Buck Current/Voltage Fed Push-Pull PWM Controllers

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

FEATURES

• Ideal for Multiple Output and/or High

Voltage Output Voltage Converters

• Up to 500kHz Operation

• High Voltage, High Current Floating

Driver for Buck Converter Stage

• UC3827-1 Current Fed Controller has

Push-Pull Drivers with Overlapping

Conduction Periods

• UC3827-2 Voltage Fed Controller has

Push-Pull Drivers with

Non-overlapping Conduction Periods

• Average Current Mode, Peak Current

Mode or Voltage Mode with Input

Voltage Feedforward Control for Buck

Power Stage

• Wide Bandwidth, Low Offset,

Differential Current Sense Amplifier

• Precise Short Circuit Current Control

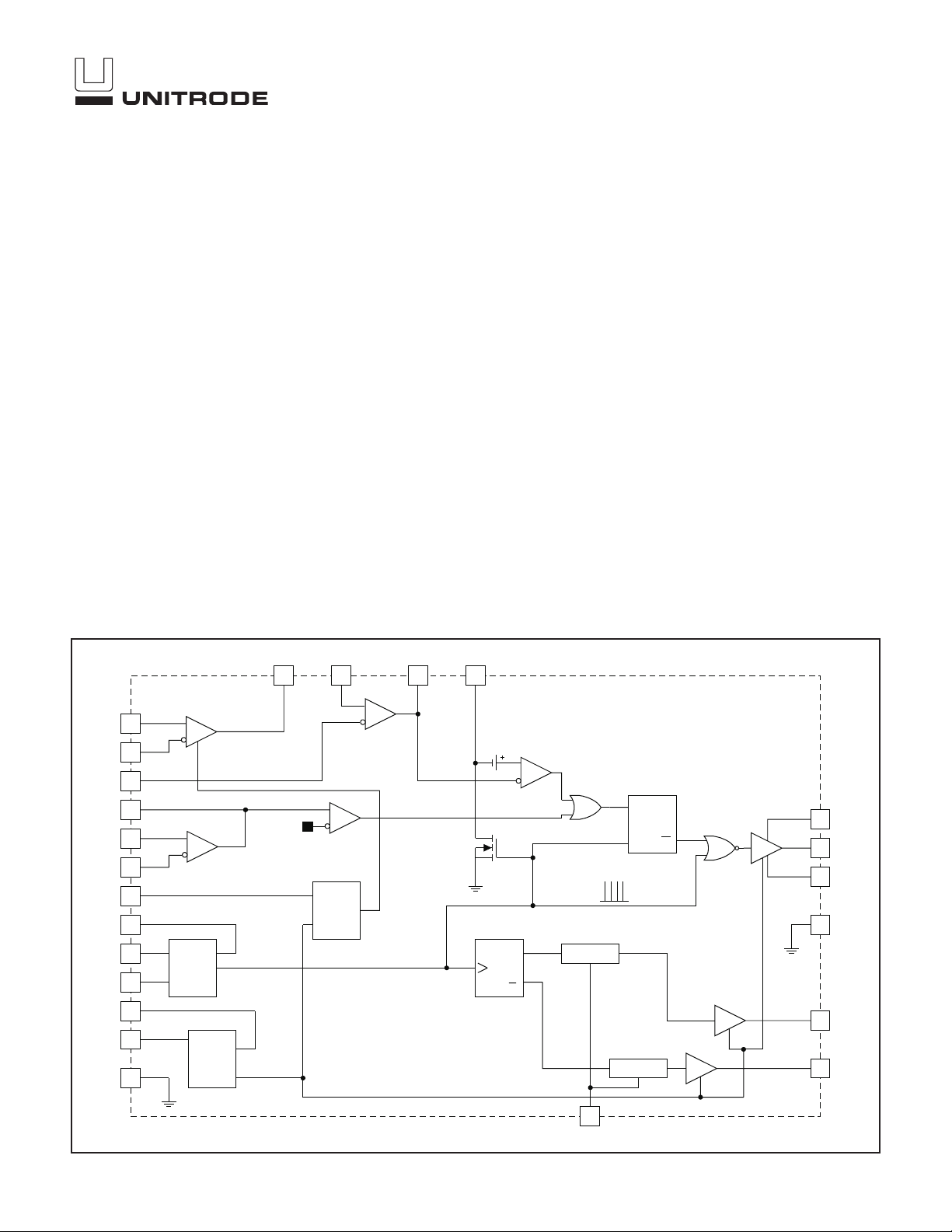

BLOCK DIAGRAM

DESCRIPTION

The UC3827 family of controller ICs provides an integrated control solution

for cascaded buck and push-pull converters. These converters are known

as current fed or voltage fed push-pull converters and are ideally suited for

multiple output and/or high voltage output applications. In both current fed

and voltage fed modes, the push-pull switches are driven at 50% nominal

duty cycles and at one half the switching frequency of the buck stage. In

the current fed mode, the two switches are driven with a guaranteed overlap period to prevent ringing and voltage stress on the devices. In the voltage fed mode, the two switches are driven with a guaranteed gap time

between the switches to prevent shorting the transformer across the energy storage capacitor and to prohibit excessive currents flowing through

the devices.

The converter’s output voltage is regulated by pulse width modulation of

the buck switch. The UC3827 contains complete protection and PWM control functions for the buck converter. Easy control of the floating switch is

accomplished by the floating drive circuitry. The gate drive waveform is

level shifted to support an input voltage up to 72Vdc.

(continued)

VEA+

VEA–

CEA–

CSAO

CSA+

CSA–

SS

SYNC 19

CT

RT

REF

VCC

GND

14

16

13

7

8

9

4

18

17

15

23

11

VOLTAGE ERROR

AMPLIFIER

CURRENT

SENSE AMPLIFIER

OSC

500kHz

MAX

REF

&

UVLO

UVLO

10

+3V

ILIM

COMPARATOR

SS

UV

12

CURRENT

ERROR

AMPLIFIER

INHBT

CEAOVEAO

6 5

RAMPCEA+

0.7V

PWM

COMPARATOR

T

R

D

QS

OSC

Q

Q

DELAY

DELAY

FLYING

DRIVER

PUSH-PULL

DRIVERS

1

V+

2

BUCK

3

SRC

21

PGND

24

PUSH

22

PULL

04/99

20

DELAY

UDG-97172

DESCRIPTION (cont.)

The UC3827 can be set up in traditional voltage mode

control using input voltage feedforward technique or in

current mode control. Using current mode control prevents

potential core saturation of the push-pull transformer due

to mismatches in timing and in component tolerances.

With average current mode control, precise control of the

inductor current feeding the push-pull stage is possible

without the noise sensitivity associated with peak current

mode control. The UC3827 average current mode loop

can also be connected in parallel with the voltage regulation loop to assist only in fault conditions.

Other valuable features of the UC3827 include

bidirectional synchronization capability, user programmable overlap time (UC3827-1), user programmable gap

time (UC3827-2), a high bandwidth differential current

sense amplifier, and soft start circuitry.

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20V

Input Voltage Range

For all pins except V+, BUCK, SRC. . . . . . . . . . –0.3V to 5V

For V+ and BUCK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90V

For SRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90V–VCC

BUCK Driver

IO Continuous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 250mA

IO Peak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 1A

PUSH/PULL Driver

IO Continuous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 200mA

IO Peak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 0.8A

Storage Temperature . . . . . . . . . . . . . . . . . . . −65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

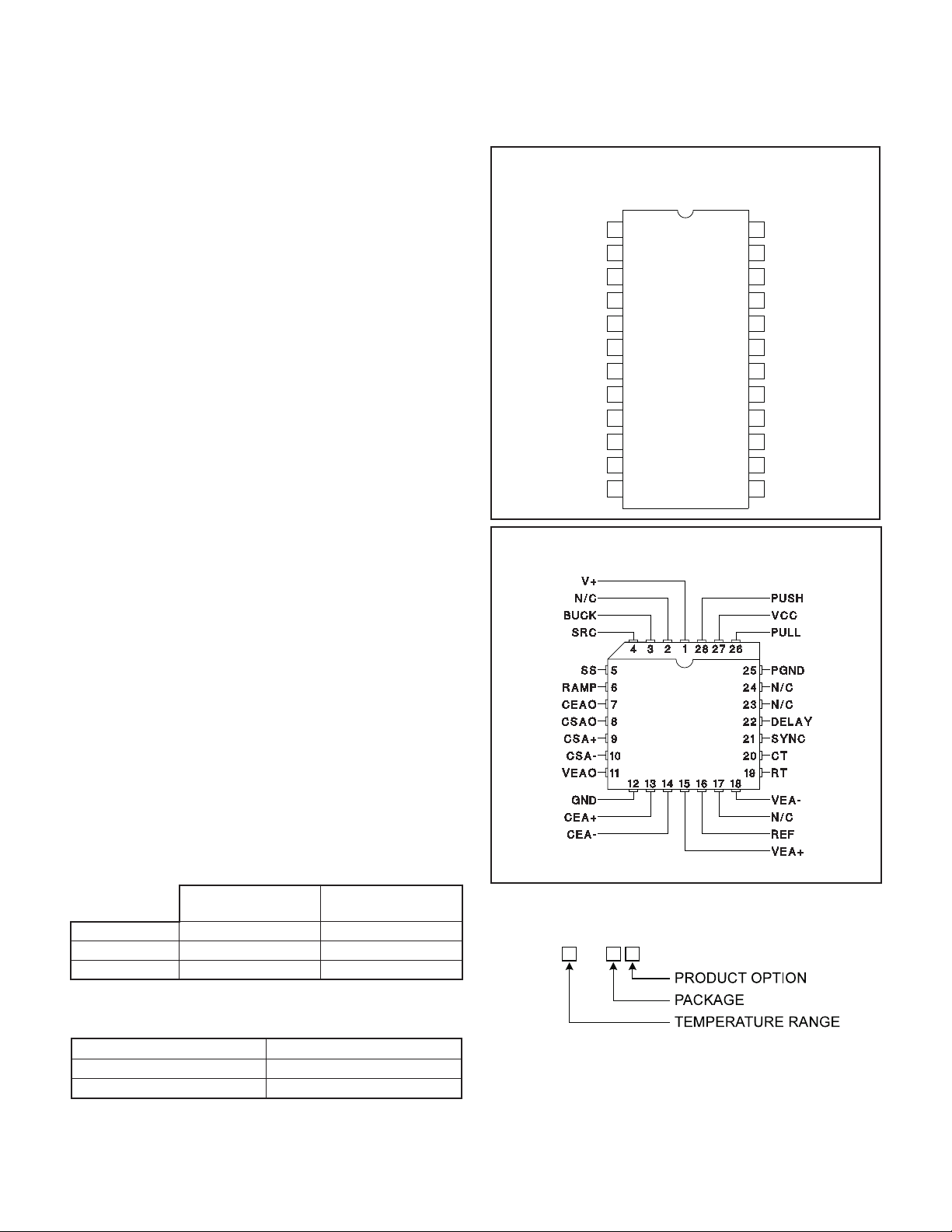

CONNECTION DIAGRAMS

DIL-24 (Top View)

N or J, DW Packages

V+

1

2

BUCK

SRC

3

4

SS

5

RAMP

6

CEAO

7

CSAO

8

CSA+

9

CSA–

VEAO

10

11

GND

12

CEA+ CEA–

PLCC-28 (Top View)

Q Package

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

24

PUSH

VCC

23

PULL

22

PGND

21

DELAY

20

SYNC

19

CT

18

RT

17

VEA–

16

15

REF

1413VEA+

Voltages are referenced to ground. Currents are positive into,

negative out of the specified terminal. Consult Packaging

Section of Databook for thermal limitations and considerations

of packages.

TEMPERATURE AND PACKAGE

SELECTION GUIDE

TEMPERATURE

RANGE

UC1827-X –55°C to +125°C J

UC2827-X –40°C to +85°C N, DW, Q

UC3827-X 0°C to +70°C N, DW, Q

AVAILABLE

PACKAGES

PART VERSION GUIDE

PART NUMBER TOPOLOGY

UCX827-1 Current Fed Push-Pull

UCX827-2 Voltage Fed Push-Pull

ORDERING INFORMATION

UC 827

2

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

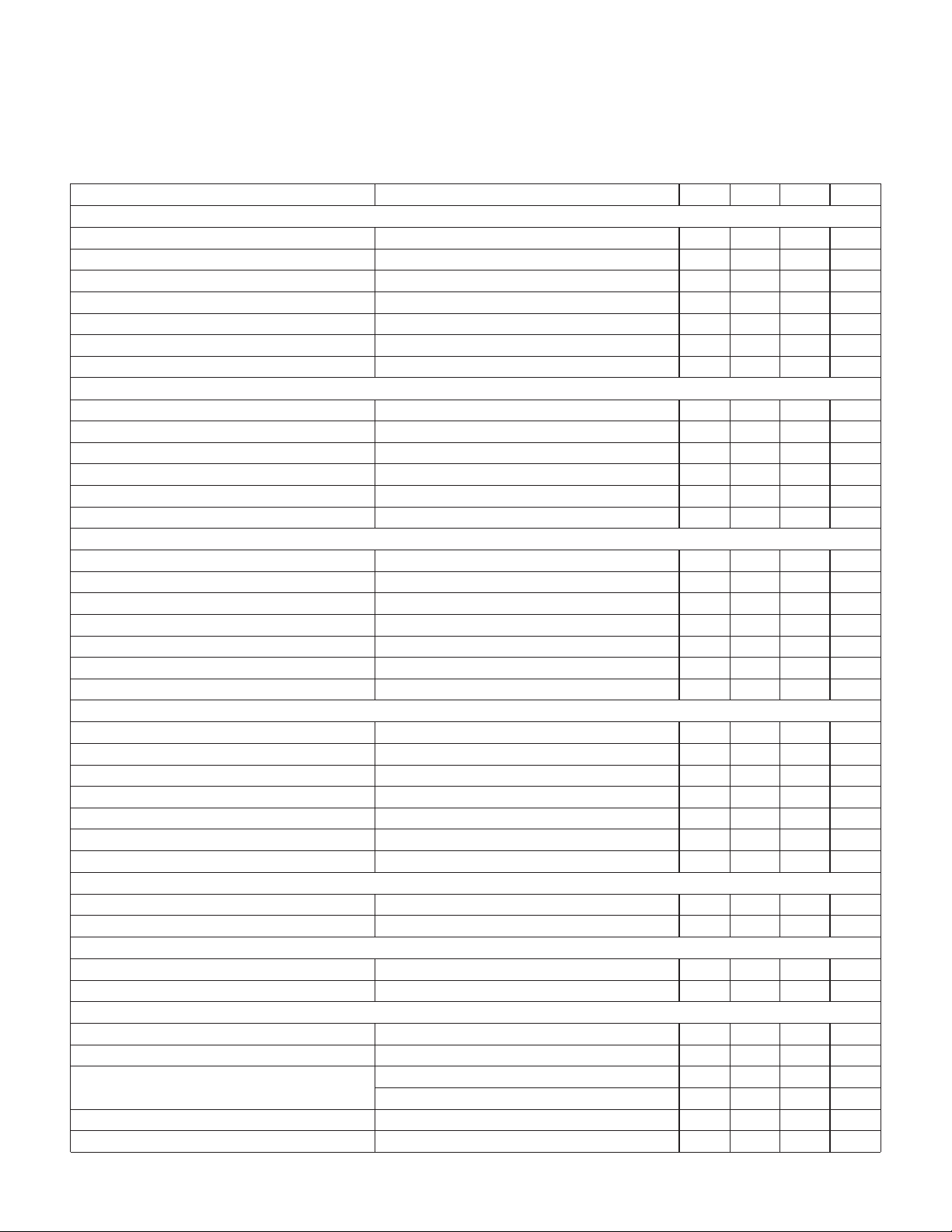

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VCC = 15V, V+ = 14.3V, CT = 340pF, RT = 10K,

RDELAY = 24.3k, SRC = GND, BUCK, PUSH and PULL outputs no load. TJ = TA.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Supply

VCC UVLO, Turn-On 8.3 8.8 9.5 V

Hysteresis 0.9 1.2 1.5 V

I

Start VCC = 8V 1000 µA

VCC

I

Run 32 45 mA

VCC

V+ UVLO, Turn-On 7.1 7.5 8.3 V

V+ Hysteresis 0.2 0.4 0.9 V

I

+

Buck High 0.2 1 2 mA

V

Voltage Error Amplifier

IB 0.5 3 µA

VIO 10 mV

AVOL 80 95 dB

GBW (Note 7) 1 4 MHz

VOL I

VOH I

= 0µA (No Load) 0.3 0.5 V

VEAO

= 0µA (No Load) 2.85 3 3.20 V

VEAO

Current Sense Amplifier

IB –1 –5 uA

VIO 5mV

AVOL 80 110 dB

GBW (Note 7) 15 29 MHz

VOL I

VOH I

= 0µA (No Load) 0.25 0.5 V

CEAO

= 0µA (No Load) 3 3.3 V

CEAO

Common Mode Range (Note 7) 0 2 V

Current Error Amplifier

IB –1 –5 µA

VIO 10 mV

AVOL 80 110 dB

GBW At 100kHz, Measure Gain 2 4.5 MHz

VOL I

VOH I

= 0µA (No Load) 0.25 0.5 V

CEAO

= 0µA (No Load) 3.3 3.5 V

CEAO

Common Mode Range (Note 7) 0 5 V

Oscillator Section

Frequency 180 220 250 kHz

CT Discharge Current 3.5V at CT when CT removed 5 mA

PWM Comparator

Minimum Duty Cycle 200kHz 0 %

Maximum Duty Cycle 200kHz 85 91 95 %

Buck Output Stage

Rise Time 1nF Load, (Note 3) 40 100 ns

Fall Time 1nF, Load 30 80 ns

VOH I

VOL I

= –15mA , V+ –BUCK (Note 4) 1.5 2.5 V

BUCK

I

= –150mA, V+ – BUCK (Note 4) 2 2.5 V

BUCK

= 15mA (Note 5) 0.2 0.4 V

BUCK

I

= 150mA (Note 5) 0.7 1.2 V

BUCK

3

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

ELECTRICAL CHARACTERISTICS Unless otherwise specified, VCC = 15V, V+ = 14.3V, CT = 340pF, RT = 10K,

RDELAY = 24.3k, SRC = GND, BUCK, PUSH and PULL outputs no load. TJ = TA.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Push/Pull Output Stages

Rise Time 1nF Load 50 100 ns

Fall Time 1nF Load 35 100 ns

Overlap Time, -1 Only 1nF loads (Note 1) 100 250 400 ns

Non-Overlapping Time, -2 Only (Note 2) 100 250 500 ns

VOH I

VOL I

Reference

REF Voltage 4.8 5 5.2 V

Short Circuit Current REF = 0V –35 –50 –65 mA

Line Regulation 9.5V < VCC < 20V 5 20 mV

Load Regulation 0mA < IO < 10mA 8 20 mV

Soft Start

VOL, Saturation VCC = 7V 250 500 mV

I

SS –5 –12 –25 µA

Note 1: The overlap time is measured from the point at which the rising edge of PUSH/PULL crosses 5V until the falling edge of

Note 2: The non-overlap time is measured from the point at which the falling edge of PUSH/PULL crosses 5V until the rising edge

Note 3: Measure the rise time from when BUCK crosses 1V until it crosses 9V.

Note 4: To force BUCK high, force CSAO=2.5V, CEAO = 2.5V, a 25k pulldown resistor form RAMP to ground, and CT = 0.5V.

Note 5: To force BUCK low, force CSAO = 2.5V, CEAO = 2.5V, a 10k pulldown resistor from RAMP to ground, and CT = 3.5V.

Note 6: To toggle PUSH or PULL into a desired state, pulse CT from 0.5V to 3.5V. PUSH and PULL toggle on the rising edge of

Note 7: Guaranteed by design. Not 100% tested in production.

PULL/PUSH crosses 5V.

of PULL/PUSH crosses 5V.

CT.

PUSH/PULL = –10mA, VCC – PUSH (Note 6) 2 3 V

I

PUSH/PULL = –100mA, VCC – PUSH (Note 6) 2.5 3 V

PUSH/PULL = 10mA (Note 6) 0.2 0.8 V

I

PUSH/PULL = 100mA (Note 6) 0.6 1.2 V

PIN DESCRIPTIONS

BUCK: Output of the buck PWM controller. The BUCK

output is a floating driver, optimized for controlling the

gate of an N-channel MOSFET. The peak sink and

source currents are 1A. Any undervoltage faults will disable BUCK to an off condition (low).

CEA+: The non-inverting input of the current error amplifier.

CEA–: The inverting input of the current error amplifier.

CEAO: The output of the current error amplifier and the

inverting input of the PWM comparator of the buck converter.

CSA+: The noninverting input of the current sense amplifier.

CSA–: The inverting input of the current sense amplifier.

CSAO: The output of the current sense amplifier and the

noninverting input of the current limit comparator. When

the signal level on this pin exceeds the 3V threshold of

the current limit comparator, the buck gate drive pulse is

terminated. This feature is useful to implement cycle-by-cycle current limiting for the buck converter.

CT: This pin is provided for the timing capacitor which is

connected between CT and GND. The oscillator frequency is set by CT and a resistor RT, connected between pin RT and GND. The CT discharge current is

approximately 40X the bias current through the resistor

connected to RT. A practical maximum value for the discharge current is 20mA. The frequency of the oscillator is

given by:

fOSC =

0.77

RT •CT

4

PIN DESCRIPTIONS (cont.)

DELAY: A resistor to GND programs the overlap time of

the PUSH and PULL outputs of the UC3827-1 and the

dead time of the PUSH and PULL outputs of the

UC3827-2. The minimum value of the resistor, RDELAY,

is 18kΩ. The delay or overlap time is given by:

TDELAY =

GND: This pin is the ground reference for all sensitive

setup components not related to driving the outputs.

They include all timing, voltage sense, current sense,

and bypass components.

PGND: Ground connection for the PUSH and PULL outputs. PGND must be connected to GND at a single point

on the printed circuit board. This is imperative to prevent

large, high frequency switching currents flowing through

the ground metalization inside the IC.

PULL: Ground referenced output to drive an N-channel

MOSFET. The PULL and the PUSH outputs are driving

the two switches of the push-pull converter with complementary signals at close to a 50% duty cycle. Any

undervoltage faults will disable PULL to an off condition

(low).

PUSH: Ground referenced output to drive an N-channel

MOSFET. The PULL and the PUSH outputs are driving

the two switches of the push-pull converter with complementary signals at close to a 50% duty cycle. Any

undervoltage faults will disable PUSH to an off condition

(low).

RAMP: The RAMP voltage, after a 700mV internal level

shift, is fed to the noninverting input of the buck PWM

comparator.A resistor to Vin and a capacitor to GND provide an input voltage feedforward signal for the buck controller in voltage mode control. In peak current mode

control, the RAMP pin receives the current signal of the

buck converter. In an average current mode setup, the

RAMP pin has a linearly increasing ramp signal. This

waveform may be generated either by connecting RAMP

directly to CT, or by connecting both a resistor from VCC

to RAMP and a capacitor from RAMP to GND.

REF: The output of the +5V on board reference. Bypass

this pin with a capacitor to GND. The reference is off

when the chip is in undervoltage lockout mode.

RDELAY

Ω

200

–9

•10 sec.

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

REF

2•

RT

The charge current should be less than 500µAtokeep

CT’s discharge peak current less than 20mA, which is

CT’s maximum practical discharge value. The discharge

time, which sets the maximum duty cycle, is set internally

and is influenced by the charge current.

SRC: The source connection for the floating buck switch.

The voltage on the SRC pin can exceed VCC but must

be lower than 90V-VCC.Also, during turn-off transients of

the buck switch, the voltage at SRC can go to –2V.

SS: The soft start pin requires a capacitor to GND. During soft start the output of the voltage error amplifier is

clamped to the soft start capacitor voltage which is slowly

charged by an internal current source. In UVLO, SS is

held low.

SYNC: SYNC is a bidirectional pin for the oscillator. This

pin can be used to synchronize several chips to the fastest oscillator. Its input synchronization threshold is 1.4V.

The SYNC voltage is 3.6V when the oscillator capacitor,

CT, is discharged. Otherwise it is 0V. If the recommended

synchronization circuit is not used, a 1k or lower value

resistor from SYNC to GND may be needed to increase

the fall time of the signal at SYNC.

VCC: A voltage source connected to this pin supplies the

power for the UC3827. It is recommended to bypass this

pin to both GND and PGND ground connections with

good quality high frequency capacitors.

VEA+: The non-inverting input of the voltage error amplifier.

VEA–: The inverting input of the voltage error amplifier.

VEAO:The output of the voltage error amplifier.

V+: Supply voltage for the buck output.The floating driver

of the UC3827 uses the bootstrap technique which requires a reservoir capacitor to store the required energy

for the on time of the buck switch. A diode must be connected from VCC to V+ to charge the reservoir capacitor.

This diode must be able to withstand Vin. The reservoir

capacitor must be connected between V+ and SRC and

its voltage is monitored directly by the undervoltage lockout circuitry of the buck driver.

RT: A resistor to GND programs the charge current of the

timing capacitor connected to CT. The charge current approximately equals:

5

APPLICATION INFORMATION

UC1827-1/-2

UC2827-1/-2

UC3827-1/-2

V

REF

RT

CT

R

T

C

T

2.5V

–

+

1.4V

2.5V

2.9V

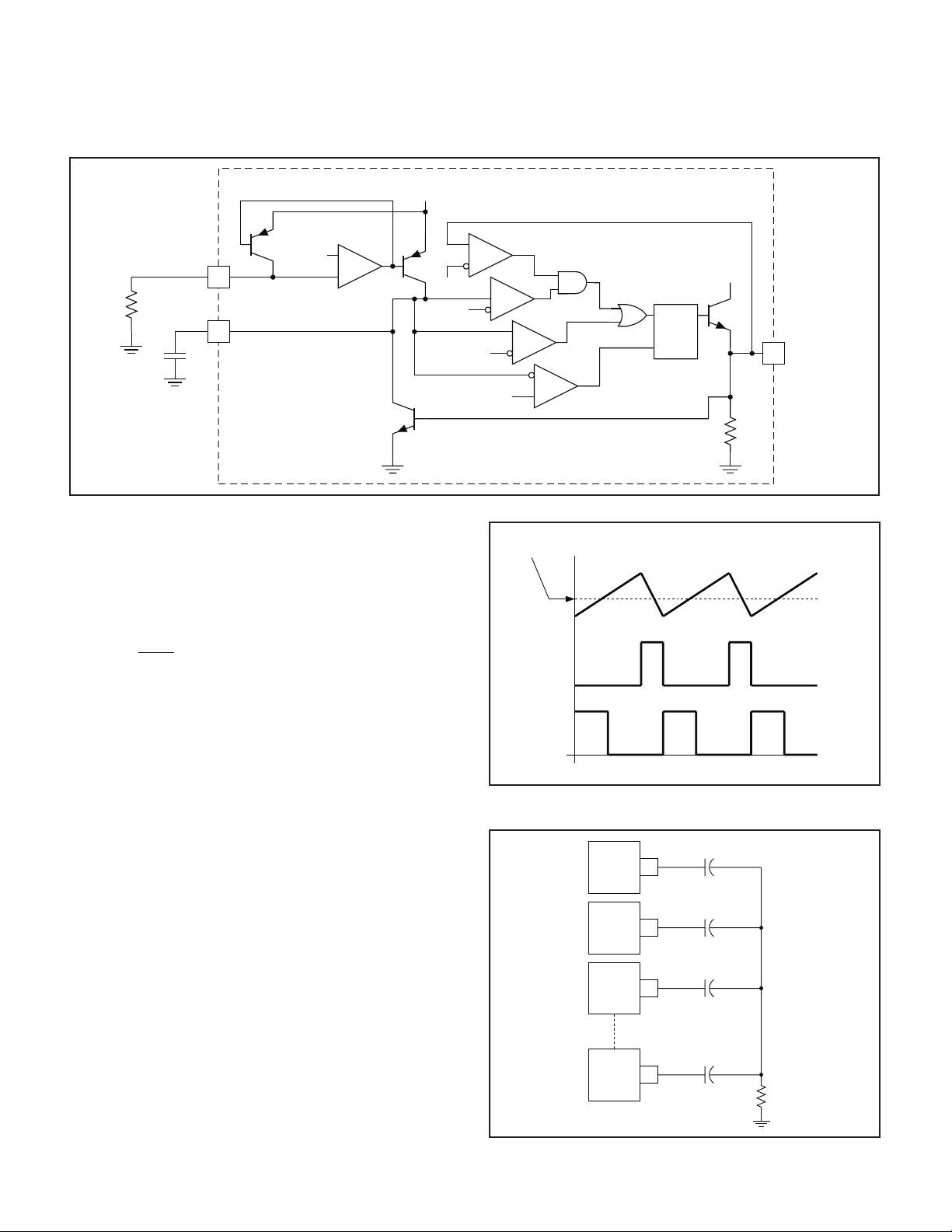

Figure 1. Oscillator block with external connections.

CIRCUIT BLOCK DESCRIPTION

PWM Oscillator.

nal connections is shown in Fig. 1. A resistor (R

The oscillator block diagram with exter-

) con-

T

nected to pin RT sets the linear charge current:

V

25.

I

≈

RT

R

T

The timing capacitor (C

) is linearly charged with the

T

charge current forcing the OSC pin to charge to a 3.4V

threshold. After exceeding this threshold, the RS flip-flop

is set driving CLKSYN high and RDEAD low which discharges C

. CT continues to discharge until it reaches a

T

0.5V threshold and resets the RS flip-flop which repeats

the charging sequence as shown in Fig.2.

OSCILLATOR

V

REF

S

R

0.5V

10k

VAO CURRENT

COMMAND

2.9V

0.5V

3.6V

1.4V

8.5V

0V

CHARGING

THRESHOLD

DISCHARGING

Figure 2. Oscillator and PWM output waveform.

SYNC

UDG-99087

UDG-99086

OSC

CLKSYN

OUT

As shown in Fig. 3, several oscillators are synchronized to

the highest free running frequency by connecting 100pF

capacitors in series with each CLKSYN pin and connecting the other side of the capacitors together forming the

CLKSYN bus. The CLKSYN bus is then pulled down to

ground with a resistance of approximately 10k. Referring

to Fig. 1, the synchronization threshold is 1.4V. The oscillator blanks any synchronization pulse that occurs when

OSC is below 2.5V. This allows units, once they discharge

below 2.5V, to continue through the current discharge and

subsequent charge cycles whether or not other units on

the CLKSYN bus are still synchronizing. This requires the

frequency of all free running oscillators to be within 17%

of each other to guarantee synchronization.

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

100pF

OSC1

OSC2

OSC3

OSC10

SYNC

SYNC

SYNC

SYNC

100pF

100pF

CLKSYN BUS

100pF

10k

Figure 3. Oscillator synchronization connection

diagram.

6

UDG-99085

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICA TIONS USING SEMICONDUCTOR PRODUCTS MA Y INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...