TEXAS INSTRUMENTS TLV320AIC12, TLV320AIC13, TLV320AIC14, TLV320AIC15, TLV320AIC20 Technical data

...

查询TLV320AIC12供应商

www.ti.com

Texas Instruments (TI) has recently identified a problem in the product models listed above related to DLL

clock-generation. When a clock-generation mode is used that powers up the delay-locked-loop (DLL), the DLL

may not startup properly when initiated, resulting in the audio master clock not functioning. This results in the

codec in the products not functioning. This issue does not affect applications that do not enable the product’s

DLL.

TLV320AIC14, TLV320AIC15, TLV320AIC20

TLV320AIC21, TLV320AIC24, TLV320AIC25

PRODUCT NOTIFICATION

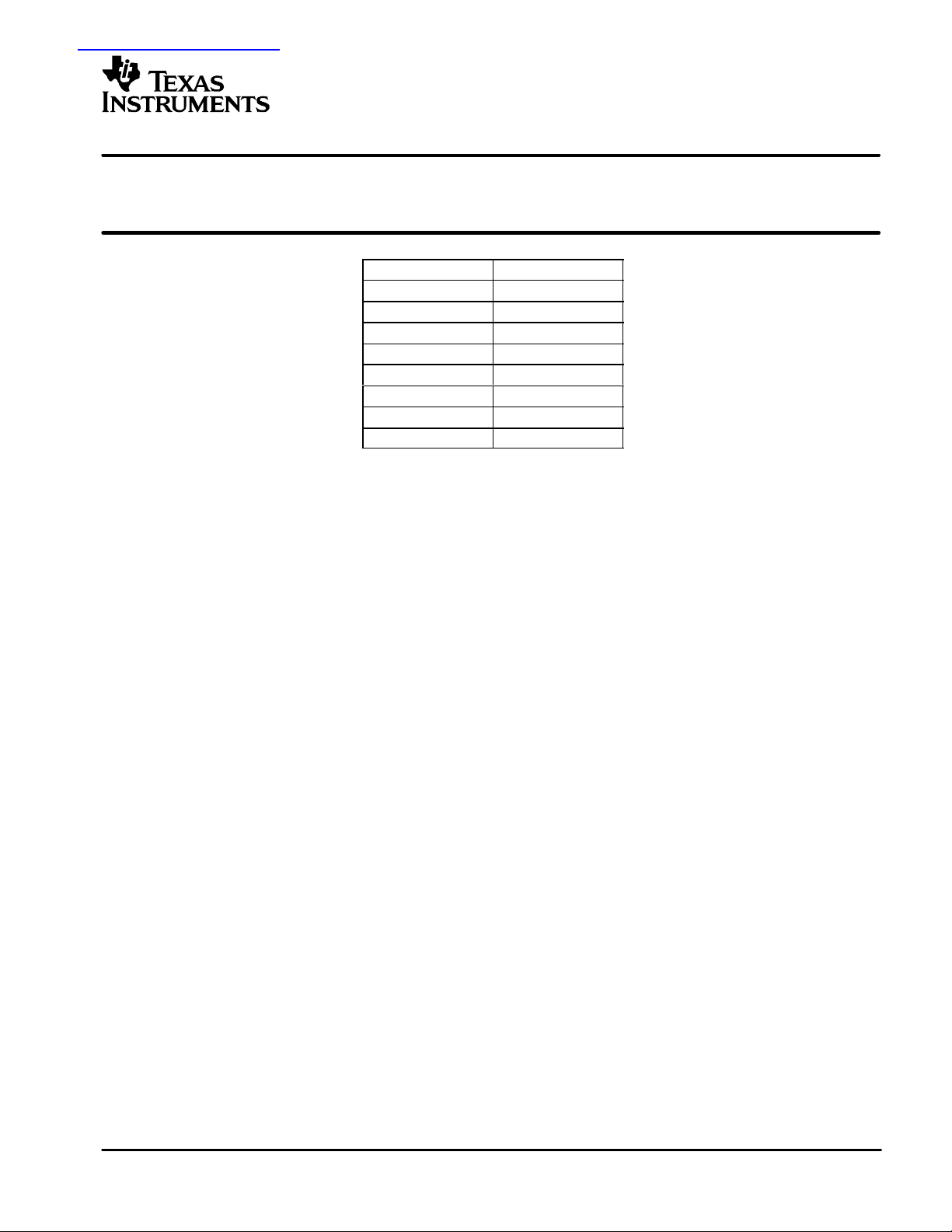

DEVICE LITERATURE NO.

TLV320AIC12 SLWS115

TLV320AIC13 SLWS139

TLV320AIC14 SLWS140

TLV320AIC15 SLWS141

TLV320AIC20 SLAS363

TLV320AIC21 SLAS365

TLV320AIC24 SLAS366

TLV320AIC25 SLAS367

TLV320AIC12, TLV320AIC13

OCTOBER 2003

Since this issue does not af fect operation if the DLL is not enabled, customers are recommended to ensure their

system does not enable the product’s DLL. The DLL is enabled anytime the P value in control register #4

(pertaining to clock generation) is NOT set equal to 8. The DLL is used whenever the part is in fine sampling

mode, as described in Section 3.1 of the data manual, so the recommended mode to use is the coarse sampling

mode, which requires P=8.

At present, TI does not have a screening procedure in place to detect product with the DLL issue, but the

company also realizes that many customers do not use the DLL in their systems and will be unaffected by this

issue.

TI is not confident of the operation of the DLL in this product at this time. To ensure customers have been made

aware of this issue, orders for these parts will only be filled upon return of a signed waiver until this issue is

resolved. The company has initiated an investigation to fully understand the root cause of this problem and

determine what appropriate long-term corrective action should be taken. TI recommends that all customers

presently using these parts contact the company immediately, so they can receive updates on this investigation

and plans for its resolution.

We apologize for the inconvenience placed upon customers in ordering this product. However, we wish to

ensure that our customers are aware of the device shortcomings from the specification. We are working in

earnest to remove this waiver requirement.

For further information, please contact

Neeraj Magotra

WW Strategic Marketing Manager for Voice/Audio Systems

Office: (214) 480-7486

nmagotra@ti.com

Copyright 2003, Texas Instruments Incorporated

Data Manual

May 2002 HPA Data Acquisition

SLWS140A

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI pro d u cts or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Contents

Section Title Page

1 Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Features 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Functional Block Diagram 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Terminal Descriptions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Ordering Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Terminal Functions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Definitions and Terminology 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Functional Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Operating Frequencies 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Internal Architecture 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Antialiasing Filter 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Sigma-Delta ADC 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Decimation Filter 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Sigma-Delta DAC 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Interpolation Filter 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Analog/Digital/Side-Tone Loopback 3–2. . . . . . . . . . . . . . . . . . .

3.2.7 ADC PGA 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 DAC PGA 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Analog Input/Output 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 MIC Input 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 INP and INM Input 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Single-Ended Analog Input 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Analog Output 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 IIR/FIR Control 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Overflow Flags 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 IIR/FIR Bypass Mode 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 System Reset and Power Management 3–4. . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Software and Hardware Reset 3–4. . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Power Management 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Digital Interface 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Clock Source (MCLK, SCLK) 3–5. . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Serial Data Out (DOUT) 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 Serial Data In (DIN) 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 Frame-Sync FS 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.5 Cascade Mode and Frame-Sync Delayed (FSD) 3–6. . . . . . . .

3.6.6 Stand-Alone Slave 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.7 Asynchronous Sampling (Codecs in cascade

are sampled at different sampling frequency) 3–6. . . . . . . . . . .

v

3.7 Host Port Interface 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 S

3.7.2 I

2

C (Start-Stop Communication) 3–9. . . . . . . . . . . . . . . . . . . . .

2

C3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Smart Time Division Multiplexed Serial Port (SMARTDM) 3–11. . . . . . . . .

3.8.1 Programming Mode 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.2 Continuous Data Transfer Mode 3–12. . . . . . . . . . . . . . . . . . . . . .

3.8.3 Turbo Mode (SCLK) 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Control Register Programming 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Data Frame Format 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 Control Frame Format (Programming Mode) 3–15. . . . . . . . . . .

3.9.3 Broadcast Register Write 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.4 Register Map 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Control Register Content Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Control Register 1 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Control Register 2 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Control Register 3 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Control Register 4 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Control Register 5A 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Control Register 5B 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Control Register 5C 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Control Register 5D 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Control Register 6 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical Characteristics 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Absolute Maximum Ratings Over Operating Free-Air

Temperature Range 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Recommended Operating Conditions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Electrical Characteristics Over Recommended Operating

Free-Air Temperature Range, AV

= 1.8 V, IOVDD = 3.3 V 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DV

DD

5.3.1 Digital Inputs and Outputs, f

= 3.3 V,

DD

= 8 kHz,

s

Outputs Not Loaded 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 ADC Path Digital Filter, f

= 8 kHz 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

s

5.4.1 FIR Filter 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 IIR Filter 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 ADC Dynamic Performance, f

= 8 kHz 5–3. . . . . . . . . . . . . . . . . . . . . . . . .

s

5.5.1 ADC Signal-to-Noise 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 ADC Signal-to-Distortion 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 ADC Signal-to-Distortion + Noise 5–3. . . . . . . . . . . . . . . . . . . . .

5.5.4 ADC Channel Characteristics 5–3. . . . . . . . . . . . . . . . . . . . . . . .

5.6 DAC Path Digital Filter, fs = 8 kHz 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 FIR Filter 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 IIR Filter 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 DAC Dynamic Performance 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 OUTP/OUTM Signal-to-Noise When Load Is 600 Ω 5–4. . . . .

5.7.2 OUTP/OUTM Signal-to-Distortion When Load Is 600 Ω 5–4. .

vi

5.7.3 OUTP/OUTM Signal-to-Distortion + Noise When Load

Is 600 Ω 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.4 DAC Channel Characteristics 5–5. . . . . . . . . . . . . . . . . . . . . . . .

5.8 BIAS Amplifier Characteristics 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Power-Supply Rejection 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Power Supply 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 Timing Requirements 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 Layout and Grounding Guidelines for TLV320AIC14 5–13. . . . . . . . . . . . .

List of Illustrations

Figure Title Page

3–1 Microphone Interface 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 INP and INM Internal Self-Biased Circuit 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Single-Ended Input 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 OUTP1/OUTM1 Output 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 Timing Diagram of FS 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Timing Diagram for FSD Output 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 Cascade Connection (To DSP Interface) 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–8 Master-Slave Frame-Sync Timing in Continuous Data

Transfer Mode 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–9S

3–10 I

3–11 I

3–12 Index Register Addresses 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–13 Standard Operation/Programming Mode: Stand-Alone Timing 3–12. . . . . . . . .

3–14 Standard Operation/Programming Mode: Master-Slave Cascade Timing 3–12

3–15 Standard Operation/Continuous Data Transfer Mode:

3–16 Standard Operation/Continuous Data Transfer Mode:

3–17 Timing Diagram for Turbo Operation 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–18 Data Frame Format 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–19 Control Frame Data Format 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–20 Broadcast Register Write Example 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–1 Hardware Reset Timing 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–2 Serial Communication Timing 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–3 FFT—ADC Channel (–3 dB Input) 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–4 FFT—ADC Channel (–1 dB Input) 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–5 FFT—ADC Channel (–3 dB Input) 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

C Programming 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

C Write Sequence 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

C Read Sequence 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand-Alone Timing 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master-Slave Cascade Timing 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

5–6 FFT—DAC Channel (–3 dB Input) 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–7 FFT—DAC Channel (0 dB Input) 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–8 FFT—DAC Channel (–3 dB Input) 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–9 FFT—DAC Channel (0 dB Input) 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–10. FFT—ADC Channel (–1 dB Input) 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–11 ADC FIR Frequency Response 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–12 ADC IIR Frequency Response 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–13 DAC IIR Frequency Response (OSR = 512) 5–10. . . . . . . . . . . . . . . . . . . . . . . . .

5–14 DAC IIR Frequency Response (OSR = 256) 5–10. . . . . . . . . . . . . . . . . . . . . . . . .

5–15 DAC IIR Frequency Response (OSR = 128) 5–11. . . . . . . . . . . . . . . . . . . . . . . . .

5–16 DAC FIR Frequency Response (OSR = 512) 5–11. . . . . . . . . . . . . . . . . . . . . . . .

5–17 DAC FIR Frequency Response (OSR = 256) 5–11. . . . . . . . . . . . . . . . . . . . . . . .

5–18 DAC FIR Frequency Response (OSR = 128) 5–11. . . . . . . . . . . . . . . . . . . . . . . .

5–19 Single-Ended Microphone Input (Internal Common Mode) 5–12. . . . . . . . . . . . .

5–20 Pseudo-Differential Microphone Input (External Common Mode) 5–13. . . . . . .

List of Tables

Table Title Page

3–1 SMARTDM Device Addresses 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Serial Interface Configurations 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Register Map 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Register Addresses 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1 Control Register 1 Bit Summary 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 Control Register 2 Bit Summary 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3 Control Register 3 Bit Summary 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4 Control Register 4 Bit Summary 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–5 Control Register 5A Bit Summary 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6 A/D PGA Gain 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–7 Control Register 5B Bit Summary 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8 D/A PGA Gain 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–9 Digital Sidetone Gain 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10 Input Buffer Gain 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–11 Control Register 6 Bit Summary 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

1 Introduction

The TLV320AIC14 is a true low-cost, low-power, high-performance, highly-integrated voiceband codec designed with

new technological advances. The TLV320AIC14 provides high resolution signal conversion from digital-to-analog

(D/A) and from analog-to-digital (A/D) using oversampling sigma-delta technology with programmable sampling rate.

1.1 Description

The TLV320AIC14 implements the smart time division multiplexed serial port (SMARTDM). This is TI’s design

innovation to optimize DSP performance with its most advanced synchronous serial port in TDM format for glue-free

interface to popular DSPs (i.e., C5x, C6x) and microcontrollers. The SMARTDM supports both continuous data

transfer mode and on-the-fly reconfiguration programming mode. SMARTDM maximizes the bandwidth of data

transfer between the TLV320AIC14 DSP codec and the DSP. In normal operation, it automatically detects the number

of codecs in the serial interface and adjusts the number of time slots to match the number of codecs so that no time

slot in the TDM frame is wasted. In the turbo mode, it maintains the same number of time slots but maximizes the

bit transferred rate to 25 MHz to give the DSP more bandwidth to process other tasks in the same sampling period.

The SMARTDM technology allows up to 16 codecs to share a single 4-wire serial bus.

The TL V320AIC14 also provides a flexible host port. The host port interface is a two-wire serial interface that can be

programmed to be either an industrial standard I

The TLV320AIC14 also integrates all of the critical functions needed for most voice-band applications including MIC

preamp, handset/headset preamps, antialiasing filter (AAF), input/output programmable gain amplifier (PGA), and

selectable low-pass IIR/FIR filters.

The TLV320AIC14 implements an extensive power management; including device power-down, independent

software control for turning off ADC, DAC, op-amps, and IIR/FIR filter (bypassable) to maximize system power

conservation. The TLV320AIC14 consumes only 10 mW at 3 V.

The TLV320AIC14’s low power operation from 2.7 V to 3.6 V for analog and I/O and 1.65 V to 1.95 V for digital core

power supplies, along with extensive power management, make it ideal for portable applications including wireless

accessories, hands free car kits, VOIP, cable modem, and speech processing. Its low group delay characteristic

makes it suitable for single or multichannel active control applications.

The TLV320AIC14 is characterized for commercial operation from 0°C to 70°C and industrial operation from –40°C

to 85°C.

2

C or a simple S2C (start-stop communication protocol).

1.2 Features

• C54x Software Driver Available

• 16-Bit Oversampling Sigma-Delta A/D Converter

• 16-Bit Oversampling Sigma-Delta D/A Converter

• Support Maximum Master Clock of 100 MHz to Allow DSPs Output Clock to Be Used as Master Clock

• Selectable FIR/IIR Filter With Bypassing Option

• Programmable Sampling Rate up to:

– Max 26 KSPS With On-Chip IIR/FIR Filter

– Max 104 KSPS With IIR/FIR Bypassed

• On-Chip FIR Produced 84-dB SNR for ADC and 91-dB SNR for DAC Over 13-kHz BW

• External DSPs IIR/FIR for a Final Sampling Rate of 8 Ksps (IIR/FIR Bypassed) Produced 87-dB SNR for

ADC and 92-dB SNR for DAC.

SMARTDM is a trademark of Texas Instruments.

1–1

• Smart Time Division Multiplexed Serial Port (SMARTDM)

– Glueless 4-Wire Interface to DSP

– Automatic Cascade Detection (ACD) Self-Generates Master/Slave Device Addresses

– Programming Mode to Allow On-the-Fly Reconfiguration

– Continuous Data Transfer Mode to Support DSP’s DMA/Autobuffering Mode

– Turbo Mode to Maximize Bit Clock for Faster Data Transfer and Higher Data Bandwidth

– Total Number of Time Slots Dynamically Proportional to Number of Codecs in the Cascade to Eliminate

Unused Time Slots and Optimize DSP Memory Allocation

– Allows up to 16 Codecs to Be Connected to a Single Serial Port

• Host Port

– 2-Wire Interface

2

– Selectable I

C or S2C

• Differential and Single-Ended Analog Input/Output

• Built-In Functions:

– Sidetone

– Antialiasing Filter (AAF)

– Programmable Input and Output Gain Control (PGA)

– Microphone Amplifiers

– Power Management With Hardware/Software Power-Down Modes 30 µW

• Separate Software Control for ADC and DAC Power Down

• Fully Compatible With TI C54x DSP Power Supplies

– 1.65 V–1.95 V Digital Core Power

– 2.7 V–3.6 V Digital I/O

– 2.7 V–3.6 V Analog

• Power Dissipation (P

• Internal Reference Voltage (V

) 10 mW at 3 V in Standard Operation

D

)

ref

• 2s Complement Data Format

• Test Mode Which Includes Digital Loopback and Analog Loopback

1–2

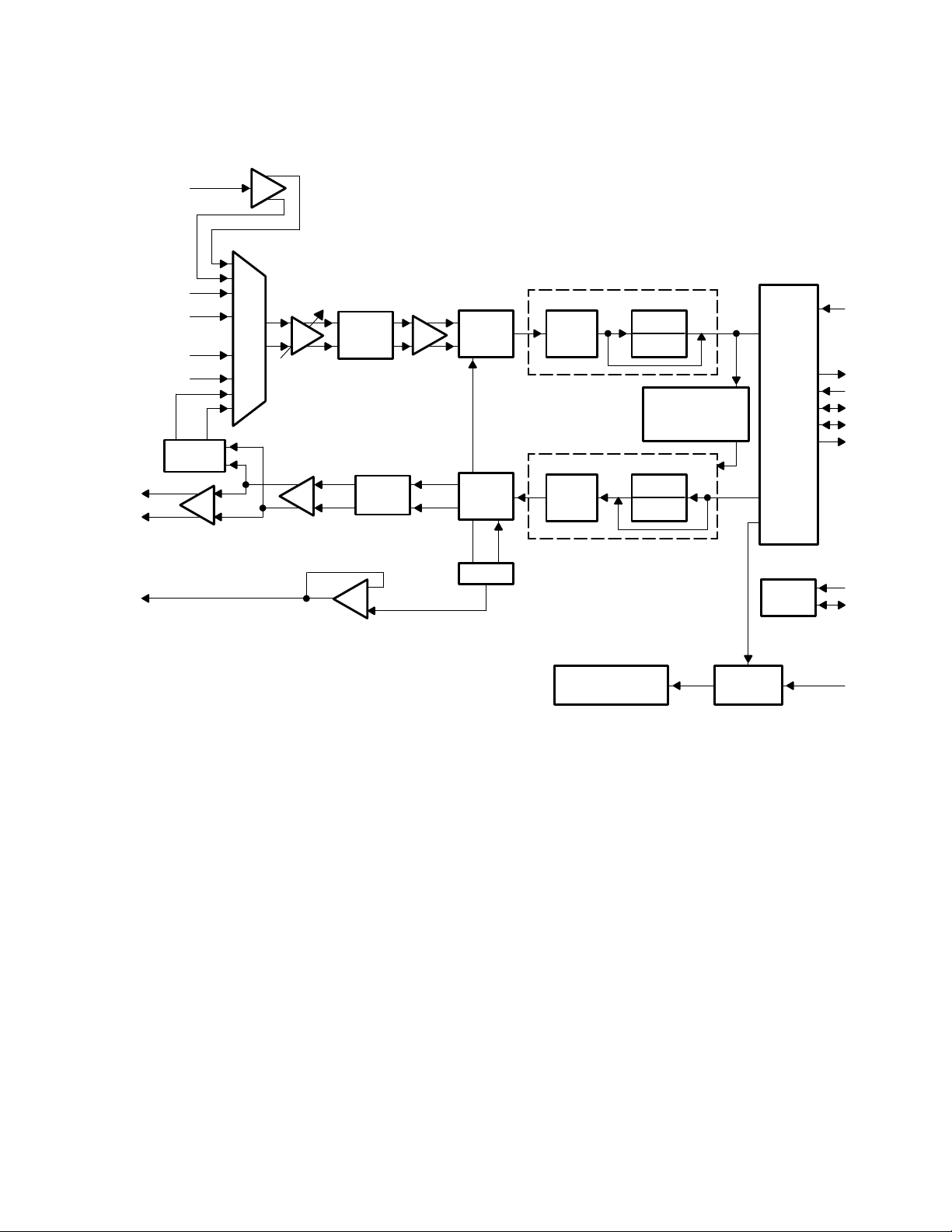

1.3 Functional Block Diagram

MICIN

INP2

INM2

INP1

INM1

Analog

Loopback

OUTP1

(600 ΩDriver)

OUTM1

BIAS

1.35 V/2.35 V @ 5 mA max

s2d

MUX

– 42 dB to 20 dB

Step Size = 1 dB

Preamplifier

24, 12, 6, 0 dB

PGA

Anti-

Aliasing

Filter

– 42 dB to 20 dB

Step Size = 1 dB

Low-Pass

Filter

PGA

Sigma-

Delta

ADC

Sigma-

Delta

DAC

V

ref

Decimation Filter

Sinc

Filter

Interpolation Filter

Sinc

Filter

FIR Filter

IIR Filter

Digital Loopback

w/ Sidetone Control

and Mute

–3 dB to –21 dB

FIR Filter

IIR Filter

SMARTDM

Serial

Port

Host Port

M/S

DOUT

DIN

FS

SCLK

FSD

SCL

SDA

Internal Clock Circuit MCLK

Div

16xMxNxP

1–3

1–4

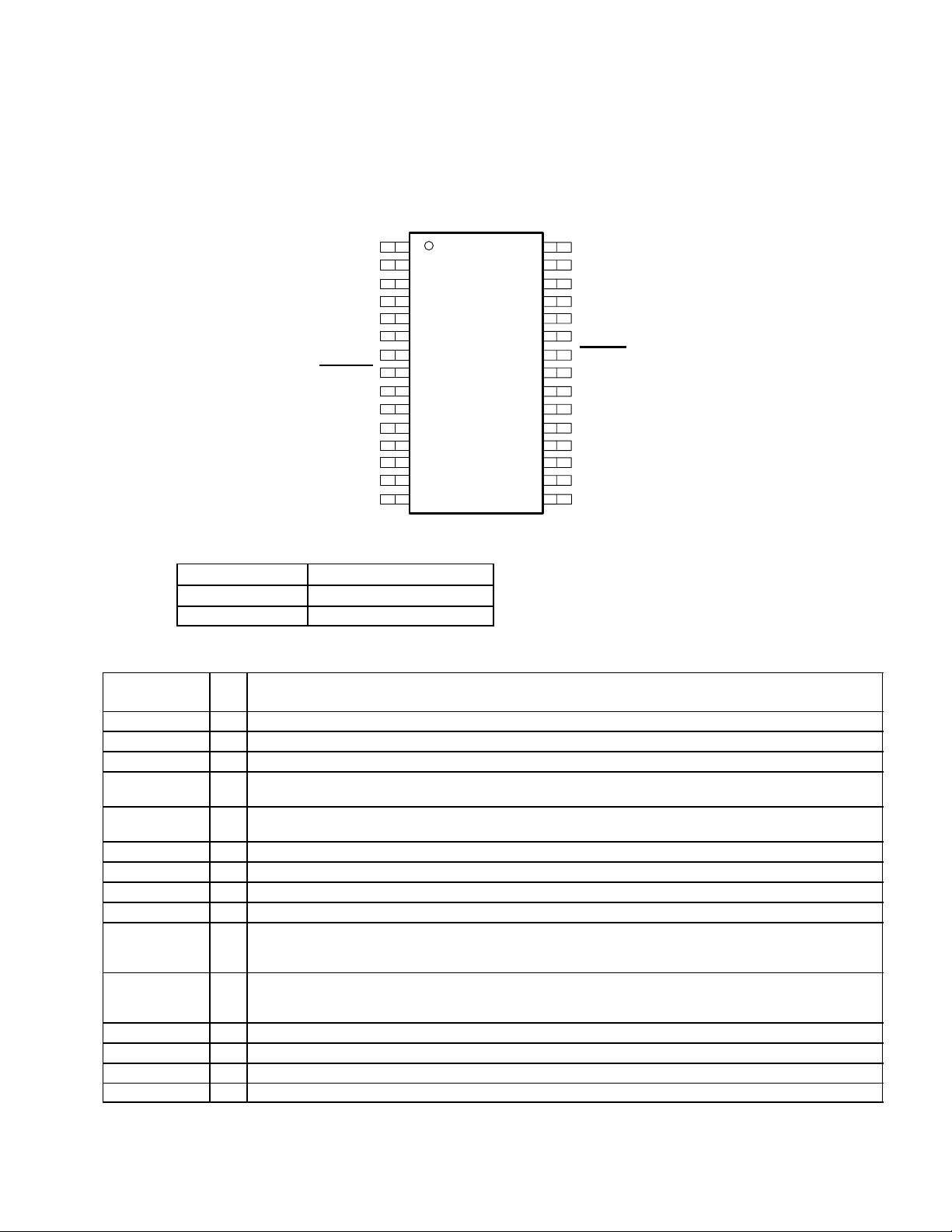

2 Terminal Descriptions

DBT PACKAGE

(TOP VIEW)

IOVSS

IOVDD

FSD

FS

DOUT

DIN

M/S

PWRDN

OUTM1

OUTP1

DRVDD

DRVSS

NC

NC

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

DVSS

DVDD

SCLK

SDA

SCL

MCLK

RESET

INP1

INM1

BIAS

INM2

INP2

MICIN

AVDD

AVSS

2.1 Ordering Information

T

A

0°C to 70°C TLV320AIC14C

–40°C to 85°C TLV320AIC14I

30-TSSOP DBT PACKAGE

2.2 Terminal Functions

TERMINAL

NAME NO.

AVDD 17 I Analog power supply

AVSS 16 I Analog ground

BIAS 21 O Bias output voltage is software selectable between 1.35 V and 2.35 V. Its output current is 5 mA.

DIN 6 I Data input. DIN receives the DAC input data and register data from the external DSP (digital signal processor) and is

DOUT 5 O Data output. DOUT transmits the ADC output bits and registers data, and is synchronized to SCLK and FS. Data is

DRVDD 11 I Analog power supply for the 600-Ω driver

DRVSS 12 I Analog ground for the 600-Ω driver

DVDD 29 I Digital power supply

DVSS 30 I Digital ground

FS 4 I/O Frame sync. When FS goes low, DIN begins receiving data bits and DOUT begins transmitting data bits. In master

FSD 3 O Frame sync delayed output. The FSD output synchronizes a slave device to the frame sync of the master device. FSD

INM1 22 I Inverting analog input 1. It must be connected to AVSS if not used.

INM2 20 I Inverting analog input 2. It must be connected to AVSS if not used.

INP1 23 I Noninverting analog input 1. It must be connected to AVSS if not used.

INP2 19 I Noninverting analog input 2. It must be connected to AVSS if not used.

I/O

synchronized to SCLK and FS. Data is latched at the falling edge of SCLK when FS is low.

sent out at the rising edge of SCLK when FS is low. Outside data/control frame, DOUT is put in 3-state.

mode, FS is internally generated and is low during the data transmission to DIN and from DOUT. In slave mode, FS is

externally generated.

is applied to the slave FS input and is the same duration as the master FS signal. This pin must be pulled low if AIC14 is

a stand-alone slave. It may be pulled high if the AIC14 is a stand-alone master or the last slave in the cascade.

DESCRIPTION

2–1

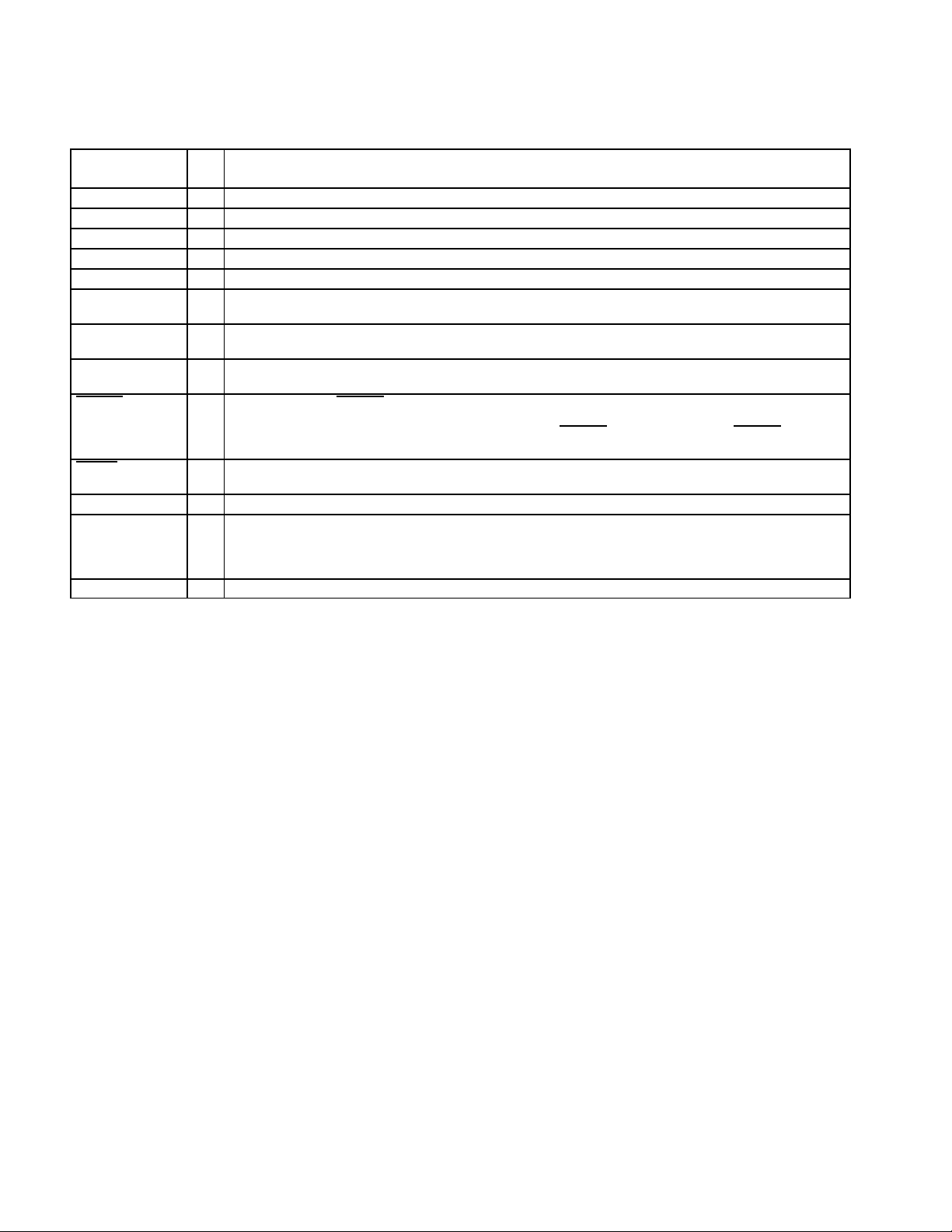

2.2 Terminal Functions (Continued)

TERMINAL

NAME NO.

IOVDD 2 I Digital I/O power supply

IOVSS 1 I Digital I/O ground

MCLK 25 I Master clock. MCLK derives the internal clocks of the sigma-delta analog interface circuit.

MICIN 18 I MIC preamplifier input. It must be connected to AVSS if not used.

M/S 7 I Master/slave select input. When M/S is high, the device is the master, and when low it is a slave.

OUTM1 9 O Inverting output of the DAC. OUTM1 is functionally identical with and complementary to OUTP1. This differential

NC 13, 14,

OUTP1 10 O Noninverting output of the DAC. This differential output can drive a minimum load of 600 Ω. This output can also be

PWRDN 8 I Power down. When PWRDN is pulled low, the device goes into a power-down mode, the serial interface is disabled,

RESET 24 I Hardware reset. The reset function is provided to initialize all of the internal registers to their default values. The

SCL 26 I Programmable host port (I2C or S2C) clock input.

SCLK 28 I/O Shift clock. SCLK signal clocks serial data into DIN and out of DOUT during the frame-sync interval. When

SDA 27 I/O Programmable host port (I2C or S2C) data line.

I/O

output can drive a minimum load of 600 Ω. This output can also be used alone for single-ended operation.

15

used alone for single-ended operation.

and most of the high-speed clocks are disabled. However, all the register values are sustained and the device

resumes full-power operation without reinitialization when PWRDN

counters only and preserves the programmed register contents.

serial port is configured to the default state accordingly.

configured as an output (M/S high), SCLK is generated internally by multiplying the frame-sync signal frequency b y

16 and the number of codecs in cascade in standard and continuous mode. When configured as an input (M/S low),

SCLK is generated externally and must be synchronous with the master clock and frame sync.

DESCRIPTION

is pulled high again. PWRDN resets the

2.3 Definitions and Terminology

Data Transfer

Interval

Signal Data This refers to the input signal and all of the converted representations through the ADC channel and the

Frame Sync Frame sync refers only to the falling edge of the signal FS that initiates the data transfer interval

Frame Sync and

Sampling Period

f

s

ADC Channel ADC channel refers to all signal processing circuits between the analog input and the digital

DAC channel DAC channel refers to all signal processing circuits between the digital data word applied to DIN and the

Dxx Bit position in the primary data word (xx is the bit number)

DSxx Bit position in the secondary data word (xx is the bit number)

PGA Programmable gain amplifier

IIR Infinite impulse response

FIR Finite impulse response

The time during which data is transferred from DOUT and to DIN. The interval is 16 shift clocks and the data

transfer is initiated by the falling edge of the FS signal in standard and continuous mode.

signal through the DAC channel to the analog output. This is contrasted with the purely digital software

control data.

Frame sync and sampling period is the time between falling edges of successive FS signals.

The sampling frequency

conversion result at DOUT.

differential output analog signal available at OUTP1 and OUTM1.

2–2

3 Functional Description

3.1 Operating Frequencies (see Notes)

The sampling frequency is the frequency of the frame sync (FS) signal whose falling edge starts digital-data transfer

for both ADC and DAC. The sampling frequency is derived from the master clock (MCLK) input by the following

equations:

• Coarse sampling frequency (default):

The coarse sampling is selected by programming P = 8 in the control register 4, which is the default

configuration of AIC14 on power-up or reset.

FS = Sampling (conversion) frequency = MCLK / (16 × M × N x 8)

• Fine sampling frequency (see Note 5):

FS = Sampling (conversion) frequency = MCLK/ (16 × M × N × P)

NOTES: 1. Use control register 4 to set the following values of M, N, and P

2. M = 1,2, . . . ,128

3. N = 1,2, . . . ,16

4. P = 1,2, . . . ,8

5. The fine sampling rate needs an on-chip DLL to generate internal clocks. The DLL requires the relationship

between MCLK and P to meet the following condition: 10 MHz ≤ (MCLK/P) ≤ 25 MHz

6. Both equations of FS require that the following conditions should be met:

S (M × N × P) ≥ (devnum × mode) if the FIR/IIR filter is not bypassed.

S [Integer(M/4) × N × P] ≥ (devnum × mode) if the FIR/IIR filter is bypassed.

where

devnum is the number of devices connecting in cascade

mode is equal to 1 for continuous data transfer mode and 2 for programming mode

EXAMPLE:

The MCLK comes from the DSP C5402’s CLKOUT and equals to 20.48 MHz and the conversion rate of 8 kHz is

desired. First, set P = 1 to satisfy the condition 5 so that (MCLK/P) = 20.48 MHz/1 = 20.48 MHz. Next, pick

M = 10 and N = 16 to satisfy condition 6 and derive 8 kHz for FS. That is,

FS = 20.48 MHz/ (16 × 10 × 16 × 1) = 8 kHz

3.2 Internal Architecture

3.2.1 Antialiasing Filter

The built-in antialiasing filter is a two-pole filter that has a 20-dB attenuation at 1 MHz.

3.2.2 Sigma-Delta ADC

The sigma-delta analog-to-digital converter is a sigma-delta modulator with 128-x oversampling. The ADC provides

high-resolution, low-noise performance using oversampling techniques. Due to the oversampling employed, only

single pole R-C filters are required on the analog inputs.

3.2.3 Decimation Filter

The decimation filters are either FIR filters or IIR filters, selected by bit D5 of the control register 1. The FIR filter

provides linear-phase output with 17/f group delay, whereas the IIR filter generates nonlinear phase output with

negligible group delay. The decimation filters reduce the digital data rate to the sampling rate. This is accomplished

by decimating with a ratio of 1:128. The output of the decimation filter is a 16-bit 2s-complement data word clocking

at the sample rate selected for that particular data channel. The BW of the filter is (0.45 × FS) and scales linearly with

the sample rate.

3–1

3.2.4 Sigma-Delta DAC

The sigma-delta digital-to-analog converter is a sigma-delta modulator with 128/256/512 x oversampling. The DAC

provides high-resolution, low-noise performance using oversampling techniques. The oversampling ratio in DAC is

programmable to 256/512 using bits D4–D3 of control register 3, the default being 128. Oversampling ratio of 512

can be used when FS is a maximum of 8 Ksps and an oversampling ratio of 256 can be used when FS is a maximum

of 16 Ksps. M should be a multiple of 2 for an oversampling ratio of 256 and 4 for oversampling ratio of 512.

3.2.5 Interpolation Filter

The interpolation filters are either FIR filters or IIR filters selected by bit D5 of the control register 1. The FIR filter

provides linear-phase output with 16/f group delay, whereas the IIR filter generates nonlinear phase output with

negligible group delay . The interpolation filter resamples the digital data at a rate of 128/256/512 times the incoming

sample rate, based on the oversampling rate of DAC. The high-speed data output from the interpolation filter is then

used in the sigma-delta DAC. The BW of the filter is (0.45 × FS) and scales linearly with the sample rate.

3.2.6 Analog/Digital/Side-Tone Loopback

The analog and digital loopbacks provide a means of testing the data ADC/DAC channels and can be used for

in-circuit system level tests. The analog loopback always has the priority to route the DAC low pass filter output into

the analog input where it is then converted by the ADC to a digital word. The digital loopback routes the ADC output

to the DAC input on the device. Analog loopback is enabled by writing a 1 to bit D2 in the control register 1. Digital

loopback is enabled by writing a 1 to bit D1 in control register 1. The side-tone digital loopback attenuates the ADC

output and mixes it with the input of the DAC. The level of the side tone is set by DSTG, bits D5–D3 of the control

register 5C.

3.2.7 ADC PGA

TLV320AIC14 has a built-in PGA for controlling the signal levels at ADC outputs. ADC PGA gain setting can be

selected by writing into bits D5–D0 of register 5A. The PGA range of the ADC channel is 20 dB to –42 dB in steps

of 1 dB and mute. To avoid sudden jumps in signal levels with PGA changes, the gains are applied internally with

zero-crossovers.

3.2.8 DAC PGA

TLV320AIC14 has a built-in PGA for controlling the analog output signal levels in DAC channel. DAC PGA gain setting

can selected by writing into bits D5–D0 of register 5B. The PGA range of the DAC channel is 20 dB to –42 dB in steps

of 1 dB, and mute. T o avoid sudden pop-sounds with power-up/down and gain changes the power-up/down and gain

changes for DAC channel are applied internally with zero-crossovers.

3.3 Analog Input/Output

The TLV320AIC14 has three programmable analog inputs and three programmable analog outputs. Bits D2–D1 of

control register 6 select the analog input source from MICIN, INP1/M1, or INP2/M2. All analog I/O is either

single-ended or d i fferentia l. Al l analog input signals are self-biased to 1.35 V. The three analog outputs are configured

by bits D7, D6, D5, and D4–D3 of control register 6.

3.3.1 MIC Input

TLV320AIC14 supports single ended microphone input. This can be used by connecting the external single ended

source through ac coupling to the MICIN pin. This channel is selected by writing 01 or 10 into bits D2–D1 in control

register 6. The single ended input is supported in two modes.

Writing 01 into bits D2–D1 chooses self biased MICIN mode. In this mode the device internally self-biases the input

at 1.35V. For best noise performance the user should bias the microphone circuit using the BIAS voltage generated

by the device as shown in Figure 5–19.

3–2

Writing 10 into bits D2–D1 chooses pseudo-differential MICIN mode. In this mode the single ended input is connected

through ac-coupling to MICIN and the bias voltage used to generate the signal is also ac coupled to INM1 as shown

in Figure 5–20. For best noise performance the MICIN and INM1 lines must be routed in similar fashion from the

microphone to the device for noise cancellation.

For high quality performance the single ended signal is converted internally into differential signal before being

converted. To improve the dynamic range with different types of microphones the device supports a pre-amp with

gain settings of 0/6/12/24 dB. This can be chosen by writing into bits D1–D0 of control register 5C.

0.1 µF

INM1

BIAS

MICIN

Electret

Microphone

10 kΩ

0.1 µF

BIAS

MICIN

TLV320AIC14 TLV320AIC14

(a) Single Ended (b) Pseudo -Differential (High Quality)

Electret

Microphone

10 kΩ

0.1 µF

Figure 3–1. Microphone Interface

3.3.2 INP and INM Input

To produce common-mode rejection of unwanted signal performance, the analog signal is processed differentially

until it is converted to digital data. The signal applied to the terminals INM1/2 and INP1/2 are differential to preserve

device specifications (see Figure 3–2). The signal source driving analog inputs (INP1/2 and INM1/2) should have low

source impedance for lowest noise performance and accuracy . T o obtain maximum dynamic range, the signal should

be ac-coupled to the input terminal.

INP1 or INP2

V

(INP)

1.35 V

INM1 or INM2

V

(INM)

TLV320AIC14

Figure 3–2. INP and INM Internal Self-Biased Circuit

3.3.3 Single-Ended Analog Input

The two differential inputs of (INP1/M1 and INP2/M2) can be configured to work as single-ended inputs by connecting

INP to the analog input and INM to ground (see Figure 3–3).

C

Analog Input

Figure 3–3. Single-Ended Input

INP1 or INP2

C

INM1 or INM2

3–3

3.3.4 Analog Output

The OUTP1 and OUTM1 are differential output from the DAC channel. The OUTP1 and OUTM1 can drive a load of

600-Ω directly and be either differential or single-ended (see Figure 3–4).

C

OUTP1

OUTP1

RL

OUTM1

Differential Output OUTP/OUTM

RL

OUTM1

Single-Ended Output OUTP/OUTM

Figure 3–4. OUTP1/OUTM1 Output

3.4 IIR/FIR Control

3.4.1 Overflow Flags

The decimation IIR/FIR filter sets an overflow flag (bit D7) of control register 1 indicating that the input analog signal

has exceeded the range of internal decimation filter calculations. The interpolation IIR/FIR filter sets an overflow flag

(bit D4) of control register 1 indicating that the digital input has exceeded the range of internal interpolation filter

calculations. When the IIR/FIR overflow flag is set in the register, it remains set until the user reads the register.

Reading this value resets the overflow flag. These flags need to be reset after power-up by reading the register. If

FIR/IIR overflow occurs, the input signal is attenuated by either the PGA or some other method.

3.4.2 IIR/FIR Bypass Mode

An option is provided to bypass IIR/FIR filter sections of the decimation filter and the interpolation filter. This mode

is selected through bit D6 of control register 2 and effectively increases the frequency of the FS signal to four times

normal output rate of the IIR/FIR-filter. For example, for a normal sampling rate of 8 Ksps (i.e., FS = 8 kHz) with IIR/FIR,

if the IIR/FIR is bypassed, the frequency of FS is readjusted to 4×8 kHz = 32 kHz. The sinc filters of the two paths

can not be bypassed. A maximum of eight devices in cascade can be supported in the IIR/FIR bypassed mode.

In this mode , the ADC channel outputs data which has been decimated only till 4Fs. Similarly DAC channel input

needs to be pre-interpolated to 4Fs before being given to the device. This mode allows users the flexibility to

implement their own filter in DSP for decimation and interpolation. M should be a multiple of 4 during IIR/FIR Bypass

mode.

3.5 System Reset and Power Management

3.5.1 Software and Hardware Reset

The TLV320AIC14 resets internal counters and registers in response to either of two events:

• A low-going reset pulse is applied to terminal RESET

• A 1 is written to the programmable software reset bits (D3 of control register 3)

NOTE:The TLV320AIC14 requires a power-up reset applied to the RESET pin.

Either event resets the control registers and clears all sequential circuits in the device. The H/W RESET (active low)

signal is at least 6 master clock periods long. As soon as the RESET input is applied, the TLV320AIC14 enters the

3–4

initialization cycle that lasts for 132 MCLKs, during which the DSPs serial port is put in 3-state. For a cascaded system

the rise time of H/W RESET needs to be less than the MCLK period and should satisfy setup time requirement of 2 ns

with respect to MCLK rise-edge. In stand-alone-slave mode SCLK must be running during RESET. RESET must be

synchronized with MCLK in all cases.

3.5.2 Power Management

Most of the device (except the digital interface) enters the power-down mode when D7 and D6, in control register 3,

are set to 1. When the PWRDN

preserved and the output of the amplifier is held at midpoint voltage to minimize pops and clicks.

The amount of power drawn during software power down is higher than during a hardware power down because of

the current required to keep the digital interface active. Additional differences between software and hardware

power-down modes are detailed in the following paragraphs.

pin is low, the entire device is powered down. In either case, register contents are

3.5.2.1 Software Power-Down

Data bits D7 and D6 of control register 3 are used by TLV320AIC14 to turn on or off the software power-down mode,

which takes effect in the next frame FS. The ADC and DAC can be powered down individually. In the software

power-down, the digital interface circuit is still active while the internal ADC and DAC channel and differential output

OUTP1 and OUTM1 are disabled, and DOUT is put in 3-state in the data frame only. Register data in the control frame

is still accepted via DIN, but data in the data frame is ignored. The device returns to normal operation when D7 and

D6 of control register 3 are reset.

3.5.2.2 Hardware Power-Down

The TLV320AIC14 requires the PWRDN signal to be synchronized with MCLK. When PWRDN is held low, the device

enters hardware power-down mode. In this state, the internal clock control circuit and the differential outputs are

disabled. All other digital I/Os are disabled and DIN can not accept any data input. The device can only be returned

to normal operation by holding PWRDN

PWRDN

must be tied high.

high. When not holding the device in the hardware power-down mode,

3.6 Digital Interface

3.6.1 Clock Source (MCLK, SCLK)

MCLK is the external master clock input. The clock circuit generates and distributes necessary clocks throughout the

device. SCLK is the bit clock used to receive and transmit data synchronously. When the device is in the master mode,

SCLK and FS are output and derived from MCLK in order to provide clocking the serial communications between the

device and a digital signal processor (DSP). When in the slave mode, SCLK and FS are inputs. In the non-turbo mode

(TURBO = 0), SCLK frequency is defined by:

SCLK = (16 × FS × #Devices × mode)

Where:

FS is the frame-sync frequency.

#Device is the number of the device in cascade.

Mode is equal to 1 for continuous data transfer mode and 2 for programming mode.

In turbo mode, see Section 3.8.3.

3.6.2 Serial Data Out (DOUT)

DOUT is placed in the high-impedance state after transmission of the LSB is completed. In data frame, the data word

is the ADC conversion result. In the control frame, the data is the register read results when requested by the

read/write (R/W) bit. If a register read is not requested, the low eight bits of the secondary word are all zeroes. Valid

data on DOUT is taken from the high-impedance state by the falling edge of frame-sync (FS). The first bit transmitted

on the falling edge of FS is the MSB of valid data.

3–5

3.6.3 Serial Data In (DIN)

The data format of DIN is the same as that of DOUT, in which MSB is received first on the falling edge of FS. In a data

frame, the data word is the input digital signal to the DAC channel. If (15+1)-bit data format is used, the LSB (D0) is

set to 1 to switch from the continuous data transfer mode to the programming mode. In a control frame, the data is

the control and configuration data that sets the device for a particular function as described in Section 3.9, Control

Register Programming.

3.6.4 Frame-Sync FS

The frame-sync signal (FS) indicates the device is ready to send and receive data. FS is an output if the M/S pin is

connected to HI (master mode) and an input if the M/S pin is connected to LO (slave mode).

Data is valid on the falling edge of the FS signal.

The frequency of FS is defined as the sampling rate of the TLV320AIC14 and derived from the master clock MCLK

as followed (see Section 3.1 Operating Frequencies for details):

FS = MCLK / (16× P × N × M)

0 1 15 1614

SCLK

16 SCLKs

FS

DIN/DOUT

(16 Bit)

D15 D14

MSB LSB

D2 D1

D0

Figure 3–5. Timing Diagram of FS

3.6.5 Cascade Mode and Frame-Sync Delayed (FSD)

In cascade mode, the DSP receives all frame-sync pulses from the master though the master’s FS. The master’s FSD

is output to the first slave and the first slave’s FSD is output to the second slave device and so on. Figure 3–7 shows

the cascade of 4 TLV320AIC14s in which the closest one to DSP is the master and the rest are slaves. The FSD output

of each device is input to the FS terminal of the succeeding device. Figure 3–8 shows the FSD timing sequence in

the cascade.

3.6.6 Stand-Alone Slave

In the stand-alone slave connection, the FS and SCLK are input in which they need to be synchronized to each other

and programmed according to Section 3.1 (Operating Frequencies). The FS and SCLK input are not required to

synchronize to the MCLK input but must remain active at all times to assure continuous sampling in the data converter .

FS is output for initial 132 MCLK and it must be kept low. DSP needs to keep FS low-or high-impedance state for this

period to avoid contention on FS.

3.6.7 Asynchronous Sampling

(Codecs in cascade are sampled at different sampling frequency)

The AIC14’s SMARTDM support different sampling frequency between the different codecs in cascade connecting

to a single serial port. In this case, all codecs are required to sample at the same fdrequency that is the frequency

of FS signal. Then the desired sampling frequency of each codec is calculated by D2–D0 of control register 3. For

example: fs1 and fs2 are desired sampling rates for CODEC1 and CODEC2 respectively:

3–6

1. FS = MCLK/(16xMxNxP)

2. FS = n1 x fs1 (n1 = 1,2, 0, 8 defined in the control register 3 of CODEC1)

3. FS = n2 x fs2 (n2 = 1,2, 0, 8 defined in the control register 3 of CODEC2)

For validating the conversion data from this operation:

For DAC: DSP need to give same data for n1 samples. CODEC1 picks one of n1 samples.

For ADC: CODEC1 gives same data for n1 samples. DSP should pick one of n1 samples.

0 1 14 1513

SCLK

FS

16 SCLKs

FSD

(Output)

CLKOUT

FSX

FSR

CLKX

CLKR

TMS320C5x

DIN/DOUT

(16 Bit)

DX

DR

100 MHz Max

MCLK

FS

SCLK

DOUT

Figure 3–7. Cascade Connection (To DSP Interface)

D15 D14

MSB LSB

D1 D0

D15

Figure 3–6. Timing Diagram for FSD Output

Slave 2 Slave 1 Slave 0Master

MCLK

DIN

FSD

IOVDD

M/S M/S M/S M/S

DIN

DOUT

FS

SCLK

FSD FSD

MCLK

DIN

DOUT

FS

SCLK

MCLK

DIN

DOUT

FS

SCLK

FSD

IOVDD

1 kΩ

3–7

Master FS

DIN/DOUT

Master FSD,

Slave 2 FS

Slave 2 FSD,

Slave 1 FS

Slave 1 FSD,

Slave 0 FS

Slave 0 FSD,

(see Note)

NOTE: Slave 0 FSD should be pulled high for stand-alone-master or cascade configuration. FSD must be pulled low for stand-alone-slave

configuration.

Master Slave2 Slave1 Slave0 Slave2Master

Figure 3–8. Master-Slave Frame-Sync Timing in Continuous Data Transfer Mode

3.7 Host Port Interface

The host port uses a 2-wire serial interface (SCL, SDA) to program the AIC14s six control registers and selectable

protocol between S2C mode and I2C mode. The S2C is a write-only mode and the I

by setting the MSB (I2CSEL bit) of control register 4 to 1. If the host interface is not needed, the two pins of SCL and

SDA can be programmed to become general-purpose I/Os by setting the MSB of the control register 4 to 0. If selected

to be used as I/O pins, the SDA and SCL pins become output and input pins respectively, determined by D1 and D0.

Both S2C and I2C require a SMARTDM device address to communicate with the AIC14. One of SMARTDMs

advanced features is the automatic cascade detection (ACD) that enables SMARTDM to automatically detect the total

number of codecs in the serial connection and use this information to assign each codec a distinct SMARTDM device

address. Table 3–1 lists device addresses assigned to each codec in the cascade by the SMARTDM. The master

always has the highest position in the cascade. For example, if there is a total of 8 codecs in the cascade (i.e., one

master and 7 slaves), then the device addresses in row 8 are used in which the master is codec 7 with a device

address of 0111.

Table 3–1. SMARTDM Device Addresses

TOTAL

CODECS

1 0000

2 0001 0000

3 0010 0001 0000

4 0011 0010 0001 0000

5 0100 0011 0010 0001 0000

6 0101 0100 0011 0010 0001 0000

7 0110 0101 0100 0011 0010 0001 0000

8 0111 0110 0101 0100 0011 0010 0001 0000

9 1000 0111 0110 0101 0100 0011 0010 0001 0000

10 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

11 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

12 1011 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

13 1100 1011 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

14 1101 1100 1011 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

15 1110 1101 1100 1011 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

16 1111 1110 1101 1100 1011 1010 1001 1000 0111 0110 0101 0100 0011 0010 0001 0000

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CODECs POSITION IN CASCADE

2

C is a read-write mode selected

3–8

3.7.1 S2C (Start-Stop Communication)

The S2C is a write-only interface selected by programming bits D1-D0 of control register 2 to 01. The SDA input is

normally in a high state, pulled low (START bit) to start the communication, and pulled high (STOP bit) after the

transmission of the LSB. Figure 3–9 shows the timing diagram of S2C. The S2C also supports a broadcast mode in

which the same register of all devices in cascade is programmed in a single write. To use S2Cs broadcast mode,

execute the following steps:

1. Write 111 1000 1111 1111 after the start bit to enable the broadcast mode.

2. Write data to program control register as specified in with bits D14–D11 = XXXX (don’t care).

3. Write 111 1000 0000 0000 after the start bit to disable the broadcast mode.

SCL

SDA

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Start Bit = 0 Stop Bit = 1

SMARTDM Device

Address

(see Table 3–1)

Register

Address

Register Content

Figure 3–9. S2C Programming

3.7.2 I2C

• Each I2C read-from or write-to AIC14s control register is given by index register address.

• Read/write sequence always starts with the first byte as I2C address followed by 0. During the second byte,

default/broadcast mode is set and the index register address is initialized. For write operation control

register, data to be written is given from the third byte onwards. For read operation, stop-start is performed

after the second byte. Now the first byte is I

register data appears.

• Each time read/write is performed, the index register address is incremented so that next read/write is

performed on the next control register.

• During the first write cycle and all write cycles in the broadcast, only the device with address 0000 issues

ACK to the I

2

C.

2

C address followed by 1. From the second byte onwards, control

I2C Write Sequence

SCL

SDA

Start Bit = 0

Programmable I2C Device Address

A5 A4 A3 A2A1A0 0

I2C5I2C4I2C

6

Set by Control Register 2

SMARTDM Device

Address

(see Table 3-1)

B7 B6 B5 B4 B3 R2 R1 R0A6 D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

ACK

00000 = Default

11111 = Broadcast Mode

Index Register Address

ACK ACK ACK

(Index)

Control Register Data for Write

(Index)

Control Register Data for Write

(Index+1)

Figure 3–10. I2C Write Sequence

3–9

I2C Read Sequence

SCL

SDA

Start Bit = 0

SCL

SDA

Start Bit = 0

Programmable I2C Device Address

A6 ACK

6

Programmable I2C Device Address

Set by Control Register 2

A5 A4 A3 A2

I2CI2CI2C

654

Set by Control Register 2

A5 A4 A3 A2

I2CI2CI2C

54

SMARTDM Device Address

SMARTDM Device Address

(see Table 3-1)

A0 0

A1

(see Table 3-1)

A0 0

A1

ACK

B7 B6 B5 B4 B3 R2 R1 R0

xxxxx = Don’t Care

ACK

D7 D6 D5 D4 D3 D2 D1 D0A6

Control Register Data

(Index)

Index Register Address

(Index)

ACK ACK

Stop Bit = 1

D7 D6 D5 D4 D3 D2 D1 D0

Control Register Data

(Index+1)

Figure 3–11. I2C Read Sequence

Each AIC has an index register address. To perform a write operation, make the LSB of the first byte as 0 (write) (see

Figure 3–12). During the second byte, the index register address is initialized and mode (broadcast/default) is set.

From the third byte onwards, write data to the control register (given by index register) and increment the index

register until stop or repeated start occurs. For operation, make the LSB of the first byte as 1 (read). From the second

byte onwards, AIC starts transmitting data from the control register (given by the index register) and increments the

index register. For setting the index register perform operation the same as write case for 2 bytes, and then give a

stop or repeated start.

S/Sr –> Start/Repeated Start.

Write Mode

7 Bit 1 Bit 8 Bit 8 Bit 8 Bit

S/Sr I2C Device Address (3 Bit)+

Dtdmsp Device Address (+)

Read Mode

7 Bit 1 Bit 8 Bit 8 Bit

S/Sr I2C Device Address (3 Bit)+

Dtdmsp Device Address (+)

For Initializing Index Reg Address

7 Bit 1 Bit 8 Bit

S/Sr I2C Device Address (3 Bit)+

Dtdmsp Device Address (+)

Default/Broadcast

(00000/11111)

R/W

= 0

R/W

= 1

Mode (5 Bit) + Index Reg

Ack

Control Reg. Data

Ack

(Read)

Address

(3 Bit)

Ack Control Reg. Data

Ack Control Reg. Data

From The Address Given

by Index Reg. Address

R/W

= 0

Mode (5 Bit) + Index Reg.

Ack

Address

(3 Bit)

Ack

Figure 3–12. Index Register Addresses

(Write)

To The Address Given

by Index Reg. Address

Increment Index Reg. AddressIncrement Index Reg. Address

(Read)

From The Address Given

by Index Reg. Address

Stop

Increment Index Reg. Address

Ack Control Reg. Data

(Write)

To The Address Given

by Index Reg. Address

Ack

3–10

3.8 Smart Time Division Multiplexed Serial Port (SMARTDM)

TLV320AIC14

The SMART time division multiplexed serial port (SMARTDM) uses the 4 wires of DOUT, DIN, SCLK, and FS to

transfer data into and out of the AIC14. The TLV320AIC14s SMARTDM supports three serial interface configurations

(see Table 3–2): stand-alone master, stand-alone slave, and master-slave cascade, employing a time division

multiplexed (TDM) scheme (a cascade of only-slaves is not supported). The SMARTDM allows for a serial connection

of up to 16 codecs to a single serial port. Data communication in these three serial interface configurations can be

carried out in either standard operation (default) or turbo operation. Each operation has two modes; programming

mode (default mode) and continuous data transfer mode. To switch from the programming mode to the continuous

data transfer mode, set bit D6 of control register 1 to 1, which resets after switching back to programming mode. The

TLV320AIC14 can be switched back from the continuous data transfer mode to the programming mode by setting

the LSB of the data on DIN to 1, only if the data format is (15+1), as selected by bit 0 of control register 1. The

SMARTDM automatically adjusts the number of time slots per frame sync (FS) to match the number of codecs in the

serial interface so that no time slot is wasted. Both the programming mode and the continuous data transfer mode

of the TLV320AIC14 are compatible with the TLV320AIC10. The TLV320AIC14 provides primary/secondary

communication and continuous data transfer with improvements and eliminates the requirements for hardware and

software requests for secondary communication as seen in the TLV320AIC10. The TLV320AIC14 continuous data

transfer mode now supports both master/slave stand-alone and cascade.

Table 3–2. Serial Interface Configurations

TLV320AIC14

CONNECTIONS

Stand-alone master High NA Pull high NA

Stand-alone slave NA Low NA Pull-low

Master-slave cascade High Low

Slave-slave cascade NA NA NA NA Not supported

M/S PIN FSD PIN

MASTER SLAVE MASTER SLAVE

Connect to the next slave’s FS

(see Figure 3–7)

COMMENTS

Last slave’s FSD pin is pulled high

3.8.1 Programming Mode

In the programming mode, the FS signal starts the input/output data stream. Each period of FS contains two frames

as shown in Figures 3–13 and 3–14: data frame and control frame. The data frame contains data transmitted from

the ADC or to the DAC. The control frame contains data to program the AIC14s control registers. The SMARTDM

automatically sets the number of time slots per frame equal to 2 times the number of AIC14 codecs in the interface.

Each time slot contains 16-bit data. The SCLK is used to perform data transfer for the serial interface between the

AIC14 codecs and the DSP. The frequency of SCLK varies depending on the selected mode of serial interface. In

the stand-alone mode, there are 32 SCLKs (or two time slots) per sampling period. In the master-slave cascade

mode, the number of SLCKs equals 32x(Number of codecs in the cascade). The digital output data from the ADC

is taken from DOUT. The digital input data for the DAC is applied to DIN. The synchronization clock for the serial

communication data and the frame-sync is taken from SCLK. The frame-sync signal that starts the ADC and DAC

data transfer interval is taken from FS. The SMARTDM also provides a turbo mode, in which the FS’s frequency is

always the device’s sampling frequency, but SCLK is running at a much higher speed. Thus, there are more than 32

SCLKs per sampling period, in which the data frame and control frame occupy only the first 32 SCLKs from the falling

edge of the frame-sync FS (also see Section 3.6 for more details).

3–11

SCLK

FS

Slot Number 0

Slot Number 1

DIN

DOUT

16–Bit DAC Data Register Data Write

16–Bit ADC Data Register Data Read

Figure 3–13. Standard Operation/Programming Mode: Stand-Alone Timing

Slot

Number

SCLK

FS

DIN/

DOUT

NOTE: n is the total number of AIC14s in the cascade

0 12 2n–12n–22n–3

Master Slave

n–2

Slave

n–3

Data Frame Control Frame

Figure 3–14. Standard Operation/Programming Mode: Master-Slave Cascade Timing

3.8.2 Continuous Data Transfer Mode

16 SCLKs Per Slot

Slave2Slave1Slave0Master Slave

n–2

Slave

n–3

(Register R/W)

Slave2Slave1Slave

0

The continuous data transfer mode, selected by setting bit D6 of the control register 1 to 1, contains conversion data

only . In continuous data transfer mode, the control frame is eliminated and the period of FS signal contains only the

data frame in which the 16-bit data is transferred contiguously , with no inactivity between bits. The control frame c a n

be reactivated by setting the LSB of DIN data to 1 if the data is in the 15+1 format. To return the programming mode

in the 16-bit DAC data format mode, write 0 in bit D6 of control register 1 using I

2

C or S2C, or do a hardware reset

to come out of continuous data transfer mode. The continuous data transfer mode can support the TI DSP McBSPs

autobuffering unit (ABU) operation in which the serial port interrupts are not generated with each word transferred

to prevent CPU’s ISR overheads.

3–12

SCLK

FS

Slot Number 0

Data Frame Data Frame

Slot Number 0

DIN

DOUT

16-Bit DAC Data (Sample 1)

16-Bit ADC Data (Sample 1)

16-Bit DAC Data (Sample 2)

16-Bit ADC Data (Sample 2)

(Sample 3)

(Sample 3)

Figure 3–15. Standard Operation/Continuous Data Transfer Mode: Stand-Alone Timing

Slot

Number

SCLK

FS

DIN/

DOUT

NOTE: n is the total number of AIC14s in the cascade

0 12 n–1n–2n–3 01 2 n–1n–2n–3

16 SCLKs Per Time Slot

Master Slave

n–2

Slave

n–3

Data Frame / Sample 1

Slave2Slave1Slave0Master Slave

Slave

n–2

n–3

Data Frame / Sample 2

Slave

2

Slave1Slave

Figure 3–16. Standard Operation/Continuous Data Transfer Mode: Master-Slave Cascade Timing

0

3.8.3 Turbo Mode (SCLK)

Setting TURBO = 1 (bit D7) in control register 2 enables the turbo mode that requires the following condition to be

met:

• For master with SCLK as output, M × N > #Devices × mode

Where:

M, N, and P are clock divider values defined in the control register 4.

#Device is the number of the device in cascade.

Mode is equal to 1 for continuous data transfer mode and 2 for programming mode.

• For slave, SCLK is the input with max allowable speed of 25 MHz (no condition is required)

The turbo mode is useful for applications that require more bandwidth for multitasking processing per sampling

period. In the turbo mode (see Figure 3–17), the FSs frequency is always the device’s sampling frequency but the

SCLK is running at much higher speed than that described in Section 3.6.1. The output SCLK frequency is equal to

(MCLK/P) in master mode and up to a maximum speed of 25 MHz for both master and slave AIC14. The data/control

frame is still 16-SCLK long and the FS is one-SCLK pulse. Therefore, the DSP can maximize its data processing

bandwidth by taking advantage of time available between the end of AIC14s control frame and the next frame-sync

FS to process other tasks.

3–13

TURBO PROGRAMMING MODE

Stand-Alone Case:

Turbo SCLK

FS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

One SCLK

Sampling Period

DIN / DOUT

Data Frame

15 14 1 0 1415 1 0 1415 1 0

...

Control Frame

...

Cascade Case (Master + 4 Slaves):

Turbo SCLK

FS

DIN / DOUT

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Sampling Period

Data Frame Control Frame Data Frame

TURBO CONTINUOUS DATA TRANSFER MODE

Stand-Alone Case:

Turbo SCLK

FS

DIN / DOUT

•••••••••••••••••••••••••••••••••••••••••••••••••••••

One SCLK

Data Frame

... ...

15 14

10 1415 1 0

Cascade Case (Master + 4 Slaves):

Sampling Period

Hi-Z

Hi-Z

Hi-Z

Data Frame Control Frame

...

Data Frame

...

1415 1 0

Hi-Z

Control Frame

Turbo SCLK

FS

DIN / DOUT

•••••••••••••••••••••••••••••••••••••••••••••••••

Sampling Period

Data Frame

Hi-Z

Data Frame

Hi-Z

NOTE: SCLK is not drawn to scale.

Figure 3–17. Timing Diagram for Turbo Operation

3.9 Control Register Programming

The TLV320AIC14 contains six control registers that are used to program available modes of operation. All register

programming occurs during the control frame through DIN. New configuration takes effect after a delay of one frame

sync FS except the software reset, which happens after 6 MCLKs from the falling edge of the next frame sync FS.

The TLV320AIC14 is defaulted to the programming mode upon power up. Set bit 6 in control register 1 to switch to

continuous data transfer mode. If the 15+1 data format of DIN has been selected, the LSB of the DIN to 1 to switch

from continuous data transfer mode to programming set mode. Otherwise, either the device needs to be reset or the

host port writes 0 to bit D6 of control register 1 during the continuous data transfer mode to switch back to the

programming mode.

3–14

3.9.1 Data Frame Format

(15+1) Bit Mode

DIN

(Continuous Data Transfer Mode Only)

DOUT

(16 Bit A/D Data)

DIN

16 Bit Mode

DOUT

16 Bit Mode

D15 – D1

A/D and D/A Data

D15 – D0

D15 – D0

A/D and D/A Data

D15 – D0

D0

Control Frame

Request

Figure 3–18. Data Frame Format

3.9.2 Control Frame Format (Programming Mode)

During the control frame, the DSP sends 16-bit words to the SMARTDM(TM) through DIN to read or write control

registers shown in Table 3–3. The upper byte (Bits D15–D8) of the 16-bit control-frame word defines the read/write

command. Bits D15–D13 define the control register address with register content occupied the lower byte D7–D0.

Bit D12 is set to 0 for a write or to 1 for a read. Bit D11 in the write command is used to perform the broadcast mode.

During a register write, the register content is located in the lower byte of DIN. During a register read, the register

content is output in the lower byte of DOUT in the same control frame, whereas the lower byte of DIN is ignored.

3.9.3 Broadcast Register Write

Broadcast operation is very useful for a cascading system of SMARTDM DSP codecs in which all register

programming can be completed in one control frame. During the control frame and in any register-write time slot, if

the broadcast bit (D11) is set to 1, the register content of that time slot is written into the specified register of all devices

in cascade (see Figure 3–20). This reduces the DSP’s overhead of doing multiple writes to program same data into

cascaded devices.

Data to be Written Into Register

DIN (Write)

D15

D15 D13D14

SMARTDM Device

Register

Address

Address

D13D14

R/W Broadcast

1DIN (Read)

0

Register

Address

Figure 3–19. Control Frame Data Format

111D110

111

0D9D10D11DOUT (Read) D15 D13D14 D12

D7 – D0

Don’t care

D7 – D0

Register Content

D7 – D0

3–15

Master FS

Data Frame Control Frame

DIN

Time Slot

Master Slave2 Slave1 Slave0 Master Slave2 Slave1 Slave0 Master Slave2 Slave1 Slave0Slave0

Write

Command

Reg Addr (D15–D13)

R/W (D12)

Broadcast (D11)

D10–D8

001(1)

0

1

111

010(2)

0

1

111

100(4)

0

1

111

110(6)

0

1

111

NOTE: In this example, the broadcast operation (D11 = 1) is used to program the four control registers of Reg.1, Reg.2, Reg.4, and Reg.6 in all

4 DSP codecs (Master, Slave2, Slave1, and Slave0) shown in Figure 3–8. These registers are programmed during the same frame.

Figure 3–20. Broadcast Register Write Example

3.9.4 Register Map

Bits D15 through D13 represent the control register address that is written with data carried in D7 through D0. Bit D12

determines a read or a write cycle to the addressed register. When D12 = 0, a write cycle is selected. When

D12 = 1, a read cycle is selected. Bit D11 controls the broadcast mode as described above, in which the broadcast

mode is enabled if D11 is set to 1. Always write 1s to bits D10 through D8.

Table 3–3 shows the register map.

Table 3–3. Register Map

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Register Address RW BC 1 1 1 Control Register Content

Table 3–4. Register Addresses

REGISTER NO. D15 D14 D13 REGISTER NAME

0 0 0 0 No operation

1 0 0 1 control 1

2 0 1 0 control 2

3 0 1 1 control 3

4 1 0 0 control 4

5 1 0 1 control 5

6 1 1 0 control 6

3–16

4 Control Register Content Description

4.1 Control Register 1

D7 D6 D5 D4 D3 D2 D1 D0

ADOVF CX IIR DAOVF BIASV ALB DLB DAC16

R R/W R/W R R/W R/W R/W R/W

NOTE: R = Read, W = Write

Table 4–1. Control Register 1 Bit Summary

BIT NAME

D7 ADOVF 0 ADC over flow. This bit indicates whether the ADC is overflow.

D6 CX 0 Continuous data transfer mode. This bit selects between programming mode and continuous data transfer

D5 IIR 0 IIR Filter. This bit selects between FIR and IIR for decimation/interpolation low-pass filter.

D4 DAOVF 0 DAC over flow. This bit indicates whether the DAC is overflow

D3 BIASV 0 Bias voltage. This bit selects the output voltage for BIAS pin

D2 ALB 0 Analog loop back

D1 DLB 0 Digital loop back

D0 DAC16 0 DAC 16-bit data format. This bit applies to the continuous data transfer mode only to enable the 16-bit data

RESET

VALUE

FUNCTION

ADOVF = 0 No overflow.

ADOVF = 1 A/D is overflow.

mode.

CX = 0 Programming mode.

CX = 1 Continuous data transfer mode.

IIR = 0 FIR filter is selected.

IIR = 1 IIR filter is selected.

DAOVF = 0 No overflow.

DAOVF = 1 DAC is overflow

BIASV = 0 BIAS pin = 2.35V

BIASV = 1 BIAS pin = 1.35V

DLB = 0 Analog loopback disabled

DLB = 1 Analog loopback enabled

DLB = 0 Digital loopback disabled

DLB = 1 Digital loopback enabled

format for DAC input.

DAC16 = 0 DAC input data length is 15 bits. Writing a 1 to the LSB of the DAC input to switch from continuous

data transfer mode to programming mode.

DAC16 = 1 DAC input data length is 16 bit.

4–1

4.2 Control Register 2

D7 D6 D5 D4 D3 D2 D1 D0

TURBO

R/W R/W R/W R/W R/W R/W R/W R/W

NOTE: R = Read, W = Write

BIT NAME

D7 TURBO 0 Turbo mode. This bit is used to set the SCLK rate.

D6 DIFBP 0 Decimation/interpolation filter bypass. This bit is used to bypass both decimation and interpolation filters.

D5–D3 I2Cx 100 I2C device address. These three bits are programmable to define three MSBs of the I2C device address (reset

D2 GPO 0 General-purpose output

D1–D0 HPC 00 Host port control bits.

DIFBP I2C6 I2C5 I2C4 GPO HPC

Table 4–2. Control Register 2 Bit Summary

RESET

VALUE

TURBO = 0 SCLK = (16 × FS × #Device × mode)

TURBO = 1 SCLK = MCLK/P (P is determined in register 4)

DIFBP = 0 Decimation/interpolation filters are operated.

DIFBP = 1 Decimation/interpolation filters are bypassed.

value is 100). These three bits are combined with the 4-bit SMARTDM device address to form 7-bit I2C device

address.

Write the following values into D1–D0 to select the appropriate configuration for two pins SDA and SCL. SDA pin

is set to be equal to D2 if D1–D0 = 10.

D1–D0

0 0 SDA and SCL pins are used for I2C interface

1 1 SDA and SCL pins are used for S2C interface

0 0 SDA pin = D2, input going into SCL pin is output to DOUT

1 1 SDA pin = Control frame flag.

FUNCTION

4.3 Control Register 3

D7 D6 D5 D4 D3 D2 D1 D0

PWDN SWRS OSR-option ASRF

R/W R/W R/W R/W R/W

NOTE: R = Read, W = Write