D

Step-Down DC-DC Converter

D

Three Operation-Mode

– Heavy Load:

– Fixed Frequency PWM

– Hysteretic (User Selctable)

– Light Load:

– Skip Mode

D

4.5 V to 25 V Input Voltage Range

D

Adjustable Output Voltage Down to 1.2 V

D

95% Efficiency

D

Stand-By Control

D

Over Current Protection

D

UVLO for Internal 5 V Regulation

D

Low Standby Current . . . 0.5 mA Typical

D

TA = –40°C to 85°C

description

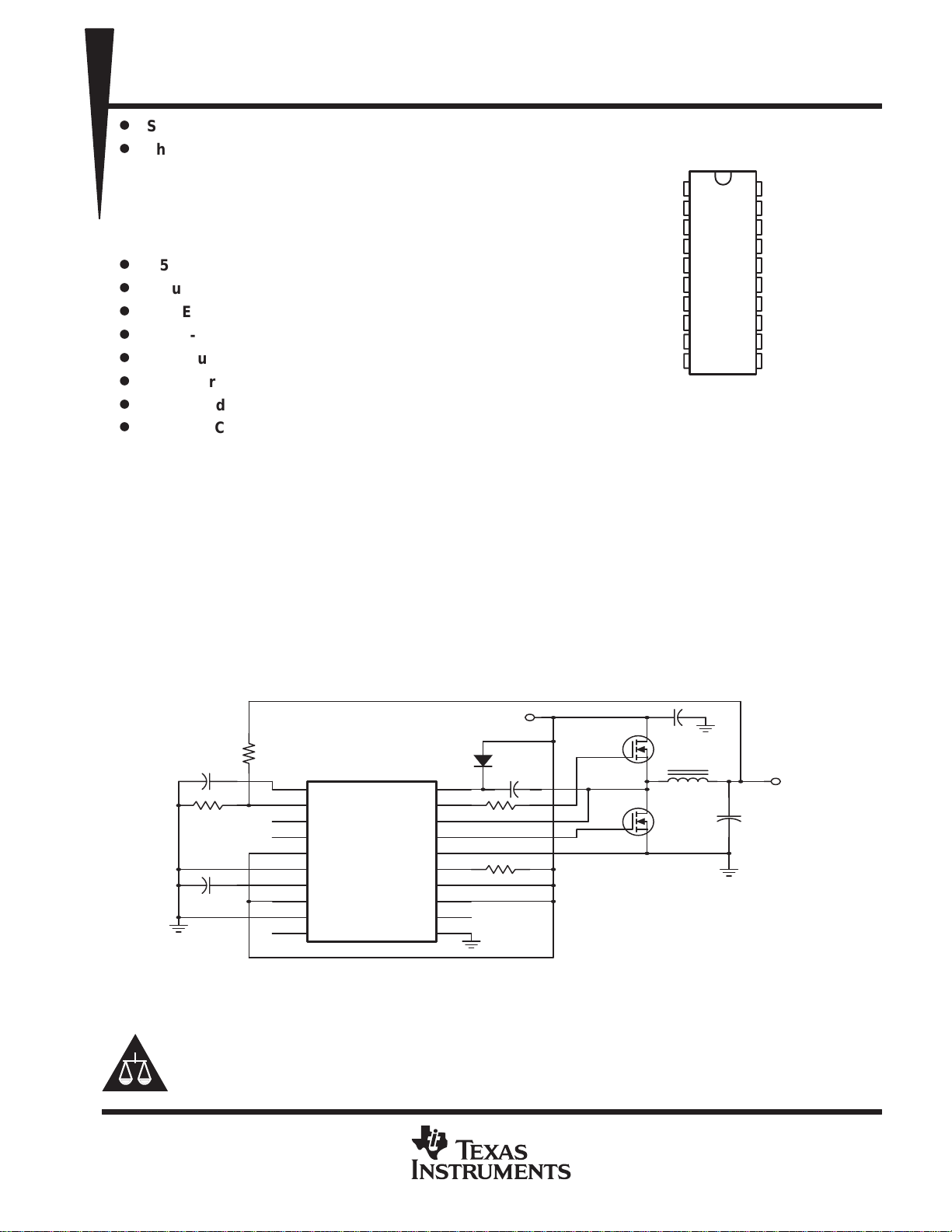

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

DB PACKAGE

(TOP VIEW)

1

20

SOFTSTART

INV

FB

C

R

GND

REF

COMP

PWMSKIP

STBY

2

3

4

T

5

T

6

7

8

9

10

LH

19

OUT_u

18

LL

17

OUT_d

16

OUTGND

15

TRIP

14

VCC_SENSE

13

VCC

12

VREF5

11

VREG5V_IN

The TPS5103 is a synchronous buck dc/dc controller, designed for notebook PC system power . The controller

has three user-selectable operation modes available; hysteretic mode, fixed frequency PWM control, or SKIP

control.

In high current applications, where fast transient response is advantageous for reducing bulk capacitance, the

hysteretic mode is selected by connecting the Rt pin to Vref5. Selecting the PWM/SKIP modes for less

demanding transient applications is ideal for conserving notebook battery life under light load conditions. The

device includes high-side and low-side MOSFET drivers capable of driving low Rds (on) N–channel MOSFET s.

The user-selectable overcurrent protection (OCP) threshold is set by an external TRIP pin resister in order to

protect the system. The TPS5103 is configured so that a current sense resistor is not required, improving the

operating efficiency.

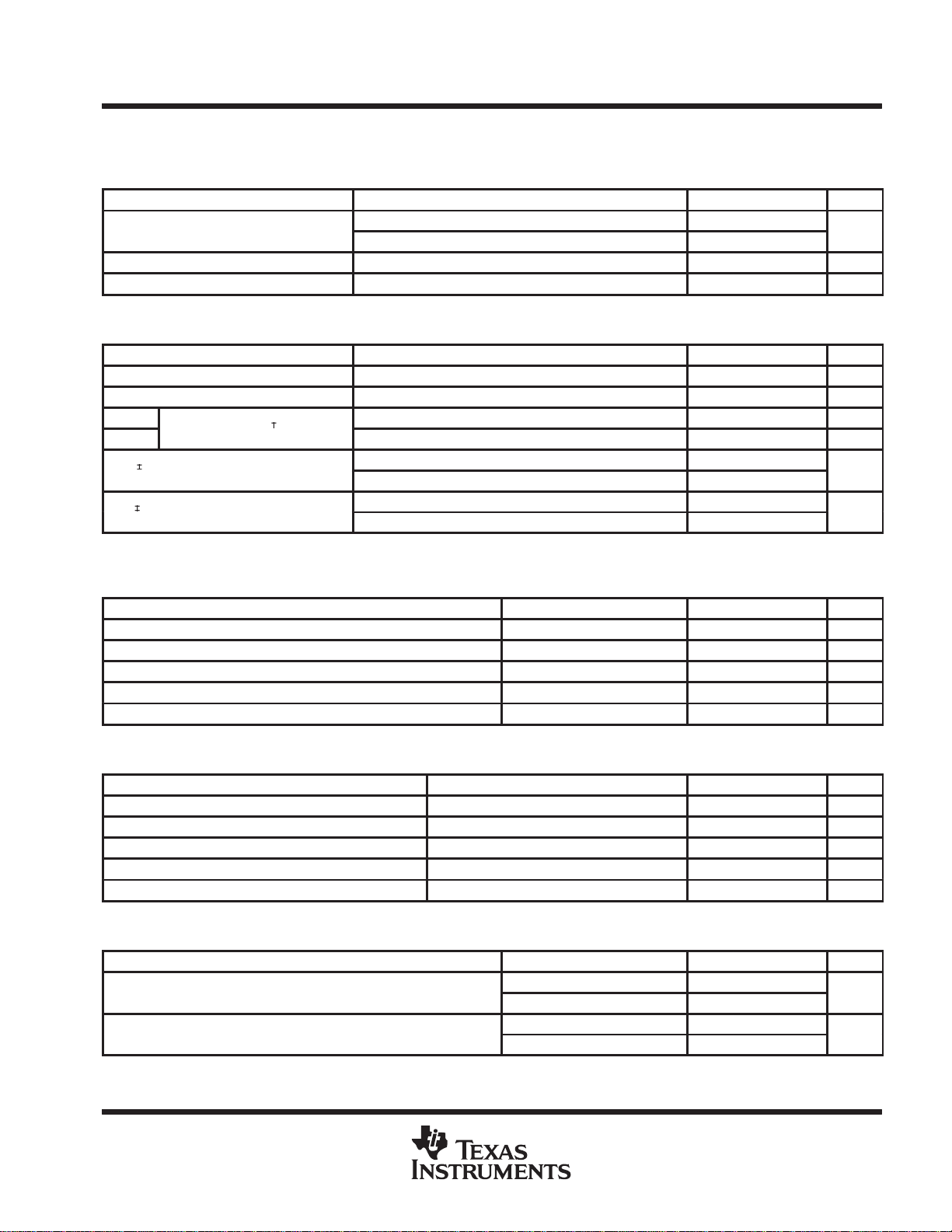

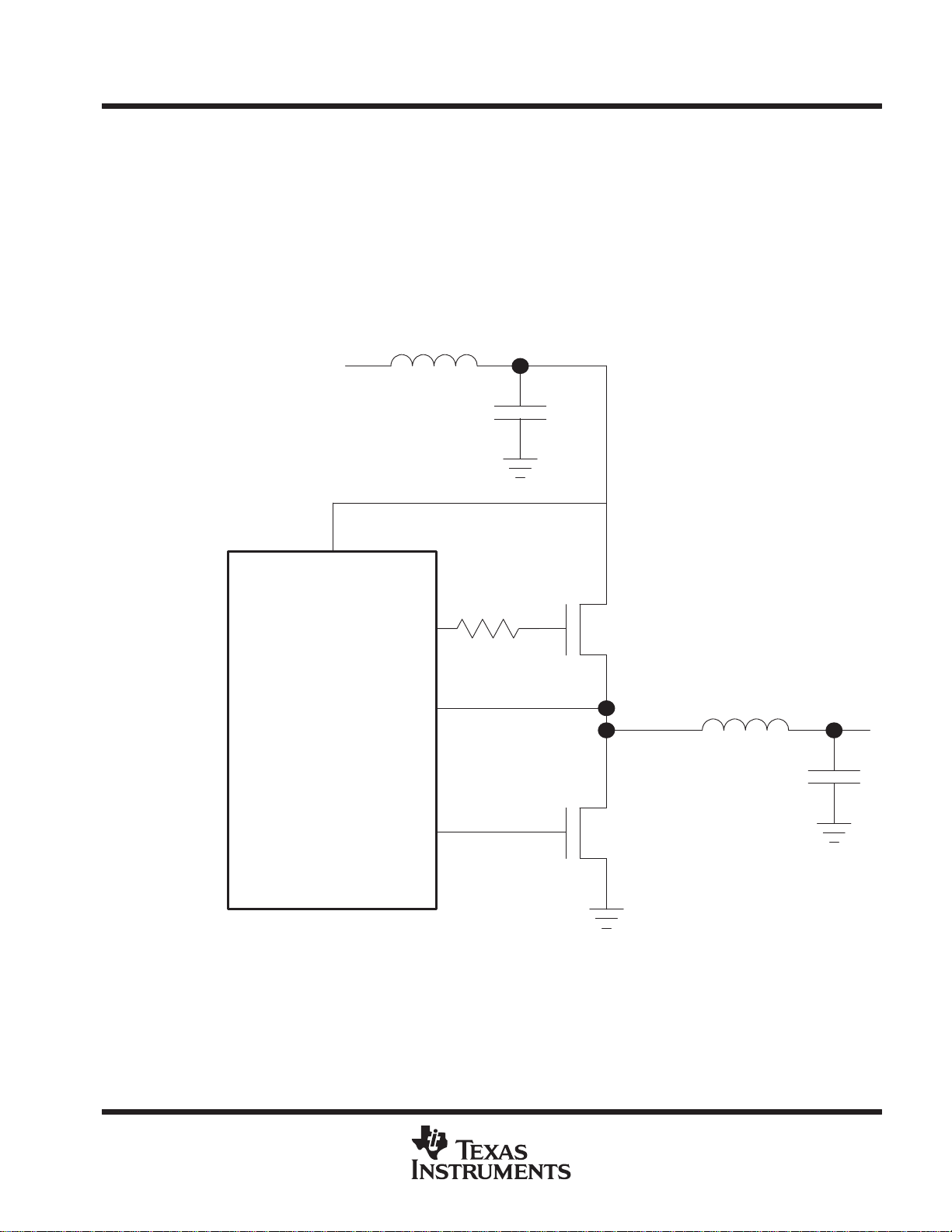

L1

C4

C5

OUTPUT

+

R2

C1

C2

R1

1

2

3

4

5

6

7

8

9

10

TPS5103

SOFTSTART

INV

FB

CT

RT

GND

REF

COMP

PWM/SKIP

STBY

U1

OUTU

OUTD

OUTGND

VCCSENSE

VREF5

VREG5V_IN

LH

LL

TRIP

VCC

5 V

D1

20

19

18

17

16

15

14

13

12

11

C3

R3

R4

Q1

Q2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

TI is a trademark of Texas Instruments Incorporated.

PRODUCT PREVIEW information concerns products in the formative or

design phase of development. Characteristic data and other

specifications are design goals. Texas Instruments reserves the right to

change or discontinue these products without notice.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 1. Typical Design

Copyright 1999, Texas Instruments Incorporated

1

TPS5103

T

°C

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

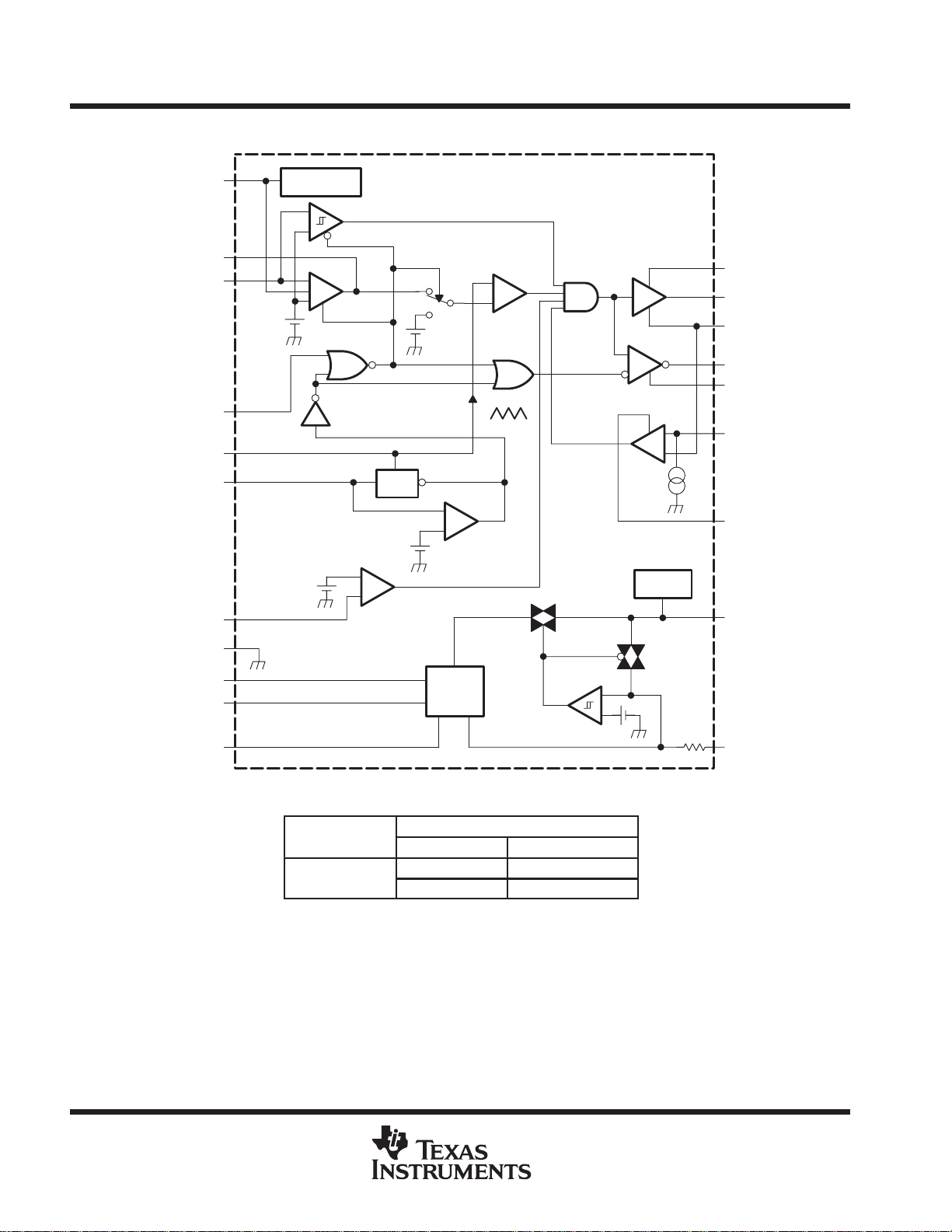

functional block diagram

SOFT START

FB

INV

PWMSKIP

C

R

Comp

T

T

1.185 V

Soft Start

1.185 V

_

+

_

+

Error Amp

PWM Comp.

_

+

One Shot ON

_

+

OSC

_

+

Disable

_

+

UVLO

LH

OUT_u

LL

OUT_d

OUTGND

TRIP

VCC_SENSE

VREF5

GND

V

CC

STBY

REF

1.185 V

°

–40 °C to 85

VREF

AVAILABLE OPTIONS

A

°

SSOP(DB) EVM

TPS5103IDB TPS5103EVM–136

TPS5103IDBR

PACKAGE

_

+

VREG5V_IN

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

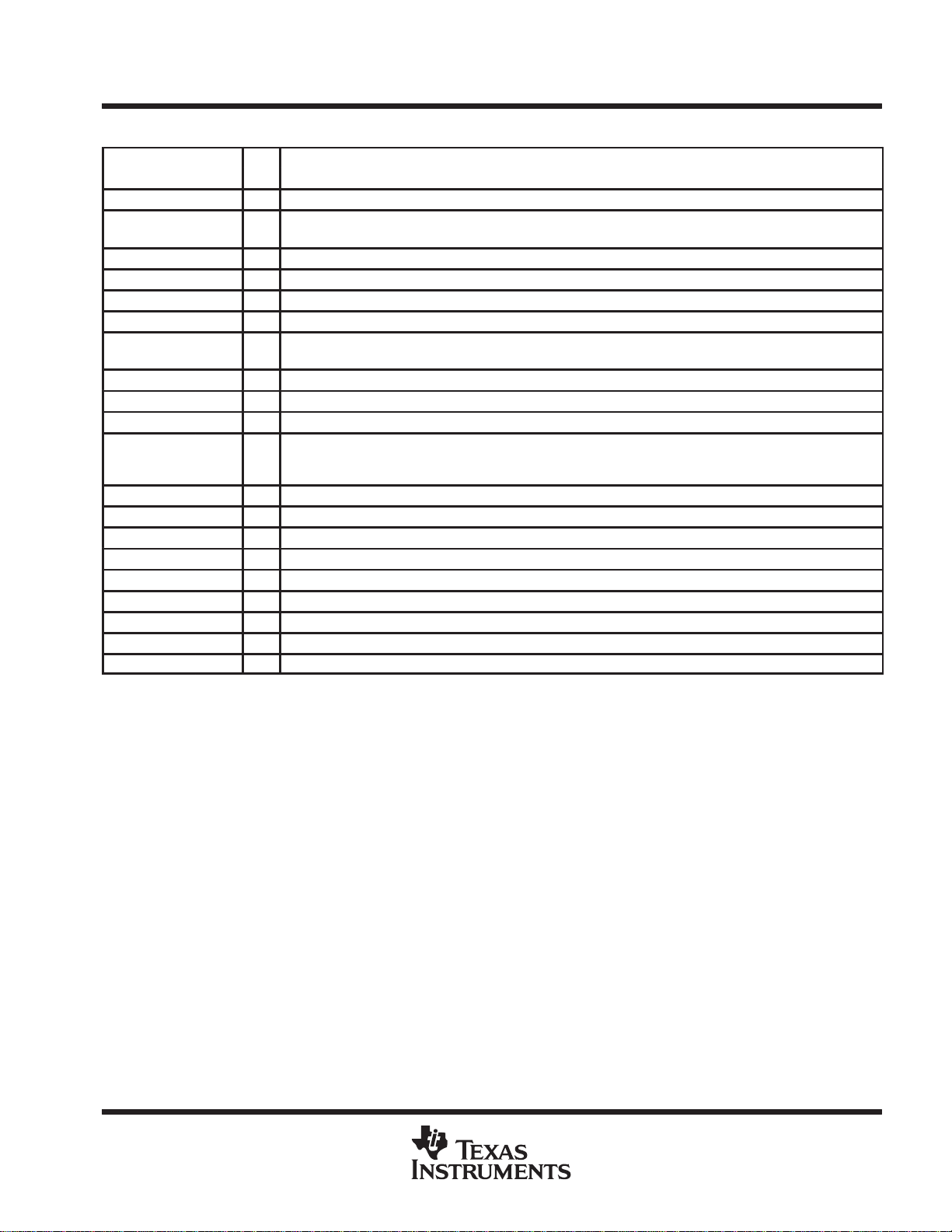

I/O

DESCRIPTION

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

Terminal Functions

TERMINAL

NAME NO.

COMP 8 I Comparator input for voltage monitor

C

T

FB 3 O Feedback output of error amp

GND 6 Control GND

INV 2 I Inverting input of both error amp and hysteretic comparator

LH 20 I/O Bootstrap. Connect 1 µF low-ESR capacitor from LH to LL.

LL 18 I/O

OUT_d 17 I/O Gate-drive output for low-side power switching FET s

OUTGND 16 Ground for FET drivers

OUT_u 19 O Gate-drive output for high-side power switching FET s

PWMSKIP 9 I

REF 7 O 1.185-V reference voltage output

R

T

SOFTSTAR T 1 I External capacitor from SOFTST ART to GND for soft start control

STBY 10 I Standby control

TRIP 15 I External resistor connection for output current control

V

CC

VCC_SENSE 14 I Supply voltage sense for current protection

VREF5 12 O 5-V-internal regulator output

VREG5V_IN 11 I External 5-V input (input voltage range = 4.5 V to 25 V)

4 I/O

5 I/O External resistor connection for adjusting the triangle oscillator.

13 I Supply voltage input

External capacitor from CT to GND for adjusting the triangle oscillator and decreasing the current limiting

voltage

Bootstrap low. High side gate driving return and output current protection. Connect to the junction of the high

side and low side FETs for floating drive configuration.

PWM/SKIP mode select

L:PWM mode

H:SKIP mode

TPS5103

SLVS240 – SEPTEMBER 1999

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

detailed description

REF

The reference voltage is used for the output voltage setting and the voltage protection(COMP). The tolerance

is 1.5% typically.

VREF5

An internal linear voltage regulator is used for the high-side driver bootstrap voltage. Since the input voltage

range is from 4.5 V to 25 V, this voltage offers a fixed voltage for the bootstrap voltage so that the design for

the bootstrap is much easier. The tolerance is 6%.

hysteretic comparator

The hysteretic comparator is used to regulate the output voltage of the synchronous-buck converter. The

hysteresis is set internally and is typically 9.7 mV. The total delay time from the comparator input to the driver

output is typically 400 ns for going both high and low.

error amplifier

The error amplifier is used to sense the output voltage of the synchronous buck converter. The negative input

of the error amplifier is connected to the Vref voltage(1.185 V) with a resistive divider network. The output of

the error amplifier is brought out to the FB terminal to be used for loop gain compensation.

low-side driver

The low-side driver is designed to drive low-Rds(on) n-channel MOSFETs. The maximum drive voltage is 5 V

from VREF5. The current rating of driver is typically 1.2 A at sink current, –1.5 A at source current.

high-side driver

The high-side driver is designed to drive low-Rds(on) n-channel MOSFETs. The current rating of the driver is

1.2 A at sink current, –1.7 A at source current. When configured as a floating driver, the bias voltage to the driver

is developed from the VREF5, limiting the maximum drive voltage between OUT_u and LL to 5 V . The maximum

voltage that can be applied between LH and OUTGND is 30 V.

driver deadtime control

The deadtime control prevents shoot-through current from flowing through the main power FETs. During

switching transitions the

deadtime from the low-side-driver-off to the high-side-driver-on is 90 ns, and 110 ns from high-side-driver-off

to low-side-driver-on.

COMP

COMP is designed for use with a regulation output monitor. COMP also functions as an internal comparator

used for any voltage protection such as the input under voltage protection. If the input voltage is lower than the

setpoint, the comparator turns off and prevents external parts from damage. The investing terminal of the

comparator is internally connected to REF(1.185 V).

current protection

Current protection is achieved by sensing the high-side power MOSFET drain-to-source voltage drop during

on-time through VCC_SENSE and LL terminals. An external resistor between Vin and TRIP terminal with the

internal current source connected to the current comparator negative input adjusts the current limit. The typical

internal current source value is 15 µA in PWM mode, 5 µA in SKIP mode. When the voltage on the positive

terminal is lower than the negative terminal, the current comparator turns on the trigger, and then activates the

oscillator. This oscillator repeatedly reset the trigger until the over current condition is removed. The capacitor

on the C

terminal can be open or added to adjust the reset frequency.

T

deadtime control actively controls the turnon time of the MOSFET drivers. The typical

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

detailed description (continued)

softstart

SOFTST ART sets the sequencing of the output for any possibility. The capacitor value for a start-up time can

be calculated by the following equation: C = 2xT (uF) where C is the external capacitor value, T is the required

start-up time in (ms).

standby

This controller can be switched into standby mode by grounding the STBY terminal. When it is in standby mode,

the quiescent current is less than 1.0 uA.

UVLO

The under-voltage-lock-out (ULVO) threshold is approximately 3.8 V. The typical hysteresis is 55 mV.

5-V Switch

5-V Switch if the internal 5-V switch senses a 5-V input from REG5V terminal, the internal 5-V linear regulator

will be disconnected from the MOSFET drivers. The external 5 V will be used for both the low-side driver and

the high-side bootstrap, thus increasing the efficiency.

PWM/SKIP switch

TPS5103

The PWM/SKIP switch selects the output operating mode. This controller has three operational modes, PWM,

SKIP, and Hysteretic. The PWM and SKIP mode control should be used for slower transient applications.

oscillator

The oscillator gives a triangle wave by connecting an external resistor to the R

terminal and an external

T

capacitor to the CT terminal. The voltage amplitude is 0.43 V ~ 1.17 V. This wave is connected to the noninverting input of the PWM comparator.

Comparison Table Between PWM Mode and Hysteretic Mode

MODE PWM HYSTERETIC

Frequency Fixed Not Fixed

Transient Response Normal Very fast

Feed back compensation Need Needless

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TPS5103

VIInput voltage

V

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

Supply voltage, VCC (see Note 1) –0.3 V to 27 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, VI, INV, CT, RT, PWM/SKIP, SOFTSTART, COMP –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, VREG5V_IN –0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, STBY –0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, TRIP, VCC_SENSE –0.3 V to 27 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, I

3 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

Low level output voltage, VOL –0.3 V to 27 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High level output voltage, V

Reference voltage, V

–0.3 V to 3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ref

–0.3 V to 32 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OH

Operating free-air temperature range, TA –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, TJ –125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to the network ground terminal.

2. See Dissipation Rating Table for free-air temperature range above 25°C.

PACKAGE

DB 801 mW 6.408mW/ °C 416 mW

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

DISSIPATION RATING TABLE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 85°C

POWER RATING

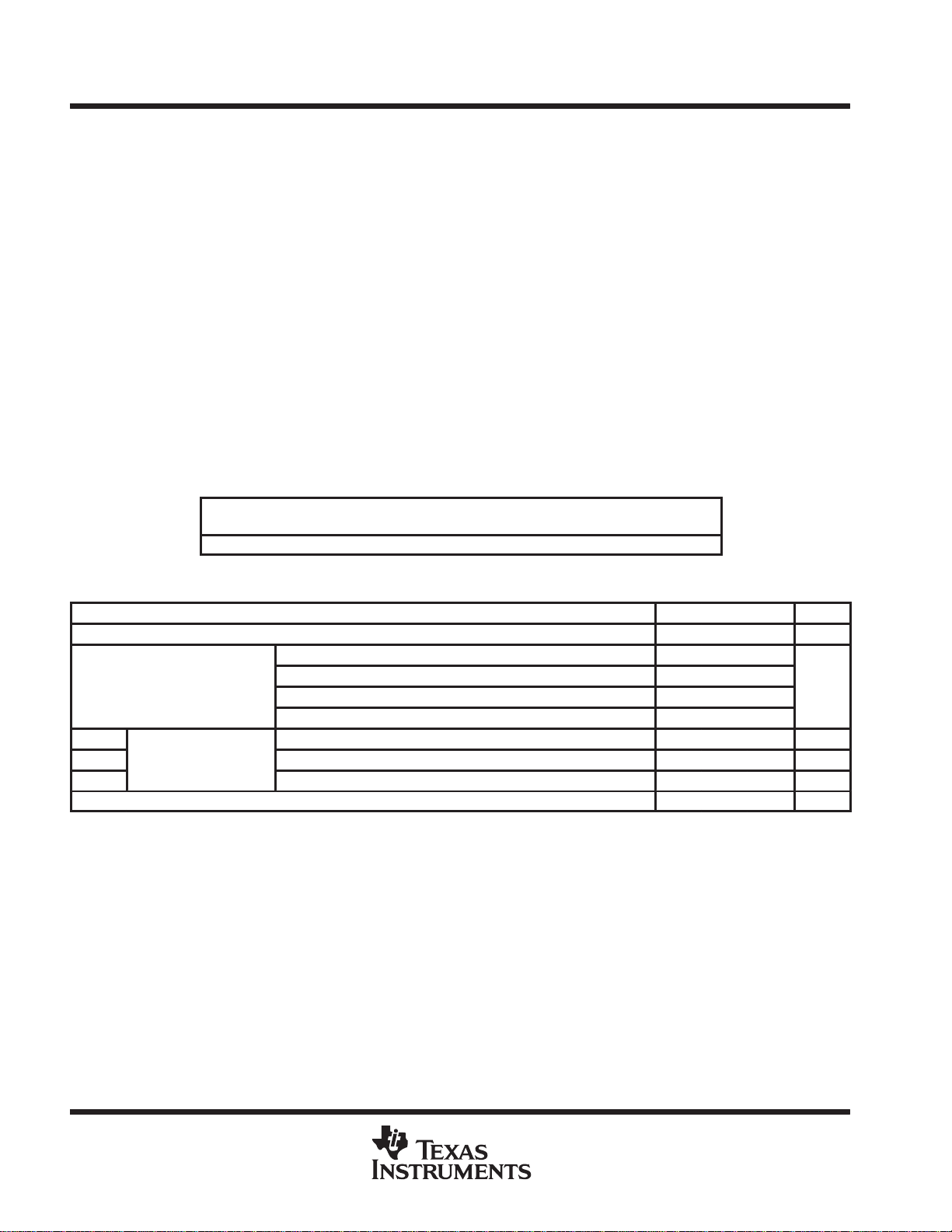

recommended operating conditions

MIN NOM MAX UNIT

V

CC

R

T

C

T

f Frequency 200 kHz

T

A

‡

Not a JEDEC symbol.

Supply voltage 4.5 25 V

INV, CT, RT, COMP, PWM_SKIP, SOFTSTART 6

p

‡

‡

Oscillator frequency

Operating temperature range –40 85 °C

VREG5V_IN 5.5

STBY 12

TRIP, VCC_SENCE 25

Timing register 82 kΩ

Timing capacitor 100 pF

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

V

Reference voltage

V

Frequency change

†

V

‡

High-level output voltage

V

V

‡

Low-level output voltage

V

V

High-level input voltage

V

V

Low-level input voltage

V

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

electrical characteristics over recommended operating free-air temperature range, VCC = 7 V

(unless otherwise noted)

reference voltage

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ref

Regin Line regulation

Regl Load regulation

†

Not a JEDEC symbol.

†

†

TA = 25°C, I

= 50 µA

‡

I

vref

VCC = 4.5 V to 25 V, I = 50 µA 0.2 12 mV

I = 1 µA to 1 mA 0.5 10 mV

oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f Frequency PWM mode 500 kHz

R

T

fdv

fdt

HL

LL

†

Not a JEDEC symbol.

‡

The output voltages of oscillator (f = 200 kHz) are ensured by design.

Timing resistor 47 kΩ

VCC = 4.5 V to 25 V 0.1%

TA = –40°C to 85°C 2%

p

p

DC includes internal comparator error 1 1.1 1.2

f = 200 kHz, includes internal comparator error 1.17

DC includes internal comparator error 0.4 0.5 0.6

f = 200 kHz, includes internal comparator error 0.43

= 50 µA 1.167 1.185 1.203

vref

1.155 1.215

error amp

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V Input offset voltage TA = 25°C 2 10 mV

Av Open-loop voltage gain

GB Unity-gain bandwidth

I

O

I

S

†

Not a JEDEC symbol.

Output sink current VO = 0.4 V 30 45 µA

Output source current VO = 1 V 300 µA

hysteresis comparator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

hsy

Vp-VSOffset voltage 2 mV

I Bias current 10 pA

t

PHL

t

PLH

§

The numbers in the table include the driver delay. All numbers are ensured by design.

Hysteresis window Hysteretic mode 6 9.7 13 mV

Propagation delay from INV to OUT_U TTL input signal 230 ns

†

†

50 dB

0.8 MHz

§

10 mV overdrive on hysteresis band signal 400 ns

control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

IHA

ILA

p

p

STBY 2.5

PWM_SKIP 2

STBY 0.5

PWM_SKIP 0.5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TPS5103

Threshold voltage

†

V

Threshold voltage

†

V

I

TRIP terminal current

A

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

electrical characteristics over recommended operating free-air temperature range, VCC = 7 V

(unless otherwise noted) (continued)

5-V regulator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

O

Regin Line regulation

Regl Load regulation

I

OS

†

Not a JEDEC symbol.

5-V switch

V

IT(high)

V

IT(low)

V

hsy

†

Not a JEDEC symbol.

UVLO

V

IT(high)

V

IT(low)

V

hys

†

Not a JEDEC symbol.

Output voltage I = 10 mA 4.7 5.3 V

†

†

Short-circuit output current V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Hysteresis) 50 150 250 mV

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Hysteresis 10 150 mV

VCC = 5.5 V to 25 V, I = 10 mA 20 mV

I = 1 mA to 10 mA, VCC = 5.5 V 40 mV

= 0 V 70 mA

ref

4.2 4.9

4.1 4.8

3.6 4.2

3.5 4.1

output

I

O

I

S

I

O

I

S

t

r

t

f

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

OUT_u sink curent VO = 3 V 0.5 1.2 A

OUT_u source current VO = 2 V –1 –1.7 A

OUT_d sink current VO = 3 V 0.5 1.2 A

OUT_d source current VO = 2 V –1 –1.5 A

PWM mode, VTRIP = 7 V 10 15 20

SKIP mode, VTRIP = 7 V 3 5 7

High side driver is GND referenced.

Input: INV = 0 – 3V

Rise time

Fall time

tr/tf = 10 ns,

CL = 2200 pF 28

CL = 3300 pF 39

High side driver is GND referenced.

Input: INV = 0 – 3 V

tr/tf = 10 ns,

CL = 2200 pF 30

CL = 3300 pF 38

Frequency = 200 kHz

Frequency = 200 kHz

µ

ns

ns

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

†

V

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

electrical characteristics over recommended operating free-air temperature range, VCC = 7 V

(unless otherwise noted) (continued)

softstart

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

(CTRL)

V

IT(high)

V

IT(low)

†

Not a JEDEC symbol.

output voltage monitor

V

IT

driver deadtime section

T

DRVLH

T

DRVHL

whole device

I

CC

I Shutdown current STBY = 0 V 0.01 10 µA

Softstart current 1.9 2.5 3 µA

Threshold voltage (SKIP mode)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Threshold voltage 1.08 1.18 1.28 V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Low-side to high-side 90 ns

High-side to low-side 110 ns

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Supply current 0.5 1.2 mA

3.9

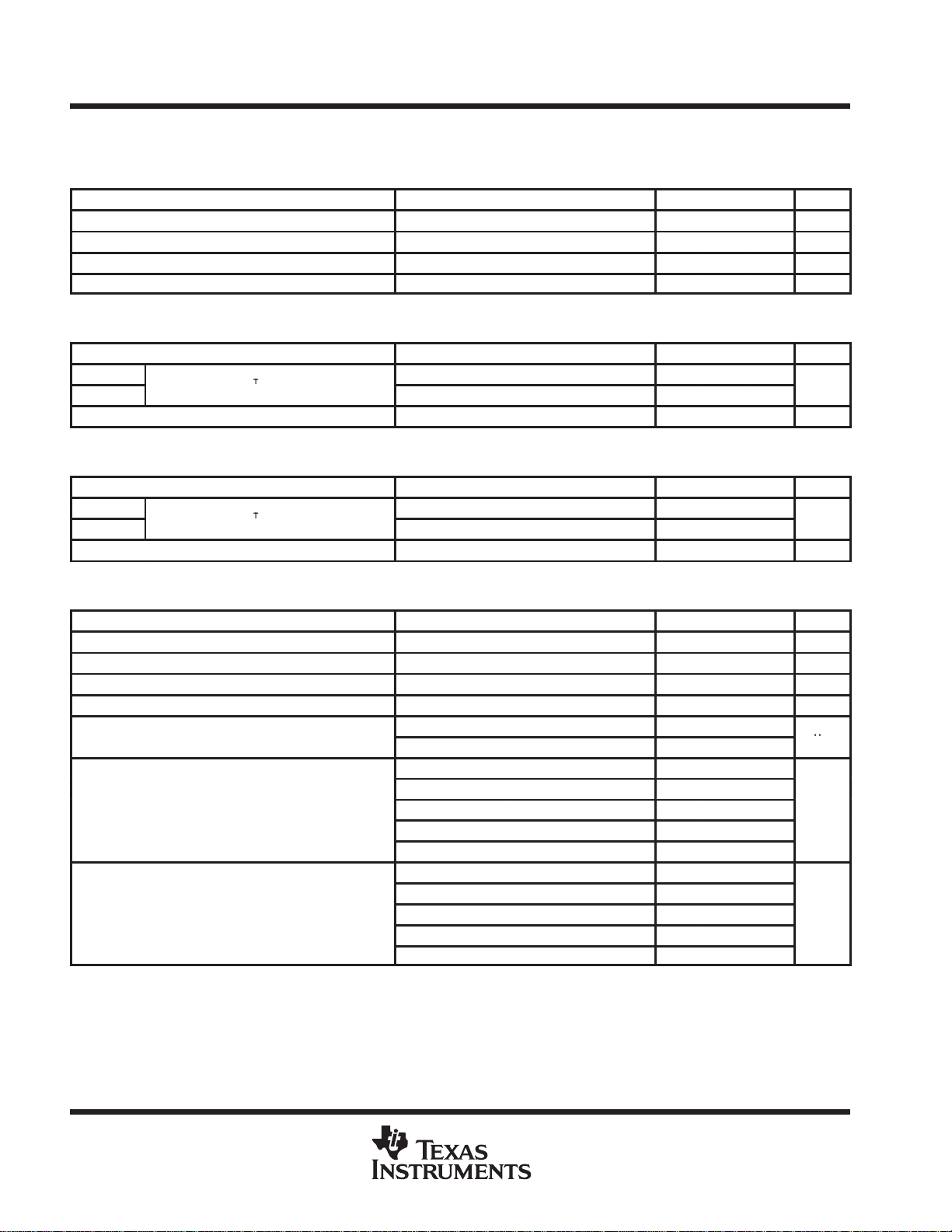

2.6

0.1 µF

5V

SOFTSTART

INV

FB

C

T

R

T

GND

VCC_SENSE

REF

COMP

PWM SKIP

STBY

OUTGND

TRIP

VCC

VREF5

5V_IN

Figure 2. Test Circuit

LH

OUT_u

LL

OUT_d

0.1 µF

7V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

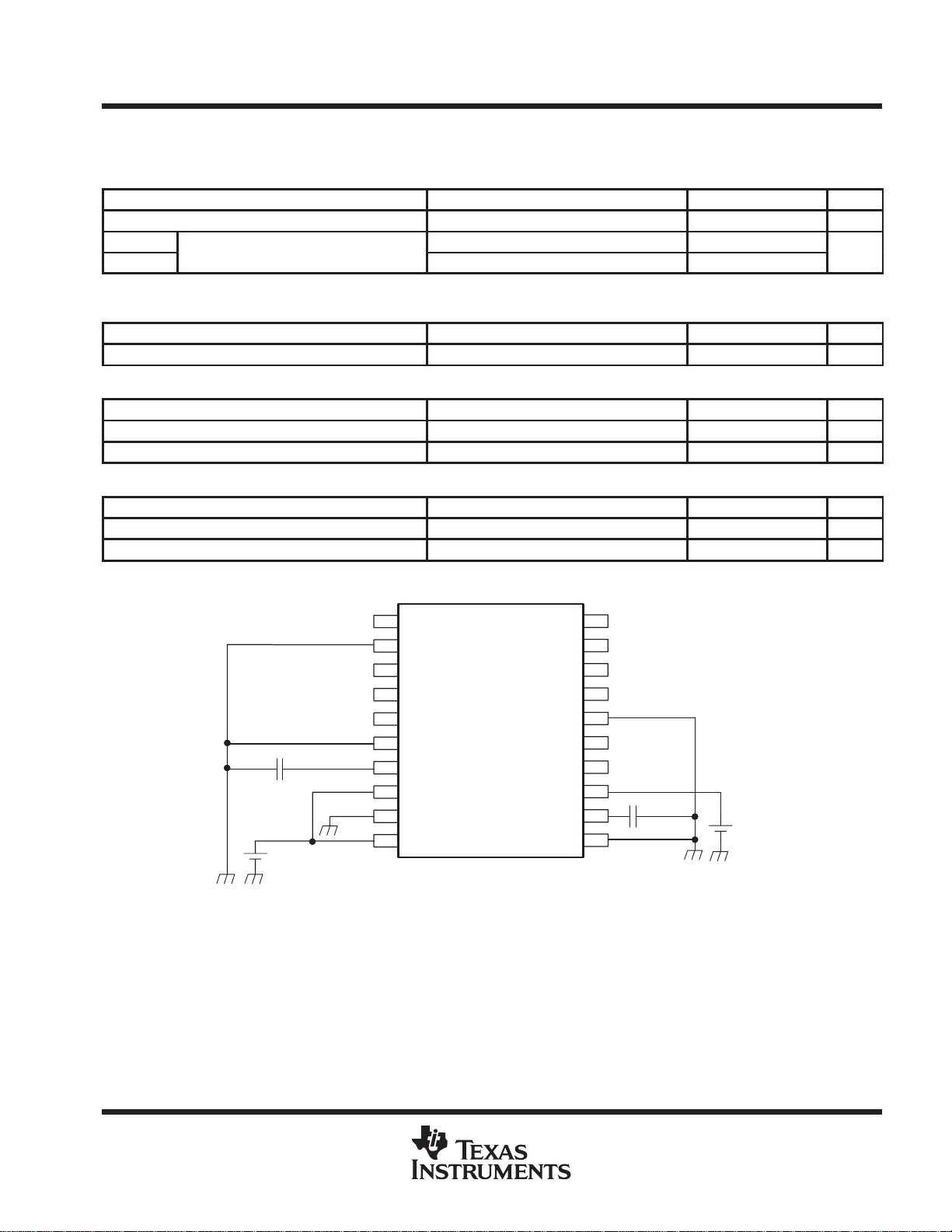

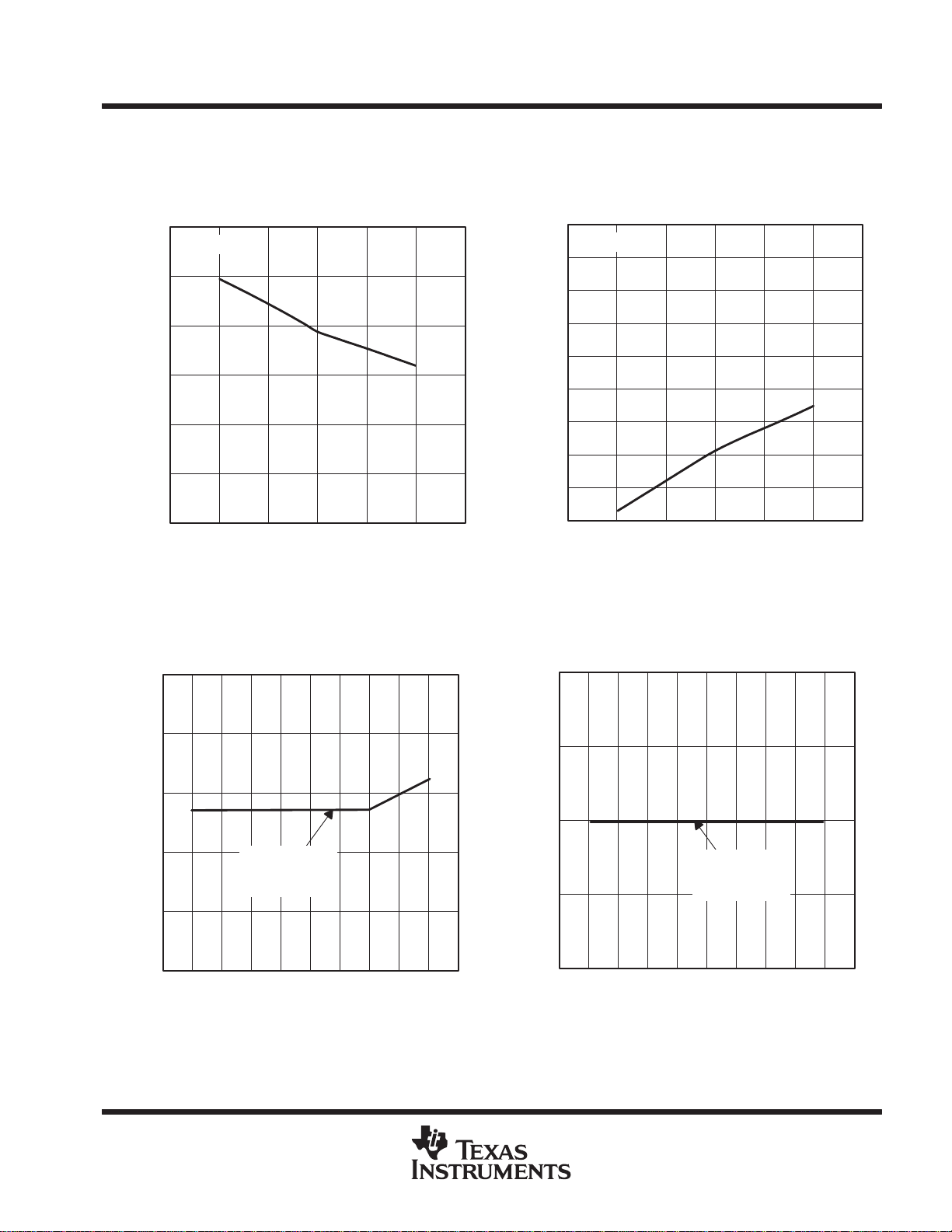

QUIESCENT CURRENT

JUNCTION TEMPERATURE

700

650

Aµ

600

550

500

450

– Quiescent Current –

400

CC

I

350

300

–40 –20 25

TJ – Junction Temperature – °C

DRIVE OUTPUT VOLTAGE

5.5

VCC = 7 V,

TJ = 25°C

5

vs

VCC = 25 V

VCC = 7 V

Figure 3

vs

DRIVE CURRENT

VCC = 4.5 V

85 125

QUIESCENT CURRENT

JUNCTION TEMPERATURE

50

45

Aµ

40

35

30

25

20

– Quiescent Current –

15

CCS

I

10

5

0

–40 –20 25

TJ – Junction Temperature – °C

DRIVE OUTPUT VOLTAGE

3

VCC = 7 V,

TJ = 25°C

2.5

vs

VCC = 25 V

VCC = 7 V

VCC = 4.5 V

85 125

Figure 4

vs

DRIVE CURRENT

10

4.5

– Drive Output Voltage – VV

3.5

(OUT_u)

4

3

0.1 0.7

I

(OUT_source)

– Drive Source Current – A

Figure 5

2

1.5

1

– Drive Output Voltage – VV

(OUT_u)

0.5

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0

0.1 0.7

I

(OUT_sink)

– Drive Source Current – A

Figure 6

1

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

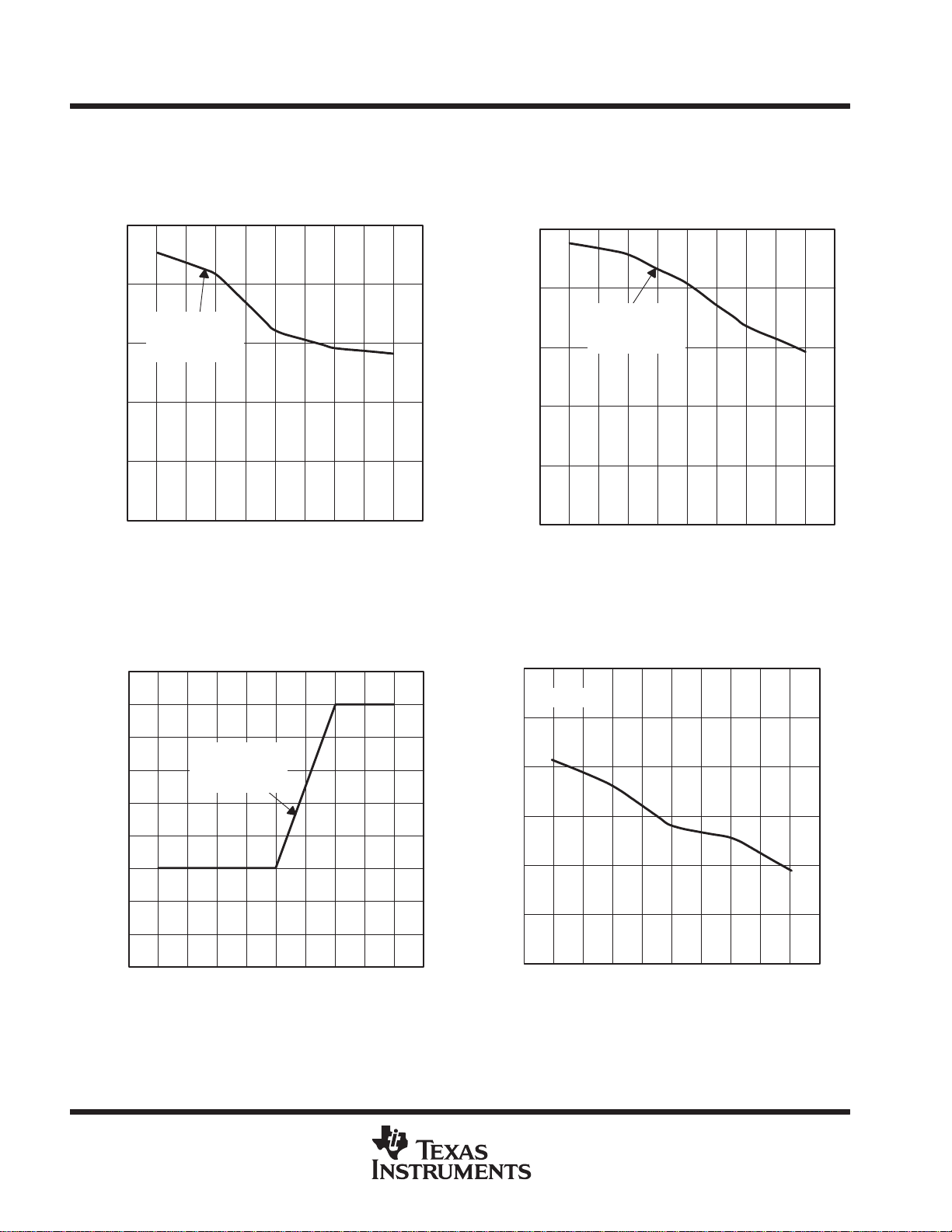

TYPICAL CHARACTERISTICS

– Drive Output Voltage – VV

(OUT_d)

1.125

DRIVE OUTPUT VOLTAGE

vs

DRIVE CURRENT

6

TJ = 25°C

5

4

3

2

1

0

0.1 0.7

I

(OUT_source)

– Drive Source Current – A

Figure 7

OSCILLATOR OUTPUT VOLTAGE

vs

JUNCTION TEMPERATURE

DRIVE OUTPUT VOLTAGE

vs

DRIVE CURRENT

4.5

TJ = 25°C

4

3.5

3

2.5

2

– Drive Output Voltage – VV

1.5

1

(OUT_d)

0.5

1

0

0.1 0.7

I

(OUT_sink)

– Drive Source Current – A

1

Figure 8

OSCILLATOR OUTPUT VOLTAGE

vs

JUNCTION TEMPERATURE

500

1.115

1.105

1.095

– Oscillator Output Voltage – V

1.085

(osch)

V

1.075

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

–40 –20 25

TJ – Junction Temperature – °C

Figure 9

85 125

495

490

– Oscillator Output Voltage – V

485

(oscl)

V

480

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

–40 –20 25

TJ – Junction Temperature – °C

Figure 10

85 125

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

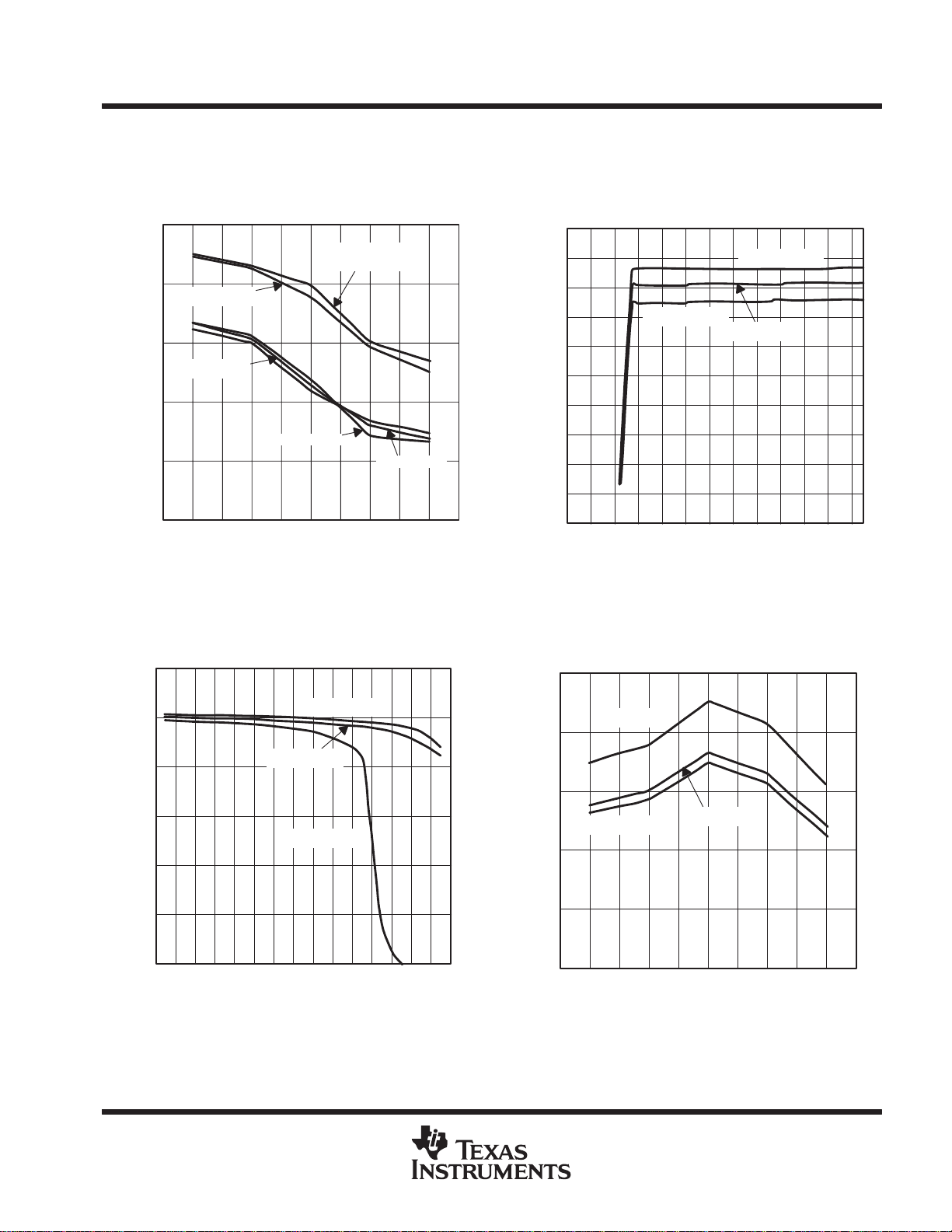

TYPICAL CHARACTERISTICS

ERROR AMPLIFIER INPUT OFFSET VOLTAGE

vs

JUNCTION TEMPERATURE

2.5

2

VCC = 4.5 V,

VCC = 7 V,

1.5

VCC = 25 V

1

0.5

– Error Amplifier Input Offset Voltage – mV

io

V

0

–40 –20 25

TJ – Junction Temperature – °C

85 125

Figure 11

ERROR AMPLIFIER OUTPUT VOLTAGE

vs

JUNCTION TEMPERATURE

6.2

6

5.8

5.6

5.4

5.2

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

ERROR AMPLIFIER OUTPUT VOLTAGE

vs

JUNCTION TEMPERATURE

2.5

2

VCC = 4.5 V,

VCC = 7 V,

1.5

1

– Error Amplifier Output V oltage – mV

0.5

om+

V

0

VCC = 25 V

–40 –20 25

TJ – Junction Temperature – °C

85 125

Figure 12

HYSTERESIS COMPARATOR HYSTERESIS VOLTAGE

vs

JUNCTION TEMPERATURE

10.5

VCC = 7 V

10.25

10

9.75

4.8

– Error Amplifier Output V oltage – mV

om–

4.6

V

4.4

12

5

–40 –20 25

TJ – Junction Temperature – °C

Figure 13

9.5

9.25

– Hysteresis Comparator Hysteresis Voltage – mV

hys

9

85 125

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

V

–40 –20 25 85 125

TJ – Junction Temperature – °C

Figure 14

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

2.5

2

1.5

1

0.5

– Standby Switch Threshold Voltage – V

IL

V

IH,

V

0

6

STANDBY SWITCH THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

VCC = 4.5 V,

VCC = 7 V

VCC = 25 V

VCC = 25 V

VCC = 4.5 V

VCC = 7 V

–45 –25 25

TJ – Junction Temperature – °C

95 135

Figure 15

VREF5 OUTPUT VOLTAGE

vs

OUTPUT CURRENT

VREF5 OUTPUT VOLTAGE

SUPPLY VOLTAGE

5.2

5.1

5

4.9

4.8

4.7

4.6

4.5

– VREF5 Output Voltage – V

O

V

4.4

4.3

4.2

010

TJ = 125°C

VCC – Supply Voltage – V

Figure 16

VREF5 SHORT CURRENT

JUNCTION TEMPERATURE

–100

vs

TJ = –40°C

TJ = 25°C

20

vs

5

4

3

2

– VREF5 Output Voltage – V

O

V

1

0

TJ = 125°C

TJ = 25°C

TJ = –40°C

0 –10 –20 –30 –40

IO – Output Current – mA

Figure 17

–50 –60 –70

VCC = 25 V

–80

–60

VCC = 4.5 V

–40

– VREF5 Short Current – mA

–20

OS

I

0

–40 –20 25

TJ – Junction Temperature – °C

Figure 18

VCC = 7 V

85 125

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

4

3.95

3.90

3.85

3.80

– UVOL Threshold Voltage – V

TLH

V

3.75

THL,

V

3.70

4.80

UVLO THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

V

TLH

V

THL

–40 –20 25

TJ – Junction Temperature – °C

Figure 19

5 VSW THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

85 125

80

70

60

50

40

30

20

– UVLO Hysteresis Voltage – mV

hys

V

10

0

200

UVLO HYSTERESIS VOLTAGE

vs

JUNCTION TEMPERATURE

–40 –20 25

TJ – Junction Temperature – °C

Figure 20

5 VSW HYSTERESIS VOLTAGE

vs

JUNCTION TEMPERATURE

85 125

4.75

4.70

4.65

4.60

4.55

– 5 VSW Threshold Voltage – V

4.50

TLH

4.45

V

THL,

4.40

V

4.35

V

TLH

V

THL

–45 –25 25

TJ – Junction Temperature – °C

Figure 21

95 135

180

160

140

120

100

80

60

– 5V SW Hysteresis Voltage – mV

40

hys

V

20

0

–45 –25 25

TJ – Junction Temperature – °C

Figure 22

95 135

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

JUNCTION TEMPERATURE

–2.45

–2.40

Aµ

–2.35

VCC = 4.5 V

–2.30

– Softstart Current –

CTRL

–2.25

I

–2.20

–40 –20 25

TJ – Junction Temperature – °C

SOFTSTART CURRENT

vs

VCC = 7 V

VCC = 25 V

85 125

Figure 23

4.5

4

3.5

3

2.5

2

1.5

– Softstart Threshold Voltage – V

1

TLH

V

0.5

0

SOFTSTART THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

VCC = 7 V,

VCC = 25 V

–40 –20 25

TJ – Junction Temperature – °C

VCC = 4.5 V

85 125

Figure 24

3.5

3

2.5

2

– Softstart Threshold Voltage – V

1.5

THL

V

1

SOFTSTART THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

VCC = 7 V,

VCC = 25 V

VCC = 4.5 V

–40 –20 25

TJ – Junction Temperature – °C

85 125

Figure 25

1.195

1.193

1.190

1.188

1.185

Threshold Voltage – V

– Output Voltage Monitor Comparator

1.183

TH

V

1.180

OUTPUT VOLTAGE MONITOR COMPARATOR

THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

–40 –20 25

TJ – Junction Temperature – °C

85 125

Figure 26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

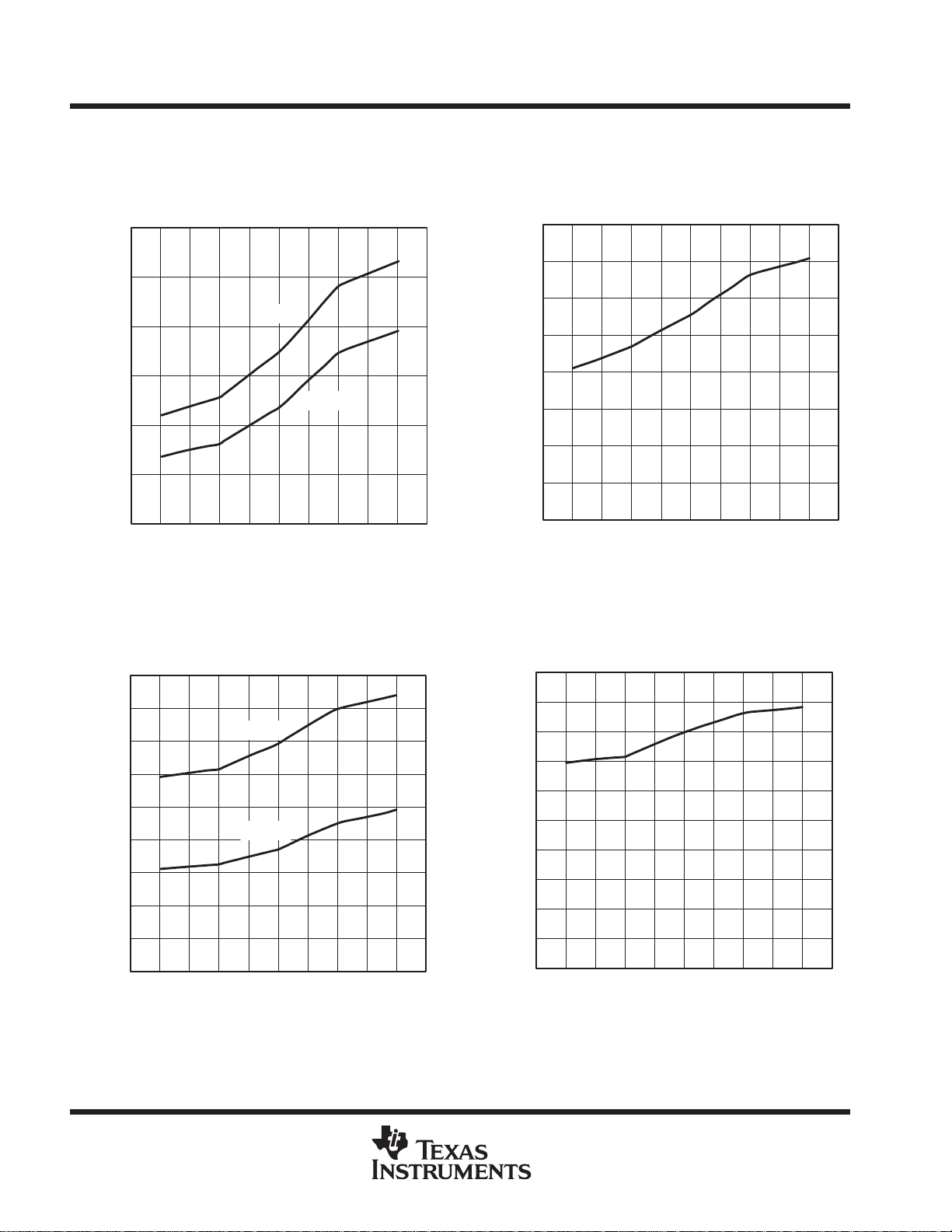

OSCILLATOR FREQUENCY

JUNCTION TEMPERATURE

600

500

400

300

200

– Oscillator Frequency – kHz

osc

F

100

0

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

F = 200 kHz

–40 –20 25

TJ – Junction Temperature – °C

Figure 27

vs

1.6

F = 500 kHz

VCC = 4.5 V,

VCC = 7 V,

VCC = 25 V

85 125

1.4

1.2

1

0.8

0.6

– Oscillator Output Voltahe – V

0.4

OSCL

V

0.2

OSCH,

V

0

10 100

ERROR AMPLIFIER GAIN AND PHASE SHIFT

60

Rs = 100 Ω,

50

40

30

Phase

Rf = 10 kΩ

OSCILLATOR OUTPUT VOLTAGE

vs

FREQUENCY

V

OSCH

V

OSCL

F

– Frequency – kHz

OSC

Figure 28

180

140

100

1000

16

20

10

Error Amplifier Gain – dB

0

–10

–20

1.E+03 1.E+04 1.E+05

Gain

f – Frequency – Hz

Figure 29

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1.E+06 1.E+07

60

Phase Shift – Deg

20

–20

–60

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

MAXIMUM DUTY CYCLE

JUNCTION TEMPERATURE

100

99.5

99

98.5

98

97.5

97

96.5

Maximum Duty Cycle – %

96

95.5

95

–40 –20 25

TJ – Junction Temperature – °C

DRIVER DEAD TIME

JUNCTION TEMPERATURE

140

VCC = 4.5 V

120

T

DRVHL

vs

Figure 30

vs

f = 200 kHz

85 125

SOFTSTART CAPACITANCE

SOFTSTART TIME

4

10

3

10

2

10

– Softstart Capacitance – pF

SS

C

100

0.01 0.1 1

TSS – Soft Start Time – ms

Figure 31

CURRENT PROTECTION SOURCE CURRENT

INPUT VOLTAGE PWM MODE

14.5

Aµ

14.25

vs

10 100

vs

100

80

– Driver Dead Time – ns

60

DRVHL

T

40

DRVLH,

20

T

0

VCC = 7 V,

VCC = 25 V

VCC = 7 V,

VCC = 25 V

–45 –25 25

TJ – Junction Temperature – °C

Figure 32

T

DRVLH

VCC = 4.5 V

95 135

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

14

13.75

13.5

13.25

13

– Corrent Protection Source Current –

12.75

TRIP

I

12.5

4.5 7

TA = 125°C

TA = 25°C

TA = –40°C

V

– Input Voltage – V

TRIP

Figure 33

25

17

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

TYPICAL CHARACTERISTICS

CURRENT PROTECTION SOURCE CURRENT

vs

INPUT VOLTAGE SKIP MODE

4.6

Aµ

TA = 125°C

4.5

4.4

TA = 25°C

4.3

4.2

– Corrent Protection Source Current –

4.1

TRIP

I

4

4.5 7

TA = –40°C

V

– Input Voltage – V

TRIP

Figure 34

OSCILLATOR FREQUENCY

vs

RESISTOR

700

600

500

400

300

CT = 22 pF

CT = 33 pF

25

CT = 10 pF

CT = 15 pF

18

– Oscillator Frequency – kHzF

200

osc

100

0

CT = 470 pF

10 100

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

CT = 680 pF

1000

RT – Resistor – kΩ

Figure 35

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

overshoot of output rectangle wave

The drivers in the TPS5103 controller are fast and can produce high transients on VCC or the junction of Q1 and

Q2(shown below). Care must be taken to insure that these transients do not exceed the absolute maximum

rating for the device or associated external component. A low-ESR capacitor connected directly from Q1 drain

to Q2 source can greatly reduce transient pulses on VCC. Also, Q1 turn-on-speed can be reduced by adding

a resistor (5 – 15 Ω) in series with OUT_u. Poor layout of the switching node (V1 in figure) can result in the

requirement for additional snubber circuitry require from V1 to ground.

C1

TPS5103

V

CC

OUT_u

Q1

V1

Q2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

application for general power

The design shown in this data sheet is a reference design for a general power supply application. An evaluation

module (EVM), TPS5103EVM-136 (SLVP136), is available for customer testing and evaluation. The intent is

to allow a customer to fully evaluate the given design using the plug-in EVM supply shown here. For subsequent

customer board revisions, the EVM design can be copied onto the users PCB to shorten design cycle time,

component count, and board cost.

To help the customers to design the power supply using TPS5103, some key design procedures are shown

below.

R2

R6B

R6A

R7

JP1 JP2

C8

C9

R10

C4

C15

C5

R4

R5

C7

C6

R9

R3

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP18

TP17

TP16

TP15

TP14

TP13

TP12

TP11

D2

R13

C12

C10

C13

R11

R12

C11

TP26

J13

J14

Q2

Q1

C14

C1

+

C2

L1

+

D1

C3

J1

J2

J3

J4

J5

R1

J6

J7

J8

J9

J10

J11

J12

Vi

Vi

Input GND

Input GND

Input GND

SENSE

Vo

Vo

Vo

VoGND

VoGND

VoGND

Figure 36. EVM Schematic

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

output voltage setpoint calculation

The output voltage is set by the reference voltage and the voltage divider. In TPS5102, the reference voltage

is 1.185 V , and the divider is composed of two resistors in the EVM design that are R4 and R5, or R14 and R15.

The equation for the setpoint is:

R1 Vr

R2

+

Vo*Vr

Where R1 is the top resistor (kΩ) like R4 or R15; R2 is the bottom resistor (kΩ) such as R5 or R14; Vo is the

required output voltage (V); Vr is the reference voltage (1.185 V in TPS5103).

Example: R1 = 1 kΩ; Vr = 1.185 V; Vo = 1.8 V, then R2 = 1.9 kΩ.

For your convenience, some of the most popular output voltage setpoints are calculated in the table below:

Vo 1.3 V 1.5 V 1.8 V 2.5 V 3.3 V 5.0 V

R1 (top) (kΩ) 1 1 1 1 1 1

R2 (bottom) (kΩ) 10 3.7 1.9 0.9 0.56 0.31

If higher precision resistor is used, the output voltage setpoint can be more accurate.

TPS5103

In some applications, the output voltage is required to be lower than the reference voltage. With few extra

components, the lower voltage can be easily achieved. The drawing below shows the method.

R

Zener

z1

V

CC

V

O

R

(top)

R

(bottom)

INV

TPS5103

R

z2

In the schematic, the Rz1, Rz1, and the zener are the extra components. Rz1 is used to give zener enough

current to build up the zener voltage. The zener voltage is added to INV through Rz2. Therefore, the voltage

on INV is still equal to the IC internal voltage (1.185 V) even if the output voltage is regulated at lower setpoint.

The equation for setting up the output voltage is shown below:

Rz2

+

ǒ

Vr–Vo

Rtop

(

Vz–Vr

Ǔ

)

)

Vr

Rbtm

Where Rz2 is the adjusting resistor for low output voltage; Vz is the zener voltage; Vr is the internal reference

voltage; Rtop is the top resistor of voltage sensing network; Rbtm is the bottom resistor of the sensing network;

Vo is the required output voltage setpoint.

Example: Assuming the required output voltage setpoint is Vo = 0.8 V, Vz = 5 V; Rtop = 1 kΩ; Rbottom = 1 kΩ,

then the Rz2 = 2.43 kΩ.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

switching frequency

With hysteretic control, the switching frequency is a function of the input voltage, the output voltage, the

hysteresis window, the delay of the hysteresis comparator and the driver , the output inductance, the resistance

in the output inductor, the output capacitance, the ESR and ESL in the output capacitor , the output current, and

the turnon resistance of high side and low side MOSFET . It is a very complex equation if everything is included.

To make it more useful to the designers, a simplified equation only considers the most influential factors. The

tolerance of this equation is about 30%:

*

7

)

Td)ńC

*

out

)

out

ESL Vin)

ƒs

+

Vin

V

out

(Vin

(V

*

V

in

out

ESR (10 10

) (ESR*(10 10

*

7

)

Td))0.0097 L

Where fs is the switching frequency (Hz);

output capacitance;

series inductance in the output capacitor (H);

time constant (S).

In the EVM module design, for the 1.8 V output, for example: Vin = 5 V, Vout = 1.8 V, Cout = 680 µF; ESR =

40 mΩ; ESL = 3 nH; Lout = 6 µH; Td = 0.5 µs.

Then, the frequency

ESR

is the equivalent series resistance in the output capacitor (Ω);

fs = 122 kHz.

Vout

is the output voltage (V);

Lout

is the output inductance (H);

Vin

is the input voltage (V);

ESL

Td

is output feedback RC filter

is the equivalent

output inductor ripple current

The output inductor current ripple can affect not only the efficiency and the inductor saturation, but also the

output voltage capacitor selection. The equation is exhibited as below:

Iripple

Where

the

cycle; and Ts is the switching cycle (S). From the equation, it can be seen that the current ripple can be adjusted

by changing the output inductor value.

Example: Vin = 5 V; Vout = 1.8 V; Iout = 5 A; Rdson = 10 mΩ; RL = 5 mΩ; D = 0.36; Ts = 10 µS; Lout = 6 µH

Then, the ripple Iripple = 2 A.

Iripple

output voltage (V);

Vin*Vout*Iout

+

is the peak-to-peak ripple current (A) through inductor;

Iout

is the output current;

Lout

(

Rdson)RL

)

D

Rdson

Ts

Vin

is the input voltage (V);

is the on-time resistance of MOSFET (Ω); D is the duty

Cout

is the

Vout

is

output capacitor RMS current

Assuming the inductor ripple current totally goes through the output capacitor to the ground, the RMS current

in the output capacitor can be calculated as:

D

Io(rms)

Where

current (A).

Example: ∆I = 2 A, so Io(rms) = 0.58 A

22

I(orms)

I

+

Ǹ

12

is the maximum RMS current in the output capacitor (A); ∆I is the peak-to-peak inductor ripple

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

input capacitor RMS current

Assuming the input ripple current totally goes into the input capacitor to the power ground, the RMS current in

the input capacitor can be calculated as:

TPS5103

2

Ii(rms)

Where

From the equation, it can be seen that the highest input RMS current usually occurs at the lowest input voltage,

so it is the worst case design for input capacitor ripple current.

Ii(rms)

Ǹ

+

I

D (1*D))

o

is the input RMS current in the input capacitor (A); Io is the output current (A); D is the duty cycle.

1

12

D

Iripple

2

Example: Io = 5 A; D = 0.36

Then, Ii(rms)= 3.36 A

softstart

The softstart timing can be adjusted by selecting the soft-start capacitor value. The equation is

C

+2

soft

Where

Example: Tsoft = 5 mS, so Csoft = 0.01 µF.

C

soft

T

soft

is the softstart capacitance (µF); T

is the start-up time on softstart terminal (S).

soft

current protection

The current protection in TPS5103 is set using an internal current source and an external resistor to set up the

current limit. The sensed high side MOSFET drain-to-source voltage drop is compared to the set point, if the

voltage drop exceeds the limit, the internal oscillator is activated, and it continuously resets the current limit until

the over-current condition is removed. The equation below should be used for calculating the external resistor

value for current protection:

Rds(on) (Itrip)Iind(p-p)ń2)

Rcl

PWM or HYS mode

SKIP mode

Where Rcl is the external current limit resistor (R10,R1 1); Rds(on) is the high side MOSFET on-time resistance.

Itrip is the required current limit; Iind(p-p) is the peak-to-peak output inductor current.

Example: PWM mode or HYS mode

Rds(on) = 10 mΩ, Itrip =5 A, Iind = 2 A, so Rcl = 4 kΩ

Example: SKIP mode

Rds(on) = 10 mΩ, Itrip = 2 A, Iind = 1 A, so Rcl = 5 kΩ

+

Rds(on) (Itrip)Iind(p-p)ń2)

Rcl

+

0.000015

0.000005

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

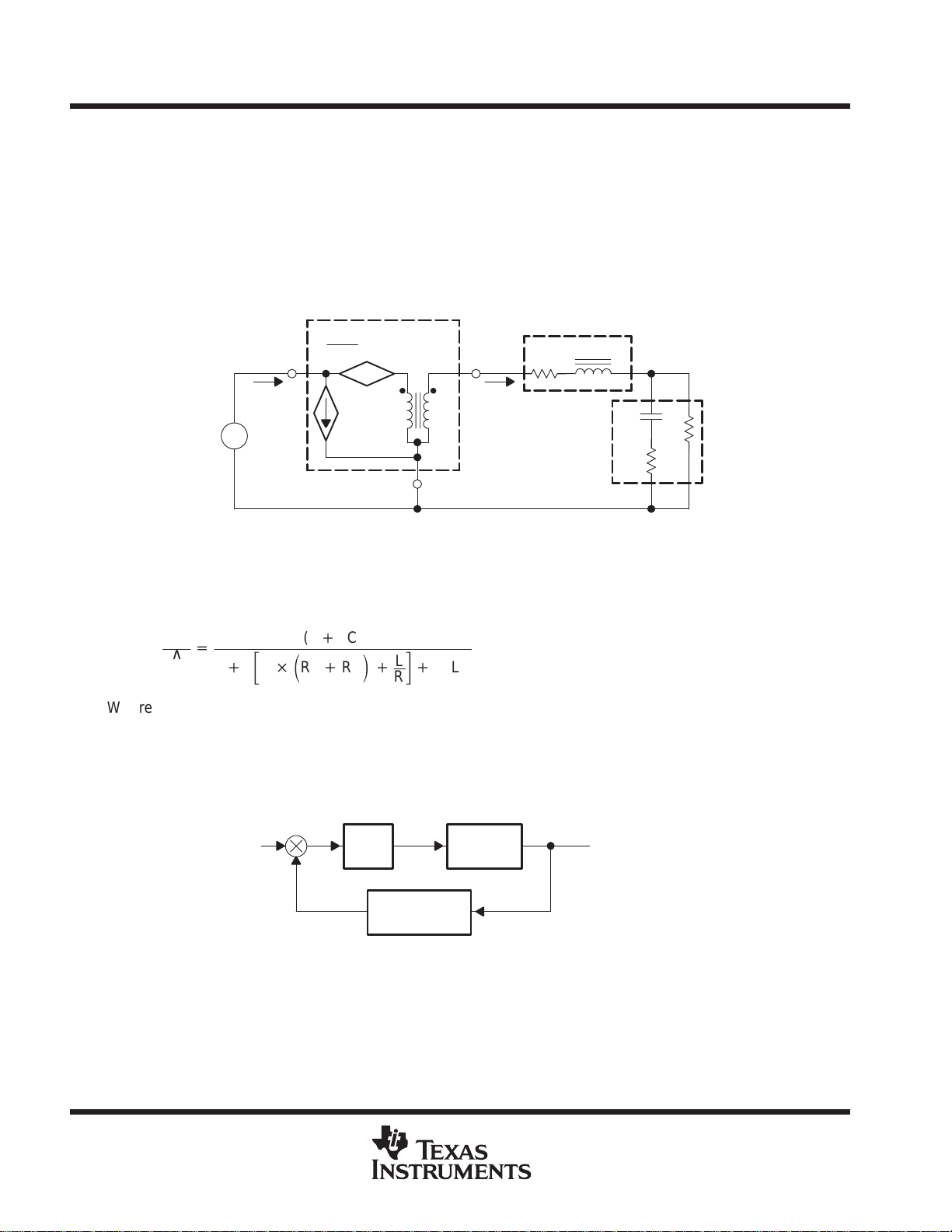

loop gain compensation

Voltage mode control is used in this controller for the output voltage regulation. To achieve fast, stabilized

control, two parts are discussed in this section: the power stage small signal modeling and the compensation

circuit design.

For the buck converter, the small signal modeling circuit is shown below:

Z

∧

V

ap

d

ac

i

a

+

V

I

D

Ic d

+

–

i

1

∧

D

p

c

L

R

L

L

C

Z

RC

R

C

V

O

R

From this equivalent circuit, several control transfer functions can be derived: input-to-output, output

impedance, and control-to-output. Typically the control-to-output transfer function is used for the feedback

control design.

Assuming Rc and RL are much smaller than R, the simplified small signal control-to-output transfer function is:

∧

Vod

∧

d

+

1)sƪC

(

1)sCRc

ǒRc)R

)

L

Ǔ

ƫ

)

)

L

s2LC

R

Where C is the output capacitance; Rc is the equivalent serial resistance (ESR) in the output capacitor; L is the

output inductor; RL is the equivalent serial resistance (ESR) in the output inductor; R is the load resistance.

T o achieve the fast transient response and the better output voltage regulation, a compensation circuit is added

to improve the feedback control. The whole system is shown below:

V

ref

PWM

Compensation

Power

Stage

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

The typical compensation circuit used as an option in the EVM design is a part of the output feedback circuit.

The circuitry is displayed below.

TPS5103

C3

R4

C2

_

+

C1

R3

R2R1

V

ref

This circuit is composed of one integrator, two poles, and two zeros:

Assuming R1 << R2 and C2 << C3, the equation is:

Comp

(

1)sC3R4) (1)sC2R2

+

sC3R2(1)sC2R4)(1)sC1R1

)

)

Therefore,

Pole1

+

Zero2

+

Integrator

1

2pC1R1

1

2pC3R4

+

2pƒC3R2

Pole2

Zero1

1

+

2pC2R4

+

2pC2R2

1

1

To PWM

A simplified version used in the EVM design is exhibited below.

Vo

R2

R3

V

ref

C3

R4

C2

_

+

Assuming C2 << C3, the equation is:

Comp

(

+

1)sC3R4

sC3R2(1)sC2R4

)

)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

25

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

there is one pole, one zero and one integrator:

Zero

+

2pC3R4

1

Pole

+

2pC2R4

1

Integrator

+

1

2pƒC3R2

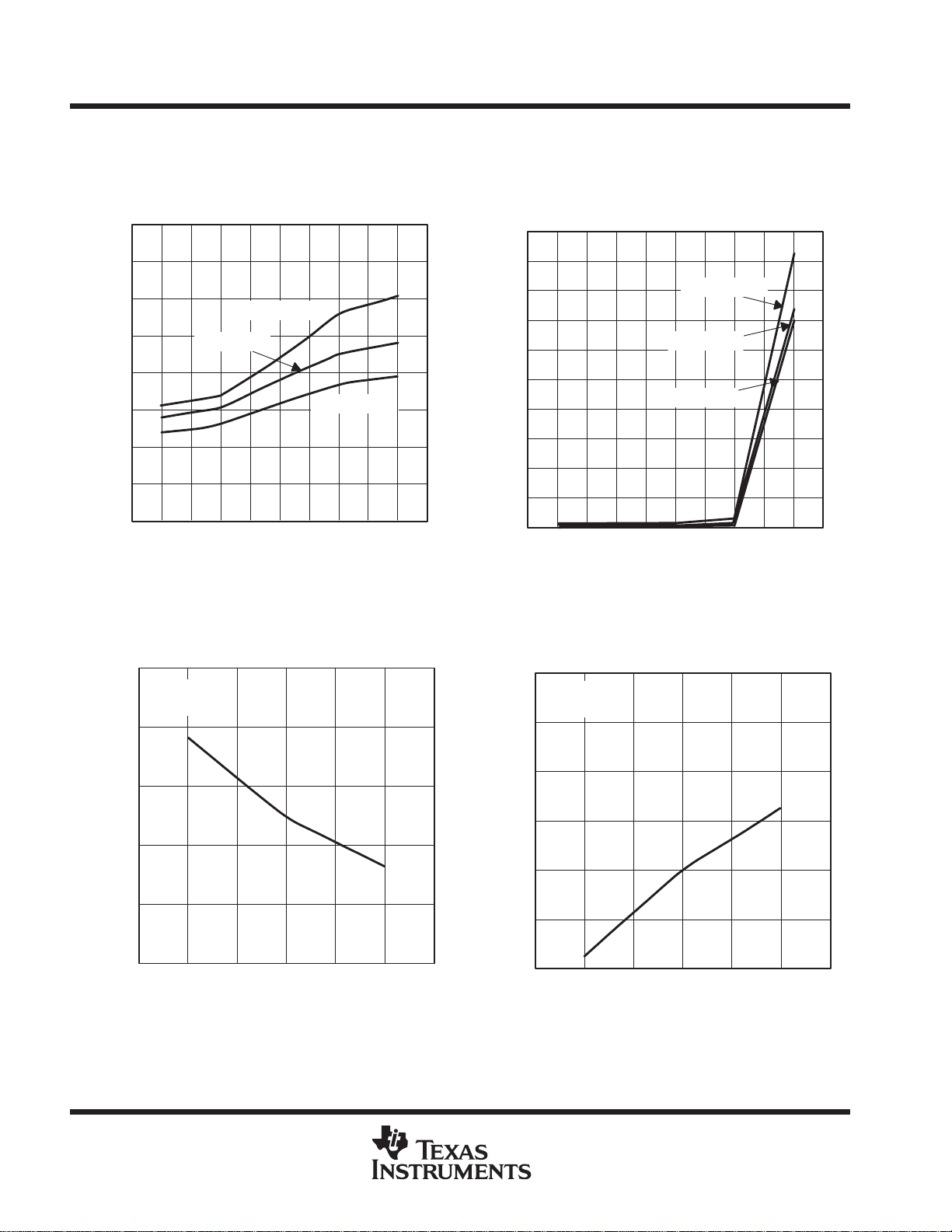

The loop-gain concept is used to design a stable and fast feedback control. The loop-gain equation is derived

by that the control-to-output transfer function times the compensation:

Loop*gain+Vod X Comp

By using a bode plot, the amplitude and the phase of this equation can be drawn with software such as MathCad.

In turn, the stability can be easily designed by adjusting the compensation perimeters. The sample bode plot

is shown below to explain the phase margin, gain margin and the crossover frequency.

The gain is drawn as 20 log (loop-gain), and the phase is in degrees. To explain them clearer, 180 degrees is

added to the phase, so that the gain and phase share the same zero.

Where the gain curve touches the zero is the crossover frequency . The higher this frequency is, the faster the

transient response is, since the transient recovery time is 1/(crossover frequency). The phase to the zero is the

phase margin at the crossover frequency. The phase margin should be at least 60 degrees to cover all the

condition changes such as temperature. The gain margin is the gap between gain curve and the zero when the

phase curve touches the zero. This margin should be at least 20 dB to guarantee the stability over all conditions.

180

166

20 Log (Loop-Gain)

180 + Phase

152

138

124

110

96

82

68

54

40

26

12

–2

–16

–30

–44

–58

–72

–86

–100

Gain

10 100 10

Phase

Margin

Phase

Crossover

f – Frequency – Hz

Gain

Margin

3

10

4

10

5

10

6

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

synchronization

Some applications require switching clock synchronization. Two methods are used for synchronization:

D

Triangle wave synchronization

TPS5103

D

Square wave synchronization

740 mV

740 mV

C

R

t

t

TPS5103

It can be seen that RT and CT are removed from the circuit. Therefore, two components are saved. This method

is good for the synchronization between two controllers. If the controller needs to be synchronized with digital

circuit such as DSP, usually the square-type clock signal is used. The configuration exhibited below is for this

type of application:

C

t

TPS5103

R

t

An external resistor is added into the circuit, but R

is still removed. C

T

is kept to be a part of RC circuit generating

T

triangle waveform for the controller. Assuming the peak value of the square is known, the resistor and the

capacitor can be adjusted to achieve the correct peak–to–peak value and the offset value.

layout guidelines

Good power supply results will only occur when care is given to proper design and layout. Layout will affect noise

pickup and generation and can cause a good design to perform with less than expected results. With a range

of currents from milliamps to tens or even hundreds of amps, good power supply layout is much more difficult

than most general PCB designs. The general design should proceed from the switching node to the output, then

back to the driver section and, finally, place the low-level components. Below are several specific points to

consider before layout of a TPS5103 design begins.

D

All sensitive analog components should be referenced to ANAGND. These include components connected

to Vref5, Vref, INV, LH, and COMP .

D

Analog ground and drive ground should be isolated as much as possible. Ideally , analog ground will connect

to the ground side of the bulk storage capacitors on VO, and drive ground will connect to the main ground

plane close to the source of the low-side FET.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

D

Connections from the drivers to the gate of the power FETs should be as short and wide as possible to

reduce stray inductance. This becomes more critical if external gate resistors are not being used.

D

The bypass capacitor for VCC should be placed close to the TPS5103.

D

When configuring the high-side driver as a floating driver, the connection from LL to the power FETs should

be as short and as wide as possible.

D

When configuring the high-side driver as a floating driver, the bootstrap capacitor (connected from LH to

LL) should be placed close to the TPS5103.

D

When configuring the high-side driver as a ground-referenced driver, LL should be connected to DR VGND.

D

The bulk storage capacitors across VIN should be placed close to the power FETS. High-frequency bypass

capacitors should be placed in parallel with the bulk capacitors and connected close to the drain of the

high-side FET and to the source of the low-side FET.

D

High-frequency bypass capacitors should be placed across the bulk storage capacitors on VO.

D

LH and LL should be connected very close to the drain and source, respectively , of the high-side FET. LH

and LL should be routed very close to each other to minimize differential-mode noise coupling to these

traces. Ceramic decoupling capacitors should be placed close to where VCC connects to Vin, to reduce

high-frequency noise coupling on V

D

The output voltage sensing trace should be isolated by either ground trace or VCC trace.

CC

.

test results

The tests are conducted at TA = 25°C, the point voltage is 5 V.

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

EFFICIENCY

OUTPUT CURRENT

95

1.8 V Output Efficiency

90

85

80

75

Efficiency – %

70

65

60

0 0.5 1 1.5 2 2.5 3

PWM Mode

SKIP Mode

IO – Output Current – A

Figure 37

OUTPUT VOLTAGE

INPUT VOLTAGE

1.790

1.8 V Line Regulation

vs

vs

3.5 4

95

1.8 V Output Efficiency

90

85

80

75

Efficiency – %

70

65

60

0 0.1 0.2 0.3

IO – Output Current – A

1.790

1.8 V Output Load Regulation

EFFICIENCY

vs

OUTPUT CURRENT

PWM Mode

SKIP Mode

0.4 0.5

Figure 38

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

1.785

1.780

– Output Voltage – V

O

V

1.775

1.770

51015

VI – Input Voltage – V

Figure 39

1.790

1.780

1.780

– Output Voltage – VV

1.770

O

1.770

20 250

1.760

0 0.5 1 1.5 2 2.5 3

IO – Output Current – A

3.5 4

Figure 40

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

29

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

EFFICIENCY

OUTPUT CURRENT

95

1.8 V Output Diode Type Efficiency

90

85

80

75

Efficiency – %

70

65

60

0 0.5 1 1.5 2 2.5 3

IO – Output Current – A

Figure 41

TRANSIENT RESPONSE (OVERSHOOT)

vs

OUTPUT/VOLTAGE

OUTPUT VOLTAGE

3.5 4

Figure 42

TRANSIENT RESPONSE (UNDERSHOOT)

30

Figure 43

Figure 44

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

Table 1. Bill of Materials (see Note 3)

REF PN DESCRIPTION MFG SIZE

C1opt 10TPB220M Capacitor, POSCAP, 220 µF, 10 V Sanyo 7.3x4.3mm

C1 RV-35V221MH10-R Capacitor, electrolytic, 220 µF, 35 V ELNA 10x10mm

C2 GMK325F106ZH Capacitor, ceramic, 10 µF, 35 V T aiyo Yuden 1210

C3 4TPB470M Capacitor, POSCAP, 470 µF, 4 V Sanyo 7.3x4.3mm

†

C4

C5 std Capacitor, ceramic, 1 µF, 16 V 805

C6 std Capacitor, ceramic, 0.01 µF, 16 V 805

C7 std Capacitor, ceramic, 220 pF, 16 V 805

C8 std Capacitor, ceramic, 100 pF, 16 V 805

C9 std Capacitor, ceramic, 1 µF, 16 V 805

C10 GMK316F225ZG Capacitor, ceramic, 2.2 µF, 35 V Taiyo Yuden 1206

†

C11

C12 GMK316F225ZG Capacitor, Ceramic, 2.2 µF, 35 V Taiyo Yuden 1206

C13 GMK325F106ZH Capacitor, Ceramic, 10 µF, 35 V Taiyo Yuden 1210

C14 Open

C14†opt Open 10x10mm

†

C15

D1 MBRS340T3 Diode, Schottky, 40 V, 3 A Motorola SMC

D1opt MBRS130LT3 Diode, Schottky, 30 V, 1 A Motorola SMB

D2 SD103-AWDICT-ND Diode, Schottky, 40 V, 200 mA, 400 mW Digikey 3.5x1.5mm

L1 DO3316P-682 Inductor, 6.8 uH, 4.4 A Coilcraft 0.5x0.37 in

J1–J14 CA26DA-D36W-0FC Edge connector, surface-mount, 0.040” board, 0.090” standoff NAS Interplex 0.040”

JP1 S1132-2-ND Header, straight, 2–pin, 0.1 ctrs, 0.3” pins Sullins DigiKey #

JP1 Shunt 929950-00-ND Shunt, jumper, 0.1” 3M DigiKey

JP2 S1132-2-ND Header, straight, 2–pin, 0.1 ctrs, 0.3” pins Sullins DigiKey

R1 std Resistor, 5.1 kΩ, 5 % 805

†

R2

R3 std Resistor, 910 Ω, 1% 805

R4 std Resistor, 1.74 kΩ, 1% 805

R5 std Resistor, 5.1 kΩ, 5% 805

R6A std Resistor, 82 kΩ, 5% 805

†

R6B

R7 std Resistor, 1 kΩ, 5% 805

R9 std Resistor, 1 kΩ, 5% 805

R10 std Resistor, 1 kΩ, 5% 805

R11 std Resistor, 10 Ω, 5% 805

R12 std Resistor, 51 kΩ, 5% 805

†

R13

Q1 Si4410DY Transistor, MOSFET, n-ch, 30-V, 10-A, 13–mΩ Siliconix SO–8

Q2 Si4410DY Transistor, MOSFET, n-ch, 30-V, 10-A, 13-mΩ Siliconix SO–8

U1 TPS5103 IC, controller TI SSOP–20

†

Components for optional mode test only.

NOTE 3: This operation mode is PWM mode only.

std Open, capacitor, Ceramic, 2.2 µF, 16 V 805

std Open 805

std Open, capacitor, ceramic, 1000 pF, 16 V 805

S1132-2-ND

#929950-00-ND

#S1132-2-ND

std Open, resistor, 1 kΩ, 5% 805

std Open, 0 Ω, 5% 805

std Open 805

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

31

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

Top Layer

.

Bottom Layer (Top View)

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

Top Assembly

NOTE: All wire pairs should be twisted.

–

Load

0 – 4 A

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

+

Test Setup

Power Supply

5–V, 5–A Supply

–

+

33

TPS5103

MOSFETS (Q1–Q2)

Local distributor

INPUT CAPACITORS (C1)

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

Table 2. Test Specifications

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input voltage range 5 25 V

Output voltage range Vi = 5 – 25 V Io = 0 – 4 A 1.7 1.8 1.9 V

Output current range Vi = 5 – 10 V 0 4 A

Output current limit Vi = 5 V 4.3 A

Output ripple Vi =5 V, Io = 4 A 50 mVp–p

Operating frequency Io = 4 A 150 250 KHz

Efficiency Vi = 5 V, Vo = 1.8 V, Io = 4 A 90 %

Table 3. EVM Operating Specifications

SKIP MODE HYS MODE

Remove JP1 shunt Remove R5, C6 and C7

Remove R6A

Add R6B

Add C15

If it needs the loop-compensation, add R2 and C4

This EVM is designed to cover as many applications as possible. For some more specific applications, the circuit

can be simpler. The table below gives some recommendations.

Table 4. EVM Application Recommendations

5-V INPUT VOLTAGE <3-A OUTPUT CURRENT DIODE VERSION

Change C1 to low profile capacitor

Sanyo 10TPB220M (220 µF, 10 V)

Or 6TPB330M (330 µF, 6.3 V)

Remove R10

Change Q1 and Q2 to dual pack MOSFET,

IRF7311 to reduce the cost.

Remove Q2 to reduce the cost.

Table 5. Vendor and Source Information

MATERIAL SOURCE PART NUMBER DISTRIBUTORS

In EVM design Si4410

Second source IRF7811 (International Rectifier)

In EVM design RV–35V221MH10–R (ELNA) Bell Microproducts 972–783–4191

Second source 35CV330AX/GX (Sanyo) 870–633–5030

UUR1V221MNR1GS (Nichicon) Future Electronics (Local Office)

MAIN DIODES (D1) In EVM design MBRS340T3 (Motorola) Local distributors

Second source U3FWJ44N (Toshiba) Local distributors

INDUCTORS (L1) In EVM design DO3316P–682 (Coilcraft) 972–458–2645

CTDO3316P–682

(Inductor Warehouse)

GMK325F106ZH

GMK316F225ZG

(Taiyo Yuden)

800–533–8295

SMEC

512–331–1877

CERAMIC CAPACITORS

(C2, C14) (C12, C10)

Second source

IN EVM design

Taiyo Yuden representative e–mail: mike@millsales.com

34

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

APPLICATION INFORMATION

High current applications are described in Table 6. The values are recommendations based on actual test

circuits. Many variations are possible based on the requirements of the user. Performance of the circuit is

dependent upon the layout rather than on the specific components, if the device parameters are not exceeded.

The power stage, having the highest current levels and greatest dv/dt rates, should be given the most attention,

as both the supply and load can be severely affected by the power levels and edge rates.

Table 6. High Current Applications

TPS5103

REFERENCE

DESIGNATIONS

C1 Input bulk capacitor

C2 Input bypass capacitor

L1 Output filter indicator

C3 Output filter capacitor

Q1 Power switch

Q2 Power switch

R11 Gate drive resistor 7 Ω 5 Ω 4 Ω

R12 Current limit resistor 10 kΩ 15 kΩ 20 kΩ

Switching frequency 200 kHz 150 kHz 100 kHz

FUNCTION 8-A OUTPUT 12-A OUTPUT 16-A OUTPUT

2x ELNA

RV-35V221MH10-R

220 µF, 35 V

2x Taiyo Yuden

GMK325F106ZH

10 µF, 35 V

Coiltronics UP3B-2R2

2.2 µΗ, 9.2 A

2x Sanyo 4TPB470M

470 µF, 4 V

2x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

2x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

3x ELNA

RV-35V221MH10-R

220 µF, 35 V

3x Taiyo Yuden

GMK325F106ZH

10 µF, 35 V

Coiltronics UP4B-1R5

1.5 µΗ, 13.4 A

3x Sanyo 4TPB470M

470 µF, 4 V

3x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

3x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

4x ELNA

RV-35V221MH10-R

220 µF, 35 V

4x Taiyo Yuden

GMK325F106ZH

10 µF, 35 V

MicorMetals T68-8/90

Core w/7T, #16

1.0 µΗ, 25 A

4x Sanyo 4TPB470M

470 µF, 4 V

4x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

4x Siliconix Si4410DY

30 V, 10 A, 13 mΩ

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

35

TPS5103

MULTIPLE MODE SYNCHRONOUS DC/DC CONTROLLER

SLVS240 – SEPTEMBER 1999

MECHANICAL DATA

DB (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

28 PINS SHOWN

0,65

28

1

2,00 MAX

0,38

0,22

15

14

A

0,05 MIN

0,15

5,60

5,00

M

8,20

7,40

Seating Plane

0,10

0,15 NOM

Gage Plane

0°–8°

0,25

1,03

0,63

PINS **

DIM

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-150

8

3,30

2,70

14

6,50

6,50

5,905,90

2016

7,50

6,90

24

8,50

28

10,50

9,907,90

30

10,50

9,90

38

12,90

12,30

4040065 /C 10/95

36

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...