Datasheet TLV4112IP, TLV4112IDR, TLV4112ID, TLV4112CP, TLV4112CDR Datasheet (Texas Instruments)

...

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

High Output Drive . . . >300 mA

D

Rail-To-Rail Output

D

Unity-Gain Bandwidth ...2 MHz

D

Slew Rate . . . 1.5 V/µs

D

Supply Current . . . 700-µA/Per Channel

D

Supply Voltage Range . . . 2.5 V to 6 V

D

Specified Temperature Range:

– TA = 0°C to 70°C . . . Commercial Grade

– TA = –40°C to 125°C . . . Industrial Grade

D

Universal OpAmp EVM

description

The TLV411x single supply operational amplifiers provide output currents in excess of 300 mA at 5 V. This

enables standard pin-out amplifiers to be used as high current buffers or in coil driver applications. The TL V4110

and TLV41 13 comes with a shutdown feature.

The TLV411x is available in the ultra small MSOP PowerPAD package, which of fers the exceptional thermal

impedance required for amplifiers delivering high current levels.

All TLV41 1x devices are offered in PDIP, SOIC (single and dual) and MSOP PowerPAD (dual).

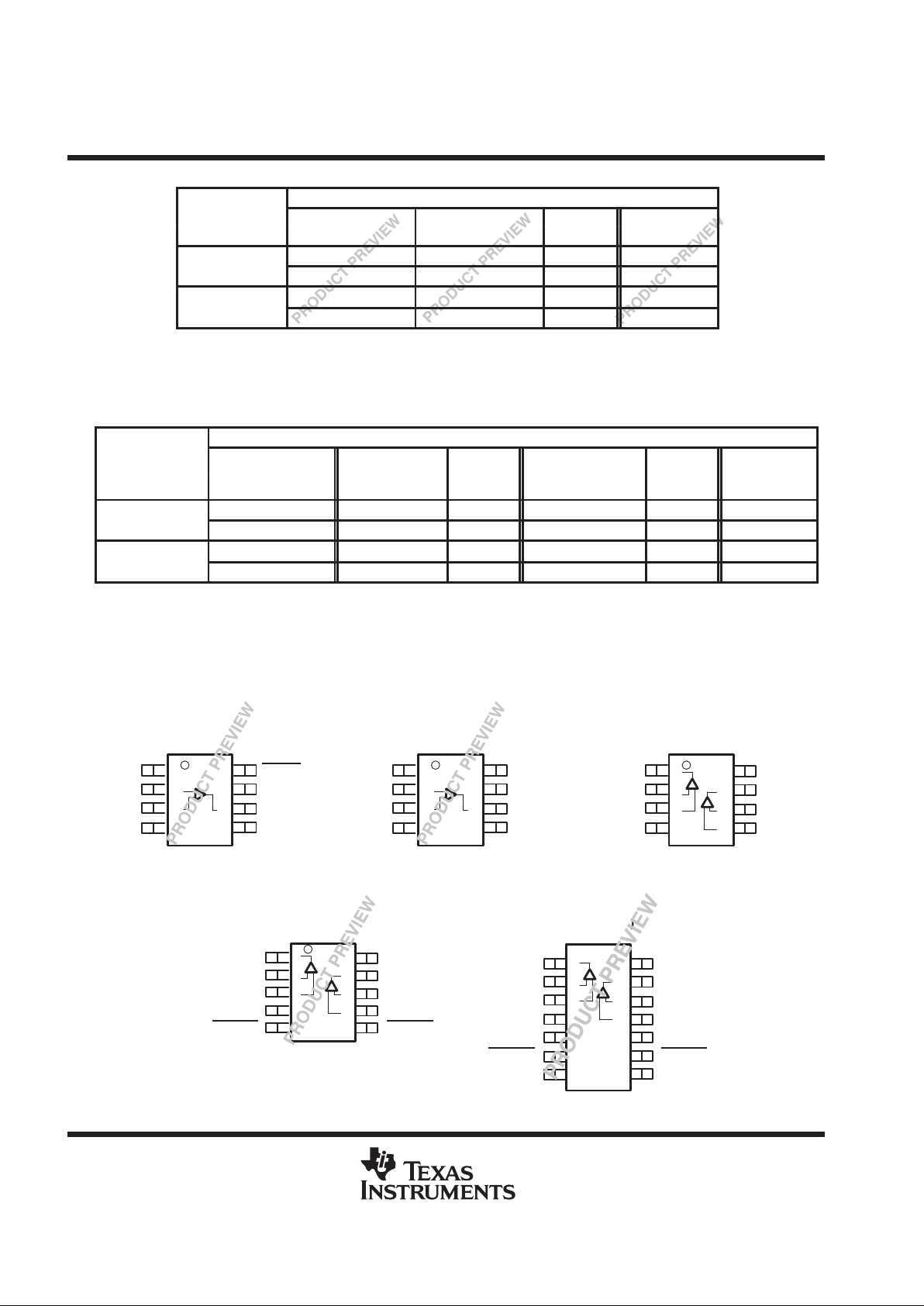

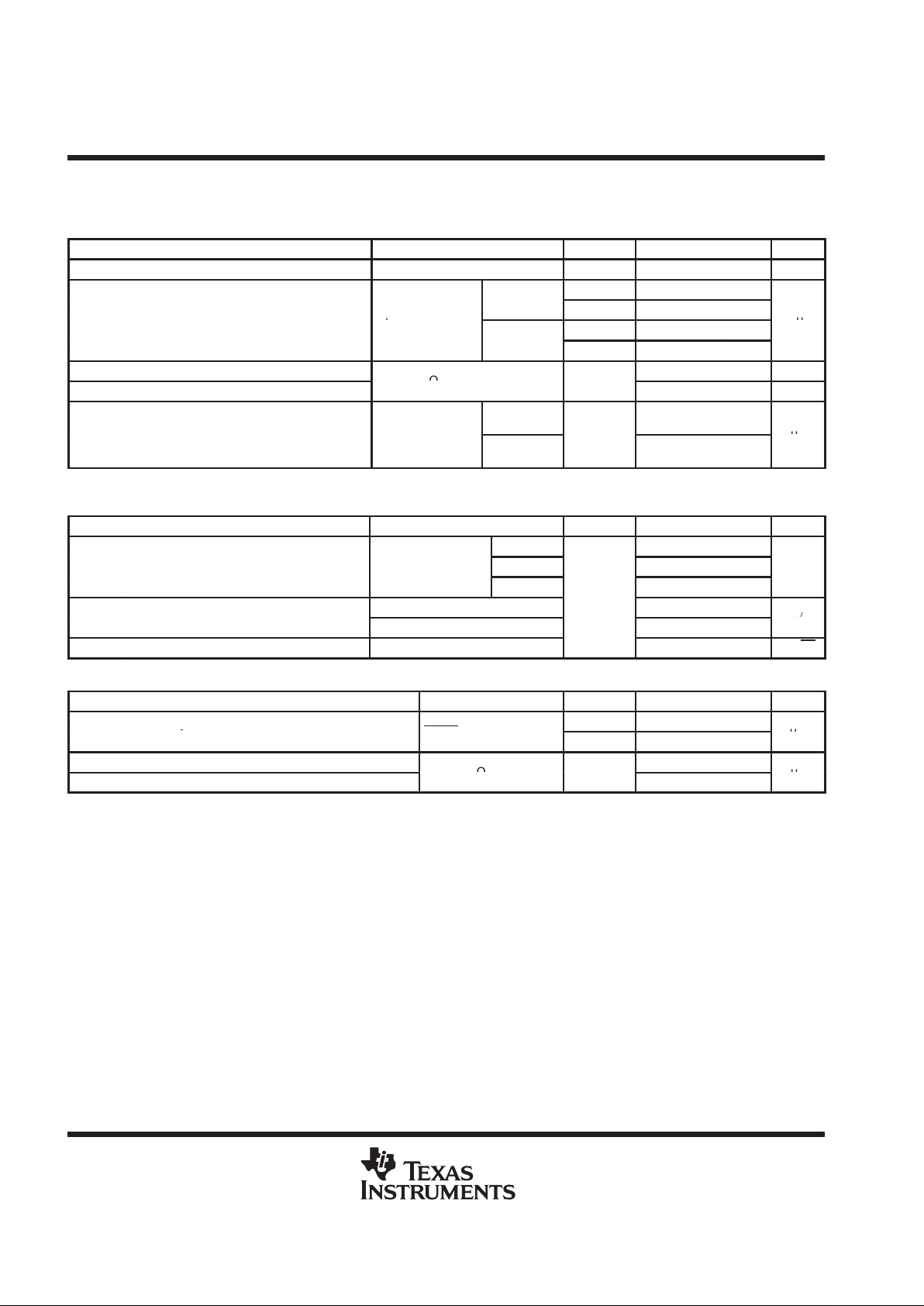

FAMILY PACKAGE TABLE

NUMBER OF

PACKAGE TYPES

UNIVERSAL

DEVICE

CHANNELS

MSOP PDIP SOIC

SHUTDOWN

EVM BOARD

TLV4110

†

1 8 8 8 Yes

TLV4111

†

1 8 8 8 —

Refer to the EVM

TLV4112 2 8 8 8 —

Selecti

on Guide

(

Lit# SL

OU060)

TLV4113

†

2 10 14 14 Yes

(Lit# SLOU060)

†

This device is in the Product Preview stage of development. Contact the local TI sales office for more

information.

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

VDD = 3 V

IOH – High-Level Output Current – mA

V

OH

– High-Level Output Voltage – V

TA = 70°C

TA = 25°C

TA = 0°C

TA = –40°C

3.0

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.0

0 50 200100 150 250 300

2.2

2.1

TA = 125°C

TA = –40°C

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

VDD = 3 V

IOL – Low-Level Output Current – mA

TA = 70°C

TA = 25°C

TA = 0°C

OL

V – Low-Level Output Voltage – V

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.0

0 50 200100 150 250 300

0.2

0.1

TA = 125°C

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

1

2

3

4

8

7

6

5

1OUT

1IN–

1IN+

GND

V

DD

2OUT

2IN–

2IN+

TLV4112

D, DGN, OR P PACKAGE

(TOP VIEW)

PowerPAD is a trademark of Texas Instruments.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

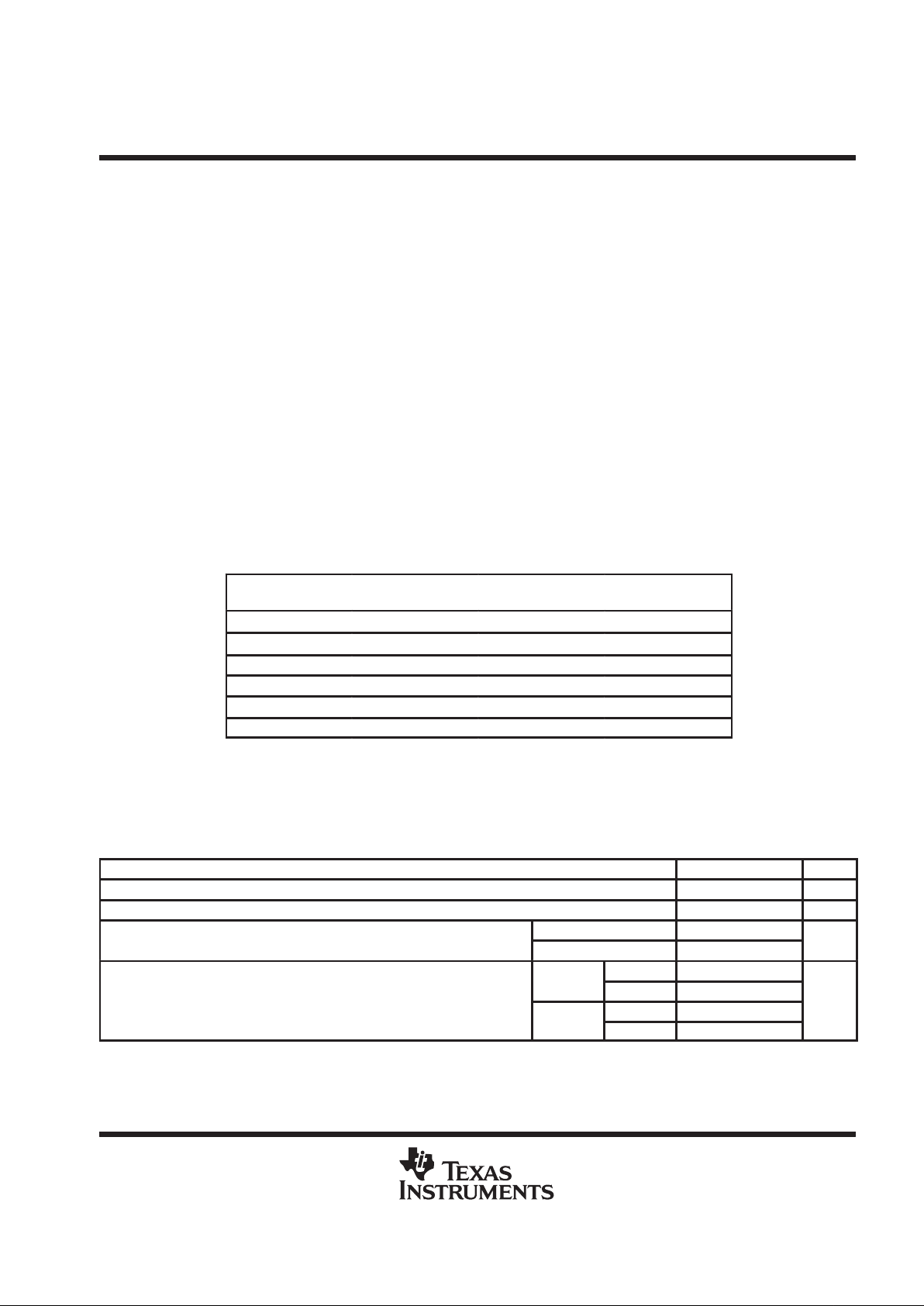

TLV4110 AND TLV4111 AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

SMALL OUTLINE SMALL OUTLINE

PLASTIC DIP

(D)

†‡

(DGN)

†

SYMBOL

(P)

°

°

TLV4110CD TLV4110CDGN xxTIAHL TLV4110CP

0°C to 70°C

TLV4111CD TLV4111CDGN xxTIAHN TLV4111CP

°

°

TLV4110ID TLV4110IDGN xxTIAHM TLV4110IP

–

40°C to 125°C

TLV4111ID TLV4111IDGN xxTIAHO TLV4111IP

†

This package is available taped and reeled. T o order this packaging option, add an R suf fix to the part

number (e.g., TL V4110CDR).

‡

In the SOIC package, the maximum RMS output power is thermally limited to 350 mW; 700 mW peaks can be driven, as

long as the RMS value is less than 350 mW.

TLV4112 AND TLV4113 AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

SMALL OUTLINE

SMALL OUT-

SMALL OUTLINE

PLASTIC DIP

(D)

†§

LINE

(DGN)

†

SYMBOL

(DGQ)

†

SYMBOL

(P)

°

°

TLV4112CD TLV4112DGN xxTIAHP — — TLV4112CP

0°C to 70°C

TLV4113CD

‡

— — TLV4113CDGN

‡

xxTIAHR TLV4113CN

‡

°

°

TLV4112ID TLV4112IDGN xxTIAHQ — — TLV4112IP

–

40°C to 125°C

TLV4113ID

‡

— — TLV4113IDGN

‡

xxTIAHS TLV4113IN

‡

†

This package is available taped and reeled. To order this packaging option, add an R suffix to the part number (e.g., TLV4112CDR).

‡

This device is in the Product Preview stage of development. Contact the local TI sales office for more information.

§

In the SOIC package, the maximum RMS output power is thermally limited to 350 mW; 700 mW peaks can be driven, as long as the

RMS value is less than 350 mW.

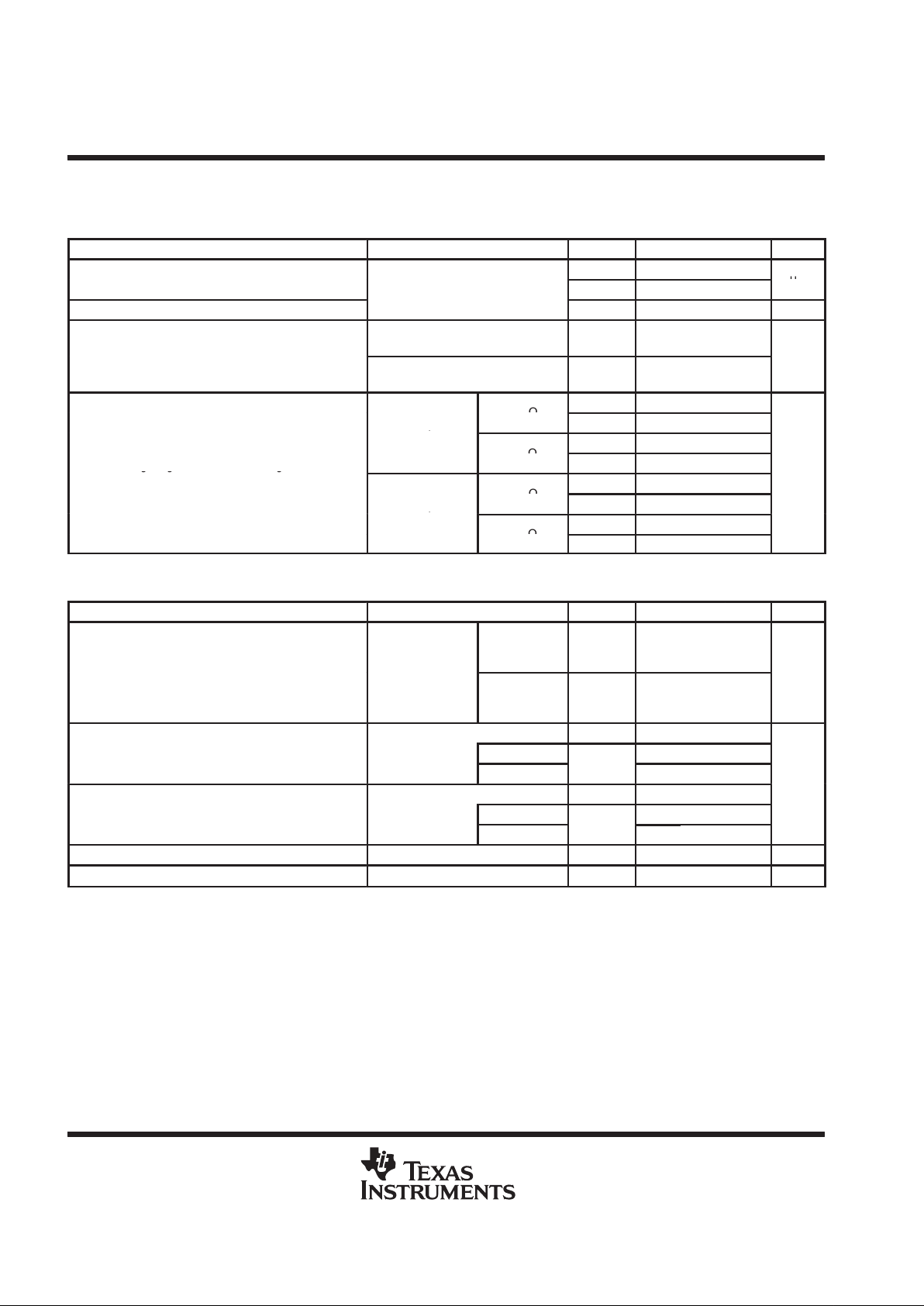

TLV411x PACKAGE PINOUTS

1

2

3

4

5

6

7

14

13

12

11

10

9

8

1OUT

1IN–

1IN+

GND

NC

1SHDN

NC

V

DD

2OUT

2IN–

2IN+

NC

2SHDN

NC

(TOP VIEW)

1

2

3

4

8

7

6

5

NC

IN–

IN+

GND

SHDN

NC

V

DD

OUT

TLV4110

D, DGN OR P PACKAGE

(TOP VIEW)

1

2

3

4

8

7

6

5

1OUT

1IN–

1IN+

GND

V

DD

2OUT

2IN–

2IN+

TLV4112

D, DGN, OR P PACKAGE

(TOP VIEW)

TLV4113

D OR N PACKAGE

NC – No internal connection

1

2

3

4

5

10

9

8

7

6

1OUT

1IN–

1IN+

GND

1SHDN

VDD+

2OUT

2IN–

2IN+

2SHDN

TLV4113

DGQ PACKAGE

(TOP VIEW)

1

2

3

4

8

7

6

5

NC

IN–

IN+

GND

NC

V

DD

OUT

NC

TLV4111

D, DGN OR P PACKAGE

(TOP VIEW)

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage, VDD (see Note 1) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage, VID ±V

DD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, V

I

±V

DD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current,IO (see Note 2) 800 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous /RMS output current, IO (each output of amplifier): TJ ≤ 105°C 350 mA. . . . . . . . . . . . . . . . . . . .

TJ ≤ 150°C 110 mA. . . . . . . . . . . . . . . . . . . .

Peak output current, IO (each output of amplifier: TJ ≤ 105°C 500 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

J

≤ 150°C 155 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA: C suffix 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I suffix –40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to GND.

2. To prevent permanent damage the die temperature must not exceed the maximum junction temperature.

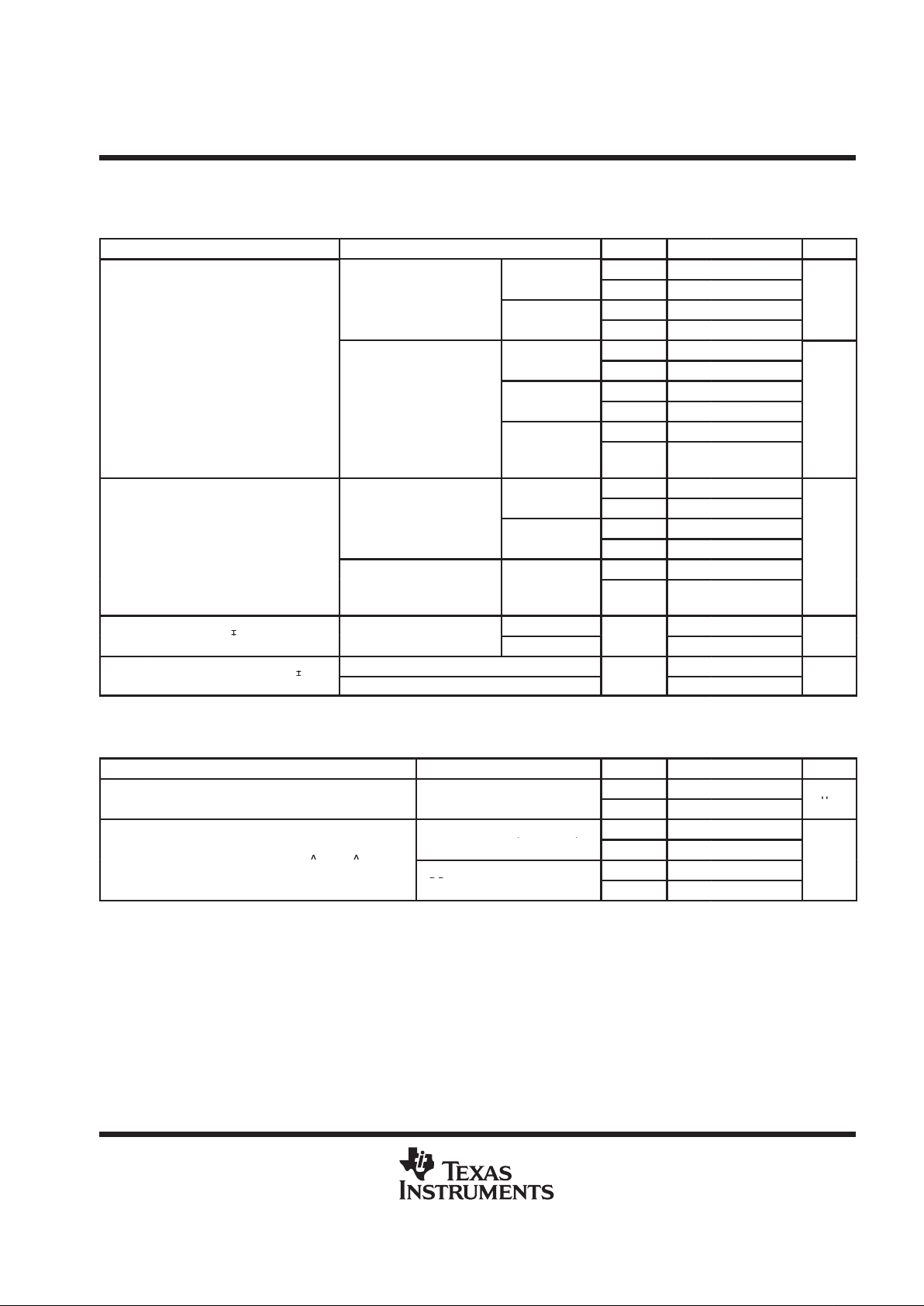

DISSIPATION RATING TABLE

PACKAGE

θ

JC

(°C/W)

θ

JA

(°C/W)

TA ≤ 25°C

POWER RATING

D (8) 38.3 176 710 mW

D (14) 26.9 122.3 1022 mW

DGN (8)

‡

4.7 52.7 2.37 W

DGQ (10)

‡

4.7 52.3 2.39 W

P (8) 41 104 1200 mW

N (14) 32 78 1600 mW

‡

See The Texas Instruments document,

PowerPAD Thermally Enhanced Package Application

Report

(literature number SLMA002), for more information on the PowerPAD package. The

thermal data was measured on a PCB layout based on the information in the section entitled

Texas Instruments Recommended Board for PowerPAD

on page 33 of the before mentioned

document.

recommended operating conditions

MIN MAX UNIT

Supply voltage, V

DD

2.5 6 V

Common-mode input voltage range, V

ICR

0 VDD–1.5 V

p

p

C-suffix 0 70

°

Operating free-air temperature, T

A

I-suffix –40 125

°C

VDD = 3 V 2.1

V(on)

VDD = 5 V 3.8

Shutdown turn on/off voltage level

§

VDD = 3 V 0.9

V

V(off)

VDD = 5 V 1.65

§

Relative to GND

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at recommend operating conditions, VDD = 3 V and 5 V (unless otherwise

noted)

dc performance

PARAMETER TEST CONDITIONS T

A

†

MIN TYP MAX UNITS

p

25°C 175 3500

VIOInput offset voltage

VIC = VDD/2,

VO = VDD/2 ,

Full range 4000

µ

V

αVIO Offset voltage draft

R

L

=

100 Ω

,

R

S

= 50

Ω

25°C 3 µV/°C

VDD = 3 V,

RS = 50 Ω

VIC = 0 to 2 V,

25°C 63

CMRR

Common-mode rejection ratio

VDD = 5 V,

RS = 50 Ω

VIC = 0 to 4 V,

25°C 68

dB

25°C 78 84

V

= 3 V,

R

L

=

100 Ω

Full range 67

DD

,

V

O(PP)

=0 to 1V

25°C 85 100

Large-signal differential voltage

R

L

=10

kΩ

Full range 75

A

VD

gg g

amplification

25°C 88 94

dB

V

= 5 V,

R

L

=

100 Ω

Full range 75

DD

,

V

O(PP)

=0 to 3V

25°C 90 110

R

L

=

10 kΩ

Full range 85

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

input characteristics

PARAMETER TEST CONDITIONS T

A

†

MIN TYP MAX UNITS

p

Measured over

VDD = 3 V

25°C and

Full range

0

to

1.5

V

ICR

Common-mode input voltage range

CMRR

range,

RS = 50 Ω

VDD = 5 V

25°C and

Full range

0

to

3.5

V

25°C 0.3 25

I

IO

Input offset current VIC = VDD/2

TLV411xC

50

TLV411xI

Full range

250

p

25°C 0.3 50

pA

I

IB

Input bias current

VO = VDD/2,

TLV411xC

100

R

S

= 50

Ω

TLV411xI

Full range

500

r

i(d)

Differential input resistance 25°C 1000 GΩ

C

IC

Common-mode input capacitance f = 100 Hz 25°C 5 pF

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at specified free-air temperature, VDD = 3 V and 5 V (unless otherwise

noted) (continued)

output characteristics

PARAMETER TEST CONDITIONS T

A

†

MIN TYP MAX UNITS

25°C 2.7 2.97

I

OH

= –10

mA

Full range 2.7

V

DD

=

3 V

,

V

IC

=

VDD/2

25°C 2.6 2.73

V

I

OH

=–

100 mA

Full range 2.6

25°C 4.7 4.96

V

OH

High-level output voltage

I

OH

= –10

mA

Full range 4.7

25°C 4.6 4.76

VDD = 5 V, VIC = VDD/2

I

OH

= –

100 mA

Full range 4.6

V

25°C 4.45 4.6

IOH = –200 mA

–40°C to

85°C

4.35

25°C 0.03 0.1

V

= 3 V and 5 V,

I

OL

= 10

mA

Full range 0.1

DD

,

VIC = VDD/2

25°C 0.33 0.4

V

OL

Low–level output voltage

I

OL

=

100 mA

Full range 0.55

V

25°C 0.38 0.6

VDD = 5 V, VIC = VDD/2 IOL = 200 mA

–40°C to

85°C

0.7

p

VDD = 3 V

°

±220

IOOutput current

‡

Measured at 0.5 V from rail

VDD = 5 V

25°C

±320

mA

p

Sourcing

°

800

IOSShort-circuit output current

‡

Sinking

25°C

800

mA

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

‡

When driving output currents in excess of 200 mA, the MSOP PowerPAD package is required for thermal dissipation.

power supply

PARAMETER TEST CONDITIONS T

A

MIN TYP MAX UNITS

pp

p

25°C 700 1000

IDDSupply current (per channel)

V

O

=

VDD/2

Full range 1500

µ

A

V

=2.7 to 3.3 V , No load,

25°C 70 82

pp

DD

,

VIC = VDD/2 V

,

Full range 65

K

SVR

Power supply rejection ratio (∆V

DD

/

∆VIO)

VDD =4.5 to 5.5 V , No load,

25°C 70 79

dB

DD

VIC = VDD/2 V

Full range 65

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at specified free-air temperature, VDD = 3 V and 5 V (unless otherwise

noted) (continued)

dynamic performance

PARAMETER TEST CONDITIONS T

A

†

MIN TYP MAX UNITS

GBWP Gain bandwidth product RL=100 Ω CL=10 pF 25°C 2.7 MHz

25°C 0.8 1.57

V

o(pp)

= 2 V,

V

DD

= 3

V

Full range 0.55

SR

Slew rate at unity gain

R

L

=

100 Ω

,

C

= 10 pF

25°C 1 1.57

V/µs

C

L

= 10

F

V

DD

= 5

V

Full range 0.7

φM Phase margin

p

°

66

Gain margin

R

L

=

100 Ω

,

C

L

=

10 pF

25°C

16 dB

V

(STEP)pp

= 1 V,

AV = –1,

0.1%

°

0.7

tsSettling time

V

CL = 10 pF,

RL = 100 Ω

0.01%

25°C

1.3

µ

s

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

noise/distortion performance

PARAMETER TEST CONDITIONS T

A

MIN TYP MAX UNITS

pp

=

A

V

= 1 0.025

THD+N Total harmonic distortion plus noise

V

O( )

=

VDD/2 V

,

RL = 100 Ω,

AV = 10 0.035

f = 100 Hz

AV = 100

°

0.15

p

f = 100 Hz

25°C

55

VnEquivalent input noise voltage

f = 10 kHz 10

n

V/√H

z

I

n

Equivalent input noise current f = 1 kHz 0.31 fA/√Hz

shutdown characteristics

PARAMETER TEST CONDITIONS T

A

†

MIN TYP MAX UNITS

Supply current in shutdown mode (per channel)

25°C TBD

I

DD(SHDN)

y()

(TLV4110, TLV41 13)

SHDN

= 0

V

Full range TBD

µ

A

t

(ON)

Amplifier turnon time

‡

°

TBD

t

(Off)

Amplifier turnoff time

‡

R

L

=

100 Ω

25°C

TBD

µ

s

†

Full range is 0°C to 70°C for C suffix and –40°C to 125°C for I suffix. If not specified, full range is –40°C to 125°C.

‡

Disable time and enable time are defined as the interval between application of the logic signal to SHDN and the point at which the supply current

has reached half its final value.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

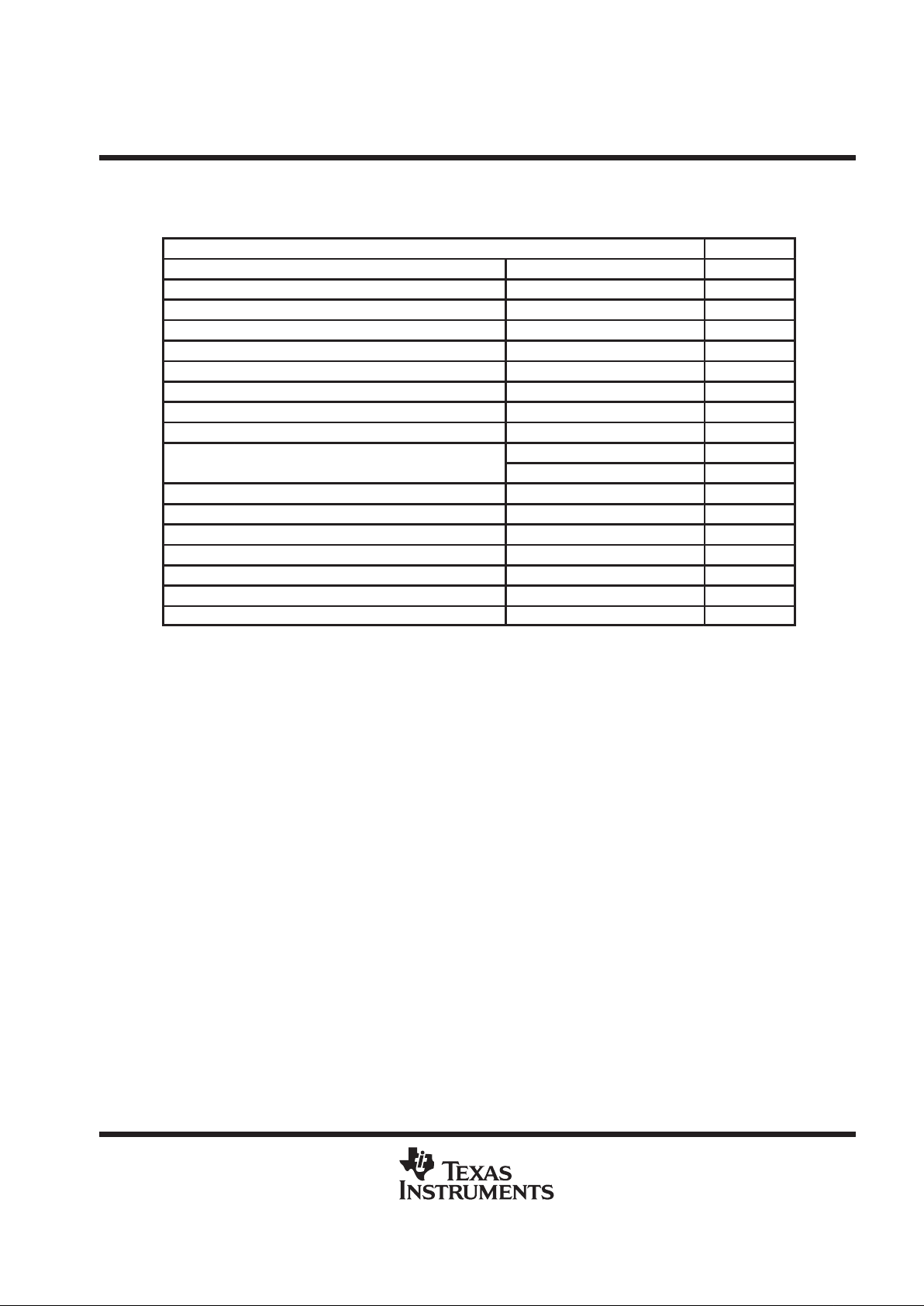

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

V

IO

Input offset voltage vs Common-mode input voltage 1, 2

CMRR Common-mode rejection ratio vs Frequency 3

V

OH

High-level output voltage vs High-level output current 4, 6

V

OL

Low-level output voltage vs Low-level output current 5, 7

Z

o

Output impedance vs Frequency 8

I

DD

Supply current vs Supply voltage 9

k

SVR

Supply voltage rejection ratio vs Frequency 10

A

VD

Differential voltage amplification and phase vs Frequency 11

Gain-bandwidth product vs Supply voltage 12

vs Supply voltage 13

SR

Slew rate

vs Temperature 14

T otal harmonic distortion+noise vs Frequency 15

V

n

Equivalent input voltage noise vs Frequency 16

Phase margin vs Capacitive load 17

Voltage-follower signal pulse response vs Time 18, 19

Inverting large-signal pulse response vs Time 20, 21

Small-signal inverting pulse response vs Time 22

Crosstalk vs Frequency 23

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 1

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

V

ICR

– Common-Mode Input Voltage – V

V

IO

– Input Offset Voltage – V

µ

0 0.4 0.8 1.2 1.6 2 2.4 2.8 3.2–0.2

6000

4000

2000

0

–2000

–4000

–6000

VDD = 3 V

TA = 25°C

Figure 2

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

VDD = 5 V

TA = 25°C

V

ICR

– Common-Mode Input Voltage – V

V

IO

– Input Offset Voltage – V

µ

6000

4000

2000

0

–2000

–4000

–6000

–0.2 0.4 2.21.0 1.6 2.8 3.4 4.0 4.6 5.2

0

Figure 3

COMMON-MODE REJECTION RATIO

vs

FREQUENCY

VDD = 3 V

TA = 25°C

f – Frequency – Hz

100 1 k 1 M10 k 100 k 10 M

CMRR – Common-Mode Rejection Ratio – dB

120

110

100

90

80

70

60

50

40

Figure 4

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

VDD = 3 V

IOH – High-Level Output Current – mA

V

OH

– High-Level Output Voltage – V

TA = 70°C

TA = 25°C

TA = 0°C

TA = –40°C

3.0

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.0

0 50 200100 150 250 300

2.2

2.1

TA = 125°C

Figure 5

TA = –40°C

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

VDD = 3 V

IOL – Low-Level Output Current – mA

TA = 70°C

TA = 25°C

TA = 0°C

OL

V – Low-Level Output Voltage – V

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.0

0 50 200100 150 250 300

0.2

0.1

TA = 125°C

Figure 6

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

VDD = 5 V

IOH – High-Level Output Current – mA

V

OH

– High-Level Output Voltage – V

5.0

4.9

4.8

4.7

4.6

4.5

4.4

4.3

4.0

0 50 200100 150 250 300

4.2

4.1

TA = –40°C

TA = 70°C

TA = 25°C

TA = 0°C

TA = 125°C

Figure 7

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

VDD = 5 V

IOL – Low-Level Output Current – mA

TA = –40°C

TA = 125°C

TA = 70°C

TA = 25°C

TA = 0°C

OL

V – Low-Level Output Voltage – V

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.0

0 50 200100 150 250 300

0.2

0.1

Figure 8

OUTPUT IMPEDANCE

vs

FREQUENCY

VDD = 3 & 5 V

TA = 25°C

f – Frequency – Hz

100 1k 10k

0.10

1

10

100

– Output Impedance –Z

o

Ω

A = 1

A = 100

A = 10

100k 1M 10M

Figure 9

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

AV = 1

VIN = VDD/2 V

VDD – Supply Voltage – V

TA = –40°C

TA = 125°C

TA = 70°C

TA = 25°C

TA = 0°C

DD

I Supply Current – –Aµ

1200

1000

800

600

400

200

0

01 423 5

6

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 10

SUPPLY VOLTAGE REJECTION RATIO

vs

FREQUENCY

f – Frequency – Hz

100 1 k 1 M10 k 100 k 10 M

k

SVR

– Supply Voltage Rejection Ratio – V

VDD = 3 & 5 V

RF = 1 kΩ

RI = 100 Ω

VIN = 0 V

TA = 25°C

100

90

80

70

60

50

40

30

0

20

10

Figure 11

45

90

135

–45

0

AMPLIFICATION AND PHASE

vs

FREQUENCY

f – Frequency – Hz

100 1 k 1 M10 k 100 k 10 M

– Differential Voltage Amplification – dBA

VD

Phase Margin –

°

VDD = 3 & 5 V

RL = 100 kΩ

CL = 10 pF

TA = 25°C

PHASE

GAIN

120

100

80

60

40

20

0

–20

–40

Figure 12

GAIN-BANDWIDTH PRODUCT

vs

SUPPLY VOLTAGE

TA = 25°C

RL = 100 Ω

CL = 10 pF

f = 1 kHz

AV =open loop

VDD – Supply Voltage – V

Gain-Bandwidth Product – MHz

2.5 3 4.53.5 4 5

5.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

Figure 13

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

SLEW RATE

vs

SUPPLY VOLTAGE

AV = 1

RL = 100 Ω

CL = 10 pF

VDD – Supply Voltage – V

SR – Slew Rate – V/µ s

SR+

SR–

2.5 3 4.53.5 4 5

5.5 6

Figure 14

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

–40–25 –10 5 20 35 50 65 80 95 110 125

SLEW RATE

vs

TEMPERATURE

VDD = 3 & 5 V

AV = 1

RL = 100 Ω

CL = 10 pF

TA – Temperature – °C

SR – Slew Rate – V/µ s

SR+

SR–

Figure 15

TOTAL HARMONIC DISTORTION+NOIS

E

vs

FREQUENCY

f – Frequency – Hz

10 100 100

k

1 k 10 k

0.01

0.1

1

10

VDD = 5 V

RL = 100 Ω

V

O(PP)

= VDD/2

AV = 1, 10, & 100

A = 1

A = 100

A = 10

THD+N –Total Harmonic Distortion + Noise

Figure 16

EQUIVALENT INPUT VOLTAGE NOISE

vs

FREQUENCY

VDD = 3 V

f – Frequency – Hz

10 1 k 10 k 100 k

VDD = 5 V

100

nV/ Hz– Voltage Noise –V

n

0

60

100

160

20

40

80

120

140

Figure 17

PHASE MARGIN

vs

CAPACITIVE LOAD

VDD = 3 & 5 V

TA = 25°C

Capacitive Load – pF

100 1 k 10 k 100 k

RL = 100

10

Phase Margin – °

R

NULL

= 0

R

NULL

= 20

R

NULL

= 20

RL = 600

R

NULL

= 0

20

50

70

100

30

40

60

80

90

10

0

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 18

–2 0 2 4 6 8 10 12 14

VOLTAGE-FOLLOWER

LARGE-SIGNAL PULSE RESPONSE

VDD = 5 V

AV = 1

RL = 100 Ω

CL = 10 pF

TA = 25°C

t – TIME – µs

0

1

2

3

4

0

1

2

3

4

5

– Output Voltage – V

V

O

V

I

– Input Voltage – V

V

IN

V

O

Figure 19

–0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

VOLTAGE-FOLLOWER

SMALL-SIGNAL PULSE RESPONSE

VDD = 5 V

AV = 1

RL = 100 Ω

CL = 10 pF

TA = 25°C

VIN = 100 mV

t – TIME – µs

2.4

2.45

2.5

2.55

2.45

2.5

2.55

2.6

– Output Voltage – V

V

O

V

I

– Input Voltage – V

V

IN

V

O

Figure 20

–1012345678

INVERTING LARGE-SIGNAL

PULSE RESPONSE

t – TIME – µs

0

1

2

3

–1

0

2

3

– Output Voltage – V

V

O

V

I

– Input Voltage – V

VDD = 5 V

AV = –1

RL = 100 Ω

CL = 50 pF

TA = 25°C

VIN = 2.5 V

V

IN

V

O

1

–2

4

5

Figure 21

–1012345678

INVERTING LARGE-SIGNAL

PULSE RESPONSE

t – TIME – µs

0

1

2

3

–1

0

2

3

– Output Voltage – V

V

O

V

I

– Input Voltage – V

VDD = 5 V

AV = –1

RL = 100 Ω

CL = 50 pF

TA = 25°C

VIN = 2.5 V

V

IN

V

O

1

–2

4

5

Figure 22

SMALL-SIGNAL INVERTING

PULSE RESPONSE

t – TIME – µs

2.42

2.46

2.5

2.42

2.46

2.5

2.54

2.58

– Output Voltage – V

V

O

V

I

– Input Voltage – V

VDD = 5 V

AV = –1

RL = 100 Ω

CL = 50 pF

TA = 25°C

VIN = 2.5 V

V

IN

V

O

2.54

0 0.2 0.6 1.0 1.4 1.8 2.2 2.6 3.0

Figure 23

CROSSTALK

vs

FREQUENCY

VDD = 3 & 5 V

RL = 100 Ω

All Channels

f – Frequency – Hz

100 1 k 10 k 100 k10

VIN = 4 V

PP

VIN = 2 V

PP

Crosstalk – dB

–120

–100

–60

–40

–20

0

–80

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

shutdown function

Two members of the TLV411x family (TLV4110/3) have a shutdown terminal for conserving battery life in

portable applications. When the shutdown terminal is tied low, the supply current is reduced to just nano amps

per channel, the amplifier is disabled, and the outputs are placed in a high impedance mode. In order to save

power in shutdown mode, an external pullup resistor is required, thererfore, to enable the amplifier the shutdown

terminal must be pulled high. When the shutdown terminal is left floating, care should be taken to ensure that

parasitic leakage current at the shutdown terminal does not inadvertently place the operational amplifier into

shutdown.

driving a capacitive load

When the amplifier is configured in this manner, capacitive loading directly on the output will decrease the

device’s phase margin leading to high frequency ringing or oscillations. Therefore, for capacitive loads of greater

than 1 nF , it is recommended that a resistor be placed in series (R

NULL

) with the output of the amplifier, as shown

in Figure 24. A maximum value of 20 Ω should work well for most applications.

C

LOAD

R

F

Input

Output

R

G

R

NULL

+

–

R

L

C

L

R

F

Input

Output

R

G

R

NULL

+

–

R

L

Snubber

C

(a) (b)

Figure 24. Driving a Capacitive Load

offset voltage

The output offset voltage, (VOO) is the sum of the input offset voltage (VIO) and both input bias currents (IIB) times

the corresponding gains. The following schematic and formula can be used to calculate the output offset

voltage:

VOO+

V

IO

ǒ

1

) ǒ

R

F

R

G

Ǔ

Ǔ

"

I

IB

)

R

S

ǒ

1

) ǒ

R

F

R

G

Ǔ

Ǔ

"

I

IB–RF

+

–

V

I

+

R

G

R

S

R

F

I

IB–

V

O

I

IB+

Figure 25. Output Offset Voltage Model

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

_

+

R

null

R

L

C

L

Figure 26

general power design considerations

When driving heavy loads at high junction temperatures there is an increased probability of electromigration

affecting the long term reliability of ICs. Therefore for this not to be an issue either

D

the output current must be limited (at these high junction temperatures) or

D

the junction temperature must be limited.

The maximum continuous output current at a die temperature 150°C will be 1/3 of the current at 105°C.

The junction temperature will be dependent on the ambient temperature around the IC, thermal impedance from

the die to the ambient and power dissipated within the IC.

T

J

= TA + θJA × P

DIS

Where

P

DIS

is the IC power dissipation and is equal to the output current multiplied by the voltage dropped across the

output of the IC.

θJA is the thermal impedance between the junction and the ambient temperature of the IC.

TJ is the junction temperature.

TA is the ambient temperature.

Reducing one or more of these factors will result in a reduced die temperature. The 8-pin SOIC (small outline

integrated circuit) has a thermal impedance from junction to ambient of 176°C/W. For this reason we

recommend that the maximum power dissipation of the 8-pin SOIC package be limited to 350 mW, with peak

dissipation of 700 mW as long as the RMS value is less than 350 mW.

The use of the MSOP PowerP AD dramatically reduces the thermal impedance from junction to case. And with

correct mounting, the reduced thermal impedance will greatly increase the IC’s permissible power dissipation

and output current handling capability . For example, the power dissipation of the PowerPAD is increased to

above 1 W. Sinusoidal and pulse-width modulated output signals will also increase the output current capability .

The equivalent dc current is proportional to the square-root of the duty cycle:

I

DC(EQ)

+

I

Cont

(duty cycle

)

Ǹ

CURRENT DUTY CYCLE

AT PEAK RATED CURRENT

EQUIVALENT DC CURRENT

AS A PERCENTAGE OF PEAK

100 100

70 84

50 71

Note that with an operational amplifier, a duty cycle of 70% would often result in the op amp sourcing current

70% of the time and sinking current 30%, therefore, the equivalent dc current would still be 0.84 times the

continuous current rating at a particular junction temperature.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general PowerPAD design considerations

The TLV411x is available in a thermally-enhanced PowerPAD family of packages. These packages are

constructed using a downset leadframe upon which the die is mounted [see Figure 27(a) and Figure 27(b)]. This

arrangement results in the lead frame being exposed as a thermal pad on the underside of the package [see

Figure 27(c)]. Because this thermal pad has direct thermal contact with the die, excellent thermal performance

can be achieved by providing a good thermal path away from the thermal pad.

The PowerP AD package allows for both assembly and thermal management in one manufacturing operation.

During the surface-mount solder operation (when the leads are being soldered), the thermal pad can also be

soldered to a copper area underneath the package. Through the use of thermal paths within this copper area,

heat can be conducted away from the package into either a ground plane or other heat dissipating device.

The PowerPAD package represents a breakthrough in combining the small area and ease of assembly of

surface mount with the, heretofore, awkward mechanical methods of heatsinking.

DIE

Side View (a)

End View (b) Bottom View (c)

DIE

Thermal

Pad

NOTE A: The thermal pad is electrically isolated from all terminals in the package.

Figure 27. Views of Thermally Enhanced DGN Package

Although there are many ways to properly heatsink the PowerPAD package, the following steps illustrate the

recommended approach.

68 mils x 70 mils) with 5 vias

(Via diameter = 13 mils

Thermal Pad Area

Single or Dual

Figure 28. PowerPAD PCB Etch and Via Pattern

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general PowerPAD design considerations (continued)

1. Prepare the PCB with a top side etch pattern as shown in Figure 28. There should be etch for the leads as

well as etch for the thermal pad.

2. Place five holes (dual) or nine holes (quad) in the area of the thermal pad. These holes should be 13 mils

in diameter. Keep them small so that solder wicking through the holes is not a problem during reflow.

3. Additional vias may be placed anywhere along the thermal plane outside of the thermal pad area. This helps

dissipate the heat generated by the TLV411x IC. These additional vias may be larger than the 13-mil

diameter vias directly under the thermal pad. They can be larger because they are not in the thermal pad

area to be soldered so that wicking is not a problem.

4. Connect all holes to the internal ground plane.

5. When connecting these holes to the ground plane, do not use the typical web or spoke via connection

methodology . Web connections have a high thermal resistance connection that is useful for slowing the heat

transfer during soldering operations. This makes the soldering of vias that have plane connections easier.

In this application, however , low thermal resistance is desired for the most efficient heat transfer. Therefore,

the holes under the TL V411x PowerP AD package should make their connection to the internal ground plane

with a complete connection around the entire circumference of the plated-through hole.

6. The top-side solder mask should leave the terminals of the package and the thermal pad area with its five

holes (dual) or nine holes (quad) exposed. The bottom-side solder mask should cover the five or nine holes

of the thermal pad area. This prevents solder from being pulled away from the thermal pad area during the

reflow process.

7. Apply solder paste to the exposed thermal pad area and all of the IC terminals.

8. With these preparatory steps in place, the TLV41 1x IC is simply placed in position and run through the solder

reflow operation as any standard surface-mount component. This results in a part that is properly installed.

For a given θJA, the maximum power dissipation is shown in Figure 30 and is calculated by the following formula:

PD+

ǒ

T

MAX–TA

q

JA

Ǔ

Where:

PD= Maximum power dissipation of TLV41 1x IC (watts)

T

MAX

= Absolute maximum junction temperature (150°C)

T

A

= Free-ambient air temperature (°C)

θ

JA

= θ

JC

+ θ

CA

θJC= Thermal coefficient from junction to case

θCA= Thermal coefficient from case to ambient air (°C/W)

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general PowerPAD design considerations (continued)

TJ = 150°C

4

3

2

0

–55 –40 –10 20 35

Maximum Power Dissipation – W

MAXIMUM POWER DISSIPATION

vs

FREE-AIR TEMPERATURE

65 95 125

1

TA – Free-Air Temperature – °C

–25 5 50 80 110

3.5

2.5

1.0

0.5

DGN Package

Low-K Test PCB

θJA = 52.7°C/W

PDIP Package

Low-K Test PCB

θJA = 104°C/W

SOIC Package

Low-K Test PCB

θJA = 176°C/W

NOTE A: Results are with no air flow and using JEDEC Standard Low-K test PCB.

Figure 29. Maximum Power Dissipation vs Free-Air Temperature

The next consideration is the package constraints. The two sources of heat within an amplifier are quiescent

power and output power. The designer should never forget about the quiescent heat generated within the

device, especially muti-amplifier devices. Because these devices have linear output stages (Class A-B), most

of the heat dissipation is at low output voltages with high output currents.

The other key factor when dealing with power dissipation is how the devices are mounted on the PCB. The

PowerPAD devices are extremely useful for heat dissipation. But, the device should always be soldered to a

copper plane to fully use the heat dissipation properties of the PowerPAD. The SOIC package, on the other

hand, is highly dependent on how it is mounted on the PCB. As more trace and copper area is placed around

the device, θ

JA

decreases and the heat dissipation capability increases. The currents and voltages shown in

these graphs are for the total package. For the dual or quad amplifier packages, the sum of the RMS output

currents and voltages should be used to choose the proper package.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

macromodel information

Macromodel information provided was derived using Microsim

Parts

, the model generation software used

with Microsim

PSpice

. The Boyle macromodel (see Note 3) and subcircuit in Figure 30 are generated using

the TLV411x typical electrical and operating characteristics at TA = 25°C. Using this information, output

simulations of the following key parameters can be generated to a tolerance of 20% (in most cases):

D

Maximum positive output voltage swing

D

Maximum negative output voltage swing

D

Slew rate

D

Quiescent power dissipation

D

Input bias current

D

Open-loop voltage amplification

D

Unity-gain frequency

D

Common-mode rejection ratio

D

Phase margin

D

DC output resistance

D

AC output resistance

D

Short-circuit output current limit

NOTE 3: G. R. Boyle, B. M. Cohn, D. O. Pederson, and J. E. Solomon, “Macromodeling of Integrated Circuit Operational Amplifiers,”

IEEE Journal

of Solid-State Circuits,

SC-9, 353 (1974).

* TLV4112_5V operational amplifier ”macromodel” subcircuit

* updated using Model Editor release 9.1 on 01/18/00 at 15:50

Model Editor is an OrCAD product.

*

* connections: non–inverting input

* | inverting input

* | | positive power supply

* | | | negative power supply

* | | | | output

* | | | | |

.subckt TLV4112_5V 1 2 3 4 5

*

c1 11 12 2.2439E–12

c2 6 7 10.000E–12

css 10 99 454.55E–15

dc 5 53 dy

de 54 5 dy

dlp 90 91 dx

dln 92 90 dx

dp 4 3 dx

egnd 99 0 poly(2) (3,0) (4,0) 0 .5 .5

fb 7 99 poly(5) vb vc ve vlp vln 0

+ 33.395E6 –1E3 1E3 33E6 –33E6

ga 6 0 11 12 168.39E–6

gcm 0 6 10 99 168.39E–12

iss 10 4 dc 13.800E–6

hlim 90 0 vlim 1K

ioff 0 6 dc 75E–9

j1 11 2 10 jx1

J2 12 1 10 jx2

r2 6 9 100.00E3

rd1 3 1 1 5.9386E3

rd2 3 12 5.9386E3

ro1 8 5 10

ro2 7 99 10

rp 3 4 3.3333E3

rss 10 99 14.493E6

vb 9 0 dc 0

vc 3 53 dc .86795

ve 54 4 dc .86795

vlim 7 8 dc 0

vlp 91 0 dc 300

vln 0 92 dc 300

.model dx D(Is=800.00E–18)

.model dy D(Is=800.00E–18 Rs=1m Cjo=10p)

.model jx1 NJF(Is=150.00E–12 Beta=2.0547E–3 +Vto=–1)

.model jx2 NJF(Is=150.00E–12 Beta=2.0547E–3 + Vto=–1)

.ends

*$

IN–

G

DSD

S

G

rp

IN+

rd1 rd2

rss

egnd

fb

ro2

ro1

vlim

OUT

ga

ioffgcm

vb

c1

dc

iss

dp

GND

V

DD

css

c2

ve

de

dlp dln

vlnhlimvlp

10

4

1

11 12

3

53

54

96

8

5

7

91 90 92

vc

99

+

+

+

+

+

+

+

–

–

–

–

––

–

–

+

r2

2

Figure 30. Boyle Macromodel and Subcircuit

PSpice

and

Parts

are trademarks of MicroSim Corporation.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

DGN (S-PDSO-G8) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

0,69

0,41

0,25

Thermal Pad

(See Note D)

0,15 NOM

Gage Plane

4073271/A 04/98

4,98

0,25

5

3,05

4,78

2,95

8

4

3,05

2,95

1

0,38

0,15

0,05

1,07 MAX

Seating Plane

0,10

0,65

M

0,25

0°–6°

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions include mold flash or protrusions.

D. The package thermal performance may be enhanced by attaching an external heat sink to the thermal pad.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-187

PowerPAD is a trademark of Texas Instruments.

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

N (R-PDIP-T**) PLASTIC DUAL-IN-LINE PACKAGE

14

0.775

0.745

(19,69)

(18,92)

A MIN

DIM

A MAX

PINS **

0.310 (7,87)

0.290 (7,37)

Seating Plane

0.010 (0,25) NOM

14/18 PIN ONL Y

4040049/C 08/95

9

8

0.070 (1,78) MAX

A

0.035 (0,89) MAX

0.020 (0,51) MIN

16

1

0.015 (0,38)

0.021 (0,53)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.240 (6,10)

0.260 (6,60)

M

0.010 (0,25)

0.100 (2,54)

0°–15°

16 PIN SHOWN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001 (20 pin package is shorter then MS-001.)

TLV4110, TLV4111, TLV4112, TLV4113

FAMILY OF HIGH OUTPUT DRIVE OPERATIONAL

AMPLIFIERS WITH SHUTDOWN

SLOS289A – DECEMBER 1999 – REVISED APRIL 2000

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

P (R-PDIP-T8) PLASTIC DUAL-IN-LINE PACKAGE

4040082/B 03/95

0.310 (7,87)

0.290 (7,37)

0.010 (0,25) NOM

0.400 (10,60)

0.355 (9,02)

58

41

0.020 (0,51) MIN

0.070 (1,78) MAX

0.240 (6,10)

0.260 (6,60)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.015 (0,38)

0.021 (0,53)

Seating Plane

M

0.010 (0,25)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...