Page 1

TSW3000 Demo Kit

User's Guide

September 2005

SLWU013A

Page 2

TSW3000 Demo Kit

User's Guide

Literature Number: SLWU013A

March 2004 – Revised September 2005

Page 3

Contents

1 Demo Kit Configuration Options ................................................................................... 7

1.1 DAC Component .................................................................................................... 7

1.2 VComm Configuration .............................................................................................. 7

1.3 VCXO ................................................................................................................. 7

1.4 VCO .................................................................................................................. 7

2 Block Diagrams .......................................................................................................... 8

2.1 System Block Diagram ............................................................................................. 8

2.2 Demo Kit Block Diagram ........................................................................................... 8

3 Key Texas Instruments Components ............................................................................. 9

3.1 CDCM7005 .......................................................................................................... 9

3.2 DAC5687 ............................................................................................................. 9

3.3 TRF370x ............................................................................................................. 9

3.4 TRF3750 ............................................................................................................. 9

4 Software Installation .................................................................................................... 9

5 Software Operation ..................................................................................................... 9

5.1 CDCM7005 Software ............................................................................................. 10

5.2 TRF3750 Software ................................................................................................ 12

5.3 DAC5687 Software ................................................................................................ 13

5.4 DAC5687 GUI Register Descriptions ........................................................................... 14

6 Board Setup .............................................................................................................. 16

6.1 Jumper Settings ................................................................................................... 16

6.2 Input/Output Connectors ......................................................................................... 17

6.3 Parallel Port ........................................................................................................ 17

6.4 DC Power Requirements ......................................................................................... 17

7 Demo Kit Test Configuration ....................................................................................... 17

7.1 Test Setup Block Diagram ....................................................................................... 18

7.2 Test Equipment .................................................................................................... 18

7.3 Calibration .......................................................................................................... 18

7.4 Test Specifications ................................................................................................ 18

8 Basic Test Procedure ................................................................................................. 19

8.1 Initial Inspection ................................................................................................... 19

8.2 Engage Power Supplies .......................................................................................... 19

8.3 Program the CDCM7005 ......................................................................................... 19

8.4 Program the TRF3750 ............................................................................................ 19

8.5 DAC5687 Program ................................................................................................ 20

8.6 Carrier Suppression ............................................................................................... 21

8.7 Sideband Rejection ............................................................................................... 22

9 Optional Configurations ............................................................................................. 24

9.1 External LO ........................................................................................................ 24

9.2 External Reference ................................................................................................ 24

9.3 Monitor DAC Output .............................................................................................. 24

SLWU013A – March 2004 – Revised September 2005 Table of Contents 3

Page 4

10 Filter Specifications ................................................................................................... 25

10.1 Baseband Filter .................................................................................................... 25

11 Layers and Schematics .............................................................................................. 25

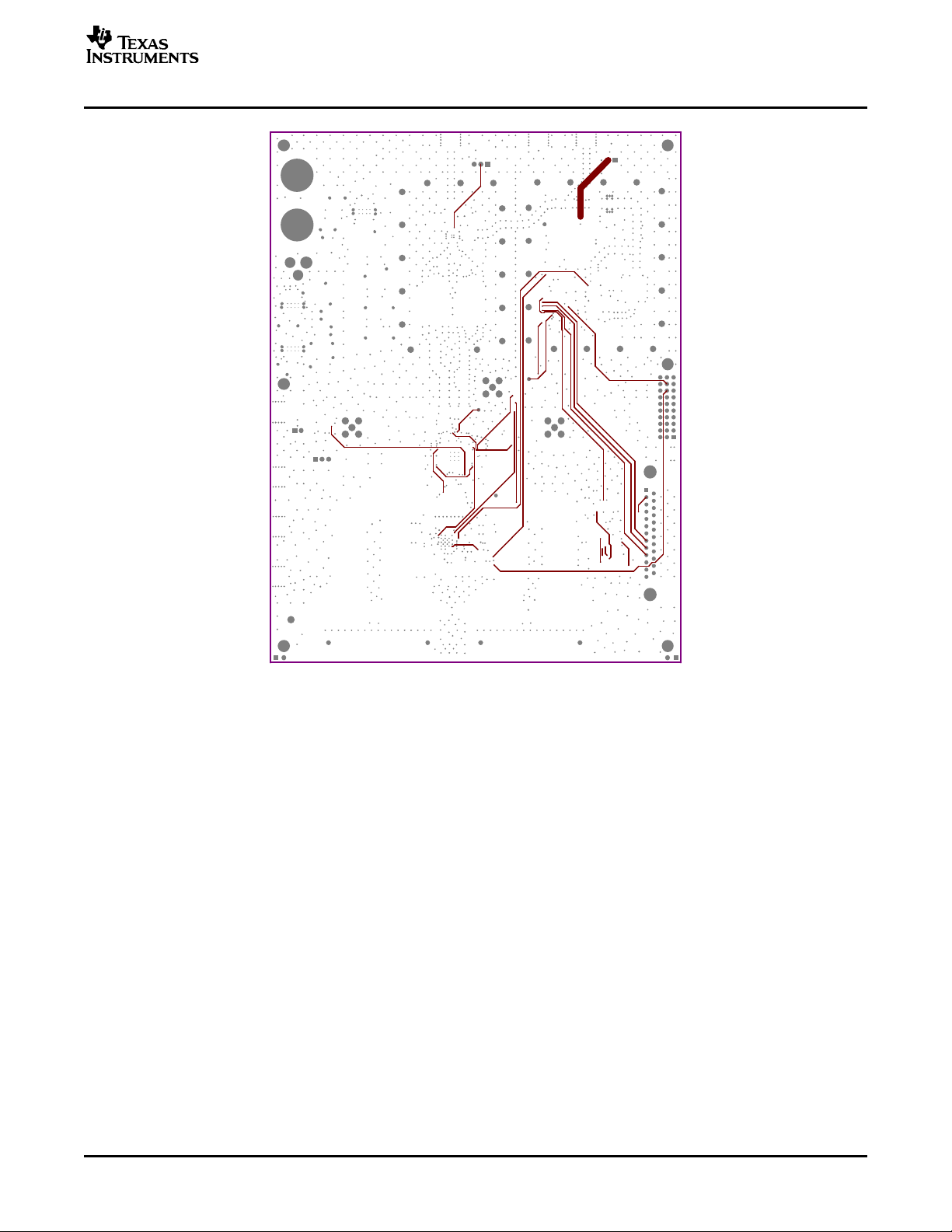

11.1 Layers ............................................................................................................... 26

11.2 Schematics ......................................................................................................... 35

Contents 4 SLWU013A – March 2004 – Revised September 2005

Page 5

List of Figures

1 System Block Diagram ...................................................................................................... 8

2 Demo Kit Block Diagram .................................................................................................... 8

3 TSW3000 Startup Screen ................................................................................................. 10

4 Default CDCM7005 SPI GUI .............................................................................................. 11

5 TRF3750 GUI - Main Menu ............................................................................................... 12

6 TRF3750 GUI - Advanced Menu ......................................................................................... 13

7 DAC5687 GUI .............................................................................................................. 14

8 Test System Block Diagram .............................................................................................. 18

9 Default DAC GUI With f

10 Single Sideband Spectrum Output Before DAC Offset and QMC Adjustments ................................... 22

11 DAC GUI With Typical Settings To Minimize LO and Sideband ..................................................... 23

12 Sideband and LO ........................................................................................................... 24

13 Top Layer .................................................................................................................... 26

14 Top Layer (NH) ............................................................................................................. 27

15 Layer 2 ....................................................................................................................... 28

16 Layer 3 ....................................................................................................................... 29

17 Layer 4 ....................................................................................................................... 30

18 Layer 4 (NH) ................................................................................................................ 31

19 Layer 5 ....................................................................................................................... 32

20 Bottom Layer ................................................................................................................ 33

21 Bottom Silkscreen .......................................................................................................... 34

22 Drill Drawing ................................................................................................................ 35

/8 Tone From NCO ........................................................................ 21

DAC

SLWU013A – March 2004 – Revised September 2005 List of Figures 5

Page 6

List of Tables

1 Frequency Bands ............................................................................................................ 7

2 CDCM7005 Register Values .............................................................................................. 11

3 Jumper List .................................................................................................................. 16

4 Input/Output Connections ................................................................................................. 17

5 Demo Kit Specifications ................................................................................................... 18

6 Frequency Designations ................................................................................................... 19

List of Tables6 SLWU013A – March 2004 – Revised September 2005

Page 7

1 Demo Kit Configuration Options

The TSW3000 Demo Kit can be configured in different ways to evaluate different components in different

frequency bands. This section outlines the various component configurations. Based on the configuration,

testing and board setup must be altered to accommodate the given components and features.

1.1 DAC Component

The TSW3000 Demo Kit is built for the DAC5687, although this Demo Kit can also support the DAC5686

since the two devices are pin compatible. The procedures outlined in this document are primarily suited for

the DAC5687, but can be modified easily for the DAC5686 if desired.

1.2 VComm Configuration

The analog quadrature modulator requires a common-mode dc voltage of approximately 3.7 V. In order to

utilize the dc-offset adjustment capabilities of the DAC568x for carrier suppression, it is imperative to

maintain a dc path from the DAC output to the modulator input. The common-mode voltage for the

modulator is maitained with a passive resistor network that is designed to provide the proper operation

point for the DAC568x and the TRF370x modulator. By design, in order to preserve the proper dc levels,

the DAC gain should be kept at maximum (15), though deviation by a few steps is generally acceptable

with no degradation in performance.

User's Guide

SLWU013A – March 2004 – Revised September 2005

1.3 VCXO

The CDCM7005 requires a VCXO source to derive its output clock signals. The VCXO is at reference

designator U10 on the back side of the board. The frequency of the VCXO can be changed to operate the

Demo Kit with different clocking schemes for different modulation standards or for specific customer

requirements. Denote which VCXO frequency is on the board so that the CDCM7005 part can be set up

properly. The following conventions are typically used:

• WCDMA: Derivatives of 61.44 MHz (i.e., 122.88 MHz, 245.76 MHz, 491.52 MHz)

• GSM: Derivatives of 52 MHz (i.e., 104 MHz, 208 MHz)

• CDMA2K: Derivativies of 78.6432 (i.e., 157.2864 MHz, 314.5728 MHz)

1.4 VCO

The VCO outputs the RF signal used for the LO drive on the analog quadrature modulator. The RF output

frequency is contingent on the LO frequency value.

The RF frequency band of the VCO must be noted in order to know how to program the TRF3750 and

where to measure the output RF signal from the modulator. The typical bands of operation are shown in

Table 1 .

Table 1. Frequency Bands

UMTS PCS GSM900 DCS1800

FREQUENCY 2110-2170 MHz 1930-1990 MHz 935-960 MHz 1805-1880 MHz

SLWU013A – March 2004 – Revised September 2005 7

Page 8

www.ti.com

DAC

I/Q

Modulator

90°

0°

LPA

TX

Diplexer

ANT

RX

LNA

A/D

I/Q

Demod

16

DAC5687

16

CLK1

I

Q

TRF370x

I/Q

Modulator

RF

LO

VCO

TRF3750

VCXO

PLL

Ref Osc

CDCM7005

CLK2

Block Diagrams

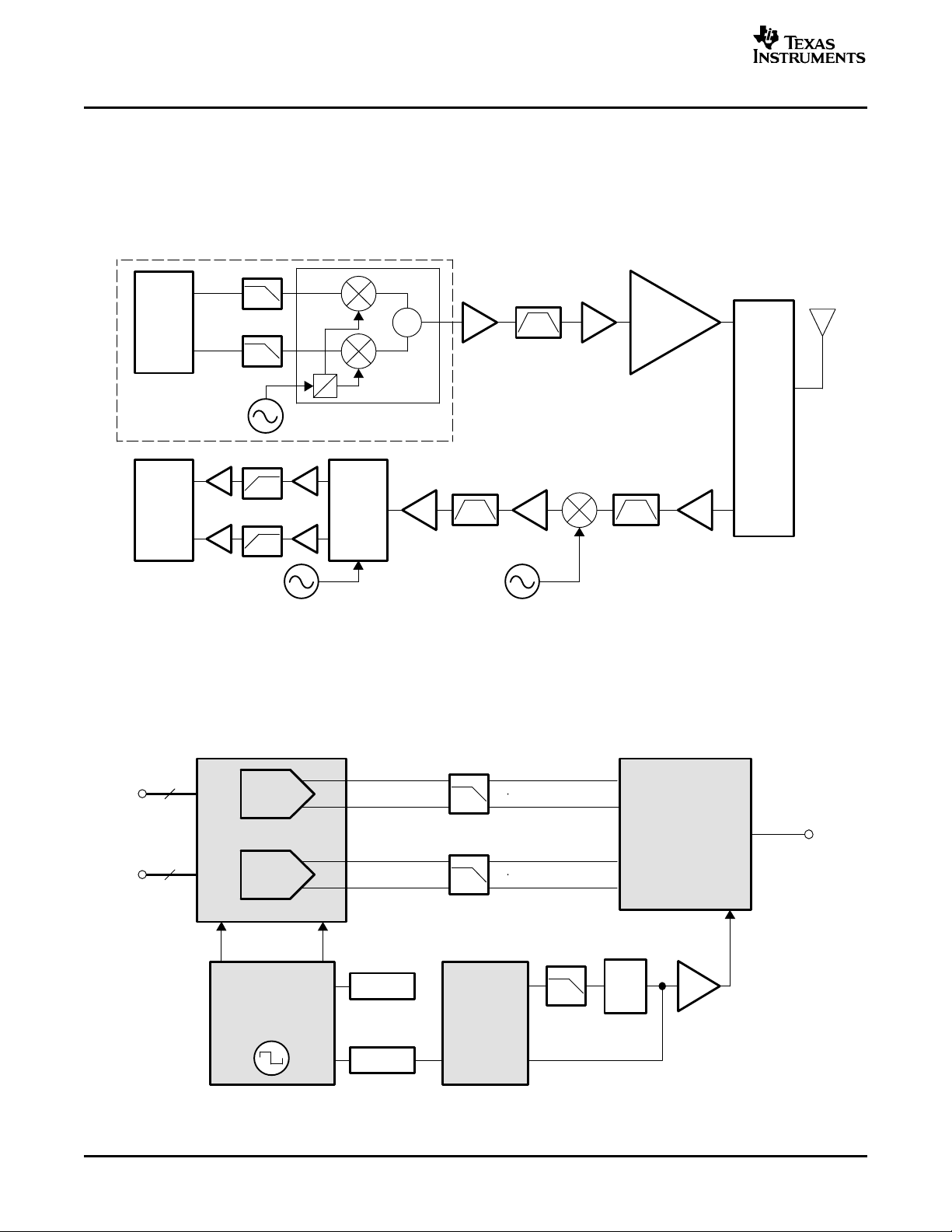

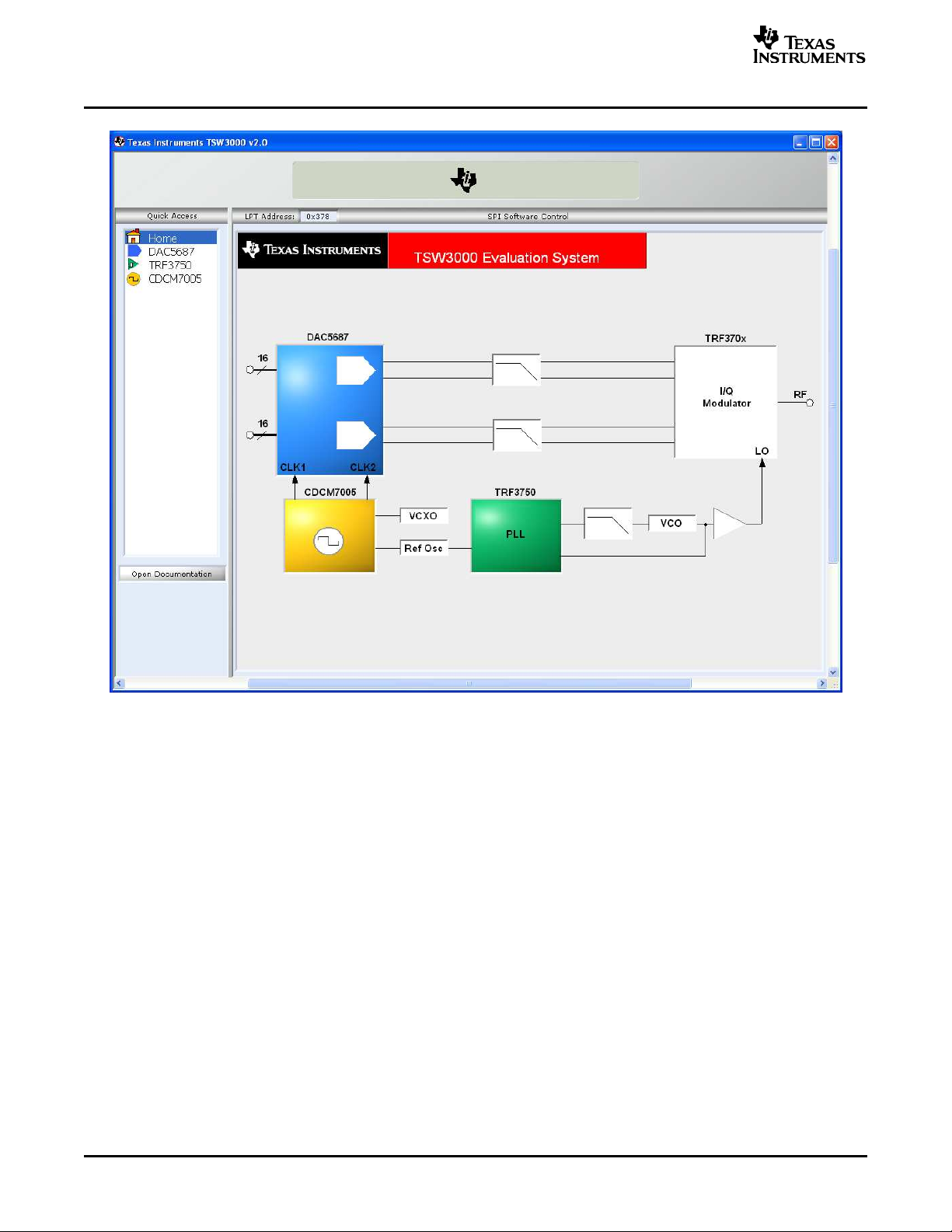

2 Block Diagrams

2.1 System Block Diagram

The basic radio system block diagram in Figure 1 demonstrates where the TSW3000 Demo Kit fits in the

overall transceiver. The dash-line box illustrates the components found on the TSW3000 Demo Kit board.

2.2 Demo Kit Block Diagram

Figure 1. System Block Diagram

The basic Demo Kit block diagram is shown in Figure 2 . The shaded boxes illustrate the key Texas

Instruments components found on the TSW3000 Demo Kit board.

Figure 2. Demo Kit Block Diagram

8 SLWU013A – March 2004 – Revised September 2005

Page 9

www.ti.com

3 Key Texas Instruments Components

3.1 CDCM7005

The CDCM7005 clock distribution chip is used to generate and synchronize the clock outputs to the

system. The device has five outputs which can be either LVPECL or LVCMOS and can be divided down

by 1, 2, 3, 4, 6, 8, and 16. The divide by 16 can be replaced with a divide by 4 or 8 with a 90 degree

phase shift.

3.2 DAC5687

The DAC5687 is a 16-bit interpolating dual digital-to-analog converter (DAC). The device incorporates a

digital modulator, independent differential offset control, and I/Q amplitude control. The device is typically

used in baseband mode or in low IF mode in conjunction with an analog quadrature modulator.

3.3 TRF370x

The TRF370x is a direct upconvert I/Q modulator. The device accepts differential input voltage at

baseband or low IF frequencies and outputs an RF signal based on the LO drive frequency.

3.4 TRF3750

The TRF3750 is a PLL chip used in the synthesizer section to generate the LO frequency required for the

I/Q modulator.

Key Texas Instruments Components

4 Software Installation

5 Software Operation

This section summarizes the installation procedures for the software required to operate the Demo Kit.

Once all of the software is loaded, it is recommended to reboot the computer.

• Extract TSW3000-Installv2p0.zip

• Execute setup.exe

The following describes the use of the software required to set the TSW3000 Demo Kit in the baseline

configuration for the CDCM7005, TRF3750, and DAC5687. The software should be configured in the

order presented below. The first step requires starting the TSW3000 software. This opens a window as

shown in Figure 3 . The tabs on the left side of the window allow selection of different GUI controllers for

the DAC5687, TRF3750, and CDCM7005. The lower left portion of the screen contains links to this user's

guide as well as the data sheets for the DAC5687, TRF3750, and the CDCM7005.

SLWU013A – March 2004 – Revised September 2005 9

Page 10

www.ti.com

Software Operation

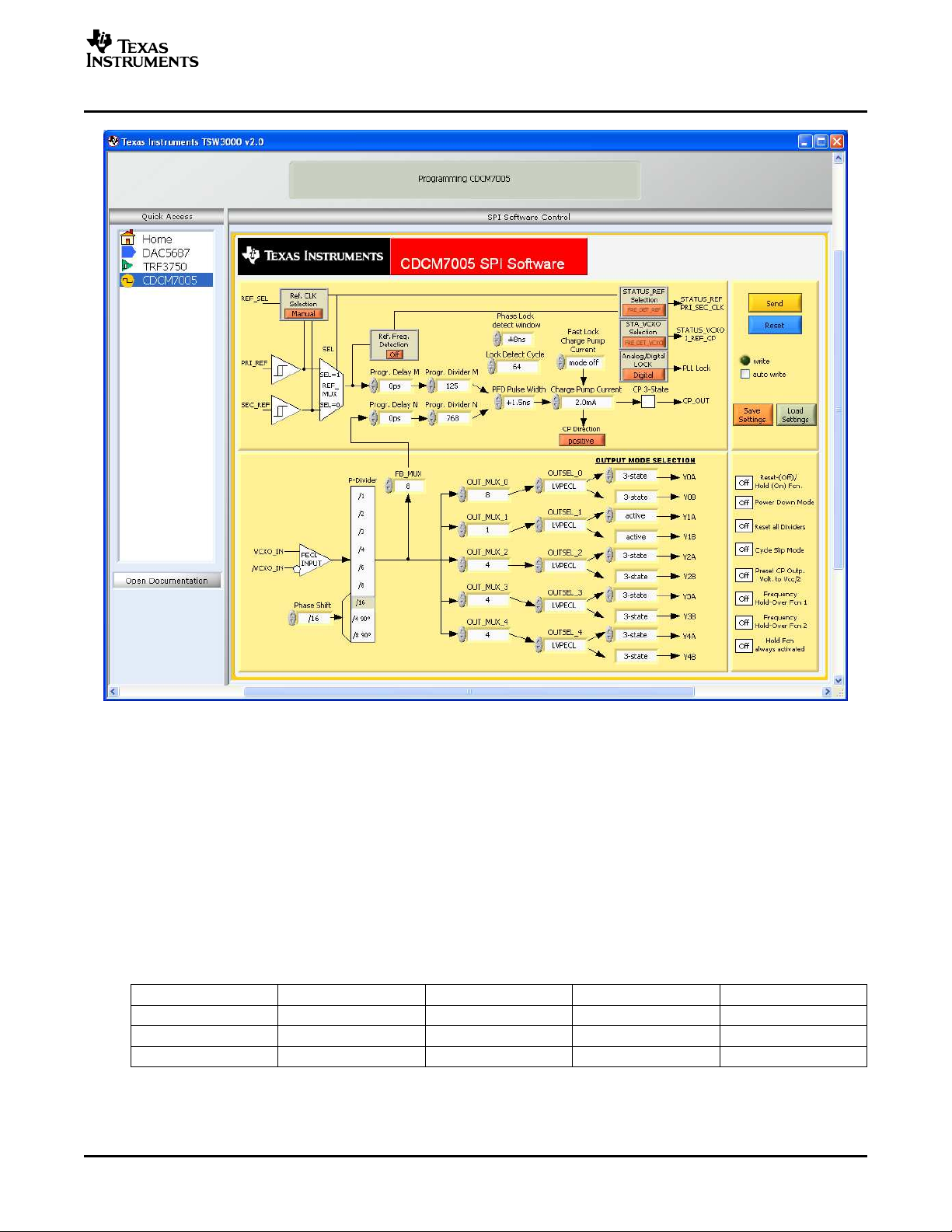

5.1 CDCM7005 Software

By using the provided CDCM7005 serial peripheral interface (SPI) software, the user can load settings to

the CDCM7005 internal registers. This must be performed every time the TSW3000 Demo Kit is powered

up, since the CDCM7005 has default settings that are loaded at power up and the settings may be slightly

different than the ones required to operate the Demo Kit. Executing the program brings up the interface

seen in Figure 4 . The default settings are correct for a VCXO of 491.52 MHz and a 10 MHz reference as

on the TSW3000. The CDCM7005 GUI allows register settings to be saved and can be loaded back in

afterwards. This can be accomplished with the Save and Load Settings buttons near the right side of the

GUI.

It is recommended that any unused output clocks be tri-stated. In this case the TSW3000 only uses

OUT_MUX_1 to drive the DAC5687. OUT_MUX_0, OUT_MUX_2, OUT_MUX_3, OUT_MUX_4 should be

tri-stated unless there is a need to use the other output clocks.

Figure 3. TSW3000 Startup Screen

10 SLWU013A – March 2004 – Revised September 2005

Page 11

www.ti.com

Software Operation

Figure 4. Default CDCM7005 SPI GUI

The divider parameters, M and N, are determined according to the following equation based on the

internal reference frequency and internal VCXO frequency.

F

= (F

REF

VCXO

× M)/(N × P)

The p parameter is the VCXO input divider and set through the FB_MUX value. The M and N counter

values need to be adjusted depending on the board configuration. The M and N counter registers are

determined by the reference frequency and the VCXO frequency. The OUT_MUX sets the divide ratios for

the individual output clocks. The OUTSEL determines whether the output clocks will be used as

single-ended CMOS or differential LVPECL. With a 10-MHz reference oscillator the CDCM7005 settings

are shown in Table 2 for a variety of common VCXO frequencies. For other frequencies, see to the

CDCM7005 data sheet for more details.

Table 2. CDCM7005 Register Values

VCXO Freq. (MHz) 491.52 245.76 122.88 61.44

Divider M 125 125 125 125

Divider N 768 768 768 768

FB_MUX 8 4 2 1

SLWU013A – March 2004 – Revised September 2005 11

Page 12

www.ti.com

Software Operation

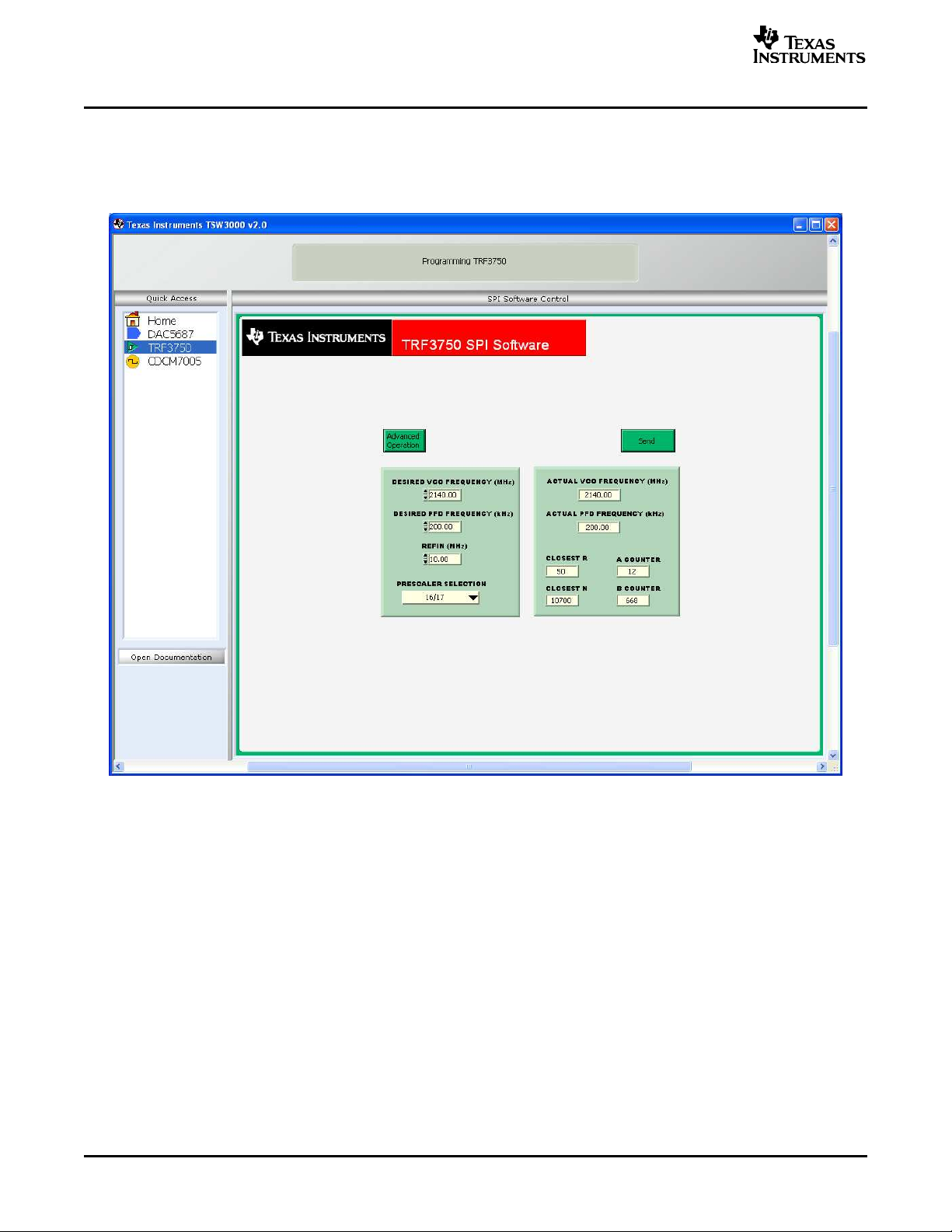

5.2 TRF3750 Software

The TRF3750 software is used to program the PLL chip to lock the VCO oto a desired frequency output.

The main menu of the program is shown in Figure 5 .

Figure 5. TRF3750 GUI - Main Menu

The options in the front panel allow the user to program the desired frequency of the VCO, the desired

frequency of the PFD, the reference frequency, and the prescaler selection. The software then displays

the actual VCO frequency, PFD frequency and the R, N, A, and B counter values to be programmed into

the TRF3750. Hitting the Send button writes these values to the TRF3750. In default mode on a default

board, only the desired VCO frequency (2100 MHz to 2200 MHz) needs to be changed. For other VCO

ranges, other parameters may need to be changed.

The Advanced Operation button will bring up another user interface as shown in Figure 6 .

12 SLWU013A – March 2004 – Revised September 2005

Page 13

www.ti.com

Software Operation

5.3 DAC5687 Software

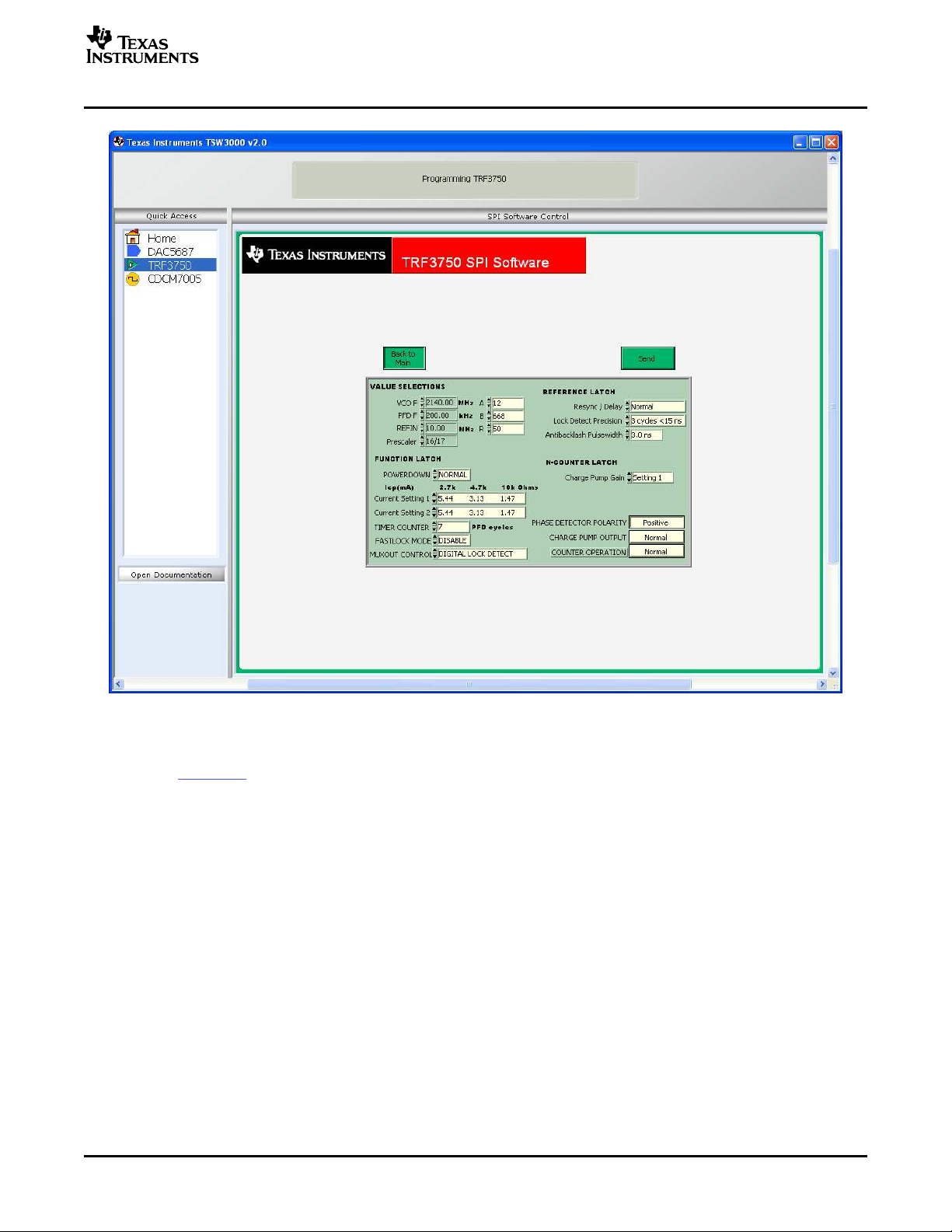

Figure 6. TRF3750 GUI - Advanced Menu

This menu allows control of more register settings. For details on these settings, see the TRF3750 data

sheet (SLWS146 ). The register of interest in this menu is the MUXOUT CONTROL which can be used to

determine the function of LED D4. This mode defaults to Digital PLL Lock Detect and causes the LED D4

to light up when the PLL successfully locks. Normally, these menu settings do not need to be changed.

By using the provided software, the user can write and read control register information to the DAC5687.

At first startup of this software, it is imperative to select the Pll Port Config button to bring up the parallel

port configuration settings. From the menu, select the TSW3000 setting. This configures the port to be

compatible with the TSW3000. Once the Demo Kit is powered on with the parallel port configured and

connected properly, then the GUI shown in Figure 7 is displayed with the default settings read from the

device. If there is a problem with the communication, such as the Demo Kit is not powered on or the

parallel port cable is not connected, an error message will be displayed instructing the user to correct the

problem. Once corrected, hit the Read All button to read the default settings of the device.

SLWU013A – March 2004 – Revised September 2005 13

Page 14

www.ti.com

Software Operation

For normal operation, the user needs only to select values and switches as desired. The values are

automatically sent to the device and read back to verify their configuration.

5.4 DAC5687 GUI Register Descriptions

5.4.1 Register Controls

• Load Regs– Loads register values from a saved file to the DAC5687 and updates the GUI.

• Save Regs– Saves current GUI registers settings to a text file for future use.

• Read All– Reads the current registers of the DAC5687. This is used to verify settings on the front

panel.

• Send All– Sends the current front panel registers to the device. This is generally only used when the

Demo Kit power has recycled or the device has been reset and the user wants to load the displayed

settings to the device.

5.4.2 Configuration Controls

• Full Bypass– When set, all filtering, QMC, and NCO functions are bypassed.

• FIR Bypass– Bypass all interpolation filters. QMC INCO functional. Limited to FDAC = 250 MHz

• FIFO Bypass– When set to bypass, the internal four sample FIFO is disabled. When cleared, the FIFO

is enabled.

• FIR A– A side first FIR filter in high-pass mode when set, low-pass mode when cleared.

Figure 7. DAC5687 GUI

14 SLWU013A – March 2004 – Revised September 2005

Page 15

www.ti.com

Software Operation

• FIR B– B side first FIR filter in high-pass mode when set, low-pass mode when cleared.

• Dual Clk– Only used when the PLL is disabled. When set, two differential clocks are used to input the

data to the chip; CLK1/CLK1C is used to latch the input data into the chip, and CLK2/CLK2C is used

as the DAC sample clock.

• Interleave– When set, interleaved input data mode is enabled; both A and B data streams are input at

the DA(15:0) input pins.

• Inverse Sinc– Enables inverse sinc filter.

• Half Rate Input– Enables half rate input mode. Input data for the DAC A data path is input to the chip

at half speed using both the DA(15:0) and DB(15:0) input pins.

• Sif– Sets sif_4-pin bit. A 4-pin serial interface mode is enabled when on, 3-pin mode when off. The

DAC5687 Demo Kit is configured for a 3-pin serial interface, so setting to a 4-bit serial interface makes

reading registers impossible with the GUI.

• Inv. PLL Lock– Only used when PLL is disabled and dual clock mode is disabled. When cleared, input

data is latched into the chip on rising edges of the PLLLOCK output pin. When set, input data is

latched into the chip on falling edges of the PLLLOCK output pin.

• PLL Freq– Sets PLL VCO center frequency to low or high center frequency.

• PLL Kv– Sets PLL VCO gain to either high or low gain.

• Qflag– Sets qflag bit. When set, the QFLAG input pin operates as a B sample indicator when

interleaved data is enabled. When cleared, the TXENABLE rising determines the A/B timing

relationship.

• 2's Comp– When set, input data is interpreted as 2's complement. When cleared, input data is

interpreted as offset binary.

• Rev A Bus– When cleared, DA input data MSB to LSB order is DA(15) = MSB and DA(0) = LSB.

When set, DA input data MSB to LSB order is reversed, DA(15) = LSB and DA(0) = MSB.

• Rev B Bus– When cleared, DB input data MSB to LSB order is DB(15) = MSB and DB(0) = LSB.

When set, DB input data MSB to LSB order is reversed, DB(15) = LSB and DB(0) = MSB.

• USB– When set, the data to DACB is inverted to generate upper side band output.

• Inv. Clk I(Q)– Inverts the DAC core sample clock when set, normal when cleared.

• Sync_Phstr– When set, the internal clock divider logic is initialized with a PHSTR pin low to high

transition.

• Sync_cm– When set, the coarse mixer is synchronized with a PHSTR low-to-high transition.

• Sync_NCO– When set, the NCO phase accumulator is cleared with a phstr low-to-high transition.

• Phstr Clk Div Select– Selects the clock used to latch the PHSTR input when restarting the internal

clock dividers. When set, the full rate CLK2 signal latches PHSTR and when cleared, the divided down

input clock signal latches PHSTR.

• DAC Serial Data– When set, both DAC A and DAC B input data is replaced with fixed data loaded into

the 16-bit serial interface DAC Static Data.

– Counter Mode– Controls the internal counter that can be used as the DAC data source: {off; all

16b; 7b LSBs; 5b MIDs; 5b MSBs}.

– DAC Static Data– When DAC Serial Data is set, both DAC A and DAC B input data is replaced

with fixed data loaded with this value. Range = 0 - 65535.

• Alt. PLLLOCK Output– Can be used to determine alternate outputs on the PLLLOCK pin when using

the internal PLL mode. The EXTLO pin must be open when using this mode.

• NCO– When set, enables NCO.

– NCO Gain– Sets NCO gain resulting in a 2x increase in NCO output amplitude. Except for Fs/2 and

Fs/4 mixing NCO frequencies, this selection can result in saturation for full-scale inputs. Consider

using QMC gain for lower gains.

• QMC– When set, enables the QMC.

– QMCA Gain– Sets QMC gain A to a range = 0 to 2047. See the data sheet for more information.

– QMC B Gain– Sets QMC gain B to a range = 0 to 2047. See the data sheet for more information.

– QMC Phase– Sets QMC phase to a range = -512 to 511. See the data sheet for more information.

Used to adjust for I/Q phase imbalance.

• Mode– Used to select the coarse mixer mode. See the DAC5687 data sheet for more information.

SLWU013A – March 2004 – Revised September 2005 15

Page 16

www.ti.com

Board Setup

• PLL Divider– Sets VCO divider to div by 1, 2, 4, or 8.

• Interpolation – Sets FIR Interpolation factor: {X2, X4, X4L, X8}. X4 uses lower power than 4xL, but

F

dac

• Phstr Init. Phase – Adjusts the initial phase of the fs/2 and fs/4 cmix block at PHSTR.

• Sync FIFO– Sync source selection mode for the FIFO. When a low to high transition is detected on

the selected sync source, the FIFO input and output pointers are initialized. See the DAC5687 data

sheet for source description.

5.4.3 DAC A(B) Gain

• DAC Coarse Gain– Sets coarse gain of DAC A(B) full-scale current. Range is 0 to 15. See the

DAC5687 data sheet for full-scale gain equation.

• DAC Fine Gain– Sets fine gain of DAC A(B) full scale current. Range is -128 to127. See the DAC5687

data sheet for full-scale gain equation. Used to adjust for I/Q amplitude imbalance.

• DAC DCOffset– Sets DAC A(B) dc-offset register. Range is -4096 to 4095. Used to adjust for carrier

suppression.

• Sleep– DAC A(B) sleeps when set, operational when cleared.

5.4.4 NCO

• NCO DDS– Sets NCO DDS registers. See the DAC5687 data sheet for formula.

• NCO Phase– Sets initial NCO phase registers. See the DAC5687 data sheet for more information.

• F

DAC

= 320 MHz max when NCO or QMC are used.

(MHz), NCO IF (MHz)– Used to calculate the required NCO DDS value.

5.4.5 Additional Control/Monitor Registers

• Version– Displays the version of the silicon. If a version of 0 is read then the communication is not

functioning and an error message will be displayed.

6 Board Setup

6.1 Jumper Settings

The TSW3000 Demo Kit has on-board jumpers that allow the user to selectively disengage devices as

desired. The unit is shipped with jumpers in place that activate all of the devices on board. Table 3

explains the functionality of the jumpers on the board.

JUMPER LABEL FUNCTION CONDITION DEFAULT

W1 PLL Lock 2-pin access port for monitoring PLL lock of the Open Installed

W2 PWD Power down for the TRF370x Powered Pin 1, 2

W6 LO Buffer Disengages power to LO buffer amp Powered Installed

W5 IOVDD Toggles 3.3 V or 1.8 V to IOVDD on the DAC5687 3.3 V Engaged Pin 1, 2

J15 pin 2 PLLVDD Toggles power to the DAC PLL Not Powered Pin 1, 2

J15 pin 5 SLEEP Power down for the DAC5687 Open Removed

J15 pin 8 EXTLO Toggles internal reference ground Grounded Pin 7, 8

J15 pin 11 TXENABLE Selects interleaved data Powered Pin 11, 12

J15 pin 14 TESTMODE DO NOT POPULATE! Open Removed

J15 pin 17 QFLAG Used to flag the DAC5687 channel B data in Open Removed

J15 pin 20 CDC_PD Power down of the CDCM7005 Open Removed

J15 pin 23 REF_SEL Selecets reference for CDCM7005 Open Removed

Table 3. Jumper List

DAC5687

interleave mode

16 SLWU013A – March 2004 – Revised September 2005

Page 17

www.ti.com

6.2 Input/Output Connectors

The input and output connections are shown in Table 4 .

Demo Kit Test Configuration

Table 3. Jumper List (continued)

JUMPER LABEL FUNCTION CONDITION DEFAULT

J15 pin 27 PLL_PWD Power down the TRF3750 Powered Pin 26, 27

J15 pin 29 RESET Resets the DAC5687 when low Open Removed

Table 4. Input/Output Connections

REFERENCE DESIGNATOR CONNECTOR TYPE DESCRIPTION

J13 34-pin header I channel data input

J14 34-pin header Q channel data input

J9 SMA RF output

J10 SMA Optional LO input

J8 SMA Optional external reference

J2 SMA Output clock 1 from CDCM7005

J3 SMA Output clock 2 from CDCM7005

J5 SMA Optional I out A from DAC5687

J19 SMA Optional Q out B from DAC5687

J6 SMA Input for external VCXO for CDCM7005

J7 SMA PLL lock status on DAC5687

J4 SMA Phase synchronization on DAC5687

RF shield covers should be in place over the synthesizer section and the RF modulator section. These

shields provide isolation of the RF sections on the board.

6.3 Parallel Port

The TSW3000 Demo Kit contains a 25-pin parallel port connector (J1) to interface to a standard computer

parallel port. Programming of the CDCM7005, DAC5687, and TRF3750 are accomplished through this

port.

6.4 DC Power Requirements

The Demo Kit requires a single dc-voltage supply that is nominally 6 V. From that supply, the 5 V, 3.3 V,

and 1.8 V required for the devices on the board are generated internally through linear voltage regulators.

It is possible to use a higher input voltage; however, care should be taken not to over dissipate the

on-board voltage regulators.

7 Demo Kit Test Configuration

SLWU013A – March 2004 – Revised September 2005 17

Page 18

www.ti.com

TSW3000

EVM DUT

J7

Clock

Power

Supply

GND

+6 V

16

25

J9

Pattern

Generator

16

J17 J11

PC Controller

J14

J13

J1

Spectrum

Analyzer

Demo Kit Test Configuration

7.1 Test Setup Block Diagram

The test set up for general testing of the TSW3000 Demo Kit is shown in Figure 8 .

Figure 8. Test System Block Diagram

7.2 Test Equipment

7.3 Calibration

7.4 Test Specifications

The following is a list of the test equipment required for testing the TSW3000 Demo Kit. Equivalent models

may be used for certain applications, but may produce different results due to limitations within the

instrument.

• Dual Power Supply: Any with current readout capability

• Spectrum Analyzer: Rhode & Schwartz FSU, Agilent PSA, or equivalent

This particular piece can measure >70-dBc ACPR with the noise cancellation option active. This

amount of dynamic range is required to accurately measure the ACPR of the Demo Kit. Another

spectrum analyzer can be substituted if it achieves as good or better dynamic range.

• Pattern Generator: Agilent 16702B

• Oscilloscope: Tektronix 650 or equivalent

Used to probe clock output signals and for debugging.

• Digital Voltmeter: Agilent 34401A or equivalent

In order to record proper output power the insertion loss of the output cable must calibrated. Measure the

insertion loss of the cable from J9 to the spectrum analyzer; set the analyzer's reference level offset to

that value.

The test specifications are outlined in Table 5 .

Table 5. Demo Kit Specifications

CURRENT

+6 V 1.5 A

CW TESTS

Carrier suppression 30 dBc

MIN MAX UNITS

18 SLWU013A – March 2004 – Revised September 2005

Page 19

www.ti.com

8 Basic Test Procedure

Basic Test Procedure

Table 5. Demo Kit Specifications (continued)

MIN MAX UNITS

Sideband rejection 25 dBc

Spurious Output

2nd harmonic 45 dBc

Aliased LSB (pos) 40 dBc

Output clock 40 dBc

Aliased USB 15 dBc

Aliased USB (neg) 8 dBc

WCDMA ACPR

Channel power -14 dBm

ACPR -Low 70 dBc

ACPR -High 70 dBc

This section outlines the basic test procedure to get the Demo Kit operational. Disconnect the cables at

J13 and J14 that connect to the pattern generator. Connect the power supply cable and the RF output to

the spectrum analyzer.

8.1 Initial Inspection

Inspect the board to determine which devices were used.

• Note the VCXO frequency (U10) that is on the board

• Note the VCO frequency band (Y3) that is on the board

8.2 Engage Power Supplies

Engage 6-V power supply

• Verify the current reading is between 0.8 A to 1.3 A when configured with the DAC5687

8.3 Program the CDCM7005

Use the Default Settings on the CDCM7005 GUI (See Section 5.1 ). This generates a 491.52-MHz clock.

• Set the OUT_MUX_0, 2, 3, 4 to tristate. Only OUT_MUX_1 is used for clocking the DAC5687

• Hit the GUI Send button

• Verify that LEDs D1, D2, and D3 are illuminated

8.4 Program the TRF3750

Use the Default Settings in the TRF3750 GUI (See Section 5.2 ). This places a carrier at 2.14 GHz

• Hit the GUI send button.

• Verify the LED D4 is illuminated. This indicates lock of the VCXO and TCXO reference.

• Monitor RF output from the spectrum analyzer

• Verify a single frequency tone at the default 2.14 GHz.

Table 6. Frequency Designations

VCO BAND UMTS GSM900 PCS DCS1800

Midband (MHz) 2140 950 1960 1850

Low (MHz) 2110 935 1930 1805

SLWU013A – March 2004 – Revised September 2005 19

Page 20

www.ti.com

Basic Test Procedure

8.5 DAC5687 Program

Table 6. Frequency Designations (continued)

VCO BAND UMTS GSM900 PCS DCS1800

High (MHz) 2170 960 1990 1880

• Disable the PLL by removing the jumper at J15, pins 2 and 3, if not already removed.

• Verify DACA and DACB Coarse Gain is set to 15

• Set Mode to 0000 (No Coarse Mixing)

• Ensure DAC Offsets and DAC fine gain for both A and B are set to 0

• Set the spectrum analyzer as follows:

– Center Freq: 2.14 GHz

– RBW: 30 kHz, VBW: 300 kHz

– Span: 491.52 MHz

– Attn: 5 dB

– Ref Level: 10 dBm

20 SLWU013A – March 2004 – Revised September 2005

Page 21

www.ti.com

Basic Test Procedure

8.6 Carrier Suppression

The carrier suppression can be tuned for better performance by adjusting the dc-offset controls on the

DAC5687. The default DAC GUI is shown below with the NCO mixer turned on to output a 61.44-MHz

tone. The output spectrum is illustrated in Figure 10 .

Figure 9. Default DAC GUI With f

SLWU013A – March 2004 – Revised September 2005 21

/8 Tone From NCO

DAC

Page 22

www.ti.com

Basic Test Procedure

8.7 Sideband Rejection

Figure 10. Single Sideband Spectrum Output Before DAC Offset and QMC Adjustments

An iterative process is used to achieve the best performance.

• Place a normal marker at the peak upper sideband, place a delta marker at the carrier signal, and note

the initial delta value.

• Set initial DACA offset to 1000 and DACB offset to -1000

• Change DACA offset by 1000 steps and monitor the output performance change.

• If performance gets better, then repeat the process with an additional 1000 steps. If the performance

gets worse or doesn't change, then change the offset in the other direction by 1000 steps.

• Once the performance remains basically unchanged, repeat the process on DACB offset with 1000

step changes.

• Once optimized, go back to the A side and repeat the tuning process with a step size of 100.

• Continue tuning. After each complete cycle, reduce the step size down (i.e., to 10, then to 1 if desired).

• A performance greater that 65 dBc should be achievable.

Sideband rejection is determined by the two quadrature signals to the modulator being exactly 180

degrees out of phase and exactly the same amplitude. Amplitude and phase imbalance between the two

paths yield an unwanted lower sideband. The amplitude variation between the two paths can be

compensated for by adjusting the DAC fine gain controls or by adjusting the QMC gain controls if the

device is operating with the QMC on. The phase can be compensated by using the QMC phase

adjustment. Note this is only possible when the coarse mixer is not used in the f

mixing in the f

f

/2 mode there are no cross terms (terms are 0) and the relative phase information is maintained

DAC

/4 mode causes the relative phase information between I and Q paths to be mixed. In the

DAC

/4 mode. Coarse

DAC

between I and Q paths.

22 SLWU013A – March 2004 – Revised September 2005

Page 23

www.ti.com

Basic Test Procedure

• Place marker delta on the lower sideband

• Turn on the QMC. Set the Gain of the QMC to 1024 for gain of 0 dB for I and Q paths. Other initial

settings may be needed depending on the state of the NCO gain and signal amplitude.

• Change the phase of the QMC by small increments until the sideband is minimized.

• Change the QMC A or B gains in increments of 1 until the sideband is minimized.

• The overall performance should be greater than 60 dBc from the other sideband with amplitude and

phase corrections.

• Re-optimized the dc-offset values as required to maintain carrier suppression performance as

specified.

Figure 11. DAC GUI With Typical Settings To Minimize LO and Sideband

Sideband and LO are reduced into the noise floor. Clock related spurs can be filtered out using an RF

filter.

SLWU013A – March 2004 – Revised September 2005 23

Page 24

www.ti.com

Optional Configurations

9 Optional Configurations

9.1 External LO

To configure the board for external LO implement the following modifications

• Remove R225

• Place R2: 0- Ω resistor, this connects the external LO on J10 to the TRF3702 modulator

• Remove W6 (disengages power to RF amplifier)

• Disable the TRF3750 PLL CE by setting J15-25, 26. This puts GND on CE of the TRF3750 and

disables the PLL.

9.2 External Reference

To configure the board for an external reference implement the following modifications.

• Remove R144, this disconnects the on board 10-MHz reference

• Place R201: 0- Ω resistor, external reference can be hooked up to J8

9.3 Monitor DAC Output

Figure 12. Sideband and LO

24 SLWU013A – March 2004 – Revised September 2005

Page 25

www.ti.com

9.3.1 Single Ended

To configure the board to monitor the DAC output by utilizing the transformers on board to achieve a

single-ended output, implement the following modifications.

• Remove R187, R188, R191, R190, R208, R209, R210, R211

• Place R200, R224, R222, R223: 0- Ω resistors

• Place R179, R183, R212, R213: 100- Ω resistor. This configures the DAC output as in the DAC5687

data sheet for 4:1 impedance transformer.

Monitor outputs at J5 and J19.

10 Filter Specifications

10.1 Baseband Filter

The TSW3000 Demo Kit layout provides the opportunity to place components to realize up to a 7thorder

LC filter. The Demo Kit is by default populated with a 500-MHz LC low-pass filter to help eliminate DAC

images and also out of band clock spurs which may mix into RF frequencies.

10.1.1 RF Filter/Output Match

The TSW3000 Demo Kit layout also provides the opportunity to place a small 3

output of the modulator for either filtering or impedance matching purposes. This filter has been disabled

by removing the shunt capacitive elements and replacing the series inductor element with a 0- Ω resistor.

Filter Specifications

rd

order LC filter on the

11 Layers and Schematics

This chapter contains the layers and schematics for the TSW3000 Demo Kit.

SLWU013A – March 2004 – Revised September 2005 25

Page 26

www.ti.com

Layers and Schematics

11.1 Layers

The Demo Kit is constructed on a 6-layer, 6.2 inch x 8 inch, 0.062-inch thick PCB using FR-4 material.

See Figure 13 through Figure 22 show the PCB layout for the Demo Kit.

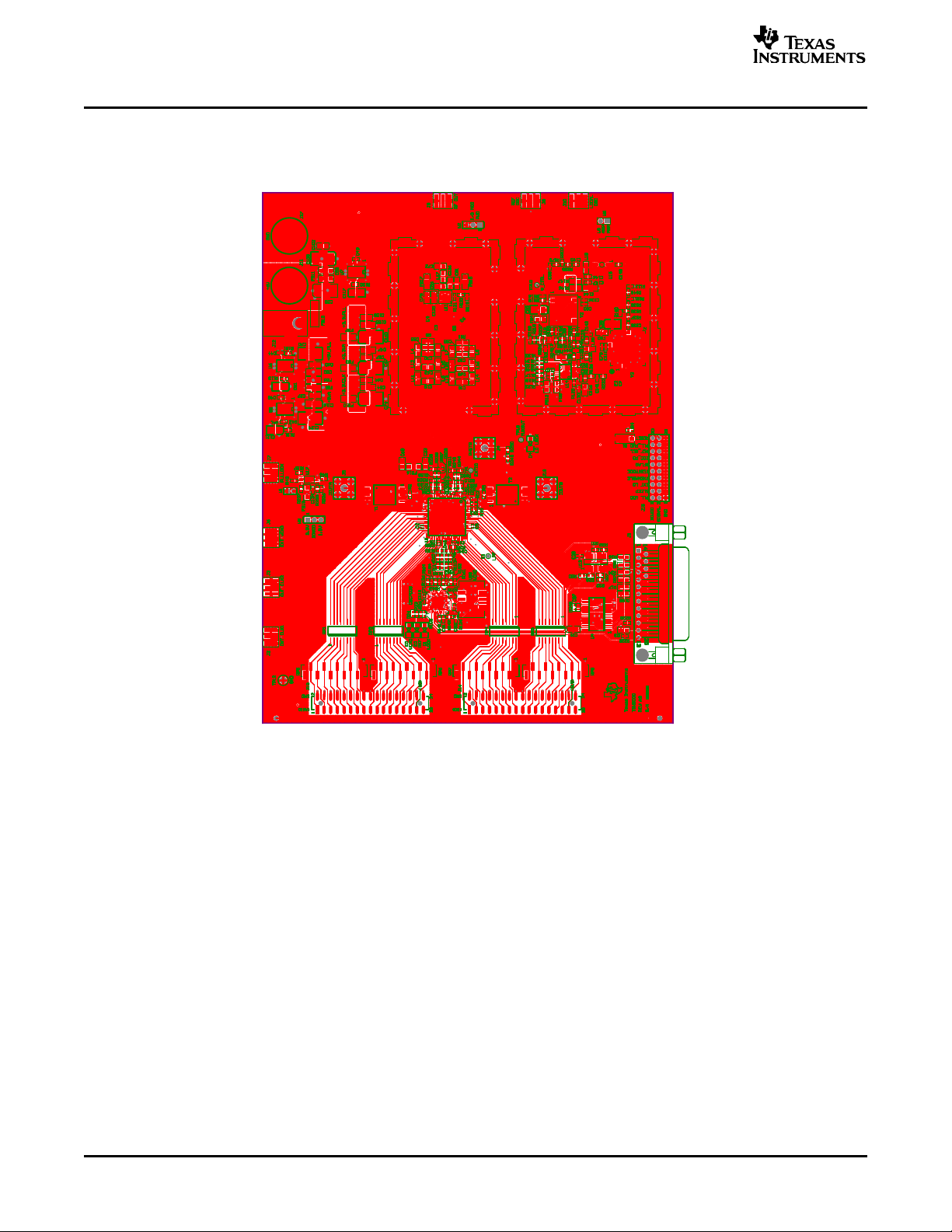

Figure 13. Top Layer

26 SLWU013A – March 2004 – Revised September 2005

Page 27

www.ti.com

Layers and Schematics

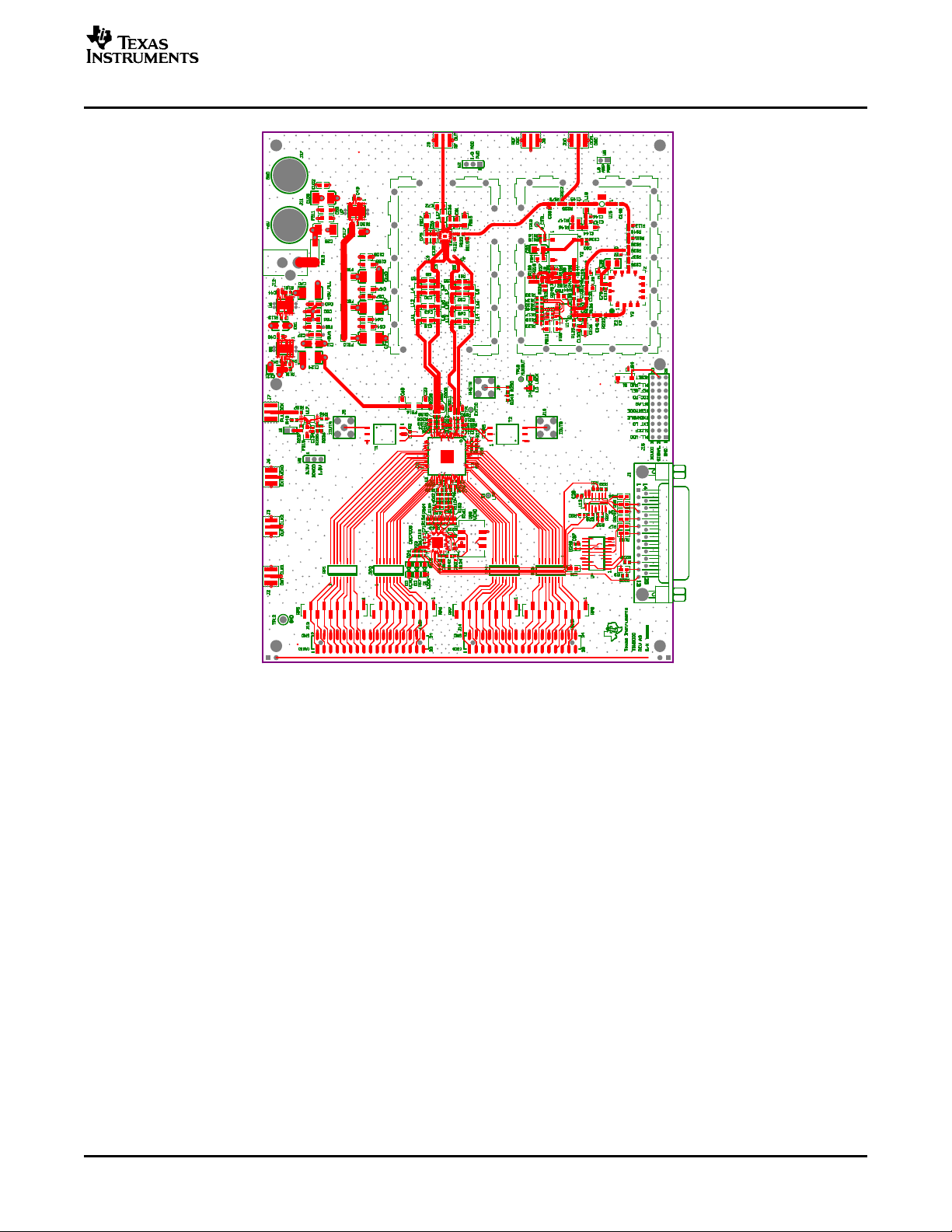

Figure 14. Top Layer (NH)

SLWU013A – March 2004 – Revised September 2005 27

Page 28

www.ti.com

Layers and Schematics

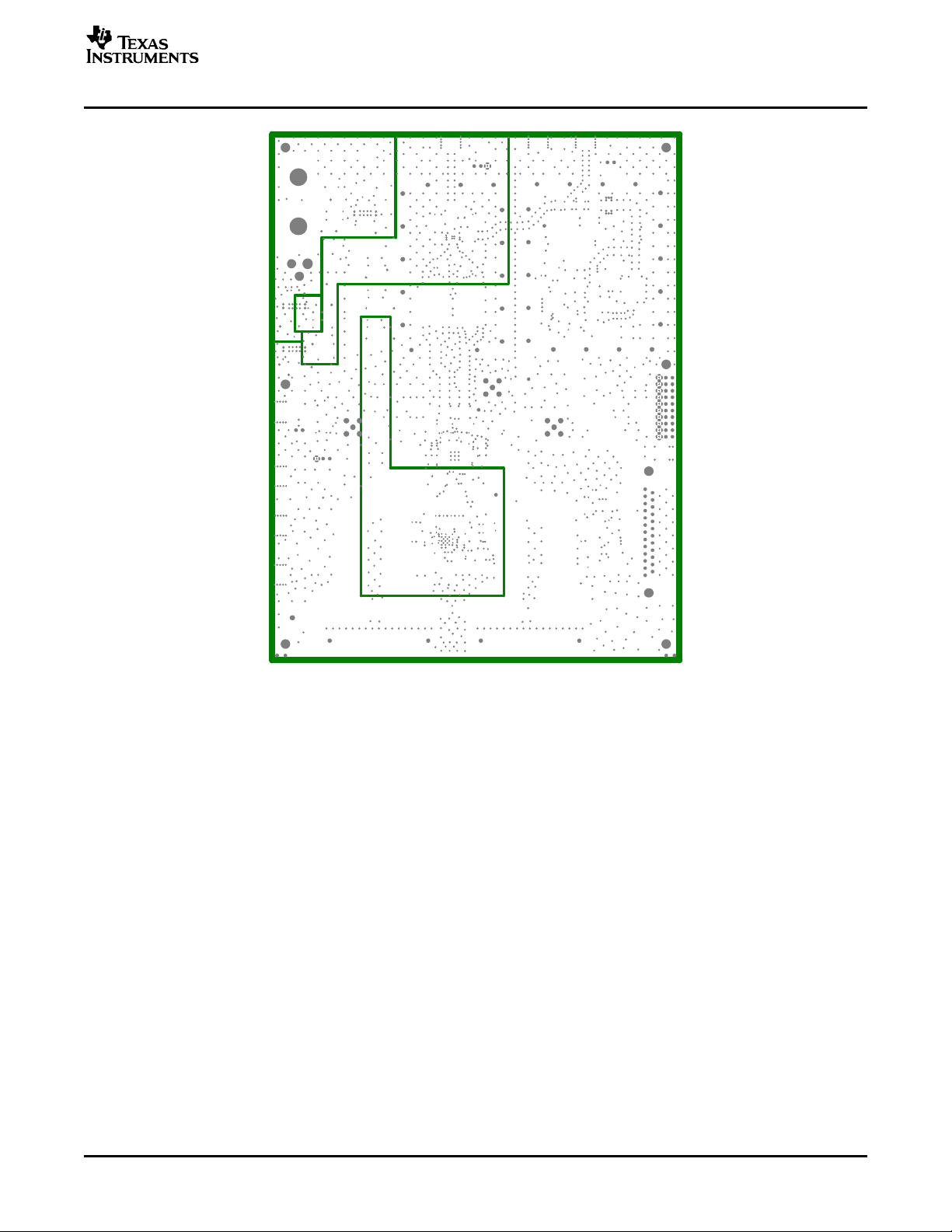

Figure 15. Layer 2

28 SLWU013A – March 2004 – Revised September 2005

Page 29

www.ti.com

Layers and Schematics

Figure 16. Layer 3

SLWU013A – March 2004 – Revised September 2005 29

Page 30

www.ti.com

Layers and Schematics

Figure 17. Layer 4

30 SLWU013A – March 2004 – Revised September 2005

Page 31

www.ti.com

Layers and Schematics

Figure 18. Layer 4 (NH)

SLWU013A – March 2004 – Revised September 2005 31

Page 32

www.ti.com

Layers and Schematics

Figure 19. Layer 5

32 SLWU013A – March 2004 – Revised September 2005

Page 33

www.ti.com

Layers and Schematics

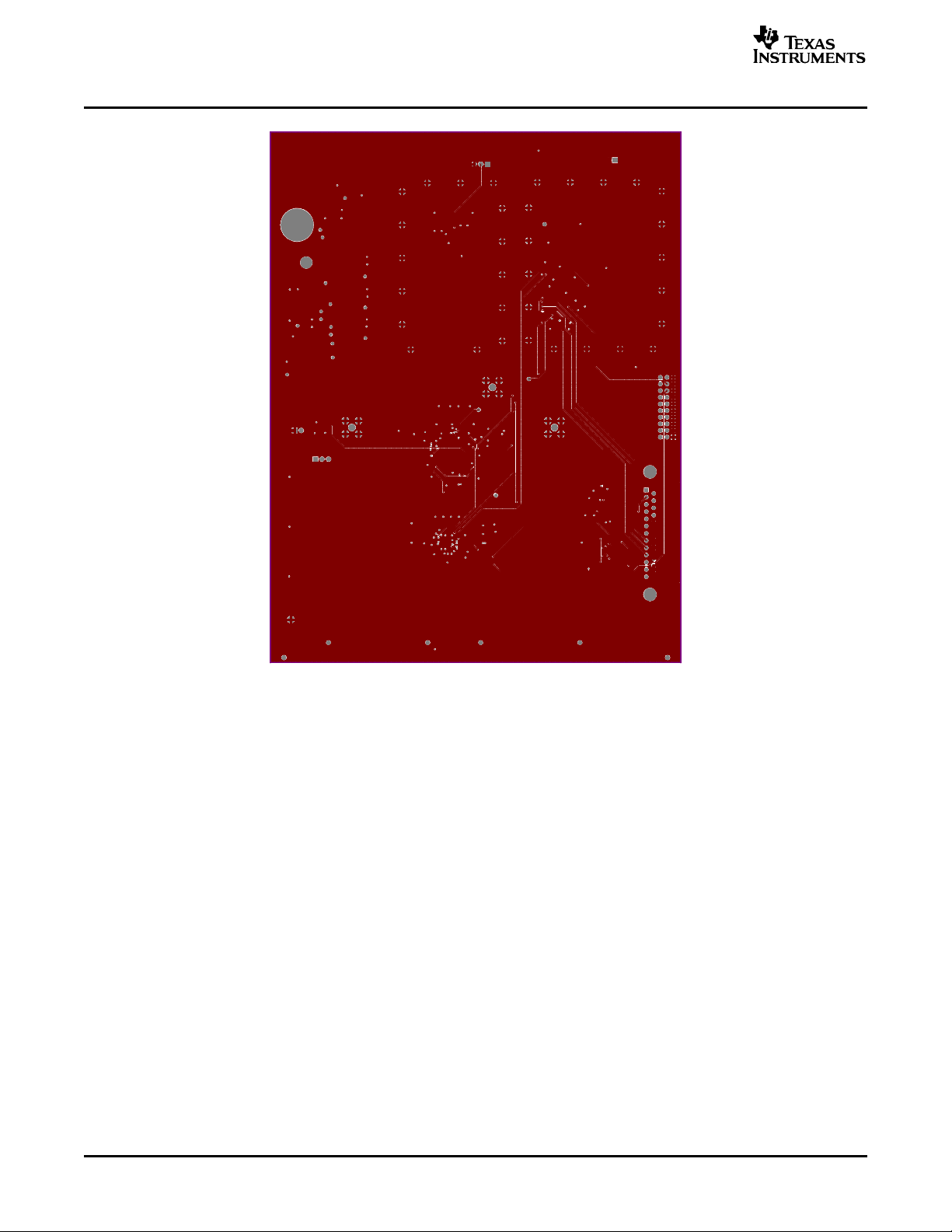

Figure 20. Bottom Layer

SLWU013A – March 2004 – Revised September 2005 33

Page 34

www.ti.com

Layers and Schematics

Figure 21. Bottom Silkscreen

34 SLWU013A – March 2004 – Revised September 2005

Page 35

www.ti.com

Layers and Schematics

Figure 22. Drill Drawing

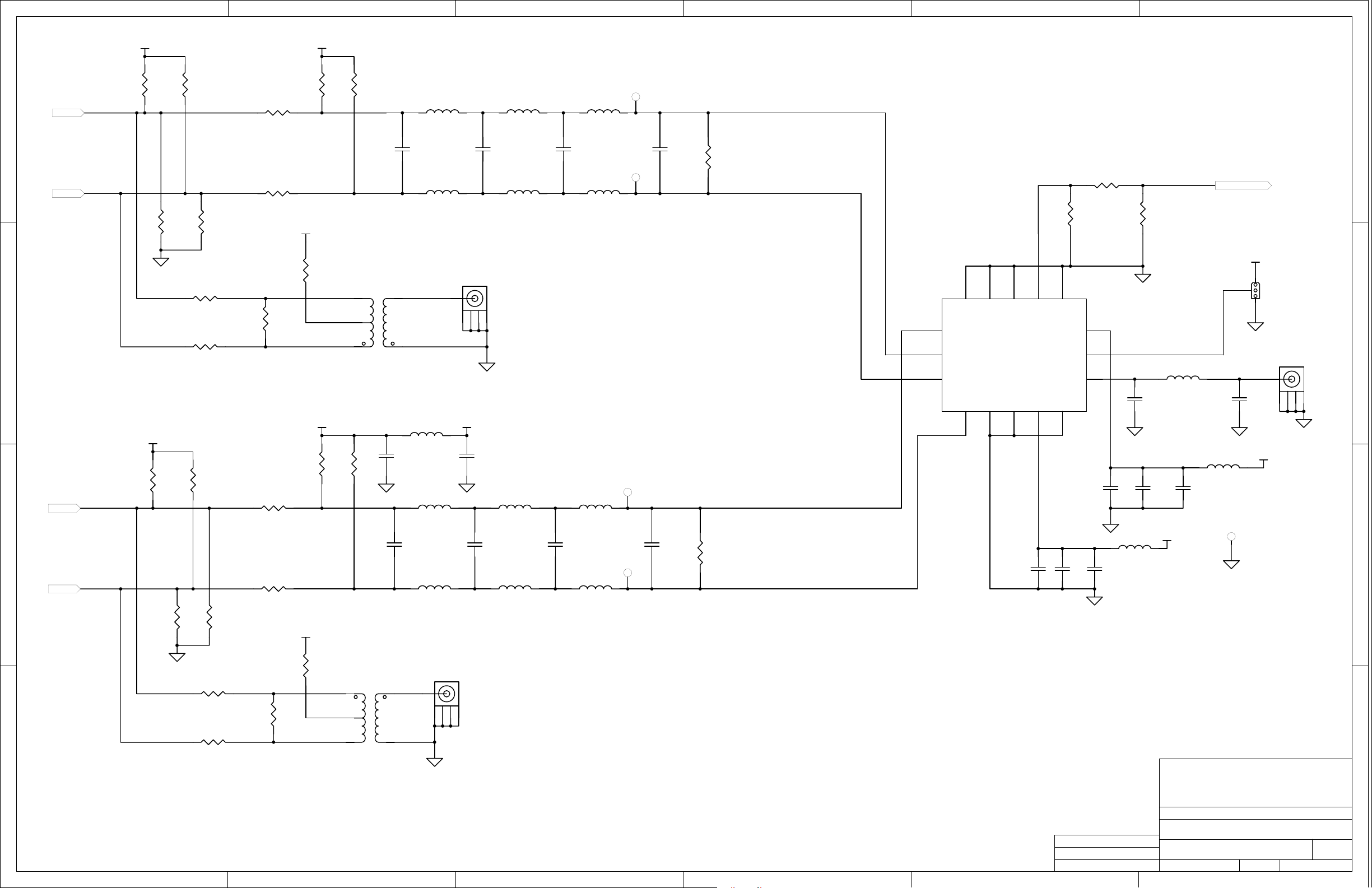

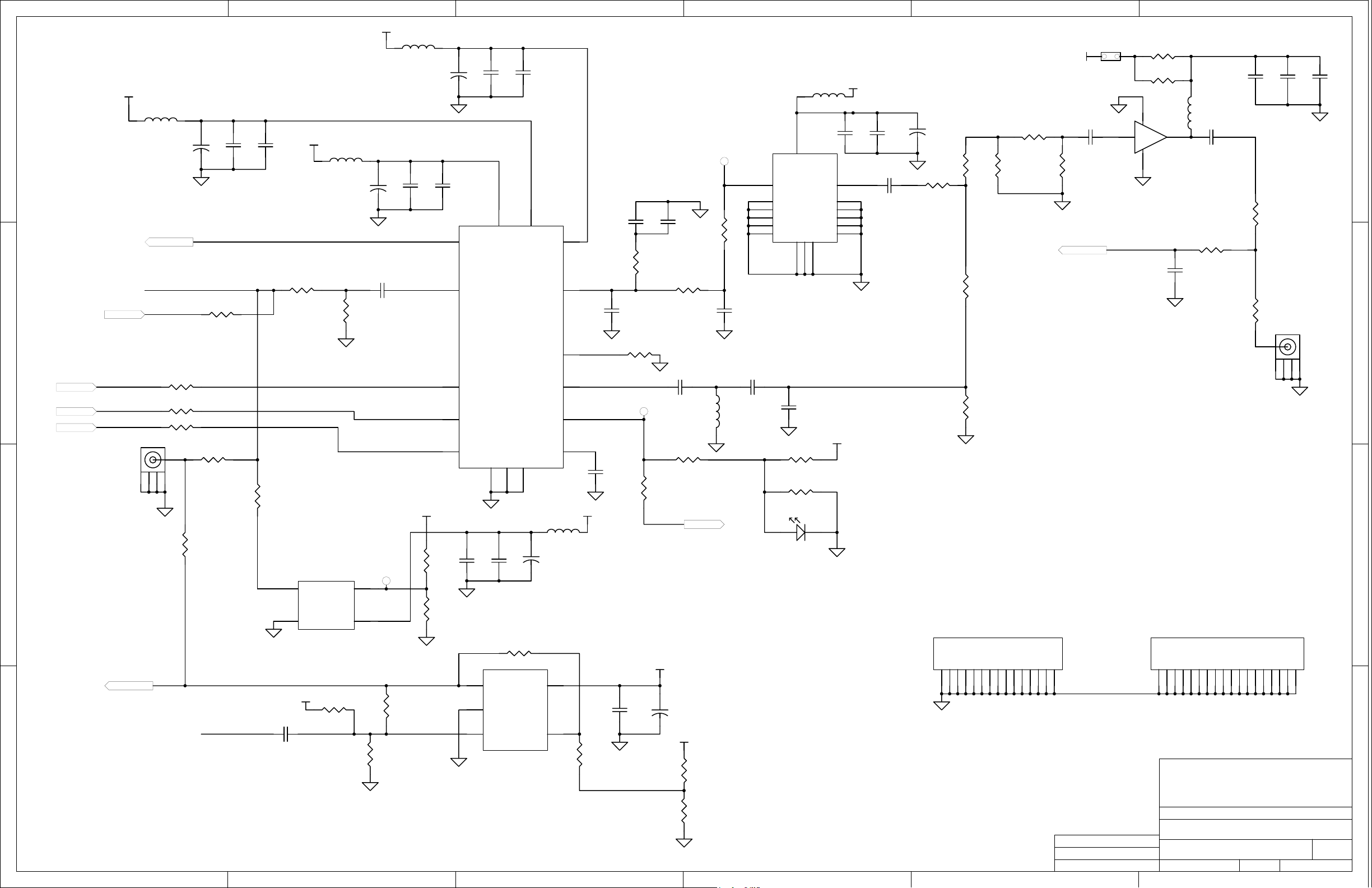

11.2 Schematics

The following figures show the schematic for the TSW3000 Demo Kit.

SLWU013A – March 2004 – Revised September 2005 35

Page 36

+3.3VA

C15

.1uF

C29

.1uF

C84

.1uF

C85

.1uF

C86

.1uF

C24

+

10uF, 10V

(SH 2)

EXT_LO

EXT_LO

TP1

54321

+1.8VD

+3.3VA

R4

1K

S1

R1

1K

6

D

+1.8VD

C38

+

10uF, 10V

(SH 5)

SDEN1

(SH 5)

(SH 5)

C

B

A

(SH 2)

TXENABLE

IOVDD

(SH 2)

SCLK

SDIO

C39

+

10uF, 10V

DA(0..15)

C1

.1uF

C37

+

10uF, 10V

C2

.1uF

SDEN1

SCLK

SDIO

TXENABLE

R40

49.9

NOTES:

1. DO NOT INSTALL

2. CHANGE TO 0 OHM FOR 50 OHM LOAD

1 2 3 4 56

C4

.1uF

DA15

DA14

DA13

DA12

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

C5

.1uF

.1uF

C17

C6

.1uF

+1.8VD

C7

.1uF

26

DVDD

27

DGND

28

SDENB

29

SCLK

30

SDIO

31

SDO

32

DVDD

33

TXENABLE

34

DA15

35

DA14

36

DA13

37

DVDD

38

DGND

39

DA12

40

DA11

41

DA10

42

DA9

43

DA8

44

DVDD

45

DGND

46

IOVDD

47

IOGND

48

DA7

49

DA6

50

DA5

R255

10

+3.3VCLK

C41

10uF, 10V

C16

.1uF

+3.3VA +3.3VA

8

10

13

14

16

22

21

AGND

.1uF

C13

.1uF

19

20

AGND

IOUTA2

IOUTA1

18

AVDD

17

AGND

15

AVDD

AVDD

EXTLO

U1

DAC5687

KIT A

12

BIASJ

AGND

11

EXTIO

C14

.1uF

9

AVDD

AGND

7

AVDD

AGND

E1

C40

+

10uF, 10V

5

6

IOUTB2

70

23

24

25

AVDD

AVDD

AGND

DA451DA352DA253DA154DA055DVDD56DGND57CLKGND58CLK159CLK1C60CLKVDD61CLK262CLK2C63CLKGND64PLLGND65LPF66PLLVDD67DVDD68DGND69PLLLOCK

C3

+

2

3

1

4

AVDD

AVDD

AGND

AGND

IOUTB1

QFLAG

TESTMODE

SLEEP

/RESETB

PHSTR

IOVDD

IOGND

DB071DB172DB273DB374DB4

75

CLK2C

CLK2

CLK1C

CLK1

C8

.1uF

DVDD

DGND

DGND

DB15

DB14

DB13

DVDD

DGND

DB12

DB11

DB10

DB9

DB8

DVDD

DGND

DB7

DB6

DB5

93.1

R25

R45

100

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

C33

.01uF

R150

100

330pF

C46

C56

C34

.01uF

.033uF

C52

C62

DB4

DB3

DB2

DB1

DB0

.01uF

.01uF

SW-PB

RESET

C9

.1uF

QFLAG

TESTMODE

SLEEP

DB15

DB14

DB13

DB12

DB11

DB10

DB9

DB8

DB7

DB6

DB5

PLL_VDD

CLK2CB

CLK2B

CLK1CB

CLK1B

RESET

C10

.1uF

(Sh 2, 4)

C11

.1uF

R12

49.9

(Note 1)

IOVDD

DB[0..15]

PLL_VDD

CLK2CB

CLK2B

CLK1CB

CLK1B

C18

.1uF

(SH 2)

(SH 5)

(SH 5)

(SH 5)

(SH 5)

C12

.1uF

QFLAG

TESTMODE

SLEEP

R39

49.9

DB(0..15)

(SH 2)

R13

+3.3VA

1

2

3

(SH 2)

49.9

W5

(1-2)

IOUTA1

IOUTA2

IOUTB2

IOUTB1

(SH 2)

R249

0

PHSTR

+1.8VD

(SH 2)

(Note 1)

R250

0

PHSTR

(SH 2)

+3.3VA

1

2

+3.3VA

FB15

FERRITE

3 4

5

R235

110

(Note 1)

(Note 1)

J4

MCX

R236

221

C134

.1uF

C153

+

10uF, 10V

1

CLKIN

6

VDD/3.3V

2

OE

4

GND

IOUTA1

IOUTA2

IOUTB2

IOUTB1

U17

CDCV304

(SH 3)

(SH 3)

(SH 3)

(SH 3)

1Y0

1Y1

1Y2

1Y3

Engineer:

Drawn By:

FILE:

3

5

7

8

R46

R43

R237

22.1

R. HOPPENSTEIN

Y. DEWONCK

49.9

49.9

W1

R197

22.1

(Note 2)

1

2

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

SIZE: DATE: REV:

TSW3000

14-Jul-2005

3 4

J7

SMA

5

A3

17

SHEET: OF:

D

C

B

A

Page 37

54321

6

DATA PORT 1

J13

12

34

56

78

910

D

C

1112

1314

1516

1718

1920

2122

2324

2526

2728

2930

3132

3334

34PIN_IDC

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

PHSTR

PHSTR

(SH 1)

RP5

51

(Note 1)

2345678910

RP6

51

(Note 1)

1

2345678910

1

DATA PORT 2

J14

1112

1314

1516

1718

B

1920

2122

2324

2526

2728

2930

3132

3334

34PIN_IDC

B0

12

B1

34

B2

56

B3

78

B4

910

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

RP1

22

1 16

2 15

3 14

4 13

5

6

7

8

1 16

2 15

3 14

4 13

5

6

7

8

RP2

22

RP4

22

9

10

11

12

9

10

11

12

RP3

22

DA15

DA14

DA13

DA12

12

11

10

9

12

11

10

9

8

7

6

5

413

314

215

116

8

7

6

5

413

314

215

116

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9

DB10

DB11

DB12

DB13

DB14

DB15

DA(0..15)

DB(0..15)

(SH 1)

(SH 1)

+3.3VA

J15

1

3

4

6

7

9

101112

131415

161718

192021

222324

252627

282930

2

5

8

PLL_VDD

SLEEP

EXT_LO

TXENABLE

TESTMODE

QFLAG

CDC_PD

REF_SEL

PLL_PWD

RESET

3 ROW 30 PIN CONNECTOR

PLL_VDD

SLEEP

EXT_LO

TXENABLE

TESTMODE

QFLAG

CDC_PD

REF_SEL

PLL_PWD

RESET

D

C

(SH 1)

(SH 1)

(SH 1)

(SH 1)

(SH 1)

(SH 1)

(SH 4)

(Sh 4)

(Sh 7)

(SH 1, 4)

B

A

NOTES:

1. DO NOT INSTALL

2345678910

RP7

51

(Note 1)

1 2 3 4 56

1

RP8

51

(Note 1)

2345678910

A

1

Title:

Engineer:

Drawn By:

FILE:

R. HOPPENSTEIN

Y. DEWONCK

DOCUMENTCONTROL #

DATE:

ti

12500 TI Boulevard. Dallas, Texas 75243

TSW3000

14-Jul-2005

SIZE:

SHEET: OF:

A3

REV:

7

2

Page 38

54321

6

R189

15

+3.3VA

0

+3.3VA

VCM

VCM

R238

49.9

R243

49.9

R239

49.9

T1

1

2

3

T4-1T-KK81

R244

49.9

C23

.1uF

6

4

C31

2.2pF

C19

2.2pF

FB16

L13

18 nH

L14

18 nH

L9

18nH

L11

18 nH

1

2

+5VA

IOUTA

3 4

C68

2.2pF

5

C65

6.8pF

C63

6.8pF

J5

SMA

L10

2.7 nH

L12

2.7 nH

L15

2.7 nH

L16

2.7 nH

C32

1pF

C30

1pF

L7

0 nH

L8

0 nH

L2

0nH

L4

0nH

E3

IREF

C93

E4

E5

E6

47pF

(Note 1)

C95

47pF

(Note 1)

R11

R8

2K

5

9

GND

VCC

PWD

GND

C125

1pF

R122

18.2

R121

274

6

7

8

C26

.1uF

FB17

C75

.1uF

ISIG

3

4

11

GND

LO

RFOUT

VCC

10

C20

.1uF

GND1GND2GND

16

QREF

15

IREF

14

IVIN

QVIN

13

QREF

2K

QSIG

U11

TRF3702

GND

12

R119

274

C66

(Note 2)

(Note 1)

C126

1pF

LOCAL_OSC

L17

(Note 2)

+5VA

C81

.1uF

0

(Note 2)

(Note 1)

LOCAL_OSC

FB18

TP12

+5VA

2

1

3

C72

+5VA

(SH 7)

W2

(1-2)

1

J9

SMA

3 4

5

2

REFOUT

D

C

B

+3.3VA

R179

100

(Note 1) (Note 1)

(Sh 1)

(Sh 1)

(Sh 1)

(Sh 1)

IOUTA1

IOUTA2

IOUTB1

IOUTB2

D

C

B

IOUTA1

IOUTA2

+3.3VA

IOUTB1

IOUTB2

R183

100

R208

221

R212

100

(Note 1) (Note 1)

R209

221

(Note 1)

R200

0

(Note 1)

R224

0

R213

100

R210

221

R187

R188 15

R2

100

(Note 1)

R191 15

R190 15

R211

221

A

NOTES:

1. DO NOT INSTALL

R193

(Note 1)

R222

0

(Note 1)

R223

0

R5

100

(Note 1)

0

T2

3

2

1

T4-1T-KK81

4

6

1

IOUTB

2

3 4

5

J19

SMA

A

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

Engineer:

R. HOPPENSTEIN

Drawn By:

Y. DEWONCK

FILE:

1 2 3 4 56

DOCUMENTCONTROL #

DATE:

14-Jul-2005

TSW3000

SIZE:

REV:

37

SHEET: OF:

A3

Page 39

54321

6

D

(Sh 7)

C

B

C99

10uF, 10V

A

NOTES:

1. DO NOT INSTALL

REF_OSC

R124

(Note 1)

V_CTRL

+3.3VCLK

+

0

REF_OSC

CDC_PD

U10

VCXO1

3

GND

EN2OUT_B

1

V_CTRL

TOYOCOM

2115-491.52MHZ

C110

560pF

C89

.1uF

R7

1K

(Note 1)

OUT

VCC

J6

SMA END

5

4

5

6

1

3 4

2

C88 1000pF

R6

0

R9

0

+3.3VCLK

R151

10K

R128

130

(Sh 2)

(Sh 1, 2)

R126

82.5

(Sh 2)

CDC_PD

RESET

R14

0

R149

10K

(Sh 5)

CTRL_LE

(Sh 5)

CTRL_DATA

(Sh 5)

CTRL_CLK

+3.3VCLK

C36

.1uF

+3.3VCLK

R129

130

R10

0

(Note 1) (Note 1)

C45

.1uF

R127

82.5

REF_SEL

REF_IN

CTRL_LE

CTRL_DATA

CTRL_CLK

VBB

REF_SEL

CDC_REF

CDC_PD

RESET

VCXO_INB

VCXO_IN

OUT CLK2

OUT CLK1

J2

SMA END

3 4

5

2

J3

SMA END

3 4

5

2

35

REF_SEL

36

PRI_REF

29

CTRL_LE

26

CTRL_DATA

28

CTRL_CLK

37

SEC_REF

1

/PD

33

VCC_CP

14

/RESET/HOLD

42

/VCXO_IN

43

VCXO_IN

1

1

R16

22.1

R18

22.1

CDCM7005

+3.3VCLK

R19

100

+3.3VCLK

R20

100

U12A

VBB

STATUS_REF

STATUS_VCXO

PLL_LOCK

CP_OUT

YOA

YOB

Y1A

Y1B

Y2A

Y2B

Y3A

Y3B

Y4A

Y4B

C87

.1uF

R21

100

C90

.1uF

R22

100

40

23

22

25

31

46

47

3

4

7

8

11

12

16

17

Y4

R33

150

(Note 1)

Y3

R38

150

(Note 1)

VBB

R221

150

R15

150

+3.3VCLK

CDC_LCK

R152

R153

R154

R156

130

130

130

130

R161

R162

R163

R164

82.5

82.5

82.5

82.5

U12B

CDCM7005

24

GND

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

AVCC

AVCC

AVCC

AVCC

AVCC

2

5

6

9

10

13

15

18

19

20

21

41

44

45

48

27

30

32

38

39

R109

0

(Note 1)

CP_OUT

CDC_REF

C101

+

10uF

C22

+

10uF

CDC_REF

C49

.1uF

FB14

FERRITE

R23

R24

R26

R172

R110

R114

R171

C114

.1uF

CDC_LCK

750

750

750

(SH 7)

0

0

0

0

C58

.1uF

C69

.1uF

C73

.1uF

CLK2B

CLK2CB

CLK1B

CLK1CB

(Sh 5)

C71

.01uF

C104

.1uF

D2

D1

CLK2B

CLK2CB

CLK1B

CLK1CB

C100

.1uF

C122

.01uF

CLOCK DISTRIBUTION

D3

R142

162

C96

22uF

C91

1uF

+3.3VCLK

C119

.001uF

C120

.1uF

AVCC

C112

.1uF

C131

.001uF

(Sh 1)

(Sh 1)

(Sh 1)

(Sh 1)

C113

.1uF

R141

4.75K

+

C115

.1uF

D

V_CTRL

C92

.47uF

C

B

A

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

Engineer:

R. HOPPENSTEIN

Drawn By:

Y. DEWONCK

FILE:

1 2 3 4 56

DOCUMENTCONTROL #

DATE:

14-Jul-2005

TSW3000

SIZE:

REV:

47

SHEET: OF:

A3

Page 40

+3.3VA

D

J1

DB25F-RA

1

DATA

CLK

SDEN1

SDEN2

SDIO

C

B

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

VCOMM_CS

CDC_LCK

PLL_DATA

PLL_CLK

PLL_LCK

CDC_LCK

R228

0

(Note 1)

VCOMM_CS

PLL_DATA

PLL_CLK

PLL_LCK

(Sh 4)

(Sh 4)

(SH 7)

(SH 7)

(SH 7)

VCOMM_CLK

VCOMM_DATA

R34

R35

R36

R37

R17

R155

R247

VCOMM_CLK

VCOMM_DATA

10K

10K

10K

10K

10K

10K

0

(Sh 4)

(Sh 4)

R3

R229

0

(Note 1)

1

2

4

6

8

11

13

15

17

10

10

2

5

9

12

1

4

7

SN74HC241DW

OE1

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

GND

SN74LV125AD

1A

2A

3A

4A

1OE

2OE

GND

U4

20

VCC

19

OE2

18

1Y1

16

1Y2

14

1Y3

12

1Y4

9

2Y1

7

2Y2

5

2Y3

3

2Y4

U13

14

VCC

3

1Y

6

2Y

8

3Y

11

4Y

13

4OE

10

3OE

C97

10pF

+3.3VA

C21

.1uF

SDIO

SCLK

SDEN1

R248

10K

C28

.1uF

R28

R27

R29

+3.3VA

+3.3VA +3.3VA

100

100

+3.3VA

100

SDIO

SCLK

SDEN1

R30

100K

R31

100K

C61

10pF

C127

10pF

(Sh 1)

(Sh 1)

(Sh 1)

R32

100K

C128

10pF

CTRL_CLK

CTRL_DATA

CTRL_CLK

CTRL_DATA

CTRL_LE

(Sh 4)

(Sh 4)

(Sh 4)

D

C

B

PLL_LE

A

PLL_LE

(SH 7)

A

ti

12500 TI Boulevard. Dallas, Texas 75243

NOTES:

1. DO NOT INSTALL

1 2 3 4 56

Engineer:

Drawn By:

FILE:

R. HOPPENSTEIN

Y. DEWONCK

Title:

DOCUMENTCONTROL #

DATE:

14-Jul-2005

TSW3000

SIZE:

REV:

57

SHEET: OF:

A3

Page 41

6V

J11

C57

.01uF

+3.3VA

+

C67

47uF

C54

1uF

+3.3VCLK

C64

.01uF

+

47uF

C74

J12

1

2

3

3POS-POWER-JACK

RED

J17

BLACK

FB13

AVDD

D

+6V

C43

.1uF

1

GND/HSINK

2

GND/HSINK

3

GND

4

NC

5

EN_

6

IN

7

IN

8

NC

9

GND/HSINK

10

GND/HSINK

GND/HSINK

GND/HSINK

U7

TPS76733QPWP

GND/HSINK

GND/HSINK

NC

NC

RESET_

FB/NC

OUT

OUT

20

19

18

17

16

15

14

13

12

11

R130

100K

C117

+

10uF, 10V

FB3

C47

1uF

FB10

6V

+

C25

47uF

FB11

C53

1uF

C102

.01uF

+6V

+

47uF

C105

D

C

C109

.01uF

+6V

R181

0

+

+3.3VPLL

(Note 1)

C116

10uF, 10V

+

47uF

C160

C50

1uF

+5VA

C27

.1uF

C60

.01uF

+5V_PLL

+

47uF

+6V

C48

.1uF

C70

FB7

C159

1uF

B

+6V

C44

.1uF

1

GND/HSINK

2

GND/HSINK

3

GND

4

NC

5

EN_

6

IN

7

IN

8

NC

9

GND/HSINK

10

GND/HSINK

GND/HSINK

GND/HSINK

U6

TPS76750QPWP

GND/HSINK

GND/HSINK

NC

NC

RESET_

FB/NC

OUT

OUT

20

19

18

17

16

15

14

13

12

11

R113

100K

C51

+

10uF, 10V

FB6

FB1

+

47uF

C124

1

GND/HSINK

2

GND/HSINK

3

GND

4

NC

5

EN_

6

IN

7

IN

8

NC

9

GND/HSINK

10

GND/HSINK

GND/HSINK

GND/HSINK

U8

TPS76701QPWP

GND/HSINK

GND/HSINK

NC

NC

RESET_

FB/NC

OUT

OUT

20

19

18

R131

100K

10uF, 10V

C121

+1.8VD

+

R41

15.8K

R42

30.1K

17

16

15

14

13

12

11

C

B

A

A

ti

12500 TI Boulevard. Dallas, Texas 75243

NOTES:

1. DO NOT INSTALL

1 2 3 4 56

Engineer:

Drawn By:

FILE:

R. HOPPENSTEIN

Y. DEWONCK

Title:

DOCUMENTCONTROL #

DATE:

14-Jul-2005

TSW3000

SIZE:

REV:

67

SHEET: OF:

A3

Page 42

+3.3VA

D

C

B

A

(SH 5)

(SH 5)

(SH 5)

NOTES:

(SH 4)

PLL_CLK

PLL_DATA

PLL_LE

CDC_REF

PLL_CLK

PLL_DATA

PLL_LE

REF IN

FB8

PLL_PWD(SH 2)

TCXO_OUT

CDC_REF

R132 200

R134 200

R133 0

J8

SMA

REF_OSC(SH 4) VOUT

3 4

2

5

1. DO NOT INSTALL

2. OPTIMIZED VALUES FOR 2 GHz OPERATION

1 2 3 4 56

C123

10uF, 10V

1

+

R201

0

(Note 1)

R182

0

(Note 1)

PLL_PWD

R48 0

(Note 1)

REF_OSC

TCXO_OUT

C76

.1uF

C107

+3.3VPLL

10pF

R47

R144

0

3

2

+3.3VA R245

C80

.1uF

FB9

0

Y2

OSC-VECTRON

R195

10K

C129

10uF, 10V

R44

1K

(Note 1)

1

4

+5V_PLL

C139

R196

10K

+

TP19

FB12

1000pF

CLK

DATA

LE

0

(Note 1)

C161

10uF, 10V

C78

.1uF

R115

10K

R116

10K

C108

10pF

10

11

12

13

8

+

CE

REFIN

CLK

DATA

LE

C136

100pF

C151

.1uF

7

AVDD

TRF3750

CPGND3AGND4DGND

C82

.1uF

1

2

VS-

3

IN+

THS4221

U18

U14

9

R227

1K

C158

10pF

15

DVDD

RSET

RFINA

MUXOUT

RFINB

C83

+

10uF, 10V

VS+

IN-

FB4

5

4

VP

CP

+5V_PLL

+5V_PLL

FB2

C79

C111

.1uF

E2

C130

RSET

.01uF

C140

1000pF

R125

4.75K

TP18

16

2

1

6

14

R135

3.92K

C106

.1uF

C132

100pF

20K

R136

R232

0

C141

82pF

L19

2.2nH

C133

100pF

(Note 1)

5

C137

100pF

+3.3VPLL+3.3VPLL

C152

.1uF

R226

1K

R145

0

(Note 1)

PLL_LCK

+3.3VPLL

+

10uF, 10V

R117

475

PLL_LCK (SH 6)

C156

+3.3VA

R218

10K

R199

10K

14

2

VT

1

GND

3

GND

4

GND

5

GND

6

N/C

R118

(Note 1)

R123

(Note 1)

D4

SM_LED_1206

VCC

RFOUT

GND7GND8GND

9

C142

33pF

(Note 1)

475

475

GND

GND

GND

GND

GND

Y3

V613ME05

(Note 3)

+3.3VPLL

10

16

15

12

11

13

10pF

C135

100pF

C35

+

10uF, 10V

R137

5.62

123456789

R138

5.62

R139

27.4

R140

100

R111

825

FENCE7

1011121314

R148

5.62

C148

LOCAL_OSC(SH 3)

15

Engineer:

Drawn By:

FILE:

W6

22pF

(Note 2)

R112

825

R. HOPPENSTEIN

Y. DEWONCK

4

1

2

LOCAL_OSC

R147

47.5

R146

47.5

SGA-5386

C98

1pF

123456789

(Note 2)

L18

0805CS-220X_B_

3

U15

R178

(Note 1)

12500 TI Boulevard. Dallas, Texas 75243

Title:

DOCUMENTCONTROL #

DATE:

14-Jul-2005

C146

C144

22pF

1uF

C149

22pF

(Note 2)

R225

0

0

R202

0

(Note 1)

1

FENCE6

101112131415161718

J10

SMA

3 4

2

5

ti

TSW3000

SIZE:

SHEET: OF:

7

REV:

C147

1000pF

A3

7

D

C

B

A

Page 43

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...