D

High-Performance Static CMOS Technology

D

Includes the T320C2xLP Core CPU

– Object Compatible With the TMS320C2xx

– Source Code Compatible With

TMS320C25

– Upwardly Compatible With TMS320C5x

– 132-Pin Plastic Quad Flat Package

(PQ Suffix)

– 50-ns Instruction Cycle Time

D

Industrial and Automotive Temperature

Available

D

Memory

– 544 Words × 16 Bits of On-Chip

Data/Program Dual-Access RAM

– 16K Words × 16 Bits of On-Chip Program

ROM (’C240)/Flash EEPROM (’F240)

– 224K Words × 16 Bits of Total Memory

Address Reach (64K Data, 64K Program

and 64K I/O, and 32K Global Memory

Space)

D

Event-Manager Module

– 12 Compare/Pulse-Width Modulation

(PWM) Channels

– Three 16-Bit General-Purpose Timers

With Six Modes, Including Continuous

Upand Up/Down Counting

– Three 16-Bit Full-Compare Units With

Deadband

– Three 16-Bit Simple-Compare Units

– Four Capture Units (Two With

Quadrature Encoder-Pulse Interface

Capability)

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

D

Dual 10-Bit Analog-to-Digital Conversion

Module

D

28 Individually Programmable, Multiplexed

I/O Pins

D

Phase-Locked-Loop (PLL)-Based Clock

Module

D

Watchdog Timer Module (With Real-Time

Interrupt)

D

Serial Communications Interface (SCI)

Module

D

Serial Peripheral Interface (SPI) Module

D

Six External Interrupts (Power Drive

Protect, Reset, NMI, and Three Maskable

Interrupts)

D

Four Power-Down Modes for Low-Power

Operation

D

Scan-Based Emulation

D

Development Tools Available:

– Texas Instruments (TI) ANSI

C Compiler, Assembler/Linker, and

C-Source Debugger

– Scan-Based Self-Emulation (XDS510)

– Third-Party Digital Motor Control and

Fuzzy-Logic Development Support

description

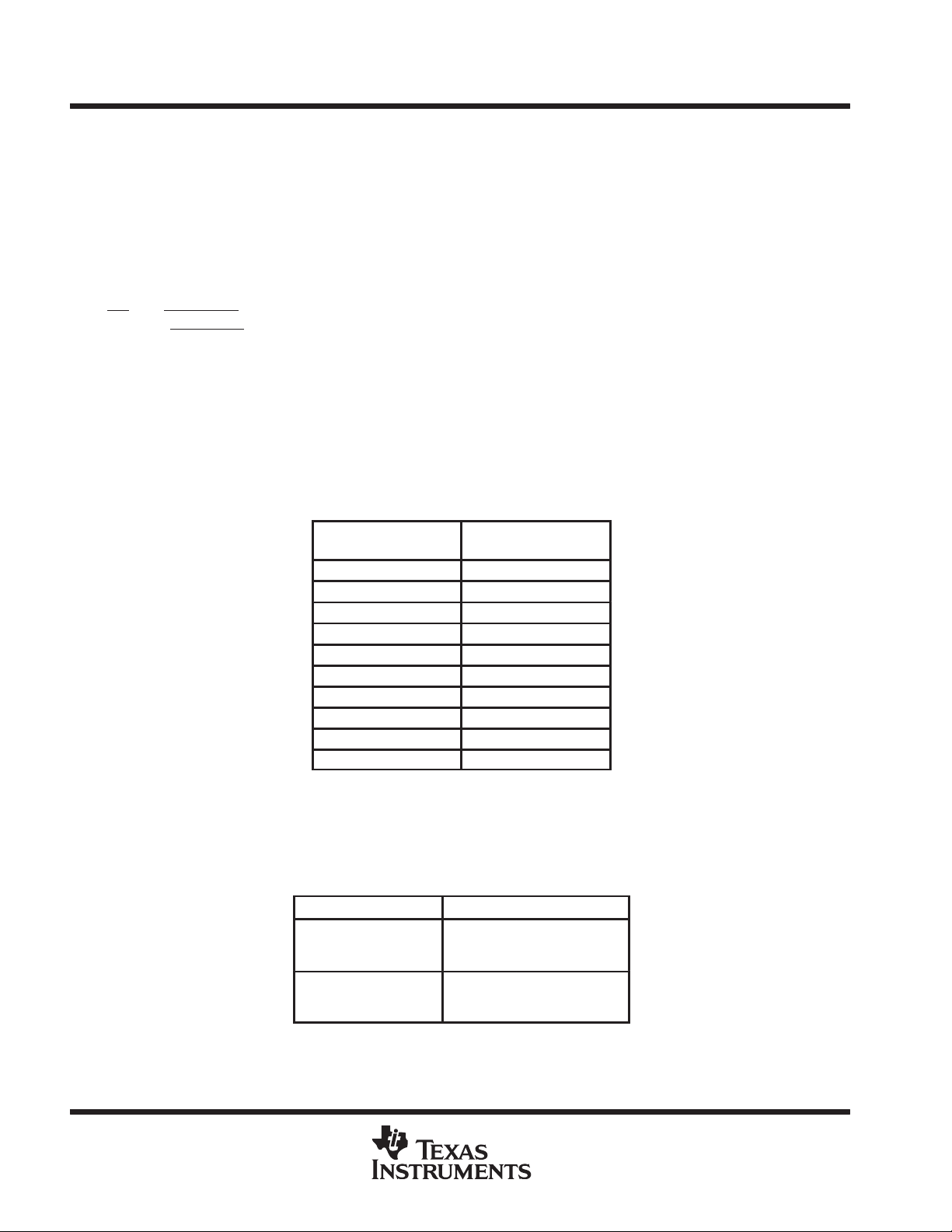

The TMS320C240 and TMS320F240 devices are the first members of a new family of DSP controllers based

on the TMS320C2xx generation of 16-bit fixed-point digital signal processors (DSPs). Unless otherwise noted,

the term ’x240 refers to both the TMS320C240 and the TMS320F240. Table 1 provides a comparison of the

features of each device. The only difference between these two devices is the type of program memory: the

’C240 contains 16K words of ROM and the ’F240 contains 16K words of flash. This new family is optimized for

digital motor/motion control applications. The DSP controllers combine the enhanced TMS320 architectural

design of the ’C2xLP core CPU for low-cost, high-performance processing capabilities and several advanced

peripherals optimized for motor/motion control applications. These peripherals include the event manager

module, which provides general-purpose timers and compare registers to generate up to 12 PWM outputs, and

a dual10-bit analog-to-digital converter (ADC), which can perform two simultaneous conversions within 6.1 µs.

See the functional block diagram.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

TI and XDS510 are trademarks of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

Copyright 1998, Texas Instruments Incorporated

1

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQ Package (Top View) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

terminal functions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

functional block diagram 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

architectural overview 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

system-level functions 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

device memory map 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

peripheral memory map 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

digital I/O and shared pin functions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

description of group1 shared I/O pins 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

description of group2 shared I/O pins 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

digital I/O control registers 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

device reset and interrupts 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

reset 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

hardware-generated interrupts 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

external interrupts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

clock generation 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

low-power modes 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

functional block diagram of the TMS320x240 DSP CPU 30. . . . . . . . . . . . . . .

’x240 DSP core CPU 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

status and control registers 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

central processing unit 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

input scaling shifter 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

multiplier 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

central arithmetic logic unit 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

accumulator 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

auxiliary registers and auxiliary-register arithmetic unit (ARAU) 37. . . . . . . . .

internal memory 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

dual-access RAM (DARAM) 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROM (TMS320C240 only) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flash EEPROM (TMS320F240 only) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flash serial loader 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flash control mode register 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

peripherals 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

external memory interface 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

INTRODUCTION

DETAILED DESCRIPTION

2

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Contents

DETAILED DESCRIPTION (continued)

event-manager (EV) module 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

general-purpose (GP) timers 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

full compare units 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

programmable-deadband generator 42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

simple compares 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

compare/PWM waveform generation 42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

compare/PWMs characteristics 42

capture unit 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

quadrature-encoder pulse (QEP) circuit 43. . . . . . . . . . . . . . . . . . . . . . . . .

analog-to-digital converter (ADC) module 43. . . . . . . . . . . . . . . . . . . . . . . . . .

serial peripheral interface (SPI) module 45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

serial communications interface (SCI) module 47. . . . . . . . . . . . . . . . . . . . . .

watchdog (WD) and real-time interrupt (RTI) module 49. . . . . . . . . . . . . . . .

scan-based emulation 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS320x240 instruction set 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

addressing modes 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

repeat feature 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

instruction set summary 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

development support 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

device and development-support tool nomenclature 59. . . . . . . . . . . . . . . .

documentation support 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL SPECIFICATIONS

absolute maximum ratings over operating free-air temperature range 61.

recommended operating conditions 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

output current variation with output voltage: SPICE simulation results 62

elec characteristics over recommended oper free-air temperature range 62

signal transition levels 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

timing parameter symbology 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

general notes on timing parameters 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

clock options 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

timings with the PLL circuit disabled 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

external reference crystal with PLL-circuit-enabled clock option 67. . . . . . . . .

timings with the PLL circuit enabled 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

low-power mode timings 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

3

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

ELECTRICAL SPECIFICATIONS (continued)

Contents

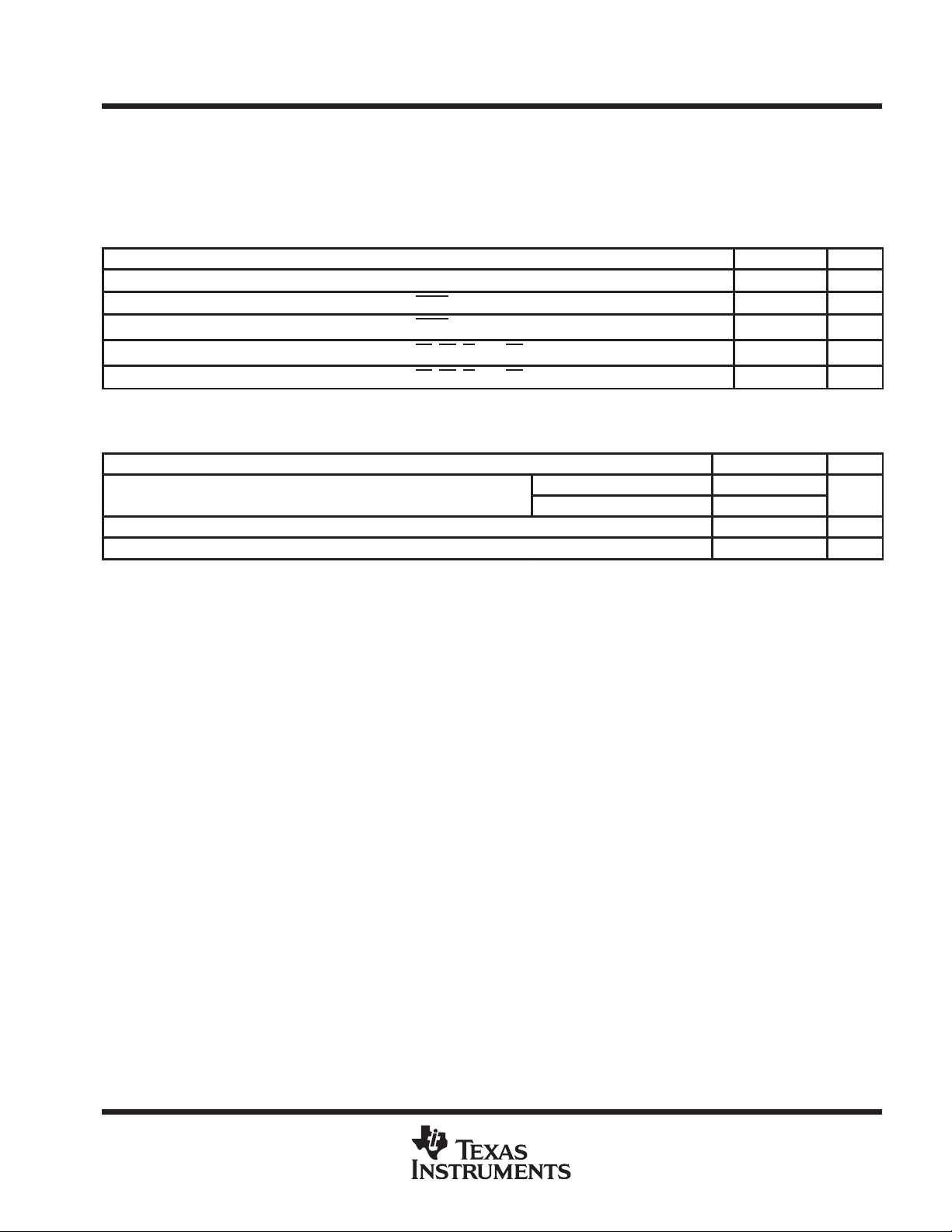

memory and parallel I/O interface

memory and parallel I/O interface

I/O timing variation with load capacitance: SPICE simulation results 75. . .

READY timings 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS and PORESET timings 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XF, BIO, and MP/MC timings 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

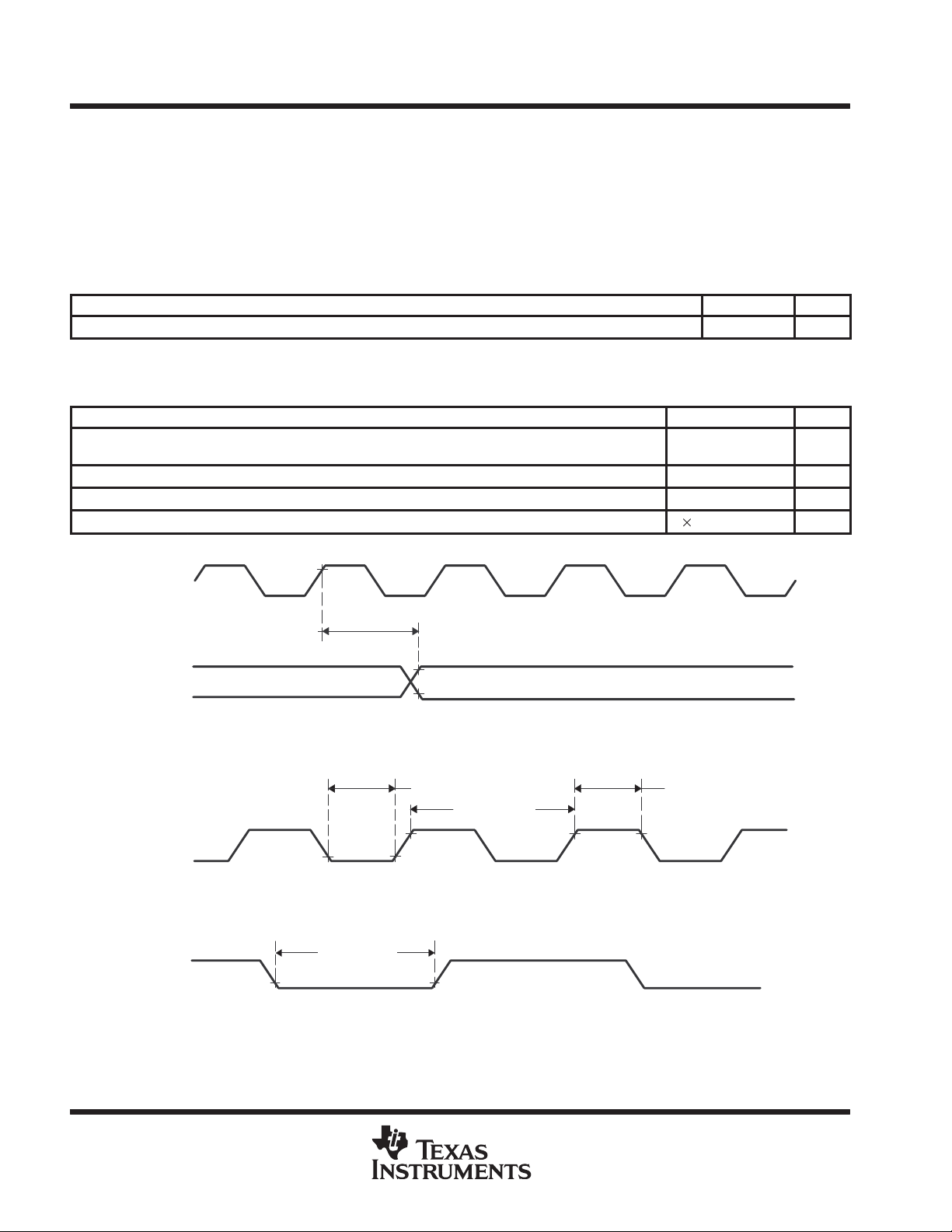

PWM/CMP timings 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

capture and QEP timings 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

interrupt timings 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

general-purpose input/output timings 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

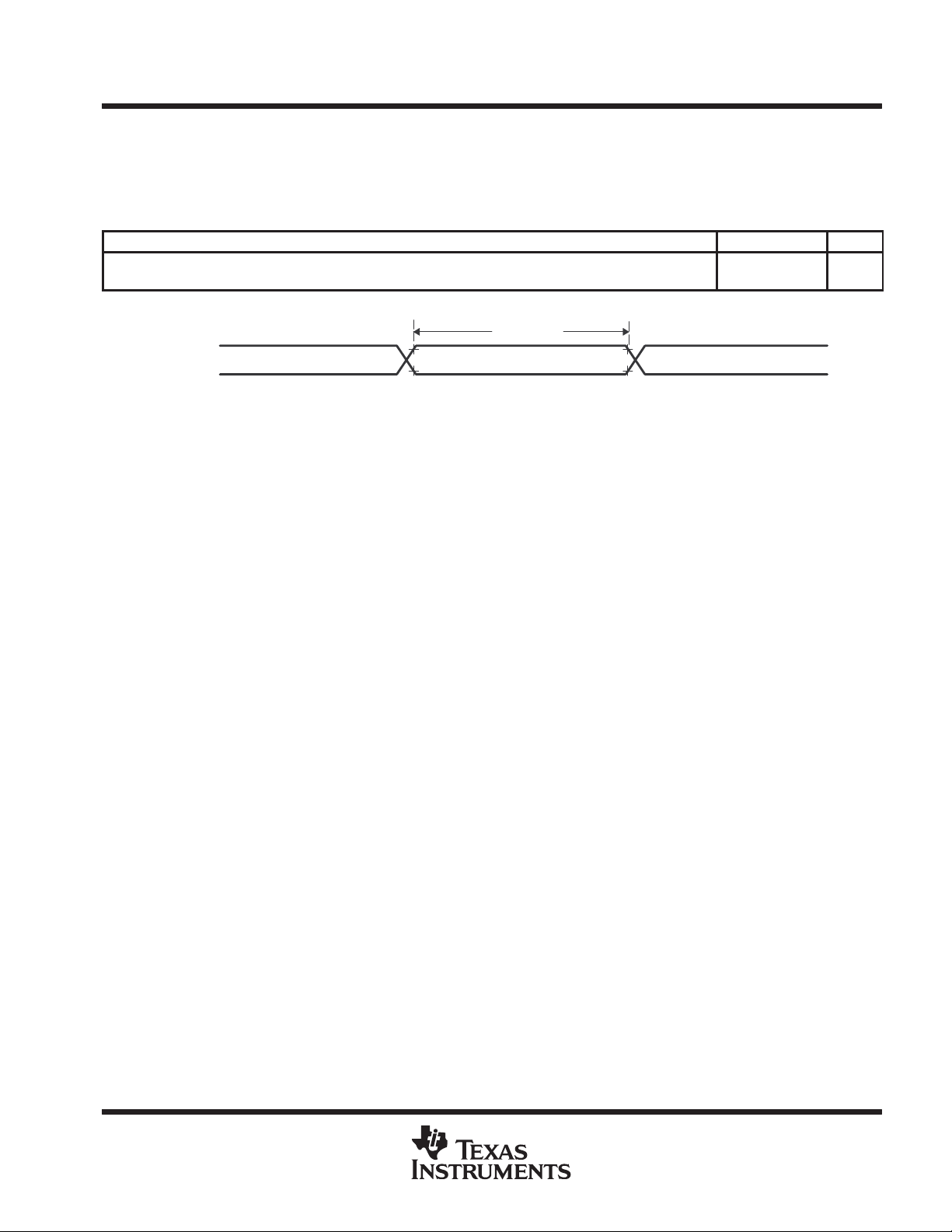

serial communications interface (SCI) I/O timings 84. . . . . . . . . . . . . . . . . . . .

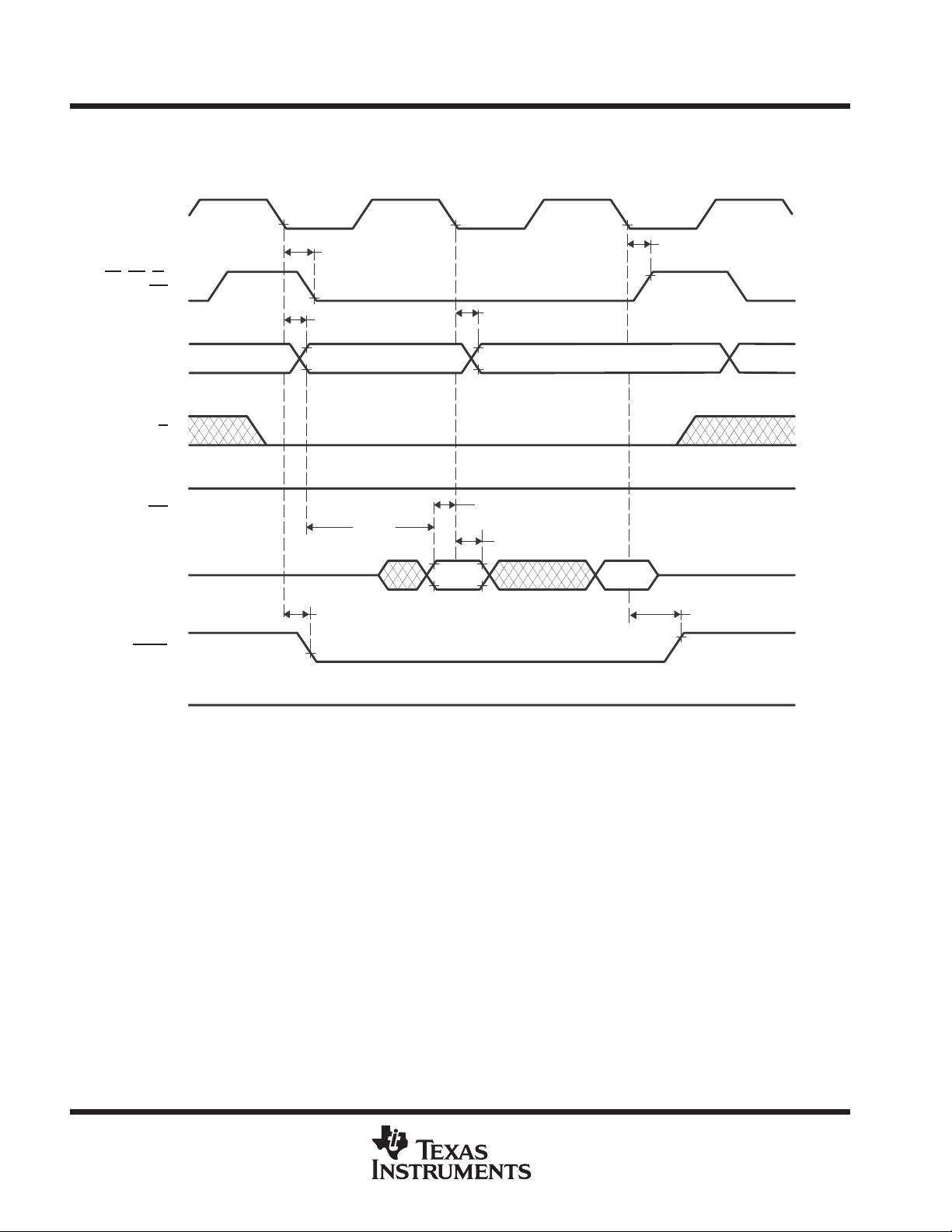

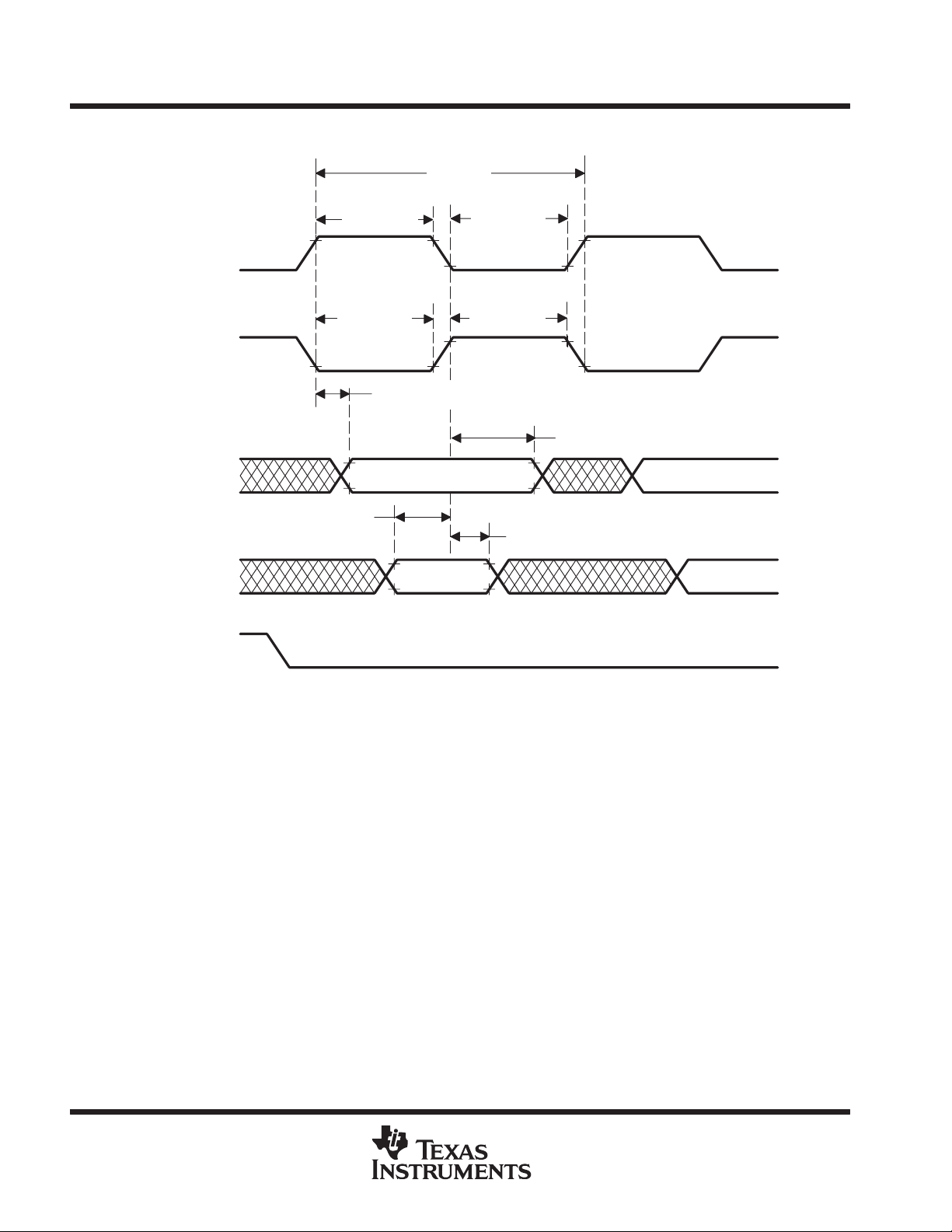

SPI master mode external timing parameters (clock phase = 0) 85. . . . . . . .

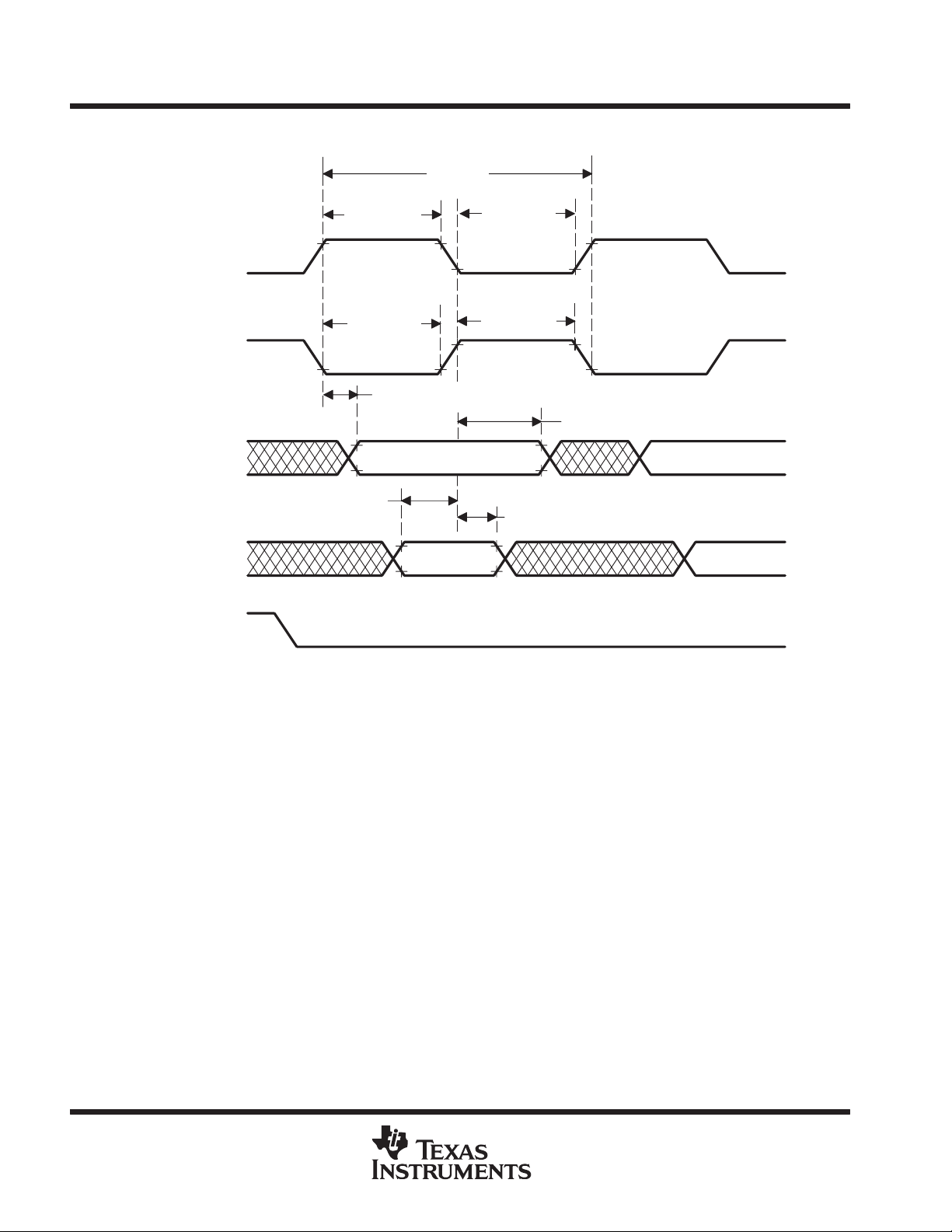

SPI master mode external timing parameters (clock phase = 1) 87. . . . . . . .

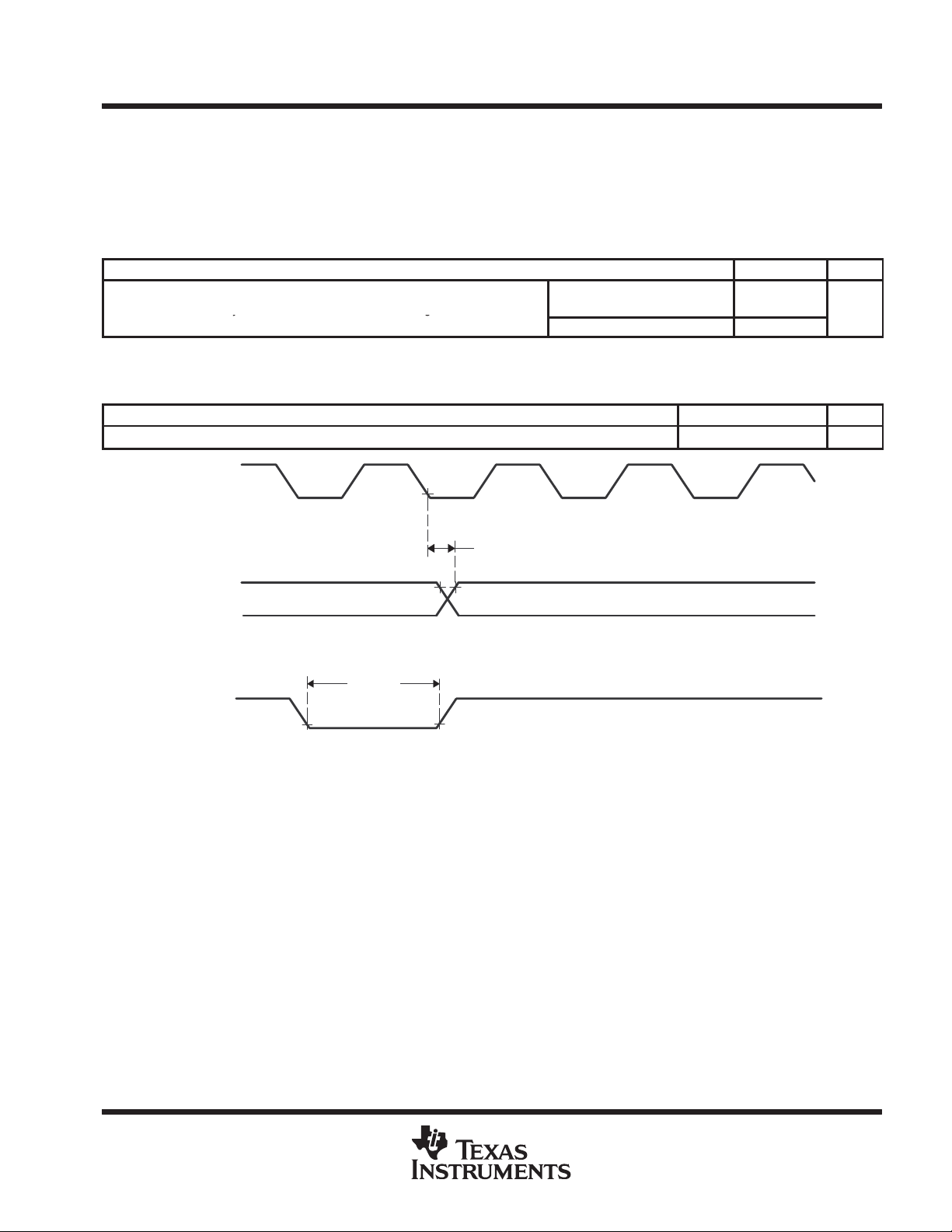

SPI slave mode external timing parameters (clock phase = 0) 89. . . . . . . . .

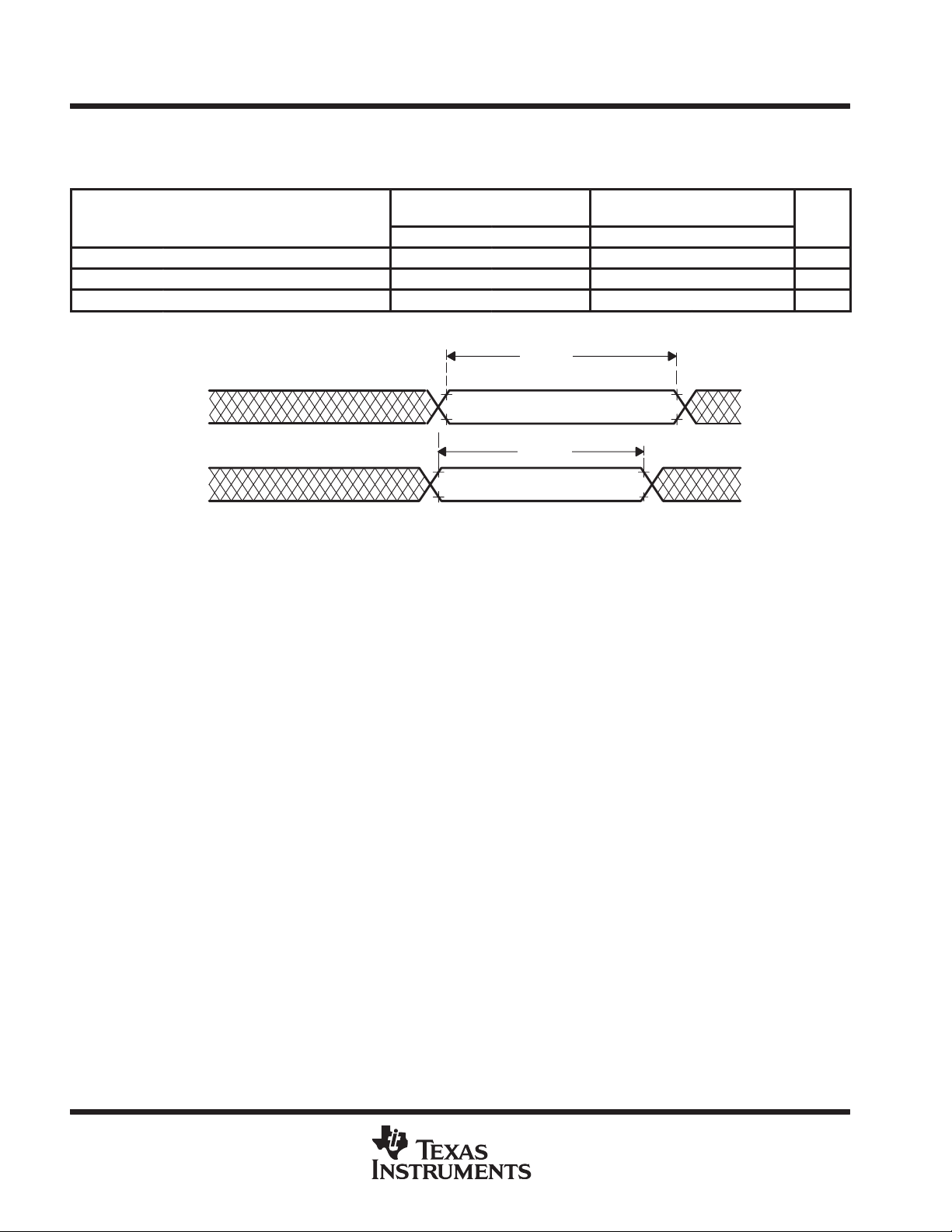

SPI slave mode external timing parameters (clock phase = 1) 91. . . . . . . . .

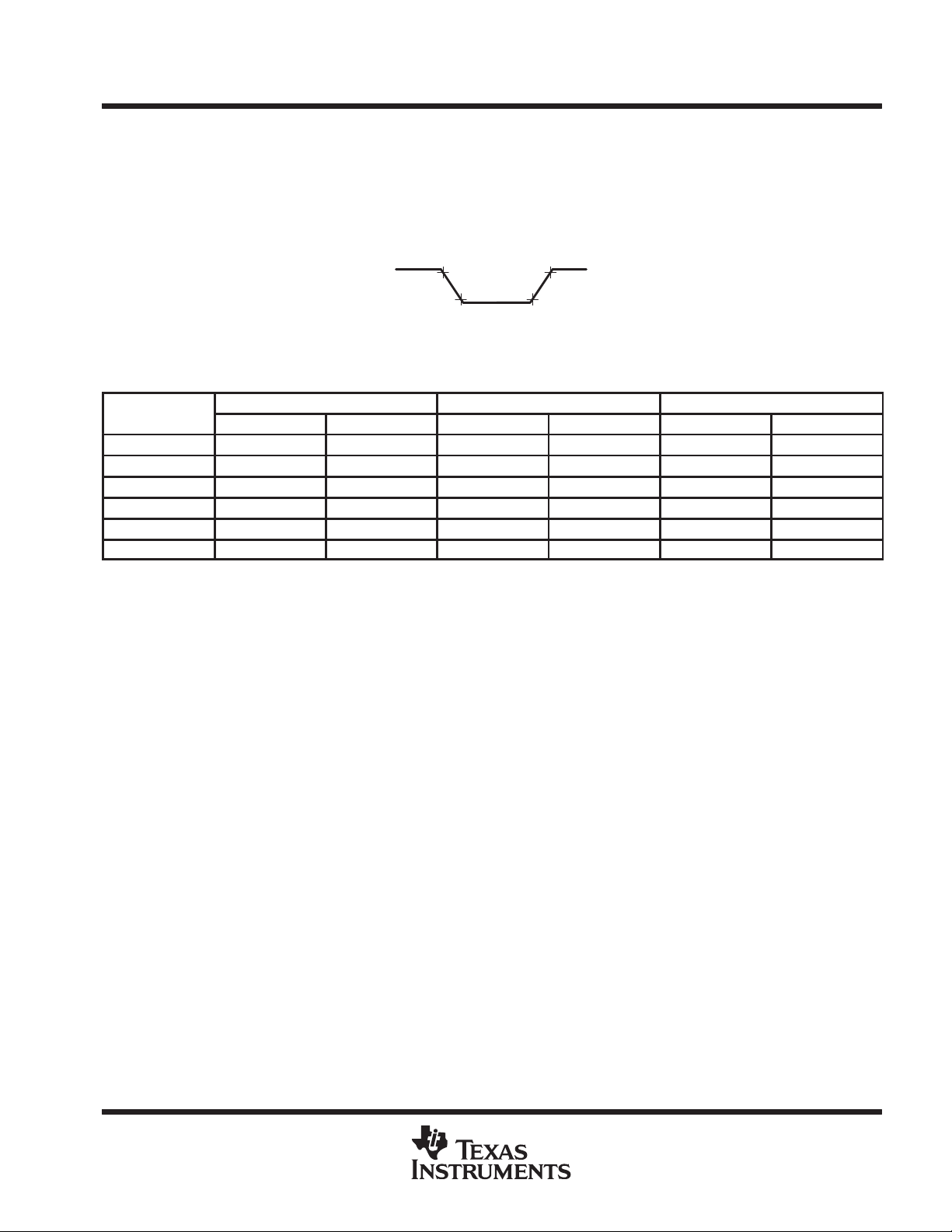

10-bit dual analog-to-digital converter (ADC) 93. . . . . . . . . . . . . . . . . . . . . . . . .

ADC input pin circuit 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flash EEPROM 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

programming operation 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erase operation 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flash-write operation 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

register file compilation 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

package drawing, PQ (S-PQFP-G***), PLASTIC QUAD FLATPACK 104. . . . . .

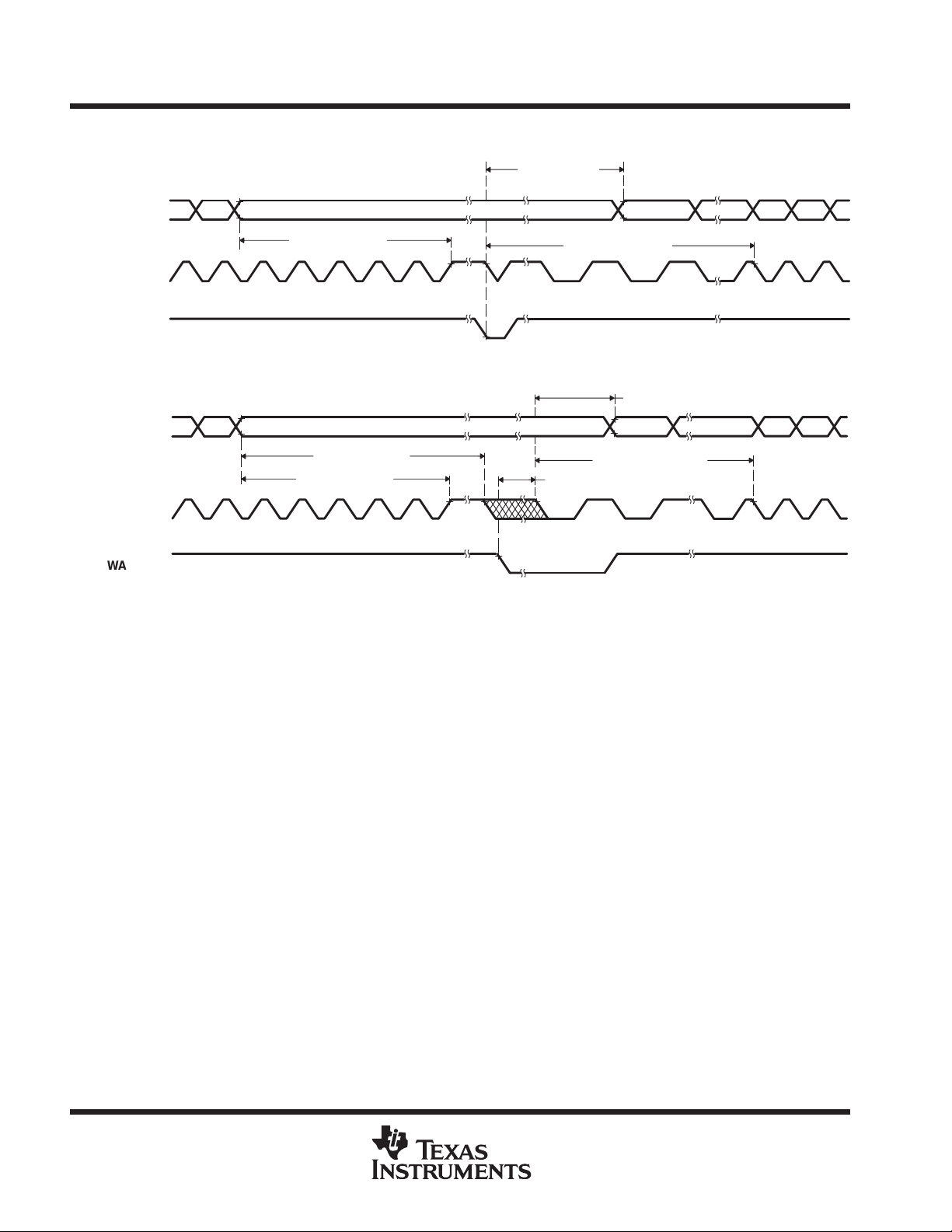

read

timings 71. . . . . . . . . . . . . . . . . . . . . . .

write

timings 73. . . . . . . . . . . . . . . . . . . . . .

4

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

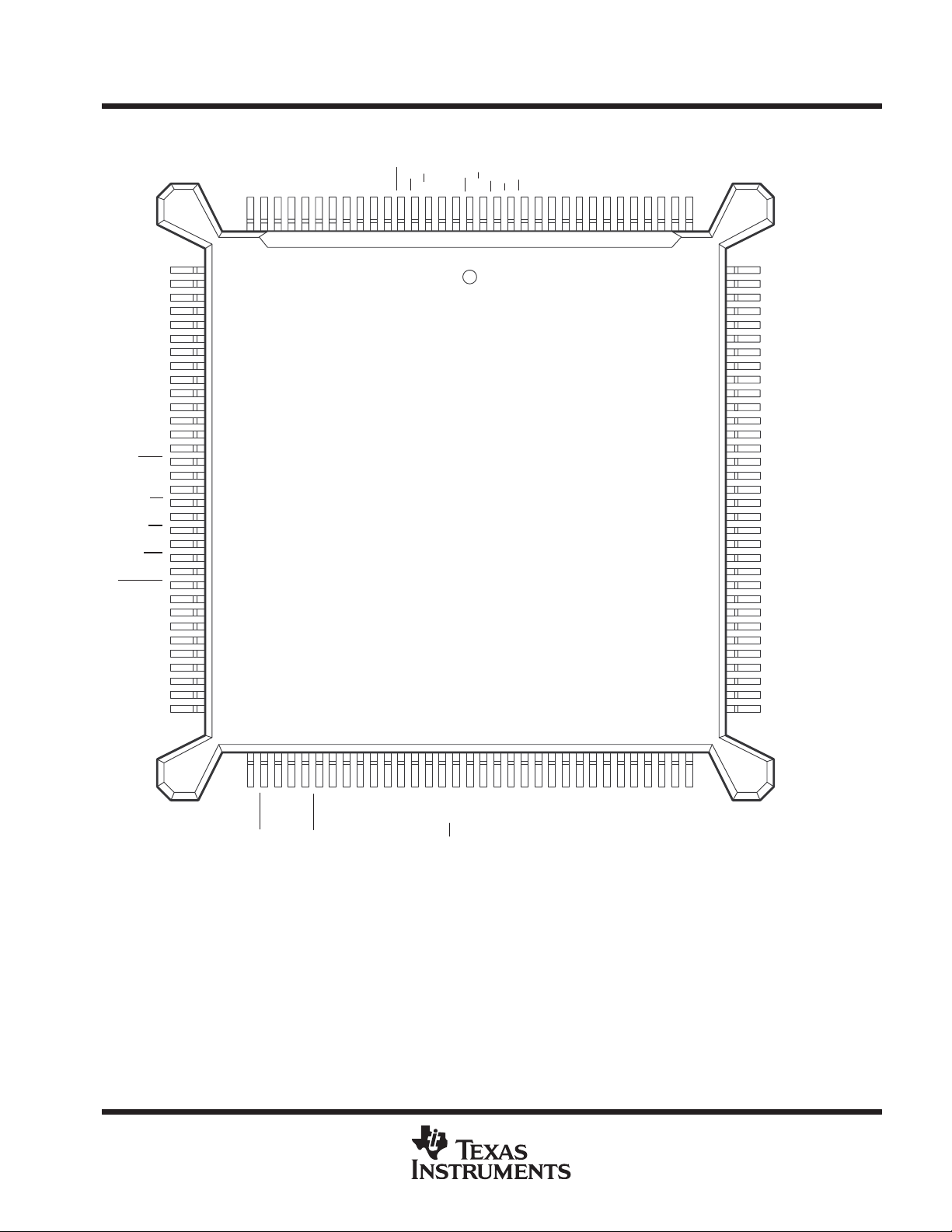

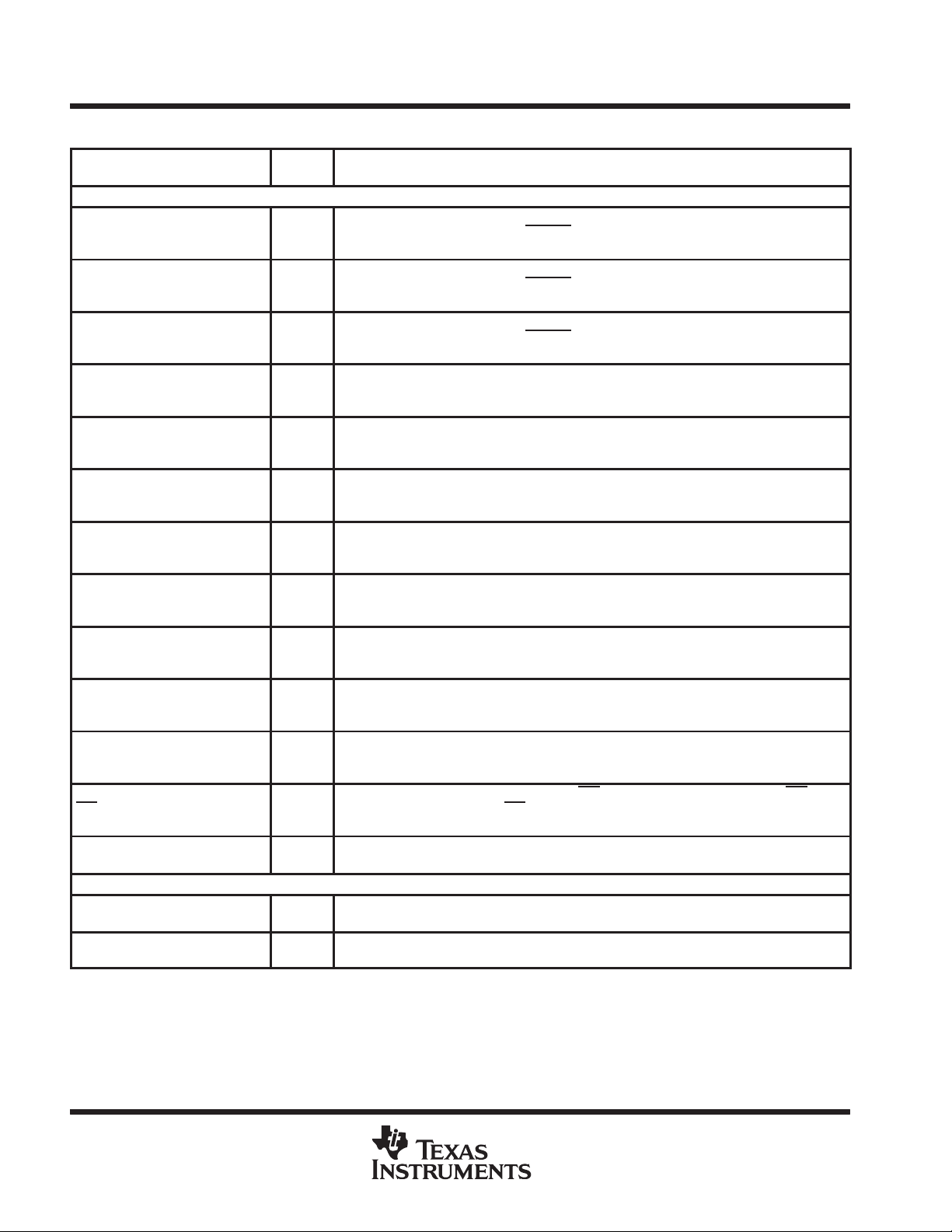

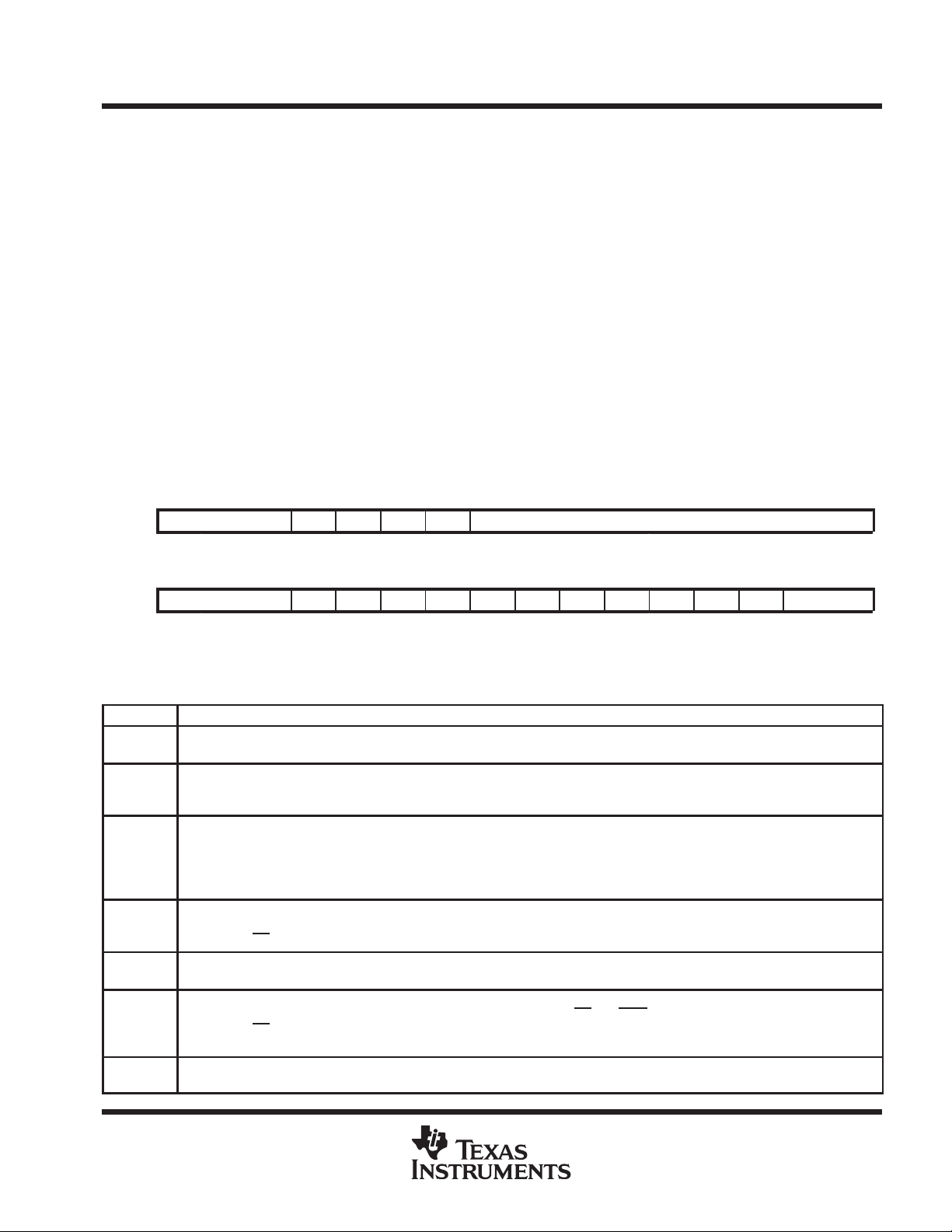

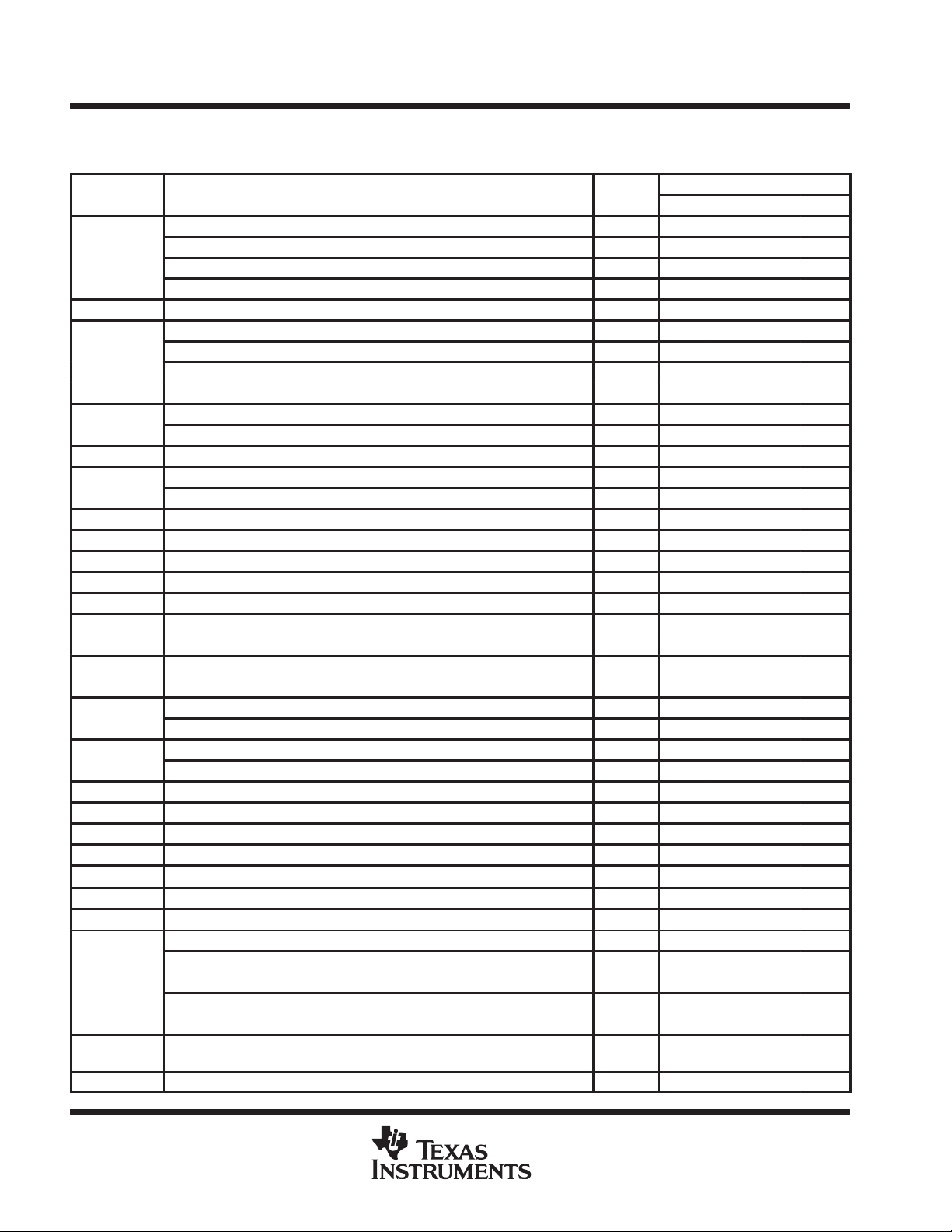

PQ PACKAGE

(TOP VIEW)

V

DV

DD

D10

D11

D12

D13

D14

D15

V

TCK

TDI

TRST

TMS

TDO

RS

READY

MP/MC

EMU0

EMU1/OFF

NMI

PORESET

RESERVED

SCIRXD/IO

SCITXD/IO

SPISIMO/IO

V

DV

DD

SPISOMI/IO

SPICLK/IO

WDDIS

D7

D8

SS

D9

SS

SS

DD

SS

V

D5

D4

D3D6D2

DV

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

†

49

50

525354

555156

SS

DD

D0

CV

D1

11

10

STRBBRR/W

CV

9

867

TMS320C240

TMS320F240

58

59

6067626361

DD

SS

V

DV

234

5

64

65

66

ISDSA15

A14

A13

128

127

126

A12

125

W/R

PS

WE

1

131

129

130

132

695768

70717273747576777879808182

A11

124

A10

123

A9

122

DV

121

DD

SS

V

120

A8A7A6

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

A5

A4

A3

V

SS

A2

A1

A0

TMRCLK/IOPB7

TMRDIR/IOPB6

T3PWM/T3CMP/IOPB5

T2PWM/T2CMP/IOPB4

T1PWM/T1CMP/IOPB3

V

SS

DV

DD

PWM9/CMP9/IOPB2

PWM8/CMP8/IOPB1

PWM7/CMP7/IOPB0

PWM6/CMP6

PWM5/CMP5

PWM4/CMP4

PWM3/CMP3

PWM2/CMP2

PWM1/CMP1

DV

DD

V

SS

ADCIN8/IOPA3

ADCIN9/IOPA2

ADCIN10

ADCIN11

V

SSA

V

REFLO

V

REFHI

V

CCA

XINT1

PDPINT

XINT3/IO

XINT2/IO

SPISTE/IO

†

For the TMS320F240 devices, this pin is V

OSCBYP

DD

SS

DD

VSSV

CV

XTAL2

XTAL1/CLKIN

DV

XF/IOPC2

BIO/IOPC3

CLKOUT/IOPC1

ADCSOC/IOPC0

/WDDIS.

CCP

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

CAP1/QEP1/IOPC4

SS

V

CAP3/IOPC6

CAP4/IOPC7

ADCIN0/IOPA0

CAP2/QEP2/IOPC5

ADCIN1/IOPA1

ADCIN2

ADCIN3

ADCIN5

ADCIN4

ADCIN7

ADCIN6

ADCIN15

ADCIN14

ADCIN12

ADCIN13

5

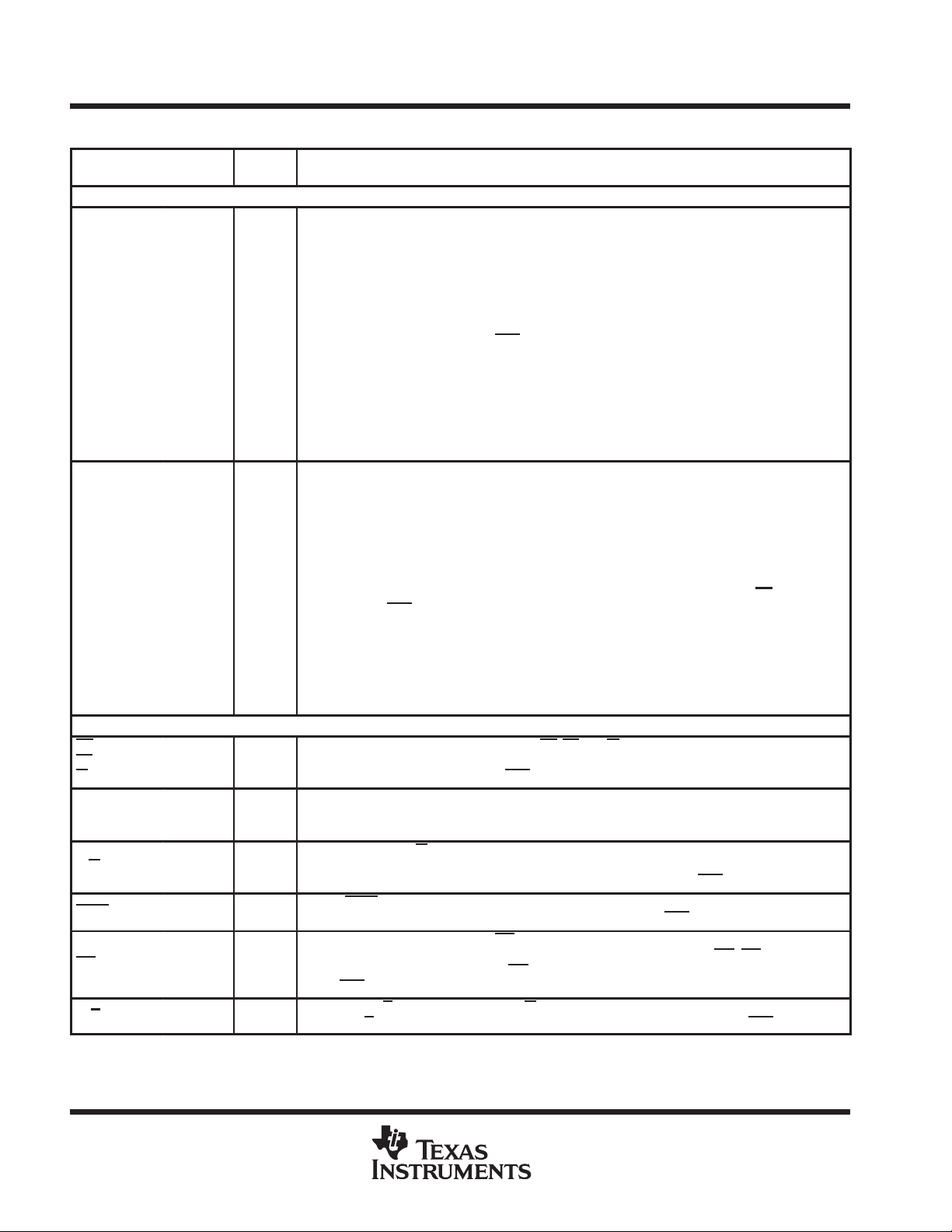

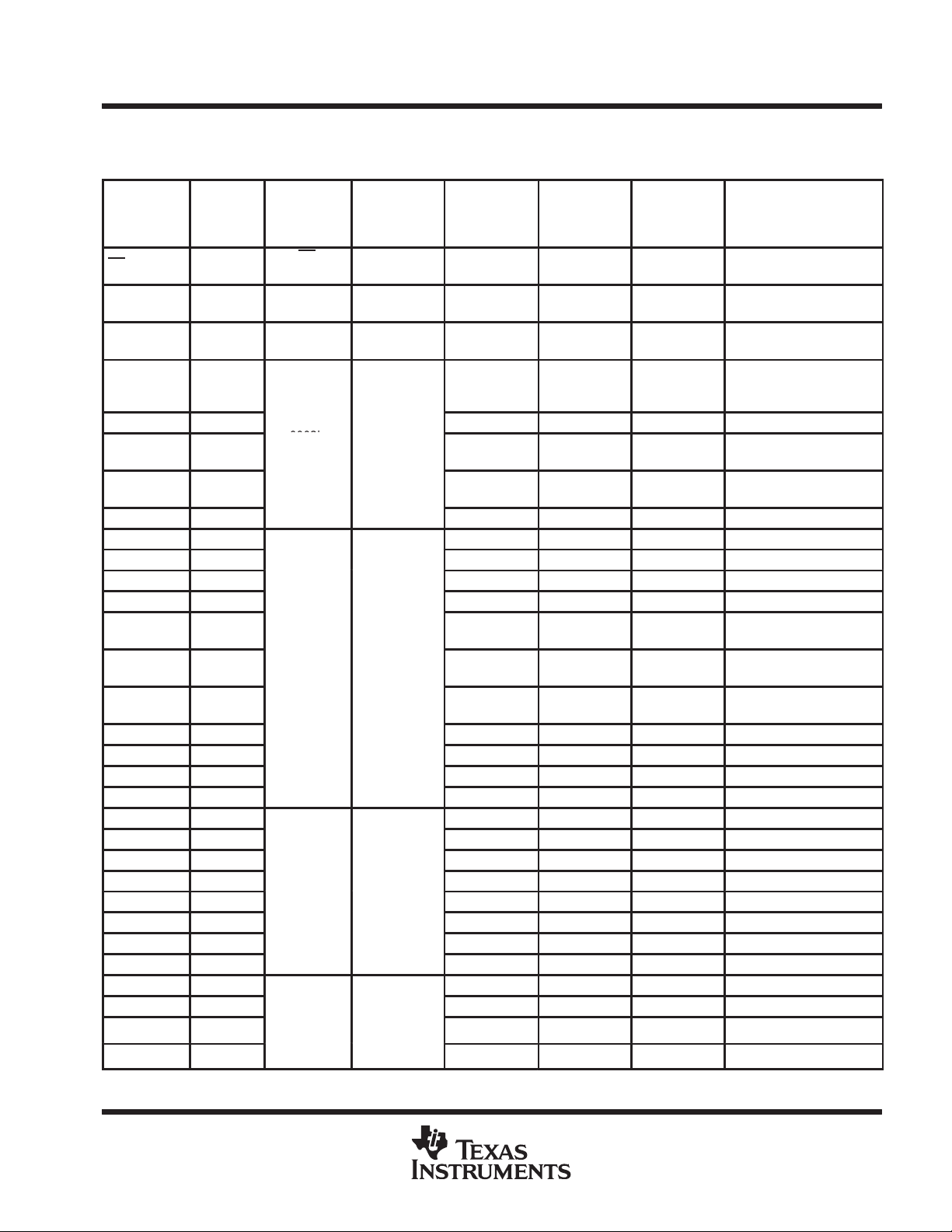

TMS320C240, TMS320F240

TYPE

†

DESCRIPTION

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

TERMINAL

NAME NO.

EXTERNAL INTERFACE DATA/ADDRESS SIGNALS

A0 (LSB)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15 (MSB)

D0 (LSB)

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15 (MSB)

DS

PS

IS

READY 36 I

R/W 4 O/Z

STRB 6 O/Z

WE 1 O/Z

W/R 132 O/Z

†

I = input, O = output, Z = high impedance

110

111

112

114

115

116

117

118

119

122

123

124

125

126

127

128

9

10

11

12

15

16

17

18

19

22

23

24

25

26

27

28

129

131

130

O/Z

I/O/Z

O/Z

Parallel address bus A0 [least significant bit (LSB)] through A15 [most significant bit (MSB)]. A15–A0

are multiplexed to address external data/program memory or I/O. A15–A0 are placed in

high-impedance state when EMU1/OFF

modes.

Parallel data bus D0 (LSB) through D15 (MSB). D15–D0 are multiplexed to transfer data between the

TMS320x240 and external data/program memory and I/O space (devices). D15–D0 are placed in the

high-impedance state when not outputting, when in power-down mode, when reset (RS

or when EMU1/OFF

EXTERNAL INTERFACE CONTROL SIGNALS

Data, program, and I/O space select signals. DS, PS, and IS are always high unless low-level asserted

for communication to a particular external space. They are placed in the high-impedance state during

reset, power down, and when EMU1/OFF

Data ready. READY indicates that an external device is prepared for the bus transaction to be

completed. If the device is not ready (READY is low), the processor waits one cycle and checks

READY again.

Read/write signal. R/W indicates transfer direction during communication to an external device. It is

normally in read mode (high), unless low level is asserted for performing a write operation. It is placed

in the high-impedance state during reset, power down, and when EMU1/OFF

Strobe. STRB is always high unless asserted low to indicate an external bus cycle. It is placed in the

high-impedance state during reset, power down, and when EMU1/OFF

Write enable. The falling edge of WE indicates that the device is driving the external data bus

(D15–D0). Data can be latched by an external device on the rising edge of WE

external program, data, and I/O writes. WE

EMU1/OFF

Write/read. W/R is an inverted form of R/W and can connect directly to the output enable of external

devices. W/R

Terminal Functions

is active low and hold their previous states in power-down

) is asserted,

is active low.

is active low.

is active low.

is active low.

. WE is active on all

goes in the high-impedance state following reset and when

is active low.

is placed in the high-impedance state following reset and when EMU1/OFF is active low.

6

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

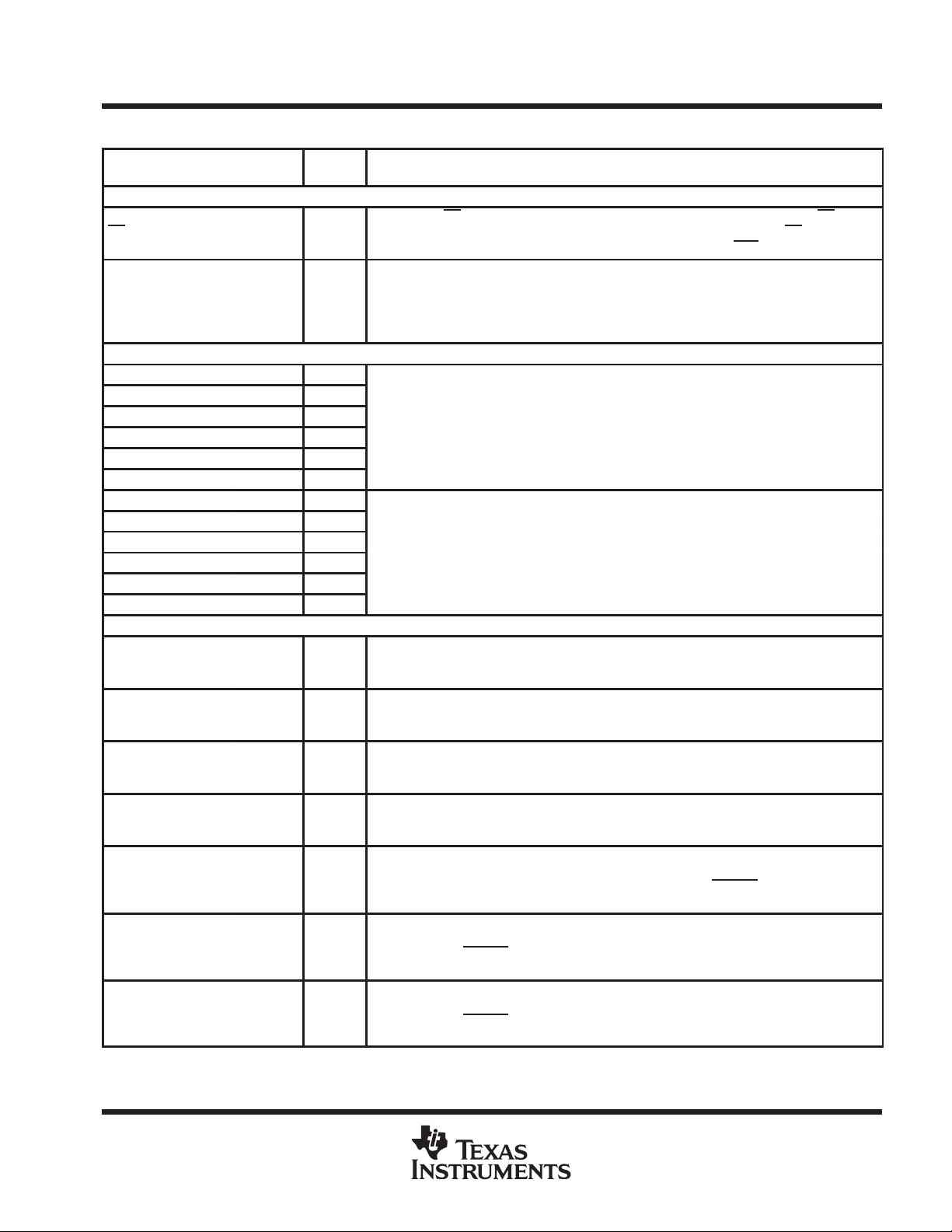

TYPE

†

DESCRIPTION

Analog inputs to the first ADC

Analog inputs to the second ADC

TERMINAL

NAME NO.

EXTERNAL INTERFACE CONTROL SIGNALS (CONTINUED)

BR 5 O/Z

‡

WDDIS

ADCIN2 74 I

ADCIN3 75 I

ADCIN4 76 I

ADCIN5 77 I

ADCIN6 78 I

ADCIN7 79 I

ADCIN10 89 I

ADCIN11 88 I

ADCIN12 83 I

ADCIN13 82 I

ADCIN14 81 I

ADCIN15 80 I

ADCIN0/IOPA0 72 I/O

ADCIN1/IOPA1 73 I/O

ADCIN9/IOPA2 90 I/O

ADCIN8/IOPA3 91 I/O

PWM7/CMP7/IOPB0 100 I/O/Z

PWM8/CMP8/IOPB1 101 I/O/Z

PWM9/CMP9/IOPB2 102 I/O/Z

†

I = input, O = output, Z = high impedance

‡

For the TMS320F240 devices, this pin is V

50 I

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Terminal Functions (Continued)

Bus request. BR is asserted during access of external global data memory space. BR can be

used to extend the data memory address space by up to 32K words. BR

high-impedance state during reset, power down, and when EMU1/OFF

Flash-programming voltage supply. If V

ENTIRE on-chip flash memory block—that is, for programming the flash. If V

WRITE/ERASE of the flash memory is not allowed, thereby protecting the entire memory block

from being overwritten. WDDIS also functions as a hardware watchdog disable. The watchdog

timer is disabled when V

ADC INPUTS (UNSHARED)

p

p

BIT I/O AND SHARED FUNCTIONS PINS

Bidirectional digital I/O.

Analog input to the first ADC.

ADCIN0/IOPA0 is configured as a digital input by all device resets.

Bidirectional digital I/O.

Analog input to the first ADC.

ADCIN1/IOPA1 is configured as a digital input by all device resets.

Bidirectional digital I/O.

Analog input to the second ADC.

ADCIN9/IOPA2 is configured as a digital input by all device resets.

Bidirectional digital I/O.

Analog input to the second ADC.

ADCIN8/IOPA3 is configured as a digital input by all device resets.

Bidirectional digital I/O. Simple compare/PWM 1 output. The state of PWM7/CMP7/IOPB0 is

determined by the simple compare/PWM and the simple action control register (SACTR). It

goes to the high-impedance state when unmasked PDPINT

PWM7/CMP7/IOPB0 is configured as a digital input by all device resets.

Bidirectional digital I/O. Simple compare/PWM 2 output. The state of PWM8/CMP8/IOPB1 is

determined by the simple compare/PWM and the SACTR. It goes to the high-impedance state

when unmasked PDPINT

by all device resets.

Bidirectional digital I/O. Simple compare/PWM 3 output. The state of PWM9/CMP9/IOPB2 is

determined by the simple compare/PWM and SACTR. It goes to the high-impedance state

when unmasked PDPINT

by all device resets.

CCP/WDDIS

.

/WDDIS = 5 V and bit 6 in WDCR is set to 1.

CCP

goes active low. PWM8/CMP8/IOPB1 is configured as a digital input

goes active low. PWM9/CMP9/IOPB2 is configured as a digital input

= 5 V, then WRITE/ERASE can be made to the

CCP

goes in the

is active low.

CCP

goes active low.

= 0 V , then

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

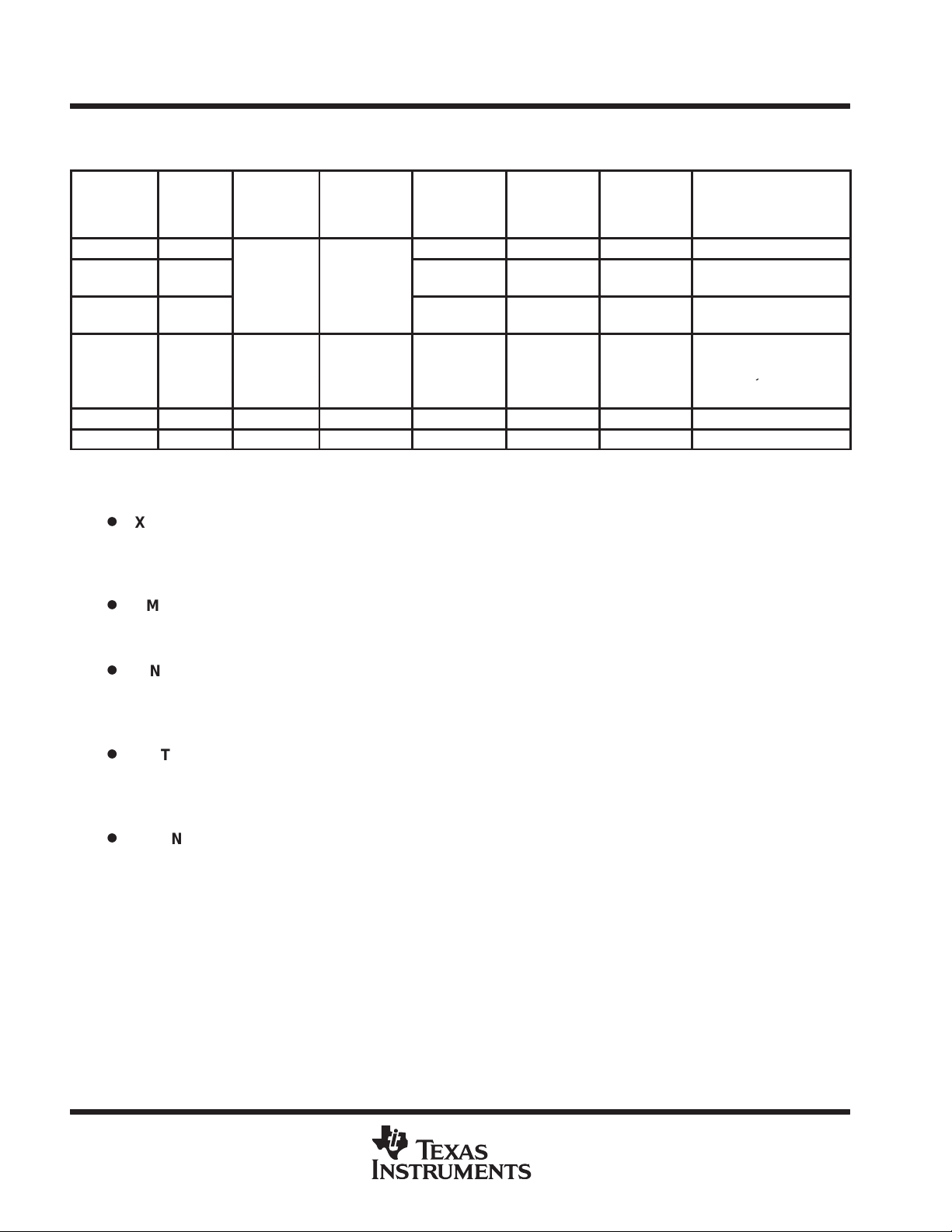

7

TMS320C240, TMS320F240

TYPE

†

DESCRIPTION

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Terminal Functions (Continued)

TERMINAL

NAME NO.

BIT I/O AND SHARED FUNCTIONS PINS (CONTINUED)

T1PWM/T1CMP/

IOPB3

T2PWM/T2CMP/

IOPB4

T3PWM/T3CMP/

IOPB5

TMRDIR/IOPB6 108 I/O

TMRCLK/IOPB7 109 I/O

ADCSOC/IOPC0 63 I/O

CAP1/QEP1/IOPC4 67 I/O

CAP2/QEP2/IOPC5 68 I/O

CAP3/IOPC6 69 I/O

CAP4/IOPC7 70 I/O

XF/IOPC2 65 I/O

BIO/IOPC3 66 I/O

CLKOUT/IOPC1 64 I/O

SCITXD/IO 44 I/O

SCIRXD/IO 43 I/O

†

I = input, O = output, Z = high impedance

105 I/O/Z

106 I/O/Z

107 I/O/Z

SERIAL COMMUNICATIONS INTERFACE (SCI) AND BIT I/O PINS

Bidirectional digital I/O. Timer 1 compare output. T1PWM/T1CMP/IOPB3 goes to the highimpedance state when unmasked PDPINT

input by all device resets.

Bidirectional digital I/O. Timer 2 compare output. T2PWM/T2CMP/IOPB4 goes to the highimpedance state when unmasked PDPINT

input by all device resets.

Bidirectional digital I/O. Timer 3 compare output. T3PWM/T3CMP/IOPB5 goes to the highimpedance state when unmasked PDPINT

input by all device resets.

Bidirectional digital I/O. Direction signal for the timers. Up-counting direction if TMRDIR/IOPB6

is low, down-counting direction if this pin is high.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

External clock input for general-purpose timers.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

External start of conversion input for ADC.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

Capture 1 or QEP 1 input.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

Capture 2 or QEP 2 input.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

Capture 3 input.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O.

Capture 4 input.

This pin is configured as a digital input by all device resets.

Bidirectional digital I/O. External flag output (latched software-programmable signal). XF is

used for signaling other processors in multiprocessing configurations or as a general-purpose

output pin. This pin is configured as an external flag output by all device resets.

Bidirectional digital I/O. Branch control input. BIO is polled by the BIOZ instruction. If BIO is low,

the CPU executes a branch. If BIO

as a branch-control input by all device resets.

Bidirectional digital I/O. Clock output. Clock output is selected by the CLKSRC bits in the

SYSCR register. This pin is configured as a DSP clock output by a power-on reset.

SCI asynchronous serial port transmit data, or general-purpose bidirectional I/O. This pin is

configured as a digital input by all device resets.

SCI asynchronous serial port receive data, or general-purpose bidirectional I/O. This pin is

configured as a digital input by all device resets.

goes active low. This pin is configured as a digital

goes active low. This pin is configured as a digital

goes active low. This pin is configured as a digital

is not used , it should be pulled high. This pin is configured

8

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TYPE

†

DESCRIPTION

Terminal Functions (Continued)

TERMINAL

NAME NO.

SERIAL PERIPHERAL INTERFACE (SPI) AND BIT I/O PINS

SPISIMO/IO 45 I/O

SPISOMI/IO 48 I/O

SPICLK/IO 49 I/O

SPISTE/IO 51 I/O

PWM1/CMP1

PWM2/CMP2

PWM3/CMP3

PWM4/CMP4

PWM5/CMP5

PWM6/CMP6

RS 35 I/O

MP/MC 37 I

NMI 40 I

PORESET 41 I

XINT1 53 I External user interrupt no. 1

XINT2/IO 54 I/O

XINT3/IO 55 I/O

PDPINT 52 I

XTAL2 57 O

XTAL1/CLKIN 58 I/Z

OSCBYP 56 I Bypass oscillator if low

†

I = input, O = output, Z = high impedance

94

95

96

97

98

99

O/Z

SPI slave in, master out , or general-purpose bidirectional I/O. This pin is configured as a digital

input by all device resets.

SPI slave out, master in, or general-purpose bidirectional I/O. This pin is configured as a digital

input by all device resets.

SPI clock, or general-purpose bidirectional I/O. This pin is configured as a digital input by all

device resets.

SPI slave transmit enable (optional), or general-purpose bidirectional I/O. This pin is configured

as a digital input by all device resets.

COMPARE SIGNALS

Compare units compare or PWM outputs. The state of these pins is determined by the

compare/PWM and the full action control register (ACTR). CMP1–CMP6 go to the highimpedance state when unmasked PDPINT

INTERRUPT AND MISCELLANEOUS SIGNALS

Reset input. RS causes the TMS320x240 to terminate execution and sets PC = 0. When RS

is brought to a high level, execution begins at location zero of program memory. RS af fects (or

sets to zero) various registers and status bits.

MP/MC (microprocessor/microcomputer) select. If MP/MC is low, internal program memory is

selected. If it is high, external program memory is selected.

Nonmaskable interrupt. When NMI is activated, the device is interrupted regardless of the state

of the INTM bit of the status register. NMI has programmable polarity.

Power-on reset. PORESET causes the TMS320x240 to terminate execution and sets PC = 0.

When PORESET

memory. PORESET

tion, PORESET

External user interrupt no. 2. General-purpose bidirectional I/O. This pin is configured as a

digital input by all device resets.

External user interrupt no. 3. General-purpose bidirectional I/O. This pin is configured as a

digital input by all device resets.

Maskable power-drive protection interrupt. If PDPINT is unmasked and it goes active low, the

timer compare outputs immediately go to the high-impedance state.

PLL oscillator output. XT AL2 is tied to one side of a reference crystal when the device is in PLL

mode (CLKMD[1:0] = 1x, CKCR0.7–6). This pin can be left unconnected in oscillator bypass

mode (OSCBYP

low.

PLL oscillator input. XTAL1/CLKIN is tied to one side of a reference crystal in PLL mode

(CLKMD[1:0] = 1x, CKCR0.7–6), or is connected to an external clock source in oscillator

bypass mode (OSCBYP

is brought to a high level, execution begins at location zero of program

affects (or sets to zero) the same registers and status bits as RS. In addi-

initializes the PLL control registers.

CLOCK SIGNALS

≤ VIL). This pin goes in the high-impedance state when EMU1/OFF is active

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

goes active low, and when reset (RS) is asserted.

≤ VIL).

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

9

TMS320C240, TMS320F240

TYPE

†

DESCRIPTION

V

I

Digital logic ground reference

DV

I

Digital I/O logic suppl

oltage

CV

I

Digital core logic suppl

oltage

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Terminal Functions (Continued)

TERMINAL

NAME NO.

CV

SS

SS

8 I Digital core logic ground reference

3

14

20

29

46

59

61

71

92

104

113

120

SUPPLY SIGNALS

V

SSA

DD

DD

V

CCA

V

REFHI

V

REFLO

TCK 30 I

TDI 31 I

TDO 34 O/Z

TMS 33 I

†

I = input, O = output, Z = high impedance

87 I Analog ground reference

2

13

21

47

62

93

103

121

7

60

84 I Analog supply voltage

85 I ADC analog voltage reference high

86 I ADC analog voltage reference low

pp

y v

pp

y v

TEST SIGNALS

IEEE standard test clock. TCK is normally a free-running clock signal with a 50% duty cycle. The

changes on test-access port (TAP) input signals (TMS and TDI) are clocked into the TAP controller,

instruction register, or selected test data register of the ’C2xx core on the rising edge of TCK. Changes

at the TAP output signal (TDO) occur on the falling edge of TCK.

IEEE standard test data input (TDI). TDI is clocked into the selected register (instruction or data) on

a rising edge of TCK.

IEEE standard test data output (TDO). The contents of the selected register (instruction or data) are

shifted out of TDO on the falling edge of TCK. TDO is in the high-impedance state when OFF

low.

IEEE standard test mode select. This serial control input is clocked into the TAP controller on the rising

edge of TCK.

is active

10

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TYPE

†

DESCRIPTION

TERMINAL

NAME NO.

TRST 32 I

EMU0 38 I/O/Z

EMU1/OFF 39 I/O/Z

RESERVED 42 I

†

I = input, O = output, Z = high impedance

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Terminal Functions (Continued)

TEST SIGNALS (CONTINUED)

IEEE standard test reset. TRST, when active low, gives the scan system control of the operations of

the device. If this signal is not connected or driven low, the device operates in its functional mode, and

the test reset signals are ignored.

Emulator pin 0. When TRST is driven low, EMU0 must be high for activation of the /OFF condition.

When TRST

as input/output through the scan.

Emulator pin 1/disable all outputs. When TRST is driven high, EMU1/OFF is used as an interrupt to

or from the emulator system and is defined as input/output through JTAG scan. When TRST

low, this pin is configured as OFF

high-impedance state. OFF

multiprocessing applications); therefore, for OFF

low, EMU0 = high, EMU1/OFF

Reserved for test. This pin has an internal pulldown and must be left unconnected for the ’F240. On

the ’C240, this pin is a no connect.

is driven high, EMU0 is used as an interrupt to or from the emulator system and is defined

is driven

. When EMU1/OFF is active low, it puts all output drivers in the

is used exclusively for testing and emulation purposes (not for

condition, the following conditions apply: TRST =

= low.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

11

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

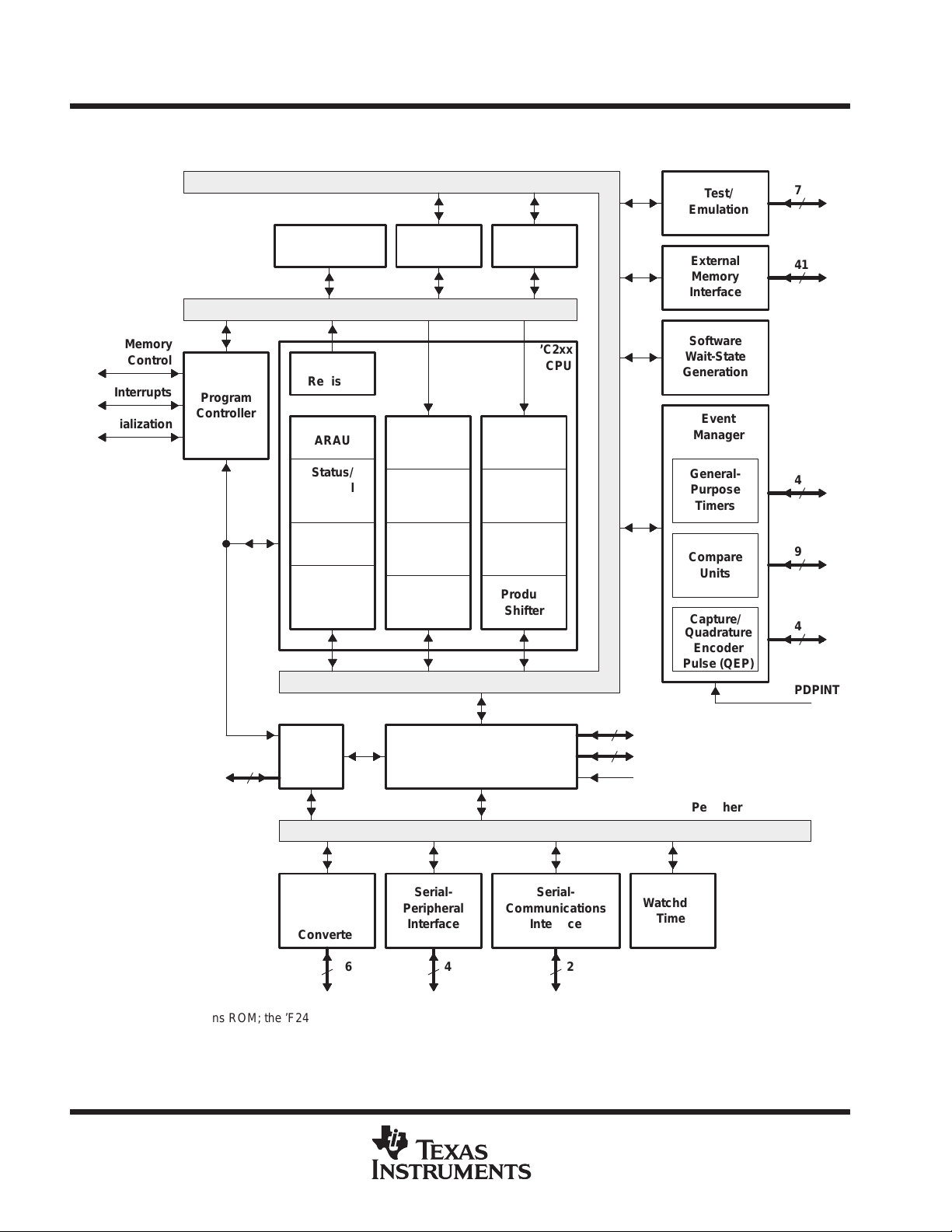

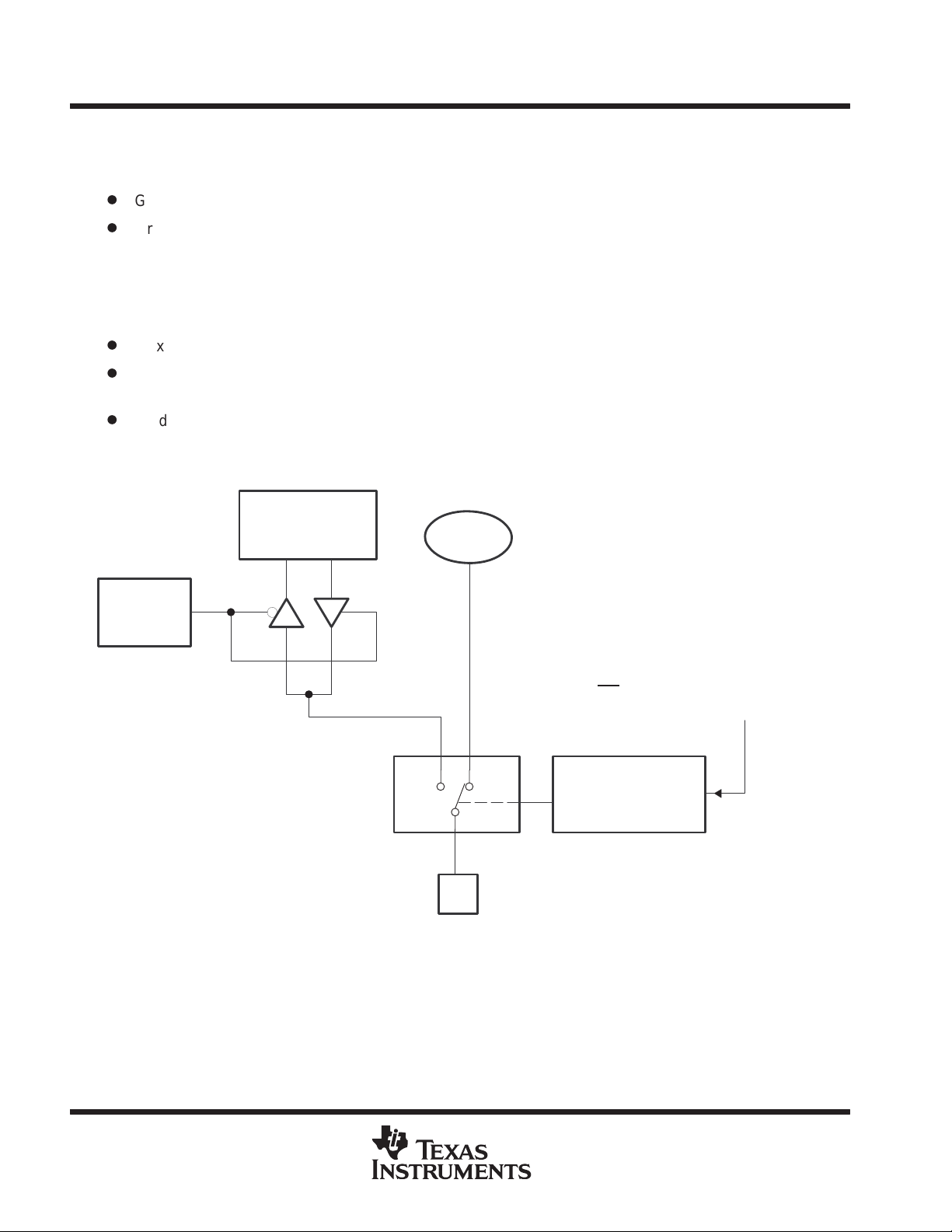

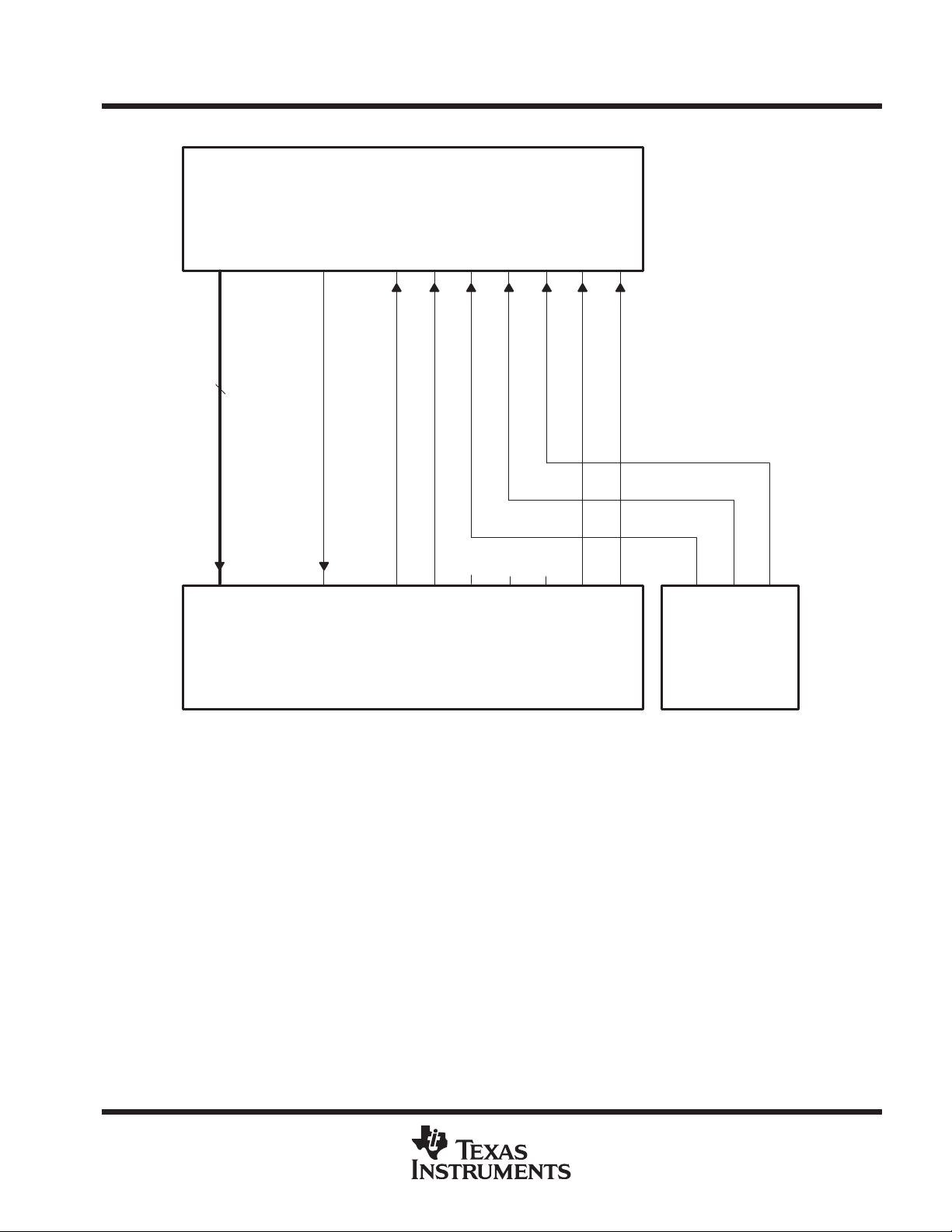

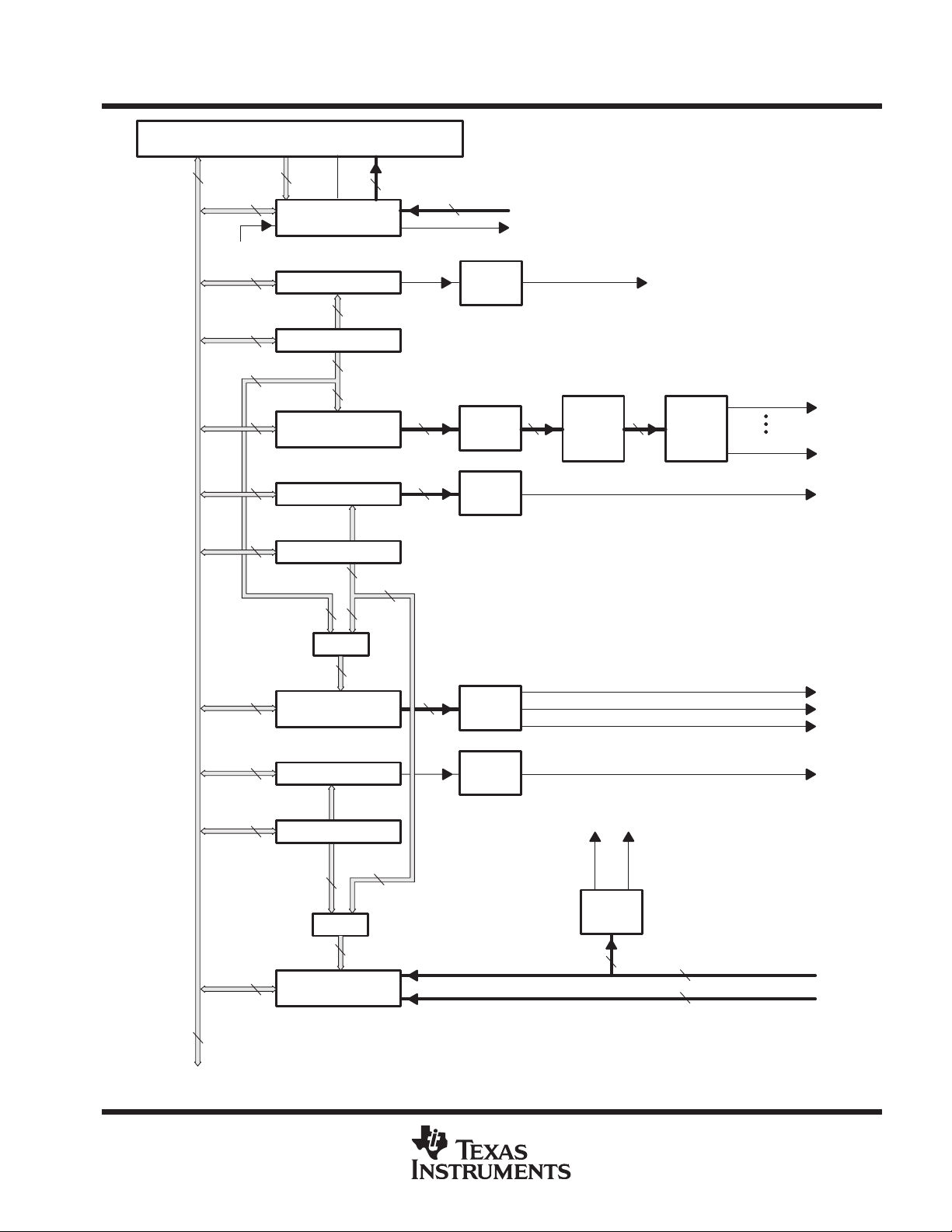

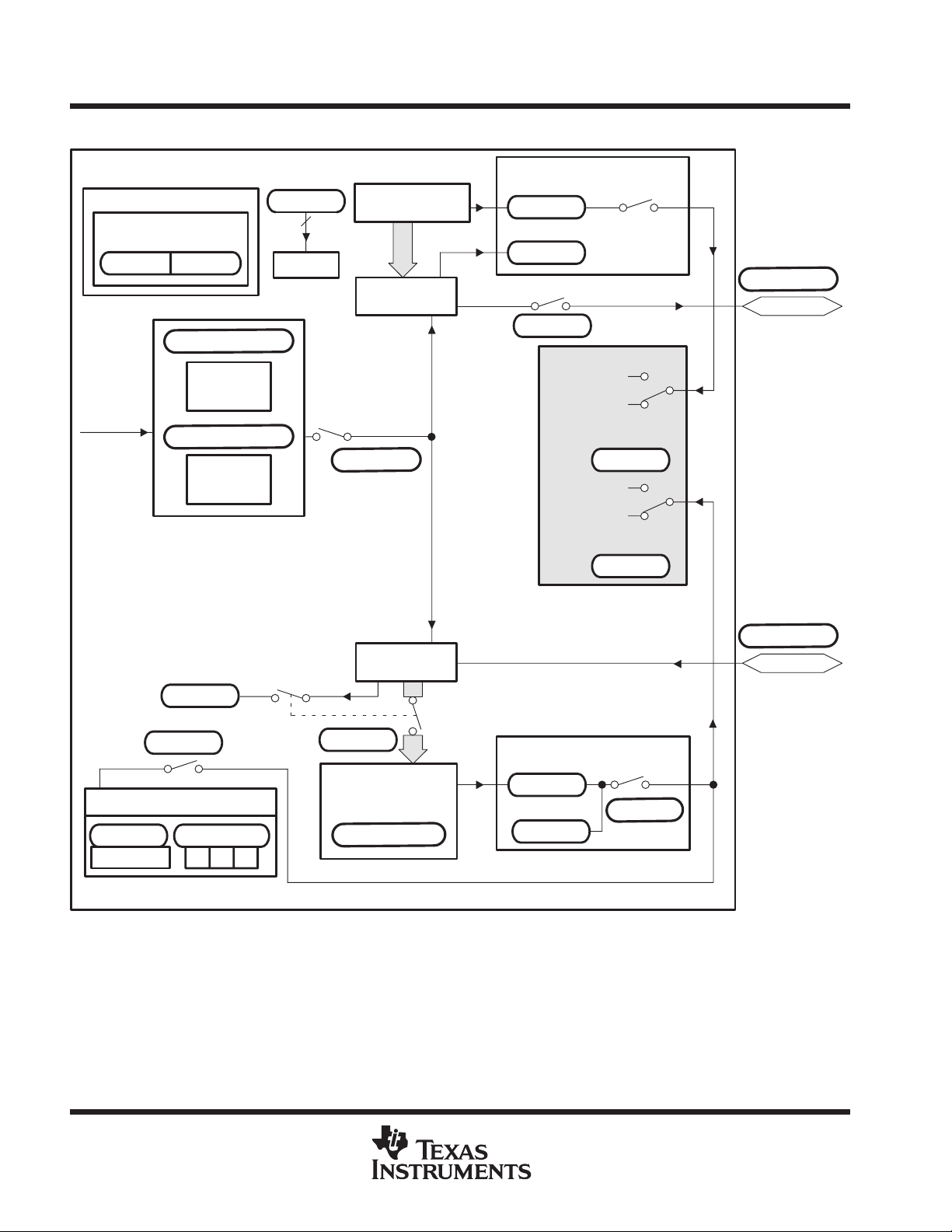

functional block diagram

Data Bus

Memory

Control

Interrupts

Initialization

Program Bus

Program

Controller

EEPROM

Instruction

Register

ARAU

Status/

Control

Registers

Auxiliary

Registers

Memory-

Mapped

Registers

†

DARAMROM or Flash

B0

Input

Shifter

ALU

Accumulator

Output

Shifter

DARAM

B1/B2

Multiplier

TREG

PREG

Product

Shifter

’C2xx

CPU

Test/

Emulation

External

Memory

Interface

Software

Wait-State

Generation

Event

Manager

General-

Purpose

Timers

Compare

Units

Capture/

Quadrature

Encoder

Pulse (QEP)

7

41

4

9

4

Clock

3

†

The ’C240 device contains ROM; the ’F240 device contains Flash EEPROM.

Module

Dual 10-Bit

Analog-

to-Digital

Converter

System-Interface

Module

Serial-

Peripheral

Interface

4

Serial-

Communications

Interface

216

4

Interrupts

20

Digital Input/Output

Reset

Watchdog

Timer

PDPINT

Peripheral Bus

12

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

(V)

(ns)

PIN COUNT

description (continued)

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

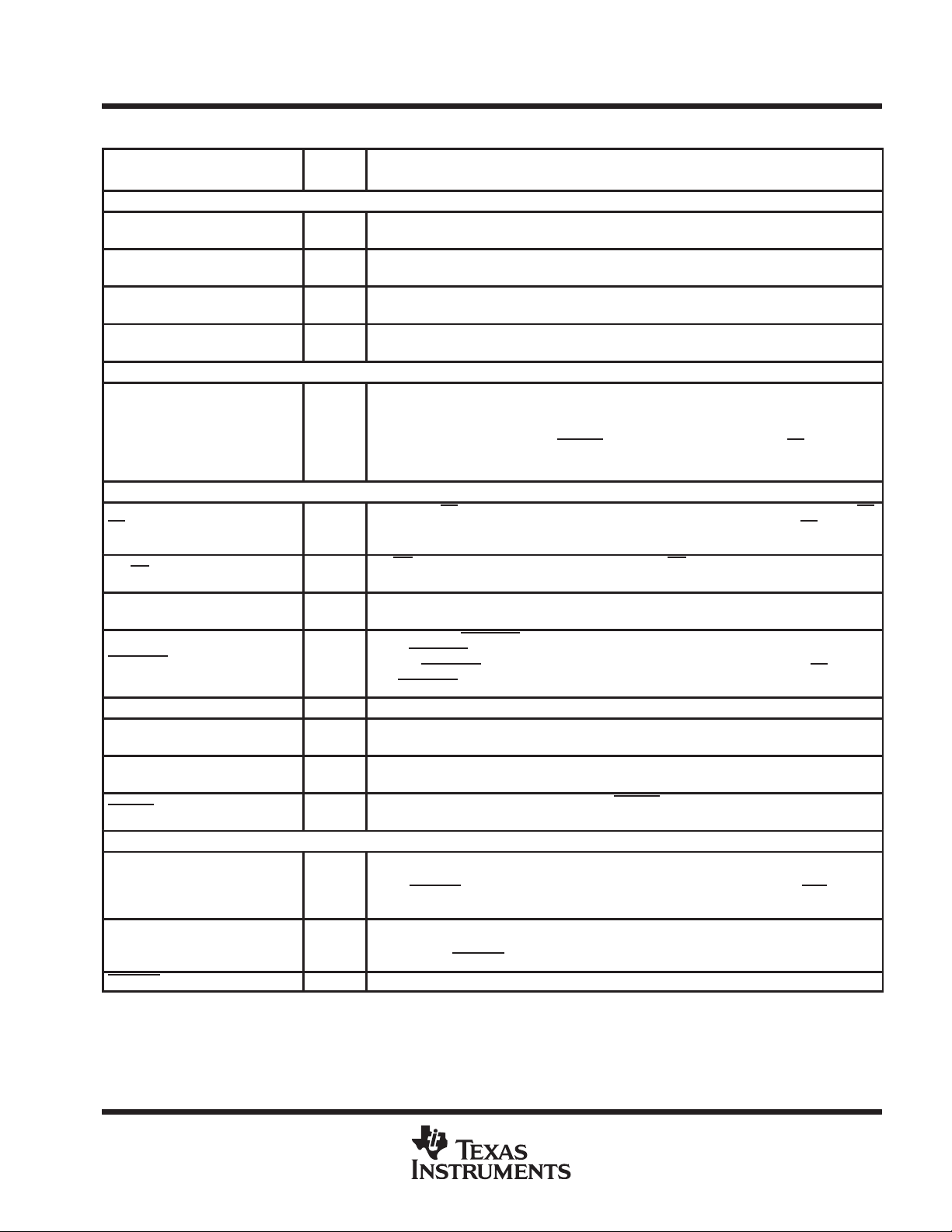

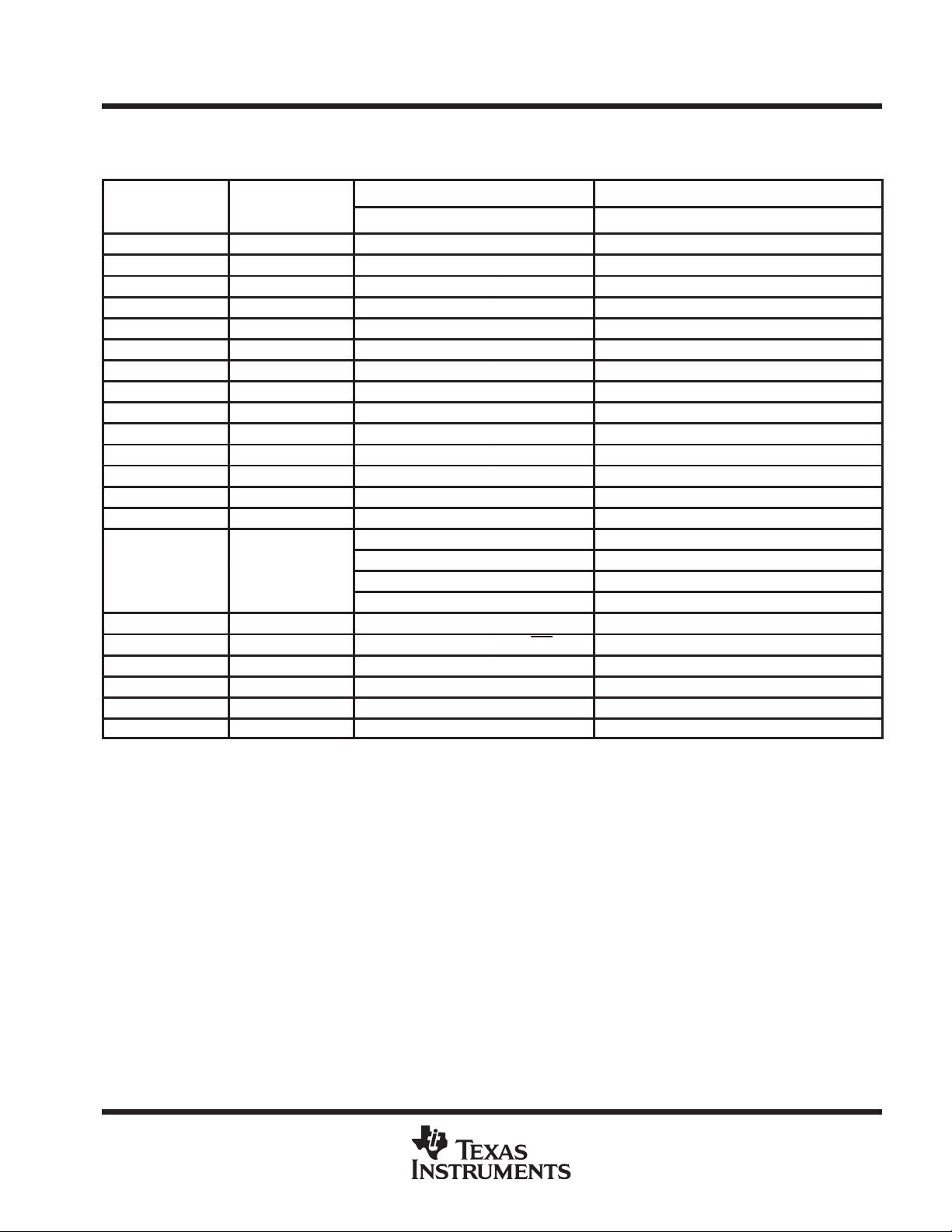

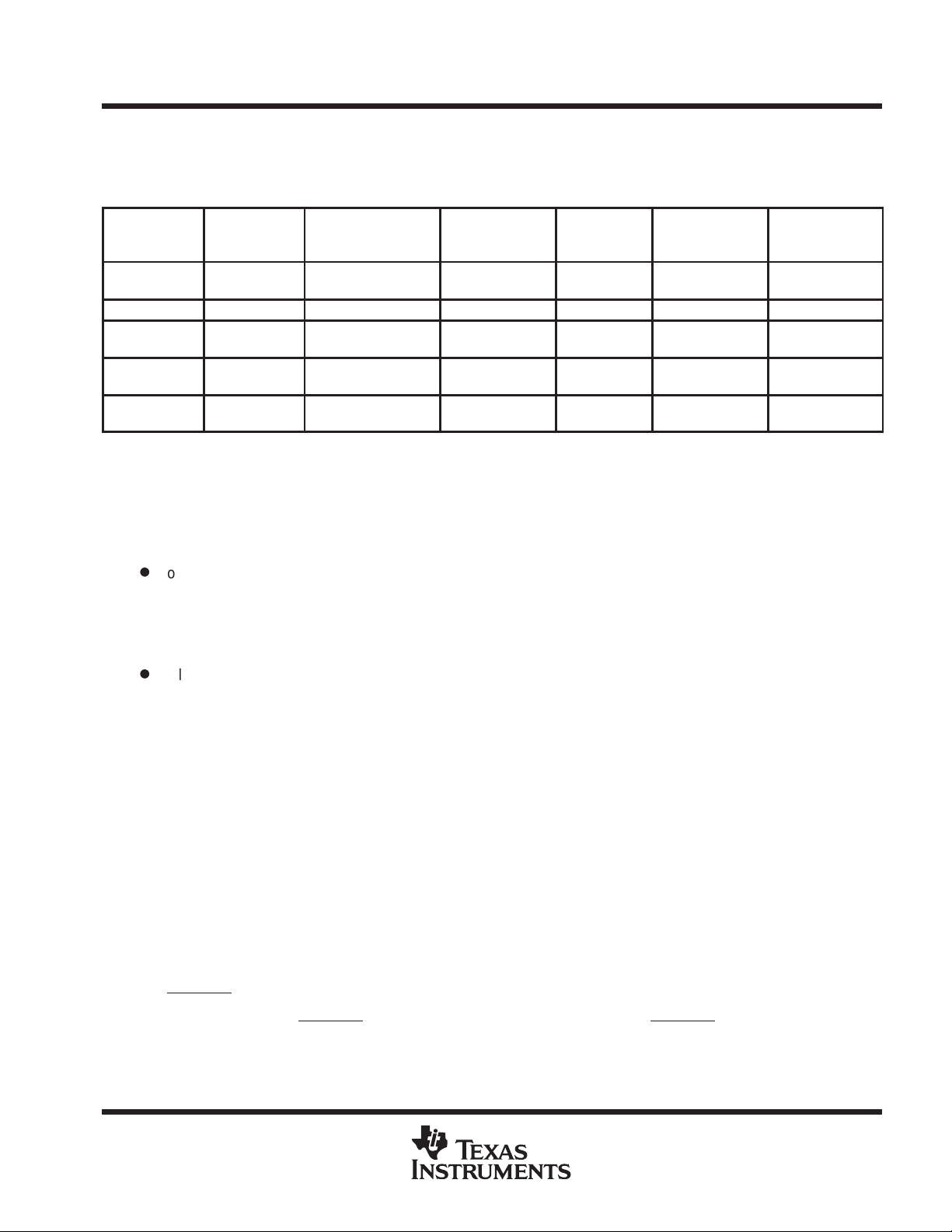

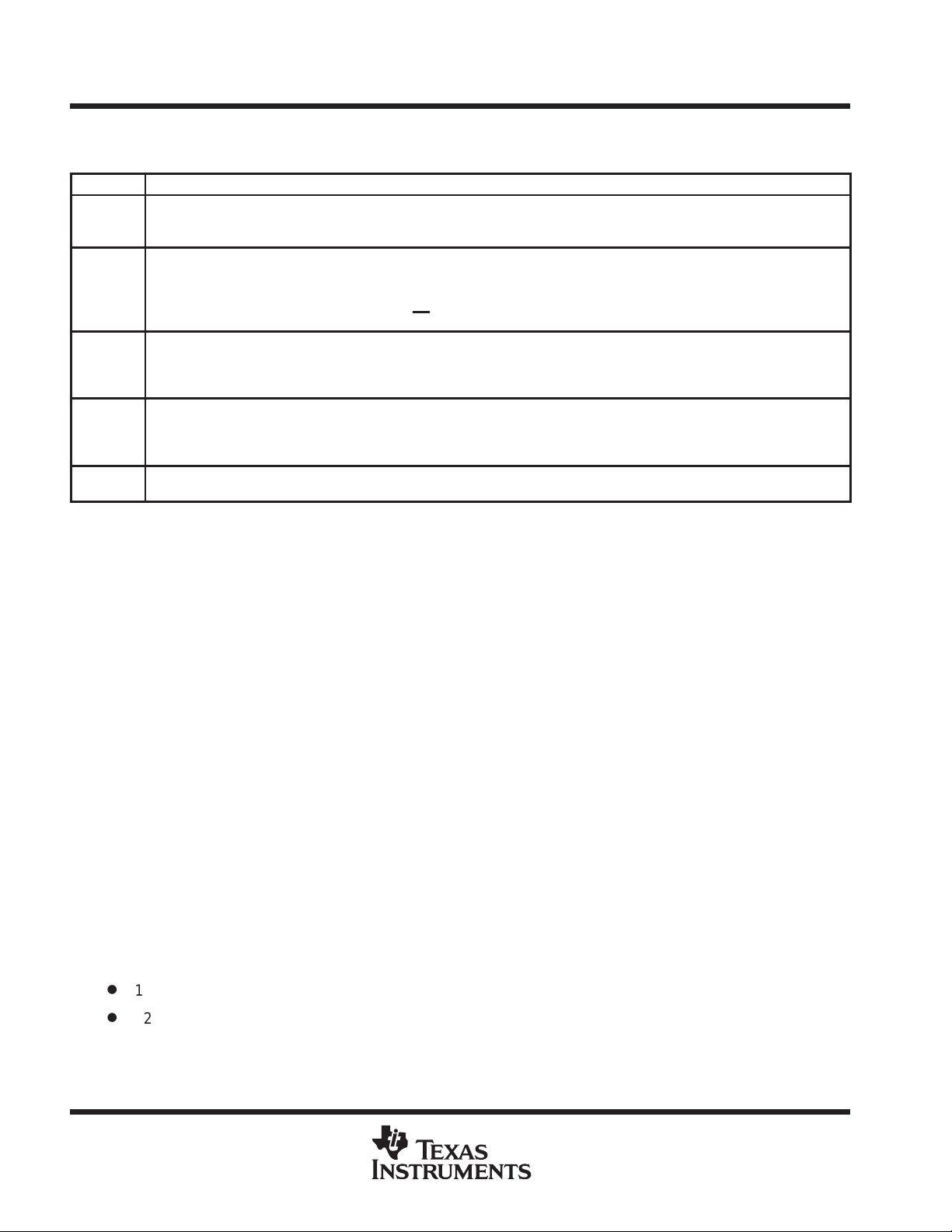

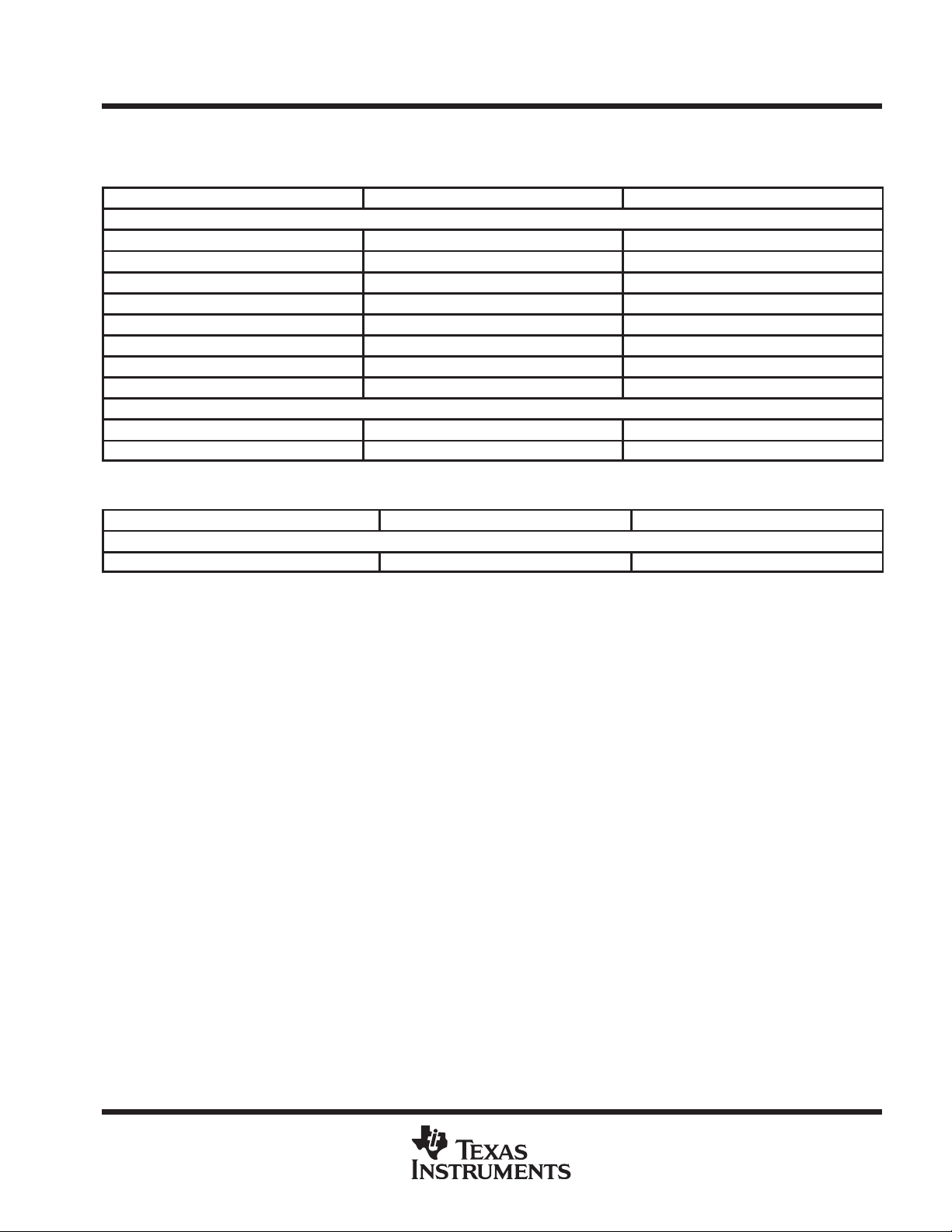

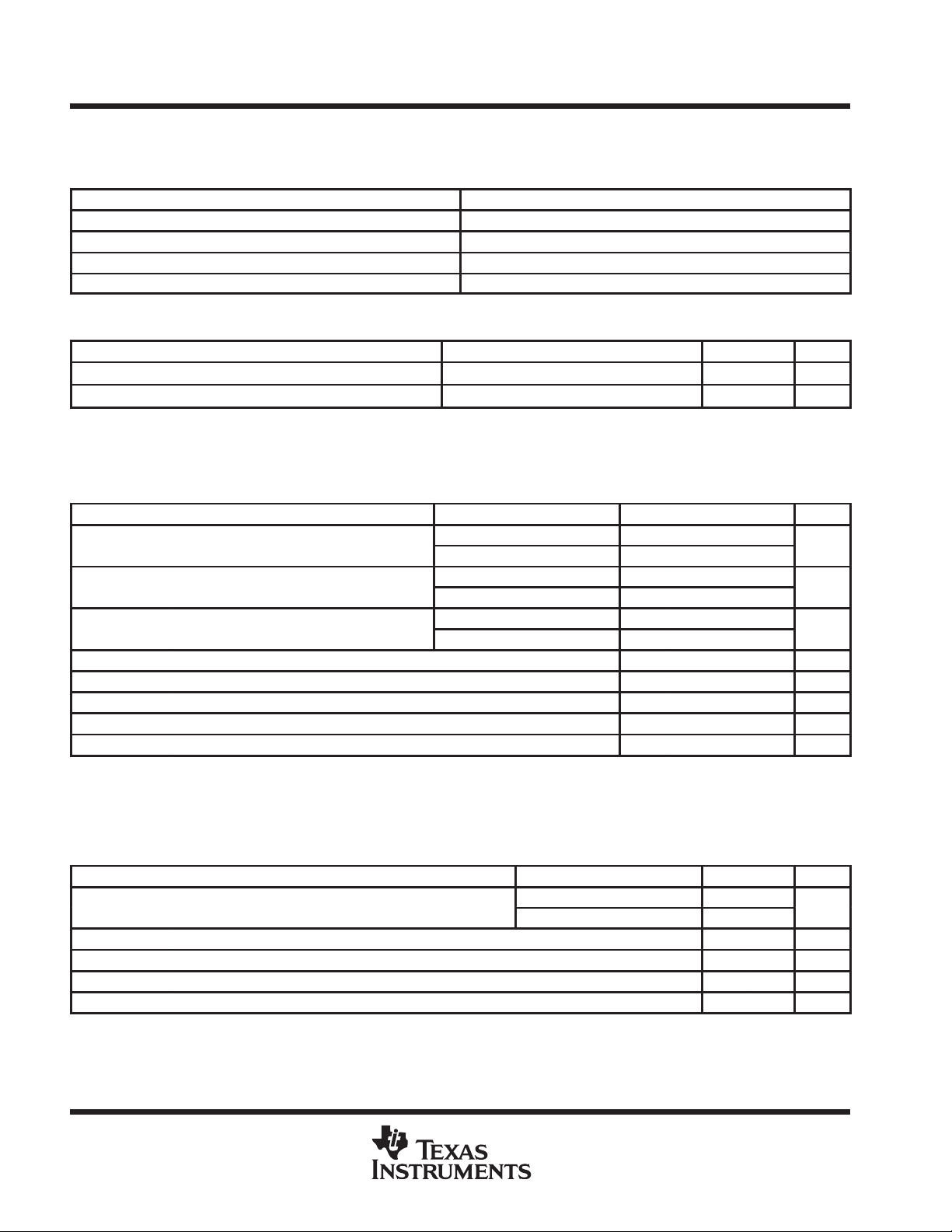

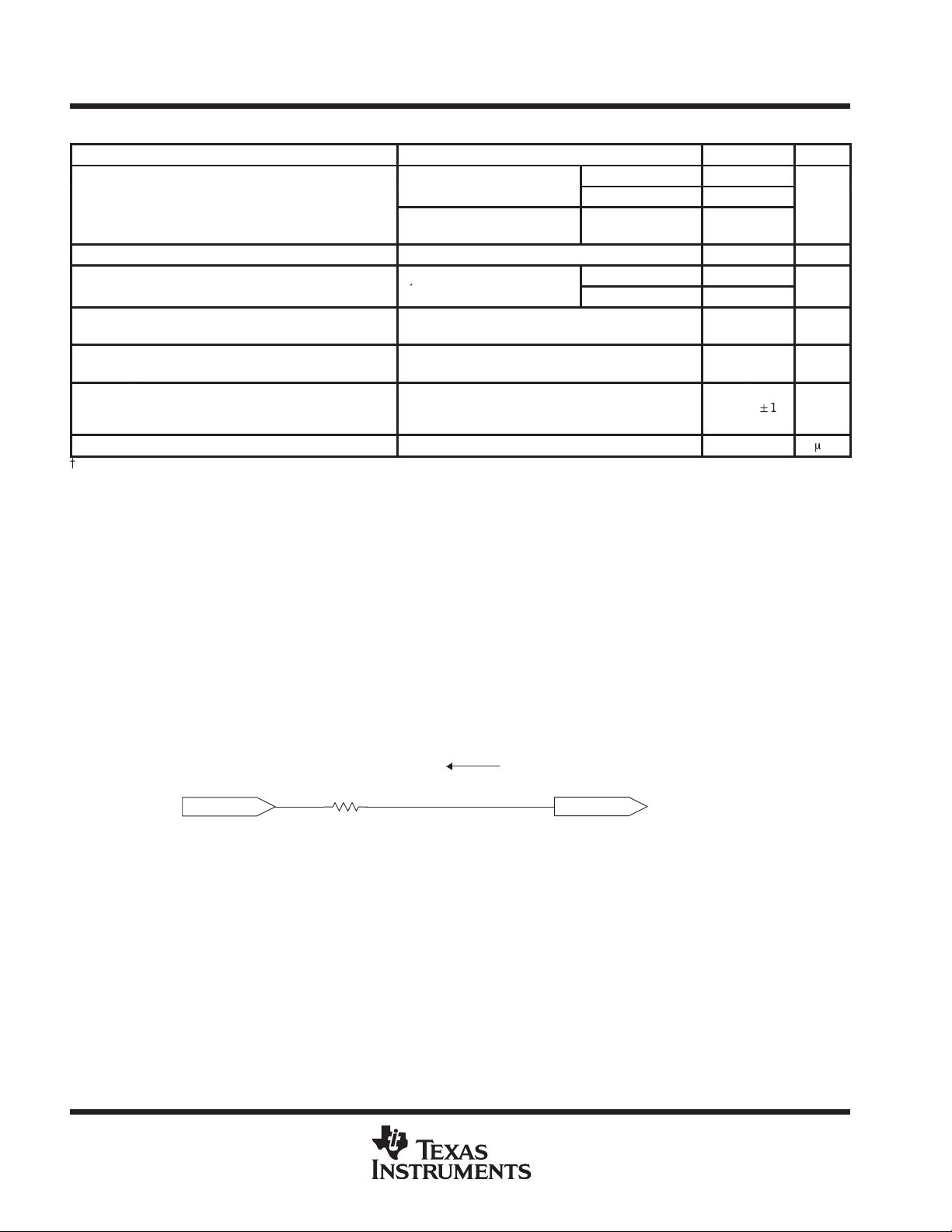

Table 1. Characteristics of the ’x240 DSP Controllers

ON-CHIP MEMORY (WORDS)

TMS320x240

DEVICES

DATA DATA/PROG PROG PROG

TMS320C240 288 256 16K – 5 50 PQ 132–P

TMS320F240 288 256 – 16K 5 50 PQ 132–P

RAM ROM

FLASH

EEPROM

POWER

SUPPLY

CYCLE

TIME

PACKAGE

TYPE

architectural overview

The functional block diagram provides a high-level description of each component in the ’x240 DSP controller.

The TMS320x240 devices are composed of three main functional units: a ’C2xx DSP core, internal memory,

and peripherals. In addition to these three functional units, there are several system-level features of the ’x240

that are distributed. These system features include the memory map, device reset, interrupts, digital

input/output (I/O), clock generation, and low-power operation.

system-level functions

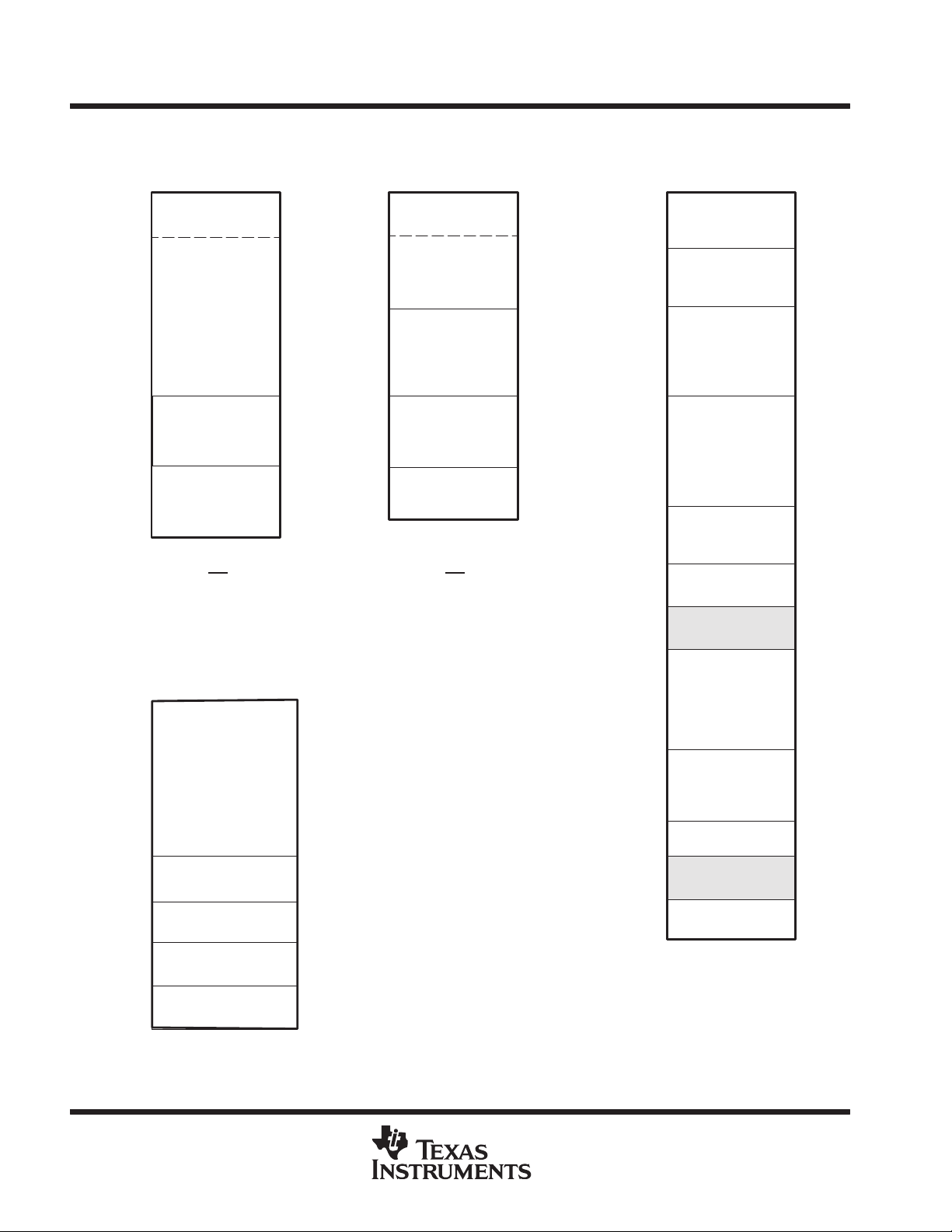

device memory map

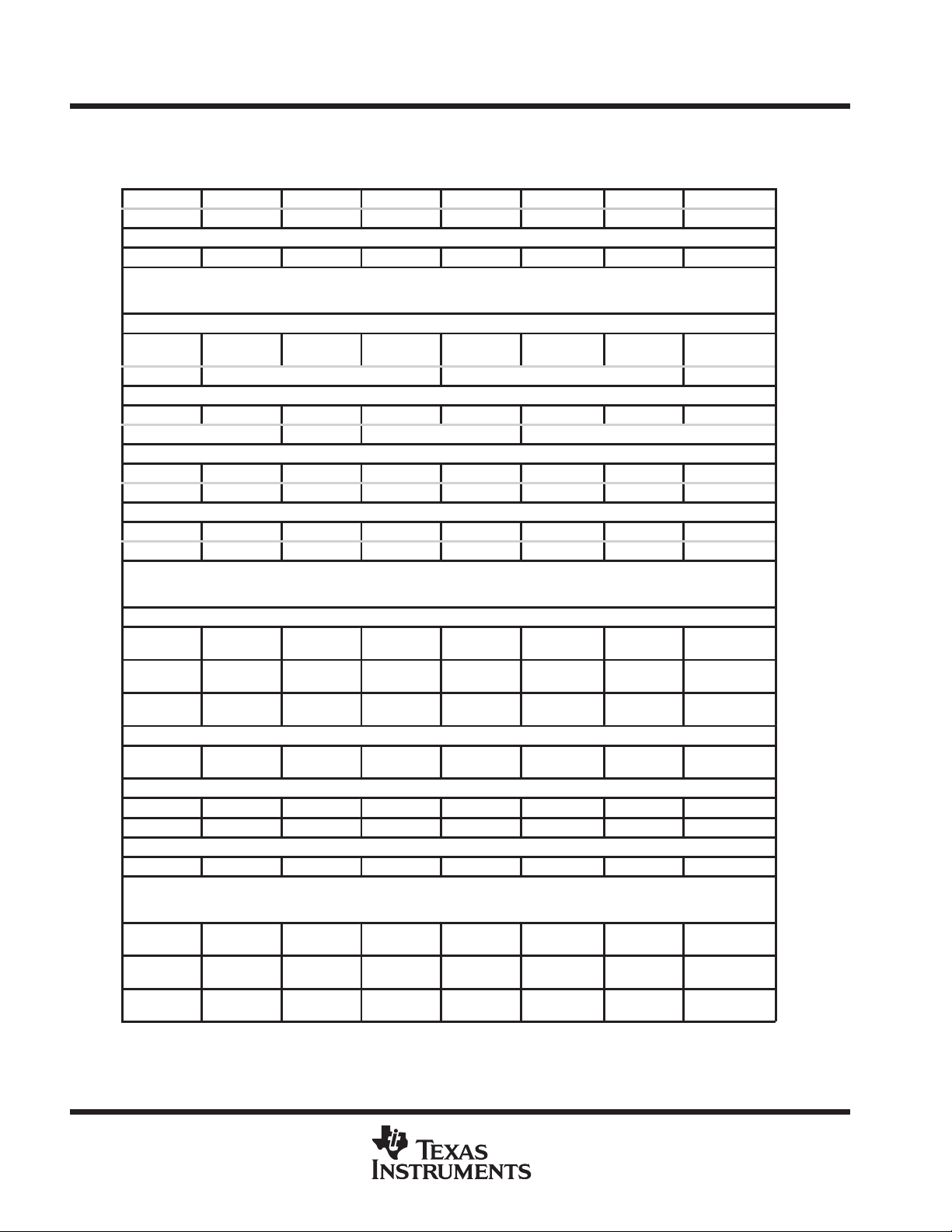

The TMS320x240 implements three separate address spaces for program memory, data memory, and I /O.

Each space accommodates a total of 64K 16-bit words. Within the 64K words of data space, the 256 to

32K words at the top of the address range can be defined to be external global memory in increments of powers

of two, as specified by the contents of the global memory allocation register (GREG). Access to global memory

is arbitrated using the global memory bus request (BR) signal.

On the ’x240, the first 96 (0–5Fh) data memory locations are either allocated for memory-mapped registers or

are reserved. This memory-mapped register space contains various control and status registers including those

for the CPU.

All the on-chip peripherals of the ’x240 device are mapped into data memory space. Access to these registers

is made by the CPU instructions addressing their data-memory locations. Figure 1 shows the memory map.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

13

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

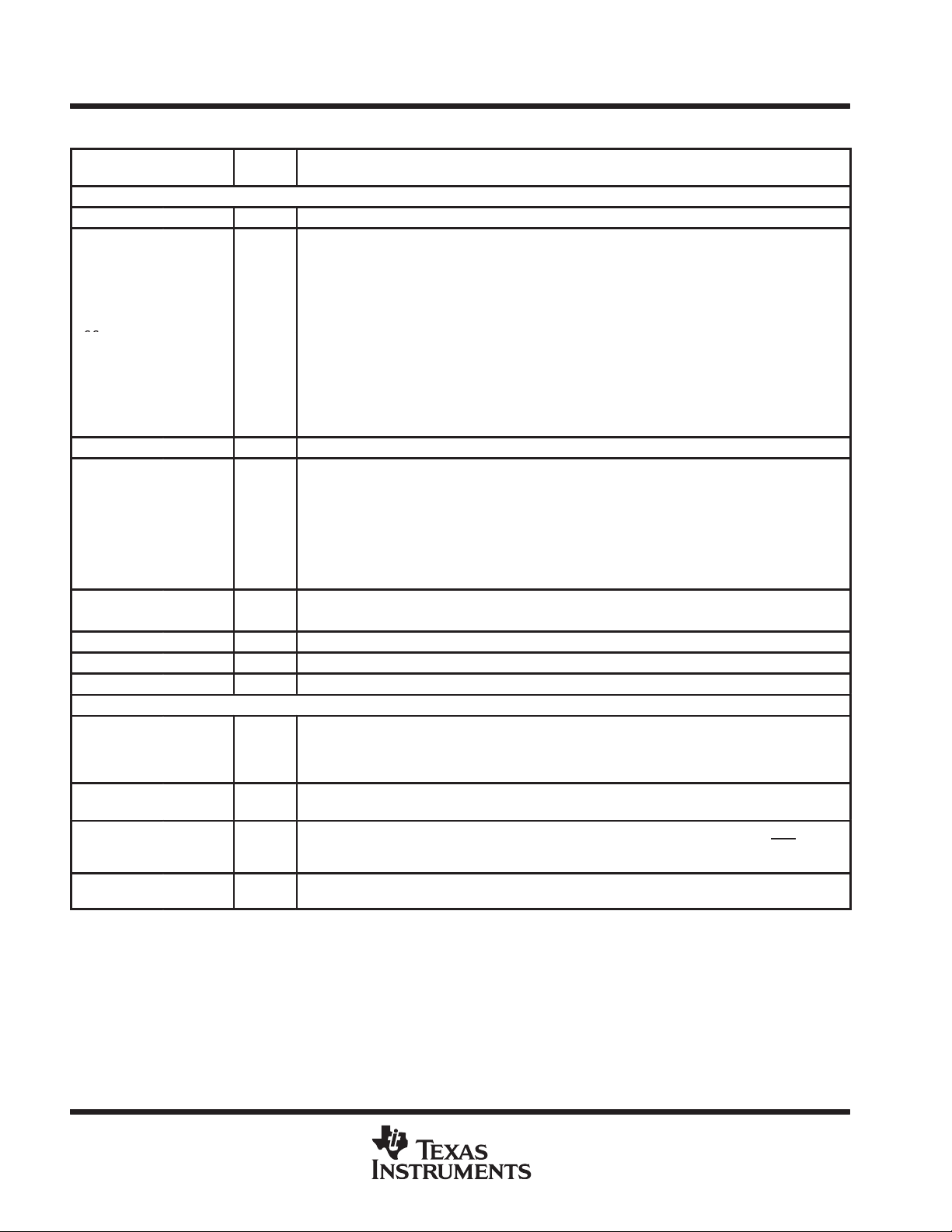

device memory map (continued)

Program

Program

Data

Hex

0000

003F

0040

FDFF

FE00

On-Chip DARAM B0

External (CNF = 0)

FEFF

FF00

FFFF

Microprocessor

Hex

0000

FEFF

FF00

FF0E

FF0F

FF10

FFFE

FFFF

Wait-state Generator

Interrupts

(External)

External

(CNF = 1)

or

Reserved

= 1

MP/MC

Mode

I/O

External

Reserved

Flash Control

Mode Register

Reserved

Control Register

Hex

0000

003F

0040

3FFF

4000

FDFF

FE00

FEFF

FF00

FFFF

†

ROM/Flash memory includes

address range 0000h–003Fh

Interrupts

(On-Chip)

On-Chip ROM

(Flash EEPROM)

(8 x 2K Segments)

External

On-Chip DARAM B0

(CNF = 1)

External (CNF = 0)

Reserved

MP/MC = 0

Microcomputer

Mode

†

or

Hex

0000

005F

0060

007F

0080

01FF

0200

02FF

0300

03FF

0400

07FF

0800

6FFF

7000

73FF

7400

743F

7440

77FF

7800

7FFF

8000

FFFF

Memory-Mapped

Registers and

Reserved

On-Chip

DARAM B2

Reserved

On-Chip DARAM B0

(CNF = 0)

or

Reserved (CNF = 1)

On-Chip

DARAM B1

Reserved

Illegal

Peripheral Memory-

Mapped Registers

(System, WD,

ADC, SPI, SCI,

Interrupts, I/O)

Peripheral

Memory-Mapped

Registers

(Event Manager)

Reserved

Illegal

External

14

Figure 1. TMS320x240 Memory Map

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

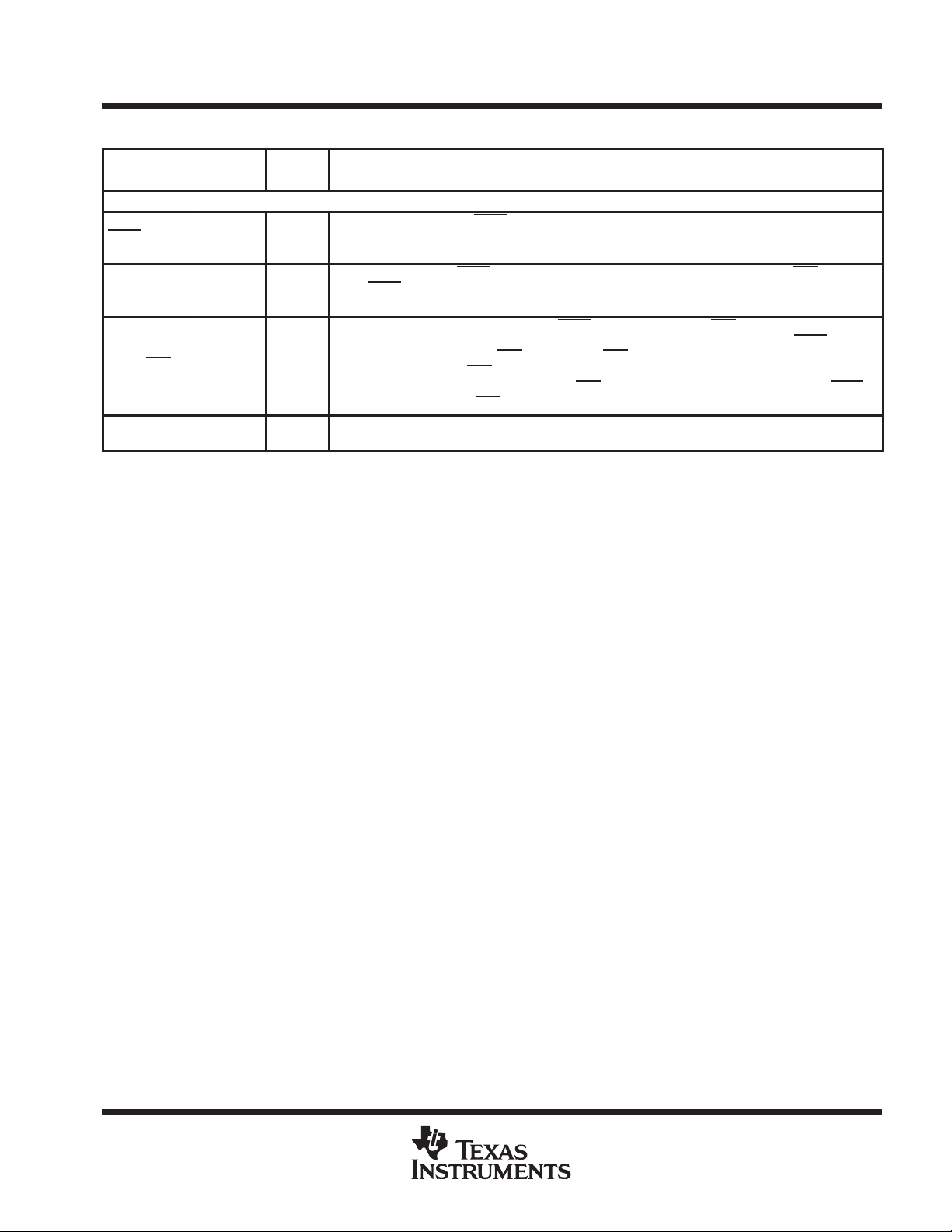

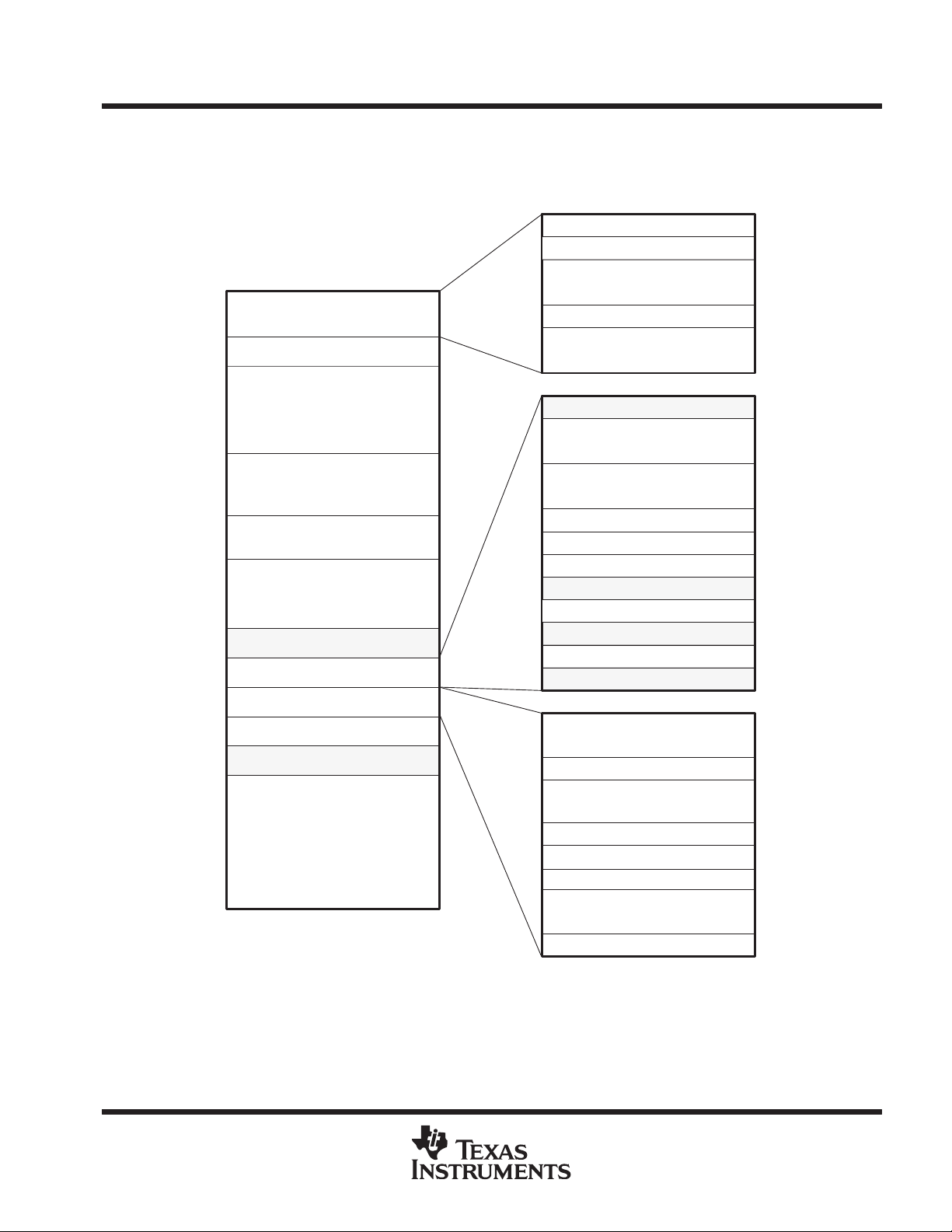

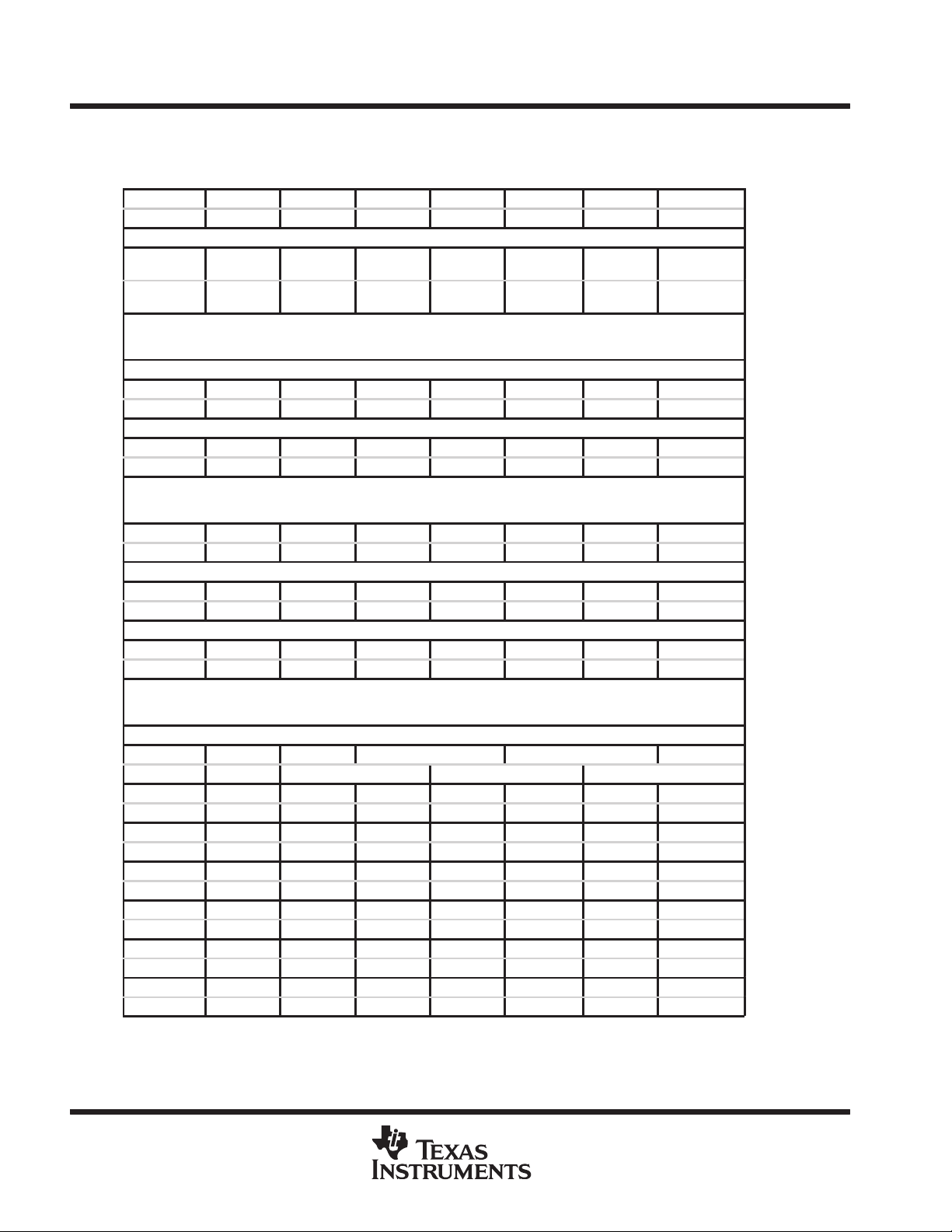

peripheral memory map

The TMS320x240 system and peripheral control register frame contains all the data, status, and control bits

to operate the system and peripheral modules on the device (excluding the event manager).

Hex

0000

0003

0004

0005

0006

0007

005F

Hex

0000

005F

0060

007F

0080

Memory-Mapped Registers

and Reserved

On-Chip DARAM B2

Reserved

Interrupt-Mask Register

Global-Memory Allocation

Register

Interrupt Flag Register

Emulation Registers

and Reserved

01FF

0200

02FF

0300

03FF

0400

07FF

0800

6FFF

7000

73FF

7400

743F

7440

77FF

7800

7FFF

8000

FFFF

Reserved

On-Chip DARAM

B0 (CNF = 0)

Reserved (CNF = 1)

On-Chip

DARAM B1

Reserved

Illegal

Peripheral Frame 1

Peripheral Frame 2

Reserved

Illegal

External

Illegal

System Configuration and

Control Registers

Watchdog Timer and

PLL Control Registers

ADC

SPI

SCI

Illegal

External-Interrupt Registers

Illegal

Digital-I/O Control Registers

Illegal

General-Purpose

Timer Registers

Reserved

Compare, PWM, and

Deadband Registers

Reserved

Capture & QEP Registers

Reserved

Interrupt Mask, Vector and

Flag Registers

Reserved

7000–700F

7010–701F

7020–702F

7030–703F

7040–704F

7050–705F

7060–706F

7070–707F

7080–708F

7090–709F

70A0–73FF

7400–740C

740D–7410

7411–741C

741D–741F

7420–7426

7427–742B

742C–7434

7435–743F

Figure 2. Peripheral Memory Map

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

15

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

digital I/O and shared pin functions

The ’C240 has a total of 28 pins shared between primary functions and I/Os. These pins are divided into two

groups:

D

Group1 — Primary functions shared with I/Os belonging to dedicated I/O ports, Port A, Port B, and Port C.

D

Group2 — Primary functions belonging to peripheral modules which also have a built-in I/O feature as a

secondary function (for example, SCI, SPI, external interrupts, and PLL clock modules).

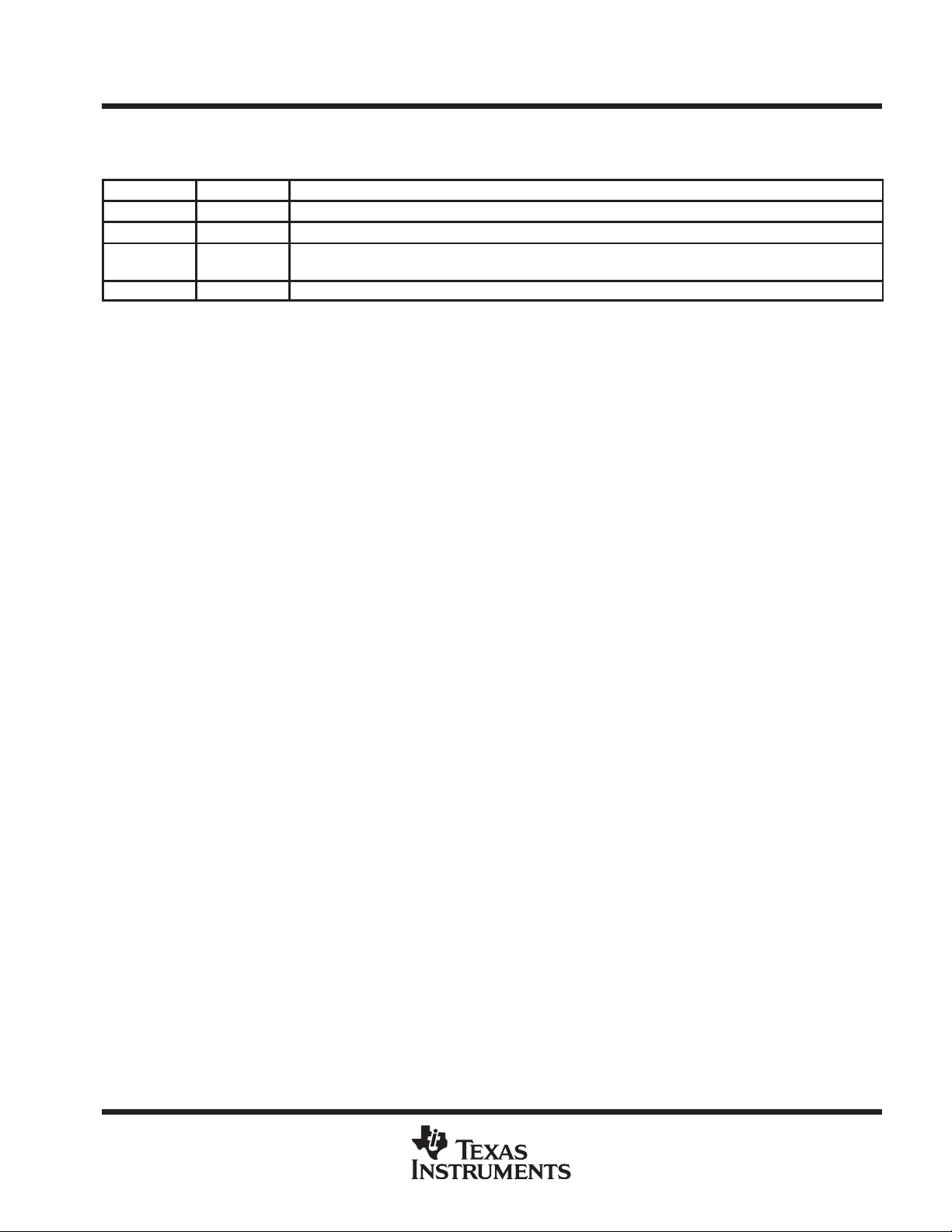

description of group1 shared I/O pins

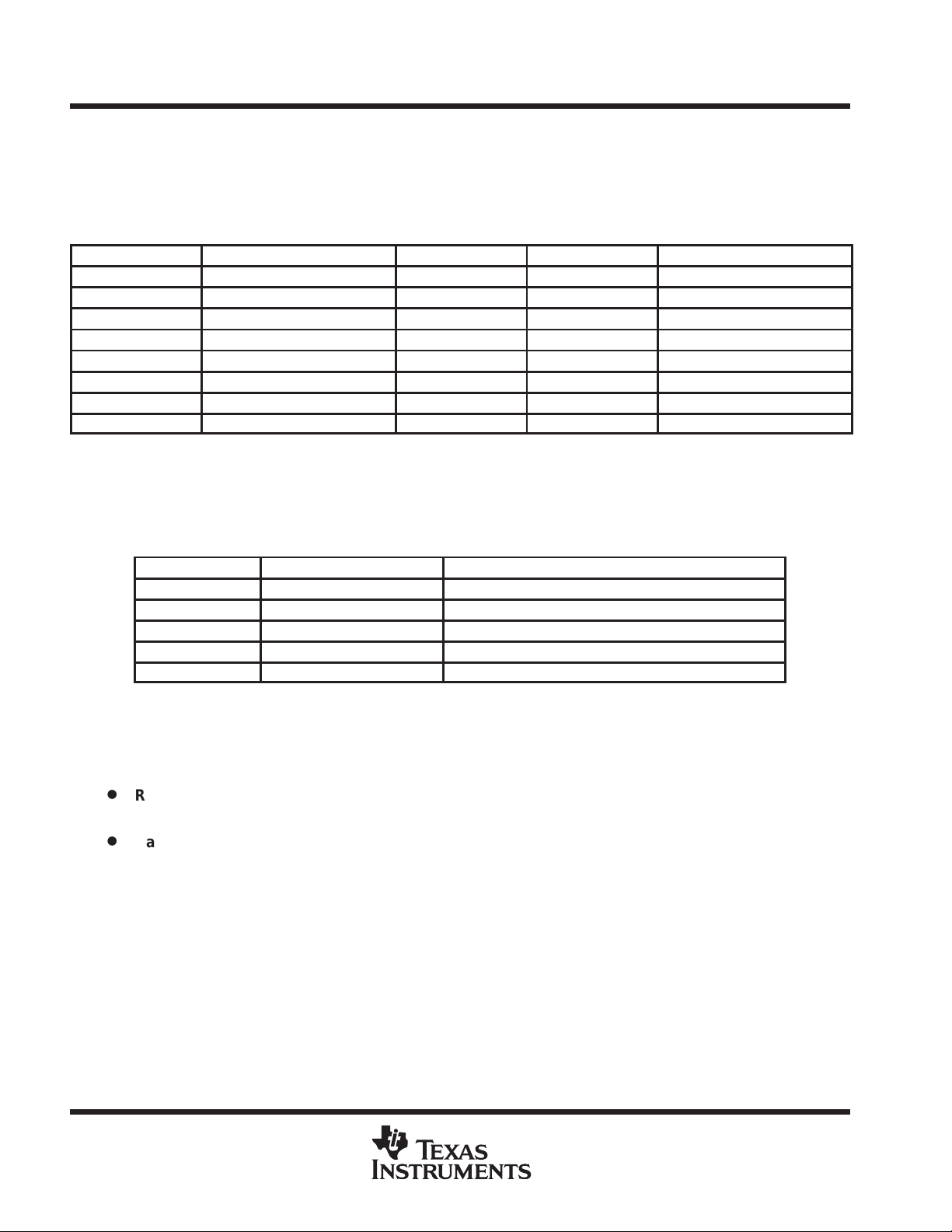

The control structure for Group1 type shared I/O pins is shown in Figure 3. The only exception to this

configuration is the CLKOUT/IOPC1 pin. In Figure 3, each pin has three bits that define its operation:

D

Mux control bit — this bit selects between the primary function (1) and I/O function (0) of the pin.

D

I/O direction bit — if the I/O function is selected for the pin (mux control bit is set to 0), this bit determines

whether the pin is an input (0) or an output (1).

D

I/O data bit — if the I/O function is selected for the pin (mux control bit is set to 0) and the direction selected

is an input, data is read from this bit; if the direction selected is an output, data is written to this bit.

The mux control bit, I/O direction bit, and I/O data bit are in the I/O control registers.

IOP DIR Bit

0 = Input

1 = Output

IOP Data Bit

(Read/Write)

In Out

Figure 3. Shared Pin Configuration

Primary

Function

or I/O Pin

Primary

Function

01

Pin

Note:

When the MUX control bit = 1, the primary

function is selected in all cases except

for the following pins:

1. XF/IOPC2 (0 = Primary Function)

/IOPC3 (0 = Primary Function)

2. BIO

MUX Control Bit

0 = I/O Function

1 = Primary Function

A summary of Group1 pin configurations and associated bits is shown in Table 2.

16

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

PIN #

REGISTER

description of group1 shared I/O pins (continued)

Table 2. Group1 Shared Pin Configurations

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

MUX CONTROL

(name.bit #)

72 OCRA.0 ADCIN0 IOPA0 PADATDIR 0 8

73 OCRA.1 ADCIN1 IOPA1 PADATDIR 1 9

90 OCRA.2 ADCIN9 IOPA2 PADATDIR 2 10

91 OCRA.3 ADCIN8 IOPA3 PADATDIR 3 11

100 OCRA.8 PWM7/CMP7 IOPB0 PBDATDIR 0 8

101 OCRA.9 PWM8/CMP8 IOPB1 PBDATDIR 1 9

102 OCRA.10 PWM9/CMP9 IOPB2 PBDATDIR 2 10

105 OCRA.11 T1PWM/T1CMP IOPB3 PBDATDIR 3 11

106 OCRA.12 T2PWM/T2CMP IOPB4 PBDATDIR 4 12

107 OCRA.13 T3PWM/T3CMP IOPB5 PBDATDIR 5 13

108 OCRA.14 TMRDIR IOPB6 PBDATDIR 6 14

109 OCRA.15 TMRCLK IOPB7 PBDATDIR 7 15

63 OCRB.0 ADCSOC IOPC0 PCDATDIR 0 8

64 SYSCR.7–6

0 0 IOPC1 PCDATDIR 1 9

0 1 WDCLK — — —

1 0 SYSCLK — — —

1 1 CPUCLK — — —

65 OCRB.2 IOPC2 XF PCDATDIR 2 10

66 OCRB.3 IOPC3 BIO PCDATDIR 3 11

67 OCRB.4 CAP1/QEP1 IOPC4 PCDATDIR 4 12

68 OCRB.5 CAP2/QEP2 IOPC5 PCDATDIR 5 13

69 OCRB.6 CAP3 IOPC6 PCDATDIR 6 14

70 OCRB.7 CAP4 IOPC7 PCDATDIR 7 15

†

Valid only if the I/O function is selected on the pin.

PIN FUNCTION SELECTED I/O PORT DATA AND DIRECTION

(CRx.n = 1) (CRx.n = 0) REGISTER DATA BIT # DIR BIT #

†

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

17

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

description of group2 shared I/O pins

Group2 shared pins belong to peripherals that have built-in general-purpose I/O capability. Control and

configuration for these pins are achieved by setting the appropriate bits within the control and configuration

registers of the peripherals. Table 3 lists the Group2 shared pins.

Table 3. Group2 Shared Pin Configurations

PIN # PRIMARY FUNCTION REGISTER ADDRESS PERIPHERAL MODULE

43 SCIRXD SCIPC2 705Eh SCI

44 SCITXD SCIPC2 705Eh SCI

45 SPISIMO SPIPC2 704Eh SPI

48 SPISOMI SPIPC2 704Eh SPI

49 SPICLK SPIPC1 704Dh SPI

51 SPISTE SPIPC1 704Dh SPI

54 XINT2 XINT2CR 7078h External Interrupts

55 XINT3 XINT3CR 707Ah External Interrupts

digital I/O control registers

Table 4 lists the registers available to the digital I/O module. As with other ’x240 peripherals, the registers are

memory-mapped to the data space.

Table 4. Addresses of Digital I/O Control Registers

ADDRESS REGISTER NAME

7090h OCRA I/O mux control register A

7092h OCRB I/O mux control register B

7098h PADATDIR I/O port A data and direction register

709Ah PBDATDIR I/O port B data and direction register

709Ch PCDATDIR I/O port C data and direction register

device reset and interrupts

The TMS320x240 software-programmable interrupt structure supports flexible on-chip and external interrupt

configurations to meet real-time interrupt-driven application requirements. The ’x240 recognizes three types of

interrupt sources:

D

Reset (hardware- or software-initiated) is unarbitrated by the CPU and takes immediate priority over any

other executing functions. All maskable interrupts are disabled until the reset service routine enables them.

D

Hardware-generated interrupts are requested by external pins or by on-chip peripherals. There are two

types:

–

External interrupts

are generated by one of five external pins corresponding to the interrupts XINT1,

XINT2, XINT3, PDPINT , and NMI. The first four can be masked both by dedicated enable bits and by t he

CPU’ s interrup t mask regi ster (IMR ), which c an mask ea ch maskab le interr upt line a t the DSP cor e. NMI,

which is not maskable, takes priority over peripheral interrupts and software-generated interrupts. It can

be locked out only by an already executing NMI or a reset.

18

–

Peripheral interrupts

are initiated internally by these on-chip peripheral modules: the event manager,

SPI, SCI, watchdog/real-time interrupt (WD/RTI), and ADC. They can be masked both by enable bits

for each event in each peripheral and by the CPU’s IMR, which can mask each maskable interrupt line at

the DSP core.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

device reset and interrupts (continued)

D

Software-generated interrupts for the ’x240 device include:

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

The INTR instruction.

–

This instruction allows initialization of any ’x240 interrupt with software. Its

operand indicates to which interrupt vector location the CPU branches. This instruction globally

disables maskable interrupts (sets the INTM bit to 1).

–

The NMI instruction.

This instruction forces a branch to interrupt vector location 24h, the same location

used for the nonmaskable hardware interrupt NMI. NMI can be initiated by driving the NMI pin low or by

executing an NMI instruction. This instruction globally disables maskable interrupts.

–

The TRAP instruction.

TRAP instruction does

This instruction forces the CPU to branch to interrupt vector location 22h. The

not

disable maskable interrupts (INTM is not set to 1); therefore, when the CPU

branches to the interrupt service routine, that routine can be interrupted by the maskable hardware

interrupts.

–

An emulator trap.

This interrupt can be generated with either an INTR instruction or a TRAP instruction.

reset

The reset operation ensures an orderly startup sequence for the device. There are five possible causes of a

reset, as shown in Figure 4. Three of these causes are internally generated; the other two causes, the RS and

PORESET pins, are controlled externally.

To Device

Watchdog Timer Reset

Software-Generated Reset

Illegal Address Reset

Power-On Reset (PORESET

Reset (RS

) Pin Active

) Pin

Active

Reset

Signal

To Reset Out

Figure 4. Reset Signals

The five possible reset signals are generated as follows:

D

Watchdog timer reset. A watchdog-timer-generated reset occurs if the watchdog timer overflows or an

improper value is written to either the watchdog key register or the watchdog control register. (Note that

when the device is powered on, the watchdog timer is automatically active.)

D

Software-generated reset. This is implemented with the system control register (SYSCR). Clearing the

RESET0 bit (bit 14) or setting the RESET1 bit (bit 15) causes a system reset.

D

Illegal address reset. The system and peripheral module control register frame address map contains

unimplemented address locations in the ranges labeled illegal. Any access to an address located in the

Illegal ranges generate an illegal-address reset.

D

Reset pin active. To generate an external reset pulse on the RS pin, a low-level pulse duration of as little

as a few nanoseconds is usually effective; however , pulses of one SYSCLK cycle are necessary to ensure

that the device recognizes the reset signal.

D

Power-on reset pin active. To generate a power-on reset pulse on the PORESET pin, a low-level pulse

of one SYSCLK cycle is necessary to ensure that the device recognizes the reset signal.

Once a reset source is activated, the external RS

pin is driven (active) low for a minimum of eight SYSCLK

cycles. This allows the TMS320x240 device to reset external system components. Additionally , if a brown-out

condition (VCC < VCCmin for several microseconds causing PORESET to go low) occurs or the RS pin is held

low, then the reset logic holds the device in a reset state for as long as these actions are active.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

19

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

reset (continued)

The occurrence of a reset condition causes the TMS320x240 to terminate program execution and affects

various registers and status bits. During a reset, RAM contents remain unchanged, and all control bits that are

affected by a reset are initialized to their reset state. In the case of a power-on reset, the PLL control registers

are initialized to zero. The program needs to recognize power-on resets and configure the PLL for correct

operation.

After a reset, the program can check the power-on reset flag (PORST flag, SYSSR.15), the illegal address flag

(ILLADR flag, SYSSR.12), the software reset flag (SWRST flag, SYSSR.10), and the watchdog reset flag

(WDRST flag, SYSSR.9) to determine the source of the reset. A reset does not clear these flags.

RS

and PORESET must be held low until the clock signal is valid and VCC is within the operating range. In

addition, PORESET must be driven low when VCC drops below the minimum operating voltage.

hardware-generated interrupts

All the hardware interrupt lines of the DSP core are given a priority rank from 1 to 10 (1 being highest). When

more than one of these hardware interrupts is pending acknowledgment, the interrupt of highest rank gets

acknowledged first. The others are acknowledged in order after that. Of those ten lines, six are for maskable

interrupt lines (INT1–INT6) and one is for the nonmaskable interrupt (NMI) line. INT1–INT6 and NMI have the

priorities shown in Table 5.

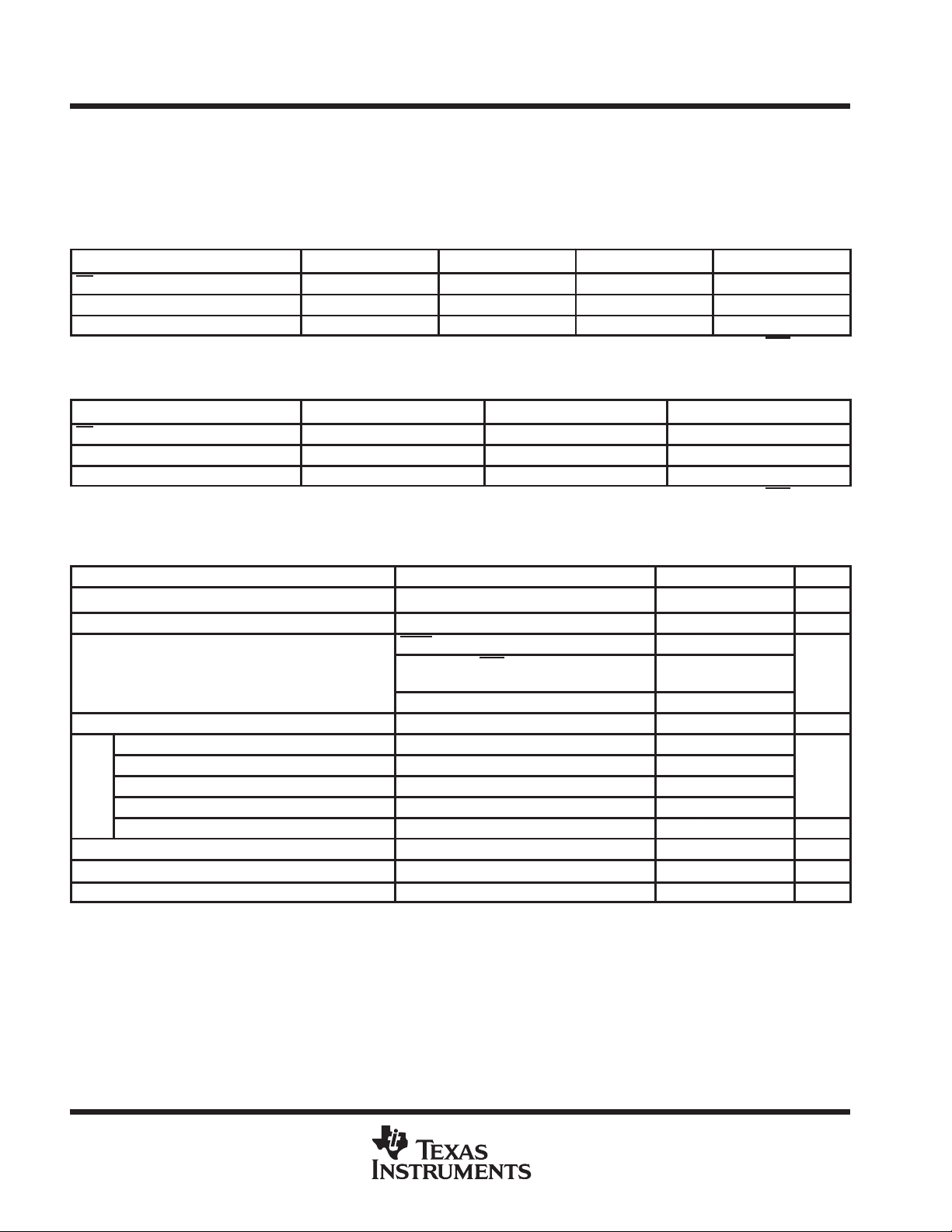

Table 5. Interrupt Priorities at the Level of the DSP Core

INTERRUPT

RESET 1

TI RESERVED

NMI 3

INT1 4

INT2 5

INT3 6

INT4 7

INT5 8

INT6 9

TI RESERVED

†

TI Reserved means that the address space is

reserved for Texas Instruments.

†

†

PRIORITY AT THE

DSP CORE

2

10

The inputs to these lines are controlled by the system module and the event manager as summarized in T able 6

and shown in Figure 5.

Table 6. Interrupt Lines Controlled by the System Module and Event Manager

PERIPHERAL INTERRUPT LINES

INT1

System Module

Event Manager

INT5

INT6

INT2

INT3

INT4

NMI

20

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

hardware-generated interrupts (continued)

DSP Core

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

Address

Lines 5–1

5

Address

Lines 5–1

IACK

INT6 INT5 INT4 INT3 INT2 INT1 NMI

NC NC NC

INT6 INT5 INT4 INT3 INT2 INT1 NMIIACK

System Module Event Manager

INTC INTB INTA

Figure 5. DSP Interrupt Structure

At the level of the system module and the event manager, each of the maskable interrupt lines (INT1–INT6) is

connected to multiple maskable interrupt sources. Sources connected to interrupt line INT1 are called Level 1

interrupts; sources connected to interrupt line INT2 are called Level 2 interrupts; and so on. For each interrupt

line, the multiple sources also have a set priority ranking. The source with the highest priority has its interrupt

request responded to by the DSP core first.

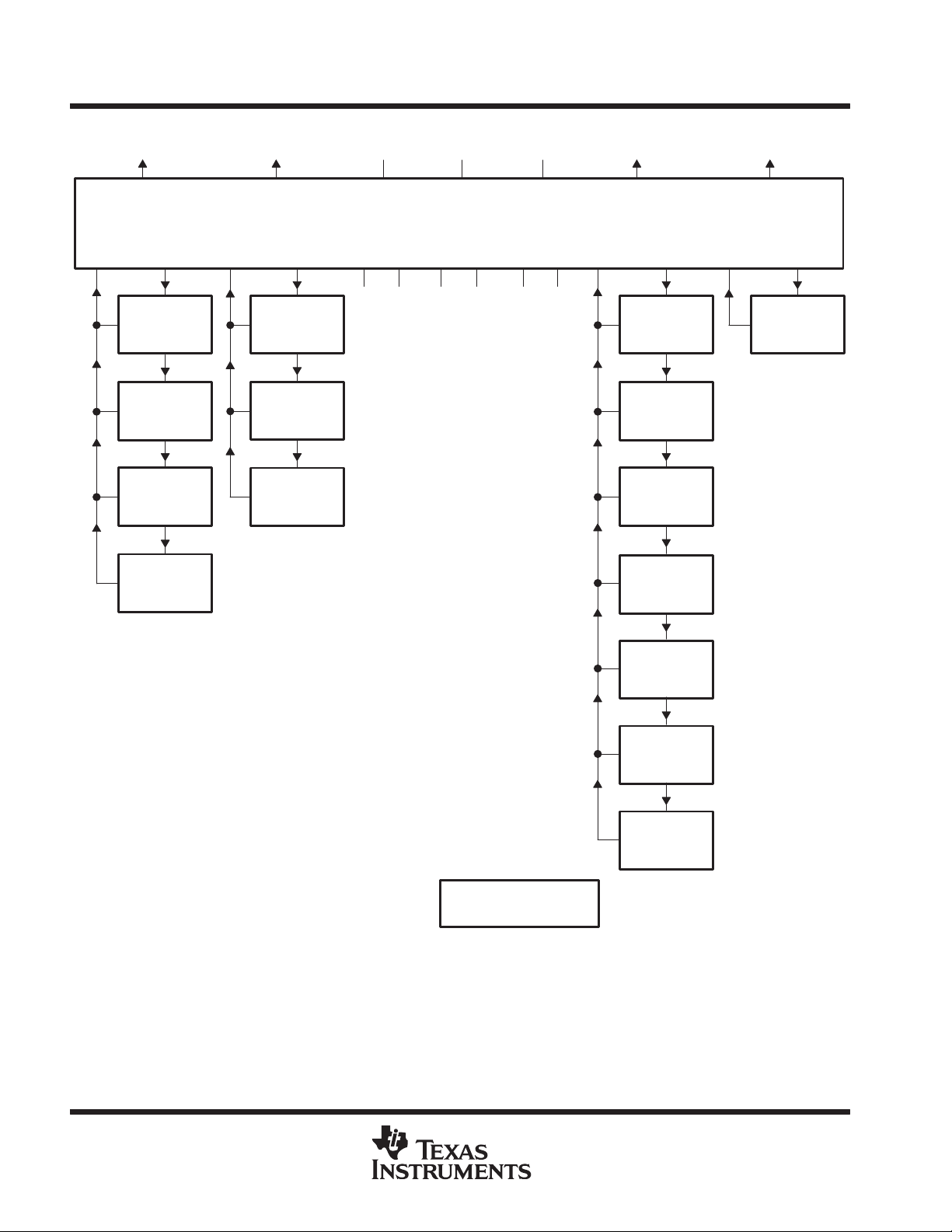

Figure 6 shows the sources and priority ranking for the interrupts controlled by the system module. For each

interrupt chain, the interrupt source of highest priority is at the top. Priority decreases from the top of the chain

to the bottom. Figure 7 shows the interrupt sources and priority ranking for the event manager interrupts.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

21

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

hardware-generated interrupts (continued)

To DSP INT6 To DSP INT1 To DSP NMI

To DSP INT5

NCNCNC

Dual ADC

Interrupt

System-Module

External Interrupt

XINT1

(low priority)

System-Module

External Interrupt

XINT2

(low priority)

System-Module

External Interrupt

XINT3

(low priority)

INT5

SPI

Interrupt

(low priority)

SCI

Receiver

Interrupt

(low priority)

SCI

Transmitter

Interrupt

(low priority)

System Module

INT2INT3INT4

IACK1IRQ1IACK5IRQ5IACK6IRQ6

NCNCNCNCNCNC

System-Module

External Interrupt

XINT1

(high priority)

System-Module

External Interrupt

XINT2

(high priority)

System-Module

External Interrupt

XINT3

(high priority)

Watchdog

Timer

Interrupt

NMIINT1INT6

IACK_NMIIRQ_NMIIACK2IRQ2IACK3IRQ3IACK4IRQ4

System-Module

External Interrupt

NMI

Legend:

NC = No connection

IACK = interrupt acknowledge

IRQ = interrupt request

Figure 6. System-Module Interrupt Structure

SPI

Interrupt

(high priority)

SCI

Receiver

Interrupt

(high priority)

SCI

Transmitter

Interrupt

(high priority)

22

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

hardware-generated interrupts (continued)

To DSP INT4 To DSP INT3 To DSP INT2

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

INTAINTBINTC

Event Manager

IACKAIRQAIACKBIRQBIACKCIRQC

Legend:

Capture 1

Interrupt

Capture 2

Interrupt

Capture 3

Interrupt

Capture 4

Interrupt

IACK = Interrupt acknowledge

IRQ = Interrupt request

Timer 2

Period

Interrupt

Timer 2

Compare

Interrupt

Timer 2

Underflow

Interrupt

Timer 2

Overflow

Interrupt

Timer 3

Period

Interrupt

Timer 3

Compare

Interrupt

Timer 3

Underflow

Interrupt

Power-Drive

Protection

Interrupt

Compare1

Interrupt

Compare 2

Interrupt

Compare 3

Interrupt

Simple-

Compare 1

Interrupt

Simple-

Compare 2

Interrupt

Simple-

Compare 3

Interrupt

Timer 3

Overflow

Interrupt

Figure 7. Event-Manager Interrupt Structure

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

Timer 1

Period

Interrupt

Timer 1

Compare

Interrupt

Timer 1

Underflow

Interrupt

Timer 1

Overflow

Interrupt

23

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

hardware-generated interrupts (continued)

Each of the interrupt sources has its own control register with a flag bit and an enable bit. When an interrupt

request is received, the flag bit in the corresponding control register is set. If the enable bit is also set, a signal

is sent to arbitration logic, which can simultaneously receive similar signals from one or more of the other control

registers. The arbitration logic compares the priority level of competing interrupt requests, and it passes the

interrupt of highest priority to the CPU. The corresponding flag is set in the interrupt flag register (IFR), indicating

that the interrupt is pending. The CPU then must decide whether to acknowledge the request. Maskable

hardware interrupts are acknowledged only after certain conditions are met:

D

Priority is highest. When more than one hardware interrupt is requested at the same time, the ’x240

services them according to the set priority ranking.

D

INTM bit is 0. The interrupt mode (INTM) bit, bit 9 of status register ST0, enables or disables all maskable

interrupts:

– When INTM = 0, all unmasked interrupts are enabled.

– When INTM = 1, all unmasked interrupts are disabled.

INTM is set to 1 automatically when the CPU acknowledges an interrupt (except when initiated by the TRAP

instruction) and at reset. It can be set and cleared by software.

D

IMR mask bit is 1. Each of the maskable interrupt lines has a mask bit in the interrupt mask register (IMR).

To unmask an interrupt line, set its IMR bit to 1.

When the CPU acknowledges a maskable hardware interrupt, it jams the instruction bus with the INTR

instruction. This instruction forces the PC to the appropriate address from which the CPU fetches the software

vector. This vector leads to an interrupt service routine.

Usually, the interrupt service routine reads the peripheral-vector-address offset from the peripheral-vectoraddress register (see Table 7) to branch to code that is meant for the specific interrupt source that initiated the

interrupt request. The ’x240 includes a phantom-interrupt vector offset (0000h), which is a system interrupt

integrity feature that allows a controlled exit from an improper interrupt sequence. If the CPU acknowledges a

request from a peripheral when, in fact, no peripheral has requested an interrupt, the phantom-interrupt vector

is read from the interrupt-vector register.

Table 7 summarizes the interrupt sources, overall priority, vector address/offset, source, and function of each

interrupt available on the TMS320x240.

24

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

(System)

0004h

0006h

M

Grou B)

M

hardware-generated interrupts (continued)

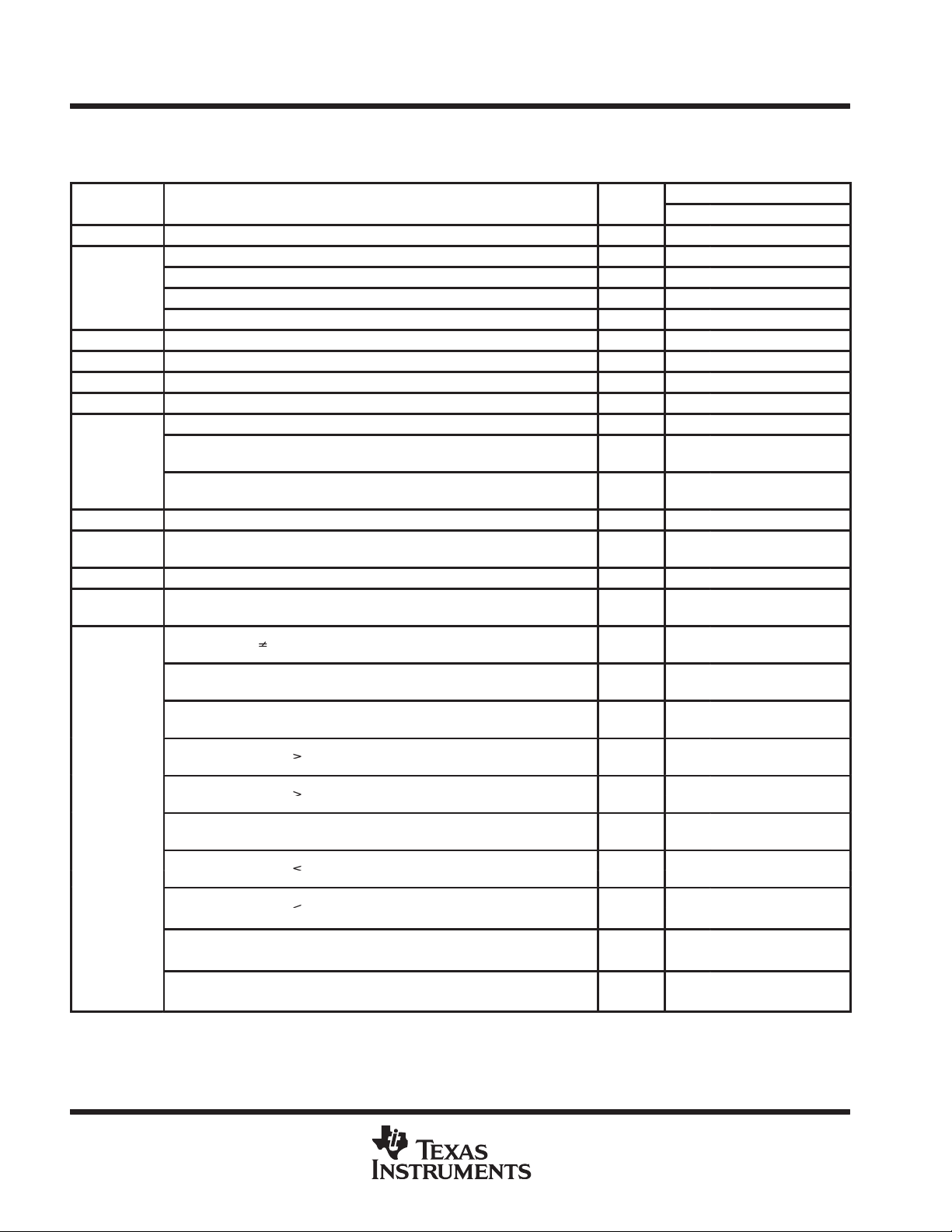

Table 7. ’x240 Interrupt Locations and Priorities

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

INTERRUPT

NAME

RS

RESERVED 2

NMI 3

XINT1

XINT2

XINT3

SPIINT 7

RXINT 8

TXINT 9

WDTINT 10 0010h Y WDT Watchdog timer interrupt

PDPINT 11 0020h Y External Power-drive protection Int.

CMP1INT 12 0021h Y EV.CMP1 Full Compare 1 interrupt

CMP2INT 13 0022h Y EV.CMP2 Full Compare 2 interrupt

CMP3INT 14 0023h Y EV.CMP3 Full Compare 3 interrupt

SCMP1INT 15

SCMP2INT 16

SCMP3INT 17

TPINT1 18 0027h Y EV.GPT1 Timer1-period interrupt

TCINT1 19 0028h Y EV.GPT1 Timer1-compare interrupt

TUFINT1 20 0029h Y EV.GPT1 Timer1-underflow interrupt

TOFINT1 21 002Ah Y EV.GPT1 T imer1-overflow interrupt

TPINT2 22 002Bh Y EV.GPT2 T imer2-period interrupt

TCINT2 23

TUFINT2 24

TOFINT2 25

TPINT3 26

TCINT3 27

TUFINT3 28

TOFINT3 29 0032h Y EV.GPT3 Timer3-overflow interrupt

CAPINT1 30 INT4 0033h Y EV.CAP1 Capture 1 interrupt

CAPINT2 31 0008h

CAPINT3 32

CAPINT4 33

OVERALL

PRIORITY

1

Highest

4

5

6

DSP-CORE

INTERRUPT,

AND

ADDRESS

RS

0000h

INT7

0026h

NMI

0024h

INT1

0002h

INT2

(Event

Manager

Group A)

INT3

(Event

anager

p

(Event

anager

Group C)

PERIPHERAL

VECTOR

ADDRESS

N/A N Core, SD

N/A N/A N DSP Core Emulator trap

N/A 0002h N Core, SD External user interrupt

SYSIVR

(701Eh)

EVIVRA

(7432h)

EVIVRB

(7433h)

EVIVRC

(7434h)

PERIPHERAL

VECTOR

ADDRESS

OFFSET

0001h

0011h

001Fh

0005h Y SPI High-priority SPI interrupt

0006h Y SCI

0007h Y SCI

0024h Y EV.CMP4

0025h Y EV.CMP5

0026h Y EV.CMP6

002Ch Y EV.GPT2 Timer2-compare interrupt

002Dh Y EV.GPT2 Timer2-underflow interrupt

002Eh Y EV.GPT2 T imer2-overflow interrupt

002Fh Y EV.GPT3 Timer3-period interrupt

0030h Y EV.GPT3 Timer3-compare interrupt

0031h Y EV.GPT3 Timer3-underflow interrupt

0034h Y EV.CAP2 Capture 2 interrupt

0035h Y EV.CAP3 Capture 3 interrupt

0036h Y EV.CAP4 Capture 4 interrupt

MASKABLE?

Y SD

’x240

SOURCE

PERIPHERAL

MODULE

FUNCTION

INTERRUPT

External, system reset

(RESET)

High-priority external user

interrupts

SCI receiver interrupt

(high priority)

SCI transmitter interrupt

(high priority)

Simple compare 1

interrupt

Simple compare 2

interrupt

Simple compare 3

interrupt

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

25

TMS320C240, TMS320F240

SYSIVR

XINT2

39

(701Eh)

0011h

Y

y

DSP CONTROLLERS

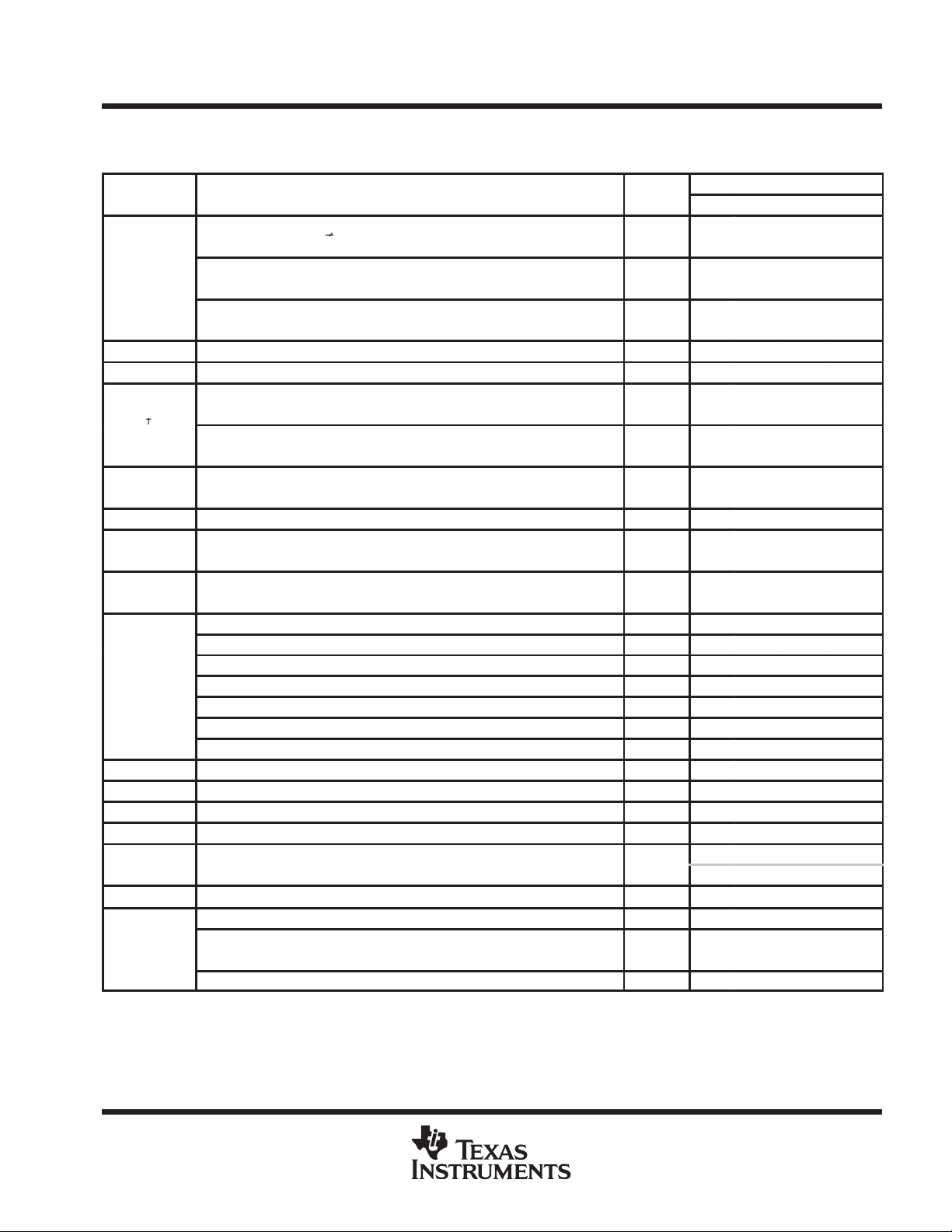

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

hardware-generated interrupts (continued)

Table 7. ’x240 Interrupt Locations and Priorities (Continued)

INTERRUPT

NAME

SPIINT 34 INT5

RXINT 35

TXINT 36

ADCINT 37 INT6 SYSIVR 0004h Y ADC Analog-to-digital interrupt

XINT1

XINT3

RESERVED 41 000Eh N/A Y DSP Core Used for analysis

TRAP N/A 0022h N/A N/A TRAP instruction vector

OVERALL

PRIORITY

38

40

DSP-CORE

INTERRUPT,

AND

ADDRESS

000Ah

(System)

000Ch

(System)

PERIPHERAL

VECTOR

ADDRESS

(701Eh)

PERIPHERAL

VECTOR

ADDRESS

OFFSET

0005h Y SPI Low-priority SPI interrupt

0006h Y SCI

0007h Y SCI

0001h

001Fh

MASKABLE?

Y

Y

’x240

SOURCE

PERIPHERAL

MODULE

External Low-priority external

pins

FUNCTION

INTERRUPT

SCI receiver interrupt

(low priority)

SCI transmitter interrupt

(low priority)

user interrupts

external interrupts

The ’x240 has five external interrupts. These interrupts include:

D

XINT1. Type A interrupt. The XINT1 control register (at 7070h) provides control and status for this interrupt.

XINT1 can be used as a high-priority (Level 1) or low-priority (Level 6) maskable interrupt or as a

general-purpose input pin. XINT1 can also be programmed to trigger an interrupt on either the rising or the

falling edge.

D

NMI. T ype A inter rupt. The NMI control register (at 7072h) provides control and status for this interrupt. NMI

is a nonmaskable external interrupt or a general-purpose input pin. NMI can also be programmed to trigger

an interrupt on either the rising or the falling edge.

D

XINT2. Type C interrupt. The XINT2 control register (at 7078h) provides control and status for this interrupt.

XINT2 can be used as a high-priority (Level 1) or low-priority (Level 6) maskable interrupt or a

general-purpose I/O pin. XINT2 can also be programmed to trigger an interrupt on either the rising or the

falling edge.

D

XINT3. Type C interrupt. The XINT3 control register (at 707Ah) provides control and status for this interrupt.

XINT3 can be used as a high-priority (Level 1) or low-priority (Level 6) maskable interrupt or as a

general-purpose I/O pin. XINT3 can also be programmed to trigger an interrupt on either the rising or the

falling edge.

D

PDPINT. This interrupt is provided for safe operation of the power converter and motor drive. This maskable

interrupt can put the timers and PWM output pins in the high-impedance state and inform the CPU in case

of motor drive abnormalities such as overvoltage, overcurrent, and excessive temperature rise. PDP IN T is

a Level 2 interrupt.

26

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

external interrupts (continued)

Table 8 is a summary of the external interrupt capability of the ’x240.

Table 8. External Interrupt Types and Functions

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

EXTERNAL

INTERRUPT

XINT1 XINT1CR 7070h A No Input only

NMI NMICR 7072h A Yes Input only No

XINT2 XINT2CR 7078h C No I/O

XINT3 XINT3CR 707Ah C No I/O

PDPINT EVIMRA 742Ch N/A N/A N/A

CONTROL

REGISTER

NAME

CONTROL

REGISTER

ADDRESS

INTERRUPT

TYPE

CAN DO

NMI?

DIGITAL

I/O PIN

MASKABLE?

(Level 1 or 6)

(Level 1 or 6)

(Level 1 or 6)

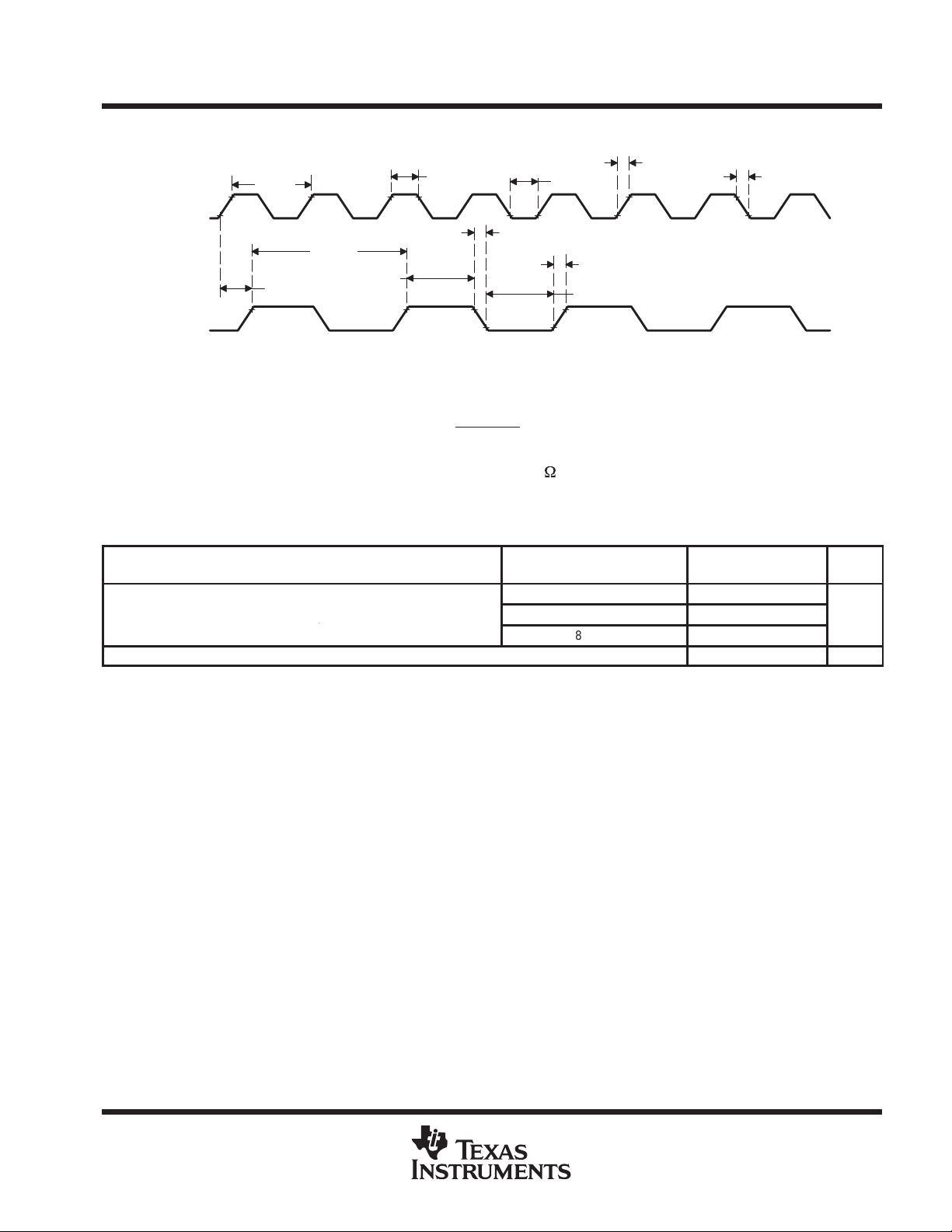

clock generation

The TMS320x240 has an on-chip, PLL-based clock module. This module provides all the necessary clocking

signals for the device, as well as control for low-power mode entry . The only external component necessary for

this module is an external fundamental crystal, or oscillator.

The PLL-based clock module provides two basic modes of operation: oscillator mode and clock-in mode.

D

oscillator mode

This mode allows the use of a 4-, 6-, or 8-MHz external reference crystal to provide the time base to the

device. The internal oscillator circuitry is initialized by software to select the desired CPUCLK frequency,

which can be the input clock frequency , the input clock frequency divided by 2 (default), or a clock frequency

determined by the PLL.

Yes

Yes

Yes

Yes

(Level 2)

D

Clock-in mode

This mode allows the internal crystal oscillator circuitry to be bypassed. The device clocks are generated

from an external clock source input on the XTAL1/CLKIN pin. The device can be configured by software

to operate on the input clock frequency, the input clock frequency divided by 2, or a clock frequency

determined by the PLL.

The ’x240 runs on two clock frequencies: the CPU clock (CPUCLK) frequency , and the system clock (SYSCLK)

frequency . The CPU, memories, external memory interface, and event manager run at the CPUCLK frequency .

All other peripherals run at the SYSCLK frequency . The CPUCLK runs at 2x or 4x the frequency of the SYSCLK;

for example, for 2x, CPUCLK = 20 MHz and SYSCLK = 10 MHz. There is also a clock for the watchdog timer,

WDCLK. This clock has a nominal frequency of 16384 Hz (214 Hz) when XTAL1/CLKIN is a power of two or

a sum of two powers of two; for example, 4194304 Hz (222 Hz), 6291456 (222 + 221 Hz), or 8388608 Hz

(223 Hz).

The clock module includes three external pins:

1. XTAL1/CLKIN clock source/crystal input

2. XTAL2 output to crystal

3. OSCBYP oscillator bypass

For the external pins, if OSCBYP ≥ VIH, then the oscillator is enabled and if OSCBYP ≤ VIL, then the oscillator

is bypassed and the device is in clock-in mode. In clock-in mode, an external TTL clock must be applied to the

XTAL1/CLKIN pin. The XTAL2 pin can be left unconnected.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

27

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

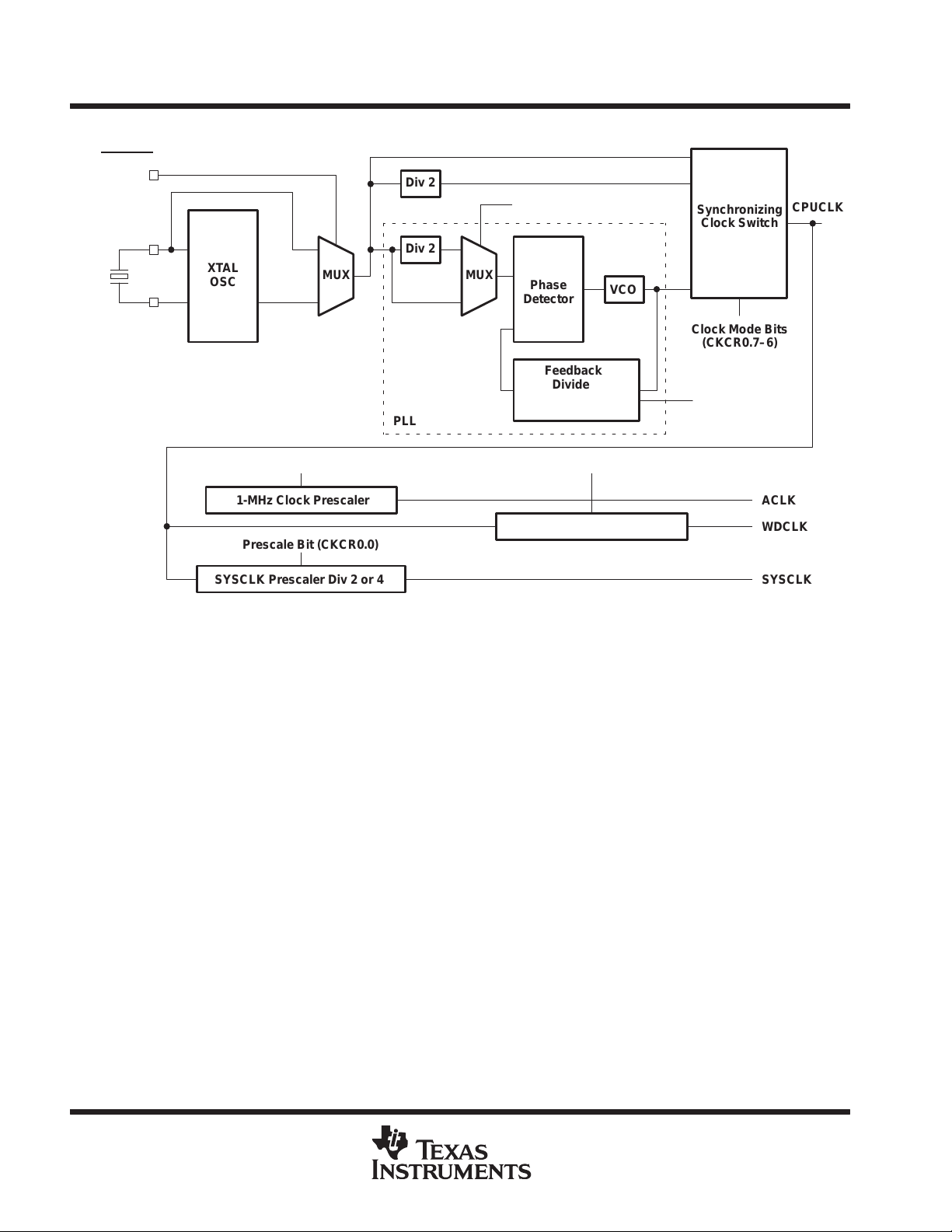

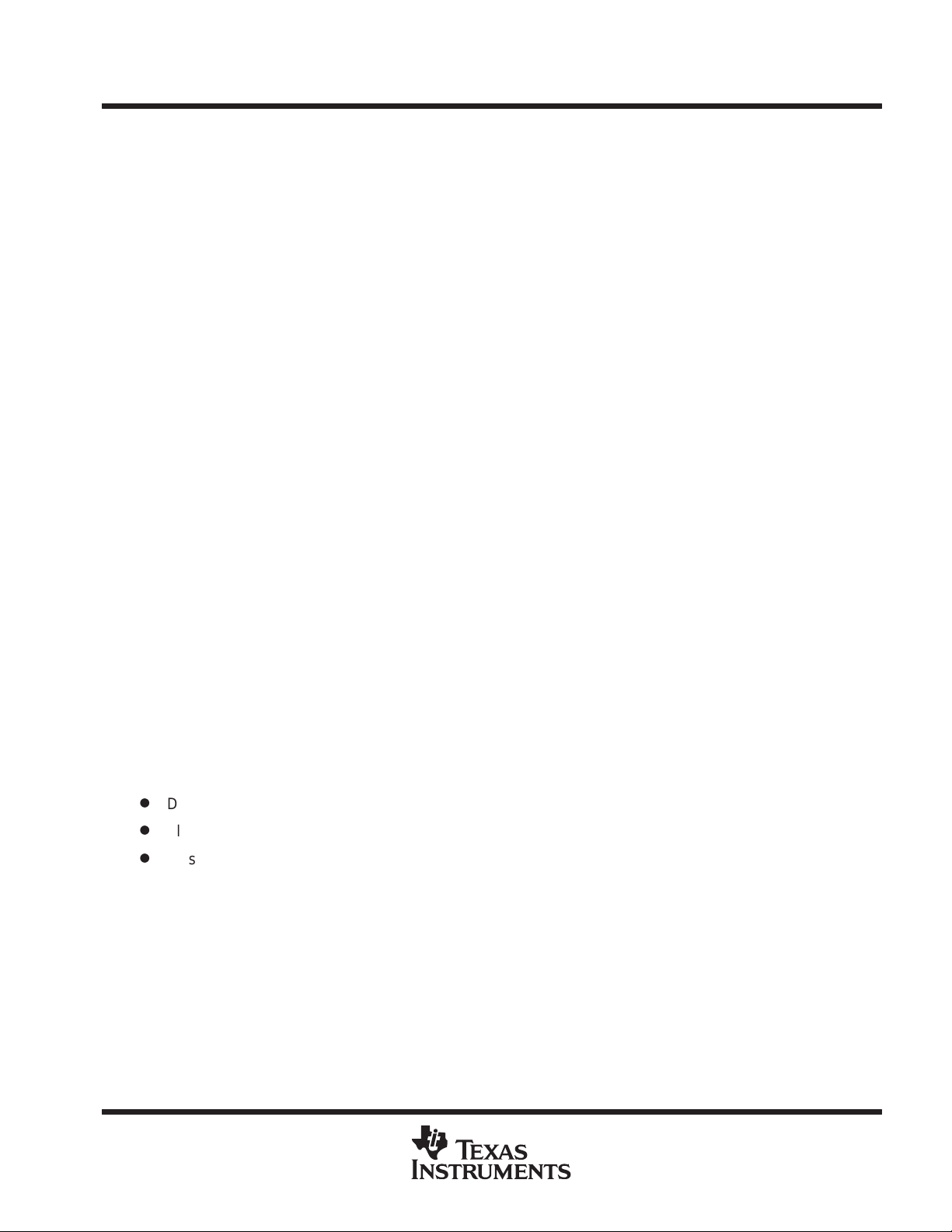

clock generation (continued)

OSCBYP

XTAL1/CLKIN

XTAL

OSC

XTAL2

Clock Frequency and PLL Multiply Bits (CKCR1.7–4)

PLL

Div 2

Div 2

PLL divide-by-2 bit

(CKCR1.3)

MUXMUX

Phase

Detector

Feedback

Divider

Div 1, 2, 3, 4, 5,

or 9

VCO

Synchronizing

Clock Switch

Clock Mode Bits

(CKCR0.7–6)

PLL multiply ratio

(CKCR1.2–0)

CPUCLK

1-MHz Clock Prescaler

Prescale Bit (CKCR0.0)

SYSCLK Prescaler Div 2 or 4

Figure 8. PLL Clock Module Block Diagram

Watchdog Clock Prescaler

ACLK

WDCLK

SYSCLK

28

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

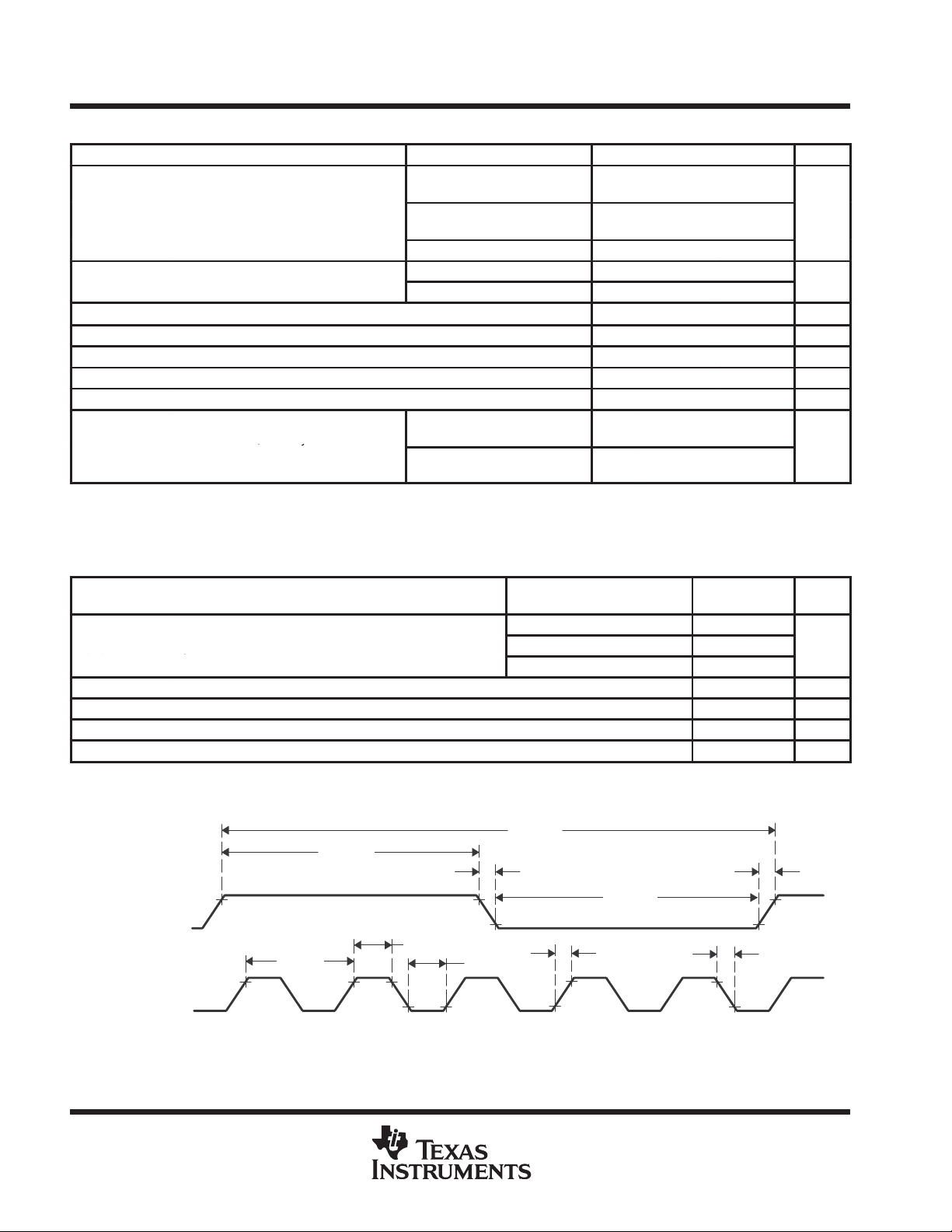

low-power modes

The TMS320x240 has four low-power modes (idle 1, idle 2, PLL power down, and oscillator power down). The

low-power modes reduce the operating power by reducing or stopping the activity of various modules (by

stopping their clocks). The two PLLPM bits of the clock module control register, CKCR0, select which of the

low-power modes the device enters when executing an IDLE instruction. Reset or an unmasked interrupt from

any source causes the device to exit from idle 1 low-power mode. A real-time interrupt from the watchdog timer

module causes the device to exit from all low-power modes except oscillator power down. This is a wake-up

interrupt. When enabled, reset or any of the four external interrupts (NMI, XINT1, XINT2, or XINT3) causes the

device to exit from any of the low-power modes (idle 1, idle 2, PLL power down, and oscillator power down).

The external interrupts are all wake-up interrupts. The maskable external interrupts (XINT1, XINT2, and XINT3)

must be enabled individually and globally to bring the device out of a low-power mode properly . It is, therefore,

important to ensure that the desired low-power-mode exit path is enabled before entering a low-power mode.

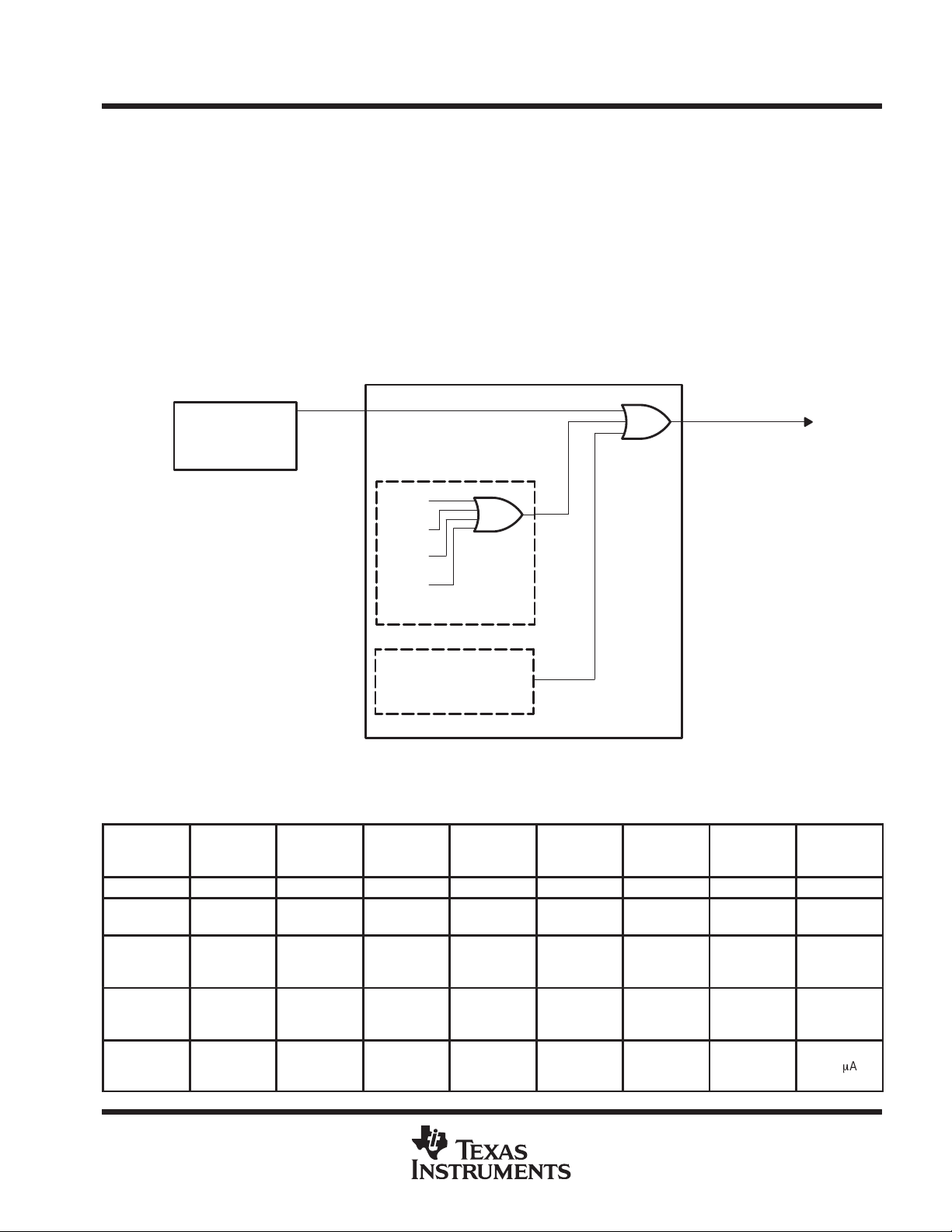

Figure 9 shows the wake-up sequence from a power down. Table 9 summarizes the low-power modes.

Watchdog Timer

and

Real-Time Interrupt

Module

Wake-up

Signal

Wake-up Signal

to CPU

NMI

XINT1

XINT2

XINT3

External-Interrupt Logic

Reset

Signal

Reset Logic

System Module

Figure 9. Waking Up the Device From Power Down

Table 9. Low-Power Modes

LOW-

POWER

MODE

Run XX On On On On On – 80 mA

Idle 1 00 Off On On On On

Idle 2 01 Off Off On On On

PLL Power

Down

OSC Power

Down

PLLPM(x)

BITS IN

CKCR0[2:3]

10 Off Off On Off On

11 Off Off Off Off Off

CPUCLK

STATUS

SYSCLK

STATUS

WDCLK

STATUS

PLL

STATUS

OSC

STATUS

EXIT

CONDITION

Any interrupt

or reset

Wake-up

interrupt or

reset

Wake-up

interrupt or

reset

Wake-up

interrupt or

reset

TYPICAL

POWER

50 mA

7 mA

1 mA

400 mA

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77251–1443

29

TMS320C240, TMS320F240

DSP CONTROLLERS

SPRS042D – OCTOBER 1996 – REVISED NOVEMBER 1998

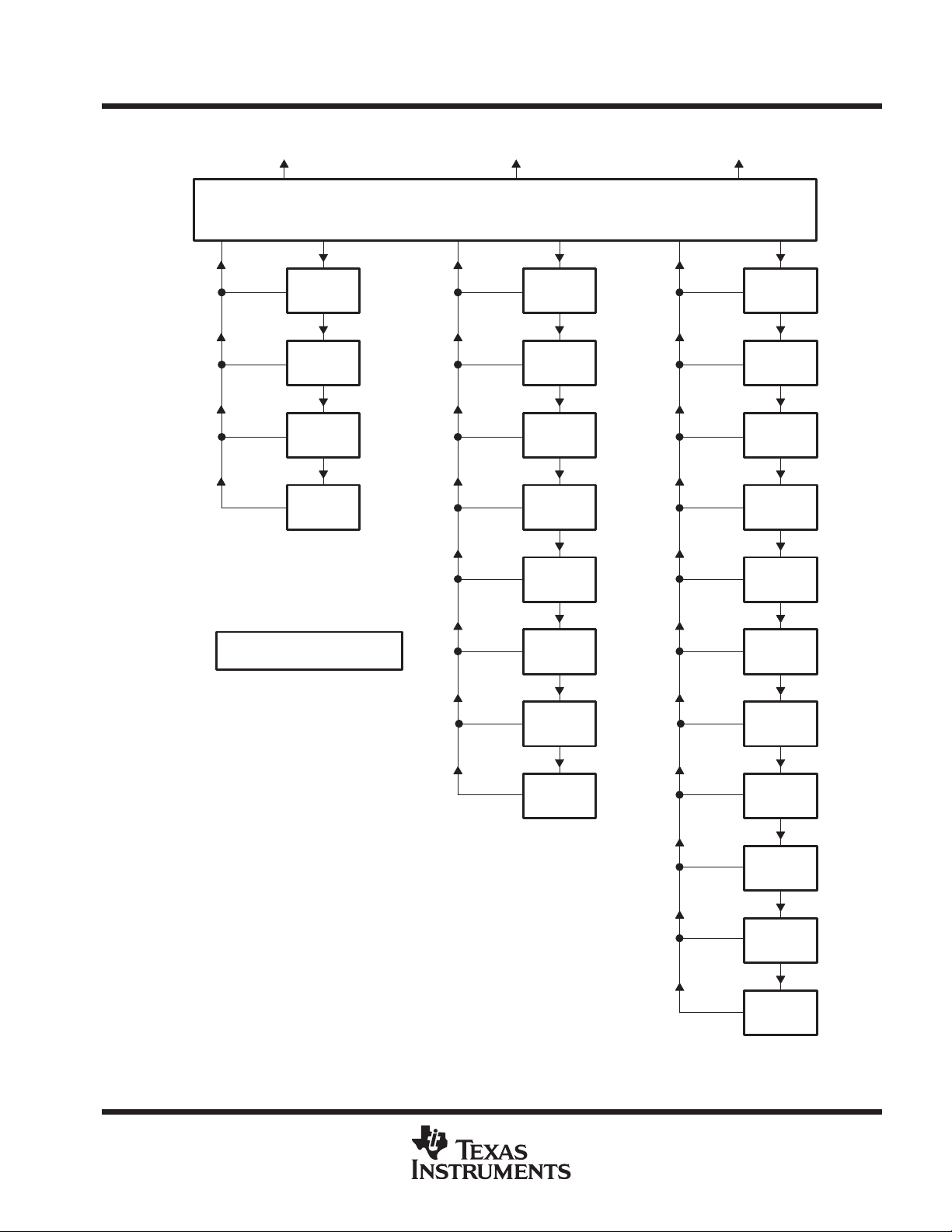

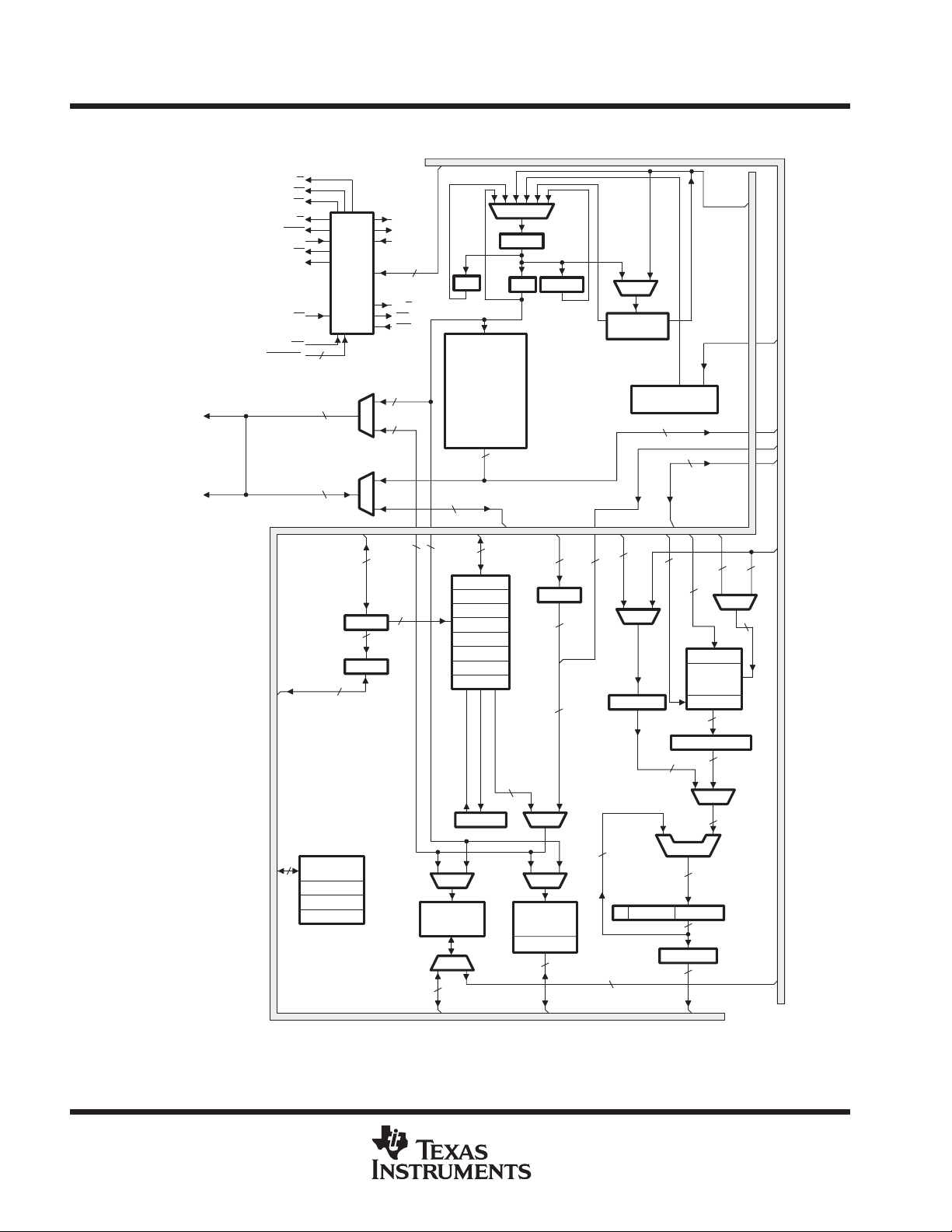

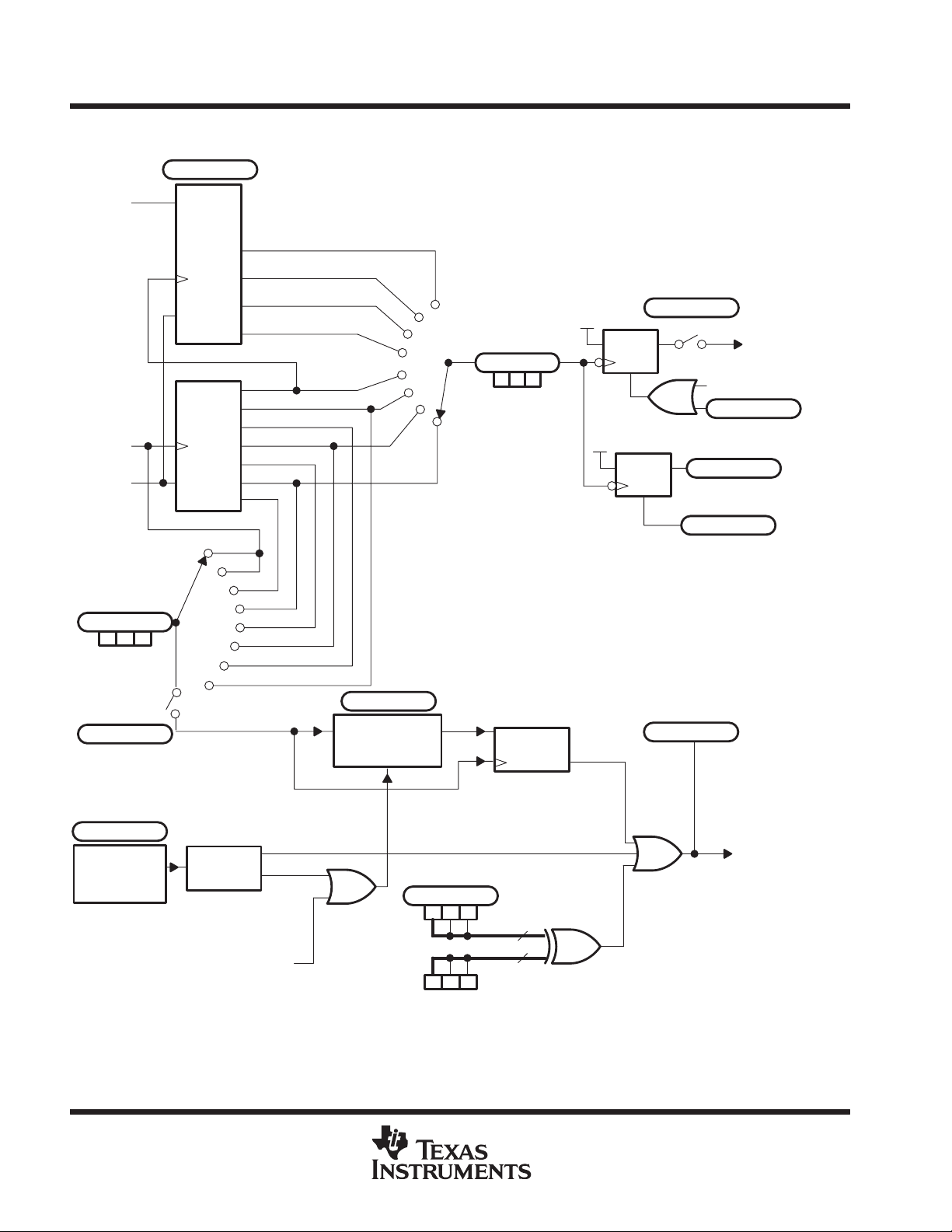

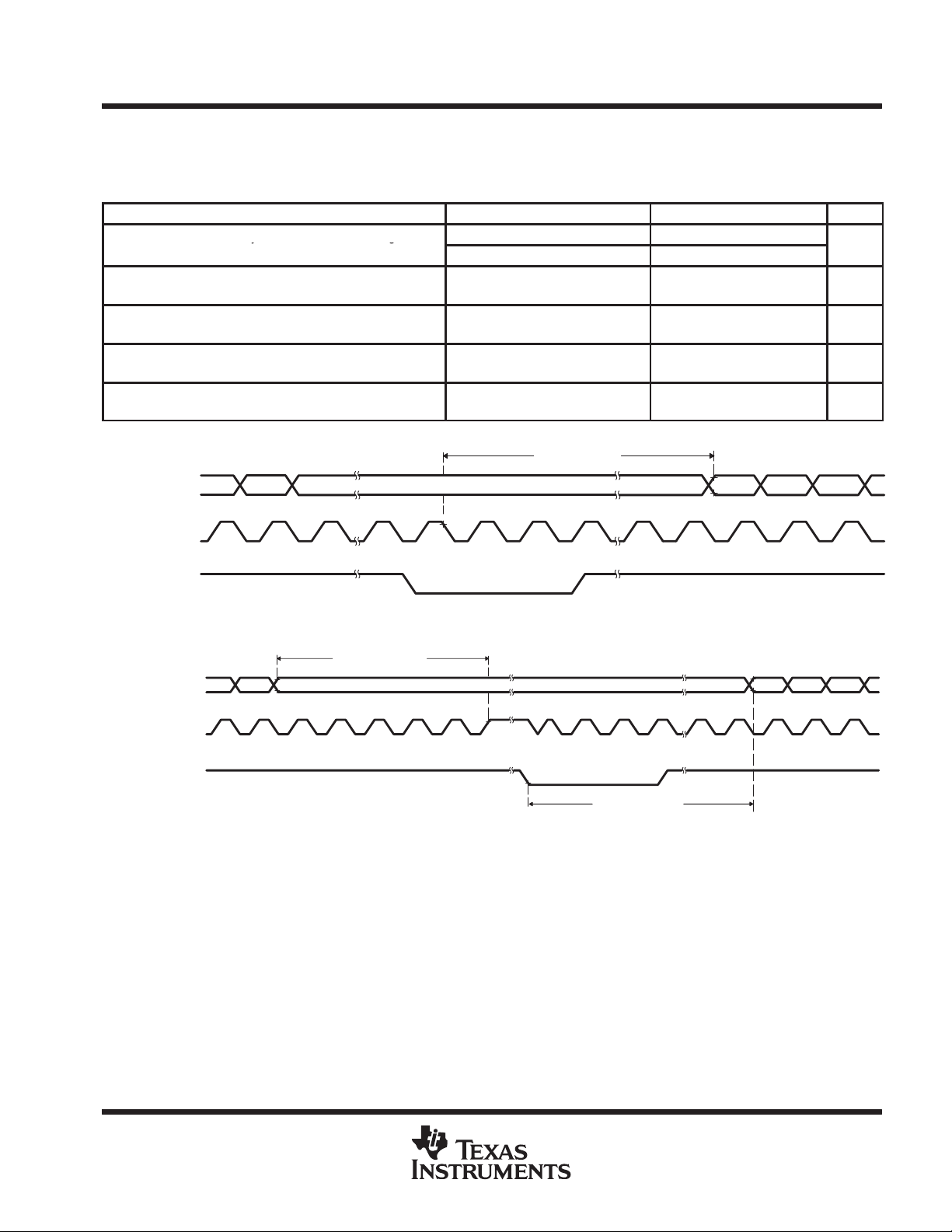

functional block diagram of the TMS320x240 DSP CPU

IS

DS

PS

Control

MUXMUX

ARP(3)

ARB(3)

X1

CLKOUT1

CLKIN/X2

16

PC

W/R

WE

NMI

FLASH EEPROM/

16

1616

MUX

Data/Prog

DARAM

MUX

16

ROM

16

16

AR0(16)

AR1(16)

AR2(16)

AR3(16)

AR4(16)

AR5(16)

AR6(16)

AR7(16)

ARAU(16)

16

16

3

3

3

B0 (256 × 16)

A15–A0

D15–D0

R/W

STRB

READY

MP/MC

XINT[1–3]

16

BR

XF

RS

Data Bus

Memory Map

GREG (16)

3

16

16

3

Register

IMR (16)

IFR (16)

MUX

NPAR

PAR MSTACK

DP(9)

16

MUX

MUX

Data

DARAM

B2 (32 × 16)

B1 (256 × 16)

16

Program Bus

9

9

16

MUX

Stack 8 × 16

16

7

LSB

from

IR

MUX

ISCALE (0–16)

32

16

Program Control

(PCTRL)

16

16

16

16

PSCALE (–6, 0,1,4)

CALU(32)

ACCL(16)ACCH(16)C

OSCALE (0–7)

Data Bus

TREG0(16)

Multiplier

PREG(32)

32

3232

MUX

32

32

32

16

MUX

Data Bus

1616

16

Program Bus

Program Bus

NOTES: A. Symbol descriptions appear in Table 10.

B. For clarity the data and program buses are shown as single buses although they include address and data bits.

30