Texas Instruments UCC3809PW-1, UCC3809P-1, UCC3809N-2, UCC3809N-1, UCC3809DTR-2 Datasheet

...

Economy Primary Side Controller

application

INFO

available

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

FEATURES

User Programmable Soft Start With

•

Active Low Shutdown

User Programmable Maximum Duty

•

Cycle

Accessible 5V Reference

•

Undervoltage Lockout

•

Operation to 1MHz

•

0.4A Source/0.8A Sink FET Driver

•

Low 100µA Startup Current

•

PART

NUMBER

UCCX809-1 10V 8V

UCCX809-2 15V 8V

TURN ON

THRESHOLD

TURN OFF

THRESHOLD

DESCRIPTION

The UCC3809 family of BCDMOS economy low power integrated circuits

contains all the control and drive circuitry required for off-line and isolated

DC-to-DC fixed frequency current mode switching power supplies with

minimal external parts count. Internally implemented circuits include

undervoltage lockout featuring startup current less than 100µA, a user ac

cessible voltage reference, logic to ensure latched operation, a PWM com

parator, and a totem pole output stage to sink or source peak current. The

output stage, suitable for driving N-Channel MOSFETs, is low in the off

state.

Oscillator frequency and maximum duty cycle are programmed with two

resistors and a capacitor. The UCC3809 family also features full cycle soft

start.

The family has UVLO thresholds and hysteresis levels for off-line and

DC-to-DC systems as shown in the table to the left.

The UCC3809 and the UCC2809 are offered in the 8 pin SOIC (D), PDIP

(N), TSSOP (PW), and MSOP (P) packages. The small TSSOP and

MSOP packages make the device ideal for applications where board

space and height are at a premium.

-

-

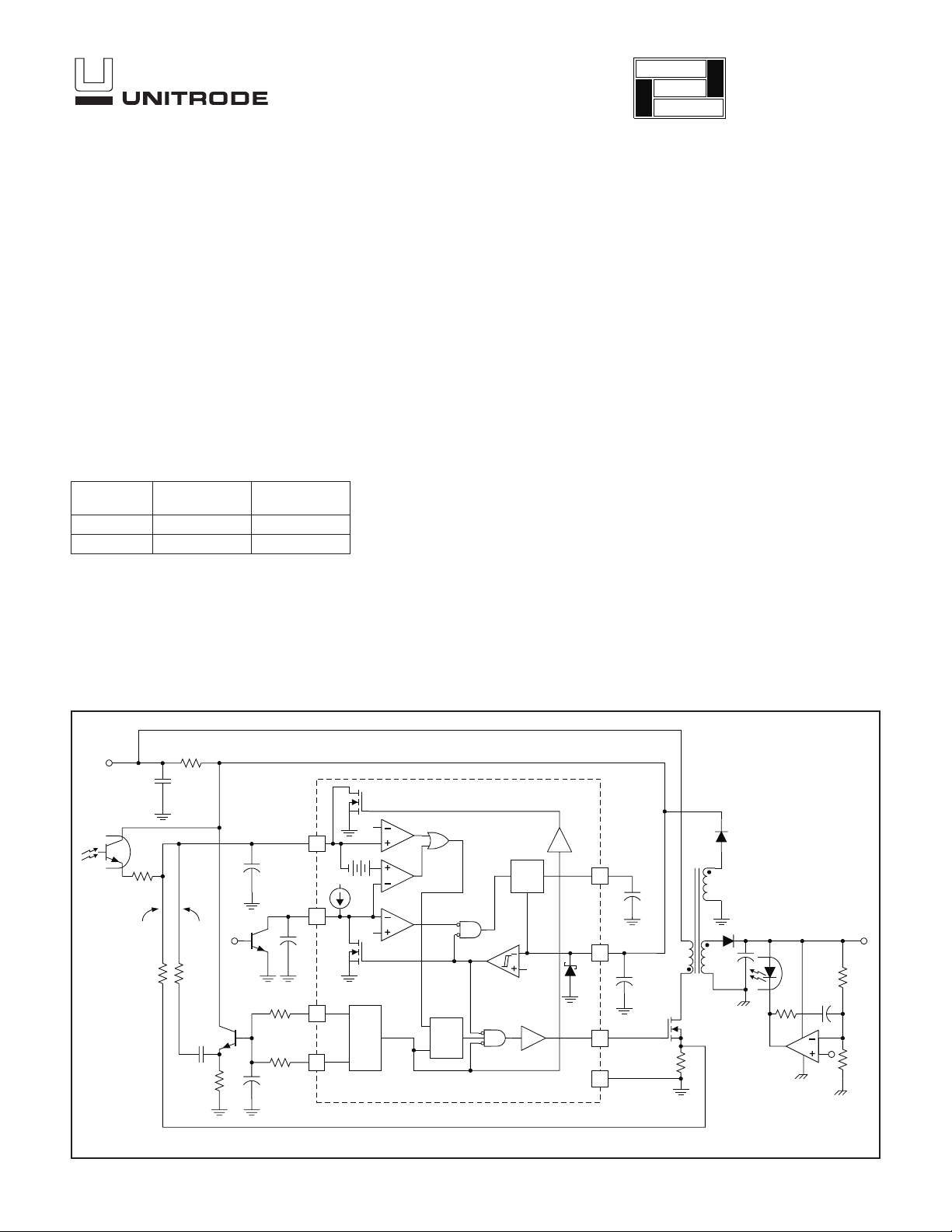

TYPICAL APPLICATION DIAGRAM

R

V

IN

FEEDBACK

CURRENT

SENSE

START

SLOPE

COMP

DISABLE

NOISE

FILTER

C

T

RT1

RT2

FB

1

+5V

SS

2

C

SS

3

4

1V

6µA

0.5V

OSC

1V

17.5V

REF

8

C

REF

V

V

REF

UDG-99036

OUT

VDD

7

C

VDD

OUT

6

GND

5

CLK

PWM

LATCH

R

S

5V

REF

15/8V

10/8V

UVLO

Q

SLUS166A - NOVEMBER 1999

ABSOLUTE MAXIMUM RATINGS*

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19V

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

VDD

I

(tpw < 1µs and Duty Cycle < 10%). . . . . . . . –0.4A to 0.8A

OUT

RT1, RT2, SS . . . . . . . . . . . . . . . . . . . . . . –0.3V to REF + 0.3V

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –15mA

REF

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

* Values beyond which damage may occur.

All voltages are with respect to ground unless otherwise stated.

Currents are positive into, negative out of the specified termi

nal. Consult Packaging Section of Databook for thermal limita

tions and considerations of packages.

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

CONNECTION DIAGRAM

SOIC-8, DIL-8 (Top View)

D, N and J Packages

-

-

TSSOP-8 (Top View)

PW Package

FB

1

SS

2

RT1

3

RT2

4

REF

VDD

OUT

GND

8

7

6

5

MSOP-8 (Top View)

P Package

1

FB

2

SS

3

RT1

4

RT2

REF

VDD

OUT

GND

8

7

6

5

ORDERING INFORMATION

Temperature Range Available Packages

UCC1809-X –55°C to +125°C J

UCC2809-X –40°C to +85°C N, D, P, PW

UCC3809-X 0°C to +70°C N, D, P, PW

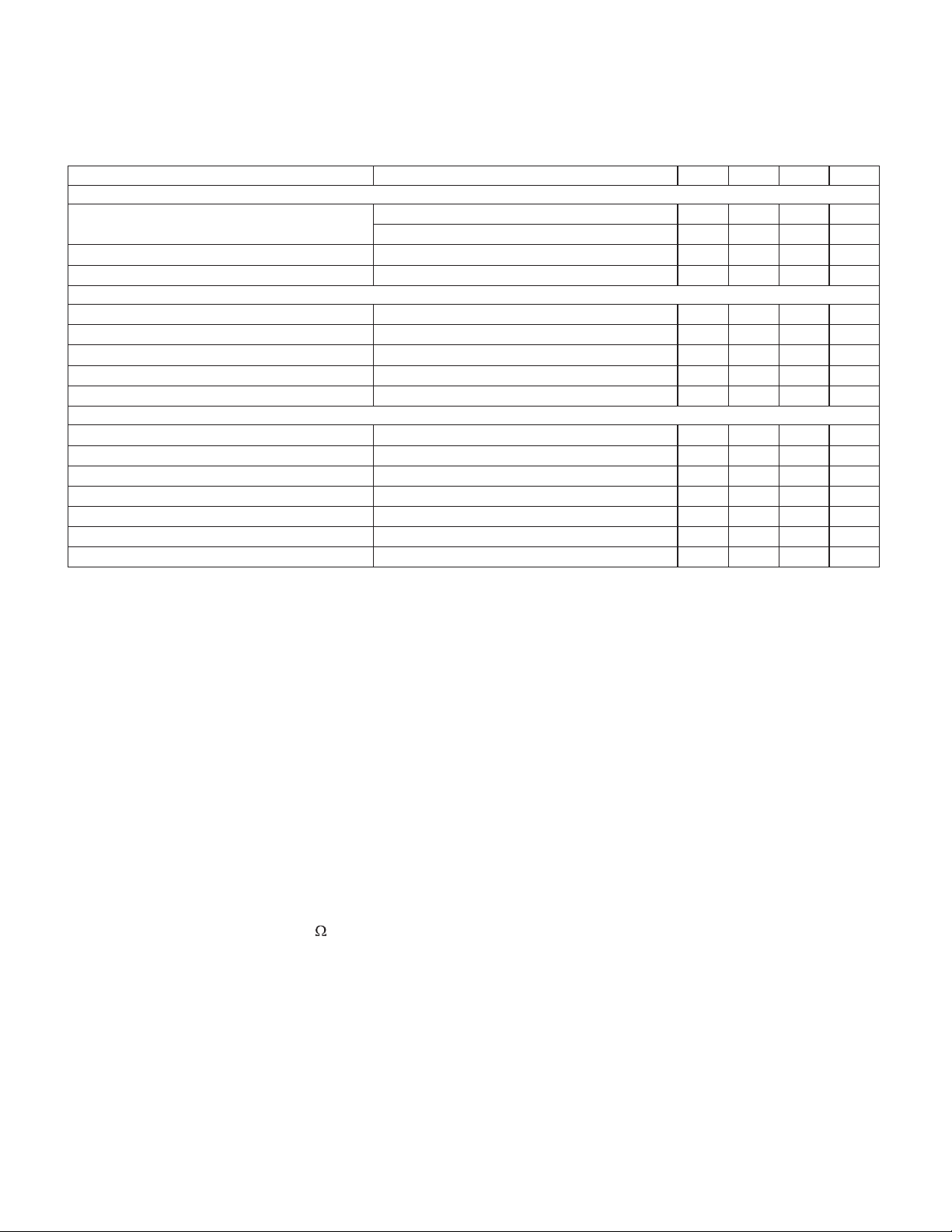

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, VDD = 12V. T

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Supply Section

VDD Clamp I

I

VDD

I

Starting 100 µA

VDD

Undervoltage Lockout Section

Start Threshold (UCCx809-1) 9.4 10.4 V

UVLO Hysteresis (UCCx809-1) 1.65 V

Start Threshold (UCCx809-2) 14.0 15.6 V

UVLO Hysteresis (UCCx809-2) 6.2 V

Voltage Reference Section

Output Voltage I

Line Regulation VDD = 10V to 15V 2 mV

Load Regulation I

Comparator Section

I

FB

Comparator Threshold 0.9 0.95 1 V

OUT Propagation Delay (No Load) V

= 10mA 16 17.5 19 V

VDD

No Load 600 900 µA

= 0mA 4.75 5 5.25 V

REF

= 0mA to 5mA 2 mV

REF

Output Off –100 nA

= 0.8V to 1.2V at TR= 10ns 50 100 ns

FB

UCC 809 –

A=TJ

.

2

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, VDD = 12V. T

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Soft Start Section

I

SS

V

Low VDD = 7.5V, ISS = 200µA 0.2 V

SS

Shutdown Threshold 0.44 0.48 0.52 V

Oscillator Section

Frequency RT1 = 10k, RT2 = 4.32k, CT = 820pF 90 100 110 kHz

Frequency Change with Voltage VDD = 10V to 15V 0.1 %/V

C

Peak Voltage 3.33 V

T

C

Valley Voltage 1.67 V

T

C

Peak to Peak Voltage 1.54 1.67 1.80 V

T

Output Section

Output V

Output V

Output Low Voltage During UVLO I

Minimum Duty Cycle V

Maximum Duty Cycle 70 %

Rise Time C

Fall Time C

Low I

SAT

High I

SAT

VDD = 16V, VSS = 0V; –40°C to +85°C –4.9 –7.0 –9.1 µA

VDD = 16V, V

= 80mA (dc) 0.8 1.5 V

OUT

= –40mA (dc), VDD – OUT 0.8 1.5 V

OUT

= 20mA (dc) 1.5 V

OUT

= 2V 0 %

FB

= 1nF 35 ns

OUT

= 1nF 18 ns

OUT

SS = 0V; < –40°C; >+85°C –4.0 –7.0 –10.0 µA

A=TJ

.

PIN DESCRIPTIONS

FB: This pin is the summing node for current sense

feedback, voltage sense feedback (by optocoupler) and

slope compensation. Slope compensation is derived

from the rising voltage at the timing capacitor and can be

buffered with an external small signal NPN transistor.

External high frequency filter capacitance applied from

this node to GND is discharged by an internal 250Ω on

resistance NMOS FET during PWM off time and offers

effective leading edge blanking set by the RC time

constant of the feedback resistance from current sense

resistor to FB input and the high frequency filter

capacitor capacitance at this node to GND.

GND: Reference ground and power ground for all

functions.

OUT: This pin is the high current power driver output. A

minimum series gate resistor of 3.9

is recommended to

limit the gate drive current when operating with high bias

voltages.

REF: The internal 5V reference output. This reference is

buffered and is available on the REF pin. REF should be

bypassed with a 0.47µF ceramic capacitor.

RT2: This pin connects to timing resistor RT2 and

controls the negative ramp time of the internal oscillator

(Tf = 0.74 • (C

+ 27pF) • RT2). The negative threshold

T

of the internal oscillator is sensed through inactive timing

resistor RT1 which connects to pin RT1 and timing

capacitor C

.

T

SS: This pin serves two functions. The soft start timing

capacitor connects to SS and is charged by an internal

6µA current source. Under normal soft start SS is

discharged to at least 0.4V and then ramps positive to

1V during which time the output driver is held low. As SS

charges from 1V to 2V soft start is implemented by an

increasing output duty cycle. If SS is taken below 0.5V,

the output driver is inhibited and held low. The user

accessible 5V voltage reference also goes low and I

< 100µA.

VDD: The power input connection for this device. This

pin is shunt regulated at 17.5V which is sufficiently below

the voltage rating of the DMOS output driver stage. VDD

should be bypassed with a 1µF ceramic capacitor.

VDD

RT1: This pin connects to timing resistor RT1 and

controls the positive ramp time of the internal oscillator

(Tr = 0.74 • (C

+ 27pF) • RT1). The positive threshold

T

of the internal oscillator is sensed through inactive timing

resistor RT2 which connects to pin RT2 and timing

capacitor C

.

T

3

APPLICATION INFORMATION

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

OUT

+V

C19

C18

1%

R17

12.1K

C14

470pF

C13

0.1µF

R15

750

R14

2

1

H11AV1

4

5

1%

R16

12.1K

10K

U4

TL431

U3

C17

C16

U2

MBR2535CTL

2

3W

R19

5.1K

C10

D3

0.22µF

2K

R9

3W

R13

1.1K

OUT

–V

6.3V

330µF

6.3V

330µF

6.3V

330µF

6.3V

330µF

3

1

µF

C15

0.015

T1

SF24

Q2

80µH

2N2907A

5:1

Q3

IRF640

1K

10

R10

680

R11

R6

R8

3W

0.15

R7

15K

D2

1N5245

+VIN

D4

R5

C3

1µF

1N5240

470

27K

R12

UCC3809

PGND1

C2

150µF

C1

150µF

TP1

C7

0.47µF

C9

0.1µF

C8

1µF

8

7

REF

VDD

SS

FB

2

1

6

OUT

RT1

3

5

GND

RT2

4

R20

5.62K

U1

R4

6.19K

R3

12.1K

R1

5.1k

ON/OFF

Q1

C22

Q4

2N2222A

D1

0.1µF

2N2222A

C4

C6

0.01µF

R2

5231B

330pF

C5

1.1K

R18

3.01K

1nF

PGND1

–VIN

UDG-99179

Figure 1. Isolated 50W flyback converter utilizing the UCC3809. The switching frequency is 70kHz, Vin = -32V

to -72V, Vout = +5V, Iout = 0A to 10A

4

APPLICATION INFORMATION (cont.)

K

The Typical Application Diagram shows an isolated

flyback converter utilizing the UCC3809. Note that the

capacitors C

REF

and C

tors for the reference and IC input voltage, respectively.

Both capacitors should be low ESR and ESL ceramic,

placed as close to the IC pins as possible, and returned

directly to the ground pin of the chip for best stability.

REF provides the internal bias to many of the IC func

tions and C

should be at least 0.47µF to prevent REF

REF

from drooping.

FB Pin

The basic premise of the UCC3809 is that the voltage

sense feedback signal originates from an optocoupler

that is modulated by an external error amplifier located

on the secondary side. This signal is summed with the

current sense signal and any slope compensation at the

FB pin and compared to a 1V threshold, as shown in the

Typical Application Diagram. Crossing this 1V threshold

resets the PWM latch and modulates the output driver

on-time much like the current sense comparator used in

the UC3842. In the absence of a FB signal, the output

will follow the programmed maximum on-time of the oscillator.

When adding slope compensation, it is important to use

a small capacitor to AC couple the oscillator waveform

before summing this signal into the FB pin. By correctly

selecting the emitter resistor of the optocoupler, the voltage sense signal can force the FB node to exceed the

1V threshold when the output that is being compared ex

ceeds a desired level. Doing so drives the UCC3809 to

zero percent duty cycle.

Oscillator

are local decoupling capaci

VDD

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

5.0V reference) sensed through RT1. The R input to the

oscillator latch, R(OSC), is also level sensitive and resets

the CLK signal low when CT crosses the 1.67V thresh

old, turning off Q2 and turning on Q1, initiating another

charging cycle.

Figure 3 shows the waveforms associated with the oscil

lator latch and the PWM latch (shown in the Typical Ap

plication Diagram). A high CLK signal not only initiates a

discharge cycle for CT, it also turns on the internal

NMOS FET on the FB pin causing any external capaci

tance used for leading edge blanking connected to this

pin to be discharged to ground. By discharging any ex

ternal capacitor completely to ground during the external

switch’s off-time, the noise immunity of the converter is

enhanced allowing the user to design in smaller RC com

ponents for leading edge blanking. A high CLK signal

also sets the level sensitive S input of the PWM latch,

S(PWM), high, resulting in a high output, Q(PWM), as

shown in Figure 3. This Q(PWM) signal will remain high

until a reset signal, R(PWM) is received. A high R(PWM)

signal results from the FB signal crossing the 1V threshold, or during soft start or if the SS pin is disabled.

Assuming the UVLO threshold is satisfied, the OUT signal of the IC will be high as long as Q(PWM) is high and

S(PWM), also referred to as CLK, is low. The OUT signal will be dominated by the FB signal as long as the FB

signal trips the 1V threshold while CLK is low. If the FB

signal does not cross the 1V threshold while CLK is low,

the OUT signal will be dominated by the maximum duty

cycle programmed by the user. Figure 3 illustrates the

various waveforms for a design set up for a maximum

duty cycle of 70%.

-

-

-

-

-

-

The following equation sets the oscillator frequency:

−

FCTpFRTRT

=•+ • +

074 27 1 2

.

[]

OSC

DRTCTpFF

=•• + •074 1 27.

MAX OSC

()()

()

1

Referring to Figure 2 and the waveforms in Figure 3,

when Q1is on, CT charges via the R

DS(on)

of Q1 and

RT1. During this charging process, the voltage of CT is

sensed through RT2. The S input of the oscillator latch,

S(OSC), is level sensitive, so crossing the upper thresh

old (set at 2/3 VREF or 3.33V for a typical 5.0V refer

ence) sets the Q output (CLK signal) of the oscillator

latch high. A high CLK signal results in turning off Q1

and turning on Q2. CT now discharges through RT2 and

the R

DS(on)

of Q2. CT discharges from 3.33V to the

lower threshold (set at 1/3 VREF or 1.67V for a typical

V

REF

Q1

3

RT1

CT

RT2

4

Q2

-

-

Figure 2. UCC3809 oscillator.

5

3.33V

1.67V

OSC

SQ

R

OSCILLATOR

LATCH

CL

UDG-97195

APPLICATION INFORMATION (cont.)

CT

CHARGINGCTDISCHARGING

3.33V

1.67V

CT

S(OSC)

R(OSC)

Q(OSC)=CLK

=S(PWM)

1V

FB

R(PWM)

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

Q(PWM)

OUT

FB SIGNAL DOMINANT MAX. DUTY CYCLE DOMINANT

Figure 3. Waveforms associated with the oscillator latch and the PWM latch.

The recommended value for CT is 1nF for frequencies in

the 100 kHz or less range and smaller CT for higher fre

quencies. The minimum recommended values of RT1

and RT2 are 10kΩ and 4.32kΩ, respectively. Using these

values maintains a ratio of at least 20:1 between the

R

DS(on)

of the internal FETs and the external timing re

sistors, resulting in minimal change in frequency over

temperature. Because of the oscillator's susceptibility to

capacitive coupling, examine the oscillator frequency by

looking at the common RT1-RT2-CT node on the circuit

board as opposed to looking at pins 3 and 4 directly. For

good noise immunity, RT1 and RT2 should be placed as

close to pins 3 and 4 of the IC as possible. CT should be

returned directly to the ground pin of the IC with minimal

stray inductance and capacitance.

70%

ON

30%

OFF

UDG-99037

Figure 4. Oscillator frequency vs. CT(RT1 = 10k,

RT2 = 4.32k)

6

APPLICATION INFORMATION (cont.)

Synchronization

UCC1809-1/-2

UCC2809-1/-2

UCC3809-1/-2

changed.

Both of the synchronization schemes shown in Figure 5

can be successfully implemented with the internal oscilla

tor of the UCC3809. Both schemes allow access to the

timing ramp needed for slope compensation and have

minimal impact on the programmed maximum duty cycle.

In the absence of a sync pulse, the PWM controller will

run independently at the frequency set by RT1, RT2, and

CT. This free running frequency must be approximately

15 to 20% lower than the sync pulse frequency to insure

the free running oscillator does not cross the comparator

threshold before the desired sync pulse.

Option I uses the synchronization pulse to pull pin 3 low,

triggering the internal 1.67V comparator to reset the RS

latch and initiate a charging cycle. The valley voltage of

the CT waveform is higher when synchronized using this

configuration, decreasing the ramp charge and discharge

times, thereby increasing the operating frequency; other

wise the overall shape of the CT voltage waveform is un-

Option II uses the synchronization pulse to superimpose

the sync voltage onto the peak of the CT waveform. This

triggers the internal 3.33V comparator, initiating a dis

charge cycle. The sync pulse is summed with the free

running oscillator waveform at the CT node, resulting in a

spike on top of the CT peak voltage.

ADDITIONAL INFORMATION

Please refer to the following Unitrode application topics

for additional information.

[1] Application Note U-165,

Design Review: Isolated 50W

Flyback Converter with the UCC3809 Primary Side Con

by Lisa Dinwoodie.

troller

[2] Design Note DN-89,

Comparing the UC3842,

UCC3802, and UCC3809 Primary Side PWM Controllers

by Lisa Dinwoodie.

-

-

-

1k

SYNC

PULSE

2N2222A

424

RT1

3

4

RT2

CT

OPTION I

UCC3809

OSCILLATOR

Figure 5. UCC3809 synchronization options.

+5V

SYNC

PULSE

2N2222A

0.1µF

424

RT1

RT2

CT

24

OPTION II

3

UCC3809

OSCILLATOR

4

UDG-99006

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

7

Loading...

Loading...