www.ti.com

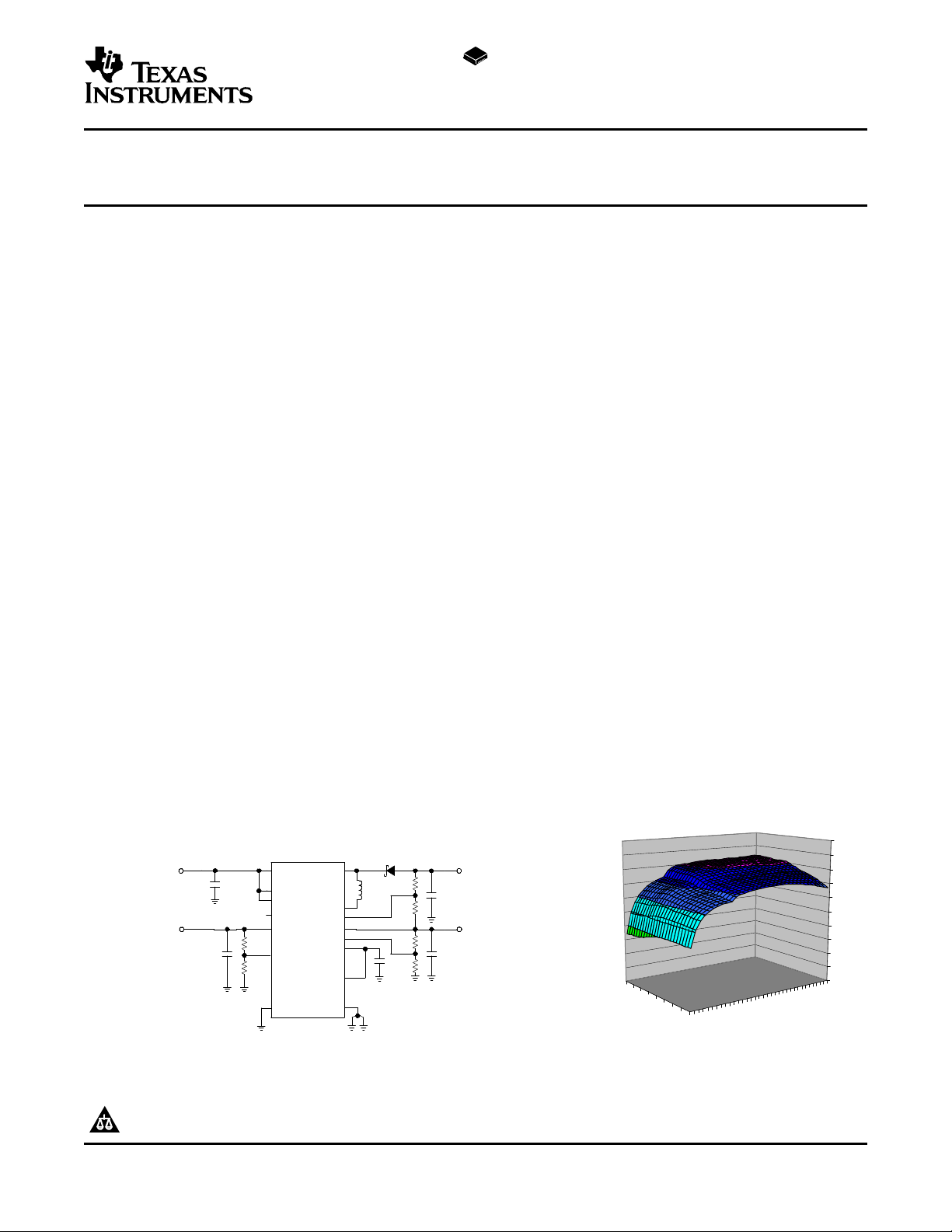

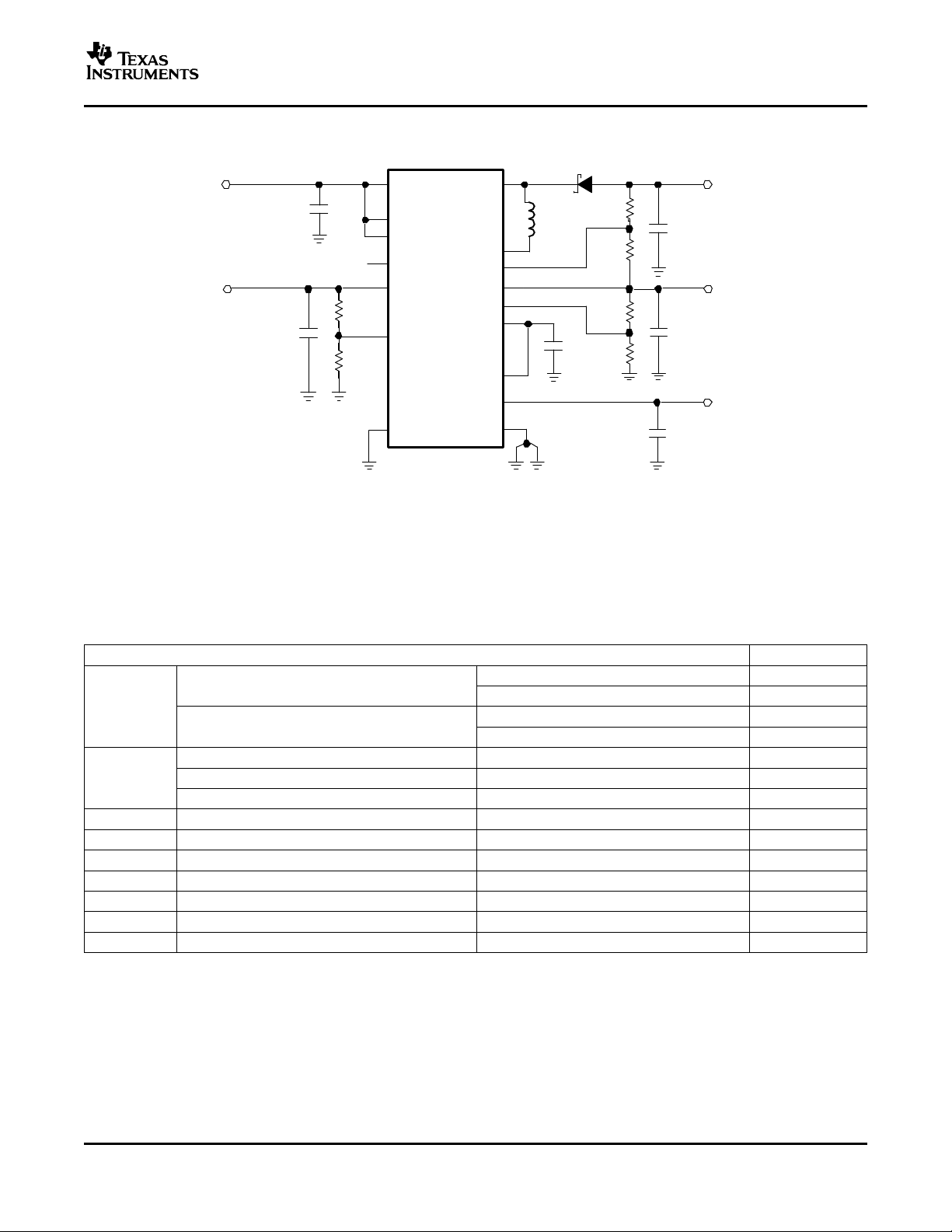

SWN

TPS65123

D1

L1

10

C1

2.2

V

IN

2.7 V to 5.5 V

V

GL

down to −18 V/2 mA

C3

100 nFR4

R3

SWP

FBL

VMAIN

FBM

C5

220 nF

R6

R5

V

MAIN

3.0 V to 5.3 V/25 mA

C4

1

BOOT

VGH

C2

100 nF

V

GH

up to 20 V/2 mA

PGND

AGND

FBH

RUN

EN

VIN

A

A

GATE

R2

R1

Fµ

µFµH

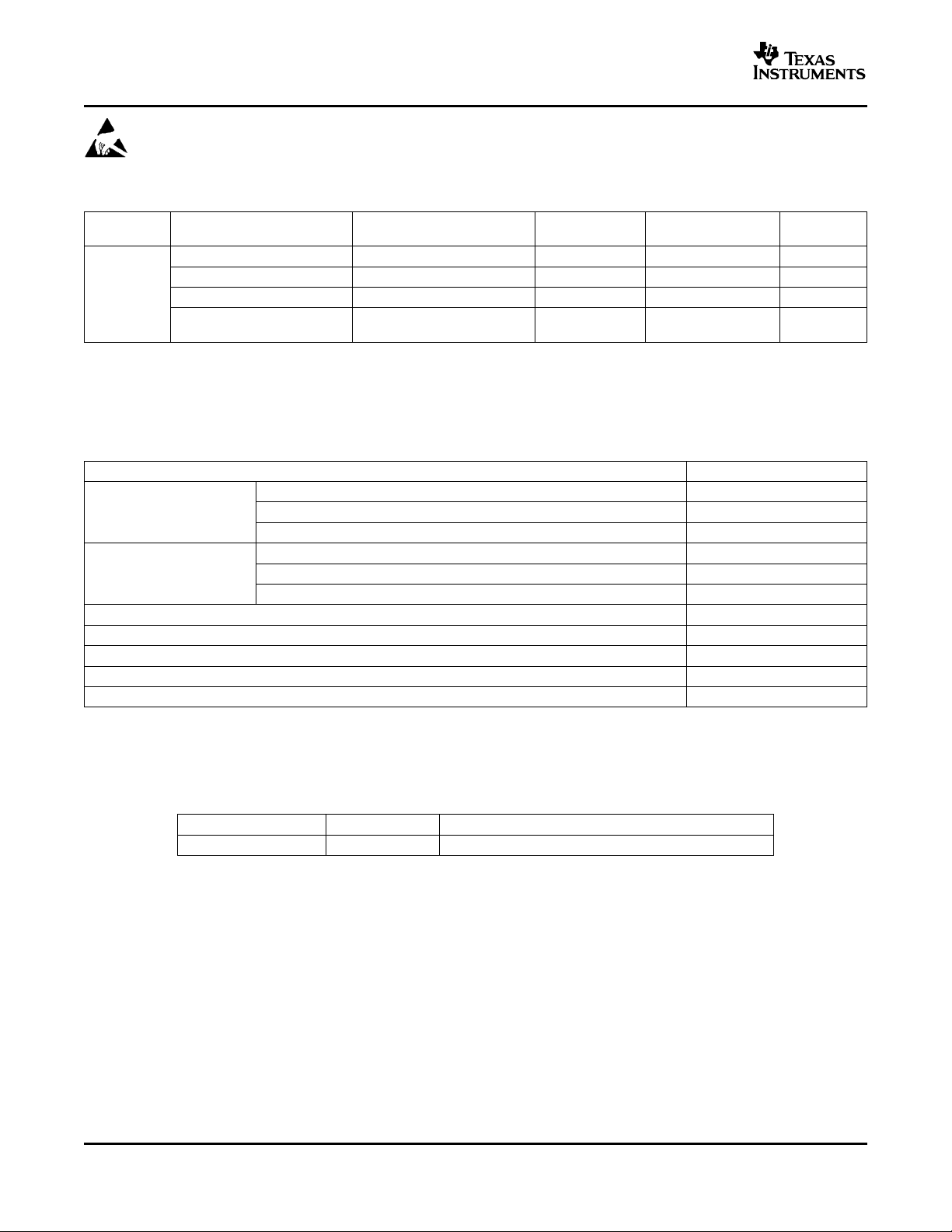

0.1

0.5

0.9

4.0

8.0

12.0

16.0

20.0

24.0

2.3

2.4

2.6

2.8

3.2

4.0

4.7

5.2

5.5

0

10

20

30

40

50

60

70

80

90

100

Core Converter Efficiency − %

VIN − Input Voltage − V

I

BOOT

− Load Current − mA

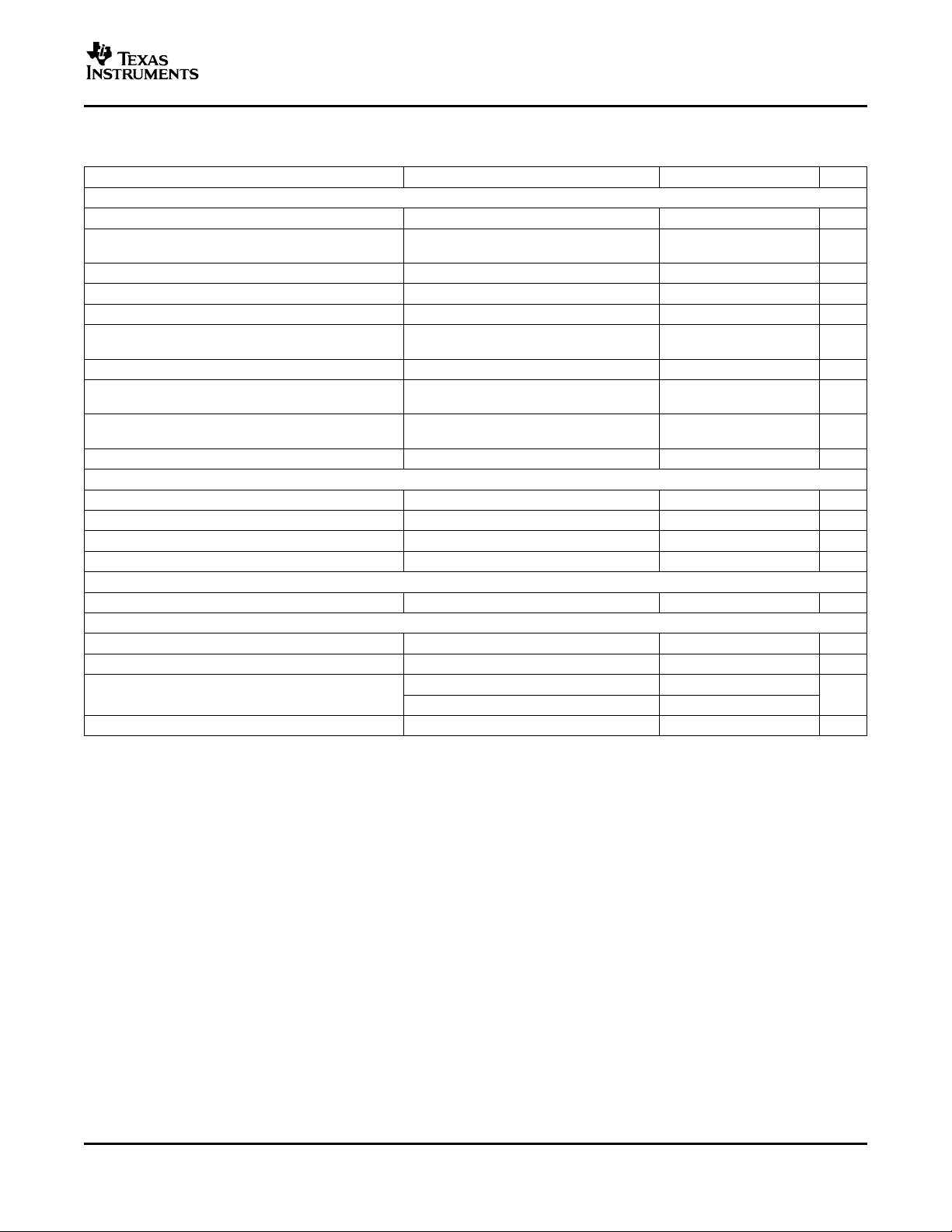

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

SINGLE-INDUCTOR QUADRUPLE-OUTPUT

TFT LCD POWER SUPPLY

FEATURES

• Main Output, V

– Adjustable Voltage, 3.0 V to 5.6 V/25 mA

– Post-Regulated for Low Ripple (5mV

– ±0.8% Typical Accuracy

MAIN

)

PP

• Automatic or Programmable Power

Sequencing

• Complete 1 mm Component Profile Solution

• 2.5 V to 5.5 V Input Voltage Range

• Output Short Circuit Protected

– Efficiency up to 83% • 16-Pin QFN Package (3 × 3 × 0,9 mm)

• Positive Output, V

– Adjustable Voltage up to 20 V/2 mA

– ±3% Typical Accuracy

• Negative Output, V

– Adjustable Voltage down to -18 V/2 mA

– ±3% Typical Accuracy

• Auxiliary 1.8 V/3.3 V Linear Regulator

GH

APPLICATIONS

• Small Form Factor a-Si and LTPS TFT LCD

• Cell Phones, Smart Phones

GL

• PDAs, Pocket PCs

• Portable DVD

• Digital-Still Cameras, Camcorders

• Handheld Instruments

• Portable GPS

• Car Navigation Systems

DESCRIPTION

The TPS6512x DC-DC converter supplies all three voltages required by amorphous-silicon (a-Si) and

low-temperature poly-silicon (LTPS) TFT-LCD displays. The compact layout of the TPS6512x uses a single

inductor to generate independently-regulated positive and negative outputs. A free-running variable peak current

PWM control scheme time-multiplexes the inductor between outputs. This control architecture operates at a

pseudo-fixed-frequency to provide fast response to line and load transients while maintaining a relatively

constant switching frequency and high efficiency over a wide range of input and output voltages. Due to the high

switching frequency capability of the device, inexpensive and ultra-thin 8.2 or 10 µH inductors can be used.

The main output, V

auxiliary outputs generate a boosted output voltage, V

-18 V for the LCD gate drive. The device has internal current limiting for high reliability under fault conditions.

Additionally, the device offers a fixed output linear regulator for the LCD logic circuitry.

, is post-regulated to provide a low-ripple source drive voltage for the LCD display. The

MAIN

, up to 20 V, and a negative output voltage, V

GH

GL

, down to

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Figure 1. Typical Application Figure 2. Core Converter Efficiency

Copyright © 2004–2005, Texas Instruments Incorporated

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

These devices have limited built-in ESD protection. The leads should be shorted together or the device

placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

T

A

-40 to 85°C

(1) The xyz package is available in tape and reel. Add R suffix (xyzR) to order quantities of TBD parts. Add T suffix (xyzT) to order

quantities of 250 parts.

INTEGRATED POWER SEQUENCING PACKAGE PART NUMBER

LINEAR REGULATOR MARKING

Fixed 3.3V output voltage Automatic Power-Up/Down 3 × 3 QFN-16 TPS65120RGT BKA

Fixed 1.8V output voltage Automatic Power-Up/Down 3 × 3 QFN-16 TPS65121RGT BKB

NO Automatic Power-Up/Down 3 × 3 QFN-16 TPS65123RGT BKC

NO Programmable 3 × 3 QFN-16 TPS65124RGT BKD

Power-Up/Down

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

VIN -0.3 V to +6 V

Input voltage

Voltage

Input voltage at GATE, EN, RUN

Power dissipation Internally limited

Operating temperature range -40°C to 85°C

Maximum operating junction temperature, TJ(max) 135°C

Storage temperature range 65°C to 150°C

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(2)

(2)

SWN VIN- 24 V to VIN+0.3 V

SWP - 0.3 V to +23 V

VGH - 0.3 V to +21 V

VMAIN, LDOIN, LDOOUT, ENVGL, ENVGH - 0.3 V to +6 V

BOOT - 0.3 V to +6.2 V

(2)

(1)

(1)

UNIT

-0.3 V to VIN+ 0.3 V

PACKAGE

DISSIPATION RATINGS

PACKAGE R

RGT 68°C/W 15mW/°C

(1) Maximum power dissipation is a function of TJ(max), θJAand TA. The maximum allowable power

dissipation at any allowable ambient temperature is PD= [TJ(max)-T

2

θ JA

DERATING FACTOR ABOVE TA= 25°C

(1)

]/ θJA.

A

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

ELECTRICAL CHARACTERISTICS

V

= 3.6 V, EN = RUN = VIN, L = 10 µH, TA= -40°C to 85°C, typical values are at TA= 25°C (unless otherwise noted)

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CONVERTER STAGE

R

≥ 330 Ω at V

L_MAIN

R

≥ 12 k Ω at V

Input voltage for full load operation 2.7 5.5 V

V

IN

Minimum input voltage for start-up 2.5 V

f Switching frequency 4.0 MHz

P

GH

P

GL

Output power on V

Output power on V

GH

GL

L_VGH

R

≥ 12 k Ω at V

L_VGL

V

= GND, TA= -40°C to 85°C

LDOIN

R

≥ 660 Ω at V

L_MAIN

R

≥ 24 k Ω at V

L_VGH

R

≥ 24 k Ω at V

L_VGL

V

= GND, TA= -20°C to 85°C

LDOIN

R

= 250 Ω at V

L_MAIN

V

= ENVGH = ENVGL = GND

LDOIN

VIN≥ 2.7 V 35

VIN≥ 2.5 V 15

VIN≥ 2.7 V 35

VIN≥ 2.5 V 15

VIN≥ 2.5 V 60

P

TOT

Total output power on

V

+ V

BOOT

+ V

GH

GL

VIN≥ 2.7 V 120

VIN≥ 3 V 150

VIN≥ 4.5 V 250

η Power efficiency V

I

LIM

I

START-UP

P-MOS1 current limit 2.7 V ≤ VIN≤ 5.5 V 150 200 mA

P-MOS1 start-up current limit 2.7 V ≤ VIN≤ 5.5 V 65 mA

P-MOS1 switch on-resistance Ω

r

DS(ON)

N-MOS1 switch on-resistance Ω

P-MOS1 leakage current 0.01

N-MOS1 leakage current 0.01

N-MOS2 + P-MOS2 forward voltage drop 400 600 mV

N-MOS3 + D1 forward voltage drop 900 1100 mV

MAIN

= 15 V, V

GH

IGH= IGL= 100 µA, V

VIN= V

VIN= V

V

= V

BOOT

V

= V

BOOT

V

= 6 V, TA= 25°C µA

DS

V

= V

GS

I

= ID= 50 mA

BOOT

V

= V

GS

IGH= ID= 50 mA

BOOT

GL

= 3.6 V 2.5 4.3

GS

= 2.5 V 3.8 6.9

GS

= 3.7 V 1.9 3.5

GS

= 5 V 1.4 2.3

GS

= 5.5 V, V

BOOT

= 5.5 V, V

BOOT

V

= 5.0 V, I

CONVERTER SUPPLY CURRENT

Quiescent current into VIN I

Quiescent current into BOOT 30 60

I

Q

Quiescent current into VGH 0.1 1

I

SD

Shutdown current TA= 25°C 0.1 1 µA

= IGH= IGL= 0 mA, 140 170

MAIN

V

= +15 V, V

GH

V

MAIN

V

FBL

V

LDOIN

TA= 25°C

= 5 V, V

= -0.2 V, V

GL

FBH

= GND, EN = RUN = VIN,

BOOT

= 5 V,

MAIN

= 12 V,

GH

= -12 V,

GL

= 5 V,

MAIN

= 12 V,

GH

= -12 V,

GL

= 5 V

MAIN

= 20 mA,

= -10 V, 83%

= GND

LDOIN

= 2 V,

SWP

= 2 V,

SWP

= -15 V,

= V

= +1.5 V,

FBM

= 5.25 V,

mW

mW

mW

µA

3

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

ELECTRICAL CHARACTERISTICS (continued)

V

= 3.6 V, EN = RUN = VIN, L = 10 µH, TA= -40°C to 85°C, typical values are at TA= 25°C (unless otherwise noted)

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

MAIN OUTPUT

V

MAIN

I

MAIN

V

FBM

I

FBM

I

SC_MAIN

R

DIS_VMAIN

VGH OUTPUT

V

GH

I

GH

V

FBH

I

FBH

R

DIS_VGH

VGL OUTPUT

V

GL

I

GL

V

FBL

I

FBL

Main output voltage range 3.0 5.6 V

V

≤ 5.3 V 25

Maximum main output current mA

Feedback regulation voltage

Feedback input bias current V

Load regulation I

Minimum dropout voltage I

Main output voltage ripple I

Short-circuit current limit V

MAIN

V

≥ 5.3 V 7.5

MAIN

2.7 V ≤ VIN≤ 5.5 V, 100 µA ≤ I

TA= -20°C to 50°C

≤ 25 mA,

MAIN

2.7 V ≤ VIN≤ 5.5 V,

0 mA ≤ I

FBM

MAIN

MAIN

MAIN

BOOT

≤ 25 mA

MAIN

= V

REF

= 0 to 25 mA, V

= 5 V 0.006 %/mA

MAIN

= 10 mA 130 mV

= 10 mA 5 mV

= 5.5 V 50 mA

Discharge resistor for power-down sequence

V

output voltage range VIN+ 0.5 20 V

GH

Maximum DC output current 6 mA

V

precharge resistor 1 k Ω

GH

Feedback regulation voltage 2.7 V ≤ VIN≤ 5.5 V, 0 mA ≤ IGH≤ 2 mA 1.177 1.213 1.249 V

Feedback input bias current V

Load regulation IGH= 0 to 2 mA, V

= 0 V 0.01 0.1 µA

FBH

= 15 V -0.11 %/mA

GH

Line regulation VIN= 2.7 V to 5.5 V, IGH= 100 µA 0.01 %/V

V

output voltage ripple 20 mV

GH

200 µA load, V

C

= 220 nF, C

OUT

= 15 V,

GH

= 10 pF

FF

Discharge resistor for power-down sequence

V

Output voltage range -18 -2.5 V

GL

Maximum DC output current 6 mA

Feedback regulation voltage 2.7 V ≤ VIN≤ 5.5 V, 0 mA ≤ IGL≤ 2 mA -0.036 0 0.036 V

Feedback input bias current V

Load regulation IGL= 0 to 2 mA, V

= 0 V 0.01 0.1 µA

FBL

= -15 V 0.13 %/mA

GL

Line regulation VIN= 2.7 V to 5.5 V, IGL= 100 µA 0.1 %/V

V

output voltage ripple 20 mV

GL

200 µA load, V

C

= 220 nF

OUT

= -15 V,

GL

1.203 1.213 1.223 V

1.195 1.213 1.231 V

0.01 0.1 µA

P-P

10 k Ω

10 k Ω

4

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

ELECTRICAL CHARACTERISTICS (continued)

V

= 3.6 V, EN = RUN = VIN, L = 10 µH, TA= -40°C to 85°C, typical values are at TA= 25°C (unless otherwise noted)

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LINEAR REGULATOR STAGE - AUXILIARY OUTPUT

V

LDOIN

V

LDOOUT

I

LDOOUT

I

SC_LDO

I

Q_LDO

I

SD_LDO

GATE DRIVER

V

IH

V

IL

UNDERVOLTAGE LOCKOUT

V

UVLO

LOGIC SIGNALS EN, RUN, ENVGL, ENVGH

V

IH

V

IL

I

LKG

Input voltage range 2.5 5.8 V

Output voltage range 1.8 V

Maximum output current 20 mA

Short-circuit current limit V

Minimum dropout voltage I

Total accuracy ±3%

Load regulation I

Line regulation 0.013 %/V

Linear regulator quiescent current 11 20 µA

LDOOUT

2.5 V ≤ V

0 mA ≤ I

LDOOUT

V

to 5.5 V, I

V

TA= 25°C

= 0 V 50 mA

LDOOUT

= 10 mA 400 mV

≤ 5.5 V,

LDOIN

≤ 20 mA

LDOOUT

= 0 to 20 mA 0.006 %/mA

= V

LDOIN

LDOOUT

= V

LDOIN

LDOOUT

LDOOUT

+ 0.5 V (min 2.5 V)

= 20 mA

+ 0.4 V (min 2.5 V),

Linear regulator shutdown current GATE = VIN 0.2 1 µA

Gate output pull-down resistance V

< 500 mV 100 k Ω

GATE

Gate output pull-up resistance 100 k Ω

High level input voltage 1.4 V

Low level input voltage 0.4 V

Undervoltage lockout threshold VINfalling 2.15 2.3 V

High level input voltage 1.4 V

Low level input voltage 0.4 V

Logic input leakage current µA

ENVGL, ENVGH = VINor GND (TPS65124) 0.01 0.1

EN, RUN = V

IN

EN, RUN pin pull-down resistance EN, RUN ≤ 0.4 v 100 k Ω

0.01 0.1

V

LDOIN

-0.5

5

www.ti.com

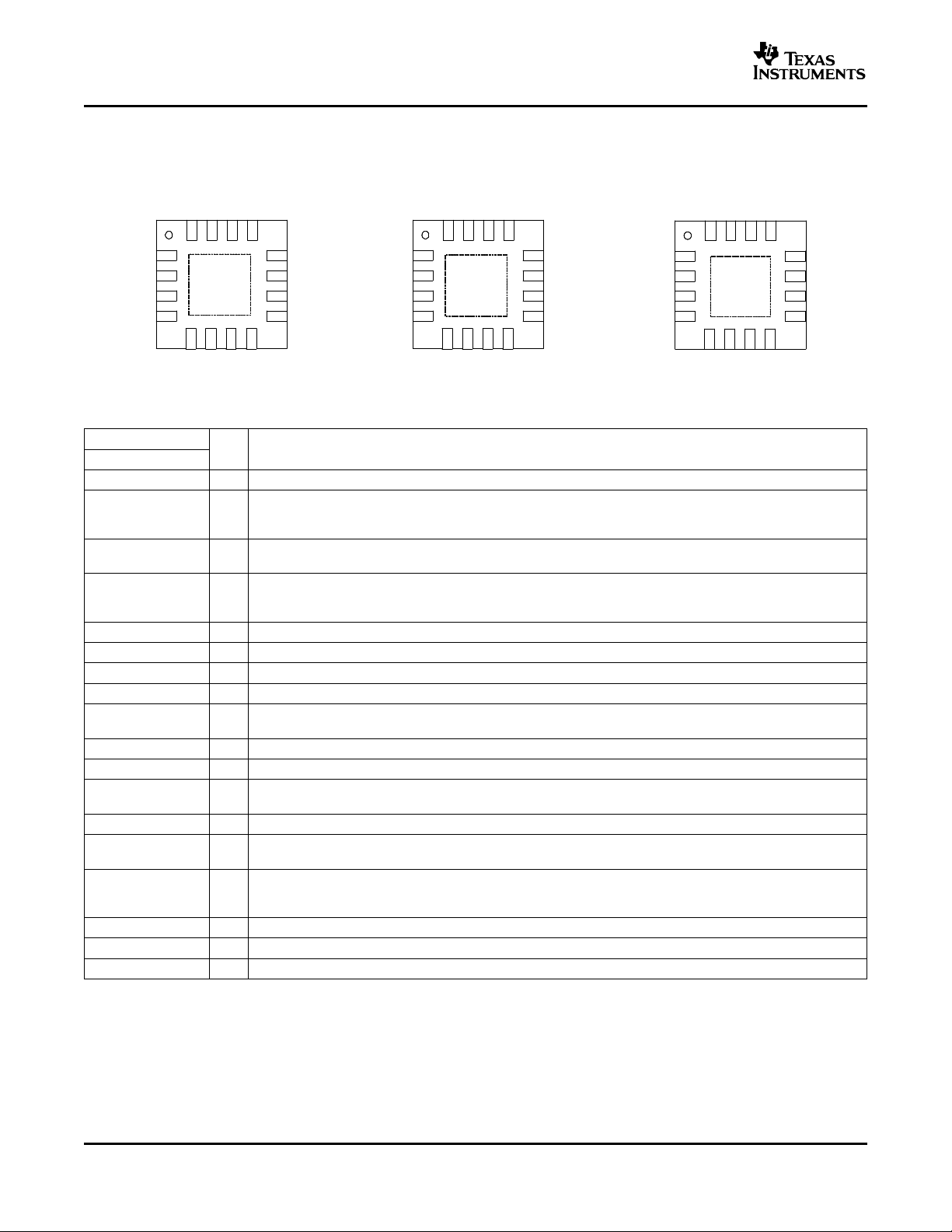

1

2

3

4

12

11

10

9

5 6 7 8

131516

EN

RUN

ENVGL

ENVGH

FBL

FBM

AGND

VMAIN

PGND

BOOT

VGH

FBH

GATE

VIN

SWN

SWP

1

2

3

4

12

11

10

9

5 6

7

8

13141516

EN

RUN

AGND

AGND

FBL

FBM

AGND

VMAIN

PGND

BOOT

VGH

FBH

GATE

VIN

SWP

1

2

3

4

12

11

10

9

5 6

7

8

13141516

Exposed

Thermal Die*

EN

RUN

LDOIN

LDOOUT

FBL

FBM

AGND

VMAIN

PGND

BOOT

VGH

FBH

GATE

VIN

SWN

SWP

AGND

SWN

Exposed

Thermal Die*

AGND

14

Exposed

Thermal Die*

AGND

TPS65120/1/2

(TOP VIEW)

TPS65123

(TOP VIEW)

TPS65124

(TOP VIEW)

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

PIN ASSIGNMENTS

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

VIN 15 I This is the input voltage pin of the device.

GATE 16 I/O section), or an active high control input. Pulling GATE above the 1.4 V logic-high level and RUN to a logic-low

RUN 2 I

EN 1 I floating. A simultaneous logic-high level on EN and RUN enables the converter and a logic-low shuts down

SWN 14 I/O Connect the inductor to this pin. This pin is connected to the source of the high-side MOSFET switch.

SWP 13 I/O Connect the inductor to this pin. This pin is connected to the drain of the low-side MOSFET switch.

PGND 12 O Power ground. Connect to AGND underneath the IC.

VGH 10 O Positive output

BOOT 11 O

VMAIN 8 I Main output

FBH 9 I Feedback pin for the positive output voltage divider. Regulates to 1.213 V nominal.

FBL 5 I

FBM 6 I Feedback pin for the main output voltage divider. Regulates to 1.213V nominal.

AGND 7, 3, 4

LDOIN 3 I (TPS65120/1/2). The low-dropout series-pass regulator (LDO) is enabled according to the GATE signal

LDOOUT 4 O Auxiliary linear regulator output (TPS65120/1/2).

ENVGL 3 I Enable pin for negative output (TPS65124). This pin should be terminated and not be left floating.

ENVGH 4 I Enable pin for positive output (TPS65124). This pin should be terminated and not be left floating.

I/O DESCRIPTION

This pin can either be the gate driver output to an external small P-Channel MOSFET (see application

level disables the integrated active power-down sequencing.

RUN controls the external P-Channel MOSFET. This pin must be terminated and not be left floating. Forcing

this pin to a logic-high level turns on the external MOSFET switch.

This is the enable pin of the multiple-output dc-to-dc converter. This pin must be terminated and not be left

the device.

Provides a bootstrapped supply for the rectifier MOSFET driver, enabling the gate of the MOSFET to be

driven above the output voltage.

Feedback pin for the negative output voltage divider. Regulates to 0 V nominal. Connect feedback resistor

divider between VGL and main output.

Analog ground. Connect to power ground (PGND) underneath IC. Pins 3 and 4 are only used for AGND in

TPS65123.

Auxiliary linear regulator input. If this pin is connected to GND, the voltage regulator is disabled

timing.

6

www.ti.com

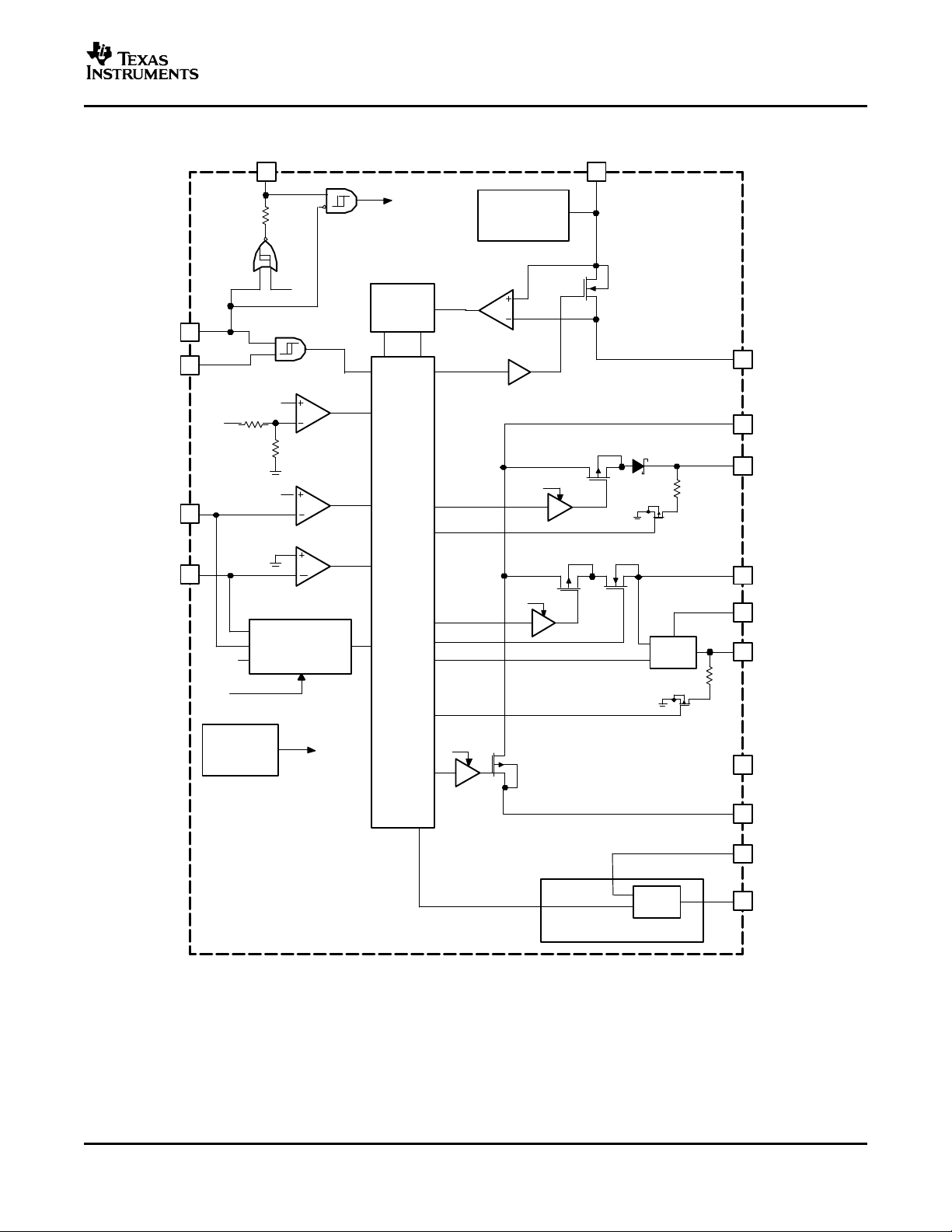

Current Limit

Comparator

Undervoltage

Lockout

Bias Supply

VIN

SWP

LDOOUT

SWN

T

on

VGH

BOOT

PGND

VMAINLDO

BOOT

V

REF

R

V

REF

R

FBH

R

FBL

BOOT

FBM

AGND

Bandgap

V

REF

= 1.213V

Power Up/Down

Sequencer

Oscillator

S

Min Off Time

VMAIN

Control

Logic

EN

BOOT

BOOT

P−MOS1

P−MOS2

N−MOS1

N−MOS2

N−MOS3

D1

RUN

VMAIN

GATE

EN

100kR

Power Down Seq Off

Power Down Seq Off

R

DIS_VGH

R

DIS_VMAIN

EN

LDO

LDOIN

EN_LDOAUX

NOT PRESENT IN TPS65123

FUNCTIONAL BLOCK DIAGRAM - TPS65120/1/2/3

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

7

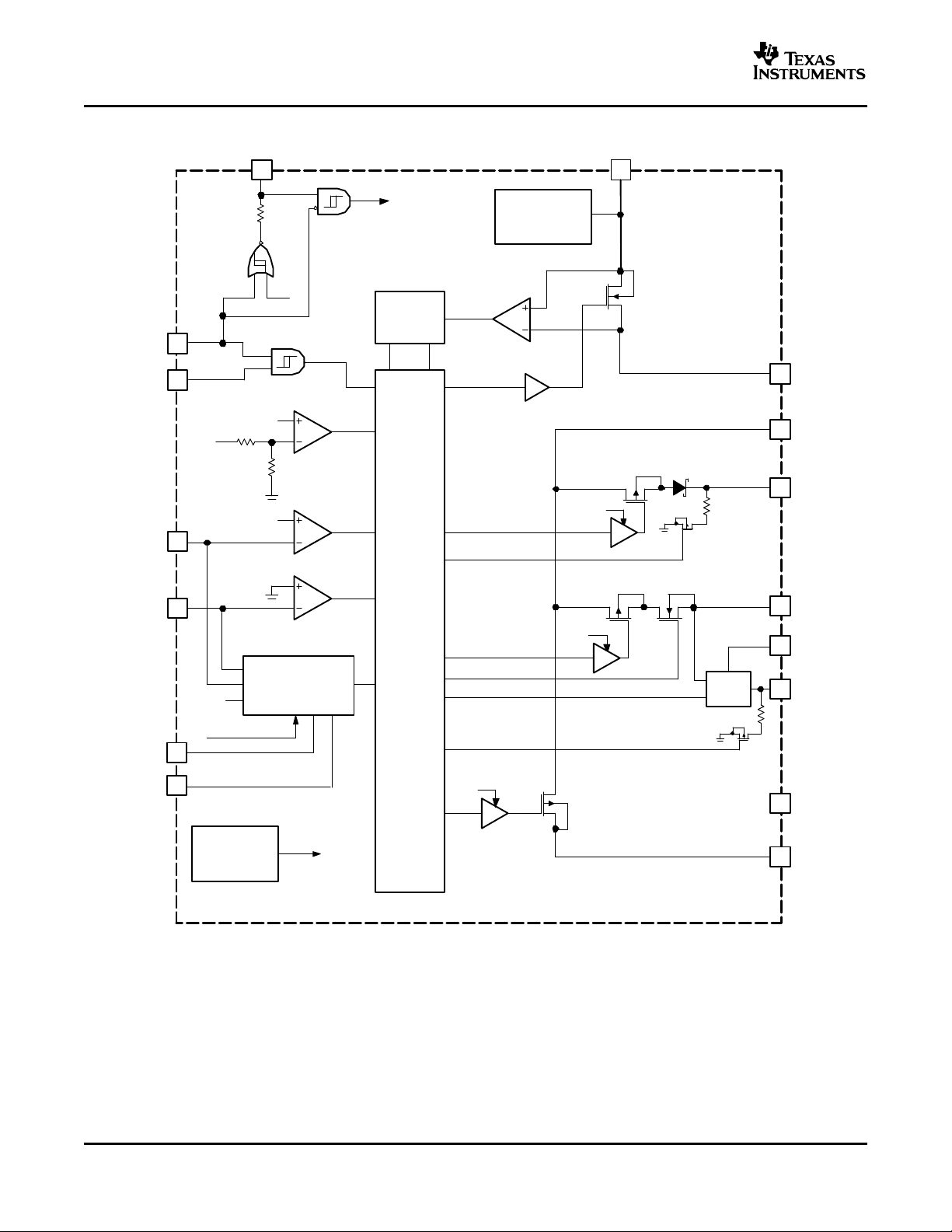

www.ti.com

Current Limit

Comparator

Undervoltage

Lockout

Bias Supply

VIN

SWP

SWN

T

on

VGH

BOOT

PGND

VMAIN

BOOT

V

REF

R

V

REF

R

FBH

R

FBL

BOOT

FBM

AGND

Power Up/Down

Sequencer

Oscillator

S Min Off Time

VMAIN

Control

Logic

EN

BOOT

BOOT

P−MOS1

P−MOS2

N−MOS1

N−MOS2

N−MOS3

D1

RUN

VMAIN

GATE

EN

100kR

Power Down Seq Off

Power Down Seq Off

R

DIS_VGH

R

DIS_VMAIN

EN

ENVGH

ENVGL

Bandgap

V

REF

= 1.213V

LDO

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

FUNCTIONAL BLOCK DIAGRAM - TPS65124

8

www.ti.com

PARAMETER MEASUREMENT INFORMATION

SWN

TPS65120

D1

L1

10

C1

F

V

IN

2.7 V to 5.5 V

V

GL

down to −18 V/2 mA

C3

220 nF

R4

R3

SWP

FBL

VMAIN

FBM

C5

220 nF

R6

R5

V

MAIN

3.0 V to 5.3 V/20 mA

C4

1

BOOT

VGH

C2

220 nF

V

GH

up to 20 V/2 mA

PGND

AGND

FBH

RUN

V

AUX

3.3 V/20 mA

EN

VIN

A

A

GATE

LDOIN

LDOOUT

C6

220 nF

R2

R1

List of Components:

U1 = TPS6512x

L1 = EPCOS SIMID1812-C

D1 = ZETEX ZUMD54C

CX = X5R/X7R

2.2 FH

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

η Core converter efficiency vs Load current 3

V

MAIN

V

, V

GH

V

GH

V

GL

f

s

I

Q

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

vs Input voltage 4

Main output efficiency vs Load current 5

vs Input voltage 6

Output ripple voltage 7

DC output voltage vs Load current 8

Load transient response 9

GL

Positive, negative output ripple voltage 10, 11

DC output voltage vs Load current 12

DC output voltage vs Load current 13

Switching frequency vs Load current 14

No load quiescent current vs Input voltage 15

Power-Up Sequencing (TPS65120) 16

Power-Down Sequencing (TPS65120) 17

9

www.ti.com

60

65

70

75

80

85

90

95

100

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

I

BOOT

= 15 mA

I

BOOT

= 5 mA

VIN = 3.6 V ,

V

MAIN

= 5 V,

ENVGL = ENVGH = GND

VIN − Input Voltage − V

Core Converter Efficiency − %

0

10

20

30

40

50

60

70

80

90

100

0.1 1 10 100

Core Converter Efficiency − %

I

BOOT

− Output Current − mA

VIN = 3.6 V

ENVGL = ENVGH = GND

V

MAIN

= 5 V

30

40

50

60

70

80

90

100

0 2 4 6 8 10 12 14 16 18 20

I

MAIN

− Output Current − mA

Main Output Efficiency − %

V

MAIN

= 5 V ,

VGH = 15 V @ 200 A,

VGL = −10 V @ 200 A

V

MAIN

= 3.3 V ,

VGH = 7.5 V @ 200 A,

VGL = −3 V @ 200 A

VIN = 3.6 V

40

45

50

55

60

65

70

75

80

85

90

95

100

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

V

MAIN

= 5 V @ 10 mA,

VGH = 15 V @ 200 A,

VGL = −10 V @ 200 A

V

MAIN

= 5 V @ 5 mA,

VGH = 15 V @ 200 A,

VGL = −10 V @ 200 A

V

MAIN

= 3.3 V @ 10 mA,

VGH = 7.5 V @ 200 A,

VGL = −3 V @ 200 A

VIN − Input Voltage − V

Main Output Efficiency − %

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

CORE CONVERTER EFFICIENCY CORE CONVERTER EFFICIENCY

TPS65124 TPS65124

vs vs

LOAD CURRENT INPUT VOLTAGE

Figure 3. Figure 4.

MAIN OUTPUT EFFICIENCY MAIN OUTPUT EFFICIENCY

vs vs

LOAD CURRENT INPUT VOLTAGE

10

Figure 5. Figure 6.

www.ti.com

V

BOOT

(50 mV/div,

5.8 V Offset)

V

MAIN

(10 mV/div,

5 V Offset)

V

IN

= 3.6 V ,

V

MAIN

= 5 V @ 20 mA,

ENVGL = ENVGH = LOW

t − Time − 5 s/div

4.95

4.96

4.97

4.98

4.99

5

5.01

5.02

5.03

5.04

5.05

0 2 4 6 8 10 12 14 16 18 20

I

MAIN

− Output Current − mA

VIN = 3.6 V ,

VGH = 15 V @ 200 A,

VGL = −10 V @ 200 A

V − Output Voltage − V

MAIN

V

GH

(50 mV/div,

AC Coupled)

V

GL

(20 mV/div,

AC Coupled)

V

IN

= 3.6 V ,

V

MAIN

= 5 V @ 5 mA,

VGH = 15 V @ 100 A,

VGL = −10 V @ 100 A

t − Time − 20 s/div

V

MAIN

(50 mV/div,

5 V Offset)

I

MAIN

(10 mA/div)

t − Time − 10 s/div

V

IN

= 3.6 V ,

V

MAIN

= 5 V ,

ENVGL = ENVGH = LOW

C

OUT

= 220 nF

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

MAIN DC OUTPUT VOLTAGE

MAIN OUTPUT RIPPLE VOLTAGE LOAD CURRENT

Figure 7. Figure 8.

MAIN OUTPUT LOAD

TRANSIENT RESPONSE POSITIVE, NEGATIVE OUTPUT RIPPLE

vs

Figure 9. Figure 10.

11

www.ti.com

V

GH

(20 mV/div,

AC Coupled)

V

GL

(20 mV/div,

AC Coupled)

t − Time − 10 s/div

V

IN

= 3.6 V ,

V

MAIN

= 5 V @ 5 mA,

VGH = 15 V @ 100 A,

VGL = −10 V @ 100 A

10 pF Feed-Forward

Capacitor Across R

1

14.85

14.90

14.95

15

15.05

15.10

15.15

0.1 1 10

IGH − Output Current − mA

V

GH

− DC Output Voltage − V

VIN = 3.6 V ,

V

MAIN

= 5 V, @ 5 mA

VGL = −10 V @ 200 A

−10.10

−10.08

−10.06

−10.04

−10.02

−10

−9.98

−9.96

−9.94

−9.92

−9.90

0.1

1

10

VIN = 3.6 V ,

V

MAIN

= 5 V @ 5 mA,

VGH = 15 V @ 200 A

IGL − Output Current − mA

V

GL

− DC Output Voltage − V

1

10

0.1 1 10 100

VIN = 3.6 V ,

V

MAIN

= 5 V ,

ENVGH = ENVGL = GND

Switching Frequency − MHz

I

MAIN

− Output Current − mA

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

POSITIVE, NEGATIVE OUTPUT

RIPPLE VOLTAGE POSITIVE OUTPUT (VGH) LOAD REGULATION

Figure 11. Figure 12.

NEGATIVE OUTPUT (VGL) LOAD REGULATION LOAD CURRENT

SWITCHING FREQUENCY

Figure 13. Figure 14.

vs

12

www.ti.com

V

LOGIC

V

MAIN

V

GH

V

GL

VIN = 3.6 V , EN = HIGH,

R

MAIN

= 1 k,

RGH = 120 k,

RGL = 100 k,

RUN

V

LOGIC

(5 V/div)

V

MAIN

(2 V/div)

V

GH

(5 V/div)

V

GL

(5 V/div)

t − Time − 100 s/div

0

50

100

150

200

250

300

2.5 2.8 3 3.3 3.5 3.8 4 4.3 4.5 4.8 5 5.3 5.5

V

MAIN

= 3.3 V , VGH = 7.5 V , VGL = −3 V

No-Load Quiescent Current Includes

Output Voltage Divider Network Bias Current

I

Q

− Quiescent Current − I

Q

A

VIN − Input Voltage − V

V

LOGIC

V

MAIN

V

GH

V

GL

VIN = 3.6 V, EN = HIGH,

R

MAIN

= 1 k,

RGH = 120 k,

RGL = 100 k,

RUN

V

MAIN

(2 V/div)

V

GH

(5 V/div)

V

GL

(5 V/div)

t − Time − 5 ms/div

V

LOGIC

(5 V/div)

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

QUIESCENT CURRENT

vs TPS65120

INPUT VOLTAGE POWER-UP SEQUENCING

Figure 15. Figure 16.

TPS65120

POWER-DOWN SEQUENCING

Figure 17.

13

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

DETAILED DESCRIPTION

The standard application circuit ( Figure 1 ) of the TPS65120 is a complete power supply for TFT LCD displays.

The circuit generates four independent supplies for the source driver (V

logic supply for the timing controller. The input voltage range is from 2.5 V to 5.5 V.

The TPS65120/1/2 contains a high-performance switching regulator and two low-dropout linear regulators

(LDOs). One of the LDOs generates V

and the other powers the logic inside the panel. The TPS65123

MAIN

includes only one linear regulator to provide the main output with low ripple voltage and can be set from 3.0 V to

5.3 V with an external resistor voltage divider. The TPS65124 integrates programmable power sequencing for

highest flexibility.

OPERATION

The TPS6512x generates both positive and negative supply voltages using a single inductor. It alternates

between acting as a step-up converter and an inverting converter on a cycle-by-cycle basis. All output voltages

are independently regulated.

A free-running, variable-peak-current PWM control scheme is used to time-multiplex the inductor between BOOT,

V

, and V

GH

fast response to line and load transients while maintaining a relatively constant switching frequency and high

efficiency over a wide range of input and output voltages.

During the first cycle of operation, internal switches N-MOS1 and P-MOS1 are turned on. SWN connects to VIN,

SWP pulls to ground and the inductor current rises. Once the inductor current reaches the DC current limit (I

of 150 mA (typ) the internal control logic can either turn off N-MOS1 or P-MOS1 to service the requesting output.

Depending on the required output power, the converter starts another cycle or enters a pulse-skipping

modulation scheme to increase efficiency under light loads. The current into the SWN pin measures the inductor

current. The TPS6512x controls the inductor current to regulate BOOT, V

To achieve low ripple voltage and high accuracy, the main output (V

This LDO regulator regulates energy from the BOOT output down to 5.3 V (max). To achieve the highest

efficiency, the BOOT voltage is regulated to minimize the dropout voltage across the LDO to approximately V

+ 0.5 V.

In addition, the VMAIN, VGH, VGL outputs are monitored for fault conditions that last longer than the fault-timer

period of 100 µs (typ). The device goes into a latched shutdown state in case of a fault condition.

outputs. This inherently-stable control architecture operates at a pseudo fixed frequency, providing

GL

MAIN

), the gate drivers (V

MAIN

, and V

GH

GL

output voltages.

, V

GH

) is post-regulated by an integrated LDO.

GL

) and a

)

LIM

MAIN

Soft Start

The TPS6512x has an internal soft-start circuit that limits the inrush current during startup. This prevents possible

voltage drops of the input voltage in case the battery or a high impedance power source is connected to the input

of the device.

The device powers up by precharging the BOOT output capacitor to VIN. During the precharge phase, the

current through the rectifying switch N-MOS2 is limited. This also limits the output current under short-circuit

conditions on the BOOT output. To ensure proper startup of the device, the BOOT output must be left unloaded

during the precharge phase.

After the precharge phase, the converter operates with an I

START-UP

current limit of 65 mA (typ), then increases

gradually to the full current limit of 150 mA (typ).

Undervoltage Lockout

To ensure that the input voltage is high enough for reliable operation, the TPS6512x includes an under-voltage

lockout (UVLO) circuit. The UVLO threshold at the VIN pin is 2.15 V (typ) falling and 2.25 V (typ) rising. The 100

mV (typ) hysteresis prevents supply transients from causing restarts.

Once the input voltage exceeds the UVLO rising threshold, the controller can enable the reference voltage and

precharges BOOT. When the input voltage falls below the UVLO falling threshold, the controller turns off the

reference and all the regulator outputs, and pulls GATE high with an internal 100 k Ω resistor to turn off P1 (

Figure 18 ).

14

www.ti.com

SWN

TPS65120

D1

L1C1

C3

R4

R3

SWP

FBL

VMAIN

FBM

C5

R6

R5

C4

BOOT

VGH

C2

FBH

RUN

EN

VIN

GATE

R10

R9

C7

P1

PGND

AGND

A A

LDOIN

LDOOUT

VIN = 3.3 V

V

GH

V

LOGIC

= 3.3 V

V

GL

V

MAIN

R1

R2

V

IN

RUN

V

LOGIC

, EN

V

MAIN

V

GL

V

GH

V

BOOT

5.75V

GATE, EN_LDOAUX

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

DETAILED DESCRIPTION (continued)

Enable and Power Sequencing (TPS65120/1/2/3)

To correctly power up most TFT panels, the gate-drive supplies must be sequenced such that the negative

supply (V

enable pin.

Once RUN is high, the TPS65120/1/2/3 turns on the external P-channel MOSFET P1 (see Figure 18 ) by pulling

GATE low. GATE is pulled down with a 100 k Ω resistor. The DC/DC converter then starts, enabling the BOOT

output.

Pulling the enable pin (EN) high enables the MAIN output. When the output voltage V

nominal value, the negative output enables. V

nominal value.

Pulling the RUN pin low shuts down the device. Power-down sequencing starts by switching off V

The V

feedback voltage divider. The required time to discharge the output capacitor at V

current. Once V

This sequence is shown in Figure 19 .

When no power sequencing is required on the digital supply voltage (V

and GATE can be connected to a logic-high level to disable the power-down sequencer. Each output turns off

depending upon load current and output capacitance.

) powers up before the positive supply (V

GL

GH

output capacitor is actively discharged by an internal resistor while V

GH

has reached 1.2 V (typ) the main output is turned off followed by the output voltage V

FBL

). The TPS65120/1/2/3 controls this sequence through an

GH

is delayed until the negative voltage has reached 90% of its

GL

GL

), tie EN and RUN signals together

LOGIC

has reached 90% of its

MAIN

and V

GH

is only discharged by its

output depends on the load

GL

.

.

LOGIC

Figure 18. Power Sequencing on Digital Supply Voltage, Figure 19. TPS65120/1/2/3 Power Sequence

V

LOGIC

15

www.ti.com

SWN

TPS65124

D1

L1

C1

VIN = 3.3V

V

GL

C3

R4

R3

SWP

FBL

VMAIN

FBM

C5

R6

R5

V

MAIN

C4

BOOT

VGH

C2

V

GH

FBH

RUN

GATE

VIN

EN

V

LOGIC

= 3.3V

P1

PGND

AGND

A

A

ENVGH

ENVGL

ENVGH

ENVGL

EN

D2

optional

R1

R2

V

LOGIC

V

IN

RUN

GATE

V

MAIN

V

GL

V

GH

V

BOOT

5.75V

ENVGH

ENVGL

EN

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

DETAILED DESCRIPTION (continued)

Enable and Power Sequencing (TPS65124)

The TPS65124 controls the power sequencing of V

These pins must be terminated and not be left floating to prevent instability.

Once RUN is pulled high and the input voltage on VIN exceeds the rising input UVLO threshold, the reference is

turned on and the external P-channel MOSFET P1 (see Figure 20 ) is switched on by pulling GATE low. The

GATE is pulled down with a 100 k Ω resistor. The DC/DC converter then starts up, enabling the BOOT output.

Pulling enable pin high (EN) powers on the MAIN output. This power sequencing must occur before the gate

voltages are enabled. Conversely V

and V

GL

output voltages must be turned off by pulling ENVGL and ENVGH

GH

inputs to ground before the MAIN output is switch off.

To clamp the V

output near zero when the MAIN output is still on, an external diode (D2) can be used. In some

GL

applications this diode may already be implemented in the display.

, V

LOGIC

, V

MAIN

and V

GH

with four separate enable pins.

GL

Figure 20. Power Sequencing on Digital Supply Voltage, Figure 21. TPS65124 Programmable Power Sequence

V

LOGIC

Fault Protection

All TPS6512x outputs are protected against a short circuit to ground. During steady-state operation, if the output

V

, V

MAIN

Once V

or V

GH

comes down to 700 mV typ, the GATE output is pulled to V

MAIN

falls below its fault detection threshold the device simultaneously turns off all three outputs.

GL

, the auxiliary LDO (TPS65120/1/2) is

IN

disabled and the device enters a shutdown state.

The auxiliary LDO present in TPS65120/1/2 has an integrated current foldback circuit for reliable short-circuit

protection.

The device can be enabled again by toggling the enable pins (RUN, EN) below 0.4 V or by cycling the input

voltage below the UVLO falling threshold (2.15 V typ).

16

www.ti.com

GHGHGH

IVP ×=

GLGLGL

IVP ×=

5.0VVforI

0.5V

V

PP

MAININMAIN

MAIN

MAIN

MAIN_LDOMAINBOOT

2

+<×

+

≈η×=

MAININMAIN

IN

MAIN

MAIN_LDOMAINBOOT

VVforI

V

V

PP

2

>×≈η×=

FBMMAIN

R6

R6R5VV+

×=

FBHGH

R2

R2R1VV+

×=

MAINGL

R4

R3

VV ×=

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

APPLICATION INFORMATION

OUTPUT POWER CAPABILITY

The first step in the design procedure is to calculate the maximum output current for each output under certain

input and output voltage conditions. The TPS6512x uses time-multiplex operation to share the inductive storage

element between BOOT, VGH and VGL outputs. To avoid complex calculations it is recommended to use the

specified output-power data from the electrical characteristics table to determine the maximum output-power

capability.

The following example shows how to proceed for given requirements:

• Input Voltage = 3.0 V

• MAIN Output = 5.0 V @ 10 mA

• VGH output = 12 V @ 500 µA

• VGL output = -12 V @ 300 µA

1. Calculate Maximum Output Power on VGH Output

2. Calculate Maximum Output Power on VGL Output

3. Calculate Maximum Output Power on BOOT Output

4. Maximum Output Power Verification

The electrical characteristics table states that for V

must be lower than 35 mW each. Furthermore, the total output power (P

> 3.0 V, the maximum power on VGH and VGL outputs

IN

+ P

BOOT

+ P

GH

GL

) must be lower than

150 mW.

In our design example, P

GH

= 6 mW, P

= 3.6 mW, and P

GL

= 55 mW. Since these numbers are well below

BOOT

the specified values, we can conclude that TPS6512x can reasonably power such a display.

SETTING THE OUTPUT VOLTAGE

The output voltages are defined as shown in Figure 22 .

with an internal reference voltage V

with an internal reference voltage V

To minimize the operating quiescent current, set R2, R4 and R6 in the range 100 k Ω to 300 k Ω . Great care

should be taken to route the FBx lines away from noise sources such as the inductor or the SWN and SWP lines.

A feed-forward capacitor across the upper feedback resistor (R1, R3) on VGH and VGL outputs can be used to

provide more overdrive for the error comparator. This feed-forward capacitor helps to reduce the output ripple

voltage. A good starting value is 10 pF.

typical = 1.213V.

FBM

typical = 1.213V.

FBH

17

www.ti.com

SWN

TPS65120

D1

L1

10

C1

2.2

V

IN

2.7 V to 5.5 V

V

GL

down to −18 V/2 mA

C3

100 nF

R4

R3

SWP

FBL

VMAIN

FBM

C5

220 nF

R6

R5

V

MAIN

3.0 V to 5.3 V/25 mA

C4

1

BOOT

VGH

C2

100 nF

V

GH

up to 20 V/2 mA

PGND

AGND

FBH

RUN

V

AUX

3.3 V/20 mA

EN

VIN

A

A

GATE

LDOIN

LDOOUT

C6

220 nF

R1

R2

µF

µF

Hµ

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

APPLICATION INFORMATION (continued)

The larger the feed-forward capacitor the worse the load regulation of the device. Therefore, when concern for

load regulation is paramount, select a capacitor value as small as possible. Another possibility to further reduce

ripple voltage on VGH and VGL outputs is to increase output-capacitor values (C2, C3).

Figure 22. Typical Application

INDUCTOR SELECTION

Since the control scheme of the TPS6512x device is inherently stable, the inductor value does not affect the

stability of the converter. To operate the TPS6512x properly at full performance, choose inductors in the range

8.2 µH to 10 µH.

The selection of the inductor is primarily based on the required output power. The variable peak current PWM

control scheme used in TPS6512x automatically adapts the peak inductor current (between 65mA typ. and

150mA typ.) depending on output power and input voltage.

At moderate loads, the converter typically operates with a peak inductor current in the range of 65mA to 100mA,

allowing the use of inductors in the 0603 case size. In order not to saturate the inductor when operating at a

higher output power, select an inductor with a higher saturation-current rating.

The inductor series in Table 1 from various suppliers have been used with the TPS6512x converter.

Table 1. List of Inductors

MANUFACTURER SERIES DIMENSIONS

LQ LB1608 1.6 x 0.8 x 0.8 = 1.02 mm

TAIYO YUDEN LQ CB2012 2.0 x 1.2 x 1.2 = 2.88 mm

LQ CBL2012 2.0 x 1.2 x 1.0 = 2.40 mm

TDK

18

GLF1608 1.6 x 0.8 x 0.8 = 1.02 mm

GLF2012 2.0 x 1.2 x 1.2 = 2.88 mm

3

3

3

3

3

www.ti.com

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

DIODE SELECTION

To achieve high efficiency, use a Schottky diode. The voltage rating must be higher than the input voltage plus

the absolute value of the negative output. The current rating of the diode must meet the converter peak

inductor-current rating when servicing the VGL output. The main parameter affecting the efficiency of the

converter is the forward voltage and the reverse leakage current of the diode, both should be as low as possible.

The following diodes from different suppliers listed in Table 2 have been used with the TPS6512x converter.

Table 2. List of Diodes

MANUFACTURER REFERENCE REVERSE VOLTAGE

ROHM RB521G-30 30 V

VISHAY BAT54-HT3 30 V

ZETEX ZUMD54 30 V

CAPACITOR SELECTION

The TPS65120 converter requires six capacitors. The input capacitor is primarily a function of the board layout.

In designs with long traces, for good input filtering, we recommend a ceramic input capacitor (X5R/X7R type) of

at least 1 µF placed as close as possible to the converter.

To operate properly, the TPS6512x requires a bootstrap capacitor of 1 µF (or larger) on the BOOT output.

Additionally the minimum BOOT capacitance must be larger than two times the capacitor value connected to the

MAIN and AUXILIARY LDO outputs (in case LDO AUX is connected to the BOOT output).

The TPS6512x peak-current control scheme is inherently stable. The filtering capacitors on VGH and VGL

outputs are basically determined as a function of the required current and permissible ripple voltage. For small

form-factor TFT-LCD applications, typical values in the range of 100 nF to 1 µF are usually required. A good

starting point is 220 nF. For high output power on VGH and VGL outputs, the capacitance may need to approach

2 µF.

For stable operation, TPS6512x requires a 220-nF ceramic capacitor on the MAIN and AUXILIARY LDO outputs.

Larger capacitor values can be used to achieve lower output-voltage noise without sacrificing stability.

In general, ceramic X5R types are strongly recommended for their low ESR and ESL and capacitance-versus-bias-voltage stability. Be certain that the capacitors used are rated for the maximum voltage with

adequate safety margin.

LAYOUT CONSIDERATIONS

As for all switching power supplies, the layout is an important step in the design. If the layout is not carefully

done, the regulator could become unstable, displaying double or missing pulses as well as EMI problems.

Therefore, use wide, short traces for the main current paths. Route these traces first.

Place the input capacitor as close as possible to the IC pins as well as the inductor and output capacitors. Place

the inductor and diode as close as possible to the switch pins to minimize noise coupling into other circuits.

Use a common ground node for power ground and a different one for control ground (AGND) to minimize the

effects of ground noise. Connect these ground nodes together (star point) at any place close to one of the

ground pins of the IC and make sure that small-signal components returning to the AGND pin do not share the

switching-current paths.

Feedback pins and divider networks are high-impedance nodes and should therefore be routed away from the

inductor and shielded with a ground plane or trace to minimize noise coupling into the control loop.

19

www.ti.com

SWN

TPS65120

D1

L1

10

C1

2.2

V

IN

2.7 V to 5.5 V

V

GL

down to −18 V/2 mA

C3

220 nFR4

R3

SWP

FBL

VMAIN

FBM

C5

220 nFR6

R5

V

MAIN

3.0 V to 5.3 V/25 mA

C4

1

BOOT

VGH

C2

220 nF

V

GH

up to +20 V/2 mA

PGND

AGND

FBH

RUN

V

LOGIC

= 3.3 V

EN

VIN

A

A

GATE

LDOIN

LDOOUT

C6

220 nF

R2

R1

GPIO

µF

H

µ

µ

F

SWN

TPS65123

D1

L1

C1

V

IN

2.7 V to 5.5 V

V

GL

C3

220 nF

R4b

R3

SWP

FBL

VMAIN

FBM

C5

220 nF

R6

R5

V

MAIN

C4

1

BOOT

VGH

C2

220 nF

V

GH

PGND

AGND

FBH

RUN

EN

VIN

A

A

GATE

R2

R1

RUN

R4a

N−MOS

VISHAY SI1032

RUN

V

MAIN

= 5.0 V , VGH = 15 V , V

GL

= −10 V

R3 = 540 kΩ, R4a = 270 kΩ, R4b = 680 kΩ

a4

ldOFFThresho_GL

MAIN

3b4

R

2.1V

V2.1

RR −

−

−

=

a4

3

MAINGL

R

R

VV ×=

µF

SWN

TPS65121

D1

L1

C1

V

IN V

GL1

C3

R4

R3

SWP

FBL

VMAIN

FBM

C5

220 nFR6

R5

V

MAIN

C4

1

BOOT

VGH

C2

220 nF

V

GH

PGND

AGND

FBH

RUN

V

LOGIC

EN

VIN

A A

GATE

LDOIN

LDOOUT

C6

220 nF

R2

R1

GPIO

V

GL2

C7

Negative LDO = TPS723xx series

Negative

LDO

EN

Fµ

C7

>

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

APPLICATION EXAMPLES

Figure 23. Complete TFT-LCD Power Supply from 1 cell Li-Ion

Figure 24. V

20

→ V

GL

Figure 25. Additonal Negative Gate Driver Voltage

Power Down-Sequencing Threshold Shifting

MAIN

www.ti.com

SWN

TPS65124

D1

L1

C1

2.2

V

IN

V

GL

C3

220 nF

R4

R3

SWP

FBL

VMAIN

FBM

C5

R6

R5

C4

4.7

BOOT

VGH

C2

220 nF

V

GH

FBH

RUN

GATE

VIN

EN

PGND

AGND

A

A

ENVGH

ENVGL

R2

R1

N&P MOS = VISHAY Si1016

D1 = VISHAY BAT54A−HT3

GPIO1

GPIO2

GPIO3

V

MAIN

N&P MOS

GPIO4

C7

C6

Fµ

Fµ

10 pF

2.2

Fµ

C8

100 nF

10 pF

SWN

TPS65124

D1

L1

C1

V

IN

V

NEG

C3

220 nF

R4

R3

SWP

FBL

VMAIN

FBM

C5

220 nF

R6

R5

C4

1

BOOT

VGH

C2

220 nF

V

POS

FBH

RUN

GATE

VIN

EN

PGND

AGND

A

A

ENVGH

ENVGL

EN

V

POS

R2

R1

R1 = 887 kΩ

R2 = 100 kΩ

R3 = R4 = 680 kΩ

R5 = 845 kΩ

R6 = 270 kΩ

V

REF

µ

F

12 V

−12 V

ENVGH,

ENVGL

(2V/div)

V

GL

(5V/div)

V

GH

(5V/div)

VIN = 3.6V

EN = RUN = HIGH

RGH = 60 kΩ

RGL = 60 kΩ

V

GL

V

GH

SWN

TPS65123 D1

L1

C1

V

IN

V

GL

C3

R4

R3

SWP

FBL

VMAIN

FBM

C5

1uF

R6

R5

V

MAIN

C4

2.2

BOOT

VGH

C2

V

GH

PGND

AGND

FBH

RUN

EN

VIN

A

A

GATE

R2

R1

RUN

LDO

External LDO = TPS792xx series

Ext. LDO nominal output voltage setting recommended at 1% lower than VMAIN.

EN

IN

OUT

µ

F

EN TPS65120

TPS65120, TPS65121, TPS65123, TPS65124

SLVS531A – JUNE 2004 – REVISED MARCH 2005

Figure 26. Fully Programmable Sequencing Featuring Very Low Gate Ripple Voltage

Figure 27. Dual Output Tracking Regulator with High Accuracy Reference Voltage

Figure 28. Boosting Main Output Current, I

> 25mA

MAIN

21

PACKAGE OPTION ADDENDUM

www.ti.com

18-Jul-2006

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS65120RGTR ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65120RGTRG4 ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65120RGTT ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65120RGTTG4 ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65121RGTR ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65121RGTRG4 ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65121RGTT ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65121RGTTG4 ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65123RGTR ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65123RGTRG4 ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65123RGTT ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65123RGTTG4 ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65124RGTR ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65124RGTRG4 ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS65124RGTT ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS65124RGTTG4 ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

18-Jul-2006

Addendum-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...