TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

700 KHz Operation

D

1.25 MHz Operation With External Driver

D

1.5% Reference Over Full Operating

T emperature Range

D

Synchronous Rectifier Driver for Greater

Than 90% Efficiency

D

Programmable Reference V oltage Range of

1.3 V to 3.5 V

D

User–Selectable Hysteretic T ype Control

D

Droop Compensation for Improved Load

Transient Regulation

D

Adjustable Overcurrent Protection

D

Programmable Softstart

D

Overvoltage Protection

D

Active Deadtime Control

D

Power Good Output

D

Internal Bootstrap Schottky Diode

D

Low Supply Current . . . 3-mA T yp

D

Reduced System Component Count and

Size

description

The TPS521 1 is a hysteretic regulator controller which provides an accurate, programmable supply voltage to

microprocessors. An internal 5-bit DAC is used to program the reference voltage to within a range of 1.3 V to

3.5 V. The output voltage can be set to equal the reference voltage or some multiple of the reference voltage.

A hysteretic controller with user-selectable hysteresis and programmable droop compensation is used to

dramatically reduce overshoot and undershoot caused by load transients. Propagation delay from the

comparator inputs to the output drivers is less than 250 ns. Overcurrent shutdown and crossover protection for

the output drivers combine to eliminate destructive faults in the output FETs. The softstart current source is

proportional to the reference voltage, thereby eliminating variation of the softstart timing when changes are

made to the output voltage. PWRGD monitors the output voltage and pulls the open-collector output low when

the output drops 7% below the nominal output voltage. An overvoltage circuit disables the output drivers if the

output voltage rises 15% above the nominal value. The inhibit pin can be used to control power sequencing.

Inhibit and undervoltage lockout assures the 12-V supply voltage and system supply voltage (5 V or 3.3 V) is

within proper operating limits before the controller starts. Single-supply (12 V) operation is easily accomplished

using a low-current divider for the required 5-V signals. The output driver circuits include 2-A drivers with internal

8-V gate-voltage regulators. The high-side driver can be configured either as a ground-referenced driver or as

a floating bootstrap driver. The TPS521 1 is available in a 28-pin TSSOP PowerP AD package. It operates over

a junction temperature range of 0°C to 125°C.

AVAILABLE OPTIONS

PACKAGE

T

J

TSSOP

(PWP)

0°C to 125°C TPS5211PWPR

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

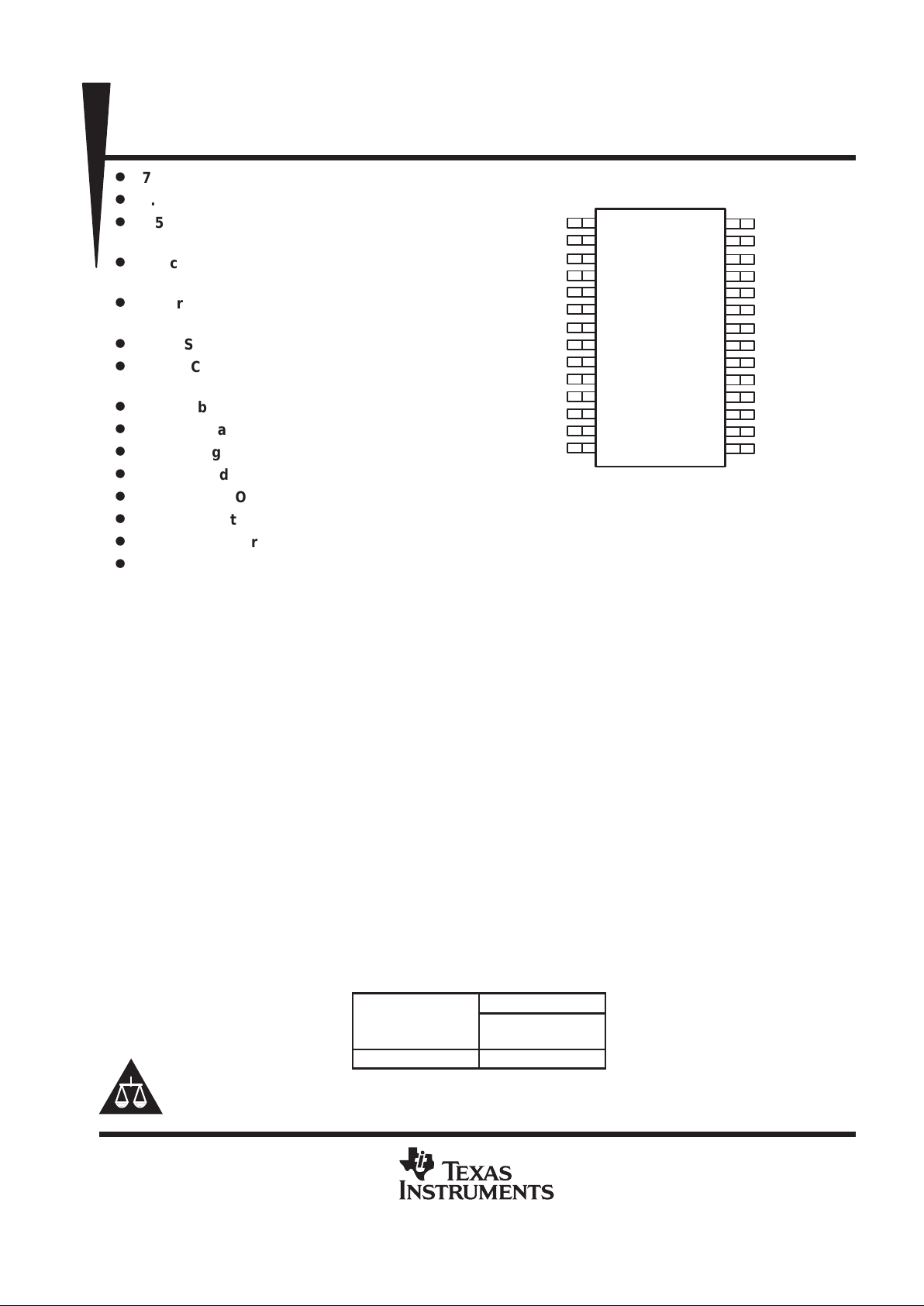

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

IOUT

DROOP

OCP

VHYST

VREFB

VSENSE

ANAGND

SLOWST

BIAS

LODRV

LOHIB

DRVGND

LOWDR

DRV

PWRGD

VID0

VID1

VID2

VID3

VID4

INHIBIT

IOUTLO

LOSENSE

HISENSE

BOOTLO

HIGHDR

BOOT

V

CC

PWP PACKAGE

(TOP VIEW)

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

2

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

11111

Decode

VID0

VID1

VID2

VID3

VID4

SQ

R

Deglitch

Deglitch

100 mV

+

V

OVP

1.15 V

ref

V

PGD

0.93 V

ref

Rising

Edge

Delay

–

+

+

–

PREREG

DRV REG

–

+

–

+

Hysteresis

Setting

–+

VID

MUX

and

Decoder

2x

SLOWST

OCP

INHIBIT

Bandgap Shutdown

I

VREFB

5

Shutdown

VSENSE

HIGHIN

HIGHDR

V

CC

Analog

Bias

Analog Bias

Slowstart

Comp

Hysteresis

Comp

CM Filters

VREF

–

+

Σ

28 20 21 1915 7

V

CC

ANAGND PWRGD LOSENSE IOUTLO HISENSE

2 V

10 V

V

CC

UVLO

NOCPU

Fault

Shutdown

IOUT

BIAS

DRV

BOOT

HIGHDR

BOOTLO

LOWDR

DRVGND

1

9

14

16

17

18

13

12

6

11 1042523

VID0 VID1 VID2 VID3 VID4

24252627

VREFB DROOP VHYST VSENSE LOHIB LODRV

8

3

22

200 kΩ

200 kΩ

I

VREFB

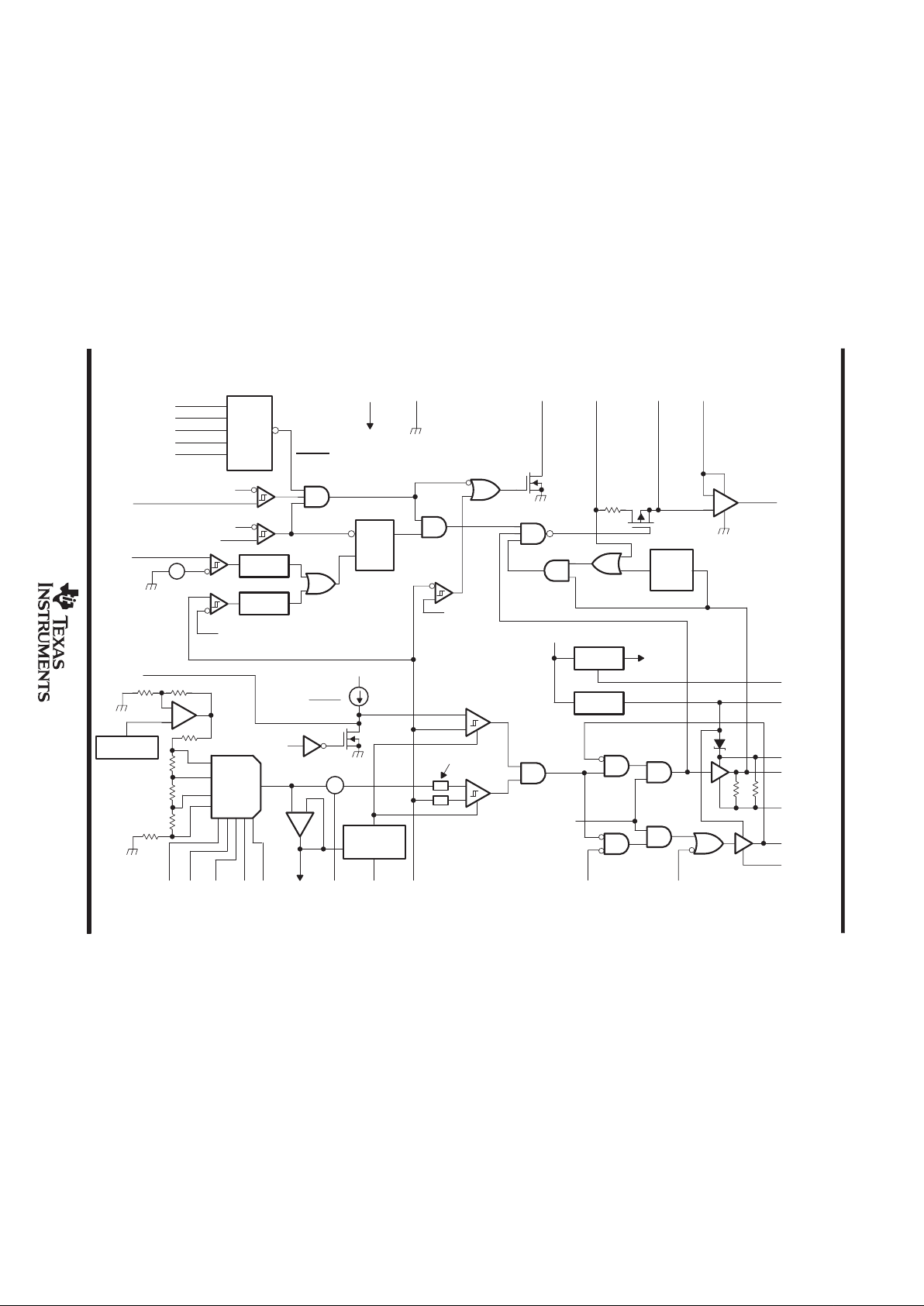

functional block diagram

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

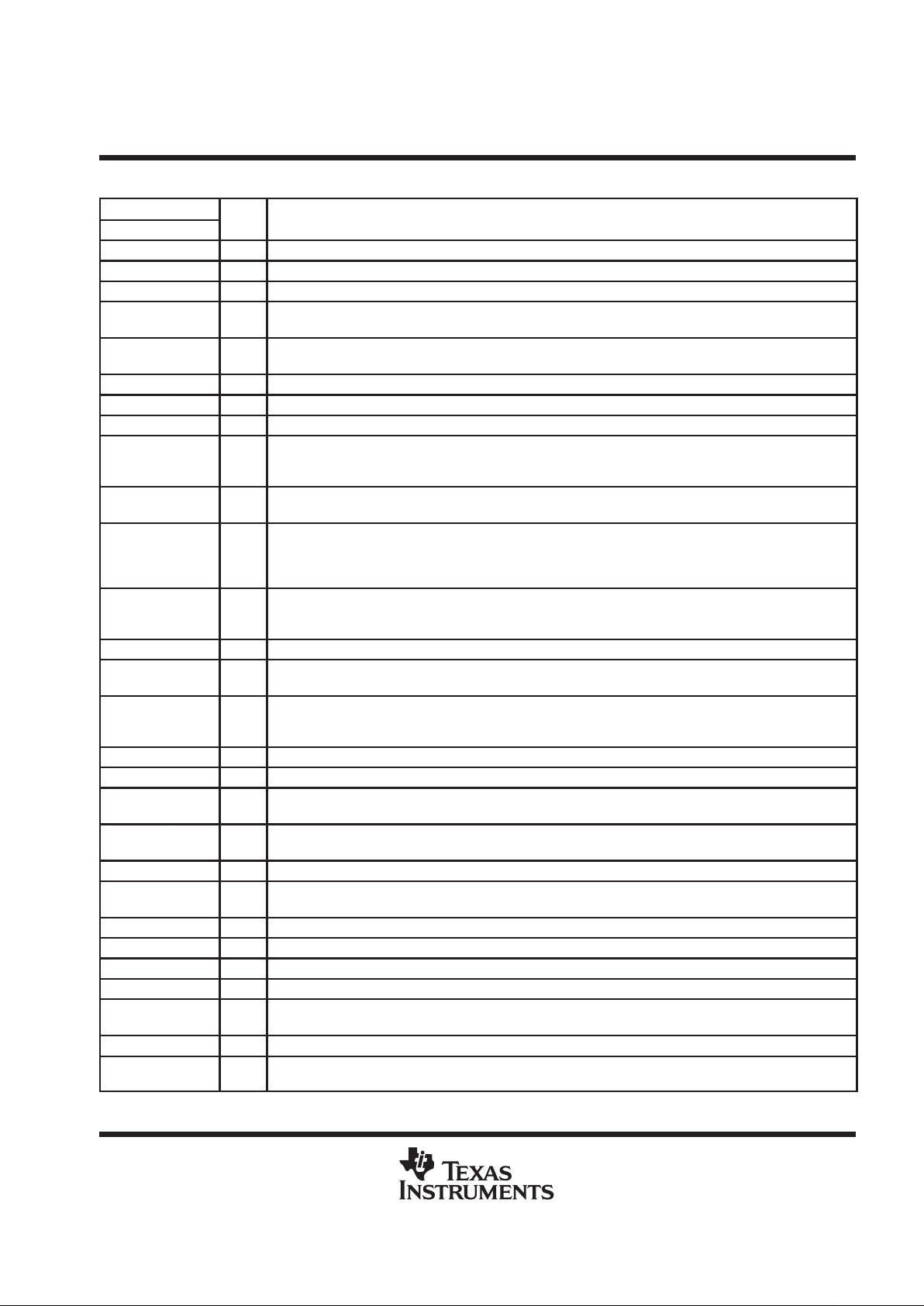

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ANAGND 7 Analog ground

BIAS 9 O Analog BIAS pin. A 1-µF ceramic capacitor should be connected from BIAS to ANAGND.

BOOT 16 I Bootstrap. Connect a 1-µF low-ESR capacitor from BOOT to BOOTLO.

BOOTLO 18 O Bootstrap low. Connect BOOTLO to the junction of the high-side and low-side FETs for floating drive

configuration. Connect BOOTLO to PGND for ground reference drive configuration.

DROOP 2 I Droop voltage. Voltage input used to set the amount of output-voltage set-point droop as a function of load

current. The amount of droop compensation is set with a resistor divider between IOUT and ANAGND.

DRV 14 O Drive regulator for the FET drivers. A 1-µF ceramic capacitor should be connected from DRV to DR VGND.

DRVGND 12 Drive ground. Ground for FET drivers. Connect to FET PWRGND.

HIGHDR 17 O High drive. Output drive to high-side power switching FETs

HISENSE 19 I High current sense. For current sensing across high-side FETs, connect to the drain of the high-side FETs; for

optional resistor sensing scheme, connect to power supply side of current-sense resistor placed in series with

high-side FET drain.

INHIBIT 22 I Disables the drive signals to the MOSFET drivers. Can also serve as UVLO for system logic supply (either 3.3 V

or 5 V).

IOUT 1 O Current out. Output voltage on this pin is proportional to the load current as measured across the Rds(on) of the

high-side FETs. The voltage on this pin equals 2×R

ds(on)×IOUT. In applications requiring very accurate

current sensing, a sense resistor should be connected between the input supply and the drain of the high-side

FET s.

IOUTLO 21 O Current sense low output. This is the voltage on the LOSENSE pin when the high-side FETs are on. A ceramic

capacitor should be connected from IOUTLO to HISENSE to hold the sensed voltage while the high-side FET s

are off. Capacitance range should be between 0.033 µF and 0.1 µF.

LODRV 10 I Low drive enable. Normally tied to 5 V. To activate the low-side FETs as a crowbar , pull LODRV low.

LOHIB 11 I Low side inhibit. Connect to the junction of the high and low side FETs to control the anti-cross-conduction and

eliminate shoot-through current. Disabled when configured in crowbar mode.

LOSENSE 20 I Low current sense. For current sensing across high-side FETs, connect to the source of the high-side FET s; for

optional resistor sensing scheme, connect to high-side FET drain side of current-sense resistor placed in series

with high-side FET drain.

LOWDR 13 O Low drive. Output drive to synchronous rectifier FETs

OCP 3 I Over current protection. Current limit trip point is set with a resistor divider between IOUT and ANAGND.

PWRGD 28 O Power good. Power good signal goes high when output voltage is within 7% of voltage set by VID pins.

Open-drain output.

SLOWST 8 O Slowstart (soft start). A capacitor from SLOWST to ANAGND sets the slowstart time.

Slowstart current = I

VREFB

/5

V

CC

15 12-V supply. A 1-µF ceramic capacitor should be connected from VCC to DRVGND.

VHYST 4 I HYSTERESIS set pin. The hysteresis is set with a resistor divider from V

REFB

to ANAGND.

The hysteresis window = 2 × (V

REFB

– V

HYST

)

VID0 27 I Voltage identification input 0

VID1 26 I Voltage identification input 1

VID2 25 I Voltage identification input 2

VID3 24 I Voltage identification input 3

VID4 23 I Voltage Identification input 4. Digital inputs that set the output voltage of the converter. The code pattern for

setting the output voltage is located in T able 1. Internally pulled up to 5 V with a resistor divider biased from V

CC

.

VREFB 5 O Buffered reference voltage from VID network

VSENSE 6 I Voltage sense input. To be connected to converter output voltage bus to sense and control output voltage. It is

recommended an RC low pass filter be connected at this pin to filter noise.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

V

REF

The reference/voltage identification (VID) section consists of a temperature-compensated bandgap reference

and a 5-bit voltage selection network. The 5 VID terminals are inputs to the VID selection network and are

TTL-compatible inputs internally pulled up to 5 V by a resistor divider connected to VCC. The VID codes conform

to the Intel

VRM 8.3 DC-DC Converter Specification

for voltage settings between 1.8 V and 3.5 V , and they are

decremented by 50 mV , down to 1.3 V, for the lower VID settings. V oltages higher than V

REF

can be implemented

using an external divider. Refer to T able 1 for the VID code settings. The output voltage of the VID network, V

REF

,

is within ±1.5% of the nominal setting over the VID range of 1.3 V to 2.5 V , including a junction temperature range

of 5°C to +125°C, and a VCC supply voltage range of 1 1.4 V to 12.6 V . The output of the reference/VID network

is indirectly brought out through a buffer to the V

REFB

pin. The voltage on this pin will be within 5mV of V

REF

.

It is not recommended to drive loads with V

REFB

, other than setting the hysteresis of the hysteretic comparator,

because the current drawn from V

REFB

sets the charging current for the slowstart capacitor. Refer to the

slowstart section for additional information.

hysteretic comparator

The hysteretic comparator regulates the output voltage of the synchronous-buck converter. The hysteresis is

set by 2 external resistors and is centered on V

REF

. The 2 external resistors form a resistor divider from V

REFB

to ANAGND, with the output voltage connecting to the VHYST pin. The hysteresis of the comparator will be

equal to twice the voltage

difference

between the VREFB and VHYST pins. The propagation delay from the

comparator inputs to the driver outputs is 250 ns (maximum). The maximum hysteresis setting is 60 mV.

low-side driver

The low-side driver is designed to drive low-Rds(on) n-channel MOSFETs. The current rating of the driver is

2 A, source and sink. The bias to the low-side driver is internally connected to the DRV regulator.

high-side driver

The high-side driver is designed to drive low-Rds(on) n-channel MOSFETs. The current rating of the driver is

2 A, source and sink. The high-side driver can be configured either as a ground-referenced driver or as a floating

bootstrap driver. When configured as a floating driver , the bias voltage to the driver is developed from the DR V

regulator. The internal bootstrap diode, connected between the DR V and BOOT pins, is a Schottky for improved

drive efficiency. The maximum voltage that can be applied between BOOT and DRVGND is 30 V. The driver

can be referenced to ground by connecting BOOTLO to DRVGND, and connecting BOOT to either DRV or VCC.

The rms current through the drivers output should not exceed 110 mA. Refer to the application information

section to determine how to calculate an operating frequency to meet this requirement.

deadtime control

Deadtime control prevents shoot-through current from flowing through the main power FETs during switching

transitions by actively controlling the turnon times of the MOSFET drivers. The high-side driver is not allowed

to turn on until the gate-drive voltage to the low-side FET s is below 2 V ; the low-side driver is not allowed to turn

on until the voltage at the junction of the high-side and low-side FETs (Vphase) is below 2 V.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description (continued)

current sensing

Current sensing is achieved by sampling and holding the voltage across the high-side power FETs while the

high-side FET s are on. The sampling network consists of an internal 60-Ω switch and an external ceramic hold

capacitor. Recommended value of the hold capacitor is between 0.033 µF and 0.1 µF. Internal logic controls

the turnon and turnoff of the sample/hold switch such that the switch does not turn on until the Vphase voltage

transitions high, and the switch turns off when the input to the high-side driver goes low . The sampling will occur

only when the high-side FETs are conducting current. The voltage on the IOUT pin equals 2 times the sensed

high-side voltage. In applications where a higher accuracy in current sensing is required, a sense resistor can

be placed in series with the high-side FETs, and the voltage across the sense resistor can be sampled by the

current sensing circuit.

droop compensation

The droop compensation network reduces the load transient overshoot/undershoot on V

O

, relative to V

REF

. V

O

is programmed to a voltage greater than V

REF

by an external resistor divider from VO to VSENSE to reduce the

undershoot on VO during a low-to-high load transient. The overshoot during a high-to-low load transient is

reduced by subtracting the voltage on DROOP from V

REF

. The voltage on IOUT is divided with an external

resistor divider, and connected to DROOP.

inhibit

INHIBIT is a TTL-compatible digital input used to enable the controller. When INHIBIT is low , the output drivers

are low and the slowstart capacitor is discharged. When INHIBIT goes high, the short across the slowstart

capacitor is released and normal converter operation begins. When the system-logic supply is connected to

INHIBIT, it also controls power sequencing by locking out controller operation until the system-logic supply

exceeds the input threshold voltage of the inhibit circuit. The 12-V supply and the system logic supply (either

5 V or 3.3 V) must be above UVLO thresholds before the controller is allowed to start up. The start threshold

is 2.1 V and the hysteresis is 100 mV for the INHIBIT comparator.

VCC undervoltage lockout (UVLO)

The undervoltage lockout circuit disables the controller while the VCC supply is below the 10-V start threshold

during power up. When the controller is disabled, the output drivers will be low and the slowstart capacitor is

discharged. When VCC exceeds the start threshold, the short across the slowstart capacitor is released and

normal converter operation begins. There is a 2-V hysteresis in the undervoltage lockout circuit for noise

immunity.

slowstart

The slowstart circuit controls the rate at which VO powers up. A capacitor is connected between SLOWST and

ANAGND and is charged by an internal current source. The current source is proportional to the reference

voltage, so that the charging rate of C

SLOWST

is proportional to the reference voltage. By making the charging

current proportional to V

REF

, the power-up time for VO will be independent of V

REF

. Thus, C

SLOWST

can remain

the same value for all VID settings. The slowstart charging current is determined by the following equation:

I

slowstart

= I(VREFB) / 5 (amps)

Where I(VREFB) is the current flowing out of VREFB.

It is recommended that no additional loads be connected to VREFB, other than the resistor divider for setting

the hysteresis voltage. The maximum current that can be sourced by the VREFB circuit is 500 µA. The equation

for setting the slowstart time is:

t

SLOWST

= 5 × C

SLOWST

× R

VREFB

(seconds)

Where R

VREFB

is the total external resistance from V

REFB

to ANAGND.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description (continued)

power good

The power-good circuit monitors for an undervoltage condition on VO. If VO is 7% below V

REF

, then the PWRGD

pin is pulled low. PWRGD is an open-drain output.

overvoltage protection

The overvoltage protection (OVP) circuit monitors V

O

for an overvoltage condition. If VO is 15% above V

REF

,

then a fault latch is set and both output drivers are turned off. The latch will remain set until V

CC

goes below the

undervoltage lockout value. A 3-µs deglitch timer is included for noise immunity. Refer to the LODRV section

for information on how to protect the microprocessor against overvoltages due to a shorted fault across the

high-side power FET.

overcurrent protection

The overcurrent protection (OCP) circuit monitors the current through the high-side FET. The overcurrent

threshold is adjustable with an external resistor divider between IOUT and ANAGND, with the divider voltage

connected to the OCP pin. If the voltage on OCP exceeds 100 mV , then a fault latch is set and the output drivers

are turned off. The latch will remain set until VCC goes below the undervoltage lockout value. A 3-µs deglitch

timer is included for noise immunity . The OCP circuit is also designed to protect the high-side power FET against

a short-to-ground fault on the terminal common to both power FETs.

drive regulator

The drive regulator provides drive voltage to the output drivers. The minimum drive voltage is 7 V . The minimum

short circuit current is 100 mA. Connect a 1-µF ceramic capacitor from DRV to DRVGND.

LODRV

The LODRV circuit is designed to protect the microprocessor against overvoltages that can occur if the high-side

power FETs become shorted. External components to sense an overvoltage condition are required to use this

feature. When an overvoltage fault occurs, the low-side FET s are used as a crowbar . LODR V is pulled low and

the low-side FET will be turned on, overriding all control signals inside the TPS5211 controller. The crowbar

action will short the input supply to ground through the faulted high-side FETs and the low-side FETs. A fuse

in series with Vin should be added to disconnect the short-circuit.

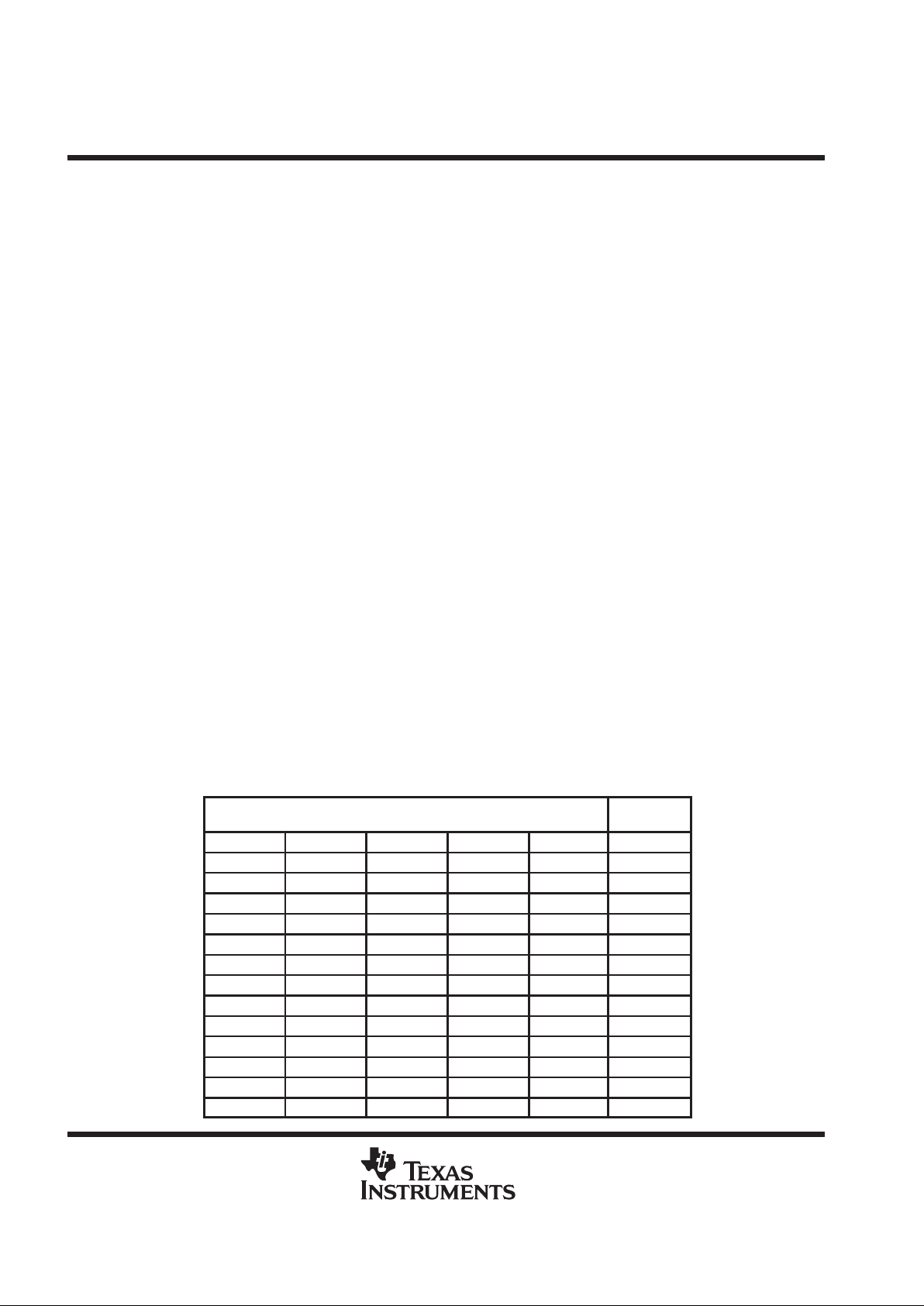

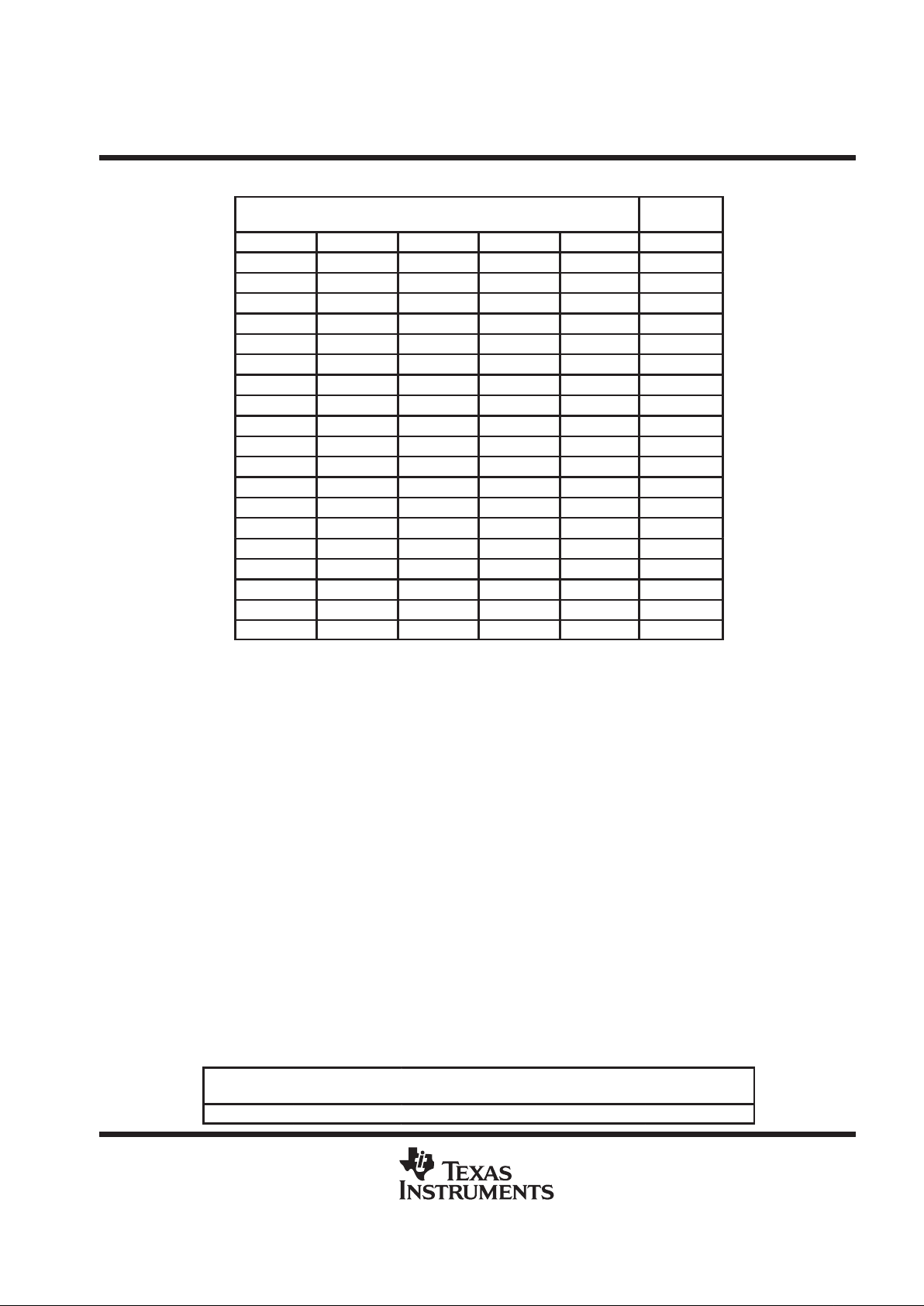

Table 1. Voltage Identification Codes

VID TERMINALS

(0 = GND, 1 = floating or pull-up to 5 V)

V

REF

VID4 VID3 VID2 VID1 VID0 (Vdc)

0 1 1 1 1 1.30

0 1 1 1 0 1.35

0 1 1 0 1 1.40

0 1 1 0 0 1.45

0 1 0 1 1 1.50

0 1 0 1 0 1.55

0 1 0 0 1 1.60

0 1 0 0 0 1.65

0 0 1 1 1 1.70

0 0 1 1 0 1.75

0 0 1 0 1 1.80

0 0 1 0 0 1.85

0 0 0 1 1 1.90

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Table 1. Voltage Identification Codes (Continued)

VID TERMINALS

(0 = GND, 1 = floating or pull-up to 5 V)

V

REF

VID4 VID3 VID2 VID1 VID0 (Vdc)

0 0 0 1 0 1.95

0 0 0 0 1 2.00

0 0 0 0 0 2.05

1 1 1 1 1 No CPU

1 1 1 1 0 2.10

1 1 1 0 1 2.20

1 1 1 0 0 2.30

1 1 0 1 1 2.40

1 1 0 1 0 2.50

1 1 0 0 1 2.60

1 1 0 0 0 2.70

1 0 1 1 1 2.80

1 0 1 1 0 2.90

1 0 1 0 1 3.00

1 0 1 0 0 3.10

1 0 0 1 1 3.20

1 0 0 1 0 3.30

1 0 0 0 1 3.40

1 0 0 0 0 3.50

absolute maximum ratings over operating virtual junction temperature (unless otherwise noted)

†

Supply voltage range, V

CC

(see Note1) –0.3 V to 14 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range: BOOT to DRVGND (High-side Driver ON) –0.3 V to 30 V. . . . . . . . . . . . . . . . . . . . . . . . .

BOOT to HIGHDRV –0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BOOT to BOOTLO –0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INHIBIT, VIDx, LODRV –0.3 V to 7.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWRGD, OCP, DROOP –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOHIB, LOSENSE, IOUTLO, HISENSE –0.3 V to 14 V. . . . . . . . . . . . . . . . . . . . . . . . . .

VSENSE –0.3 V to 5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage difference between ANAGND and DRVGND ±0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, V

REFB

0.5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short circuit duration, DRV Continuous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, TJ 0°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature soldering 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: Unless otherwise specified, all voltages are with respect to ANAGND.

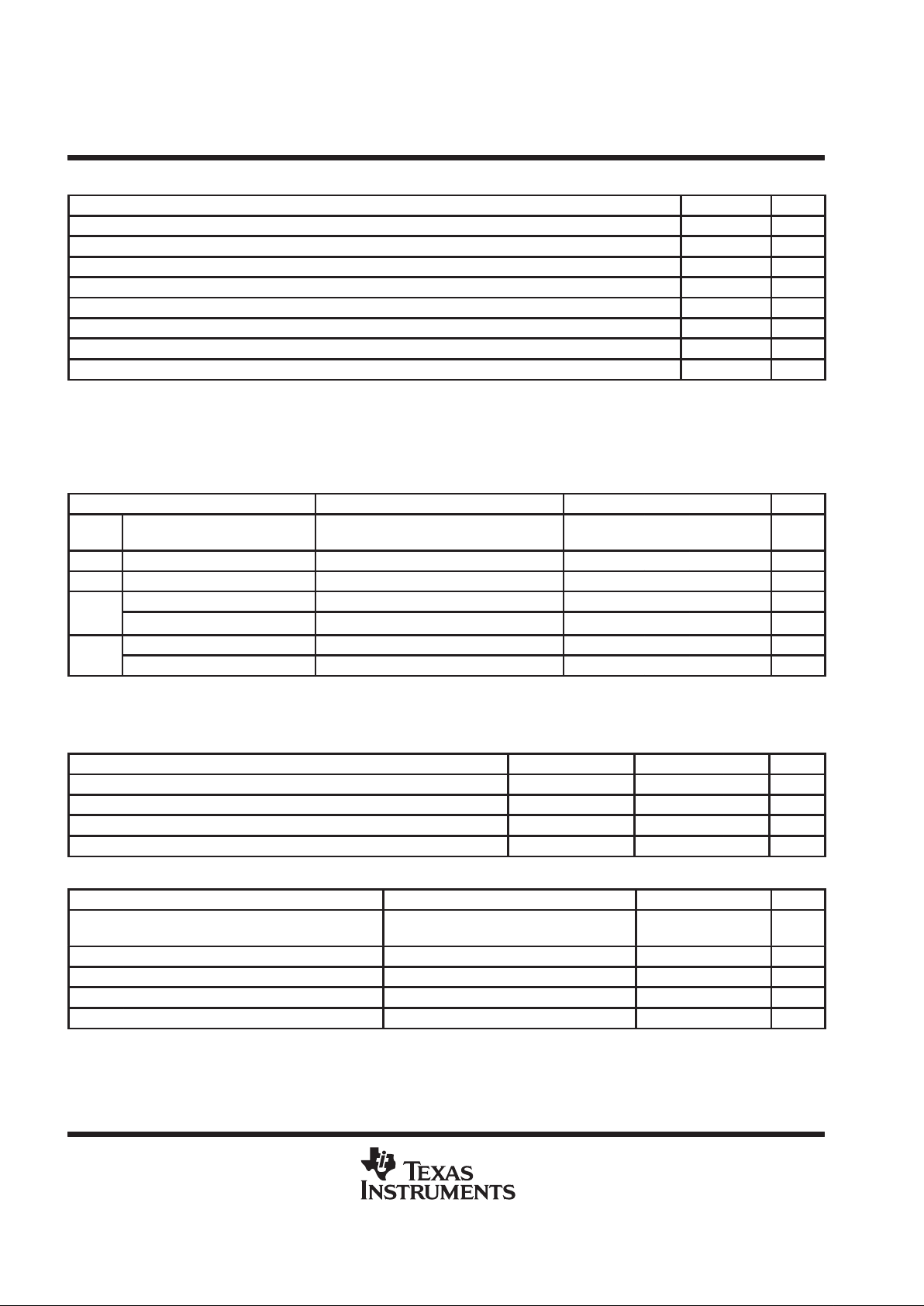

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

PWP 1 150 mW 11.5 mW/°C 630 mW 460 mW

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

recommended operating conditions

MIN MAX UNIT

Supply voltage, V

CC

11.4 13 V

Input voltage, BOOT to DRVGND 0 28 V

Input voltage, BOOT to BOOTLO 0 13 V

Input voltage, INHIBIT, VIDx, LODRV , PWRGD, OCP, DROOP 0 6 V

Input voltage, LOHIB, LOSENSE, IOUTLO, HISENSE 0 13 V

Input voltage, VSENSE 0 4.5 V

Voltage dif ference between ANAGND and DRVGND 0 ±0.2 V

Output current, V

REFB

†

0 0.4 mA

†

Not recommended to load V

REFB

other than to set hystersis since I

VREFB

sets slowstart time.

electrical characteristics over recommended operating virtual junction temperature range,

V

CC

= 12 V, I

DRV

= 0 A (unless otherwise noted)

reference/voltage identification

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

REF

Cumulative reference accuracy

(see Note 2)

VCC = 11.4 to 12.6 V, 1.3 V ≤ V

REF

≤ 3.5 V –0.015 0.015 V/V

VIDx High-level input voltage 2.25 V

VIDx Low-level input voltage 1 V

Output voltage I

VREFB

= 50 µA V

REF

–5mV V

REFVREF

+5mV V

V

REFB

Output regulation 10 µA ≤ IO ≤ 500 µA 2 mV

Input resistance VIDx = 0 V 36 73 95 kΩ

VID

x

Input pull-up voltage divider 4.8 4.9 5 V

NOTES: 2. Cumulative reference accuracy is the combined accuracy of the reference voltage and the input offset voltage of the hysteretic

comparator. Cumulative accuracy equals the average of the high-level and low-level thresholds of the hysteretic comparator.

3. This parameter is ensured by design and is not production tested.

power good

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Undervoltage trip threshold 90 93 95 %V

REF

V

OL

Low-level output voltage IO = 5 mA 0.5 0.75 V

I

OH

High-level input current V

PWRGD

= 6 V 1 µA

V

hys

Hysteresis voltage 1.3 2.9 4.5 %V

REF

slowstart

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Charge current

V

SLOWST

= 0.5 V,

I

VREFB

= 65 µA

V

VREFB

= 1.3 V,

10.4 13 15.6 µA

Discharge current V

SLOWST

= 1 V 3 mA

Comparator input offset voltage 10 mV

Comparator input bias current See Note 3 10 100 nA

Comparator hysteresis –7.5 7.5 mV

NOTE 3: This parameter is ensured by design and is not production tested.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating virtual junction temperature range,

V

CC

= 12 V, I

DRV

= 0 A (unless otherwise noted) (continued)

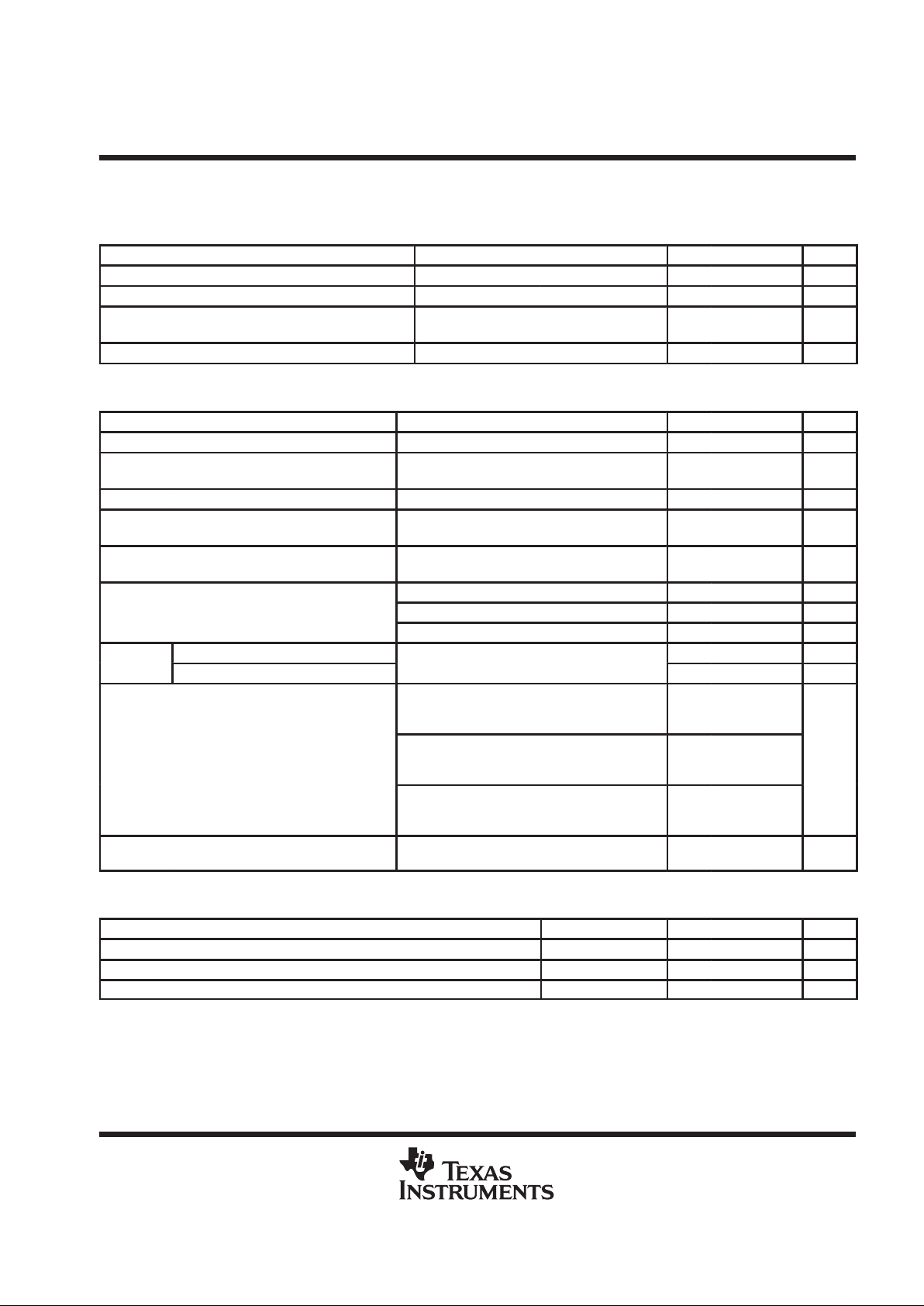

hysteretic comparator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Input offset voltage V

DROOP

= 0 V (see Note 3) –2.5 2.5 mV

Input bias current See Note 3 500 nA

Hysteresis accuracy V

REFB

– V

HYST

= 15 mV

(Hysteresis window = 30 mV)

–3.5 3.5 mV

Maximum hysteresis setting V

REFB

– V

HYST

= 30 mV 60 mV

NOTE 3: This parameter is ensured by design and is not production tested.

high-side VDS sensing

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Gain 2 V/V

Initial accuracy

V

HISENSE

= 12 V, V

LOSENSE

= 11.9 V,

Differential input to Vds sensing amp = 100 mV

194 206 mV

IOUTLO Sink current 5 V ≤ V

IOUTLO

≤ 13 V 250 nA

IOUT Source current

V

IOUT

= 0.5 V, V

HISENSE

= 12 V,

V

IOUTLO

= 11.5 V

500 µA

IOUT Sink current

V

IOUT

= 0.05 V, V

HISENSE

= 12 V,

V

IOUTLO

= 12 V

50 µA

V

HISENSE

= 11 V, R

IOUT

= 10 kΩ 0 2 V

Output voltage swing

V

HISENSE

= 4.5 V, R

IOUT

= 10 kΩ

0 1.5 V

V

HISENSE

= 3 V, R

IOUT

= 10 kΩ 0 0.75 V

High-level input voltage

2.85 V

LOSENSE

Low-level input voltage

V

HISENSE

= 4.5 V

(see Note 3)

2.4 V

11.4 V ≤ V

HISENSE

≤ 12.6 V,

LOSENSE connected to HISENSE,

V

HISENSE

– V

IOUTLO

= 0.15 V

50 60 80

Sample/hold resistance

4.5 V ≤ V

HISENSE

≤ 5.5 V,

LOSENSE connected to HISENSE,

V

HISENSE

– V

IOUTLO

= 0.15 V

62 85 123

Ω

3 V ≤ V

HISENSE

≤ 3.6 V,

LOSENSE connected to HISENSE,

V

HISENSE

– V

IOUTLO

= 0.15 V

67 95 144

CMRR

V

HISENSE

= 12.6 V to 3 V,

V

HISENSE

– V

OUTLO

= 100 mV

69 75 dB

NOTE 3. This parameter is ensured by design and is not production tested.

inhibit

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Start threshold 1.9 2.1 2.35 V

Hysteresis 0.08 0.1 0.12 V

Stop threshold 1.85 V

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating virtual junction temperature range,

V

CC

= 12 V, I

DRV

= 0 A (unless otherwise noted) (continued)

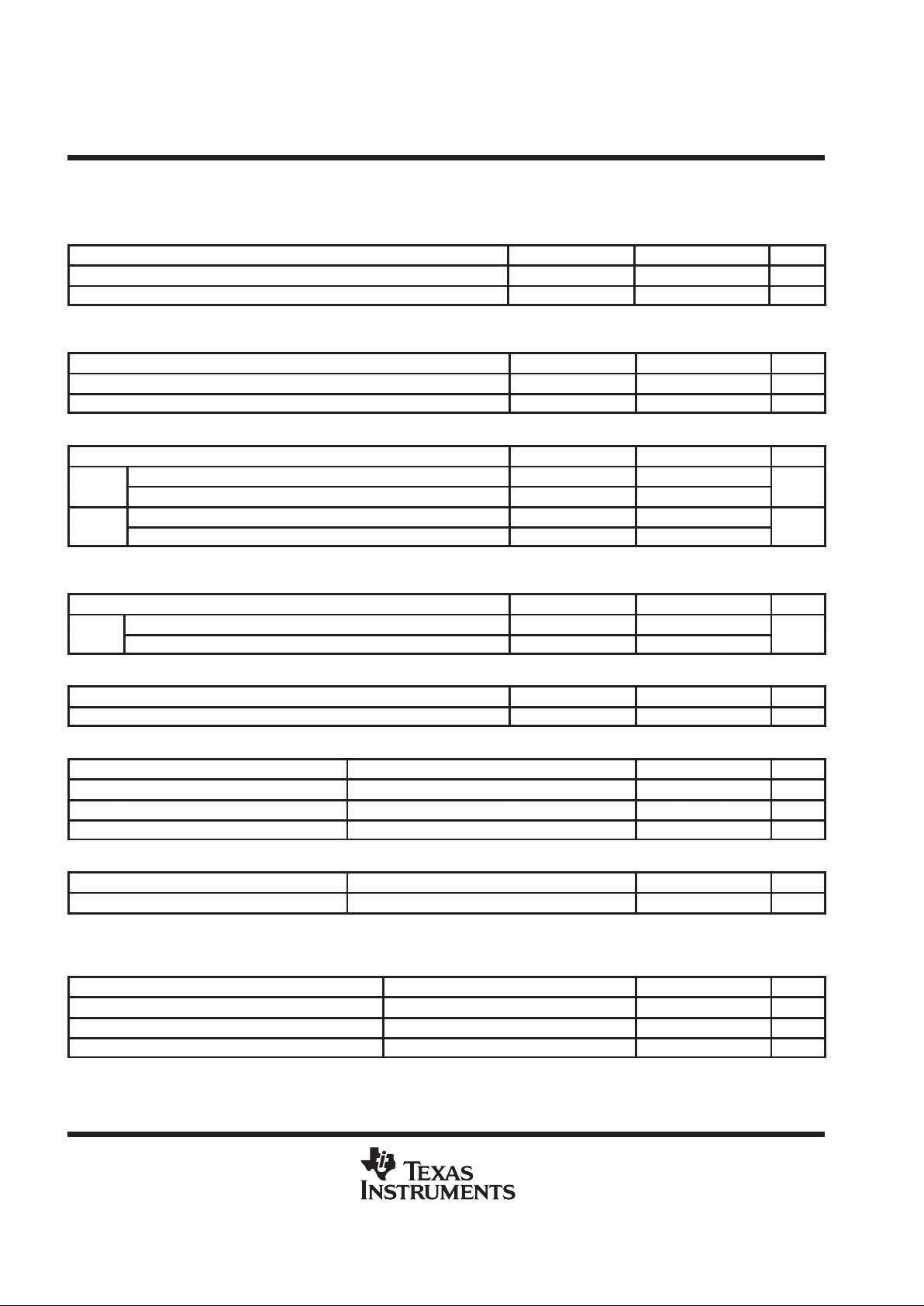

overvoltage protection

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Overvoltage trip threshold 112 115 120 %V

REF

Hysteresis See Note 3 10 mV

NOTE 3: This parameter is ensured by design and is not production tested.

overcurrent protection

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

OCP trip threshold 90 100 110 mV

Input bias current 100 nA

deadtime

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage 2.4

LOHIB

Low-level input voltage 1.4

V

High-level input voltage See Note 3 3

LOWDR

Low-level input voltage See Note 3 1.7

V

NOTE 3: This parameter is ensured by design and is not production tested.

LODRV

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage 1.85

LODRV

Low-level input voltage 0.95

V

droop compensation

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Initial accuracy V

DROOP

= 50 mV 46 54 mV

drive regulator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage 11.4 V ≤ VCC ≤ 12.6 V, I

DRV

= 120 mA 7 9 V

Output regulation 1 mA ≤ I

DRV

≤ 50 mA 100 mV

Short-circuit current 120 mA

bias regulator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage 11.4 V ≤ VCC ≤ 12.6 V, See Note 4 6 V

NOTE 4: The bias regulator is designed to provide a quiet bias supply for the TPS5211 controller. External loads should not be driven by the bias

regulator.

input undervoltage lockout

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Start threshold 9.25 10 10.75 V

Hysteresis 1.9 2 2.2 V

Stop threshold 7.5 V

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating virtual junction temperature range,

V

CC

= 12 V, I

DRV

= 0 A (unless otherwise noted) (continued)

output drivers

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-side sink

Duty cycle < 2%,

TJ = 125°C,

tpw < 100 µs,

V

BOOT

– V

BOOTLO

= 6.5 V,

2

Peak output

High-side source

V

HIGHDR

= 1.5 V (source) or 6 V (sink),

See Note 3

2

curren

t

(see Note 5)

Low-side sink

Duty Cycle < 2%,

TJ = 125°C,

tpw < 100 µs,

V

DRV

= 6.5 V,

2

A

Low-side source

V

LOWDR

= 1.5 V (source) or 5 V (sink),

See Note 3

2

High-side sink

T

= 125°C, V

– V

= 6.5 V,

3

Output

High-side source

J

,

BOOT BOOTLO

,

V

HIGHDR

= 6 V (source) or 0.5 V (sink)

45

resistance

(

see Note 5

)

Low-side sink

TJ = 125°C, V

DRV

= 6.5 V,

5.7

Ω

(see Note 5)

Low-side source

J DRV

V

LOWDR

= 6 V (source) or 0.5 V (sink)

45

NOTES: 3. This parameter is ensured by design and is not production tested.

5. The pullup/pulldown circuits of the drivers are bipolar and MOSFET transistors in parallel. The peak output current rating is the

combined current from the bipolar and MOSFET transistors. The output resistance is the R

ds(on)

of the MOSFET transistor when

the voltage on the driver output is less than the saturation voltage of the bipolar transistor.

supply current

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

CC

Supply voltage

range

11.4 12 13 V

V

INHIBIT

= 5 V,

VCC > 10.75 V at startup,

VID code ≠ 11111,

V

BOOTLO

= 0 V

3 10

V

CC

Quiescent

current

V

INHIBIT

= 5 V,

VCC > 10.75 V at startup,

C

HIGHDR

= 50 pF,

f

SWX

= 200 kHz,

VID code ≠ 11111,

V

BOOTLO

= 0 V,

C

LOWDR

= 50 pF,

See Note 3

5

mA

High-side

V

INHIBIT

= 0 V or VID code = 11111 or VCC < 9.25 V at startup,

V

BOOT

= 13 V, V

BOOTLO

= 0 V

80 µA

driver

quiescent

current

V

INHIBIT

= 5 V,

V

BOOT

= 13 V,

C

HIGHDR

= 50 pF,

VID code ≠ 11111, VCC > 10.75 V at startup,

V

BOOTLO

= 0 V,

f

SWX

= 200 kHz (see Note 3)

2 mA

NOTE 3: This parameter is ensured by design and is not production tested.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

switching characteristics over recommended operating virtual-junction temperature range,

V

CC

= 12 V, I

DRV

= 0 A (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

1.3 V ≤ V

VREF

≤ 3.5 V, 10 mV overdrive

(see Note 3)

150 250

VSENSE to HIGHDR or

LOWDR (excluding dead-

1.3 V ≤ V

VREF

≤ 3.5 V, 20 mV overdrive 200

ns

(g

time)

1.3 V ≤ V

VREF

≤ 3.5 V, 30 mV overdrive 190

Propagation delay

1.3 V ≤ V

VREF

≤ 3.5 V, 40 mV overdrive 180

gy

OCP comparator 1

OVP comparator

See Note 3

1

µs

PWRGD comparator 1

SLOWST comparator Overdrive = 10 mV (see Note 3) 560 900 ns

p

CL = 50 pF, V

BOOTLO

= 0 V 8

HIGHDR output

CL = 3 nF 35

Rise time

p

CL = 50 pF 8

ns

LOWDR output

CL = 3 nF 40

p

CL = 50 pF, V

BOOTLO

= 0 V TBD

HIGHDR output

CL = 3 nF 35

Fall time

p

CL = 50 pF TBD

ns

LOWDR output

CL = 3 nF 40

Deglitch time (Includes

p

p

p

OCP

2 5

comparator propagation

delay)

OVP

See Note 3

2 5

µ

s

V

HISENSE

= 12 V,

V

IOUTLO

pulsed from 12 V to 11.9 V,

100 ns rise/fall times (see Note 3)

2

Response time High-side VDS sensing

V

HISENSE

= 4.5 V,

V

IOUTLO

pulsed from 4.5 V to 4.4 V ,

100 ns rise/fall times (see Note 3)

3

µs

V

HISENSE

= 3 V,

V

IOUTLO

pulsed from 3 V to 2.9 V ,

100 ns rise/fall times (see Note 3)

3

Short-circuit protection

rising-edge delay

SCP LOSENSE = 0 V (see Note 3) 300 500 ns

Turnon/turnoff delay

VDS sensing sample/hold

switch

3 V ≤ V

HISENSE

≤ 11 V,

V

LOSENSE

= V

HISENSE

(see Note 3)

30 100 ns

Crossover delay time

LOWDR to HIGHDRV, and

LOHIB to LOWDR

See Note 3 30 100 ns

Prefilter pole frequency Hysteretic comparator See Note 3 5 MHz

Propagation delay LODRV See Note 3 400 ns

NOTE 3: This parameter is ensured by design and is not production tested.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 1

SLOWSTART TIME

vs

SLOWSTART CAPACITANCE

0.0001 0.0010

Slowstart Capacitance – µF

100

0

10

1

0.1

Slowstart Time – ms

V

(VREFB)

= 2 V

I

(VREFB)

= 100 µA

TJ = 25°C

0.0100 0.1000 1

Figure 2

SLOWSTART TIME

vs

SUPPLY CURRENT (VREFB)

110

ICC – Supply Current (VREFB) – µA

1000

1

10

Slowstart Time – ms

V

(VREFB)

= 2 V

CS = 0.1 µF

TJ = 25°C

100 1000

100

Figure 3

DRIVER

OUTPUT RISE TIME

vs

LOAD CAPACITANCE

CL – Load Capacitance – nF

– Rise Time – nst

r

1

10

100

1000

0.01 0.10 1.00 10.00 100.

0

High Side

Low Side

Tj = 27 °C

Figure 4

DRIVER

OUTPUT FALL TIME

vs

LOAD CAPACITANCE

1

10

100

1000

0.01 0.10 1.00 10.00 100.

0

CL – Load Capacitance – nF

High Side

Low Side

Tj = 27 °C

– Rise Time – nst

r

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 5

TJ – Junction Temperature – °C

OVP THRESHOLD

vs

JUNCTION TEMPERATURE

117

114

112

25 75

116

115

113

50 100 125

118

0

OVP Threshold – %

Figure 6

TJ – Junction Temperature – °C

OCP THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

99

95

25 75

103

101

97

50 100 125

105

0

OCP Threshold V oltage – mV

Figure 7

TJ – Junction Temperature – °C

INHIBIT START THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

2

1.9

25 75

2.05

1.95

50 100 125

2.1

0

Inhibit Start Threshold Voltage – V

Figure 8

TJ – Junction Temperature – °C

INHIBIT HYSTERESIS VOLTAGE

vs

JUNCTION TEMPERATURE

100

50

25 75

125

75

50 100 125

150

0

Inhibit Hysteresis Voltage – mV

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 9

TJ – Junction Temperature – °C

UVLO START THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

10

9

25 75

9.5

50 100 125

10.5

0

UVLO Start Threshold Voltage – V

VI = 12 V

Figure 10

TJ – Junction Temperature – °C

UVLO HYSTERESIS

vs

JUNCTION TEMPERATURE

1.9

1.5

25 75

2.3

2.1

1.7

50 100 125

2.5

0

UVLO Hysteresis – V

VI = 12 V

Figure 11

TJ – Junction Temperature – °C

QUIESCENT CURRENT

vs

JUNCTION TEMPERATURE

4

0

25 75

2

50 100 125

6

0

Quiescent Current – mA

VI = 12 V

Figure 12

TJ – Junction Temperature – °C

POWERGOOD THRESHOLD

vs

JUNCTION TEMPERATURE

92

90

25 75

94

93

91

50 100 125

95

0

Powergood Threshold – %

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 13

TJ – Junction Temperature – °C

SLOWSTART CHARGE CURRENT

vs

JUNCTION TEMPERATURE

12

10

25 75

14

13

11

50 100 125

15

0

Slow Start Charge Current – Aµ

V

(VREFB)

= 1.3 V

R

(VREFB)

= 20 kΩ

Figure 14

TJ – Junction Temperature – °C

DRIVER

REGULATOR VOLTAGE

vs

JUNCTION TEMPERATURE

8

7.5

25 75

8.25

7.75

50 100 125

8.5

0

Regulator Voltage – V

Figure 15

TJ – Junction Temperature – °C

DRIVER

HIGH-SIDE OUTPUT RESISTANCE

vs

JUNCTION TEMPERATURE

2

0

25 75

4

3

1

50 100 125

5

0

– High-Side Output Resistance – R

O

Ω

Figure 16

TJ – Junction Temperature – °C

DRIVER

LOW-SIDE OUTPUT RESISTANCE

vs

JUNCTION TEMPERATURE

4

0

25 75

2

50 100 125

6

0

– Low-Side Output Resistance – R

O

Ω

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

TJ – Junction Temperature – °C

SENSING SAMPLE/HOLD RESISTANCE

vs

JUNCTION TEMPERATURE

50

0

25 75

75

25

50 100 125

100

0

– Sensing Sample/Hold Resistance – R

O

Ω

V

(HISENSE)

= 12 V

Figure 17

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The following figure is a typical application schematic. The circuit can be divided into the power-stage section

and the control-circuit section. The power stage must be tailored to the input/output requirements of the

application. The control circuit is basically the same for all applications with some minor tweaking of specific

values. Table 2 shows the values of the power stage components for various output-current options.

1 uF

C1

1%

C8

2200 pF

ENABLE

1%

R4

2.55 k

1 uF

C3

C6

0.033 uF

10

LODRV

11

LOHIB

12

DRVGND

13

LOWDR

14

DRV

16

BOOT

17

HIGHDR

18

BOOTLO

19

HISENSE

15

VCC

23

VID4

24

VID3

25

VID2

26

VID1

27

VID0

22

INHIBIT

28

PWRGD

1

IOUT

9

BIAS

3

OCP

4

VHYST

6

VSENSE

5

VREFB

7

ANAGND

8

SLOWST

2

DROOP

20

LOSENSE

21

IOUTLO

U1

TPS5211

3.40 k

R1

GND

Control Section

Power Stage

12V

L101

Q102

LOSENSE

BOOTLO

12V

R102

C101

HIGHDRV

HISENSE

Q101

R101

DRVGND

Vo

L102

RTN

RTN

C102

+

C103

C104

R103

VSENSE

LOHIB

LODRV

VSENSE_HF

R9

4.32 k

R10

1.00 k

R11

10.0 k

1 uF

C2

R2

150

C4

1 uF

C5

0.1 uF

10.0 kR3

100

R5

20.0 k

R6

R7

3.92 k

1.00 k

R8

C7

1000pF

(see Note A)

NOTE A: VID0 – VID4 User – selected to set output voltage.

Figure 18. Standard Application Schematic

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Table 2. Power Stage Components

12-V–Input Power Stage Components

Reference Designation

Function

4–A Out 8–A Out 12–A Out 20–A Out

C101 Input capacitor

muRata,

GRM235Y106Z016A,

2 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

4 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

6 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

10 x 10–uF , 16–V, Y5V

C102 Snubber capacitor

muRata,

GRM39X7R102K050A,

1000–pF, 50–V, X7R

muRata,

GRM39X7R102K050A,

1000–pF, 50–V, X7R

muRata,

GRM39X7R102K050A,

2 x 1000–pF , 50–V, X7R

muRata,

GRM39X7R102K050A,

3 x 1000–pF , 50–V, X7R

C103

Output bulk

capacitor

Sanyo,

4TPC150M,

150–uF, 4–V, 20%

Sanyo,

4TPC150M,

2 x 150–uF , 4–V, 20%

Sanyo,

4TPC150M,

3 x 150–uF , 4–V, 20%

Sanyo,

4TPC150M,

4 x 150–uF , 4–V, 20%

C104

Output hi–freq

bypass capacitor

muRata,

GRM235Y106Z016A,

2 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

4 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

6 x 10–uF , 16–V, Y5V

muRata,

GRM235Y106Z016A,

8 x 10–uF , 16–V, Y5V

L101

Input filter

inductor

CoilCraft,

DO1607C–152,

1.5–uH, 2.1–A

CoilCraft,

DO1813HC–122,

1.2–uH, 4.4–A

CoilCraft,

DO1813HC–122,

1.2–uH, 4.4–A

CoilCraft,

DO3316P–152HC,

1.5–uH, 9.0–A

L102

Output filter

inductor

CoilCraft,

DO1813HCP–561,

0.56–uH, 6–A

CoilCraft,

DO3316P–681HC,

0.68–uH, 12–A

Vishay–Dale,

IHLP–5050CE–XX,

0.82–uH, 16–A,

New product

Vishay–Dale,

IHLP–5050CE–XX,

0.5–uH, 25–A,

New product

R101

High–side gate

resistor

10.0–Ohm,

1/16–W, 5%

10.0–Ohm,

1/16–W, 5%

2 x 10.0–Ohm,

1/16–W, 5%

2 x 10.0–Ohm,

1/16–W, 5%

R102

Lo–side gate

resistor

3.3–Ohm,

1/16–W, 5%

3.3–Ohm,

1/16–W, 5%

2 x 3.3–Ohm,

1/16–W, 5%

3 x 3.3–Ohm,

1/16–W, 5%

R103 Snubber resistor

2.7–Ohm,

1/10–W, 5%

2.7–Ohm,

1/10–W, 5%

2 x 2.7–Ohm,

1/10–W, 5%

3 x 2.7–Ohm,

1/10–W, 5%

Q101 Power switch

IR, IRF7811,

NMOS, 11–mOhm

IR, IRF7811,

NMOS, 11–mOhm

IR, 2 x IRF7811,

NMOS, 11–mOhm

IR, 2 x IRF7811,

NMOS, 11–mOhm

Q102 Synchronous switch

IR, IRF7811,

NMOS, 11–mOhm

IR, IRF7811,

NMOS, 11–mOhm

IR, 2 x IRF7811,

NMOS, 11–mOhm

IR, 2 x IRF7811,

NMOS, 11–mOhm

Nominal frequency

†

700 KHz

Hysteresis window 20 mV

†

Nominal frequency measured with Vo set to 2 V.

The values listed above are recommendations based on actual test circuits. Many variations of the above are

possible based upon the desires and/or requirements of the user. Performance of the circuit is equally, if not

more, dependent upon the layout than on the specific components, as long as the device parameters are not

exceeded. Fast-response, low-noise circuits require critical attention to the layout details. Even though the

operating frequencies of typical power supplies are relatively low compared to today’s microprocessor circuits,

the power levels and edge rates can cause severe problems both in the supply and the load. The power stage,

having the highest current levels and greatest dv/dt rates, should be given the greatest attention.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

frequency calculation

The simplified equation shown below can be used for a preliminary frequency calculation:

f

s

≅

V

REF

x(VI*

V

REF

)

VI

R11 C7 x Hysteresis Window

x0.85

(1)

High frequency operations require special attention not to exceed maxium current through the controller

(120mA), and the maximum total power dissipation.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

Fmax D()

kHz

Fm D()

kHz

D

Fmax With

External Driver

Fmax With

Internal Driver

Figure 19

Another restriction relates to the maximum rms current through the output of the highside driver, (1 10mA.) The

maximum allowable operating frequency can be defined by the following equation:

Fmax

+

(

110mA)2

60ohm

)

Qg xǒVI)

Vdrv

Ǔ

(2)

Where Qg = Total gate charge of the upper FETs in the hysteretic converter (in nanocoulombs)

Vdrv = 8 V and is the drive regulator voltage of the TPS5211 controller

V

I

= Input voltage

Fmax = Maximum switching frequency in kHz

Figure 19 and equation (2) should be used to determine the maximum operating frequency of a converter. The

operating frequency should not exceed the lower of the two values determined by Figure 19 and equation (2).

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Control Section

Below are the equations needed to select the various components within the control section.

output voltage selection

The most important function of the power supply is to regulate the output voltage to a specific value. Values

between 1.3 V and 3.5 V can be easily set by shorting the correct VID inputs to ground. Values above the

maximum reference voltage (3.5 V) can be set by setting the reference voltage to any convenient voltage within

its range and selecting values for R2 and R3 to give the correct output. Select R3:

R3 << than V

REF/IBIAS(VSENSE)

; a recommended value is 10 kΩ

Then, calculate R2 using:

VO+

V

REF

ǒ

1

)

R2

R3

Ǔ

R2

+

R3

ǒVO*

V

REF

Ǔ

V

REF

or

These equations are accurate if R2<<R1 1. If this condition is not fullfilled, the following equation must be used:

V

O

+

V

REF

ǒ

1

)

R2 x R11

R3 x (R2)R11)

Ǔ

Another soultion is to use 0.1-µF DC decoupling capacitor in series with R11. In such a case, R11 does not

influence the output voltage value.

R2 and R3 can also be used to make small adjusts to the output voltage within the reference-voltage range

and/or to adjust for load-current active droop compensation. If there is no need to adjust the output voltage, R3

can be eliminated. R2, R3 (if used), and C7 are used as a noise filter; calculate using:

C7

+

150 ns

ǒ

R2øR3

Ǔ

slowstart timing

Slowstart reduces the startup stresses on the power-stage components and reduces the input current surge.

Slowstart timing is a function of the reference-voltage current (determined by R6) and is independent of the

reference voltage. The first step in setting slowstart timing will be to determine R6:

R6 should be between 7 kΩ and 300 kΩ, a recommended value is 20 kΩ.

Set the slowstart timing using the formula:

C5

+

t

SS

ǒ

5 R

VREFB

Ǔ

≅

t

SS

(

5 R6

)

Where C5 = Slowstart capacitance in µF

tSS = Slowstart timing in µs

R

VREFB

= Resistance from VREFB to GND in ohms (≈ R6)

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

hysteresis voltage

A hysteretic controller regulates by self-oscillation, thus requiring a small ripple voltage on the VSENSE pin

which the input comparator uses for sensing. Once selected, the TPS5211 hysteresis is proportional to the

reference voltage; programming Vref to a new value automatically adjusts the hysteresis to be the same

percentage of Vref. Since the output current from VREFB should be less than 500 µA, the total divider resistance

(R5 + R6) should be greater than 7 KΩ. The hysteresis voltage should be no greater than 60 mV so R6 will

dominate the divider.

R5

R6

VHSYT

VREFB

Hysteresis Window = 2 × V

R5

Figure 20. Hysteresis Divider Circuit

The upper divider resistor, R5, is calculated using:

()

()

()

6

1002

6

2

5

0

0

R

V

R

WindowHysteresisVREFB

WindowHysteresis

R

HYST

×

×

≅×

–×

=

Where Hysteresis Window = The desired peak-to-peak hysteresis voltage

VREFB = Selected reference voltage

V

HYST

(%) = [(Hysteresis Window)/VREFB] * 100 < V

O(Ripple)(P–P)

(%)

current limit

Current limit can be implemented using the on-resistance of the upper FETs as the sensing elements. Select

R8:

()

Ω≤

×

≤<<

nA

V

I

V

R

OCPBias

OCP

10 k

100100

1.0

8

)(

(A recommended value is 1 kΩ)

The IOUT signal is used to drive the current limit and droop-circuit dividers. The voltage at IOUT at the output

current trip point will be:

()

I

NumFETs

TF

R

V

TripO

ONDS

TripIOUT

)(

)(

)(

2

×

××

=

Where NumFETS = Number of upper FETS in parallel

TF = R

DS(ON)

temperature correction factor

I

O(Trip)

= Desired output current trip level (A)

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Calculate R7 using:

R7

+

ǒ

V

IOUT(Trip)

0.1 V

*

1Ǔ

R8

Note that since R

DS(ON)

of MOSFET s can vary from lot to lot and with temperature, tight current-limit control (less

than 1.5 x IO) using this method is not practical. If tight control is required, an external current-sense resistor

in series with the drain of the upper FET can be used with HISENSE and LOSENSE connected across the

resistor.

droop compensation

Active voltage droop positioning is used to reduce the output voltage range during load transients by increasing

the output voltage setpoint toward the upper tolerance limit during light loads and decreasing the voltage

setpoint toward the lower tolerance limit during heavy loads. This allows the output voltage to swing a greater

amount and still remain within the tolerance window. The maximum droop voltage is set with R9 and R10.

Select R10:

()

Ω≤

×

≤<<

nA

V

I

V

R

MaxDROOPBias

MinDROOP

1 k

100100

01.0

10

),(

)(

(Again, a value of 1 kΩ is recommended)

The voltage at IOUT during normal operation (0 to 100% load) will vary from 0 V up to:

()

I

NumFETs

TF

R

V

MaxO

ONDS

MaxIOUT

)(

)(

)(

2

×

××

=

Where I

O(Max)

= Maximum output load current (A).

droop compensation (continued)

Then, calculate R9:

R9

+

ǒ

V

IOUT(Max)

V

DROOP

*

1Ǔ

R10

Where V

DROOP

= Desired droop voltage

At full load, the output voltage will be:

V

O

+

V

REF

ǒ1

)

R2

R3

Ǔ

*

V

DROOP

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

using the TPS5211 when both 12 V and 5 V are available

When both 12 V and 5 V are available, several components can be removed from the basic schematic shown

in Figure 18. R1, R4, and C9 are no longer required if 5 V is brought in directly to INHIBIT and LODRV . However ,

if undervoltage lockout for the 5-V input is desired, R1 and R4 can be used to set the startup setpoint. The

INHIBIT pin trip level is 2.1 V. Select R4:

()

Ω≤

×

≤<<

k

nA

V

I

V

R

MaxINH

INH

210

100100

1.2

4

)(

Then, set the 5-V UVLO trip level with R1:

()

4

2

2

5

1

R

V

V

V

R

Trip

×

–

=

R1

R4

INHIBIT

LODRV

5 V IN

Figure 21. 5-V Input With UVLO

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

using the TPS5211 when only 5 V is available

The TPS5211 controller requires 12 V for internal control of the device. If an external source for 12 V is not

available, a small onboard source must be included in the design. A simple boost circuitry is described in TIs

application report AN452

Providing a DSP Power Solution from +5 V or +3.3 V only Systems.

T otal 12-V current

depends on switching frequency and power FETs gate charge characteristics. For reliable operation, this

current should not exceed 120 mA. The power stage is not voltage dependent, but component values must be

selected for 5-V inputs. The frequency of operation is dependent upon the power stage input voltage. A typical

5-V only application circuit is shown in Figure 22.

ENABLE

R4

11.0 k

C8

2200 pF

1%

12V

10.0 k

R1

1%

1 uF

C1

1 uF

C3

C6

0.033 uF

10

LODRV

11

LOHIB

12

DRVGND

13

LOWDR

14

DRV

16

BOOT

17

HIGHDR

18

BOOTLO

19

HISENSE

15

VCC

23

VID4

24

VID3

25

VID2

26

VID1

27

VID0

22

INHIBIT

28

PWRGD

1

IOUT

9

BIAS

3

OCP

4

VHYST

6

VSENSE

5

VREFB

7

ANAGND

8

SLOWST

2

DROOP

20

LOSENSE

21

IOUTLO

U1

TPS5211

R102

BOOTLO

LOSENSE

Q102

L101

GND

C101

HIGHDRV

Q101

R101

DRVGND

Power Stage

Control Section

HISENSE

5V

L102

RTN

RTN

C102

+

C103

C104

R103

VSENSE

LOHIB

LODRV

VSENSE_HF

R9 4.32 k

R10

1.00 k

1 uF

C2

R2

150

C4

1 uF

C5

0.1 uF

10.0 kR3

100

R5

20.0 k

R6

R7 3.92 k

1.00 k

R8

C7

1000pF

R11

7.5k

V

O

NOTE A: VID0 – VID4 User – selected to set output voltage.

(see Note A)

Figure 22. Typical 5-V-Only Application Circuit

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

controller operation

Operation of the TPS5211 controller differs from a regular hysteretic controller. The additional ramp signal

through the input of the hysteretic comparator is formed by R1 1 and C7. The two signals are summed through

the inputs of the comparator. The two signals are the ramp signal from R11 - C7 circuitry and the signal from

the output converter. By proper selection of R1 1 and C7, one can get the amplitude of an additional ramp signal

which is greater than the output ripple of the converter. As a result, the switching frequency is greater while the

output ripple becomes lower. The additional ramp signal and output ripple waveforms are shown in Figure 23.

The switching frequency now depends on R11 and C7 values and does not depend on the output filter

characteristics including ESR, ESL, and C of the output capacitor (see frequency calculation section).

The dc feedback signal from the output of the converter through resistor R2 controls the dc level of the output

voltage. Because the switching frequency of TPS5211 is high and it does not depend on output capacitor

characteristics, low cost cermic or film capacitors can be used in a dc to dc converter while having the same

load current transient response characteristics.

Additional Ramp-Signal

t

Output Ripple

(VHI – VLO) – Hysteresis Window

(V

MAX

– V

MIN

) – Overshoot

Because of Delays

V

HC

V

MAX

V

HI

V

REF

V

LO

V

MIN

VO

(P–P)

Figure 23. The Additional Ramp-Signal and Output Voltage Ripple Waveforms

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

27

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

application examples

Below are waveforms and test results measured on the EVM for a 12-V input and a 2-V , 20-A output application.

The output voltage ripple and power switches midpoints are shown in Figure 24. The converter operates at 450

kHz. The peak to peak output ripple is 9.6 mV , while the hysteresis window is set at 20 mV . Therefore, the output

ripple for converter with TPS5211 is much lower than the hysteresis window.

Output Voltage

Ripple (20 mV/div)

Low FET

Drain-Source

Voltage (5 V/div)

Figure 24. The Output Voltage Ripple ans Low FET Drain-Source Voltage Waveforms

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The load current transient response waveforms are shown in Figure 25 to illustrate the excellent load current

transient response characteristics of TPS5211.

Output Voltage

(100 mV/div)

Load Current

(10 A/div)

Low FET

Drain-Source Voltage

(10 V/div)

Figure 25

The output voltage transient response of the converter with TPS521 1 controller. The load current has 14 A step

with slew rate of 30 A/µS.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

29

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Comparison of TPS5210 and TPS5211 controller applications

The TPS5210 and TPS5211 hysteretic controllers have excellent load current transient response

characteristics, which is one of the most important advantages of hysteretic mode. There are specific

application areas where one of the hysteretic controllers is preferable over the other. The table below gives a

comparative view on application areas for the TPS5210 and TPS5211 controllers

comparison of TPS5210 and TPS5211 applications

Controller TPS5210 TPS5211

Switching frequency, kHz 100 – 400 400 – 700

Frequency variation Depends on outout filter characteristics

Independent of output filter and easy to

evaluate

Output current, A up to 40

up to 18 – 20 (can be increased in multiphase configuration)

Efficiency, % (depends on frequency, output current, Vin, Vout, components, etc.)

85 – 95 75 – 85

Input and output filter

Requires bulk electrolytic capacitors especially if Iout > 12A and larger inductor

Surface-mount ceramic and POSCAP

type capacitors and 40% – 65% smaller

inductors.

Component Cost 20% – 40% lower for TPS5211

System cost including reliability, power losses,

cooling, etc.

Can be estimated only during design for a given specific application.

Layout and design

Special attention to the noise sensitive

places such as the hysteresis comparator

and the sample hold circuitry.

Special attention not to exceed frequency

and lcc limits. The high frequency dc –

dc converter design rules should be

used.

Compatibility with the whole system

For high current applications, it is difficult to

meet high density minimum size requirements.

A dc – dc converter can be placed close

to the microprocessor or DSP to de-

crease the number of decoupling capaci-

tors.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

layout guidelines

Good power supply results will only occur when care is given to proper design and layout. Layout will affect noise

pickup and generation and can cause a good design to perform with less than expected results. With a range

of currents from milliamps to tens or even hundreds of amps, good power supply layout is much more difficult

than most general PCB design. The general design should proceed from the switching node to the output, then

back to the driver section, and, finally, to placing the low-level components. Below are several specific points

to consider

before

layout of a TPS5211 design begins.

1. All sensitive analog components should be referenced to ANAGND. These include components connected

to SLOWST, DROOP, IOUT, OCP, VSENSE, VREFB, VHYST, BIAS, and LOHIB.

2. Analog ground and drive ground should be isolated as much as possible. Ideally , analog ground will connect

to the ground side of the bulk storage capacitors on V

O

, and drive ground will connect to the main ground

plane close to the source of the low-side FET.

3. Connections from the drivers to the gate of the power FETs, should be as short and wide as possible to

reduce stray inductance. This becomes more critical if external gate resistors are not being used.

4. The bypass capacitor for the DRV regulator should be placed close to the TPS5210 and be connected to

DRVGND.

5. The bypass capacitor for VCC should be placed close to the TPS5210 and be connected to DRVGND.

6. When configuring the high-side driver as a floating driver , the connection from BOOTLO to the power FET s

should be as short and as wide as possible. The other pins that also connect to the power FETs, LOHIB

and LOSENSE, should have a separate connection to the FETS since BOOTLO will have large peak

currents flowing through it.

7. When configuring the high-side driver as a floating driver , the bootstrap capacitor (connected from BOOT

to BOOTLO) should be placed close to the TPS5210.

8. When configuring the high-side driver as a ground-referenced driver, BOOTLO should be connected to

DRVGND.

9. The bulk storage capacitors across V

I

should be placed close to the power FETS. High-frequency bypass

capacitors should be placed in parallel with the bulk capacitors and connected close to the drain of the

high-side FET and to the source of the low-side FET.

10. High-frequency bypass capacitors should be placed across the bulk storage capacitors on VO.

11. HISENSE and LOSENSE should be connected very close to the drain and source, respectively, of the

high-side FET. HISENSE and LOSENSE should be routed very close to each other to minimize

differential-mode noise coupling to these traces. Ceramic decoupling capacitors should be placed close to

where HISENSE connects to Vin, to reduce high-frequency noise coupling on HISENSE.

TPS5211

HIGH FREQUENCY PROGRAMMABLE HYSTERETIC

REGULATOR CONTROLLER

SLVS243 – SEPTEMBER 1999

31

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

PWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

4073225/E 03/97

0,50

0,75

0,25

0,15 NOM

Thermal Pad

(See Note D)

Gage Plane

2824

7,70

7,90

20

6,40

6,60

9,60

9,80

6,60

6,20

11

0,19

4,50

4,30

10

0,15

20

A

1

0,30

1,20 MAX

1614

5,10

4,90

PINS **

4,90

5,10

DIM

A MIN

A MAX

0,05

Seating Plane

0,65

0,10

M

0,10

0°–8°

20-PIN SHOWN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane. This pad is electrically

and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...