Page 1

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

MULTI-STANDARD FULLY INTEGRATED 13.56-MHZ RFID

ANALOG FRONT END AND DATA-FRAMING READER SYSTEM

Check for Samples: TRF7960, TRF7961

1 Introduction

1.1 Features

12

• Completely Integrated Protocol Handling • Parallel 8-Bit or Serial 4-Pin SPI Interface With

• Separate Internal High-PSRR Power Supplies

for Analog, Digital, and PA Sections Provide • Ultra-Small 32-Pin QFN Package

Noise Isolation for Superior Read Range and (5 mm × 5 mm)

Reliability

• Dual Receiver Inputs With AM and PM

Demodulation to Minimize Communication

Holes

• Receiver AM and PM RSSI

• Reader-to-Reader Anti-Collision

• High Integration Reduces Total BOM and Board

Area

– Single External 13.56-MHz Crystal Oscillator

– MCU-Selectable Clock-Frequency Output of

RF, RF/2, or RF/4

– Adjustable 20-mA, High-PSRR LDO for

Powering External MCU

• Easy to Use With High Flexibility

– Auto-Configured Default Modes for Each

Supported ISO Protocol

– 12 User-Programmable Registers

– Selectable Receiver Gain and AGC

– Programmable Output Power

(100 mW or 200 mW)

– Adjustable ASK Modulation Range

(8% to 30%)

– Built-In Receiver Band-Pass Filter With

User-Selectable Corner Frequencies

• Wide Operating Voltage Range of 2.7 V to 5.5 V

• Ultra-Low-Power Modes

– Power Down < 1 μA

– Standby 120 μA

– Active (Rx only) 10 mA

MCU Using 12-Byte FIFO

• Available Tools

– Reference Design/EVM With Development

Software

– Source Code Available for MSP430

1.2 APPLICATIONS

• Secure Access Control

• Product Authentication

– Printer Ink Cartridges

– Blood Glucose Monitors

• Contactless Payment Systems

• Medical Systems

1.3 Description

The TRF7960/61 is an integrated analog front end and data-framing system for a 13.56-MHz RFID reader

system. Built-in programming options make it suitable for a wide range of applications for proximity and

vicinity RFID systems.

The reader is configured by selecting the desired protocol in the control registers. Direct access to all

control registers allows fine tuning of various reader parameters as needed.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Tag-it is a trademark of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testingof all parameters.

Copyright © 2006–2010, Texas Instruments Incorporated

Page 2

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

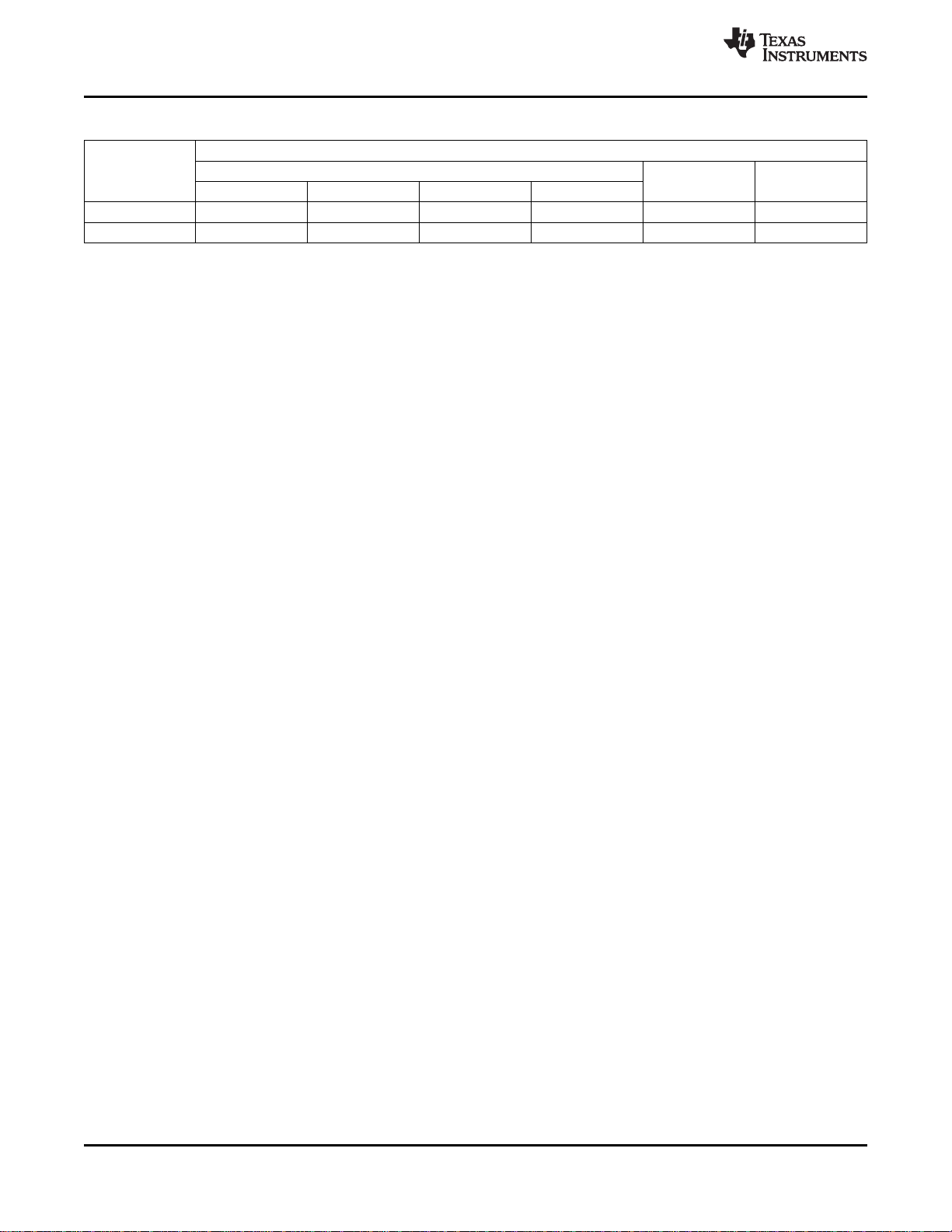

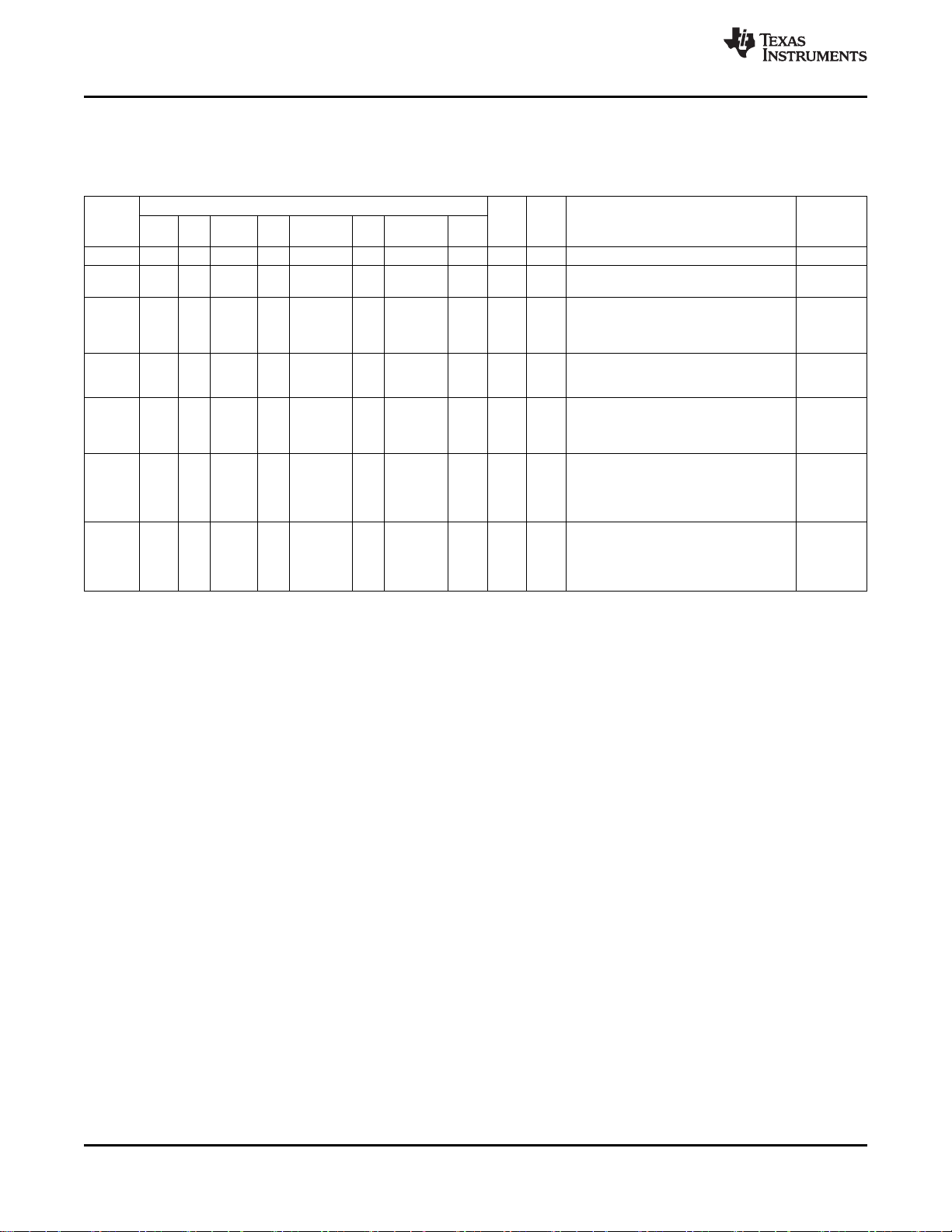

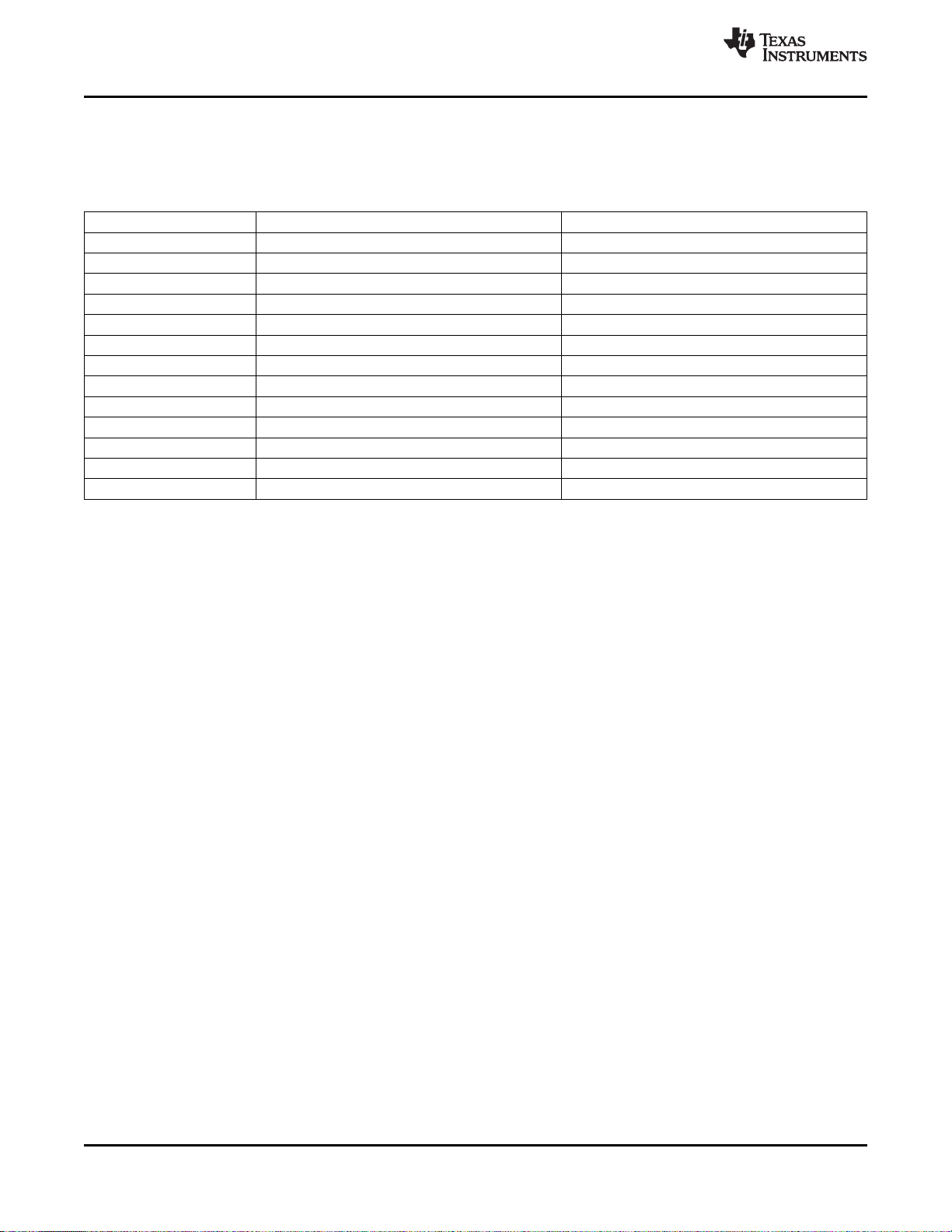

Table 1-1. PRODUCT SELECTION TABLE

PROTOCOLS

DEVICE ISO14443A/B

106 kbps 212 kbps 424 kbps 848 kbps

TRF7960 √ √ √ √ √ √

TRF7961 √ √

ISO15693

ISO18000-3

www.ti.com

Tag-it™

2 Introduction Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 3

TRF7960

TRF7961

www.ti.com

1 Introduction .............................................. 1

1.1 Features .............................................. 1

1.2 APPLICATIONS ...................................... 1

1.3 Description ........................................... 1

2 Description (continued) ................................ 4

3 Physical Characteristics ............................... 5

3.1 Terminal Functions ................................... 5

3.2 PACKAGING/ORDERING INFORMATION .......... 6

4 ELECTRICAL SPECIFICATIONS ..................... 7

4.1 ABSOLUTE MAXIMUM RATINGS .................. 7

4.2 DISSIPATION RATINGS TABLE .................... 7

4.3 RECOMMENDED OPERATING CONDITIONS ..... 7

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

4.4 ELECTRICAL CHARACTERISTICS ................. 8

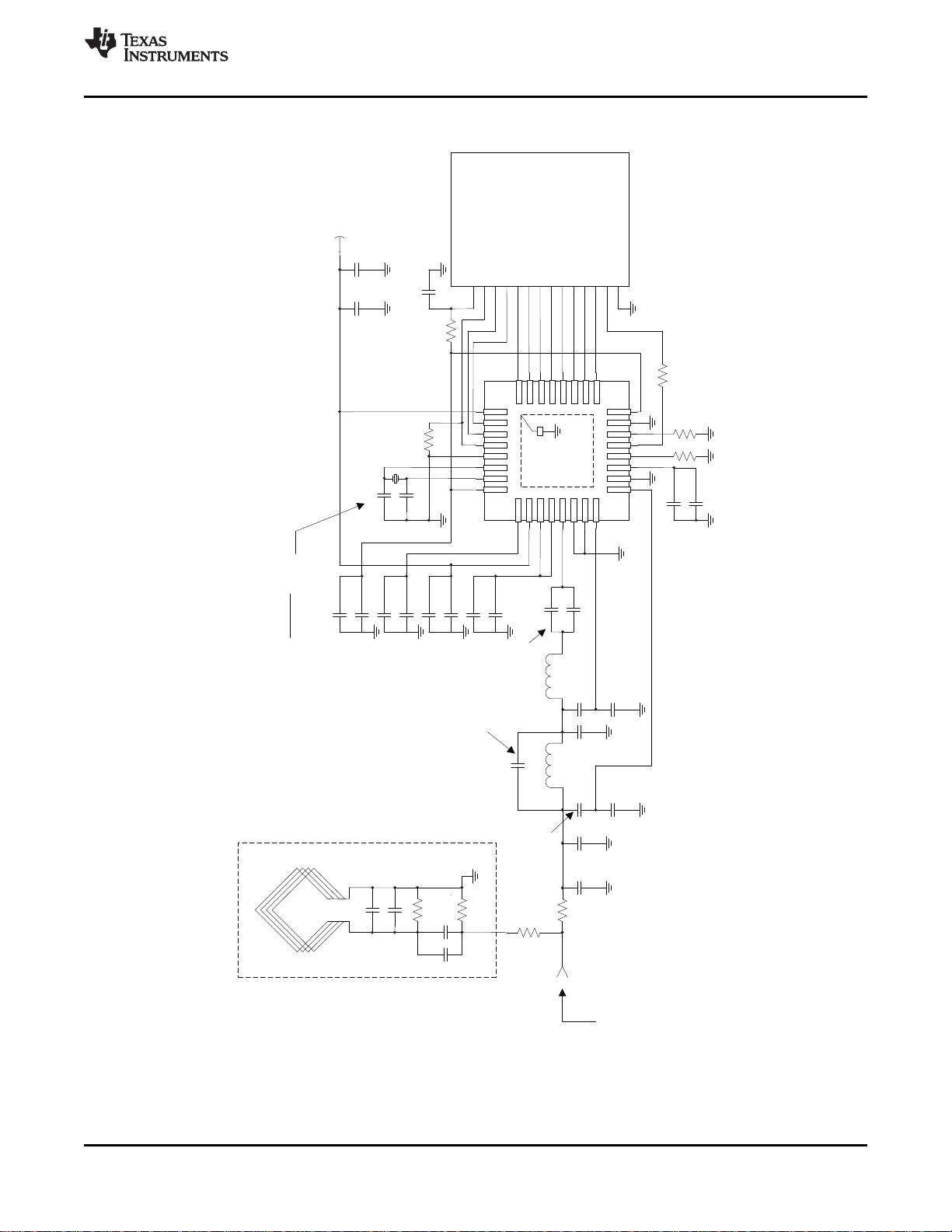

4.5 Application Schematic for the TRF796x EVM

(Parallel Mode) ....................................... 9

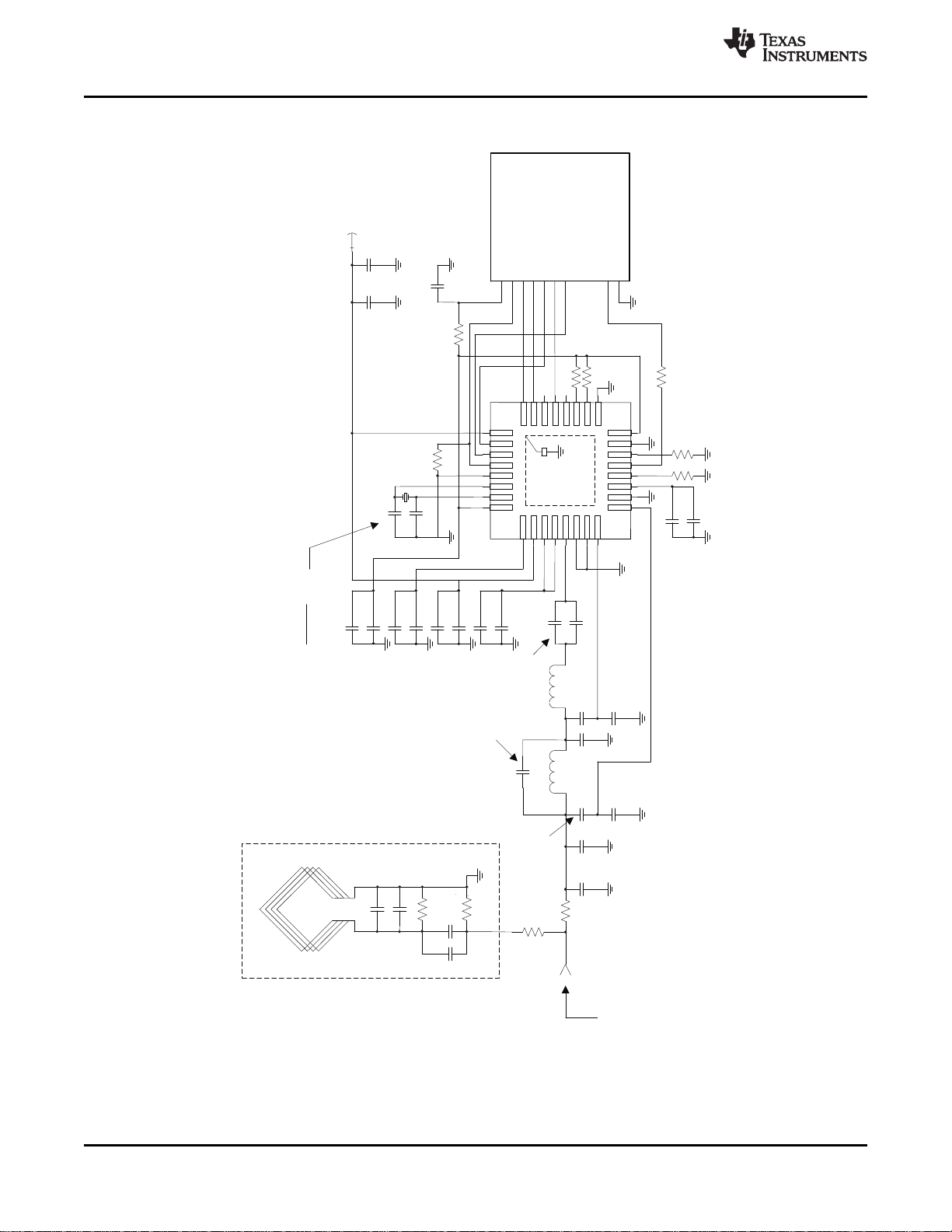

4.6 Application Schematic for the TRF796x EVM (SPI

Mode) ............................................... 10

5 System Description ................................... 11

5.1 Power Supplies ..................................... 11

5.2 Receiver – Analog Section ......................... 17

5.3 Register Descriptions ............................... 24

5.4 Direct Commands From MCU to Reader ........... 34

5.5 Reader Communication Interface .................. 36

5.6 Parallel Interface Communication .................. 38

5.7 Serial Interface Communication .................... 40

5.8 External Power Amplifier Application ............... 44

Copyright © 2006–2010, Texas Instruments Incorporated Contents 3

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 4

8(Parallel)

3(SPI)

Z – Matching

Circuit

Tx_Out

Rx_IN1

Rx_IN2

VDD_X

VDD_I/O

SYS_CLK

DATA_CLK

VDD

TRF796x MSP430

Xtal

13.56MHz

IRQ

XtalIn

XtalOut

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

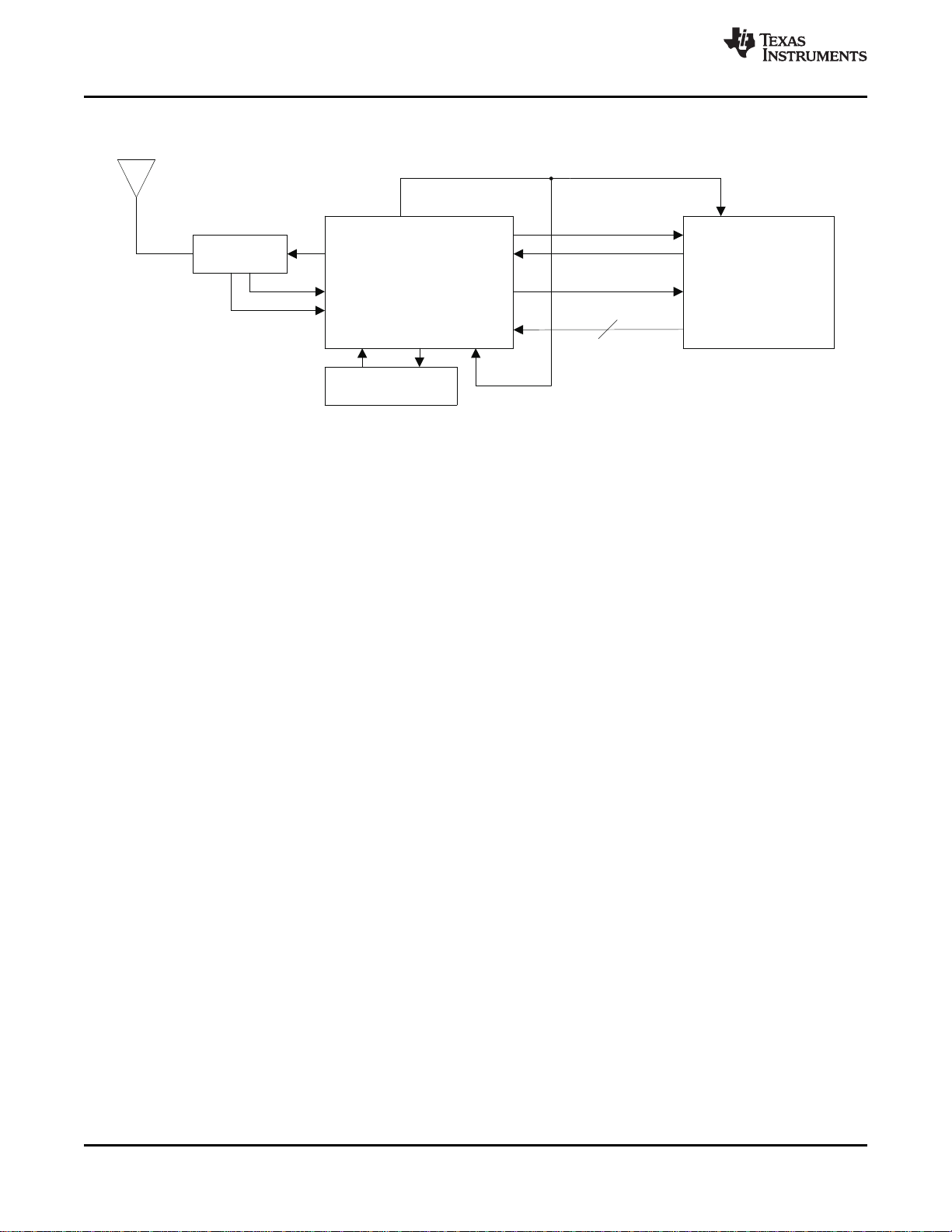

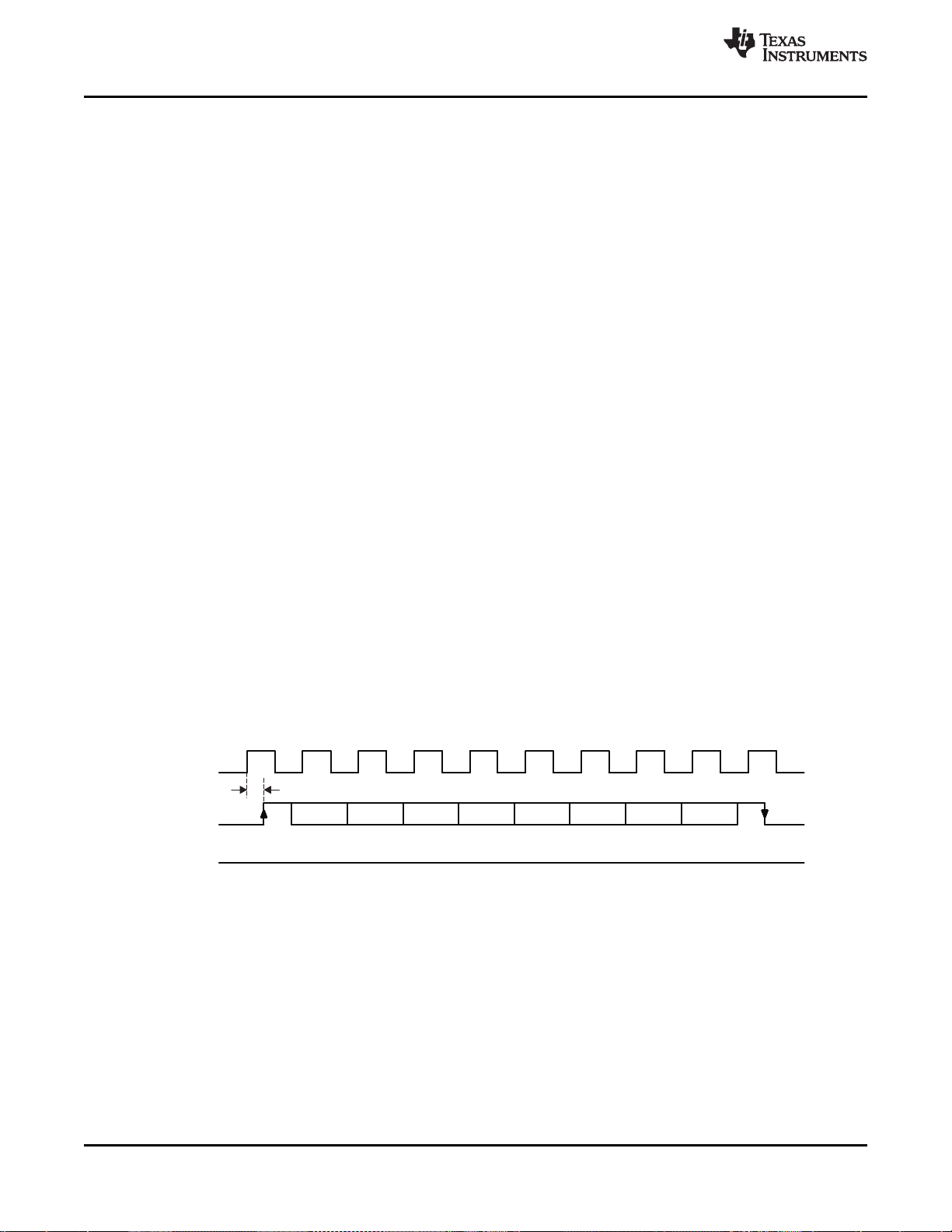

2 Description (continued)

A parallel or serial interface can be implemented for communication between the MCU and reader.

Transmit and receive functions use internal encoders and decoders with a 12-byte FIFO register. For

direct transmit or receive functions, the encoders / decoders can be bypassed so the MCU can process

the data in real time. The transmitter has selectable output power levels of 100 mW (20 dBm) or 200 mW

(23 dBm) into a 50-Ω load (5 -V supply) and is capable of ASK or OOK modulation. Integrated voltage

regulators ensure power-supply noise rejection for the complete reader system.

www.ti.com

Figure 2-1. Typical Application

Data transmission comprises low-level encoding for ISO15693, modified Miller for ISO14443-A,

high-bit-rate systems for ISO14443 and Tag-it coding systems. Included with the data encoding is

automatic generation of SOF, EOF, CRC, and / or parity bits.

The receiver system enables AM and PM demodulation using a dual-input architecture. The receiver also

includes an automatic gain control option and selectable gain. Also included is a selectable bandwidth to

cover a broad range of input sub-carrier signal options. The received signal strength for AM and PM

modulation is accessible via the RSSI register. The receiver output is a digitized sub-carrier signal among

a selectable protocol and bit rate as outlined in Table 5-11. A selected decoder delivers bit stream and a

data clock as outputs.

The receiver system also includes a framing system. This system performs CRC and / or parity check,

removes the EOF and SOF settings, and organizes the data in bytes. Framed data is then accessible to

the MCU via a 12-byte FIFO register and MCU interface. The framing supports ISO14443 and ISO15693

protocols.

The TRF7960/61 supports data communication levels from 1.8 V to 5.5 V for the MCU I/O interface, while

also providing a data synchronization clock. An auxiliary 20-mA regulator (pin 32) is available for

additional system circuits.

4 Description (continued) Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 5

TRF7960

TRF7961

www.ti.com

3 Physical Characteristics

3.1 Terminal Functions

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

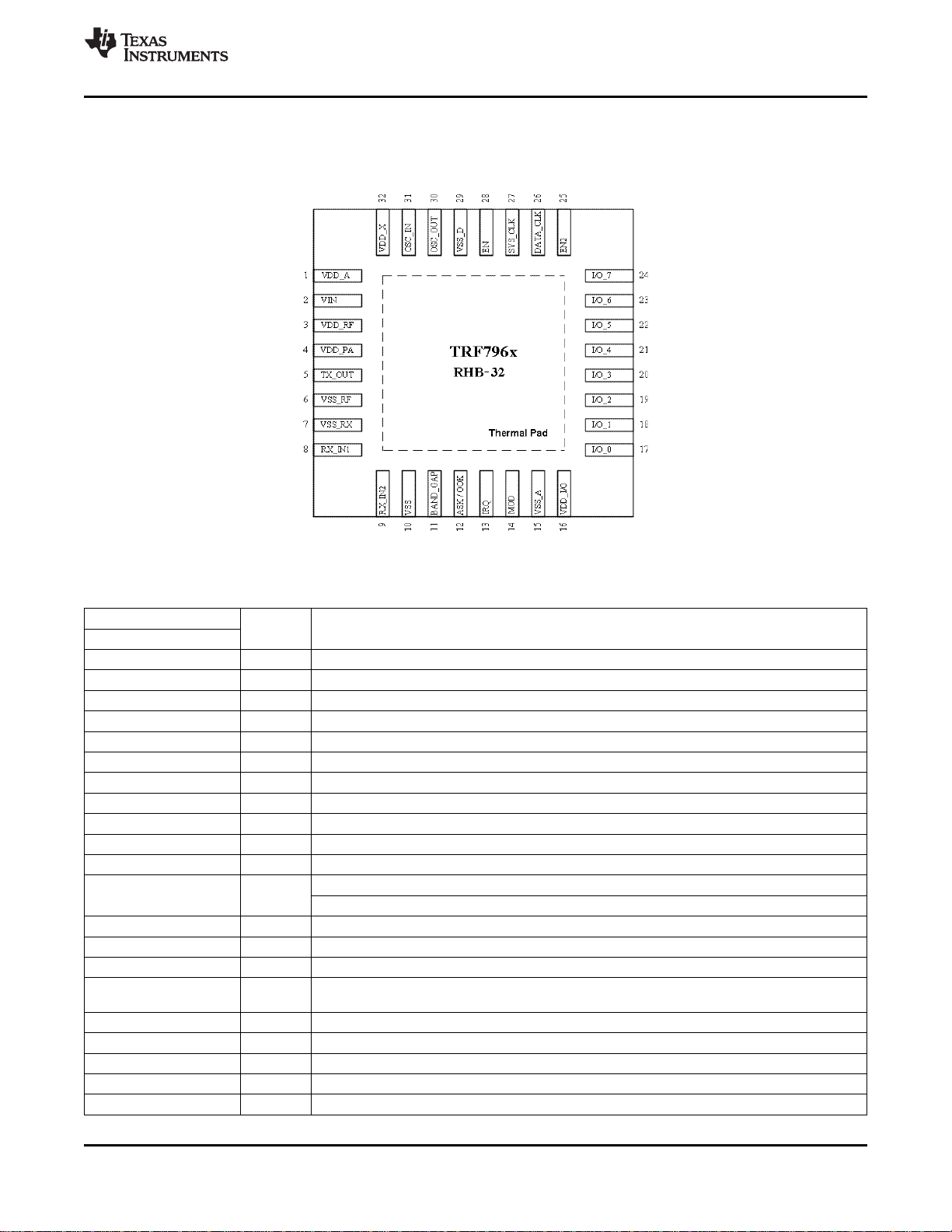

Figure 3-1. TRF796x Pin Assignments (Top View)

Table 3-1. Terminal Functions

TERMINAL

NAME NO.

VDD_A 1 OUT Internal regulated supply (2.7 V – 3.4 V) for analog circuitry

VIN 2 SUP External supply input to chip (2.7 V – 5.5 V)

VDD_RF 3 OUT Internal regulated supply (2.7 V – 5 V), normally connected to VDD_PA (pin 4)

VDD_PA 4 INP Supply for PA; normally connected externally to VDD_RF (pin 3)

TX_OUT 5 OUT RF output (selectable output power, 100 mW at 8 Ω or 200 mW at 4 Ω, with VDD = 5 V)

VSS_RF 6 SUP Negative supply for PA; normally connected to circuit ground

VSS_RX 7 SUP Negative supply for RX inputs; normally connected to circuit ground

RX_IN1 8 INP RX input, used for AM reception

RX_IN2 9 INP RX input, used for PM reception

VSS 10 SUP Chip substrate ground

BAND_GAP 11 OUT Band-gap voltage (1.6 V); internal analog voltage reference; must be ac-bypassed to ground.

ASK/OOK 12 BID

IRQ 13 OUT Interrupt request

MOD 14 INP Direct mode, external modulation input

VSS_A 15 SUP Negative supply for internal analog circuits; normally connected to circuit ground

VDD_I/O 16 SUP

I/O_0 17 BID I/O pin for parallel communication

I/O_1 18 BID I/O pin for parallel communication

I/O_2 19 BID I/O pin for parallel communication

I/O_3 20 BID I/O pin for parallel communication

I/O_4 21 BID I/O pin for parallel communication

TYPE

(1)

Also can be configured to provide the received analog signal output (ANA_OUT)

Direct mode, selection between ASK and OOK modulation (0 = ASK, 1 = OOK)

Supply for I/O communications (1.8 V – 5.5 V). Should be connected to VIN for 5-V

communication, VDD_X for 3.3-V communication, or any other voltage from 1.8 V to 5.5 V.

DESCRIPTION

(1) SUP = Supply, INP = Input, BID = Bi-directional, OUT = Output

Copyright © 2006–2010, Texas Instruments Incorporated Physical Characteristics 5

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 6

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

www.ti.com

Table 3-1. Terminal Functions (continued)

TERMINAL

NAME NO.

I/O_5 22 BID Strobe out clock for serial communication

I/O_6 23 BID MISO for serial communication (SPI)

I/O_7 24 BID

EN2 25 INP active during power down to support the MCU. Pin can also be used for pulse wake-up from

DATA_CLK 26 INP Clock input for MCU communication (parallel and serial)

SYS_CLK 27 OUT

EN 28 INP Chip enable input (If EN = 0, then chip is in power-down mode).

VSS_D 29 SUP Negative supply for internal digital circuits; normally connected to circuit ground

OSC_OUT 30 OUT Crystal oscillator output

OSC_IN 31 INP Crystal oscillator input

VDD_X 32 OUT Internally regulated supply (2.7 V – 3.4 V) for external circuitry (MCU)

Thermal Pad Connected to circuit ground

TYPE

(1)

I/O pin for parallel communication

Data clock output in direct mode

I/O pin for parallel communication

Serial bit data output in direct mode 1 or sub-carrier signal in direct mode 0

I/O pin for parallel communication.

MOSI for serial communication (SPI)

Pulse enable and selection of power down mode. If EN2 is connected to VIN, then VDD_X is

power-down mode.

Clock for MCU (3.39 / 6.78 / 13.56 MHz) at EN = 1 and EN2 = don't care

If EN = 0 and EN2 = 1, then system clock is set to 60 kHz

DESCRIPTION

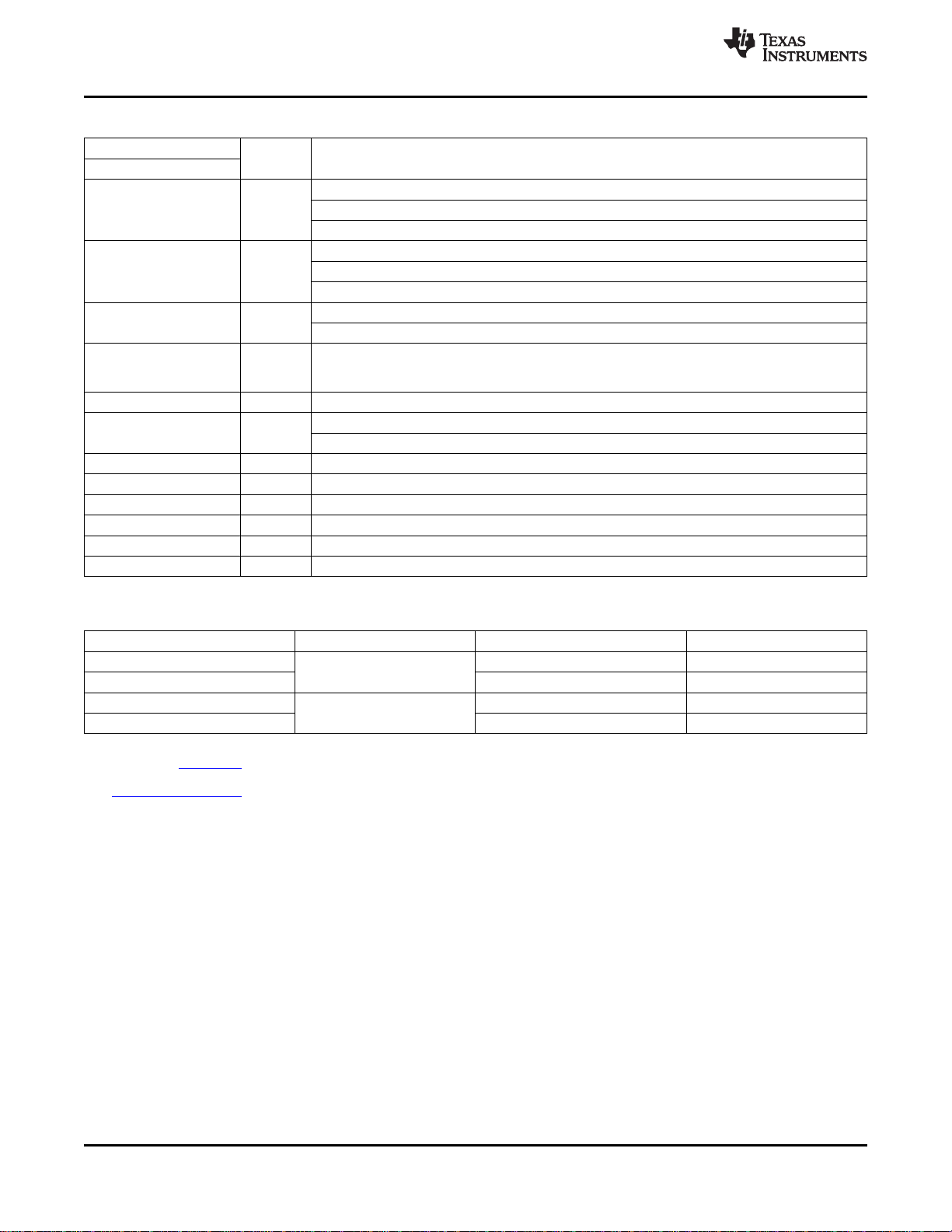

3.2 PACKAGING/ORDERING INFORMATION

PACKAGED DEVICES PACKAGE TYPE

TRF7960RHBT Tape and reel 250

TRF7960RHBR Tape and reel 3000

TRF7961RHBT Tape and reel 250

TRF7961RHBR Tape and reel 3000

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com.

(2) Package drawings, standard packing quantities, thermal data, symbolization, and PCB design guidelines are available at

www.ti.com/sc/package .

RHB-32

RHB-32

(1)

(2)

TRANSPORT MEDIA QUANTITY

6 Physical Characteristics Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 7

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

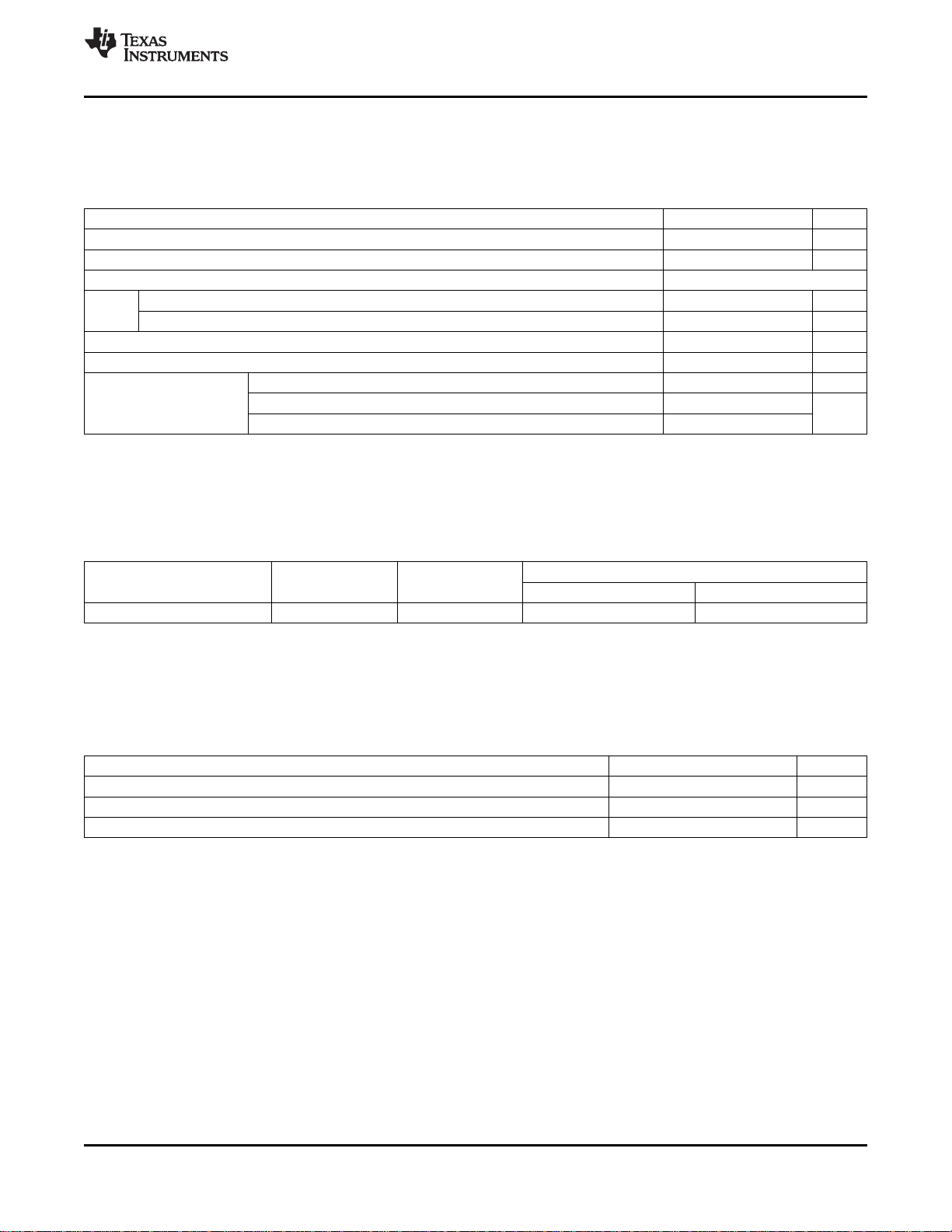

4 ELECTRICAL SPECIFICATIONS

4.1 ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

VIN Supply voltage 6 V

I

O

T

J

T

stg

(1) The absolute maximum ratings under any condition is limited by the constraints of the silicon process. Stresses above these ratings may

(2) The maximum junction temperature for continuous operation is limited by package constraints. Operation above this temperature may

Output current 150 mA

Continuous power dissipation See Dissipation Ratings Table

Maximum junction temperature, any condition

Maximum junction temperature, continuous operation, long-term reliability

Storage temperature range –55 to 150 °C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300 °C

HBM (human body model) 2 kV

ESDS rating CDM (charged device model) 500

MM (machine model) 200

cause permanent damage. Exposure to absolute maximum conditions for extended periods may degrade device reliability. These are

stress ratings only and functional operation of the device at these or any other conditions beyond those specified are not implied.

result in reduced reliability and/or lifetime of the device.

(2)

(1)

VALUE UNIT

140 °C

(2)

125 °C

V

4.2 DISSIPATION RATINGS TABLE

θ

PACKAGE

RHB (32) 31 36.4 2.7 W 1.1 W

(1) This data was taken using the JEDEC standard high-K test PCB.

(2) Power rating is determined with a junction temperature of 125°C. This is the point where distortion starts to increase substantially.

Thermal management of the final PCB should strive to keep the junction temperature at or below 125°C for best performance and

long-term reliability.

JC

(°C/W) (°C/W)

(1)

θ

JA

TA≤ 25°C TA= 85°C

POWER RATING

(2)

4.3 RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

MIN TYP MAX UNIT

VIN Supply voltage 2.7 5 5.5 V

T

J

T

A

Operating virtual junction temperature range –40 125 °C

Operating ambient temperature range –40 25 110 °C

Copyright © 2006–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 7

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 8

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

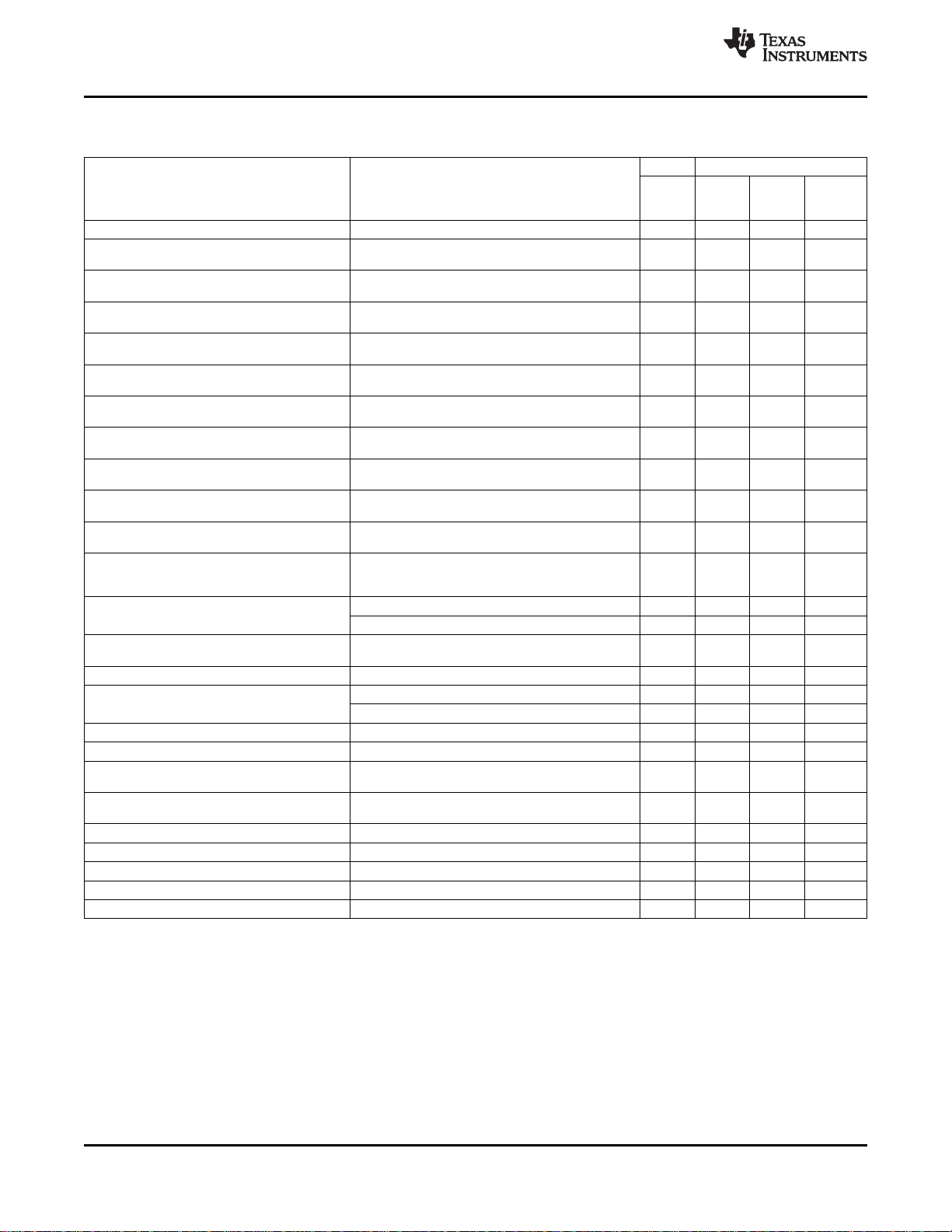

4.4 ELECTRICAL CHARACTERISTICS

over temperature range VS= 5 V (unless otherwise noted)

TYP

–40°C

110°C

10 16 mA MAX

70 mA MAX

1.4 MIN

1.7 MAX

1.4 MIN

2.5 MAX

3.1 MIN

3.8 MAX

4 MIN

5.2 MAX

3.1 MIN

3.8 MAX

5 MIN

20 MAX

30 MIN

120 MAX

I

PD

I

PD2

I

STBY

I

ON1

I

ON2

I

ON3

PARAMETER CONDITIONS

Supply current in power-down mode All systems disabled, including supply-voltage regulators 1 10 μA MAX

Supply current in power-down mode 2 120 300 μA MAX

Supply current in standby mode 1.5 4 mA MAX

The reference voltage generator and the VDD_X remain

active to support external circuitry.

Oscillator running, supply-voltage regulators in

low-consumption mode

Supply current without antenna driver Oscillator, regulators, Rx and AGC, are all active. Tx is

current off.

Supply current with antenna driver Oscillator, regulators, Rx, AGC, and Tx are all active.

current Pout = 100 mW.

Supply current with antenna driver Oscillator, regulators, Rx, AGC, and Tx are all active.

current Pout = 200 mW.

25°C TO UNIT

120 mA MAX

BG Band Gap voltage Internal analog reference voltage 1.6 V

V

POR

V

DD_A

V

DD_RF

V

DD_X

P

PSRR

R

RFOUT

R

RFIN

V

RFIN

V

SENS

t

SET_PD

t

SET_STBY

t

REC

f

SYS_CLK

CLK

MAX

V

IL

V

IH

R

OUT

R

SYS_CLK

Power on reset voltage (POR) 2 V

Regulated supply for analog circuitry 3.5 V

Regulated supply for RF circuitry Regulator set for 5-V system with 250-mV difference. 4.6 V

Regulated supply for external circuitry 3.4 V

Rejection of external supply noise on

the supply VDD_RF regulator

PA driver output resistance

The difference between the external supply and the

regulated voltage is higher than 250 mV. Measured at 26 20 dB MIN

212 kHz.

Half-power mode 8 12 Ω MAX

Full- power mode 4 6 Ω MAX

RX_IN1 and RX_IN2 input resistance 10 kΩ

Maximum input voltage At RX_IN1 and RX_IN2 inputs 3.5 V

Input sensitivity

f

SUB-CARRIER

f

SUB-CARRIER

= 424 kHz 1.2 2.5 mV

= 848 kHz 1.2 3 mV

Set up time after power down 10 20 ms MAX

Set up time after standby mode 30 100 μs MAX

Recovery time after modulation

(ISO14443)

Modulation signal: sine, 424-kHz, 10-mVpp 60 μs MAX

SYS_CLK frequency In PD2 mode EN = 0 and EN2 = 1 60 kHz

Maximum CLK frequency 2 MHz TYP

Input logic low 0.2 0.2 VDD_I/O MAX

Input logic high 0.8 VDD_I/O MIN

Output resistance I/O_0 to I/O_7 low_io = H for VDD_I/O < 2.7 V 400 800 Ω MAX

Output resistance SYS_CLK low_io = H for VDD_I/O< 2.7 V 200 400 Ω MAX

PP

PP

PP

www.ti.com

MIN/

MAX

MAX

MAX

MAX

8 ELECTRICAL SPECIFICATIONS Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 9

Test Port

or

Ext AntPort

1

TRF796x

RHB-32

234

5

6

7

8

9 10 11 12 13 14 15 16

32

31

30

29 28

27

26

25

17

18

19

20

21

22

23

24

33

ThermalPad

VDD_X

OSC_IN

OSC_OUT

VSS_D

EN

SYS_CLK

DATA_CLK

EN2

VDD_I/O

VSS_A

MOD

IRQ

ASK/OOK

BANDGAP

VSS

RX2_PM

RX1_AM

VDD_A

VSS_RX

VSS_RF

TX_OUT

VDD_PA

VDD_RF

VIN

I/O_0

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

1000pF

1000pF

1500pF

1500pF

680pF

680pF

220pF

VSWR

Adj

Phase

Adj

330nH

150nH

Freq Adj

100pF

27pF

2.2uF

10nF

10nF

10nF

10nF

2.2uF

2.2uF

2.2uF

0Ohms

0Ohms

27pF

27pF

13.56MHz

VSWR

Adj

DVcc

D/AVss

XIN

1K

1K

ReaderPwrEnable(GPIO)

InterruptCapableGPIO

MSP430

(Family)

4.7uF

10V

0.1uF

1K

CLK(GPIO)

PX.7

PX.6

PX.5

PX.4

PX.3

PX.2

PX.1

PX.0

Vcc

100

0.1uF

2.2uF

10nF

10K

10pF

Harmonic

Suppression

C1

C2´

Xtal C

L

C

S

C1+C

2

=

+

Antenna

Circuit

Ant “Q”

Adj

R “cal”

open/short/load

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

4.5 Application Schematic for the TRF796x EVM (Parallel Mode)

Copyright © 2006–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 9

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 10

TestPort

or

Ext AntPort

1

TRF796x

RHB-32

234

5

6

7

8

9 10 11 12 13 14 15 16

32 31 30 29 28 27 26 25

17

18

19

20

21

22

23

24

33

ThermalPad

VDD_X

OSC_IN

OSC_OUT

VSS_D

EN

SYS_CL

DATA_CLK

EN2

VDD_I/O

VSS_A

MOD

IRQ

ASK/

BANDGAP

VSS

RX2_PM

RX1_AM

VDD_A

VSS_RX

VSS_RF

TX_OUT

VDD_PA

VDD_RF

VIN

I/O_0

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

1000pF

1000pF

1500pF

1500pF

680pF

680pF

220pF

VSWR

Adj

Phase

Adj

330nH

150nH

Freq

Adj

100pF

27pF

2.2

Fµ

10nF

10nF

10nF

10nF

2.2

Fµ

2.2

Fµ

2.2

Fµ

0Ohms

0Ohms

27pF

27pF

13.56MHz

VSWR

Adj

Vcc

DVcc

D/AVss

MISO

MOSI

XIN

10K

10K

1K

1K

CLK(GPIO)

SlaveSelect(GPIO)

ReaderPwrEnable(GPIO)

InterruptCapableGPIO

MSP430(Family)

4.7

F

10V

µ

0.1

Fµ

1K

100

0.1

Fµ

2.2

Fµ

10nF

10pF

Harmonic

Suppression

10K

C1

C2´

Xtal C

L

C

S

C1+C

2

=

+

Antenna

Circuit

Ant “Q”

Adj

R “cal”

open/short/load

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

4.6 Application Schematic for the TRF796x EVM (SPI Mode)

www.ti.com

10 ELECTRICAL SPECIFICATIONS Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 11

TRF7960

TRF7961

www.ti.com

5 System Description

5.1 Power Supplies

The positive supply pin, VIN (pin 2) has an input voltage range of 2.7 V to 5.5 V. The positive supply input

sources three internal regulators with output voltages V

capacitors for supply noise filtering. These regulators provide enhanced PSRR for the RFID reader

system.

The regulators are not independent and have common control bits for output voltage setting. The

regulators can be configured to operate in either automatic or manual mode. The automatic regulator

mode setting ensures an optimal compromise between regulator PSRR and highest possible supply

voltage for RF output power. Whereas, the manual mode allows the user to manually configure the

regulator settings.

V

DD_RF

V

DD_A

The regulator V

be set for either 5-V or 3-V operation. When configured for the 5-V operation, the output

voltage can be set from 4.3 V to 5 V in 100-mV steps. The current sourcing capability for 5-V

operation is 150 mA maximum over the adjusted output voltage range.

When configured for 3-V operation, the output can be set from 2.7 V to 3.4 V, also in 100-mV

steps. The current sourcing capability for 3-V operation is 100 mA maximum over the adjusted

output voltage range.

Regulator V

setting is divided in two ranges. When configured for 5-V operation, the output voltage is fixed

at 3.5 V.

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

, V

DD_RF

(pin 3) is used to source the RF output stage. The voltage regulator can

DD_RF

(pin 1) supplies voltage to analog circuits within the reader chip. The voltage

DD_A

DD_A

and V

that use external bypass

DD_X

When configured for 3-V operation, the output can be set from 2.7 V to 3.4 V in 100-mV steps.

Note that when configured, both V

(their settings are not independent).

V

DD_X

Regulator V

(pin 32) can be used to source the digital I/O of the reader chip together with

DD_X

other external system components. When configured for 5-V operation, the output voltage is

fixed at 3.4 V.

When configured for 3-V operation, the output voltage can be set from 2.7 to 3.4 V in 100-mV

steps. The total current sourcing capability of the V

adjusted output range. Note that when configured, both V

configured together (their settings are not independent).

V

DD_PA

The V

pin (pin 4) is the positive supply pin for the RF output stage and is externally

DD_PA

connected to the regulator output V

5.1.1 Negative Supply Connections

The negative supply connections are all externally connected together (to GND). The substrate connection

is VSS(pin 10), the analog negative supply is V

the RF output stage negative supply is V

V

SS_RX

(pin 7).

5.1.2 Digital I/O Interface

To allow compatible I/O signal levels, the TRF7960/61 has a separate supply input V

an input voltage range of 1.8 V to 5.5 V. This pin is used to supply the I/O interface pins (I/O_0 to I/O_7),

IRQ, SYS_CLK, and DATA_CLK pins of the reader. In typical applications, V

V

to ensure that the I/O signal levels of the MCU are the same as the internal logic levels of the

DD_X

reader.

and V

DD_A

(pin 3).

DD_RF

(pin 15), the logic negative supply is V

SS_A

(pin 6), and the negative supply for the RF receiver input is

SS_TX

regulators are configured together

DD_X

regulator is 20 mA maximum over the

DD_X

DD_A

and V

is connected directly to

DD_I/O

regulators are

DD_X

SS_D

DD_I/O

(pin 29),

(pin 16), with

Copyright © 2006–2010, Texas Instruments Incorporated System Description 11

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 12

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

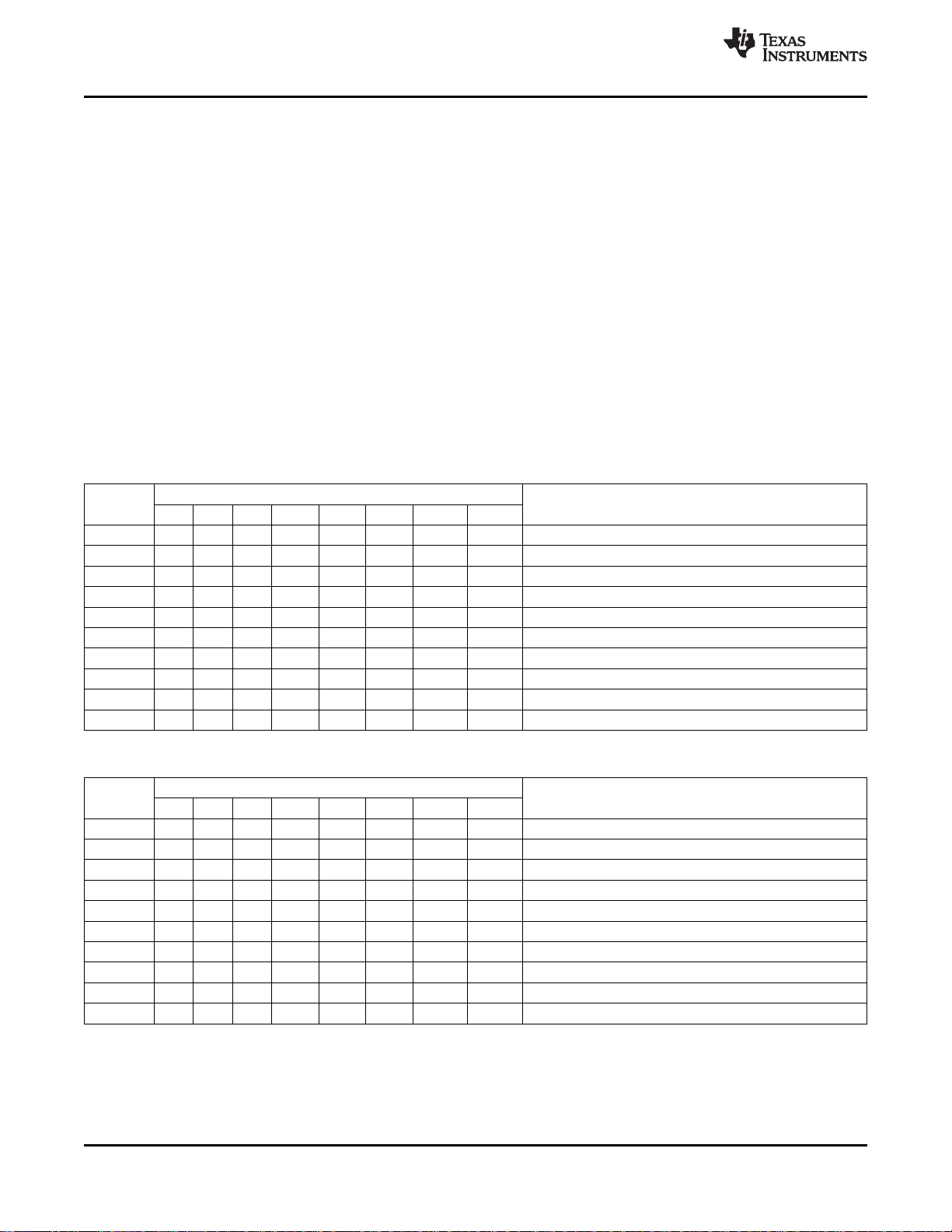

5.1.3 Supply Regulator Configuration

The supply regulators can be automatically or manually configured by the control bits. The available

options are shown in Table 5-1 through Table 5-4. Table 5-1 shows a 5-V system and the manual-mode

regulator settings. Table 5-2 shows manual mode for selection of a 3-V system. Table 5-3 and Table 5-4

show the automatic-mode gain settings for 5-V and 3-V systems.

The automatic mode is the default configuration. In automatic mode, the regulators are automatically set

every time the system is activated by asserting the EN input HIGH. The internal regulators are also

automatically reconfigured every time the automatic regulator selection bit is set HIGH (on the rising

edge).

The user can re-run the automatic mode setting from a state in which the automatic setting bit is already

high by changing the automatic setting bit from high to low to high. The regulator-configuration algorithm

adjusts the regulator outputs 250 mV below the VINlevel, but not higher than 5 V for V

V

, and 3.4 V for V

DD_A

maintaining an adequate PSRR (power supply rejection ratio). As an example, the user can improve the

PSRR if there is a noisy supply voltage from V

V

regulator as shown for automatic regulator settings in Table 5-3 and Table 5-4.

DD_X

Table 5-1. Supply-Regulator Setting – Manual – 5-V System

Byte Option Bits Setting in Control Register Action

Address

00 1 5-V system

0B 0 Manual regulator setting

0B 0 1 1 1 V

0B 0 1 1 0 V

0B 0 1 0 1 V

0B 0 1 0 0 V

0B 0 0 1 1 V

0B 0 0 1 0 V

0B 0 0 0 1 V

0B 0 0 0 0 V

B7 B6 B5 B4 B3 B2 B1 B0

. This ensures the highest possible supply voltage for the RF output stage while

DD_X

by increasing the target voltage difference across the

DD_X

= 5 V, V

DD_RF

= 4.9 V, V

DD_RF

= 4.8 V, V

DD_RF

= 4.7 V, V

DD_RF

= 4.6 V, V

DD_RF

= 4.5 V, V

DD_RF

= 4.4 V, V

DD_RF

= 4.3 V, V

DD_RF

= 3.5 V, and V

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

= 3.5 V, and V

= 3.5 V, and V

= 3.5 V, and V

= 3.5 V, and V

= 3.5 V, and V

= 3.5 V, and V

= 3.5 V, and V

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

DD_RF

= 3.4 V

= 3.4 V

= 3.4 V

= 3.4 V

= 3.4 V

= 3.4 V

= 3.4 V

= 3.4 V

www.ti.com

, 3.5 V for

Table 5-2. Supply-Regulator Setting – Manual – 3-V System

Byte Option Bits Setting in Control Register Action

Address

00 0 3V system

0B 0 Manual regulator setting

0B 0 1 1 1 V

0B 0 1 1 0 V

0B 0 1 0 1 V

0B 0 1 0 0 V

0B 0 0 1 1 V

0B 0 0 1 0 V

0B 0 0 0 1 V

0B 0 0 0 0 V

12 System Description Copyright © 2006–2010, Texas Instruments Incorporated

B7 B6 B5 B4 B3 B2 B1 B0

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

DD_RF

DD_RF

DD_RF

F = 3.1 V, V

DD_R

DD_RF

DD_RF

DD_RF

DD_RF

= 3.4 V, V

= 3.3 V, V

= 3.2 V, V

= 3.0 V, V

= 2.9 V, V

= 2.8 V, V

= 2.7 V, V

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

DD_A

, and V

, and V

, and V

, and V

, and V

, and V

, and V

, and V

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

DD_X

= 3.4 V

= 3.3 V

= 3.2 V

= 3.1 V

= 3.0 V

= 2.9 V

= 2.8 V

= 2.7 V

Page 13

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

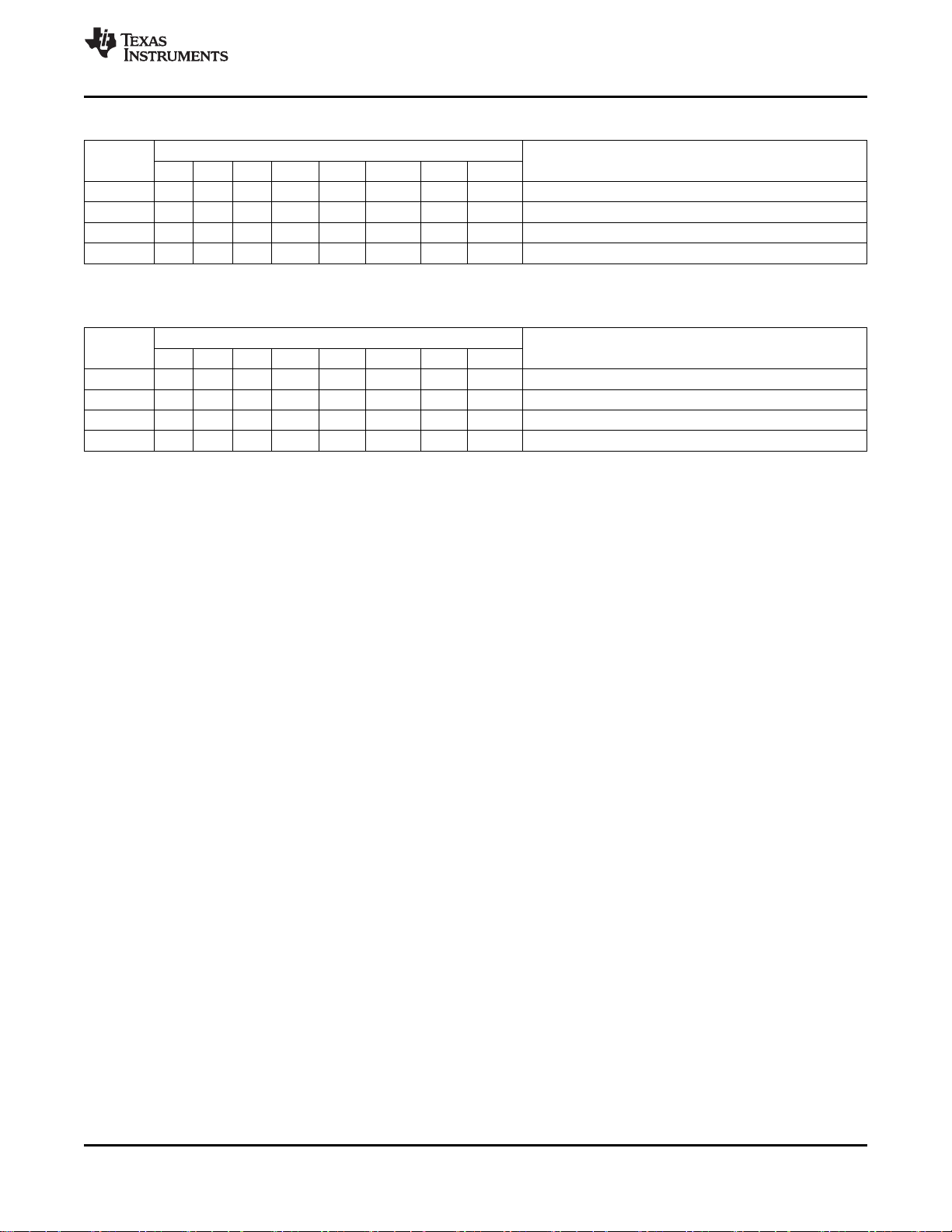

Table 5-3. Supply-Regulator Setting – Automatic – 5-V System

Byte Option Bits Setting in Control Register Action

Address

00 1 5-V system

0B 1 x 1 1 Automatic regulator setting ≉ 250-mV difference

0B 1 x 1 0 Automatic regulator setting ≉ 350-mV difference

0B 1 x 0 0 Automatic regulator setting ≉ 400-mV difference

(1) X are don't cares

B7 B6 B5 B4 B3 B2

(1)

B1 B0

Table 5-4. Supply-Regulator Setting – Automatic – 3-V System

Byte Option Bits Setting in Control Register Action

Address

00 0 3-V system

0B 1 x 1 1 Automatic regulator setting ≉ 250-mV difference

0B 1 x 1 0 Automatic regulator setting ≉ 350-mV difference

0B 1 x 0 0 Automatic regulator setting ≉ 400-mV difference

(1) X are don't cares

B7 B6 B5 B4 B3 B2

(1)

B1 B0

5.1.4 Power Modes

The chip has seven power states, which are controlled by two input pins (EN and EN2) and three bits in

the chip status control register (00h).

The main reader enable input is EN (which has a threshold level of 1 V minimum). Any input signal level

from 1.8 V to VINcan be used. When EN is set high, all of the reader regulators are enabled, together with

the 13.56-MHz oscillator, while the SYS_CLK (output clock for external micro controller) is made available.

The auxiliary-enable input EN2 has two functions. A direct connection from EN2 to VINensures availability

of the regulated supply (V

) and an auxiliary clock signal (60 kHz) on the SYS_CLK output (same for

DD_X

the case EN = 0). This mode is intended for systems in which the MCU controlling the reader is also being

supplied by the reader supply regulator (V

) and the MCU clock is supplied by the SYS_CLK output of

DD_X

the reader. This allows the MCU supply and clock to be available during power-down.

A second function of the EN2 input is to enable start-up of the reader system from complete power down

(EN = 0, EN2 = 0). In this case the EN input is being controlled by the MCU or other system device that is

without supply voltage during complete power down (thus unable to control the EN input). A rising edge

applied to the EN2 input (which has a 1-V threshold level) starts the reader supply system and 13.56-MHz

oscillator (identical to condition EN = 1). This start-up mode lasts until all of the regulators have settled

and the 13.56-MHz oscillator has stabilized. If the EN input is set high by the MCU (or other system

device), the reader stays active. If the EN input is not set high within 100 μs after the SYS_CLK output is

switched from auxiliary clock (60 kHz) to high-frequency clock (derived from the crystal oscillator), the

reader system returns to complete power-down mode. This option can be used to wake the reader system

from complete power down by using a push-button switch or by sending a single pulse.

Copyright © 2006–2010, Texas Instruments Incorporated System Description 13

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 14

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

www.ti.com

After the reader EN line is high, the other power modes are selected by control bits. The power mode

options and functions are listed in Table 5-5.

Table 5-5. Power Modes

Byte Option Bits Setting in Chip Status Control Register EN EN2 Functionality Current

Address

B7 B6 B5 B4 B3 B2 B1 B0

STBY RFON RF PWR REC ON

00 0 0 Complete power down <1 μA

00 0 1 VDD_X available 120 μA

SYS_CLK auxiliary frequency 60 kHz is ON

00 1 x x x 1 x All supply regulators active and in low power 1.5 mA

mode

13.56-MHz oscillator ON

SYS_CLK clock available

00 0 0 x 0 1 x All supply regulators active 3.5 mA

13.56-MHz oscillator ON

SYS_CLK clock available

00 0 0 x 1 1 x All supply regulators active 10 mA

13.56-MHz oscillator ON

SYS_CLK clock available

Receiver active

00 0 1 1 x 1 x All supply regulators active 70 mA

13.56-MHz oscillator ON (at 5 V)

SYS_CLK clock available

Receiver active

Transmitter active – half-power mode

00 0 1 0 x 1 x All supply regulators active 120 mA

13.56-MHz oscillator running (at 5 V)

SYS_CLK clock available

Receiver active

Transmitter active – full-power mode

During reader inactivity, the TRF7960/61 can be placed in power down-mode (EN = 0). The power down

can be complete (EN = 0, EN2 = 0) with no function running, or partial (EN = 0, EN2 = 1) where the

regulated supply (V

) and auxiliary clock 60 kHz (SYS_CLK) are available to the MCU or other system

DD_X

device.

When EN is set high (or on rising edge of EN2 and then confirmed by EN = 1), the supply regulators are

activated and the 13.56-MHz oscillator started. When the supplies are settled and the oscillator frequency

is stable, the SYS_CLK output is switched from the auxiliary frequency of 60 kHz to the selected

frequency derived from the crystal oscillator. At this point, the reader is ready to communicate and perform

the required tasks. The control system (MCU) can then write appropriate bits to the chip status control

register (address 00) and select the operation mode.

The STANDBY mode (bit 7 = 1 of register 00) is the active mode with the lowest current consumption. The

reader is capable of recovering from this mode to full operation in 100 μs.

The active mode with RF section disabled (bit 5 = 0 and bit 1 = 0 of register 00) is the next active mode

with low power consumption. The reader is capable of recovering from this mode to full operation in 25 μs.

The active mode with only the RF receiver section active (bit 1 = 1 of register 00) can be used to measure

the external RF field (as described in RSSI measurements paragraph) if reader-to-reader anticollision is

implemented.

The active mode with the entire RF section active (bit 5 = 1 of register 00) is the normal mode used for

transmit and receive operations.

14 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 15

C001

C002

TRF7960

TRF7961

www.ti.com

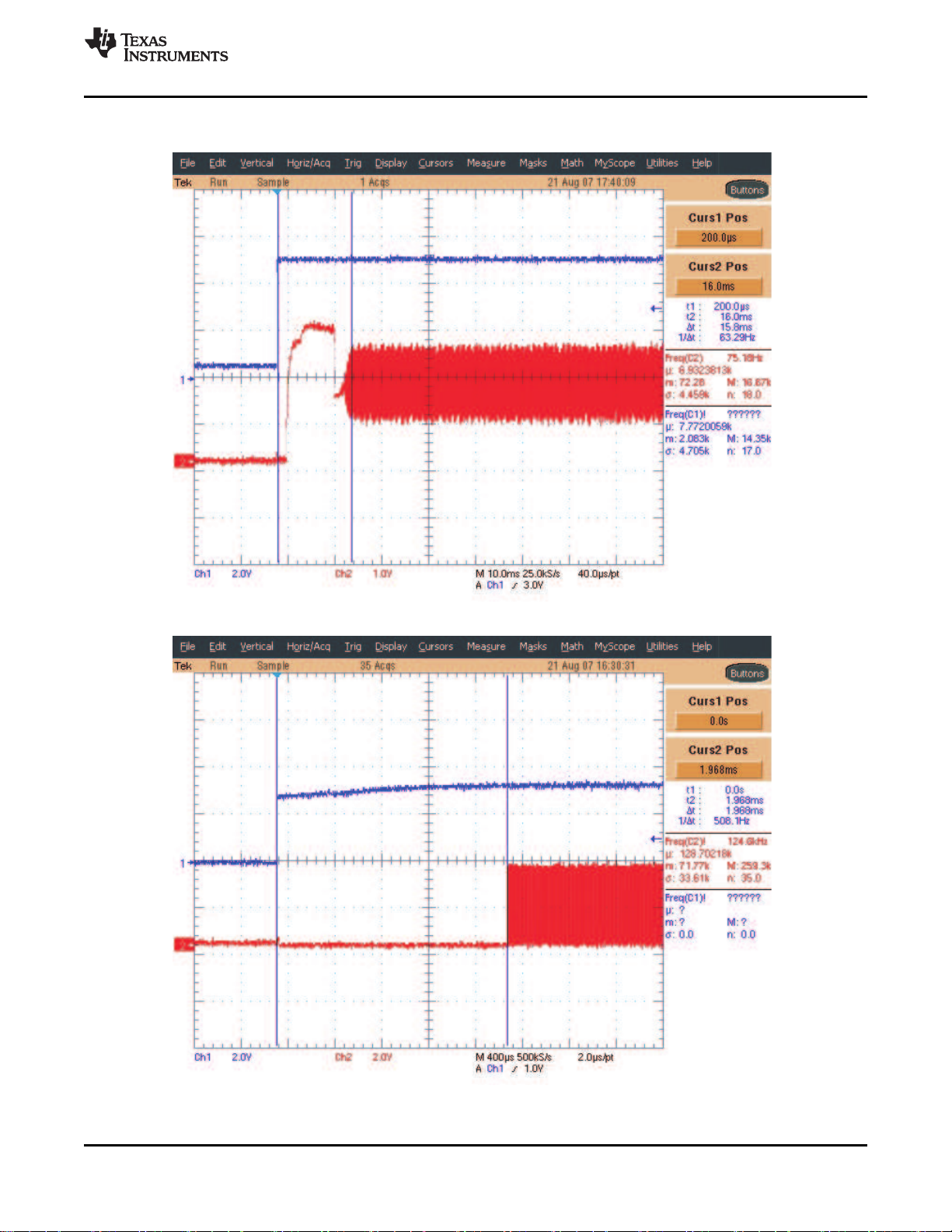

5.1.5 Timing Diagrams

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

CHIP POWER UP TO CLOCK START

Figure 5-1. Power Up [VIN(Blue) to Crystal Start (Red)]

CHIP ENABLE TO CLOCK START

Figure 5-2. EN2 Low and EN High (Blue) to Start of System Clock (Red)

Copyright © 2006–2010, Texas Instruments Incorporated System Description 15

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

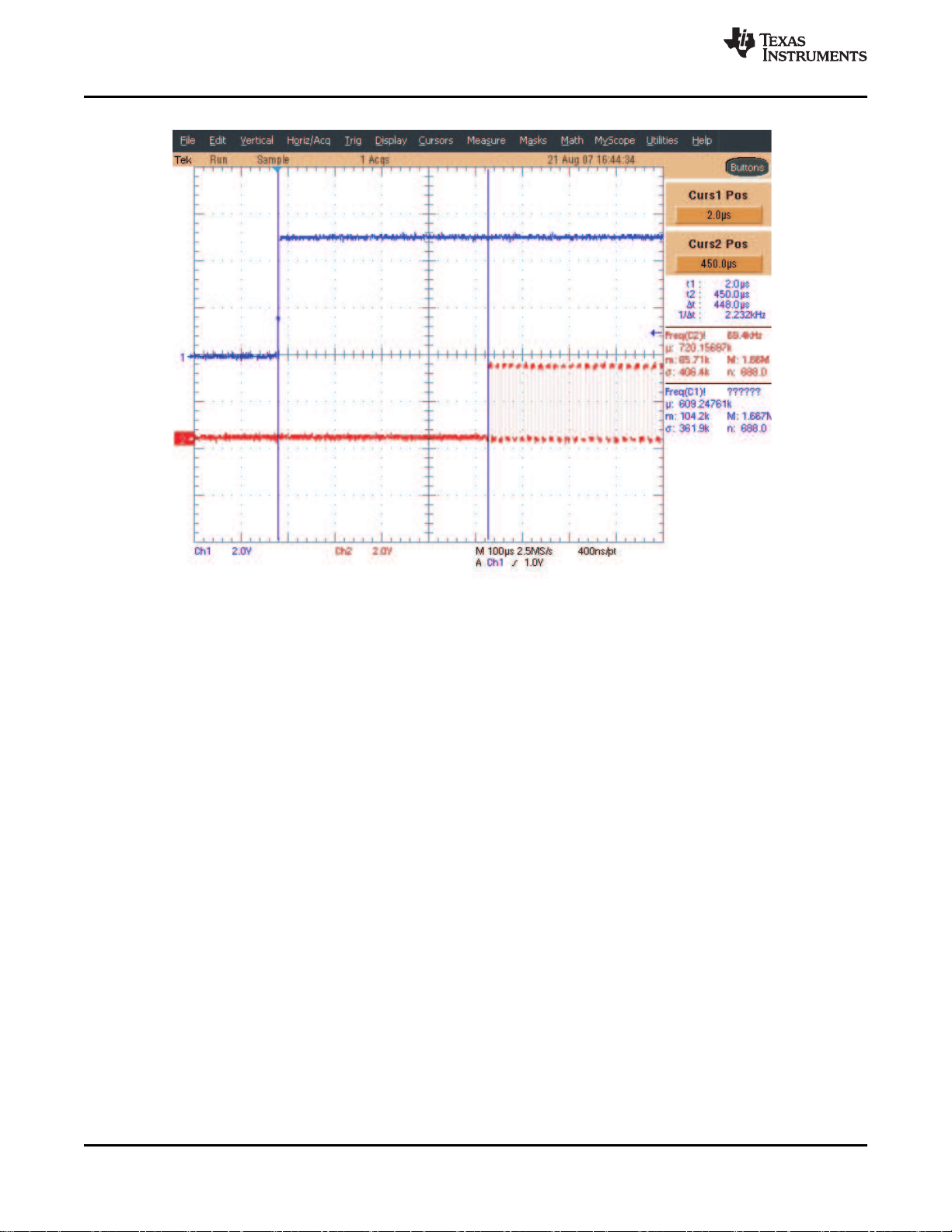

Page 16

C003

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

www.ti.com

CHIP ENABLE TO CLOCK START

Figure 5-3. EN2 High and EN Low (Blue) to Start of System Clock (Red)

16 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 17

TRF7960

TRF7961

www.ti.com

5.2 Receiver – Analog Section

The TRF7960/61 has two receiver inputs, RX_IN1 (pin 8) and RX_IN2 (pin 9). The two inputs are

connected to an external filter to ensure that AM modulation from the tag is available on at least one of the

two inputs. The external filter provides a 45° phase shift for the RX_IN2 input to allow further processing of

a received PM-modulated signal (if it appears) from the tag. This architecture eliminates any possible

communication holes that may occur from the tag to the reader.

The two RX inputs are multiplexed to two receiver channels: the main receiver and the auxiliary receiver.

Receiver input multiplexing is controlled by control bit B3 (pm-on) in the chip status control register

(address 00). The main receiver is composed of an RF-detection stage, gain, filtering with AGC, and a

digitizing stage whose output is connected to the digital processing block. The main receiver also has an

RSSI measuring stage, which measures the strength of the demodulated signal.

The primary function of the auxiliary receiver is to measure the RSSI of the modulation signal. It also has

similar RF-detection, gain, filtering with AGC, and RSSI blocks.

The default setting is RX_IN1 connected to the main receiver and RX_IN2 connected to the auxiliary

receiver (bit pm_on = 0). When a response from the tag is detected by the RSSI, values on both inputs

are measured and stored in the RSSI level register (address 0F). The control system reads the RSSI

values and switches to the stronger receiver input (RX_IN1 or RX_IN2 by setting pm_on = 1).

The receiver input stage is an RF level detector. The RF amplitude level on RX_IN1 and RX_IN2 inputs

should be approximately 3 VPPfor a VINsupply level greater than 3.3 V. If the VINlevel is lower, the RF

input peak-to-peak voltage level should not exceed the VINlevel. Note: VINis the main supply voltage to

the device at pin 2.

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

The first gain and filtering stage following the RF-envelope detector has a nominal gain of 15 dB with an

adjustable bandpass filter. The bandpass filter has adjustable 3-dB frequency steps (100 kHz to 400 kHz

for high pass and 600 kHz to 1500 kHz for low pass). Following the bandpass filter is another

gain-and-filtering stage with a nominal gain of 8 dB and with frequency characteristics identical to the first

stage.

The internal filters are configured automatically, with internal presets for each new selection of a

communication standard in the ISO control register (address 01). If required, additional fine tuning can be

accomplished by writing directly to the RX special setting registers (address 0A).

The second receiver gain stage and digitizer stage are included in the AGC loop. The AGC loop is

activated by setting the bit B2 = 1 (agc-on) in the chip status control register (address 00). When

activated, the AGC continuously monitors the input signal level. If the signal level is significantly higher

than an internal threshold level, gain reduction is activated. AGC activation is by default five times the

internal threshold level. It can be reduced to three times the internal level by setting bit B1 = 1 (agcr) in the

RX special setting register (address 0A). The AGC action is fast, typically finishing after four sub-carrier

pulses. By default, the AGC action is blocked after the first few pulses of the sub-carrier signal. This

prevents the AGC from interfering with the reception of the remaining data packet. In certain situations,

this type of blocking is not optimal, so it can be removed by setting B0 = 1 (no_lim) in the RX special

setting register (address 0A).

The bits of the RX special settings register (address 0A), which control the receiver analog section, are

shown in Table 5-20.

5.2.1 Received Signal Strength Indicator (RSSI)

The RSSI measurement block measures the demodulated signal (except in the case of a direct command

for RF-amplitude measurement described in the Direct Commands section). The measuring system

latches the peak value, so the RSSI level can be read after the end of the receive packet. The RSSI

register values reset with every transmission by the reader. This allows an updated RSSI measurement

for each new tag response.

Copyright © 2006–2010, Texas Instruments Incorporated System Description 17

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 18

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

Correlation between the RF input level and RSSI designation levels on the RX_IN1 and RX_IN2 are

shown in Table 5-6 and Table 5-7.

Table 5-6 shows the RSSI level versus RSSI bit value. The RSSI has seven levels (3 bits each) with 4-dB

increments. The input level is the peak-to-peak modulation level of the RF signal as measured on one side

envelope (positive or negative).

Table 5-6. RSSI Level Versus Register Bit Value

RSSI 1 2 3 4 5 6 7

Input level 2 mVpp 3.2 mVpp 5 mVpp 8 mVpp 13 mVpp 20 mVpp 32 mVpp

As an example, from Table 5-7, let B2 = 1, B1 = 1, B0 = 0; this yields an RSSI value of 6. From Table 5-6

a Bit value of 6 would yield an RSSI level of 20 mVpp.

Table 5-7. RSSI Bit Value and Oscillator Status Register (0F)

Bit Signal Name Function Comments

B7 Unused

B6 osc_ok Crystal oscillator stable

B5 rssi_x2 MSB of auxiliary receiver RSSI

B4 rssi_x1 Auxiliary receiver RSSI

B3 rssi_x1 LSB of auxiliary receiver RSSI

B2 rssi_2 MSB of main receiver RSSI

B1 rssi_1 Main receiver RSSI

B0 rssi_0 LSB of main receiver RSSI

4 dB per step

www.ti.com

5.2.2 Receiver – Digital Section

The received sub-carrier is digitized to form a digital representation of the modulated RF envelope. This

digitized signal is applied to digital decoders and framing circuits for further processing.

The digital part of the receiver consists of two sections, which partly overlap. The first section is the bit

decoders for the various protocols, whereas the second section consists of framing logic. The bit decoders

convert the sub-carrier coded signal to a bit stream and also to the data clock. Thus, the sub-carrier-coded

signal is transformed to serial data and the data clock is extracted. The decoder logic is designed for

maximum error tolerance. This enables the decoders to successfully decode even partly corrupted (due to

noise or interference) sub-carrier signals.

In the framing section, the serial bit-stream data is formatted in bytes. In this process, special signals like

the start of frame (SOF), end of frame (EOF), start of communication, and end of communication are

automatically removed. The parity bits and CRC bytes are checked and also removed. The end result is

clean or raw data, which is sent to the 12-byte FIFO register where it can be read by the external

microcontroller system.

The start of the receive operation (successfully received SOF) sets the flags in the IRQ and status

register. The end of the receive operation is indicated to the external system (MCU) by sending an

interrupt request (pin 13 IRQ). If the receive data packet is longer than 8 bytes, an interrupt is sent to the

MCU when the received data occupies 75% of the FIFO capacity to signal that the data should be

removed from the FIFO.

Any error in data format, parity, or CRC is detected, and the external system is notified of the error by an

interrupt-request pulse. The source condition of the interrupt-request pulse is available in the IRQ and

status register (address 0C). The bit-coding description of this register is given in Table 5-22.

18 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 19

TRF7960

TRF7961

www.ti.com

The main register controlling the digital part of the receiver is the ISO control register (address 01). By

writing to this register, the user selects the protocol to be used. With each new write in this register, the

default presets are loaded in all related registers, so no further adjustments in other registers are needed

for proper operation.

Table 5-10 shows the coding of the ISO control register. Note that the TRF7961 does not include the

ISO14443 functionality; its features/commands in this area are non-functional.

The framing section also supports the bit-collision detection as specified in ISO14443A. When a bit

collision is detected, an interrupt request is sent and flag set in the IRQ and status register. The position of

the bit collision is written in two registers. Register collision position, with address 0E, and in register

collision position and interrupt mask (address 0D), in which only the bits B7 and B6 are used for collision

position. The collision position is presented as a sequential bit number, where the count starts immediately

after the start bit. For example, the collision in the first bit of the UID would give the value 00 0001 0000 in

the collision-position registers. The count starts with 0, and the first 16 bits are the command code and the

NVB byte. Note: the NVB byte is the number of valid bits.

The receive section also has two timers. The RX-wait-time timer is controlled by the value in the RX wait

time register (address 08). This timer defines the time after the end of the transmit operation in which the

receive decoders are not active (held in reset state). This prevents incorrect detections resulting from

transients following the transmit operation. The value of the RX wait time register defines this time in

increments of 9.44 μs. This register is preset at every write to ISO control register (address 01) according

to the minimum tag-response time defined by each standard.

The RX no-response timer is controlled by the RX no response wait time register (address 07). This timer

measures the time from the start of slot in the anti-collision sequence until the start of tag response. If

there is no tag response in the defined time, an interrupt request is sent and a flag is set in IRQ status

control register. This enables the external controller to be relieved of the task of detecting empty slots. The

wait time is stored in the register in increments of 37.76 μs. This register is also preset, automatically, for

every new protocol selection.

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

5.2.3 Transmitter

The transmitter section consists of the 13.56-MHz oscillator, digital protocol processing, and RF output

stage.

5.2.3.1 Transmitter – Analog

The 13.56-MHz crystal oscillator (connected to pins 31 and 32) directly generates the RF frequency for the

RF output stage. Additionally, it also generates the clock signal for the digital section and clock signal

displayed for the SYS_CLK (pin 27) which can be used by an external MCU system.

During partial power-down mode (EN = 0, EN2 = 1), the frequency of SYS_CLK is 60 kHz. During normal

reader operation, SYS_CLK can be programmed by bits B4 and B5 in the modulator and SYS_CLK

control register (address 09); available clock frequencies are 13.56 MHz, 6.78 MHz, or 3.39 MHz.

The reference crystal (HC49U) should have the following characteristics:

Parameter Specification

Frequency 13.560000 MHz

Mode of operation Fundamental

Type of resonance Parallel

Frequency tolerance ±20 ppm

Aging < 5 ppm/year

Operation temperature range –40°C to 85°C

Equivalent series resistance 50 Ω, minimum

Copyright © 2006–2010, Texas Instruments Incorporated System Description 19

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 20

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

The crystal oscillator’s two external shunt capacitor values are calculated based on the

crystal’s specified load capacitance. The external capacitors (connected to the OSC pins 30

and 31), are calculated as two capacitors in series plus CS(oscillator's gate internal

input/output capacitance plus PCB stray capacitance). The stray capacitance (CS) can be

estimated at approximately 5 ±2 pF (typical).

As an example, given a crystal with a required load capacitance (CL) of 18 pF,

CL= ((C1× C2) / (C1+ C2)) + C

18 pF = ((27 pF × 27 pF) / (27 pF + 27 pF)) + 4.5 pF

Hence, from this example, a 27-pF capacitor would be placed on pins 30 and 31 to ensure

proper crystal oscillator operation.

The transmit power level is selectable between half power of 100 mW (20 dBm) or full power of 200 mW

(23 dBm) when configured for 5-V automatic operation. The transmit output impedance is 8 Ω when

configured for half power and 4 Ω when configured for full power. Selection of the transmit power level is

set by bit B4 (rf_pwr) in the chip status control register (Table 5-9). When configured for 3-V automatic

operation, the transmit power level is typically selectable between 33 mW (15 dBm) in half-power mode

and 70 mW (18 dBm) in full-power mode (Vdd_RF at 3.3 V). Note that lower operating voltages result in

reduced transmit power levels.

www.ti.com

NOTE

S

In normal operation, the transmit modulation is configured by the selected ISO control register (address

01). External control of the transmit modulation is possible by setting the ISO control register (address 01)

to direct mode. While in direct mode, the transmit modulation is made possible by selecting the modulation

type ASK or OOK at pin 12. External control of the modulation type is made possible only if enabled by

setting B6 = 1 (en_ook_p) in the modulator and SYS_CLK control register (address 09). ASK modulation

depth is controlled by bits B0, B1 and B2 in the Modulator and SYS_CLK Control register (address 09).

The range of the ASK modulation is 7%–30%, or 100% (OOK).

The coding of the modulator and SYS_CLK control register is shown in Table 5-19.

The length of the modulation pulse is defined by the protocol selected in the ISO control register. With a

high-Q antenna, the modulation pulse is typically prolonged, and the tag detects a longer pulse than

intended. For such cases, the modulation pulse length can be corrected by using the TX pulse length

register. If the register contains all zeros, then the pulse length is governed by the protocol selection. If the

register contains a value other than 00h, the pulse length is equal to the value of the register in 73.7-ns

increments. This means the range of adjustment can be between 73.7 ns and 18.8 μs.

5.2.3.2 Transmitter - Digital

The digital portion of the transmitter is very similar to that of the receiver. Before beginning data

transmission, the FIFO should be cleared with a Reset command (0F). Data transmission is initiated with a

selected command (described in the Direct Commands section, Table 5-29). The MCU then commands

the reader to do a continuous Write command (3Dh, see Table 5-31) starting from register 1Dh. Data

written into register 1Dh is the TX length byte1 (upper and middle nibbles), while the following byte in

register 1Eh is the TX length byte2 (lower nibble and broken byte length). The TX byte length determines

when the reader sends the EOF byte. After the TX length bytes, FIFO data is loaded in register 1Fh with

byte storage locations 0 to 11. Data transmission begins automatically after the first byte is written into the

FIFO. The TX length bytes and FIFO can be loaded with a continuous-write command because the

addresses are sequential.

If the data length is longer than the allowable size of the FIFO, the external system (MCU) is warned when

the majority of data from the FIFO has already been transmitted by sending an interrupt request with a

flag in the IRQ register signaling FIFO low/high status. The external system should respond by loading the

next data packet into the FIFO.

20 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 21

TRF7960

TRF7961

www.ti.com

At the end of the transmit operation, the external system is notified by another interrupt request with a flag

in the IRQ register that signals the end of TX.

The TX length register also supports incomplete bytes transmitted. The high two nibbles in register 1D and

the nibble composed of bits B4–B7 in register 1E store the number of complete bytes to be transmitted.

Bit 0 (in register 1E) is a flag that signals the presence of additional bits to be transmitted that do not form

a complete byte. The number of bits are stored in bits B1–B3 of the same register (1E).

The protocol is selected by the ISO control register (address 01), which also selects the receiver protocol.

As defined by the selected protocol, the reader automatically adds all the special signals, like start of

communication, end of communication, SOF, EOF, parity bits, and CRC bytes. The data is then coded to

the modulation pulse level and sent to the modulation control of the RF output stage. This means that the

external system is only required to load the FIFO with data, and all the low-level coding is done

automatically. Also, all registers used in transmission are automatically preset to the optimum value when

a new selection is entered into the ISO control register.

Some protocols have options; two registers are provided to select the TX-protocol options. The first such

register is ISO14443B TX options (address 02). It controls the SOF and EOF selection and EGT (extra

guard time) selection for the ISO14443B protocol. The bit definitions of this register are given in

Table 5-12.

The second register controls the ISO14443 high bit-rate options. This register enables the use of different

bit rates for RX and TX operations in the ISO14443 high bit-rate protocol. Additionally, it also selects the

parity system for the ISO14443A high bit-rate selection. The bit definitions of this register are given in

Table 5-13.

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

The transmit section also has a timer that can be used to start the transmit operation at a precise time

interval from a selected event. This is necessary if the tag requires a reply in an exact window of time

following the tag response. The TX timer uses two registers (addresses 04 and 05). In first register

(address 04); two bits (B7 and B6) are used to define the trigger conditions. The remaining 6 bits are the

upper bits and the 8 bits in register address 05 are lower bits, which are preset to the counter. The

increment is 590 ns and the range of this counter is from 590 ns to 9.7 ms. The bit definitions (trigger

conditions) are shown in Table 5-14.

Copyright © 2006–2010, Texas Instruments Incorporated System Description 21

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 22

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

5.2.4 Direct Mode

Direct mode allows the user to configure the reader in one of two ways. Direct mode 0 (bit 6 = 0, as

defined in ISO control register) allows the user to use only the front-end functions of the reader, bypassing

the protocol implementation in the reader. For transmit functions, the user has direct access to the

transmit modulator through the MOD pin (pin 14). On the receive side, the user has direct access to the

sub-carrier signal (digitized RF envelope signal) on I/O_6 (pin 23).

Direct mode1 (bit 6 = 1, as defined in ISO control register) uses the sub-carrier signal decoder of the

selected protocol (as defined in ISO control register). This means that the receive output is not the

sub-carrier signal but the decoded serial bit stream and bit clock signals. The serial data is available on

I/O_6 (pin 23) and the bit clock is available on I/O_5 (pin 22). The transmit side is identical; the user has

direct control over the RF modulation through the MOD input. This mode is provided so that the user can

implement a protocol that has the same bit coding as one of the protocols implemented in the reader, but

needs a different framing format.

To select direct mode, the user must first choose which direct mode to enter by writing B6 in the ISO

control register. This bit determines if the receive output is the direct sub-carrier signal (B6 = 0) or the

serial data of the selected decoder. If B6 = 1, then the user must also define which protocol should be

used for bit decoding by writing the appropriate setting in the ISO control register.

The reader actually enters the direct mode when B6 (direct) is set to 1 in the chip status control register.

Direct mode starts immediately. The write command should not be terminated with a stop condition (see

communication protocol), because the stop condition terminates the direct mode and clears B6. This is

necessary as the direct mode uses one or two I/O pins (I/O_6, I/O_5). Normal parallel communication is

not possible in direct mode. Sending a stop condition terminates direct mode.

www.ti.com

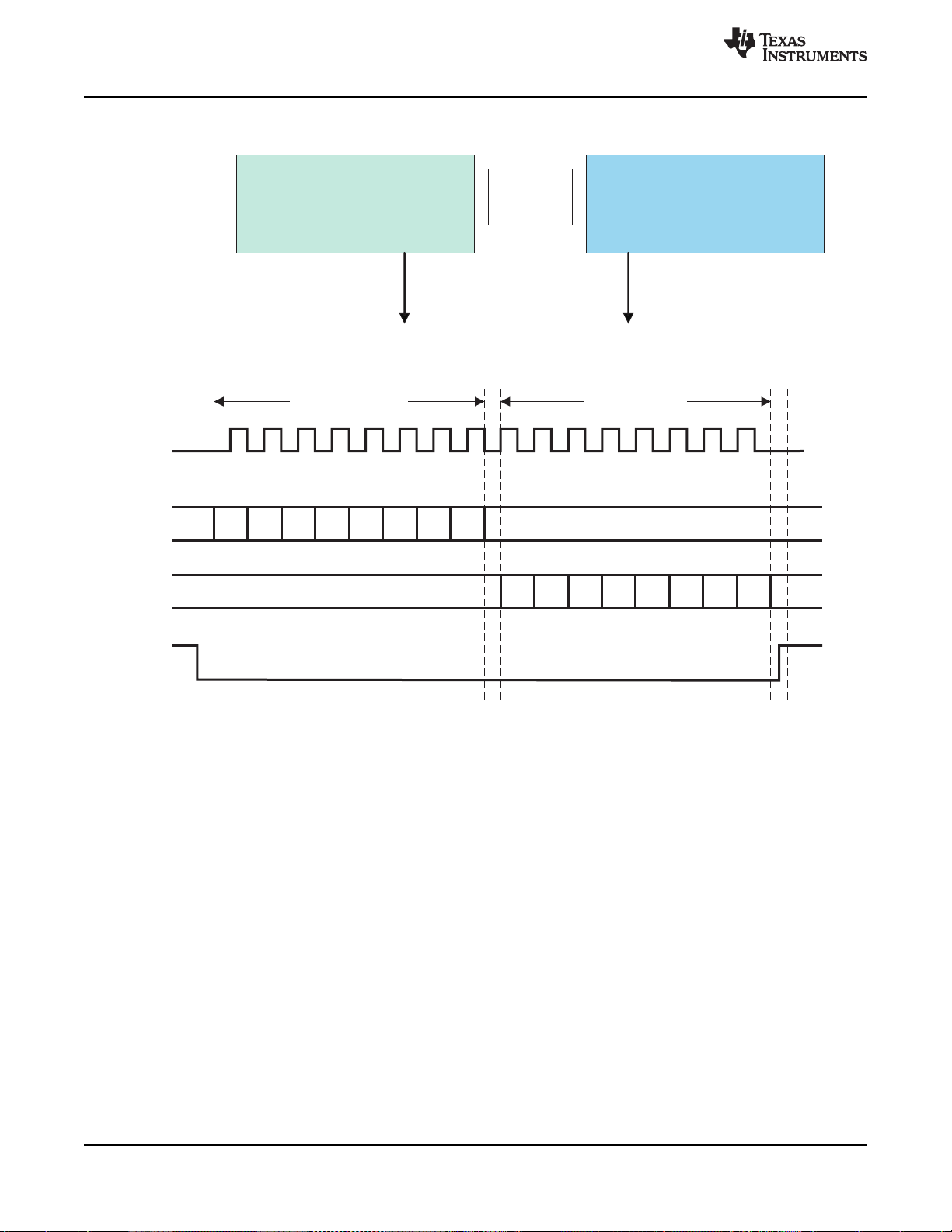

Figure 5-4 shows the different configurations available in direct mode.

• In mode 0, the reader is used as an AFE only, and protocol handling is bypassed.

• In mode 1, framing is not done, but SOF and EOF are present. This allows for a user-selectable

framing level based on an existing ISO standard.

• In mode 2, data is ISO-standard formatted. SOF, EOF, and error checking are removed, so the

microprocessor receives only bytes of raw data via a 12-byte FIFO.

22 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 23

Mode 2: Full ISO With Framing and Error Checking (Typical Mode)

AnalogFrontEnd(AFE)

Packetization/Framing

14443A 14443B 15693

Tag-it

ISOEncoder/Decoders

Mode0:

Raw,Sub-CarrierData

Mode1:

Un-FramedRawISO

FormattedData

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

Figure 5-4. User-Configurable Modes

5.2.5 Register Preset

After power-up and the EN pin low-to-high transition, the reader is in the default mode. The default

configuration is ISO15693, single sub-carrier, high data rate, 1-out-of-4 operation. The low-level option

registers (02…0B) are automatically set to adapt the circuitry optimally to the appropriate protocol

parameters.

When entering another protocol (writing to the ISO control register 01), the low-level option registers

(02…0B) are automatically configured to the new protocol parameters.

After selecting the protocol, it is possible to change some low-level register contents if needed. However,

changing to another protocol and then back, reloads the default settings, and the user must reload the

custom settings.

The Clo1 and Clo0 (register 09) bits, which define the microcontroller frequency available on the

SYS_CLK pin, are the only two bits in the configuration registers that are not cleared during protocol

selection.

Copyright © 2006–2010, Texas Instruments Incorporated System Description 23

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 24

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

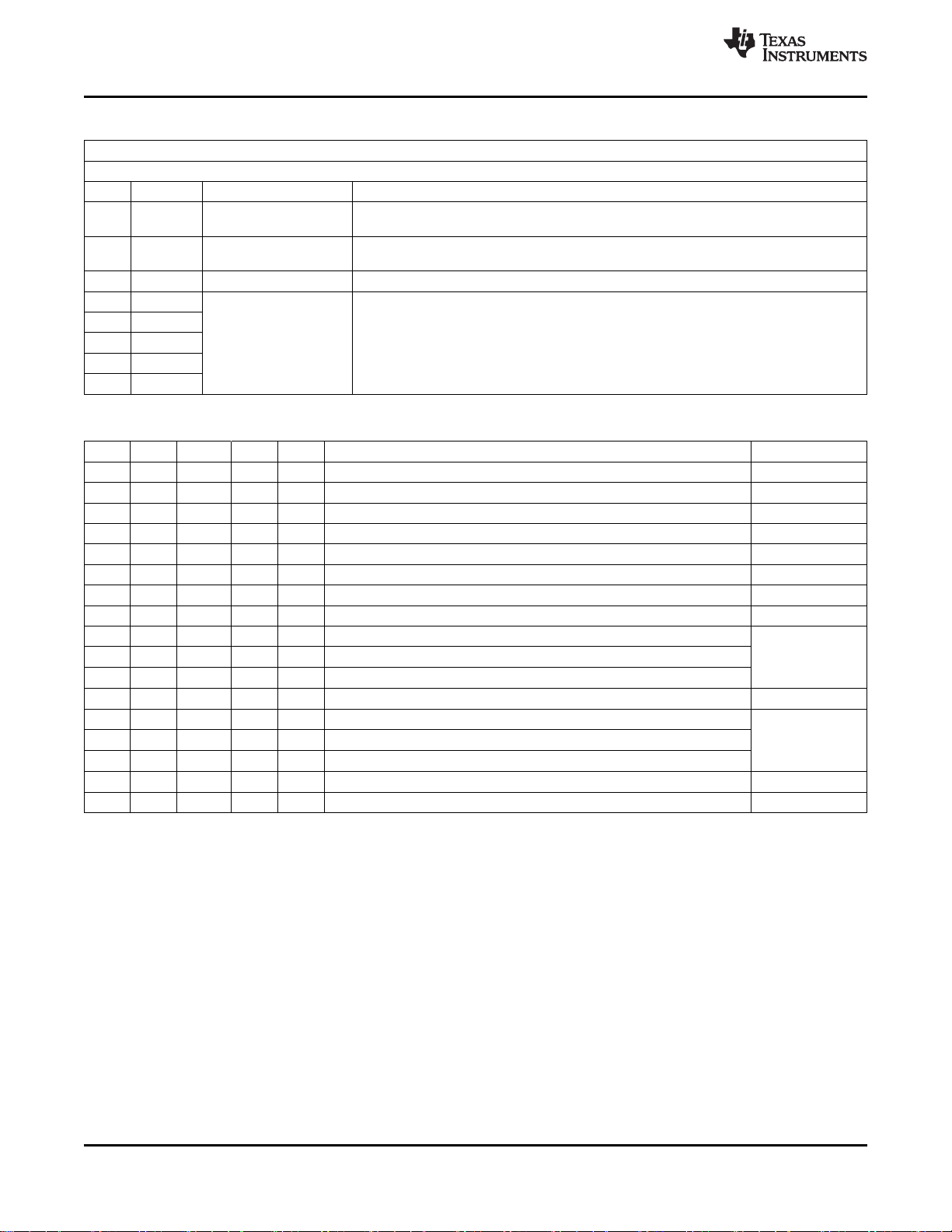

5.3 Register Descriptions

Adr (hex) Register Read/Write

Main Control Registers

00 Chip status control R/W

01 ISO control R/W

Protocol Sub-Setting Registers

02 ISO14443B TX options R/W

03 ISO 14443A high bit rate options R/W

04 TX timer setting, H-byte R/W

05 TX timer setting, L-byte R/W

06 TX pulse-length control R/W

07 RX no response wait R/W

08 RX wait time R/W

09 Modulator and SYS_CLK control R/W

0A RX special setting R/W

0B Regulator and I/O control R/W

16 Unused NA

17 Unused NA

18 Unused NA

19 Unused NA

Status Registers

0C IRQ status R

0D Collision position and interrupt mask register R/W

0E Collision position R

0F RSSI levels and oscillator status R

FIFO Registers

1C FIFO status R

1D TX length byte1 R/W

1E TX length byte2 R/W

1F FIFO I/O register R/W

www.ti.com

Table 5-8. Register Address Space

24 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 25

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

5.3.1 Control Registers – Main Configuration Registers

Table 5-9. Chip Status Control (00h)

Controls the power mode, RF on / off, AGC, AM / PM

Register default is 0x01. It is preset at EN = L or POR = H

Bit Bit Name Function Comments

B7 stby 1 = standby mode Standby mode keeps regulators and oscillator running en_rec =

B6 direct 1 = received sub-carrier signal (decoders The modulation control is direct through MOD input. The receiver

B5 rf_on 1 = RF output active When B5 = 1, it activates the RF field.

B4 rf_pwr 1 = half output power 1 = RF driver at 8 Ω

B3 pm_on 1 = RX_IN2 1 = Selects PM signal input

B2 agc_on 1 = AGC on AGC selection

B1 rec_on 1 = Reciever enable for external field Receiver and oscillator are enabled; intended for external field

B0 vrs5_3 1 = 5 V operation (VIN) Selects the V

0 = active mode L, en_tx = L

bypassed) sub-carrier signal is on I/0_6.

0 = received decoded signal from selected

decoder

0 = RF output not active

0 = full output power 0 = RF driver at 4 Ω

0 = RX_IN1 0 = Selects AM signal input

0 = AGC off

measurement measurement.

range; 5 V (4.3 V – 5 V), or 3 V (2.7 V – 3.4

0 = 3 V operation (VIN) V)

DD_RF

Copyright © 2006–2010, Texas Instruments Incorporated System Description 25

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 26

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

www.ti.com

Table 5-10. ISO Control (01h)

Controls the ISO selection

Register default is 0x02, which is ISO15693 high bit rate, one sub-carrier, 1 out of 4. It is preset at EN = L or POR = H.

Bit Bit Name Function Comments

B7 rx_crc_n Receiving without CRC 1 = no RX CRC

B6 dir_mode Direct mode type 0 = output is sub-carrier data.

B5 rfid RFID mode Should always be set to 0

B4 iso_4

B3 iso_3

B2 iso_2 RFID mode See Table 5-11

B1 iso_1

B0 iso_0

0 = RX CRC

1 = output is bit stream (I/O_6) and bit clock (I/O_5) from decoder selected by ISO bits

Table 5-11. RFID Mode Selections

Iso_4 Iso_3 Iso_2 Iso_1 Iso_0 Protocol Remarks

0 0 0 0 0 ISO15693 low bit rate 6.62 kbps one sub-carrier 1 out of 4

0 0 0 0 1 ISO15693 low bit rate 6.62 kbps one sub-carrier 1 out of 256

0 0 0 1 0 ISO15693 high bit rate 26.48 kbps one sub-carrier 1 out of 4 Default for reader

0 0 0 1 1 ISO15693 high bit rate 26.48 kbps one sub-carrier 1 out of 256

0 0 1 0 0 ISO15693 low bit rate 6.67 kbps double sub-carrier 1 out of 4

0 0 1 0 1 ISO15693 low bit rate 6.67 kbps double sub-carrier 1 out of 256

0 0 1 1 0 ISO15693 high bit rate 26.69 kbps double sub-carrier 1 out of 4

0 0 1 1 1 ISO15693 high bit rate 26.69 kbps double sub-carrier 1 out of 256

0 1 0 0 0 ISO14443A bit rate 106 kbps RX bit rate when

0 1 0 0 1 ISO14443A high bit rate 212 kbps

0 1 0 1 0 ISO14443A high bit rate 424 kbps

0 1 0 1 1 ISO14443A high bit rate 848 kbps

0 1 1 0 0 ISO14443B bit rate 106 kbps RX bit rate when

0 1 1 0 1 ISO14443B high bit rate 212 kbps

0 1 1 1 0 ISO14443B high bit rate 424 kbps

0 1 1 1 1 ISO14443B high bit rate 848 kbps

1 0 0 1 1 Tag-it

TX bit rate is

different than RX

(reg03)

TX bit rate is

different than RX

(reg03)

26 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 27

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

5.3.2 Control Registers – Sub Level Configuration Registers

Table 5-12. ISO14443B TX Options (02h)

Selects the ISO subsets for ISO14443B – TX

Register default is set to 0x00 at POR = H or EN = L

Bit Bit Name Function Comments

B7 egt2 TX EGT time select MSB Three bit code defines the number of etu (0-7) which

B6 egt1 TX EGT time select

B5 egt0 TX EGT time select LSB

B4 eof_l0 1 = EOF, 0 length 11 etu ISO14443B TX only

0 = EOF, 0 length 10 etu

B3 sof_l1 1 = SOF, 1 length 03 etu

0 = SOF, 1 length 02 etu

B2 sof _l0 1 = SOF, 0 length 11 etu

0 = SOF, 0 length 10 etu

B1 l_egt 1 = EGT after each byte

0 = EGT after last byte is omitted

B0 Unused

Table 5-13. ISO 14443A High-Bit-Rate Options (03h)

separate two characters. ISO14443B TX only

Parity

Register default is set to 0x00 at POR = H, or EN = L and at each write to ISO control register

Bit Bit Name Function Comments

B7 dif_tx_br TX bit rate different than RX bit rate enable Valid for ISO14443A/B high bit rate

B6 tx_br1 TX bit rate tx_br1 = 0, tx_br = 0 106 kbps

B5 tx_br0

B4 parity-2tx 1 = parity odd except last byte which is even for TX For 14443A high bit rate, coding and decoding

B3 parity-2rx 1 = parity odd except last byte which is even for RX

B2 Unused

B1 Unused

B0 Unused

tx_br1 = 0, tx_br = 1 212 kbps

tx_br1 = 1, tx_br = 0 424 kbps

tx_br1 = 1, tx_br = 1 848 kbps

Table 5-14. TX Timer H-Byte (04h)

Register default is set to 0xC2 at POR = H or EN = L and at each write to ISO control register

Bit Bit Name Function Comments

B7 Tm_st1 Timer start condition tm_st1 = 0, tm_st0 = 0 beginning of TX SOF

B6 Tm_st0 Timer start condition

B5 Tm_lengthD Timer length MSB

B4 Tm_lengthC Timer length

B3 Tm_lengthB Timer length

B2 Tm_lengthA Timer length

B1 Tm_length9 Timer length

B0 Tm_length8 Timer length LSB

tm_st1 = 0, tm_st0 = 1 end of TX SOF

tm_st1 = 1, tm_st0 = 0 beginning of RX SOF

tm_st1 = 1, tm_st0 = 1 end of RX SOF

Copyright © 2006–2010, Texas Instruments Incorporated System Description 27

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 28

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

Table 5-15. TX Timer L-Byte (05h)

Register default is set to 0x00 at POR = H or EN = L and at each write to ISO control register

Bit Bit Name Function Comments

B7 Tm_length7 Timer length MSB Defines the time when delayed transmission is started.

B6 Tm_length6 Timer length

B5 Tm_length5 Timer length

B4 Tm_length4 Timer length

B3 Tm_length3 Timer length

B2 Tm_length2 Timer length

B1 Tm_length1 Timer length

B0 Tm_length0 Timer length LSB

RX wait range is 590 ns to 9.76 ms (1..16383)

Step size 590 ns

All bits low (00): Timer is disabled.

Preset: 00 all other protocols

Table 5-16. TX Pulse Length Control (06h)

Controls the length of TX pulse

Register default is set to 0x00 at POR = H or EN = L and at each write to ISO control register.

Bit Bit Name Function Comments

B7 Pul_p2 Pulse length MSB The pulse range is 73.7 ns to 18.8 μs (1…255), step size 73.7 ns

B6 Pul_p1

B5 Pul_p0

B4 Pul_c4

B3 Pul_c3

B2 Pul_c2

B1 Pul_c1

B0 Pul_c0 Pulse length LSB

All bits low (00): pulse length control is disabled

Preset: 9.44 μs ISO15693

Preset: 11 μs Tag-It

Preset: 2.36 μs ISO14443A

Preset: 1.4 μs ISO14443A at 212 kbps

Preset: 737 ns ISO14443A at 424 kbps

Preset: 442 ns ISO14443A at 848 kbps): pulse length control is disabled

www.ti.com

Table 5-17. RX No Response Wait Time (07h)

Defines the time when no response Interrupt is sent

Default: default is set to 0x0E at POR = H or EN = L and at each write to ISO control register.

Bit Bit Name Function Comments

B7 NoResp7 No response MSB Defines the time when no response interrupt is sent It starts from the end of TX EOF.

B6 NoResp6

B5 NoResp5

B4 NoResp4

B3 NoResp3

B2 NoResp2

B1 NoResp1

B0 NoResp0 No response LSB

RX no response wait range is 37.76 μs to 962 8μs (1...255),

Step size 37.76 μs

Preset: 755 μs ISO15693

Preset: 1812 μs ISO15693 low data rate

Preset: 604 μs Tag-It

Preset: 529 μs all other protocols

28 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 29

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

Table 5-18. RX Wait Time (08h)

Defines the time after TX EOF when the RX input is disregarded

Register default is set to 0x1F at POR = H or EN = L and at each write to ISO control register.

Bit Bit Name Function Comments

B7 Rxw7 RX wait Defines the time during which the RX input is ignored.

B6 Rxw6

B5 Rxw5

B4 Rxw4

B3 Rxw3

B2 Rxw2

B1 Rxw1

It starts from the end of TX EOF.

RX wait range is 9.44 μs to 2407 μs (1...255),

Step size 9.44 μs

Preset: 293 μs ISO15693

Preset: 66 μs ISO14443A and B

Preset: 180 μs Tag-It

Table 5-19. Modulator and SYS_CLK Control (09h)

Controls the modulation depth, modulation input and ASK / OOK control

Register default is set to 0x11 at POR = H or EN = L, and at each write to ISO control register, except Clo1 and Clo0.

Bit Bit Name Function Comments

B7 Unused

B6 en_ook_p 1 = enables external selection of ASK or OOK Valid only when ISO control register (01) is configured to direct mode

B5 Clo1 SYS_CLK output frequency MSB Clo1 Clo0 CL_SYS Output state

B4 Clo0 SYS_CLK output frequency LSB 0 0 disabled

B3 en_ana 1 = Enables analog output on ASK/OOK pin For test and measurement

B2 Pm2 Modulation depth MSB Pm2 Pm1 Pm0 Mod Type and %

B1 Pm1 Modulation depth

B0 Pm0 Modulation depth LSB

modulation

0 1 3.3 MHz

1 0 6.78 MHz

1 1 13.56 MHz

(pin12)

0 0 0 ASK 10%

0 0 1 OOK (100%)

0 1 0 ASK 7%

0 1 1 ASK 8.5%

1 0 0 ASK 13%

1 0 1 ASK 16%

1 1 0 ASK 22%

1 1 1 ASK 30%

Copyright © 2006–2010, Texas Instruments Incorporated System Description 29

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 30

TRF7960

TRF7961

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

www.ti.com

Table 5-20. RX Special Setting Register (Address 0Ah)

Sets the gains and filters directly

Register default is set to 0x40 at POR = H or EN = L, and at each write to the ISO control register.

Bit Bit Name Function Comments

B7 C212 Bandpass 110 kHz to 570 kHz Appropriate for 212-kHz sub-carrier system

B6 C424 Bandpass 200 kHz to 900 kHz Appropriate for 424-kHz sub-carrier used in ISO15693 and Tag-It

B5 M848 Bandpass 450 kHz to 1.5 MHz Appropriate for Manchester-coded 848-kHz sub-carrier used in ISO14443A

B4 hbt Bandpass 100 kHz to 1.5 MHz Appropriate for highest bit rate (848 kbps) used in high-bit-rate ISO14443

B3 gd1 01 gain reduction for 5 dB

B2 gd2

B1 agcr AGC activation level change AGC activation level changed from 5 times the digitizing level to 3 times the

B0 no-lim AGC action is not limited in time AGC action can be done any time during receive process. It is not limited to the

Gain reduced for 7 dB

10 gain reduction for 10 dB Sets the RX gain reduction

11 gain reduction for 15 dB

digitizing level.

start of receive.

Table 5-21. Regulator and I/O Control (0Bh)

Control the three voltage regulators

Register default is set to 0x87 at POR = H or EN = L

Bit Bit Name Function Comments

B7 auto_reg 0 = setting regulator by option bits Auto system sets VDD_RF to VIN – 250 mV and VDD_A and VDD_X to VIN –

B6 en_ext_pa Support for external power Receiver inputs accept externally demodulated sub-carrier, OOK pin becomes

B5 io_low 1 = enable low peripheral When HIGH, it decreases output resistance of logic outputs. Should be set

B4 Unused Default is LOW.

B3 Unused Default is LOW.

B2 vrs2 Voltage set MSB vrs3_5 = L: VDD_RF, VDD_A, VDD_X range 2.7 V to 3.4 V

B1 vrs1

B0 vrs0 Voltage set LSB

(vrs3_5 and vrs2, vrs1 and vrs0) 250 mV, but not higher than 3.4 V.

1 = automatic setting

amplifier modulation output for external amplifier.

communication voltage HIGH when VDD_I/O voltage is below 2.7 V.

30 System Description Copyright © 2006–2010, Texas Instruments Incorporated

Submit Documentation Feedback

focus.ti.com: TRF7960 TRF7961

Page 31

TRF7960

TRF7961

www.ti.com

SLOU186F–AUGUST 2006–REVISED AUGUST 2010

5.3.3 Status Registers

Table 5-22. IRQ Status Register (0Ch)

Displays the cause of IRQ and TX/RX status

Register default is set to 0x00 at POR = H or EN = L, and at each write to the ISO control register. It is also automatically reset at the end

of a read phase. The reset also removes the IRQ flag.

Bit Bit Name Function Comments

B7 Irq_tx IRQ set due to end of TX Signals that TX is in progress. The flag is set at the start of TX but the

B6 Irg_srx IRQ set due to RX start Signals that RX SOF was received and RX is in progress. The flag is set at

B5 Irq_fifo Signals the FIFO is 1/3 > FIFO > Signals FIFO high or low (less than 4 or more than 8)

2/3

B4 Irq_err1 CRC error Indicates receive CRC error

B3 Irq_err2 Parity error Indicates parity error

B2 Irq_err3 Byte framing or EOF error Indicates framing error

B1 Irq_col Collision error For ISO14443A and ISO15693 single sub-carrier

B0 Irq_noresp No-response interrupt Signal to MCU that next slot command can be sent

Table 5-23. Collision Position and Interrupt Mask Register (0Dh)

Register default is set to 3E at POR = H and EN = L. Collision bits reset automatically after read operation.

Bit Bit Name Function Comments

B7 Col9 Bit position of collision MSB Supported: ISO15693, single sub-carrier, and ISO14443A

B6 Col8 Bit position of collision

B5 En_irq_fifo Interrupt enable for FIFO

B4 En_irq_err1 Interrupt enable for CRC

B3 En_irq_err2 Interrupt enable for Parity

B2 En_irq_err3 Interrupt enable for Framing

error or EOF

B1 En_irq_col Interrupt enable for collision

error

B0 En_irq_noresp Enables no-response interrupt

interrupt request is sent when TX is finished.

the start of RX but the interrupt request is sent when RX is finished.

Table 5-24. Collision Position (0Eh)

Displays the bit position of collision or error

Register default is set to 0x00 at POR = H and EN = L. Automatically reset after read operation.

Bit Bit Name Function Comments

B7 Col7 Bit position of collision MSB Supported is ISO15693, single sub-carrier, and ISO14443A

B6 Col6 In other protocols, it shows the bit position of error, either frame, SOF-EOF,

B5 Col5

B4 Col4

B3 Col3

B2 Col2

B1 Col1

B0 Col0 Bit position of collision LSB