Page 1

TPS51427

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

DUAL D-CAP™ SYNCHRONOUS STEP-DOWN CONTROLLER

FOR NOTEBOOK POWER RAILS

1

FEATURES

23

• Fixed-Frequency Emulated On-Time Control;

Frequency Selectable from Three Options

• D-CAP™ Mode Enables Fast Transient

Response Less than 100 ns

• Advanced Ramp Compensation Allows Low

Output Ripple with Minimal Jitter

• Selectable PWM-Only/ OOA™/Auto-Skip Modes

• Wide Input Voltage Range: 5.5 V to 28 V

• Dual Fixed or Adjustable SMPS:

– 0.7 V to 5.9 V (Channel1)

– 0.5 V to 2.5 V (Channel2)

• Fixed 3.3-V/5-V, or Adjustable Output 0.7-V to

4.5-V LDO; Capable of Sourcing 100 mA

• Fixed 3.3-VREF Output Capable of Sourcing

10 mA

• Temperature Compensated Low-Side R

Current Sensing

• Adaptive Gate Drivers with Integrated Boost

Switch

• Bootstrap Charge Auto Refresh

• Integrated Soft Start, Tracking Soft Stop

• Independent PGOOD and EN for Each Channel

APPLICATIONS

• Notebook I/O and System Bus Rails

• Graphics Application

• PDAs and Mobile Communication Devices

DS(on)

DESCRIPTION

The TPS51427 is a dual synchronous step-down

controller designed for notebook and mobile

communications applications. This device is part of a

low-cost suite of notebook power bus regulators that

enables system designs with low external component

counts. The TPS51427 includes two

pulse-width-modulation (PWM) controllers, SMPS1

and SMPS2. The output of SMPS1 can be adjusted

from 0.7 V to 5.9 V, while the output of SMPS2 can

be adjusted from 0.5 V to 2.5 V. This device also

features a low-dropout (LDO) regulator that provides

a 5-V/3.3-V output, or adjustable from 0.7-V to 4.5-V

output via LDOREFIN. The fixed-frequency emulated

adaptive on-time control supports seamless operation

between PWM mode under heavy load conditions

and reduced frequency operation at light loads for

high-efficiency down to the milliampere range. An

integrated boost switch enhances the high-side

MOSFET to further improve efficiency. The main

control loop is the D-CAP™ mode that is optimized

for low equivalent series resistance (ESR) output

capacitors such as POSCAP or SP-CAP. Advanced

ramp compensation minimizes jitter without degrading

line and load regulation. R

methods offers maximum cost saving.

The TPS51427 supports supply input voltages that

range from 5.5 V to 28 V. It is available in the 32-pin,

5-mm × 5-mm QFN package (Green, RoHscompliant, and Pb-free). The device is specified from

– 40 ° C to +85 ° C.

current sensing

DS(on)

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2 D-CAP, OOA are trademarks of Texas Instruments.

3 All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2008, Texas Instruments Incorporated

Page 2

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

(1)

ORDERABLE

T

A

– 40 ° C to +85 ° C Tape and Reel

PACKAGE PART NO. TRANSPORT MEDIA QUANTITY ECO STATUS

Plastic Quad Flatpack

(32-pin QFN)

TPS51427RHBT 250 Green

TPS51427RHBR 3000

(RoHs and No

Sb/Br)

(1) For the most current package and ordering information see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com .

(2) Eco-Status information: Additional details including specific material content can be accessed at www.ti.com/leadfree

GREEN: Ti defines Green to mean Lead (Pb)-Free and in addition, uses less package materials that do not contain halogens, including

bromine (Br), or antimony (Sb) above 0.1% of total product weight.

N/A: Not yet available Lead (Pb)-Free; for estimated conversion dates, go to www.ti.com/leadfree .

Pb-FREE: Ti defines Lead (Pb)-Free to mean RoHS compatible, including a lead concentration that does not exceed 0.1% of total

product weight, and, if designed to be soldered, suitable for use in specified lead-free soldering processes.

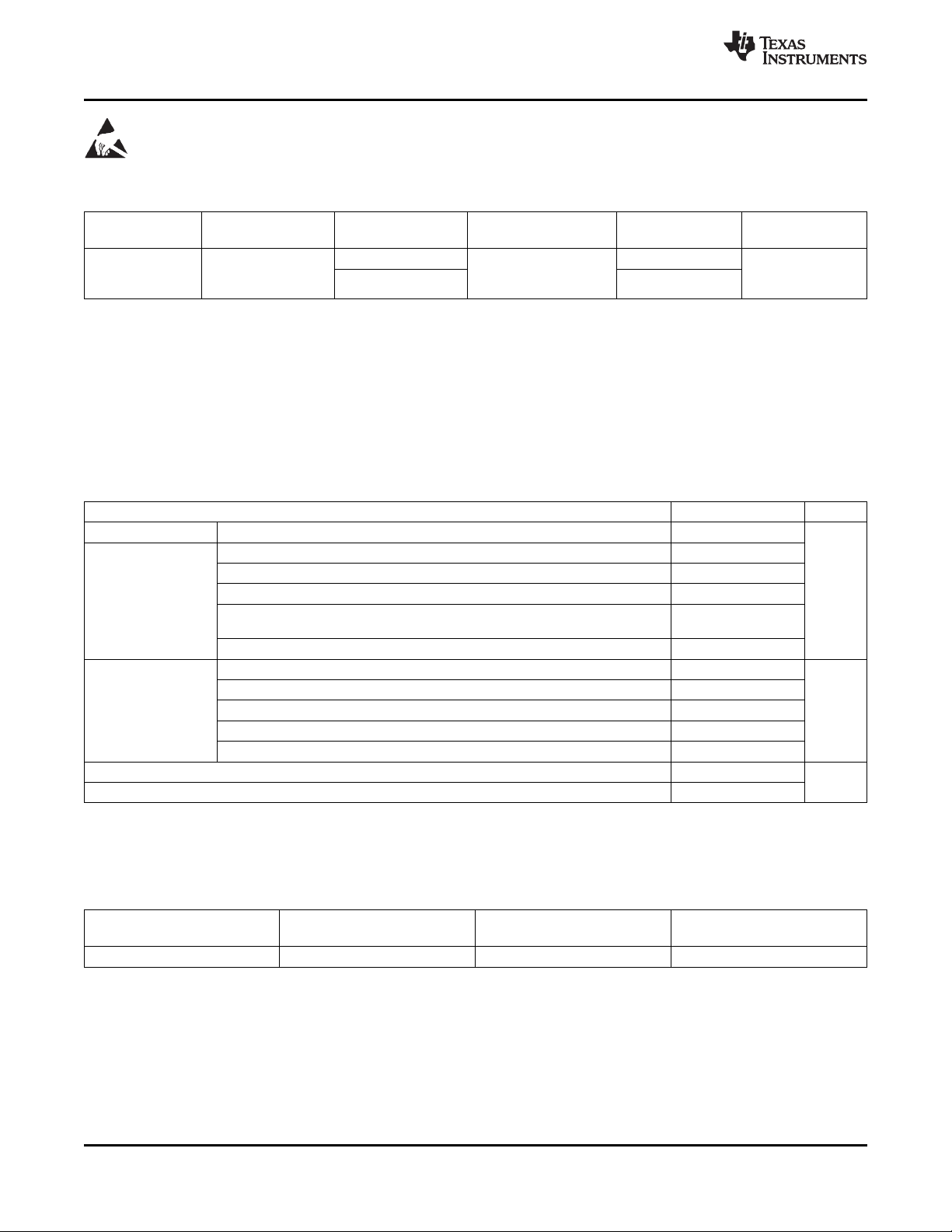

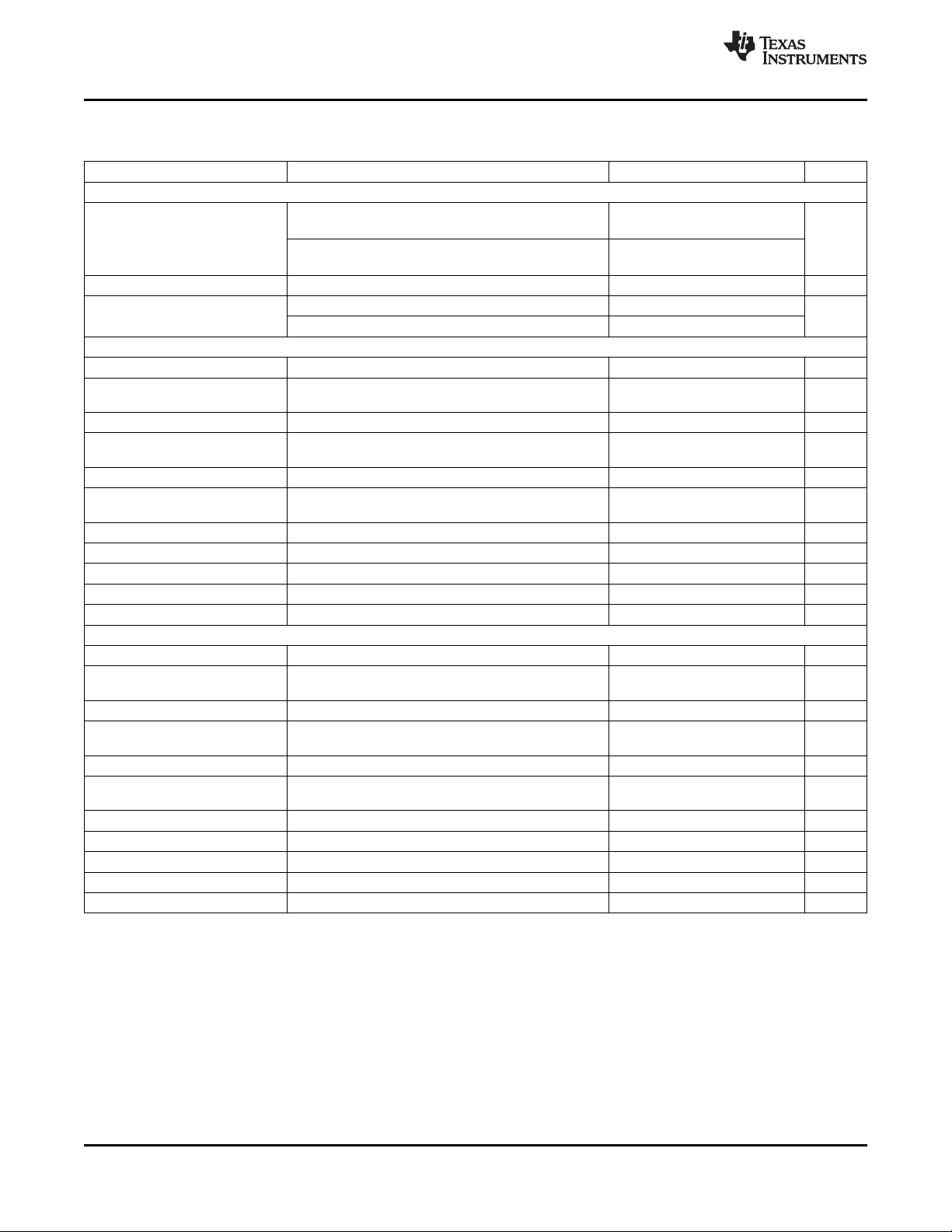

ABSOLUTE MAXIMUM RATINGS

(1)

Over operating free-air temperature range; all voltages are with respect to GND (unless otherwise noted).

PARAMETER VALUE UNIT

5V voltage range V5DRV, V5FILT – 0.3 to 7

VIN, ENLDO – 0.3 to 30

VBST1, VBST2 – 0.3 to 37

VBST1, VBST2 (w.r.t. LLx) – 0.3 to 7

Input voltage range

Output voltage

(2)

range

T

Storage temperature range – 55 to +150

stg

T

Junction temperature range +150

J

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to the network ground terminal unless otherwise noted.

(2)

EN1, EN2, VOUT1, VOUT2, VFB1, REFIN2, TRIP1, TRIP2, SKIPSEL,

TONSEL, VSW, LDOREFIN

– 0.3 to 7

TRIP1, TRIP2 – 0.3 to (V5FILT + 0.3)

DRVH1, DRVH2 – 2 to 37

DRVH1, DRVH2 (w.r.t. LLx) – 0.3 to 7

LL1, LL2 – 2 to 30 V

DRVL1, DRVL2, VREF2, PGOOD1, PGOOD2, LDO, VREF3 – 0.3 to 7

PGND – 0.3 to 0.3

(2)

V

° C

DISSIPATION RATINGS

(1)

TA< +25 ° C DERATING FACTOR TA= +85 ° C

PACKAGE POWER RATING ABOVE TA= +25 ° C POWER RATING

32Ld 5 × 5 QFN 2.320 W 23.2 mW/ ° C 0.93 W

(1) Dissipation ratings are calculated based on the usage of nine standard thermal vias and thermal pad soldered on the PCB. If thermal

pad is not soldered to the PCB, the junction-to-ambient thermal resistance is 88.6 ° C/W.

2 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 3

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

RECOMMENDED OPERATING CONDITIONS

Over operating free-air temperature range (unless otherwise noted).

MIN TYP MAX UNIT

Supply input voltage range V5DRV, V5FILT 4.5 5.5 V

Input voltage range VBST1, VBST2 – 0.1 34

VBST1, VBST2 (with regard to LLx) – 0.1 5.5

EN1, EN2, VOUT1, VFB1, REFIN2, TRIP1, TRIP2, SKIPSEL, TONSEL, – 0.1 5.5

ENLDO,VSW, LDOREFIN

VOUT2 – 0.1 3.7

Output voltage range DRVH1, DRVH2 – 0.8 34 V

DRVH1, DRVH2 (w.r.t. LLx) – 0.1 5.5

LL1, LL2 – 0.8 28

DRVL1, DRVL2, VREF2, PGOOD1, PGOOD2, LDO, VREF3 – 0.1 5.5

PGND – 0.1 0.1

Operating free-air temperature, T

A

– 40 +85 ° C

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TPS51427

Page 4

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

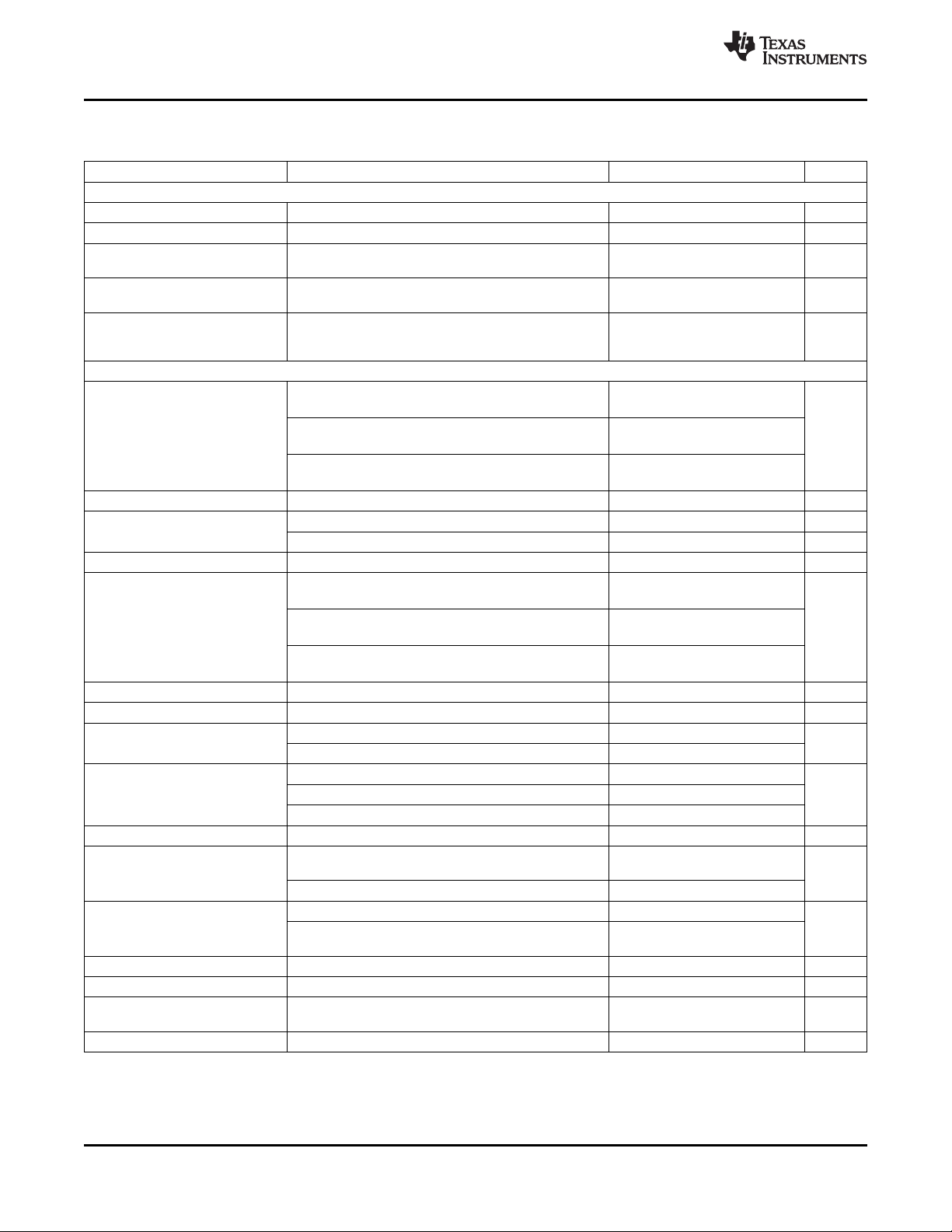

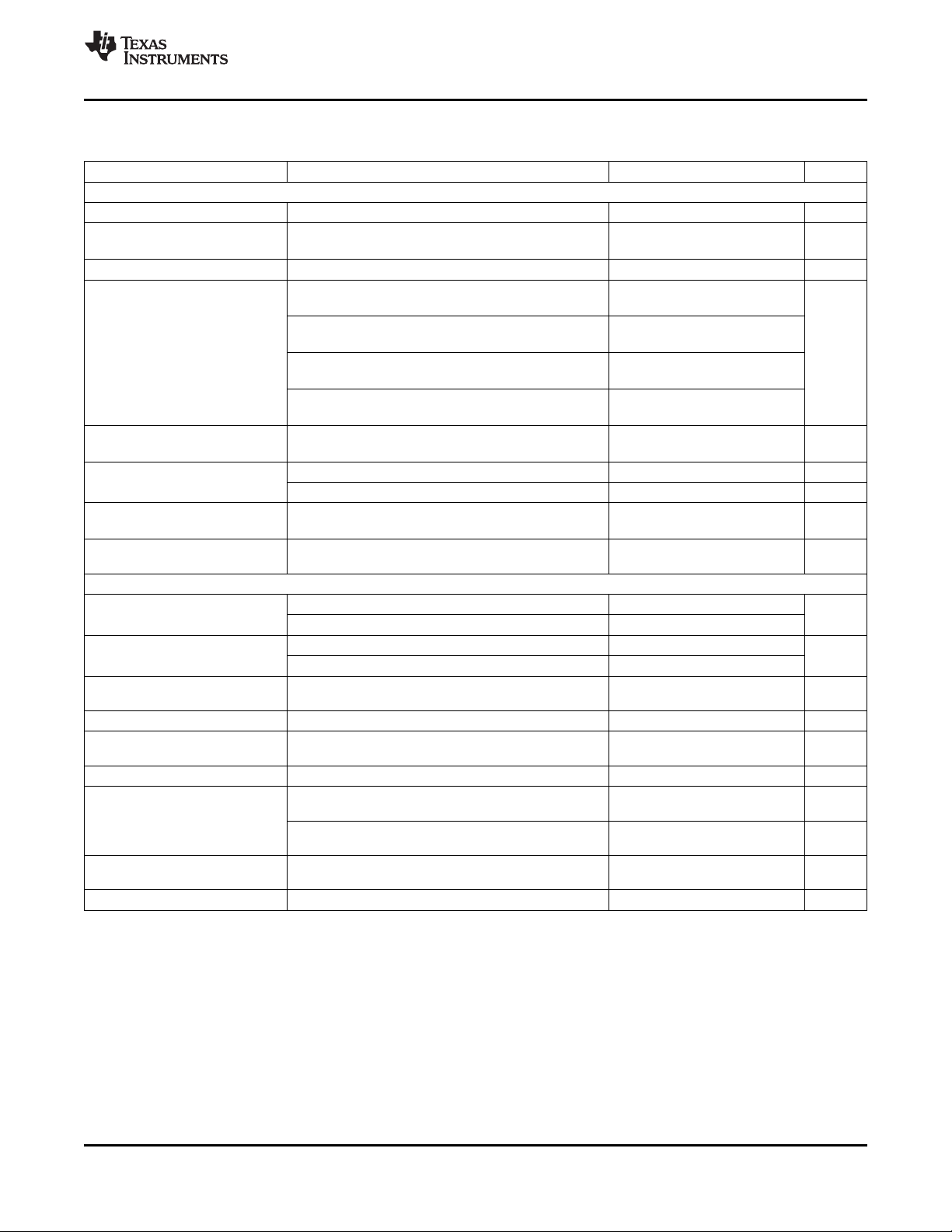

ELECTRICAL CHARACTERISTICS

Over recommended free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT SUPPLIES

VIN Input Voltage Range LDO in regulation 5.5 28 V

VIN Operating Supply Current LDO switched over to VSW, 4.5-V to 5.5-V SMPS 5 10 µ A

VIN Standby Current 115 150 µ A

VIN Shutdown Current 12 20 µ A

5.5 V ≤ V

V, EN1 = EN2 = VSW = 0 V

5.5 V ≤ V

EN1 = EN2 = VSW = 0 V

TA= +25 ° C, no load, EN_LDO = EN1 = EN2 = REFIN2

Quiescent Power Consumption = 5 V, VFB1 = SKIPSEL = 0 V, VOUT1 = VSW = 5.3 V, 5 7 mW

VOUT2 = 3.5 V

PWM CONTROLLERS

5-V Preset output: 5.5 V ≤ V

VFB1 = 0 V, SKIPSEL = 5 V ( – 1.5%) (+1.5%)

VOUT1 Output Voltage Accuracy 1.50 V

1.5-V Preset output: 5.5 V ≤ V

VFB1 = 5V, SKIPSEL = 5V ( – 1.2%) (+1.2%)

Adjustable feedback output, 0.693 0.707

5.5 V ≤ V

VOUT1 Voltage Adjust Range 0.707 5.900 V

VFB1 Threshold Voltage

5-V Preset output 0.20 V

1.5-V Preset output 3.90 V

VFB1 Input Current VFB1 = 0.8 V – 0.20 0.20 µ A

3.3-V Preset output: REFIN2 = 5 V, 5.5 V ≤ V

SKIPSEL = 5 V

VOUT2 Output Voltage Accuracy 1.05 V

1.05-V Preset output: REFIN2 = 3.3 V,

5.5 V ≤ V

Tracking output: REFIN2 = 1.0 V, 5.5 V ≤ V

SKIPSEL = 5 V

REFIN2 Voltage Adjust Range 0.50 2.50 V

REFIN2 Input Current 0.5 V ≤ V

REFIN2 Threshold Voltage V

1.05-V Preset output 3.00 3.45

3.3-V Preset output 3.90

Either SMPS, SKIPSEL = 5 V, 0 A to 5 A

DC Load Regulation Either SMPS, SKIPSEL = 2 V, 0 A to 5 A

Either SMPS, SKIPSEL = GND, 0 A to 5 A

Line Regulation Either SMPS, 5.5 V < VIN < 28 V

TONSEL = 0 V, 2 V, or OPEN (400 kHz),

Channel1 On-Time ns

VOUT1 = 5.05 V

TONSEL = 5 V (200 kHz), VOUT1 = 5.05 V 1895 2105 2315

TONSEL = 0 V (500 kHz), VOUT2 = 3.33 V 475 555 635

Channel2 On-Time ns

TONSEL = 2 V, OPEN, or 5 V (300 kHz),

VOUT2 = 3.33 V

Minimum Off-Time 300 400 500 ns

Soft Start Ramp Time Zero to full limit 1.8 ms

VOUT1, VOUT2 Discharge On

Resistance

EN1 = EN2 = 0 V, VOUT1 = VOUT2 = 0.5 V 17 35 Ω

OOA Operating Frequency SKIPSEL = 2 V or OPEN 22 30 kHz

(1) Ensured by design. Not production tested.

≤ 28 V, TA= +25 ° C, no load, EN_LDO = 5

VIN

≤ 28 V, TA= +25 ° C, no load, EN_LDO =

VIN

≤ 28 V, SKIPSEL = 5 V ( – 1%) (+1%)

VIN

≤ 28 V, SKIPSEL= 5 V

VIN

VREFIN2

= 5 V, V

V5DRV

VIN

= 12 V (unless otherwise noted).

VIN

≤ 28 V, 4.975 5.125

≤ 28 V, 1.482 1.518

VIN

5.05

0.70

≤ 28 V,

VIN

3.285 3.375

( – 1.4%) (+1.4%)

3.33

1.038 1.062

(-1.2%) (+1.2%)

≤ 28 V,

VIN

0.99 1.01

(-1%) (+1%)

1.00

≤ 2.5 V – 0.2 0.2 µ A

(1)

(1)

(1)

(1)

– 0.10%

– 2.20%

– 0.50%

0.005 %/V

895 1052 1209

833 925 1017

4 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 5

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

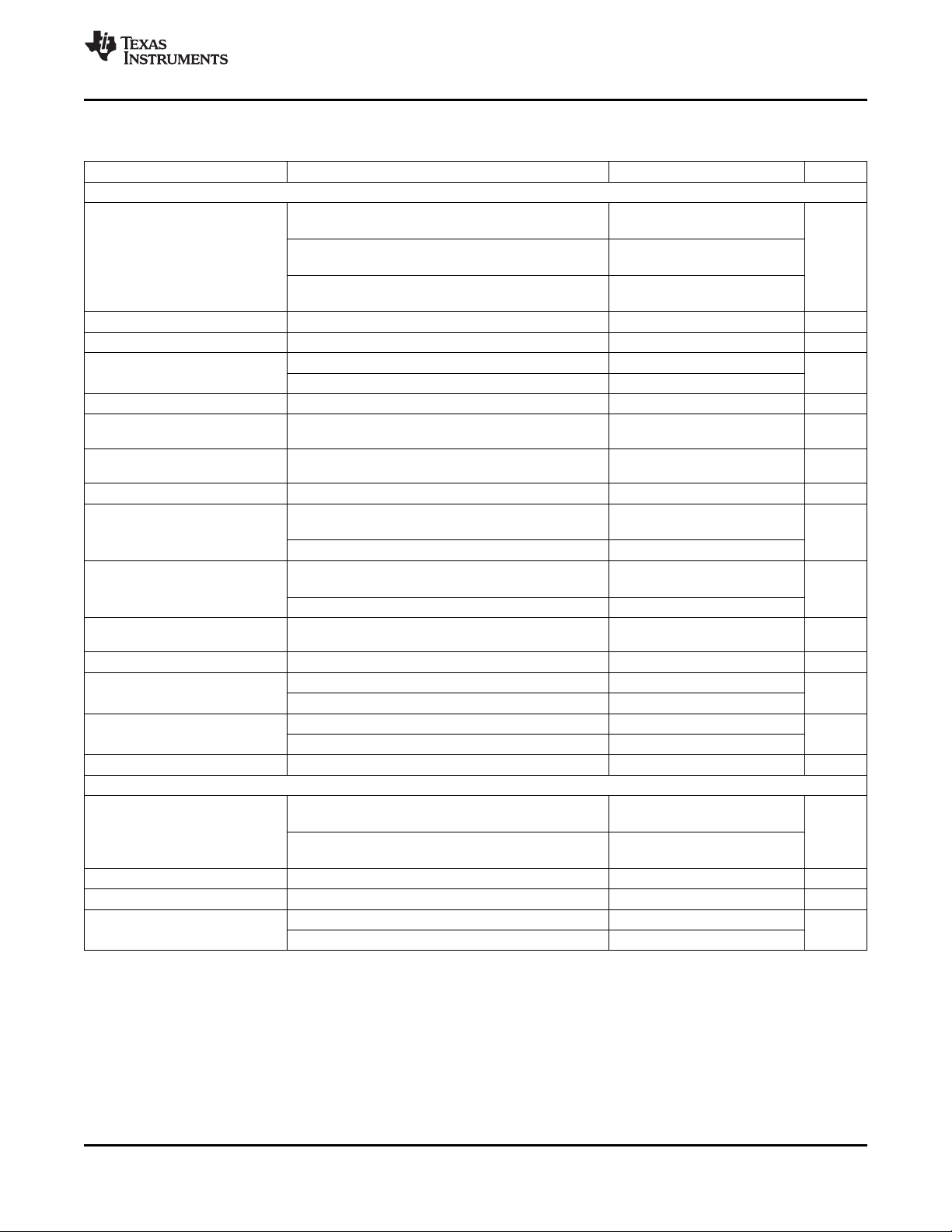

ELECTRICAL CHARACTERISTICS (continued)

Over recommended free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LINEAR REGULATOR (LDO)

LDOREFIN = VSW = 0 V, 0 < I

6 V < VIN < 28 V

LDO Output Voltage 3.33 V

LDOREFIN Input Range VLDO = 2 × VLDOREFIN 0.35 2.25 V

LDOREFIN Leakage Current VLDOREFIN = 0 V or 5 V – 0.5 0.5 µ A

LDOREFIN Threshold Voltage V

LDO Output Current VSW = GND , VIN = 5.5 V to 28 V 100 mA

LDO Output Current During

Switchover to 5 V

LDO Output Current During

Switchover to 3.3 V

LDO Short-Circuit Current VSW = LDO = 0 V 140 180 220 mA

LDO 5-V Switchover Threshold V

LDO 3.3-V Switchover Threshold V

LDO Switchover Switch On

Resistance

LDO Switchover Delay Turning on 3.96 ms

LDO Undervoltage Lockout

Threshold

VIN POR Threshold V

Thermal-Shutdown Threshold Hysteresis = +10 ° C

3.3V ALWAYS-ON LINEAR REGULATOR (VREF3)

VREF3 Output Voltage V

VREF3 Load Regulation 0 mA < I

VREF3 Current Limit VREF3 = GND 15 20 mA

VREF3 Undervoltage Lockout

Threshold

(2) Ensured by design. Not production tested.

LDOREFIN = 5 V, VSW = 0 V, 0 < I

5.5 V < VIN < 28 V

LDOREFIN = 0.5 V, VSW = 0 V, 0 < I

5.5V < VIN < 28 V

Fixed LDO = 5 V 0.15

Fixed LDO = 3.3 V 3.90

VSW = 5 V , VIN = 5.5 V to 28 V, LDOREFIN = 0 V 340 500 mA

VSW = 3.3 V , VIN = 5.5 V to 28 V, LDOREFIN = 5 V 330 500 mA

Rising edge of VSW, LDOREFIN = 0 V

Hysteresis 0.20

Rising edge of VSW, LDOREFIN = 5 V

Hysteresis 0.150

LDO to VSW, VSW = 5 V, ILDO = 100 mA 0.7 1.5 Ω

Falling edge of V5FILT 3.80 3.93 4.10

Rising edge of V5FILT 4.20 4.37 4.50

Falling edge of VIN 1.8

Rising edge of VIN 2.1

No external load, V

No external load, V

< 10 mA 60 mV

LOAD

Falling edge of VREF3 2.96

Hysteresis 0.17

= 5 V, V

V5DRV

(2)

> 4.5 V 3.300

VSW

< 4.0 V 3.300

VSW

= 12 V (unless otherwise noted).

VIN

< 10 0mA,

LDO

< 100 mA,

LDO

< 50 mA,

LDO

4.94 5.11

( – 1.7%) (+1.7%)

3.28 3.38

( – 1.5%) (+1.5%)

0.98 1.02

( – 2%) (+2%)

4.63 4.78 4.93

(92.6%) (95.6%) (98.6%)

3.05 3.15 3.25

(92.5%) (95.5%) (98.5%)

3.250 3.350

( – 1.5%) (+1.5%)

3.220 3.380

( – 2.4%) (+2.4%)

5.025

1.00

+140 ° C

V

V

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TPS51427

Page 6

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

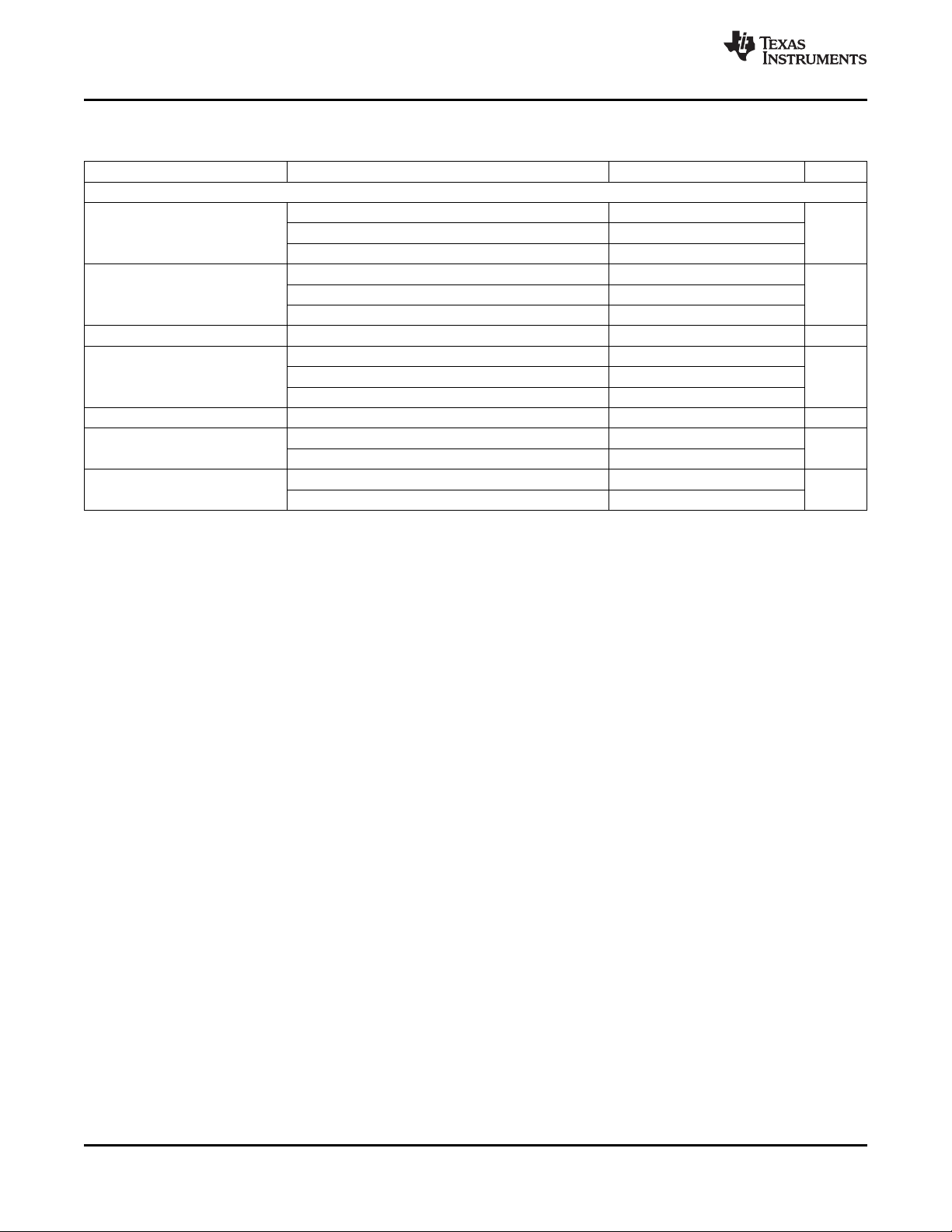

ELECTRICAL CHARACTERISTICS (continued)

Over recommended free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

REFERENCE (REF)

|I

| = 0 µ A 2.00

VREF2

VREF2 Output Voltage V

|I

| < 50 µ A 2.00

VREF2

VREF2 Sink Current VREF2 in regulation 50 µ A

VREF2 Undervoltage Lockout

Threshold

OUT1 FAULT DETECTION

Overvoltage Trip Threshold VFB1 with respect to nominal regulation point +12.5% +15% +17.5%

Overvoltage Fault Propagation

Delay

Undervoltage Trip Threshold VFB1 with respect to nominal output voltage – 35% – 30% – 25%

Undervoltage Fault Propagation

Delay

Undervoltage Fault Enable Delay From ENx signal 10 20 30 ms

PGOOD1 Lower Trip Threshold – 12.5% – 10% – 7.5%

PGOOD1 Low Propagation Delay Falling edge, 50-mV overdrive 10 µ s

PGOOD1 High Propagation Delay Rising edge, 50-mV overdrive 0.8 1.0 1.2 ms

PGOOD1 Output Low Voltage PGOOD1 Low impedance, I

Out-Of-Bound Threshold VFB1 with respect to nominal output voltage +5%

PGOOD1 Leakage Current PGOOD1 High impedance, forced to 5.5 V 1 µ A

OUT2 FAULT DETECTION

Overvoltage Trip Threshold REFIN2 with respect to nominal regulation point +12.5% +15.0% +17.5%

Overvoltage Fault Propagation

Delay

Undervoltage Trip Threshold REFIN2 with respect to nominal output voltage – 35% – 30% – 25%

Undervoltage Fault Propagation

Delay

Undervoltage Fault Enable Delay From ENx signal 10 20 30 ms

PGOOD2 Lower Trip Threshold – 12.5% – 10% – 7.5%

Out-Of-Bound Threshold REFIN2 with respect to nominal output voltage +5%

PGOOD2 Low Propagation Delay Falling edge, 50-mV overdrive 10 µ s

PGOOD2 High Propagation Delay Rising edge, 50-mV overdrive 0.8 1.0 1.2 ms

PGOOD2 Output Low Voltage PGOOD2 Low impedance, I

PGOOD2 Leakage Current PGOOD2 High impedance, forced to 5.5 V 1 µ A

Falling edge of VREF2 1.575 1.700 1.825

Hysteresis 0.1

VFB1 delay with 50-mV overdrive 10 µ s

VFB1 with respect to nominal output, falling edge,

typical hysteresis = 5%

REFIN2 delay with 50-mV overdrive 10 µ s

REFIN2 with respect to nominal output, falling edge,

typical hysteresis = 5%

= 5 V, V

V5DRV

= 12 V (unless otherwise noted).

VIN

1.98 2.02

( – 1%) (+1%)

1.975 2.025

( – 1.25%) (+1.25%)

0.8 1 1.2 ms

= 4 mA 0.4 0.8 V

SINK

0.8 1 1.2 ms

= 4 mA 0.4 0.8 V

SINK

V

6 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 7

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

ELECTRICAL CHARACTERISTICS (continued)

Over recommended free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CURRENT LIMIT

TRIPx Adjustment Range 0.2 2.0 V

TRIPx Source Current 0.2 V < V

TRIPx Current Temperature Coefficient on the basis of TA= +25 ° C

GND – LLx, V

Current-Limit Threshold (Positive,

Adjustable)

GND – LLx, V

GND – LLx, V

GND – LLx, V

Current-Limit Threshold (Positive, V

Default) compensation)

Fixed 100-mV OCL TRIPx

Threshold Voltage

Current Limit Threshold (Negative) – 100%

Zero-Crossing Current Limit

Threshold

TRIPx

High threshold 3.0 3.2 3.3 V

Hysteresis 40 70 100 mV

With respect to valley current limit threshold,

SKIPSEL = 5 V

SKIPSEL = 0 V, 2 V, or OPEN, GND – LLx – 3.5 0 3.5 mV

GATE DRIVERS

DRVHx Gate-Driver

On-Resistance

DRVLx Gate-Driver On-Resistance Ω

DRVHx Gate-Driver Source

Current

Source, VBSTx-DRVHx = 0.1 V 1.0 3.6

Sink, DRVHx-LLx = 0.1 V 0.8 2.6

Source, V5DRV-DRVLx = 0.1 V 1.2 4.0

Sink, DRVLx-PGND = 0.1 V 0.6 1.5

VBSTx-LLx = 5 V, DRVHx = 2.0 V

DRVHx Gate-Driver Sink Current VBSTx-LLx = 5 V, DRVHx = 2.0 V

DRVLx Gate-Driver Source

Current

V5DRV-PGND = 5 V, DRVLx = 2.0 V

DRVLx Gate-Driver Sink Current V5DRV-PGND = 5 V, DRVLx = 2.0 V

DRVHx low (DRVHx = 1 V) to DRVLx high (DRVLx = 4

Dead Time

V), LLx = – 0.05 V

DRVLx low (DRVLx = 1 V) to DRVHx high (DRVHx = 4

V), LLx = – 0.05 V

Internal BST_ Switch

On-Resistance

VBSTx Leakage Current V

I

VBSTx

VBSTx

(3) Ensured by design. Not production tested.

< 2 V, TA= +25 ° C 5 µ A

TRIPx

TRIPx

TRIPx

TRIPx

TRIPx

= 5.0 V, GND – LLx (no temperature

= 10 mA, V5DRV = 5 V, TA= +25 ° C 10 Ω

= 35 V, LLx = 28 V 0.01 2.0 µ A

= 5 V, V

V5DRV

= 12 V (unless otherwise noted).

VIN

4.75 5.25

( – 5%) (+5%)

(3)

= 0.2 V 20

= 0.5 V 50

= 1 V 100

= 2 V 200

13 27

( – 35%) (+35%)

42.5 57.5

( – 15%) (+15%)

93 107

( – 7%) (+7%)

190 210

( – 5%) (+5%)

93 107

( – 7%) (+7%)

(3)

(3)

(3)

(3)

20 30 50 ns

25 40 60 ns

2900 ppm/ ° C

100 mV

1.8 A

1.6 A

1.4 A

2.6 A

mV

Ω

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): TPS51427

Page 8

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

Over recommended free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUTS AND OUTPUTS

High level 2.9

TONSEL Input Logic Levels Float level 1.85 2.25 V

Low level 0.45

High threshold (PWM Only) 2.9

SKIPSEL Input Logic Levels Float level (OOA) 1.85 2.25 V

Low level (Auto Skip) 0.45

SKIPSEL, TONSEL Input Current SKIPSEL = TONSEL = 0 V 2.5 4.0 5.5 µ A

SMPS On level 2.9

EN1, EN2 Input Logic Levels Delay start level 1.85 2.25 V

SMPS Off level 0.45

EN1, EN2 Leakage Current EN1 = EN2 = 0 V – 0.1 0.1 µ A

EN_LDO Input Logic Levels V

EN_LDO Input Current µ A

Rising edge 1.3 1.65 1.9

Hysteresis 0.6

EN_LDO = 0 V 0.7 1.0 1.3

EN_LDO = 30 V – 0.1 0 0.1

= 5 V, V

V5DRV

= 12 V (unless otherwise noted).

VIN

8 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 9

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

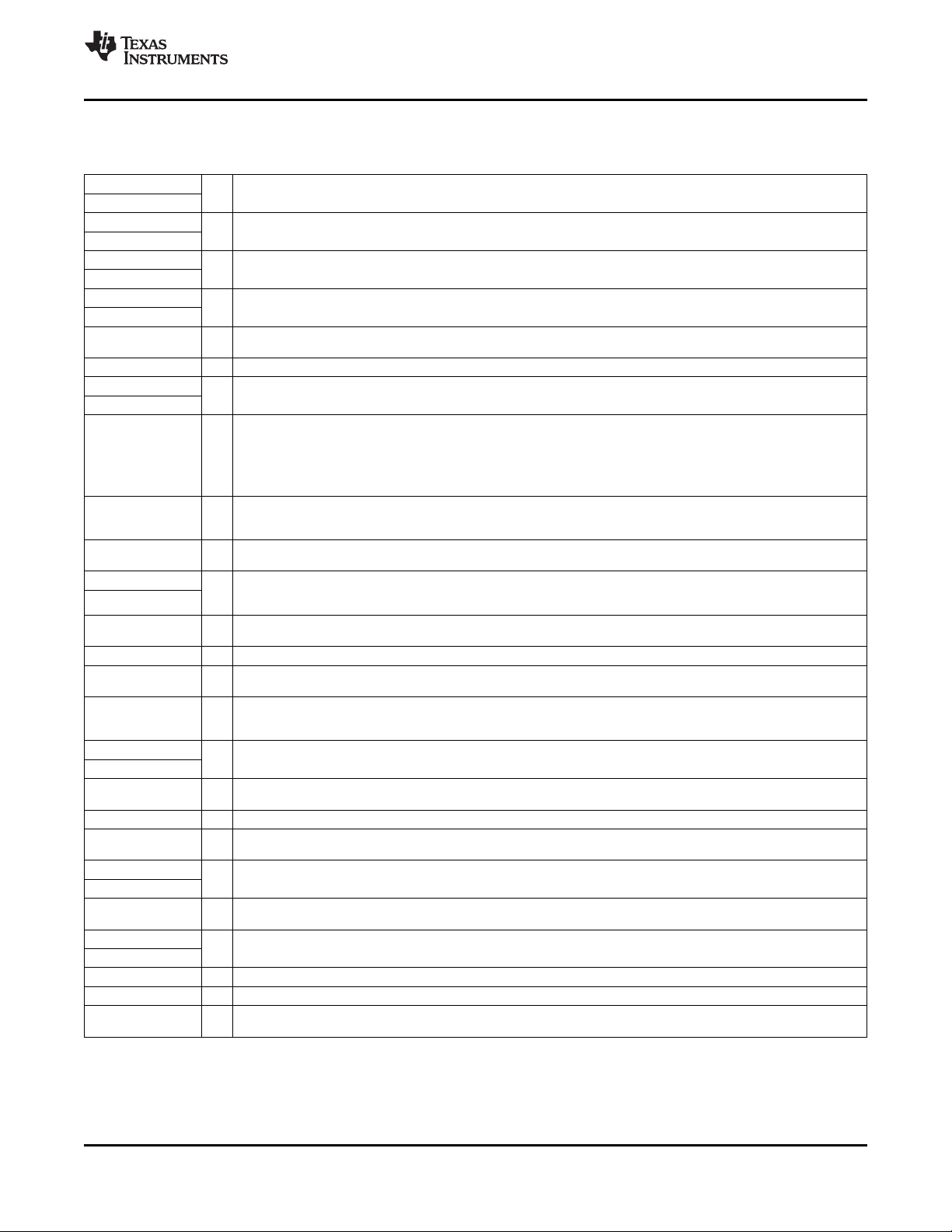

DEVICE INFORMATION

TERMINAL FUNCTIONS

TERMINAL

NAME NO. I/O DESCRIPTION

DRVH1 15

DRVH2 26

DRVL1 18

DRVL2 23

EN1 14

EN2 27

EN_LDO 4 I

GND 21 I Analog ground for both channels and LDO.

LL1 16

LL2 25

LDO 7 O

LDOREFIN 8 I operation. LDOREFIN can be used to program LDO output voltage from 0.7 V to 4.5 V. LDO output is twice the voltage of

PGND 22 I

PGOOD1 13 Channel1/Channel2 power-good open-drain output. PGOOD1/PGOOD2 is low when the Channel1/Channel2 output voltage is

PGOOD2 28

REFIN2 32 I

NC 20 SKIPSEL 29 I

TONSEL 2 I 400-kHz/300-kHz operation. Connect to V5FILT for 200-kHz/300-kHz operation (5-V/3.3-V SMPS switching frequencies,

TRIP1 12

TRIP2 31

V5DRV 19 I

V5FILT 3 I 5-V analog supply input.

VFB1 11 I

VBST1 17

VBST2 24

VIN 6 I

VOUT1 10

VOUT2 30

VREF2 1 O 2-V reference output. Bypass to GND with a 0.1- µ F capacitor. VREF2 can source up to 50 µ A for external loads.

VREF3 5 O 3.3-V reference output. VREF3 can source up to 10 mA for external loads. Bypass to GND with a 1- µ F capacitor.

VSW 9 I

High-side N-Channel FET driver outputs. LL referenced floating drivers. The gate drive voltage is defined by the voltage across

O

VBST to LL node bootstrap capacitor.

O Synchronous low-side MOSFET driver outputs. Ground referenced drivers. The gate drive voltage is defined by V5DRV voltage.

Channel enable pins. If EN1 is connected to VREF2, Channel1 starts after Channel2 reaches regulation (delay start). If EN2 is

I

connected to VREF2, Channel2 starts after Chanel1 reaches regulation.

LDO Enable Input. The LDO is enabled if EN_LDO is within logic high level and disabled if EN_LDO is less than the logic low

level.

Phase node connections for high-side drivers. These connections also serve as inputs to current comparators for R

I/O

and input voltage monitor for on-time control circuitry.

Linear regulator output. The LDO regulator can provide a total of 100-mA external loads. The LDO regulates at 5 V If LDOREFIN

is connected to GND. When the LDO is set at 5 V and VSW is within a 5-V switchover threshold, the internal regulator shuts

down and the LDO output pin connects to VSW through a 0.7- Ω switch. The LDO regulates at 3.3 V if LDOREFIN is connected

to V5FILT. When the LDO is set at 3.3 V and VSW is within a 3.3-V switchover threshold, the internal regulator shuts down and

the LDO output pin connects to VSW through a 0.7- Ω switch. Bypass the LDO output with a minimum of 4.7- µ F ceramic

capacitance.

LDO Reference Input. Connect LDOREFIN to GND for fixed 5-V operation. Connect LDOREFIN to V5FILT for fixed 3.3-V

LDOREFIN. There is no switchover in adjustable mode.

Ground pin for drivers and LS synchronous FET source terminals. This pin is also the input to zero crossing comparator and

overcurrent comparator.

O 10% less than the normal regulation point, at onset of OVP events, or during soft start. PGOOD1/PGOOD2 is high impedance

when the output is in regulation and the soft-start circuit has terminated. PGOOD1/PGOOD2 is low in shutdown.

Output voltage control for Channel2. Connect REFIN2 to V5FILT for fixed 3.3-V operation. Connect REFIN2 to VREF3 for fixed

1.05-V operation. REFIN2 can be used to program Channel2 output voltage from 0.5 V to 2.5 V.

Low-noise mode control. Connect SKIPSEL to GND for Auto Skip mode operation or to V5FILT for PWM mode (fixed frequency).

Connect to VREF2 or leave floating for OOA™ mode operation.

Frequency select input. Connect to GND for 400-kHz/500-kHz operation. Connect to VREF2 (or leave open) for

respectively).

I Overcurrent trip point set input. Sourcing current is 5 µ A at RT with 2900 ppm/ ° C temperature coefficient.

Supply voltage for the low-side MOSFET driver DRVL1/DRVL2. Connect a 5-V power source to the V5DRV pin (bypass with

4.7- µ F MLCC capacitor to PGND if necessary).

Channel1 feedback input. Connect VFB1 to GND for fixed 5-V operation. Connect VFB1 to V5FILT for fixed 1.5-V operation.

Connect VFB1 to a resistive voltage divider from OUT1 to GND to adjust the output from 0.7 V to 5.9 V.

I Supply input for high-side MOSFET driver (bootstrap terminal). Connect a capacitor from this pin to the respective LL terminals.

Power supply input. VIN supplies power to the linear regulators. The linear regulators are powered by Channel1 if VOUT1 is set

greater than 5 V and VSW is tied to VOUT1.

O Output connections to SMPS. These terminals serve two functions: on-time adjustment and output discharge.

VSW is the switchover source voltage for the LDO when LDOREFIN is connected to GND or V5FILT. Connect VSW to 5 V if

LDOREFIN is tied GND. Connect VSW to 3.3 V if LDOREFIN is tied to V5FILT.

DS(on)

sensing

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): TPS51427

Page 10

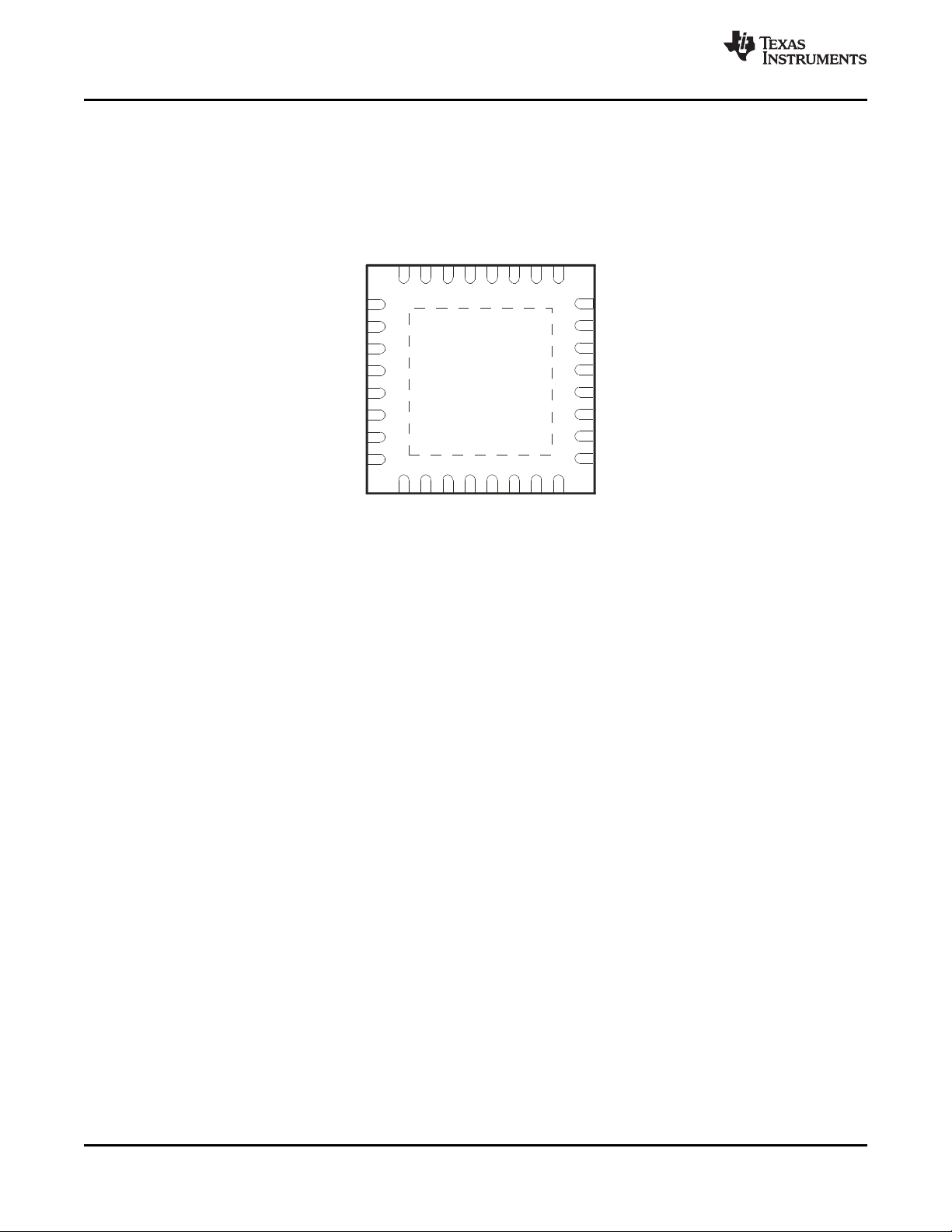

1

2

3

4

5

6

7

8

24

23

22

21

20

19

18

17

9 10 11 12 13 14 15 16

VREF2

VBST2

VSW

REFIN2

VOUT1

VFB1

TRIP1

PGOOD1

EN1

DRVH1

LL1

252627

282930

3132

TONSEL

V5FILT

EN_LDO

VREF3

VIN

LDO

LDOREFIN

DRVL2

NC

GND

PGND

V5DRV

DRVL1

VBST1

TRIP2

VOUT2

SKIPSEL

PGOOD2

EN2

DVRH2

LL2

TPS51427

RHB PACKAGE

(TOP VIEW)

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

QFN-32, 5-mm × 5-mm

(TOP VIEW)

www.ti.com

NC = No connection.

10 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 11

140°C

/125°C

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

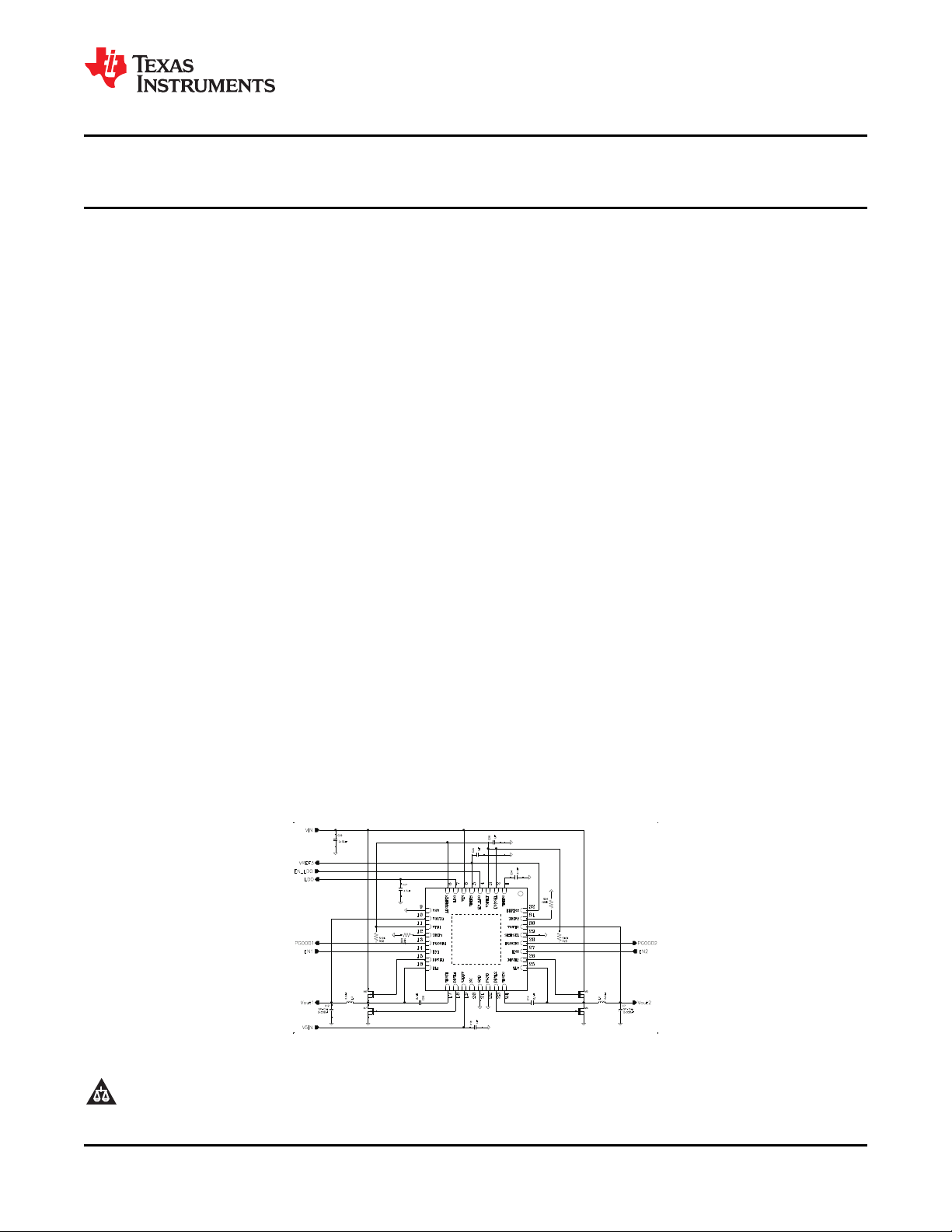

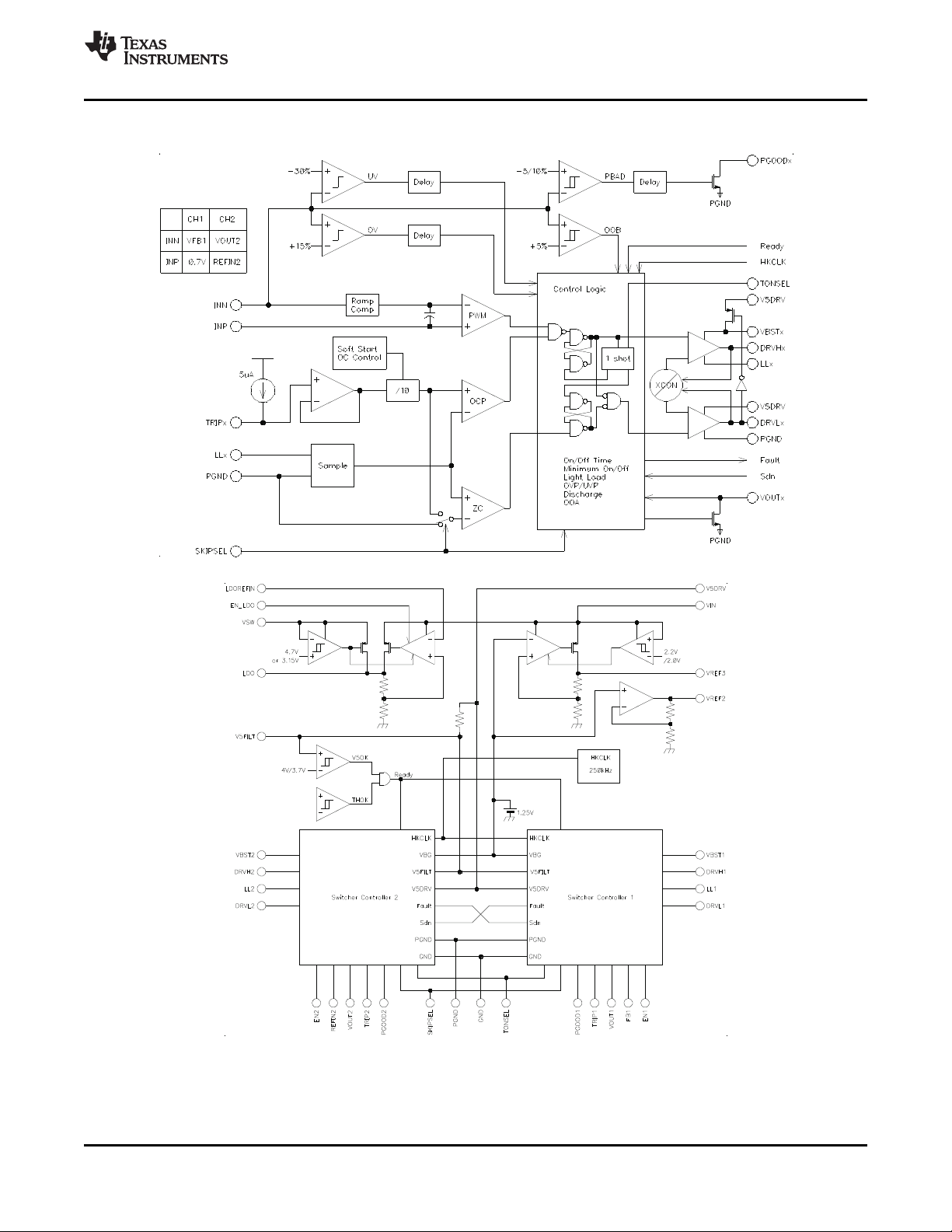

FUNCTIONAL BLOCK DIAGRAMS

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): TPS51427

Page 12

( )

f

VIN VOUT VOUT

OUT(LL)

SW VIN

V V V

1

I

2 L V

æ ö

- ´

æ ö

= ´

ç ÷

ç ÷

ç ÷

´ ´

è ø

è ø

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

DETAILED DESCRIPTION

BASIC PWM OPERATION

The main control loop of the TPS51427 is designed as an adaptive on-time pulse width modulation (PWM)

controller. It supports a proprietary D-CAP™ mode that uses internal compensation circuitry and is suitable for a

minimal external component count configuration when an appropriate amount of ESR at the output capacitor(s) is

allowed. D-CAP mode can also enable stable operation when using capacitors with low ESR, such as specialty

polymer capacitors.

The basic operation of D-CAP mode can be described in this way: At the beginning of each cycle, the

synchronous high-side MOSFET turns on or goes to an ON state. This MOSFET turns off, or returns to an OFF

state, after an internal one-shot timer expires. The one-shot timer is determined by VIN and VOUT and keeps the

frequency fairly constant over the input voltage range under steady-state conditions; it is an adaptive on-time

control or fixed-frequency emulated on-time control. The MOSFET turns on again when the following two

conditions occur:

• Feedback information, monitored at the VFB1/VOUT2 voltage, indicates insufficient output voltage; and

• the inductor current information indicates that current is below the overcurrent limit.

Operating in this manner, the controller regulates the output voltage. The synchronous low-side or the rectifying

MOSFET is turned on each OFF state to keep the conduction loss minimum.

LIGHT LOAD CONDITIONS

The TPS51427 supports three selectable operating modes: PWM-only, Out-Of-Audio ( OOA™), and Auto-Skip.

If the SKIPSEL pin is connected to GND, Auto-Skip mode is selected. This mode enables a seamless transition

to the reduced frequency operation under light load conditions so that high efficiency is maintained over a wide

range of load current. This frequency reduction is achieved smoothly and without an increase in V

load regulation.

Auto-Skip operation can be described in this way: As the output current decreases from a heavy load condition,

the inductor current is also reduced. Eventually, the inductor current reaches the point that its valley equals zero

current; that is, the boundary between continuous conduction and discontinuous conduction modes. The

rectifying MOSFET turns off when this zero inductor current is detected. Because the output voltage remains

higher than the reference voltage at this point, both high-side and low-side MOSFETs are turned off and wait for

the next cycle. As the load current decreases further, the converter runs in discontinuous conduction mode and

takes longer to discharge the output capacitor below the reference voltage. Note that the ON time remains the

same as that in the heavy load condition. On the other hand, when the output current increases from a light load

to a heavy load, the switching frequency increases to the preset value as the inductor current reaches the

continuous conduction limit. The transition load point to the light load operation I

OUT(LL)

(that is, the threshold

between continuous conduction and discontinuous conduction mode) can be calculated as shown in Equation 1 :

ripple or

OUT

Where f

condition is a function of L, fSW, V

from the I

is the PWM switching frequency. Switching frequency versus output current under a light load

SW

threshold. For example, the frequency is approximately 60 kHz at I

OUT(LL)

IN

, and V

, but decreases at a near-proportional rate to the output current

OUT

/5 if the PWM switching

OUT(LL)

frequency is 300 kHz.

PWM-only mode is selected if the SKIPSEL pin is connected to 5 V. The rectifying MOSFET does not turn off

when the inductor current reaches zero. The converter runs in forced continuous conduction mode over the

entire load range. System designers may want to use this mode to avoid certain frequencies under light load

conditions but do so at the cost of lower efficiency. However, keep in mind that the output has the capability to

both source and sink current in this mode. If the output terminal is connected to a voltage source that is higher

than the regulator target value, the converter sinks current from the output and boosts the charge into the input

capacitors. This operation may cause an unexpected high voltage at VIN and may damage the power FETs.

If SKIPSEL pin is connected to VREF2 or left floating, OOA mode operation is selected.

12 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

(1)

Page 13

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

Table 1. SKIPSEL Operating Modes

SKIPSEL GND FLOAT/VREF2 V5IN

Operating Mode Auto Skip OOA™ PWM Only

OUT-OF-AUDIO ( OOA™) OPERATION

If out-of-audio (OOA) operation is enabled, the switching frequency of the channel remains higher than the

audible frequency under any load condition, at a minimum of 22 kHz to minimize the audible noise in the system.

The TPS51427 automatically reduces switching frequencies under light load conditions. The OOA control circuit

monitors the switching period and forces the high-side MOSFET to turn on if the switching frequency goes below

the 22-kHz threshold.

The high-side MOSFET turns on even if the output voltage is higher than the target value; therefore, the output

voltage tends to be higher when operating in OOA mode. The OOA control circuit detects the overvoltage

condition and prevents the voltage from rising by re-modulating the device on time. The overvoltage condition is

detected by the VFB1/VOUT2 voltages.

The inductor current ripple (peak-to-peak) should be less than two-thirds of the OCL setting for the OOA circuit to

work properly at a 0-A load. To keep the OOA mode loop stable, the output voltage ripple cannot be too large. If

OOA mode operation is desired, the recommended output ripple voltage cannot be more than 1% of the target

dc voltage.

RAMP COMPENSATION

The TPS51427 employs an advanced ramp compensation technique in D-CAP mode to optimize jitter

performance. An internal ramp signal is added to the reference voltage to virtually increase the slope of the

VFB1/VOUT2 down ramp, which the PWM comparator uses to determine the turn-on timing.

LOW-SIDE DRIVER

The low-side driver is designed to drive high-current, low R

represented by its internal resistance: 1.2 Ω for V5DRV to DRVLx and 0.6 Ω for DRVLx to PGND. A dead time to

prevent shoot-through is generated internally between the two transistors, with the top MOSFET off and bottom

MOSFET on, and then with the bottom MOSFET off and the top MOSFET on. A 5-V bias voltage is delivered

from the V5DRV supply. The instantaneous drive current is supplied by an input capacitor connected between

V5DRV and GND. The average drive current is equal to the gate charge at V

frequency.

, N-channel MOSFET(s). The drive capability is

DS(on)

= 5 V times the switching

GS

HIGH-SIDE DRIVER

The high-side driver is also designed to drive high-current, low R

as a floating driver, a 5-V bias voltage is delivered from the V5DRV supply. The average drive current is also

calculated by the gate charge at V

= 5 V times the switching frequency. The instantaneous drive current is

GS

supplied by the floating capacitor between the VBSTx and LLx pins. The drive capability is represented by its

internal resistance: 1.0 Ω for VBSTx to DRVHx and 0.8 Ω for DRVHx to LLx.

, N-channel MOSFET(s). When configured

DS(on)

BOOSTRAP CHARGE AUTO REFRESH

Boost undervoltage protection is activated during the device ON time when the voltage difference between

DRVH and LL becomes less than 1.8 V. Upon detection of the undervoltage condition, the high-side gate driver

immediately turns off and the low-side gate driver turns on after the deadtime expires for the minimum off time in

an attempt to recharge the boost capacitor.

PWM FREQUENCY AND ADAPTIVE ON-TIME CONTROL

The TPS51427 employs an adaptive on-time control scheme and does not have a dedicated onboard oscillator.

However, the device runs with pseudo-constant frequency by feed-forwarding the input voltage and output

voltage into the on-time one-shot timer. The frequencies are set by the TONSEL terminal connection as Table 2

shows. The on-time is controlled: it is inversely proportional to the input voltage and proportional to the output

voltage, so that the duty ratio maintains technically as VOUT/VIN with the same cycle time. Although the

TPS51427 does not use VIN directly, the input voltage is monitored at the LLx pin during the ON state.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): TPS51427

Page 14

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

Table 2. TONSEL Terminal Connection Options

TONSEL GND VREF2 or Float V5FILT

Channel1 Frequency 400 kHz 400 kHz 200 kHz

Channel2 Frequency 500 kHz 300 kHz 300 kHz

ENABLE AND SOFT START

TPS51427 has an internal digital soft-start timer that begins to ramp up to the maximum allowed current limit

during device startup. The soft-start ramp occurs in five steps of positive current limit; step sizes are 20%, 40%,

60%, 80%, and 100%. Smooth control of the output voltage during device startup is maintained. In addition, if

tracking discharge is required, the ENx pin can be used to control the output voltage discharge smoothly. At the

beginning of the soft-start period, the rectifying MOSFET maintains an off state until the top MOSFET turns on at

least once. This architecture prevents a high negative current from flowing back from the output capacitor in the

event of an output capacitor pre-charged condition.

If EN1 is connected to VREF2, Channel1 starts up after the Channel2 reaches regulation (delay start). If EN2 is

connected to VREF2, Channel2 starts up after the Channel1 reaches regulation (delay start).

When both ENx are low and ENLDO is low, the TPS51427 enters a shutdown state and consumes less than

15 µ A.

POWER-GOOD AND OUT-OF-BOUND OPERATION

The TPS51427 has a power-good output (PGOODx) for each switching channel. The power-good function

activates after the soft start finishes. If the output voltage reaches within ± 95% of the target value, internal

comparators detect a power-good state and the power-good signal goes high after a 1-ms internal delay. If the

output voltage falls below 90% of the target value, the power-good signal goes low after a 10- µ s internal delay.

When the output voltage exceeds +5% above of the target value while SKIPSEL is selected as auto-skip or OOA

skip-mode, the out-of-bound operation starts. During the out-of-bound condition, the controller operates in forced

PWM-only mode. Turning on the low-side MOSFET beyond the zero inductor current quickly discharges the

output capacitor. During this operation, the cycle-by-cycle negative overcurrent limit is also valid. Once the output

voltage becomes back within regulation range, the controller resumes to auto-skip or OOA skip mode."

OUTPUT SHUTDOWN AND DISCHARGE CONTROL

The TPS51427 discharges the output when ENx is low, or when the controller is shut down by the circuit

protection functions (OVP, UVP, UVLO, and thermal shutdown). The TPS51427 discharges the outputs using an

internal, 17- Ω MOSFET that is connected to VOUTx and PGND. The external low-side MOSFET does not turn

on during the output discharge operation to avoid the possibility of causing a negative voltage at the output. The

output discharge time constant is a function of the output capacitance and the resistance of the internal

discharge MOSFET. This discharge ensures that on device restart, the regulated voltage always starts from 0 V.

If an SMPS restarts before the discharge completes, the discharge action is terminated and switching resumes

after the reference level (ramped up by an internal digital-to-analog converter, or DAC) returns to the remaining

output voltage. When shutdown mode activates, the 3.3-V VREF3 remains on.

2-V REFERENCE (VREF2)

The 2-V reference is useful for generating auxiliary voltages. The tolerance for this reference voltage is ± 1.25%

over a 50- µ A load and – 40 ° C to +85 ° C ambient temperature range. This reference is enabled when ENLDO

goes high, and shuts down after both switching channels are turned off and ENLDO is shut down. If this output is

forcibly tied to ground, both SMPSs are turned off without a latch. Bypass the VREF2 pin to GND with a

minimum 0.1- µ F ceramic capacitor.

3-V REFERENCE (VREF3)

The 3.3-V reference (VREF3) is accurate to ± 1.5% over temperature, making VREF3 useful as a precision

system reference for the real-time clock (RTC) circuit in many notebook applications. VREF3 can supply up to 10

mA for external loads. Bypass VREF3 to GND with a 1- µ F capacitor. VREF3 is activated when VIN rises above

2.1 V, and remains on even when the SMPS and LDO are both shut down. VREF3 is deactivated if VIN falls

below 1.8 V. In thermal shutdown conditions, VREF3 remains activate.

14 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 15

( )

LDO min

LDO

5 V

C 4.7 F

V

= ´ m

( )

f

VIN VOUT VOUT

RIPPLE

OCP TRIP TRIP

VIN

V V V

I

1

I I I

2 2 L V

æ ö

- ´

æ ö

æ ö

= + = + ´

ç ÷

ç ÷

ç ÷

ç ÷

´ ´

è ø

è ø

è ø

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

LDO

When the LDOREFIN pin is connected to GND, the TPS51427 internal linear regulator produces a fixed 5-V LDO

output; when LDOREFIN is connected to V5FILT, the linear regulator produces a fixed 3.3-V LDO output. The

LDO regulator can supply up to 100 mA for external loads. Bypass the LDO with a minimum 4.7- µ F ceramic

capacitor. When the LDO is fixed at 5 V, and VSW voltage is equal to or greater than 4.7 V, the 5 V LDO

switches off after a 3.8-ms delay, and the 5V rail is bootstrapped to the VSW output, thereby improving the

efficiency of the converter. A glitch-free switchover is also accomplished. The switchover impedance from the

VSW pin to the LDO pin is typically 0.7 Ω . In the same way, when the LDO is fixed at 3.3-V and the VSW voltage

is equal to or greater than 3.15 V, the 3.3-V LDO switches off after a delay of 4 ms, and the 3.3-V rail is

bootstrapped to the VSW output.

In adjustable mode, the LDO output can be set from 0.7 V to 4.5 V. The LDO output voltage is equal to two times

the LDOREFIN voltage. There is no switchover action in adjustable mode.

For the 5-V LDO output, a 4.7- µ F ceramic capacitor (minimum) is required from the LDO to GND. For the 3.3-V

LDO output, a 10- µ F ceramic capacitor (minimum) is required from the LDO to GND. If a lower voltage LDO

output is desired, scale the output capacitance of the LDO according to Equation 2 .

For example, if V

= 1 V, C

LDO

LDO(min)

= 23.5 µ F. Use the standard capacitance value to choose 27 µ F for the 1-V

LDO output.

CURRENT SENSING AND OVERCURRENT PROTECTION

In order to provide the most cost-effective solution, the TPS51427 supports low-side MOSFET R

overcurrent protection. In any setting, the output signal of the current amplifier becomes 100 mV at the

overcurrent limit (OCL) set point. This configuration means that the current sensing amplifier normalizes the

current information signal based on the OCL setting.

The TPS51427 supports cycle-by-cycle OCL control. The controller does not allow the next ON cycle while the

current level is above the trip threshold. The overcurrent trip threshold voltage is determined by the TRIPx pin as

Table 3 shows. The TRIPx terminal sources 5- µ A current with a 2900ppm/ ° C temperature slope, with respect to

its +25 ° C value, to compensate the temperature dependency of the MOS R

voltage across R

when TRIPx is between 200 mV and 2 V at room temperature. When the TRIPx pin is tied

TRIPx

. The trip level is set to the

DS(on)

to 5 V directly, the controller defaults to 100 mV fixed OCL setting. With this option, temperature compensation is

not obtained.

sensing for

DS(on)

(2)

OCL threshold in R

Temperature Coefficient (ppm/ ° C) 2900 None

The overcurrent condition is detected during the OFF state; therefore, I

current. Thus, the load current at overcurrent threshold, I

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 15

TRIPx 0.2 V to 2 V 5 V

Table 3. Overcurrent Trip Threshold Voltage

sensing 20 mV to 200 mV 100 mV

DS(on)

, can be calculated in Equation 3 .

OCP

Product Folder Link(s): TPS51427

sets the valley level of the inductor

TRIP

(3)

Page 16

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

In an overcurrent condition, the current to the load exceeds the current to the output capacitor. As a result, the

output voltage tends to drop, and ends up crossing the undervoltage protection threshold, and the device shuts

down.

The TPS51427 also supports a cycle-by-cycle negative overcurrent limit in PWM-only mode. The negative

overcurrent limit is set to be negative, but at the same absolute value as the positive overcurrent limit. If the

output voltage continues to rise, the bottom MOSFET is always on; the inductor current reduces and reverse

direction after it reaches zero. When there is too much negative current in the inductor, the bottom MOSFET

turns off and a new on-time period is initiated; that is, the top MOSEFET turns on to allow current to flow into

VIN. After the on-time expires, the bottom MOSFET turns on again. This protection ensures a maximum

allowable discharge capability when the output voltage continues to rise, effectively reducing the possibility of the

overvoltage protection (OVP) circuitry.

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

The TPS51427 monitors the feedback voltage for Channel1 and output voltage for Channel2 to detect both overand undervoltage conditions. When the output voltage becomes 15% higher than the target value, the OVP

comparator output goes high after a 10- µ s propagation delay; the circuit then latches the top MOSFET driver off

and the bottom MOSFET driver on, until the negative OCL limit is reached. At that time, the bottom MOSFET

turns off and the top MOSFET turns on for the minimum on-time. Once the minimum on-time expires, the bottom

MOSFET turns on again. This process repeats until the valley current of the inductor is above the negative

overcurrent limit. Once the inductor valley current is greater than the OCL, the bottom MOSFET remains on until

it is reset. Upon OVP activation, both PGOODx outputs are pulled low.

When the voltage becomes lower than 70% of the target voltage, the undervoltage protection (UVP) comparator

output goes high and an internal UVP delay counter begins counting. After 1 ms, the TPS51427 latches both top

and bottom MOSFETs off and shuts off the other channel as well. This function is enabled after the device soft

start completes.

UNDERVOLTATGE LOCKOUT (UVLO) PROTECTION

The TPS51427 has V5FILT undervoltage lockout (UVLO) protection. When the V5FILT voltage is lower than the

UVLO threshold voltage, the TPS51427 shuts off. This feature is a non-latched protection circuit.

THERMAL SHUTDOWN

The TPS51427 monitors the temperature of the die itself. If the temperature exceeds the threshold value

(typically +140 ° C), the TPS51427 shuts down. This feature is a non-latched protection circuit.

16 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 17

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH1

Auto-Skip Mode

V

TONSEL

= V5FILT

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH2

Auto-Skip Mode

V

TONSEL

= V5FILT

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

I

OUT

– Output Current – A

VIN(V)

8

12

20

CH1

OOA Mode

V

TONSEL

= V5FILT

0.001

0

20

h – Efficiency – %

60

80

40

100

I

OUT

– Output Current – A

101

VIN(V)

8

12

20

0.10.01

CH2

OOA Mode

V

TONSEL

= V5FILT

TPS51427

www.ti.com

SYSTEM DUAL RAILS

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

TYPICAL CHARACTERISTICS

EFFICIENCY EFFICIENCY

vs vs

OUTPUT CURRENT OUTPUT CURRENT

Figure 1. 5-V Efficiency in Auto-Skip Mode Figure 2. 3.3-V Efficiency in Auto-Skip Mode

EFFICIENCY EFFICIENCY

vs vs

OUTPUT CURRENT OUTPUT CURRENT

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 17

Figure 3. 5-V Efficiency in OOA Mode Figure 4. 3.3-V Efficiency in OOA Mode

Product Folder Link(s): TPS51427

Page 18

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH1

PWM Mode

V

TONSEL

= V5FILT

0.001

0

20

h – Efficiency – %

60

80

40

100

I

OUT

– Output Current – A

1010.10.01

CH2

PWM Mode

V

TONSEL

= V5FILT

VIN(V)

8

12

20

Auto-skip, 8 A

OOA, 8 A

OOA, 0 A

PWM Only, 0 A

Auto-skip, 0A

OOA, 8 A

PWM Only, 8 A

5

5.03

2520

VIN– Input Voltage – V

5.04

5.10

5.12

5.14

V

OUT

– Output Voltage – V

1510

5.08

5.11

5.06

5.05

5.07

5.09

5.13

5

3.20

2520

VIN– Input Voltage – V

3.22

3.24

3.28

3.32

3.34

3.38

3.40

3.42

V

OUT

– Output Voltage – V

1510

Mode, I

OUT

(A)

Auto-skip, 8 A

Auto-skip, 0A

OOA, 8 A

OOA, 0 A

PWM Only, 8A

PWM Only, 0A

Auto-skip, 8 A

Auto-skip, 0A

OOA, 8 A

OOA, 0 A

PWM Only, 8 A

3.30

3.36

3.26

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

EFFICIENCY EFFICIENCY

OUTPUT CURRENT OUTPUT CURRENT

vs vs

Figure 5. 5-V Efficiency in PWM Mode Figure 6. 3.3-V Efficiency in PWM Mode

OUTPUT VOLTAGE OUTPUT VOLTAGE

vs vs

INPUT VOLTAGE INPUT VOLTAGE

18 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Figure 7. 5-V Line Regulation Figure 8. 3.3-V Line Regulation

Product Folder Link(s): TPS51427

Page 19

0.001

4.98

1010.01

OOA

Auto-Skip

PWM Only

I

OUT

– Output Current – mA

V

OUT

– Output Voltage – V

5.00

5.02

5.06

5.08

5.10

5.12

5.14

5.16

5.18

Mode

OOA

Auto-Skip

PWM Only

5.04

0.1

CH1

V

IN

= 12 V

V

TONSEL

= V5FILT

0.001

3.24

1010.01

OOA

Auto-Skip

PWM Only

I

OUT

– Output Current – mA

V

OUT

– Output Voltage – V

3.26

3.28

3.30

3.32

3.34

3.36

3.38

3.40

3.42

Mode

OOA

Auto-Skip

PWM Only

0.1

CH2

V

IN

= 12 V

V

TONSEL

= V5FILT

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH1

Auto-Skip Mode

V

TONSEL

= GND

10

30

50

70

90

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH2

Auto-Skip Mode

V

TONSEL

= GND

10

30

50

70

90

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

TYPICAL CHARACTERISTICS (continued)

OUTPUT VOLTAGE OUTPUT VOLTAGE

OUTPUT CURRENT OUTPUT CURRENT

vs vs

Figure 9. 5-V Load Regulation Figure 10. 3.3-V Load Regulation

LOW VOLTAGE DUAL RAILS

EFFICIENCY EFFICIENCY

OUTPUT CURRENT OUTPUT CURRENT

Figure 11. 1.5-V Efficiency in Auto-Skip mode Figure 12. 1.05-V Efficiency in Auto-Skip Mode

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 19

vs vs

Product Folder Link(s): TPS51427

Page 20

0.001

0

20

h – Efficiency – %

60

80

40

100

I

OUT

– Output Current – A

101

VIN(V)

8

12

20

0.10.01

CH1

OOA Mode

V

TONSEL

= GND

10

30

50

70

90

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH2

Auto-Skip Mode

V

TONSEL

= GND

0.001

0

101

20

h – Efficiency – %

0.10.01

60

80

40

100

VIN(V)

8

12

20

I

OUT

– Output Current – A

CH1

PWM Mode

V

TONSEL

= GND

0.001

0

20

h – Efficiency – %

60

80

40

100

I

OUT

– Output Current – A

1010.10.01

CH2

PWM Mode

V

TONSEL

= GND

VIN(V)

8

12

20

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

EFFICIENCY EFFICIENCY

OUTPUT CURRENT OUTPUT CURRENT

vs vs

Figure 13. 1.5-V Efficiency in OOA mode Figure 14. 1.05-V Efficiency in OOA mode

EFFICIENCY EFFICIENCY

vs vs

OUTPUT CURRENT OUTPUT CURRENT

20 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Figure 15. 1.5-V Efficiency in PWM mode Figure 16. 1.05-V Efficiency in PWM mode

Product Folder Link(s): TPS51427

Page 21

Mode, I

OUT

(A)

Auto-skip, 8 A

Auto-skip, 0A

OOA, 8 A

OOA, 0 A

PWM Only, 8A

PWM Only, 0A

5

1.495

2520

VIN– Input Voltage – V

1.500

1.515

1.525

1.530

V

OUT

– Output Voltage – V

1510

Auto-skip, 8 A

OOA, 8 A

OOA, 0 A

PWM Only, 0 A

1.510

1.520

1.505

Auto-skip, 0A

PWM Only, 8 A

5

1.050

2520

VIN– Input Voltage – V

1.055

1.075

V

OUT

– Output Voltage – V

1510

1.065

1.070

1.060

1.080

Mode, I

OUT

(A)

Auto-skip, 10 A

Auto-skip, 0A

OOA, 10 A

OOA, 0 A

PWM Only, 10A

PWM Only, 0A

0.001

1.500

1010.01

OOA

Auto-Skip

PWM Only

I

OUT

– Output Current – A

V

OUT

– Output Voltage – V

1.505

1.515

1.520

1.525

1.530

Mode

OOA

Auto-Skip

PWM Only

1.510

0.1

CH1

V

IN

= 12 V

V

TONSEL

= GND

0.001

1.054

1010.01

OOA

Auto-Skip

PWM Only

I

OUT

– Output Current – mA

V

OUT

– Output Voltage – V

1.056

1.058

1.062

1.066

1.068

1.070

1.072

1.074

1.076

Mode

OOA

Auto-Skip

PWM Only

1.060

0.1

1.064

CH2

V

IN

= 12 V

V

TONSEL

= GND

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

TYPICAL CHARACTERISTICS (continued)

OUTPUT VOLTAGE OUTPUT VOLTAGE

vs vs

INPUT VOLTAGE INPUT VOLTAGE

Figure 17. 1.5-V Line Regulation Figure 18. 1.05-V Line Regulation

OUTPUT VOLTAGE OUTPUT VOLTAGE

vs vs

OUTPUT CURRENT OUTPUT CURRENT

Figure 19. 1.5-V Load Regulation Figure 20. 1.05-V Load Regulation

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): TPS51427

Page 22

0

3.0

20010050

VIN(V)

6

12

25

VIN= 6 V

VIN= 12 V

VIN= 25 V

I

OUT

– Output Current – mA

3.5

4.0

4.5

5.0

5.5

150

V

OUT

– Output Voltage – V

0

2.0

20010050

VIN(V)

6

12

25

VIN= 6 V

VIN= 12 V

VIN= 25 V

I

OUT

– Output Current – mA

2.5

3.0

3.5

4.0

150

V

OUT

– Output Voltage – V

0

1.991

15010050

VIN= 6 V

VIN= 12 V

VIN= 25 V

I

OUT

– Output Current – mA

V

VREF

– Voltage Reference – V

1.992

1.993

1.994

1.995

1.996

1.997

1.998

1.999

2.000

VIN(V)

6

12

25

0

3.270

1073

I

OUT

– Output Current – mA

3.275

3.280

3.285

3.290

3.295

3.300

3.305

3.310

VIN= 6 V

VIN= 12 V

VIN= 25 V

V

VREF

– Voltage Reference – V

841 5 6 92

VIN(V)

6

12

25

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

OUTPUT VOLTAGE OUTPUT VOLTAGE

OUTPUT CURRENT OUTPUT CURRENT

vs vs

Figure 21. 5-V LDO Load Regulation Figure 22. 3.3-V LDO Load Regulation

OUTPUT VOLTAGE OUTPUT VOLTAGE

vs vs

OUTPUT CURRENT OUTPUT CURRENT

22 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Figure 23. 2-V Reference Load Regulation Figure 24. 3.3-V Reference Load Regulation

Product Folder Link(s): TPS51427

Page 23

5

100

252010

VIN– Input Voltage – V

f

SW

– Frequency – kHz

200

300

500

400

15

V

TONSEL

(V)

V

V5FILT

GND

V

VREF2

V

TONSEL=

GND

V

TONSEL

= V

V5FILT

V

TONSEL

= V

VREF2

5

100

252010

VIN– Input Voltage – V

f

SW

– Frequency – kHz

200

300

400

15

V

TONSEL

(V)

V

V5FILT

GND

V

VREF2

V

TONSEL=

GND

V

TONSEL

= V

V5FILT

V

TONSEL

= V

VREF2

500

600

0

f

SW

– Frequency – kHz

50

200

250

100

150

OOA

Auto-Skip

CH1

VIN= 12 V

V

TONSEL

= V

V5VFILT

0.001 1010.01

I

OUT

– Output Current – A

0.1

0

f

SW

– Frequency – kHz

100

200

400

300

CH2

VIN= 12 V

V

TONSEL

= V

V5VFILT

50

150

350

250

OOA

Auto-Skip

0.001 1010.01

I

OUT

– Output Current – A

0.1

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

TYPICAL CHARACTERISTICS (continued)

FREQUENCY FREQUENCY

vs vs

INPUT VOLTAGE INPUT VOLTAGE

Figure 25. Channel 1 (5-V Setting) Figure 26. Channel 2 (3.3-V Setting)

FREQUENCY FREQUENCY

vs vs

OUTPUT CURRENT OUTPUT CURRENT

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 23

Figure 27. Load Current (5-V Setting) Figure 28. Load Current (3.3-V Setting)

Product Folder Link(s): TPS51427

Page 24

5

100

251510

VIN– Input Voltage – V

300

400

500

20

200

V

TONSEL=

GND

V

TONSEL

= V

VREF2

V

TONSEL

= V

V5FILT

V

TONSEL

(V)

GND

VREF2

V5FILT

f

SW

– Frequency – kHz

5

100

251510

V

IN

– Input Voltage – V

f

SW

– Frequency – kHz

300

400

600

20

200

500

V

TONSEL

(V)

GND

VREF2

V5FILT

V

TONSEL

= V

VREF2

V

TONSEL

= V

V5FILT

V

TONSEL=

GND

0.001

0

1010.01

OOA

Auto-Skip

I

OUT

– Output Current – A

50

200

250

300

350

100

0.1

CH1

V

IN

= 19 V

V

TONSEL

= GND

150

f

SW

– Frequency – kHz

0.001

0

1010.01

I

OUT

– Output Current – A

50

200

250

300

350

100

0.1

CH2

V

IN

= 19 V

V

TONSEL

= GND

150

OOA

Auto-Skip

f

SW

– Frequency – kHz

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

FREQUENCY FREQUENCY

vs vs

INPUT VOLTAGE INPUT VOLTAGE

Figure 29. Channel 1 (1.5-V Setting) Figure 30. Channel 2 (1.05-V Setting)

FREQUENCY FREQUENCY

vs vs

OUTPUT CURRENT OUTPUT CURRENT

Figure 31. Load Current (5-V Setting) Figure 32. Load Current (3.3-V Setting)

24 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 25

0

150

531

V

TONSEL=

GND

V

OUT

– Output Voltage – V

f

SW

– Frequency – kHz

200

300

400

450

4

V

TONSEL

(V)

GND

2

5

250

350

2

V

TONSEL=

2 V

V

TONSEL=

5 V

0

200

3.0

1.5

0.5

V

TONSEL=

GND

V

OUT

– Output Voltage – V

f

SW

– Frequency – kHz

250

350

450

500

2.5

V

TONSEL

(V)

GND

2

5

300

400

1.0

V

TONSEL=

2 V

V

TONSEL=

5 V

2.0

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

TYPICAL CHARACTERISTICS (continued)

FREQUENCY FREQUENCY

OUTPUT VOLTAGE OUTPUT VOLTAGE

vs vs

Figure 33. Channel 1 Setting Figure 34. Channel 2 Setting

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TPS51427

Page 26

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

Figure 35. Channel 1 Gate Driver Performance Figure 36. Channel 2 Gate Driver Performance

Figure 37. Channel 1 Load Step Figure 38. Channel 1 Load Release

Figure 39. Channel 2 Load Step Figure 40. Channel 2 Load Release

26 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 27

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

APPLICATION INFORMATION

Table 4. List of Materials

COMPONENTS CONFIGURATION NO. 1 CONFIGURATION NO. 2 CONFIGURATION NO. 3

400 kHz/300 kHz Channel1: 5 400 kHz/500 kHz Channel1: 400kHz/500kHz Channel1:

V/8 A (fixed) Channel2: 3.3 V/10 1.5V/10A (fixed) Channel2: 1.05 1.8V/10A (adj) Channel2:

A (fixed) V/15 A(fixed) 1.1V/15A (adj)

Input voltage 8 V ≤ VIN≤ 22 V

Input MLCC capacitors Murata Murata Murata

Channel1

Output capacitor

Output inductor

High-side MOSFET

Low-side MOSFET IRF7811AV, 30 V, 10.8 A, 0.011

R

OCL

R

UPPER_DIV

R

LOWER_DIV

Channel2

Output capacitor

Output inductor

High-side MOSFET

Low-side MOSFET

R

OCL

R

UPPER_DIV

R

LOWER_DIV

4 x 10 µ F, 25 V 4 x 10 µ F, 25 V 4 x 10 µ F, 25 V

GRM31CR61E106KA12L GRM31CR61E106KA12L GRM31CR61E106KA12L

1 x 330 µ F, 6 V, 25 m Ω , Sanyo, 2 x 330 µ F, 2.5 V, 12 m Ω , 2 x 330 µ F, 2.5 V, 12 m Ω ,

6TPE330ML Sanyo, 2R5TPE330MC Sanyo, 2R5TPE330MC

Sumida, 4.3 µ H, Sumida, 2.2 µ H, Sumida, 2.2 µ H,

CEP125NP-4R3M-U, 11.4 m Ω CEP125NP-2R2M-U, 5.4 m Ω CEP125NP-2R2M-U, 5.4 m Ω

International Rectifier, IRF7807V, International Rectifier, IRF7807V, International Rectifier, IRF7807V,

30 V, 8.3 A, 0.017 Ω 30V, 8.3A, 0.017 Ω 30V, 8.3A, 0.017 Ω

International Rectifier,

Ω

International Rectifier, IRF7832, International Rectifier, IRF7832,

30V, 20A, 0.004 Ω 30V, 20A, 0.004 Ω

267 k Ω for OCL of 10 A to 14 A 110 k Ω for OCL of 12 A to 18 A 110 k Ω for OCL of 12 A to 18 A

Tie VFB1 to GND Tie VFB1 to V5FILT

1 x 330 µ F, 4 V, 18 m Ω Sanyo, 2 x 470 µ F, 2.5 V, 9 m Ω , Sanyo, 2 x 470 µ F, 2.5 V, 9 m Ω , Sanyo,

4TPE330MI 2R5TPE470M9 2R5TPE470M9

Sumida, 3.2 µ H, 8.0 m Ω , Vishay, 1 µ H, 3 m Ω , Vishay, 1 µ H, 3 m Ω ,

CEP125NP-3R2M-U IHLP5050CE IHLP5050CE

International Rectifier, IRF7807V, International Rectifier, IRF7821, International Rectifier, IRF7821,

30 V, 8.3 A, 0.017 Ω 30 V, 13 A, 0.009 Ω 30 V, 13 A, 0.009 Ω

International Rectifier, IRF7832, International Rectifier, IRF7832, International Rectifier, IRF7832,

30 V, 20 A, 0.004 Ω 30 V, 20 A, 0.004 Ω 30 V, 20 A, 0.004 Ω

110 k Ω for OCL of 12 A to 18 A 169 k Ω for OCL of 18 A to 26 A 169 k Ω for OCL of 18 A to 26 A

Tie REFIN2 to V5FILT Tie REFIN2 to VREF3

39.2 k Ω , 1%

24.9 k Ω , 1%

44.2 k Ω , 1%

54.9 k Ω

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): TPS51427

Page 28

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

Figure 41. Configuration 1: System Rail

28 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 29

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

Figure 42. Configuration 2: Low Voltage Rail (Fixed Voltage Settings)

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): TPS51427

Page 30

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

www.ti.com

Figure 43. Configuration 3: Low-Voltage Dual Rail (Adjustable Voltage Settings)

30 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): TPS51427

Page 31

Switching

Logic

DRVH

TPS51427

DRVL

One Shot

Blanking

Period

+

R

FB

Q1

Q2

I

L

ESR

C

OUT

L

O

A

D

I

LOAD

V

OUT

VFB

High-Speed Comparator

VREF

UDG-08056

V

IN

Lo

I

t

ON

tONtriggered when V

OUT

declines to V

REF

level

V

RIPPLE

= I

RIPPLE

x ESR

I

LOAD

V

REF

I

RIPPLE

V

RIPPLE

TPS51427

www.ti.com

................................................................................................................................................ SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008

Loop Compensation and External Part Selection

A simplified buck converter system using D-CAP mode is shown below in Figure 44 .

Figure 44. D-CAP Mode Operation Schematic

Figure 45. D-CAP Mode Operation Waveforms

The output voltage is compared with an internal reference voltage through scaling. The PWM comparator

determines the timing to turn on the high side MOSFET. The gain and speed of the comparator is high enough to

keep the voltage at the beginning of each on cycle (or the end of off cycle) substantially constant. The DC output

voltage changes when the input voltage changes due to the fact that voltage regulation is maintained at the

valley point. Therefore, as the output ripple amplitude increases when the input voltage increases, the DC output

voltage increases as well.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Link(s): TPS51427

Page 32

SW

0

OUT

f

1

f

2 ESR C 4

= £

p´ ´

( )

( )

(

)

( )

( )

( )

(

)

( )

f f

OUT OUT OUT OUT

IN max IN max

IND ripple IN max OUT max IN max

V V V V V V

1 3

L

I V I V

- ´ - ´

= ´ = ´

´ ´

OUT

RIPPLE

1.5%

ESR VI= ´

TPS51427

SLUS819B – APRIL 2008 – REVISED SEPTEMBER 2008 ................................................................................................................................................

For loop stability, the 0-dB frequency, f0, defined in Equation 4 must be lower than of the switching frequency.

As f0is determined solely by the output capacitor ’ s characteristics, loop stability of D-CAP mode is determined by

the capacitor ’ s chemistry. For example, the output capacitance of specialty polymer capacitors (SP-CAP) is on

the order of several hundred microfarads and an ESR of approximately 10 m Ω . These values yield a 0-dB

frequency of 100 kHz or less and the loop is stable. However, ceramic capacitors yield a f0at more than 700 kHz

which is not suitable for this operational mode.

Although D-CAP mode provides many advantages such as ease-of-use, minimum external components, and

extremely fast transient response, a sufficient amount of feedback signal needs to be provided to reduce the jitter

level. In a TPS51427 design, it is generally recommended to optimize the output voltage ripple at around 1.5% of

the targeted DC voltage in both Auto-skip and PWM mode operations. For example, if V

desired output ripple should be at least 1.5 V x 1.5% = 22.5 mV. This can be achieved by taking advantage of

the output bulk capacitor ESR.

The external component selection is much simpler in D-CAP mode. Below is a simplified design procedure

targeting to the customers that are very familiar with SMPS design.

1. Determine the output voltage setting.

For the fixed 5 V/3.3 V option, tie VFB1 pin to GND and REFIN2 to V5FILT. For the fixed 1.5 V/1.05 V

configuration, tie VFB1 to V5FILT and REFIN2 to VREF3. TPS51427 also supports adjustable voltage

options for both channels. The adjustable range for Channel1 is between 0.7 V and 5.9 V and for Channel2

is between 0.5 V and 2.5 V. Figure 46 shows how to configure the adjustable voltage option for Channel1

and Figure 47 shows the configuration for Channel2. Also, equations are provided in Table 5 to aid the

design process.

2. Choose the output inductor.

Output inductance is a function of V

frequency settings with TPS51427, refer to Table 2 . The process of choosing the right output inductance is

an iterative one; many considerations need to be taken, such as the desired transient response, efficiency

over the entire load range, load/line regulation, component availability and cost. Base the initial output

inductance value upon where the ripple current is 25% to 50% of the maximum loading current. For transient

optimized design, ripple factor can be higher; and for efficiency and load/line regulation optimized design, the

ripple factor can be lower.

, V

, f

IN

OUT

and the desired ripple current. For available switching

SW

VOUT1

www.ti.com

= 1.5 V, the

(4)

3. Choose the output capacitor(s).

Organic semiconductor capacitors or specialty polymer capacitor(s) are recommended. Determine ESR to