TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Dedicated PWM Input Port

D

Optimized for Reversible Operation of

Motors

D

Two Input Control Lines for Reduced

Microcontroller Overhead

D

Internal Current Shutdown of 5 A

D

40 V Load Dump Rating

D

Integrated Fault Protection and Diagnostics

D

CMOS Compatible Schmitt Trigger Inputs

for High Noise Immunity

description

The TPIC0107B is a PWM control intelligent H-bridge designed specifically for dc motor applications. The

device provides forward, reverse, and brake modes of operation. A logic supply voltage of 5 V is internally

derived from V

CC

.

The TPIC0107B has an extremely low r

DS(on)

, 280 mΩ typical, to minimize system power dissipation. The

direction control (DIR) and PWM control (PWM) inputs greatly simplify the microcontroller overhead

requirement. The PWM input can be driven from a dedicated PWM port while the DIR input is driven as a simple

low speed toggle.

The TPIC0107B provides protection against over-voltage, over-current, over-temperature, and cross

conduction faults. Fault diagnostics can be obtained by monitoring the ST ATUS1 and STATUS2 terminals and

the two input control lines. STATUS1 is an open-drain output suitable for wired-or connection. STATUS2 is a

push-pull output that provides a latched status output. Under-voltage protection ensures that the outputs, OUT1

and OUT2, will be disabled when V

CC

is less than the under-voltage detection voltage V

(UVCC)

.

The TPIC0107B is designed using TI’s LinBiCMOS process. LinBiCMOS allows the integration of low power

CMOS structures, precision bipolar cells, and low impedance DMOS transistors.

The TPIC0107B is offered in a 20-pin thermally enhanced small-outline package (DWP) and is characterized

for operation over the operating case temperature of –40°C to 125°C.

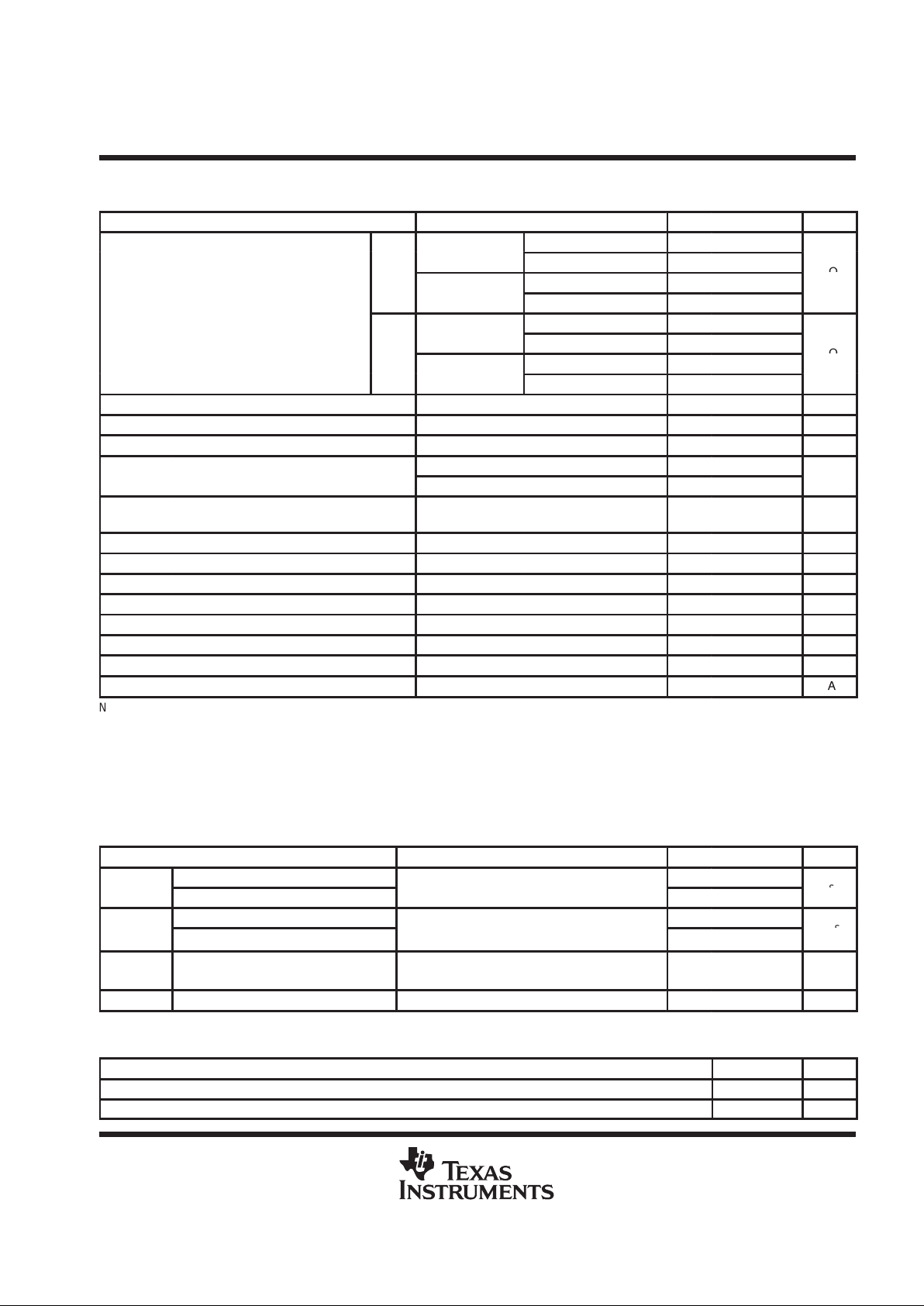

FUNCTION TABLE

DIR

PWM OUT1 OUT2 MODE

0 0 HS HS Brake, both HSDs turned on hard

0 1 HS LS Motor turns counter clockwise

1 0 HS HS Brake, both HSDs turned on hard

1 1 LS HS Motor turns clockwise

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

LinBiCMOS is a trademark of Texas Instruments Incorporated.

Copyright 1998, Texas Instruments Incorporated

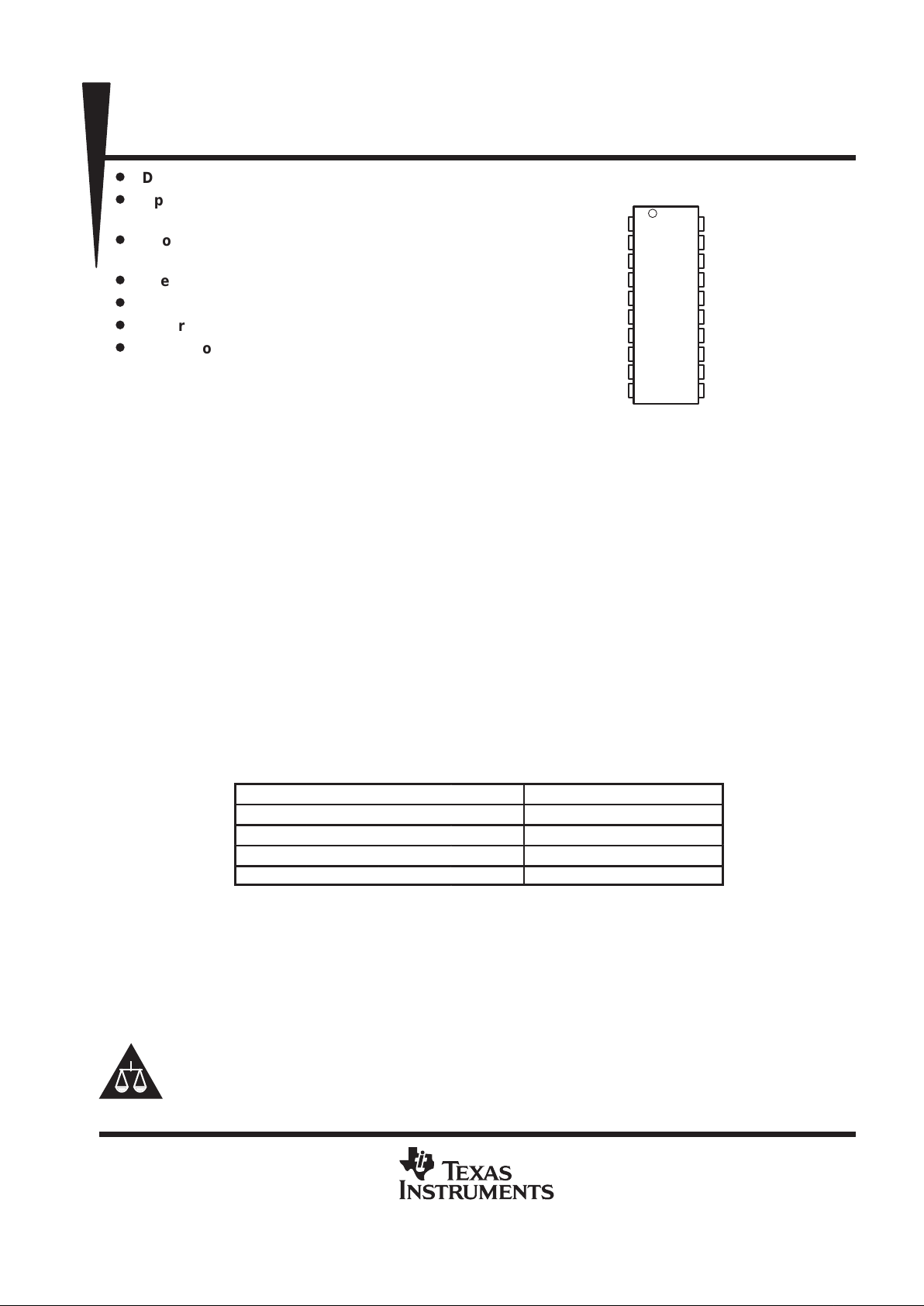

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

GNDS

V

CC

DIR

V

CC

OUT1

OUT1

GND

PWM

GND

GNDS

GNDS

V

CC

STATUS2

V

CC

OUT2

OUT2

GND

STATUS1

GND

GNDS

DWP PACKAGE

(TOP VIEW)

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

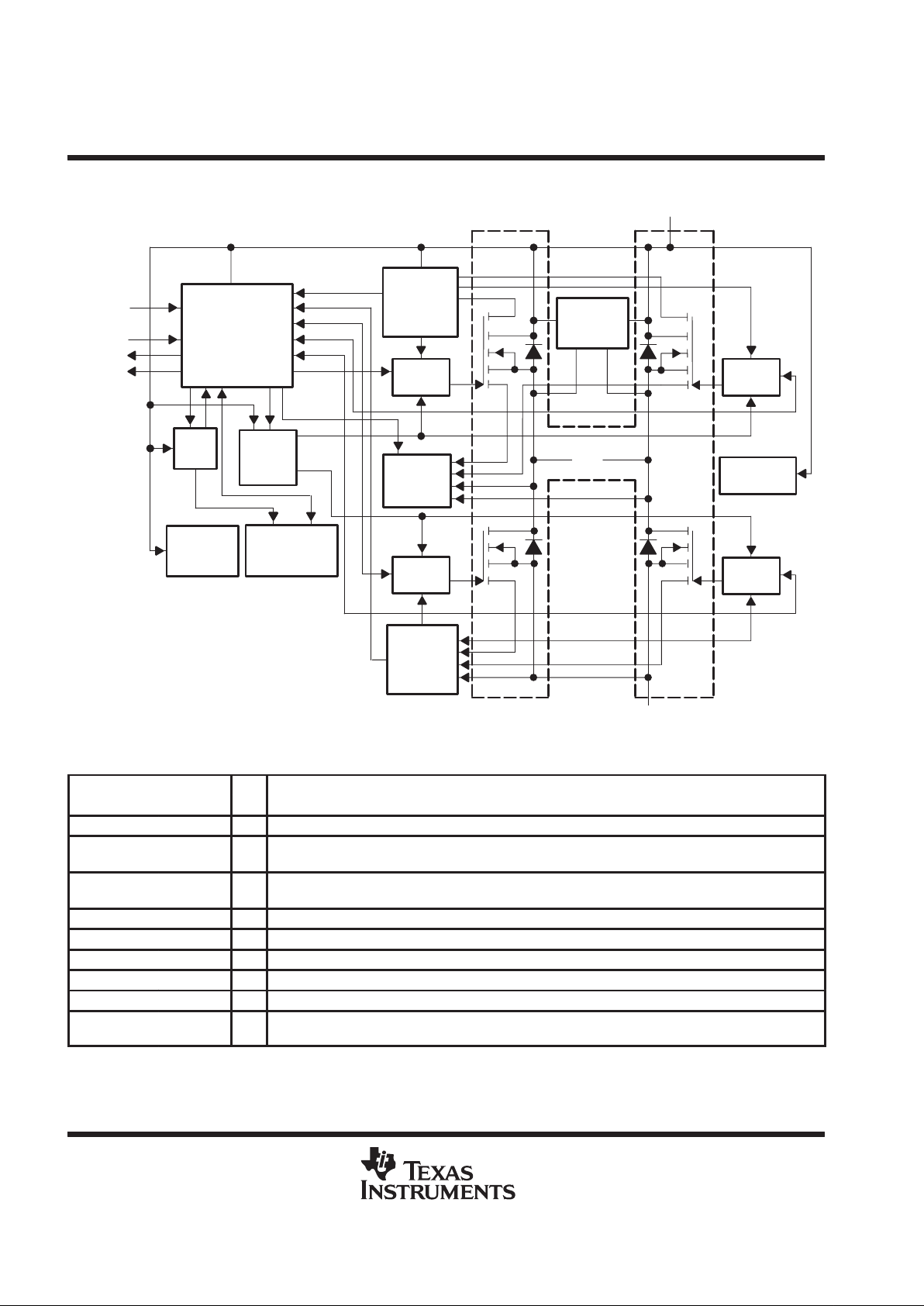

block diagram

Logic

5 V

Reg.

Charge

Pump

(2 MHz)

Over-

Current

Protection

HSD

DMOS

Driver

OpenCircuit

Detect

Under-

Voltage

Detection

Over-

Temperature

Detection

DMOS

Driver

Over-

Current

Protection

LSD

Over-

Voltage

Detection

DMOS

Driver

DMOS

Driver

OUT2 OUT1

DMOS

Driver

Load-Dump

Protection

GND

PWM

DIR

STATUS1

STATUS2

V

CC

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

DIR 3 I Direction control input

GND 7, 9,

12, 14

I Power ground

GNDS 1, 10,

11, 20

I Substrate ground

OUT1 5, 6 O Half-H output. DMOS output

OUT2 15, 16 O Half-H output. DMOS output

PWM 8 I PWM control input

STATUS1 13 O Status output

STATUS2 18 O Latched status output

V

CC

2, 4,

17, 19

I Supply voltage

NOTE: It is mandatory that all four ground terminals plus at least one substrate terminal are connected to the system ground. Use all VCC and

OUT terminals.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

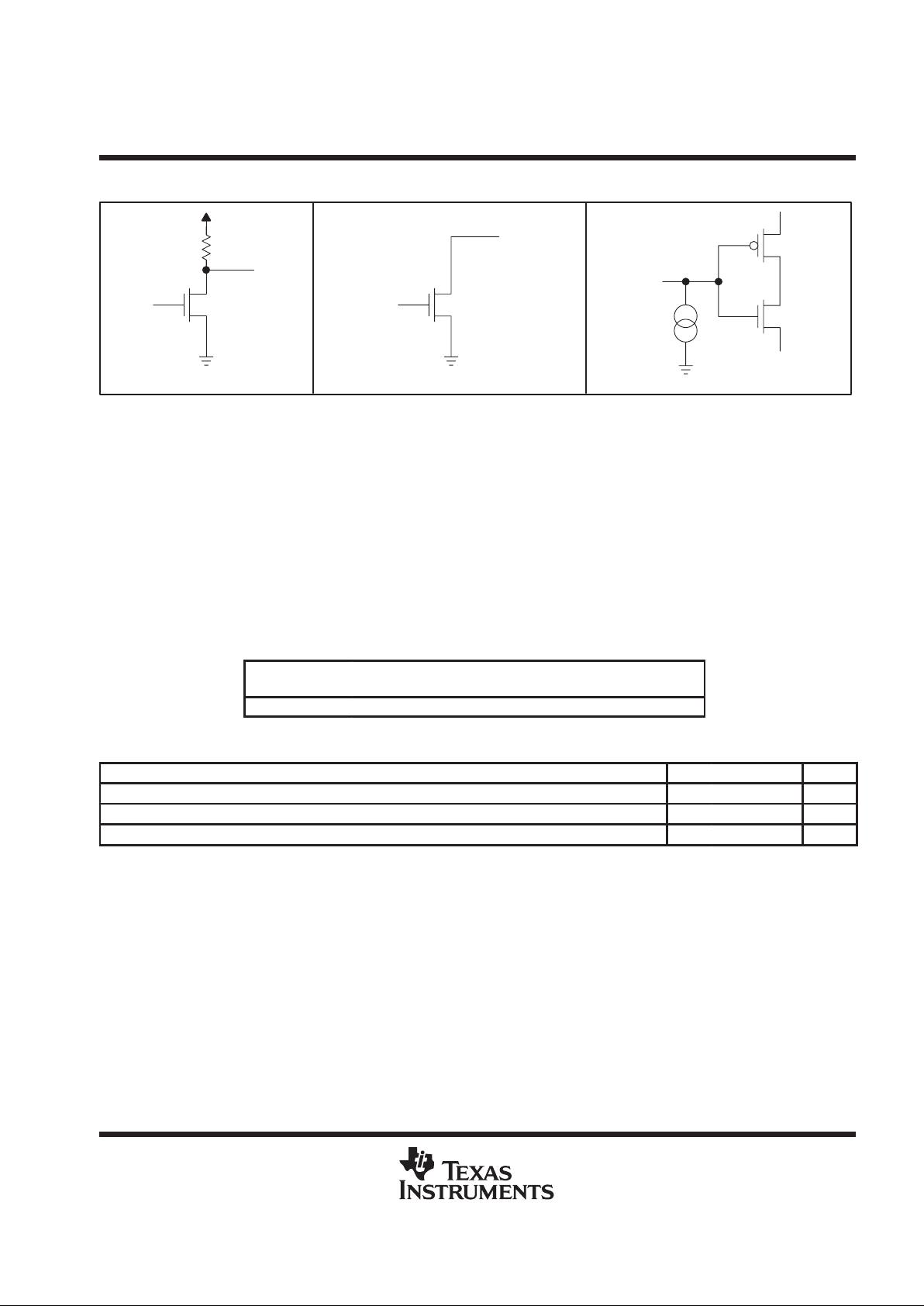

schematics of inputs and outputs

STATUS2

STATUS1

DIR/PWM

absolute maximum ratings over operating case temperature range (unless otherwise noted)

†

Power supply voltage range, V

CC

–0.3 V to 33 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic input voltage range, V

IN

–0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load dump (for 400 ms, T

C

= 25°C) 40 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status output voltage range, V

O(status)

–0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation, T

C

= 25°C 25 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATING TABLE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 125°C

POWER RATING

25 W –0.2 W/°C 16 W 5 W

recommended operating conditions

MIN MAX UNIT

Supply voltage, V

CC

6 18 V

Operating case temperature, T

C

–40 125 °C

Switching frequency, f

PWM

2 kHz

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating case temperature range and V

CC

= 5 V to

6 V (unless otherwise noted)

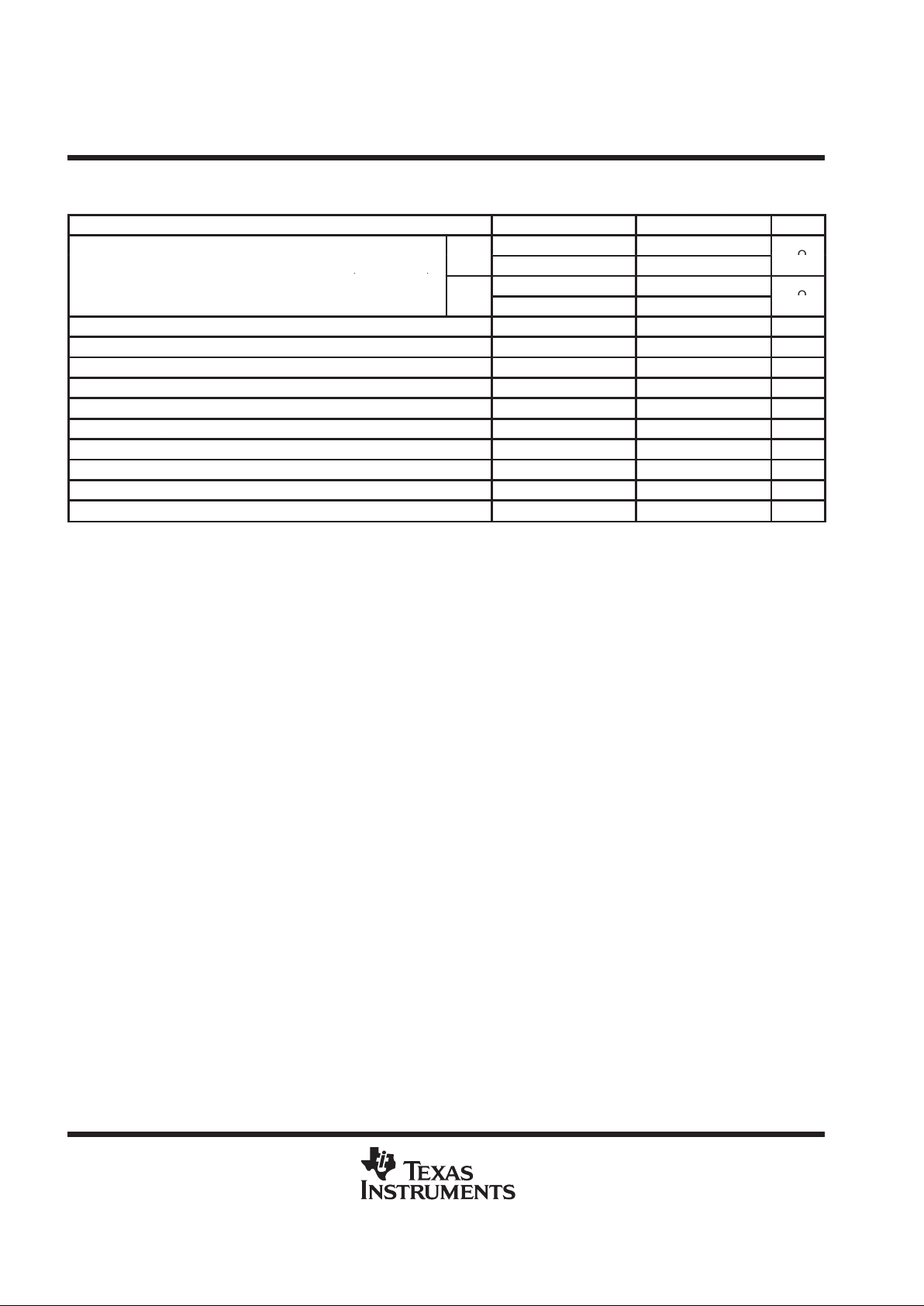

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TJ = 25°C 550

Static drain-source on-resistance (per transistor)

LSD

TJ = 150°C 850

mΩ

r

DS(on)

()

I

(BR)

= 1 A

TJ = 25°C 600

HSD

TJ = 150°C 870

mΩ

I

(QCD)

Open circuit detection current 10 40 100 mA

V

(UVCC(OFF))

Under voltage detection on VCC, switch off voltage See Note 1 5 V

V

(UVCC(ON))

Under voltage detection on VCC, switch on voltage See Note 1 5.2 V

V

(STL)

STATUS low output voltage IO = 100 µA, See Note 1 0.8 V

V

(ST2H)

STATUS2 high output voltage IO = 20 µA, See Note 1 3 5.4 V

I

(ST(OFF))

STATUS output leakage current V

(ST)

= 5 V, See Note 1 5 µA

V

IL

Low level logic input voltage –0.3 0.5 V

V

IH

High level logic input voltage 3.6 7 V

∆V

I

Hysteresis of input voltage 0.3 V

I

IH

High level logic input current VIH = 3.5 V 2 10 50 µA

NOTE 1: The device functions according to the function table for VCC between V

(UVCC)

and 5 V (no parameters specified). STA TUS outputs are

not defined for VCC less than V

(UVCC)

.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating case temperature and supply voltage

ranges (unless otherwise noted) (see Note 2)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

°

VCC = 6 V to 9 V 380

T

J

=

25°C

VCC = 9 V to 18 V 280 340

LSD

°

VCC = 6 V to 9 V 620

mΩ

Static drain-source on-resistance

T

J

=

150°C

VCC = 9 V to 18 V 400 560

r

DS(on)

(per transistor) IBR = 1 A

°

VCC = 6 V to 9 V 430

T

J

=

25°C

VCC = 9 V to 18 V 280 340

HSD

°

VCC = 6 V to 9 V 640

mΩ

T

J

=

150°C

VCC = 9 V to 18 V 400 560

I

(QCD)

Open circuit detection current 10 40 100 mA

T

SDS

Static thermal shutdown temperature See Notes 3 and 4 140 °C

T

SDD

Dynamic thermal shutdown temperature See Notes 3 and 5 160 ° C

VCC = 6 V to 9 V 4.8 7.5

ICSCurrent shutdown limit

VCC = 9 V to 18 V 5 7.5

A

I

(CON)

Continuous bridge current

TJ = 125°C, Operating lifetime 10,000 hours,

(see Figure 1)

3 A

V

(OVCC)

Over voltage detection on V

CC

27 36 V

V

(STL)

STATUS low output voltage IO = 100 µA 0.8 V

V

(ST2H)

STATUS2 high output voltage IO = 20 µA 3.9 5.4 V

I

(ST(OFF))

STATUS output leakage current V

(ST)

= 5 V 5 µA

V

IL

Low level logic input voltage –0.3 0.8 V

V

IH

High level logic input voltage 3.6 7 V

∆V

I

Hysteresis of input voltage 0.3 V

I

IH

High level logic input current VIH = 3.5 V 2 10 50 µ

A

NOTES: 2. The device functions according to the function table for VCC between 18 V and V

(OVCC)

, but only up to a maximum supply voltage

of 33 V (no parameters specified). Exposure beyond 18 V for extended periods may affect device reliability.

3. Exposure beyond absolute-maximum-rated condition of junction temperature may affect device reliability.

4. No temperature gradient between DMOS transistor and temperature sensor .

5. With temperature gradient between DMOS transistor and temperature sensor in a typical application (DMOS transistor as heat

source).

switching characteristics over recommended operating case temperature and supply voltage

ranges (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-side driver turn-on time

100

t

out(on)

Low-side driver turn-on time

V

DS(on)

<

1 V at 1 A

,

V

CC

=

13.2 V

100

µ

s

Slew rate, low-to-high sinusoidal (δV/δt)

1 6

SR

Slew rate, high-to-low sinusoidal (δV/δt)

V

CC

=

13.2 V

,

I

O

=

1 A resistive load

1 6

V/µs

t

d(QCD)

Under current spike duration to trigger

open circuit detection

VCC = 5 V to 18 V 1 10 ms

t

d(CS)

Delay time for over current shutdown 5 10 25 µs

thermal resistance

PARAMETER MIN MAX

UNIT

R

θJA

Junction-to-ambient thermal resistance 5 °C/W

R

θJC

Junction-to-case thermal resistance 97 °C/W

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

Maximum continuous bridge current versus time based on 50 FITs at 100,000 hours operating life (90%

confidence model)

5

0

01020304050601070 80 90 100

TJ = 75°C

TJ = 100°C

TJ = 125°C

TJ = 150°C

– Continuous Bridge Current – A

I

(CON)

t – Time × 1000-h

Figure 1. Electromigration Reliability Data

Example:

Average continuous bridge current, I

CON

Average junction temperature, TJOperating lifetime of device based on electromigration

2 A 125°C >20,000 h

3 A 125°C >10,000 h

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

operating wave forms

<1 ms (min.)

DIR (Low)

PWM

STATUS1

STATUS2

OUT1 (High)

OUT2

Open Circuit

Figure 2. Open Circuit

DIR (Low)

PWM

STATUS1

STATUS2

OUT1

OUT2

Short Circuit

I

LIM

Bridge Current

Figure 3. Short Circuit (e.g., OUT2 to V

CC

)

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

operating wave forms (continued)

DIR (Low)

PWM

STATUS1

STATUS2

OUT1

OUT2

Over Temperature

Figure 4. Over Temperature

DIR

Brake

Counter-

Clockwise

Rotation

Clockwise

Rotation

PWM

STATUS1 (High)

STATUS2 (High)

OUT1

OUT2

Brake Brake

Figure 5. No Fault

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

protective functions and diagnostics

†

over current/short circuit

‡

The TPIC0107B detects shorts to VCC, ground, or across the load being driven, by comparing the VDS voltage

drop across the DMOS outputs against the threshold voltage. The DMOS outputs of the TPIC0107B will be

disabled and the fault flags will be generated 10 µs after an over-current or short-circuit fault is detected. This

10 µs delay is long enough to serve as a de-glitch filter for high current transients, yet short enough to prevent

damage to the DMOS outputs. The DMOS outputs remain latched off until either DIR or PWM input is toggled.

In cases where the outputs have a continuous short-to-ground with a current rise time faster than 0.5 A/µs, the

over-current shutdown threshold will decrease to 3 A to reduce power dissipation. This reduction to 3 A is

achieved since the DMOS outputs will not be fully enhanced when the over-current threshold is reached if the

current rise time exceeds 0.5 A/µs. Over-current and/or short-circuit protection is provided up to V

CC

= 16.5 V

and a junction temperature of 90°C.

over temperature

The TPIC0107B disables all DMOS outputs and the fault flags will be set when T

J

≥140°C (min.). The DMOS

outputs remain latched off until either DIR or PWM input is toggled.

under voltage

The TPIC0107B disables all DMOS outputs when V

CC

≤V

(UVCC)

. The outputs will be re-enabled when

V

CC

≥V

(UVCC)

. No fault flags are set when under-voltage lockout occurs.

over voltage

In order to protect the DMOS outputs from damage caused by excessive supply voltage, the TPIC0107B

disables all outputs when V

CC

≥V

(OVCC)

. Once VCC ≤V

(OVCC)

, either DIR or PWM input must be toggled to

re-enable the DMOS outputs.

cross conduction

Monitoring circuitry for each transistor detects whether the particular transistor is active to prevent the HSD or

LSD of the corresponding half H-bridge from conducting.

open circuit

During operation, the bridge current is controlled continuously . If the bridge current is >10 mA (min.) for a period

>1 ms (min.), the fault flags are set. However, the output transistors will not be disabled.

†

All limits mentioned are typical values unless otherwise noted.

‡

If a short circuit occurs (i.e., the over-current detection circuitry is activated) at a supply voltage higher than 16.5 V and a junction temperature

higher than 90°C, damage to the device may occur.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

DIAGNOSTICS TABLE (see Note 6)

FLAG

DIR PWM OUT1 OUT2 STATUS1†STATUS2

Normal operation

0

0

1

1

0

1

0

1

HS

HS

HS

LS

HS

LS

HS

HS

1

1

1

1

1

1

1

1

Open circuit between OUT1 and OUT2

0

0

1

1

0

1

0

1

HS

HS

HS

LS

HS

LS

HS

HS

1

0

1

0

1

0

1

0

Short circuit from OUT1 to OUT2 (see Notes 7 and 8)

0

1

1

1

X

X

X

X

0

0

0

0

Short circuit from OUT1 to GND (see Notes 7 and 8)

0

1

0

0

0

1

X

X

X

X

X

X

0

0

0

0

0

0

Short circuit from OUT2 to GND (see Notes 7 and 8)

0

1

1

0

0

1

X

X

X

X

X

X

0

0

0

0

0

0

Short circuit from OUT1 to VCC (see Notes 7 and 8) 1 1 X X 0 0

Short circuit from OUT2 to VCC (see Notes 7 and 8) 0 1 X X 0 0

Over temperature

0

0

1

1

0

1

0

1

Z

Z

Z

Z

Z

Z

Z

Z

0

0

0

0

0

0

0

0

†

When wired with a pull-up resistor

SYMBOL V ALUE

0 Logic low

1 Logic high

HS High-side MOSFET conducting

LS Low-side MOSFET conducting

Z No output transistors conducting

X Voltage level undefined

NOTES: 6. All input combinations not stated result in STATUS output = 1.

7. STA TUS1 active for a minimum of 3 µs.

8. STA TUS2 active until an input is toggled.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 6

200

100

0

–40 –20 0 20 40 60 80

– Static Drain-Source On-Resistance – m

300

STATIC DRAIN-SOURCE ON-RESISTANCE

vs

JUNCTION TEMPERATURE

400

100 120 140

VCC = 9.18 V

Ω

r

DS(on)

TJ – Junction Temperature – °C

Figure 7

300

200

100

0

0 5 10 15

400

500

STATIC-DRAIN-SOURCE ON-RESISTANCE

vs

SUPPLY VOLTAGE

600

20 25

VCC – Supply Voltage – V

HSD, TJ = 125°C

LSD, TJ = 125°C

LSD, TJ = 25°C

HSD, TJ = 25°C

– Static Drain-Source On-Resistance – mΩ

r

DS(on)

Figure 8

10

5

0

–40 –20 0 20 40 60 80

– Output Stage Turn-On Time –

15

OUTPUT STAGE TURN-ON TIME

vs

JUNCTION TEMPERATURE

20

100 120 140

sµ

t

out(on)

HSD, VCC = 13.2 V

LSD, VCC = 13.2 V

TJ – Junction Temperature – °C

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

†

Necessary for isolating supply voltage or interruption (e.g., 47 µF).

V

CC

M

CONTROL DIAGNOSTIC

Microcontroller

DIR

PWM

STATUS1

STATUS2

GND GNDS

OUT1

OUT2

V

CC

TPIC0107B

100 kΩ

5 V

100 nF

47 µF

†

NOTE: If a STATUS output is not connected to the appropriate microcontroller input, it shall remain unconnected.

TPIC0107B

PWM CONTROL INTELLIGENT H-BRIDGE

SLIS067 – NOVEMBER 1998

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

Gage Plane

0.419 (10,65)

0.400 (10,16)

0.010 (0,25) NOM

Thermal Pad

(See Note D)

0.010 (0,25)

0.016 (0,40)

0.050 (1,27)

Seating Plane

4147575/A 02/98

11

10

A

20-PIN SHOWN

20

1

0.104 (2,65) MAX

0.293 (7,45)

0.299 (7,59)

0.020 (0,51)

0.014 (0,35)

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

0.710

28

0.510200.610

24

0.700

(18,03)

(17,78)

0.500

(15,49)

(15,24)

0.600

0.410

16

DIM

PINS **

(10,41)

(10,16)

0.400

A MIN

A MAX

(12,95)

(12,70)

0.006 (0,15)

0.002 (0,05)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane. This pad is electrically

and thermally connected to the backside of the die and possibly selected leads.

PowerPAD is a trademark of Texas Instruments Incorporated.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...