TPS51120

www.ti.com

SLUS670A–JULY 2005–REVISED AUGUST 2005

DUAL CURRENT MODE, SYNCHRONOUS STEP-DOWN CONTROLLER WITH 100-mA

STANDBY REGULATORS FOR NOTEBOOK SYSTEM POWER

FEATURES DESCRIPTION

• 3.3-V and 5-V 100-mA Bootstrapped Standby

Regulators with Independent Enables

• Selectable D-CAP®Mode Enables Fast

Transient Response Less than 100 ns

• Selectable Low Ripple Current Mode

• Less than 1% Internal Reference Accuracy

• Selectable PWM-only/Auto-skip Modes

• Low-side R

• R

Accurate Current Sense Option

SENSE

• Internal Soft-start and Integrated V

Loss-less Current Sensing

DS(on)

OUT

Discharge Transistors

• Integrated 2-V Reference

• Adaptive Gate Drivers with Integrated Boost

Diode

• Power Good for Each Channel with Delay

Timer

• Fault Disable Mode

• Supply Input Voltage Range: 4.5 V to 28 V

APPLICATIONS

• Notebook Computers System Bus and I/O

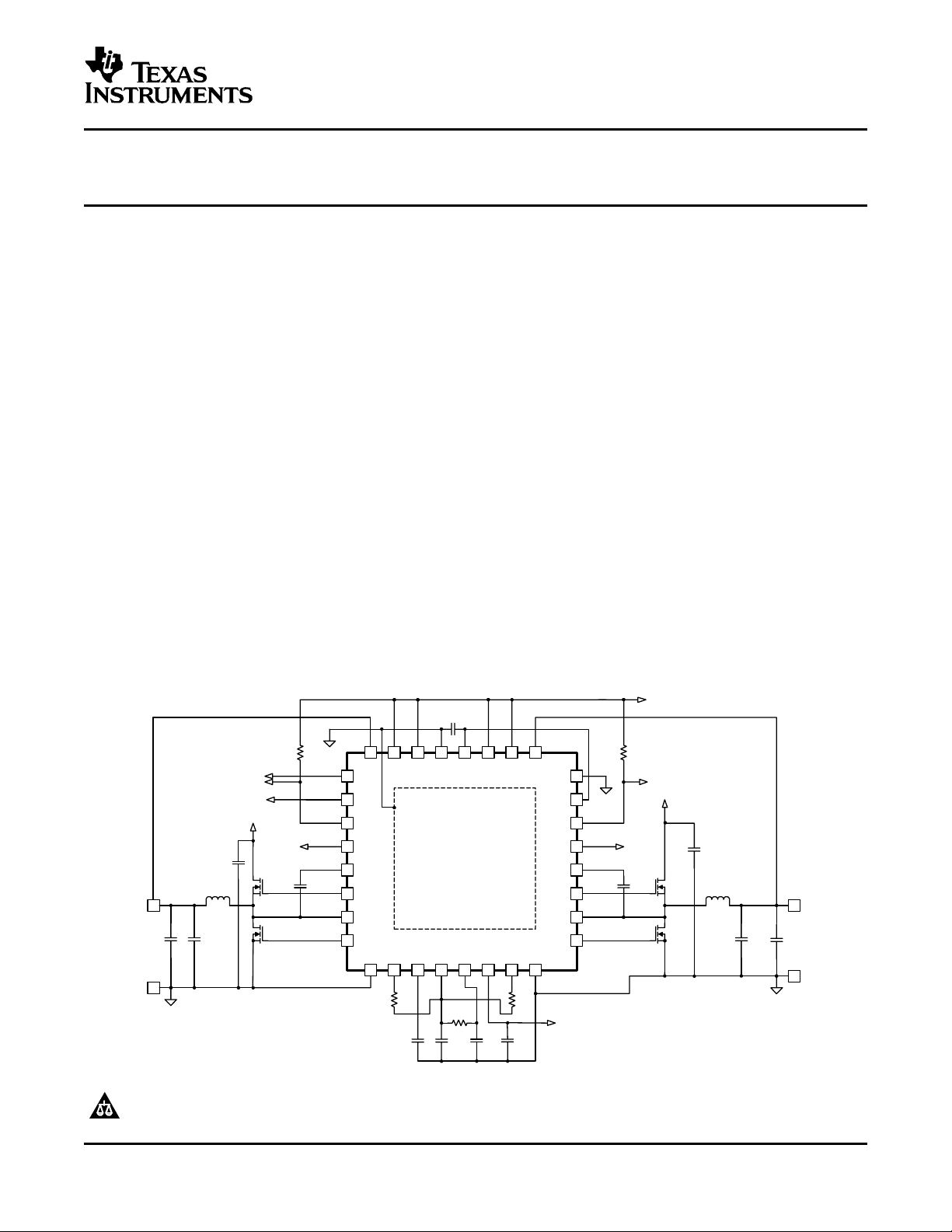

The TPS51120 is a highly sophisticated dual current

mode synchronous step-down controller. It is a full

featured controller designed to run directly off a threeor four-cell Li-ion battery and provide high-power and

5-V and/or 3.3-V standby regulation for all the downstream circuitry in a notebook computer system. High

current, 100-mA, 5-V or 3.3-V on-board linear regulators have glitch-free switch over function to SMPS

and can be kept alive independently during standby

state. The pseudo-constant frequency adaptive

on-time control scheme supports full range of current

mode operation including simplified loop compensation, ceramic output capacitors as well as seamless

transition to reduced frequency operation at light-load

condition. Optional D-CAP™ mode operation

optimized for SP-CAP or POSCAP output capacitors

allows further reduction of external compensation

parts. Dynamic UVP supports VIN line sag without

latch off by hitting 5V UVP. No negative voltage

appears at output voltage node during UVLO, UVP,

and OCP, OTP or loss of VIN.

The TPS51120 32-pin QFN package is specified from

–40°Cto85°C ambient temperature.

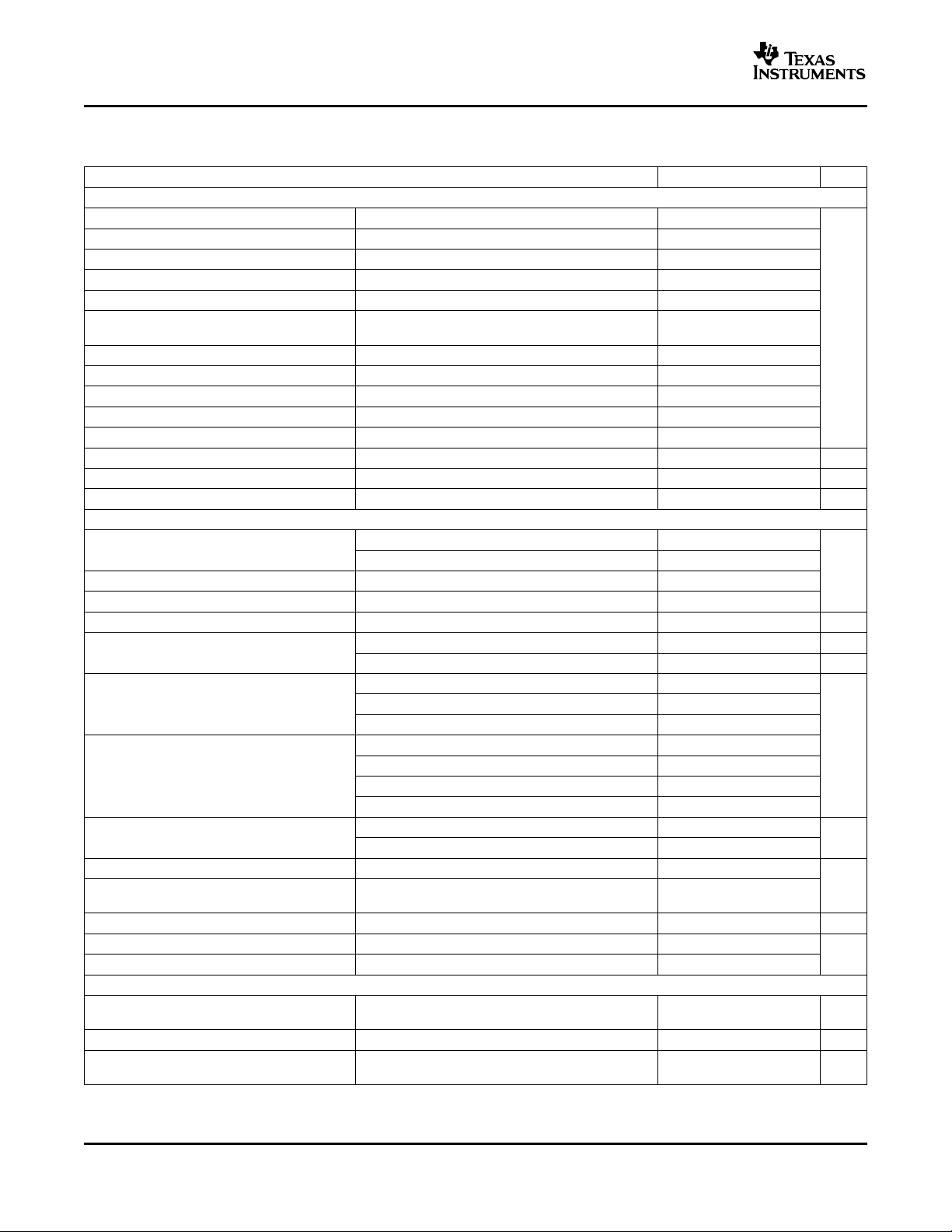

C31

1 nF

V5FILT

R21

VO2

3.3V/6A

+

C2B

150 µF

−VO2_GND

PGND2

20 µF

2.2 µH

C2A

150 µF

C10

L2

EN_LDO5

P_GOOD2

EN_LDO3

VBAT

100 kΩ

Q3

IRF7821

IRF7832

EN_2

Q4

C21

0.1 µF

GND

9

10

11

12

13

14

15

16

8

EN5

EN3

PGOOD2

EN2

VBST2

DRVH2

LL2

DRVL2

PGND2

17

R22

3.3 kΩ

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

D-CAP is a registered trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

VO2

7

COMP2

CS2

18

C30

10 µF

6

VREG3

19

VFB2

5

4

GND

VREF2

TPS51120RHB

(QFN−32)

V5FILT

V5REG

20

21

R50

5.1

W

C51

1 µF

3

VFB1

PowerPAD

VIN

22

C50

10 µF

2

COMP1

CS1

23

R12

3.6 kΩ

C30

GND

R11

100 kΩ

EN_1

C11

0.1 µF

P_GOOD1

VBAT

IRF7821

IRF7832

C10

20 µF

Q1

L1

4.7 µH

Q2

C1A

150 µF

PGND1

+

C1B

150 µF

−

VO1

5V/6A

VO1_GND

UDG−05074

1

VO1

32

SKIPSEL

31

TONSEL

30

PGOOD1

29

EN1

28

VBST1

27

DRVH1

26

LL1

DRVL1

25

PGND1

24

VBAT

NA

Copyright © 2005, Texas Instruments Incorporated

www.ti.com

TPS51120

SLUS670A–JULY 2005–REVISED AUGUST 2005

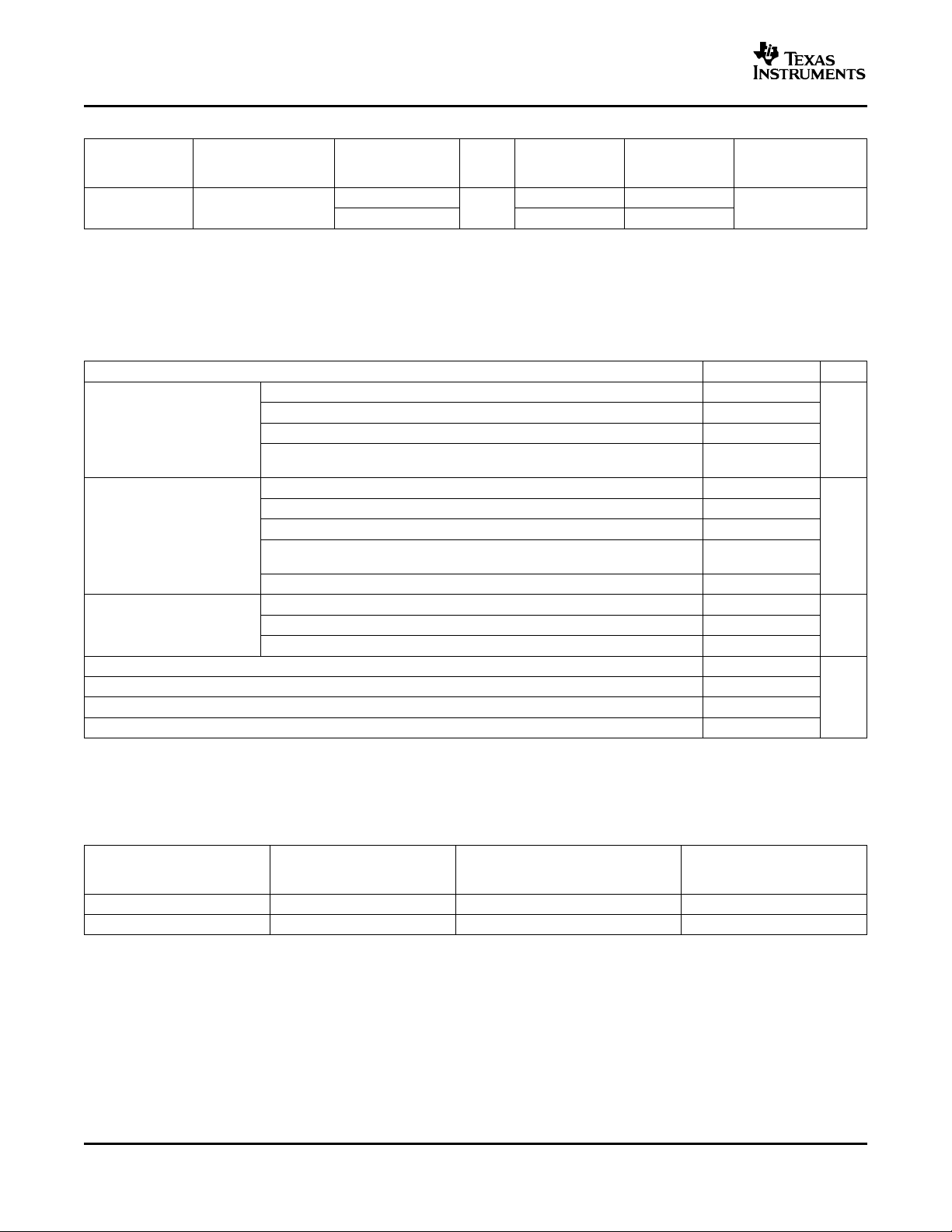

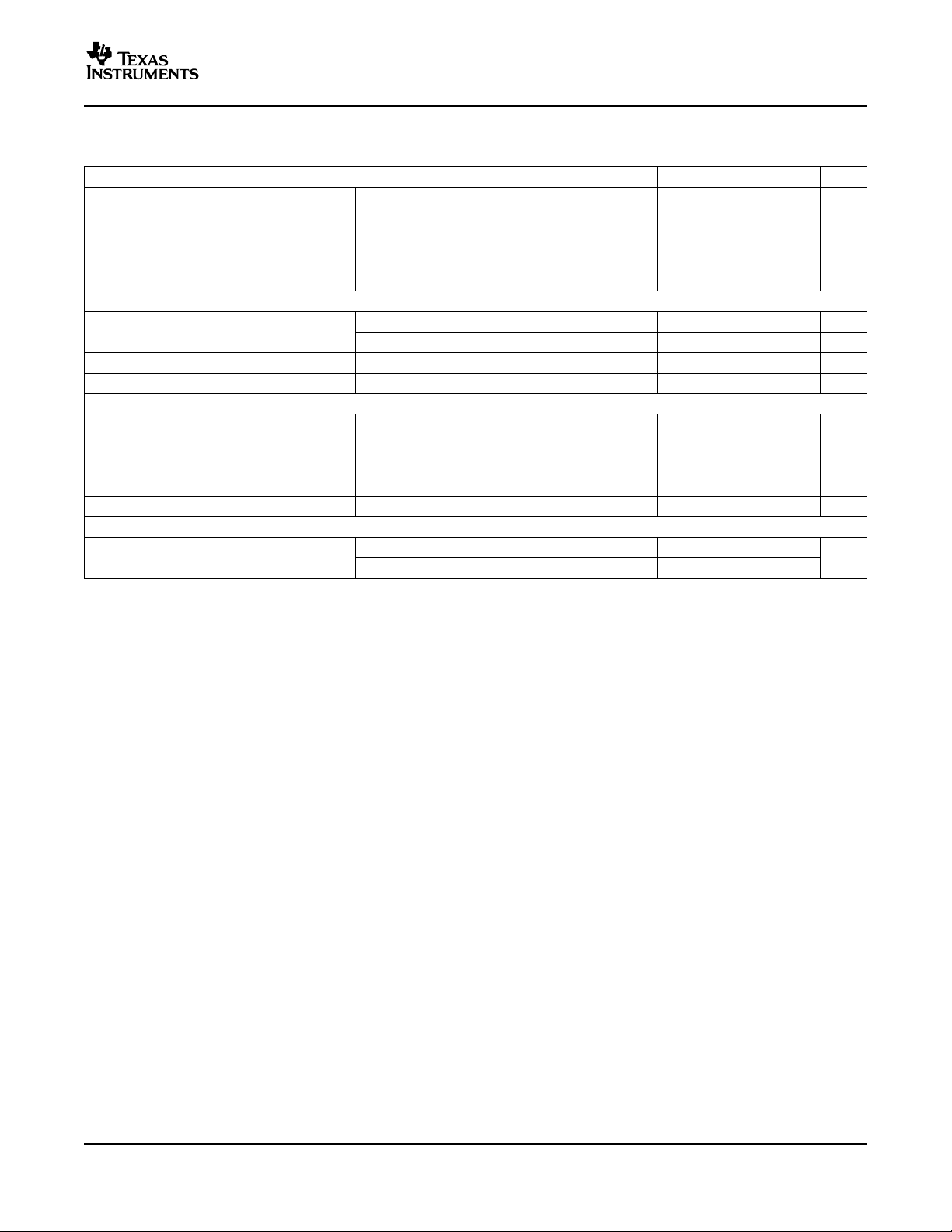

ORDERING INFORMATION

T

A

-40°Cto85°C32

PACKAGE PART PINS ORDER ECO PLAN

PLASTIC QUAD Green

FLAT PACK (QFN) (RoHS and no Sb/Br)

(1) All packaging options have Cu NIPdAu lead/ball finish.

(2) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

website at www.ti.com.

ORDERABLE MINIMUM

NUMBER QUANTITY

TPS51120RHBT Tape-and-reel 250

TPS51120RHBR Tape-and-reel 3000

(1)(2)

OUTPUT

SUPPLY

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range unless otherwise noted

TPS51120 UNITS

VBST1, VBST2 -0.3 to 36

VBST1, VBST2 wrt LL -0.3 to 6

Input voltage range V

Output voltage range V

Source/sink current VBST 100 mA

T

Operating ambient temperature range -40 to 85

A

T

Storage temperature -55to150

stg

T

Junction temperature -40to125

J

Lead temperature 1.6 mm (1/16 inch) from case for 10 seconds 255

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability. All voltage

values are with respect to the network ground terminal unless otherwise noted.

VIN, EN5 -0.3 to 30

SKIPSEL, TONSEL, EN1, EN2, CS1, CS2, V5FILT, VFB1, VFB2, EN3, VO1,

VO2

-0.3 to 6

DRVH1, DRVH2 -1 to 36

DRVH1, DRVH2 (wrt LL) -0.3 to 6

LL1, LL2 -1 to 30

VREF2, VREG3, VREG5, PGOOD1, PGOOD2, DRVL1, DRVL2, COMP1,

COMP2

-0.3 to 6

PGND1, PGND2 -0.3 to 0.3

VREF2 1

VREG5, VREG3 (source only) 200

°C

DISSIPATION RATINGS

PACKAGE ABOVE TA=25°C POWER RATING

32-pin QFN

32-pin QFN

(1)

(2)

TA<25°C POWER RATING

(W)

2.6 0.026 1.0

2.9 0.029 1.2

(1) JEDEC standard PCB.

(2) Enhanced thermal conductance by 3 x 3 thermal vias beneath thermal pad.

2

DERATING FACTOR TA=85°C

(W/°C) (W)

TPS51120

www.ti.com

SLUS670A–JULY 2005–REVISED AUGUST 2005

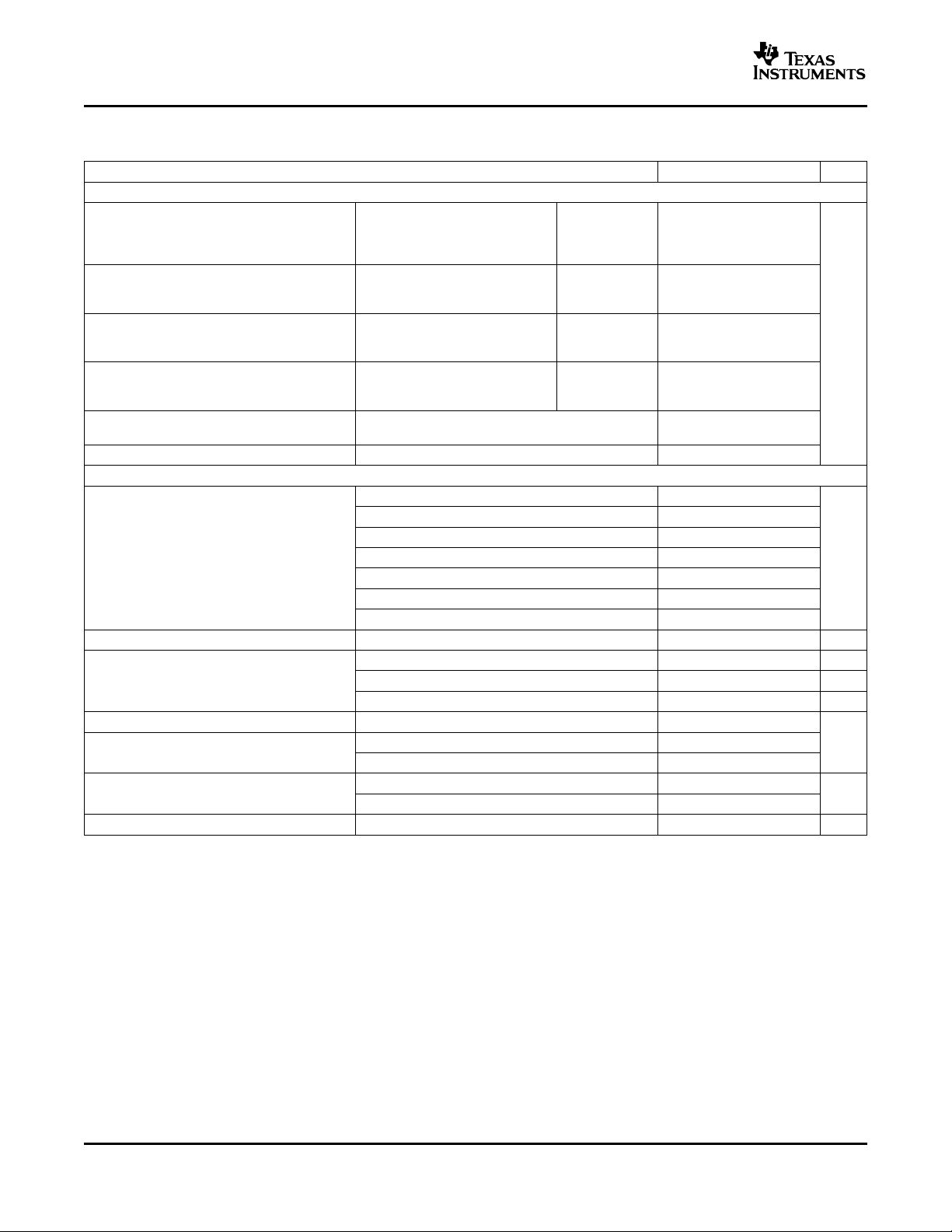

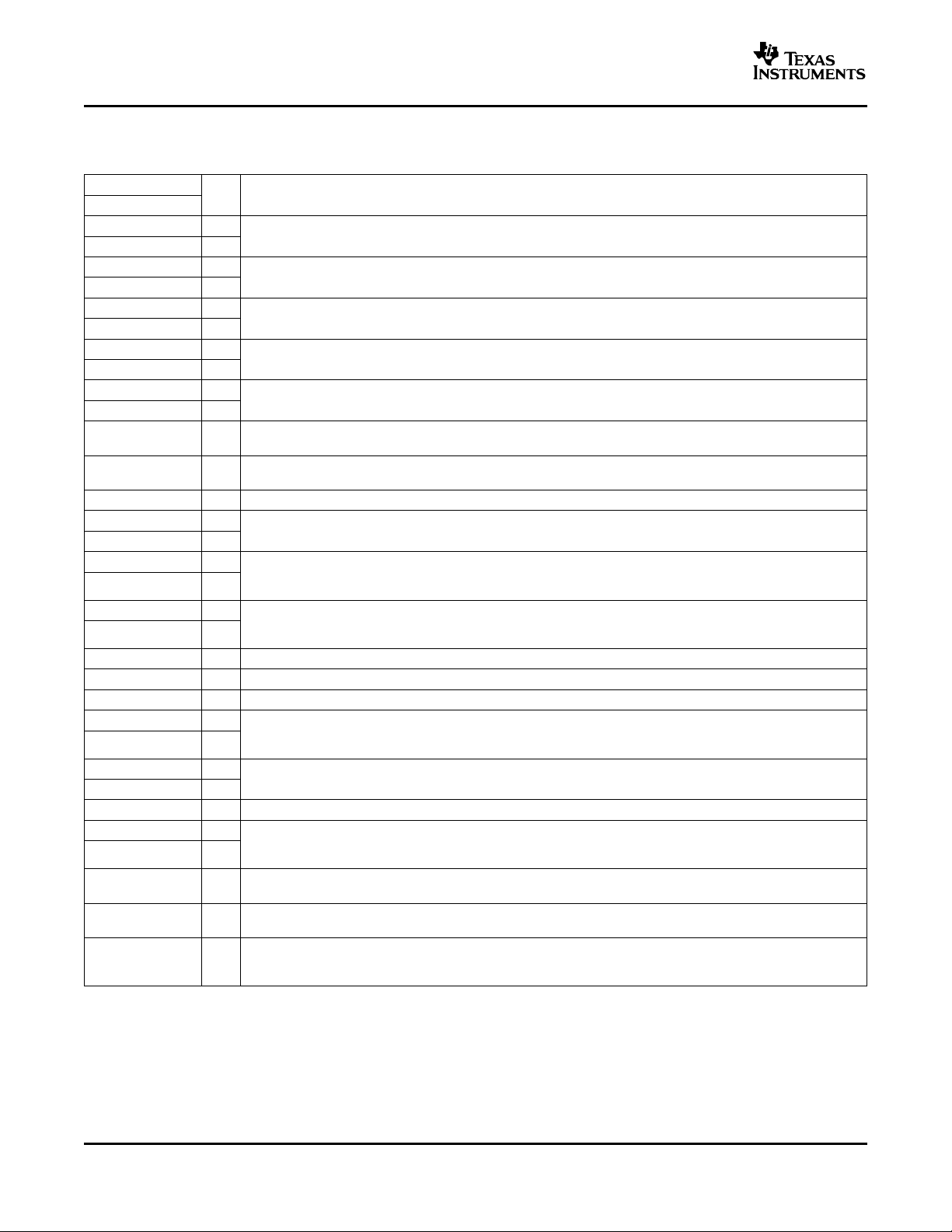

RECOMMENDED OPERATING CONDITIONS

MIN MAX UNIT

Input voltage, V5FILT 4.5 5.5 V

VBST1, VBST2 -0.1 34

VBST1, VBST2 wrt LL -0.1 5.5

Input voltage range VIN, EN5 -0.1 28 V

SKIPSEL, TONSEL, EN1, EN2, CS1, CS2, V5FILT, VFB1, VFB2, EN3 -0.1 5.5

VO1, VO2 -0.1 5.5

DRVH1, DRVH2 -0.8 34

DRVH1, DRVH2 (wrt LL) -0.1 5.5

Output voltage range V

Source/sink current VBST 50 mA

Operating ambient temperature range, T

LL1, LL2 -0.8 28

VREF2, VREG5, VREG3, PGOOD1, PGOOD2, DRVL1, DRVL2, COMP1,

COMP2

PGND1, PGND2 -0.1 0.1

VREF2 0.08

VREG5, VREF3 (source only) 100

A

-0.1 5.5

-40 85 °C

3

www.ti.com

TPS51120

SLUS670A–JULY 2005–REVISED AUGUST 2005

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY CURRENT

I

INCCAP

I

INNOCAP

I

IN5(STBY)

I

IN3(STBY)

I

IN532(STBY)

I

IN(SHDN)

VOUT and VREF2 VOLTAGES

V

OUT

V

ADJ

V

ADJ T

V

VREF2

V

VREF2T

I

VFB

R

DISCHARG

Supply current Current mode 750 1500

Supply current Load, EN3=EN5=FLOAT; D-CAP mode 700 1400

Stand-by current EN3=0V, EN5=FLOAT, 5-V only 30 45

Stand-by current EN3=FLOAT, EN5=0, 3.3-V only 12 20

Stand-by current 100 150

Shut down current VIN current, EN3=EN5=EN1=EN2=0V 10 20

Output voltage V

Output regulation voltage Adjustable mode 1.00 V

Output regulation voltage tolerance

2-V output regulation voltage I

2-V output regulation voltage tolerance

VFB input current µA

Discharge switch resistance VOx=0.5V, TA=25°C1020Ω

=12V,V

VIN

VREG5=VV5FILT

= 5 V (unless otherwise noted)

VIN current, VREG5=VREG3=No

Load, EN3=EN5=FLOAT,

EN1=EN2=5V, CS=5V, COMP

connected to Cap

VIN current, VREG5=VREG3=No

EN1=EN2=5V, CS=5V, COMP=5V

VIN current, VREG5=No Load

EN1=EN2=0

VIN current, VREG3=No Load

EN1=EN2=0

VIN current, VREG5=VREG3=VREF2=No Load

EN3=EN5=FLOAT, EN1=EN2=0

V

=5V, TA=25°C, No Load 3.255 3.300 3.345

FB2

V

=5V, TA=0to85°C, No Load 3.241 3.300 3.359

FB2

V

=5V, TA= -40 to 85°C, No Load 3.234 3.300 3.366

FB2

=5V, TA=25°C, No Load 4.935 5.000 5.065 V

FB1

V

=5V, TA=0to85°C, No Load 4.910 5.000 5.090

FB1

V

=5V, TA= -40 to 85°C, No Load 4.900 5.000 5.100

FB1

Adjustable mode output range 1.0 5.5

Adjustable mode, TA=25°C -0.9% 0.9%

Adjustable mode, TA=0to85°C -1.3% 1.3%

Adjustable mode, TA= -40 to 85°C -1.6% 1.6%

± 50 µA, TA=25°C 1.97 2.00 2.03

VREF2

I

± 50 µA, TA=0to85°C 1.96 2.04 V

VREF2

I

± 50 µA, TA=-40to85°C 1.95 2.05

VREF2

VFBx=1.02V, COMPx=open 0.02

VFBx=1.02V, COMPx=5V 0.02

µA

4

TPS51120

www.ti.com

SLUS670A–JULY 2005–REVISED AUGUST 2005

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VREG3 VOLTAGE

V

VREG3

V

VREG3T

I

VREG3

V

LDO3SW

R

LDO3SW

VREG5 VOLTAGE

V

VREG5

V

VREG5T

I

VREG5

V

LDO5SW

R

LDO5SW

TRANSCONDUCTANCE AMPLIFIER

Gm Gain TA=25°C 280 µS

I

COMPSINK

I

COMPSRC

V

COMPHI

V

COMPLO

OUTPUT DRIVER

R

DRVH

R

DRVL

T

D

V

DTH

V

DTL

INTERNAL BST DIODE

V

FBST

I

RBST

I

BST(LEAK)

(1) Ensured by design. Not production tested.

VREG3 Output Regulation Voltage I

VREG3 Output Voltage Tolerance

VREG3 Output Current TA=25°C, VREG3=3.14V

VREG3 Bootstrap Switch

Threshold

VREG3 Bootstrap Switch Resistance

VREG5 Output Regulation Voltage I

VREG5 Output Voltage Tolerance I

VREG5 Output Current TA=25°C, VREG5=4.75 V

VREG5 Bootstrap Switch

Threshold

VREG5 Bootstrap Switch Resistance

COMP Maximum Sink Current VFBx=1.05V, COMPx=1.28V 8 12 16

COMP Maximum Source Current VFBx=0.95V, COMPx=1.28V -15 -11 -7

COMP High Clamp Voltage CSx=0V, VFBx=0.95V 1.26 1.34 1.42

COMP Low Clamp Voltage CSx=0V, VFBx=1.05V 1.08 1.12 1.20

DRVH resistance

DRVL resistance

Dead time ns

DRVH-off threshold LL to GND

DRVL-off threshold DRVL to GND

Forward Voltage V

Reverse Current VBST = 34 V, VREG5=5V 0.1 1.0

VBST Leakage current VBST=34V, LL=28V, EN3=EN5=EN1=EN2=0V 0.1 1.0

=12V,V

VIN

VREG3

I

VREG3

I

VREG3

85°C

VREG5=VV5FILT

=20mA,6V<VIN<28V,TA=25°C 3.25 3.30 3.35

=1-50mA,6V<VIN<28V,TA=0to85°C 3.21 3.37

=1-100mA,6V<VIN<28V,TA=-40to

= 5 V (unless otherwise noted)

(1)

3.16 3.39

170 mA

Rising edge of VO2, VREG3 drops to VO2 voltage 2.85 3.10 V

Hysteresis 120 mV

1.3 3.0 Ω

=20mA,6V<VIN<28V,TA=25°C 4.925 5.00 5.075

VREG5

=1-50mA,6V<VIN<28V,TA=0to85°C 4.89 5.11

VREG5

I

=1-100mA,6V<VIN<28V,TA=-40to

VREG5

85°C

(1)

4.80 5.15

200 mA

Rising edge of VO1, VREG5 drops to VO1 voltage 4.30 4.85 V

Hysteresis 140 mV

1.3 3.0 Ω

Source, V

Sink, V

DRVH-LL

Source, V

Sink, V

DRVL-PGND

VBST-DRVH

VREG5-DRVL

=1V 3.5 7

=1V 1.5 3

=1V 3.5 7

=1V 1.5 3

DRVH-off to DRVL-on, TA=25°C20

DRVL-off to DRVH-on, TA=25°C3060

(1)

VREG5-VBST,IF

(1)

= 10 mA, TA=25°C 0.7 0.8 0.9 V

2

1.1

V

V

µA

V

Ω

V

µA

5

www.ti.com

TPS51120

SLUS670A–JULY 2005–REVISED AUGUST 2005

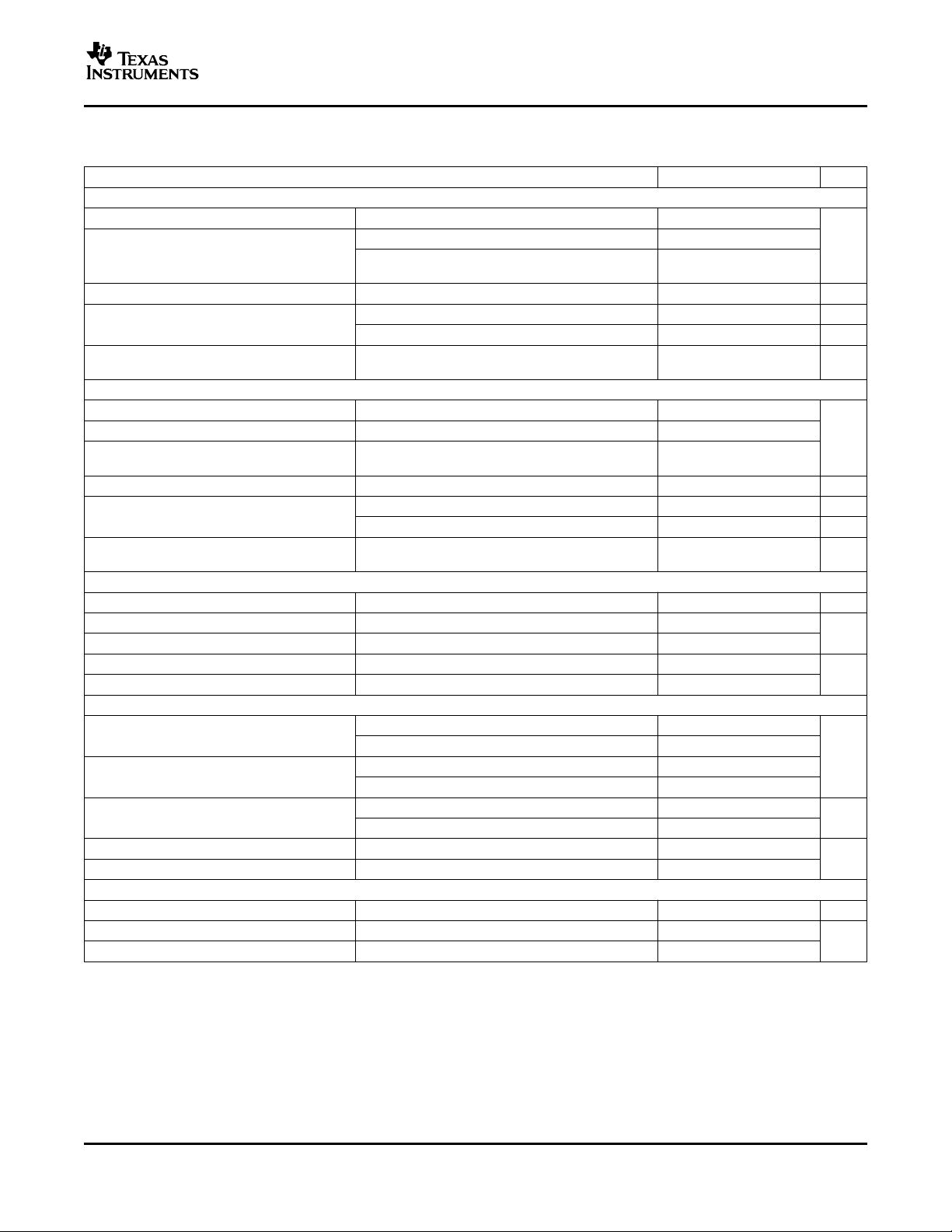

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ON-TIME TIMER, INTERNAL SOFT-START and HOUSEKEEPING CLOCK

T

ON1a

T

ON1b

T

ON1c

T

ON1d

T

ON2a

T

ON2b

T

ON2c

T

ON2d

T

ON(MIN)1

T

ON(MIN)2

T

OFF(MIN)

T

SS

SL

SS

F

CLK

UVLO/LOGIC THRESHOLD

V

ENLDOH

V

ENLDOFL3

V

ENLDOFL5

I

ENLDOFL

V

UV(VREG5)

V

SKIPSEL

V

TONSEL

I

SEL

V

ENSWSTAT

V

ENSWEND

I

ENSW1,2

V

THVFB1

V

THVFB2

CURRENT SENSE

V

OCL

I

TRIP

TC

ITRIP

On time, 5V, 180 kHz V

On time, 5V, 220 kHz V

On time, 5V, 280 kHz V

On time, 5V, 380 kHz V

On time, 3.3V, 270 kHz V

On time, 3.3V, 330 kHz 780 850 920 ns

On time, 3.3V, 430 kHz V

On time, 3.3V, 580 kHz V

Minimum on time, 5V TA=25°C, TONSEL=GND, V

Minimum on time, 3.3V TA=25°C, TONSEL=GND, V

Minimum off time TA=25°C, VFB=0.9V, LL=0.5V 480

Internal Soft Start Timer TA=25°C, ENx>3V 772 clks

Internal Soft Start Slope TA=25°C, ENx>3V, Slope wrt. VFB

HK clock frequency 230 290 350 kHz

LDO enable threshold

EN3 pullup voltage EN3 = FLOAT (OPEN)

EN5 pullup voltage EN5= FLOAT (OPEN)

EN3, EN5 pullup current VENx < 0.5V 1.5 4.0 µA

VREG5 UVLO threshold

SKIPSEL threshold Auto-SKIP Mode Enabled, Faults Off 1.3 2.2

TONSEL threshold

SKIPSEL/TONSEL input current µA

EN1, EN2 SS Start Voltage BJT Base input, Switcher begins to Track ENx 0.5 0.9 1.2

EN1, EN2 SS End Voltage 2.75 2.90

EN1, EN2 Pullup Current EN1, EN2=0.6V 1 2 3 µA

VFB1 threshold 5.0V preset output V5FILT -0.3

VFB2 threshold 3.3V preset output V5FILT -0.3

Current limit threshold 67 80 93 mV

CS Sink Current R

I

temperature Coefficient R

TRIP

=12V,V

VIN

LL1

LL1

LL1

LL1

LL2

V

LL2

25°C

LL2

LL2

=12V, V

=12V, V

=12V, V

=12V, V

=12V, V

==12V, V

==12V, V

==12V, V

VREG5=VV5FILT

=5V, TONSEL=5V, TA=25°C 2150 2340 2530

OUT1

=5V, TONSEL=FLOAT, TA=25°C 1790 1950 2110

OUT1

=5V, TONSEL=2V, TA=25°C 1370 1490 1610

OUT1

=5V, TONSEL=GND, TA=25°C 1020 1110 1200

OUT1

=3.3V, TONSEL=5V, TA=25°C 940 1030 1120

OUT2

=3.3V, TONSEL=FLOAT, TA=

OUT1

=3.3V, TONSEL=2V, TA=25°C 580 650 720

OUT1

=3.3V, TONSEL=GND, TA=25°C 430 480 530

OUT1

EN3, EN5, low to high 0.4 0.6 0.8

Hysteresis 0.2

(2)

(2)

Wake up 3.8 4.0 4.2 V

Hysteresis 100 200 300 mV

Auto-SKIP Mode Enabled 0 0.7

PWM-Only Mode Enabled 2.7 5.5

Fast Switching Frequency 0 0.7 V

Medium Switching Frequency #2 1.3 2.2

Medium Switching Frequency #1 2.7 3.0

Slow Switching Frequency 4.5 5.5

SKIPSEL, TONSEL=0V 1 3

SKIPSEL, TONSEL=5V 1 2

‘Logic High’ Level for Switcher Enable when using

Internal Softstart, 0°C ≤ TA≤ 85°C

Resistor sense scheme , V

PGOOD=Hi

sense scheme, PGOOD=Hi, TA=25°C 9 10 11 µA

DS(ON)

sense scheme, On the basis of 25°C 4500

DS(ON)

= 5 V (unless otherwise noted)

=28V, VO1=1V 70

LL1

=28V, VO2=1V 45

LL2

(2)

PGND - VCS

voltage,

0.3 V/ms

1.7

V

3.3

V

V

ppm/°

C

(2) Ensured by design. Not production tested.

6

TPS51120

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OCLoff

V

R(trip)

V

ZC

POWERGOOD COMPARATOR

V

TH(PG)

I

PG(MAX

T

PGDEL

UNDERVOLTAGE and OVERVOLTAGE PROTECTION

V

OVP

T

OVPDEL

V

UVP

T

UVPDEL

THERMAL SHUTDOWN

T

SDN1

OCP Comparator Offset -10 0 10

Current limit threshold setting

range

Zero cross detection Comparator

offset

PGOOD Threshold

PGOOD Sink Current PGOOD=0.5 V 2.5 5.0 mA

PGOOD Delay Timer Delay for PGOOD in, ‘clks’=HK Clock 256 clks

VFBx OVP Trip Threshold OVP detect 110% 115% 120%

VFBx OVP Delay Time 2ms

VFBx UVP Trip Threshold

VFBx UVP Delay Timer ‘clks’=HK Clock 128 clks

Thermal shutdown threshold °C

=12V,V

VIN

(V

VREG5-CS-VPGND-LL

R

DS(ON)

V

V5FILT-VCS

V

PGNDx-VLLx

VREG5=VV5FILT

sense

voltage 30 150 mV

voltage, SKIPSEL=0V -5 1 5

Power Bad Threshold ±7% ±10% ±13%

Hysteresis ±5%

UVP detect 65% 70% 75%

Hysteresis 6%

Shutdown temperature 145

Hysteresis 10

) voltage, V

SLUS670A–JULY 2005–REVISED AUGUST 2005

= 5 V (unless otherwise noted)

VREG5-CS

= 80mV,

7

www.ti.com

TPS51120

SLUS670A–JULY 2005–REVISED AUGUST 2005

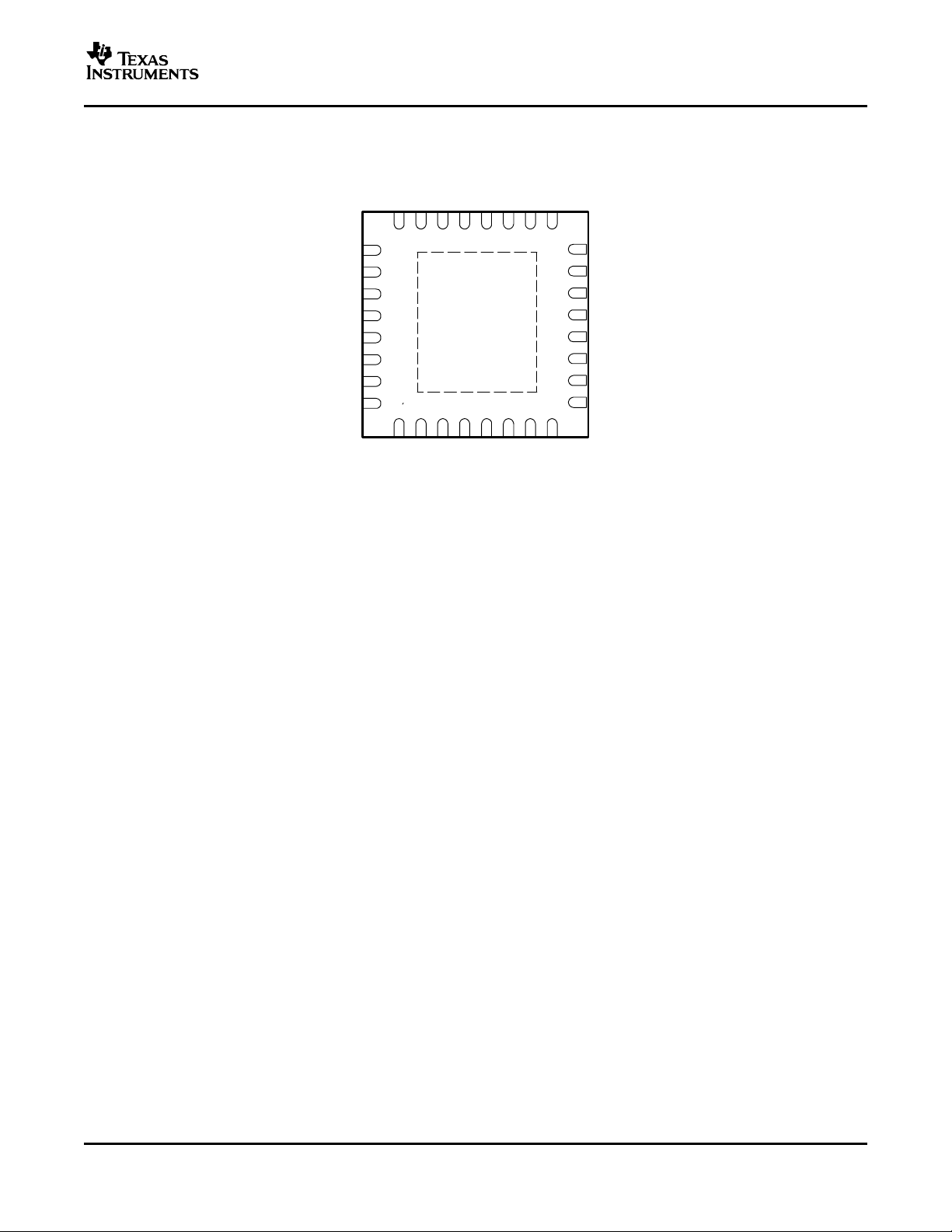

DEVICE INFORMATION

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

COMP1 2 O

COMP2 7 O

CS1 23 I

CS2 18 I

DRVH1 27 O

DRVH2 14 O

DRVL1 25 O

DRVL2 16 O

EN1 29 I

EN2 12 I

EN3 10 I

EN5 9 I

GND 5 I Signal ground pin.

LL1 26 I/O

LL2 15 I/O

PGND1 24 I/O Ground return for rectifying MOSFET gate driver. Connect PGND2, PGND1 and GND strongly together near

PGND2 17 I/O

PGOOD1 30 O Power-good window comparator open drain output. Pull up with resistor to V5FILT or appropriate signal

PGOOD2 11 O

SKIPSEL 32 I Skip and fault mode selection pin. Refer to Table 2

TONSEL 31 I On-time selection pin. Refer to Table 1 and Table 2.

V5FILT 20 I 5-V supply input for the entire control circuit. Should be provided from VREG5 via RC filter.

VBST1 28 I Supply Input for High-side MOSFET Driver. Connect capacitor from this pin to respective LL terminal. An

VBST2 13 I

VFB1 3 I

VFB2 6 I

VIN 22 I Supply Input for 5-V and 3.3-V linear regulator. Typically connected to VBAT.

VO1 1 I These terminals serve four functions: on-time adjustment, output discharge, VREG5, VREG3 switchover input

VO2 8 I

VREF2 4 O

VREG3 19 O

VREG5 21 O supply. Internally connected to VBST and DRVL. Shuts off with EN5. Switches over to VO1 when 4.8 V or

I/O DESCRIPTION

Loop compensation pin (error amplifier output). Connect RC from this pin to GND for proper loop compensation

with current mode operation. Tie this pin to V5FILT for D-CAP™ mode operation.

Current sense comparator input (-) for resistor sensing scheme. Or, overcurrent trip setting input for R

current sense scheme if connected to V5FILT through the threshold setting resistor.

High-side MOSFET gate drive output. Source 3.5 Ω, sink 1.5 Ω, LL-node referenced floating driver. Drive

voltage corresponds to VBST to LL voltage.

Rectifying (low-side) MOSFET gate drive output. Source 3.5 Ω, sink 1.5 Ω, PGND referenced driver. Drive

voltage is VREG5 voltage.

Channel 1 and Channel 2 SMPS enable pins. Connect to 5 V to turn on with internal 3-ms soft-start. Slower

soft-start is possible by applying an external capacitor from each of these pins to ground to program ramp rate.

VREG3, 3.3-V low dropout linear regulator enable pin. Connect to GND to disable. Float or tie to enabled

VREG5 to turn on the regulator.

VREG5, 5-V low dropout linear regulator enable pin. Connect to GND to disable. Float or tie to VBAT to turn on

the regulator.

High-side MOSFET gate driver return. Also serve as current sense comparator input (-) for R

input voltage monitor for on-time control circuitry

the source of the rectifying FET or the GND connection of the current sense resistor. Also serve as current

sense comparator input (+).

voltage. Current capability is 5-mA. PGOOD goes high 1-ms after VFB is within specified limits. Power bad

(terminal goes low) is within 10 µs.

internal PN diode is connected between VREG5 to each of these pins. User can add external schottky diode if

forward drop is critical to drive the power MOSFET.

SMPS feedback input. Connect the feedback resistor divider here for adjustable outputs. Tie these pins to

V5FILT or for fixed output option. Refer to Table 2

and feedback inputs for 5-V, 3.3-V fixed-output option. Connect to positive terminal of respective switch mode

power supply’s output capacitor.

2-V reference output. Capable of ±50-µA, ±2% over 0 - 85°C temperature range. Bypass to GND by 1-nF

ceramic capacitor. Tie this pin to GND disables both SMPS.

3.3-V, 100-mA low dropout linear regulator output. Bypass to PGND by 10-µF ceramic capacitor. Runs from

VIN supply. Shuts off with EN3. Switches over to VO2 when 3.1 V or above is provided.

5-V, 100-mA low dropout linear regulator output. Bypass to PGND by 10-µF ceramic capacitor. Runs from VIN

above is provided.

DS(on)

DS(on)

sensing, and

8

TPS51120

www.ti.com

SKIPSEL

TONSEL

PGOOD1

EN1

VBST1

DRVH1

LL1

DRVL1

QFN PACKAGE

(BOTTOM VIEW)

VO1

COMP1

VFB1

VREF2

GND

VFB2

COMP2

12345678

32

31

30

29

28

27

26

25

24 23 22 21 20 19 18 17

VIN

CS1

PGND1

VREG5

V5FILT

CS2

VREG3

VO2

9

10

11

12

13

14

15

16

PGND2

SLUS670A–JULY 2005–REVISED AUGUST 2005

EN5

EN3

PGOOD2

EN2

VBST2

DRVH2

LL2

DRVL2

9

www.ti.com

TPS51120

SLUS670A–JULY 2005–REVISED AUGUST 2005

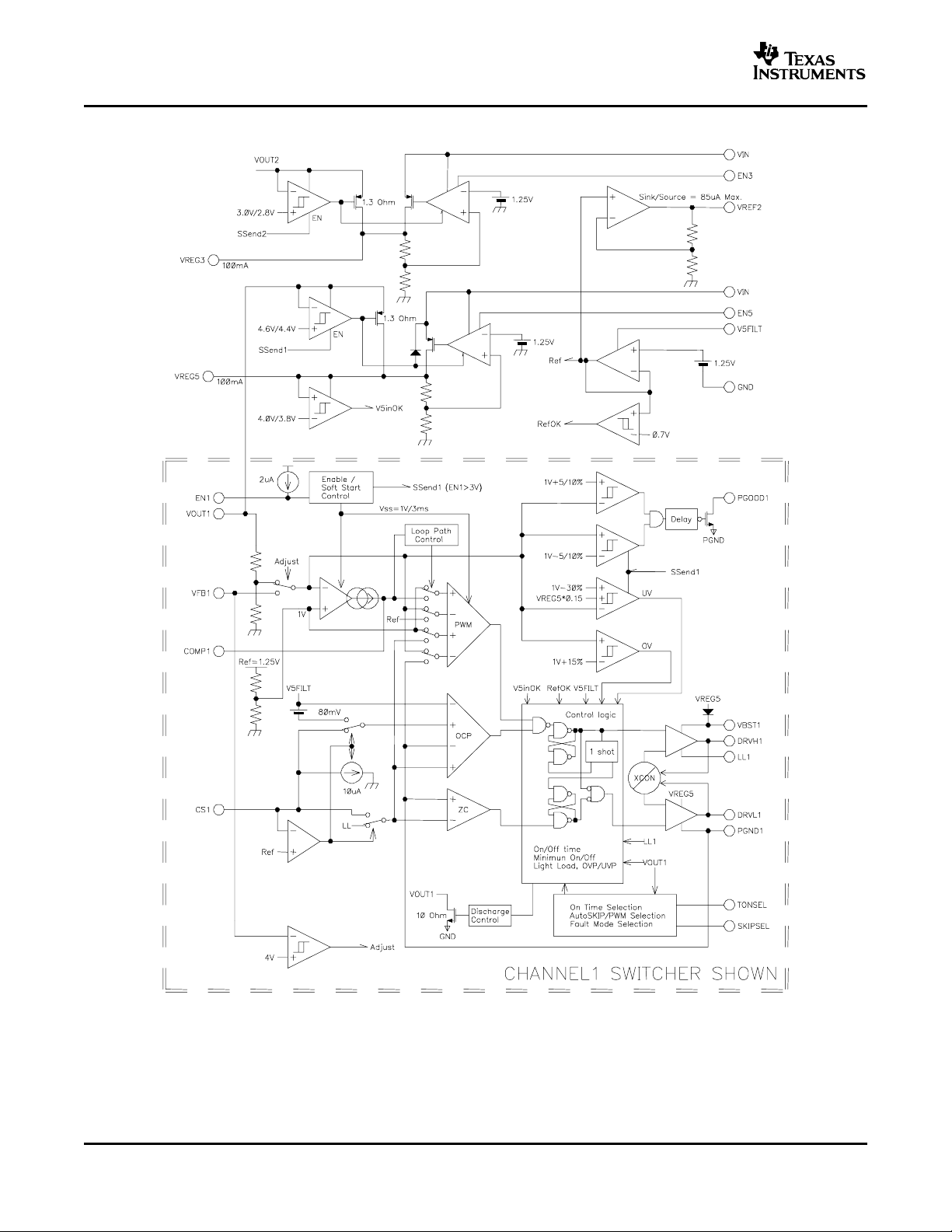

BLOCK DIAGRAM (One Channel Only Shown)

10

TPS51120

www.ti.com

SLUS670A–JULY 2005–REVISED AUGUST 2005

DETAILED DESCRIPTION

PWM Operation

The switching mode power supply (SMPS) block of TPS51120 supports an adaptive on time control

pulse-width-modulation (PWM). Switching frequency is selectable from four choices for maximum efficiency

(5 V/180 kHz, 3.3 V/270 kHz), minimum component size (5 V/380 kHz, 3.3 V/580 kHz) or the other two

intermediates. The TPS51120 supports both true current mode control and D-CAP™ mode control, selectable up

to the requirements from system design. All N-channel MOSFET totem-pole architecture is employed for external

switches. The synchronous top (high-side) MOSFET is turned on, or is “SET”, at the beginning of each cycle.

This MOSFET is turned off, or is “RESET” after a constant “on-time” period which is defined by the frequency of

customer’s choice and input and output voltage ratio. The top MOSFET is turned on again if inductor current is

reduced to meet both conditions of,

1. the current level corresponds to the error amount of output voltage and,

2. below the overcurrent limit level

Repeating operation in this manner, the controller regulates the output voltage. The synchronous bottom

(low-side) or the rectifying MOSFET is turned on each cycle in the negative phase to the top MOSFET to keep

the conduction loss minimum. The rectifying MOSFET turns off on the event reverse inductor current flow is

detected. This enables seamless transition to skip mode function so that high efficiency is kept over a broad

range of load current. At the beginning of the soft start period, the rectifying MOSFET remains in the off state

until the top MOSFET is turned on for at least once.

Current Mode

The current mode scheme is a sequence of feedback control described as follows. The output voltage is

monitored at the middle point of voltage divider resistors and fed back to a transconductance amplifier. The

amplifier outputs target current level proportional to error amount between the feedback voltage and the internal

1 V reference voltage. The inductor current level is monitored during the off-cycle, when rectifying MOSFET is

turned on. The PWM comparator compares the inductor current signal with this target current level that is

indicated at the COMP pin voltage. When both signals are equal (at the valley of the current sense signal), the

comparator provides the “SET” signal to the gate driver latch. The current mode option has relatively higher

flexibility by the external compensation network provided to the COMP pin. And it is suitable for lowest ripple

design with output capacitor(s) having ultra-low ESR. More detail information about loop compensation and

parameter design can be found in the Loop Compensation and External Parts section. When sensing the

inductor current, accuracy and cost always trades off. In order to give the circuit designer a choice between

these two, TPS51120 supports both of external resistor sensing and MOSFET R

factory for current mode EVM with R

SENSE

capability.

sensing. Please contact

DS(on)

D-CAP™ Mode

The D-CAP™ mode operation is enabled by tying the COMP pin to V5FILT. In this mode, the PWM comparator

monitors the feedback voltage directly and compares the voltage with the internal 1-V reference. When both

signals are equal at the valley of the voltage sense signal, the comparator provides the “SET” signal to the top

MOSFET gate driver. Because the compensation network is implemented on the part and the output waveform

itself is used as the error signal, external circuit design is largely simplified. Another advantage of the D-CAP™

mode is its inherent fast transient response. A trade-off is a sufficient amount of ESR required in the output

capacitor. SPCAP or POSCAP is recommended. The inductor current information is still used in the D-CAP™

mode for over current protection and light load operation. Do NOT neglect current sensing design in this mode.

To summarize, the D-CAP™ mode is suitable for the lowest external component count with the fastest transient

response, but with relatively large ripple voltage. It is easy to design the loop once appropriate output capacitor

and inductor current ripple is selected. Please refer to loop compensation and parameter design in the Loop

Compensation and External Parts section for more information.

11

Loading...

Loading...