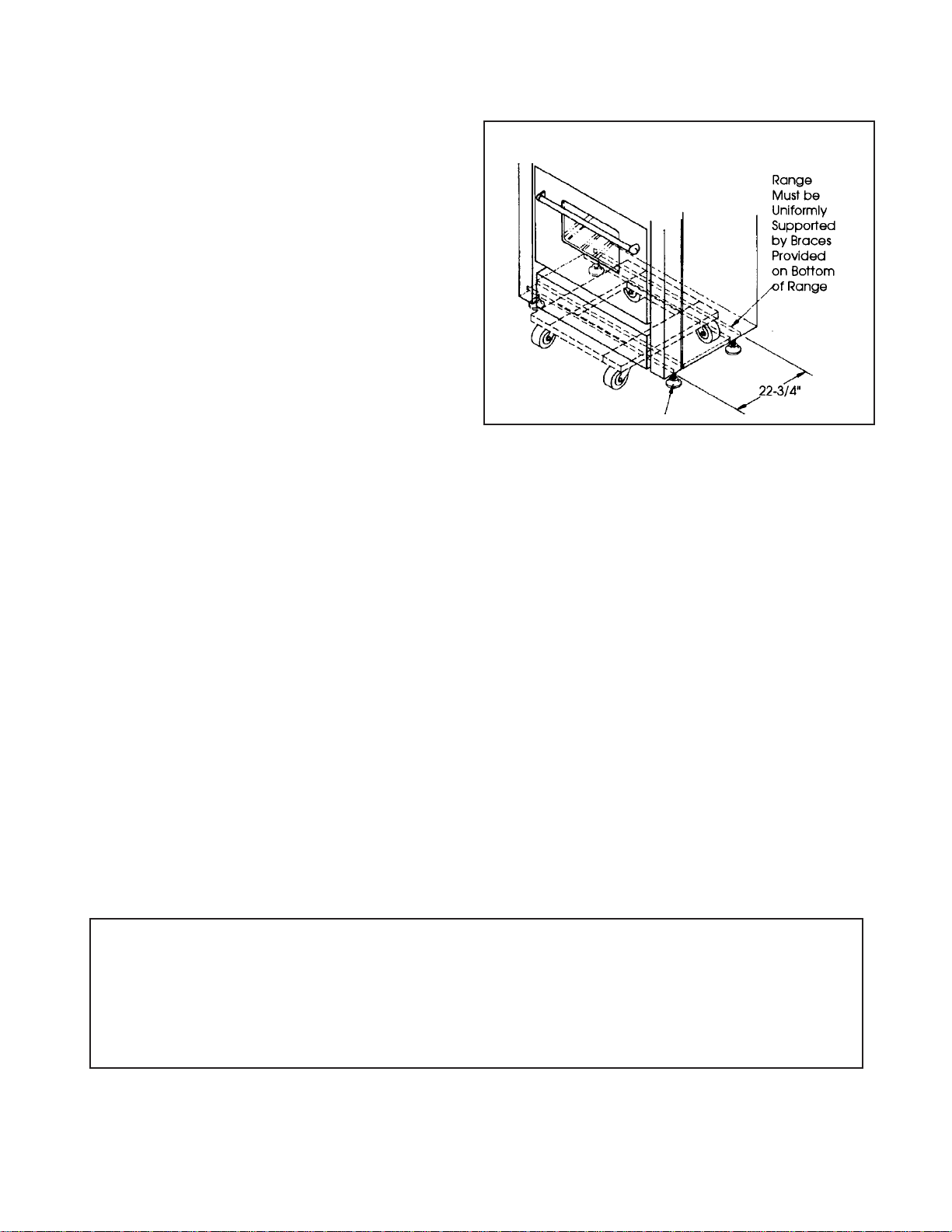

Step 3: Unpacking, Moving and Placing The Range

• Due to the weight, a dolly with soft wheels

should be used to move this unit. The weight

must be supported uniformly across the bottom

(See Fig. 6).

• After transporting the professional range by

dolly close to its final location, the range can be

tipped back and supported on the rear legs

while the dolly is carefully removed.

THE FLOOR UNDER THE LEGS

SHOULD BE PROTECTED (WOOD

STRIPS, CARPET, PANELING,

ETC.) BEFORE PUSHING THE

UNIT INTO POSITION.

vice must be installed (STEP 4), gas and

electrical connections should be made (STEPS

5 and 6), and the backguard installed (STEP 7)

before the range is placed in its final position.

• For proper performance the professional

range must be level. (It is very important for

all products that have the griddle feature). The

range is leveled by adjusting the legs with a

wrench.

The anti-tip de-

Fig. 6- Dolly Positioning

• Replace the kick panel and install the oven

door. To install door, see Page 18. Do not

install the oven door until the range is in its

final location. It is important that the two (2)

screws retaining the kick panel are secure

to prevent accidental access to hot surfaces.

• Ensure that the burner caps are correctly

seated on the burner bases of the range's

cooktop.

Griddle Tilt Adjustment

Check the griddle frame adjustment by pouring two tablespoons of water on the back of the griddle

plate. The water should slowly roll into the grease tray. If not, adjust the two screws under the back

of the griddle frame. Start with one half turn CCW of the screws. Further adjustment should be made

by one-quarter turn until water slowly flows into the grease tray.

10

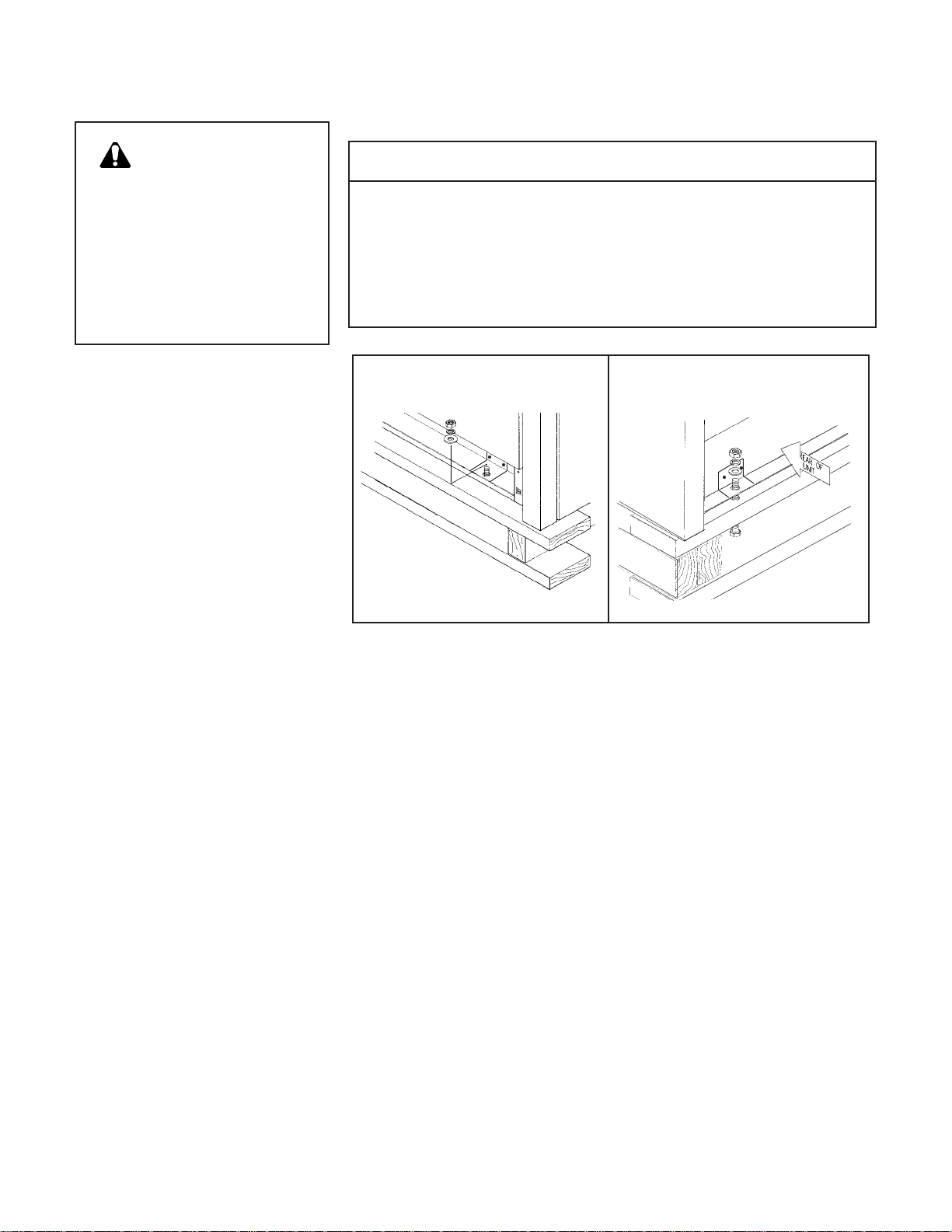

Step 4: Installing Anti-Tip Device

For all 30" and 36" ranges, an anti-tip device must be installed as per these

instructions.

WARNING

RANGE TIPPING HAZARD

• All ranges can tip and injury can result. To

prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

installing the Anti-Tip Device supplied.

• A risk of tip-over may exist if the appliance

is not installed in accordance with these

instructions.

• If the range is pulled away from the wall

for cleaning, service or any other reason,

ensure that the Anti-Tip Device is properly reengaged when the range is pushed

back against the wall. In the event of

abnormal usage (such as a person standing, sitting, or leaning on an open door),

failure to take this precaution can result

in tipping of the range. Personal injury

might result from spilled hot liquids or

from the range itself.

W ARNING

• ALL RANGES CAN

TIP

• INJURY

TO PERSONS COULD

RESULT

• INSTALL

ANTI-TIP

DEVICES PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

WARNING

CAUTION

ELECTRICAL SHOCK HAZARD

• Use extreme caution when drilling holes

into the wall or floor. There may be

concealed electrical wires located

behind the wall or under the floor.

• Identify the electrical circuits that could

be affected by the installation of the

Anti-Tip Device, then turn off power to

these circuits.

• Failure to follow these instructions may

result in electrical shock or other personal injury.

PROPERTY DAMAGE

• Contact a qualified installer or contractor

to determine the proper method for drilling holes through the wall or floor material

(such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions may

result in damage to wall or floor coverings.

Tools Needed for Installation of Anti-Tip Device:

- Screwdriver, Phillips - Hammer

- Drill, electric or hand - Pencil or other marker

- Measuring tape or ruler

- 1/8" drill bit (wood or metal wall or floor)

- 3/16" carbide-tipped masonry drill bit (concrete or concrete block wall or floor)

- 3/16" anchors, drywall or concrete, 2 each (not required if mounting bracket is being attached to solid wood or

metal)

11

Step 4: Installing Anti-Tip Device

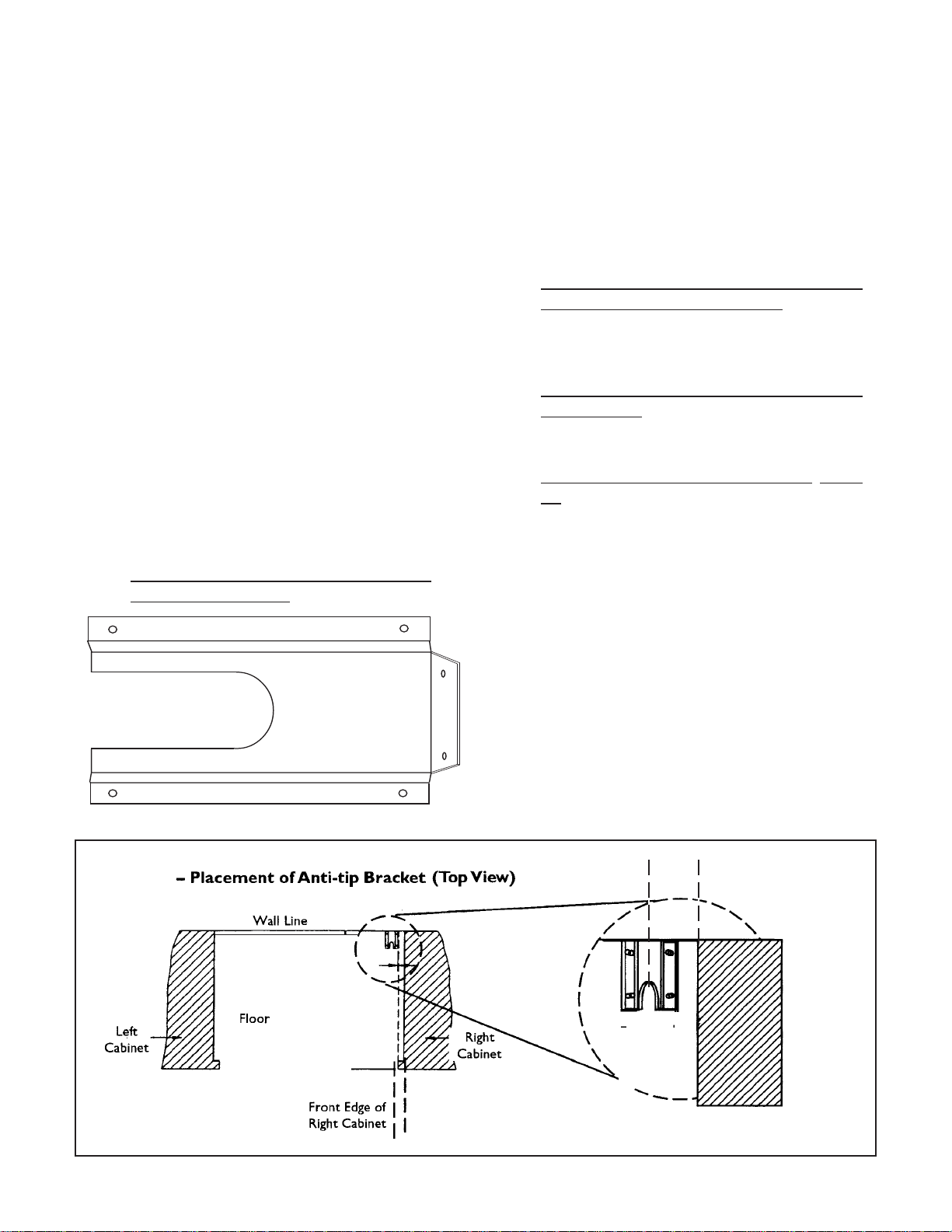

PD30 and PD36 Duel Fuel Ranges (Figures 8A and 8B)

Thermador Service Part No. Qty Description

415078 4 Screw, Phillips, #10 x 1-1/2"

487310 1 Anti-Tip Bracket, Floor-Mounted

IMPORTANT INSTALLATION

INFORMATION:

-

• The anti-tip bracket may be attached to a solid

wood cabinet having a minimum wall thickness of 3/

4".

• The thickness of the wall or floor may require use

of longer screws, available at your local hardware

store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood or metal.

• Use appropriate anchors when fastening the mounting bracket to any material other than hardwood or

metal.

• Prepare holes at fastener locations as identified

below:

-

For walls, wall studs, or floors composed

of solid wood or metal, drill 1/8" pilot holes.

• If the range is moved to a new location, the Anti-

For walls or floors composed of drywall,

sheet-rock or other soft materials, drill 3/16"

holes to a minimum depth of 1-3/4", then tap

plastic anchors into each of the holes using a

hammer.

-

For walls or floors composed of concrete or

concrete block, drill 3/16" holes to a minimum

depth of 1-3/4", then tap concrete anchors

into each of the holes using a hammer.

-

For walls or floors having ceramic tile covering, drill 3/16" holes through the tile only, then

drill into the material behind the tile as indicated immediately above.

Tip Device must be removed and reinstalled.

MOUNTING ANTI-TIP BRACKET

Figure 8A - Mounting Anti-tip Bracket

Figure 8B

³

³

2-1/2"

(typical either side)

The alternative floor mounted bracket shall be installed

as follows:

a) Place bracket on floor in position shown in Figure

8B.

b) Secure to floor or wall stud.

c) Later, when the unit is installed,the adjustable leg

will slide under the bracket.

³

2-1/2"

³

from edge of range

12

Loading...

Loading...