www.ti.com

R

D

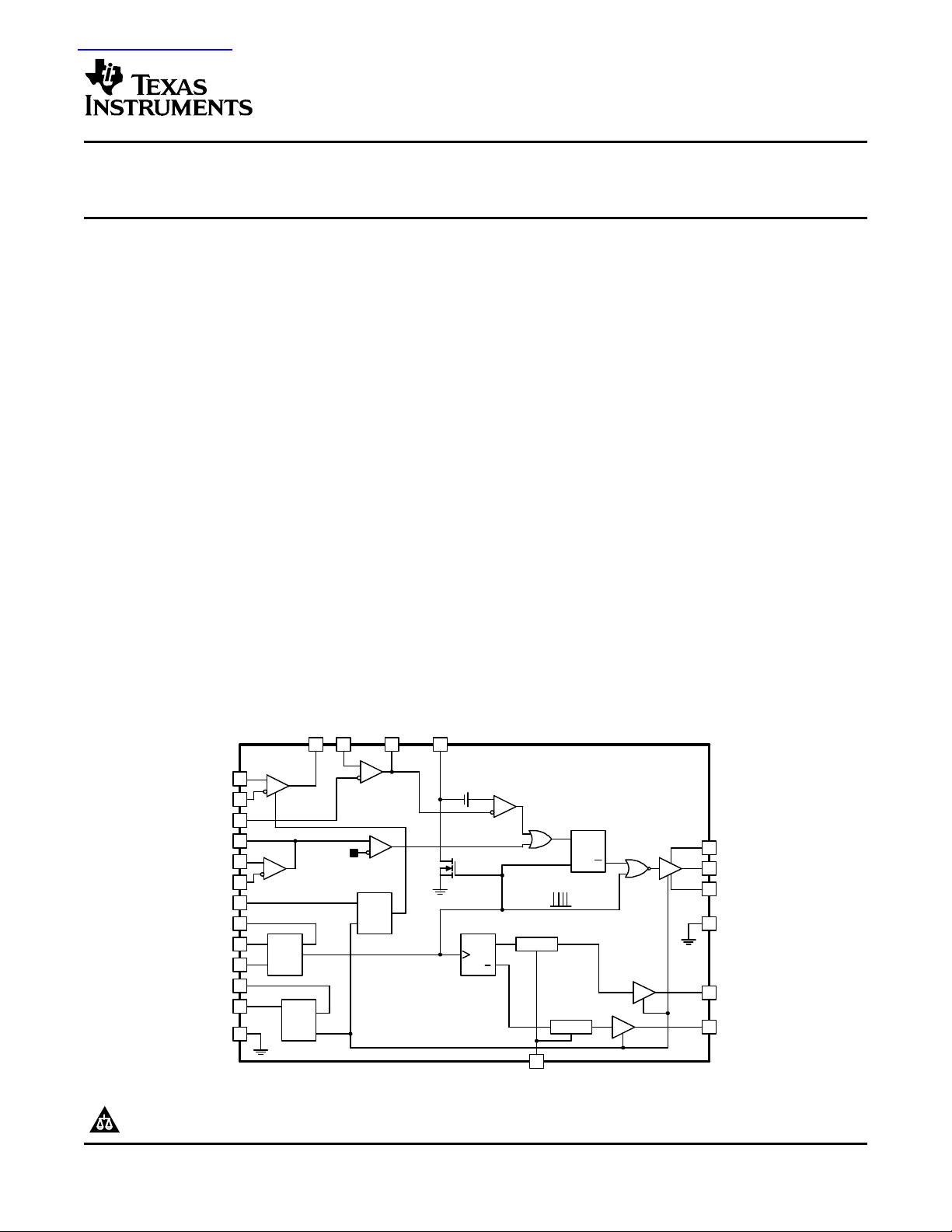

QS

20

DELAY

23

GND

11

VCC

REF

15

RT

17

CT

18

SYNC

19

CSA−

9

CSA+

8

SS

4

CSAO

7

CEA−

13

VEA−

16

VEA+

14

22

24

3

2

1

RAMPCEA+12CEAOVEAO

10

PULL

PGND

PUSH

SRC

BUCK

V+

DELAY

DELAY

T

Q

Q

REF

&

UVLO

SS

INHBT

UV

OSC

500 kHz

MAX

6 5

21

Current Sense

Amplifier

ILIM Comparator

+3 V

Current Error

Amplifier

PWM Comparator0.7 V

Flying

Driver

Push/Pull

Drivers

OSC

UVLO

Voltage Error

Amplifier

+

查询UC1827供应商

BUCK CURRENT/VOLTAGE FED PUSH-PULL

FEATURES DESCRIPTION

• Ideal for Multiple Output and/or High

Voltage Output Voltage Converters

• Up to 500 kHz Operation

• High Voltage, High Current Floating

Driver for Buck Converter Stage

• UC3827-1 Current Fed Controller has

Push-Pull Drivers with Overlapping

Conduction Periods

• UC3827-2 Voltage Fed Controller has

Push-Pull Drivers with Nonoverlapping

Conduction Periods

• Average Current Mode, Peak Current

Mode or Voltage Mode with Input

Voltage Feedforward Control for Buck

Power Stage

• Wide Bandwidth, Low Offset,

Differential Current Sense Amplifier

• Precise Short Circuit Current Control

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

PWM CONTROLLERS

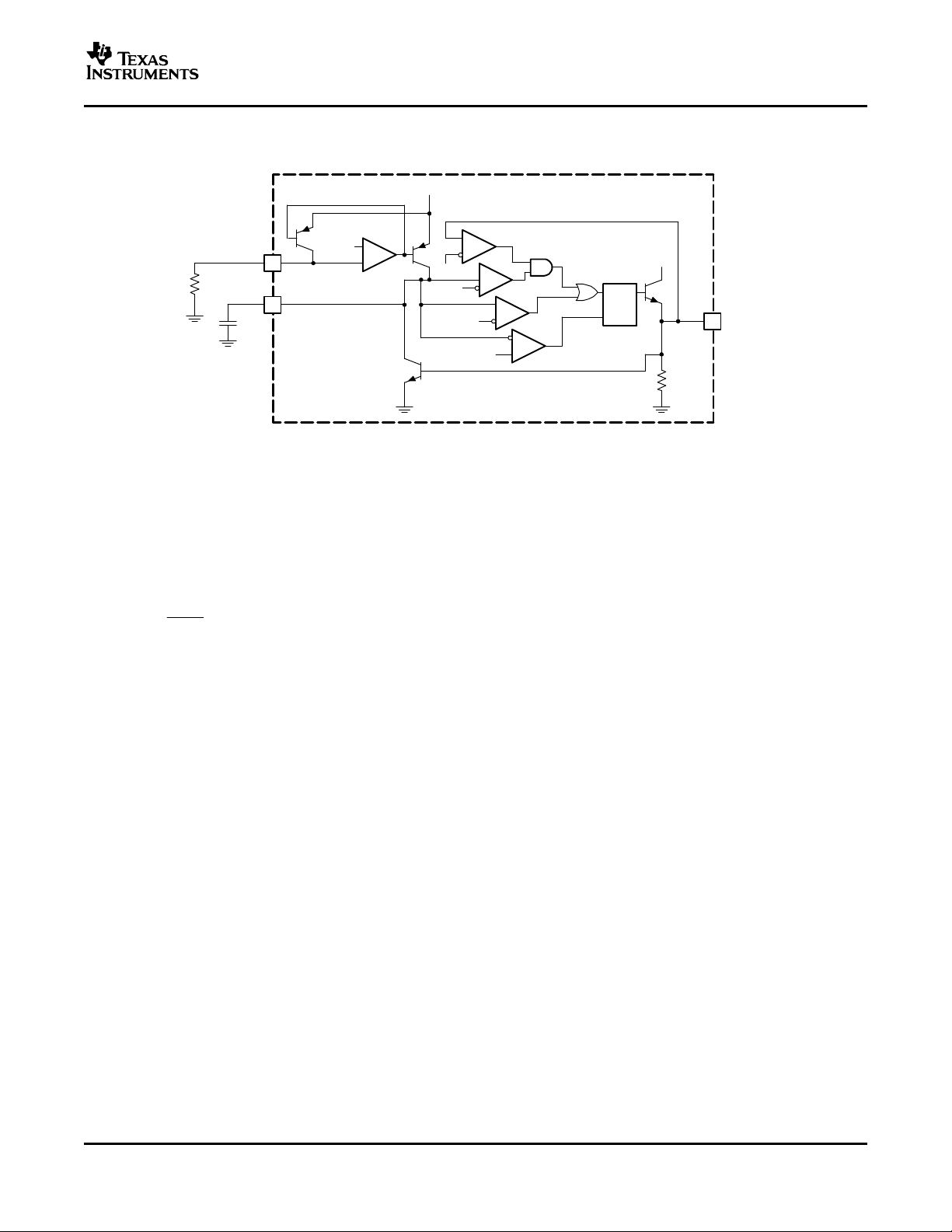

The UC3827 family of controller devices provides an

integrated control solution for cascaded buck and

push-pull converters. These converters are known as

current fed or voltage fed push-pull converters and

are ideally suited for multiple output and/or high

voltage output applications. In both current fed and

voltage fed modes, the push-pull switches are driven

at 50% nominal duty cycles and at one half the

switching frequency of the buck stage. In the current

fed mode, the two switches are driven with a specified over-lap period to prevent ringing and voltage

stress on the devices. In the voltage fed mode, the

two switches are driven with a specified gap time

between the switches to prevent shorting the transformer across the energy storage capacitor and to

prohibit excessive currents flowing through the devices.

The converter's output voltage is regulated by pulse

width modulation of the buck switch. The UC3827

contains complete protection and PWM control functions for the buck converter. Easy control of the

floating switch is accomplished by the floating drive

circuitry. The gate drive waveform is level shifted to

support an input voltage up to 72 V

BLOCK DIAGRAM

.

DC

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 1999–2005, Texas Instruments Incorporated

www.ti.com

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

DESCRIPTION (CONTINUED)

The UC3827 can be set up in traditional voltage mode control using input voltage feedforward technique or in

current mode control. Using current mode control prevents potential core saturation of the push-pull transformer

due to mismatches in timing and in component tolerances. With average current mode control, precise control of

the inductor current feeding the push-pull stage is possible without the noise sensitivity associated with peak

current mode control. The UC3827 average current mode loop can also be connected in parallel with the voltage

regulation loop to assist only in fault conditions.

Other valuable features of the UC3827 include bidirectional synchronization capability, user programmable

overlap time (UC3827-1), user programmable gap time (UC3827-2), a high bandwidth differential current sense

amplifier, and soft start circuitry.

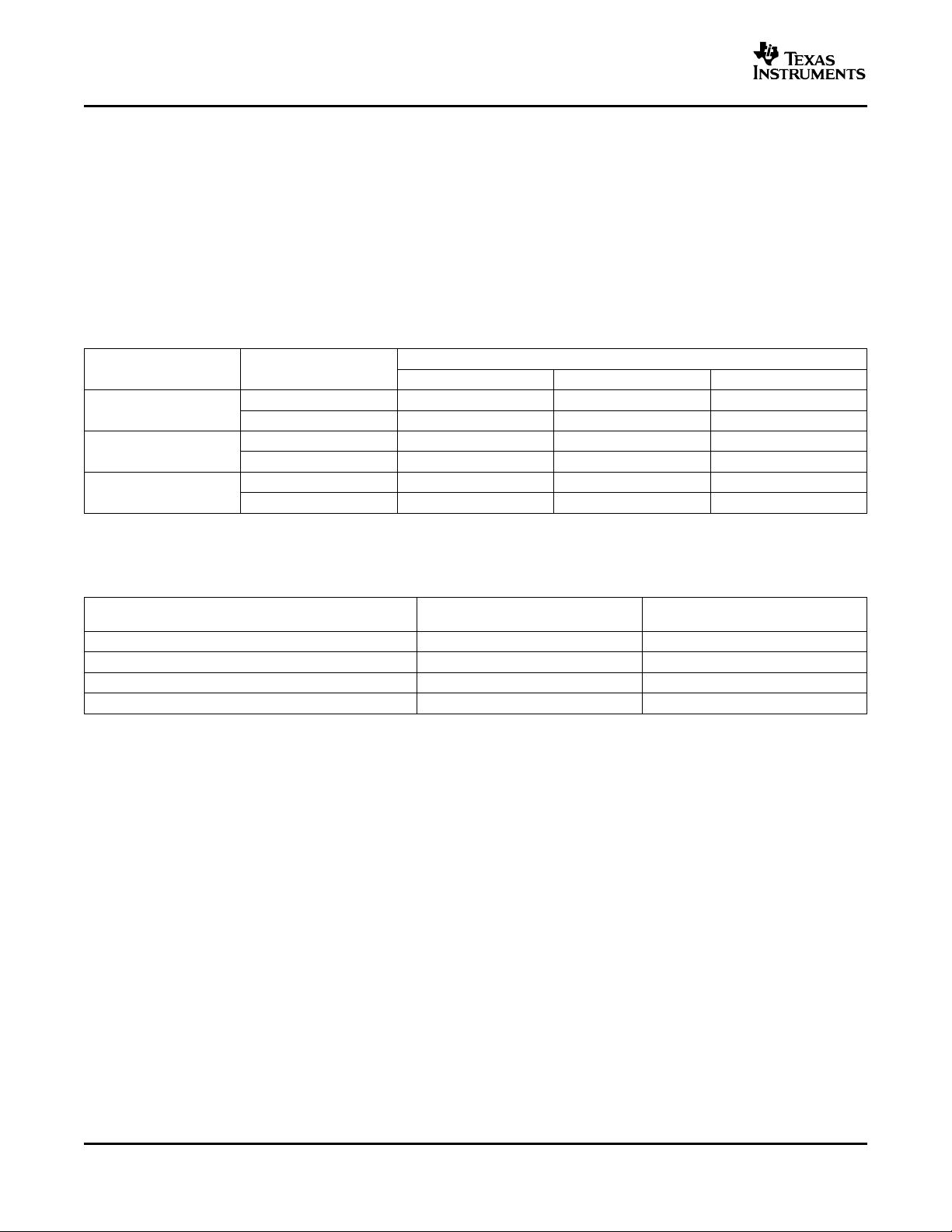

ORDERING INFORMATION

TA= T

J

-55°C to 125°C

-40°C to 85°C

0°C to 70°C

(1) The DW and Q packages are also available taped and reeled. Add a TR suffix to the device type (i.e., UC2827DWTR-1).

PUSH-PULL TOPOLOGY

Current Fed UC1827J-1 UC1827J-1

Voltage Fed UC1827J-2 UC1827J-2

Current Fed UC2827DW-1 UC2827N-1 Voltage Fed UC2827DW-2 UC2827N-2 Current Fed UC3827DW-1 UC3827N-1 UC3827Q-1

Voltage Fed UC3827DW-2 UC3827N-2 -

SOIC-24 PDIP-24 PLCC-28

(1)

PACKAGES

DISSIPATION RATINGS

PACKAGE ( θJA) JUNCTION-TO-AMBIENT ( θJC) JUNCTION-TO-WHAT?

24-pin (N) 60

24-pin (J) 70 to 90 28

28-pin (DW) 71 to 83

28-pin (QLCC) 40-65

(1) Specified θJA(junction-to-ambient) refers to devices mounted to 5-in

range is given, the lower values refer to a 5-in

trace widths for power packages and 1.3 mm trace widths for non-power packages with a 100 × 100 mil probe land area at the end of

each trace.

(2) Specified θJC(junction-to-what?) data values stated were derived from MIL-STD-1835B which states " The baseline values shown are

worst case (mean + 2s) for a 60 x 60 mil microcircuit device silicon die and applicable for devices with die sizes up to 14400 mils

device sizes greater than 14400 mils

array, 10 °C/W."

(3) Modeled data. If there is a value range given for θJA, the lower value refers to a 3 x 3 in., 1-oz, internal copper ground plane. The higher

value refers to a 1 x 1 in. ground plane. All model data assumes only one trace for each non-fused lead.

2

2

aluminum PC board. The test PWB is 0.062 inches thick and typically used 0.635 mm

use the following values; dual-in-line, 11 °C/W; flat pack, 10 °C/W; pin grid array, 10 °C/W pin grid

TEMPERATURE (°C/W) TEMPERATURE (°C/W)

(1)

(3)

(1)

2

FR4 PC board with 1 oz. copper where noted. When a resistance

30

24

30

(2)

(3)

2

. For

2

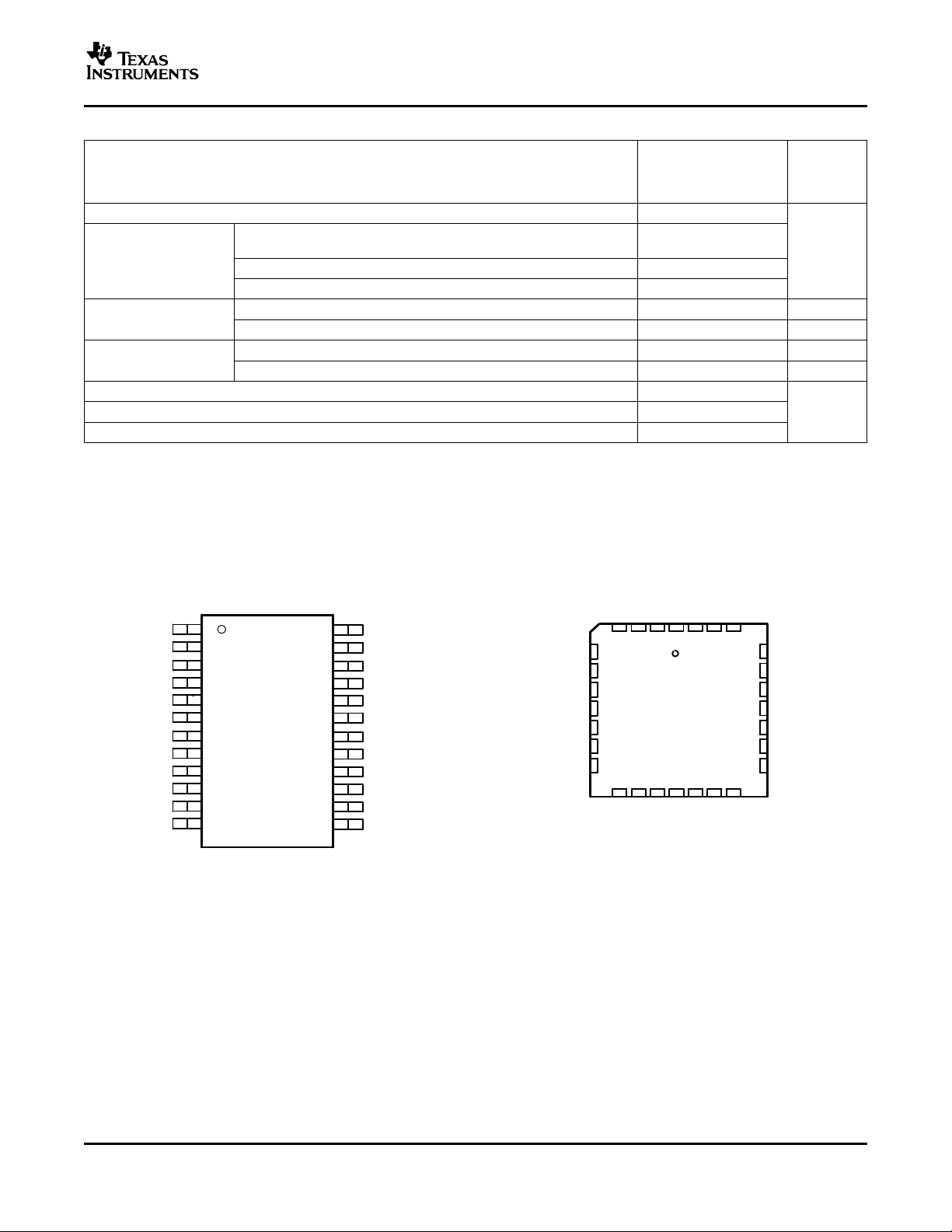

www.ti.com

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

V+

BUCK

SRC

SS

RAMP

CEAO

CSAO

CSA+

CSA−

VEAO

GND

CEA+

PUSH

VCC

PULL

PGND

DELAY

SYNC

CT

RT

VEA−

REF

VEA+

CEA−

N, J OR DW PACKAGES

(TOP VIEW)

3 2 1

13 14

5

6

7

8

9

10

11

PGND

NC

NC

DELAY

SYNC

CT

RT

SS

RAMP

CEAO

CSAO

CSA+

CSA−

VEAO

4

15 16 17 18

CEA+

CEA−

VEA+

REF

NC

VEA−

SRC

BUCKNCV+

Q PACKAGE

(TOP VIEW)

28 27 26

25

24

23

22

21

20

19

12

GND

PUSH

VCC

PULL

NC − No internal connection

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

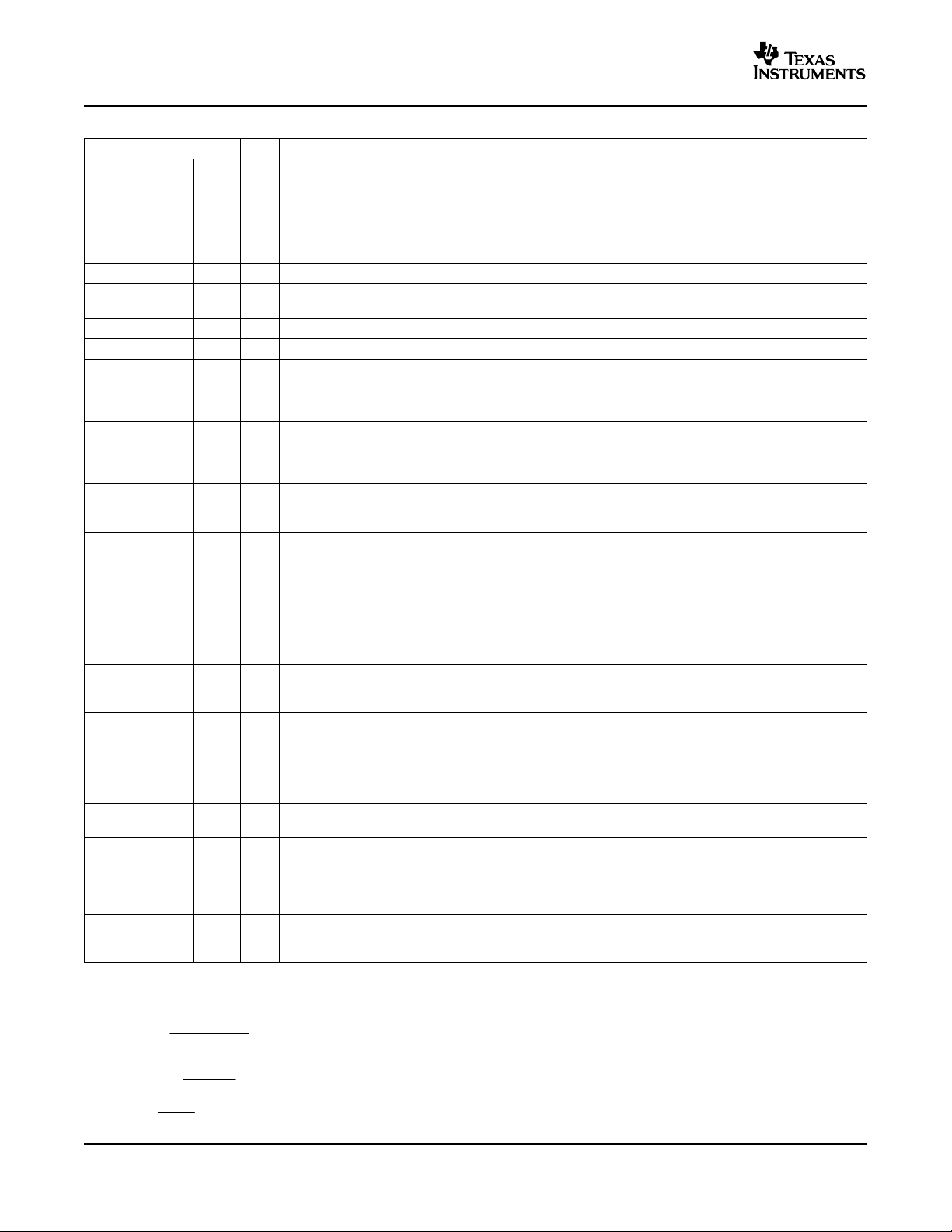

ABSOLUTE MAXIMUM RATINGS

Supply voltage, VCC 20

CEAO, CEA+, CEA-, CSAO, CSA+, CSA-, CT, DELAY, PUSH, PULL,

Input voltage range

BUCK driver

PUSH/PULL driver

Storage temperature –65 to 150

Junction temperature –55 to 150 °C

Lead temperature (soldering, 10 sec) 300

(1) Voltages are referenced to ground. Currents are positive into, negative out of the specified terminal. Consult Packaging section of

databook for thermal limitations and considerations of packages.

RAMP, RT, SS, SYNC, VEA+, VEAO,

V+ and BUCK 90

SRC 90-VCC

I/O continuous ±250 mA

I/O peak ±1 A

I/O continuous ±200 mA

I/O peak ±0.8 A

(1)

UC2827-1

UC2827-2

UC3827-1

UC3827-2

–0.3 to 5

UNITS

V

CONNECTION DIAGRAMS

PLCC-28 (Q PACKAGE)

(TOP VIEW)

DIL-24 (N or J, DW PACKAGES)

(TOP VIEW)

3

www.ti.com

f

OSC

0.77

RRT C

CT

(Hz)

t

DELAY

R

DELAY

200

109(s)

I

RT

2.5 V

R

RT

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

Terminal Functions

TERMINAL

NAME Q

BUCK 2 3 O gate of an N-channel MOSFET. The peak sink and source currents are 1 A. V

CEA+ 12 13 I Non-inverting input of the current error amplifier.

CEA- 13 14 I Inverting input of the current error amplifier

CEAO 6 7 O

CSA+ 8 9 I Noninverting input of the current sense amplifier.

CSA– 9 10 I Inverting input of the current sense amplifier.

CSAO 7 8 O

CT 18 20 I

DELAY 20 22 I dead time of the PUSH and PULL outputs of the UC3827-2. The minimum value of the resistor, R

GND 11 12 -

PGND 21 25 - on the printed circuit board. This is imperative to prevent large, high frequency switching currents

PULL 22 26 O the two switches of the push-pull converter with complementary signals at close to a 50% duty cycle.

PUSH 24 28 O the two switches of the push-pull converter with complementary signals at close to a 50% duty cycle.

RAMP 5 6 I

REF 15 16 O

RT 17 19 I to keep CT's discharge peak current less than 20 mA, which is CT's maximum practical discharge value.

SRC 3 4 I must be lower than 90 V–V

N or

DW

I/O DESCRIPTION

Output of the buck PWM controller. The BUCK output is a floating driver, optimized for controlling the

disables BUCK to an off condition (low).

Output of the current error amplifier and the inverting input of the PWM comparator of the buck

converter.

Output of the current sense amplifier and the noninverting input of the current limit comparator. When

the signal level on this pin exceeds the 3V threshold of the current limit comparator, the buck gate drive

pulse is terminated. This feature is useful to implement cycle-by-cycle current limiting for the buck

converter.

Provides for the timing capacitor which is connected between CT and GND. The oscillator frequency is

set by CT and a resistor RT, connected between pin RT and GND. The CT discharge current is

approximately 40 x the bias current through the resistor connected to RT. A practical maximum value for

the discharge current is 20 mA. The frequency of the oscillator is given by equation

A resistor to GND programs the overlap time of the PUSH and PULL outputs of the UC3827-1 and the

is 18 k Ω . The delay or overlap time is given by equation

Ground reference for all sensitive setup components not related to driving the outputs. They include all

timing, voltage sense, current sense, and bypass components.

Ground connection for the PUSH and PULL outputs. PGND must be connected to GND at a single point

flowing through the ground metalization inside the device.

Ground referenced output to drive an N-channel MOSFET. The PULL and the PUSH outputs are driving

Any undervoltage faults will disable PULL to an off condition (low).

Ground referenced output to drive an N-channel MOSFET. The PULL and the PUSH outputs are driving

Any undervoltage faults disables PUSH to an off condition (low).

The RAMP voltage, after a 700 mV internal level shift, is fed to the noninverting input of the buck PWM

comparator. A resistor to VINand a capacitor to GND provide an input voltage feedforward signal for the

buck controller in voltage mode control. In peak current mode control, the RAMP pin receives the

current signal of the buck converter. In an average current mode setup, the RAMP pin has a linearly

increasing ramp signal. This waveform may be generated either by connecting RAMP directly to CT, or

by connecting both a resistor from VCC to RAMP and a capacitor from RAMP to GND.

The output of the +5V on board reference. Bypass this pin with a capacitor to GND. The reference is off

when the chip is in undervoltage lockout mode.o

A resistor to GND programs the charge current of the timing capacitor connected to CT. The charge

current approximately equals that shown in equation

The discharge time, which sets the maximum duty cycle, is set internally and is influenced by the charge

current.

The source connection for the floating buck switch. The voltage on the SRC pin can exceed VCC but

can go to –2V.

. Also, during turn-off transients of the buck switch, the voltage at SRC

VCC

(2)

(3)

. The charge current should be less than 500 µA

CC

undervoltage faults

(1)

,

DELAY

(1)

(2)

(3)

4

www.ti.com

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

Terminal Functions (continued)

TERMINAL

NAME Q

N or

DW

SS 4 5 O clamped to the soft-start capacitor voltage which is slowly charged by an internal current source. In

SYNC 19 21 I

VCC 23 27 I

VEA+ 14 15 I Non-inverting input of the voltage error amplifier

VEA- 16 18 I Inverting input of the voltage error amplifier

VEAO 10 11 O Output of the voltage error amplifier

V+ 1 1 I

I/O DESCRIPTION

5Soft-start pin requires a capacitor to GND. During soft-start the output of the voltage error amplifier is

UVLO, SS is held low.

A bidirectional pin for the oscillator., used to synchronize several chips to the fastest oscillator. Its input

synchronization threshold is 1.4 V. The SYNC voltage is 3.6 V when the oscillator capacitor, CT, is

discharged. Otherwise it is 0 V. If the recommended synchronization circuit is not used, a 1 k Ω or lower

value resistor from SYNC to GND may be needed to increase the fall time of the signal at SYNC.

A voltage source connected to this pin supplies the power for the UC3827. It is recommended to bypass

this pin to both GND and PGND ground connections with good quality high frequency capacitors

Supply voltage for the buck output. The floating driver of the UC3827 uses the bootstrap technique

which requires a reservoir capacitor to store the required energy for the on time of the buck switch. A

diode must be connected from VCC to V+ to charge the reservoir capacitor. This diode must be able to

withstand VIN. The reservoir capacitor must be connected between V+ and SRC.

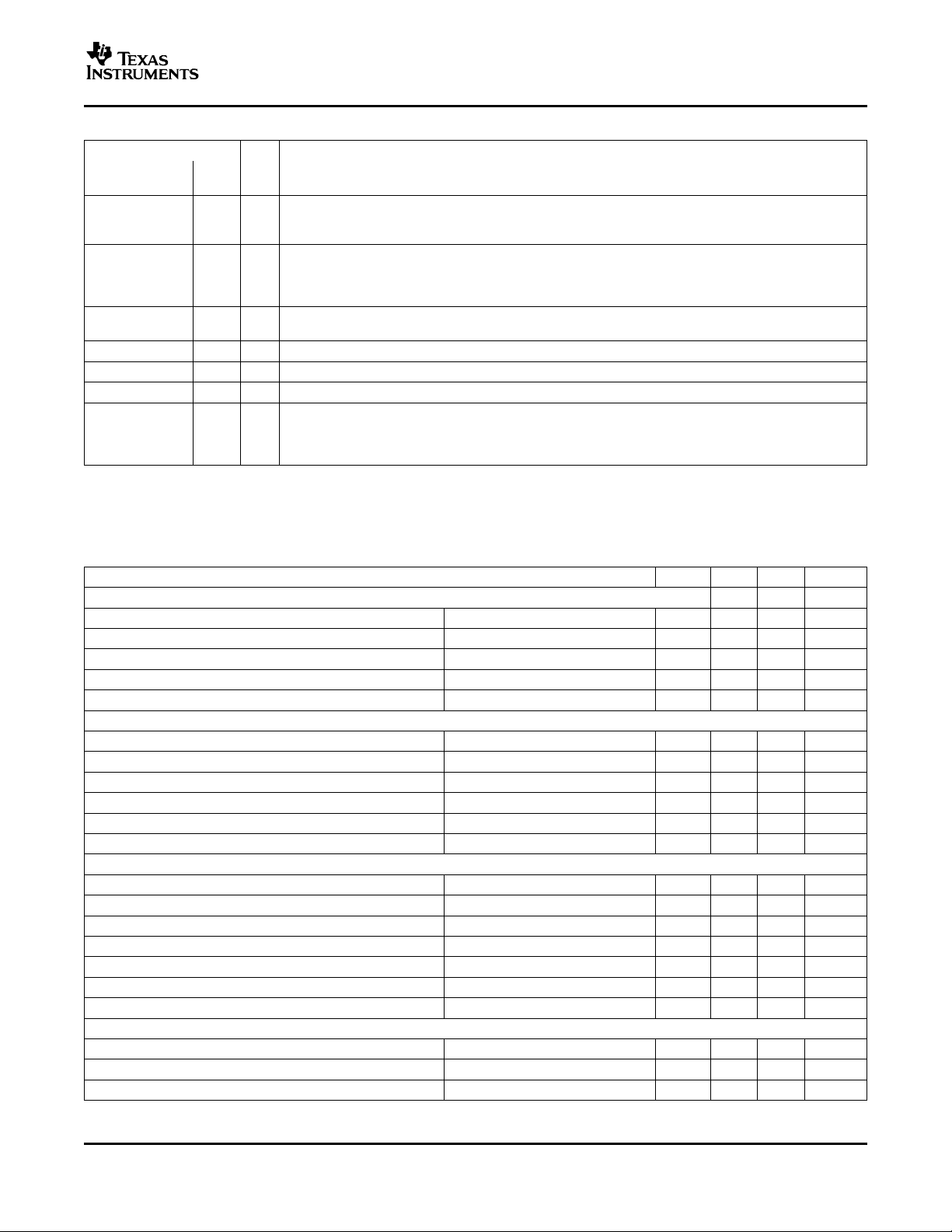

ELECTRICAL CHARACTERISTICS

Unless otherwise spsecified, V

V

= V

PUSH

SUPPLY

I

VCC

I

VCC

VOLTAGE ERROR AMPLIFIER

IB 0.5 3 µA

VIO 10 mV

AVOL 80 95 dB

(1)

GBW

V

OL

V

OH

CURRENT SENSE AMPLIFIER

IB –1 –5 µA

VIO 5 mV

AVOL 80 110 dB

(1)

GBW

V

OL

V

OH

CMRR Common mode range

CURRENT ERROR AMPLIFIER

IB –1 –5 µA

VIO 10 mV

AVOL 80 110 dB

outputs no load, TJ= T

PULL

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VCC UVLO, Turn-on 8.3 8.8 9.5 V

Hysteresis 0.9 1.2 1.5 V

Supply current start V

Supply current run 32 45 mA

IV+buck high 0.2 1 2 mA

Gain bandwidth 1 4 MHz

Low-level output voltage I

High-level output voltage I

Gain bandwidth 15 29 MHz

Low-level output voltage I

High-level output voltage I

VCC

= 15 V, V

(1)

= 14.3 V, C

V+

A

= 340 pF, R

CT

= 8 V 1000 µA

VCC

= 0 µA (No load) 0.3 0.5 V

VEAO

= 0 µA (No load) 2.85 3 3.20 V

VEAO

= 0 µA (No load) 0.25 0.5 V

CEAO

= 0 µA (No load) 3 3.3 V

CEAO

= 10 k Ω , R

RT

DELAY

= 24.3 k Ω , V

SRC

= V

= V

GND

-0.3 2 V

=

BUCK

(1) Ensured by design. Not production tested.

5

www.ti.com

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

ELECTRICAL CHARACTERISTICS (continued)

Unless otherwise spsecified, V

V

= V

PUSH

(1)

GBW

V

OL

V

OH

CMRR Common mode range

OSCILLATOR SECTION

f

OSC

I

CT(dsch)

PWM COMPARATOR

D

MAX

D

MAX

BUCK OUTPUT STAGE

t

RISE

t

FALL

V

OH

V

OL

PUSH/PULL OUTPUT STAGES

t

RISE

t

FALL

V

OH

V

OL

REFERENCE

I

SC

SOFT START

V

OL

I

SS

outputs no load, TJ= T

PULL

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Gain bandwidth At 100 kHz, Measure Gain 2 4.5 MHz

Frequency 180 220 250 kHz

CT discharge current 3.5V at CT when CT removed 5 mA

Minimum duty cycle 200 kHz 0%

Maximum duty cycle 200 kHz 85% 91% 95%

Rise time 1 nF Load

Fall tIme 1 nF, Load 30 80 ns

High-level output voltage

Low-level output voltage

Rise time 1 nF load 50 100 ns

Fall tIme 1 nF load 35 100 ns

Overlap time UCx827-1 1 nF loads

Nonoverlapping time

High-level output voltage

Low-level output voltage

Reference voltage 4.8 5 5.2 V

Shor-circuit current V

Line regulation 0.5V < V

Load regulation 0 mA < IIO< 10 mA 8 20 mV

Low-level output voltage saturation V

Soft-start current –5 –12 –25 µA

VCC

= 15 V, V

(1)

(6)

= 14.3 V, C

V+

A

= 340 pF, R

CT

I

= 0 µA (No Load) 0.25 0.5 V

CEAO

I

= 0 µA (No Load) 3.3 3.5 V

CEAO

= 10 k Ω , R

RT

DELAY

= 24.3 k Ω , V

SRC

= V

= V

GND

=

BUCK

-0.3 5 V

(2)

I

= –15 mA , V+ –BUCK

BUCK

IBUCK = –150 mA, V+ –BUCK

I

= 15 mA

BUCK

I

K = 150 mA

BUC

(4)

(5)

(3)

(3)

(4)

100 250 400 ns

40 100 ns

1.5 2.5 V

2 2.5 V

0.2 0.4 V

0.7 1.2 V

UCx827-2 100 250 500 ns

I

PUSH/PULL

(7)

I

PUSH/PULL

PUSH

I

PUSH/PULL

I

PUSH/PULL

REF

VCC

= –10 mA, VCC – PUSH

= –100 mA, VCC –

(7)

= 10 mA

= 100 mA

(7)

(7)

2 3 V

2.5 3 V

0.2 0.8 V

0.6 1.2 V

= 0V –35 –50 –65 mA

< 20 V 5 20 mV

VCC

= 7 V 250 500 mV

(2) Measure the rise time from when BUCK crosses 1 V until it crosses 9 V.

(3) To force BUCK high, force V

(4) To force BUCK low, force V

(5) The overlap time is measured from the point at which the rising edge of PUSH/PULL crosses 5 V until the falling edge of PULL/PUSH

=2.5 V, V

CSAO

= 2.5 V, V

CSAO

= 2.5 V, a 25-k Ω pulldown resistor from RAMP to ground, and V

CEAO

= 2.5 V, a 10-k Ω pulldown resistor from RAMP to ground, and V

CEAO

= 0.5 V.

CT

= 3.5 V.

CT

crosses 5V.

(6) The non-overlap time is measured from the point at which the falling edge of PUSH/PULL crosses 5 V until the rising edge of

PULL/PUSH crosses 5 V.

(7) To toggle PUSH or PULL into a desired state, pulse CT from 0.5 V to 3.5 V. PUSH and PULL toggle on the rising edge of CT.

6

www.ti.com

APPLICATION INFORMATION

+

–

RT

CT

SYNC

S

R

V

REF

2.5 V

OSCILLATOR

V

REF

10 k

1.4 V

2.5 V

2.9 V

0.5 V

R

T

C

T

VDG−99086

I

RT

2.5 V

R

RT

Figure 1. Oscillator Block With External Connections

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

CIRCUIT BLOCK DESCRIPTION

PWM Oscillator

The oscillator block diagram with external connections is shown in Equation 1 . A resistor (R

RT sets the linear charge current:

The timing capacitor (C

) is linearly charged with the charge current forcing the OSC pin to charge to a 3.4 V

CT

threshold. After exceeding this threshold, the RS flip-flop is set driving CLKSYN high and R

discharges C

. CT continues to discharge until it reaches a 0.5 V threshold and resets the RS flip-flop which

CT

repeats the charging sequence as shown in Figure 2

As shown in Figure 3 , several oscillators are synchronized to the highest free running frequency by connecting

100 pF capacitors in series with each CLKSYN pin and connecting the other side of the capacitors together

forming the CLKSYN bus. The CLKSYN bus is then pulled down to ground with a resistance of approximately

10k. Referring to Figure 1 , the synchronization threshold is 1.4 V. The oscillator blanks any synchronization pulse

that occurs when OSC is below 2.5 V. This allows units, once they discharge below 2.5 V, to continue through

the current discharge and subsequent charge cycles whether or not other units on the CLKSYN bus are still

synchronizing. This requires the frequency of all free running oscillators to be within 17% of each other to assure

synchronization.

) connected to pin

T

low which

DEAD

(1)

7

www.ti.com

OSC

CLKSYN

OUT

THRESHOLD

Charging

VAO Current

Command

Discharging

Threshold

2.9 V

0.5 V

3.6 V

1.4 V

8.5 V

0 V

VDG−99087

CLKSYN BUS

OSC1

OSC2

OSC3

OSC10

SYNC

SYNC

SYNC

SYNC

100 pF

100 pF

100 pF

100 pF

10 k

VDG−99085

UC1827-1, UC1827-2

UC2827-1, UC2827-2

UC3827-1, UC3827-2

SLUS365A – APRIL 1999 – REVISED AUGUST 2005

APPLICATION INFORMATION (continued)

Figure 2. Oscillator and PWM Output Waveform

REVISION HISTORY

8

Figure 3. Oscillator Synchronization Connection Diagram

REVISION DATE OF CHANGE DESCRIPTION

SLUS365A 8/2005

Improved CMRR of CSA from ( 0 - 2 V) to ( -0.3 - 2 V)

Improved CMRR of CEA from ( 0 - 5 V) to ( -0.3 - 5 V)

PACKAGE OPTION ADDENDUM

www.ti.com

17-Nov-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

UC1827J-1 OBSOLETE CDIP J 24 TBD Call TI Call TI

UC1827L-1 OBSOLETE TO/SOT L 20 TBD Call TI Call TI

UC2827DW-1 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC2827DW-2 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC2827DW-2G4 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC2827DWTR-1 ACTIVE SOIC DW 24 2000 Green (RoHS &

no Sb/Br)

UC2827DWTR-2 ACTIVE SOIC DW 24 2000 TBD CU NIPDAU Level-3-235C-168 HR

UC2827N-1 ACTIVE PDIP N 24 15 TBD Call TI Level-NA-NA-NA

UC2827N-2 ACTIVE PDIP N 24 15 TBD Call TI Level-NA-NA-NA

UC3827DW-1 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC3827DW-1G4 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC3827DW-2 ACTIVE SOIC DW 24 25 Green (RoHS &

no Sb/Br)

UC3827DWTR-1 ACTIVE SOIC DW 24 2000 Green (RoHS &

no Sb/Br)

UC3827DWTR-1G4 ACTIVE SOIC DW 24 2000 Green (RoHS &

no Sb/Br)

UC3827DWTR-2 ACTIVE SOIC DW 24 2000 Green (RoHS &

no Sb/Br)

UC3827DWTR-2G4 ACTIVE SOIC DW 24 2000 Green (RoHS &

no Sb/Br)

UC3827N-1 ACTIVE PDIP N 24 15 TBD Call TI Level-NA-NA-NA

UC3827N-2 ACTIVE PDIP N 24 15 TBD Call TI Level-NA-NA-NA

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

17-Nov-2005

Addendum-Page 2

MECHANICAL DATA

MCDI004A – JANUARY 1995 – REVISED NOVEMBER 1997

J (R-GDIP-T**) CERAMIC DUAL-IN-LINE PACKAGE

24 PINS SHOWN

B

24

1

0.065 (1,65)

0.045 (1,14)

0.090 (2,29)

0.060 (1,53)

0.100 (2,54)

0.022 (0,56)

0.014 (0,36)

13

12

0.175 (4,45)

0.140 (3,56)

C

Lens Protrusion (Lens Optional)

0.010 (0.25) MAX

A

Seating Plane

0.018 (0,46) MIN

0.125 (3,18) MIN

0.012 (0,30)

0.008 (0,20)

DIM

”A”

”B”

”C”

NOTES: A. All linear dimensions are in inches (millimeters).

PINS **

MAX

MIN

MAX

MIN

MAX

MIN

B. This drawing is subject to change without notice.

C. Window (lens) added to this group of packages (24-, 28-, 32-, 40-pin).

D. This package can be hermetically sealed with a ceramic lid using glass frit.

E. Index point is provided on cap for terminal identification.

NARR WIDE

0.624(15,85) 0.624(15,85)

0.590(14,99) 0.590(14,99)

1.265(32,13) 1.265(32,13)

1.235(31,37) 1.235(31,37)

0.541(13,74) 0.598(15,19)

0.514(13,06) 0.571(14,50)

24

NARR

0.624(15,85) 0.624(15,85)

0.590(14,99) 0.590(14,99)

1.465(37,21) 1.465(37,21)

1.435(36,45) 1.435(36,45)

0.541(13,74) 0.598(15,19)

0.514(13,06) 0.571(14,50)

28

32

NARRWIDE

0.624(15,85) 0.624(15,85)

0.590(14,99) 0.590(14,99)

1.668(42,37) 1.668(42,37)

1.632(41,45) 1.632(41,45)

0.541(13,74) 0.598(15,19)

0.514(13,06) 0.571(14,50)

40

WIDENARRWIDE

0.624(15,85) 0.624(15,85)

0.590(14,99) 0.590(14,99)

2.068(52,53) 2.068(52,53)

2.032(51,61) 2.032(51,61)

0.541(13,74) 0.598(15,19)

0.514(13,06) 0.571(14,50)

4040084/C 10/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

MPDI006B – SEPTEMBER 2001 – REVISED APRIL 2002

N (R–PDIP–T24) PLASTIC DUAL–IN–LINE

1.222 (31,04) MAX

24

13

0.360 (9,14) MAX

1

0.070 (1,78) MAX

0.200 (5,08) MAX

0.020 (0,51) MIN

0.100 (2,54)

0.021 (0,53)

0.015 (0,38)

0.010 (0,25)

12

0.425 (10,80) MAX

Seating Plane

0.125 (3,18) MIN

0’–15’

0.010 (0,25) NOM

4040051–3/D 09/01

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS–010

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

MPDI008 – OCTOBER 1994

N (R-PDIP-T**) PLASTIC DUAL-IN-LINE PACKAGE

24 PIN SHOWN

A

24

13

0.560 (14,22)

0.520 (13,21)

1

0.060 (1,52) TYP

0.200 (5,08) MAX

0.020 (0,51) MIN

0.100 (2,54)

0.021 (0,53)

0.015 (0,38)

0.010 (0,25)

PINS **

DIM

A MAX

A MIN

M

1.270

(32,26) (36,83)

1.230

(31,24)

1.450

1.410

(35,81)

12

0.125 (3,18) MIN

322824

1.650

(41,91)

1.610

(40,89)

Seating Plane

0.010 (0,25) NOM

2.090

2.040

(51,82)

2.450 2.650

(62,23)(53,09)

2.390

(60,71)

0.610 (15,49)

0.590 (14,99)

0°–15°

524840

(67,31)

2.590

(65,79)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-011

D. Falls within JEDEC MS-015 (32 pin only)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

4040053/B 04/95

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...