Thales ATM 435 Users Manual

-

Description, Installation, Operation, Maintenance |

Reference: Vol. 1 Code 955 900 031 C |

GROUND BEACON

DME 415/435

Technical Manual

VOLUME 1

Equipment description, Installation, Operation, Maintenance and PC user

SECTION 2

INSTALLATION

Vers. D, September 2005

THALES Italia S.p.A.- Air Systems Division

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

2-II |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

955 900 031 C |

Vol. 1-Section 2 - Installation |

Table of CONTENTS

Paragraph |

|

Page |

SECTION 2 ........................................................................................................................................... |

2-1 |

|

|

INSTALLATION................................................................................................................... |

2-1 |

2.1 |

General installation information........................................................................................ |

2-1 |

2.1.1 |

Safety Precautions ........................................................................................................... |

2-1 |

2.1.1.1 |

General rules .................................................................................................................... |

2-1 |

2.2 |

INSTALLATION PRELIMINARY....................................................................................... |

2-2 |

2.3 |

INSTALLATION SITE SELECTION.................................................................................. |

2-2 |

2.4 |

EQUIPMENT SITE LOCATION........................................................................................ |

2-3 |

2.5 |

UNPACKING, PACKING AND SHIPPING; ...................................................................... |

2-3 |

2.6 |

Typical INSTALLATION.................................................................................................... |

2-3 |

2.6.1 |

Installation cables ............................................................................................................. |

2-4 |

2.6.2 |

Grounding ......................................................................................................................... |

2-8 |

2.6.3 |

Power supply connection.................................................................................................. |

2-8 |

2.6.3.1 |

Batteries............................................................................................................................ |

2-13 |

2.6.3.1.1 |

Battery duration time (on 230Vac black-out) .................................................................... |

2-13 |

2.6.4 |

ANTENNA CONNECTION ............................................................................................... |

2-14 |

2.6.4.1 |

Antenna coax cables-Attenuations and delays ................................................................ |

2-15 |

2.6.4.2 |

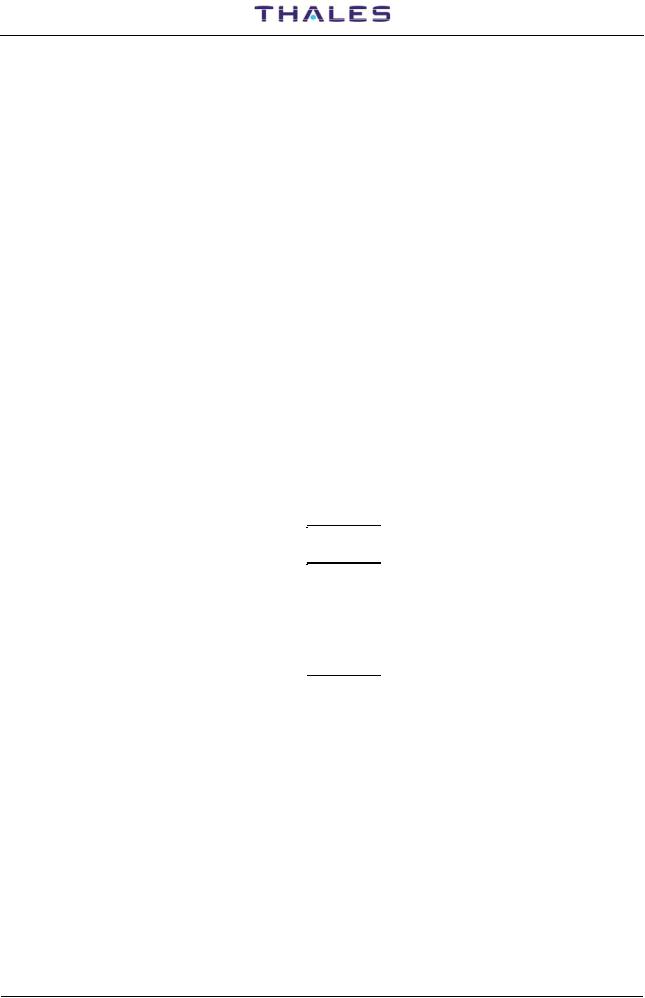

Data entry calibration procedure for “EXTENDED CONFIGURATION”........................... |

2-15 |

2.6.4.2.1 |

Check of the OUTPUT POWER measurement on transponder ...................................... |

2-17 |

2.6.4.2.2 |

Measurement calibration of the TRANSMITTED POWER (radiated) .............................. |

2-17 |

2.6.5 |

Adjustment Power Reading by monitor ............................................................................ |

2-19 |

2.6.6 |

I/O and external interface connections............................................................................. |

2-20 |

2.6.7 |

Link set - Jumper presetting ............................................................................................. |

2-30 |

2.6.8 |

Associated Facility Interface............................................................................................. |

2-35 |

2.6.9 |

Remote Control and Status Indicator ............................................................................... |

2-41 |

2.6.10 |

PC Installation................................................................................................................... |

2-42 |

2.6.11 |

Power supply with BCPS subrack of Frako type (optional version) ................................. |

2-43 |

2.6.11.1 |

External power supply 48Vdc connection (Frako subrack) .............................................. |

2-43 |

|

|

List of FIGURES |

|

Figure |

|

|

Page |

Figure 2.1. |

AUX OUT I/O cable ........................................................................................................ |

|

2-4 |

Figure 2.2. |

AUX IN I/O cable ............................................................................................................ |

|

2-5 |

Figure 2.3. |

PC serial cable ............................................................................................................... |

|

2-5 |

Figure 2.4. |

RS232 External Modem cable........................................................................................ |

2-6 |

|

Figure 2.5. |

Interface Facility cable.................................................................................................... |

|

2-6 |

Figure 2.6. |

RF coax cable - LCF 1/2" ............................................................................................... |

|

2-7 |

Figure 2.7. |

Obstruction light cable .................................................................................................... |

|

2-8 |

Figure 2.8. |

Installation connections (typical) .................................................................................... |

2-9 |

|

Figure 2.9. |

Installation - Cables connections (typical) on top end of equipment.............................. |

2-10 |

|

Figure 2.10. |

Installation - Cables connections (typical) on bottom of cabinet .................................... |

2-11 |

|

Figure 2.11. |

Cable connection - Grounding and AC power supply of the Terminal Bar .................... |

2-12 |

|

Figure 2.12. |

Cables connection - Grounding and AC power supply ................................................. |

2-12 |

|

|

|

|

|

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-a |

|

955 900 031 C |

DME 415/435 -Technical Manual |

|

Vol. 1-Section 2 - Installation |

||

Figure |

|

Page |

Figure 2.13. |

Grounding and external 48 Vdc power supply - Cables connection.............................. |

2-13 |

Figure 2.14. |

Battery connections typical ............................................................................................ |

2-13 |

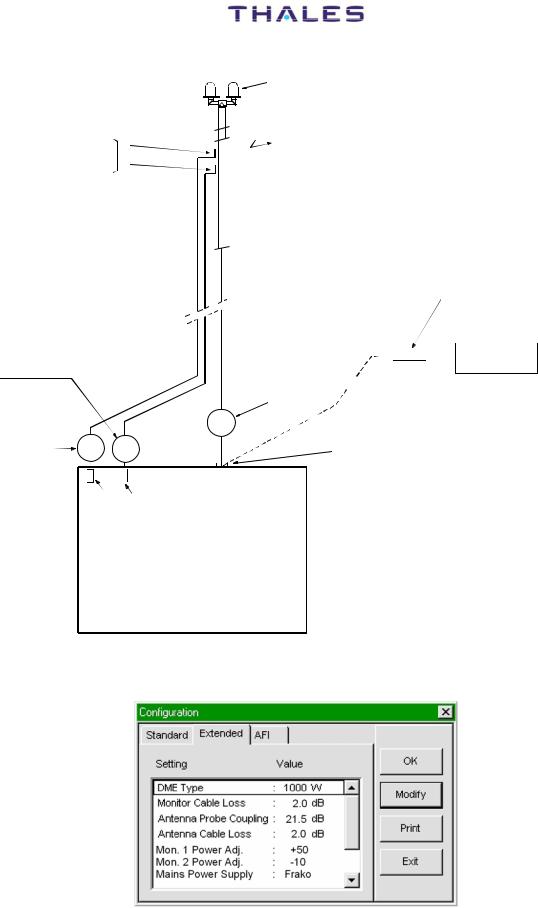

Figure 2.15. |

Cable connections to FAN 96 antenna .......................................................................... |

2-14 |

Figure 2.16a. |

Simplified diagram of Antenna coax cables................................................................... |

2-16 |

Figure 2.16b. |

“EXTENDED CONFIGURATION” – Example of data entry .......................................... |

2-16 |

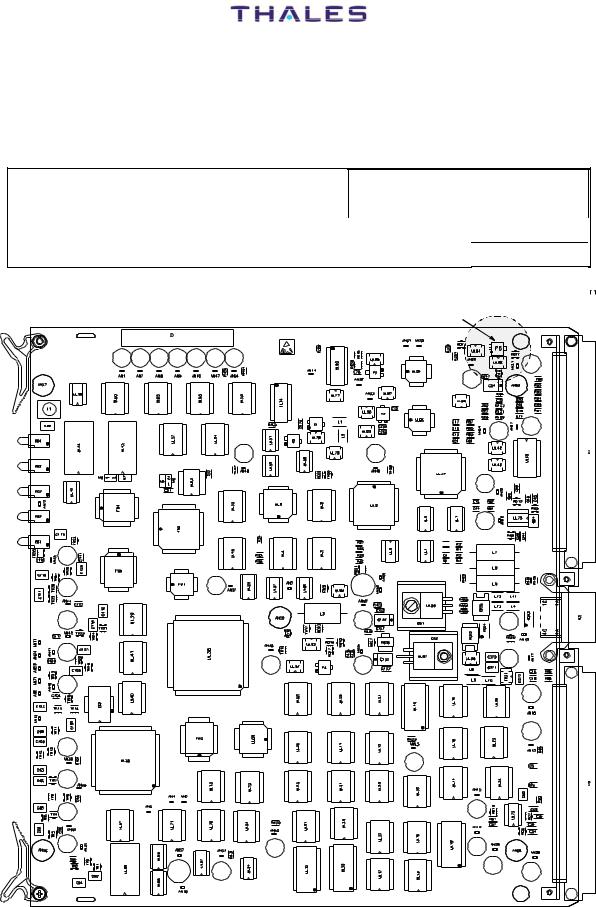

Figure 2.17. |

MON module – Trimmer adj. position of the “Transmitted Power” measurement ......... |

2-18 |

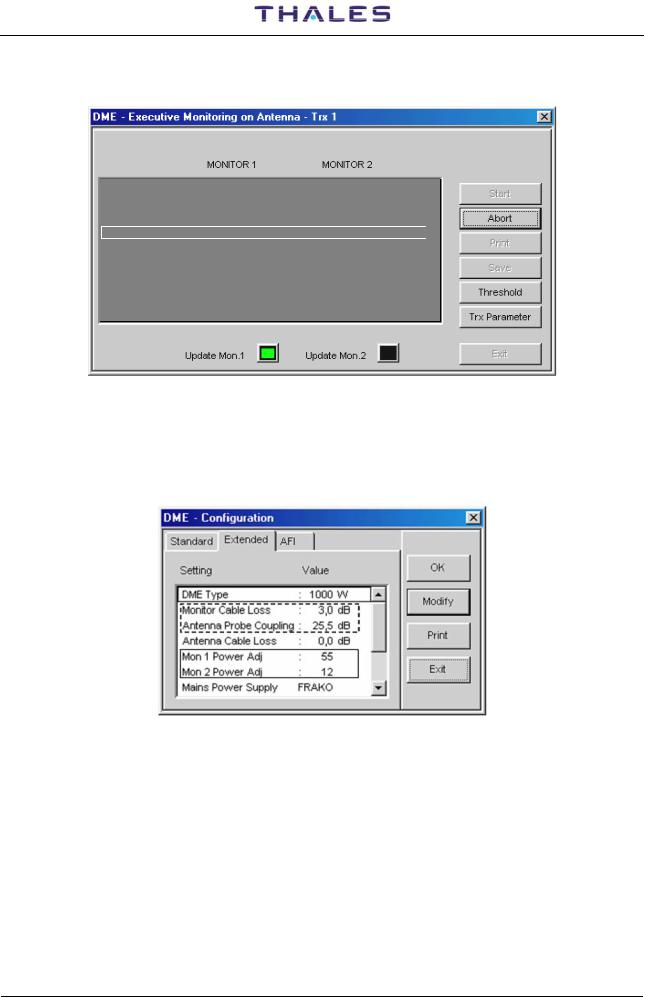

Figure 2.18 |

Screen of correct measurement by Monitor 1 & 2 ......................................................... |

2-19 |

Figure 2.19 |

Screen of configuration for power reading adjustment .................................................. |

2-19 |

Figure 2.20. |

I/O panel, top view ......................................................................................................... |

2-21 |

Figure 2.21. |

Parallel Input Lines application ...................................................................................... |

2-28 |

Figure 2.22. |

Parallel Output Lines application ................................................................................... |

2-29 |

Figure 2.23 . |

List of Links Set on CSB Module ................................................................................... |

2-30 |

Figure 2.24. |

Links Setting on CSB Module ........................................................................................ |

2-31 |

Figure 2.25. |

Links Setting on DMD Module ....................................................................................... |

2-32 |

Figure 2.26. |

Links Setting on MON Module ....................................................................................... |

2-33 |

Figure 2.27. |

Links Setting on TX Module ........................................................................................... |

2-34 |

Figure 2.28. |

Header plugs setting on AFI Module.............................................................................. |

2-36 |

Figure 2.29. |

AFI Module - Input and output signals application......................................................... |

2-37 |

Figure 2.29a. |

AFI Module – Association example with VOR/ILS 400.................................................. |

2-38 |

Figure 2.29b. |

AFI Module – Association example with VOR/ILS NORMAC........................................ |

2-39 |

Figure 2.30. |

Equipment associated examples ................................................................................... |

2-40 |

Figure 2.31. |

Remote Control and Status Indications connection examples ...................................... |

2-41 |

Figure 2.32. |

PC connection examples ............................................................................................... |

2-42 |

Figure 2.33. |

BCPS subrack of Frako type - Supply cables connection ............................................ |

2-43 |

List of TABLES

Table |

Page |

Table 2-1 - List of typical installation cables......................................................................................... |

2-4 |

Table 2-2 - RF coax cable LCF 1/2" CU2Y type - Technical specification........................................... |

2-7 |

Table 2-3 - STD Coax cables ............................................................................................................... |

2-15 |

Table 2-4 - Loss of STD coax cables ................................................................................................... |

2-17 |

Table 2-5 - Monitors power alarm threshold examples ........................................................................ |

2-18 |

Table 2-6a - SK1 on I/O panel and front panel - Serial Ports PC connector pin-out signals ............... |

2-21 |

Table 2-6b - PL1 and PL2 on I/O panel - Serial Ports MDM connector pin-out signals....................... |

2-22 |

Table 2-7a - PL3 on I/O panel - INPUT Parallel Port Connector pin-out signals ................................. |

2-23 |

Table 2-7b - SK2 on I/O panel - OUTPUT Parallel Port Connector pin-out signals............................. |

2-24 |

Table 2-7c - PL4 on I/O panel (optional) - INPUT Parallel Port connector pin-out signals .................. |

2-25 |

Table 2-7d - SK3 on I/O panel (optional) - OUTPUT Parallel Port Connector pin-out Signals ............ |

2-26 |

Table 2-8 - PL7 on I/O Panel - Telephone line Connector pin-out signals........................................... |

2-27 |

Table 2-9 - SK4 and SK5 on I/O Panel - AFI Connectors pin-out signals........................................... |

2-27 |

Table 2-10 - AFI Connectors pin-out signals........................................................................................ |

2-35 |

2-b |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

955 900 031 C |

Vol. 1-Section 2 - Installation |

SECTION 2

INSTALLATION

2.1GENERAL INSTALLATION INFORMATION

2.1.1Safety Precautions

It is the task of the site supervisor or construction manager to make available the materials supplied by THALES Italia s.p.a., independently procured special materials and tools. For every site, strict attention should be paid to safety regulations issued by the local authorities.

2.1.1.1General rules

The following rules should be observed for prevention of accidents:

-Consumption of alcohol in any form is forbidden on the installation site.

-Drunken persons or those under influence of alcohol will not be tolerated on the installation site.

-Protective goggles and safety gloves are to be worn when work is being carried out on batteries. Rinsing water, soda and several cleaning cloths should be available.

-Sturdy shoes, safety gloves and safety helmets are to be worn.

-Protruding nails, strips etc. must be removed immediately. Ladders and planks must always be carefully checked before use.

-Do not tread on protruding plank sections.

-Never leave objects on scaffolding or ladders.

-Scaffolding or frames are to be erected sturdily and must always be tested before use.

-Test electrical devices and extension cables for accident safety.

-Remove fuses before carrying out work on mains.

-Wear protective goggles when carrying out sanding or drilling operations.

-Sand off burr from chisels and punches in good time.

-Test striking tools for tightness of fit.

-Do not put pointed or sharp objects into working-clothing pockets.

-Jewelry such as chains and rings should be removed when working on building sites - especially when working with electrical devices.

-Always keep escape routes clear.

-Every employee on an installation site should know:

•where the First-Aid box is kept

•the telephone number of the nearest casualty doctor and eye specialist

•where the fire extinguisher is kept

•the location of hazardous areas on the way to the work place, or at the work place itself.

Damage caused by animals is highly improbable. The door of the shelter or equipment room should be locked in the absence of the personnel.

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-1 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

2.2INSTALLATION PRELIMINARY

The operator must perform the following operations when installing the beacon:

Select and prepare the site;

Unpacking, Paging and shipping;

Typical installation

•ground the equipment;

•connect the power supplies;

•connect the antenna.

•I/O connections

The following connections may also be necessary, depending on the beacon configuration selected and the options used:

•connection the facility with associated equipment;

•connection with other equipment.

2.3INSTALLATION SITE SELECTION

The area in which a DME is to be installed is determined by the responsible Civil Aviation Authority according to the international air traffic regulations.

The area is dependent on the type of obstacle. Also clearance and runway configuration (e.g. overrun, clearway, stopway) in case located in terminal area.

The following site selection guidelines are general recommendation and only guiding values for information. The exact values are locally dependent decisions, which are made during installation. They are computed with formulas, which take in account of terrain, obstacles and other. See Appendix "A – DME Antenna Siting Area Criteria", on this volume.

The installation is determined by means of a site survey at which a surveyor must always be present. THALES Italia s.p.a. is able to provide engineering consultants on site for this survey.

The DME installation area selection depends on the following using conditions:

1)Terminal Area beacon

a)DME (substituting or integrating MARKER functions) placed with ILS equipment

In this case, DME antenna, usually directional antenna, is mounted on Glide Slope antenna mast and the DME equipment is installed into Glide Path shelter.

b)Stand-alone

DME with omnidirectional antenna on its own mast and equipment installed into a suitable shelter. The area is dependent on clearance and runway configuration.

2)In route beacon

(External zone site and normally far away from terminal area), with or without associated VOR equipment: see Appendix "A – DME Antenna Siting Area Criteria", on this volume

2-2 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

955 900 031 C |

Vol. 1-Section 2 - Installation |

2.4EQUIPMENT SITE LOCATION

The ground beacon may be installed in a control room or inside a shelter, which complies with the environmental temperature, humidity and pressure values listed in Section 4. Bear in mind that the equipment has the following overall dimensions:

−height: 1730 mm,

−width: 580 mm,

−depth: 635 mm cabinet code 297509007or 610 mm cabinet code 297509004 the amount of space around the equipment must be as follows:

−more than a value between the rear part of the beacon and the wall or any other piece of equipment, to allow the operator to open the rear door of the equipment.

Make it possible support the back part of the cabinet to a wall, in as all the operations of cables and connectors assemblage, could be performed on front.

−a minimum of 30 cm between the top of the beacon and the ceiling of the control room or the shelter to leave space for the external connection cables and to allow access to the antenna connector and to the antenna probes connectors;

−a minimum of 60 cm between the front of the beacon and the wall or any other piece of equipment, to allow the operator to open the front door.

The base must be able to support the total weight of the equipment (approx. 200/230 kg including the optional modules) within the range of dynamic stress envisaged for the equipment.

The beacon does not normally need securing; if it is to be secured to the base, however, four M12 bolts should be used and their fixing holes.

2.5UNPACKING, PACKING AND SHIPPING;

The equipment should be unpacked as soon as possible in order to check that it is complete and intact. The place of storage used for any intermediate storage period must be dry. The temperature range specified in the technical data section 4 must be conformed to. The check list is inside the packing to which to refer.

The DME beacon and modules will be packed according to the national and international standards. The packing procedure may be slightly different according to the way of shipping or to the destination country.

2.6TYPICAL INSTALLATION

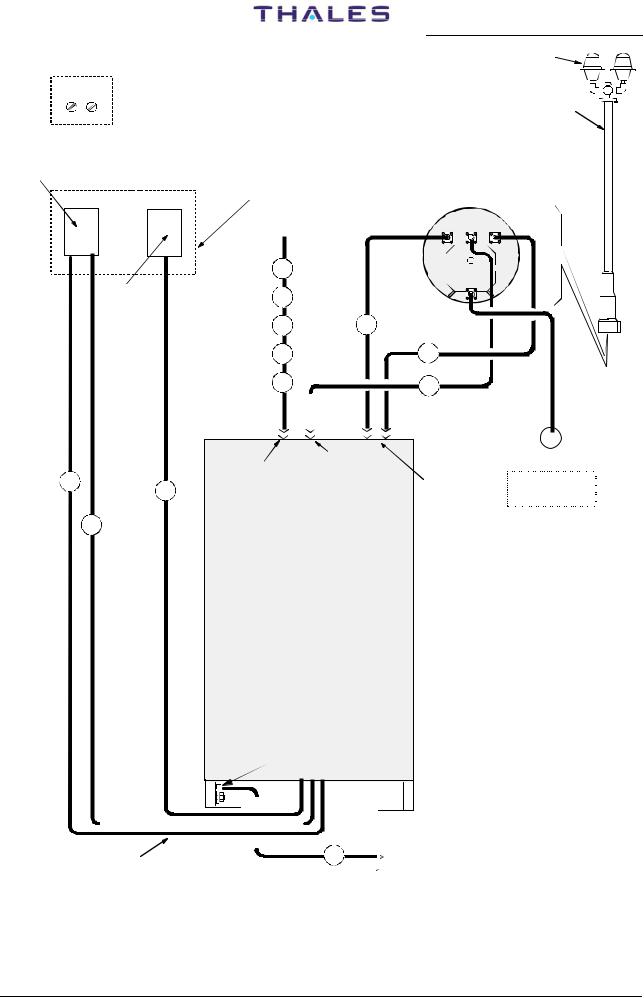

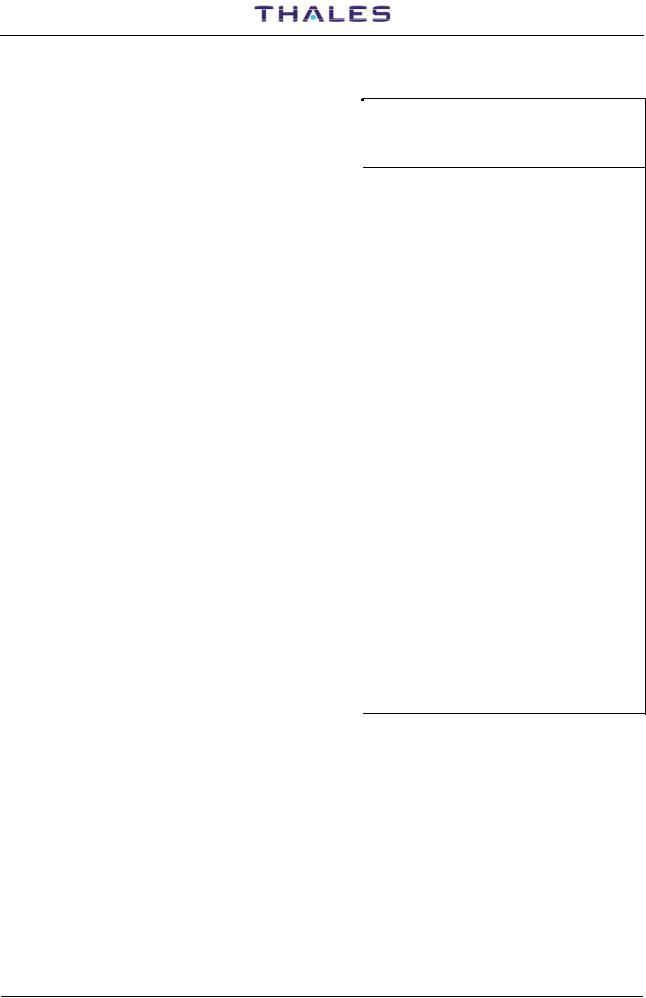

Figure 2.8 shows all the connections for beacon installation. Should this use an I/O system provided with the LCSU unit in standard configuration; this figure also illustrates the characteristics of the cables used for installation and provided by the manufacturer, as listed in table 2.1. The main characteristics of installation cables are on figures 2.1 to 2.7. The reference item is shown on figures, internal at a circle.

WARNING

Before connecting the cables check that the mains lead is dead and that the battery is not connected (the breaker of mains and battery, on external electrical switchboard, must be OFF).

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-3 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

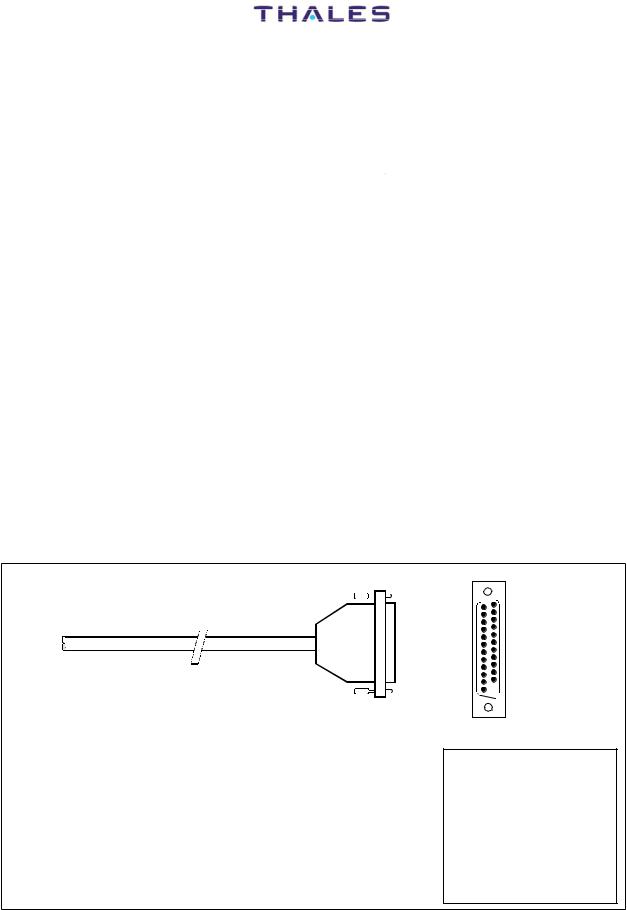

2.6.1Installation cables

. The main characteristics of installation cables are on figures 2.1 to 2.7. and in table 2-1.

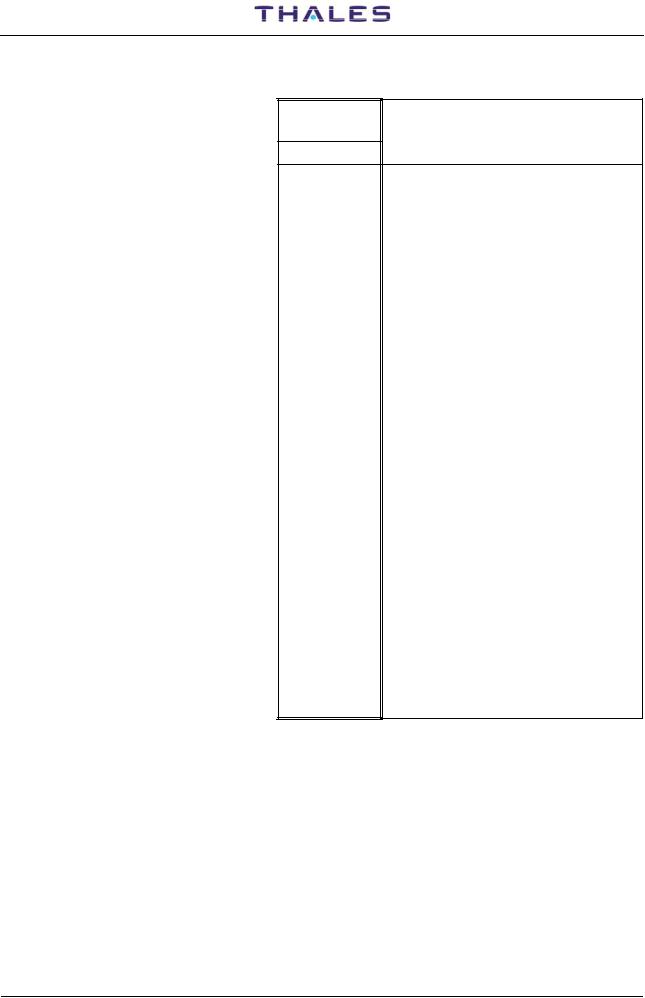

Table 2-1 - List of typical installation cables

REF. |

CABLE |

LENGTH |

NOTE |

|

|

(m) |

|

|

|

|

|

1 |

GROUND CABLE (option) |

15 |

Single wire section:25 mm2. External wire |

|

|

|

covering: Ø=11 mm, green/yellow color |

2 |

MAINS POWER SUPPLY CABLE (option) |

15 |

Three wires section 2,5mm2 each – External |

|

|

|

cable covering Ø=15,2 mm |

3 |

BATTERY CABLE (RO) (option) |

15 |

Single wire section:10 mm2 - |

|

|

|

External wire covering: Ø=7,6 mm; red color |

4 |

BATTERY CABLE (NE) (option) |

15 |

Single wire section:10 mm2 - |

|

|

|

External wire covering Ø=7,6 mm; black color |

5 |

AUX OUT I/O CABLE (option) |

10 |

see figure 2.1 |

6 |

AUX IN I/O CABLE (option) |

10 |

see figure 2.2 |

7 |

LOCAL PC SERIAL CABLE |

3 |

see figure 2.3 |

|

|

|

|

8 |

RS-232 EXTERNAL MODEM CABLE (option) |

3 |

see figure2.4 |

9 |

INTERFACE FACILITY CABLE |

10 |

see figure 2.5 |

|

|

|

|

10 |

TELEPHONE CABLE (option) |

15 |

Two pair twisted wire telephone cable (screened ) |

11 |

LOW LOSS ½” ANTENNA CABLE |

25 |

see figure 2.6. |

|

|

|

|

12 |

LOW LOSS ½” MONITOR CABLE |

25 |

see figure 2.6. |

|

|

|

|

13 |

LOW LOSS ½” MONITOR CABLE |

25 |

see figure 2.6. |

|

|

|

|

14 |

OBSTRUCTION LIGHT CABLE (option) |

25 |

see figure 2.7 Three wire 1,5 mm2 shielded cable |

PL2

|

|

|

|

|

|

|

|

|

To I/O panel (SK2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUT Parallel port |

|

|

|

|

|

|

|

|

|

|

PIN |

Wire Covering |

|

PIN |

|

Wire Covering |

|

PIN |

Wire Covering |

|

n° |

Color |

|

n° |

|

Color |

|

n° |

Color |

|

|

|

|

|

|

|

|

|

|

|

1 |

White |

|

10 |

|

Violet |

|

19 |

WHITE/brown |

|

2 |

Brown |

|

11 |

|

Orange |

|

20 |

WHITE/green |

|

3 |

Green bright |

|

12 |

|

Bleu (light) |

|

21 |

WHITE/yellow |

|

4 |

Yellow |

|

13 |

|

Green (dark) |

|

22 |

WHITE/gray |

|

5 |

Gray |

|

14 |

|

WHITE/bleu |

|

23 |

YELLOW/black |

|

6 |

Pink |

|

15 |

|

WHITE/violet |

|

24 |

YELLOW/red |

|

7 |

Bleu (dark) |

|

16 |

|

WHITE/red |

|

25 |

YELLOW/bleu |

|

8 |

Red |

|

17 |

|

WHITE/pink |

|

|

|

|

9 |

Black |

|

18 |

|

WHITE/black |

|

|

|

|

1

14

Db 25

( 25 pins Male)

25

13

13

pin side view

NOTE

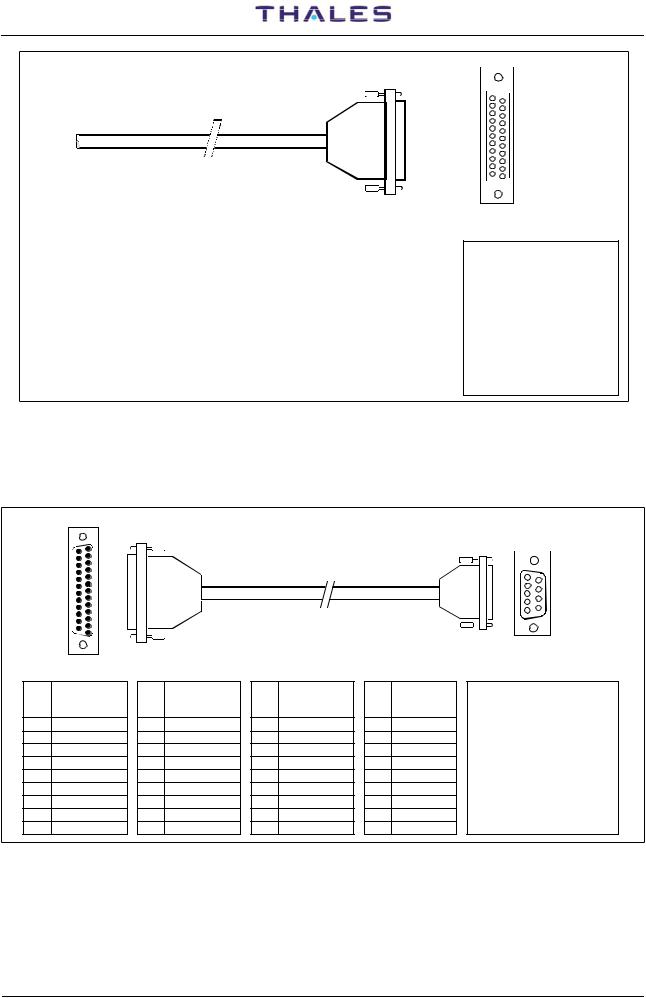

• Reference item of table 2-1: n°5

•Signal assignment: see table 2-4b

•Cable screen on the connector cover

Figure 2.1. AUX OUT I/O cable

2-4 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual

Vol. 1-Section 2 - Installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SK3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

AUX IN I/O |

cable |

|

|

|

|

|

|

||||||||

|

|

|

COD. 041917043T |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

To I/O panel (PL3) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IN Parallel port |

|||

|

|

|

|

|

|

|

|

|

|

||||||||

PIN |

Wire Covering |

|

PIN |

|

Wire Covering |

|

PIN |

|

Wire Covering |

||||||||

n° |

Color |

|

n° |

|

Color |

|

n° |

|

Color |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

1 |

White |

|

10 |

|

|

Violet |

|

19 |

|

WHITE/brown |

|||||||

2 |

Brown |

|

11 |

|

|

Orange |

|

20 |

|

WHITE/green |

|||||||

3 |

Green bright |

|

12 |

|

|

Bleu (light) |

|

21 |

|

WHITE/yellow |

|||||||

4 |

Yellow |

|

13 |

|

|

Green (dark) |

|

22 |

|

WHITE/gray |

|||||||

5 |

Gray |

|

14 |

|

|

WHITE/bleu |

|

23 |

|

YELLOW/black |

|||||||

6 |

Pink |

|

15 |

|

|

WHITE/violet |

|

24 |

|

YELLOW/red |

|||||||

7 |

Bleu (dark) |

|

16 |

|

|

WHITE/red |

|

25 |

|

YELLOW/bleu |

|||||||

8 |

Red |

|

17 |

|

|

WHITE/pink |

|

|

|

|

|

|

|||||

9 |

Black |

|

18 |

|

|

WHITE/black |

|

|

|

|

|

|

|||||

955 900 031 C

1

14

14

Db 25

( 25 pins Female)

13

25

25

pin side view

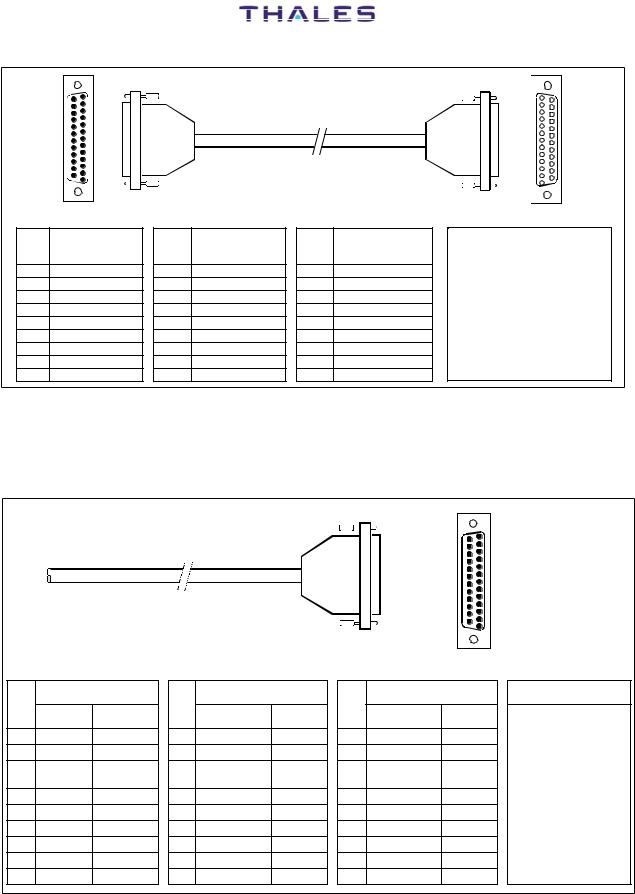

NOTE

• Reference item of table 2-1: n°6

•Signal assignment: see table 2-4a

•Cable screen on the connector cover

Figure 2.2. AUX IN I/O cable

1

14

Db 25 |

|

|

|

|

|

|

|

1 |

6 |

Db 9 |

( 25 pins |

|

PL1 |

|

|

|

|

PC |

|

( 9 pins Female) |

|

Male) |

|

|

|

|

|

|

|

5 |

9 |

|

|

|

|

|

|

|

|

|

|

||

|

25 |

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

To I/O panel (SK1) |

|

|

|

|

pin side view |

|||

|

pin side view |

|

|

|

|

To PC |

|

|

||

|

PC RS232 port |

|

|

|

typical COM1 port |

|

|

|||

PIN |

PL1 Signal |

PIN |

PL1 Signal |

PIN |

PL1 Signal |

PIN |

PC Signal |

|

NOTE |

|

n° |

assignment |

n° |

assignment |

n° |

assignment |

n° |

assignm. |

|

|

|

1 |

- |

10 |

- |

19 |

- |

1 |

DCD |

• Reference item of table 2-1: |

||

2 |

RXD |

11 |

- |

20 |

DSR |

2 |

RXD |

|

n°7 |

|

3 |

TXD |

12 |

- |

21 |

- |

3 |

TXD |

|

|

|

4 |

CTS |

13 |

- |

22 |

RI |

4 |

DTR |

|

|

|

5 |

RTS |

14 |

- |

23 |

- |

5 |

GND |

|

|

|

6 |

DTR |

15 |

- |

24 |

- |

6 |

DSR |

|

|

|

7 |

GND |

16 |

- |

25 |

- |

7 |

RTS |

|

|

|

8 |

DCD |

17 |

- |

|

|

8 |

CTS |

|

|

|

9 |

- |

18 |

- |

|

|

9 |

RI |

|

|

|

Figure 2.3. PC serial cable

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-5 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

14 |

1 |

1 |

14 |

|

Db 25 |

|

|

|

|

|

SK2 |

|

Db 25 |

( 25 pins |

|

MDM |

|

|

|

|

( 25 pins |

|

|

|

|

|

SK1 |

|

|||

Male) |

|

|

|

|

|

|

Female) |

|

|

25 |

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

13 |

25 |

|

|

|

|

|

|

To I/O panel (PL1,2) |

||

|

pin side view |

To MODEM |

|

|

|

|

|

|

|

|

|

|

RS232 Serial port 3,2 |

pin side view |

|||

|

|

|

|

|

||||

|

|

|

|

|

|

|

||

PIN |

Signal |

PIN |

Signal |

PIN |

Signal |

|

NOTE |

|

n° |

assignment |

n° |

assignment |

n° |

assignment |

|

|

|

1 |

- |

10 |

- |

19 |

- |

• Reference item of table 2-1: |

||

2 |

TXD1/2 |

11 |

- |

20 |

DTR1/2 |

|

n°8 |

|

3 |

RXD1/2 |

12 |

- |

21 |

- |

|

|

|

4 |

RTS1/2 |

13 |

- |

22 |

RI 1/2 |

|

|

|

5 |

CTS1/2 |

14 |

- |

23 |

- |

|

|

|

6 |

DSR 1/2 |

15 |

TXCK1/2 |

24 |

- |

|

|

|

7 |

GND |

16 |

- |

25 |

- |

|

|

|

8 |

DCD1/2 |

17 |

RXCK1/2 |

|

|

|

|

|

9 |

- |

18 |

- |

|

|

|

|

|

Figure 2.4. RS232 External Modem cable

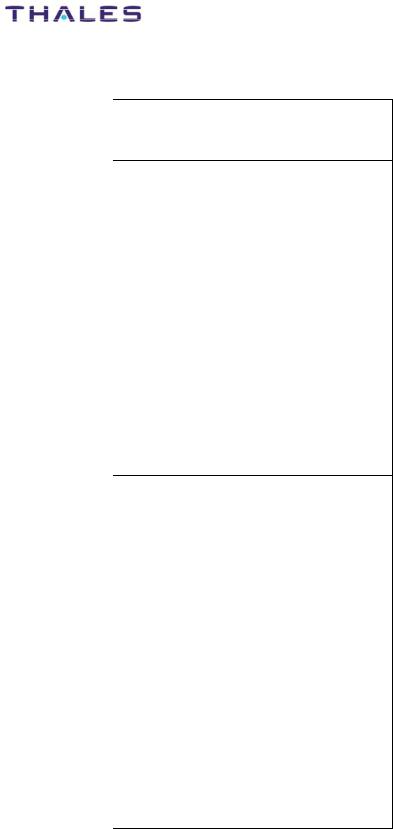

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

PL4 |

|

|

Db 25 |

|

|

|

|

|

|

PL5 |

|

|

( 25 pins |

|

|

|

|

|

|

|

|

|

Male) |

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

To I/O panel (SK4,5) |

|

|

||

|

|

|

|

|

Assoc. Facility EQPT |

pin side view |

|

||

|

|

|

|

|

AF1,2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PIN |

Wire Covering Color |

PIN |

Wire Covering Color |

PIN |

Wire Covering Color |

NOTE |

|||

n° |

STD |

Alternative |

n° |

STD |

Alternative |

n° |

STD |

Alternative |

|

|

|

|

|

||||||

1 |

White |

Black |

10 |

Violet |

Oran/blck |

19 |

WHITE/brown |

Bleu/red |

• Reference item of |

2 |

Brown |

White |

11 |

Orange |

Bleu/blk |

20 |

WHITE/green |

Red/gre |

table 2-1: n°9 |

3 |

Green |

Red |

12 |

Bleu (light) |

Black/whi |

21 |

WHITE/yellow |

Oran/gre |

|

|

bright |

|

13 |

|

|

22 |

|

|

• Signal assignment: |

4 |

Yellow |

Green |

Green (dark) |

Red/white |

WHITE/gray |

Blk/Wh/rd |

|||

5 |

Gray |

Orange |

14 |

WHITE/bleu |

Green/wh |

23 |

YELLOW/black |

Wh/blk/rd |

see table 2-6 |

6 |

Pink |

Bleu |

15 |

WHITE/violet |

Bleu/whit |

24 |

YELLOW/red |

Rd/blk/wh |

|

7 |

Bleu (dark) |

White/blk |

16 |

WHITE/red |

Black/red |

25 |

YELLOW/bleu |

Gr/blk/wh |

|

8 |

Red |

Red/black |

17 |

WHITE/pink |

White/red |

|

|

|

• Cable screen on the |

9 |

Black |

Green/blk |

18 |

WHITE/black |

Oran/blk |

|

|

|

connector cover |

Figure 2.5. Interface Facility cable

2-6 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

955 900 031 C |

Vol. 1-Section 2 - Installation |

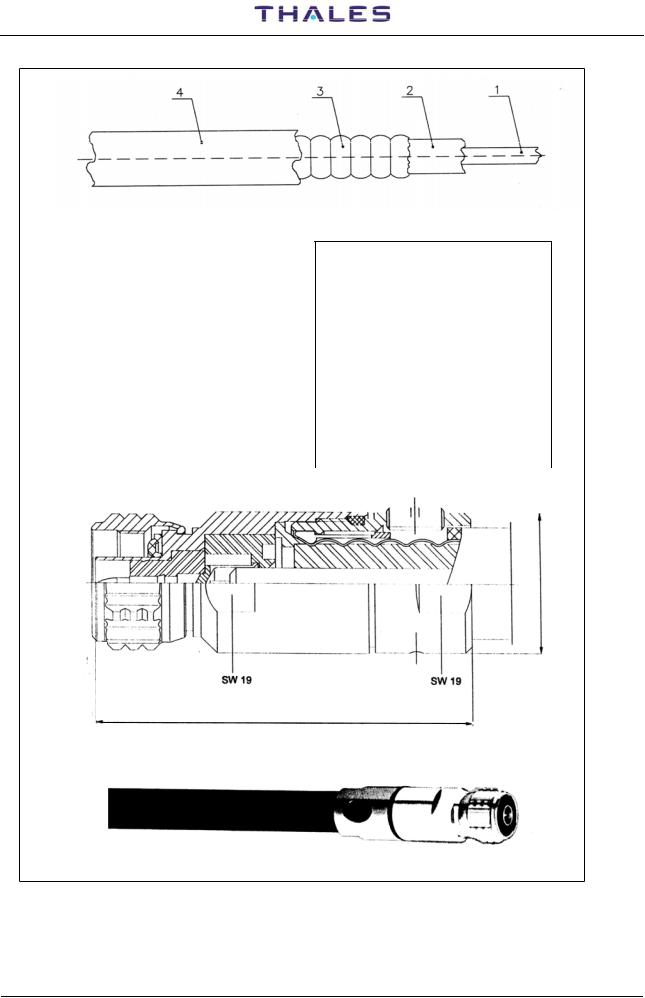

Table 2-2 - RF coax cable LCF 1/2" CU2Y type - Technical specification

item |

|

|

Mechanical |

|

|

|

|

|

|

1 |

|

Inner conductor |

|

Ø 4,8 mm AL/CU clad |

2 |

|

Dielectric |

|

Ø 11,5 mm Foam PE |

3 |

|

Outer conductor |

|

Ø 13,8 mm corrugated |

|

|

|

|

copper tube |

4 |

|

Jacket |

|

Ø 16,1 mm PE black |

- |

|

Weight |

|

Approx. 0,23 kg/m |

|

|

|||

- |

|

Minimum |

|

70 mm: single bending |

|

|

bending radius |

|

125 mm: repeated |

|

|

|

|

|

|

|

|

|

bending |

|

|

|

|

|

Electrical data

Characteristic impedance |

50 ±1Ω |

Relative propagation velocity |

88% |

Capacity |

76 pF/m |

Peak Power rating |

23 kW |

Peak RF Voltage rating |

1,5 kV |

Attenuation @ 20°C |

0,073 dB/m |

Max operating frequency |

3000 MHz |

DC-resistance inner conductor |

1,59 Ω/km |

DC-resistance outer conductor |

2,0 Ω/km |

Typical delay at 1000MHz |

0.004 µs/m |

|

|

reference plane

Ø 21,8

SW19 |

|

|

|

SW19 |

|

|

|

|

58

Connector N-plug for LCF 1/2" – 50 Ω

Coax cable with connector N-plug

Figure 2.6. RF coax cable - LCF 1/2"

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-7 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

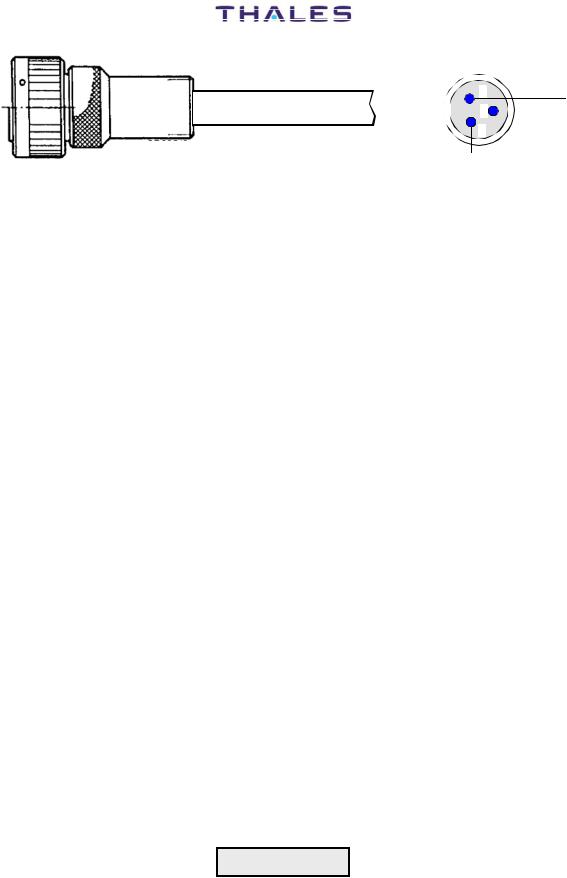

3 wire shielded cable

Connector: Cannon - CGL06PG 10SL-3S-C1L

pin solder rear view

A |

B |

C |

GND

Figure 2.7. Obstruction light cable

2.6.2Grounding

The ground cable must be laid separately and connected permanently to GND terminal of the "Terminal Board) and to the connecting bolt of the cabinet.

A ground fault external interrupter it is suggested for a rated fault leakage current of 30 mA.

The copper cable, with cross-section 25 mm2, and fitted with a lug for attaching to the ground bolt, is provided for grounding the beacon. Figures 2.10 and figure 2.12 illustrate how the beacon is grounded.

One end of the cable is inserted in the lug terminal and the other end is connected to the local ground network, which must comply with the safety regulations stipulated in the specifications.

2.6.3Power supply connection

The equipment can be powered from either mains, or battery, or both.

The standard version can be powered from a external 48 Vdc. The BCPS rack must be added for VAC operation and it can either be housed inside the equipment or installed externally as well.

Cabling connections are shown in figures 2.11 and 2.12.

The BCPS unit will have a different structure depending on the type of power supply used. Furthermore, since the beacon is not provided with any on/off breakers. It will be provided from optional breaker AC and DC recommended with independent switch for the two power supplies.

When collocated with a System 400 (D)VOR, NDB or ILS Systems a common power supply and battery will be implemented.

The equipment may be supplied by the mains with a 194 to 260 Vac voltage, 48 to 64 Hz, single phase, or by an source providing a rated 48 Vdc (external source or 48Vdc battery back-up) direct power supply (40 Vdc to 60 Vdc). Equipment consumption: refer to para. 4.10.1 section 4 on this volume

Connect the mains leads (L= mains phase; N = Neutral; Mains Ground = typical green-yellow color) and battery leads (+polarity = red cable and negative polarity = black cable) to terminals on "terminal board" as shown in figure 2.11 or 2.13.

CAUTION

When connecting the DC supply observe the correct polarity ("+ positive" and "- negative")

2-8 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

|

955 900 031 C |

|||||||||||||||||||

Vol. 1-Section 2 - Installation |

|

||||||||||||||||||||

BATTERY |

|

Obstr. Light |

|

|

|

|

|||||||||||||||

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

48Vcc |

|

FAN-96 |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

ANTENNA |

||||||||||||

|

|

|

|

|

|

220Vac |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mains |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Automatic |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

battery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

breaker |

|

|

|

|

|

|

External electrical |

||||||||||||||

|

|

|

|

|

|

|

|

switchboard |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RF |

|

|

|

M1 |

INPUT |

M2 |

|

10 |

|

|

|

Automatic |

|

|

Obs. Light |

|

9 |

|

|

|

|

mains |

|

|

|

|

breaker |

|

|

|

|

|

5 |

12 |

|

|

|

6 |

13 |

|

|

|

7 |

11 |

|

|

|

|

SK1 |

Top of cabinet |

14 |

|

|

|

||||

|

|

|

|||

|

|

|

|

||

|

I/O Panel |

Antenna |

|

|

|

|

|

|

|

||

|

connector |

|

|

|

|

4 |

see fig 2.9 |

|

Antenna |

Automatic |

|

2 |

|

monitors probes |

|||

|

|

night switch |

|||

|

|

connectors |

|||

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Obstruction light |

|

|

|

|

|

power supply |

|

DME 400

EQUIPMENT

Ground bolt

Bottom of cabinet

|

|

|

|

|

|

|

|

|

|

To local ground network |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|||

|

|

|

|

|

|

|

||||

Power supply Cables |

|

|||||||||

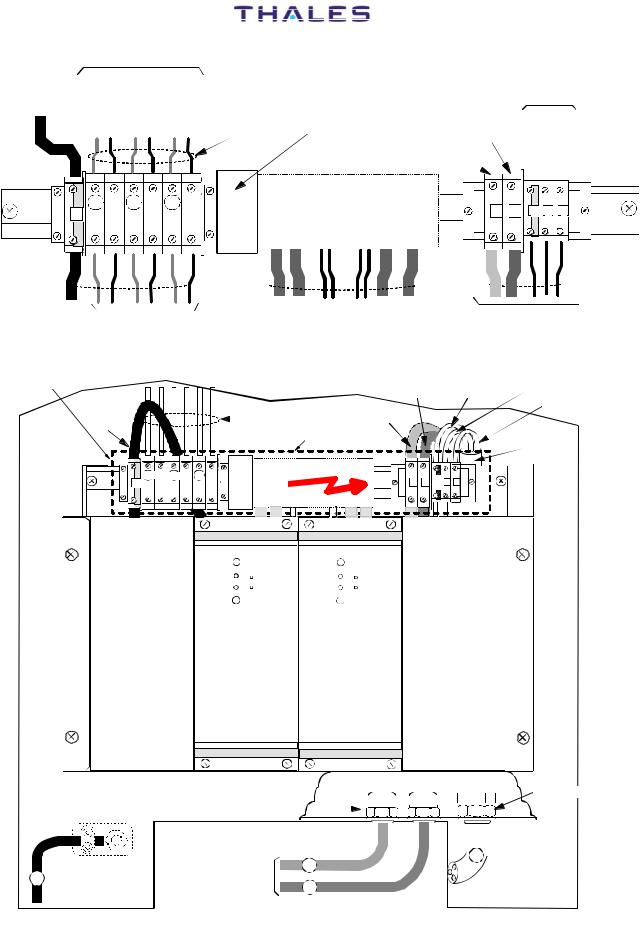

Figure 2.8. Installation connections (typical)

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-9 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

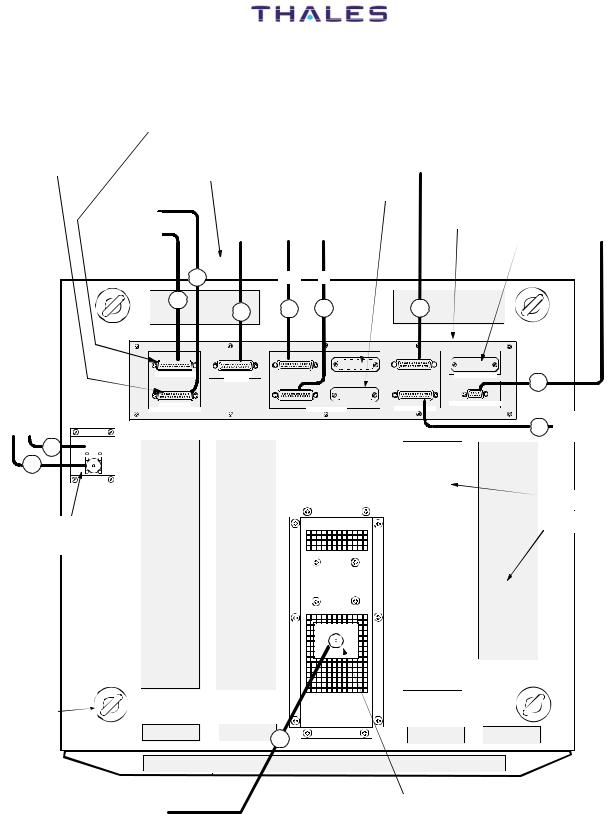

|

UNAVAILABLE IF |

|

|

|

|

|

|

MDM2 (internal modem) |

|

|

|

|

|

|

IS USED |

|

|

|

|

|

UNAVAILABLE IF |

|

|

|

To associated equipment 1 |

|

|

MDM1 (internal modem) |

|

|

|

|

||

IS USED |

Rear of cabinet |

|

|

Identity Facility |

|

|

|

|

|

|

|||

|

|

|

|

|

N.U. |

|

|

Possible external |

|

AUX. IN/OUT Parallel |

I/O PANEL |

To telephon lines |

|

|

MODEM (option) |

PC |

signals ON/OFF |

|

N.U. |

|

|

|

|

||||

|

8 |

|

OUT |

IN |

|

|

|

8 |

|

5 |

6 |

9 |

|

|

|

7 |

|

|||

|

|

|

|

|

|

|

To antenna monitors probes

12  M1

M1

13 |

M2 |

ANTENNA

MONITORS PROBES

CONNECTORS "N" type female

PL1 |

SK1 |

PORT 3 (DCE/DTE) |

PORT 1 (DCE) |

|

PC (RS232) |

PL2

PORT 2 (DTE)

SERIAL PORT (RS232)

|

SK2 |

|

|

|

|

SK3 |

|

SK4 |

|

|

SK6 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

OUT(0/15) |

|

|

|

OUT(16/31) |

|

|

AF1 |

|

TACAN ANTENNA |

|||||||

|

|

|

|

|

|

PL4 |

|

|

|

|

|

|||||

|

PL3 |

|

|

|

|

|

SK5 |

|

|

PL7 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1-6= LINE 1 3-8=LINE 2 |

|||

|

IN (0/15) |

|

|

|

|

|

|

|

|

|

AF2 |

|

||||

|

|

|

IN (16/31) |

|

|

|

|

|||||||||

|

|

|

|

|

|

ASSOC. FACILITY |

|

|

|

|

||||||

|

|

|

PARALLEL PORT |

|

|

|

|

|

|

TEL. LINES |

|

|||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10

To associated 9 equipment 2

Identity Facility

AIRING

GRIDS

To don't obstruct TOP side area

N° 4 EYE

BOLTS

11

Front of cabinet

ANTENNA

To DME antenna CONNECTOR "N" female type

NOTE: Valid for both cabinets type

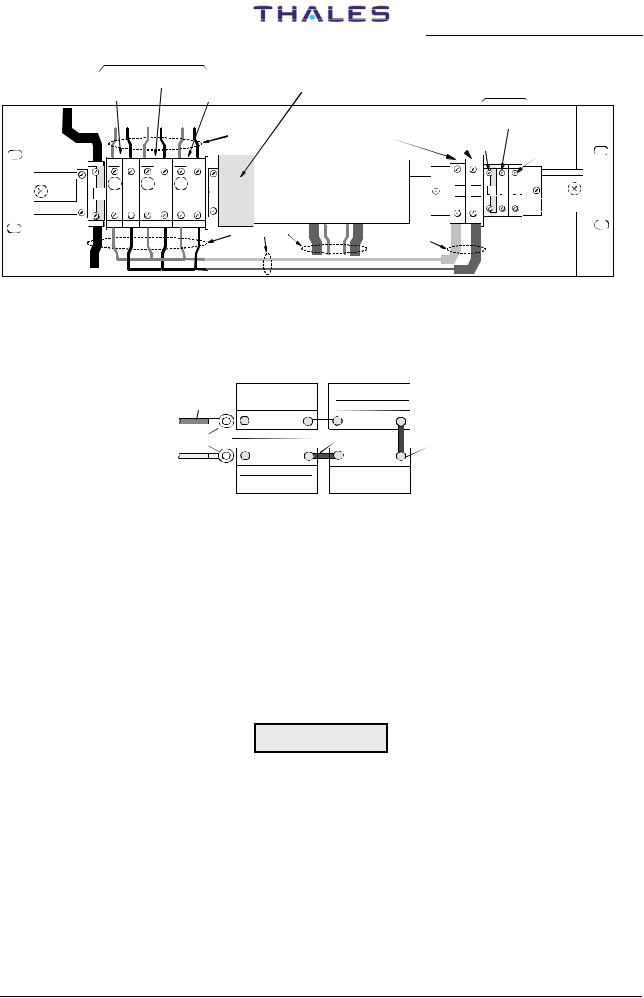

Figure 2.9. Installation - Cables connections (typical) on top end of equipment

2-10 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

955 900 031 C |

Vol. 1-Section 2 - Installation |

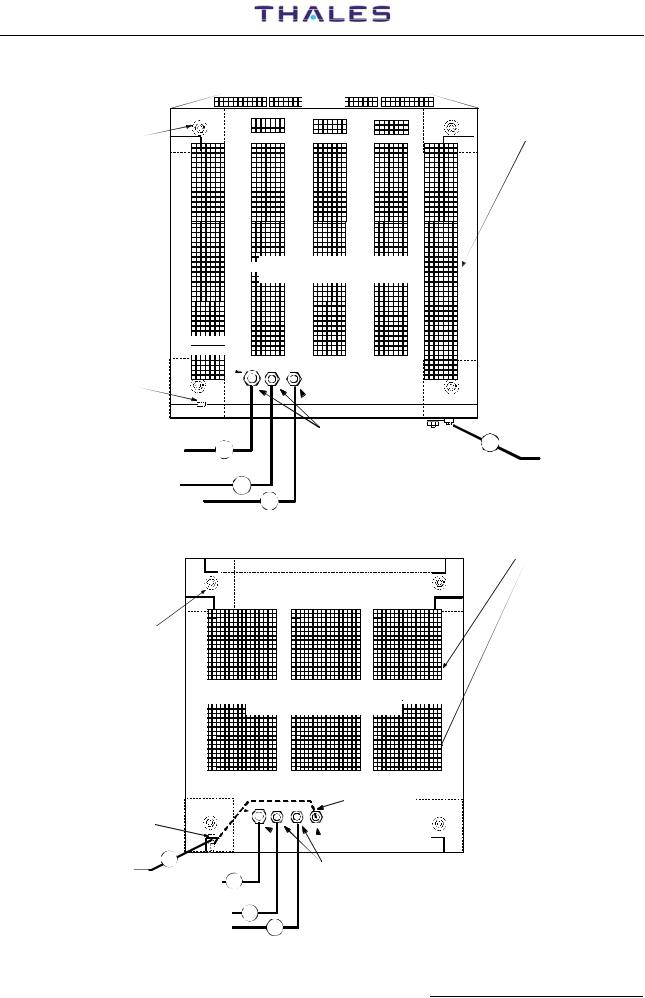

Cabinet bottom view |

|

Front door |

AIRING |

|

|

|

GRIDS |

N° 4 holes |

|

|

|

|

|

|

|

|

|

|

|

To don't obstruct |

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

BOTTOM side area |

|||||||

|

|

|

|

|

|

|

|||||||||

for fixing |

|

|

|

|

|

||||||||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

||||||||||

to the plinth |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cabinet

Cabinet 297

297 509 007

509 007

Input power supply

cable entry

cable entry

Ground bolt

Rear door

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bush fair-lead |

1 |

|||||||

|

|

|

2 |

|

GROUND CABLE |

|||||||

|

MAINS CABLE |

|

|

|

|

|

|

|

|

|

GROUND CABLE |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to local GND network |

+ BATTERY CABLE |

|

3 |

|

|

|

|

|

|

|

|

||

|

- BATTERY CABLE |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AIRING |

|

|

|

|

|

|

|

|

|

|

|

|

GRIDS |

|

|

|

|

Cabinet bottom view |

To don't obstruct |

|||||||

|

|

|

|

BOTTOM side area |

||||||||

Front door

N° 4 holes for fixing

to the plinth

Cabinet

Cabinet 297

297 509

509 004

004

Input power supply cable entry

|

|

|

|

|

|

GROUND CABLE |

|

|

|

Ground bolt |

|

|

|

||||

1 |

|

|

|

Rear door |

|

|||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

Bush fair-lead |

|

||||

|

GROUND CABLE |

|

|

|||||

|

to local GND network |

|

|

|

|

|||

|

|

MAINS CABLE |

2 |

|

|

|||

|

|

+ BATTERY CABLE |

3 |

|

|

|||

|

|

- BATTERY CABLE |

4 |

|

|

|||

Figure 2.10. Installation - Cables connections (typical) on bottom of cabinet |

|

|||||||

|

|

|

|

|

|

|

|

2-11 |

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

|||||||

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

*to GND local network

|

|

|

48 Vdc nominal |

|

|

|

TERMINAL BAR CONNECTIONS |

|

|

|

|

|

|||||||||||||

TRANSP.to 1 |

|

|

|

|

|

|

|

|

SERVICESto |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

TRANSP.2to |

|

|

|

|

|

|

|

|

|

|

|

|

GNDMAINS |

NEUTRALMAINS-N LINEMAINS-L |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

from MAINS CABLE |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery Depleted |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Factory wired |

Breaker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery return |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ 48 Vdc input |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(negative) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From Battery |

|

|

|

|

|||

+ |

|

|

- |

|

+ |

|

|

|

- |

|

+ |

|

|

- |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10A |

10A |

2A |

+ |

- |

|

|

|

|

|

I Batt. & I Nav SHUNTS |

G |

N |

L |

||

|

|

(Optional) |

Factory wired

Factory wired

Factory wired

Factory wired

from BCPS back panel |

to BCPS back panel |

|

*) INSTALLATION CONNECTED WIRES |

||

|

Figure 2.11. Cable connection - Grounding and AC power supply of the Terminal Bar

SAFETY PROTECTION |

|

|

|

|

|

|

|

|

|

|

|

|

Factory wired |

*Battery return |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

*GND |

|

|

|

|

|

|

|

|

|

|

|

*+48V battery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAFETY PROTECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10A |

10A |

2A |

WARNING |

+ |

- |

Gnd |

|

||||||

+ - |

+ - + - |

|

|

|

||

220 Vac |

|

|

|

|||

Module OK |

Module OK |

V adj |

+ |

V adj |

+ |

- |

TP |

- |

TP |

- |

- |

Mains OK |

Mains OK |

AC/DC 1 AC/DC 2

*Mains GND |

*Mains Neutral |

|||||

|

||||||

|

|

|

|

|

|

*Mains Phase |

|

|

|

|

|

|

*Mains cable |

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

||

N |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RACK BCPS front view

Bush fair-lead Bush fair-lead

Bush fair-lead Bush fair-lead

on rear of cabinet

*) INSTALLATION CONNECTED WIRES

|

GND cable |

to BATTERY |

1 |

* to local GND network

|

|

|

|

|

||

|

|

|

|

* Mains cable |

||

+ |

|

- |

||||

|

|

|

2 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

* BATTERY cables

4

NOTE: For cabinet 297 509 004 see fig. 2-10

Figure 2.12. Cables connection - Grounding and AC power supply

2-12 |

THALES Italia S.p.A.- A. S. D. |

Vers. D, September 2005 |

DME 415/435 -Technical Manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

955 900 031 C |

||||||||||||||

Vol. 1-Section 2 - Installation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

40 to 60 Vdc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

to GND |

|

|

|

|

|

to TRANSP.2 |

Battery breaker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

local |

|

to TRANSP. 1 |

to SERVICES |

|

|

|

|

|

|

|

|

Not Used |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

network |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery or 48 Vdc |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ 48 Vdc input |

|

|

|

|

|

|

|

N-MAINS |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

return (negative) |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NEUTRAL |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Factory wired |

|

From Battery or |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

externa power |

supply |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAINS |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L - MAINS |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

+ |

|

- |

|

+ |

|

- |

|

+ |

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINE |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10A |

10A |

2A |

I Batt. & I Nav SHUNTS |

+ |

- |

G |

N |

L |

|

|

|

(Optional) |

Factory wired |

|

Factory wired |

|

|

|

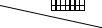

Figure 2.13. Grounding and external 48 Vdc power supply - Cables connection

2.6.3.1Batteries

The battery of back up is used in case of blackout, to allow the beacon to keep working without interruption.

Batteria 12V/50A/h |

Batteria 12V/50A/h |

cavo positivo

Terminali dei cavi

cavo negativo

+ |

|

- |

|

|

|

+ |

|

- |

|

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cavi di |

|

Tensione centrale |

||

|

|

|

|

|

connessione |

|

|||

- |

+ |

- |

+ |

Batteria 12V/50A/h |

Batteria 12V/50A/h |

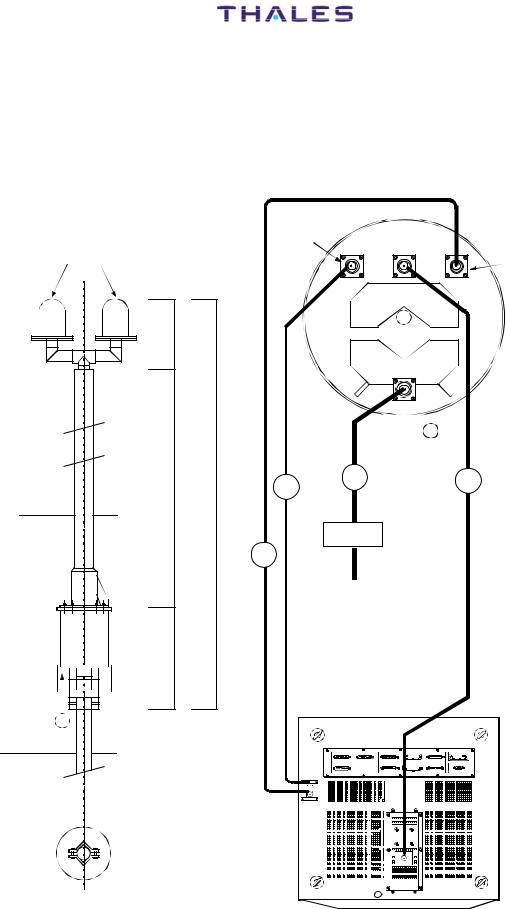

Figure 2.14. Battery connections typical

Battery type and size depend on requirements.

Suggested batteries for back-up power supply must have the following characteristics:

-Output voltage: 48 V nominal (four 12 V unit serially connected: see fig. 2.14);

-Nominal discharge capacity: 50 A/h (this capacity ensures a time duration as at para. 4.10 of section 4);

-Low maintenance types or sealed types;

-Low self-discharge;

-Long life: >4 to 5 years;

- Temperature range: |

-20 to +50 °C; |

-The charge from the equipment, at constant voltage, is typically: 2.25 V/element.

These required characteristics should be completed by technical information from the battery constructor.

CAUTION

The low maintenance battery group must be placed in a low-ventilated environment, while the other sealed types, may be installed everywhere. In any case, follow the battery constructor’s instructions.

2.6.3.1.1 Battery duration time (on 230Vac black-out)

The battery 50A/h (at end of 42V voltage), are the following:

DME415=20h - DME435=12h for TX2 stby, TX1 en service, and radiate 800 pps DME415=18h - DME435=10h for TX2 stby, TX1 en service, and radiate 2700 pps DME415=17h - DME435=7h pour TX2 stby, TX1 en service and radiate 4800 pps

NOTE: With battery 12 mounts old the back up period duration is typical degraded of 10/15% (see also the technical information from the battery constructor)

Vers. D, September 2005 |

THALES Italia S.p.A.- A. S. D. |

2-13 |

955 900 031 C |

DME 415/435 -Technical Manual |

Vol. 1-Section 2 - Installation |

2.6.4ANTENNA CONNECTION

Mechanical antenna collocation is simple and straightforward with any type of existing VOR, DVOR or ILS antenna.

Figure 2.15 shows the connections to be performed upon antenna installation and the identification of the cables supplied.

Characteristics and dimensions: see para. 4.9 on section 4 of this volume (FAN 96 type dimensions are in figure 2.15)

Antenna probe |

|

|

MONITOR 1 |

Connettore |

|

connector |

|

|

|

d'ANTENNA |

Antenna probe |

Obstructions light |

|

|

|

|

MONITOR 2 |

M1 |

M2 |

connector |

~350 |

|

|

|

|

|

|

OL |

|

|

|

View from A |

2200 |

|

14 |

11 |

3050 |

|

||

|

12 |

|

|

90 |

|

|

|

Daylight sensor

13

Obstruction light power supply

300

220

200

200

A

60.5 max

PL1 |

SK1 |

|

SK2 |

|

|

SK3 |

SK4 |

|

|

SK 6 |

||

|

|

|

|

|

|

|

|

|

||||

PORT 3 (DCE/DTE) |

PORT 1 (DCE) |

|

OUT(0/15) |

|

|

|

OUT(16/31) |

AF2 |

TACAN ANTENNA |

|||

PL2 |

PC (RS232) |

|

PL3 |

|

|

PL4 |

SK5 |

|

PL7 |

|||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|