Page 1

SBOS272B – JUNE 2003 – REVISED DECEMBER 2003

1.5°C Accurate Programmable

Digital Temperature Sensors

with SPI™ Interface

TMP122

TMP124

FEATURES

● DIGITAL OUTPUT: SPI-Compatible Interface

● PROGRAMMABLE RESOLUTION:

9- to 12-Bits + Sign

● ACCURACY:

±1.5°C from –25°C to +85°C (max)

±2.0°C from –40°C to +125°C (max)

● LOW QUIESCENT CURRENT: 50µA

● WIDE SUPPLY RANGE: 2.7V to 5.5V

● TINY SOT23-6 AND SO-8 PACKAGES

● OPERATION TO 150°C

● PROGRAMMABLE HIGH/LOW SETPOINTS

APPLICATIONS

● POWER-SUPPLY TEMPERATURE MONITORING

● COMPUTER PERIPHERAL THERMAL PROTECTION

● NOTEBOOK COMPUTERS

● CELL PHONES

● BATTERY MANAGEMENT

● OFFICE MACHINES

● THERMOSTAT CONTROLS

● ENVIRONMENTAL MONITORING and HVAC

● ELECTROMECHANICAL DEVICE TEMPERATURE

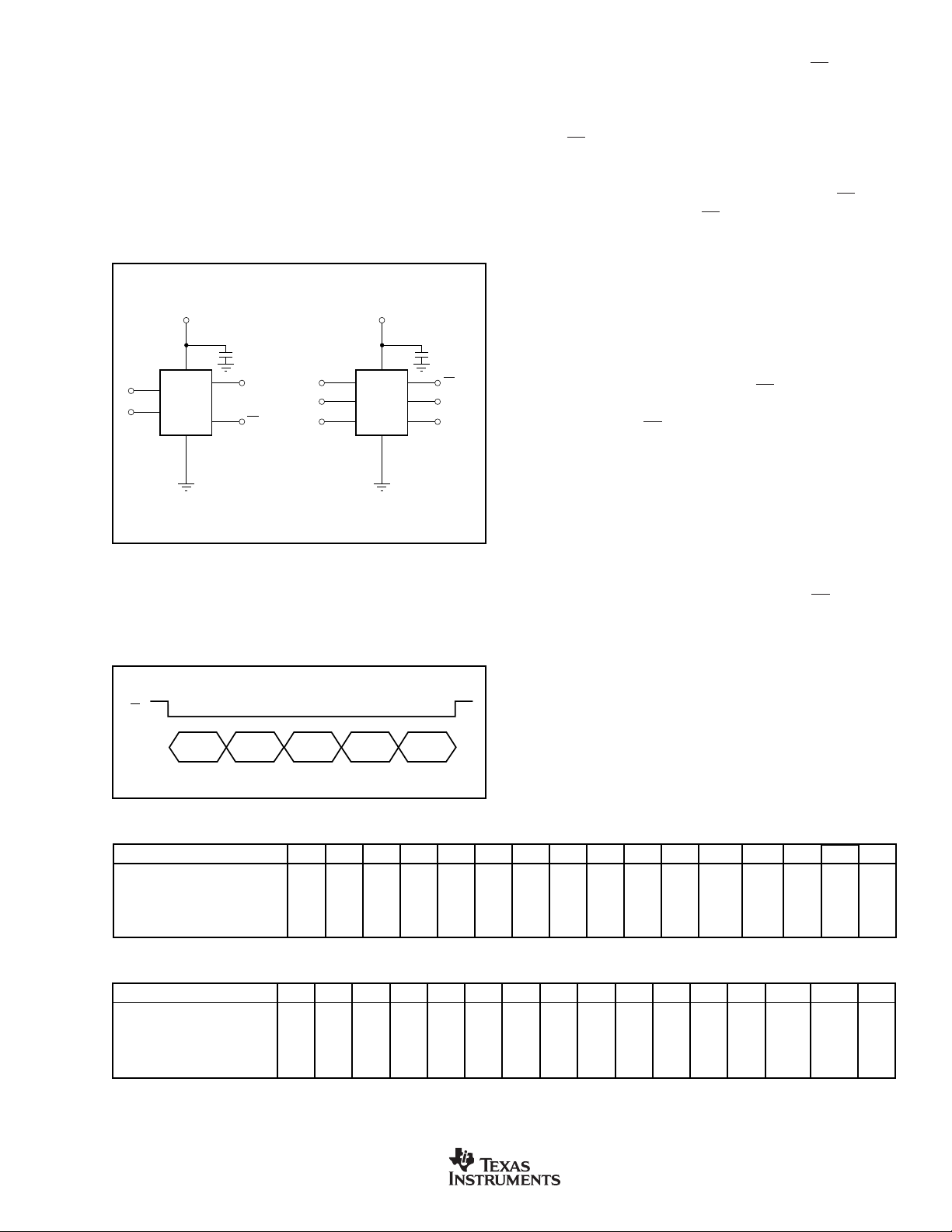

DESCRIPTION

The TMP122 and TMP124 are SPI-compatible temperature

sensors available in SOT23-6 and SO-8 packages. Requiring only a pull-up resistor for complete function, the TMP122

and TMP124 temperature sensors are capable of measuring

temperatures within 2°C of accuracy over a temperature

range of –40°C to +125°C, with operation up to 150°C.

Programmable resolution, programmable set points and shut

down function provide versatility for any application. Low

supply current and a supply range from 2.7V to 5.5V make

the TMP122 and TMP124 excellent candidates for lowpower applications.

The TMP122 and TMP124 are ideal for extended thermal

measurement in a variety of communication, computer, consumer, environmental, industrial, and instrumentation applications.

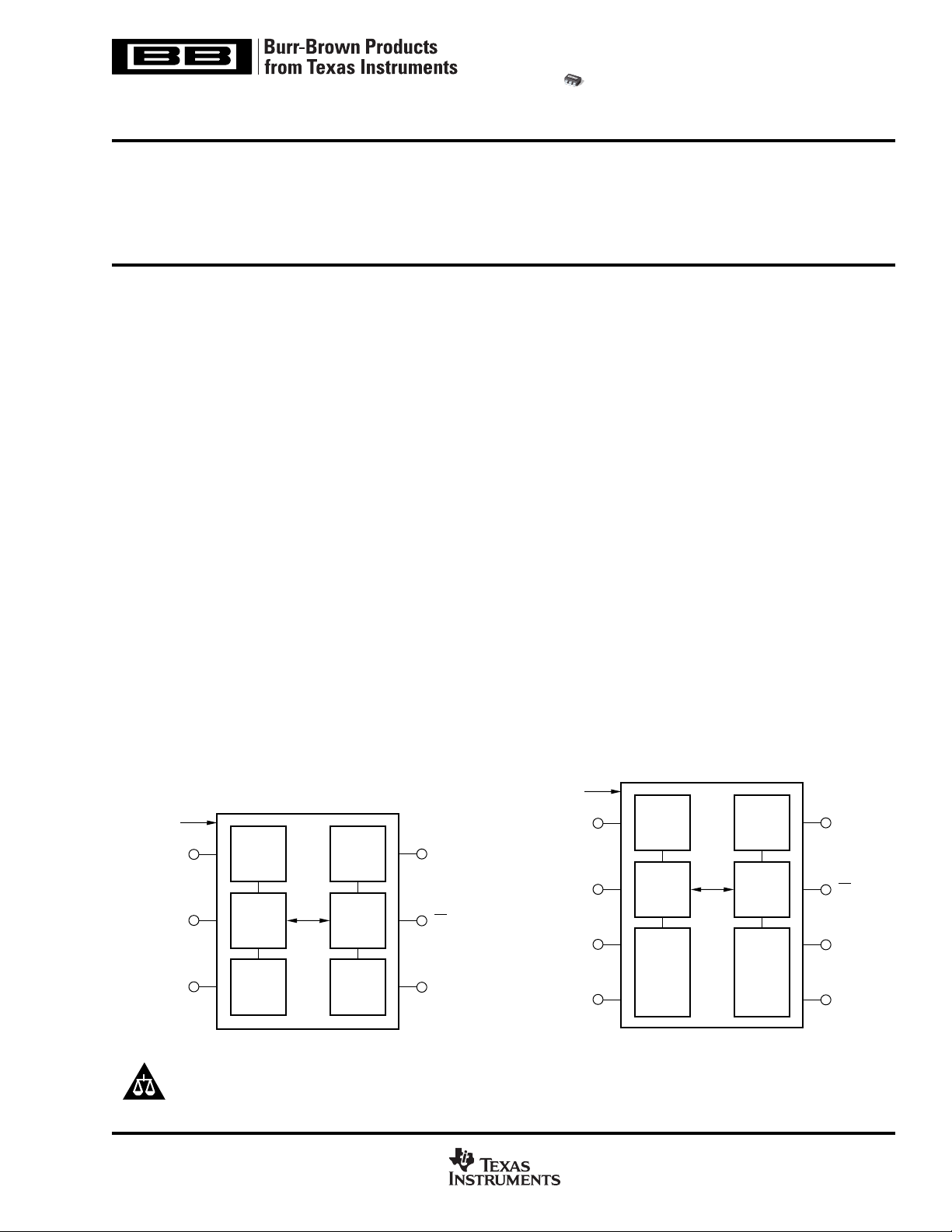

Temperature

Temperature

Diode

1

2

3

Temp.

Sensor

∆Σ

A/D

Converter

OSC

TMP122

ALERT

GND

V+

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

SPI is a registered trademark of Motorola. All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Control

Logic

Serial

Interface

Config

and T emp

Register

6

SO/I

5

CS

4

SCK

www.ti.com

SO/I

SCK

NC

GND

Diode

1

Temp.

Sensor

∆Σ

2

A/D

Converter

3

OSC

45

Copyright © 2003, Texas Instruments Incorporated

TMP124

Control

Logic

Serial

Interface

Config

and T emp

Register

8

V+

7

CS

6

NC

ALERT

Page 2

ABSOLUTE MAXIMUM RATINGS

SI/O

SC

NC

GND

V+

CS

NC

ALERT

1

2

3

4

8

7

6

5

T124

TMP124

Power Supply, V+ .................................................................................. 7V

Input Voltage

Input Current ..................................................................................... 10mA

Operating Temperature Range ......................................–55°C to +150°C

Storage Temperature Range ......................................... –60°C to +150°C

Junction Temperature (T

Lead Temperature (soldering)....................................................... +300°C

(2)

....................................................................... –0.3V to 7V

Max) .................................................... +150°C

J

(1)

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

NOTES: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability. (2) Input voltage

rating applies to all TMP122 and TMP124 input voltages.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may be

more susceptible to damage because very small parametric

changes could cause the device not to meet its published

specifications.

PACKAGE/ORDERING INFORMATION

PRODUCT PACKAGE-LEAD DESIGNATOR

PACKAGE TEMPERATURE PACKAGE ORDERING TRANSPORT

TMP122 SOT23-6 DBV –40°C to +125°C T122 TMP122AIDBVT Tape and Reel, 250

(1)

"" "" "TMP122AIDBVR Tape and Reel, 3000

TMP124 SO-8 D –40°C to +125°C T124 TMP124AID Rails, 100

"" "" "TMP124AIDR Tape and Reel, 2500

NOTE: (1) For the most current specifications and package information, refer to our web site at www.ti.com.

SPECIFIED

RANGE MARKING NUMBER MEDIA, QUANTITY

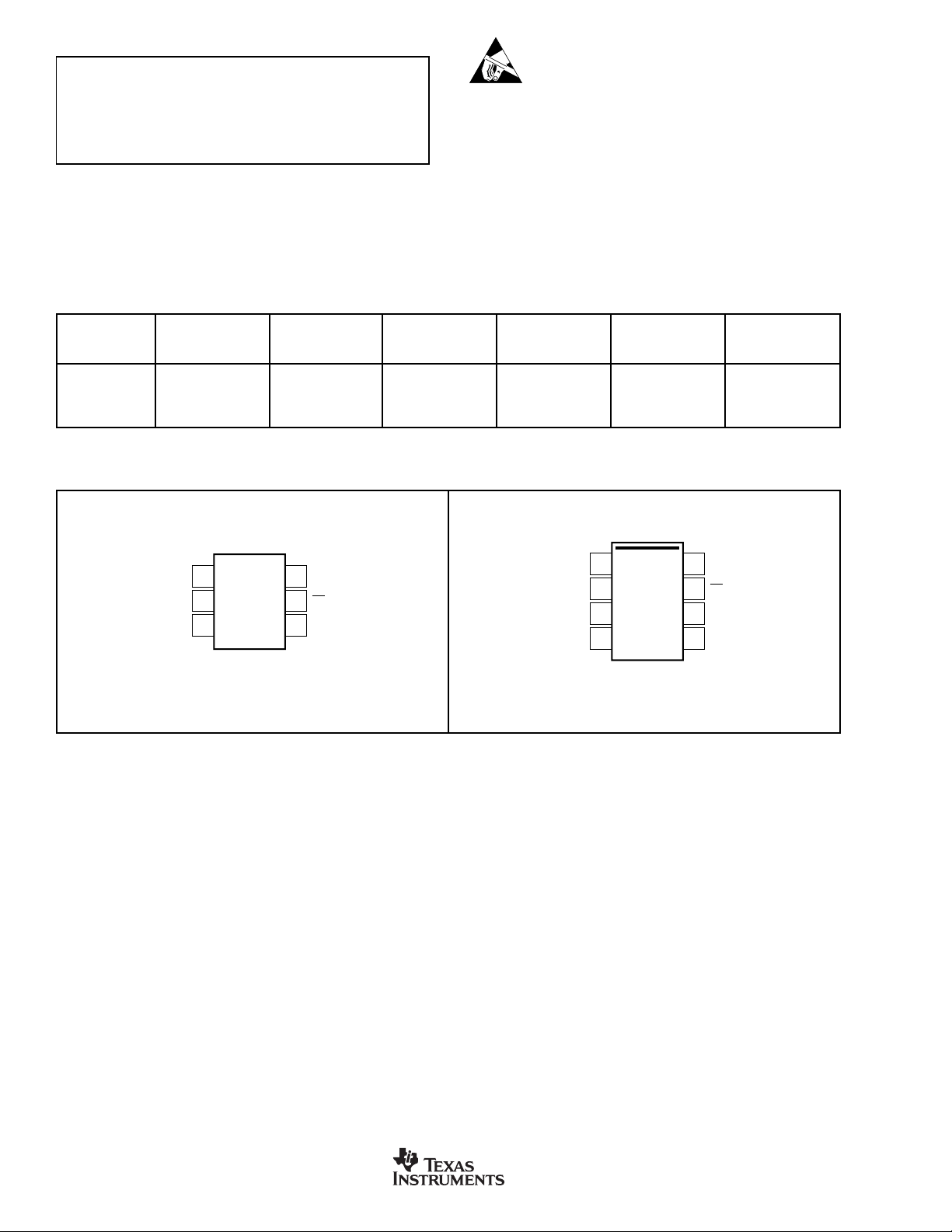

PIN CONFIGURATIONS

Top View SOT23-6

T122

ALERT

GND

V+

1

2

3

TMP122

6

SO/I

5

CS

4

SCK

Top View SO-8

NC = No Connection

2

www.ti.com

TMP122, TMP124

SBOS272B

Page 3

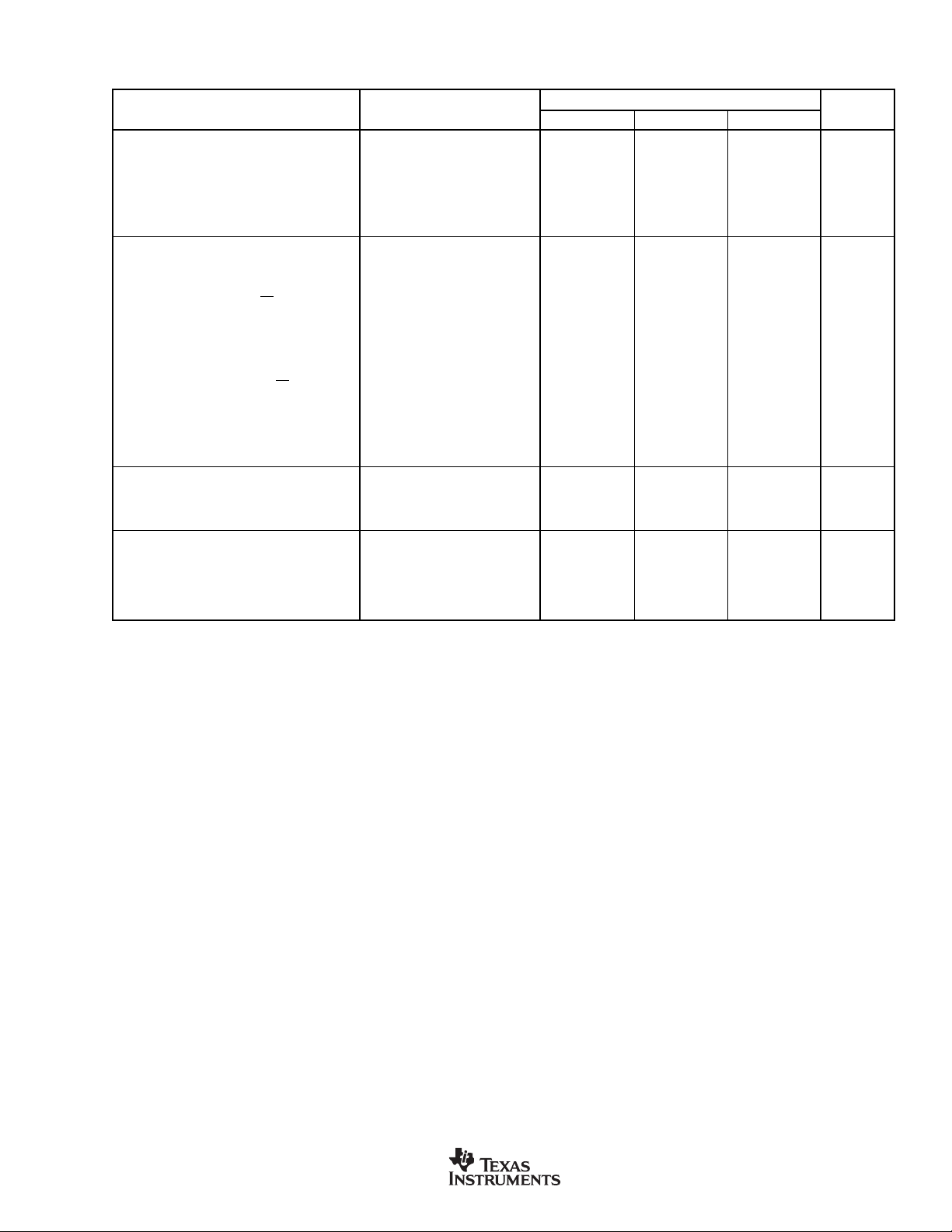

ELECTRICAL CHARACTERISTICS

At TA = –40°C to +125°C, and V+ = 2.7V to 5.5V, unless otherwise noted.

TMP122, TMP124

PARAMETER CONDITION MIN TYP MAX UNITS

TEMPERATURE INPUT

Range –40 +125 °C

Accuracy (Temperature Error) –25°C to +85°C ±0.5 ±1.5 °C

vs Supply –0.3 0.1 +0.3 °C/V

Resolution

(1)

DIGITAL INPUT/OUTPUT

Input Logic Levels:

V

IH

V

IL

Input Current, SO/I, SCK, CS 0V ≤ V

Output Logic Levels:

V

SO/I I

OL

V

SO/I I

OH

V

ALERT I

OL

Leakage Current ALERT 0V ≤ V

Input Capacitance, SO/I, SCK, CS, ALERT 2.5 pF

Resolution Selectable 9 to 12 + Sign Bits

Conversion Time 9-Bit + Sign 30 40 ms

POWER SUPPLY

Operating Range 2.7 5.5 V

Quiescent Current I

Shutdown Current I

Q

SD

TEMPERATURE RANGE

Specified Range –40 +125 °C

Operating Range –55 +150 °C

Storage Range –60 +150 °C

Thermal Resistance,

θ

JA

NOTE: (1) Specified for 12-bit resolution.

–40°C to +125°C ±1.0 ±2.0 °C

–55°C to +150°C ±1.5 °C

Selectable ±0.0625 °C

0.7(V+) V

0.3(V+) V

≤ V+ ±1 µA

IN

= 3mA 0.4 V

SINK

= 2mA (V+)–0.4 V

SOURCE

= 4mA 0.4 V

SINK

≤ 6V ±1 µA

IN

10-Bit + Sign 60 80 ms

11-Bit + Sign 120 160 ms

12-Bit + Sign 240 320 ms

Serial Bus Inactive 50 75 µA

Serial Bus Inactive 0.1 1 µA

SOT23-6 Surface-Mount 200 °C/W

SO-8 Surface-Mount 150 °C/W

TMP122, TMP124

SBOS272B

www.ti.com

3

Page 4

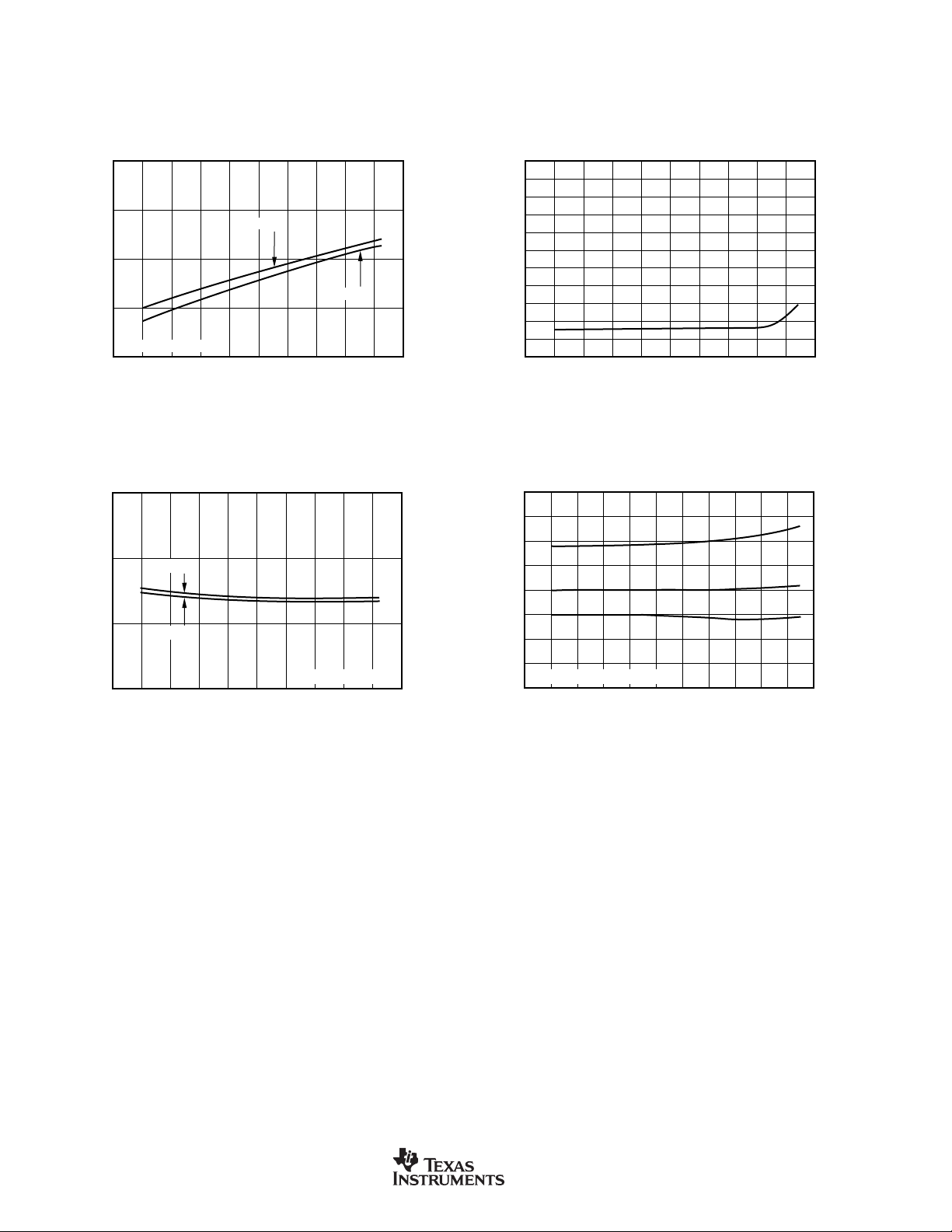

TYPICAL CHARACTERISTICS

At TA = +25°C, and V+ = 5.0V, unless otherwise noted.

70

60

50

(µA)

Q

I

40

30

400

300

200

Conversion Time (ms)

100

QUIESCENT CURRENT vs TEMPERATURE

V+ = 5V

V+ = 2.7V

Serial Bus Inactive

–60 –40 –20 0 20 40 60 80 100 120 140

Temperature (°C)

CONVERSION TIME vs TEMPERATURE

V+ = 5V

V+ = 2.7V

12-bit resolution.

–60 –40 –20 0 20 40 60 80 100 120 140

Temperature (°C)

1.0

0.9

0.8

0.7

0.6

0.5

(µA)

0.4

SD

I

0.3

0.2

0.1

0.0

–0.1

2.0

1.5

1.0

0.5

0.0

–0.5

–1.0

Temperature Error (°C)

–1.5

–2.0

SHUTDOWN CURRENT vs TEMPERATURE

–60 –40 –20 0 20 40 60 80 100 120 140

Temperature (°C)

TEMPERATURE ACCURACY vs TEMPERATURE

3 typical units 12-bit resolution.

–60 –40 –20 0 20 40 60 80 100 120 160140

Temperature (°C)

4

www.ti.com

TMP122, TMP124

SBOS272B

Page 5

APPLICATIONS INFORMATION

The TMP122 and TMP124 digital temperature sensors are

optimal for thermal management and thermal protection applications. The TMP122/TMP124 are SPI interface-compatible

and specified for a temperature range of –40°C to +125°C.

The TMP122/TMP124 require minimal external components

for operation, needing only a pull-up resistor on the ALERT

pin and a bypass capacitor on the supply. Bypass capacitors

of 0.1µF is recommended. Figure 1 shows typical connections for the TMP122 and TMP124.

V+

0.1µF

3

1

SCK

SO/I

4

6

TMP122

2

GND

ALERT

(Output)

5

CS

NOTE: Alert requires

pull-up resistor (open drain).

NC indicates pin should be left

open or floating.

SO/I

SCK

NC

FIGURE 1. Typical Connections of the TMP122 and TMP124.

To maintain accuracy in applications requiring air or surface

temperature measurement, care should be taken to isolate

the package and leads from ambient air temperature.

CS

SO/I

16-Bit

READ

16-Bit

READ

COMMAND

16-Bit

Response

FIGURE 2.Multiple Command Sequence.

1

2

TMP124

3

16-Bit

WRITE/

Embedded

Address

V+

GND

7

6

5

16-Bit

READ

0.1µF

CS

NC

ALERT

(Output)

8

4

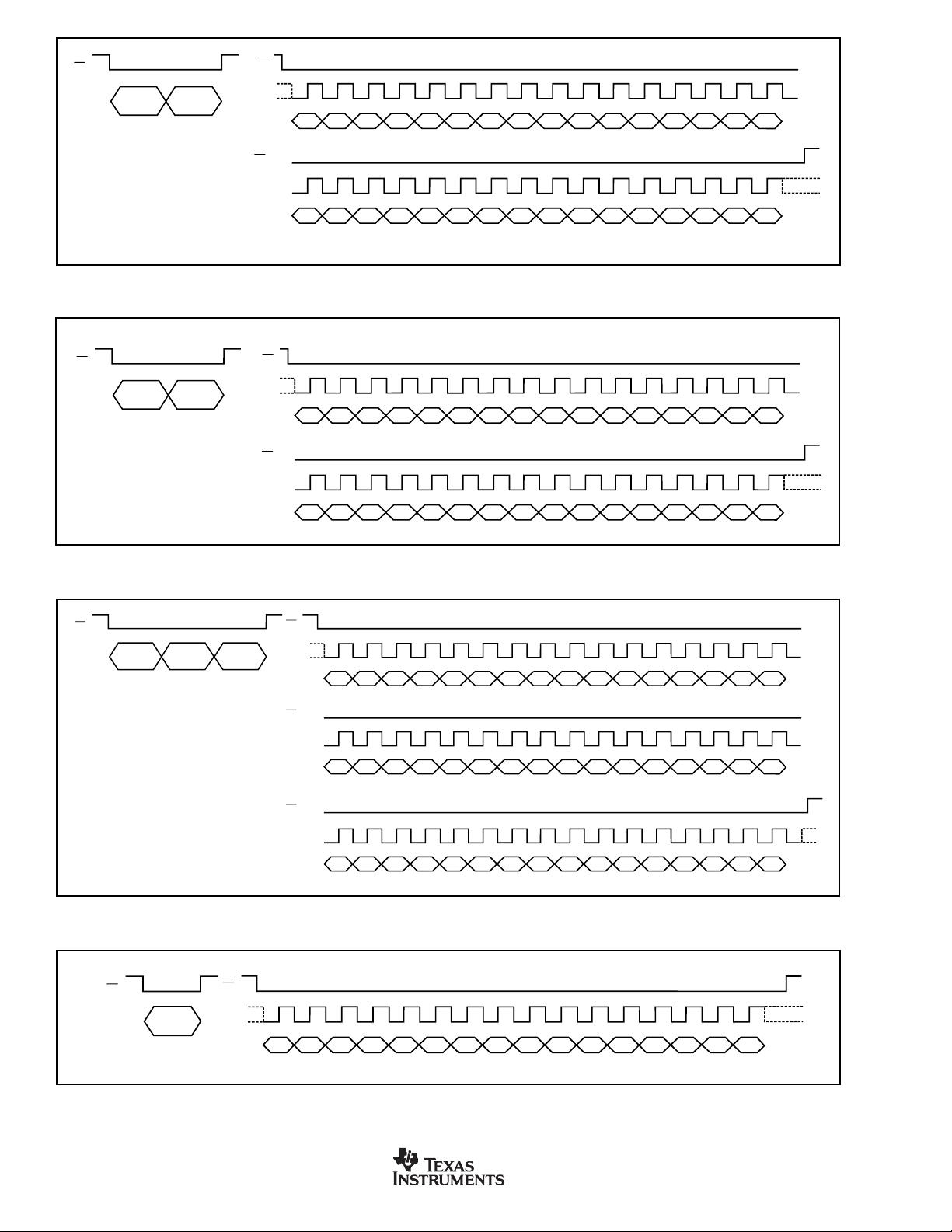

COMMUNICATING WITH THE TMP122

The TMP122/TMP124 converts continuously. If CS is brought

low during a conversion the conversion process continues, but

the last completed conversion is available at the output register. Communication with the TMP122/TMP124 is initiated by

pulling

CS

low. The first 16 clocks of data transfer will return

temperature data from the temperature sensors. The 16-bit

data word is clocked out sign bit first, followed by the MSB. Any

portion of the 16-bit word may be read before raising

user wishes to continue with

CS

low, the following 16 clocks

transfer in a READ or WRITE command. READ and WRITE

commands are described in Tables I and II.

The READ command contains an embedded address in bits

D4 and D3 to identify which register to read. Bits D4 and D3

are internally registered and will hold their value following a

READ command until a entire 16-bit read is completed by the

user. The completion of the 16-bit READ acknowledges that

the READ command has been completed. If the user issues

a READ command and then raises

CS

with less than 16

subsequent clocks, the data from that register will be available

at the next fall of

CS

. The registered READ address will

remain in effect until a full 16 clocks have been received. After

the completion of a 16-bit READ from the part, the READ

address is reset to return data from the Temperature Register.

A WRITE command to a register will not change the READ

address registered. For further discussion on the READ address register, see the

Read Address Register

Multiple commands may be strung together as illustrated in

Figure 2. The TMP122/TMP124 accepts commands alternating with 16-bit response data. On lowering

always responds with a READ from the address location

indicated by the READ address register. If the next command is a READ command then data is returned from the

address specified by the READ command with the 16th clock

resetting the READ address register to the default temperature register. The TMP122/TMP124 then expect a 16-bit

command. If the command is a WRITE command, then the

16 clocks following the command will again return temperature data.

Figures 3, 4, 5, and 6 detail the communication sequences.

CS

section.

CS

, the part

. If the

Read Command D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Temperature 10000000000 0 0 000

Configuration Register 10000000000 0 1000

Low Temp Threshold 10000000000 1 0000

High Temp Threshold 1000000 0000 1 1 000

TABLE I. Read Command.

Write Command D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Configuration Register 0000D1D0R1R0F1F0POLTM1TM00 1 0

Low Temp Threshold T12 T11 T10 T9 T8 T7 T6 T5 T4 T3 T2 T1 T0 1 0 0

High Temp Threshold T12 T11 T10 T9 T8 T7 T6 T5 T4 T3 T2 T1 T0 1 1 0

Shutdown Command xxxxxxxx11111 1 1 1

TABLE II. Write Command.

TMP122, TMP124

SBOS272B

www.ti.com

5

Page 6

SO/I

SCK

SO/I

CS

SCK

CS

...

ZZ1D3D4D5D6D7D8D9D10D11D12D13D14D15

CS

16-Bit

READ

(Continued)

16-Bit

WRITE/

Embedded

Address

...

SO/I

FIGURE 3. READ followed by WRITE COMMAND to T

CS

SCK

SO/I

CS

SCK

SO/I

SO/I

CS

16-Bit

READ

(Continued)

16-Bit

WRITE/

Embedded

Address

...

LOW/THIGH

Register.

FIGURE 4. READ followed by WRITE COMMAND to Configuration Register.

CS

SCK

SO/I

SO/I

CS

16-Bit

READ

16-Bit

READ

COMMAND

16-Bit

Response

NOTE: (1) 0 indicates T

register, 1 indicates T

LOW

(1)

HIGH

00/1

register.

1T0T1T2T3T4T5T6T7T8T9T10T11T12

...

ZZ1D3D4D5D6D7D8D9D10D11D12D13D14D15

010TM0TM1POLF0F1R0R1D0D10000

...

ZZ1D3D4D5D6D7D8D9D10D11D12D13D14D15

(Continued)

(Continued)

...

...

CS

SCK

SO/I

CS

SCK

SO/I

FIGURE 5. READ followed by READ COMMAND and Response.

CS

SO/I

16-Bit

READ

CS

SCK

SO/I

FIGURE 6. Data READ.

...

000P0P100000000001

ZZ1D3D4D5D6D7D8D9D10D11D12D13D14D15

ZZ1D3D4D5D6D7D8D9D10D11D12D13D14D15

6

www.ti.com

TMP122, TMP124

SBOS272B

Page 7

READ ADDRESS REGISTER

Figure 7 shows the internal register structure of the

TMP122/TMP124. Table III describes the addresses of the

registers available. The READ address register uses the two

bits to identify which of the data registers should respond to

a read command. Following a complete 16-bit read, the

READ address register is reset to the default power-up state

of P1/P0 equal 0/0.

READ Address

Register

Temperature

Register

Configuration

Register

T

LOW

Register

T

HIGH

Register

I/O

Control

Interface

CS

SCK

SO/I

FIGURE 7. Internal Register Structure of the TMP122 and

TMP124.

P1 P0 REGISTER

0 0 Temperature Register (READ Only)

0 1 Configuration Register (READ/WRITE)

10T

11T

Register (READ/WRITE)

LOW

Register (READ/WRITE)

HIGH

TABLE III. Pointer Addresses of the TMP122 and TMP124

Registers.

TEMPERATURE REGISTER

The Temperature Register of the TMP122/TMP124 is a 16bit, signed read-only register that stores the output of the

most recent conversion. The TMP122/TMP124 are specified for the temperature range of –40°C to +125°C with

operation from –55°C to +150°C. Up to 16 bits can be read

to obtain data and are described in Table IV. The first 13 bits

are used to indicate temperature where bit D2 is 1, and D1,

D0 are in a high impedance state. Data format for temperature is summarized in Table V. Following power-up or reset,

the Temperature Register will read 0°C until the first conversion is complete.

D15 D14 D13 D12 D11 D10 D9 D8

T12 T11 T10 T9 T8 T7 T6 T5

D7 D6 D5 D4 D3 D2 D1 D0

T4 T3 T2 T1 T0 1 Z Z

TABLE IV. Temperature Register.

TEMPERATURE DIGITAL OUTPUT

(°C) (BINARY) HEX

150 0100 1011 0000 0111 4B07

125 0011 1110 1000 0111 3E87

25 0000 1100 1000 0111 0C87

0.0625 0000 0000 0000 1111 000F

0 0000 0000 0000 0111 0007

–0.0625 1111 1111 1111 1111 FFFF

–25 1111 0011 1000 0111 F387

–55 1110 0100 1000 0111 E487

NOTE: (1) The last 2 bits are high impedance and are shown as 11 in the table.

(1)

TABLE V. Temperature Data Format.

The user can obtain 9, 10, 11, or 12 bits of resolution by

addressing the Configuration Register and setting the resolution bits accordingly.

For 9-, 10-, or 11-bit resolution, the most

significant bits in the Temperature Register are used with the

unused LSBs set to zero.

CONFIGURATION REGISTER

The Configuration Register is a 16-bit read/write register

used to store bits that control the operational modes of the

temperature sensor. Read/write operations are performed

MSB first. The format of the Configuration Register for the

TMP122/TMP124 is shown in Table VI, followed by a breakdown of the register bits. The power-up/reset value of the

Configuration Register bits R1/R0 equal 1/1, all other bits

equal zero.

D15 D14 D13 D12 D11 D10 D9 D8

0 0 0 0 D1 D0 R1 R0

D7 D6 D5 D4 D3 D2 D1 D0

F1 F0 POL TM1 TM0 0 1 0

TABLE VI. Configuration Register.

SHUTDOWN MODE (SD)

The Shutdown Mode of the TMP122/TMP124 can be used to

shut down all device circuitry except the serial interface.

Shutdown mode occurs when the last 8 bits of the WRITE

command are equal to 1, and will occur once the current

conversion is completed, reducing current consumption to

less than 1µA. To take the part out of shutdown, send any

command or pattern after the 16-bit read with the last 8 bits

not equal to one. Power on default is in active mode.

TMP122, TMP124

SBOS272B

www.ti.com

7

Page 8

THERMOSTAT MODE (TM1/TM0)

The Thermostat Mode bits of the TMP122/TMP124 indicate to

the device whether to operate in Comparator Mode, Interrupt

Mode or Interrupt Comparator Mode. For more information on

Comparator and Interrupt Mode, see text HIGH and LOW limit

registers. The bit assignments for thermostat mode are

described in Table VII. Power on default is comparator mode.

TM1 TM0 MODE OF OPERATION

0 0 Comparator Mode

0 1 Interrupt Mode

1 0 Interrupt Comparator Mode

11 —

TABLE VII. Mode Settings of the TMP122.

POLARITY (POL)

The Polarity Bit of the TMP122/TMP124 adjusts the polarity

of the ALERT pin output. By default, POL = 0 and the ALERT

pin will be active LOW, as shown in Figure 8. For POL = 1

the ALERT Pin will be active HIGH, and the state of the

ALERT Pin is inverted.

T

Read

T

HIGH

LOW

Measured

Temperature

TMP122/124 ALERT PIN

(Comparator Mode)

POL = 0

TMP122/124 ALERT PIN

(Interrupt Mode)

POL = 0

TMP122/124 ALERT PIN

(Interrupt/Comparator Mode)

POL = 0

Read Read

Time

HIGH AND LOW LIMIT REGISTERS

In Comparator Mode (TM1/TM0 = 0/0), the ALERT Pin of the

TMP122/TMP124 becomes active when the temperature

equals or exceeds the value in T

consecutive number of faults according to fault bits F1 and

F0. The ALERT pin will remain active until the temperature

falls below the indicated T

value for the same number of

LOW

faults.

In Interrupt Mode (TM1/TM0 = 0/1) the ALERT pin becomes

active when the temperature equals or exceeds T

consecutive number of fault conditions. The ALERT pin

remains active until a read operation of any register occurs.

The ALERT pin will also be cleared if the device is placed in

Shutdown Mode. Once the ALERT pin is cleared, it will only

become active again by the temperature falling below T

When the temperature falls below T

becomes active and remains active until cleared by a read

operation of any register. Once the ALERT pin is cleared, the

above cycle will repeat with the ALERT pin becoming active

when the temperature equals or exceeds T

In Interrupt/Comparator Mode (TM1/TM0 = 1/0), the ALERT

Pin of the TMP122/TMP124 becomes active when the temperature equals or exceeds the value in T

a consecutive number of faults according to fault bits F1 and

F0. The ALERT pin will remain active until the temperature

falls below the indicated T

value for the same number of

LOW

faults and a communication with the device has occurred

after that point.

Operational modes are represented in Figure 8. Tables IX

and X describe the format for the T

Power-up reset values for T

and T

= 75°C. The format of the data for T

LOW

HIGH

and T

is the same as for the Temperature Register.

All 13 bits for the Temperature, T

HIGH

used in the comparisons for the ALERT function for all converter resolutions. The three LSBs in T

affect the ALERT output even if the converter is configured for

9-bit resolution.

and generates a

HIGH

, the ALERT pin

LOW

HIGH

and generates

HIGH

and T

HIGH

LOW

, and T

are: T

LOW

HIGH

and T

LOW

HIGH

registers are

HIGH

.

registers.

= 80°C

HIGH

and T

LOW

for a

LOW

LOW

can

.

FIGURE 8. ALERT Output Transfer Function Diagrams.

FAULT QUEUE (F1/F0)

A fault condition occurs when the measured temperature

exceeds the limits set in the T

HIGH

and T

Fault Queue is provided to prevent a false alert due to

environmental noise and requires consecutive fault measurements to trigger the alert function of the TMP122/TMP124.

Table VIII defines the number of consecutive faults required

to trigger a consecutive alert condition. Power-on default for

F1/F0 is 0/0.

F1 F0 CONSECUTIVE FAULTS

00 1

01 2

10 4

11 6

TABLE VIII. Fault Settings of the TMP122 and TMP124.

8

registers. The

LOW

www.ti.com

D15 D14 D13 D12 D11 D10 D9 D8

H12 H11 H10 H9 H8 H7 H6 H5

D7 D6 D5 D4 D3 D2 D1 D0

H4 H3 H2 H1 H0 1 1 0

TABLE IX. T

D15 D14 D13 D12 D11 D10 D9 D8

L12 L11 L10 L9 L8 L7 L6 L5

D7 D6 D5 D4 D3 D2 D1 D0

L4 L3 L2 L1 L0 1 0 0

TABLE X. T

HIGH

Register.

LOW

Register.

TMP122, TMP124

SBOS272B

Page 9

CONVERTER RESOLUTION (R1/R0)

The Converter Resolution Bits control the resolution of the

internal Analog-to-Digital (A/D) converter. This allows the user

to maximize efficiency by programming for higher resolution or

faster conversion time. Table XI identifies the Resolution Bits

and the relationship between resolution and conversion time.

The TMP122/TMP124 have a default resolution of 12 bits.

D1 D0 CONVERSION TIME CONVERSION PERIOD

0 0 0.25s 0.25s

0 1 0.25s 0.5s

1 0 0.25s 1s

1 1 0.25s 8s

TABLE XII. Conversion Delay for 12-Bit Resolution.

R1 R0 RESOLUTION (typical)

0 0 9 Bits (0.5°C) plus sign 30ms

0 1 10 Bits (0.25°C) plus sign 60ms

1 0 11 Bits (0.125°C) plus sign 120ms

1 1 12 Bits (0.0625°C) plus sign 240ms

TABLE XI. Resolution of the TMP122 and TMP124.

DELAY TIME

The Delay Bits control the amount of time delay between each

CONVERSION TIME

D1/D0 = 0/1

0.25s

0.25s

D1/D0 = 1/0

0.25s

D1/D0 = 1/1

12-Bit Resolution

0.5s

1s

8s

conversion. This feature allows the user to maximize power

savings by eliminating unnecessary conversions, and minimizing current consumption. During active conversion the TMP122/

TMP124 typically requires 50µA of current for approximately

FIGURE 9. Conversion Time and Period Description.

0.25s conversion time, and approximately 20µA for idle times

between conversions. Delay settings are identified in Table XII

as conversion time and period, and are shown in Figure 9.

Default power up is D1/D0 equal 0/0. Conversion time and

conversion periods scale with resolution. Conversion period

Timing Diagrams

The TMP122/TMP124 are SPI compatible. Figures 10 to 12

describe the various timing parameters of the TMP122/

TMP124 with timing definitions in Table XIII.

denotes time between conversion starts.

PARAMETER MIN MAX UNITS

SCK Period t

Data In to Rising Edge SCK Setup Time t

SCK Falling Edge to Output Data Delay t

SCK Rising Edge to Input Data Hold Time t

CS to Rising Edge SCK Set-Up Time t

CS to Output Data Delay t

CS Rising Edge to Output High Impedance t

1

2

3

4

5

6

7

100 ns

20 ns

30 ns

20 ns

40 ns

30 ns

30 ns

TABLE XIII. Timing Description.

50µA (active)

20µA (idle)

TMP122, TMP124

SBOS272B

www.ti.com

9

Page 10

SCK

t

5

t

CS

t

6

SO/I

FIGURE 10. Output Data Timing Diagram.

SCK

CS

SO/I

FIGURE 11. High Impedance Output Timing Diagram.

1

t

3

SCK

CS

t

SO/I

t

7

7

SCK

t

4

CS

SO/I

FIGURE 12. Input Data Timing Diagram.

SCK

t

2

t

4

t

2

CS

SO/I

10

www.ti.com

TMP122, TMP124

SBOS272B

Page 11

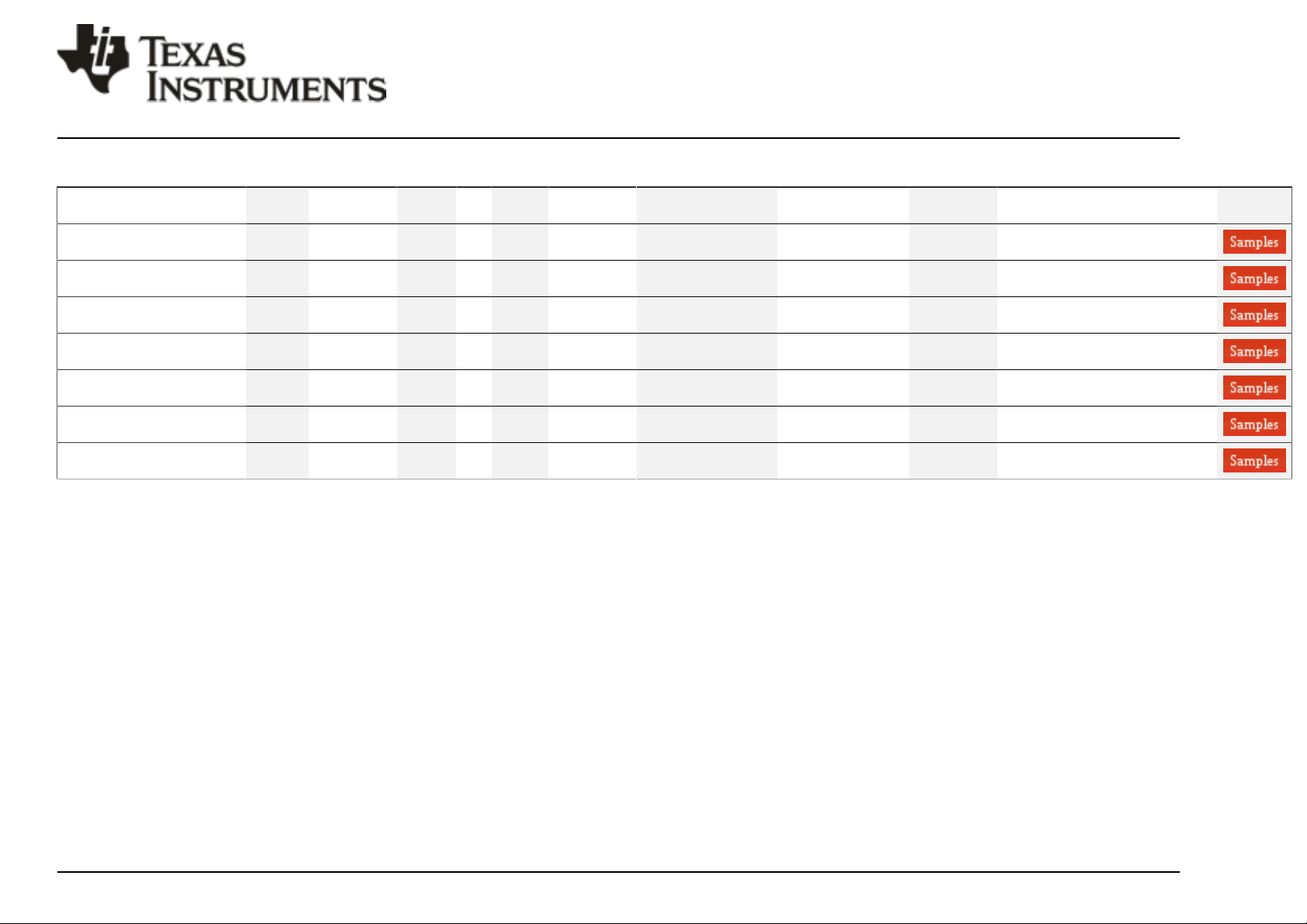

PACKAGE OPTION ADDENDUM

www.ti.com

10-Jun-2014

PACKAGING INFORMATION

Orderable Device Status

TMP122AIDBVR ACTIVE SOT-23 DBV 6 3000 Green (RoHS

TMP122AIDBVRG4 ACTIVE SOT-23 DBV 6 3000 Green (RoHS

TMP122AIDBVT ACTIVE SOT-23 DBV 6 250 Green (RoHS

TMP122AIDBVTG4 ACTIVE SOT-23 DBV 6 250 Green (RoHS

TMP124AID ACTIVE SOIC D 8 75 Green (RoHS

TMP124AIDG4 ACTIVE SOIC D 8 75 Green (RoHS

TMP124AIDR ACTIVE SOIC D 8 2500 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-2-260C-1 YEAR -40 to 125 T122

CU NIPDAU Level-2-260C-1 YEAR -40 to 125 T122

CU NIPDAU Level-2-260C-1 YEAR -40 to 125 T122

CU NIPDAU Level-2-260C-1 YEAR -40 to 125 T122

CU NIPDAU Level-1-260C-UNLIM -55 to 125 T124

CU NIPDAU Level-1-260C-UNLIM -55 to 125 T124

CU NIPDAU Level-1-260C-UNLIM -55 to 125 T124

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

Samples

Addendum-Page 1

Page 12

PACKAGE OPTION ADDENDUM

www.ti.com

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

10-Jun-2014

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

OTHER QUALIFIED VERSIONS OF TMP122 :

Enhanced Product: TMP122-EP

•

NOTE: Qualified Version Definitions:

Enhanced Product - Supports Defense, Aerospace and Medical Applications

•

Addendum-Page 2

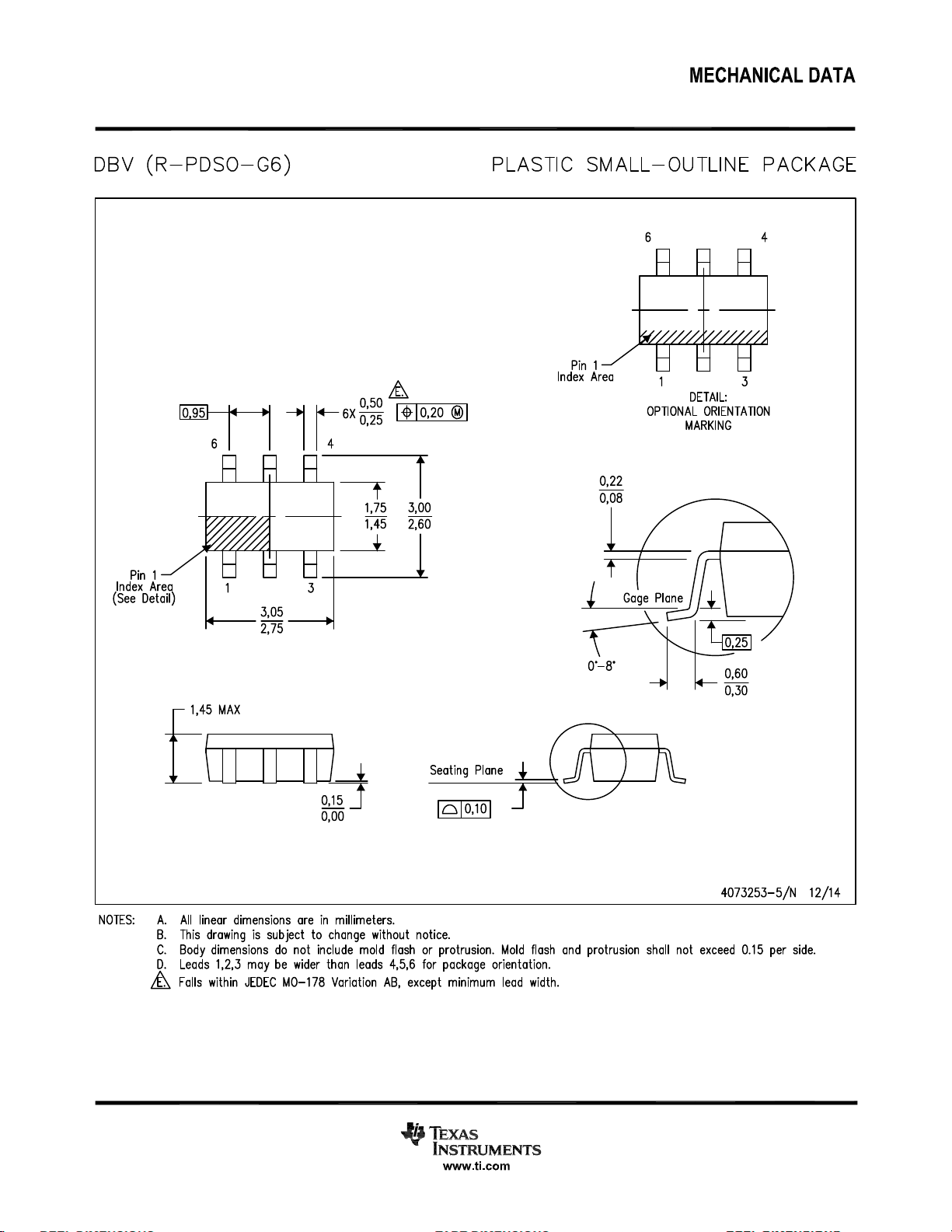

Page 13

PACKAGE MATERIALS INFORMATION

www.ti.com 8-Jul-2011

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

TMP122AIDBVR SOT-23 DBV 6 3000 178.0 9.0 3.23 3.17 1.37 4.0 8.0 Q3

TMP122AIDBVT SOT-23 DBV 6 250 178.0 9.0 3.23 3.17 1.37 4.0 8.0 Q3

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 14

PACKAGE MATERIALS INFORMATION

www.ti.com 8-Jul-2011

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TMP122AIDBVR SOT-23 DBV 6 3000 180.0 180.0 18.0

TMP122AIDBVT SOT-23 DBV 6 250 180.0 180.0 18.0

Pack Materials-Page 2

Page 15

Page 16

Page 17

Page 18

Page 19

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Page 20

Loading...

Loading...