Texas Instruments TMS320*2801 Series, TMS320*280 Series, TMS320*2804 Series Reference Manual

Page 1

TMS320x280x, 2801x, 2804x Boot ROM

Reference Guide

Literature Number: SPRU722C

November 2004 – Revised October 2006

Page 2

2 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 3

Contents

Preface ............................................................................................................................... 7

1 Boot ROM Overview .................................................................................................. 11

1.1 Boot ROM Memory Map.......................................................................................... 12

1.2 On-Chip Boot ROM IQ Math Tables ............................................................................ 13

1.3 CPU Vector Table ................................................................................................. 14

2 Bootloader Features ................................................................................................. 17

2.1 Bootloader Functional Operation ................................................................................ 18

2.2 Bootloader Device Configuration ................................................................................ 19

2.3 PLL Multiplier Selection .......................................................................................... 19

2.4 Watchdog Module ................................................................................................. 19

2.5 Taking an ITRAP Interrupt ....................................................................................... 20

2.6 Internal Pullup Resisters ......................................................................................... 20

2.7 PIE Configuration .................................................................................................. 20

2.8 Reserved Memory ................................................................................................. 20

2.9 Bootloader Modes ................................................................................................. 21

2.10 Bootloader Data Stream Structure .............................................................................. 24

2.11 Basic Transfer Procedure ........................................................................................ 28

2.12 InitBoot Assembly Routine ....................................................................................... 29

2.13 SelectBootMode Function ........................................................................................ 30

2.14 CopyData Function ................................................................................................ 33

2.15 SCI_Boot Function ................................................................................................ 33

2.16 Parallel_Boot Function (GPIO) .................................................................................. 35

2.17 SPI_Boot Function ................................................................................................ 40

2.18 I

2.19 eCAN Boot Function .............................................................................................. 45

2.20 ExitBoot Assembly Routine ...................................................................................... 47

2

C Boot Function .................................................................................................. 42

3 Building the Boot Table ............................................................................................. 49

3.1 The C2000 Hex Utility ............................................................................................ 50

3.2 Example: Preparing a COFF File For eCAN Bootloading ................................................... 51

4 Bootloader Code Overview ........................................................................................ 55

4.1 Boot ROM Version and Checksum Information ............................................................... 56

4.2 Bootloader Code Revision History .............................................................................. 56

4.3 Bootloader Code Listing (V3.0) .................................................................................. 57

4.4 Bootloader Code Listing (V4.0) .................................................................................. 87

A Revision History ....................................................................................................... 93

SPRU722C – November 2004 – Revised October 2006 Contents 3

Submit Documentation Feedback

Page 4

List of Figures

1-1 Memory Map of On-Chip ROM ........................................................................................... 12

1-2 Vector Table Map .......................................................................................................... 14

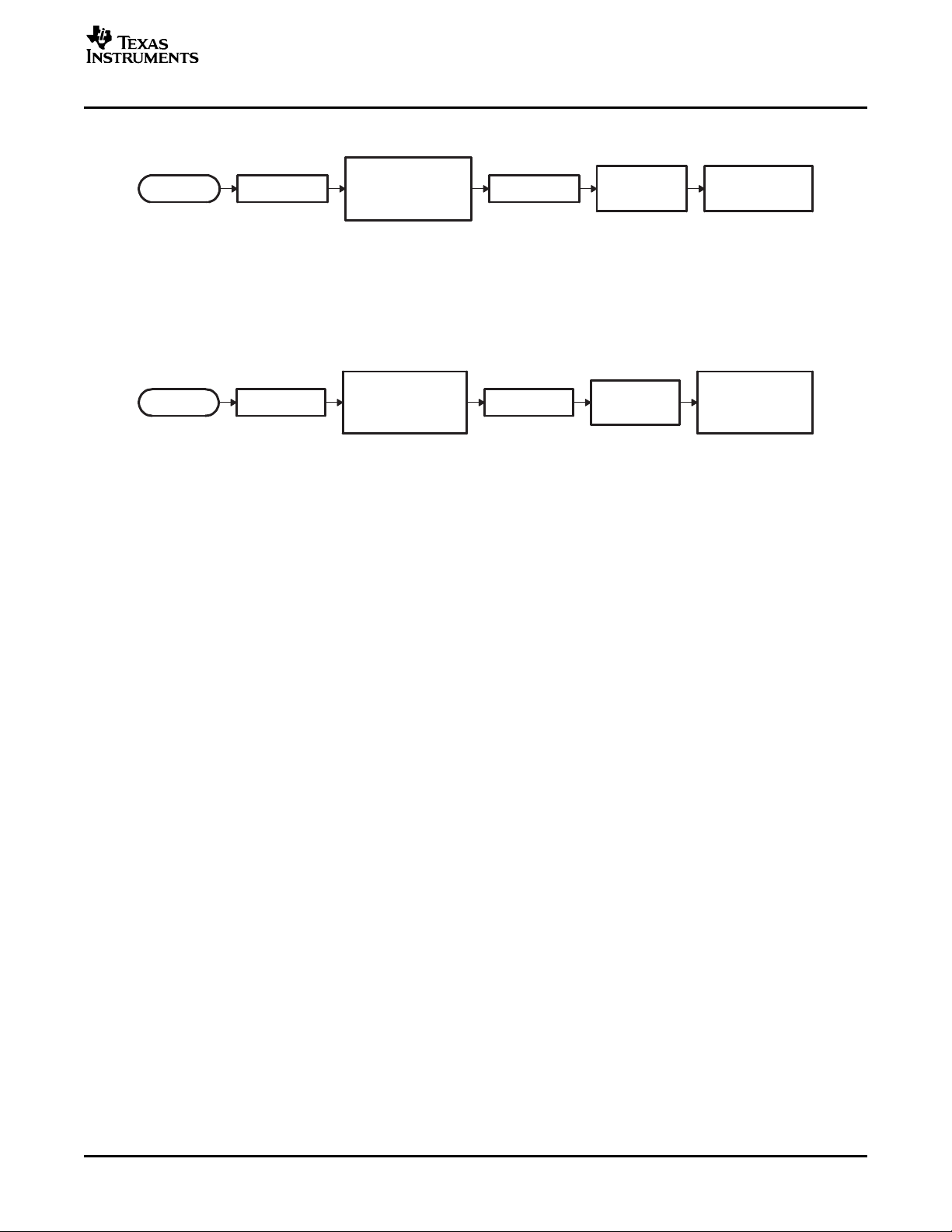

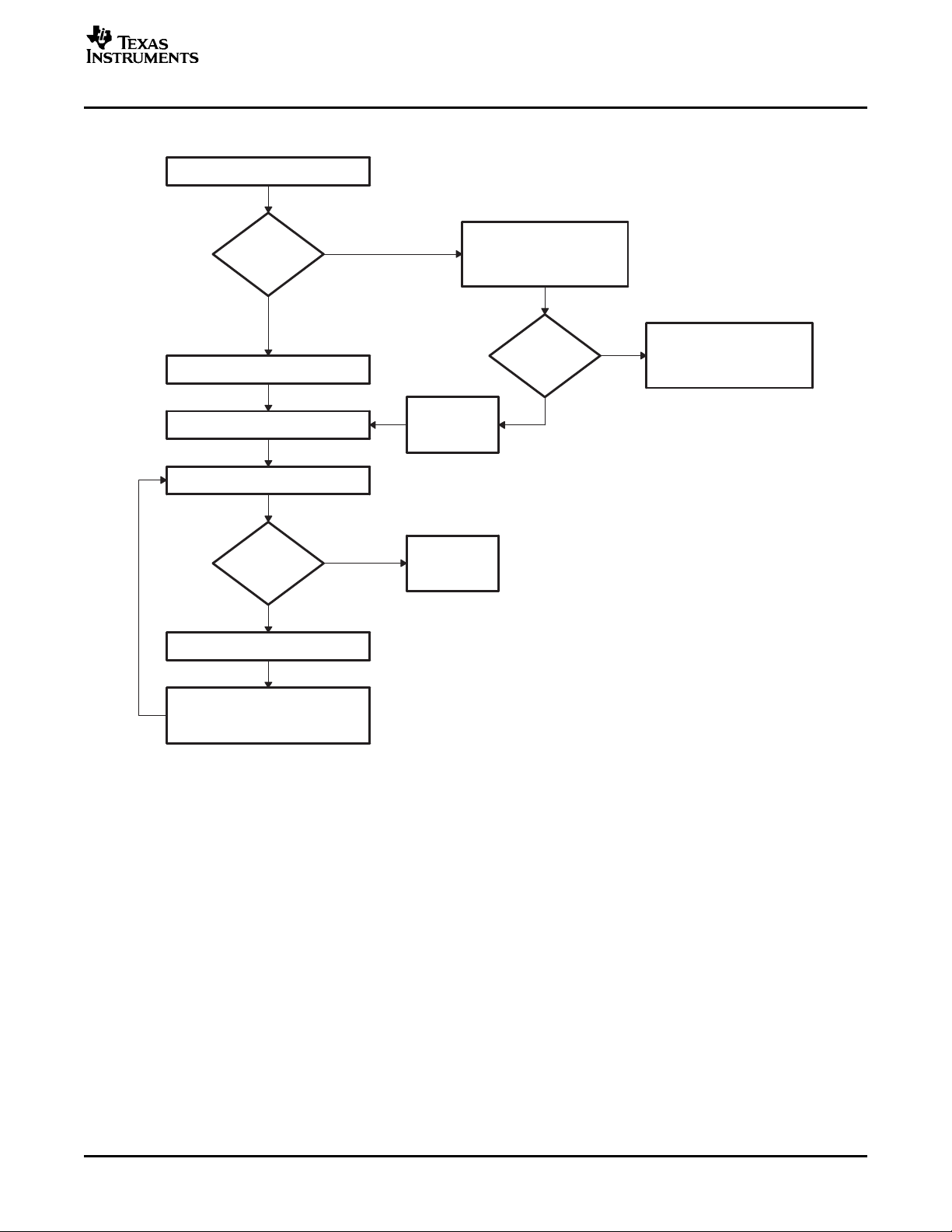

2-1 Bootloader Flow Diagram ................................................................................................. 18

2-2 Boot ROM Function Overview ............................................................................................ 22

2-3 Jump-to-Flash Flow Diagram ............................................................................................. 22

2-4 Flow Diagram of Jump to M0 SARAM ................................................................................... 23

2-5 Flow Diagram of Jump-to-OTP Memory ................................................................................ 23

2-6 Bootloader Basic Transfer Procedure .................................................................................. 29

2-7 Overview of InitBoot Assembly Function ................................................................................ 30

2-8 Overview of the SelectBootMode Function ............................................................................ 32

2-9 Overview of CopyData Function ......................................................................................... 33

2-10 Overview of SCI Bootloader Operation .................................................................................. 33

2-11 Overview of SCI_Boot Function .......................................................................................... 34

2-12 Overview of SCI_GetWordData Function .............................................................................. 35

2-13 Overview of Parallel GPIO bootloader Operation ...................................................................... 35

2-14 Parallel GPIO bootloader Handshake Protocol ........................................................................ 36

2-15 Parallel GPIO Mode Overview ............................................................................................ 36

2-16 Parallel GPIO Mode - Host Transfer Flow .............................................................................. 37

2-17 16-Bit Parallel GetWord Function ........................................................................................ 38

2-18 8-Bit Parallel GetWord Function .......................................................................................... 39

2-19 SPI Loader .................................................................................................................. 40

2-20 Data Transfer From EEPROM Flow ..................................................................................... 41

2-21 Overview of SPIA_GetWordData Function ............................................................................. 42

2-22 EEPROM Device at Address 0x50 ....................................................................................... 42

2-23 Overview of I2C_Boot Function ......................................................................................... 43

2-24 Random Read .............................................................................................................. 44

2-25 Sequential Read ............................................................................................................ 45

2-26 Overview of eCAN-A bootloader Operation ............................................................................. 45

2-27 ExitBoot Procedure Flow .................................................................................................. 47

4 List of Figures SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 5

List of Tables

1-1 Vector Locations ............................................................................................................ 15

2-1 Configuration for Device Modes .......................................................................................... 19

2-2 Boot Mode Selection ....................................................................................................... 21

2-3 General Structure Of Source Program Data Stream In 16-Bit Mode ............................................... 25

2-4 LSB/MSB Loading Sequence in 8-Bit Data Stream ................................................................... 27

2-5 Boot Mode Selection ...................................................................................................... 30

2-6 SPI 8-Bit Data Stream .................................................................................................... 40

2-7 I

2-8 Bit-Rate Values for Different XCLKIN Values .......................................................................... 45

2-9 eCAN 8-Bit Data Stream .................................................................................................. 46

2-10 CPU Register Restored Values .......................................................................................... 48

3-1 Boot-Loader Options ....................................................................................................... 51

4-1 Bootloader Revision and Checksum Information ...................................................................... 56

4-2 Bootloader Revision Per Device.......................................................................................... 56

A-1 Changes for Revision C ................................................................................................... 93

2

C 8-Bit Data Stream ..................................................................................................... 44

SPRU722C – November 2004 – Revised October 2006 List of Tables 5

Submit Documentation Feedback

Page 6

List of Tables6 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 7

Preface

SPRU722C – November 2004 – Revised October 2006

Read This First

This reference guide is applicable for the code and data stored in the on-chip boot

ROM on the TMS320x280x, TMS320x2801x and TMS320x2804x processors. This

includes all flash-based, ROM-based, and RAM-based devices within these families.

The boot ROM is factory programmed with boot-loading software. Boot-mode signals

(general purpose I/Os) are used to tell the bootloader software which mode to use on

power up. The boot ROM also contains standard math tables, such as SIN/COS

waveforms, for use in IQ math related algorithms found in the C28x™ IQMath Library -

A Virtual Floating Point Engine (literature number SPRC087).

This guide describes the purpose and features of the bootloader. It also describes other

contents of the device on-chip boot ROM and identifies where all of the information is

located within that memory.

Notational Conventions

This document uses the following conventions.

• Hexadecimal numbers are shown with the suffix h or with a leading 0x. For example, the following

number is 40 hexadecimal (decimal 64): 40h or 0x40.

• Registers in this document are shown in figures and described in tables.

– Each register figure shows a rectangle divided into fields that represent the fields of the register.

Each field is labeled with its bit name, its beginning and ending bit numbers above, and its

read/write properties below. A legend explains the notation used for the properties.

– Reserved bits in a register figure designate a bit that is used for future device expansion.

Related Documentation From Texas Instruments

The following documents describe the related devices and related support tools. Copies of these

documents are available on the Internet at www.ti.com. Tip: Enter the literature number in the search box

provided at www.ti.com .

Data Manuals —

SPRS230: — TMS320F2809, F2808, F2806, F2802, F2801, F2801x UCD9501, C2802, C2801 DSPs

Data Manual contains the pinout, signal descriptions, as well as electrical and timing specifications

for the F280x devices.

SPRS357: — TMS320F28044 Digital Signal Processor Data Manual contains the pinout, signal

descriptions, as well as electrical and timing specifications for the F28044 device.

User's Guides —

SPRU051: — TMS320x28xx, 28xxx Serial Communication Interface (SCI) Reference Guide describes the

SCI, which is a two-wire asynchronous serial port, commonly known as a UART. The SCI modules

support digital communications between the CPU and other asynchronous peripherals that use the

standard non-return-to-zero (NRZ) format.

SPRU059: — TMS320x28xx, 28xxx Serial Peripheral Interface (SPI) Reference Guide describes the SPI -

a high-speed synchronous serial input/output (I/O) port - that allows a serial bit stream of

programmed length (one to sixteen bits) to be shifted into and out of the device at a programmed

bit-transfer rate.

SPRU722C – November 2004 – Revised October 2006 Read This First 7

Submit Documentation Feedback

Page 8

www.ti.com

Related Documentation From Texas Instruments

SPRU074: — TMS320x28xx, 28xxx Enhanced Controller Area Network (eCAN) Reference Guide

describes the eCAN that uses established protocol to communicate serially with other controllers in

electrically noisy environments.

SPRU430: — TMS320C28x DSP CPU and Instruction Set Reference Guide describes the central

processing unit (CPU) and the assembly language instructions of the TMS320C28x fixed-point

digital signal processors (DSPs). It also describes emulation features available on these DSPs.

SPRU513: — TMS320C28x Assembly Language Tools User's Guide describes the assembly language

tools (assembler and other tools used to develop assembly language code), assembler directives,

macros, common object file format, and symbolic debugging directives for the TMS320C28x device.

SPRU514: — TMS320C28x Optimizing C Compiler User's Guide describes the TMS320C28x™ C/C++

compiler. This compiler accepts ANSI standard C/C++ source code and produces TMS320 DSP

assembly language source code for the TMS320C28x device.

SPRU566: — TMS320x28xx, 28xxx Peripheral Reference Guide describes the peripheral reference

guides of the 28x digital signal processors (DSPs).

SPRU608: — The TMS320C28x Instruction Set Simulator Technical Overview describes the simulator,

available within the Code Composer Studio for TMS320C2000 IDE, that simulates the instruction

set of the C28x™ core.

SPRU625: — TMS320C28x DSP/BIOS Application Programming Interface (API) Reference Guide

describes development using DSP/BIOS.

SPRU712: — TMS320x28xx, 28xxx System Control and Interrupts Reference Guide describes the

various interrupts and system control features of the 280x digital signal processors (DSPs).

SPRU716: — TMS320x280x, 2801x, 2804x Analog-to-Digital Converter (ADC) Reference Guide

describes how to configure and use the on-chip ADC module, which is a 12-bit pipelined ADC.

SPRU721: — TMS320x28xx, 28xxx Inter-Integrated Circuit (I2C) Reference Guide describes the features

and operation of the inter-integrated circuit (I2C) module that is available on the TMS320x280x

digital signal processor (DSP).

SPRU790: — TMS320x28xx, 28xxx Enhanced Quadrature Encoder Pulse (eQEP) Reference Guide

describes the eQEP module, which is used for interfacing with a linear or rotary incremental

encoder to get position, direction, and speed information from a rotating machine in high

performance motion and position control systems. It includes the module description and registers

SPRU791: — TMS320x28xx, 28xxx Enhanced Pulse Width Modulator (ePWM) Module Reference Guide

describes the main areas of the enhanced pulse width modulator that include digital motor control,

switch mode power supply control, UPS (uninterruptible power supplies), and other forms of power

conversion

SPRU807: — TMS320x28xx, 28xxx Enhanced Capture (eCAP) Module Reference Guide describes the

enhanced capture module. It includes the module description and registers.

SPRU924: — TMS320x28xx, 28xxx High-Resolution Pulse Width Modulator (HRPWM) describes the

operation of the high-resolution extension to the pulse width modulator (HRPWM)

Application Reports —

SPRAA58: — TMS320x281x to TMS320x280x Migration Overview describes differences between the

Texas Instruments TMS320x281x and TMS320x280x DSPs to assist in application migration from

the 281x to the 280x. While the main focus of this document is migration from 281x to 280x, users

considering migrating in the reverse direction (280x to 281x) will also find this document useful.

SPRA550: — 3.3 V DSP for Digital Motor Control describes a scenario of a 3.3-V-only motor controller

indicating that for most applications, no significant issue of interfacing between 3.3 V and 5 V

exists. On-chip 3.3-V analog-to-digital converter (ADC) versus 5-V ADC is also discussed.

Guidelines for component layout and printed circuit board (PCB) design that can reduce system

noise and EMI effects are summarized.

8 Read This First SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 9

www.ti.com

Related Documentation From Texas Instruments

SPRA820: — Online Stack Overflow Detection on the TMS320C28x DSP presents the methodology for

online stack overflow detection on the TMS320C28x™ DSP. C-source code is provided that

contains functions for implementing the overflow detection on both DSP/BIOS™ and

non-DSP/BIOS applications.

SPRA861: — RAMDISK: A Sample User-Defined C I/O Driver provides an easy way to use the

sophisticated buffering of the high-level CIO functions on an arbitrary device. This application report

presents a sample implementation of a user-defined device driver.

SPRA873: — Thermo-Electric Cooler Control Using a TMS320F2812 DSP & DRV592 Power Amplifier

presents a thermoelectric cooler system consisting of a Texas Instruments TMS320F2812 digital

signal processor (DSP) and DRV592 power amplifier. The DSP implements a digital

proportional-integral-derivative feedback controller using an integrated 12-bit analog-to-digital

converter to read the thermistor, and direct output of pulse-width-modulated waveforms to the

H-bridge DRV592 power amplifier. A complete description of the experimental system, along with

software and software operating instructions, is provided.

SPRA876: — Programming Examples for the TMS320F281x eCAN contains several programming

examples to illustrate how the eCAN module is set up for different modes of operation to help you

come up to speed quickly in programming the eCAN. All projects and CANalyzer configuration files

are included in the attached SPRA876.zip file.

SPRA953: — IC Package Thermal Metrics describes the traditional and new thermal metrics and will put

their application in perspective with respect to system level junction temperature estimation.

SPRA958: — Running an Application from Internal Flash Memory on the TMS320F281x DSP (Rev. B)

covers the requirements needed to properly configure application software for execution from

on-chip flash memory. Requirements for both DSP/BIOS™ and non-DSP/BIOS projects are

presented. Example code projects are included.

SPRA963: — Reliability Data for TMS320LF24x and TMS320F281x Devices describes reliability data for

TMS320LF24x and TMS320F281x devices.

SPRA989: — F2810, F2811, and F2812 ADC Calibration describes a method for improving the absolute

accuracy of the 12-bit analog-to-digital converter (ADC) found on the F2810/F2811/F2812 devices.

This application note is accompanied by an example program (ADCcalibration.zip) that executes

from RAM on the F2812 eZdsp.

SPRA991: — Simulation Fulfills its Promise for Enhancing Debug and Analysis - A White Paper describes

simulation enhancements that enable developers to speed up the development cycle by allowing

them to evaluate system alternatives more effectively.

SPRU722C – November 2004 – Revised October 2006 Read This First 9

Submit Documentation Feedback

Page 10

www.ti.com

Related Documentation From Texas Instruments

Read This First10 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 11

SPRU722C – November 2004 – Revised October 2006

Boot ROM Overview

The boot ROM is a block of read-only memory that is factory programmed.

Topic .................................................................................................. Page

1.1 Boot ROM Memory Map ............................................................. 12

1.2 On-Chip Boot ROM IQ Math Tables ............................................. 13

1.3 CPU Vector Table ...................................................................... 14

Chapter 1

SPRU722C – November 2004 – Revised October 2006 Boot ROM Overview 11

Submit Documentation Feedback

Page 12

www.ti.com

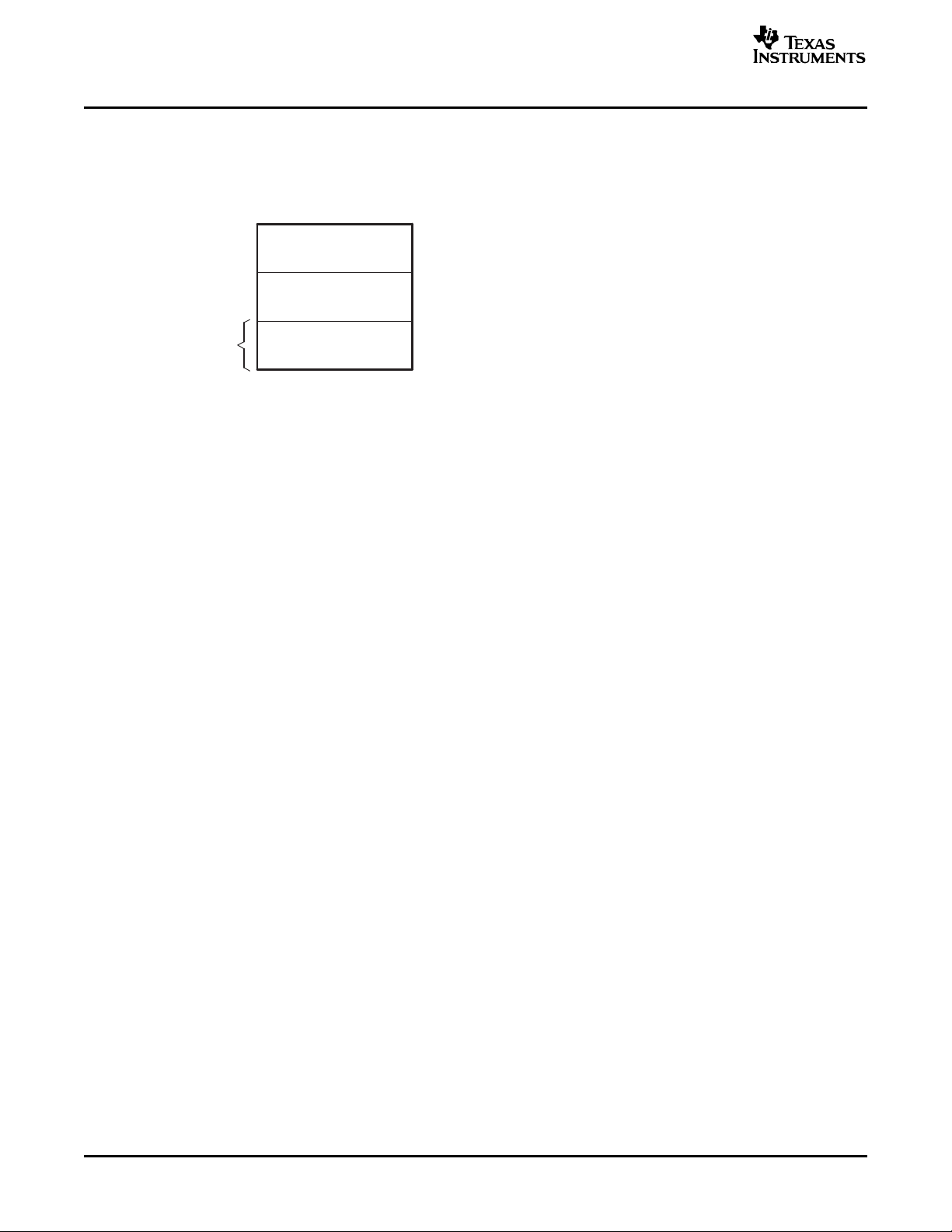

Sin/Cos

(644 x 16)

Data space Prog space

Normalized inverse

(528 x 16)

Normalized square root

(274 x 16)

Normalized Arctan

(452 x 16)

(360 x 16)

Rounding and saturation

Bootloader functions

ROM version

ROM checksum

Reset vector

CPU vector table

(64 x 16)

On-chip boot ROM

Section start

address

0x3F F000

0x3F F502

0x3F F712

0x3F F9E8

0x3F FB50

0x3F F834

0x3F FFC0

0x3F FFFF

Boot ROM Memory Map

1.1 Boot ROM Memory Map

The boot ROM is a 4K x 16 block of read-only memory located at addresses 0x3F F000 - 0x3F FFF.

The on-chip boot ROM is factory programmed with boot-load routines and math tables for use with the

C28x™ IQMath Library - A Virtual Floating Point Engine (literature number SPRC087). Chapter 4 contains

the code for each of the following items:

• Bootloader functions

• Version number, release date and checksum

• Reset vector

• CPU vector table (Used for test purposes only)

• IQmath Tables

Figure 1-1 shows the memory map of the on-chip boot ROM. The memory block is 4Kx16 in size and is

located at 0x3F F000 - 0x3F FFFF in both program and data space.

Figure 1-1. Memory Map of On-Chip ROM

Boot ROM Overview12 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 13

www.ti.com

1.2 On-Chip Boot ROM IQ Math Tables

3K x 16 words of the boot ROM memory is reserved for IQ math tables. These math tables are provided

to help improve performance and save RAM space.

The math tables included in the boot ROM are used by the Texas Instruments™ C28x™ IQMath Library -

A Virtual Floating Point Engine (literature number SPRC087). The 28x IQmath Library is a collection of

highly optimized and high precision mathematical functions for C/C++ programmers to seamlessly port a

floating-point algorithm into fixed-point code on TMS320C28x devices.

These routines are typically used in computational-intensive real-time applications where optimal

execution speed and high accuracy is critical. By using these routines you can achieve execution speeds

that are considerably faster than equivalent code written in standard ANSI C language. In addition, by

providing ready-to-use high precision functions, the TI IQmath Library can shorten significantly your DSP

application development time. The C28x™ IQMath Library - A Virtual Floating Point Engine (literature

number SPRC087) can be downloaded from the TI website.

The following math tables are included in the Boot ROM:

• Sine/Cosine Table

– Table size: 1282 words

– Q format: Q30

– Contents: 32-bit samples for one and a quarter period sine wave

This is useful for accurate sine wave generation and 32-bit FFTs. This can also be used for 16-bit

math, just skip over every second value.

• Normalized Inverse Table

– Table size: 528 words

– Q format: Q29

– Contents: 32-bit normalized inverse samples plus saturation limits

This table is used as an initial estimate in the Newton-Raphson inverse algorithm. By using a more

accurate estimate the convergence is quicker and hence cycle time is faster.

• Normalized Square Root Table

– Table size: 274 words

– Q format: Q30

– Contents: 32-bit normalized inverse square root samples plus saturation

This table is used as an initial estimate in the Newton-Raphson square-root algorithm. By using a more

accurate estimate the convergence is quicker and hence cycle time is faster.

• Normalized Arctan Table

– Table size: 452 words

– Q format: Q30

– Contents 32-bit second order coefficients for line of best fit plus normalization table

This table is used as an initial estimate in the Arctan iterative algorithm. By using a more accurate

estimate the convergence is quicker and hence cycle time is faster.

• Rounding and Saturation Table

– Table size: 360 words

– Q format: Q30

– Contents: 32-bit rounding and saturation limits for various Q values

On-Chip Boot ROM IQ Math Tables

SPRU722C – November 2004 – Revised October 2006 Boot ROM Overview 13

Submit Documentation Feedback

Page 14

www.ti.com

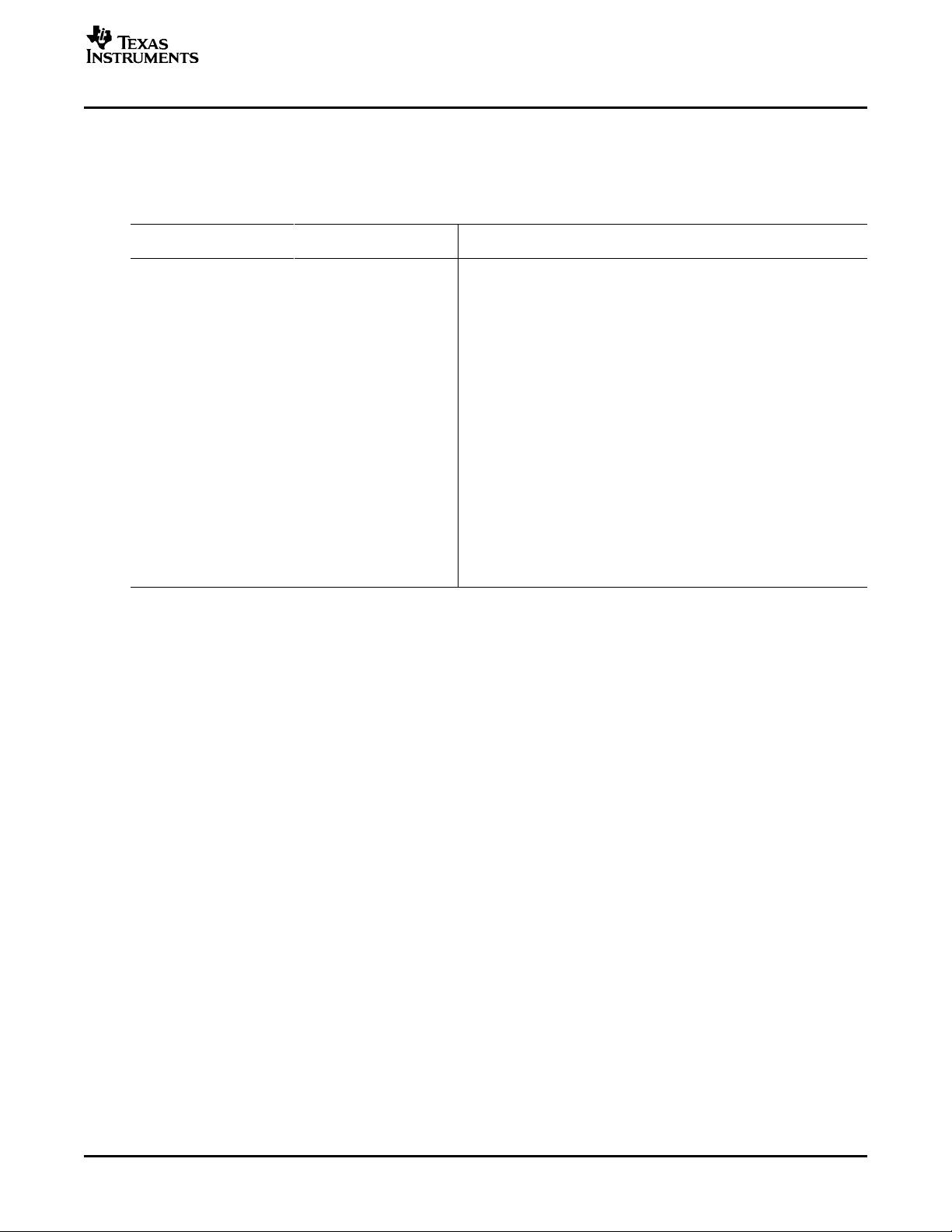

Math tables

and functions

Bootloader

functions

Reset vector

CPU vector table

64 x 16

0x3F F000

0x3F FB50

0x3F FFFF

0x3F FFC0

Reset fetched from here when

VMAP=1

Other vectors fetched from here when

VMAP=1, ENPIE=0

CPU Vector Table

1.3 CPU Vector Table

A CPU vector table resides in boot ROM memory from address 0x3F FFC0 - 0x3F FFFF. This vector table

is active after reset when VMAP = 1, ENPIE = 0 (PIE vector table disabled).

Figure 1-2. Vector Table Map

A The VMAP bit is located in Status Register 1 (ST1). VMAP is always 1 on reset. It can be changed after reset by

software, however the normal operating mode will be to leave VMAP = 1.

B The ENPIE bit is located in the PIECTRL register. The default state of this bit at reset is 0, which disables the

Peripheral Interrupt Expansion block (PIE).

The only vector that will normally be handled from the internal boot ROM memory is the reset vector

located at 0x3F FFC0. The reset vector is factory programmed to point to the InitBoot function stored in

the boot ROM. This function starts the boot load process. A series of checking operations is performed on

General Purpose I/O (GPIO I/O) pins to determine which boot mode to use. This boot mode selection is

described in Section 2.9 of this document.

The remaining vectors in the boot ROM are not used during normal operation. After the boot process is

complete, you should initialize the Peripheral Interrupt Expansion (PIE) vector table and enable the PIE

block. From that point on, all vectors, except reset, will be fetched from the PIE module and not the CPU

vector table shown in Table 1-1 .

14 Boot ROM Overview SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 15

www.ti.com

CPU Vector Table

For TI silicon debug and test purposes the vectors located in the boot ROM memory point to locations in

the M0 SARAM block as described in Table 1-1 . During silicon debug, you can program the specified

locations in M0 with branch instructions to catch any vectors fetched from boot ROM. This is not required

for normal device operation.

Table 1-1. Vector Locations

Vector Boot ROM (i.e., points to) Vector Boot ROM (i.e., points to)

RESET 0x3F FFC0 InitBoot (0x3F FB50) RTOSINT 0x3F FFE0 0x00 0060

INT1 0x3F FFC2 0x00 0042 Reserved 0x3F FFE2 0x00 0062

INT2 0x3F FFC4 0x00 0044 NMI 0x3F FFE4 0x00 0064

INT3 0x3F FFC6 0x00 0046 ILLEGAL

INT4 0x3F FFC8 0x00 0048 USER1 0x3F FFE8 0x00 0068

INT5 0x3F FFCA 0x00 004A USER2 0x3F FFEA 0x00 006A

INT6 0x3F FFCC 0x00 004C USER3 0x3F FFEC 0x00 006C

INT7 0x3F FFCE 0x00 004E USER4 0x3F FFEE 0x00 006E

INT8 0x3F FFD0 0x00 0050 USER5 0x3F FFF0 0x00 0070

INT9 0x3F FFD2 0x00 0052 USER6 0x3F FFF2 0x00 0072

INT10 0x3F FFD4 0x00 0054 USER7 0x3F FFF4 0x00 0074

INT11 0x3F FFD6 0x00 0056 USER8 0x3F FFF6 0x00 0076

INT12 0x3F FFD8 0x00 0058 USER9 0x3F FFF8 0x00 0078

INT13 0x3F FFDA 0x00 005A USER10 0x3F FFFA 0x00 007A

INT14 0x3F FFDC 0x00 005C USER11 0x3F FFFC 0x00 007C

DLOGINT 0x3F FFDE 0x00 005E USER12 0x3F FFFE 0x00 007E

Location in Contents Location in Contents

(1)

0x3F FFE6 0x00 0066 or ITRAPIsr

(1)

As of version 4 of the boot ROM code, this vector points to a ITRAP interrupt service routine, ITRAPIsr(), within the boot ROM.

This ISR attempts to enable the watchdog and loops until the watchdog resets the part. On previous revisions, this vector points

to location 0x66 in M0 SARAM. Refer to Section 4.1 to determine the version of the boot ROM code on a particular device.

SPRU722C – November 2004 – Revised October 2006 Boot ROM Overview 15

Submit Documentation Feedback

Page 16

www.ti.com

CPU Vector Table

Boot ROM Overview16 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 17

SPRU722C – November 2004 – Revised October 2006

Bootloader Features

This section describes in detail the boot mode selection process, as well as the

specifics of the bootloader operation.

Topic .................................................................................................. Page

2.1 Bootloader Functional Operation ................................................ 18

2.2 Bootloader Device Configuration ................................................ 19

2.3 PLL Multiplier Selection ............................................................. 19

2.4 Watchdog Module ..................................................................... 19

2.5 Taking an ITRAP Interrupt .......................................................... 20

2.6 Internal Pullup Resisters ............................................................ 20

2.7 PIE Configuration ...................................................................... 20

2.8 Reserved Memory ..................................................................... 20

2.9 Bootloader Modes ..................................................................... 21

2.10 Bootloader Data Stream Structure ............................................... 24

2.11 Basic Transfer Procedure .......................................................... 28

2.12 InitBoot Assembly Routine ......................................................... 29

2.13 SelectBootMode Function .......................................................... 30

2.14 CopyData Function.................................................................... 33

2.15 SCI_Boot Function .................................................................... 33

2.16 Parallel_Boot Function (GPIO) .................................................... 35

2.17 SPI_Boot Function .................................................................... 40

2.18 I

2.19 eCAN Boot Function .................................................................. 45

2.20 ExitBoot Assembly Routine ........................................................ 47

2

C Boot Function ...................................................................... 42

Chapter 2

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 17

Submit Documentation Feedback

Page 18

www.ti.com

Boot ROM

Reset vector fetched from boot ROM

address 0x3F FFC0

Jump to InitBoot function to start

boot process

Boot determined by the state of I/O pins

SelectBootMode function

Begin execution at Entry Point as

determined by selected boot mode

PIE disabled (ENPIE−0)

VMAP=1

OBJMODE=0

AMODE=0

MOM1MAP=1

Reset

(power-on reset or warm reset)

Silicon sets the following:

Bootloader Functional Operation

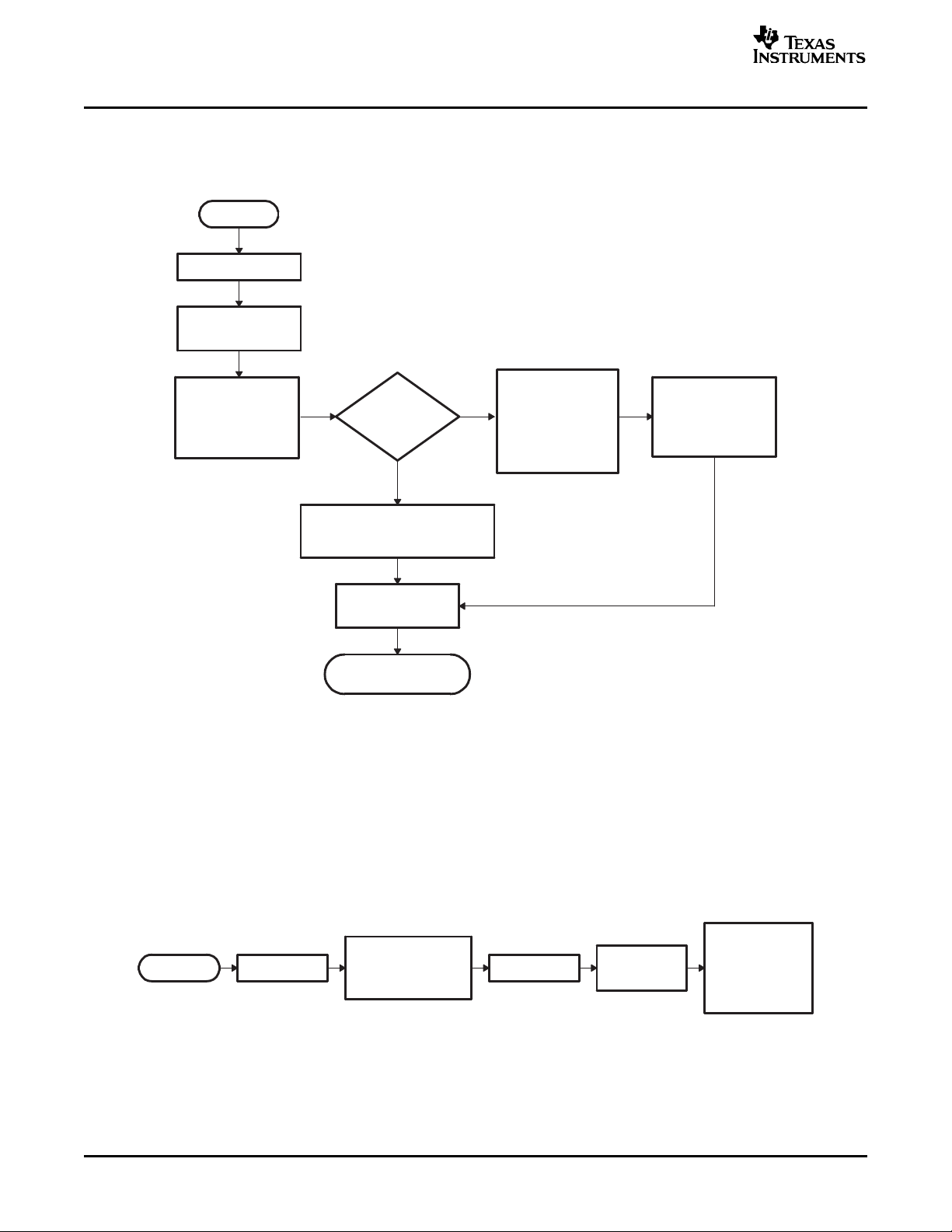

2.1 Bootloader Functional Operation

The bootloader is the program located in the on-chip boot ROM that is executed following a reset.

The bootloader is used to transfer code from an external source into internal memory following power up.

This allows code to reside in slow non-volatile memory externally, and be transferred to high-speed

memory to be executed.

The bootloader provides a variety of different ways to download code to accommodate different system

requirements. The bootloader uses various GPIO signals to determine which boot mode to use. The boot

mode selection process as well as the specifics of each bootloader are described in the remainder of this

document. Figure 2-1 shows the basic bootloader flow.

Figure 2-1. Bootloader Flow Diagram

The reset vector in boot ROM redirects program execution to the InitBoot function. After performing device

initialization the bootloader will check the state of GPIO pins to determine which boot mode you want to

execute. Options include: jump to flash, jump to SARAM, jump to OTP, or call one of the on-chip boot

loading routines.

After the selection process and if the required boot loading is complete, the processor will continue

execution at an entry point determined by the boot mode selected. If a bootloader was called, then the

input stream loaded by the peripheral determines this entry address. This data stream is described in

Section 2.10 . If, instead, you choose to boot directly to flash, OTP, or SARAM, the entry address is

predefined for each of these memory blocks.

The following sections discuss in detail the different boot modes available and the process used for

loading data code into the device.

Bootloader Features18 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 19

www.ti.com

2.2 Bootloader Device Configuration

At reset, any 28x™ CPU-based device is in 27x™ object-compatible mode. It is up to the application to

place the device in the proper operating mode before execution proceeds.

On the 28x devices, when booting from the internal boot ROM, the device is configured for 28x operating

mode by the boot ROM software. You are responsible for any additional configuration required.

For example, if your application includes C2xLP™ source, then you are responsible for configuring the

device for C2xLP source compatibility prior to execution of code generated from C2xLP source.

The configuration required for each operating mode is summarized in Table 2-1 .

Bootloader Device Configuration

Table 2-1. Configuration for Device Modes

C27x Mode (Reset) 28x Mode Compatible Mode

OBJMODE 0 1 1

AMODE 0 0 1

PAGE0 0 0 0

M0M1MAP

Other Settings SXM = 1, C = 1, SPM = 0

(1)

(1)

Normally for C27x compatibility, the M0M1MAP would be 0. On these devices, however, it is tied off

high internally; therefore, at reset, M0M1MAP is always configured for 28x mode.

1 1 1

C2xLP Source

2.3 PLL Multiplier Selection

The boot ROM does not change the state of the PLL. Note that the PLL multiplier is not affected by a

reset from the debugger. Therefore, a boot that is initialized from a reset from Code Composer Studio™

may be at a different speed than booting by pulling the external reset line ( XRS) low.

2.4 Watchdog Module

When branching directly to flash, M0 single-access RAM (SARAM), or one-time-programmable (OTP)

memory, the watchdog is not touched. In the other boot modes, the watchdog is disabled before booting

and then re-enabled and cleared before branching to the final destination address.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 19

Submit Documentation Feedback

Page 20

www.ti.com

Taking an ITRAP Interrupt

2.5 Taking an ITRAP Interrupt

If an illegal opcode is fetched, the 28x will take an ITRAP (illegal trap) interrupt. During the boot process,

the interrupt vector used by the ITRAP is within the CPU vector table of the boot ROM. As of version 4 of

the boot ROM code, the ITRAP vector points to an interrupt service routine (ISR) within the boot ROM

named ITRAPIsr(). This interrupt service routine attempts to enable the watchdog and then loops forever

until the processor is reset. This ISR will be used for any ITRAP until the user's application initializes and

enables the peripheral interrupt expansion (PIE) block. Once the PIE is enabled, the ITRAP vector located

within the PIE vector table will be used. Prior to boot ROM code version 4, the ITRAP interrupt vector in

the CPU vector table pointed to a RAM location in M0 memory. Refer to Section 4.1 to determine the boot

ROM code version of a particular device.

2.6 Internal Pullup Resisters

Each GPIO pin has an internal pullup resistor that can be enabled or disabled in software. The pins that

are read by the boot mode selection code to determine the boot mode selection have pull-ups enabled

after reset by default. In noisy conditions it is still recommended that you configure each of the three boot

mode selection pins externally.

The individual bootloaders SCI, SPI, eCAN, and parallel boot all enable the pullup resistors for the pins

that are used for control and data transfer. The bootloader leaves the resistors enabled for these pins

when it exits. For example, the SCI-A bootloader enables the pullup resistors on the SCITXA and SCIRXA

pins. It is your responsibility to disable them, if desired, after the bootloader exits.

2.7 PIE Configuration

The boot modes do not enable the PIE. It is left in its default state, which is disabled.

2.8 Reserved Memory

The first 80 words of the M1 memory block (address 0x400 - 0x44F) are reserved for the stack and .ebss

code sections during the boot-load process. If code is bootloaded into this region there is no error

checking to prevent it from corrupting the boot ROM stack.

Bootloader Features20 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 21

www.ti.com

2.9 Bootloader Modes

To accommodate different system requirements, the boot ROM offers a variety of different boot modes.

This section describes the different boot modes and gives brief summary of their functional operation. The

states of three GPIO pins are used to determine the desired boot mode as shown in Table 2-2 .

Boot to Flash

SCI-A Boot Load a data stream from SCI-A. 1 1 0

SPI-A Boot Load from an external serial SPI EEPROM on SPI-A. 1 0 1

I2C Boot Load data from an external EEPROM at address 0x50 on the 1 0 0

eCAN-A Boot

Boot to M0 SARAM

Boot to OTP

Parallel I/O Boot Load data from GPIO0 - GPIO15. 0 0 0

(1)

You must take extra care because of any effect toggling SPICLKA to select a boot mode may have on external logic.

(2)

When booting directly to flash, it is assumed that you have previously programmed a branch statement at 0x3F 7FF6 to redirect

program flow as desired.

(3)

On devices that do not have an eCAN-A module this configuration is reserved. If it is selected, then the eCAN-A bootloader will

run and will loop forever waiting for an incoming message.

(4)

When booting directly to OTP or M0 SARAM, it is assumed that you have previously programmed or loaded code starting at the

entry point location.

Bootloader Modes

Table 2-2. Boot Mode Selection

Mode Description GPIO18 GPIO29 GPIO34

SPICLKA

SCITXDB

(2)

Jump to flash address 0x3F 7FF6. You must have programmed 1 1 1

a branch instruction here prior to reset to redirect code

execution as desired.

I2C bus.

(3)

(4)

Call CAN_Boot to load from eCAN-A mailbox 1. 0 1 1

(4)

Jump to M0 SARAM address 0x00 0000. 0 1 0

Jump to OTP address 0x3D 7800. 0 0 1

(1)

SCITXDA

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 21

Submit Documentation Feedback

Page 22

www.ti.com

Reset

InitBoot

Call

SelectBootMode

Read the state

of I/O pins to

determine what

boot mode is

desired

Call

Boot Loader

?

No

Yes

EntryPoint determined

directly from state of

I/O pins

Call

boot loader,

SCI, SPI,

I2C, eCAN, or

parallel I/O

EntryPoint

and load

data/code

Read

Call

ExitBoot

Begin execution

at EntryPoint

Reset InitBoot

SelectBootMode

Select jump

to flash

ExitBoot

Jump to

0x3F 7FF6

User

programmed

branch to

desired

location

Bootloader Modes

Figure 2-2 shows an overview of the boot process. Each step is described in greater detail in following

sections.

Figure 2-2. Boot ROM Function Overview

The following boot modes do not call a bootloader. Instead, they jump to a predefined location in memory:

• Jump to branch instruction in flash memory

• Jump to M0 SARAM

22 Bootloader Features SPRU722C – November 2004 – Revised October 2006

In this mode, the boot ROM software will configure the device for 28x operation and then branch

directly to location 0x3F 7FF6 in flash memory. This location is just before the 128-bit code security

module (CSM) password locations. You are required to have previously programmed a branch

instruction at location 0x3F 7FF6 that will redirect code execution to either a custom boot-loader or the

application code.

On RAM-only devices, the boot-to-flash option jumps to reserved memory and should not be used. On

ROM-only devices, the boot-to-flash option jumps to the location 0x3F7FF6 in ROM.

Figure 2-3. Jump-to-Flash Flow Diagram

In this mode, the boot ROM software will configure the device for 28x operation and then branch

directly to 0x00 0000; the first address in the M0 SARAM memory block

Submit Documentation Feedback

Page 23

www.ti.com

Reset InitBoot

SelectBootMode

Select jump

to M0 SARAM

ExitBoot

Jump to

0x00 0000

Execution

continues

Reset InitBoot

SelectBootMode

Select jump

to OTP

ExitBoot

Jump to

0x3D 7800

Execute

preprogrammed

OTP code

Bootloader Modes

Figure 2-4. Flow Diagram of Jump to M0 SARAM

• Jump to OTP memory

In this mode, the boot ROM software will configure the device for 28x operation and then branch

directly to at 0x3D 7800; the first address in the OTP memory block.

On ROM devices, the boot-to-OTP option jumps to address 0x3D 7800 in ROM. On RAM devices, the

boot-to-OTP option jumps to reserved memory and should not be used.

Figure 2-5. Flow Diagram of Jump-to-OTP Memory

The following boot modes call a boot load routine that loads a data stream from the peripheral into

memory:

• Standard serial boot mode (SCI-A)

In this mode, the boot ROM will load code to be executed into on-chip memory via the SCI-A port.

• SPI EEPROM boot mode (SPI-A)

In this mode, the boot ROM will load code and data into on-chip memory from an external EEPROM

via the SPI-A port.

• I2C-A boot mode (I2C-A)

In this mode, the boot ROM will load code and data into on-chip memory from an external EEPROM at

address 0x50 on the I2C-A bus. The EEPROM must adhere to conventional I2C EEPROM protocol with

a 16-bit base address architecture.

• eCAN Boot Mode (eCAN-A)

In this mode, the eCAN-A peripheral is used to transfer data and code into the on-chip memory using

eCAN-A mailbox 1. The transfer is an 8-bit data stream with two 8-bit values being transferred during

each communication. On devices that do not have an eCAN-A peripheral, this mode is reserved and

should not be used.

• Boot from GPIO Port (Parallel Boot from GPIO0-GPIO15)

In this mode, the boot ROM uses GPIO port A pins GPIO0-GPIO15 to load code and data from an

external source. This mode supports both 8-bit and 16-bit data streams. Since this mode requires a

number of GPIO pins, it is typically used to download code for flash programming when the device is

connected to a platform explicitly for flash programming and not a target board.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 23

Submit Documentation Feedback

Page 24

www.ti.com

Bootloader Data Stream Structure

2.10 Bootloader Data Stream Structure

The following two tables and associated examples show the structure of the data stream incoming to the

bootloader. The basic structure is the same for all the bootloaders and is based on the C54x source data

stream generated by the C54x hex utility. The C28x hex utility (hex2000.exe) has been updated to support

this structure. The hex2000.exe utility is included with the C2000 code generation tools. All values in the

data stream structure are in hex.

The first 16-bit word in the data stream is known as the key value. The key value is used to tell the

bootloader the width of the incoming stream: 8 or 16 bits. Note that not all bootloaders will accept both 8

and 16-bit streams. Please refer to the detailed information on each loader for the valid data stream width.

For an 8-bit data stream, the key value is 0x08AA and for a 16-bit stream it is 0x10AA. If a bootloader

receives an invalid key value, then the load is aborted. In this case, the entry point for the flash memory

(0x3F 7FF6) will be used.

The next 8 words are used to initialize register values or otherwise enhance the bootloader by passing

values to it. If a bootloader does not use these values then they are reserved for future use and the

bootloader simply reads the value and then discards it. Currently only the SPI and I2C bootloaders use

these words to initialize registers.

The tenth and eleventh words comprise the 22-bit entry point address. This address is used to initialize

the PC after the boot load is complete. This address is most likely the entry point of the program

downloaded by the bootloader.

The twelfth word in the data stream is the size of the first data block to be transferred. The size of the

block is defined for both 8-bit and 16-bit data stream formats as the number of 16-bit words in the block.

For example, to transfer a block of 20 8-bit data values from an 8-bit data stream, the block size would be

0x000A to indicate 10 16-bit words.

The next two words tell the loader the destination address of the block of data. Following the size and

address will be the 16-bit words that makeup that block of data.

This pattern of block size/destination address repeats for each block of data to be transferred. Once all the

blocks have been transferred, a block size of 0x0000 signals to the loader that the transfer is complete. At

this point the loader will return the entry point address to the calling routine which in turn will cleanup and

exit. Execution will then continue at the entry point address as determined by the input data stream

contents.

Bootloader Features24 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 25

www.ti.com

Bootloader Data Stream Structure

Table 2-3. General Structure Of Source Program Data Stream In 16-Bit Mode

Word Contents

1 10AA (KeyValue for memory width = 16bits)

2 Register initialization value or reserved for future use

3 Register initialization value or reserved for future use

4 Register initialization value or reserved for future use

5 Register initialization value or reserved for future use

6 Register initialization value or reserved for future use

7 Register initialization value or reserved for future use

8 Register initialization value or reserved for future use

9 Register initialization value or reserved for future use

10 Entry point PC[22:16]

11 Entry point PC[15:0]

12 Block size (number of words) of the first block of data to load. If the block size is 0, this indicates the end

13 Destination address of first block Addr[31:16]

14 Destination address of first block Addr[15:0]

15 First word of the first block in the source being loaded

... ...

... ...

. Last word of the first block of the source being loaded

. Block size of the 2nd block to load.

. Destination address of second block Addr[31:16]

. Destination address of second block Addr[15:0]

. First word of the second block in the source being loaded

. …

. Last word of the second block of the source being loaded

. Block size of the last block to load

. Destination address of last block Addr[31:16]

. Destination address of last block Addr[15:0]

. First word of the last block in the source being loaded

... ...

... ...

n Last word of the last block of the source being loaded

n+1 Block size of 0000h - indicates end of the source program

of the source program. Otherwise another section follows.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 25

Submit Documentation Feedback

Page 26

www.ti.com

Bootloader Data Stream Structure

Example 2-1. Data Stream Structure 16-bit

10AA ; 0x10AA 16-bit key value

0000 ; 8 reserved words

0000

0000

0000

0000

0000

0000

0000

003F ; 0x003F8000 EntryAddr, starting point after boot load completes

8000

0005 ; 0x0005 - First block consists of 5 16-bit words

003F ; 0x003F9010 - First block will be loaded starting at 0x3F9010

9010

0001 ; Data loaded = 0x0001 0x0002 0x0003 0x0004 0x0005

0002

0003

0004

0005

0002 ; 0x0002 - 2nd block consists of 2 16-bit words

003F ; 0x003F8000 - 2nd block will be loaded starting at 0x3F8000

8000

7700 ; Data loaded = 0x7700 0x7625

7625

0000 ; 0x0000 - Size of 0 indicates end of data stream

After load has completed the following memory values will have been initialized as follows:

Location Value

0x3F9010 0x0001

0x3F9011 0x0002

0x3F9012 0x0003

0x3F9013 0x0004

0x3F9014 0x0005

0x3F8000 0x7700

0x3F8001 0x7625

PC Begins execution at 0x3F8000

26 Bootloader Features SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 27

www.ti.com

Bootloader Data Stream Structure

In 8-bit mode, the least significant byte (LSB) of the word is sent first followed by the most significant byte

(MSB). For 32-bit values, such as a destination address, the most significant word (MSW) is loaded first,

followed by the least significant word (LSW). The bootloaders take this into account when loading an 8-bit

data stream.

Table 2-4. LSB/MSB Loading Sequence in 8-Bit Data Stream

Byte Contents

LSB (First Byte of 2) MSB (Second Byte of 2)

1 2 LSB: AA (KeyValue for memory width = 8 bits) MSB: 08h (KeyValue for memory width = 8 bits)

3 4 LSB: Register initialization value or reserved MSB: Register initialization value or reserved

5 6 LSB: Register initialization value or reserved MSB: Register initialization value or reserved

7 8 LSB: Register initialization value or reserved MSB: Register initialization value or reserved

... ... ... ...

... ... ... ...

17 18 LSB: Register initialization value or reserved MSB: Register initialization value or reserved

19 20 LSB: Upper half of Entry point PC[23:16] MSB: Upper half of entry point PC[31:24] (Always 0x00)

21 22 LSB: Lower half of Entry point PC[7:0] MSB: Lower half of Entry point PC[15:8]

23 24 LSB: Block size in words of the first block to load. If the MSB: block size

25 26 LSB: MSW destination address, first block Addr[23:16] MSB: MSW destination address, first block Addr[31:24]

27 28 LSB: LSW destination address, first block Addr[7:0] MSB: LSW destination address, first block Addr[15:8]

29 30 LSB: First word of the first block being loaded MSB: First word of the first block being loaded

... ... ... ...

... ... ... ...

. . LSB: Last word of the first block to load MSB: Last word of the first block to load

. . LSB: Block size of the second block MSB: Block size of the second block

. . LSB: MSW destination address, second block Addr[23:16] MSB: MSW destination address, second block

. . LSB: LSW destination address, second block Addr[7:0] MSB: LSW destination address, second block Addr[15:8]

. . LSB: First word of the second block being loaded MSB: First word of the second block being loaded

... ... ... ...

... ... ... ...

. . LSB: Last word of the second block MSB: Last word of the second block

. . LSB: Block size of the last block MSB: Block size of the last block

. . LSB: MSW of destination address of last block Addr[23:16] MSB: MSW destination address, last block Addr[31:24]

. . LSB: LSW destination address, last block Addr[7:0] MSB: LSW destination address, last block Addr[15:8]

. . LSB: First word of the last block being loaded MSB: First word of the last block being loaded

... ... ... ...

... ... ... ...

. . LSB: Last word of the last block MSB: Last word of the last block

n n+1 LSB: 00h MSB: 00h - indicates the end of the source

block size is 0, this indicates the end of the source

program. Otherwise another block follows. For example, a

block size of 0x000A would indicate 10 words or 20 bytes

in the block.

Addr[31:24]

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 27

Submit Documentation Feedback

Page 28

www.ti.com

Basic Transfer Procedure

Example 2-2. Data Stream Structure 8-bit

AA 08 ; 0x08AA 8-bit key value

00 00 00 00 ; 8 reserved words

00 00 00 00

00 00 00 00

00 00 00 00

3F 00 00 80 ; 0x003F8000 EntryAddr, starting point after boot load completes

05 00 ; 0x0005 - First block consists of 5 16-bit words

3F 00 10 90 ; 0x003F9010 - First block will be loaded starting at 0x3F9010

01 00 ; Data loaded = 0x0001 0x0002 0x0003 0x0004 0x0005

02 00

03 00

04 00

05 00

02 00 ; 0x0002 - 2nd block consists of 2 16-bit words

3F 00 00 80 ; 0x003F8000 - 2nd block will be loaded starting at 0x3F8000

00 77 ; Data loaded = 0x7700 0x7625

25 76

00 00 ; 0x0000 - Size of 0 indicates end of data stream

After load has completed the following memory values will have been initialized as follows:

Location Value

0x3F9010 0x0001

0x3F9011 0x0002

0x3F9012 0x0003

0x3F9013 0x0004

0x3F9014 0x0005

0x3F8000 0x7700

0x3F8001 0x7625

PC Begins execution at 0x3F8000

2.11 Basic Transfer Procedure

Figure 2-6 illustrates the basic process a bootloader uses to determine whether 8-bit or 16-bit data stream

has been selected, transfer that data, and start program execution. This process occurs after the

bootloader finds the valid boot mode selected by the state of GPIO pins.

The loader first compares the first value sent by the host against the 16-bit key value of 0x10AA. If the

value fetched does not match then the loader will read a second value. This value will be combined with

the first value to form a word. This will then be checked against the 8-bit key value of 0x08AA. If the

loader finds that the header does not match either the 8-bit or 16-bit key value, or if the value is not valid

for the given boot mode then the load will abort. In this case the loader will return the entry point address

for the flash to the calling routine.

28 Bootloader Features SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 29

www.ti.com

Read first word (W1)

W1=

0x10AA

?

No

16-bit data size

Yes

Read EntryPoint address

Read second word

(W2) and discard

upper 8-bits

?

0x08AA

W2:W1=

Yes

No

8-bit

DataSize

Data format error

Return

FLASH_ENTRY_POINT

Read BlockSize (R)

?

R=0

No

Yes

Return

EntryPoint

Read BlockAddress

Transfer R words of

data from source to

destination

Figure 2-6. Bootloader Basic Transfer Procedure

InitBoot Assembly Routine

A 8-bit and 16-bit transfers are not valid for all boot modes. See the info specific to a particular bootloader for any

limitations.

B In 8-bit mode, the LSB of the 16-bit word is read first followed by the MSB.

2.12 InitBoot Assembly Routine

The first routine called after reset is the InitBoot assembly routine. This routine initializes the device for

operation in C28x object mode. InitBoot also performs a dummy read of the Code Security Module (CSM)

password locations. If the CSM passwords are erased (all 0xFFFFs) then this has the effect of unlocking

the CSM. Otherwise the CSM will remain locked and this dummy read of the password locations will have

no effect. This can be useful if you have a new device that you want to boot load.

After the dummy read of the CSM password locations, the InitBoot routine calls the SelectBootMode

function. This function determines the type of boot mode desired by the state of certain GPIO pins. This

process is described in Section 2.13 . Once the boot is complete, the SelectBootMode function passes

back the entry point address (EntryAddr) to the InitBoot function. EntryAddr is the location where code

execution will begin after the bootloader exits. InitBoot then calls the ExitBoot routine that then restores

CPU registers to their reset state and exits to the EntryAddr that was determined by the boot mode.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 29

Submit Documentation Feedback

Page 30

www.ti.com

Init Boot

Initialize device

OBJMODE=1

AMODE = 0

MOM1MAP=1

DP = 0

OVM = 0

SPM= 0

SP = 0x400

Dummy read of

CSM password

locations

Call

SelectBootMode

Call

ExitBoot

SelectBootMode Function

2.13 SelectBootMode Function

To determine the desired boot mode, the SelectBootMode function examines the state of 3 GPIO pins as

shown in Table 2-5 .

Mode Description GPIO18 GPIO29 GPIO34

Boot to Flash

SCI-A Boot Load from SCI-A. 1 1 0

SPI-A Boot Load from an external serial SPI EEPROM on SPI-A. 1 0 1

I2C-A Boot Load from an external EEPROM at address 0x50 on the 1 0 0

eCAN-A Boot

Boot to M0 SARAM

Boot to OTP

Parallel I/O Boot Load from GPIO0 - GPIO15. 0 0 0

Figure 2-7. Overview of InitBoot Assembly Function

Table 2-5. Boot Mode Selection

SPICLKA

(2)

(3)

(4)

Jump to flash address 0x3F 7FF6. You must have 1 1 1

programmed a branch instruction here prior to reset to

redirect code execution as desired.

I2C-A bus.

Call CAN_Boot to load from eCAN-A mailbox 1. 0 1 1

(4)

Jump to M0 SARAM address 0x00 0000. 0 1 0

Jump to OTP address 0x3D 7800. 0 0 1

(1)

SCITXB

SCITXA

30 Bootloader Features SPRU722C – November 2004 – Revised October 2006

(1)

You must take extra care because of any effect toggling SPICLKA to select a boot mode may have on external logic.

(2)

When booting directly to flash, it is assumed that you have previously programmed a branch statement at 0x3F 7FF6 to redirect

program flow as desired.

(3)

On devices without an eCAN-A module, this mode is reserved and should not be used.

(4)

When booting directly to OTP or MO, it is assumed that you have previously programmed or loaded code starting at the entry

point location.

For a boot mode to be selected, the pins corresponding to the desired boot mode have to be pulled low or

high until the selection process completes. Note that the state of the selection pins is not latched at reset;

they are sampled some cycles later in the SelectBootMode function. The internal pullup resistors are

enabled at reset for the boot mode selection pins. It is still suggested that the boot mode configuration be

made externally to avoid the effect of any noise on these pins.

The SelectBootMode function checks the missing clock detect bit (MCLKSTS) in the PLLSTS register to

determine if the PLL is operating in limp mode. If the PLL is operating in limp mode, the boot mode select

function takes an appropriate action depending on the boot mode selected:

• Boot to flash, OTP, SARAM, I2C-A, SPI-A and the parallel I/O

These modes behave as normal. The user's software must check for missing clock status and take the

appropriate action if the MCLKSTS bit is set.

Submit Documentation Feedback

Page 31

www.ti.com

SelectBootMode Function

• SCI-A boot

The SCI bootloader will be called. Depending on the requested baud rate, however, the device may

not be able to autobaud lock. In this case the boot ROM software will loop in the autobaud lock

function indefinitely. Should the SCI-A boot complete, the user's software must check for a missing

clock status and take the appropriate action.

• eCAN-A boot

The eCAN bootloader will not be called. Instead the boot ROM will loop indefinitely.

Note: The SelectBootMode routine disables the watchdog before calling the SCI, I2C, eCAN,

SPI or parallel bootloader. The bootloaders do not service the watchdog and assume that

it is disabled. Before exiting, the SelectBootMode routine will re-enable the watchdog and

reset its timer.

If a bootloader is not going to be called, then the watchdog is left untouched.

When selecting a boot mode, the pins should be pulled high or low through a weak pulldown or weak

pull-up such that the DSP can drive them to a new state when required. For example, if you wanted to

boot from the SCI-A one of the pins you pull high is the SCITXDA pin. This pullup must be weak so that

when the SCI boot process begins the DSP will be able to properly transmit through the TX pin. Likewise

for the remaining boot mode selection pins.

You must take extra care using the SPICLKA signal to select a boot mode. Toggling of this signal may

affect external logic and this effect must be taken into account.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 31

Submit Documentation Feedback

Page 32

www.ti.com

SelectBootMode

Configure GPIO18, GPIO29,

GPIO34 as input pins

Read boot mode

pins

Dummy read of

CSM password

FLASH

boot

?

Return

FLASH_ENTRY_POINT

EntryAddr: 0x3F 7FF6

Yes

No

boot

?

M0

Return

M0_ENTRY_POINT

EntryAddr: 0x00 0000

OTP

boot

?

Return

OTP_ENTRY_POINT

EntryAddr: 0x3D 7800

WatchDogDisable

Call

SCI

boot

?

Call

SCI_Boot

?

SPI

boot

SPI_Boot

Call

?

eCAN

boot

?

I2C

boot

Call

eCAN_Boot

I2C_Boot

Call

Parallel_Boot

Call

WatchDogEnable

Call

Return EntryAddr as

determined by boot

loader called.

This location is just before the

CSM password.

Direct branch to the

M0 SARAM block

Execute user custom boot

loader or TI-provided boot loader

memory without using up main

flash memory.

Bootloader selected (SCI, SPI or

parallel) will copy data from the

external device to internal memory.

A section of the data read determines

the EntryPoint for execution after the

boot routines have completed.

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

You must have previously programmed

a branch statement at flash address

0x3F 7FF6 to redirect program as

desired.

SelectBootMode Function

Figure 2-8. Overview of the SelectBootMode Function

Bootloader Features32 SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 33

www.ti.com

2.14 CopyData Function

CopyData

Call peripheral-specific

GetWordData to read

Yes

No

Return

BlockHeader.BlockSize

BlockSize=

0x0000

?

Call GetLongData

to read

BlockHeader.DestAddr

Transfer

BlockHeader.BlockSize

words of data from

port to memory

starting at DestAddr

DSP

SCIRXDA

SCITXDA

Host

(Data and program

source)

Each of the bootloaders uses the same function to copy data from the port to the DSP SARAM. This

function is the CopyData() function. This function uses a pointer to a GetWordData function that is

initialized by each of the loaders to properly read data from that port. For example, when the SPI loader is

evoked, the GetWordData function pointer is initialized to point to the SPI-specific SPI_GetWordData

function. Thus when the CopyData() function is called, the correct port is accessed. The flow of the

CopyData function is shown in Figure 2-9 .

CopyData Function

Figure 2-9. Overview of CopyData Function

2.15 SCI_Boot Function

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 33

Submit Documentation Feedback

The SCI boot mode asynchronously transfers code from SCI-A to internal memory. This boot mode only

supports an incoming 8-bit data stream and follows the same data flow as outlined in Example 2-2 .

Figure 2-10. Overview of SCI Bootloader Operation

The DSP communicates with the external host device by communication through the SCI-A Peripheral.

The autobaud feature of the SCI port is used to lock baud rates with the host. For this reason the SCI

loader is very flexible and you can use a number of different baud rates to communicate with the DSP.

After each data transfer, the DSP will echo back the 8-bit character received to the host. In this manner,

the host can perform checks that each character was received by the DSP.

Page 34

www.ti.com

SCI_Boot

Enable the SCI-A clock

set the LSPCLK to /4

functionality and pullups on

Enable the SCIA TX and RX pin

Setup SCI-A for

1 stop, 8-bit character,

no parity, use internal

SC clock, no loopback,

disable Rx/Tx interrupts

Disable SCI FIFOs

Prime SCI-A baud register

Enable autobaud detection

Autobaud

lock

?

No

Yes

Echo autobaud character

Read KeyValue

Yes

No

Valid

KeyValue

(0x08AA)

?

Return

FLASH_ENTRY_POINT

Read and discard 8

reserved words

Read EntryPoint address

Call CopyData

EntryPoint

Return

Set GetWord function pointer

to SCIA_GetWordData

TX and RX

SCI_Boot Function

At higher baud rates, the slew rate of the incoming data bits can be effected by transceiver and connector

performance. While normal serial communications may work well, this slew rate may limit reliable

auto-baud detection at higher baud rates (typically beyond 100kbaud) and cause the auto-baud lock

feature to fail. To avoid this, the following is recommended:

1. Achieve a baud-lock between the host and 28x SCI bootloader using a lower baud rate.

2. Load the incoming 28x application or custom loader at this lower baud rate.

3. The host may then handshake with the loaded 28x application to set the SCI baud rate register to the

desired high baud rate.

Figure 2-11. Overview of SCI_Boot Function

34 Bootloader Features SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 35

www.ti.com

SCIA_GetWordData

Yes

NoData

Received

?

Echoback LSB

to host

Read LSB

Data

Received

?

No

Yes

Read MSB

Echoback MSB

to host

Return MSB:LSB

DSP

DSP control − GPIO26

Host control − GPIO27

Host

(Data and program

source)

Data GP I/O port GPIO[15:0]

16

Figure 2-12. Overview of SCI_GetWordData Function

Parallel_Boot Function (GPIO)

2.16 Parallel_Boot Function (GPIO)

The parallel general purpose I/O (GPIO) boot mode asynchronously transfers code from GPIO0-GPIO15

to internal memory. Each value can be 16 bits or 8 bits long and follows the same data flow as outlined

inData Stream Structure.

Figure 2-13. Overview of Parallel GPIO bootloader Operation

The 28x communicates with the external host device by polling/driving the GPIO27 and GPIO26 lines. The

handshake protocol shown in Figure 2-14 must be used to successfully transfer each word via

GPIO[15:0]. This protocol is very robust and allows for a slower or faster host to communicate with the

DSP.

If the 8-bit mode is selected, two consecutive 8-bit words are read to form a single 16-bit word. The most

significant byte (MSB) is read first followed by the least significant byte (LSB). In this case, data is read

from the lower eight lines of GPIO[7:0] ignoring the higher byte.

The DSP first signals the host that the DSP is ready to begin data transfer by pulling the GPIO26 pin low.

The host load then initiates the data transfer by pulling the GPIO27 pin low. The complete protocol is

shown in the diagram below:

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 35

Submit Documentation Feedback

Page 36

www.ti.com

Host control

GPIO27

DSP control

GPIO26

1 2 3 4 65

Parallel_Boot

No

Yes

Initialize GP I/O MUX

and Dir registers

GPIO[15:0] = input

GPIO27 = input

GPIO26=output

Read KeyValue to

determine DataSize

Valid

KeyValue

(0x08AA or

0x10AA)

?

reserved words

Read and discard 8

Read EntryPoint

address

CopyData

Call

Return

EntryPoint

Return

FLASH_ENTRY_POINT

Enable pullups on

GPIO[15:0], GPIO26,

and GPIO27

and assign appropriate

GetWordData function

Parallel_Boot Function (GPIO)

1. The DSP indicates it is ready to start receiving data by pulling the GPIO26 pin low.

2. The bootloader waits until the host puts data on GPIO[15:0]. The host signals to the DSP that data is

ready by pulling the GPIO27 pin low.

3. The DSP reads the data and signals the host that the read is complete by pulling GPIO26 high.

4. The bootloader waits until the host acknowledges the DSP by pulling GPIO27 high.

5. The DSP again indicates it is ready for more data by pulling the GPIO26 pin low.

This process is repeated for each data value to be sent.

Figure 2-15 shows an overview of the Parallel GPIO bootloader flow.

Figure 2-14. Parallel GPIO bootloader Handshake Protocol

Figure 2-15. Parallel GPIO Mode Overview

36 Bootloader Features SPRU722C – November 2004 – Revised October 2006

Figure 2-16 shows the transfer flow from the host side. The operating speed of the CPU and host are not

critical in this mode as the host will wait for the DSP and the DSP will in turn wait for the host. In this

manner the protocol will work with both a host running faster and a host running slower then the DSP.

Submit Documentation Feedback

Page 37

www.ti.com

Start transfer

No

More

data

?

DSP ready

(GPIO26=0)

?

Yes

Load GPIO[15:0] with data

Signal that data

is ready

(GPIO27=0)

DSP ack

(GPIO26=1)

?

No

Yes

Acknowledge DSP

(GPIO27=1)

Yes

No

End transfer

Figure 2-16. Parallel GPIO Mode - Host Transfer Flow

Parallel_Boot Function (GPIO)

Figure 2-17 and Figure 2-18 show the flow used to read a single word of data from the parallel port. The

loader uses the method shown in Figure 2-6 to read the key value and to determine if the incoming data

stream width is 8-bit or 16-bit. A different GetWordData function is used by the parallel loader depending

on the data size of the incoming data stream.

• 16-bit data stream

For an 16-bit data stream, the function Parallel_GetWordData16bit is used. This function reads all

16-bits at a time. The flow of this function is shown in Figure 2-17 .

• 8-bit data stream

For an 8-bit data stream, the function Parallel_GetWordData8bit is used. The 8-bit routine, shown in

Figure 2-18 , discards the upper 8 bits of the first read from the port and treats the lower 8 bits as the

least significant byte (LSB) of the word to be fetched. The routine will then perform a second read to

fetch the most significant byte (MSB). It then combines the MSB and LSB into a single 16-bit value to

be passed back to the calling routine.

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 37

Submit Documentation Feedback

Page 38

www.ti.com

(GPIO26 = 0)

Signal host that DSP is ready

Parallel_GetWordData16bit

Data

ready

(GPIO27 = 0)

?

No

Yes

GPIO[15:0]

Read word of data from

(GPIO26 = 1)

DSP ack read complete

Host

ack

(GPIO27 = 1)

?

Yes

No

Return WordData

Parallel_Boot Function (GPIO)

Figure 2-17. 16-Bit Parallel GetWord Function

38 Bootloader Features SPRU722C – November 2004 – Revised October 2006

Submit Documentation Feedback

Page 39

www.ti.com

(GPIO26 = 0)

Signal host that DSP is ready

Parallel_GetWordData

8 bit

(GPIO27 = 0)

?

Data

ready

Yes

from GPIO 15:0

Read word of data

(GPIO26 = 1)

DSP ack read complete

(GPIO27 = 1)

ack

Host

No

?

A

ack

Host

(GPIO27 = 1)

DSP ack read complete

(GPIO26 = 1)

?

ready

Data

(GPIO27 = 0)

Signal host that DSP

(GPIO26 = 0)

is ready to read MSB

?

A

Read word from

GPIO[15:0], discard

the upper 8 bits, MSB

of data = lower 8 bits

Return WordData

WordData = MSB:LSB

No

No

No

Yes

Yes

Yes

Figure 2-18. 8-Bit Parallel GetWord Function

Parallel_Boot Function (GPIO)

SPRU722C – November 2004 – Revised October 2006 Bootloader Features 39

Submit Documentation Feedback

Page 40

www.ti.com

SPISIMOA

SPISOMIA

SPICLKA

SPIESTEA

DIN

DOUT

CLK

CS

DSP

Serial SPI

EEPROM

SPI_Boot Function

2.17 SPI_Boot Function

The SPI loader expects an 8-bit wide SPI-compatible serial EEPROM device to be present on the SPI-A

pins as indicated in Figure 2-19 . The SPI bootloader does not support a 16-bit data stream.

Figure 2-19. SPI Loader

The SPI boot ROM loader initializes the SPI module to interface to a serial SPI EEPROM. Devices of this