Page 1

查询TMS28F010A-10供应商

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

TMS28F010A

1048576-BIT FLASH

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

• Organization . . . 128K × 8-Bit Flash Memory

• Pin Compatible With Existing 1-Megabit

EPROMs

• V

Tolerance ±10%

CC

• All Inputs/Outputs TTL Compatible

• Maximum Access/Minimum Cycle Time

’28F010A-10 100 ns

’28F010A-12 120 ns

’28F010A-15 150 ns

’28F010A-17 170 ns

• Industry-Standard Programming Algorithm

• PEP4 Version Available With 168-Hour

Burn-In and Choice of Operating

T emperature Ranges

• Chip Erase Before Reprogramming

• 10000 and 1000 Program/Erase-Cycle

Versions Available

• Low Power Dissipation (V

= 5.5 V)

CC

– Active Write . . . 55 mW

– Active Read...165 mW

– Electrical Erase...82.5 mW

– Standby...0.55 mW

(CMOS-Input Levels)

• Automotive Temperature Range

description

– 40°C to 125°C

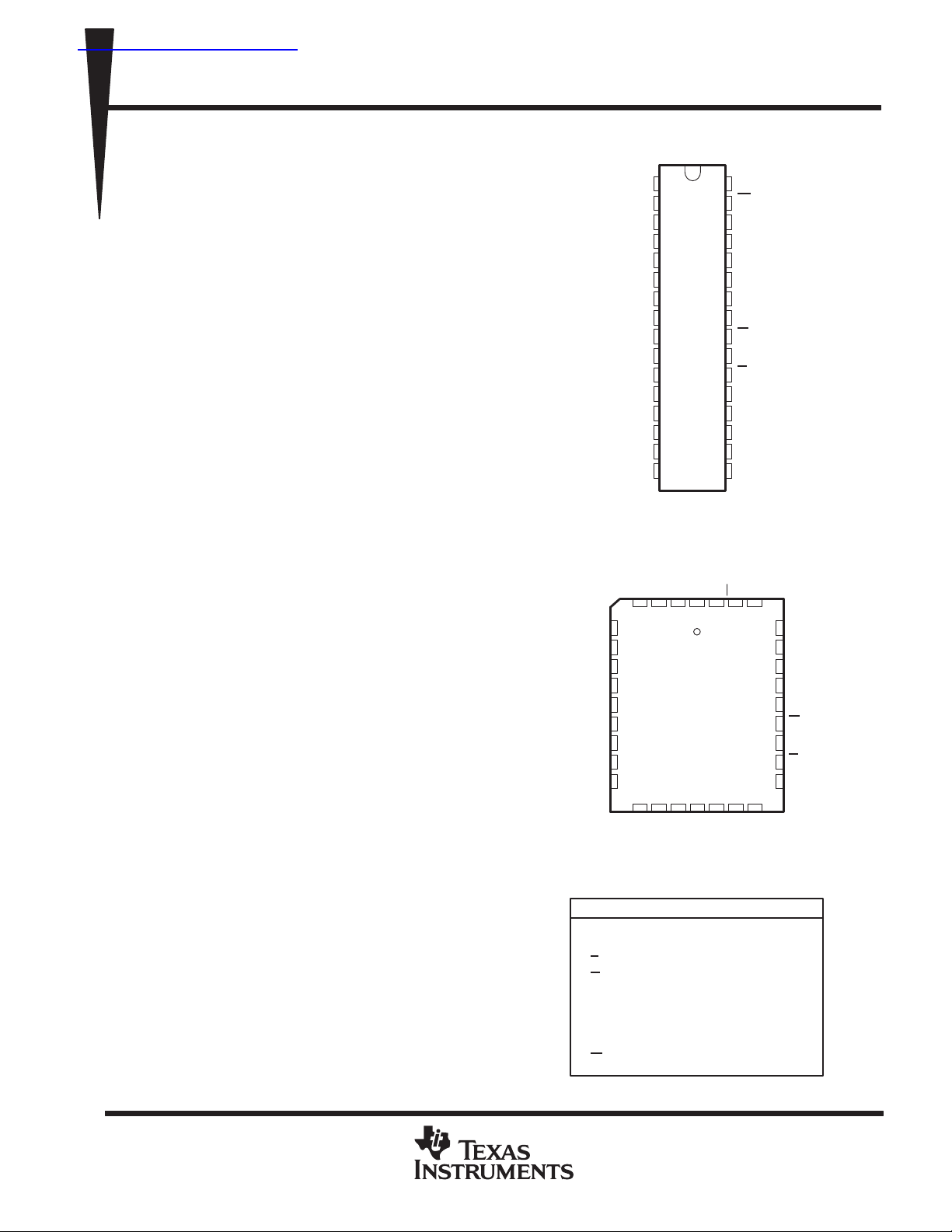

The TMS28F010A is a 1048576-bit, programmable read-only memory that can be electrically

bulk-erased and reprogrammed. It is available in

10000 and 1000 program/erase-endurancecycle versions.

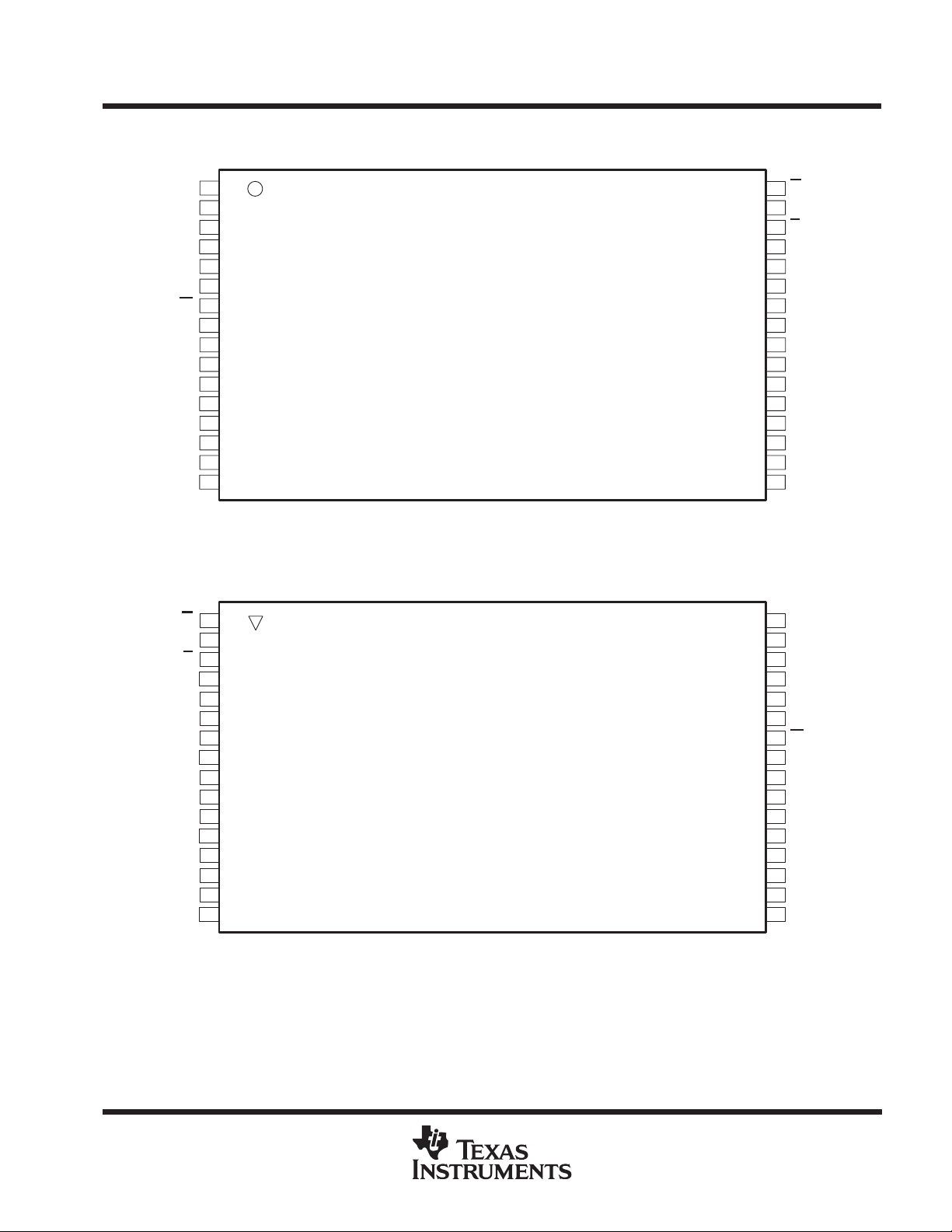

The TMS28F010A Flash EEPROM is offered in a

dual in-line plastic package (N suffix) designed for

insertion in mounting-hole rows on 15,2-mm

(600-mil) centers, a 32-lead plastic leaded

chip-carrier package using 1,25-mm (50-mil) lead

spacing (FM suffix), a 32-lead thin small-outline

package (DD suffix), and a reverse pinout TSOP

package (DU suffix).

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

N PACKAGE

(TOP VIEW)

V

1

PP

A16

2

A15

3

A12

4

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

A0

12

DQ0

13

DQ1

14

DQ2

15

V

16

SS

FM PACKAGE

(TOP VIEW)

A12

A15

A16

3213231

430

5

6

7

8

9

10

11

12

13

14

15 16 17 18 19

SS

DQ1

DQ2

V

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

PPVCC

V

DQ3

DQ4

V

CC

W

NC

A14

A13

A8

A9

A1 1

G

A10

E

DQ7

DQ6

DQ5

DQ4

DQ3

W

20

DQ5

NC

29

28

27

26

25

24

23

22

21

DQ6

A14

A13

A8

A9

A1 1

G

A10

E

DQ7

The TMS28F010A is characterized for operation

in temperature ranges of 0°C to 70°C (NL, FML,

DDL, and DUL suffixes), –40°C to 85°C (NE, FME,

DDE, and DUE suffixes), and –40°C to 125°C

(NQ, FMQ, DDQ, and DUQ suffixes). All package

types are offered with 168-hour burn-in (4 suffix).

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

A0–A16 Address Inputs

DQ0–DQ7 Data In/Data Out

E

G

NC No Internal Connection

V

CC

V

PP

V

SS

W

• HOUSTON, TEXAS 77251–1443

PIN NOMENCLATURE

Chip Enable

Output Enable

5-V Power Supply

12-V Power Supply

Ground

Write Enable

Copyright 1993, Texas Instruments Incorporated

1

Page 2

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

DD PACKAGE

(TOP VIEW)

A11

A9

A8

A13

A14

NC

W

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4

A10

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

G

A10

E

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

A1 1

A9

A8

A13

A14

NC

W

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DU PACKAGE

REVERSE PINOUT

(TOP VIEW)

1

G

2

3

E

4

5

6

7

8

9

10

11

12

13

14

15

16

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 3

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

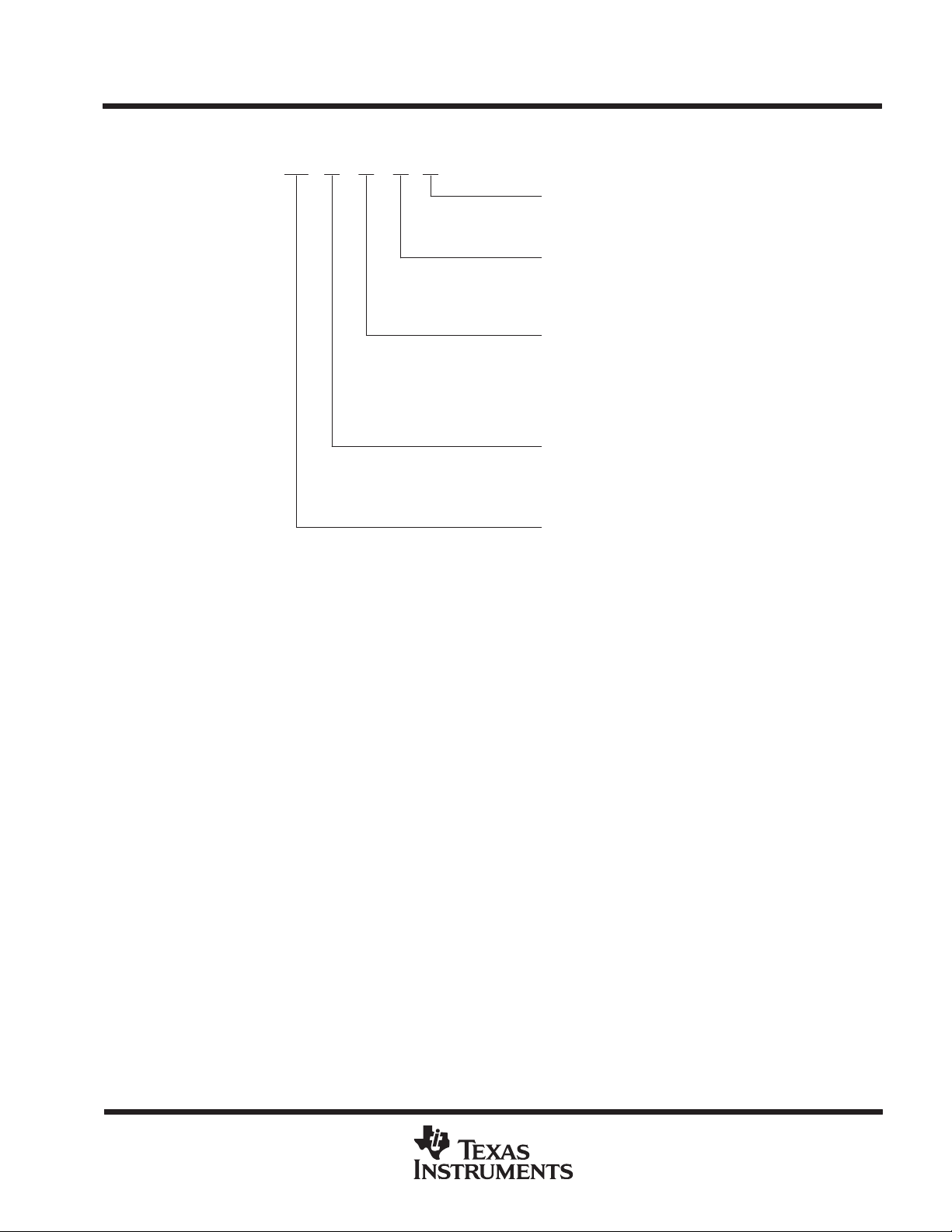

device symbol nomenclature

-12 C4 FM L 4TMS28F010A

TMS28F010A

1048576-BIT FLASH

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

PEP4 Burn-In

4 = 168-Hour Burn-In

(blank if no burn-in)

Temperature Range Designator

L= 0°Cto70°C

E=–40°Cto85°C

Q=–40°C to 125°C

Package Designator

N = Plastic Dual In-Line Package

FM = Plastic Leaded Chip Carrier

DD = Thin Small-Outline Package

DU = Thin Small-Outline Package,

Reverse Pinout

Program/Erase Endurance

C4 = 10 000 Cycles

C3 = 1 000 Cycles

Speed Designator

-10 = 100 ns

-12 = 120 ns

-15 = 150 ns

-17 = 170 ns

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

3

Page 4

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

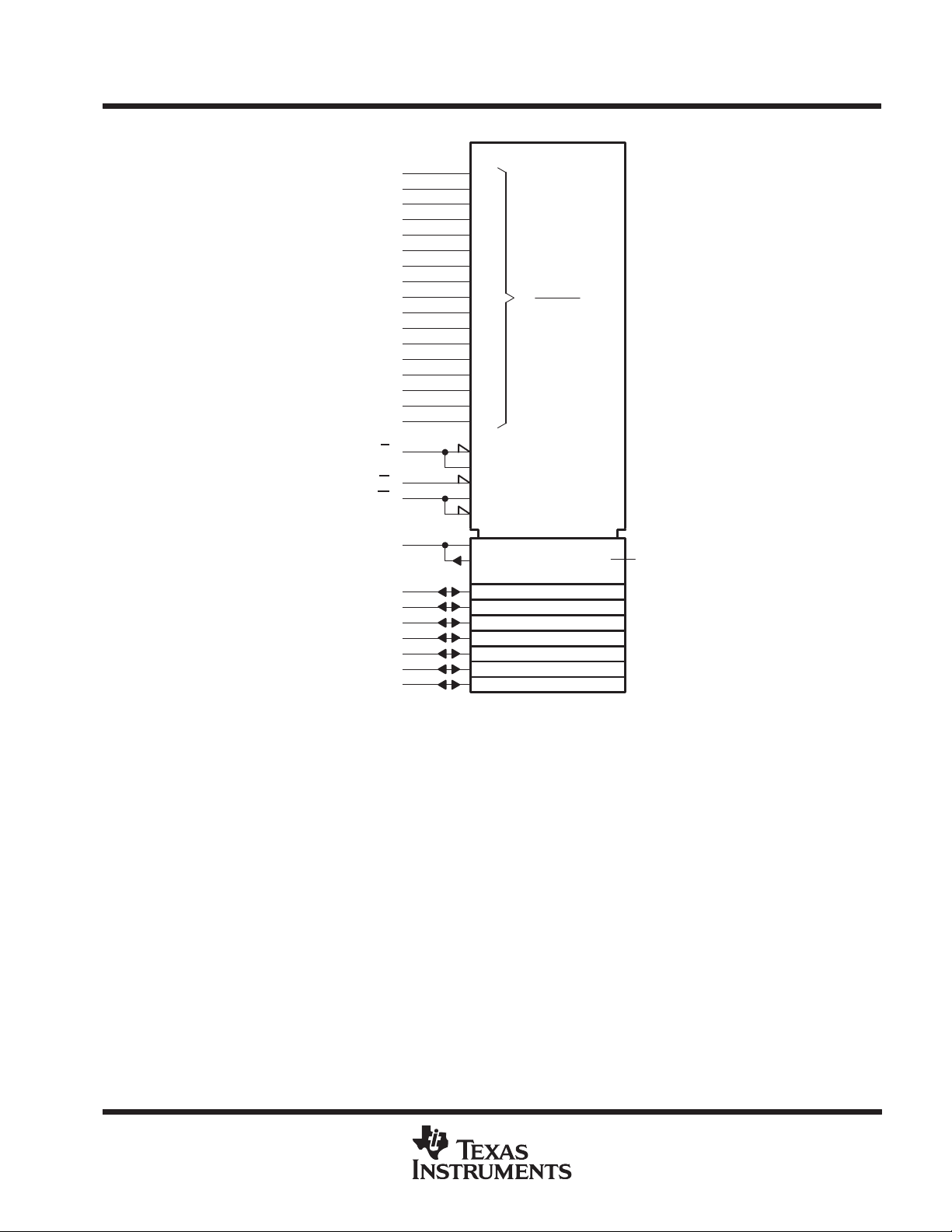

logic symbol

†

This symbol is in accordance with ANSI/IEEE Std 91-1984 and IEC Publication 617-12.

Pin numbers shown are for the N package.

†

FLASH

EEPROM

131 072 × 8

0

A

131 071

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

12

11

10

9

8

7

6

5

27

26

23

25

4

28

29

3

2

22

E

24

G

31

W

13

14

15

17

18

19

20

21

0

16

G1

[PWR DWN]

G2

1, 2 EN (READ)

1C3 (WRITE)

A, 3D

∇ 4

A, Z4

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 5

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

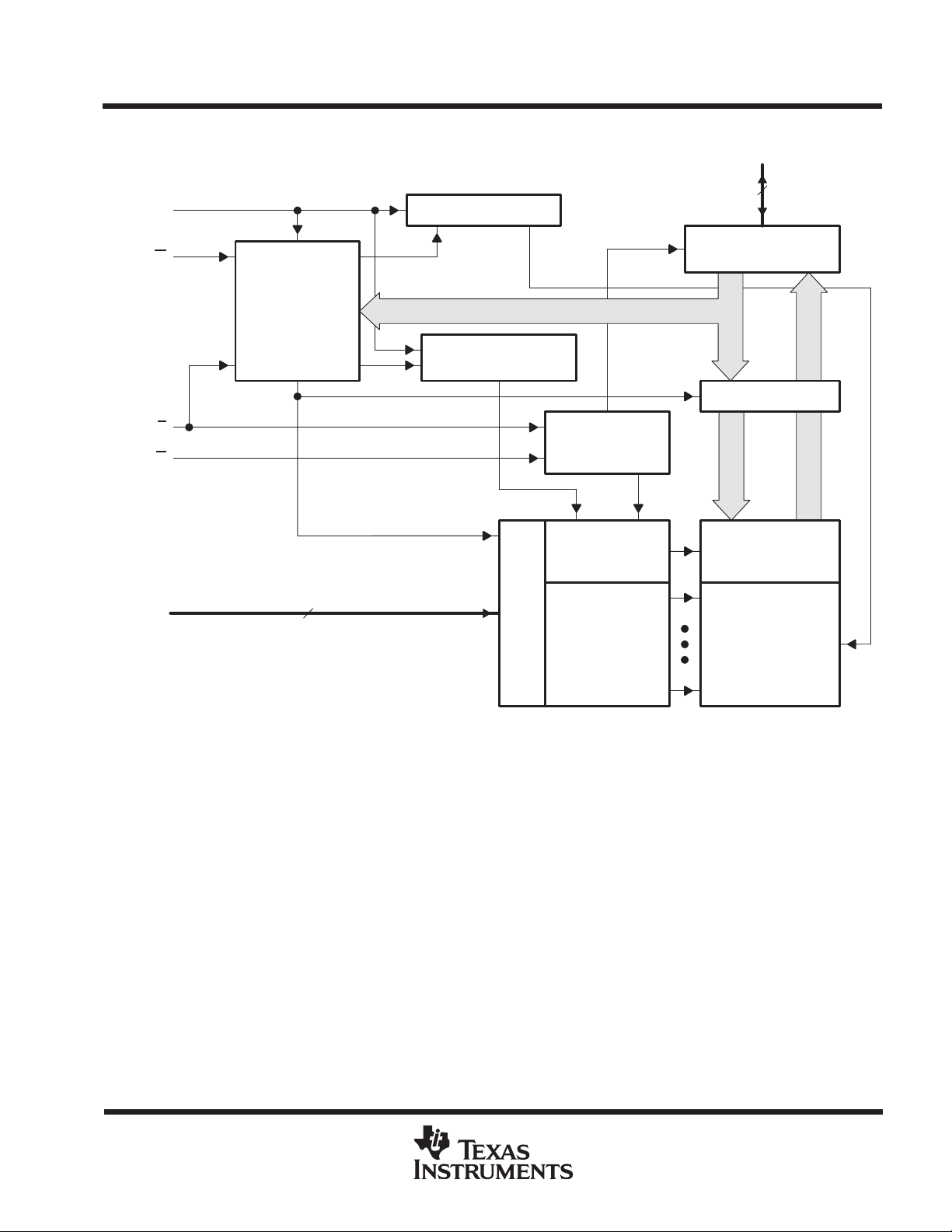

functional block diagram

TMS28F010A

1048576-BIT FLASH

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

DQ0–DQ7

V

PP

A0–A16

Erase-Voltage Switch

W

E

G

State Control

Program/Erase

Stop Timer

Command Register

17

To Array

Program-Voltage

Switch

STB

A

d

d

r

e

s

s

L

a

t

c

h

STB

Chip-Enable and

Output-Enable

Logic

Column Decoder

Row Decoder

Input/Output Buffers

8

Data Latch

Column Gating

1048576-Bit

Array Matrix

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

5

Page 6

TMS28F010A

Algorithm-Selection Mode

V

VILV

VIDV

IDENTIFIER

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

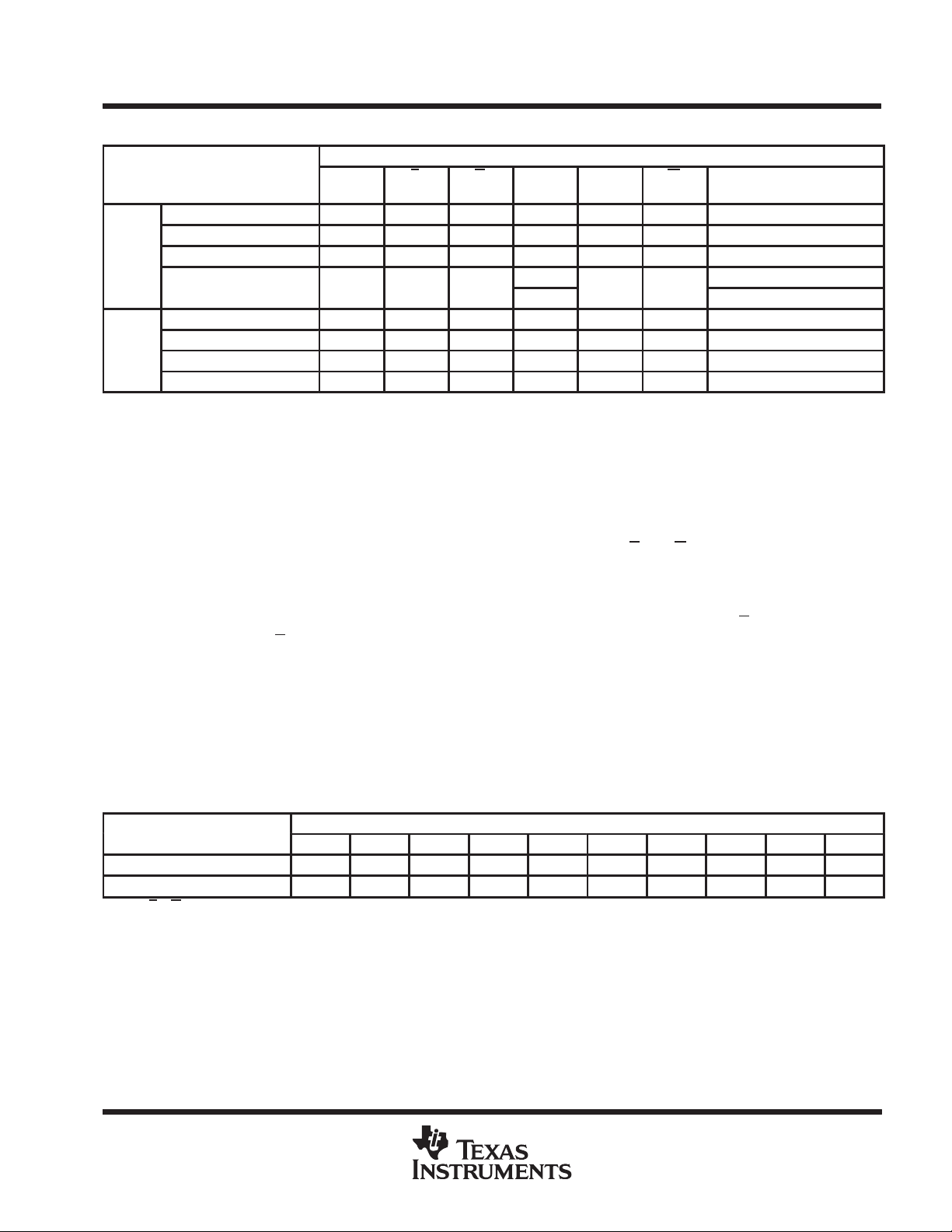

Table 1. Operation Modes

FUNCTION

MODE

Read V

Output Disable V

Read

Read/

Write

NOTE: X can be VIL or VIH.

†

V

PPL

Standby and Write Inhibit V

Read V

Output Disable V

Standby and Write Inhibit V

Write V

≤ VCC + 2 V; V

PPH

operation

read/output disable

is the programming voltage specified for the device. For more details, refer to the recommended operating conditions.

V

PP

(1)

PPL

PPL

PPL

PPL

PPH

PPH

PPH

PPH

†

E

(22)

V

V

V

IH

V

V

V

IH

V

G

(24)

IL

IL

IL

IL

IL

V

IL

V

IH

X X X

IL

V

IL

V

IH

X X X

V

IH

A0

(12)

X X

X X

V

IL

V

IH

X X

X X

X X

A9

(26)

W

(31)

V

IH

V

IH

X

IH

V

IH

V

IH

X

V

IL

DQ0–DQ7

(13–15, 17–21)

Data Out

HI-Z

HI-Z

Mfr Equivalent Code 89h

Device Equivalent Code B4h

Data Out

HI-Z

HI-Z

Data In

When the outputs of two or more TMS28F010As are connected in parallel on the same bus, the output of any

particular device in the circuit can be read with no interference from the competing outputs of other devices. T o

read the output of the TMS28F010A, a low-level signal is applied to the E

and G pins. All other devices in the

circuit should have their outputs disabled by applying a high-level signal to one of these pins.

standby and write inhibit

Active I

high CMOS level on E

current can be reduced from 30 mA to 1 mA by applying a high TTL level on E or to 100 µA with a

CC

. In this mode, all outputs are in the high-impedance state. The TMS28F010A draws active

current when it is deselected during programming, erasure, or program/erase verification. It continues to draw

active current until the operation is terminated.

algorithm-selection mode

The algorithm-selection mode provides access to a binary code identifying the correct programming and erase

agorithms. This mode is activated when A9 (pin 26) is forced to V

A0. All other addresses must be held low.

A0 low selects the manufacturer equivalent code 89h, and A0 high

. Two identifier bytes are accessed by toggling

ID

selects the device equivalent code B4h, as shown in the algorithm-selection mode table below:

PINS

A0 DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0 HEX

Manufacturer Equivalent Code V

Device Equivalent Code V

NOTE: E = G = VIL, A1–A8 = VIL, A9 = VID, A10–A16 = VIL, VPP = V

IL

IH

1 0 0 0 1 0 0 1 89

1 0 1 1 0 1 0 0 B4

.

PPL

programming and erasure

In the erased state, all bits are at a logic 1. Before erasing the device, all memory bits must be programmed to

a logic 0. Afterwards, the entire chip is erased. At this point, the bits, now logic 1s, can be programmed

accordingly. Refer to the Fastwrite and Fasterase algorithms for further detail.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 7

TMS28F010A

COMMAND

BUS

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

command register

The command register controls the program and erase functions of the TMS28F010A. The algorithm-selection

mode can be activated using the command register in addition to the above method. When V

contents of the command register and the function being performed can be changed. The command register

is written to when E

is low and W is pulsed low. The address is latched on the leading edge of the pulse, while

the data is latched on the trailing edge. Accidental programming or erasure is minimized because two

commands must be executed to invoke either operation.

power supply considerations

PP

is high, the

Each device should have a 0.1-µF ceramic capacitor connected between V

Changes in current drain on V

require it to have a bypass capacitor as well. Printed-circuit traces for both

PP

and VSS to suppress circuit noise.

CC

power supplies should be appropriate to handle the current demand.

Table 2. Command Definitions

REQUIRED

CYCLES

Read 1 Write X 00h Read RA RD

Algorithm-Selection Mode 3 Write X 90h Read

Set-Up-Erase/Erase 2 Write X 20h Write X 20h

Erase Verify 2 Write EA A0h Read X EVD

Set-Up-Program/Program 2 Write X 40h Write PA PD

Program Verify 2 Write X C0h Read X PVD

Reset 2 Write X FFh Write X FFh

†

Modes of operation are defined in Table 1.

Legend:

EA Address of memory location to be read during erase verify.

RA Address of memory location to be read.

PA Address of memory location to be programmed. Address is latched on the falling edge of W

RD Data read from location RA during the read operation.

EVD Data read from location EA during erase verify.

PD Data to be programmed at location PA. Data is latched on the rising edge of W

PVD Data read from location PA during program verify.

OPERATION†ADDRESS DATA OPERATION†ADDRESS DATA

FIRST BUS CYCLE SECOND BUS CYCLE

0000

0001

.

.

89h

B4h

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

7

Page 8

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

command definitions

read command

Memory contents can be accessed while V

register invokes the read operation. When the device is powered up, the default contents of the command

register are 00h and the read operation is enabled. The read operation remains enabled until a different valid

command is written to the command register.

algorithm-selection mode command

The algorithm-selection mode is activated by writing 90h into the command register. The manufacturer

equivalent code (89h) is identified by the value read from address location 0000h, and the device equivalent

code (B4h) is identified by the value read from address location 0001h.

set-up-erase/erase commands

The erase-algorithm initiates with E

write the set-up-erase command, 20h, into the command register. After the TMS28F010A is in the erase mode,

writing a second erase command, 20h, into the command register invokes the erase operation. The erase

operation begins on the rising edge of W

10 ms to complete before the erase-verify command, A0h, can be loaded.

Maximum erase timing is controlled by the internal stop timer. When the stop timer terminates the erase

operation, the device enters an inactive state and remains inactive until a valid erase verify, read, or reset

command is received.

erase-verify command

All bytes must be verified following an erase operation. After the erase operation is complete, an erased byte

can be verified by writing the erase-verify command, A0h, into the command register. This command causes

the device to exit the erase mode on the rising edge of W

the falling edge of W

command register.

. The erase-verify operation remains enabled until a valid command is written to the

= VIL, W = VIL, G = VIH, VPP = V

is high or low. When VPP is high, writing 00h into the command

PP

, and VCC = 5 V . T o enter the erase mode,

PPH

and ends on the rising edge of the next W. The erase operation requires

. The address of the byte to be verified is latched on

T o determine whether or not all the bytes have been erased, the TMS28F010A applies a margin voltage to each

byte. If FFh is read from the byte, all bits in the designated byte have been erased. The erase-verify operation

continues until all of the bytes have been verified. If FFh is not read from a byte, an additional erase operation

needs to be executed. Figure 2 shows the combination of commands and bus operations for electrically erasing

the TMS28F010A.

set-up-program/program commands

The programming algorithm initiates with E

programming mode, write the set-up-program command, 40h, into the command register. The programming

operation is invoked by the next write-enable pulse. Addresses are latched internally on the falling edge of W

and data is latched internally on the rising edge of W

and ends on the rising edge of the next W pulse. The program operation requires 10 µs for completion before

W

the program-verify command, C0h, can be loaded.

Maximum program timing is controlled by the internal stop timer. When the stop timer terminates the program

operation, the device enters an inactive state and remains inactive until a valid program-verify, read, or reset

command is received.

= VIL, W = VIL, G = VIH, VPP = V

. The programming operation begins on the rising edge of

, and VCC = 5 V . To enter the

PPH

,

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 9

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

program-verify command

The TMS28F010A can be programmed sequentially or randomly because it is programmed one byte at a time.

Each byte must be verified after it is programmed. The program-verify operation prepares the device to verify

the most recently programmed byte. To invoke the program-verify operation, C0h must be written into the

command register. The program-verify operation ends on the rising edge of W

While verifying a byte, the TMS28F010A applies an internal margin voltage to the designated byte. If the true

data and programmed data match, programming continues to the next designated byte location; otherwise, the

byte must be reprogrammed. Figure 1 shows how commands and bus operations are combined for byte

programming.

reset command

To reset the TMS28F010A after set-up-erase command or set-up-program command operations without

changing the contents in memory , write FFh into the command register two consecutive times. After executing

the reset command, a valid command must be written into the command register to change to a new state.

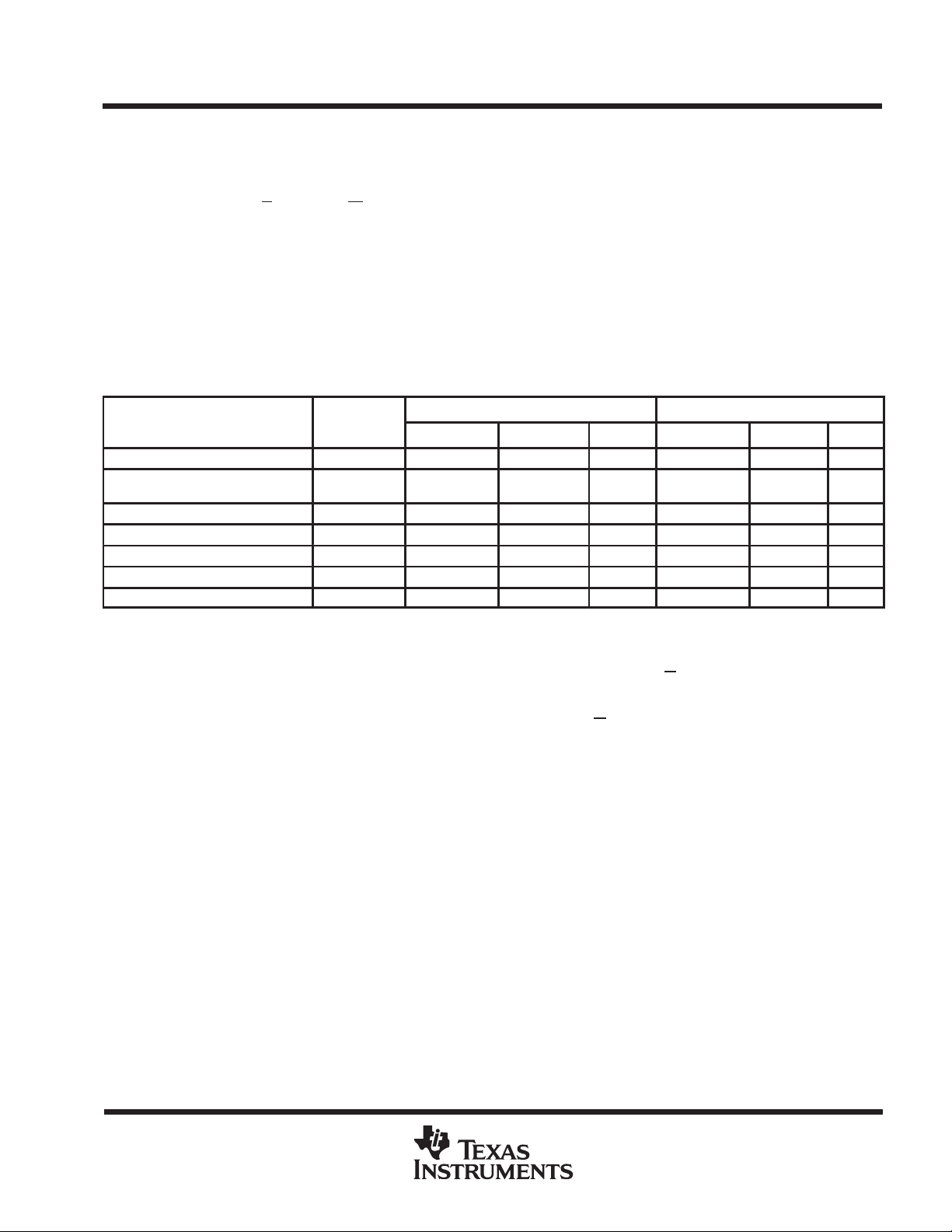

Fastwrite algorithm

The TMS28F010A is programmed using the Texas Instruments Fastwrite algorithm shown in Figure 1. This

algorithm programs in a nominal time of two seconds.

.

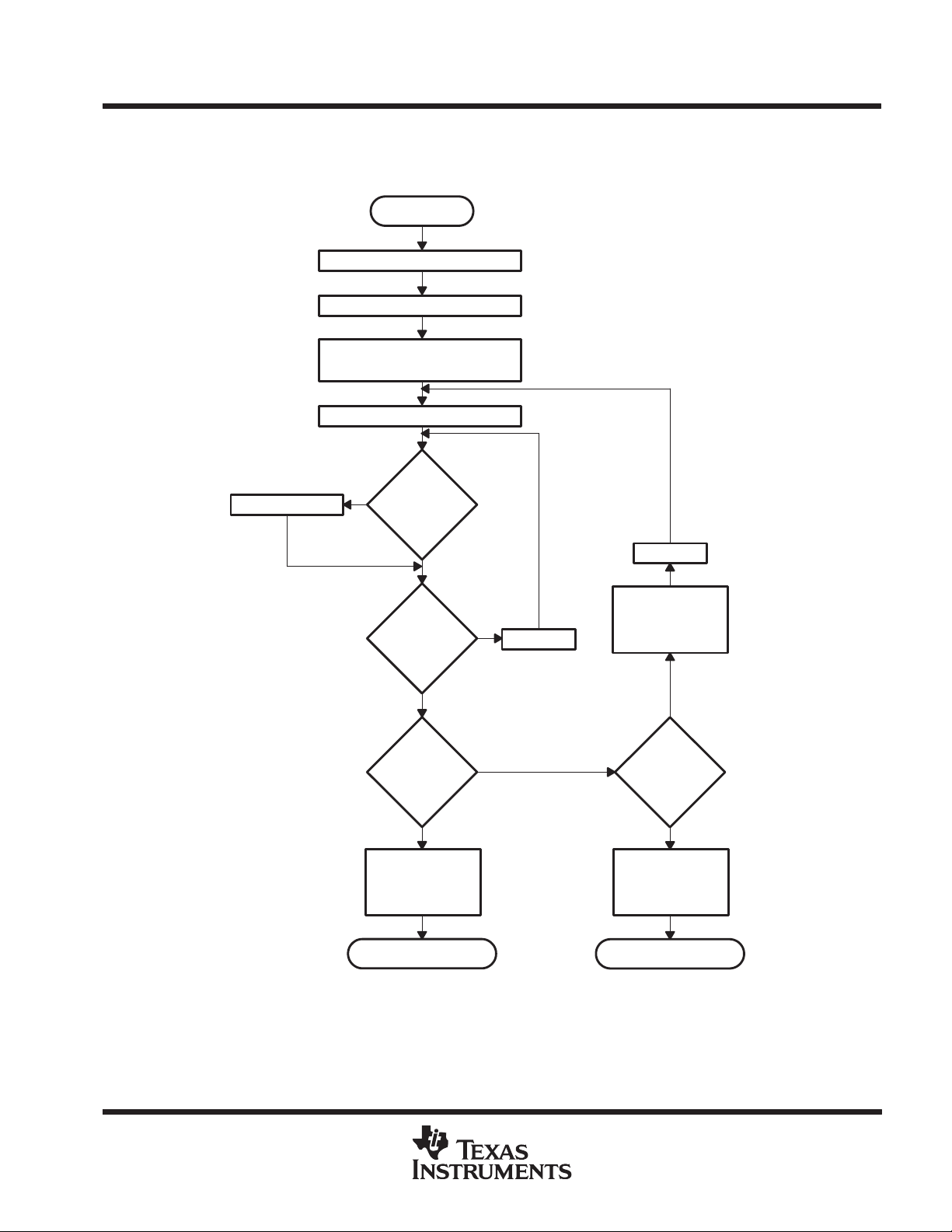

Fasterase algorithm

The TMS28F010A is erased using the T exas Instruments Fasterase algorithm shown in Figure 2. The memory

array needs to be completely programmed (using the Fastwrite algorithm) before erasure begins. Erasure

typically occurs in one second.

parallel erasure

To reduce total erase time, several devices can be erased in parallel. Since each Flash EEPROM can erase

at a different rate, every device must be verified separately after each erase pulse. After a given device has been

successfully erased, the erase command should not be issued to this device again. All devices that complete

erasure should be masked until the parallel erasure process is finished (see Figure 3).

Examples of how to mask a device during parallel erase include driving the E

(00h) to the device when the others receive a set-up-erase or erase command, or disconnecting it from all

electrical signals with relays or other types of switches.

pin high, writing the read command

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

9

Page 10

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

Increment

Address

Start

Address = 00h

VCC = 5 V ± 10%, VPP = 12 V ± 5%

X = 1

Write Set-Up-Program Command

Write Data

Wait = 10µs

Write Program-Verify Command

Wait = 6 µs

Read

and Verify

Byte

Fail

Pass

X = X + 1

No

X = 25?

Yes

Setup

Interactive

Mode

Bus

Operation

Initialize

Address

Standby

Write

Write

Standby

Write

Standby

Read

Command Comments

Wait for VPP to ramp to

V

(see Note A)

PPH

Initialize pulse count

Set-UpProgram

Write

Write Data Valid address/data

ProgramVerify

Data = 40h

Wait = 10 µs

Data = C0h; ends

Program operation

Wait = 6 µs

Read byte to verify

Programming; compare

output to expected output

No

Write Read Command

NOTES: A. Refer to the recommended operating conditions for the value of V

B. Refer to the recommended operating conditions for the value of V

Last

Address

?

Yes

Apply V

PPL

Device Passed

Apply V

PPL

Device Failed

Power

Down

Figure 1. Programming Flowchart: Fastwrite Algorithm

Write

Standby

PPH.

PPL

Read Data = 00h; resets register

.

for read operations

Wait for VPP to ramp to

V

(see Note B)

PPL

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 11

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

Start

All Bytes = 00h

?

Yes

Address = 00h

VCC = 5 V ± 10%, VPP = 12 V ± 5%

X = 1

Write Set-Up-Erase Command

Write-Erase Command

Wait = 10 ms

Write Erase-Verify Command

No

Program All

Bytes to 00h

X = X + 1

Preprogram

Setup

Interactive

Mode

Bus

Operation

Standby

Write

Write

Command Comments

Entire memory must = 00h

before erasure

Use Fastwrite

programming algorithm

Initialize addresses

Wait for VPP to ramp to

V

(see Note A)

PPH

Initialize pulse count

Set-UpErase

Erase Data = 20h

Data = 20h

Increment

Address

Wait = 6 µs

Read

and Verify

Byte

No

Last

Address?

Write Read Command

Apply V

Device Passed Device Failed

Fail

Pass

Yes

PPL

X = 1000?

Apply V

No

Yes

PPL

Power

Down

Standby

Write

Standby

Read

Write

Standby

Wait = 10 ms

Erase

Verify

Read Data = 00h; resets register

Addr = Byte to verify;

Data = A0h; ends the erase

operation

Wait = 6 µs

Read byte to verify erasure;

compare output to FFh

for read operations

Wait for VPP to ramp to

V

(see Note B)

PPL

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

11

Page 12

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

NOTES: A. Refer to the recommended operating conditions for the value of V

B. Refer to the recommended operating conditions for the value of V

Figure 2. Flash-Erase Flowchart: Fasterase Algorithm

Start

Program All Devices to 00h

X = 1

Give Erase Command to All

Mask Device #D

Yes

Devices

D = 1

Is

Device #D

Erased

?

No

PPH.

PPL

.

X = X+1

NOTE: n = number of devices being erased.

D = n

?

Are

All Devices

Erased

?

Give Read

Command to

All Devices

All Devices Pass

No

D = D+1

Yes

No

Yes

Finished With Errors

Figure 3. Parallel-Erase Flow Diagram

Give Erase

Command to

All Unmasked

Devices

No

X = 1000

?

Yes

Give Read

Command to

All Devices

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 13

TMS28F010A

VCCSuppl

oltage

During write/read/flash erase

4.555.5

V

VPPSuppl

oltage

VIHHigh-level dc input

oltage

V

VILLow-level dc input voltage

V

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage range, V

Supply voltage range, V

Input voltage range (see Note 2): All inputs except A9 –0.6 V to V

Output voltage range (see Note 3) –0.6 V to V

Operating free-air temperature range during read/erase/program, T

Storage temperature range –65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to VSS.

2. The voltage on any input pin can undershoot to –2.0 V for periods less than 20 ns.

3. The voltage on any output pin can overshoot to 7.0 V for periods less than 20 ns.

(see Note 1) –0.6 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

–0.6 V to 14 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PP

A9 –0.6 V to 13.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NL, FML, DDL, DUL 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

NE, FME, DDE, DUE – 40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NQ, FMQ, DDQ, DUQ – 40° C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

CC

+ 1 V. . . . . . . . . . . . . . . . . . . . . . . . . . . .

+ 1 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

recommended operating conditions

MIN TYP MAX UNIT

pp

y v

pp

y v

p

p

V

Voltage level on A9 for algorithm-selection mode 11.5 13 V

ID

During read only (V

During write/read/flash erase (V

v

) 0 VCC + 2 V

PPL

) 11.4 12 12.6 V

PPH

TTL 2 VCC+0.5

CMOS VCC– 0.5 VCC+0.5

TTL –0.5 0.8

CMOS GND – 0.2 GND+0.2

†

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

13

Page 14

TMS28F010A

VOHHigh-level output voltage

V

VOLLow-level output voltage

V

IIInput current (leakage)

A

I

V

pply current (read/standby)

I

pply current (standby)

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature

PARAMETER TEST CONDITIONS MIN MAX UNIT

p

p

I

ID

I

O

PP1

I

PP2

I

PP3

I

PP4

CCSVCC

I

CC1

I

CC2

I

CC3

I

CC4

NOTE 4: Not 100% tested; characterization data available.

A9 algorithm-selection-mode current A9 = VID max 200 µA

p

Output current (leakage) VO = 0 V to V

pp

su

PP

VPP supply current (during program pulse) (see Note 4) VPP = V

VPP supply current (during flash erase) (see Note 4) VPP = V

VPP supply current (during program/erase verify)

(see Note 4)

pp

su

VCC supply current (active read)

VCC average supply current (active write) (see Note 4)

VCC average supply current (flash erase) (see Note 4)

VCC average supply current (program/erase verify)

(see Note 4)

All except A9 VI = 0 V to 5.5 V ±1

A9 VI = 0 V to 13 V ±200

TTL-input level VCC = 5.5 V, E = V

CMOS-input level VCC = 5.5 V, E = V

IOH = – 2.5 mA 2.4

IOH = – 100 µA VCC– 0.4

IOL = 5.8 mA 0.45

IOL = 100 µA 0.1

CC

VPP = V

VPP = V

VPP = V

VCC = 5.5 V E = VIL,

f = 6 MHz, Outputs open

VCC = 5.5 V, E = VIL,

Programming in progress

VCC = 5.5 V, E = VIL,

Erasure in progress

VCC = 5.5 V, E = VIL,

VPP = V

Program/erase-verify in progress

, Read mode 200 µA

PPH

PPL

PPH

PPH

PPH

IH

CC

,

PPH

±10 µA

±10 µA

30 mA

30 mA

5.0 mA

100 µA

30 mA

10 mA

15 mA

15 mA

µ

1 mA

capacitance over recommended ranges of supply voltage and operating free-air temperature,

f = 1 MHz

C

i

C

o

†

Capacitance measurements are made on sample basis only.

†

PARAMETER TEST CONDITIONS MIN MAX UNIT

Input capacitance VI = 0 , f = 1 MHz 6 pF

Output capacitance VO = 0, f = 1 MHz 12 pF

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 15

TMS28F010A

PARAMETER

UNIT

L

I

t

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

switching characteristics over recommended ranges of supply voltage and operating free-air

temperature

t

a(A)

t

a(E)

t

en(G)

t

c(R)

t

d(E)

t

d(G)

t

dis(E)

t

dis(G)

t

h(D)

t

rec(W)

†

Whichever occurs first.

Access time from

address, A0–A16

Access time from

chip enable, E

Access time from

output enable, G

Cycle time, read t

Delay time, E low

to low-Z output

Delay time, G low

to low-Z output

Chip disable time

to hi-Z output

Output disable

time to hi-Z

output

Hold time, data

valid from

address, E

Write recovery

time before read

, or G

TEST ALTERNATE

CONDITIONS SYMBOL

CL = 100 pF,

1 Series 74

TTL load,

p

nput

≤ 20 ns,

r

Input tf ≤ 20 ns

†

t

AVQV

t

ELQV

t

GLQV

AVAV

t

ELQX

t

GLQX

t

EHQZ

t

GHQZ

t

AXQX

t

WHGL

’28F010A-10 ’28F010A-12 ’28F010A-15 ’28F010A-17

MIN MAX MIN MAX MIN MAX MIN MAX

100 120 150 170 ns

100 120 150 170 ns

45 50 55 60 ns

100 120 150 170 ns

0 0 0 0 ns

0 0 0 0 ns

0 55 0 55 0 55 0 55 ns

0 30 0 30 0 35 0 35 ns

0 0 0 0 ns

6 6 6 6 µs

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

15

Page 16

TMS28F010A

’28F010A-10

’28F010A-12

PARAMETER

UNIT

’28F010A-15

’28F010A-17

PARAMETER

UNIT

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

timing requirements–write/erase/program operations

t

c(W)

t

c(W)PR

t

c(W)ER

t

h(A)

t

h(E)

t

h(WHD)

t

su(A)

t

su(D)

t

su(E)

t

su(EHVPP)

t

su(VPPEL)

t

rec(W)

t

rec(R)

t

w(W)

t

w(WH)

t

r(VPP)

t

f(VPP)

t

c(W)

t

c(W)PR

t

c(W)ER

t

h(A)

t

h(E)

t

h(WHD)

t

su(A)

t

su(D)

t

su(E)

t

su(EHVPP)

t

su(VPPEL)

t

rec(W)

t

rec(R)

t

w(W)

t

w(WH)

t

r(VPP)

t

f(VPP)

NOTE 5: Rise/fall time ≤ 10 ns.

Cycle time, write using W t

Cycle time, programming operation t

Cycle time, erase operation t

Hold time, address t

Hold time, E t

Hold time, data valid after W high t

Setup time, address t

Setup time, data t

Setup time, E before W t

Setup time, E high to VPP ramp t

Setup time, VPP to E low t

Recovery time, W before read t

Recovery time, read before W t

Pulse duration, W (see Note 5) t

Pulse duration, W high t

Rise time, V

Fall time, V

Cycle time, write using W t

Cycle time, programming operation t

Cycle time, erase operation t

Hold time, address t

Hold time, E t

Hold time, data valid after W high t

Setup time, address t

Setup time, data t

Setup time, E before W t

Setup time, E high to VPP ramp t

Setup time, VPP to E low t

Recovery time, W before read t

Recovery time, read before W t

Pulse duration, W (see Note 5) t

Pulse duration, W high t

Rise time, V

Fall time, V

PP

PP

PP

PP

ALTERNA TE

SYMBOL

AVAV

WHWH1

WHWH2

WLAX

WHEH

WHDX

AVWL

DVWH

ELWL

EHVP

VPEL

WHGL

GHWL

WLWH

WHWL

t

VPPR

t

VPPF

ALTERNATE

SYMBOL

AVAV

WHWH1

WHWH2

WLAX

WHEH

WHDX

AVWL

DVWH

ELWL

EHVP

VPEL

WHGL

GHWL

WLWH

WHWL

t

VPPR

t

VPPF

’

MIN NOM MAX MIN NOM MAX

100 120 ns

10 10 µs

9.5 10 9.5 10 ms

55 60 ns

0 0 ns

10 10 ns

0 0 ns

50 50 ns

20 20 ns

100 100 ns

1.0 1.0 µs

6 6 µs

0 0 µs

60 60 ns

20 20 ns

1 1 µs

1 1 µs

’

MIN NOM MAX MIN NOM MAX

150 170 ns

10 10 µs

9.5 10 9.5 10 ms

60 70 ns

0 0 ns

10 10 ns

0 0 ns

50 50 ns

20 20 ns

100 100 ns

1.0 1.0 µs

6 6 µs

0 0 µs

60 60 ns

20 20 ns

1 1 µs

1 1 µs

’

’

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 17

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

’28F010A-10

’28F010A-12

’28F010A-15

’28F010A-17

PARAMETER

UNIT

timing requirements — alternative E-controlled writes

TMS28F010A

1048576-BIT FLASH

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

t

c(W)

t

c(E)PR

t

h(EA)

t

h(ED)

t

h(W)

t

su(A)

t

su(D)

t

su(W)

t

su(VPPEL)

t

rec(E)R

t

rec(E)W

t

w(E)

t

w(EH)

ALTERNA TE

Cycle time, write using E t

Cycle time, programming op-

eration

Hold time, address t

Hold time, data t

Hold time, W t

Setup time, address t

Setup time, data t

Setup time, W before E t

Setup time, VPP to E low t

Recovery time, write using E

before read

Recovery time, read before

write using E

Pulse duration, write using E t

Pulse duration, write, E high t

PARAMETER MEASUREMENT INFORMATION

SYMBOL

AVAV

t

EHEH

ELAX

EHDX

EHWH

AVEL

DVEH

WLEL

VPEL

t

EHGL

t

GHEL

ELEH

EHEL

’

MIN MAX MIN MAX MIN MAX MIN MAX

100 120 150 170 ns

10 10 10 10 µs

75 80 80 90 ns

10 10 10 10 ns

0 0 0 0 ns

0 0 0 0 ns

50 50 50 50 ns

0 0 0 0 ns

1.0 1.0 1.0 1.0 µs

6 6 6 6 µs

0 0 0 0 µs

70 70 70 80 ns

20 20 20 20 ns

’

’

’

2.08 V

RL = 800 Ω

Output

Under Test

CL = 100 pF

Figure 4. AC Test Output Load Circuit

AC testing input/output waveforms

2.4 V

0.45 V

2 V

0.8 V

AC testing inputs are driven at 2.4 V for logic high and 0.45 V for logic low. Timing measurements are made at

2 V for logic high and 0.8 V for logic low on both inputs and outputs. Each device should have a 0.1-µF ceramic

capacitor connected between V

and VSS as close as possible to the device pins.

CC

2 V

0.8 V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

17

Page 18

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

PARAMETER MEASUREMENT INFORMATION

t

c(R)

t

a(A)

Address Valid

t

a(E)

t

en(G)

t

d(G)

A0–A16

E

G

t

rec(W)

W

t

d(E)

DQ0–DQ7 Ouput Valid

HI-Z HI-Z

Figure 5. Read Cycle Timing

t

h(D)

t

dis(E)

t

dis(G)

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 19

A0–A16

Power Up

and

Standby

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

PARAMETER MEASUREMENT INFORMATION

Program

Set-Up-

Program

Command

Command

Latch

Address

and Data

Programming

Program

Verify

Command

Program

Verification

Standby/

Power Down

DQ0–DQ7

5 V

V

CC

0 V

V

PPH

V

PP

V

PPL

t

c(W)

t

su(A)

t

h(A)

E

t

su(E)

t

h(E)

G

t

rec(R)

W

t

h(WHD)

t

w(W)

t

su(D)

HI-Z

Data In = 40h

t

su(VPPEL)

t

r(VPP)

t

c(W)

t

su(E)

t

w(WH)

t

t

w(W)

t

su(D)

Data In

h(E)

t

c(W)PR

t

h(WHD)

t

c(W)

t

su(A)

t

t

w(W)

t

su(D)

Data In = C0h

t

h(A)

su(E)

t

rec(W)

t

t

h(E)

h(WHD)

t

d(E)

t

a(E)

t

c(R)

t

dis(E)

t

d(G)

t

dis(G)

t

h(D)

t

en(G)

Valid Data Out

t

f(VPP)

t

su(EHVPP)

Figure 6. Write Cycle Timing

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

19

Page 20

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

PARAMETER MEASUREMENT INFORMATION

Program

Command

Latch

Address

and Data

Programming

Program

Verify

Command

A0–A16

Power Up

and

Standby

Set-Up-

Program

Command

Program

Verification

Standby/

Power Down

DQ0–DQ7

5 V

V

CC

0 V

V

PPH

V

PP

V

PPL

t

c(W)

t

su(A)

t

h(EA)

W

t

su(W)

t

h(W)

G

t

rec(E)W

E

t

h(ED)

t

w(E)

t

su(D)

HI-Z

Data In = 40h

t

su(VPPEL)

t

r(VPP)

t

su(EHVPP)

t

su(D)

t

c(W)

t

su(W)

t

w(EH)

t

t

w(E)

Data In

t

h(W)

t

c(w)B

h(ED)

Data In = C0h

t

w(E)

t

su(D)

t

c(W)

t

su(A)

t

su(W)

t

h(EA)

t

t

h(W)

rec(E)R

t

h(ED)

t

d(E)

t

a(E)

t

c(R)

t

t

en(G)

t

d(G)

Valid Data Out

t

t

h(D)

dis(G)

dis(E)

t

f(VPP)

20

Figure 7. Write Cycle (Alternative E-Controlled Writes) Timing

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 21

TMS28F010A

1048576-BIT FLASH

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY MEMORY

SMJS012 – DECEMBER 1992 – REVISED NOVEMBER 1993

PARAMETER MEASUREMENT INFORMATION

A0–A16

DQ0–DQ7

5 V

V

CC

0 V

V

PPH

V

PP

V

PPL

E

G

W

Power Up

and

Standby

t

c(W)

t

su(E)

t

rec(R)

t

Set-Up-

Erase

Command

t

h(E)

t

h(WHD)

w(W)

t

su(D)

HI-Z

t

su(VPPEL)

t

r(VPP)

t

su(EHVPP)

Erase

Command

Data In = 20h

t

c(W)

t

su(E)

t

w(WH)

Data In = 20h

t

w(W)

t

su(D)

Erasing

t

h(E)

t

h(WHD)

Erase-

Verify

Command

t

c(W)

t

c(E)B

t

w(W)

t

su(D)

Data In = A0h

t

su(A)

t

su(E)

t

h(A)

t

h(E)

t

rec(W)

t

h(WHD)

t

d(E)

t

a(E)

Erase

Verification

t

c(R)

t

f(VPP)

Standby/

Power Down

t

dis(E)

t

dis(G)

t

h(D)

t

en(G)

t

d(G)

Valid Data Out

Figure 8. Flash-Erase Cycle Timing

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

21

Page 22

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOL VE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...