Page 1

TMS320C2000 Motor Control Primer

User's Guide

Literature Number: SPRUGI6

September 2010

Page 2

High-performance drive applications require fast, reliable, and robust control systems. Therefore, there is

a significant demand for well-equipped digital motor control (DMC) platforms to educate the next

generation of engineers. In this users guide, a number of introductory-level digital motor control

methodologies and laboratory tools are presented. These tools help engineers learn how to easily

construct their own systems using TI provided device drivers, APIs, utilities, and libraries. Also described

is Texas Instruments' motor control developer’s kits, software framework, and DMC library. These

documents provide a modular development strategy which allows the user to experiment incrementally

from a basic to an advanced level.

1 Introduction

Digital motor control has been a challenging subject since the beginning of early implementations.

Although digital control techniques and the availability of high-speed microcontrollers made life

significantly easier for engineers, highly non-linear motor models, designing and tuning multiple control

loops, math intensive sensorless algorithms, parameter and temperature dependencies, and complex

software structures still have the potential to slow down development.

Texas Instruments understands the challenges facing motor control developers, and provides materials

and tools that significantly accelerate development and troubleshooting of motor-control systems.

Thorough documentation, a rich set of digital motor control and math libraries, modular software

strategies, incremental build processes, code development environments with real time debugging

support, and sample motor control kits at different voltage levels designed for all major motor types with

open source hardware support, lead developers through the process of creating a complete motor-control

system. These tools enable developers to quickly determine the processing resources required to

implement basic motor control. From this baseline, they are then able to bring in advanced algorithms to

trade-off the remaining processing capacity for greater accuracy, better performance, and higher power

efficiency, control of multiple motors or integrated power stages like digital power factor correction, and a

myriad of other options. In this way, developers can architect systems specifically optimized for their

application constraints and requirements.

User's Guide

SPRUGI6–September 2010

TMS320C2000 Motor Control Primer

2 Software Tools

2.1 IQ Math Library

2.1.1 What is IQ Math Library

Real-time control algorithms used in industry are typically computationally intensive, where optimal

execution speed and high accuracy is required. When C is used to develop control algorithm code,

generic math libraries can be used for computing math functions such as trigonometric functions, division,

etc. However, this approach may not result in the most cycle efficient code. Therefore, TI provides a

library of highly optimized and high precision math functions in the form of the IQMath library. Using the

math routines in the IQ Math library the user can achieve execution speeds considerably faster than

equivalent code written in standard ANSI C language.

The IQ Math library is available in both fixed- and floating-point versions, enabling easy migration from

float to fixed devices. The fixed-point library uses Q-arithmetic to emulate the fractional point (explained in

the following section), whereas the floating-point version uses the floating-point instruction set and

hardware FPU present on the device.

2

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

S I I I I I I I . F F F F F F F F F F F F F F F F F F F F F F F F

2I+ 2

I-1

+ … + 21+ 20. 2-1+ 2

- 2

+ … + 2

-F

www.ti.com

2.1.2 Q Format and Preferred Global Q for DMC

Q Format is a way of representing a numeric value containing a sign, integer and fraction portion in a fixed

bit location field. Figure 1. The following image illustrates a 32-bit binary number where the bits are

partitioned to represent the sign, integer, and fractional parts.

Figure 1. Sign, Integer, Fractional Parts

where

S: Sign Bit (1 bit)

I: Integer Bits (7 bits)

F: Fraction Bits (24 bits)

Thus, the fixed bit location acts as a virtual floating point. The IQ Math library makes use of such a

representation to compute the functions on a fixed-point device. The IQ Math library further allows the

user to select the appropriate numeric range and resolution by choosing where the decimal point is

located, i.e., how many bits of the binary represented number are integers and how many are the

quotient/fraction.

A value of a number represented in the format above can be interpreted as:

Software Tools

The number of fraction bits determines the Q format of the number. For a given word length (e.g., 32 bits),

the greater the number of fractional bits, the higher the resolution, and the smaller the dynamic range.

Table 1 shows some examples regarding the range and resolution of 32-bit, fixed-point numbers for

different Q format representations.

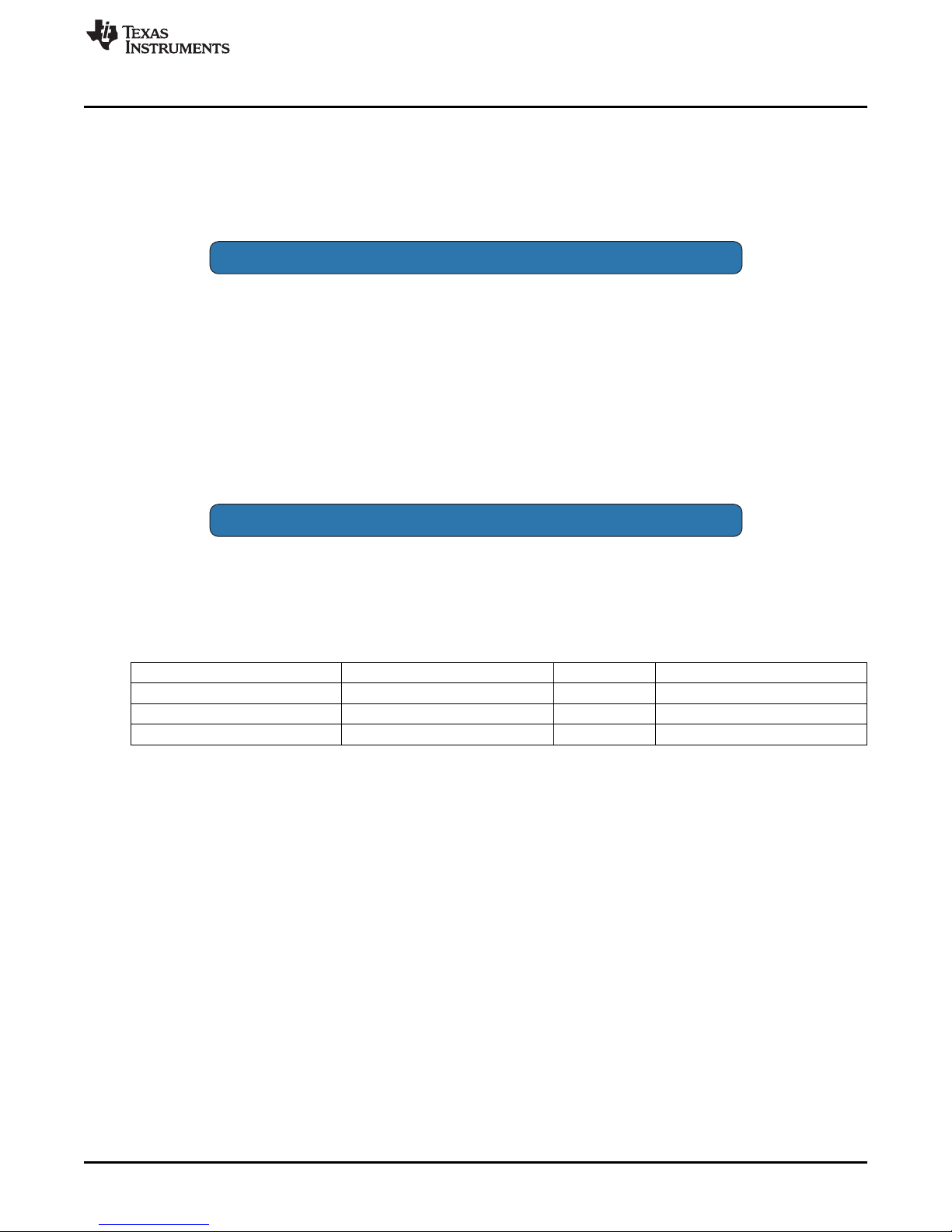

Table 1. Range and Resolution of 32-bit Fixed-point Number for Different Q-format Representation

GLOBAL_Q Max Val Min Val Resolution

28 7.999 999 996 -8 0.000 000 004

24 127.999 999 940 -128 0.000 000 060

20 2047.999 999 046 -2048 0.000 000 954

A high resolution and large dynamic range is typically needed for precise control algorithm execution.

Motor control applications formats between Q31 to Q27 do not provide enough dynamic range, and

formats of Q18 or lower result in significant quantization errors, due to insufficient resolution. Therefore, a

format of Q24 is used by the TI motor control software because it provides enough high resolution and

enough dynamic range to tackle a wide variety of motor applications. Note that all the motor control

projects are implemented based on per unit (pu) system variables and the Q used by these variables is by

default, Q24. For floating-point devices, single-precision IEEE float is used. Also note that although the

default Q is 24, the DMC library can be made to use any other Q format by changing the GLOBAL_Q

value.

2.1.3 Summary of the IQ Math Functions

The routines included within the IQmath library can be classified as:

• Arithmetic/math functions (addition, subtraction, multiply, divide, etc.)

• Trigonometric functions (sine, cosine, tangent, etc.)

• Format conversion utilities (scales numbers from one Q format to another)

• Miscellaneous (saturation, absolute value, etc.)

Some of the IQmath library functions used often in motor control are shown in Table 2.

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

3

Page 4

Software Tools

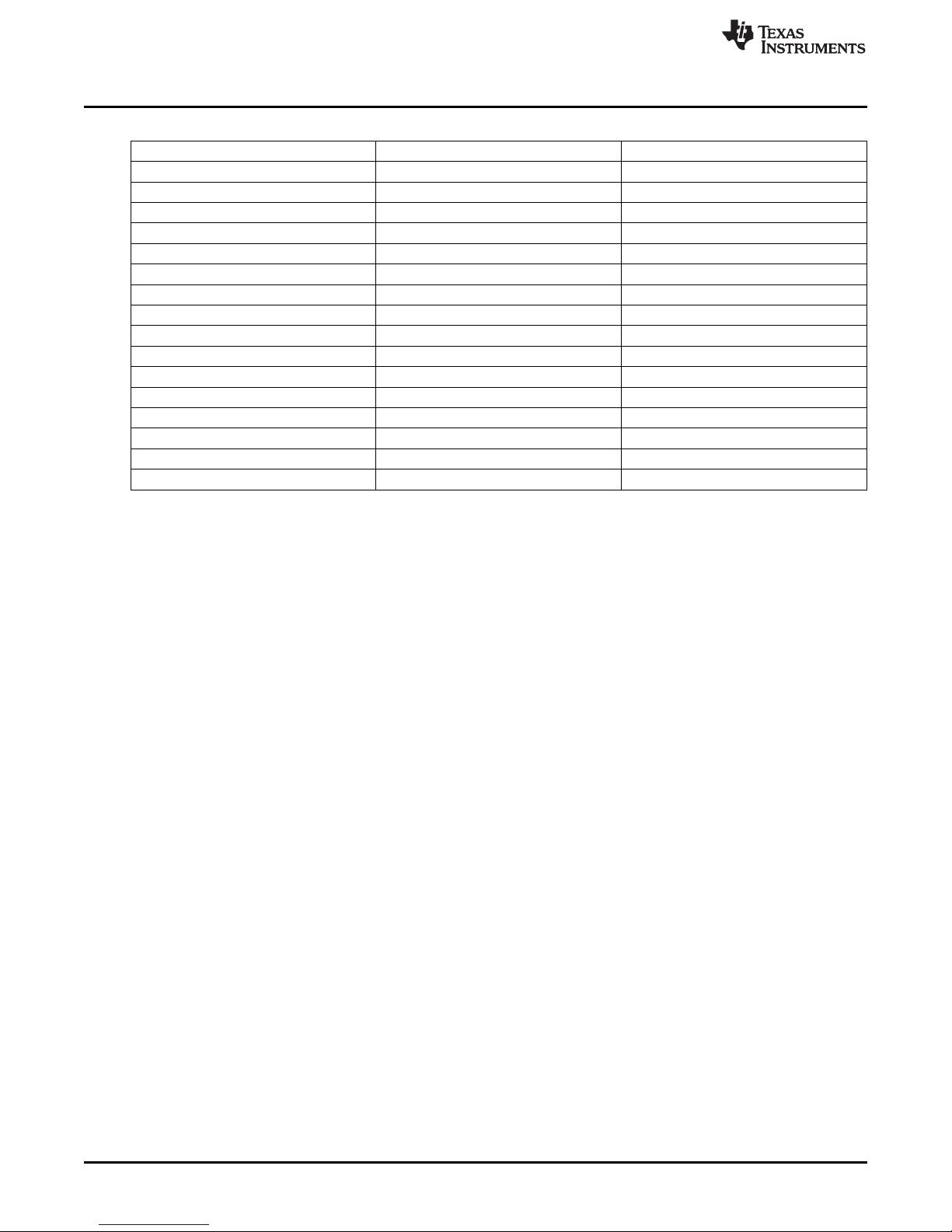

Table 2. Some IQMath Functions Used Often in Motor Control Applications

C C++ Operation

_IQ(float) IQ(float) Constant

+ + Add

- - Subtract

_IQmpy * Multiply

_IQdiv / Divide

_IQsqrt sqrt Square root

_IQisqrt isqrt 1/Square root

_IQsin sin Sine

_IQcos cos Cosine

_IQatan atan Arc tangent

_IQatan2 atan2 Arc tangent 2 opr.

_IQsinPU sinPU Sine per unit

_IQcosPU cosPU Cosine per unit

_IQatan2PU atan2PU Arc tangent 2 opr. per unit

_IQsat sat Saturation

_IQabs abs Absolute value

2.1.4 Calling an IQMath Function in C

The IQ Math library is very user-friendly and comes with detailed documentation explaining the features

and usage of each library function, along with example code. The following sample code shows how to

write a Park transform function using IQ Math library trigonometric and multiplication functions:

www.ti.com

#include "math.h"

#include "IQmathLib.h"

#define TWO_PI 6.28318530717959

void park_calc(PARK *v)

{

_iq cos_ang, sin_ang;

sin_ang = _IQsinPU (v->angle);

cos_ang = _IQcosPU (v->angle);

v->de = _IQmpy(v->ds ,cos_ang) + _IQmpy(v->qs ,sin_ang);

v->qe = _IQmpy(v->qs ,cos_ang) - _IQmpy(v->ds ,sin_ang);

}

Note that in the above example, the variables are declared not as fixed or float but as “iq.” The iq type is

interpreted at compile time, and is substituted for a fixed- or floating-point variable type, depending on the

device type being used. Consequently, the code above can be run on a fixed-point or a floating-point

device without any changes, therefore enabling easy migration between floating- and fixed-point devices.

2.1.5 Advantages of the IQMath Library for Motor Control

IQmath uses the instructions present on the C28x™ devices in the most efficient way to compute the

various math functions. Briefly, the benefits and contributions of the IQMath Library in C2000™-based

digital motor control can be summarized as follows:

• Selection of dynamic range and resolution on fixed point devices: For fixed-point devices, a

choice of Q can be made depending on dynamic range and resolution requirements of the system.

Q24 is used by default but can be changed easily to select another Q format if needed.

• Float to fixed migration: All the functions available in the floating-point version of the library are

available on fixed-point version and vice versa; hence, migration from float to fixed becomes very easy.

The use of “iq” type while writing code enables the compiler to interpret the math type to be used for

the variables at compile time. Thus, no or little change is required to the source code when migrating

from floating- to fixed-point devices.

4

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

• Highly optimized function: This function enables faster and multiple control loop execution than what

is possible using standard ANSI-C routines.

2.2 Digital Motor Control (DMC) Library

2.2.1 DMCLib Overview

The digital motor control library is composed of C functions (or macros) developed for C2000 motor

control users. These modules are represented as modular blocks in C2000 literature in order to explain

system-level block diagrams clearly by means of software modularity. The DMC library modules cover

nearly all of the target-independent mathematical functions and target-specific peripheral configuration

functions, which are essential for motor control. These modules can be classified as:

Transformation and Observer Modules Clarke, Park, Phase Voltage Calculation, Sliding Mode

Signal Generators and Control Modules PID, Commutation Trigger Generator, V/f Controller,

Peripheral Drivers PWM abstraction for multiple topologies and techniques,

Real-Time Debugging Modules DLOG module for CCS graph window utility, PWMDAC

Software Tools

Observer, BEMF Commutation, Direct Flux Estimator,

Speed Calculators and Estimators, Position Calculators

and Estimators etc.

Impulse Generator, Mod 6 Counter, Slew Rate Controllers,

Sawtooth & Ramp generators, Space Vector Generators

etc.

ADC Drivers, Hall Sensor Driver, QEP Driver, CAP Driver

etc

module for monitoring the control variables through

oscilloscope.

In the DMC library, each module is separately documented with source code, use, and background

technical theory. All DMC modules allow users to quickly build, or customize their own systems. The

library supports three principal motor types (induction motor, BLDC and PM motors) but is not limited to

these motors.

The DMC modules — implemented in IQmath — are used to construct both sensored and sensorless

control systems. An earlier version of the DMC library (legacy) was released for the F281x series

SPRC080, and F280x series SPRC215. Starting in 2010, the libraries were revised with optimized macro

usage for system examples using F2803x (Piccolo) and F2833x (Delfino) families and integrated into

controlSUITE. For more on the motor control methodology and available resources, visit the TI Motor

Control Site. There are two releases of the math_blocks in controlSUITE; the fixedv1.1 supports all three

motor types and is only valid for fixed processors. The v2.0 supports both fixed (all) and float (induction

motor and PM motors) system examples.

The DMC library components have been used by TI to provide system-level motor control examples. In

the motor control code, all DMC library modules are initialized according to the system specific

parameters, and the modules are inter-connected to each other. At run-time the modules are called in

order. Each motor control system is built using an incremental build approach, which allows some sections

of the code to be built at a time, so that the developer can verify each section of the application one step

at a time. This is critical in real-time control applications, where so many different variables can affect the

system, and where many different motor parameters need to be tuned.

2.2.2 Incremental System Build Methodology

It is well known that, regardless of how much planning has gone into a system engineering project;

chances are the final system won’t work for the first time, usually because some subtle target dependency

or requirement has been overlooked. This is normal engineering, and if a contingency plan or debug

methodology has been comprehended, it’s not a problem. However, if not anticipated ahead of time, this

can become frustrating and time-consuming. To prevent this, the system comes pre-packaged within a

framework, incorporating various system build levels or debug steps as part of the normal system software

flow. A customer can move from a current build level to any other build level quickly, and without risk of

losing configuration or run-time information related to previous build levels.

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

5

Copyright © 2010, Texas Instruments Incorporated

Page 6

Software Tools

This framework also allows a user to commission system software in a step-by-step manner, and at each

step validate key vital signs before moving on. The number of build levels may vary depending on final

system complexity, but an important point to note is that regardless of the number of build levels, this

framework becomes a common point of reference. In either case, it will greatly improve the chances of

system software success. As will be seen later, incremental system build levels are supported by

frameworks with various configurations of interconnected modules. Frameworks also provide invaluable

skeletons for users to modify or customize as required to suit their own target system requirements.

2.2.3 Well Defined Module Variables Provide Clear Debug Points

Because the system/module framework has one-to-one mapping with the system signal flow diagram, it is

easy to probe signals of interest and to visualize them in real time. TI provides useful utility modules which

can display time-varying signals (i.e., software variables) via hardware DAC using an oscilloscope, or on

screen with Code Composer Studio™ using a data-logging software module. The PWMDAC and

DATA_LOG modules can be readily connected by way of pointers during run-time, to any module terminal

variable and internal module variables for greater software visibility.

2.2.4 Known Working Library Eases the Development

Modules can provide a valuable starting point, even if they are not exactly the final requirement. Known

good modules can be used initially on a “trust-for-now” basis as a system is built up and valuable

experience is gained. Later on, these standard modules can be investigated on an as-needed basis, to

learn more, or to modify or customize to suit. A modular approach is ideal for this, allowing standard

modules to be swapped out for customized ones later on without risk or delays.

www.ti.com

2.2.5 Code Composer Studio and Documentation Completes the Package

The solutions collateral outlined so far for the digital motor control systems software is comprehensive with

many component parts. To bring it all together and to allow customers to test drive many solutions quickly,

TI offers Code Composer Studio™ (CCS) for the C2000 platform as the Integrated Development

Environment (IDE). Ready-to-run CCS projects and workspaces ensure customers are jump-started into

productivity quickly. To complement the IDE, clear module and system documentation tie the solutions

together and help customers understand how theory, implementation, and debug all come together to

provide a working solution.

2.3 Software Modularity

The benefits of structured, modular software are well known. This is especially true for large, complex

systems with many sub-blocks contributed by many individuals. In these cases, there is a strong common

set of needs. Efforts by contributors should only be used one time, and are reusable for future projects.

The contributed software blocks (modules) must be predictable in their behavior and compatible with other

blocks, both functionally and numerically. Industry has learned the benefits of these methodologies, and

has realized the impact they can make on smoother system integration; reducing debug and

troubleshooting time, providing a higher degree of visibility inside the software, and allowing quicker

system reconfiguration. These attributes have significant impact on getting quality products out to market

in a timely manner.

Such methodologies needed to be applied to high-performance motor control systems and to address this,

TI introduced the modular DMC library in early 2000. Within the digital control systems space, the

algorithm standard has been used to address the specific needs of application areas such as digital motor

control, industrial electronics, uninterruptible power supplies, plus a host of other control-related areas.

The familiar signal flow block diagram representation of digital control systems, as seen in control texts

and university publications, lend themselves well to effective implementation by software-interconnected

module blocks (i.e., functions or macros) with well-defined input and output ports.

6

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

S

PI

PI

3-phase

Inverter

Rotor Flux

Angle

Calculator

PI

SV

PWM

D,Q

D,Q

d,q

d,q

d,q

a,b,c

PWM1/2

PWM3/4

PWM5/6

-

+

W

ref

W

r

+

+

Inv. Park

Park Tr.

Clarke Tr.

-

-

ACI

Motor

ID

ref

IQ

ref

S

S

V

Q

V

D

Vq

Vd

W

r

I

Q

I

D

i

a

i

b

q

r

W

r

I

q

I

d

www.ti.com

Once a rich set of library modules is available with a well-defined and proven interconnect methodology,

systems can be realized fairly quickly. The logical extension is that various “what-if” scenarios of system

topologies and/or configurations can be explored relatively easily and with little overhead. As a more basic

or fundamental need, this same ease of module connection allows a system designer to have a number of

incremental build levels, ranging from a rudimentary system (3-4 modules) used to check out key life

signs, to a fully featured final system with a large number of connected modules. This is analogous to the

commissioning steps or process which is typical in large engineering projects. This approach to system

software commissioning is invaluable during the system integration phase and can greatly reduce the time

and effort required.

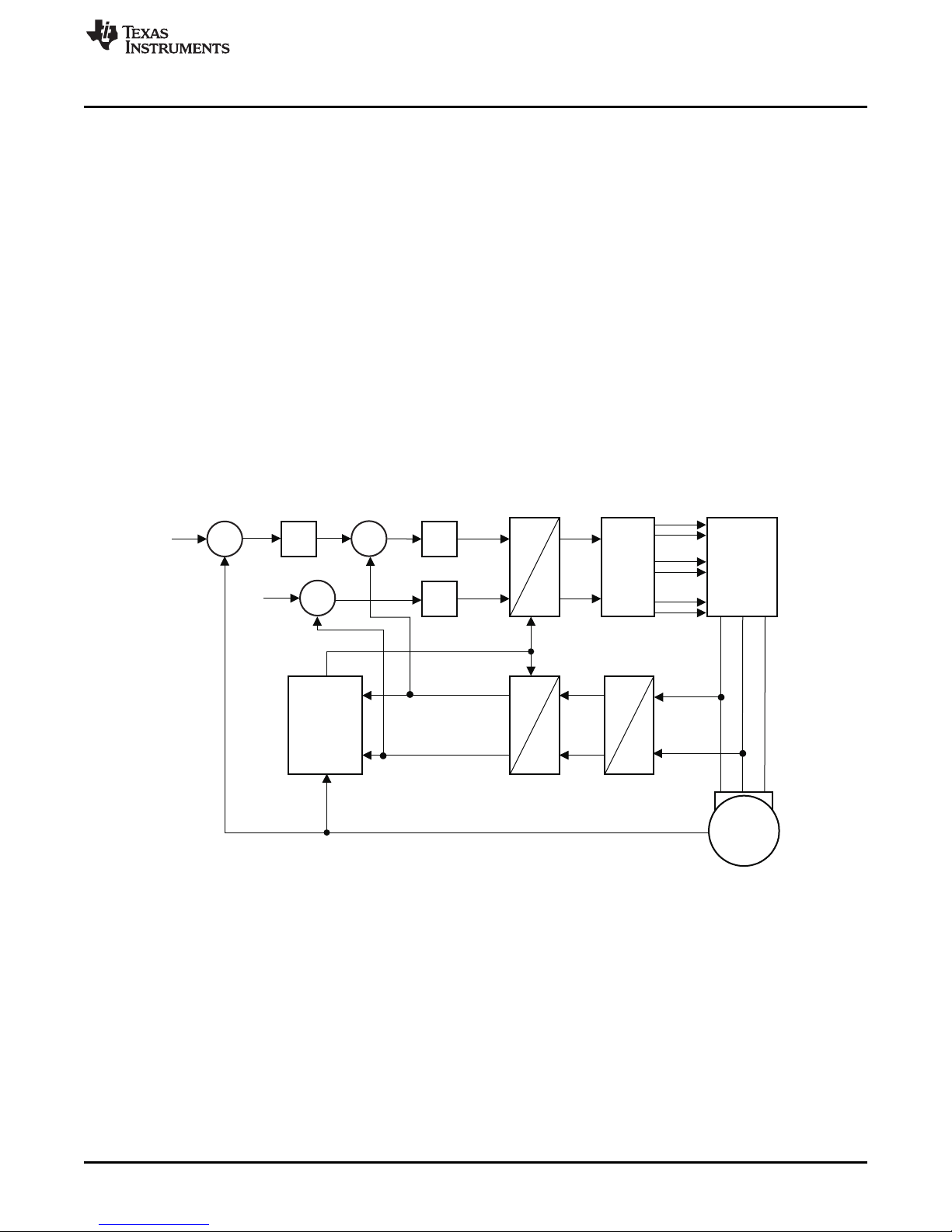

2.3.1 Consistency Between Software Modules and Control Block Diagrams

It is well known that systems and control engineers like to visualize systems or control strategies in the

form of signal flow block diagrams. It makes good sense to separate main functions and to show how

each is interrelated by explicit connection to other functions. Each function should be self-contained, and

its boundaries or interface clearly delineated. A digital motor control system is a good example of this

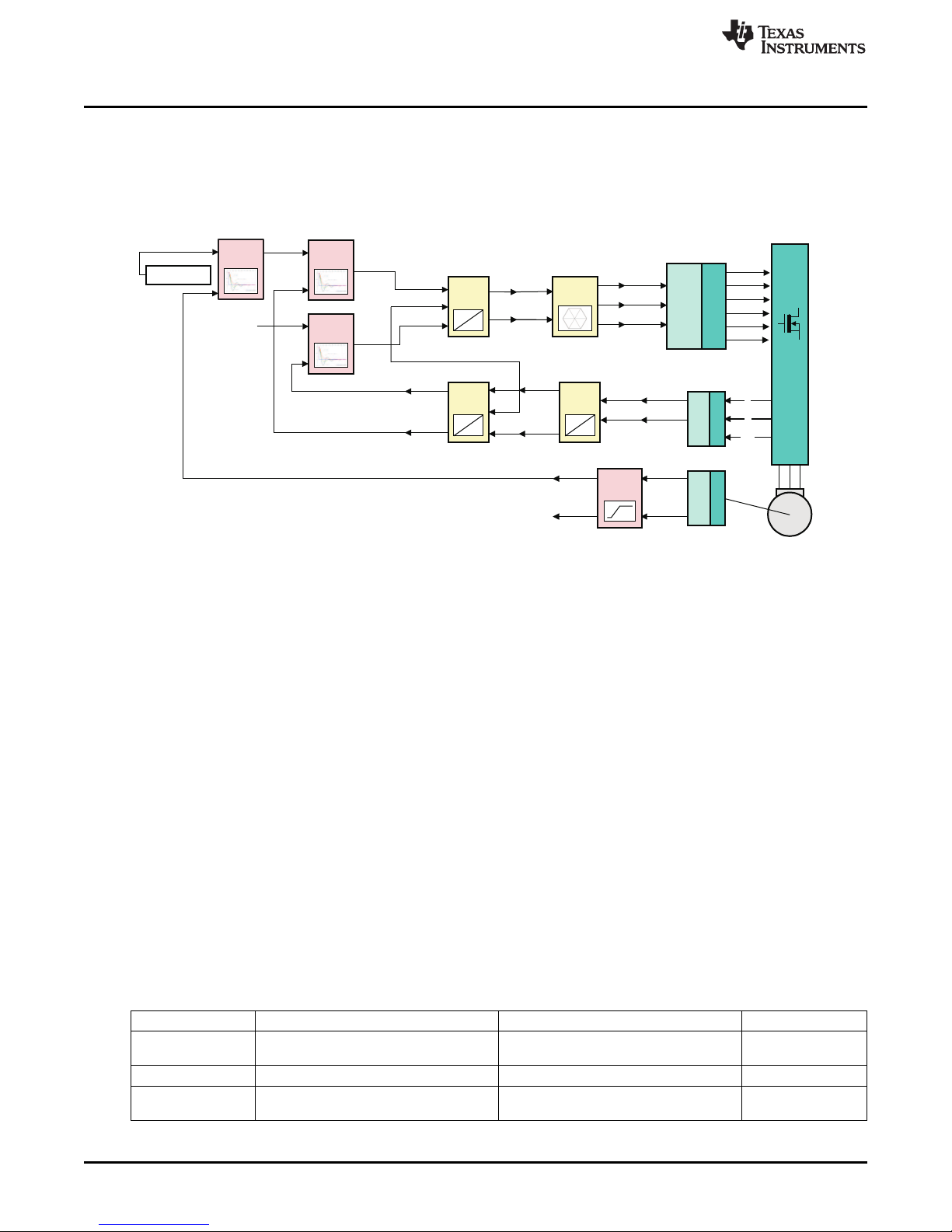

interrelation of functions. Figure 2 shows a typical signal flow block diagram of an AC induction motor

controlled by a field-oriented control strategy. This is a useful representation, and it is found in many

classical texts on motor control. However, several limitations are evident when attempting to realize this

diagram in software form.

Figure 2. ACI Sensored FOC - System Block Diagram

Software Tools

It is not usually clear how software variables are related to the signal parameters on the diagram, nor

where in the software these parameters can be found and accessed. Moreover, the boundary between

software and hardware is blurred (i.e., where the software controls the on-chip peripheral and where the

peripheral output pins control the external hardware, such as the PWM-to-inverter interface). By adopting

a modular strategy and enforcing some clear definitions, the classic block diagram shown in Figure 2 can

be rearranged and redrawn to reveal a great amount of information about the actual software which is

used to implement such a system. This new style of system representation can be seen in Figure 3. The

advantages and features of such a representation will be expanded upon in later sections, but a summary

of key points are given here:

• The system block diagram has a clear one-to-one mapping to the modular system software.

• Each module graphic or block represents a self-contained software function or object of the same

name.

• Input and output terminals of each module correspond exactly to global variables within the software

function.

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

7

Page 8

park_D

park_Q

clarke_d

clarke_q

Valpha

Vbeta

Tb

Ta

Tc

Ipark_d

Ipark_Q

Theta

Ipark_q

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

3-Phase

Inverter

PMSM

Motor

ADC

DRV

EV

HW

AdcRslt0

AdcRslt1

clarke_a

clarke_b

park_d

PARK

MACRO

CLARKE

MACRO

SVGEN

DQ

MACRO

IPARK

MACRO

theta

watch window

Speed_Ref

PID

MACRO

Iq Reg.

IdRef (=0)

PID

MACRO

Id Reg.

QEP

DRV

EV

HW

QEPA

QEPB

Index

Elec

Theta

Direction

Speed

Speed Rpm

SPEED_FR

MACRO

u_out_q

u_out_d

i_ref_d

I_ref_q

PID

MACRO

Iq Reg.

spd_fdb

Ipark_D

park_q

Ia

Vdc

Ib

Software Tools

www.ti.com

• Modules are categorized (color coded) to clearly designate dependencies on peripherals and target

hardware.

• Connections between modules show data flow via corresponding input/output variables.

• Each module is reusable and has its own documentation explaining usage and instantiation.

Figure 3. ACI Sensored FOC – System Block Diagram Showing Clear One-to-One Mapping to Software

2.3.2 Reusability, Compatibility, and Expandability

Engineering reuse in today’s competitive environment is critical and software modularity is the perfect

vehicle to achieve this, especially in DMC systems. If we examine various motor control systems, it

becomes clear that a large degree of commonality exists between them. The PID regulator, for example,

is useful across all systems. Therefore, if each module is realized only once, but implemented according

to well defined guidelines, then compatibility and predictability can be assured across all modules. Since

this approach allows efficient reusability, efforts which may typically be used to “reinvent the wheel” can be

re-deployed on expanding the module library base for greater functionality and features.

There are several DMC blocks common for 3-phase motor control in general. On the other hand, in most

cases, the difference between a sensored and sensorless system is only one or two modules, e.g., a

position or speed estimator. The remaining modules are again common. Therefore, in keeping with the

reuse philosophy, design efforts can be focused on expanding the library with more robust estimators

which meet various system requirements, rather than recreating entire system infrastructures.

2.3.3 Target Independent Modules and Drivers

Understanding the exact dependencies of a software module is very important. This knowledge is

invaluable during debugging, software porting from one target to another, and on planning a system

commissioning strategy. The modules which are part of the DMC Library (examples of which are shown in

Table 3) are categorized into two main types:

8

• Target (microcontroller) independent (TI)

• Drivers (i.e., target dependent and application configurable)

Table 3. Sample of DMC Module Descriptions and Type Category

Number Module Description Type

1 bldcpwm_drv BLDC PWM driver – uses high-side Drv

2 cap_event_drv Capture input event driver Drv

3 hall_gpio_drv Hall effect interface driver for sensored Drv

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

chopping and fixed on/off for low side

Copyright © 2010, Texas Instruments Incorporated

3-phase BLDC trapezoidal control

Submit Documentation Feedback

Page 9

www.ti.com

Software Tools

Table 3. Sample of DMC Module Descriptions and Type Category (continued)

Number Module Description Type

4 pwm_drv PWM driver (configurable for active Drv

high/low, dead-band, or asm/sym)

5 bdc_pwm_drv Brushed DC-Motor PWM driver Drv

6 qep_theta_drv Quadrature encoder pulse interface driver Drv

with position (theta) as output

7 qep_no_index_drv Quadrature encoder pulse interface driver Drv

without index pulse

8 ileg_vdc Analog to digital conversion drive Drv

9 resolver_drv Position and speed calculations for Drv

resolver sensor

10 data_log Data logging utility – useful for variable Util

graphing in code composer

11 pwm_dac_drv 4-channel DAC driver useful for displaying Util

real-time variables on scope

12 aci_fe Flux estimator for 3-phase induction TI/AC

motor vector control

13 aci_se Speed estimator of the 3-ph induction TI/AC

motor

14 clarke Clark transform – 3-phase to 2-phase TI/AI

(quadrature) conversion

15 comtn_trig Commutation trigger for BLDC sensorless TI/AC

trapezoidal/BEMF/ZC tech.

16 cur_mod Rotor flux position estimator for 3-phase TI/AC

induction motor vector control

17 i_park Inverse park transform – Rotating to TI/AI

stationary reference frame conversion

18 impulse Impulse generator module TI/AI

19 mod6_cnt Modulo 6 counter counts from state 0 TI/AI

through 5 and reset

20 park Park transform – Stationary to rotating TI/AI

reference frame conversion

21 phase_volt_calc 3-phase voltage recontruction function TI/AI

based on PWM duty cycle inputs

22 pid_reg3 Proportional/integral/derivative controller TI/AC

with anti windup feature

23 ramp_gen Sawtooth generator with adjustable gain, TI/AI

frequency and dc offset

24 rmp2cntl Ramp up and ramp down module TI/AI

25 rmp3cntl Ramp down module TI/AI

26 rmp_cntl Ramp up and ramp down module used to TI/AI

control slew rate

27 smopos sliding mode observer for position TI/AC

estimation in sensorless vector drives

28 speed_est Motor speed estimator using the TI/AC

estimated rotor position

29 speed_frq Speed calculator based on frequency TI/AI

measurement – tacho style method

30 speed_prd Speed calculator based on period TI/AI

measurement between events

31 svgen_dq Space vector generator function with TI/AI

quadrature control

32 svgen_mf Space vector generator function with TI/AI

magnitude and frequency control

33 v_hz_profile Volts/hertz profile for induction motor TI/AC

(voltage vs. frequency)

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

9

Copyright © 2010, Texas Instruments Incorporated

Page 10

Valpha

Vbeta

Tb

SVGEN

DQ

MACRO

Ta

Tc

rmp_freq

rmp_out

RG

MACRO

rmp_offset

rmp_gain

rmp_out

CLARKE

MACRO

clarke_a

clarke_b

Ref

Fdb

Out

PID

MACRO

Spd Reg.

configuration

Kp:

1.0

Ki:

0.02

Kd:

0.003

Max limit:

+0.8

Min limit:

-0.8

configuration

PWM 1/2/3:

Acitive Hi/Lo

PWM Trip:

HI_Z/LO

PWM Mode:

Sym/Asym

PWM Freq:

5-30 kHz

Deadband:

0-20 us

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

Software Tools

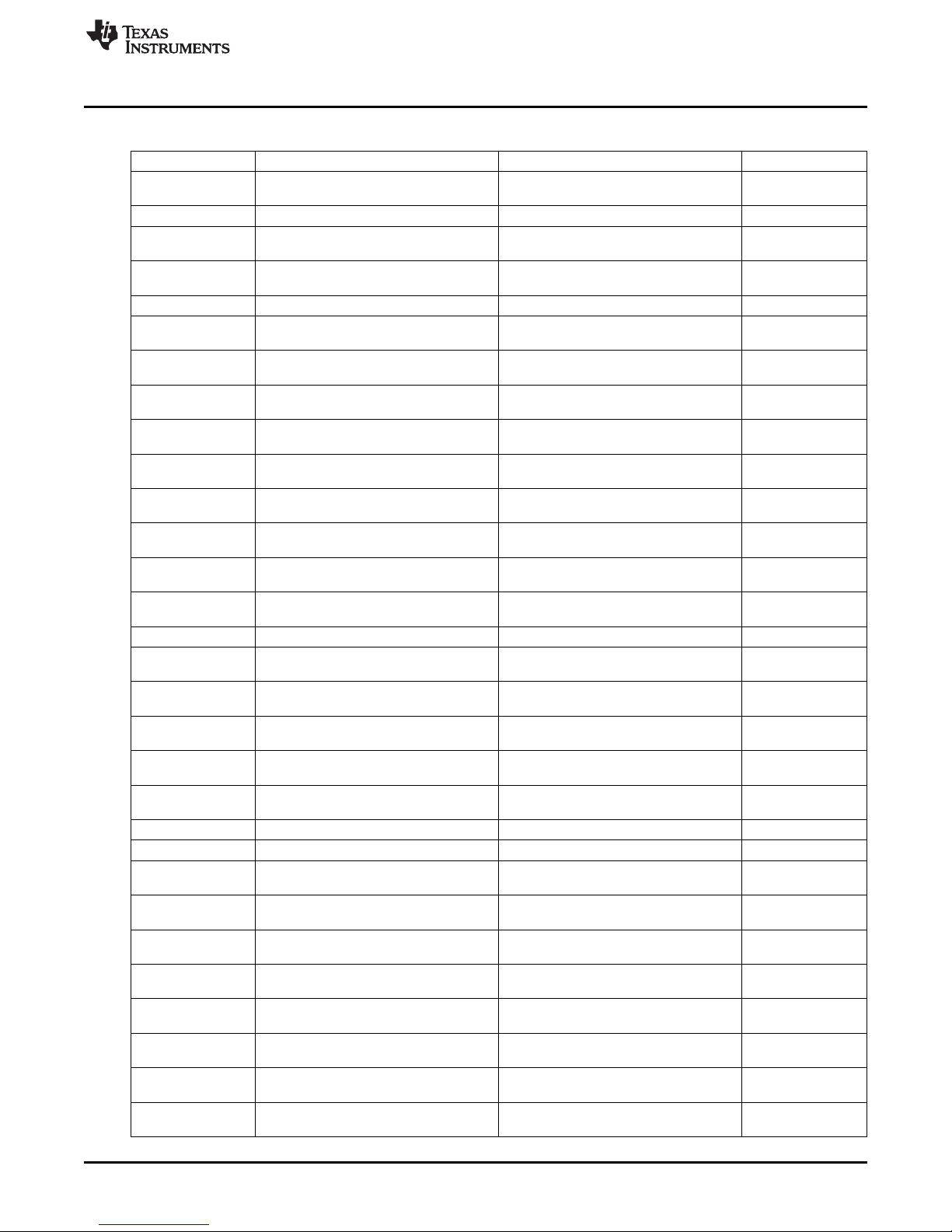

For convenience, the module graphics throughout the documentation are color coded to help customers

quickly identify a modules dependency within a system. Color designation is as follows:

• Target independent/application independent : TI/AI yellow

• Target independent/application configurable : TI/AC pale red

• Drivers (target dependent/application DRV blue

configurable) :

Examples of target independent modules are given in Figure 4 and Figure 5. Target independent modules

do not directly access or modify control or status registers of any on-chip peripherals, i.e., target

microcontroller-specific resources. These modules are dependent only on the CPU core. TI/AI modules

are typically characterized by mathematical type functions (e.g., transforms, matrix operations, waveform

generators, etc.). These functions are fixed and fairly standardized, and do not require configuration,

knowledge of peripherals, or the end application itself. TI/AC modules also do not need knowledge of

device peripherals, but do need to be configured depending on the end application. Examples of these

modules are PID controllers, position/speed estimators, voltage and current models, etc.

www.ti.com

Figure 4. Target and Application Independent Modules - Examples

Figure 5. Target Independent/Application Configurable Modules

On the other hand, driver modules are the interface between software and target microcontroller-specific

peripheral hardware. Examples of such modules are shown in Figure 6. These modules have direct

access to peripheral control and status registers. Using these driver modules or taking them as a

reference, one can easily develop application specific drivers to configure microcontroller peripherals such

as PWMs, ADCs, QEP, CAP etc., as required.

Figure 6. Target Dependent Drive Module

10

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

Dlog 1

Dlog2

Dlog3

Dlog4

DLOG

MACRO

CCS Graph

Windows

PwmDacPointer 4

Scope

Low

Pass

Filter

PwmDacPointer 3

PwmDacPointer 2

PwmDacPointer 1

DAC 1

DAC 2

DAC 4

DAC 3

PWM5A

PWM6A

PWM7B

PWM7A

PWMDAC

MACRO

www.ti.com

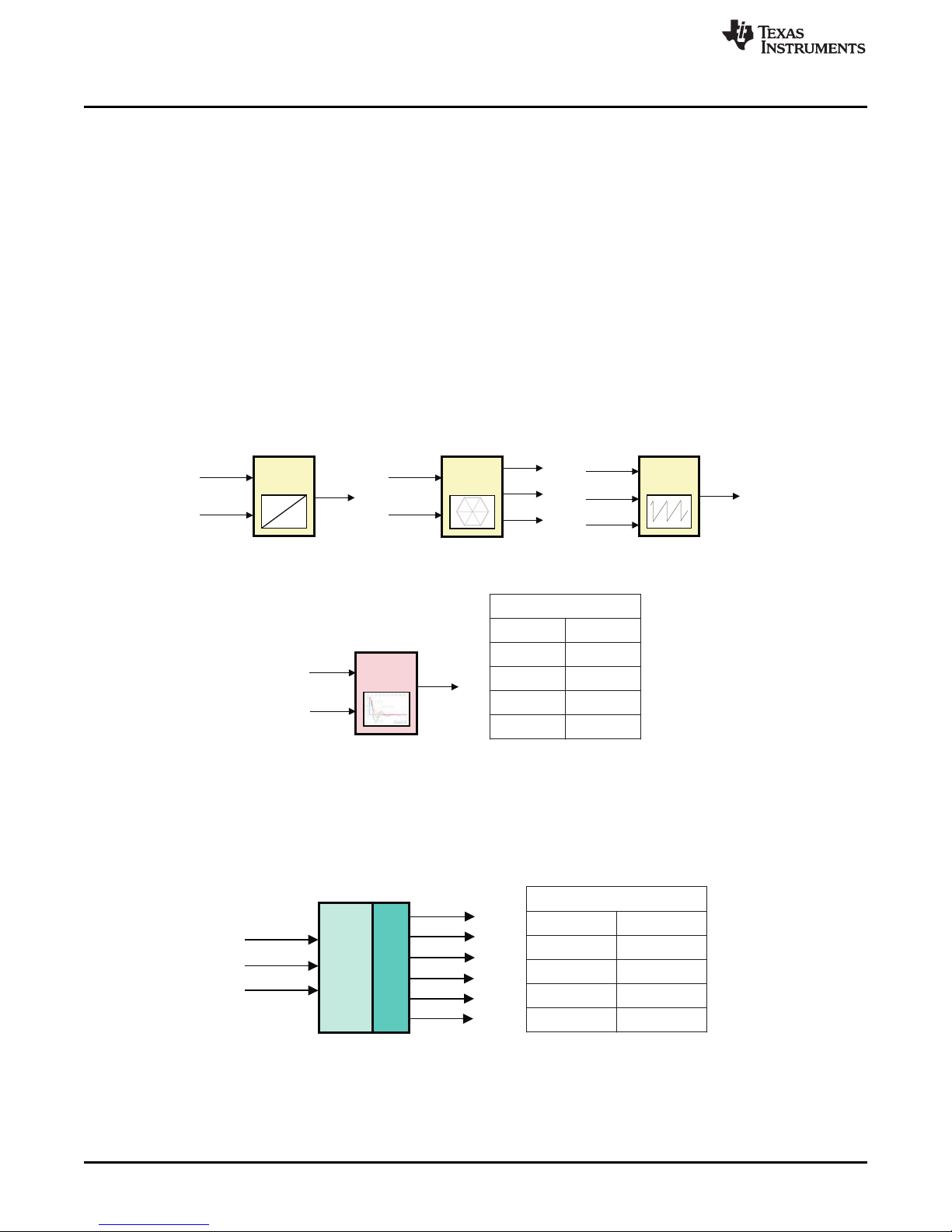

2.3.4 Utility/Debug Modules

Utility and/or debug modules are mainly used during the software development and debug process.

Typically they are removed at time of software completion; however they can also be left in the code for

system diagnosis if required during field tests or evaluation. Two examples of these modules are shown in

Figure 7. These modules allow the software designer to probe any of the system variables, and display

them in real time via a scope or a graphical output within Texas Instruments' Code Composer Studio.

The PWMDAC module allows the user to monitor waveforms of software variables through a scope, while

DLOG_VIEW provides a memory buffer with a trigger feature that allows Code Composer to display two

graphical waveforms in real-time. Graphical waveforms are continuously updated via the JTAG debug link

while the customer’s application software continues to run. Both JTAG and the real-time data flow are

non-intrusive to application software running on any devices.

Software Tools

Figure 7. Utility/Debug Modules

2.3.5 Quick Module Evaluation and Testing

Apart from the more obvious benefits of software modularity previously described, some of the same ideas

can be used to facilitate quick module testing or evaluation, i.e., checking how applicable or how a module

performs. Additionally, it becomes easy to test several “what if” scenarios by simply reconnecting modules

and evaluating several alternatives. Figure 8 shows a “module under test” setup where a known input

stimulus is applied. The input stimulus and output response of this module under test can be conveniently

monitored in real time on a scope via the PWMDAC or DLOG utility modules.

Apart from evaluating or confirming operation of a known good software module, this technique is useful

when developing new modules. During debug, input stimulus signals can be swept over the entire input

range to look for boundary condition problems or discontinuities in output response. It should be noted that

this process is valid, provided known good stimulus modules are used as input signals. This technique

allows a software designer to check validity of variable ranges, and to ensure waveform integrity over a

required frequency range and system sampling rates.

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

11

Page 12

IPARK

MACRO

Valpha

Vbeta

Tb

SVGEN

DQ

MACRO

Ta

Tc

DacPtr 4

DacPtr 3

DacPtr 2

DacPtr 1

DAC 1

DAC 2

DAC 4

DAC 3

PWMDAC

MACRO

Ipark_d

VdTesting

VqTesting

Angle

Ipark_q

Tb-Tc

Module under test

Graph

Window

Graph

Window

Software Tools

Figure 8. Testing and Evaluating Modules

2.3.6 DMC Library Documentation Support

TI seeks to offer a rich selection of software examples and working systems which are clearly

documented. One area which has received much attention and improvement is the description or

documentation of application software. Through the use of software modularity, it is possible to delineate

and give an unambiguous one-to-one mapping between a system block (signal flow) diagram and the

actual software code in question. This, together with module documentation for each software block,

shows the customer clearly where each piece of software is, what it is doing, and more importantly, the

parameters or variables being passed and executed upon. All TI applications which are part of the

software offering, now consist of module documents and system documents. System documents always

include the system block or signal flow diagram, which among control engineers, remains one of the most

useful communication tools.

www.ti.com

2.3.6.1 Module Level DMC Library Documents

The pdf files included in the library folders provide necessary information regarding the modules. The

outline of the module documents is standard and can be itemized as follows:

• Introduction: Describes the functionality of each module, and provides detailed information about

modules properties such as type, target devices, etc.

• C Interface: Module declaration details, usage, examples etc.

• Technical Background: Mathematical derivation of the module functionality.

Figure 9 shows these library documents and their location in controlSUITE , both in the desktop and in the

C: folders.

12

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

PARK

Description

This transformation converts vectors in balanced 2-phase orthogonal stationary

system into orthogonal rotating reference frame.

Availability

This IQ module is available in one interface format:

1) The C interface version

Module Properties

Type:

Target Devices:

C Version File Names:

math library files for C:

Target Independent, Application Independent

28x Fixed and Floating Point devices

park.h

IQmathLib.h, IQmath.libIQ

Park Variable Transformation

Ds

PARK

MACRO

Alpha

Beta

Sine/Cosine

Qs

www.ti.com

Software Tools

Figure 9. Library Documents and Their Location in controlSUITE

As shown in Figure 10, a target independent transformation module is described and the module

inputs/outputs are shown explicitly in the introduction part. In addition, module type, target devices, and

related files are explained in this section.

Figure 10. Snapshot of Typical Target Independent Module

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

13

Page 14

C Interface

Object Definition

The structure of PARK object is defined by following structure definition

typedef struct { _iq Alpha;

_iq Beta;

_iq Angle;

_iq Ds;

_iq Qs;

} PARK;

typedef PARK *PARK_handle;

//Input: stationary d-axis stator variable

//Input: stationary q-axis stator variable

//Input: rotating angle (pu)

//Output: rotating d-axis stator variable

//Output: rotating q-axis stator variable

Item

Name

Description

Format

Range(Hex)

Inputs

Alpha

Direct axis(d) component of the

transformed signal

GLOBAL_Q

80000000-7FFFFFFF

Beta

Quadrature axis(q) component of the

transformed signal

GLOBAL_Q

80000000-7FFFFFFF

Angle

Phase angle between stationary and

rotating frame

GLOBAL_Q

80000000-7FFFFFFF

(0-360 degree)

Sine

Sine of the phase angle between

stationary and rotating frame

GLOBAL_Q

80000000-7FFFFFFF

Cosine

Cosine of the phase angle between

stationary and rotating frame

GLOBAL_Q

80000000-7FFFFFFF

Outputs

Ds

Direct asix (D) component of

transformed signal in rotating

reference frame

GLOBAL_Q

80000000-7FFFFFFF

Qs

Quadrature axis(Q) component of

transformed signal in rotating

reference frame

GLOBAL_Q

80000000-7FFFFFFF

GLOBAL_Q valued between 1 and 30 is defined in the IQmathLib.h header file.

Software Tools

Following the module description, all the necessary information is provided for C interface of the DMC

module, the introduction of which is shown below in Figure 11. This section explains the structure of the

module object; name, description, and format of the module input and outputs. It also explains special

constants and data types, module initialization and usage, and pseudo code providing the information

about the module usage.

www.ti.com

Figure 11. Snapshot of First Part of C Interface Section

In the last section, theoretical background and mathematical derivations of the equations (if applicable) are

provided to the user as shown in Figure 12. This section helps the user to understand the philosophy

behind the module and allow the user to customize it properly.

14

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

q

Q

lq

lq cos• θ

IQ

θ

θ

ld sin• θ

θ

θ

ld cos• θ

lq sin• θ

dld

ID

D

Technical Background

Implements the following equations:

This transformation converts vectors in 2-phase orthogonal stationary system into the

rotating reference frame as shown in figure below:

The instantaneous input quantities are defined by the following equations:

(

)

(

)

sin

sin / 2

id I t

iq I tωω π

= ×

= × +

cos sin

sin cos

ID Id Iq

IQ Id Iq

θ θ

θ θ

= × + ×

= − × + ×

www.ti.com

Software Tools

Figure 12. Snapshot From the Theoretical Background Section (need equation)

2.3.7 DMC Library Optimization

There are several ways to optimize motor control systems for performance in terms of memory

consumption and CPU cycles required to achieve the given task. TI suggests the following options to

optimize the overall system performance:

• Use of the optimization levels via the –o switch on the compiler

• Use of inlining as a technique to increase speed of execution

• Transforming functions in to inline code via macro expansion

When a function is called separately, the function call must call the code at the appropriate address,

followed by a return statement when the function execution is completed. In addition, there is some

overhead associated with setting up a stack frame. In the case of a small function, this call and return

overhead may be significant, compared to the size of the function itself. In addition, when a function is

inlined, the compiler can optimize the function in context of the calling code.

Another optimization is sometimes possible: to turn the function into a macro expansion. This allows the

compiler to optimize further under certain circumstances and produces less code, and consumes fewer

cycles to execute. The disadvantage of this method is the code size increase if multiple expanded macros

are implemented. However, for single motor control, both size and cycle wise macro modules have

superiority to earlier versions where the code size becomes comparable for dual motor operation. One

must note that the number of instruction cycles is much lower in any case.

Unlike the DMC Library version in Legacy, the modules in controlSUITE are written in the form of macros

for optimization purposes (refer to Optimizing Digital Motor Control Libraries, SPRAAK2, for more details

at TI website). It is reported that the macro versions of the DMC library let the system run 2-3 times more

efficient than non-optimized version in Legacy. The macros are defined in the header files. The user can

open the respective header file and change the macro definition, if needed. In the macro definitions, there

should be a backslash ”\” at the end of each line as shown below which means that the code continues in

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

15

Page 16

#define PARK_MACRO (v) \

\

v

.Ds = _IQmpy(v.Alpha,v.Cosine) + _IQmpy(v.Beta,v.Sine); \

v

.Qs = _IQmpy(v.Beta,v.Cosine) - _IQmpy(v.Alpha,v.Sine);

#endif // __PARK_H__

/*============================================================================

File name: PARK.H (IQ version)

Originator: Digital Control Systems Group

Texas Instruments

Description: Header file containing constants, data type, and macro definitions

============================================================================*/

#ifndef __PARK_H__

#define __PARK_H__

typedef struct { _iq Alpha; // Input: stationary d-axis stator variable

_iq Beta; // Input: stationary q-axis stator variable

_iq Angle; // Input: rotating angle (pu)

_iq Ds; // Output: rotating d-axis stator variable

_iq Qs; // Output: rotating q-axis stator variable

_iq Sine;

_iq Cosine;

} PARK;

typedef PARK *PARK_handle;

/*---------------------------------------------------------------------------Default initalizer for the PARK object.

----------------------------------------------------------------------------*/

#define PARK_DEFAULTS { 0, \

0, \

0, \

0, \

0, \

0, \

0, \

}

/*----------------------------------------------------------------------------

PARK Transformation Macro Definition

----------------------------------------------------------------------------*/

for the PARK.

A typical module declaration and macro definition

Software Tools

the next line. Any character including invisible ones like “space” or “tab” after the backslash will cause

compilation error. Therefore, make sure that the backslash is the last character in the line. In terms of

code development, the macros are almost identical to C function, and the user can easily convert the

macro definitions to inline C functions. As an example, the park transformation macro definition is shown

below.

www.ti.com

Figure 13. A Typical Module Declaration and Macro Definition

2.4 Incremental Build Methodology

Irrespective of how much planning has gone into a system engineering project, the chances are that the

final (or complete) system will not work the first time, usually some subtle (or not) target dependency or

requirement has been overlooked. This is normal engineering, especially in the case of software

16

development, and if not anticipated ahead of time, can become a frustrating and time consuming disaster.

To prevent this, TI’s DMC Library system software comes prepackaged within a framework, incorporating

various system build levels or debug steps as part of the normal system software flow. A customer can

move from a current build level to any other build level very quickly and without risk of losing configuration

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

or run-time information related to previous build levels. This allows a customer to commission system

software in a step-by-step manner, and at each step validate key vital signs before moving on. The

number of build levels may vary depending on final system complexity and the type of control strategy

used. It is important to note that regardless of the number of build levels used in the reference system, this

framework is provided by TI as guidance and becomes a common point of reference in cases where

customer trouble shooting necessitates interaction with TI customer support engineers.

Incremental system build levels are supported by frameworks with various configurations of interconnected

modules. Frameworks also provide invaluable skeletons for customers to modify or customize as required

to suit their own target system requirements, forming an excellent starting point.

To better understand the philosophy and details of the incremental build approach, a typical motor control

case, a permanent magnet synchronous motor, will be used to step through the various commissioning

phases. The system shown in is the final build of a sensored PMSM project. The subsequent block

diagrams (Figure 14 to Figure 17) show examples of typical steps used to get to a solidly working final

system.

2.4.1 Check System Vital Signs - Build Level 1

Figure 14 shows the module configuration of build level 1. Although the first is the simplest build, it is

perhaps the most important one since many system fundamentals can be validated here. Build 1 removes

main external connections (power hardware, motor, feedback circuitry, etc.) and allows a customer to

focus on:

• Code compiling/linking using a Code Composer Studio (CCS) project

• Invoking and downloading to the CCS debug environment

• Setting up or importing a CCS workspace

• Running code in real-time mode

• Ensuring the hardware is functioning correctly

Assuming the above check list is correct, some key system vital signs can now be validated:

• Check Interrupt Trigger: The sensored PMSM project, like most other DMC systems, is an interrupt

driven, time sampled system, meaning that the modules shown in Figure 14 are executed and updated

on every interrupt. The Isr_Ticker, a software variable in the interrupt subroutine (ISR) behaves like a

counter, and it is updated when an interrupt is triggered and the code in the ISR is executed. In order

to confirm that the ISR is being triggered at each selected event, this variable can be added to the

watch window to see whether or not it is updating.

• Testing some target independent modules: Validating both the stimulus waveforms (output of

RAMP_GEN), and output of SVGEN via the PWMDAC utility or graph windows confirms system

interrupts are being generated and the main ISR is executing correctly. At this stage, the RAMP_GEN

function can be manipulated via CCS watch window to change its frequency and to see the

corresponding changes on the waveforms.

• PWMDAC utility test: To monitor internal software variables and signal waveforms in real time PWM

DACs are very useful tools. Present on the HVDMC board are PWM DAC’s (PWM5-7) which are

connected to external low pass filters to generate the waveforms. A simple 1st–order low-pass filter RC

circuit is placed on the board to filter out the high frequency components. The selection of R and C

value (or the time constant, t) is based on the cut-off frequency (fc). For example, R=1.8kΩ and

C=100nF, it gives fc = 884.2 Hz. This cut-off frequency has to be below the PWM frequency. Refer to

Using PWM Output as a Digital-to-Analog Converter on a TMS320F280x, SPRAA88A for more details.

• Check PWM outputs and verify PWM configuration: In addition, it is important to verify that the

space vector signals (Ta, Tb, and Tc) are correctly modulating the PWM outputs. This is easily

checked by filtering or suppressing the high frequency carrier (typically 10–20 kHz) at the PWM output

pins by a simple RC filter with approximately 1 kHz cutoff. The filtered waveforms should then

resemble the unmodulated ones seen at variables Ta, Tb, and Tc using the PWMDAC module. We

now have a working forward path for the PMSM controller running in open loop, and are ready to

connect the power inverter hardware and motor.

• Inverter test: After verifying SVGEN module, the PWM software module and the 3-phase inverter

hardware are tested by looking at the low pass filtered PWM outputs. For this purpose, if using the

external DC power supply, gradually increase the DC bus voltage and check the Vfb-U, V and W test

points using an oscilloscope; or if using AC power entry slowly change the variac to generate the DC

Software Tools

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

17

Copyright © 2010, Texas Instruments Incorporated

Page 18

SVGEN

DQ

MACRO

IPARK

MACRO

Valpha

Vbeta

Tb

Ta

Tc

Ipark_d

VdTesting

VqTesting

Theta

Ipark_q

rmp_freq

rmp_out

RG

MACRO

rmp_offset

rmp_gain

RC

MACRO

trgt_value

set_value

eq. flag

watch window

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

Dlog 1

Dlog 2

Dlog 3

Dlog 4

DLOG

MACRO

Tb

Ta

Tc

DacPtr 4

DacPtr 3

DacPtr 2

DacPtr 1

DAC 1

DAC 2

DAC 4

DAC 3

PWMDAC

MACRO

Tb

Ta

Tc

Tb-Tc

C

R

Software Tools

bus voltage. The inverter phase voltage dividers and waveform monitoring filters enable the generation

of the waveform. This circuit is used to observe the low-pass filtered phase voltage waveform to make

sure that the inverter stage is working properly.

Figure 14. Build Level I - Checking Vital Signs

2.4.2 Open Loop Motor Operation - Build Level 2

In this level, the motor is connected to the inverter and the motor is run open loop. In this level, the items

below will be verified:

• Open loop test: This is the first level that the motor is connected and run open loop. The user expects

to set VdTesting (a software variable which is supposed to generate the Vd and indirectly id

component of the stator current that produce flux) to zero since the flux will already be generated by

magnets, and apply non-zero VqTesting to generate torque. At this point, the motor should spin

smoothly, indicating that the inverter hardware is functioning properly. Since the field is not perfectly

oriented and the current loops are not closed, it is not recommended to load the motor or run it various

speeds at this level in order not to lose synchronization or stall the motor. Second, the test should

initially be run under modest dc bus level for safety reasons. Once the user confirms that everything

performs as expected, then the dc bus can be increased to the rated value. During the open loop tests,

VqTesting, SpeedRef (speed reference) and DC Bus voltages should be adjusted carefully for PM

motors so that the generated Bemf is lower than the average voltage applied to motor winding. This

will prevent the motor from stalling or vibrating. Therefore, tuning might be needed for VqTesting and

SpeedRef for different motors.

• Verify and calibrate the ADCs measurements and check ADC configuration: It is necessary to

make sure that the scaling factors of ADC measurements (voltage, current etc.) are set correctly, and

that the dc offset caused by the passive component tolerances is minimized. Note especially that low

power motors draw low amplitude current after closing the speed loop under no-load. The performance

of the sensored/sensorless control algorithms becomes prone to phase current offset which might stop

the motor or cause unstable operation. Therefore, the phase current offset values need to be

minimized at this step. Since the current drawn by the motor is non-zero, the user should be able to

monitor the current waveforms both from PMWDAC and CCS graph windows. If the current waveforms

cannot be monitored even though the motor spins, then the ADC configuration settings should be

double checked (such as channel selection, ADC system clock enable, etc.).

• Check the Clarke transform & current waveforms: With the motor running in a stable state, it is

possible to validate the current measurement feedback path. The peripheral driver ILEG2_DRV helps

the user configure ADC and measure 2 inverter leg currents and reconstructs the motor phase

currents. The 120o phase currents are transformed to 90o quadrature currents by the CLARK

transform module. Using PWMDAC or graph window, the shape, phase and quality of the current

waveforms can be inspected. The Clarke alpha component should be leading Clarke beta if everything

is set correctly, otherwise the user will not be able to run the next level and close the current loop.

www.ti.com

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

18

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

park_D

park_Q

clarke_d

clarke_q

Valpha

Vbeta

Tb

Ta

Tc

Ipark_d

VdTesting

VqTesting

Theta

Ipark_q

rmp_freq

rmp_out

rmp_offset

rmp_gain

trgt_value

set_value

eq. flag

watch window

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

Dlog 1

Dlog 2

Dlog 3

Dlog 4

DLOG

MACRO

Tb

Ta

Tc

DacPtr 4

DacPtr 3

DacPtr 2

DacPtr 1

DAC 1

DAC 2

DAC 4

DAC 3

PWMDAC

MACRO

Tb

Ta

Tc

Tb-Tc

R

3-Phase

Inverter

ADC

DRV

EV

HW

Ia

Vdc

Ib

AdcRslt0

AdcRslt1

clarke_a

clarke_b

park_d

park_q

PARK

MACRO

CLARKE

MACRO

SVG

END

QMACRO

IPARK

MACRO

RG

MACRO

RC

MACRO

theta

watch window

Speed_Ref

Motor

PMSM

C

www.ti.com

Software Tools

Figure 15. Build Level II - Inverter Test and ADC Calibration

2.4.3 Closed Current Loop Operation - Build Level 3

Assuming the previous section is completed successfully, this section verifies the dq-axis current

regulation performed by PID_REG3 modules, QEP drv and speed measurement modules.

• Current regulator (PID modules) test and tuning: 3-phase motor control mainly consists of two main

control loops: a current loop and a speed loop. At this level, current control PIDs will be tested and

tuned if needed. After a successful tuning, the user should make sure that the feedback currents

precisely follow the Id and Iq current references. While testing the PIDs, the dc bus voltage should not

be too low; otherwise the outputs of the PID modules saturate which might introduce unwanted glitches

on the current waveforms or unstable operation. Once a stable set of PID coefficients is found, the

transient response of the PIDs should be examined by changing Iq and Id references (IqRef and IdRef

respectively). This has to be repeated for various load and speed conditions. Most of the time a single

set of coefficients does not perform well at all operating points; therefore an operating point dependent

PID coefficient look-up table may be used to improve performance.

• QEP drv test: Build 3 also implements the angular position sensor feedback path, based on the QEP

driver module which outputs both the mechanical and electrical angles. The optical position sensor and

QEP interface driver are operating correctly when, while the motor is spinning, variable theta_elec can

be viewed on the scope. Its output waveform should correspond in shape to the stimulus theta angle

generated by the RAMP_GEN module. This indicates that position information is being measured

correctly.

• Speed measurement module test: The speed measurement module, SPEED_FRQ, is in the

feedback path and can also be validated at this stage. The speed measurement is dependent on motor

shaft rotation, and the SPEED_FRQ module is driven from the theta_mech output of QEP module.

Since its output value should be constant, i.e. the motor is running at constant synchronous speed, the

calculated speed, speed_frq, can be viewed via a watch window instead of on the scope. The

RAMP_GEN frequency can be increased slowly up or down to check whether the speed measurement

varies appropriately.

• Calibration angle detection: In level 3, a simple calibration angle detection subroutine is added into

the code to measure the initial angle offset. This is necessary because the exact rotor position

information is needed for precise field orientation. The detected offset angle is basically the angle

between the locked rotor (zero) position and the position where the first index signal is received.

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

19

Page 20

park_D

park_Q

clarke_d

clarke_q

Valpha

Vbeta

Tb

Ta

Tc

Ipark_d

Ipark_Q

Ipark_D

Theta

Ipark_q

rmp_freq

rmp_offset

rmp_gain

trgt_value

set_value

eq. flag

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

3-Phase

Inverter

PMSM

Motor

ADC

DRV

EV

HW

Ia

Vdc

Ib

AdcRslt0

AdcRslt1

clarke_a

clarke_b

park_d

park_q

PARK

MACRO

CLARKE

MACRO

SVGEN

DQ

MACRO

IPARK

MACRO

RG

MACRO

RC

MACRO

theta

watch window

Speed_Ref

PID

MACRO

Iq Reg.

IdRef (=0)

IqRef

watch window

PID

MACRO

Id Reg.

QEP

DRVEVHW

QEPA

QEPB

Index

Elec

Theta

Direction

Speed

Speed Rpm

SPEED_FR

MACRO

u_out_q

u_out_d

i_ref_d

i_ref_q

Software Tools

Figure 16. Build Level III - Closed Current Loop Test

2.4.4 Closed Speed Loop Operation - Build Level 4

In this level, the speed loop will be closed in addition to the current loops regulating stator current d-q

components and use the actual rotor position. This section verifies the speed PID and FOC based on

actual rotor position. The basic sensored, field-oriented control of PMSM motor implementation will be

done once this step is completed successfully.

• Torque control: If the user is interested in “torque only” control, the previous scheme allows the user

control the torque as long as the actual rotor position sensed by the QEP drv is fed to the Park and

IPark transforms. The amount of the load determines the speed of the motor at a given torque

reference since the torque control guarantees constant torque production but cannot control the speed

directly.

• Speed control and speed PID tuning: If it is intended to control both speed and the torque, then the

speed loop should be closed as given in the block diagram of level 4. The reference speed adjusted by

the user is compared to the speed feedback and then the error is compensated by speed PID module

which needs to be tuned at this level. The output of the speed PID is connected to another PID

regulating Iq (stator current torque generating component), and the system increases or decreases the

torque generation depending on the actual speed level vs speed reference. For example, when the

system is loaded, motor speed tends to reduce and the system immediately increase the torque

generation to handle the applied load and indirectly keep the speed at the reference level. Once the

speed PID is tuned at a certain operating point, the user needs to examine the robustness of the

speed loop under various torque/speed levels, step load or any other torque/speed profile applied to

user’s system.

• Now, the actual rotor position is used: It was confirmed in build level 3 that position information

(both electrical and mechanical) was correctly appearing at the outputs of the QEP drive module. In

build level 4, the simulated angle provided by RAMP_GEN is no longer needed. This can now be

replaced by the actual measured electrical angle, theta_elec, which is used as angular position

feedback for the Park and inverse Park transforms.

• Soft-switches helps to manage control loops: The latest incremental build levels are supported by

loop switches (a software variable in the code, lsw) to manage the loops. For instance, when lsw=0,

the rotor is locked to the initial rotor position which is essential for sensored applications. Afterwards,

the lsw is set to 1 to close the current loops which help the motor start up smoothly. This is often

needed for sensorless applications because the algorithms need some time to converge to the actual

position/speed value. Finally, lsw is set to 2 in order to close the speed loop which let the customer

20

control speed accurately and realize field orientation.

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

www.ti.com

Submit Documentation Feedback

Page 21

park_D

park_Q

clarke_d

clarke_q

Valpha

Vbeta

Tb

Ta

Tc

Ipark_d

Ipark_Q

Ipark_D

Theta

Ipark_q

Mfunc_c1

Mfunc_c2

Mfunc_c3

PWM1A

PWM

DRV

MACRO

PWM1B

PWM2A

PWM2B

PWM3A

PWM3B

EV

HW

3-Phase

Inverter

PMSM

Motor

ADC

DRV

EV

HW

Ia

Vdc

Ib

AdcRslt0

AdcRslt1

clarke_a

clarke_b

park_d

park_q

PARK

MACRO

CLARKE

MACRO

SVGEN

DQ

MACRO

IPARK

MACRO

theta

watch window

Speed_Ref

PID

MACRO

Iq Reg.

IdRef (=0)

PID

MACRO

Id Reg.

QEP

DRVEVHW

QEPA

QEPB

Index

Elec

Theta

Direction

Speed

Speed Rpm

SPEED_FR

MACRO

u_out_q

u_out_d

i_ref_d

i_ref_q

PID

MACRO

Iq Reg.

spd_fdb

/

/

/ , ( 2 )

/ , ( / )

pu base

pu base

pu base base base

pu base base base base

I I I

w w w w f

V w

p

=

=

= =

Y = Y Y Y =

www.ti.com

Figure 17. Build Level IV - Closed Speed Loop Test / FOC

2.5 PU System Model and Base Values

In electrical engineering, a per-unit system is the expression of system quantities as fractions of a defined

base unit quantity. Calculations are simplified because quantities expressed as per-unit (between -1 and

+1) are the same regardless of the voltage, current etc level. Advantages of using the pu system for motor

control applications include:

• Once the base values are initialized in the code, the code will handle the rest and the parameter

dependency will be minimized.

• Migrating to a new custom design system will be as easy as modifying the base values.

• For fixed point devices, pu system allows the user to reduce the amplitude of the variables in order to

get a fractional part with a maximum precision.

Conversion of per-unit quantities to volts, ohms, or amperes requires knowledge of the base that the

per-unit quantities were referenced to. In the TI DMC systems, the base values are selected as the

maximum measurable quantity of the peak of phase voltage, current etc. by the ADC. This is directly

related to the current and voltage sensing circuits and the voltage dividers used to down-scale the actual

voltage or current quantities to ADC input voltage range, which is typically 3 to 3.3V. Later, the measured

voltage by ADCs will be converted to put quantity in the code. The calculation of the pu values can be

formulated as:

Software Tools

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

The selection of the base quantities is relative and can be any appropriate value as long as it is consistent

within the whole system. For instance, assuming that the peak of the maximum measurable phase current

is 20A on a DMC kit, the base current value can be selected as 20 where ±1pu represents ±20A in the

code.

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

21

Page 22

+20A

-20A

Current

Sensing

cct

3.3 V

0 V

12-Bit

ADC

0

DMC

System

(pu)

+1.0

-1.0

2

12

Software Tools

Similarly, the base voltage can be selected as the peak of maximum measurable phase voltage in the

system. Assuming that the dc bus voltage is 400V, base voltage is selected as 400V/√3.

2.6 DMC Systems: Legacy VS controlSUITE

There are basically two separate TI DMC systems offering similar solutions for motor control with minor

differences. These differences can be summarized as:

• controlSUITE supports Piccolo (2803x, fixed point) and Delfino (2833x, floating point) whereas Legacy

supports 280x and 281x (both fixed point).

• In controlSUITE the DMC Library modules are optimized macros whereas legacy modules are regular

C functions typically 2-3 times less efficient.

• The recent TI DMC updates are announced through controlSUITE since 2010.

• Legacy is motor control specific whereas controlSUITE is more comprehensive system covering almost

all C2000 based applications.

The DMC projects in the Legacy and ControlSUITE are given in the table below:

www.ti.com/c2000dmc#dmc

www.ti.com

Table 4. Projects in controlSUITE and Legacy

Motor Type Description Legacy controlSUITE

3-ph ACI Sensored – Tacho i/p 281x 2803x

Scalar Control / SVPWM 280x

3-ph ACI Sensored – Tacho or Encoder 281x 2803x

Field Oriented Control / 280x

SVPWM

3-ph ACI Sensorless – Direct Flux 281x 2803x

3-ph PMSM Sensored – Incremental 281x 2803x

3-ph PMSM Sensorless – Sliding Mode 281x 2803x

3-ph PMSM Sensored – Incremental 281x 2803x

3-ph PMSM Sensored – Resolver 281x TBD

3-ph BLDC Sensored – Hall Effect Sensors 281x 2803x

3-ph BLDC Sensorless – BEMF Sensing 281x 2803x

Estimator

Field Oriented Control / 280x 2833x

SVPWM

Encoder

Field Oriented Control / 280x

SVPWM

Observer

Field Oriented Control / 280x 2833x

SVPWM

Encoder

Position Control / SVPWM 280x

Field Oriented Control / 280x

SVPWM

Trapezoidal Control 280x

Trapezoidal Control 280x

22

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

Table 4. Projects in controlSUITE and Legacy (continued)

Motor Type Description Legacy controlSUITE

3-ph BLDC Sensorless – Sinusoidal - 2803x

Control

Field Oriented Control /

SVPWM

Brushed DC Sensored – QEP 281x Q410

Position and speed control 280x

Stepper Motor Sensorless – Discrete Angle 280x Q410

Est.

Position and Speed Control

2.6.1 More About controlSUITE

controlSUITE™ is the content and content management tool for C2000™ development. It includes a

comprehensive suite of software that significantly decreases development time and accommodates

different experience levels and programming preferences. It is also a one-stop shop for everything needed

for C2000 system development.

controlSUITE’s main features include:

• controlSUITE desktop graphical navigation tool

• Manual or auto update, to insure synchronization with latest content

• Devices: first-level device initialization, system tasking, and example projects

• Libraries: foundational libraries and utilities for math, DSP, IQMath, CLA, floating point, flash, boot, and

specific applications

• Kits: Entry level to application specific full voltage reference designs, including open tooled hardware,

GUIs, system guides, and CCStudio projects

• Direct Links to: application notes, datasheets, user’s guides

• Training: forums, videos, on-line, in-person, and self-paced workshops

Software Tools

Figure 18. controlSUITE Desktop Graphical Navigation Tools

SPRUGI6–September 2010 TMS320C2000 Motor Control Primer

Submit Documentation Feedback

23

Copyright © 2010, Texas Instruments Incorporated

Page 24

Software Tools

2.7 System Level DMC Documentation Support

In addition to the DMC Library documents detailed in the previous sections, all C2000 motor control

projects are supported by a rich set of collateral to shorten the development time. These documents

basically provide information about the motor type used in the project, control theory (e.g. FOC,

trapezoidal control) system overview, hardware configuration, incremental build levels, hardware

components, GUI related documents etc.

2.7.1 Quickstart Guide and Graphical User Interface (GUI)

In controlSUITE™, an open source graphical user interface is designed for sensorless HVDMC projects so

that the users can visually and quickly evaluate the DMC kit and software without having to learn and

configure the underlying project software or install CCS. Note that the GUI is not a development

environment but intended for demonstration purposes only. The GUI supports all three kinds of motors

(ACI, PMSM, and BLDC). The HVDMC kit ships with both a Piccolo™ F28035 and a Delfino™ F28335

controlCARD. Only the F28035 card is pre-flashed with the code that enables interface to this GUI. The

flashed code is optimized for running sensorless FOC on ACI and PMSM motor and sensorless

trapezoidal control on a BLDC motor that are available from the TI website. Note that the performance of

the motor with the flashed image is not a metric of quality of control and performance levels achievable

using the TI DMC library. The GUI allows the user to select the motor type, visually inspect some

waveforms (e.g., current, voltage, back-emf , etc.), numerically watch bus voltage, estimated speed, set

the reference speed, and change the graph update rate and graph scale. A snapshot of GUI is shown in

Figure 19.

Figure 19. Graphical User Interface for Motor Control

www.ti.com

The GUI exe file, flash image, and related files can be found in Desktop - Kits - Folders - Example GUI, or

at the direct path of:

C:\ti\controlSUITE\development_kits\HVMotorCtrl+PfcKit_v1.3\~GUI

2.7.2 DMC System User Guides

The system user guide is the most critical document explaining the system overview, applied theory,

hardware configuration, and incremental build levels. All motor control projects have a user's guide which

includes:

• Motor Types: In this section electromechanical structure of the motor used in the project is introduced

briefly. Synchronous / asynchronous operation, advantages of the particular motor type, the industrial

areas where the motor type fits, etc., are briefly discussed.

24

TMS320C2000 Motor Control Primer SPRUGI6–September 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

• Control Theory: In this section the theory of the motor control is explained both verbally and

mathematically. The philosophy behind the motor control type (e.g., FOC), benefits of the control type,

typical applications, technical background, block diagrams and basic scheme are discussed in this

section.

• System Overview: A brief summary of the DMC modules used in the project, some benchmark

quantities like number of instruction cycles at the modular and system level, the size of the program,

and data memory necessary for each project are given in this section. System features such as

development environment, target controller, switching frequency, ISR source, used peripherals and

mapping, system level drawings and software flow are also given here.