Page 1

1

2

3

4

19

18

17

16

SYNC

PGD

LVBP

RT

SA−

SAO

GND

SS

TPS40075

15

14

13

12

KFF

ILIM

VDD

HDRV

5

6

7

8

FB

COMP

PGND

LDRV

9 DBP

20

SA+

10

SW11BOOST

SYNC IN

PowerGood OUT

UDG−04075

V

IN

V

OUT

+

V

OUT

−

V

OUT

−

(at Load)

V

OUT

+

(at Load)

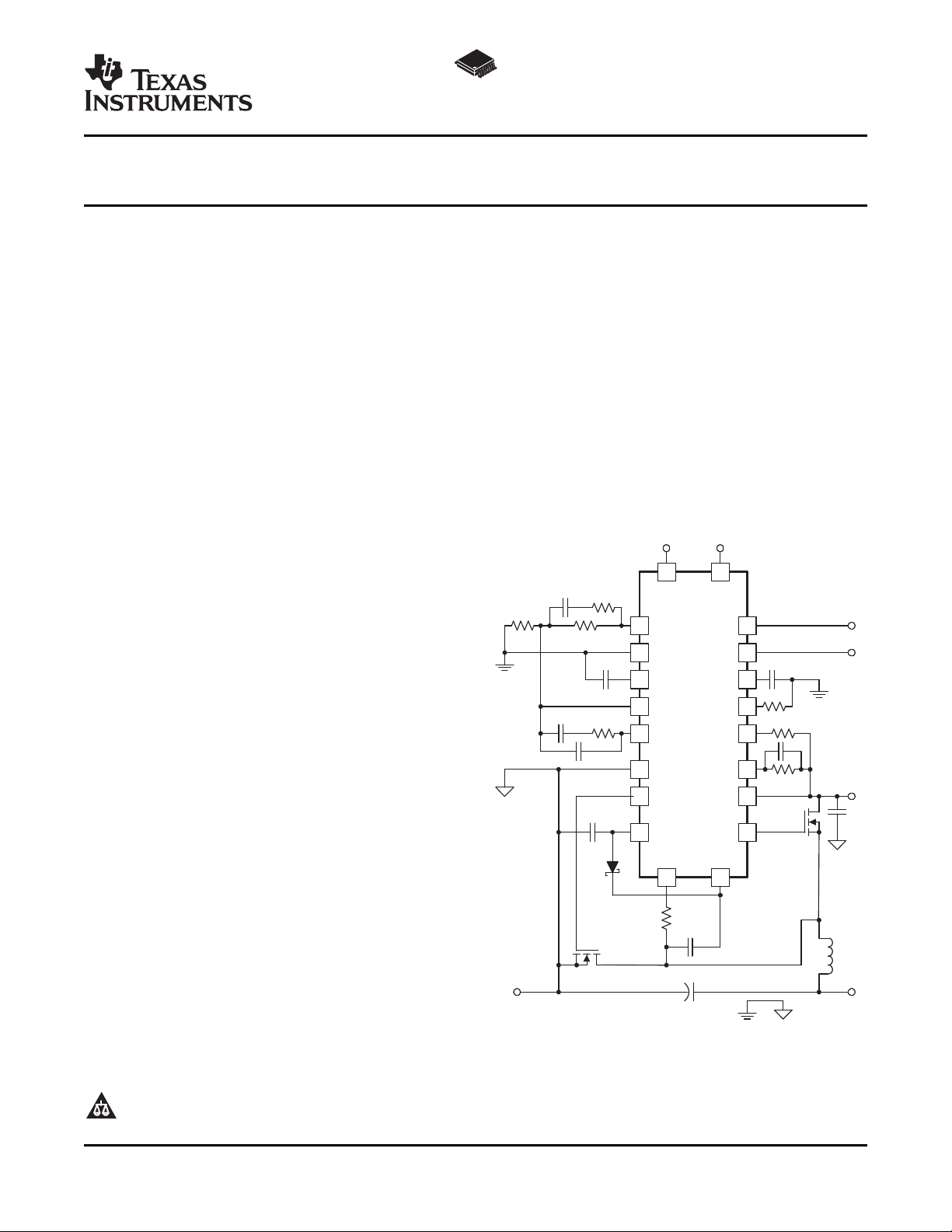

www.ti.com

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

TPS40075

MIDRANGE INPUT SYNCHRONOUS BUCK CONTROLLER

WITH VOLTAGE FEED-FORWARD

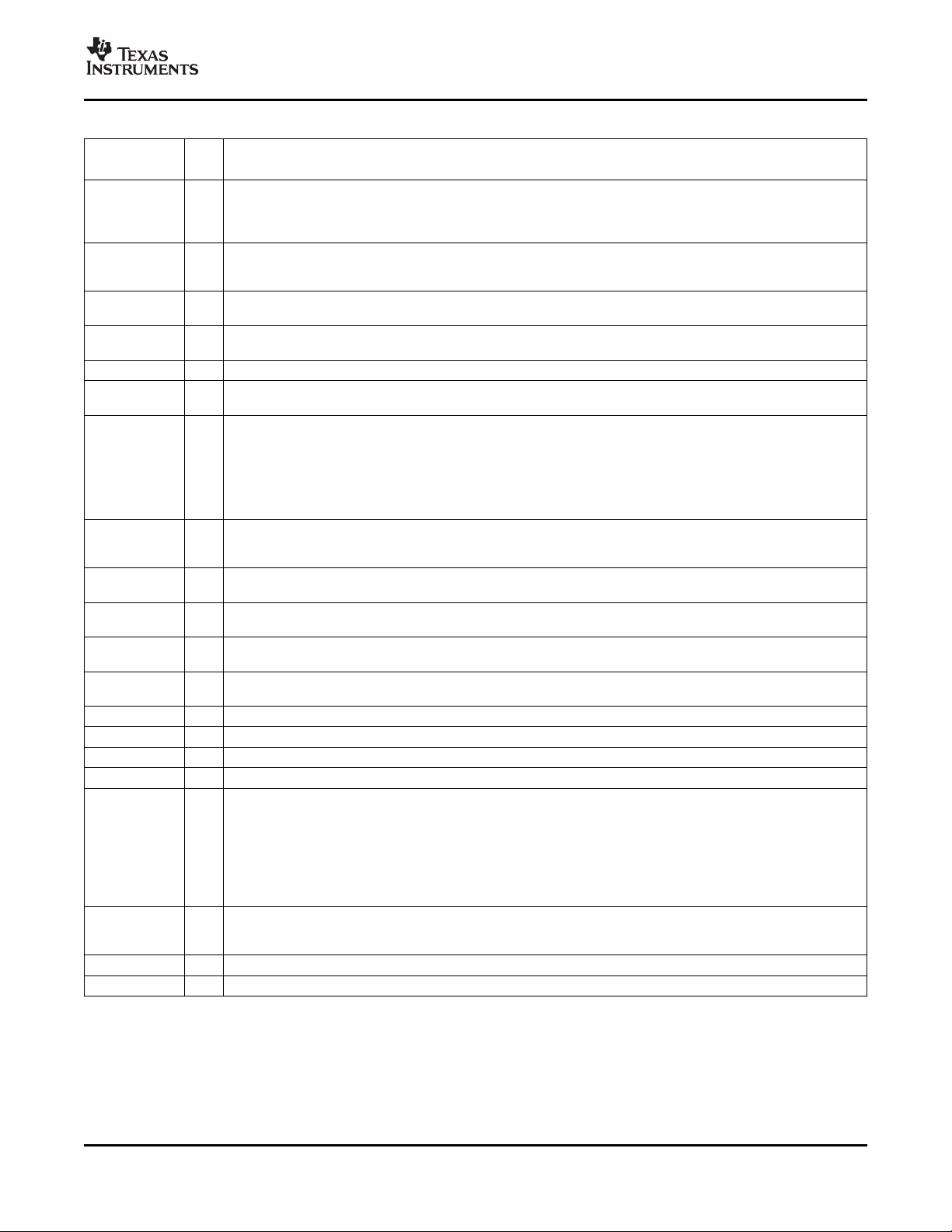

1

FEATURES

2

• Operation Over 4.5-V to 28-V Input Range

• Fixed-Frequency Voltage-Mode Controller

• Integrated Unity Gain Amplifier for Remote

Output Sensing

• Predictive Gate Drive™ Generation II for

Improved Efficiency

• <1% Internal 700-mV Reference

• Input Voltage Feed Forward Control

• Prebiased Output Compatible

• Internal Gate Drive Outputs for High-Side and

Synchronous N-Channel MOSFETs

• Switching Frequency Programmable to 1 MHz

• 20-Pin QFN Package

• Thermal Shutdown Protection

• Software Design Tool and EVM Available

APPLICATIONS

• Power Modules

• Networking/Telecom

• Industrial

• Servers

The TPS40075 drives external N-channel MOSFETs

using second generation Predictive Gate Drive to

minimize conduction in the body diode of the low side

FET and maximize efficiency. Pre-biased outputs are

supported by not allowing the low side FET to turn on

until the voltage commanded by the closed loop soft

start is greater than the pre-bias voltage. Voltage

feed forward provides good response to input

transients and provides a constant PWM gain over a

wide input voltage operating range to ease

compensation requirements. Programmable short

circuit protection provides fault current limiting and

hiccup recovery to minimize power dissipation with a

shorted output. The 20-pin QFN package gives good

thermal performance and a compact footprint.

SIMPLIFIED APPLICATION DIAGRAM

CONTENTS

Device Ratings 2

Electrical Characteristics 4

Terminal Information 12

Application Information 15

Design Example 26

Additional References 40

DESCRIPTION

The TPS40075 is a mid voltage, wide input (4.5-V to

28-V), synchronous, step-down controller, offering

design flexibility for a variety of user programmable

functions, including; soft start, UVLO, operating

frequency, voltage feed-forward and high-side FET

sensed short circuit protection.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2 Predictive Gate Drive is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2006 – 2007, Texas Instruments Incorporated

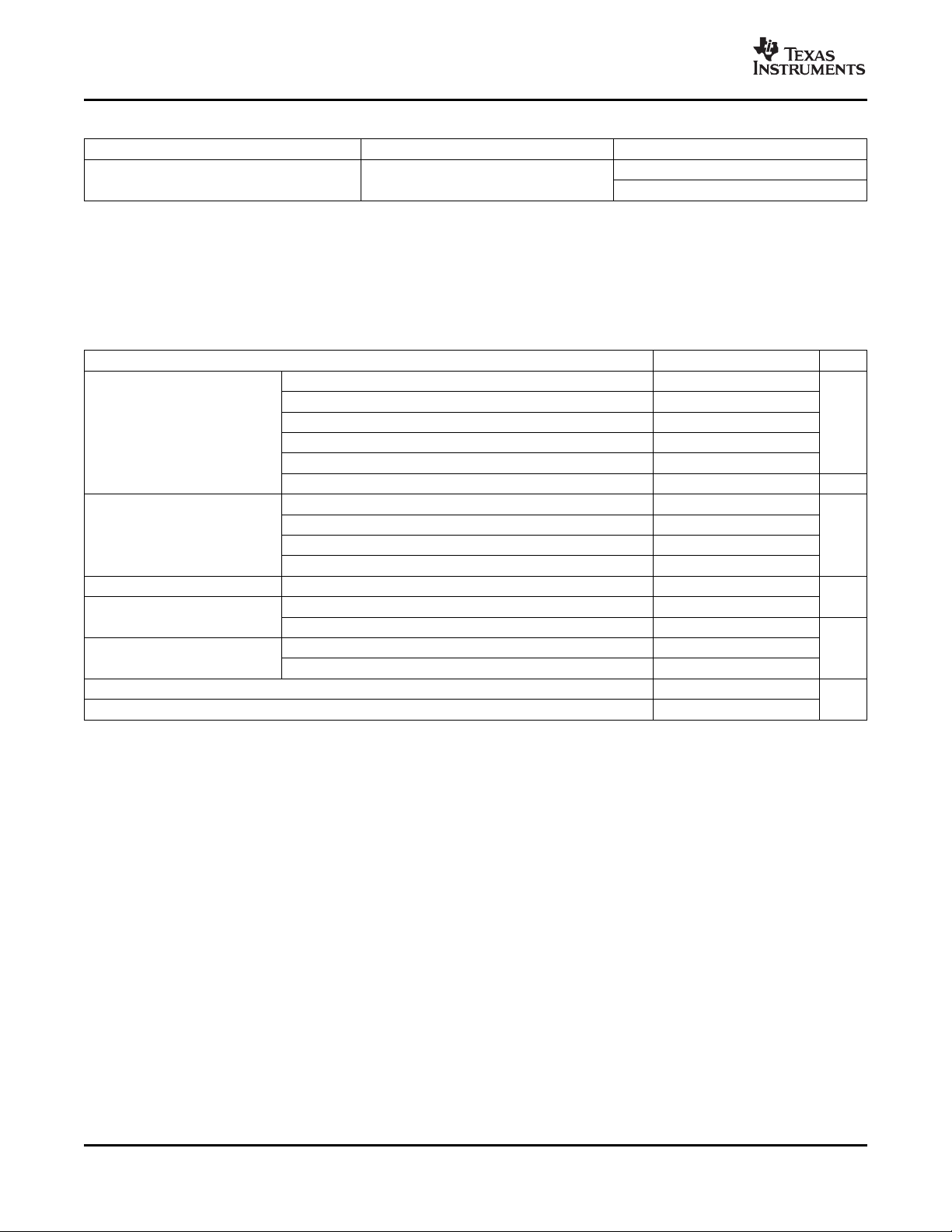

Page 2

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

ORDERING INFORMATION

T

A

40 ° C to 85 ° C Plastic QFN (RHL)

(1) The TPS40075 is available taped and reeled only. Add an T suffix (i.e. TPS40075RHLT) to the orderable part number for quantities of

250 units per small reel. .

(2) Add an R suffix (i.e. TPS40075RHLR) to the orderable part number for quantities of 3,000 units per large reel.

DEVICE RATINGS

PACKAGE PART NUMBER

TPS40075RHLT

TPS40075RHLR

(1)

(2)

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

VDD, ILIM 30

FB, KFF, PGD, SYNC – 0.3 to 6

V

V

I

I

I

T

T

Input voltage range

DD

Output voltage range V

OUT

Output current source LDRV, HDRV 1.5

OUT

Output current sink

OUT

Output current source

OUT

Operating junction temperature range – 40 to 125

J

Storage temperature – 55 to 150

stg

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

SW – 0.3 to 40 V

SA+, SA- – 0.3 to 11

SW, transient < 50 ns – 2.5

SW, transient – 125 V × ns

COMP, RT, SS – 0.3 to 6

BOOST, HDRV 50

DBP, SAO, LDRV 10.5

LVBP 6

LDRV, HDRV 2.0

KFF 10

RT 1 mA

LVBP 1.5

(1)

TPS40075 UNIT

A

° C

2 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 3

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

RECOMMENDED OPERATING CONDITIIONS

MIN NOM MAX UNIT

V

T

ELECTROSTATIC DISCHARGE (ESD) PROTECTION

Human body model 1500 V

CDM 1500

Input voltage 4.5 28 V

DD

Operating free-air temperature -40 85 ° C

A

PARAMETER MIN TYP MAX UNIT

PACKAGE DISSIPATION RATINGS

THERMAL IMPEDANCE

AIRFLOW (LFM) JUNCTION-TO-AMBIENT TA= 25 ° C POWER RATING (W) TA= 85 ° C POWER RATING (W)

Natural Convection 42 2.38 0.95

200 35 2.85 1.14

400 31 3.22 1.29

(1) For more information on the RHL package and the test method, refer to TI technical brief, literature number SZZA017. The ratings in this

table are for the JEDEC High-K board.

(1)

( ° C/W)

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s) :TPS40075

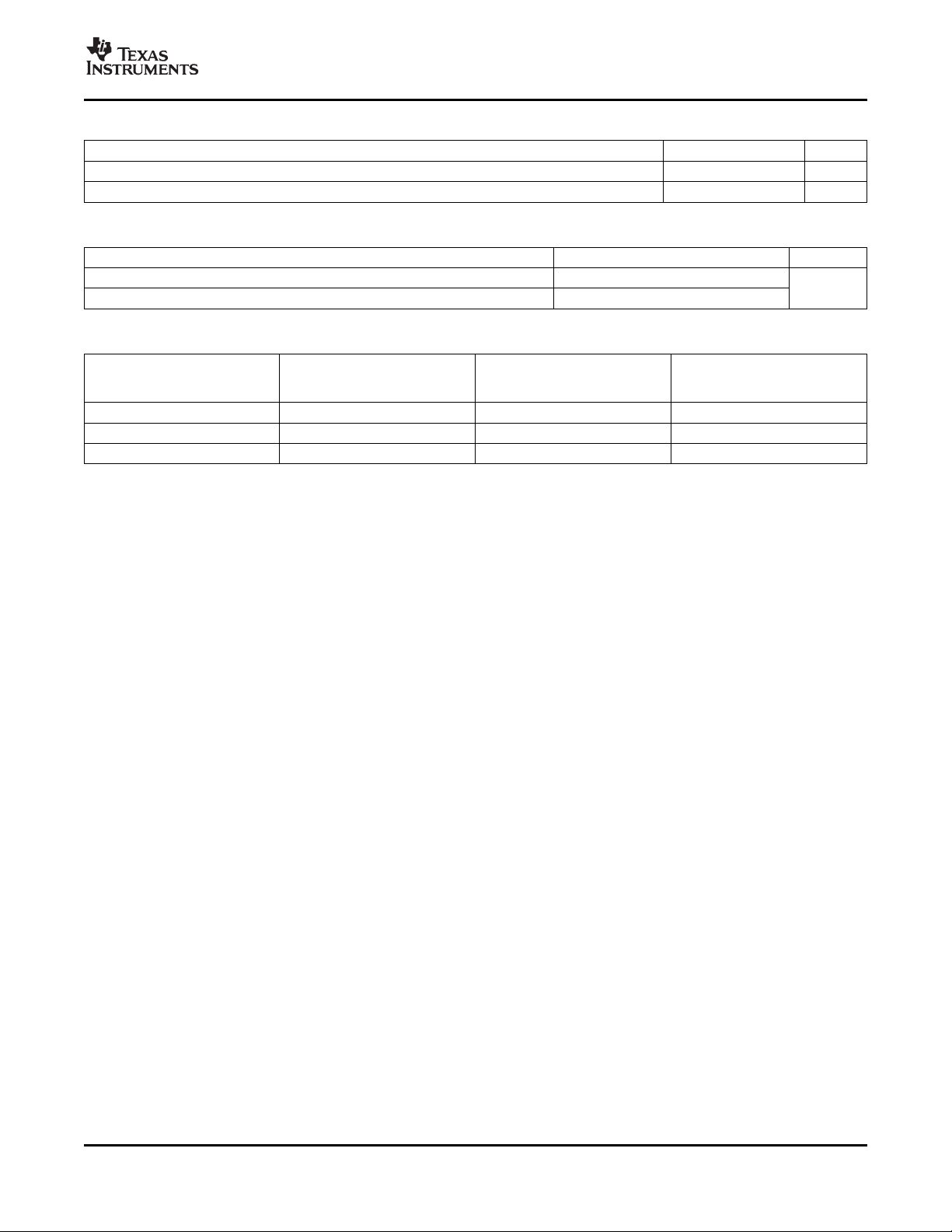

Page 4

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

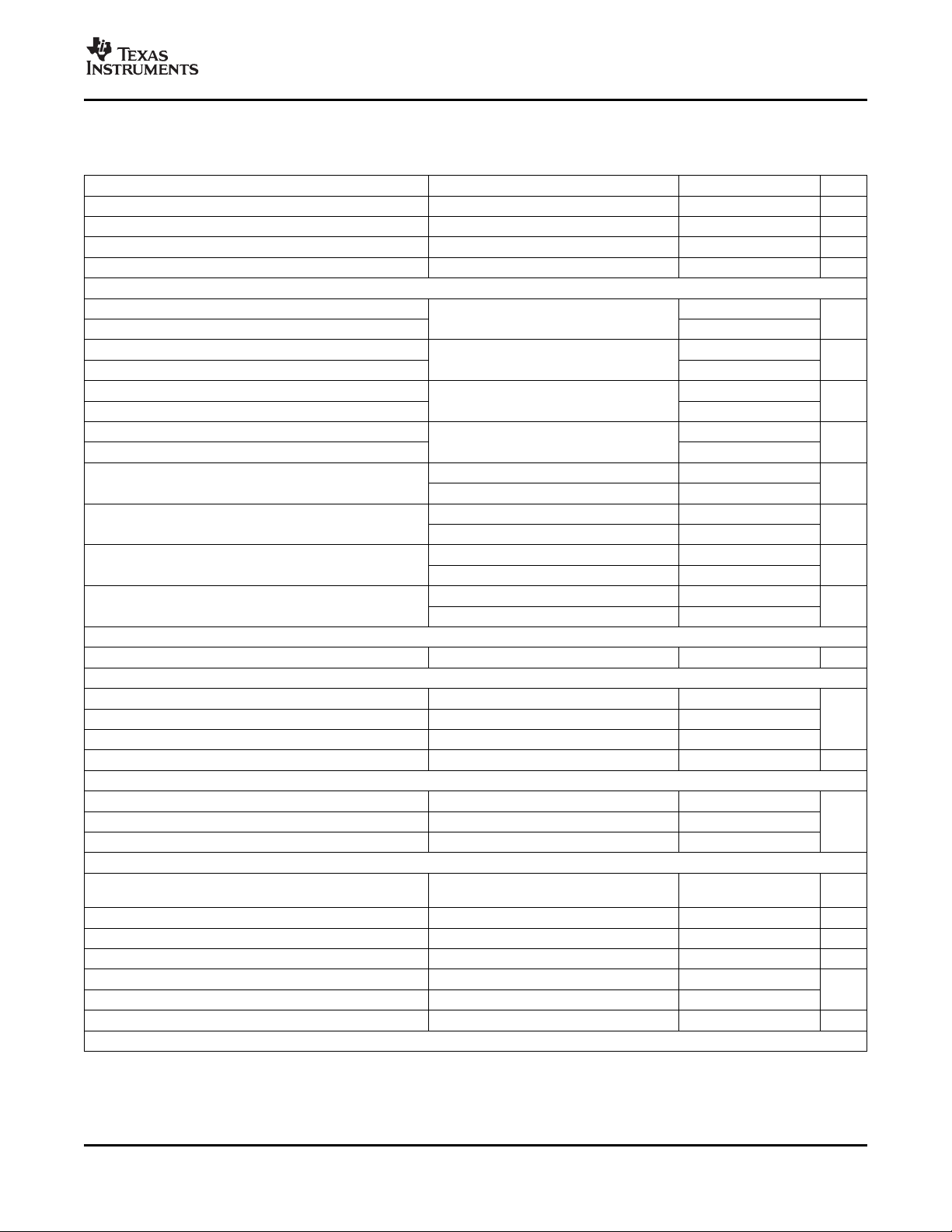

ELECTRICAL CHARACTERISTICS

TA= – 40 ° C to 85 ° C, V

(unless otherwise noted)

INPUT SUPPLY

V

DD

OPERATING CURRENT

I

DD

LVBP

V

LVBP

OSCILLATOR/RAMP GENERATOR

f

OSC

V

RT

t

ON(min)

V

IH

V

IL

I

SYNC

V

KFF

I

KFF

SOFT START

I

SS

t

DSCH

t

SS

V

SSSD

V

SSEN

V

SSSDHYS

DBP

V

DBP

ERROR AMPLIFIER

V

FB

V

SS(offset)

GBWP Gain bandwidth

A

VOL

I

SRC

I

SINK

I

BIAS

SHORT CIRCUIT CURRENT PROTECTION

I

ILIM

V

ILIM(ofst)

t

HSC

t

BLANK

Input voltage range, VIN 4.5 28 V

Quiescent current Output drivers not switching 2.5 3.5 mA

Output voltage TA= TJ= 25 ° C 3.9 4.2 4.5 V

Accuracy 450 500 550 kHz

RT voltage 2.23 2.40 2.58 V

Minimum output pulse time

High-level input voltage, SYNC 2 5

Low-level input voltage, SYNC 0.8

Input current, SYNC 5 10 µA

Maximum duty cycle

Feed-forward voltage 0.35 0.40 0.45 V

Feed-forward current operating range

Charge current 9.5 12 14.5 µA

Discharge time C

Soft-start time 210 290 500

Shutdown threshold, V

Enable threshold, V

Shutdown threshold hysteresis 35 130

Output voltage V

Feedback regulation voltage total variation 0 ° C ≤ TA= TJ≤ 85 ° C 0.690 0.700 0.707

Soft-start offset from VSS

Open loop gain 50 dB

Output source current 2.5 4.5

Output sink current 2.5 6

Input bias current V

Current sink into ILIM pin 115 135 150 µA

Current limit offset voltage V

Minimum HDRV pulse width During short circuit 135 225 ns

Propagation delay to output

Blanking time

= 12 Vdc, RT= 90.9 k Ω , I

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SS

rising 310 410 mV

SS

(1)

(1)

= 300 µA, fSW= 500 kHz, all parameters at zero power dissipation

KFF

(1)

(1)

C

= 0 nF 150 ns

HDRV

V

= 0 V, 100 kHz ≤ fSW≤ 500 kHz 84% 95%

FB

V

= 0 V, fSW= 1 MHz 76% 93%

FB

20 1100 µA

= 3.9 nF 25 75

SS

C

V

= 3.9 nF, V

SS

rising from 0.7 V to 1.6

SS

falling 225 275 325

V

> 10 V 7 8 9

DD

V

VDD

= 4.5 V, I

= 25 mA 4.0 4.3

OUT

TA= TJ= 25 ° C 0.698 0.700 0.704

-40 ° C ≤ TA= TJ≤ 85 ° C 0.690 0.700 0.715

(1)

Offset from V

to error amplifier 1

SS

5 10 MHz

= 0.7 V – 250 0 nA

FB

= 11.5 V, (V

ILIM

(1)

- V

) V

SW

ILIM

= 12 V – 50 – 30 – 10 mV

VDD

50 ns

50 ns

V

µs

V

mA

(1) Ensured by design. Not production tested.

4 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

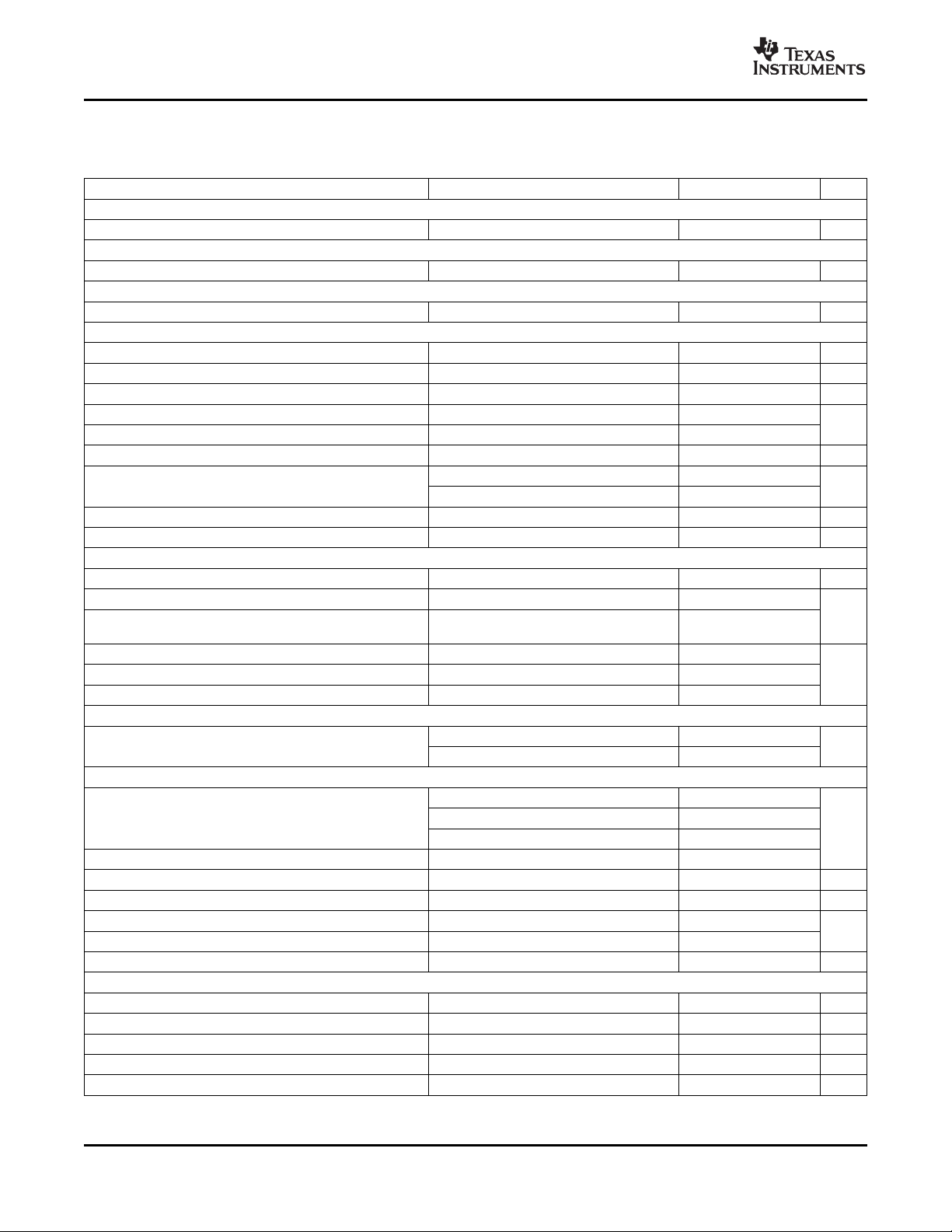

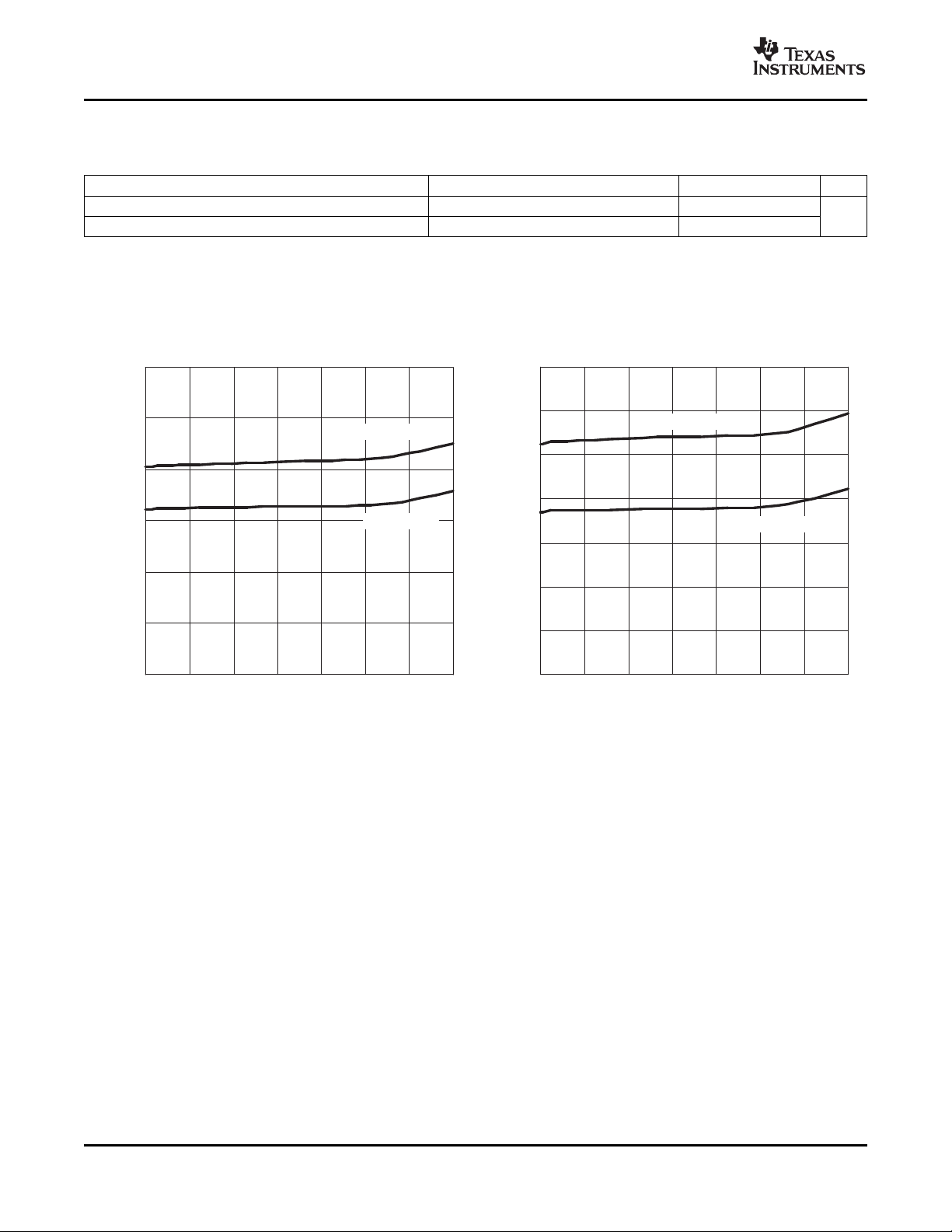

Page 5

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

TA= – 40 ° C to 85 ° C, V

(unless otherwise noted)

t

OFF

V

SW

t

PC

V

ILIM(pre)

OUTPUT DRIVERS

t

HFALL

t

HRISE

t

HFALL

t

HRISE

t

LFALL

t

LRISE

t

LFALL

t

LRISE

V

OH

V

OL

V

OH

V

OL

BOOST REGULATOR

V

BOOST

UVLO

V

UVLO

POWER GOOD

V

PGD

V

FBH

V

FBL

SENSE AMPLIFIER

V

IO

A

DIFF

V

ICM

R

G

I

OH

I

OL

GBWP Gain bandwidth

THERMAL SHUTDOWN

Off time during a fault (SS cycle times) 7 cycles

Switching level to end precondition

Precondition time

Current limit precondition voltage threshold

High-side driver fall time

High-side driver rise time

High-side driver fall time

High-side driver rise time

Low-side driver fall time

Low-side driver rise time

Low-side driver fall time

Low-side driver rise time

High-level output voltage, HDRV V

Low-level output voltage, HDRV V

High-level output voltage, LDRV V

Low-level output voltage, LDRV V

Output voltage V

Programmable UVLO threshold voltage R

Programmable UVLO hysteresis R

Fixed UVLO threshold voltage Turn-on, V

Fixed UVLO hysteresis 275 365 mV

Powergood voltage I

High-level output voltage, FB 770 mV

Low-level output voltage, FB 630

Input offset voltage -9 9 mV

Differential gain V

Input common mode range

Internal resistance for setting gain 14 20 26 k Ω

Output source current 2 10 15

Output sink current 15 25 35

= 12 Vdc, RT= 90.9 k Ω , I

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(2)

(4)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

= 300 µA, fSW= 500 kHz, all parameters at zero power dissipation

KFF

(1)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(3)

(V

- V

VDD

) 2 V

SW

100 ns

(2)

C

= 2200 pF, (HDRV - SW) ns

HDRV

C

= 2200 pF, (HDRV - SW)

HDRV

V

= 4.5 V

VDD

C

= 2200 pF ns

LDRV

C

= 2200 pF, VDD= 4.5 V ns

LDRV

I

= -0.01 A, (V

HDRV

I

= -0.1 A, (V

HDRV

(V

- V

HDRV

(V

HDRV

(V

DBP

(V

DBP

I

LDRV

I

LDRV

VDD

KFF

KFF

PGD

V

SA+

SA+ and SA-

SA+

), I

SW

- V

), I

SW

- V

), I

LDRV

- V

), I

LDRV

= 0.01 A 0.03 0.05

= 0.1 A 0.3 0.5

= 12 V 15.2 17.0 V

= 90.9 k Ω , turn-on, V

= 90.9 k Ω 1.10 1.55 2.00 V

rising 4.15 4.30 4.45

VDD

= 1 mA 370 550

= V

= 1.25 V, Offset referenced to

SA-

- V

= 4.5 V 0.995 1.000 1.005

SA-

- V

BOOST

BOOST

= 0.01A 0.06 0.10

HDRV

= 0.1 A 0.65 1.00

HDRV

= -0.01A 0.65 1.00

LDRV

= -0.1 A 0.875 1.300

LDRV

) 0.7 1.0

HDRV

- V

) 0.95 1.35

HDRV

rising 6.2 7.2 8.2

VDD

6.8 V

36

48

72

96

24

48

48

96

ns

0 6 V

mA

2 MHz

(2) Ensured by design. Not production tested.

(3) 3 V at internal amplifier terminals, 6 V at SA+ and SA- pins.

(4) Ensured by design. Not production tested.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s) :TPS40075

Page 6

www.ti.com

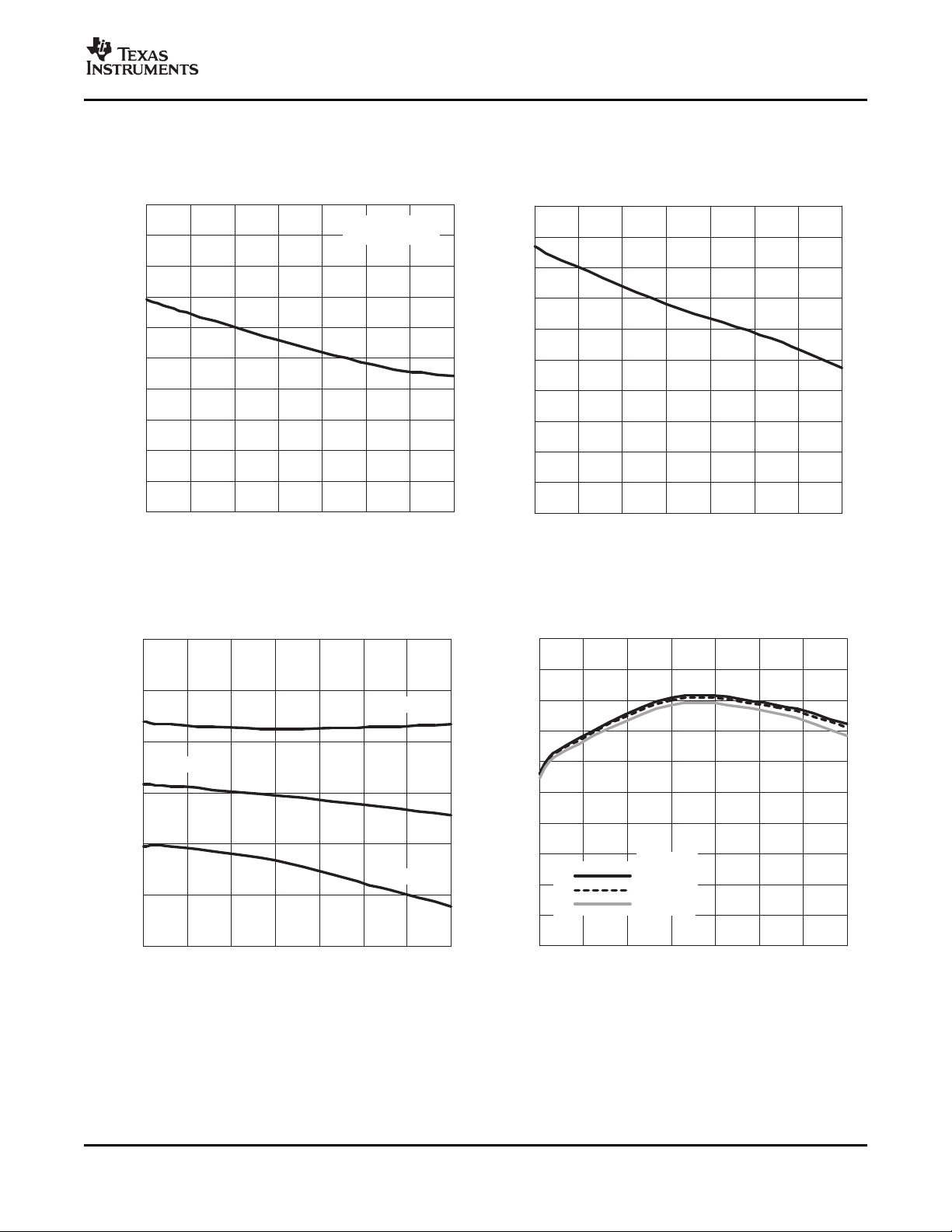

TJ − Junction Temperature − °C

V

LVPP

− LVBP Voltage − V

−50 −25 50 100 1250

4.15

4.10

4.30

4.20

4.25

4.05

4.00

25 75

VDD = 28 V

VDD = 12 V

−50 −25 50 100 1250

8.00

7.90

8.15

8.05

8.10

7.85

7.80

25 75

7.95

V

DBP

− DBP Voltage − V

VDD = 28 V

VDD = 12 V

TJ − Junction Temperature − °C

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

ELECTRICAL CHARACTERISTICS (continued)

TA= – 40 ° C to 85 ° C, V

(unless otherwise noted)

Shutdown temperature threshold

Hysteresis

= 12 Vdc, RT= 90.9 k Ω , I

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(4)

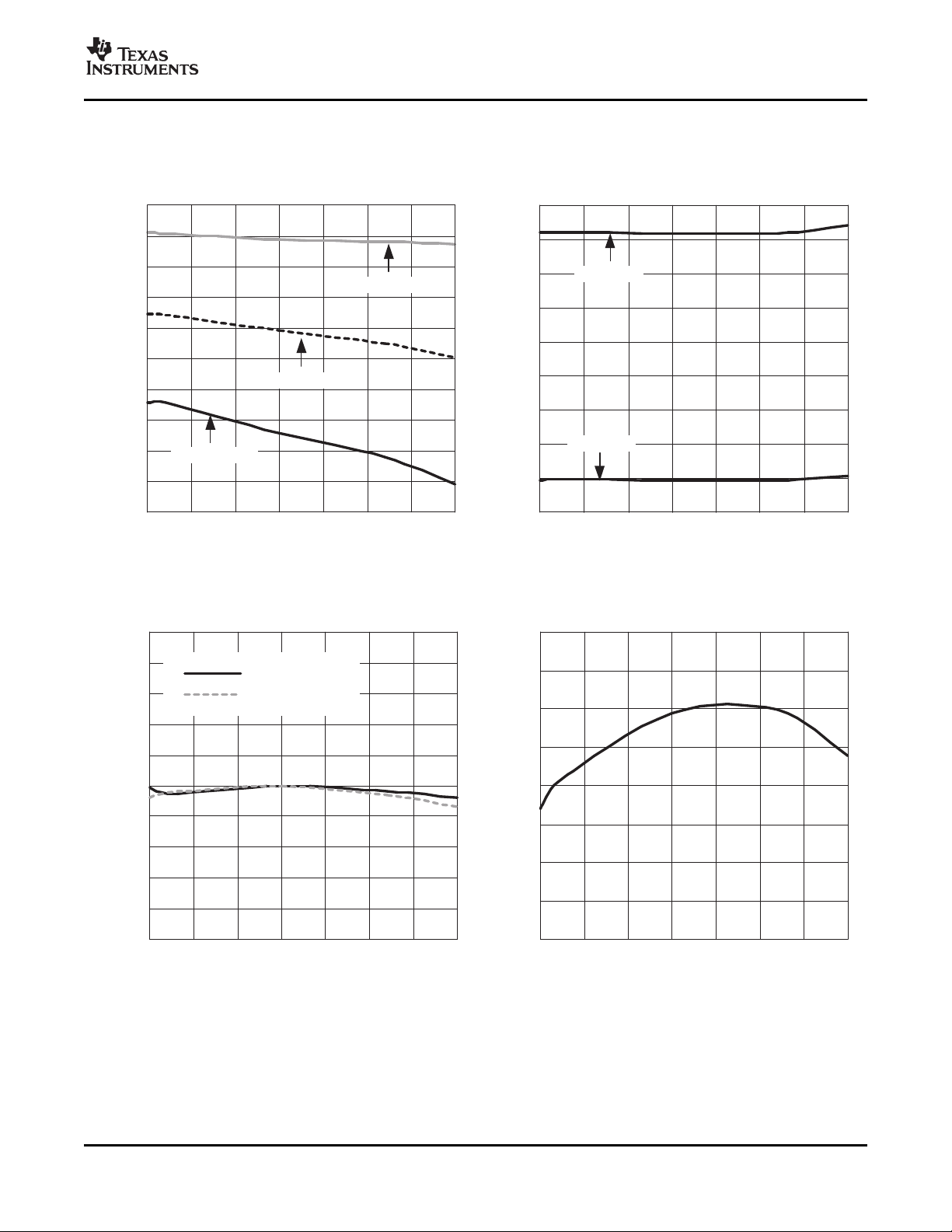

LVBP VOLTAGE DBP VOLTAGE

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

vs vs

= 300 µA, fSW= 500 kHz, all parameters at zero power dissipation

KFF

(4)

165

15

° C

TYPICAL CHARACTERISTICS

Figure 1. Figure 2.

6 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

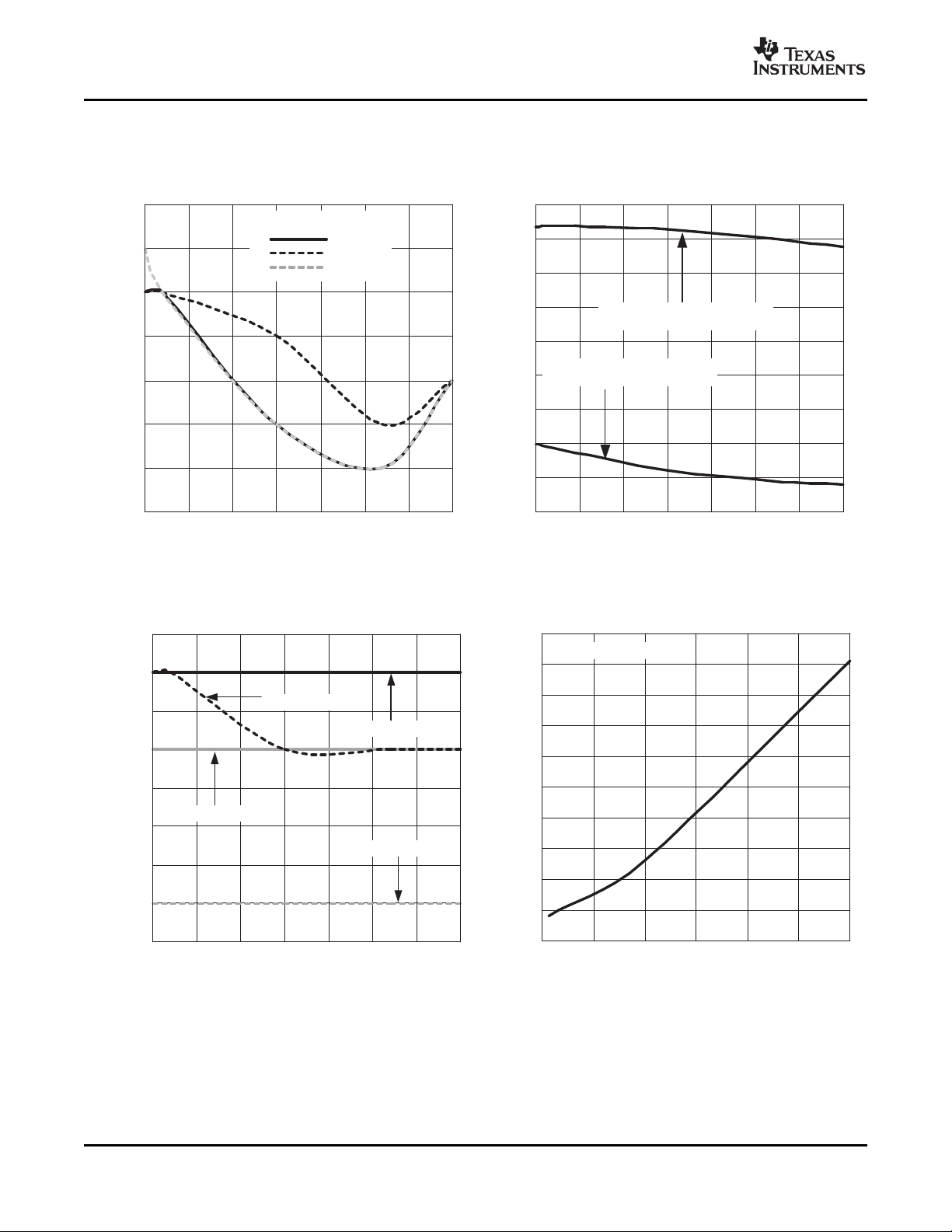

Page 7

www.ti.com

−50 −25 50 100 1250

4.46

4.43

4.50

4.48

4.49

4.41

4.40

25 75

4.44

4.42

4.47

4.45

V

DBP

− DBP Voltage − V

VDD = 4.5 V

I

LOAD

= 25 mA

TJ − Junction Temperature − °C

V

DROP

− Bootstrap Diode Voltage Drop − V

TJ − Junction Temperature − °C

−50 −25 50 100 1250

1.6

1.3

2.0

1.7

1.9

1.1

1.0

25 75

1.4

1.8

1.5

1.2

−50 −25 50 100 1250

115

150

140

100

25 75

135

125

110

105

120

145

130

I

ILIM

− Current Limit Sink Current − µA

TJ − Junction Temperature − °C

VDD

28 V

12 V

4.5 V

V

ILIM(offst)

– Current Limit Offset Voltage Drop – mV

TJ – Junction Temperature – °C

−50 −25 50 100 1250

−40

0

−10

−60

25 75

−20

−30

−50

Average

+3 S

−3 S

TYPICAL CHARACTERISTICS (continued)

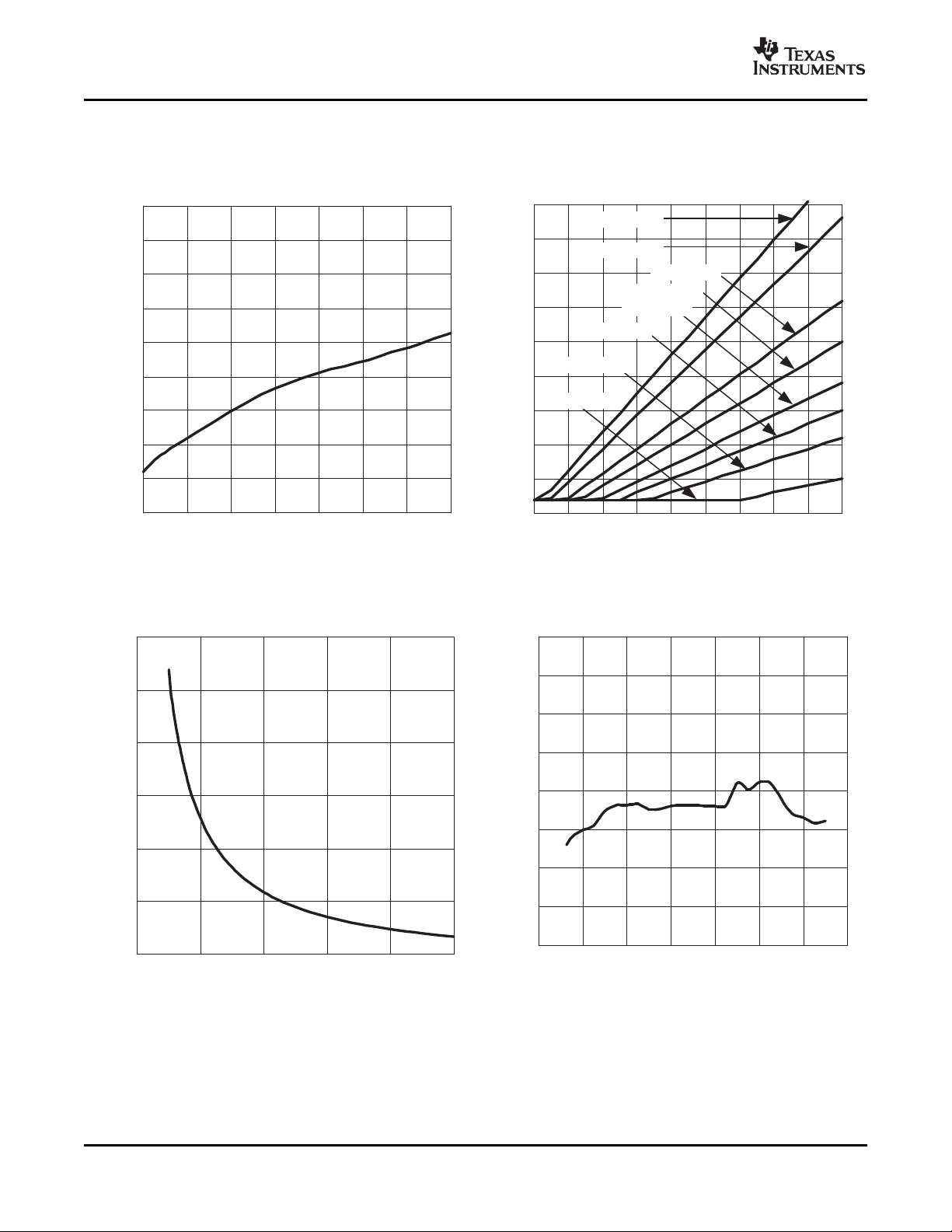

DBP VOLTAGE BOOTSTRAP DIODE VOLTAGE

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

Figure 3. Figure 4.

CURRENT LIMIT OFFSET VOLTAGE CURRENT LIMIT SINK CURRENT

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 5. Figure 6.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s) :TPS40075

Page 8

www.ti.com

−50 −25 50 100 1250

699

704

697

25 75

702

698

700

703

701

V

FB

− Feedback Voltage − V

TJ − Junction Temperature − °C

VDD

28 V

4.5 V

12 V

−50 −25 50 100 1250

0

30

−15

25 75

20

−10

5

25

10

−5

15

High Level Output Current

Low Level Output Current

I

SENSE

− Sense Amplifier Output Current − mA

TJ − Junction Temperature − °C

f

SW

− Switching Frequency − kHz

V

VDD

− Input Voltage − V

4 8 16 24 2812 20

500

490

497

491

493

498

496

494

499

495

492

RRT = 90.1kΩ

A

DIFF

− Sense Amplifier Gain − V/V

TJ − Junction Temperature − °C

−50 −25 50 100 1250 25 75

0.9965

0.9980

1.0005

0.9995

0.9970

0.9985

1.000

0.9990

0.9975

VDD = 4.5 V

VDD = 2.5 V

VDD = 1.25 V

VDD = 0.5 V

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

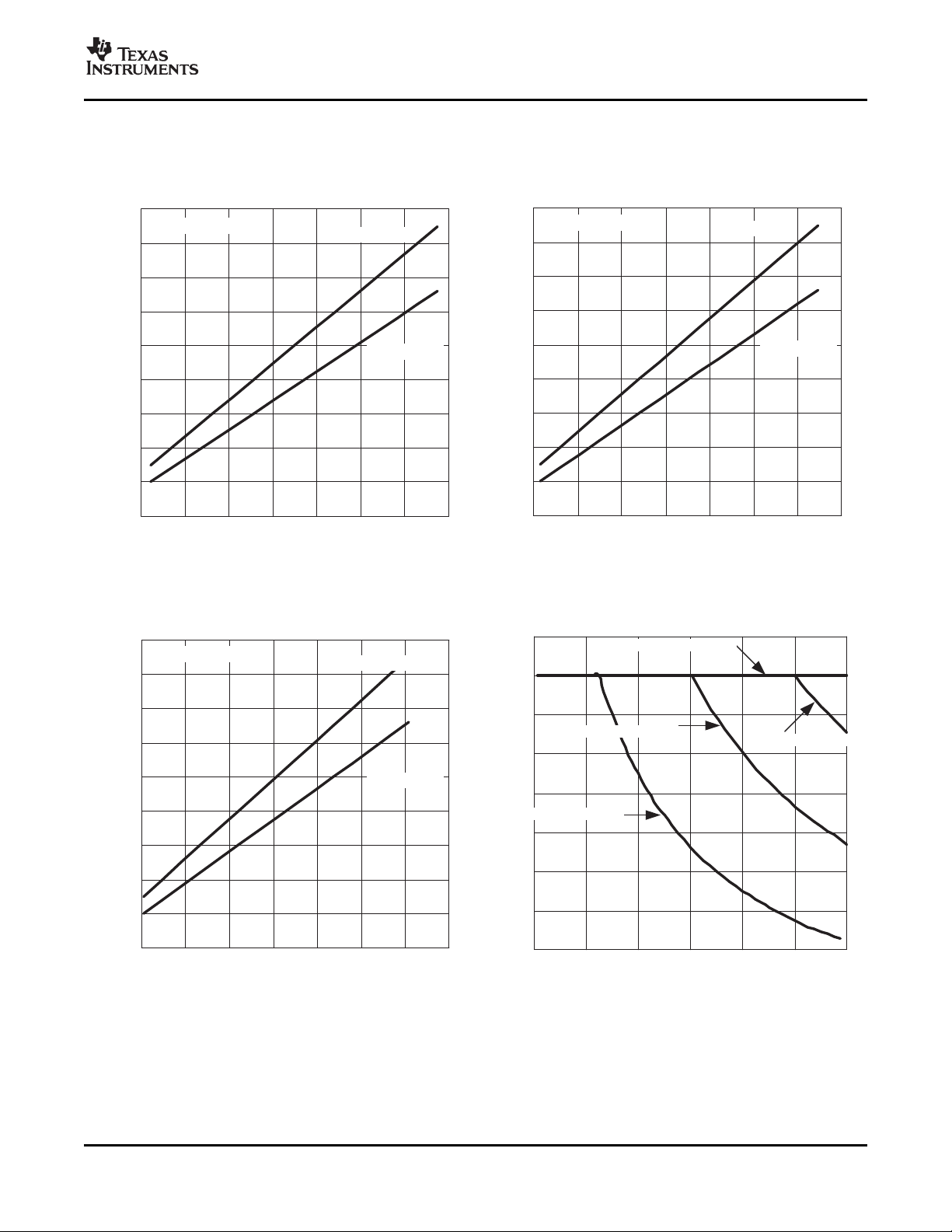

TYPICAL CHARACTERISTICS (continued)

FEEDBACK REGULATION VOLTAGE SENSE AMPLIFIER OUTPUT CURRENT

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 7. Figure 8.

CURRENT SENSE AMPLIFIER GAIN SWITCHING FREQUENCY

vs vs

JUNCTION TEMPERATURE INPUT VOLTAGE

8 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Figure 9. Figure 10.

Product Folder Link(s) :TPS40075

Page 9

www.ti.com

−50 −25 50 100 1250 25 75

4.35

3.90

4.20

3.95

4.30

4.15

4.05

4.00

4.25

4.10

TJ − Junction Temperature − °C

V

UVLO

− Undervoltage Lockout Threshold − V

V

UVLO(on)

V

UVLO(off)

TJ − Junction Temperature − °C

D

MAX

− Maximum Duty Cycle − %

−50 −25 50 100 1250 25 75

93

83

90

84

86

92

89

87

85

91

88

fSW = 100 kHZ

fSW = 500 kHZ

fSW = 1 MHZ

−50 −25 50 100 1250 25 75

1.10

0.90

1.04

0.92

0.96

1.08

1.02

0.98

0.94

1.06

1.00

TJ − Junction Temperature − °C

V

UVLO

− Relative Programmable UVLO Threshold − %

V

UVLO(on)

V

UVLO(off)

TJ − Junction Temperature − °C

I

SS

− Soft−Start Charging Current − µA

−50 −25 50 100 1250 25 75

14.0

10.0

10.5

11.0

13.5

12.5

11.5

13.0

12.0

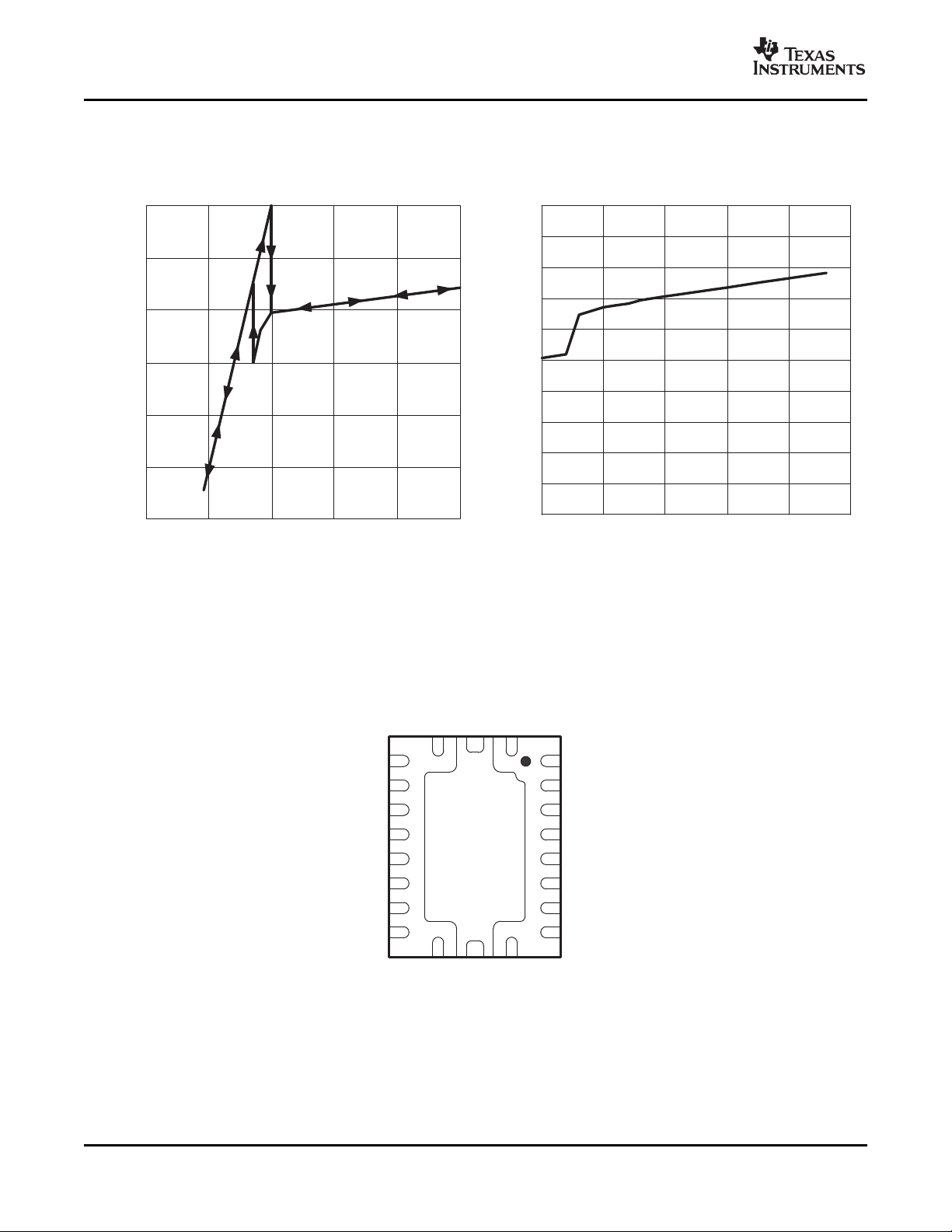

TYPICAL CHARACTERISTICS (continued)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

MAXIMUM DUTY CYCLE UNDERVOLTAGE LOCKOUT

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 11. Figure 12.

PROGRAMMABLE UVLO THRESHOLD SOFTSTART CHARGING CURRENT

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 13. Figure 14.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s) :TPS40075

Page 10

www.ti.com

100

1.5

0.5

200 300 400 500 600 700 800 900 1000

1.0

3.0

2.0

2.5

3.5

5.0

4.0

4.5

VIN = 28 V

VIN = 24 V

VIN = 18 V

VIN = 15 V

VIN = 12 V

VIN = 10 V

VIN = 8 V

VIN = 5 V

f

OSC

− Oscillator Frequency − kHz

V

OUT

− Output Voltage − V

TJ − Junction Temperature − °C

I

BIAS

− Error Amplifier Input Bias Current − nA

−50 −25 50 100 1250 25 75

0

−90

−80

−70

−10

−30

−60

−20

−40

−50

VDD − Input Voltage − V

f

OSC

− Frequency − kHz

2 6 18 26 3010

500

495

505

520

510

515

490

485

480

14 22

fSW − Switching Frequency − kHz

0

100

0

200 400 600 800 1000

200

300

400

500

600

R

T

− Timing Resistance − kΩ

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

TYPICAL CHARACTERISTICS (continued)

ERROR AMPLIFIER INPUT BIAS CURRENT MINIMUM OUTPUT VOLTAGE

vs vs

JUNCTION TEMPERATURE FREQUENCY

Figure 15. Figure 16.

SWITCHING FREQUENCY TYPICAL SWITCHING FREQUENCY

vs vs

TIMING RESISTANCE INPUT VOLTAGE

10 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Figure 17. Figure 18.

Product Folder Link(s) :TPS40075

Page 11

www.ti.com

60 90 150 180 210 270120 240

4

2

8

6

10

14

12

18

16

20

R

KFF

− Feedforward Impedance − kΩ

V

UVLO

−

Programmable UVLO Threshold − V

UVLOV

ON

f

SW

= 500 kHz

UVLOV

OFF

R

KFF

− Feedforward Impedance − kΩ

100 150 250 300 350 450200 400

4

2

8

6

10

14

12

18

16

20

V

UVLO

−

Programmable UVLO Threshold − V

UVLOV

ON

f

SW

= 300 kHz

UVLOV

OFF

40 60 100 120 140 18080 160

4

2

8

6

10

14

12

18

16

20

R

KFF

− Feedforward Impedance − kΩ

V

UVLO

−

Programmable UVLO Threshold − V

UVLOV

ON

f

SW

= 750 kHz

UVLOV

OFF

8 16 20 24 28124

40

20

30

70

50

60

100

80

90

VIN − Input Voltage − V

Duty Cycle − %

UVLO

(on)

= 8 V

UVLO

(on)

= 15 V

UVLO

(on)

= 4.5 V

UVLO

(on)

= 12 V

TYPICAL CHARACTERISTICS (continued)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

UVLO THRESHOLD VOLTAGE UVLO THRESHOLD VOLTAGE

vs vs

FEEDFORWARD IMPEDANCE FEEDFORWARD IMPEDANCE

Figure 19. Figure 20.

UVLO THRESHOLD VOLTAGE TYPICAL MAXIMUM DUTY CYCLE

vs vs

FEEDFORWARD IMPEDANCE INPUT VOLTAGE

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 21. Figure 22.

Product Folder Link(s) :TPS40075

Page 12

www.ti.com

255 10 2015 30

4.10

4.00

4.05

4.15

4.20

4.35

4.25

4.30

4.40

4.45

4.50

VDD − Input Voltage − V

V

DBP

− Low Voltage Bypass Voltage − V

VDD − Input Voltage − V

V

DBP

− Driver Bypass Voltage − V

0

5

4

5 10 15 20 25

7

6

9

8

10

SAO

GND

SS

FB

COMP

PGND

LDRV

DBP

RHL PACKAGE

(BOTTOM VIEW)

SYNC

PGD

LVBP

RT

KFF

ILIM

VDD

HDRV

SA+

SA−

BOOST

SW

20 1

11 10

2

3

4

5

6

7

8

9

19

18

17

16

15

14

13

12

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

INPUT VOLTAGE INPUT VOLTAGE

vs vs

DBP VOLTAGE LOW VOLTAGE BYPASS VOLTAGE

TYPICAL CHARACTERISTICS (continued)

Figure 23. Figure 24.

TERMINAL INFORMATION

12 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 13

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

Table 1. TERMINAL FUNCTIONS

TERMINAL

NAME NO.

BOOST 11 I

COMP 6 O FB pin to compensate the overall loop. This pin is internally clamped to a 3.4-V maximum output drive capability

DBP 9 O

FB 5 I

GND 3 - Ground reference for the device.

HDRV 12 O

ILIM 14 I conduction. Just prior to the beginning of a switching cycle this pin is pulled to approximately V

KFF 15 I into this pin is used to control the slope of the PWM ramp and program undervoltage lockout. Nominal voltage at

LDRV 8 O

LVBP 17 O

PGD 18 O

PGND 7

RT 16 I A resistor is connected from this pin to GND to set the switching frequency.

SA+ 20 I Noninverting input of the remote voltage sense amplifier.

SA- 1 I Inverting input of the remote voltage sense amplifier.

SAO 2 O Output of the remote voltage sense amplifier.

SS 4 I

SW 10 I timing. This pin is also the return path from the high-side FET for the floating high-side FET driver. A 1.5- Ω resistor

SYNC 19 I Logic input for pulse train to synchronize oscillator.

VDD 13 I Supply voltage for the device.

I/O DESCRIPTION

The BOOST voltage is 8-V greater than the input voltage. The peak voltage on BOOST is equal to the SW node

voltage plus the voltage present at DBP less the bootstrap diode drop. This drop can be 1.4 V for the internal

bootstrap diode or 300 mV for an external schottkey diode. The voltage differential between this pin and SW is the

available drive voltage for the high-side FET.

Output of the error amplifier, input to the PWM comparator. A feedback network is connected from this pin to the

for quicker recovery from a saturated feedback loop situation.

8-V regulator output used for the gate drive of the N-channel synchronous rectifier and as the supply for charging

the bootstrap capacitor. This pin should be bypassed to ground with a 1.0-µF ceramic capacitor.

Inverting input to the error amplifier. In normal operation the voltage on this pin is equal to the internal reference

voltage, 0.7 V.

Floating gate drive for the high-side N-channel MOSFET. This pin switches from BOOST (MOSFET on) to SW

(MOSFET off).

Short circuit protection programming pin. This pin is used to set the overcurrent threshold. An internal current sink

from this pin to ground sets a voltage drop across an external resistor connected from this pin to VDD. The voltage

on this pin is compared to the voltage drop (V

when SW is within 2 V of V

capacitor across the resistor from ILIM to VDD allows the ILIM threshold to decrease during the switch on time,

or after a timeout (the precondition time) - whichever occurs first. Placing a

VDD

-V

VDD

) across the high side N-channel MOSFET during

SW

VDD

effectively programming the ILIM blanking time. See Applications Information section.

A resistor is connected from this pin to VDD programs the amount of input voltage feed-forward. The current fed

this pin is maintained at 400 mV.

Gate drive for the N-channel synchronous rectifier. This pin switches from DBP (MOSFET on) to PGND (MOSFET

off). For proper operation, the total gate charge of the MOSFET connected to LDRV should be less than 50nC.

4.2-V reference used for internal device logic and analog functions. This pin should be bypassed to GND with a

0.1-µF ceramic capacitor. External loads less than 1 mA and electrically quiet may be applied.

This is an open drain output that pulls to ground when soft start is active, or when the FB pin is outside a ± 10%

band around the 700 mV reference voltage.

Power ground reference for the device. There should be a low-impedance path from this pin to the source(s) of the

lower MOSFET(s).

Soft-start programming pin. A capacitor connected from this pin to GND programs the soft-start time. The

capacitor is charged with an internal current source of 12 µA. The resulting voltage ramp on the SS pin is used as

a second non-inverting input to the error amplifier. The voltage at this error amplifier input is approximately 1 V

less that that on the SS pin. Output voltage regulation is controlled by the SS voltage ramp until the voltage on the

SS pin reaches the internal offset voltage of 1 V plus the internal reference voltage of 700 mV. If SS is below the

internal offset voltage of 1 V (300 mV minimum ensured), the resulting output voltage is zero. Also provides timing

for fault recovery attempts. Pulling this pin below 250 mV causes the controller to enter a shutdown state with

HDRV and LDRV held in a low state.

This pin is connected to the switched node of the converter and used for overcurrent sensing as well as gate drive

in series with this pin is required for protection against substrate current issues.

/2 and released

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s) :TPS40075

Page 14

www.ti.com

9

12

8

13

17

16

15

VDD

LVBP

RT

KFF

DBP

HDRV

LDRV

18

3

5

4

PGD

GND

FB

SS

6COMP

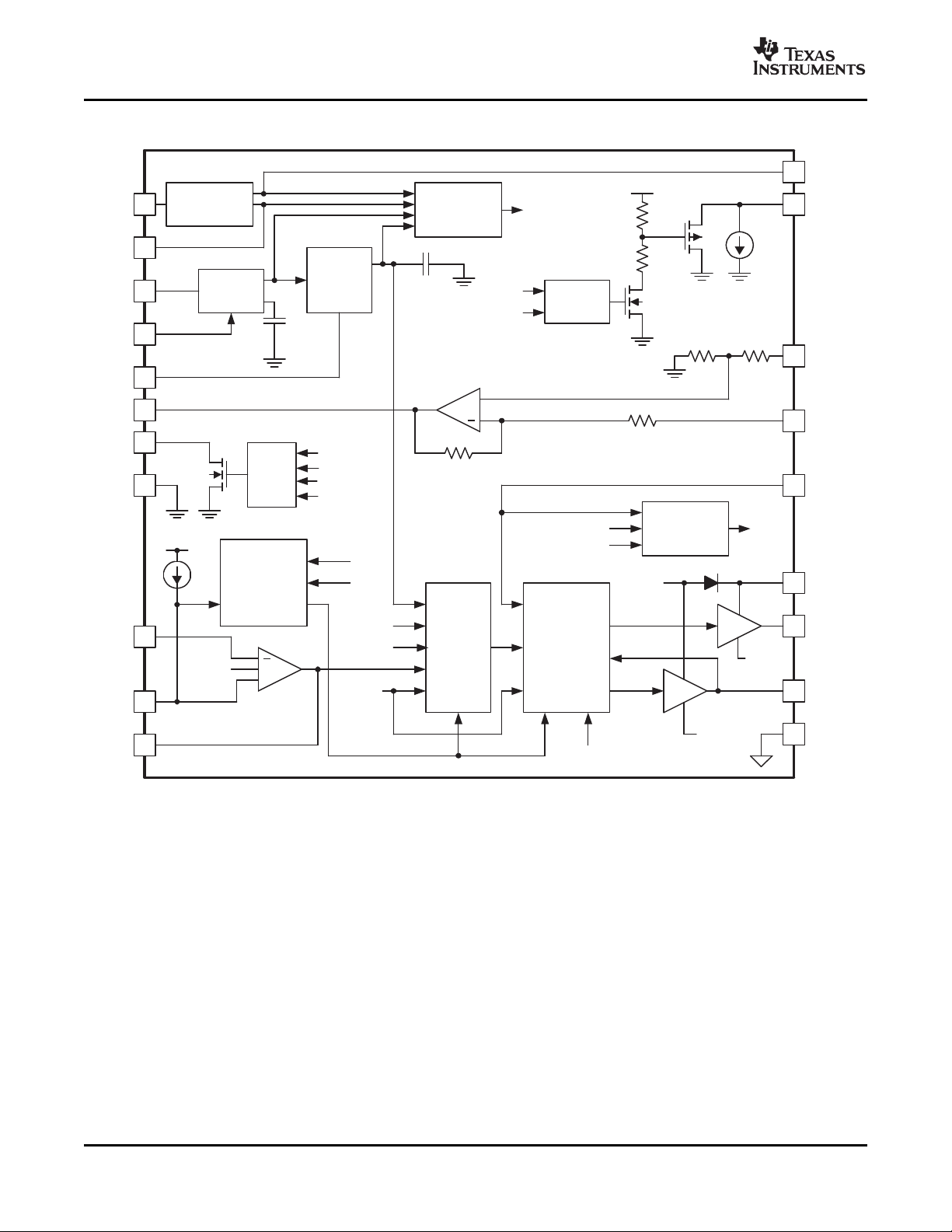

Reference

Regulator

Predictive

Gate Drive

Control

Logic

UVLO

Controller

Oscillator

14 ILIM

Pulse

Control

SW

CLK

10 SW

Overcurrent

Comparator

and Control

CLK

ILIM OC

7 PGND

11 BOOST

VDD

UVLO

Ramp

Generator

Power

Good

Logic

770 mV

FB

630 mV

SS Active

PWM

OC

CLK

UVLO

FAULT

IZERO

DBP

+

+

700 mV

RAMP

Soft Start

and

Fault Control

OC

CLK

SW

PGND

LVBP

2SAO

20 SA+

1 SA−

R

R

R

+

R

UDG−04076

19SYNC

TPS40075

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

SIMPLIFIED BLOCK DIAGRAM

14 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 15

www.ti.com

13

7

14

12

10

8

ILIM

HDRV

SW

LDRV

VDD

PGND

TPS40075

C

R

VIN

UDG−05058

+

_

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

APPLICATION INFORMATION

The TPS40075 allows the user to construct synchronous voltage mode buck converters with inputs ranging from

4.5 V to 28 V and outputs as low as 700 mV. Predictive gate drive circuitry optimizes switching delays for

increased efficiency and improved converter output power capability. Voltage feed-forward is employed to ease

loop compensation for wide input range designs and provide better line transient response.

An on-board unity gain differential amplifier is provided for remote sensing in applications that require the tightest

load regulation. The TPS40075 incorporates circuitry to allow startup into a pre-existing output voltage without

sinking current from the source of the pre-existing output voltage. This avoids damaging sensitive loads at

startup. The controller can be synchronized to an external clock source or can free run at a user programmable

frequency. An integrated power good indicator is available for logic (open drain) output of the condition of the

output of the converter.

MINIMUM PULSE WIDTH

The TPS40075 has limitations on the minimum pulse width that can be used to design a converter. Reliable

operation is guaranteed for nominal pulse widths of 150 ns and above. This places some restrictions on the

conversion ratio that can be achieved at a given switching frequency. See Figure 16 .

SLEW RATE LIMIT ON VDD

The regulator that supplies power for the drivers on the TPS40075 requires a limited rising slew rate on VDD for

proper operation if the input voltage is above 10 V. If the slew rate is too great, this regulator can over shoot and

damage to the part can occur. To ensure that the part operates properly, limit the slew rate to no more than

0.12 V/ μ s as the voltage at VDD crosses 8 V. If necessary, an R-C filter can be used on the VDD pin of the

device. Connect the resistor from the VDD pin to the input supply of the converter. Connect the capacitor from

the VDD pin to PGND. There should not be excessive (more than a 200-mV) voltage drop across the resistor in

normal operation. This places some constraints on the R-C values that can be used. Figure 25 is a schematic

fragment that shows the connection of the R-C slew rate limit circuit. Equation 1 and Equation 2 give values for R

and C that limits the slew rate in the worst case condition.

Figure 25. Limiting the Slew Rate

Product Folder Link(s) :TPS40075

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 15

Page 16

www.ti.com

R t

0.2 V

fSW Q

g(TOT)

) I

IDD

C u

V

VIN

* 8 V

R SR

R

T

+

ǒ

1

fSW(kHz) 17.82 10

*6

* 23ǓkW

R

KFF

+ 0.131 RT V

UVLO(on)

* 1.61 10*3 V

UVLO(on)

2

) 1.886 V

UVLO

* 1.363* 0.02 RT* 4.87 10*5 R

2

T

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

where

• V

• fSWis the switching frequency

• Q

• I

• SR is the maximum allowed slew rate [12 × 10

SETTING THE SWITCHING FREQUENCY (PROGRAMMING THE CLOCK OSCILLATOR)

The TPS40075 has independent clock oscillator and PWM ramp generator circuits. The clock oscillator serves as

the master clock to the ramp generator circuit. Connecting a single resistor from RT to ground sets the switching

frequency of the clock oscillator. The clock frequency is related to R

PROGRAMMING THE RAMP GENERATOR CIRCUIT AND UVLO FUNCTION

The ramp generator circuit provides the actual ramp used by the PWM comparator and provides voltage

feed-forward by varying the PWM ramp slope as the line voltage changes. As the input voltage to the converter

increases, the slope of the PWM ramp increase by a proportionate amount. The programmable UVLO circuit

works by monitoring the level reached by the PWM ramp during a clock cycle. The PWM ramp must reach

approximately 1 V in amplitude during a clock cycle, or the converter is not be allowed to start. This

programmable UVLO point is set via a single resistor (R

are related by (approximately)

is the final value of the input voltage ramp

VIN

is the combined total gate charge for both upper and lower MOSFETs (from MOSFET data sheet)

g(TOT)

is the TPS40075 input current (3.5 mA maximum)

IDD

4

] (V/s)

by:

T

) connected from KFF to VDD. R

KFF

, V

KFF

and R

START

(1)

(2)

(3)

RT

where

• V

• R

is in volts

UVLO(on)

and RTare in k Ω

KFF

This yields typical numbers for the programmed startup voltage. The minimum and maximum values may vary up

± 15% from this number. Figure 19 through Figure 21 show the typical relationship of V

UVLO(on)

, V

UVLO(off)

and R

at three common frequencies.

The programmable UVLO circuit incorporates 20% hysteresis from the start voltage to the shutdown voltage. For

example, if the startup voltage is programmed to be 10 V, the controller starts when V

down when V

falls below 8 V. The maximum duty cycle begins to decrease as the input voltage rises to twice

DD

reaches 10 V and shuts

DD

the startup voltage. Below this point, the maximum duty cycle is as specified in the electrical table. Note that with

this scheme, the theoretical maximum output voltage that the converter can produce is approximately two times

the programmed startup voltage. For design, set the programmed startup voltage equal to or greater than the

desired output voltage divided by maximum duty cycle (85% for frequencies 500 kHz and below). For example, a

5-V output converter should not have a programmed startup voltage below 5.9 V. Figure 22 shows the theoretical

maximum duty cycle (typical) for various programmed startup voltages

If the programmable UVLO voltage is set below 6.5V nominal, a possibility exists that the part may enter factory

test mode when powered down. This can cause an undesired output rise as power is removed from the

converter. To prevent this from happening, connect a 330 k Ω resistor from SS to GND. An example of this can be

seen in Figure 37

(4)

KFF

16 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 17

www.ti.com

VDG−03172

RAMP

COMP

SW

VIN

VIN

SW

COMP

RAMP

V

PEAK

V

VALLEY

T

2

t

ON1

> t

ON2

and d

1

> d

2

t

ON2

t

ON1

d +

t

ON

T

T

1

t

START

w 2p L C

OUT

Ǹ

(seconds)

CSS+ t

SS

I

SS

V

FB

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

Figure 26 shows the effect of changing input voltage on the duty cycle, and how that change takes place. The

pulse width modulator (PWM) ramp input is generated using a current that is proportional to the current into the

KFF pin. The TPS40075 holds this pin at a constant 400 mV, so connecting a resistor from KFF to the input

power supply causes a current to flow into the KFF pin that is proportional to the input voltage. The slope of the

ramp signal to the PWM is therefore proportional to the input voltage. This allows the duty cycle to change with

variations in Vin without requiring much response from the error amplifier, resulting in very good line transient

response. Another benefit is essentially constant PWM gain over the entire input voltage operating range. This

makes the output control loop easier to design for a wide input range converter.

Figure 26. Voltage Feed-Forward and PWM Duty Cycle Waveforms

PROGRAMMING SOFT START

TPS40075 uses a closed-loop approach to ensure a controlled ramp on the output during start-up. Soft-start is

programmed by connecting an external capacitor (C

fixed current, generating a ramp signal. The voltage on SS is level shifted down approximately 1 V and fed into a

separate non-inverting input to the error amplifier. The loop is closed on the lower of the level shifted SS voltage

or the 700-mV internal reference voltage. Once the level shifted SS voltage rises above the internal reference

voltage, output voltage regulation is based on the internal reference. To ensure a controlled ramp-up of the

output voltage the soft-start time should be greater than the L-C

where

• L is the value of the filter inductor

• C

• t

is the value of the output capacitance

OUT

is the output ramp up-time

START

For a desired soft-start time, the soft-start capacitance, C

Please note: There is a direct correlation between t

t

is, the higher the input current required during start-up since the output capacitance must be charged

START

faster.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s) :TPS40075

) from the SS pin to GND. This capacitor is charged by a

SS

time constant or:

OUT

, can be found from:

SS

and the input current required during start-up. The lower

START

(5)

(6)

Page 18

www.ti.com

ILIM Threshold

T2

T1

ILIM Threshold

T3

T1

ILIM

ILIM

SW

SW

VIN − 2V

VIN − 2V

UDG−03173

Overcurrent

(A)

(B)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

PROGRAMMING SHORT CIRCUIT PROTECTION

The TPS40075 uses a two-tier approach to short circuit protection. The first tier is a pulse-by-pulse protection

scheme. Short circuit protection is implemented by sensing the voltage drop across the high-side MOSFET while

it is turned on. The MOSFET drain to source voltage is compared to the voltage dropped across a resistor (R

connected from VDD to the ILIM pin. The voltage drop across this resistor is produced by a constant current sink.

If the voltage drop across the MOSFET exceeds the voltage drop across the ILIM resistor the switching pulse is

immediately terminated. The MOSFET remains off until the next switching cycle is initiated.

In addition, just prior to the high-side MOSFET turning on, the ILIM pin is pulled down to approximately half of

VDD. The ILIM pin is allowed to return to its nominal value after one of two events occur:

1. The SW node rises to within approximately 2 V of VDD

2. An internal timeout occurs, approximately 125-ns after ILIM is initially pulled down

If the SW node rises to within approximately 2-V of VDD, the device allows ILIM to go back to its nominal value.

This is illustrated in Figure 27 A. T1 is the delay time from the internal PWM signal being asserted and the rise of

SW. This includes the driver delay of 50 ns typical, and the turn on time of the high-side MOSFET. The MOSFET

used should have a turn on time less than 75 ns. T2 is the reaction time of the sensing circuit that allows ILIM to

start to return to its nominal value, typically 20ns.

)

ILIM

Figure 27. Switching and Current Limit Waveforms and Timing Relationship

The second event that can cause ILIM to return to its nominal value is for an internal timeout to expire. This is

illustrated in Figure 27 B as T3. Here SW never rises to VDD-2, for whatever reason, and the internal timer times

out. This allows the ILIM pin to start its transition back to its nominal value.

Prior to ILIM starting back to its nominal value, short circuit sensing is not enabled. In normal operation, this

insures that the SW node is at a higher voltage than ILIM when short circuit sensing starts, avoiding false trips

while allowing for a quicker blanking delay than would ordinarily be possible. Placing a capacitor across R

sets an exponential approach to the normal voltage at the ILIM pin. This exponential “ decay ” of the short circuit

threshold can be used to compensate for ringing on the SW node after its rising edge and to help compensate

for slower turn-on MOSFETs. Choosing the proper capacitance requires care. If the capacitance is too large, the

voltage at ILIM does not approach the desired short circuit level quickly enough, resulting in an apparent shift in

short circuit threshold as pulse width changes.

18 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

ILIM

Page 19

www.ti.com

VDG−03174

t

BLANKING

7 Current Limit Trips

(HDRV Cycle Terminated by Current Limit Trip)

7

Soft-Start

Cycles

HDRV

Clock

V

ILIM

V

VIN−VSW

SS

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

The comparator that looks at ILIM and SW to determine if a short circuit condition exists has a clamp on its SW

input. This clamp makes the SW node never appear to fall more than 1.4 V (approximately, could be as much as

2 V at – 40 ° C) below VDD. While ILIM is more than 1.4 V below VDD short circuit sensing is effectively disabled,

giving a programmable absolute blanking time. As a general rule, it is best to make the time constant of the R-C

at the ILIM pin 20% or less of the nominal pulse width of the converter (See Equation 11 )

The second tier protection incorporates a fault counter. The fault counter is incremented on each cycle with an

overcurrent pulse and decremented on a clock cycle without an overcurrent pulse. When the counter reaches

seven (7) a fault condition is declared by the controller. When this happens, the output drivers turn both

MOSFETs off. Seven soft-start cycles are initiated (without activity on the HDRV and LDRV outputs) and the

PWM is disabled during this period. The counter is decremented on each soft-start cycle. When the counter is

decremented to zero the PWM is re-enabled and the controller attempts to restart. If the fault has been removed

the output starts up normally. If the output fault is still present the counter counts seven overcurrent pulses and

re-enters the second tier fault mode. Refer to Figure 28 for typical fault protection waveforms.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 28. Typical Fault Protection Waveforms

Product Folder Link(s) :TPS40075

Page 20

www.ti.com

I

SCP

u

C

OUT

V

OUT

t

START

) I

LOAD

(A)

R

ILIM

+

I

SCP

R

DS(onMAX)

) V

ILIM (ofst)

I

ILIM

W

I

SCP(max)

+

I

ILIM(max)

R

ILIM

) 50 mV

R

DS(onMIN)

A

I

SCP(min)

+

I

ILIM(min)

R

ILIM

) 10 mV

R

DS(onMAX)

A

C

ILIM(max)

+

V

OUT

0.2

VIN R

ILIM

f

SW

(Farads)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

The minimum short circuit limit threshold (I

(I

).

LOAD

The short circuit limit programming resistor (R

) depends on t

SCP

) is calculated from:

ILIM

, C

, V

START

OUT

, and the load current at turn-on

OUT

where

• I

• V

• I

• R

is the current into the ILIM pin (135 μ A typical)

ILIM

is the offset voltage of the ILIM comparator (-30 mV typical)

ILIM(ofst)

is the short-circuit protection current

SCP

DS(on)MAX

is the drain-to-source resistance of the high-side MOSFET

To find the range of the short circuit threshold values use the following equations.

The TPS40075 provides short-circuit protection only. As such, it is recommended that the minimum short circuit

protection level be placed at least 20% above the maximum output current required from the converter. The

maximum output of the converter should be the steady state maximum output plus any transient specification

that may exist.

The ILIM capacitor maximum value can be found from:

(7)

(8)

(9)

(10)

Note that this is a recommended maximum value. If a smaller value can be used, it should be to improve

protection. For most applications, consider using half the maximum value shown in Equation 11 .

BOOST AND DBP BYPASS CAPACITANCE

The BOOST capacitance provides a local, low-impedance flying source for the high-side driver. The BOOST

capacitor should be a good quality, high-frequency ceramic capacitor. A minimum value of 100-nF is suggested.

The DBP capacitor has to provide energy storage for switching both the synchronous MOSFET and the high-side

MOSFET (via the BOOST capacitor). The suggested value for this capacitor is 1- μ F ceramic, minimum.

INTERNAL REGULATORS

The internal regulators are linear regulators that provide controlled voltages for the drivers and the internal

circuitry to operate from. The low-side driver operates directly from the 8-V regulator supply while the high-side

driver bootstrap capacitor is charged from this supply. The actual voltage delivered to the high-side driver is the

voltage on the DBP pin less any drop from the bootstrap diode. If the internal bootstrap diode is used, the drop

across that diode is nominally 1.4 V at room temperature. This regulator has two modes of operation. At voltages

below 8.5 V on VDD, the regulator is in a low dropout mode of operation and tries to provide as little impedance

as possible from VDD to DBP. When VDD is above 10 V, the regulator regulates DBP to 8 V. Between these two

voltages, the regulator is in whatever state it was in when VDD entered this region. The LVBP pin is connected

to a 4.2-V regulator that supplies power for the internal control circuitry. Small amounts of current can be drawn

from these pins for other external circuit functions, as long as power dissipation in the controller chip remains at

acceptable levels and junction temperature does not exceed 125 ° C. Any external load connected to LVBP should

be electrically quiet to avoid degrading performance of the TPS40075. Typical output voltages for these two

regulators are shown in Figure 23 and Figure 24 .

(11)

20 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 21

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

DIFFERENTIAL SENSE AMPLIFIER

The TPS40075 has an on board differential amplifier intended for use as a remote sensing amplifier for the

output voltage. Use of this amplifier for remote sensing eliminates load regulation issues due to voltage drops

that occur between the converter and the actual point of load. The amplifier is powered from the DBP pin and

can be used to monitor output voltages up to 6 V with a DBP voltage of 8 V. For lower DBP voltages, the sense

amplifier can be used to monitor output voltages up to 2-V below the DBP voltage. The internal resistors used to

configure the amplifier for unity gain match each other closely, but their absolute values can vary as much as

30%, so adding external resistance to alter the gain is not accurate in a production environment.

SYNCHRONIZATION

The SYNC pin accepts logic level signals and is used to synchronize the TPS40075 to an external clock source.

Synchronization occurs on the rising edge of the signal at the SYNC pin. There is a fixed delay of approximately

300 ns from the rising edge of the waveform at SYNC to the HDRV output turning on the high-side FET. The pin

may be left floating in this function is not used, or it may be connected to GND. The frequency of the external

clock must be greater than the free running frequency of the device as set by the resistor on the RT pin (R

This pin requires a totem pole drive, or open collector/drain if pull up resistor to either LVBP or a separate supply

between 2.5 V and 5 V is used. Synchronization does not affect the modulator gain due to the voltage feed

forward circuitry. The programmable UVLO thresholds are affected by synchronization. The thresholds are

shifted by the ratio of the sync frequency to the free running frequency of the converter. For example,

synchronizing to a frequency 20% higher than the free running frequency results in the programmable UVLO

thresholds shifting up 20% from their calculated free run values. The synchronization frequency should be kept

less than 1.5 times the free run frequency for best performance, although higher multiples can be used.

).

RT

POWERGOOD OPERATION

The PGD pin is an open drain output that actively pulls to GND if any of the following conditions are met

(assuming that the input voltage is above 4.5 V)

• Soft-start is active (V

• V

• V

FB

FB

< 0.63 V

> 0.77 V

• Programmable UVLO condition not satisfied (V

< 3.5 V)

VSS

below programmed level)

IN

• Overcurrent condition exists

• Die temperature is greater than 165 ° C

PRE-BIASED OUTPUTS

Some applications require that the converter not sink current during startup if a pre-existing voltage exists at the

output. Since synchronous buck converters inherently sink current some method of overcoming this characteristic

must be employed. Applications that require this operation are typically power rails for a multi supply processor

or ASIC. The method used in this controller, is to not allow the low side or rectifier FET to turn on until there the

output voltage commanded by the start up ramp is higher than the pre-existing output voltage. This is detected

by monitoring the internal pulse width modulator (PWM) for its first output pulse. Since this controller uses a

closed loop startup, the first output pulse from the PWM does not occur until the output voltage is commanded to

be higher than the pre-existing voltage. This effectively limits the controller to sourcing current only during the

startup sequence.

If the pre-existing voltage is higher that the intended regulation point for the output of the converter, the converter

starts and sinks current when the soft-start time has completed

SHUTDOWN AND SEQUENCING

The TPS40075 can be shut down by pulling the SS pin to a level below 250 mV. Pulling the pin low resets the

internal pre-bias circuitry to ensure that the converter does not damage sensitive loads.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s) :TPS40075

Page 22

www.ti.com

PD+ Qg VDR f

SW

(Wattsńdriver)

P

T

+

ǒ

2 P

D

V

DR

) I

Q

Ǔ

VIN(Watts)

P

T

+

ǒ

2 Qg fSW) I

Q

Ǔ

VIN(Watts)

P

T

+

TJ* T

A

q

JA

(Watts)

f

SW

+

ǒ

ƪ

ǒ

TJ*T

A

Ǔ

ǒ

q

JA VIN

Ǔ

ƫ* I

Q

Ǔ

ǒ

2 Q

g

Ǔ

(Hz)

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

Automatic startup sequencing can be accomplished by connecting the PGD pin of a master supply based on the

TPS40075 to the SS pin of a slave supply. The master comes up first and release the salve SS pin to allow the

slave to come up. Controlled shutdown of sequenced supplies can be accomplished by either pulling the SS pin

of the master below the shutdown threshold and letting the PGD pin pull the slave SS pin down, or by pulling

down the SS pins of all supplies simultaneously.

TPS40075 POWER DISSIPATION

The power dissipation in the TPS40075 is largely dependent on the MOSFET driver currents and the input

voltage. The driver current is proportional to the total gate charge, Qg, of the external MOSFETs. Driver power

(neglecting external gate resistance) can be calculated from:

where

• V

The total power dissipation in the TPS40075, assuming the same MOSFET is selected for both the high-side and

synchronous rectifier is described in Equation 13 .

or

is the driver output voltage

DR

(12)

(13)

where

• IQis the quiescent operating current (neglecting drivers)

The maximum power capability of the TPS40075 PowerPAD package is dependent on the layout as well as air

flow. The thermal impedance from junction to air ambient assuming 2-oz. copper trace and thermal pad with

solder and no air flow is θ

The maximum allowable package power dissipation is related to ambient temperature by Equation 15 .

Substituting Equation 15 into Equation 14 and solving for f

TPS4007x. The result is described in Equation 16 .

= 60 ° C/W

JA

yields the maximum operating frequency for the

SW

BOOST DIODE

The TPS40075 has internal diodes to charge the boost capacitor connected from SW to BOOST. The drop

across this diode is rather large at 1.4-V nominal at room temperature resulting in the drive voltage to the

high-side MOSFET being reduced by this amount from the DBP voltage. If this drop is too large for a particular

application, an external diode may be connected from DBP (anode) to BOOST (cathode). This provides

significantly improved gate drive for the high-side MOSFET, especially at lower input voltages.

(14)

(15)

(16)

22 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 23

www.ti.com

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

GROUNDING AND BOARD LAYOUT

The TPS40075 provides separate signal ground (GND) and power ground (PGND) pins. Care should be given to

proper separation of the circuit grounds. Each ground should consist of a plane to minimize its impedance if

possible. The high power noisy circuits such as the output, synchronous rectifier, MOSFET driver decoupling

capacitor (DBP), and the input capacitor should be connected to PGND plane.

Sensitive nodes such as the FB resistor divider and RT should be connected to the GND plane. The GND plane

should only make a single point connection to the PGND plane. It is suggested that the GND pin be tied to the

copper area for the PowerPAD underneath the chip. Tie the PGND to the PowerPAD copper area as well and

make the connection to the power circuit ground from the PGND pin. Reference the output voltage divider to the

GND pin.

Component placement should ensure that bypass capacitors (LVPB and DBP) are located as close as possible

to their respective power and ground pins. Also, sensitive circuits such as FB, RT and ILIM should not be located

near high dv/dt nodes such as HDRV, LDRV, BOOST, and the switch node (SW). Failure to follow careful layout

practices results in sub-optimal operation.

SYNCHRONOUS RECTIFIER CONTROL

Table 2 describes the state of the rectifier MOSFET control under various operating conditions.

Table 2. Synchronous Rectifier MOSFET States

SYNCHRONOUS RECTIFIER OPERATION DURING

SOFT-START NORMAL (FAULT RECOVERY IS SAME OVERVOLTAGE

Off until first high-side pulse is Turns off at the start of a new

detected, then on when high-side cycle. Turns on when the OFF

MOSFET is off high-side MOSFET is turned off

FAULT

AS SOFT-START)

Turns OFF only at start of next

cycle ON if duty cycle is > 0

For proper operation, the total gate charge of the MOSFET connected to LDRV should be less than 50nC.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s) :TPS40075

Page 24

www.ti.com

R

P1

R

Z1

R

PGD

C

O

C

Z2

R

SET2

R

KFF

1

2

3

4

19

18

17

16

SYNC

PGD

LVBP

RT

SA−

SAO

GND

SS

TPS40075

15

14

13

12

KFF

ILIM

VDD

HDRV

5

6

7

8

FB

COMP

PGND

LDRV

9 DBP

20

SA+

10

SW

11

BOOST

UDG−04125

SYNC

−SENSE

QSR

MLCCELCO

QSW

+SENSE

ELCO

0V

R

LIM

C

LIM

L

C

O

V

O

C

VDD

C

VLVBP

C

PZ1

C

IN

V

IN

R

PZ2

C

P2

R

SET1

C

SS

C

DBP

D

BOOST

C

BOOST

R

T

1.5 Ω

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

DESIGN EXAMPLE

1. SPECIFICATIONS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT CURRENT

V

IN

V

O

V

RIPPLE

V

OVER

V

UNDER

I

LOAD

I

SCP

η Efficiency VIN= 12 V, I

f

SW

2. SCHEMATIC

Input voltage 10.8 12.0 13.2

Output voltage I

= 10 A 1.5 5 V

OUT

Regulation 1.47 1.53

Output ripple voltage I

Output overshoot I

Output undershoot I

= 15 A 30

O(max)

= 8 A 50 mV

STEP

= 8 A 50

STEP

Output current 0 15

Short circuit current trip point 16 30

Switching frequency 400 kHz

= 15 A 85%

LOAD

A

24 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Figure 29. TPS40075 Reference Design Schematic

Product Folder Link(s) :TPS40075

Page 25

www.ti.com

L +

V

O

V

IN(max)

ǒ

V

IN(max)

* V

O

Ǔ

fSW DI

I

LOAD_RMS

+ I

LOAD

2

)

DI

2

12

Ǹ

+ 15.03 A

IPK+ I

LOAD

)

DI

2

2

+ 16.65 A

C

O

u

L I

STEP

2

2 V

UNDER

D

MAX

ǒ

VIN* V

O

Ǔ

C

O

u

L I

STEP

2

2 V

OVER

V

O

ESR t

V

RIPPLE

DI

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

3. COMPONENT SELECTION

3. 1 Power Train Components

Designers familiar with the buck converter can skip to section 3.2 Component Selection for TPS40075.

3.1.1 Output Inductor, L

O

The output inductor is one of the most important components to select. It stores the energy necessary to keep

the output regulated when the switch MOSFET is turned off. The value of the output inductor dictates the peak

and RMS currents in the converter. These currents are important when selecting other components. Equation 17

can be used to calculate a value for L.

Δ I is the allowable ripple in the inductor. Selecting Δ I also sets the output current when the converter goes into

discontinuous mode (DCM) operation. Since this converter utilizes MOSFETs for the rectifier, DCM is not a major

concern. Select Δ I to be between 20% and 30% of maximum I

. For this design, Δ I of 3 A was selected. The

LOAD

calculated L is 1.1 μ H. A standard inductor with value of 1.0 μ H was chosen. This increases Δ I by about 10% to

3.3 A.

With this Δ I value, calculate the RMS and peak current flowing in LO. Note this peak current is also seen by the

switching MOSFET and synchronous rectifier.

3.1.2 Output Capacitor, CO, ELCO and MLCC

Several parameters must be considered when selecting the output capacitor. The capacitance value should be

selected based on the output overshoot, V

, and undershoot, V

OVER

, during a transient load, I

UNDER

, on the

STEP

converter. The equivalent series resistance (ESR) is chosen to allow the converter meet the output ripple

specification, V

. The voltage rating must be greater than the maximum output voltage. Other parameters to

RIPPLE

consider are: equivalent series inductance which is important in fast transient load situations. Also size and

technology can be factors when choosing the output capacitor. In this design a large capacitance electrolytic type

capacitor, C

the output ripple specification. While a smaller multiple layer ceramic capacitor, C

ELCO, is used to meet the overshoot and under shoot specifications. Its ESR is chosen to meet

O

MLCC, is used to filter high

O

frequency noise.

The minimum required capacitance and maximum ESR can be calculated using the equations below.

(17)

(18)

(19)

Using Equation 20 through Equation 22 , the capacitance for C

should be greater than 495 μ F and its ESR

O

should be less than 9.1m Ω . The 1000 μ F/25 V capacitor from Rubycon's MBZ or Panasonic's series EEU-FL was

chosen. Its ESR is 19 m Ω , so two in parallel are used. The slightly higher ESR is offset by the four times

increase in capacitance. A 2.2 μ F/16 V MLCC is also added in parallel to reduce high frequency noise.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s) :TPS40075

(20)

(21)

(22)

Page 26

www.ti.com

I

CAP(RMS)

+

ƪǒ

I

LOAD(max)

* I

IN(avg)

2

Ǔ

)

DI

2

12

ƫ

D ) I

IN(avg)

2

(

1 * D)

Ǹ

I

D

+

V

O

V

IN(min)

ǒ

I

LOAD(max)

2

)

DI

2

12

Ǔ

Ǹ

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

3.1.3. Input Capacitor, CIN, ELCO and MLCC

The input capacitor is selected to handle the ripple current of the buck stage. Also a relative large capacitance is

used to keep the ripple voltage on the supply line low. This is especially important where the supply line is high

impedance. It is recommended that the supply line be kept low impedance. The input capacitor ripple current can

be calculated using Equation 23 .

where

• I

This is calculated simply by multiplying the output DC current by the duty cycle. The ripple current in the input

capacitor is 5.05 A. A 1206 MLCC using X7R material has a typical dissipation factor of 5%. For a 2.2 μ F

capacitor at 400 kHz the ESR is approximately 7.2 m Ω . If two capacitors are used in parallel the power

dissipation in each capacitor is less than 46 mW.

A 470 μ F/16 V electrolytic capacitor is added to maintain the voltage on the input rail.

3.1.4 Switching MOSFET, QSW

The following key parameters must be met by the selected MOSFET.

• Drain source voltage, V

switching node. For this design a V

• Drain current, ID, at 25 ° C, must be greater than that calculated using Equation 24 . For this design, IDshould

be greater than 5 A.

is the average input current

IN(avg)

, must be able to withstand the input voltage plus spikes that may be on the

DS

rating of 25 V to 30 V is recommended.

DS

(23)

• Gate source voltage, V

TPS40075 this is 9 V.

Once the above boundary parameters are defined the next step in selecting the switching MOSFET is to select

the key performance parameters. Efficiency is the performance characteristic which drives the other selection

criteria. Target efficiency for this design is 90%. Based on 1.5-V output and 15 A this equates to a power loss in

the converter of 2.5 W. Using this figure a target of 0.5 W dissipated in the switching MOSFET was chosen.

must be able to withstand the gate voltage from the control device . For the

GS

(24)

26 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

Product Folder Link(s) :TPS40075

Page 27

www.ti.com

P

QSW

+ P

QSW(CON)

) P

QSW(SW)

) P

QSW(GATE)

P

QSW(CON)

+ R

DS(on)

I

D

2

+ R

DS(on)

V

O

V

IN

ǒ

I

LOAD

2

)

DI

2

12

Ǔ

P

QSW(SW)

+ VIN f

SW

ȧ

ȱ

Ȳ

ǒ

I

LOAD

)

DI

2

Ǔ

ǒ

Q

gs1

) Q

gd

Ǔ

I

g

)

Q

OSS(SW)

) Q

OSS(SR)

2

ȧ

ȳ

ȴ

P

QSW(GATE)

+ Q

g(TOT)

Vg F

SW

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

Equation 25 through Equation 28 can be used to calculate the power loss, P

QSW

, in the switching MOSFET

where

• P

QSW(CON)

• P

QSW(SW)

• P

QSW(GATE)

• Q

gd

• Q

gs1

• Ig= gate drive current

• Q

OSS(SW)

• Q

OSS(SR)

• Qg

• Vg = gate voltage

= conduction losses

= switching losses

= gate drive losses

= drain source charge or miller charge

= gate source post threshold charge

= switching MOSFET output charge

= synchronous MOSFET output charge

= total gate charge from zero volts to the gate voltage

(TOT)

If the total estimated loss is split evenly between conduction and switching losses, Equation 25 and Equation 26

yields preliminary values for R

and (Q

DS(on)

+ Q

gs1

). Note output losses due to Q

gd

and gate losses have been

OSS

ignored here. Once a MOSFET is selected these parameters can be added.

The switching MOSFET for this design should have an R

of less than 9 m Ω . The sum of Q

DS(on)

and Q

gd

gs

be approximately 4 nC.

It is not always possible to get a MOSFET which meets both these criteria so a comprise may have to be made.

Also by selecting different MOSFETs close to this criteria and calculating power loss the final selection can be

made. It was found that the PH6325L MOSFET from Philips semiconductor gave reasonable results. This device

has an R

of 6.3 m Ω and a (Qgs1+Qgd) of 5.9 nC. The estimated conduction losses are 0.178 W and the

DS(on)

switching losses are 0.270 W. This gives a total estimated power loss of 0.448 W versus 0.5 W for our initial

boundary condition. Note this does not include gate losses of approximately 10 mW and output losses of less

than 1 mW.

(25)

(26)

(27)

(28)

should

3.1.5 Rectifier MOSFET, QSR

Similar criteria can be used for the rectifier MOSFET. There is one significant difference. Due to the body diode

conducting, the rectifier MOSFET switches with near zero voltage across its drain and source so effectively with

near zero switching losses. However, there are some losses in the body diode. These are minimized by reducing

the delay time between the transition from the switching MOSFET turn off to rectifier MOSFET turn on and vice

versa. The TPS40075 incorporates TI's proprietary predictive gate drive which helps reduce this delay to

between 10 ns and 20 ns.

Copyright © 2006 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s) :TPS40075

Page 28

www.ti.com

P

QSR

+ P

QSR(CON)

) P

DIODE

) P

QSR(GATE)

P

QSW(CON)

+ R

DS(on)

I

D

2

+ R

DS(on)

V

O

V

IN

ǒ

I

LOAD

2

)

DI

2

12

Ǔ

P

DIODE

+ Vf I

LOAD

ǒ

t1) t

2

Ǔ

f

SW

K

PWM

^

V

UVLO

1 V

R

T

+

1

fSW 17.82 10

*6

* 23

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

The calculations for the losses in the rectifier MOSFET are show in Equation 29 through Equation 32 .

where

• P

• t1= body diode conduction prior to turn on of channel = 10 ns for predictive gate drive

• t2= body diode conduction after turn off of channel = 10 ns for predictive gate drive

• Vf= body diode forward voltage

Estimating the body diode losses based on a forward voltage of 1.2 V gives 0.142 W. The gate losses are

unknown at this time so assume 0.1 W gate losses. This leaves 0.258 W for conduction losses. Using this figure

a target R

DS(on)

paralleling multiple MOSFETs. Paralleling MOSFETs increases the gate capacitance and slows down switching

speeds. This increases body diode and gate losses.

The PH2625L from Philips was chosen. Using the parameters from its data sheet the actual expected power

losses were calculated. Conduction loss is 0.527 W, body diode loss is 0.142 W and the gate loss was 0.174 W.

This totals 0.843 W associated with the rectifier MOSFET. This is somewhat greater than the initial allowance.

Because of this the converter may not hit its efficiency figure at the maximum load.

Two other criteria should be verified before finalizing on the rectifier MOSFET. One is the requirement to ensure

that predictive gate drive functions correctly. The maximum turn off delay of the PH2625L is 67 ns. The minimum

turn on delay of the PH6325L is 25 ns. These devices easily meet the 100 ns difference requirement.

Secondly the ratio between C

Cgd is 1622 pF, so the C

MOSFET. If this is likely to be a problem a small resistor may be added in series with the boost capacitor,

C

.

BOOST

= body diode losses

DIODE

of 1.1 m Ω was calculated. This is an extremely low value. It is not possible to meet this without

and C

gs

:C

ratio is 1.3:1. This helps reduce the risk of dv/dt induced turn on of the rectifier

gs

gd

should be greater than 1. The C

gd

of the PH2625L is 2133 pF and the

gs

(29)

(30)

(31)

(32)

3.2 Component Selection for TPS40075

3.2.1 Timing Resistor, R

T

The timing resistor is calculated using the following equation.

This gives a resistor value of 89.2 k Ω . Using the E24 range of resistor values a 118-k Ω resistor was selected.

The nominal frequency using this resistor is 398 kHz.

3.2.2 Feed Forward and UVLO Resistor, R

KFF

A resistor connected to the KFF pin of the device feeds into the ramp generator. This resistor provides current

into the ramp generator proportional to the input voltage. The ramp is then adjusted to compensate for different

input voltages. Is provides the voltage feed forward feature of the TPS40075.

The same resistor also sets the under voltage lock out point. The input start voltage should be used to calculate

a value for R

. For this converter the minimum input voltage is 10.8 V however due to tolerances in the device,

KFF

a start voltage of 15% less than the minimum input voltage is selected. The start voltage for R

9.18 V. Using Equation 34 R

28 Submit Documentation Feedback Copyright © 2006 – 2007, Texas Instruments Incorporated

can be selected.

KFF

Product Folder Link(s) :TPS40075

calculation is

KFF

(33)

Page 29

www.ti.com

R

KFF

+

ǒ

V

UVLO(on)

* 0.5

Ǔ

ǒ

0.018) ǒ

5

R

T

Ǔ

Ǔ

t

START

w 2p L C

O

Ǹ

C

SS

w

12 10

*6

0.7

t

START

I

SCP

w

CO V

OUT

t

START

) I

LOAD

DI

2

R

ILIM

w

I

SCP

R

DS(on)MAX

) V

ILIM(min)

I

SINK(max)

I

SCP(min)

+

I

SINK(min)

R

ILIM(min)

* V

ILIM(max)

R

DS(on)MIN

I

SCP(max)

+

I

SINK(max)

R

ILIM(max)

* V

ILIM(min)

R

DS(on)MAX

C

ILIM(max)

+

VO 0.2

VIN R

ILIM

f

SW

TPS40075

SLUS676A – MAY 2006 – REVISED SEPTEMBER 2007

This equation gives a R

and using E24 resistor range 133 k Ω was chosen. This yields a typical start voltage of 8.52 V.

3.2.3 Soft Start Capacitor

It is good practice to limit the rise time of the output voltage. This helps prevent output overshoot and possible

damage to the load. The selection of the soft start time is arbitrary, but it must meet one condition; it should be

greater than the time constant of the output filter, L and CO. This time is given by Equation 35

The soft-start time must be greater than 0.281 ms. A time of 1 ms was chosen, this time also helps keep the

initial input current during start up low. The value of C

C

should be greater than 17 nF, a 22 nF MLCC was chosen. The calculated start time using this capacitor is

SS

1.28 ms.

value of 136 k Ω . The closest lower standard value should be selected. For this design