Page 1

User's Guide

SLWU038 – August 2006

TRF2436EVM

This user’s guide provides an overview of the TRF2436 evaluation module (EVM) to

get you started using the TRF2436EVM right away. It also provides a general

description of the features and functions to be considered when using this module.

Contents

1 Introduction .......................................................................................... 1

2 TRF2436EVM Operational Procedure ........................................................... 2

3 Physical Description ................................................................................ 3

List of Figures

1 Top Layer 1 .......................................................................................... 4

2 Ground Plane Layer 2.............................................................................. 4

3 Power Plane Layer 3 ............................................................................... 5

4 Bottom Layer 4 ...................................................................................... 5

List of Tables

1 TRF2436EVM PARTS LIST ....................................................................... 6

1 Introduction

1.1 Purpose

The TRF2436 EVM provides a platform for evaluating the TRF2436 high-power, dual-band RF front-end

under various signals, reference, and supply conditions. Use this document with the EVM schematic

diagram supplied. Using the TRF2436EVM, you can rapidly evaluate the TRF2436 with a minimum of

manual setup.

1.2 System Requirements

Use the following equipment when evaluating the TRF2436EVM:

• +3.3-V power supply, 800 mA.

• Signal generator: Agilent ESG Series (with baseband I/Q modulation option for modulated testing) or

equivalent.

• Spectrum analyzer: Agilent PSA Series (with phase noise option) or equivalent.

• Vector signal analyzer: Agilent 89600 Series for 802.16x modulated EVM testing or equivalent.

1.3 Power Requirements

The demonstration board requires only one supply for proper operation. Connect +3.3 V at P1 and the

return to P2. Always terminate active PA outputs before enabling the power supply.

Voltage Limits

Exceeding the maximum input voltages can damage EVM components. Undervoltage can cause improper

operation of some or all of the EVM components.

SLWU038 – August 2006 TRF2436EVM 1

Submit Documentation Feedback

Page 2

www.ti.com

TRF2436EVM Operational Procedure

1.4 Hardware Configuration

The TRF2436EVM can be set up in a variety of configurations to accommodate a specific mode of

operation. Before starting an evaluation, decide on the configuration and make the appropriate

connections or changes. The demonstration board comes with the following factory-set configuration:

Jumper J10 installed between 1-2

Jumper J11 installed between 2-3

Jumper J12 installed between 1-2

Jumper J13 installed between 1-2

Jumper J14 installed between 1-2

LO input drive

The TRF2436 has been designed to be driven with a differential LO input. A simple balun centered at ~2.6

GHz can be used to convert a single-ended input from an RF source to a differential pair to provide a

differential LO to the EVM through SMA connectors J3 and J4.

The 2436 will function if driven single-ended, but it is not designed to operate in this condition, nor has it

been evaluated in this condition. To drive the LO single-ended, connect an RF source to the LOP SMA

(J3) and terminate the LON SMA (J4) input with 50 Ω .

Filtering

The TRF2436EVM is provided with no filtering. The mixer output, PA input/LNA output, and RF

input/output pins are brought out directly to SMA connectors on the EVM. Filtering may be incorporated

by:

• Connecting an external filter to RFANTA (J6) for filtering after the PA in TX mode or before the LNA in

RX mode.

• Connecting an external filter between the MFA (J8) and RFA (J9) jacks for filtering between the mixer

and PA/LNA stages

2 TRF2436EVM Operational Procedure

2.1 TX Operation

1. Connect +3.3 V to P1 and ground to P2 but do not turn on.

2. Connect differential LO source to LOP/LON jacks (or use external balun).

Set the appropriate frequency and power level between 0 to +4 dBm. Remember that for A-band

operation, the LO input frequency is doubled inside the TRF2436; so, the LO should be set to half the

frequency desired at the mixer LO port.

3. Connect an IF source to the IF port. Set to 374 MHz with a typical power level of –20 dBm.

4. Set ABSEL (J12) to a logic high 1.

5. Set TR (J13) to a logic high 1.

6. Set PA_B SEL (J11) to a logic low 0.

7. Set PA_A SEL (J10) to logic high 1.

8. RXDGC = don’t care

9. For mixer stage measurement:

a. Terminate RFA (J9) and RFANTA (J6) into 50 Ω .

b. Connect a spectrum analyzer to MFA (J8).

c. Turn on the 3.3-V power supply (~300 mA to 320 mA).

d. Observe the output of the mixer stage on a spectrum analyzer.

10. For PA stage measurement:

a. Terminate IF (J7) and MFA (J8) into 50 Ω .

b. Apply an RF to RFA (J9).

c. Connect a spectrum analyzer to RFANTA (J6).

d. Turn on the power supply.

e. Observe the PA output on a spectrum analyzer.

TRF2436EVM 2 SLWU038 – August 2006

Submit Documentation Feedback

Page 3

www.ti.com

Physical Description

2.2 RX Operation

1. Set TR (J13) to logic 0.

2. Set PA_A SEL (J10) to logic 0.

3. Connect a differential LO source to the LOP/LON SMAs (or use an external balun).

Set the LO to an appropriate frequency, with the power level between 0 to +4 dBm. Remember that for

A-band operation, the LO input frequency is doubled inside the TRF2436; so, the LO should be set to

half the frequency desired at the mixer LO port.

4. For mixer stage measurement:

a. Terminate RFA (J9) and RFANTA (J6) into 50 Ω .

b. Connect an RF source to MFA (J8). Set to a desired RF frequency and typical power level

of –20 dBm.

c. Connect a spectrum analyzer to the IF (J7) output.

d. Turn on the 3.3-V power supply (~90 mA).

e. Observe the IF output on a spectrum analyzer (374 MHz).

5. For LNA stage measurement:

a. Terminate IF (J7) and MFA (J8) into 50 Ω .

b. Connect an RF source to RFANTA (J6). Set to a desired frequency and typical power

level of –40 dBm.

c. Connect a spectrum analyzer to RFA (J9).

d. Turn on the power supply.

e. Observe the LNA output on a spectrum analyzer.

f. Use jumper J14 (RXDGC) to select between LNA high (pins 2-3) and low gain (pins 1-2)

modes.

3 Physical Description

This section describes the physical characteristics and PCB layout of the EVM and lists the components

used on the module.

SLWU038 – August 2006 TRF2436EVM 3

Submit Documentation Feedback

Page 4

www.ti.com

Physical Description

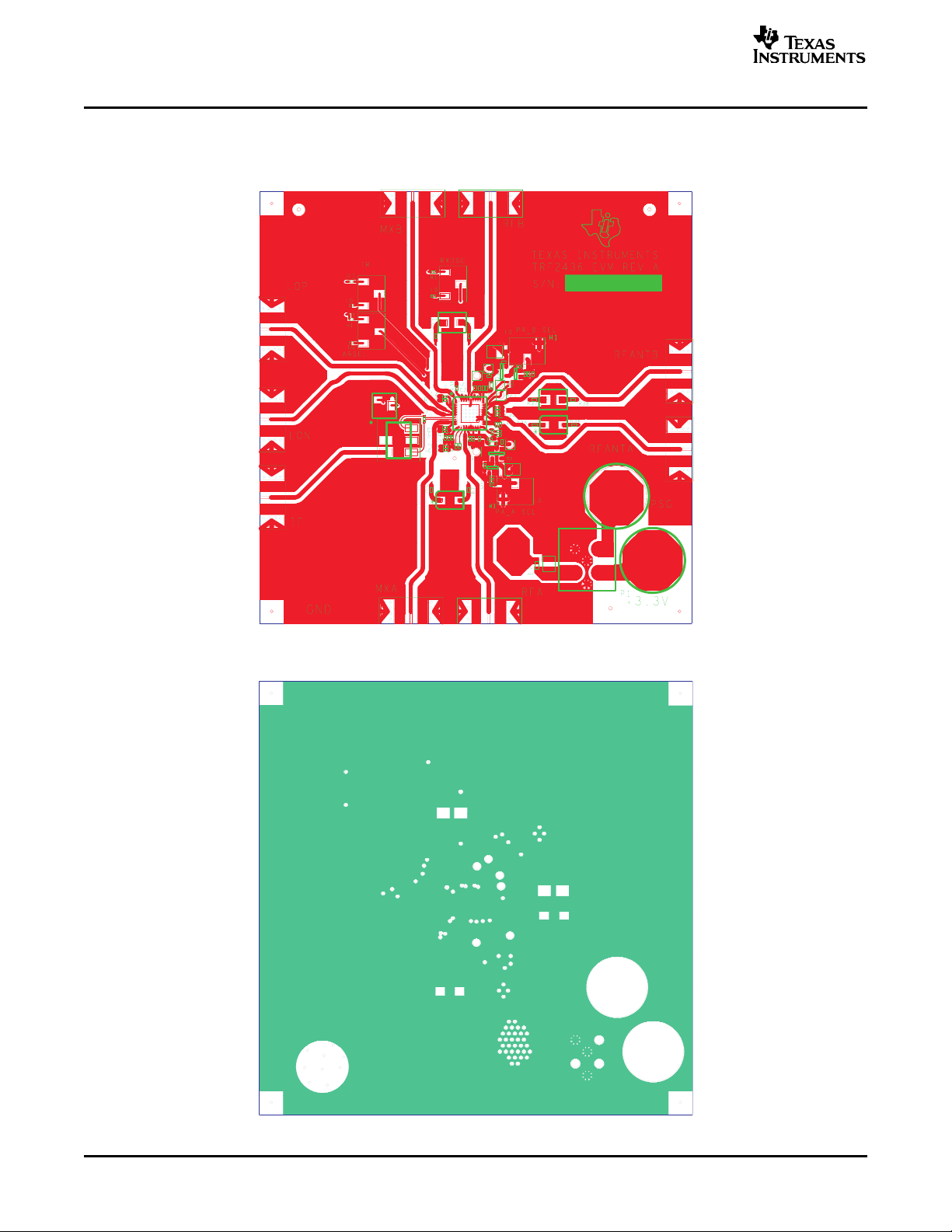

3.1 PCB Layout

The EVM is constructed on a 4-layer, 3.6-inch × 3.6-inch, 0.042-inch thick PCB using Polycad 370

Turbo/HR material. Figure 1 through Figure 4 show the PCB layout for the EVM.

Figure 1. Top Layer 1

Figure 2. Ground Plane Layer 2

4 TRF2436EVM SLWU038 – August 2006

Submit Documentation Feedback

Page 5

www.ti.com

Physical Description

Figure 3. Power Plane Layer 3

Figure 4. Bottom Layer 4

SLWU038 – August 2006 TRF2436EVM 5

Submit Documentation Feedback

Page 6

www.ti.com

Physical Description

3.2 Part List

Table 1 lists the parts used in constructing the EVM.

Table 1. TRF2436EVM PARTS LIST

QTY Ref Value Part Number Note

1 C1 470pF GRM033R71C471KD

1 C2 10pF GRM1555C1H100JZ

1 C3 5600pF C0402C562K3RACT

7 C4 C6 C11 C15 C17 C24 0.01 µ F GRM155R71E103KA

C33

12 C5 C9 C12–C14 C16 C19 100pF GRM1555C1H101JD

C20 C22 C25 C26 C31

3 C7 C8 C18 10 µ F ECJ-4YB1A106K

3 C10 C23 C29 1000pF GRM155R71H102KA

2 C21 C32 1.2pF 04025A1R2BAT2A

1 C28 0.1 µ F ECJ-0EB1A104K

2 FL1 FL2 Filter, 2400–2484MHz DFCB22G44LBJAA DNI

2 FL3 FL4 Filter, 5597.5MHz DFCB35G59LAHAA DNI

1 FL5 Filter Block, DC power BNX002-01

9 J1–J9 MXB SMA 142-0701-841

5 J10–J14 PA_A SEL 54201-S08-3

4 L1 R3 R4 R31 DNI

3 L2 L3 L7 27 Ω at 100MHz EXC-ML16A270U

4 L6 L8 L10 L12 120 Ω at 100MHz BLM15AG102SN1D

2 L9 L11 33nH LQW15AN33NJ00D

1 P1 +3.3V_IN ST-351A

1 P2 PSG ST-351B

2 Q1 Q3 IRLML6401 IRLML6401

2 Q2 Q4 MMST2222A MMST2222A-7

8 R1 R2 R6 R7 R35–R38 TRACE GAP, NO PART DNI

1 R5 634 ERJ-2RKF6340X

9 R8–R13 R15 R32 R33 10K ERJ-2GEJ103X

7 R16–R18 R24 R25 R28 1K ERJ-2GEJ102X

R29

4 R20–R23 200 ERJ-2RKF2000X

1 R26 750 ERJ-2GEJ751X

1 R27 2K POT 3214W-1-202E

1 R30 5.1K ERJ-2GEJ512X

1 T1 ADT4-1T ADT4-1T

6 TP1–TP6 T POINT R 5015

1 U1 TRF2436 TRF2436

2 U2 U3 MMDT3906 MMDT3906-7

1 U4 MMDT3904 MMDT3904-7

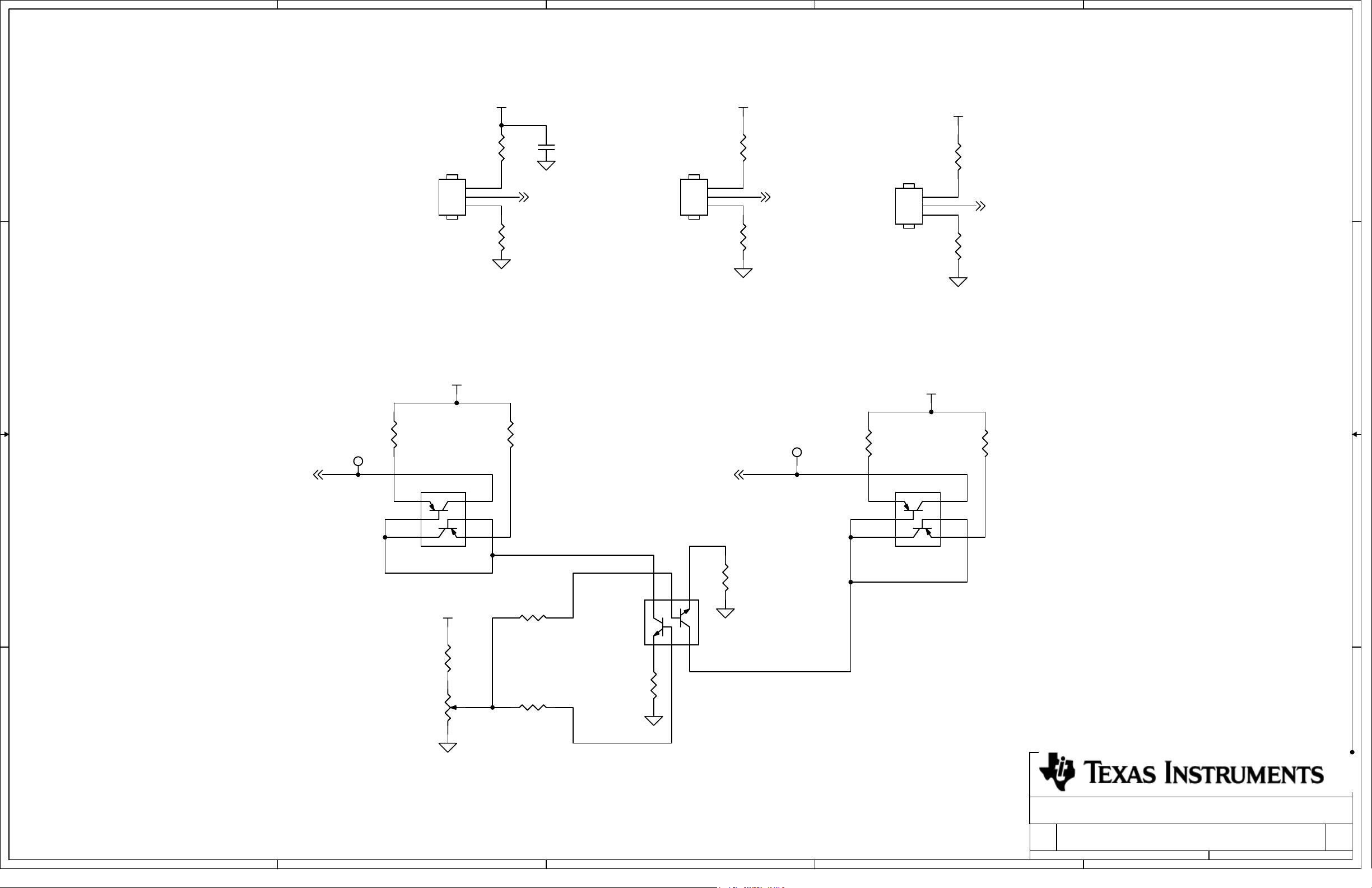

3.3 Schemtic Drawing

The schematic drawing for the TRF2436EVM appears on the following page.

6 TRF2436EVM SLWU038 – August 2006

Submit Documentation Feedback

Page 7

5

4

MXB SMA

MXB SMA

3

J1

J1

1 2

3

RFB SMA

RFB SMA

3

J2

J2

1 2

2

1

D D

LOP SMA

LOP SMA

MXB_SMA

TRACE GAP, NO PART

TRACE GAP, NO PART

R1

R1

J3

J3

3

12

50 OHM

MXB

12

DFCB22G44LBJAA_DNI

DFCB22G44LBJAA_DNI

FL1

FL1

IN1OUT

Filter, 2400-2484 MHz

Filter, 2400-2484 MHz

DNI

DNI

TRACE GAP, NO PART

TRACE GAP, NO PART

R2

RFB

2

R2

50 OHM

L1

DNIL1DNI

1 2

C14

C14

100pF

100pF

VDD

50 OHM

LOADJB

TR

1 2

ABSEL

LOADJA

LOP

LON

IFP

IFN

10

1

2

3

4

5

6

7

8

9

U1

U1

MXB

ABSEL

V+LOB

LOADJA

LOP

LON

IFP

IFN

MXA

L+LOA

39

41

40

38

TR

BACK

LOADJB

TXGADJB

TRF 2436

TRF 2436

V+IF11V+IFP12V+IFN13RFA14V+PA1A15V+GEN16V+PA2A17PABCA18V+PA3A19BCOUT

V+IFN

V+IFP

V+IF

J4

J4

3

12

C C

LON SMA

LON SMA

3

IF SMA

IF SMA

B B

J7

J7

12

50 OHM

IF_SMA

50 OHM

ADT4-1T

ADT4-1T

1 6

2

3 4

T1

T1

5

VDD

100 OHM

100 OHM

C15

C15

.01uF

.01uF

1 2

C16

C16

100pF

100pF

RXDGC

37

RXDGC

34

35

36

RFB

RSVD1

V+PA1A

V+GEN

V+PA1B

PABCB

32

33

PABCB

V+PA1B

PABCA

V+PA2A

12

BCIN

V+PA2B

31

V+PA3B

BCIN

V+PA2B

RFANTB

V+LNABA

RFANTA

BYPOUT

20

BCOUT

V+PA3A

RFB_SMA

DETP

DETN

GND2

GND1

BYPIN

30

29

28

27

26

25

24

23

22

21

R5

1 2

634R5634

12

C3

C3

5600 pF

5600 pF

V+PA3B

DETP

DETN

V+LNABA

TP1TP1

12

12

1

TP2TP2

RFANTB

RFANTA

BYPOUT

C1

C1

470pF

470pF

C4

C4

0.01uF

0.01uF

1 2

1

R3

1 2

DNIR3DNI

R4

DNIR4DNI

50 OHM

50 OHM

12

BCIN

TRACE GAP, NO PART

TRACE GAP, NO PART

TRACE GAP, NO PART

TRACE GAP, NO PART

C2

10pFC210pF

R37

R37

R35

R35

FL2

12

12

FL2

IN1OUT

Filter, 2400-2484 MHz

Filter, 2400-2484 MHz

DFCB22G44LBJAA_DNI

DFCB22G44LBJAA_DNI

DNI

DNI

IN1OUT

Filter, 5597.5MHz

Filter, 5597.5MHz

DFCB35G59LAHAA_DNI

DFCB35G59LAHAA_DNI

FL3

FL3

DNI

DNI

TRACE GAP, NO PART

TRACE GAP, NO PART

FANTB_SFANTB

2

TRACE GAP, NO PART

TRACE GAP, NO PART

FANTA_SFANTA

2

R38

R38

R36

R36

12

12

J5

J5

3

1 2

J6

J6

3

1 2

RFANTB SMA

RFANTB SMA

RFANTA SMA

RFANTA SMA

50 OHM

TRACE GAP, NO PART

TRACE GAP, NO PART

TRACE GAP, NO PART

R6

R6

1 2

A A

5

4

MXA_SMA

3

12

J8

J8

MXA SMA

MXA SMA

MXA RFA

Filter, 5597.5MHz

Filter, 5597.5MHz

DFCB35G59LAHAA_DNI

DFCB35G59LAHAA_DNI

TRACE GAP, NO PART

FL4

FL4

IN1OUT

DNI

DNI

2

50 OHM

R7

R7

1 2

3

3

RFA_SMA

12

J9

J9

RFA SMA

RFA SMA

Engineer:

Drawn By:

M. ARNOLD

L. NGUYEN

2

Title

Title

Title

TRF2436 Evaluation Module

TRF2436 Evaluation Module

TRF2436 Evaluation Module

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

B

B

B

Date: Sheet of

Date: Sheet of

Date: Sheet

TRF2436EVM-SCH

TRF2436EVM-SCH

TRF2436EVM-SCH

13Monday, April 17, 2006

13Monday, April 17, 2006

1

13Monday, April 17, 2006

of

A

A

A

Page 8

5

P1

P1

FL5

RED

RED

BLK

BLK

3.3V_IN

1

PSG

1

+3.3V_IN

+3.3V_IN

D D

PSG

PSG

P2

P2

1

1

FL5

B

PSG

Filter Block, DC power

Filter Block, DC power

Murata BNX002-01

Murata BNX002-01

CG3

CB

CG2

CG1

GND

GND

C8

10uFC810uF

4

L2

L2

1 2

27 OHM @ 100MHz

27 OHM @ 100MHz

VDD

V+PA1A

V+PA2A

V+PA3A

12

12

12

C5

C5

100pF

100pF

C9

C9

100pF

100pF

C13

C13

100pF

100pF

3

12

27 OHM @ 100MHz

27 OHM @ 100MHz

12

C10

C10

1000pF

1000pF

12

C6

.01uFC6.01uF

TP3TP3

L3

L3

3

12

C11

C11

.01uF

.01uF

IRLML6401

IRLML6401

C7

10uFC710uF

Q1

Q1

2

VDD

VDD

2

1

R8

10KR810K

3

Q2

Q2

1

MMST2222A

MMST2222A

2

R9

10KR910K

C12

C12

1 2

100pF

100pF

VDD

1

2

3

PA_A SEL

R32

R32

10K

10K

PA_A SEL

12

J10

J10

1

C C

C18

C18

10uF

10uF

VDD

VDD

R10

2

1

R10

10K

10K

3

Q4

Q4

1

MMST2222A

MMST2222A

2

R11

R11

10K

10K

C25

C25

1 2

100pF

100pF

VDD

1

J11

J11

2

3

PA_B SEL

PA_B SEL

12

R33

R33

10K

10K

VDD

VDD

B B

VDD

120 ohm @100MHz

120 ohm @100MHz

L6

L6

120 ohm @100MHz

120 ohm @100MHz

L8

L8

C20

C20

100pF

100pF

1 2

L9

33nHL933nH

C21

C21

1.2pF

1.2pF

V+IF

1 2

5 MIL trace

VDD

120 ohm @ 100MHz

120 ohm @ 100MHz

V+IFP

L10

L10

120 ohm @ 100MHz

120 ohm @ 100MHz

L12

L12

C31

C31

100pF

100pF

C28

C28

.1uF

.1uF

1 2

1 2

C32

C32

1.2pF

1.2pF

V+GEN

V+LNABA

1 2

V+PA1B

V+PA2B

V+PA3B

12

12

12

C19

C19

100pF

100pF

C22

C22

100pF

100pF

C26

C26

100pF

100pF

L7

L7

27 OHM @ 100MHz

27 OHM @ 100MHz

12

C23

C23

1000pF

1000pF

TP4TP4

12

C17

C17

.01uF

.01uF

3

12

C24

C24

.01uF

.01uF

12

Q3

Q3

IRLML6401

IRLML6401

L11

C29

C29

12

1000pF

1000pF

A A

5

L11

33nH

33nH

5 MIL trace

V+IFN

LOADJB

R31

R31

DNI

DNI

4

R30

R30

5.1K

5.1K

3

LOADJA

Title

Title

Title

TRF2436 Evaluation Module

TRF2436 Evaluation Module

TRF2436 Evaluation Module

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

B

B

B

Date: Sheet of

Date: Sheet of

2

Date: Sheet

TRF2436EVM-SCH

TRF2436EVM-SCH

TRF2436EVM-SCH

23Thursday, April 13, 2006

23Thursday, April 13, 2006

1

23Thursday, April 13, 2006

of

A

A

A

Page 9

5

4

3

2

1

VDD VDD

D D

12

.01uF

ABSEL

.01uF

C33

C33

J13TRJ13

TR

R13

R13

10K

10K

1

2

3

R171KR17

1K

TR

TP6TP6

R22

R22

200

200

J14

J14

RXDGC

RXDGC

R12

R12

10K

10K

1

J12

J12

2

3

ABSEL

ABSEL

C C

VDD

R20

R20

200

200

TP5TP5

R161KR16

1K

R21

R21

200

200

1

2

3

VDD

VDD

R15

R15

10K

10K

R181KR18

1K

RXDGC

R23

R23

200

200

PABCA PABCB

B B

A A

E1

B1

C2

2K POT

2K POT

U2

U2

MMDT3906

MMDT3906

VDD

R26

R26

750

750

R27

R27

C1

B2

E2

R251KR25

1K

R291KR29

1K

U4

U4

MMDT3904

MMDT3904

R281KR28

1K

C1

E1

B2

B1

E2

C2

R241KR24

1K

E1

B1

C2

U3

U3

MMDT3906

MMDT3906

C1

B2

E2

Title

Title

Title

TRF2436 Evaluation Module

TRF2436 Evaluation Module

TRF2436 Evaluation Module

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

B

B

B

Date: Sheet

Date: Sheet of

5

4

3

2

Date: Sheet of

TRF2436EVM-SCH

TRF2436EVM-SCH

TRF2436EVM-SCH

33Thursday, April 13, 2006

33Thursday, April 13, 2006

1

33Thursday, April 13, 2006

of

A

A

A

Page 10

EVALUATION BOARD/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the

product(s) must have electronics training and observe good engineering practice standards. As such, the goods being provided are

not intended to be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations,

including product safety and environmental measures typically found in end products that incorporate such semiconductor

components or circuit boards. This evaluation board/kit does not fall within the scope of the European Union directives regarding

electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC, CE or UL, and therefore may not meet the

technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30

days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY

SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to

take any and all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of

patents or services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the

product. This notice contains important safety information about temperatures and voltages. For additional information on TI’s

environmental and/or safety programs, please contact the TI application engineer or visit www.ti.com/esh .

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and

can radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15

of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this

equipment in other environments may cause interference with radio communications, in which case the user at his own expense

will be required to take whatever measures may be required to correct this interference.

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 0 V to 3.3 V and the output voltage range of 0 V to 3.3 V.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are

questions concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the

EVM. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load

specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 85 ° C. The EVM is designed to

operate properly with certain components above 85 ° C as long as the input and output ranges are maintained. These components

include but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of

devices can be identified using the EVM schematic located in the EVM User's Guide. When placing measurement probes near

these devices during operation, please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2006, Texas Instruments Incorporated

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...