Page 1

TIDA-00293 DLP®3D Printer User's Guide

User's Guide

Literature Number: DLPU025

September 2014

Page 2

Contents

Preface ........................................................................................................................................ 6

1 Introduction to the DLP

1.1 ................................................................................................................................. 7

1.2 Stereolithography ............................................................................................................ 7

1.3 How the DLP 3D Printer Reference Design Works ..................................................................... 7

1.3.1 DLP Structured Light SDK......................................................................................... 7

1.3.2 Photo-resins ........................................................................................................ 7

1.3.3 DLP LightCrafter™ 4500 Evaluation Module.................................................................... 7

1.3.4 Velmex XSlide™ Translation Stage.............................................................................. 7

1.3.5 Mechanical Structure............................................................................................... 8

1.3.6 DLP 3D Printer Microcontroller.................................................................................... 8

1.3.7 Front Panel User Interface ........................................................................................ 8

1.3.8 DLP 3D Printer Graphical User Interface........................................................................ 8

1.3.9 Object Layer Images ............................................................................................... 8

2 Installing the DLP

2.1 ................................................................................................................................. 9

2.2 Future Technology Devices International D2XX Driver Installation ................................................... 9

2.3 Downloading the DLP 3D Printer Reference Design .................................................................. 13

2.4 Installing the DLP 3D Printer Reference Design ....................................................................... 13

3 Using the DLP

3.1 ................................................................................................................................ 17

3.2 Programming The MSTP Cape........................................................................................... 17

3.3 Preparing The Hardware For Printing ................................................................................... 21

3.4 Printing An Object.......................................................................................................... 27

4 Building the DLP

4.1 ................................................................................................................................ 34

4.2 Qt Creator Installation ..................................................................................................... 34

4.3 OpenCV Build and Installation............................................................................................ 41

4.4 DLP 3D Printer Reference Design Project File Setup................................................................. 52

5 DLP

®

3D Printer Design Considerations ................................................................................ 56

5.1 ................................................................................................................................ 56

5.2 Hardware Design........................................................................................................... 56

5.2.1 Illumination Source................................................................................................ 56

5.2.2 Build Orientation................................................................................................... 56

5.2.3 Build Envelope And Voxel Resolution.......................................................................... 58

5.2.4 Build Platform...................................................................................................... 59

5.2.5 Mechanical Structure ............................................................................................. 59

5.3 Microcontroller Firmware Design......................................................................................... 59

5.3.1 State Machine ..................................................................................................... 59

5.3.2 Communications With The PC .................................................................................. 60

5.3.3 Motor Drive Functionality......................................................................................... 60

5.3.4 LCD Interface ...................................................................................................... 60

5.4 DLP 3D Printer GUI Design............................................................................................... 60

5.4.1 DLP Structured Light SDK ....................................................................................... 60

®

3D Printer Reference Design......................................................................... 17

®

®

3D Printer Reference Design ............................................................. 7

®

3D Printer Reference Design...................................................................... 9

3D Printer Reference Design from Source .................................................. 34

2

Contents DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

5.4.2 Multithreading...................................................................................................... 60

5.4.3 Qt Design Environment........................................................................................... 61

6 Troubleshooting................................................................................................................. 62

6.1 General Troubleshooting Steps .......................................................................................... 62

DLPU025–September 2014 Contents

Submit Documentation Feedback

3

Copyright © 2014, Texas Instruments Incorporated

Page 4

www.ti.com

List of Figures

2-1. FTDI D2XX Download....................................................................................................... 9

2-2. Extracted FTDI Driver Files................................................................................................. 9

2-3. Devices and Printers In The Windows Start Bar....................................................................... 10

2-4. TTL-232R-3V3 Properties Menu ......................................................................................... 10

2-5. Hardware Properties Button .............................................................................................. 11

2-6. Change Settings Button For Hardware Properties..................................................................... 11

2-7. Update Driver Option ...................................................................................................... 12

2-8. Browse Computer For Driver Files....................................................................................... 12

2-9. Select Driver File Folder................................................................................................... 13

2-10. Begin The Update Of Drivers............................................................................................. 13

2-11. DLP 3D Printer Reference Design Installation Executable ........................................................... 14

2-12. DLP 3D Printer Reference Design Setup Wizard Screen............................................................. 14

2-13. DLP 3D Printer Reference Design License Agreement Screen...................................................... 15

2-14. DLP 3D Printer Reference Design Installation Path Selection ....................................................... 15

2-15. DLP 3D Printer Reference Design Installation Confirmation ......................................................... 16

2-16. DLP 3D Printer Reference Design File Installation Progress......................................................... 16

2-17. DLP 3D Printer Reference Design Installation Completion........................................................... 16

3-1. Importing The DLP 3D Printer Firmware Project....................................................................... 18

3-2. CCS Project Import Source Selection ................................................................................... 19

3-3. CCS Project Importation Search ......................................................................................... 19

3-4. DLP 3D Printer Firmware Project Path Selection ...................................................................... 20

3-5. DLP 3D Printer Project Importation And Discovery.................................................................... 20

3-6. Uploading the DLP 3D Printer Firmware To The MSTP Cape....................................................... 21

3-7. DLP 3D Printer Built Hardware........................................................................................... 22

3-8. Resin Vat Placement ...................................................................................................... 23

3-9. Resin Vat Locked In Position............................................................................................. 23

3-10. TTL-232R-3V3 Connected To DLP 3D Printer......................................................................... 24

3-11. LightCrafter 4500 USB Connection ...................................................................................... 24

3-12. LightCrafter 4500 And TTL-232R-3V3 Cable Connected To PC .................................................... 25

3-13. Connecting 12 V Power To The Printer ................................................................................. 25

3-14. DLP 3D Printer Initialization Message................................................................................... 26

3-15. DLP 3D Printer Initialized And Waiting.................................................................................. 26

3-16. Perforated Aluminum Build Plate In Place.............................................................................. 27

3-17. Executing The DLP 3D Printer Program ................................................................................ 28

3-18. Setting The Image Folder ................................................................................................. 29

3-19. Layer Image Folder Selection ............................................................................................ 30

3-20. Printer Settings Check Before Sending Images To The Printer...................................................... 31

3-21. Starting The Print Sequence.............................................................................................. 32

3-22. Object Layer Image Sequence Upload Completed.................................................................... 33

3-23. Beginning Of Object Printing.............................................................................................. 33

4-1. Qt Creator IDE Installation................................................................................................ 34

4-2. Qt Creator IDE Installation Path Selection.............................................................................. 35

4-3. Qt Creator IDE Installation Component Selection ..................................................................... 35

4-4. Qt Creator IDE End User License Agreement.......................................................................... 36

4-5. Qt Creator IDE Ready To Install ......................................................................................... 36

4-6. Qt Creator IDE Installing .................................................................................................. 37

4-7. Qt IDE Installation Completed............................................................................................ 37

4

List of Figures DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

4-8. Finding the MinGW Installation Path .................................................................................... 38

4-9. System Environment Variables Editing.................................................................................. 39

4-10. System Properties Window ............................................................................................... 39

4-11. Editing the PATH Variable ................................................................................................ 40

4-12. MinGW Directory Added to the PATH Variable ........................................................................ 40

4-13. OpenCV Source Extraction Path......................................................................................... 41

4-14. OpenCV Source Extraction ............................................................................................... 41

4-15. Cmake Installation Entry .................................................................................................. 41

4-16. Cmake User License Agreement......................................................................................... 42

4-17. Cmake Installation Options ............................................................................................... 42

4-18. Cmake Installation Path ................................................................................................... 42

4-19. Cmake Installation Completed............................................................................................ 43

4-20. Cmake GUI Execution From Windows Start Button................................................................... 43

4-21. Cmake GUI Source Selection ............................................................................................ 44

4-22. OpenCV Source Selection In Cmake.................................................................................... 45

4-23. Cmake GUI Build Selection............................................................................................... 46

4-24. Cmake GUI Configure Build .............................................................................................. 46

4-25. Cmake Compiler Configuration........................................................................................... 47

4-26. Cmake Install Option Configuration...................................................................................... 48

4-27. Cmake Build Options Input ............................................................................................... 49

4-28. Cmake Make File Generation............................................................................................. 49

4-29. Opening a Command Line Window...................................................................................... 50

4-30. Starting the OpenCV Build Process ..................................................................................... 51

4-31. Long OpenCV Build Process ............................................................................................. 51

4-32. Installing the OpenCV Libraries .......................................................................................... 51

4-33. Opening the DLP 3D Printer Reference Design Project In Qt Creator.............................................. 52

4-34. QT .pro File Location ...................................................................................................... 53

4-35. Configuring the QT .pro for Building..................................................................................... 53

4-36. Opening the QT .pro for Editing.......................................................................................... 54

4-37. Editing The Include Paths For OpenCV and FTDI Libraries.......................................................... 54

4-38. Running The DLP 3D Printer Reference Design GUI ................................................................. 55

5-1. Top-Down Build Method................................................................................................... 57

5-2. Bottom-Up Build Method .................................................................................................. 58

DLPU025–September 2014 List of Figures

Submit Documentation Feedback

5

Copyright © 2014, Texas Instruments Incorporated

Page 6

About This Guide

The DLP™ 3D Printer Reference Design enables faster development of 3D printing applications utilizing

DLP platforms. This guide walks the user through the installation, operation, and recommended use

settings of the DLP 3D Printer Reference Design, as well as building the GUI and microcontroller firmware

from source code.

Related Documentation from Texas Instruments

DLPC350 Datasheet: DLP Digital Controller for the DLP4500 DMD, DLPS029

DLP4500 Datasheet: DLP®0.45 WXGA DMD, DLPS028

User's Guide: DLP®LightCrafter 4500™ Evaluation Module, DLPU011

User's Guide: MSP430x2xx Family, SLAU144

DRV8825 Datasheet: Stepper Motor Controller IC, DRV8825

If You Need Assistance

Refer to the DLP and MEMS TI E2E Community support forums

Preface

DLPU025–September 2014

Read This First

Minimum System Requirements

• PC with 1GHz, or faster, 32-bit (x86) processor

• 2 GB RAM

• 10 GB of free hard-disk space

• Microsoft®Windows®7 SP 1

• Microsoft Visual C++ 2010 Redistributable

• Microsoft Visual C++ 2012 Redistributable

• 2x USB 2.0 port

• Qt Creator 5.3.0 Integrated Design Environment (IDE)

• OpenCV v2.4.9 Libraries

• DLP®LightCrafter 4500™ Evaluation Module

• Code Composer Studio™ v6

• Future Technology Devices International Ltd. D2XX Drivers 2.10.00

• Freesteel Z-level Slicer

Note: The DLP 3D Printer Reference Design installation and setup is written for users that are familiar

with navigating through Windows command line prompts and building executable binaries from source

code.

Note: The DLP 3D Printer Reference Design was created with the above listed versions of each software

tool. Using newer versions of the software tools may render the code inoperable, and it shall be up to the

user to make appropriate changes to the source code for compatibility.

6

Read This First DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

Chapter 1

DLPU025–September 2014

Introduction to the DLP®3D Printer Reference Design

1.1 The DLP 3D Printer Reference Design is a full hardware design enabling 3-dimensional printing of objects

from cross-sectional images from meshed models. The reference design includes a lightweight GUI,

electrical schematics, cable assembly drawings, and mechanical drawings to create the printer.

1.2 Stereolithography

Stereolithography is an additive manufacturing method that employs a photo-curable resin. Exposing the

photo-resin to successive 2-dimensional object cross sections create the 3-dimensional objects a single

layer at a time. The resin, composed of monomers, cross-links when exposed to light of a sufficient energy

level. The cross-linking of the monomers generates a polymer chain, creating a solid material where the

resin was exposed. Stereolithography was traditionally achieved by outlining the object layer with a laser;

DLP technology allows an entire layer to be exposed at once by dynamically masking a broad light source.

1.3 How the DLP 3D Printer Reference Design Works

The DLP 3D Printer Reference Design consists of a LightCrafter 4500 evaluation module, a translation

stage driven by a stepper motor, and a microcontroller at its core. The DLP 3D Printer Reference Design

utilizes the DLP Structured Light SDK to perform the printed image creation and layer sequence for

printed objects.

1.3.1 DLP Structured Light SDK

A GUI on a host PC allows the user to upload the sliced object images to the DLP 3D Printer for storage

and exposure. The sliced layers are combined into composite images and uploaded to the LightCrafter

4500 along with their exposure sequence. The DLP Structured Light SDK prepares the layer images and

contains development modules for preparing image sequences. The SDK source code is made available

along with the GUI source code in the TIDA-00293 DLP 3D Printer design files package.

1.3.2 Photo-resins

A host of photo-resins are available in the SLA market, offered by a handful of commercial manufacturers.

Each resin has different physical properties lending themselves to specific applications. The DLP 3D

Printer is built with a 420 nm light source, which allows the use of any resin that is curable at this

wavelength or above. The resin used during the development of the DLP 3D Printer was sourced from

www.buy3dink.com

1.3.3 DLP LightCrafter™ 4500 Evaluation Module

The DLP 3D Printer Reference Design uses a modified LightCrafter 4500 projector to expose the photoresin. The LightCrafter 4500 is modified with a 420 nm Philips Lumileds Luxeon®UV LED. The projection

optics are also modified to allow the projector to focus at shorter distances, enabling higher resolution

printed objects.

1.3.4 Velmex XSlide™ Translation Stage

The printed objects form on a platform that translates on one axis only. The translation stage lowers the

build platform a precise and accurate distance for each printed layer. This reference design uses the

Velmex XSlide, which accepts NEMA 17 or 23 sized stepper motors and has integrated limit switches. The

stage is highly rigid for it's small size to ensure repeatable positioning of the build platform.

DLPU025–September 2014 Introduction to the DLP®3D Printer Reference Design

Submit Documentation Feedback

7

Copyright © 2014, Texas Instruments Incorporated

Page 8

How the DLP 3D Printer Reference Design Works

1.3.5 Mechanical Structure

The DLP 3D Printer mechanical assembly is constructed from 0.25" thick aluminum plates to make the

structure as rigid as possible. The structure's role is to hold the orientation of the build platform/translation

stage, photo-resin vat, and projector tightly, in relation to each other, to reduce dimensional errors in the

printed objects. The mechanical assembly features an easily removable photo-resin vat.

1.3.6 DLP 3D Printer Microcontroller

The DLP 3D Printer has to synchronize motor control along with exposure of the object layers, as well as

supply an interface with a front panel LCD screen and user buttons. An MSP430F2410 controls the

operation of the DLP 3D Printer onboard a stand-alone capable BeagleBone Black MSTP Cape. The

MSTP cape contains the microcontroller and a DRV8825 stepper motor control IC. The

MSP430/DRV8825 combination is capable of driving bipolar and unipolar stepper motors with phase

voltages between 8.2 V to 45 V. The DRV8825 can output up to 2.5 A of current at 24 V. The MSTP cape

must be modified by the addition of connections between the microcontroller and header pins. The

connections that must be added are highlighted in red in the cape schematic in the TIDA-00293 design file

package.

1.3.7 Front Panel User Interface

Users can interface with the DLP 3D Printer through a front panel once the print has been started. A 4-line

LCD screen with 20 characters per line displays information to the user such as the number of print layers

and the current layer in the print sequence. The LCD screen is controlled by the MSP430 through an

HD44780 controller. The front panel also has two buttons allowing users to interact with the printer, either

by responding to LCD prompts or pausing -- and even cancelling -- the print sequence.

www.ti.com

1.3.8 DLP 3D Printer Graphical User Interface

Object layer images are uploaded to the DLP 3D Printer hardware utilizing a GUI. Object layer images

must be 912 × 1140 resolution due to the native resolution of the LightCrafter 4500. The images are

processed by the DLP Structured Light SDK into a firmware file containing the sequence of layer images.

The GUI takes a basic set of parameters from the user including: LED current setting, layer exposure time,

z-layer step resolution, resin settling time, and the directory where object layer images are kept.

1.3.9 Object Layer Images

Object layer images can be made by hand using a drawing utility, or created by slicing STL file models.

STL files are the de facto standard input file for 3D printers, and are readily available in multiple online

libraries. STL files can be sliced using the Freesteel slicer utility found here:

http://www.freesteel.co.uk/wpblog/slicer/. The output image file format recommended is BMP. The output

images should have a 16:10 aspect ratio as output from the slicer, but be resized to 912 × 1140. Resizing

the images will change the aspect ratio, but the diamond array of the DLP4500 DMD will return the image

to the proper 16:10 aspect ratio once projected. Object features should be colored white and the

background should be black. Any white pixels in the object layer images will be printed in the resin.

The object layer images must be isolated in a file directory and stored in alpha-numeric order. Freesteel

slicer will handle this for the user if a static output file name is supplied. No other files should be kept in

the directory with the layer images.

8

Introduction to the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

Chapter 2

DLPU025–September 2014

Installing the DLP®3D Printer Reference Design

2.1 Before using the DLP 3D Printer Reference Design GUI, a few software dependencies and the reference

design software itself, must be installed. The host PC communicates with the DLP 3D Printer controller

through a USB to Serial adaptor by FTDI. The FTDI drivers must be installed before the GUI will run

properly. Please read the following sections for more detailed instructions.

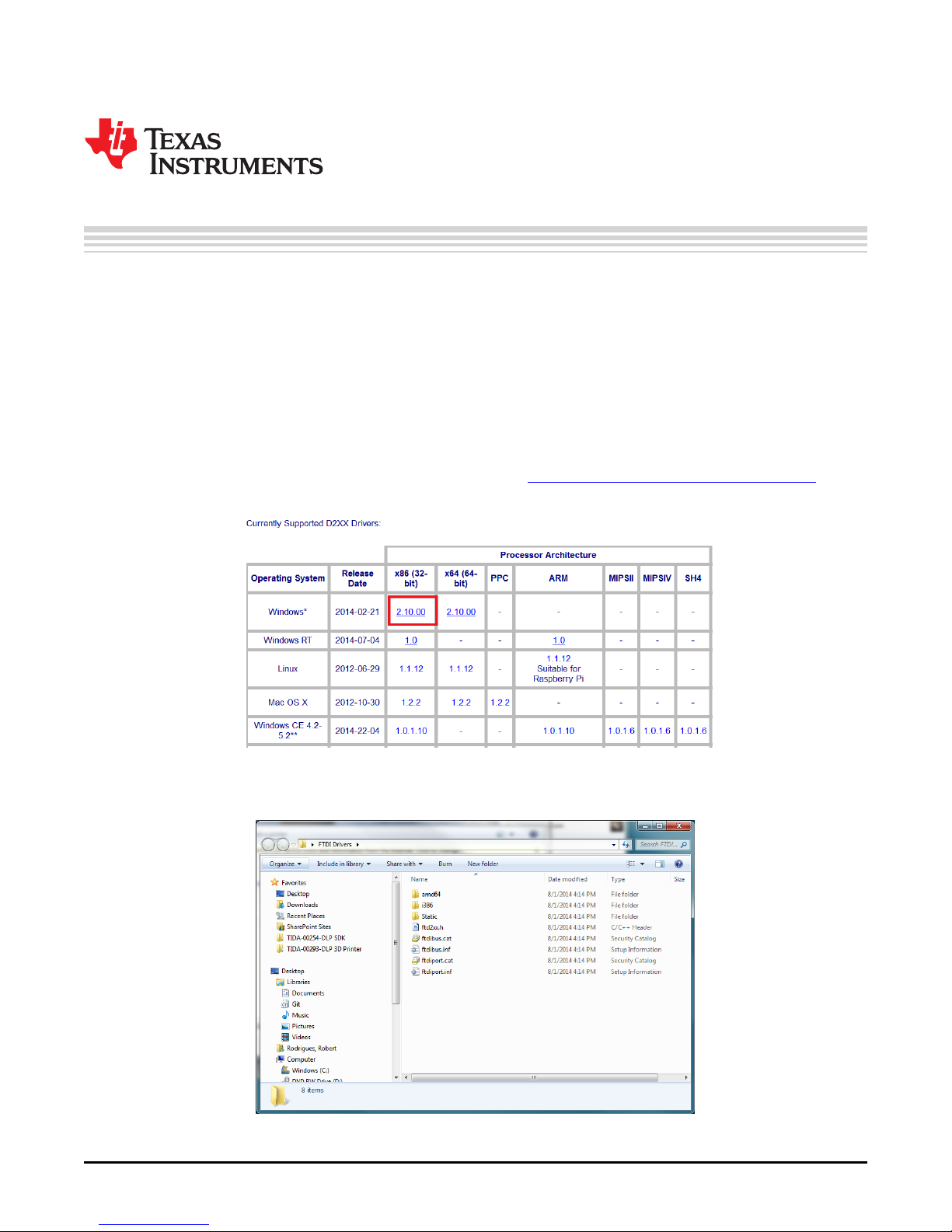

2.2 Future Technology Devices International D2XX Driver Installation

The TTL-232R-3V3 device by FTDI allows a USB port on a Windows computer to communicate with TTL

devices. The drivers are not automatically installed by Windows. Follow the procedure below to install the

proper drivers.

1. Go to the FTDI D2XX driver download site, located at http://www.ftdichip.com/Drivers/D2XX.htm and

download the 32-bit Windows, as shown in Figure 2-1.

2. Extract the downloaded .zip file into a convenient folder, as shown in Figure 2-2.

DLPU025–September 2014 Installing the DLP®3D Printer Reference Design

Submit Documentation Feedback

Figure 2-1. FTDI D2XX Download

Figure 2-2. Extracted FTDI Driver Files

9

Copyright © 2014, Texas Instruments Incorporated

Page 10

Future Technology Devices International D2XX Driver Installation

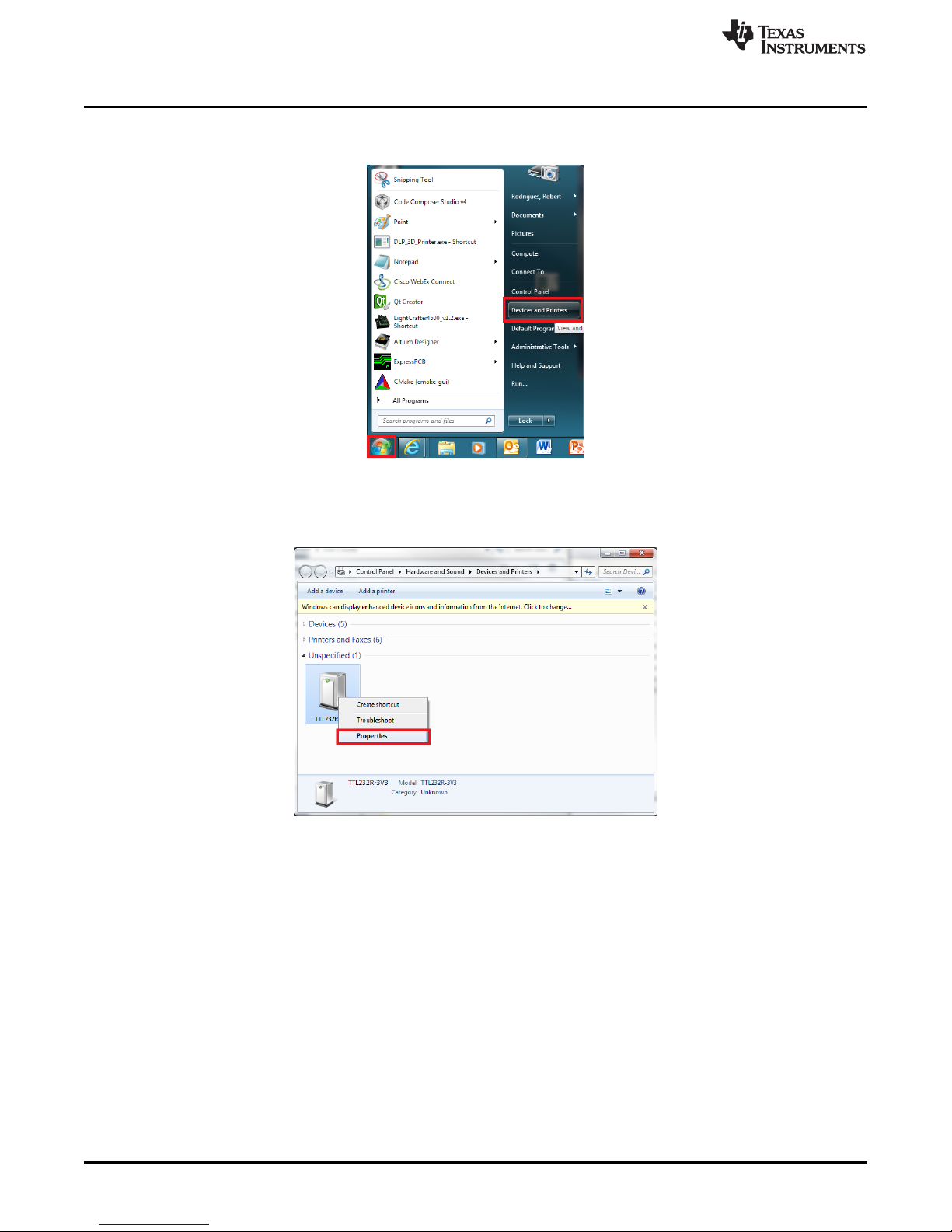

3. After extraction of the driver files, click the Windows button and open Devices and Printers, as shown

in Figure 2-3.

Figure 2-3. Devices and Printers In The Windows Start Bar

4. Find the device labeled TTL232R-3V3 in the list of devices attached to the computer. Right click the

device, and select Properties, as shown in Figure 2-4.

www.ti.com

Figure 2-4. TTL-232R-3V3 Properties Menu

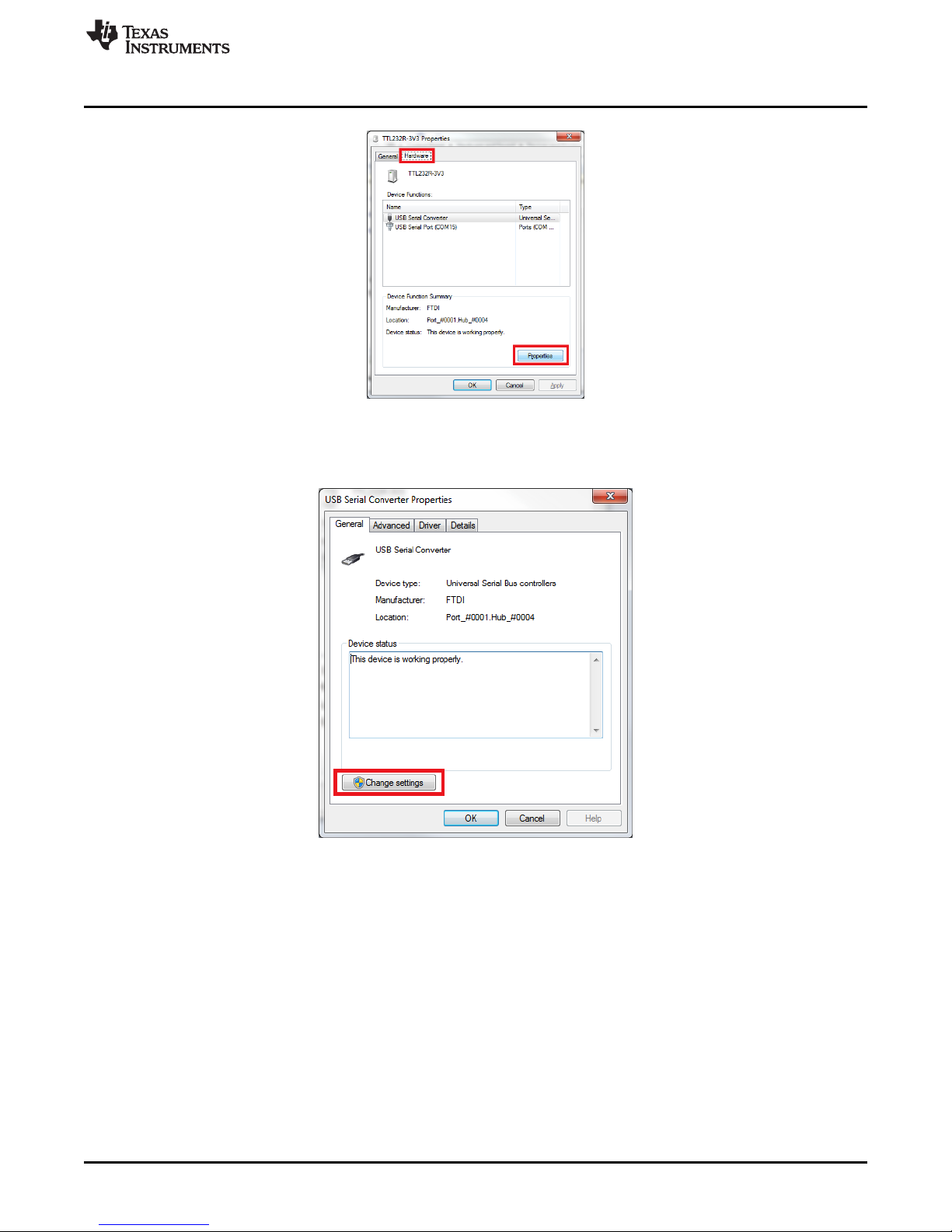

5. Enter the Hardware tab and click the Properties button, shown in Figure 2-5.

10

Installing the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

6. Click the Change Settings button, highlighted in Figure 2-6. Click Yes on the prompt for administrator

Future Technology Devices International D2XX Driver Installation

Figure 2-5. Hardware Properties Button

privileges.

Figure 2-6. Change Settings Button For Hardware Properties

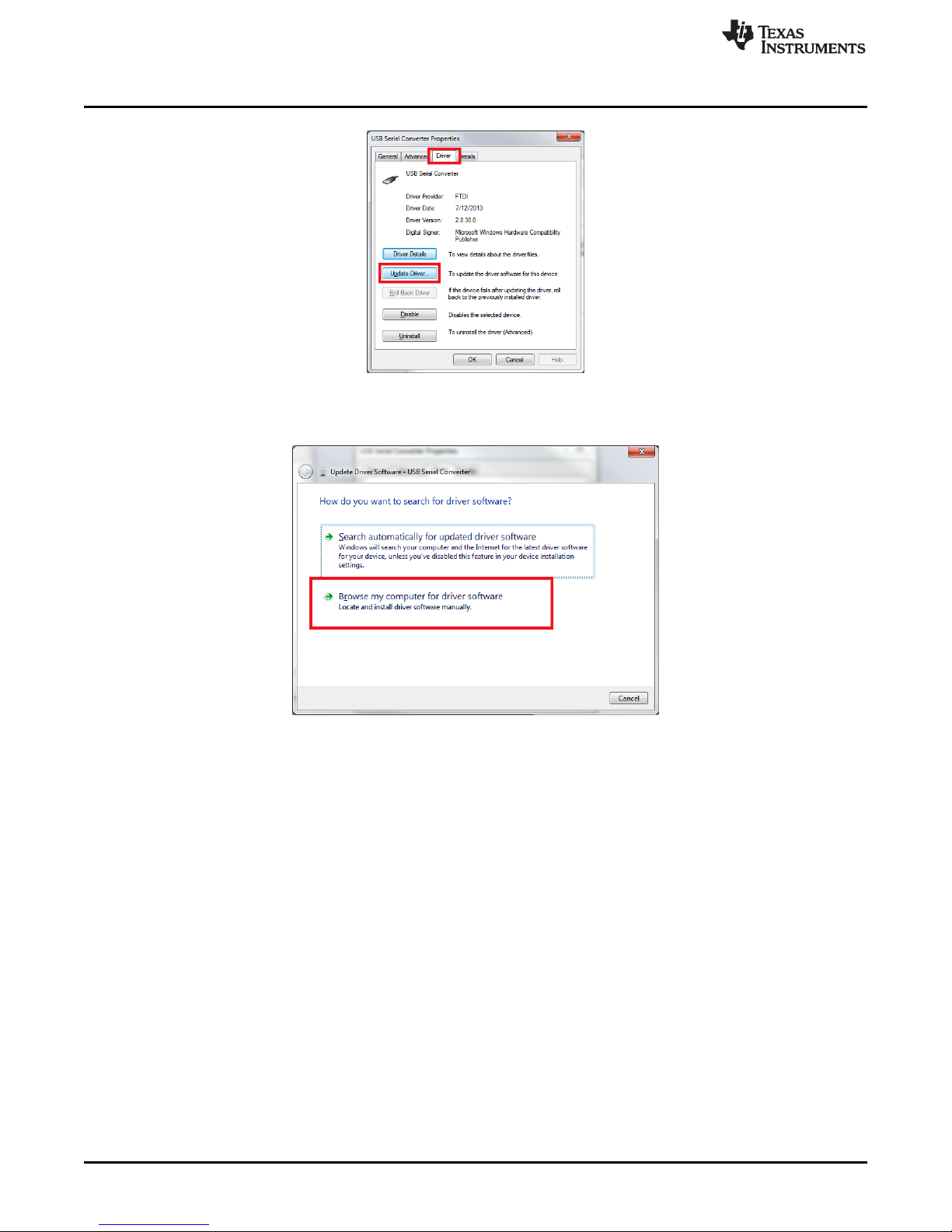

7. Enter the Driver tab, and click the Update Driver button, as shown in Figure 2-7.

DLPU025–September 2014 Installing the DLP®3D Printer Reference Design

Submit Documentation Feedback

11

Copyright © 2014, Texas Instruments Incorporated

Page 12

Future Technology Devices International D2XX Driver Installation

Figure 2-7. Update Driver Option

8. Click the Browse my computer option, shown in Figure 2-8.

www.ti.com

Figure 2-8. Browse Computer For Driver Files

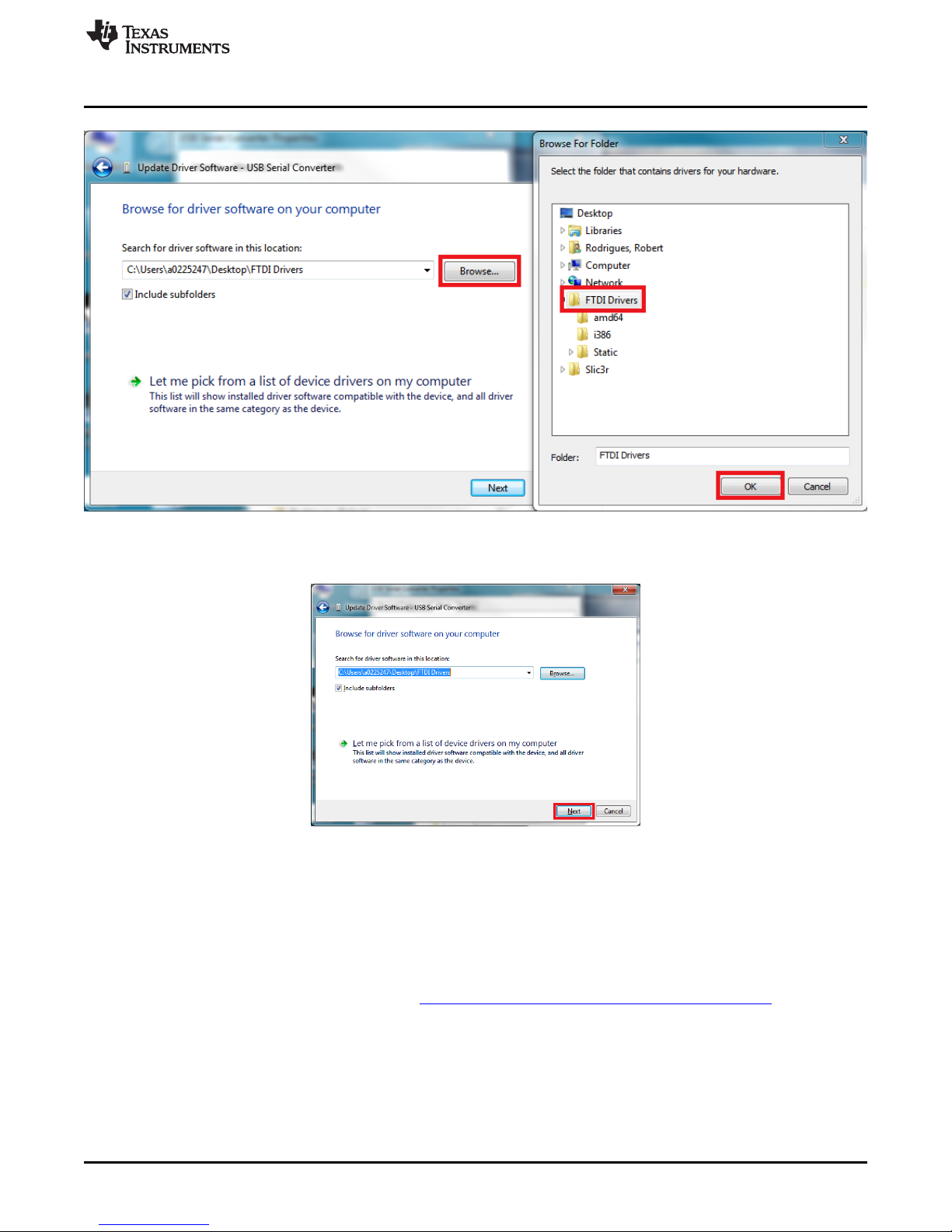

9. Click the Browse button that is highlighted in Figure 2-9. Select the folder containing the extracted

driver files from step 2, then click the OK button, as shown in Figure 2-9.

12

Installing the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

Downloading the DLP 3D Printer Reference Design

Figure 2-9. Select Driver File Folder

10. Click the Next button, shown in Figure 2-10.

Figure 2-10. Begin The Update Of Drivers

11. Windows will select the proper drivers from the extracted files and install them. The FTDI D2XX driver

installation is complete. Close all associated windows.

2.3 Downloading the DLP 3D Printer Reference Design

Compiled binaries for the DLP 3D Printer Reference Design are offered for convenience if the user does

not want to build them from source. The binaries are distributed along with the source code in a single

executable file which can be downloaded from the Texas Instruments Reference Design site. The source

code and pre-built program are distributed with the TI Design files in a .zip package.

2.4 Installing the DLP 3D Printer Reference Design

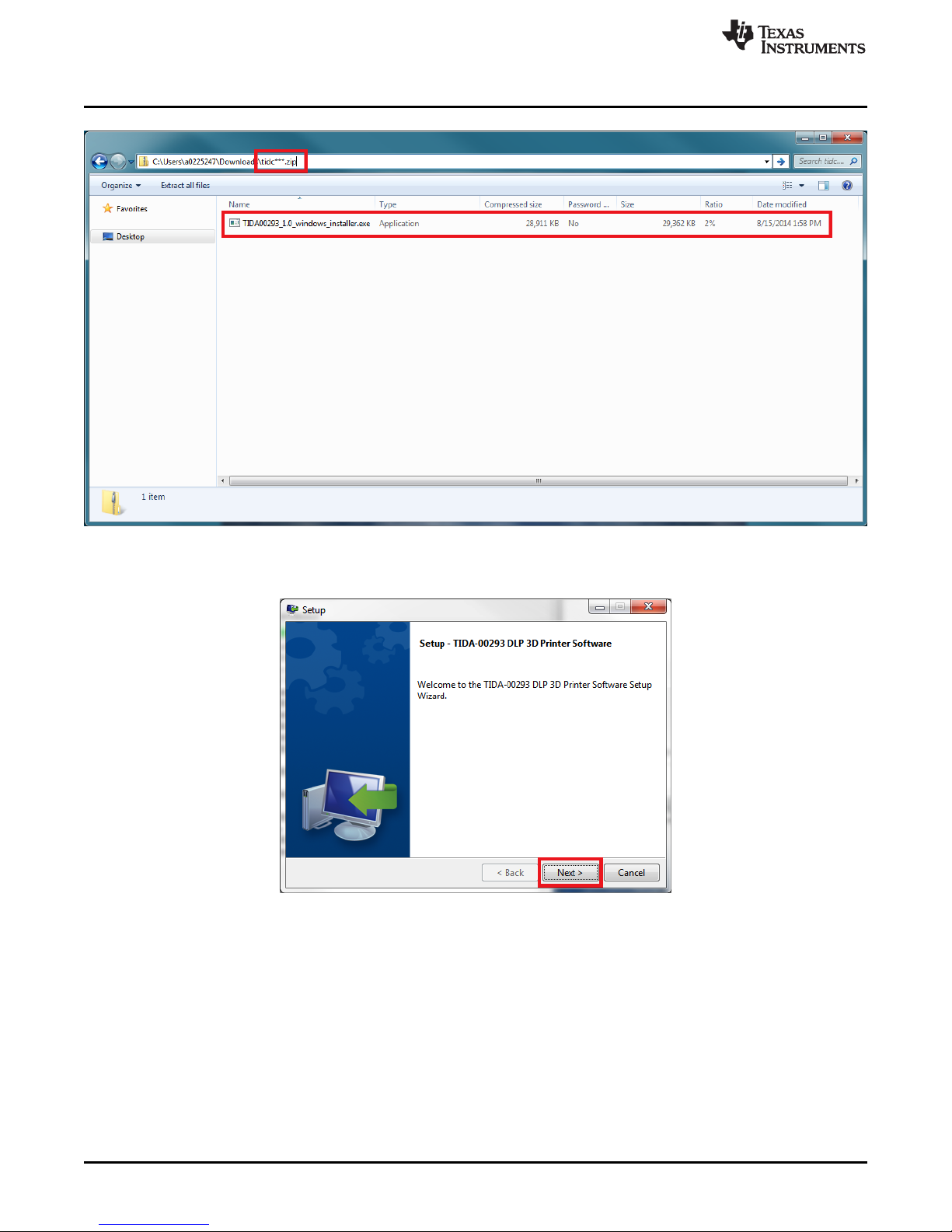

1. Decompress the "tidc***.zip" file in a convenient location.

2. Install the DLP 3D Printer Reference Design by executing the file "TIDA00293-***-windowsinstaller.exe," as shown in Figure 2-11.

DLPU025–September 2014 Installing the DLP®3D Printer Reference Design

Submit Documentation Feedback

13

Copyright © 2014, Texas Instruments Incorporated

Page 14

Installing the DLP 3D Printer Reference Design

Figure 2-11. DLP 3D Printer Reference Design Installation Executable

www.ti.com

3. Click the Next button on the install wizard setup screen, as shown in Figure 2-12.

Figure 2-12. DLP 3D Printer Reference Design Setup Wizard Screen

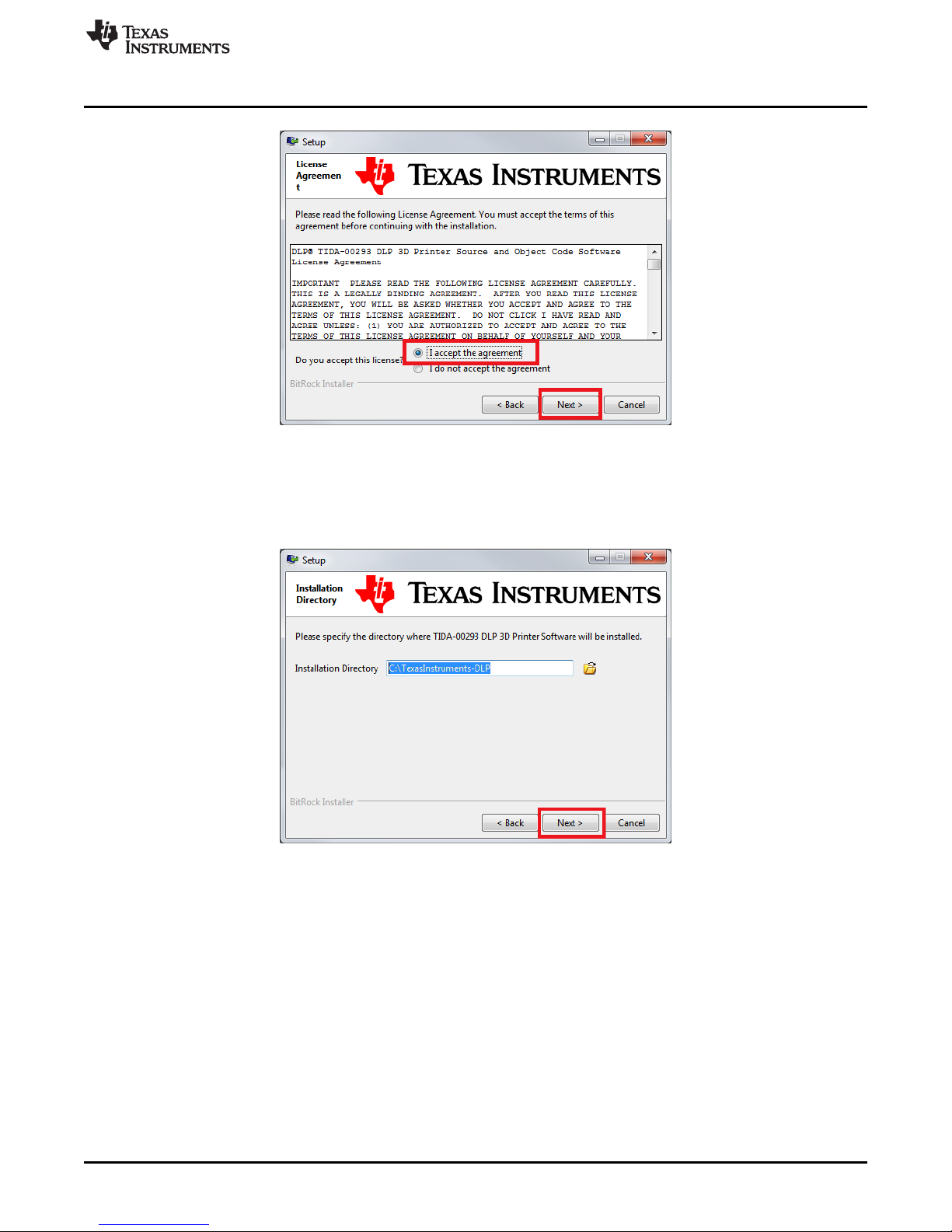

4. Read and review the license agreement for the DLP 3D Printer Reference Design, as shown in

Figure 2-13. Click the I accept the agreement radio button and then click the Next button to continue

installing the software.

14

Installing the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

5. Select an installation path where the reference design software will be located. Click the Next button,

Installing the DLP 3D Printer Reference Design

Figure 2-13. DLP 3D Printer Reference Design License Agreement Screen

as shown in Figure 2-14. Click the Next button to continue installing the software. Warning: Do not

include any spaces in the installation path for the reference design. Spaces will cause errors if the

software is built from source as described in Chapter 4!

Figure 2-14. DLP 3D Printer Reference Design Installation Path Selection

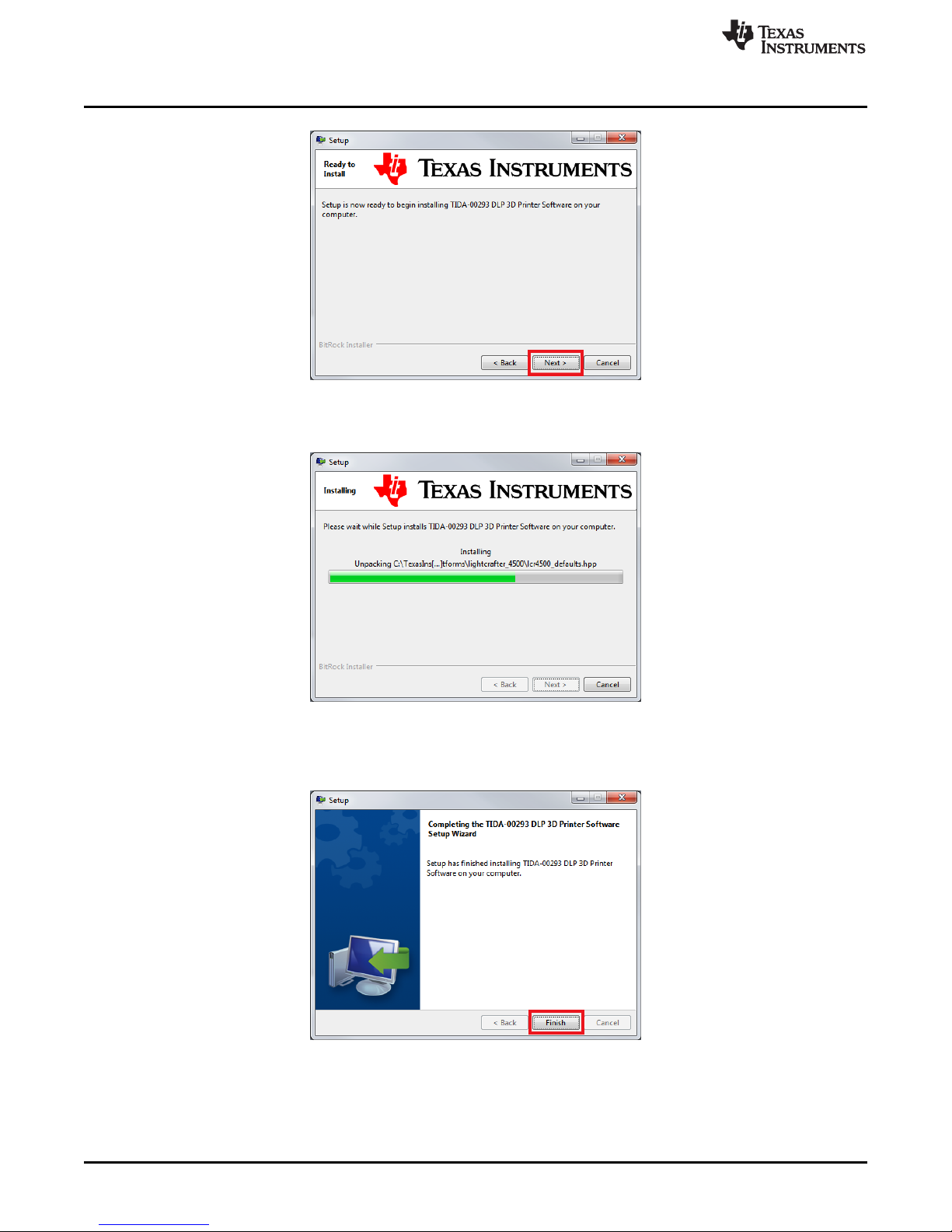

6. The installer is ready to install, click the Next button to start the process, as shown in Figure 2-15.

DLPU025–September 2014 Installing the DLP®3D Printer Reference Design

Submit Documentation Feedback

15

Copyright © 2014, Texas Instruments Incorporated

Page 16

Installing the DLP 3D Printer Reference Design

Figure 2-15. DLP 3D Printer Reference Design Installation Confirmation

7. Wait for the files to install in the location specified, as shown in Figure 2-16.

www.ti.com

Figure 2-16. DLP 3D Printer Reference Design File Installation Progress

8. Once the files have been extracted and installed, click the Finish button to close the installer, as

shown in Figure 2-17.

Figure 2-17. DLP 3D Printer Reference Design Installation Completion

16

Installing the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

Chapter 3

DLPU025–September 2014

Using the DLP®3D Printer Reference Design

3.1 The DLP 3D Printer Reference Design application allows users to upload images that represent the cross-

sectional layers of a 3-dimensional object. The layers can be generated in a few methods including by

hand, automatically through a CAD utility, or a specific slicing tool designed for cutting a 3-dimensional

model into layers. Freesteel Slicer was used and can be found here:

http://www.freesteel.co.uk/wpblog/slicer/.

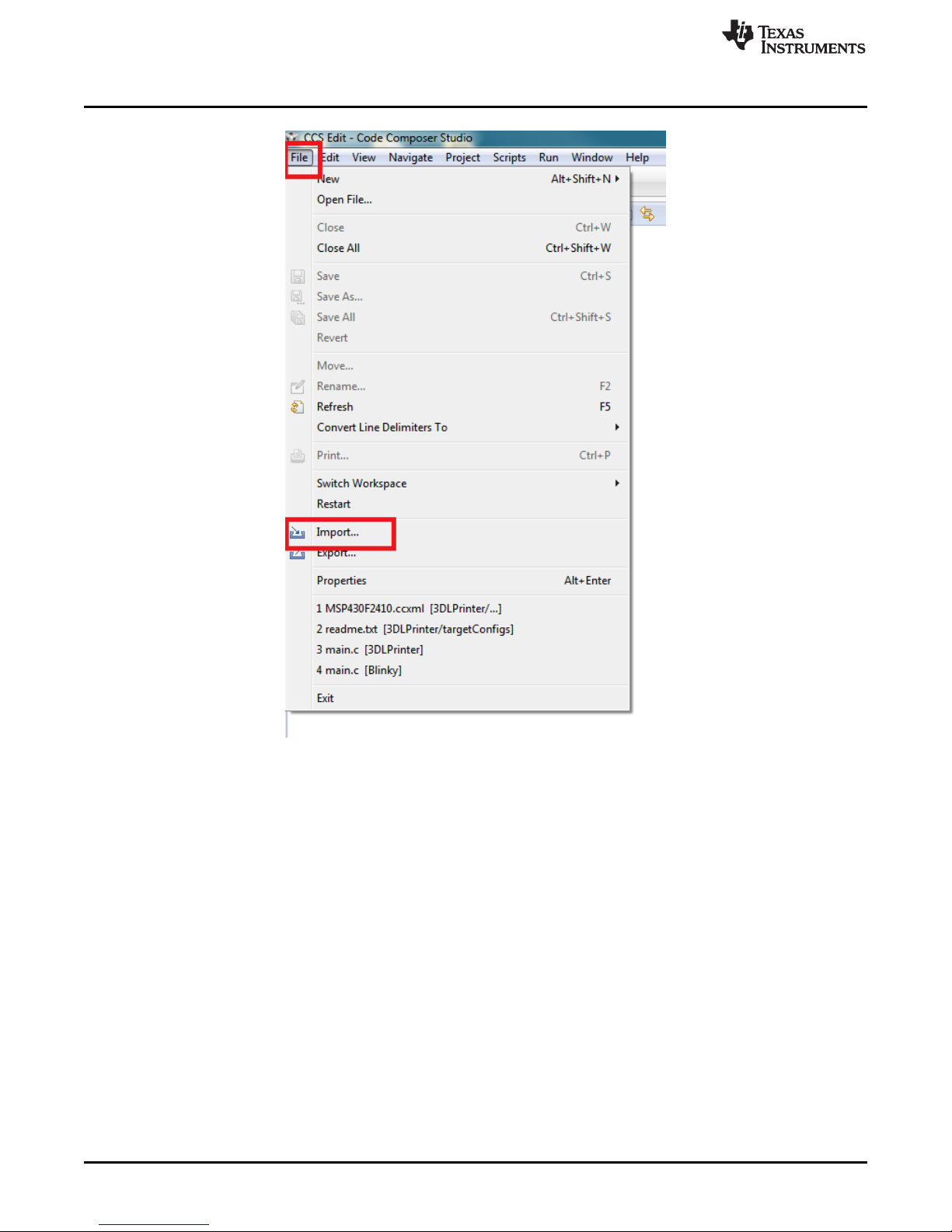

3.2 Programming The MSTP Cape

This section demonstrates how the DLP 3D Printer firmware is uploaded to the MSP430 on the MSTP

Cape. This method requires an MSP-FET430UIF JTAG debugging tool and Code Composer Studio v4 or

later.

1. Connect the MSP-FET430UIF ribbon cable to J5 of the BeagleBone MSTP cape.

2. Connect the MSP-FET430UIF USB connector to the PC loaded with Code Composer Studio v4 or

later.

3. Run Code Composer Studio.

4. Click the File tab in the menu bar, then click Import... as shown in Figure 3-1.

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

17

Copyright © 2014, Texas Instruments Incorporated

Page 18

Programming The MSTP Cape

www.ti.com

Figure 3-1. Importing The DLP 3D Printer Firmware Project

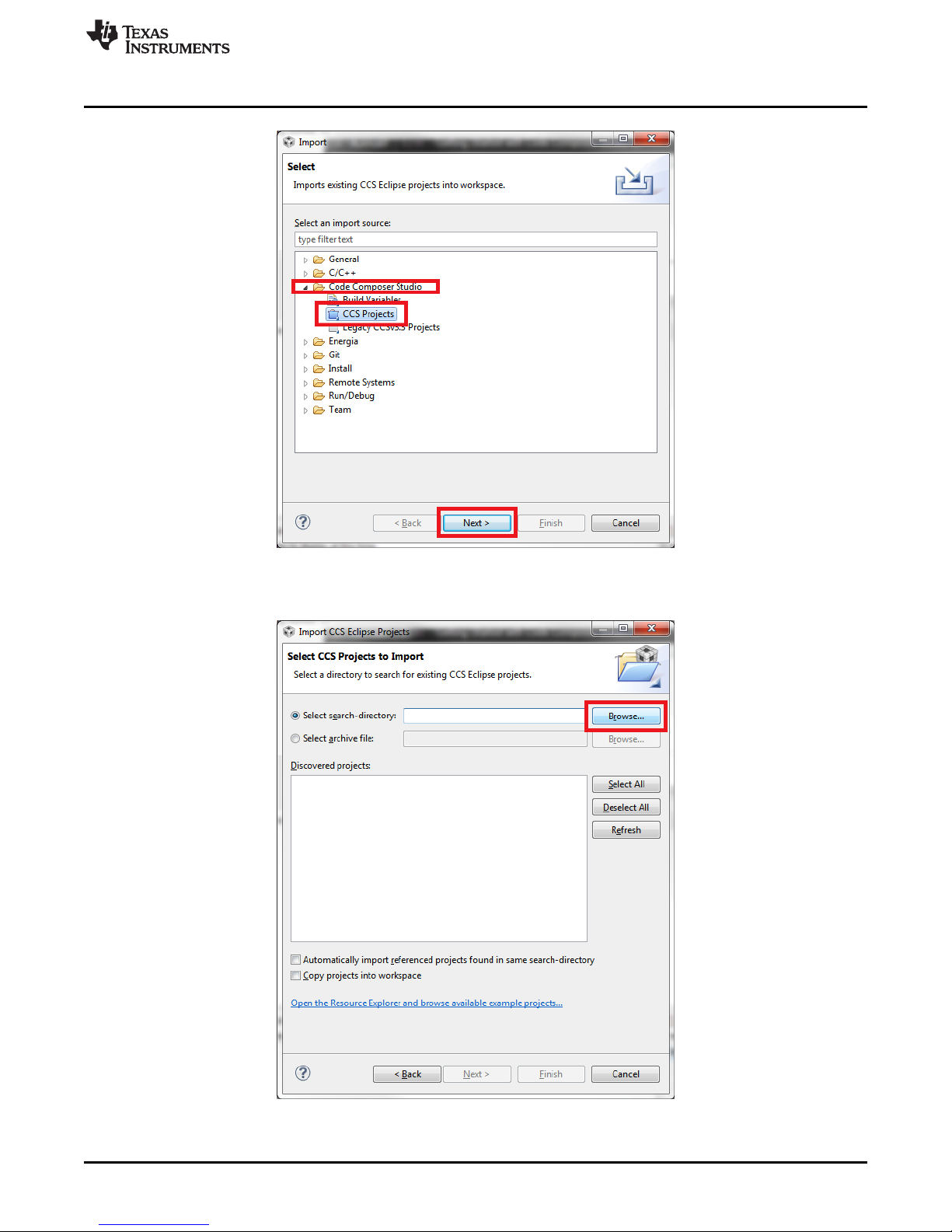

5. Expand the Code Composer Studio folder then click the CCS Projects item, as shown in Figure 3-2.

18

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

Programming The MSTP Cape

Figure 3-2. CCS Project Import Source Selection

6. Click the Browse... button next to the search directory box, as shown in Figure 3-3.

Figure 3-3. CCS Project Importation Search

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

19

Copyright © 2014, Texas Instruments Incorporated

Page 20

Programming The MSTP Cape

7. Select the folder "DLP_3D_Printer_Firmware" located in the TIDA-00293 Software installation path, as

shown in Figure 3-4, then click the OK button.

Figure 3-4. DLP 3D Printer Firmware Project Path Selection

www.ti.com

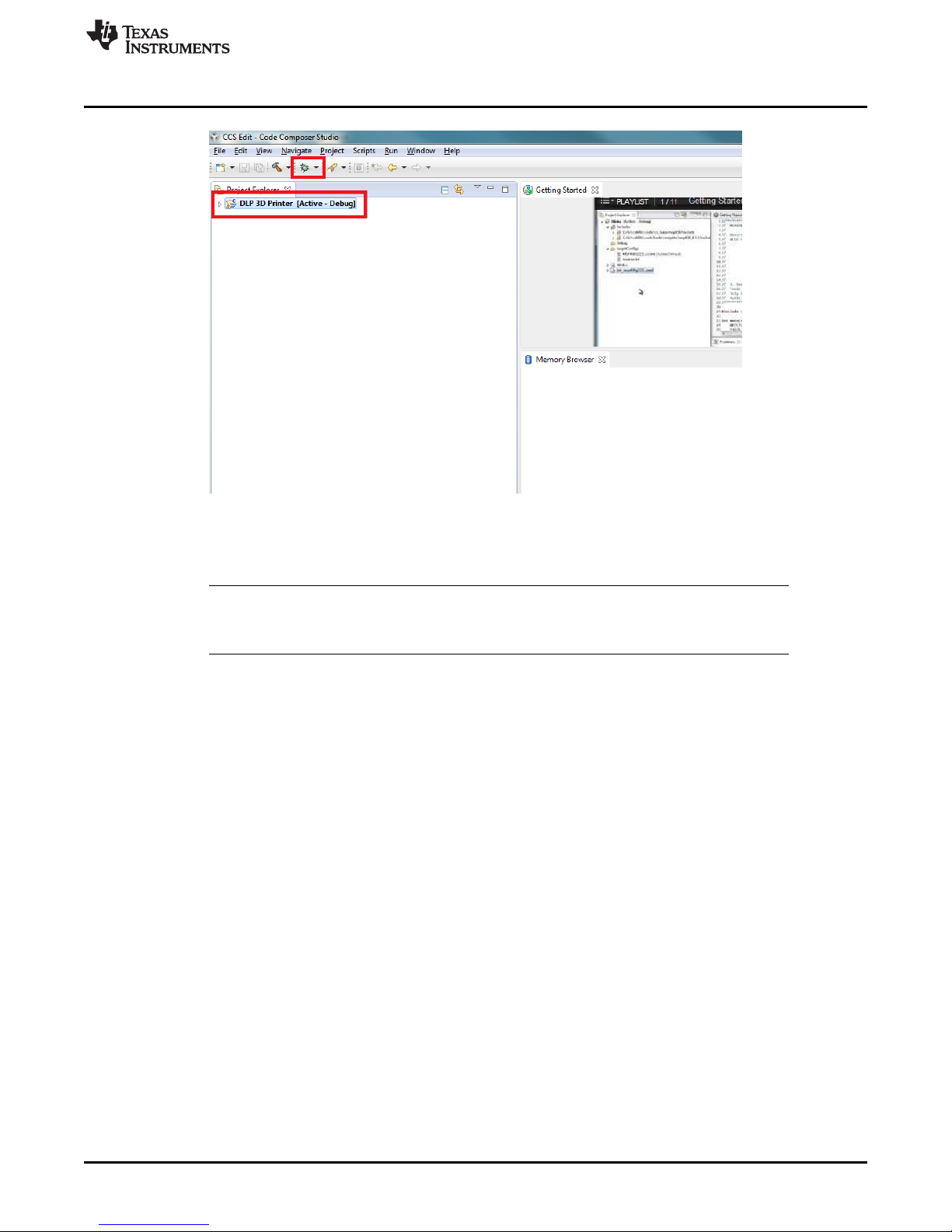

8. After the project appears in the Discovered projects section, click the Finish button, as shown in

Figure 3-5.

Figure 3-5. DLP 3D Printer Project Importation And Discovery

9. The project DLP 3D Printer will display as Active in the Project Explorer window, as shown in

Figure 3-6. Click the start debug button in the toolbar, also shown in Figure 3-6.

20

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

10. Code Composer Studio will build and upload the DLP 3D Printer microcontroller firmware to the

Preparing The Hardware For Printing

Figure 3-6. Uploading the DLP 3D Printer Firmware To The MSTP Cape

MSP430.

NOTE: During the project build and upload process, the user will likely be prompted to upgrade the

firmware on the MSP-FET430UIF. Do not accept the upgrade. Click the Ignore button to

upload the firmware.

11. After the firmware has been uploaded to the MSTP cape, disconnect the the MSP-FET430UIF from

the MSTP cape and reset the cape.

3.3 Preparing The Hardware For Printing

This section describes how to setup the DLP 3D Printer, and connect it to a PC for printing objects. The

instructions from Chapter 2 must be completed prior to these steps.

1. After constructing the hardware for the DLP 3D Printer using the TIDA-00293 design files, the printer

should look similar to Section 2.4.

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

21

Copyright © 2014, Texas Instruments Incorporated

Page 22

Preparing The Hardware For Printing

www.ti.com

2. Place the resin vat in the printer base and place it securely against the alginment tabs, as shown in

Figure 3-8.

22

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Figure 3-7. DLP 3D Printer Built Hardware

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

Preparing The Hardware For Printing

Figure 3-8. Resin Vat Placement

3. Secure the vat in place by securing the latches on the base, as shown in Figure 3-9.

4. Connect the TTL-232R-3V3 cable to the RS232 to MSTP Cape Cable Assembly (TI Drawing #

2514179), as shown in Figure 3-10. The black wire from the TTL cable aligns with the single wire pin

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

Figure 3-9. Resin Vat Locked In Position

23

Copyright © 2014, Texas Instruments Incorporated

Page 24

Preparing The Hardware For Printing

on the cable to the printer.

www.ti.com

Figure 3-10. TTL-232R-3V3 Connected To DLP 3D Printer

5. Connect the USB mini connector to the LightCrafter 4500, as shown in Figure 3-11.

Figure 3-11. LightCrafter 4500 USB Connection

24

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

6. Connect both the USB cable from the LightCrafter 4500, and the TTL-232R-3V3 cable to a Windows 7

Preparing The Hardware For Printing

based PC, as shown in Figure 3-12.

Figure 3-12. LightCrafter 4500 And TTL-232R-3V3 Cable Connected To PC

7. Plug the 12 V power supply into the jack on the side of the DLP 3D Printer, as shown in Figure 3-13.

Figure 3-13. Connecting 12 V Power To The Printer

8. The DLP 3D Printer will power up, and the build platform will start to index. The platform will move all

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

25

Copyright © 2014, Texas Instruments Incorporated

Page 26

Preparing The Hardware For Printing

the way down to its limit, then up out of the resin vat. The display will initialize and display the

message shown in Figure 3-14.

www.ti.com

Figure 3-14. DLP 3D Printer Initialization Message

9. Once the build platform has completed its travel -- and is located above the vat -- the LCD will display

the printer's name, as shown in Figure 3-15.

Figure 3-15. DLP 3D Printer Initialized And Waiting

26

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

10. Place a piece of perforated aluminum on the build platform, as shown in Figure 3-16. This step can be

Printing An Object

skipped IF the build platform is created out of aluminum. The photo-resin from www.buy3DInk.com,

tested during this design, had very poor adhesion to stainless steel.

11. The DLP 3D Printer is now ready to accept layer sequences from the PC.

3.4 Printing An Object

This section guides the user through using the DLP 3D Printer GUI to upload layer images to the printer

and start a print sequence. Ensure the steps from Section 3.3 have been completed.

1. Start the DLP 3D Printer Reference Design program, installed in Section 2.4, by running the

executable file, as shown in Figure 3-17.

Figure 3-16. Perforated Aluminum Build Plate In Place

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

27

Copyright © 2014, Texas Instruments Incorporated

Page 28

Printing An Object

www.ti.com

Figure 3-17. Executing The DLP 3D Printer Program

2. The DLP 3D Printer GUI will appear loaded with the default settings. Click the Set button to the right of

the Object Images Folder text box, as shown in Figure 3-18.

28

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

Printing An Object

Figure 3-18. Setting The Image Folder

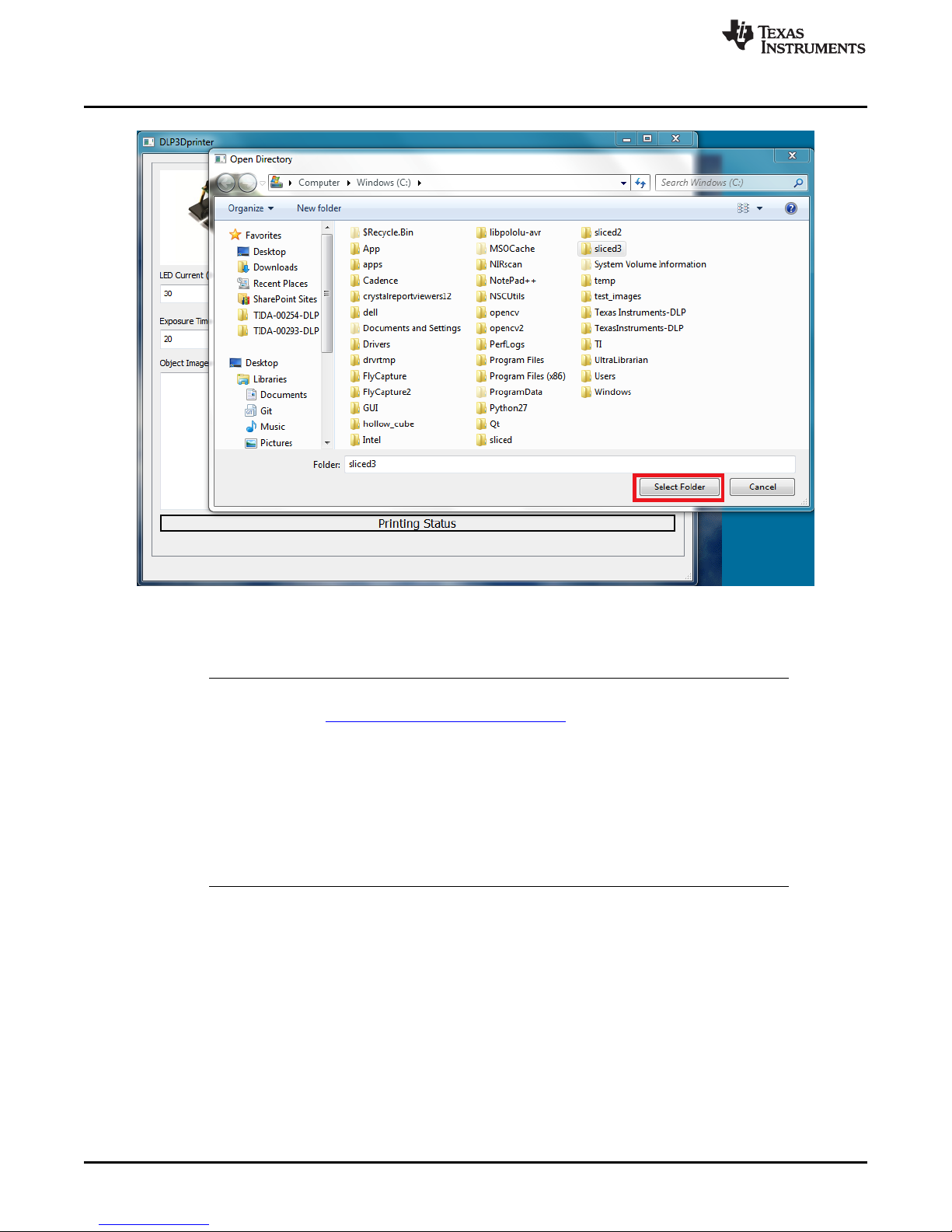

3. In the dialog box, select the folder where the cross-sectional images are located, as shown in Figure 3-

19. Highlight the folder and click the Select Folder button.

NOTE: The layer images must be 912 × 1140 resolution. Best results have been achieved with

BMP images. JPG images may be used, but layer quality will suffer due to lossy

compression methods employed in JPG.

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

29

Copyright © 2014, Texas Instruments Incorporated

Page 30

Printing An Object

www.ti.com

Figure 3-19. Layer Image Folder Selection

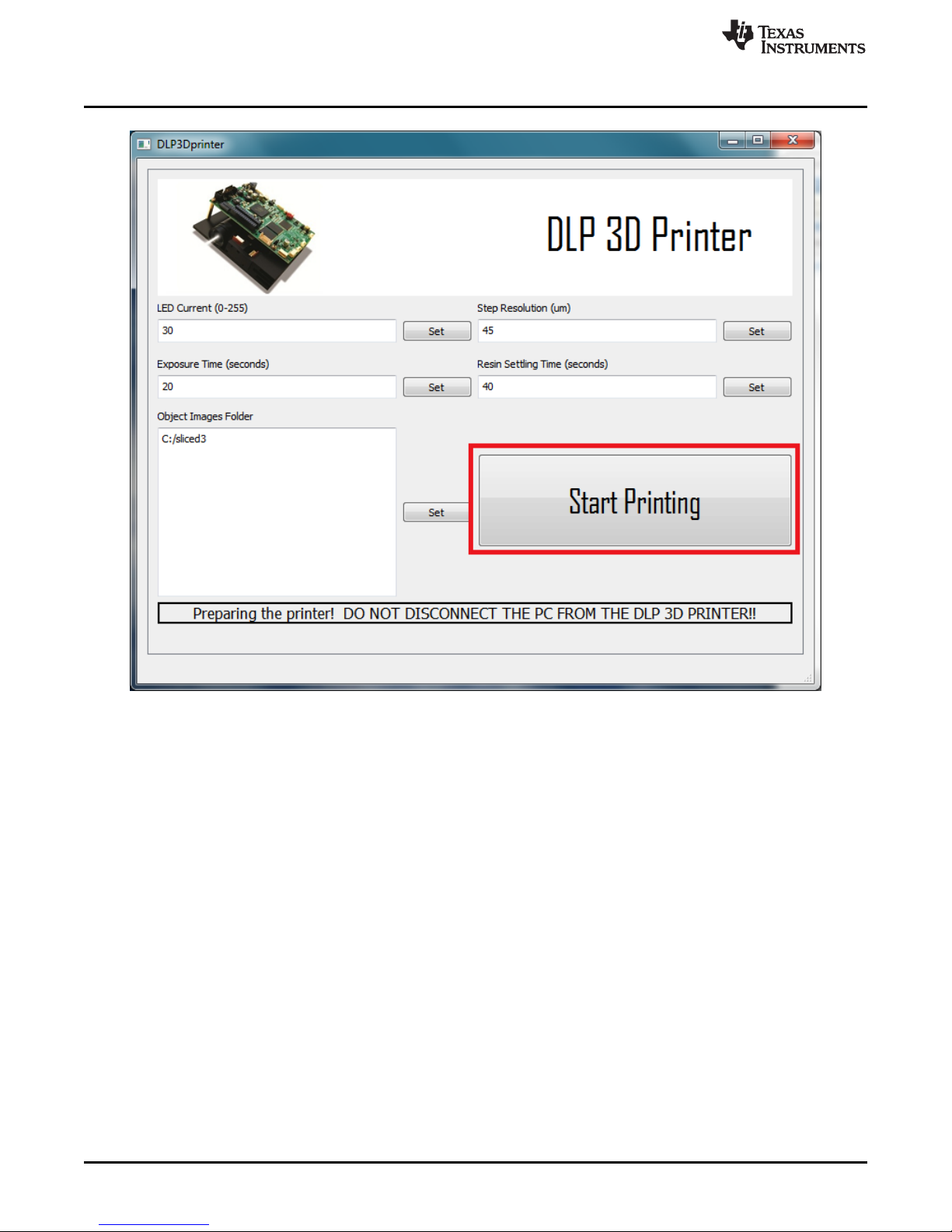

4. After the layer image folder has been selected, double check the settings for the print. The GUI should

look like Figure 3-20.

NOTE: The default settings are derived experimentally with resin produced by 3D Ink™,

purchasable here: http://www.buy3dink.com/p/59/uv-resin

Step resolution should be kept between 30 and 60 microns for best results but can be set

between 5 and 100 microns.

LED current should never be set above 35, and should only be set at 35 when the 420 nm

LED is placed on a metal core PCB.

Exposure time will be driven by a combination of layer thickness and LED current.

Resin settling time is the amount of time required for the resin's surface to return to level

after the build platform has moved.

30

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

Printing An Object

Figure 3-20. Printer Settings Check Before Sending Images To The Printer

5. After verifying the print settings, click the Start Printing button, as shown in Figure 3-21.

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

31

Copyright © 2014, Texas Instruments Incorporated

Page 32

Printing An Object

www.ti.com

Figure 3-21. Starting The Print Sequence

6. The print sequence will take up to 10 minutes to prepare, and upload to, the projector. Do not

disconnect the PC from the DLP 3D Printer or close the GUI during this process. Either could corrupt

the firmware on the LightCrafter 4500. Wait for the message "You may now disconnect the PC from

the DLP 3D Printer" to be displayed, as shown in Figure 3-22.

32

Using the DLP®3D Printer Reference Design DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

Printing An Object

Figure 3-22. Object Layer Image Sequence Upload Completed

7. The DLP 3D Printer will begin to move the build platform down and into the vat, and display the

message shown in Figure 3-23.

DLPU025–September 2014 Using the DLP®3D Printer Reference Design

Submit Documentation Feedback

Figure 3-23. Beginning Of Object Printing

33

Copyright © 2014, Texas Instruments Incorporated

Page 34

Chapter 4

DLPU025–September 2014

Building the DLP®3D Printer Reference Design from

Source

4.1 The DLP 3D Printer Reference Design application's source code is made available in the design files

installed in Chapter 2. The availability of the source allows users to modify, and build, the scanning

application on their own. Complete the installation of the necessary files before attempting to build the

application from source.

4.2 Qt Creator Installation

This section guides the user through the installation of the Qt Creator integrated development environment

(IDE.)

1. Download the Qt Creator IDE from the project webpage located here. Download the 32-bit Windows

version of Qt 5.2.1, or higher, that is bundled with MinGW. Note: This SDK uses C++11 and will not

compile using an out-of-date compiler. Use Qt 5.2.1, or later!

2. Execute the downloaded install file.

3. Click the Next button as shown in Figure 4-1.

34

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Figure 4-1. Qt Creator IDE Installation

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

4. Select an installation path for the Qt IDE. Click the Next button as seen in Figure 4-2.

5. Choose the install components as shown in Figure 4-3. Make sure that MinGW is selected and click

Qt Creator Installation

Figure 4-2. Qt Creator IDE Installation Path Selection

the Next button.

Figure 4-3. Qt Creator IDE Installation Component Selection

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

35

Copyright © 2014, Texas Instruments Incorporated

Page 36

Qt Creator Installation

6. Review the license agreement and indicate you agree with the terms, shown in Figure 4-4. Then click

the Next button.

www.ti.com

Figure 4-4. Qt Creator IDE End User License Agreement

7. Click the Next button as shown in Figure 4-5.

Figure 4-5. Qt Creator IDE Ready To Install

36

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

8. Wait for the installation to complete. Figure 4-6 shows the installation status bar.

Qt Creator Installation

Figure 4-6. Qt Creator IDE Installing

9. Once the Qt IDE installation has completed, click the Finish button as shown in Figure 4-7.

Figure 4-7. Qt IDE Installation Completed

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

37

Copyright © 2014, Texas Instruments Incorporated

Page 38

Qt Creator Installation

10. Using Windows Explorer, navigate to the Qt installation location and find the MinGW binary location.

Copy the path as shown in Figure 4-8.

www.ti.com

Figure 4-8. Finding the MinGW Installation Path

38

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 39

www.ti.com

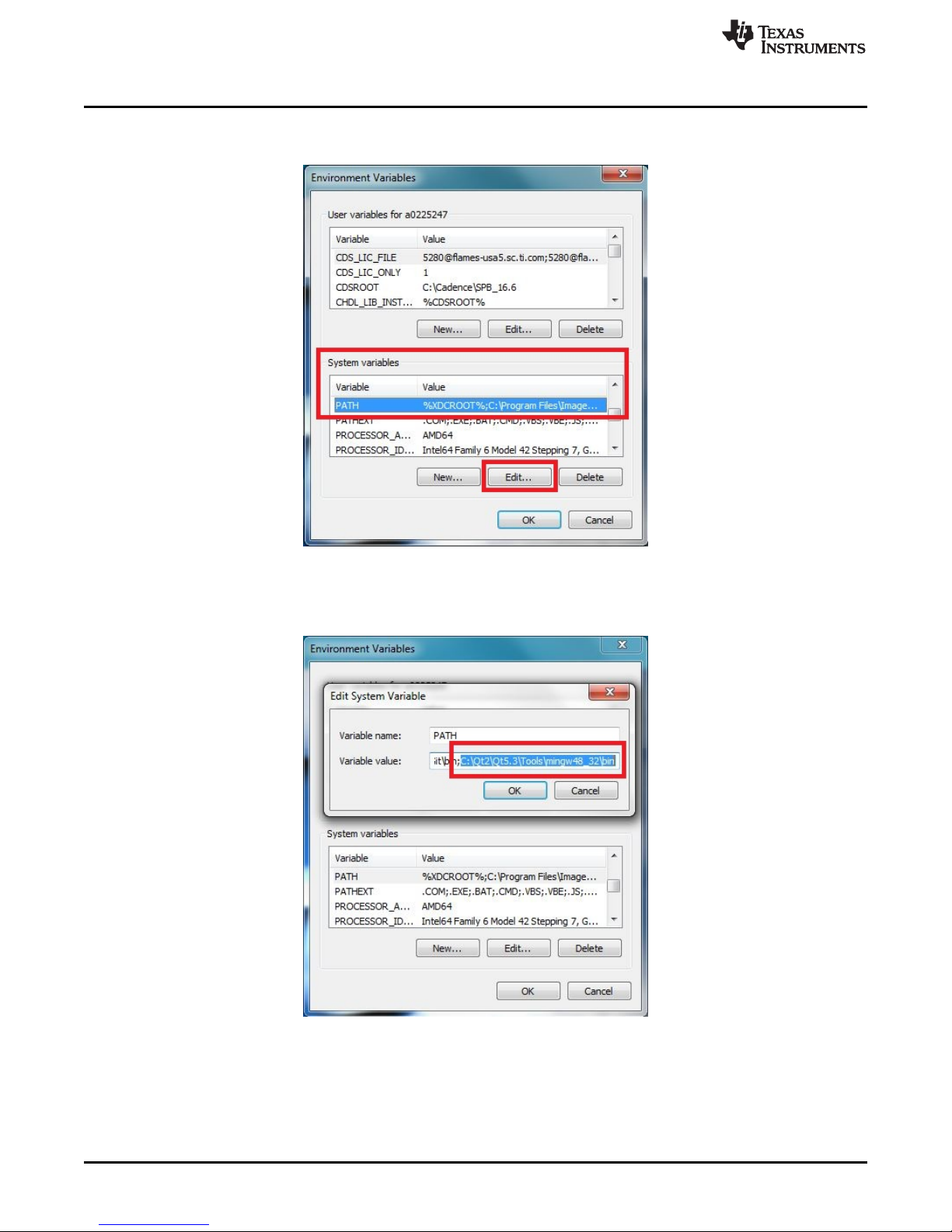

11. Click the Windows button and type "edit the system environment" into the search box, shown in

Qt Creator Installation

Figure 4-9. Click the option labeled "Edit the system environment variables".

Figure 4-9. System Environment Variables Editing

12. Click the Environment Variables... button in the lower right corner, shown in Figure 4-10.

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

Figure 4-10. System Properties Window

39

Copyright © 2014, Texas Instruments Incorporated

Page 40

Qt Creator Installation

13. In the System variables section, browse to the entry labeled PATH. Highlight the entry and click the

Edit button, shown in Figure 4-11.

www.ti.com

Figure 4-11. Editing the PATH Variable

14. Insert the path to the MinGW compiler binary directory in the PATH variable as shown in Figure 4-12,

then click the OK button. Note: Make sure that the entries are separated by a semicolon.

Figure 4-12. MinGW Directory Added to the PATH Variable

15. Click the OK button for the System properties window, then restart your computer. The installation of

the Qt IDE and MinGW is now complete.

40

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 41

www.ti.com

4.3 OpenCV Build and Installation

This section details the steps taken to build the OpenCV libraries required for MinGW from the OpenCV

source files. Careful attention must be paid in this section for a successful build.

1. Download the OpenCV Version 2.4.6, or higher, Windows installation from http://opencv.org/.

2. Download the Cmake Version 2.8.12.2, or higher, Windows (Win32 Installer) from

http://www.cmake.org/cmake/resources/software.html.

3. Run the downloaded OpenCV file and click on the Extract button, shown in Figure 4-13.

Figure 4-13. OpenCV Source Extraction Path

4. Wait for the OpenCV libraries and source files to install. The installation path is shown in Figure 4-14.

OpenCV Build and Installation

Figure 4-14. OpenCV Source Extraction

5. Run the Cmake installation program downloaded in step 2. Click the Next button as shown in Figure 4-

15.

Figure 4-15. Cmake Installation Entry

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

41

Copyright © 2014, Texas Instruments Incorporated

Page 42

OpenCV Build and Installation

6. Review the end-user license agreement for Cmake and accept the terms to continue with the

installation. The license agreement is higlighted in Figure 4-16.

7. Accept the default settings for the Cmake installation. Select Do not add Cmake to the system PATH

variable as shown in Figure 4-17.

www.ti.com

Figure 4-16. Cmake User License Agreement

8. Choose an installation path for Cmake. Click the Next button, highlighted in Figure 4-18.

42

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Figure 4-17. Cmake Installation Options

Figure 4-18. Cmake Installation Path

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 43

www.ti.com

9. Once the Cmake installation is complete, click the Finish button highlighted in Figure 4-19.

10. Search for, and run, the Cmake GUI that was installed in the previous step, an example of finding it is

OpenCV Build and Installation

Figure 4-19. Cmake Installation Completed

shown in Figure 4-20.

Figure 4-20. Cmake GUI Execution From Windows Start Button

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

43

Copyright © 2014, Texas Instruments Incorporated

Page 44

OpenCV Build and Installation

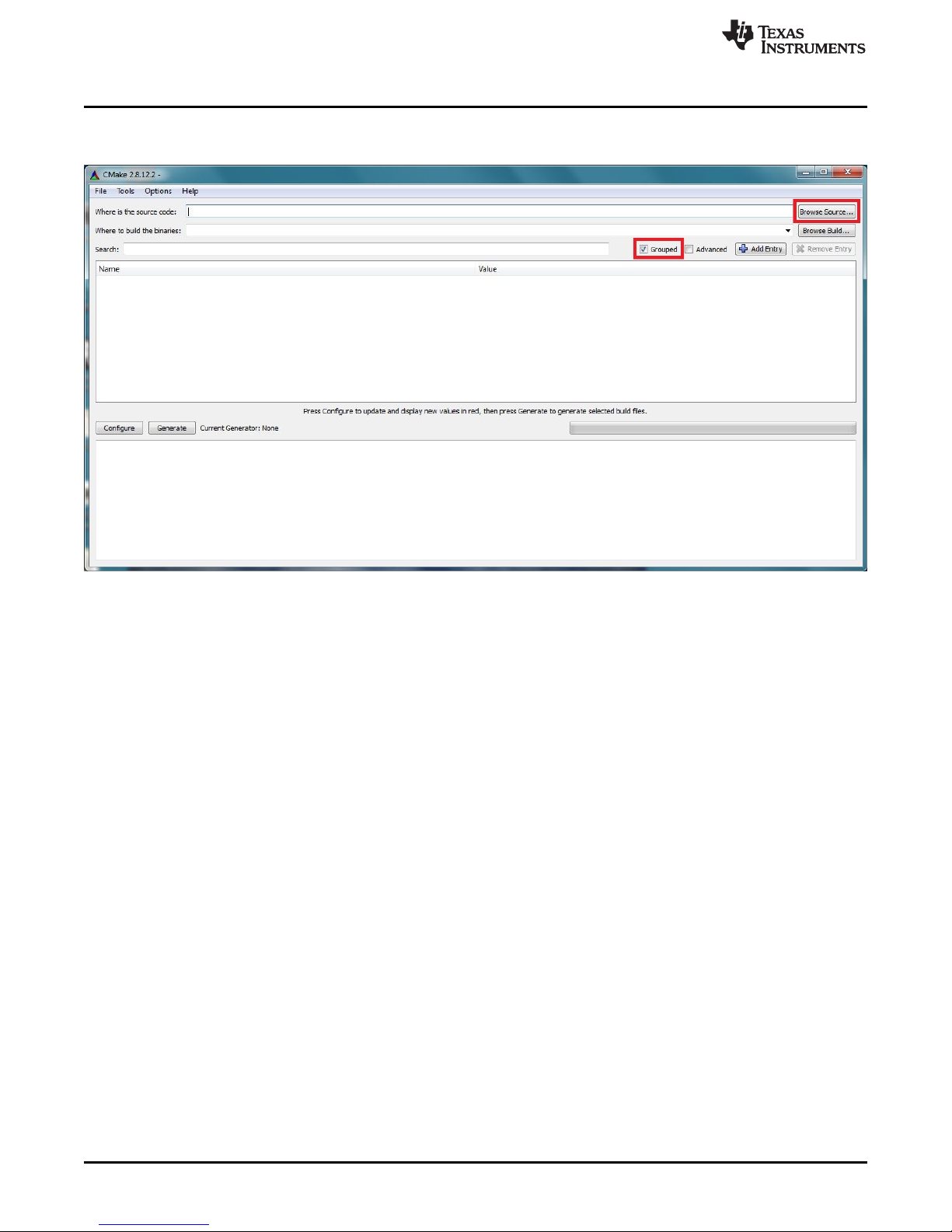

11. Inside of the Cmake GUI, check the box labeled "Grouped." Then click the Browse Source... button

highlighted in Figure 4-21.

www.ti.com

Figure 4-21. Cmake GUI Source Selection

44

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 45

www.ti.com

12. Browse to the /opencv/sources folder installed in step 3. Click the /sources folder as highlighted in

OpenCV Build and Installation

Figure 4-22, then click the OK button.

Figure 4-22. OpenCV Source Selection In Cmake

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

45

Copyright © 2014, Texas Instruments Incorporated

Page 46

OpenCV Build and Installation

13. Click the Browse Build... button and select a path for the built libraries to be installed, shown in

Figure 4-23.

www.ti.com

Figure 4-23. Cmake GUI Build Selection

14. Click the Configure button in the Cmake GUI, highlighted in Figure 4-24.

46

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Figure 4-24. Cmake GUI Configure Build

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 47

www.ti.com

15. A window will appear prompting the user to select the compilers to make the OpenCV libraries for.

OpenCV Build and Installation

Select MinGW makefiles from the drop down list, and select use default native compilers radio button.

The correct selections are highlighted in Figure 4-25. Click the Finish button.

Figure 4-25. Cmake Compiler Configuration

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

47

Copyright © 2014, Texas Instruments Incorporated

Page 48

OpenCV Build and Installation

16. Cmake uses the instruction files located in the OpenCV source directory to configure build options.

This step may take a while and should complete with no errors in the lower status window as shown in

Figure 4-26. Note: If an error occurs immediately, check the PATH variable and ensure that the

directory to the MinGW compilers is correct, and the computer was restarted to make the changes

take effect.

www.ti.com

Figure 4-26. Cmake Install Option Configuration

48

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 49

www.ti.com

17. Cmake will provide the user with a host of options for the OpenCV build. The options will appear in

OpenCV Build and Installation

red before they are accepted by Cmake. Expand the group called CMAKE and find the variable

named CMAKE_BUILD_TYPE, as shown in Figure 4-27. Populate the empty Value box next to

CMAKE_BUILD_TYPE with "Release" then click the Configure button. All the options should turn

white, and no errors should be reported in the lower status window.

Figure 4-27. Cmake Build Options Input

18. Cmake is ready to create the make file for building OpenCV. Once all options are white in the option

window, click the Generate button shown in Figure 4-28.

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

Figure 4-28. Cmake Make File Generation

49

Copyright © 2014, Texas Instruments Incorporated

Page 50

OpenCV Build and Installation

19. Once Cmake has completed generating the make file, click the Windows button to open the Start bar.

Open a command line window by typing "cmd" into the Window's search bar inside the Windows Start

button, as shown in Figure 4-29.

www.ti.com

Figure 4-29. Opening a Command Line Window

50

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 51

www.ti.com

20. Navigate to the OpenCV build path that was given to Cmake in step 13. From this path, run the

21. Depending on your system specifications, this process could take from 1 hour to 6 hours. Allow the

OpenCV Build and Installation

command "mingw32-make" as shown in Figure 4-30. Note: If the command "mingw32-make" is not

recognized, try using the command "make." This is dependent on the naming of the make.exe file

installed with Qt Creator.

Figure 4-30. Starting the OpenCV Build Process

build to complete normally, as shown in Figure 4-31.

22. After the mingw32-make command has finished running, the built libraries must be installed. Run the

command "mingw32-make install" as shown in Figure 4-32.

Figure 4-32. Installing the OpenCV Libraries

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

Figure 4-31. Long OpenCV Build Process

51

Copyright © 2014, Texas Instruments Incorporated

Page 52

DLP 3D Printer Reference Design Project File Setup

23. After the install command has executed in the command line window, the window may be closed.

OpenCV is now built and installed.

4.4 DLP 3D Printer Reference Design Project File Setup

After the design environment has been prepared, changes need to be made in the .pro file to reflect the

location of the installation of the OpenCV libraries.

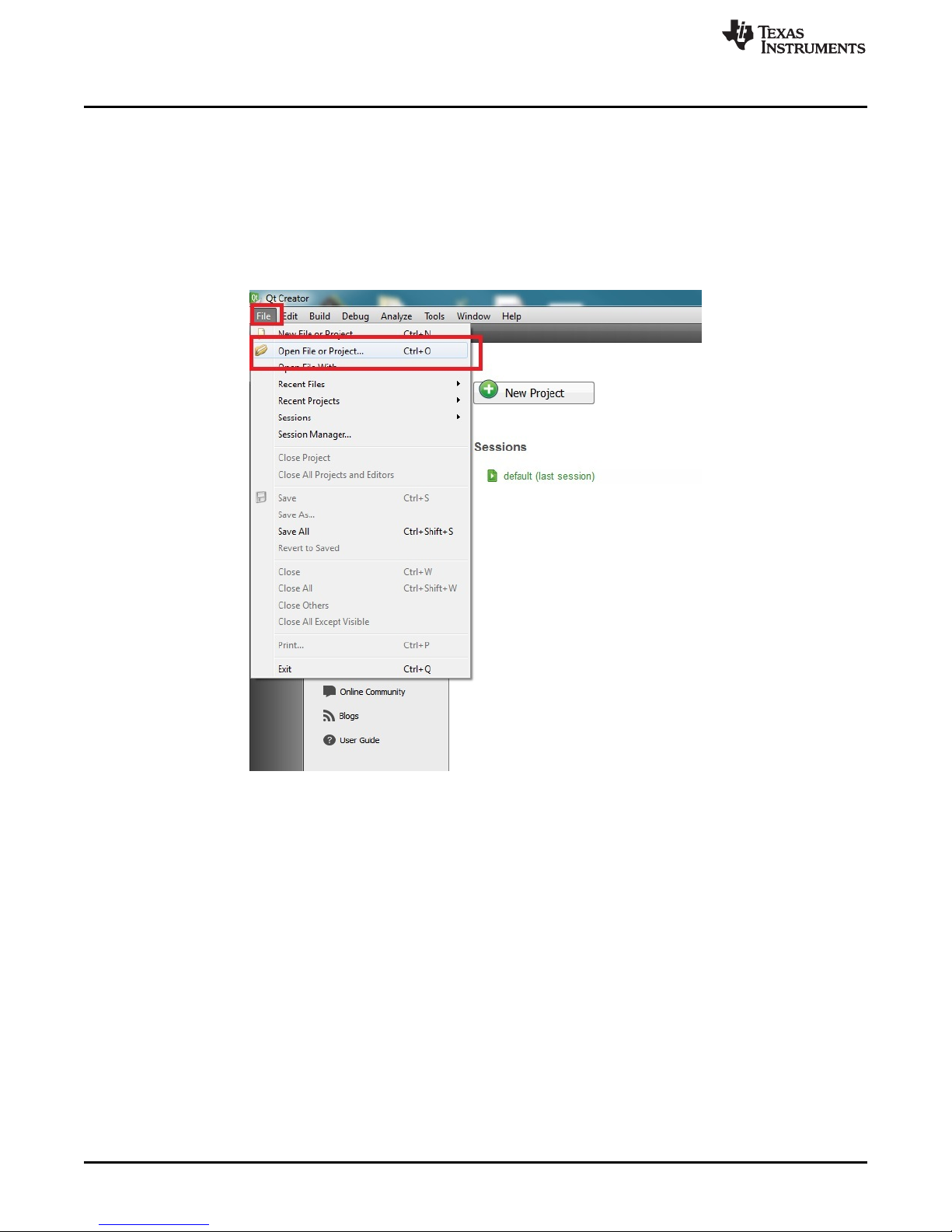

1. Open the Qt Creator IDE and click the File menu option in the upper left hand corner. Click Open File

or Project... shown in Figure 4-33.

www.ti.com

Figure 4-33. Opening the DLP 3D Printer Reference Design Project In Qt Creator

2. Navigate to, and open, the file named "DLP_3D_Printer_GUI.pro" in the DLP 3D Printer Software

install path, as shown in Figure 4-34.

52

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 53

www.ti.com

DLP 3D Printer Reference Design Project File Setup

Figure 4-34. QT .pro File Location

3. Click the Projects tab on the left of the Qt IDE and click Configure Project tab on the top bar, as

shown in Figure 4-35. Then click the Configure Project button also shown in Figure 4-35.

Figure 4-35. Configuring the QT .pro for Building

4. Click the Edit tab on the left of the Qt IDE, and in the projects view box, open the file named

"DLP_3D_Printer_GUI.pro", shown in Figure 4-36, to edit its contents.

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

53

Copyright © 2014, Texas Instruments Incorporated

Page 54

DLP 3D Printer Reference Design Project File Setup

Figure 4-36. Opening the QT .pro for Editing

5. In the top section of the project file, edit the OpenCV include path, the MinGW binary path, and the

FTDI driver path to the proper directories. The paths that require setting are highlighted in Figure 4-37 ,

blocks 1, 2 and 3 respectively. No settings should be changed below the block titled Do not change

code below.

Note: The OpenCV path will contain two separate include directories. The correct directory will be

located inside the opencv/install/ OR opencv/build/ folder, not inside the opencv/ directory.

Note: The OpenCV version number built must be changed as well. If the directions in this guide were

followed explicitly, the build number has the letter "d" appended to the end, indicating a debug build.

Check the libraries in the OpenCV lib directory for the proper version number appended to all the file

names.

Note: The FTDI headers are located in the initial extraction path used in step 2 of Section 2.2.

www.ti.com

Figure 4-37. Editing The Include Paths For OpenCV and FTDI Libraries

6. The project may now be built by clicking the Run or Build button in the lower left hand corner, as

shown in Figure 4-38.

54

Building the DLP®3D Printer Reference Design from Source DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 55

www.ti.com

7. The DLP 3D Printer GUI program may now be run from the Qt Creator IDE or from EXE file in the

DLP 3D Printer Reference Design Project File Setup

Figure 4-38. Running The DLP 3D Printer Reference Design GUI

source code path. Refer to Chapter 3 for directions on using the DLP 3D Printer program.

DLPU025–September 2014 Building the DLP®3D Printer Reference Design from Source

Submit Documentation Feedback

55

Copyright © 2014, Texas Instruments Incorporated

Page 56

Chapter 5

DLPU025–September 2014

DLP®3D Printer Design Considerations

5.1 The DLP 3D Printer is designed for ease of use and modification in the future. The design is not intended

to be a total end product. This section describes some of the design decisions that were made, and

aspects of the design that can be adjusted to tailor the printer to specific end-user applications.

5.2 Hardware Design

The hardware design section encompasses the physical aspects of the DLP 3D Printer design.

5.2.1 Illumination Source

The DLP 3D Printer utilizes a 420 nanometer light emitting diode made by Philips Lumileds. The emitter is

a 675 mW rated LED with a dominant wavelength between 420 and 425 nm. The emitter was selected for

easy, drop-in replacement in the LightCrafter 4500 light engine. The majority of the 420 nm emitter's

output falls inside the operational specification of the LightCrafter 4500, extending the operating life of the

DLP4500 DMD.

The emitter is hosted on an FR-4 printed circuit board. The design file for the board can be found in the TI

Design file path: ..\Design Files\LightCrafter 4500 Modifications\. The host board file is viewable by the

ExpressPCB freeware. Applications notes for the emitter from Philips indicate the emitter should be hosted

on a metal core PCB for maximum thermal efficiency. Note: Placement of the LED on the FR-4 board

requires a derating of emitter current to increase emitter life-span.

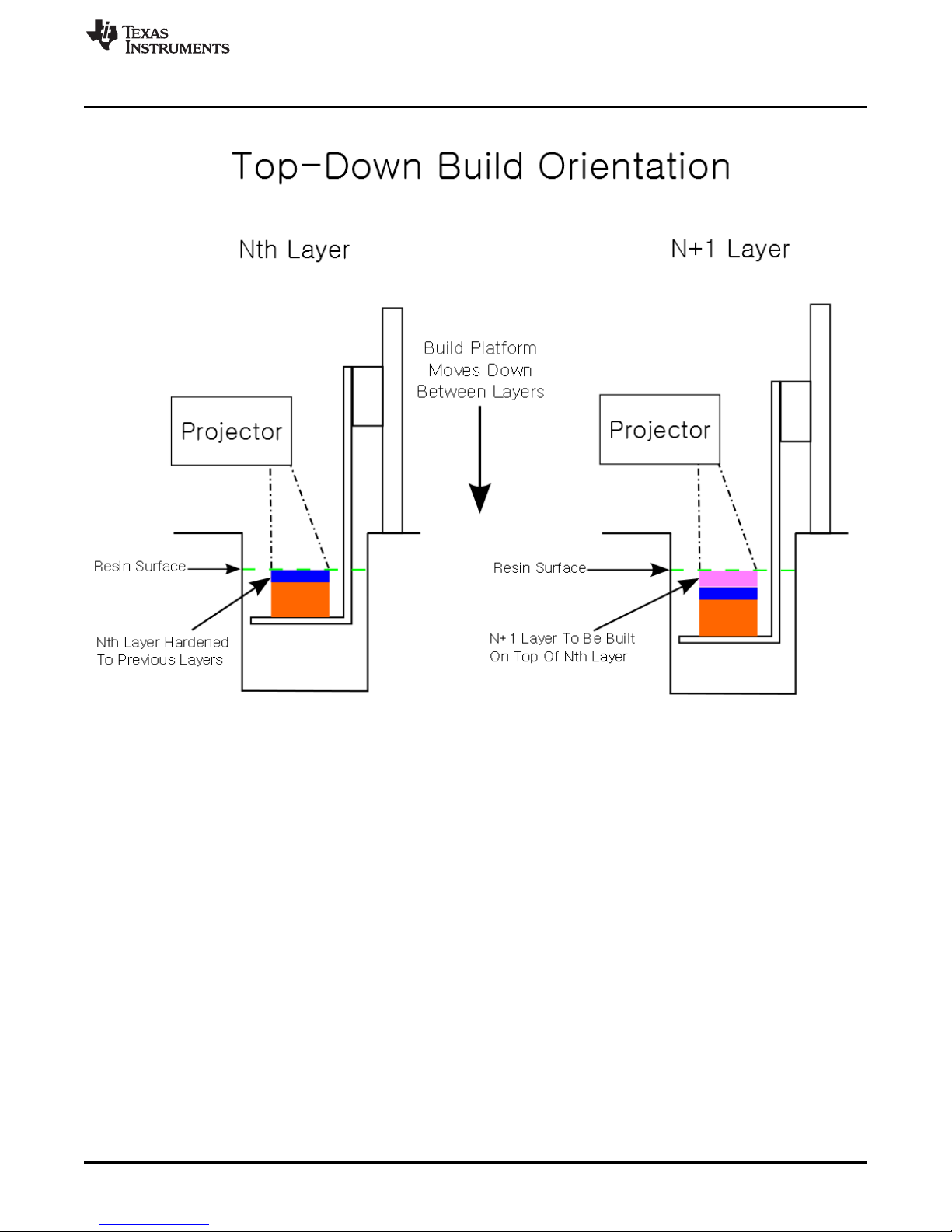

5.2.2 Build Orientation

The DLP 3D Printer is built for a top-down projection method. The top-down projection method builds

objects inside of the resin vat by lowering the build platform into the resin. The top-down build method

simplifies certain design considerations but has drawbacks. The 3D Printer reference design could be

modified for a bottom projection method with minimal code and hardware changes.

The top-down build method has it's layer thickness defined by the distance from the build platform -- or

partially-built object -- and the upper surface of the resin. This means consideration must be taken for the

time it takes the resin's surface layer to return to level after build platform movements. The DLP 3D Printer

design takes this into account by delaying a user-defined "resin settling time." Resin settling time can be

significant and dominate the total layer build time. A second item to consider with the top-down build

approach is the requirement for the printer to sit on a level surface in order to keep the resin level -defined by gravity -- parallel with the build platform. Strengths of the top-down build method include

mechanical simplicity and less maintenance of the printer. The top-down build method is visualized in

Figure 5-1.

56

DLP®3D Printer Design Considerations DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 57

www.ti.com

Hardware Design

The bottom-up build method is more popular as it solves two key issues: resin settling time and layer

thickness control. The bottom-up build orientation requires the projected layer images to be transmitted

through a material into the resin vat from below. The build platform starts flush against the transmissive

window and steps upward with each layer. The build platform's orientation to the window means the

resin's surface does not impact the build, and the layer thickness is clearly defined between the platform

and the window. The bottom-up build requires a smaller volume of resin in the vat at a time but requires

the user to constantly refill the vat as resin is used. The challenge of stiction also exists between the

hardened layers and the transmissive window. The solidified resin should separate cleanly, and easily,

from the transmissive window or else delicate features may be destroyed during the build process. The

resin should adhere strongly to the build platform material as the weight of the object will be suspended

from the platform during the build. The bottom-up build method is visualized in Figure 5-2.

DLPU025–September 2014 DLP®3D Printer Design Considerations

Submit Documentation Feedback

Figure 5-1. Top-Down Build Method

57

Copyright © 2014, Texas Instruments Incorporated

Page 58

Hardware Design

www.ti.com

5.2.3 Build Envelope And Voxel Resolution

The DLP 3D Printer design employs a fixed projector orientation to the build vat. The fixed nature of the

projector results in a fixed build envelope and related voxel size. The combination of focal distance, throw

ratio, and voxel size are interdependent and traded-off in the following ways in the design.

The DLP 3D Printer design was optimized for high resolution prints, necessitating a reduction in voxel

size. The voxel resolution was designed to be 60 micrometers. The voxel size determines the build

envelope, or vice versa. With the voxel resolution set, the build envelope can be calculated from the

physical characteristics of the DLP4500 DMD. See the DLP4500 datasheet for a diagram of the diamond

micromirror array to derive these equations. The equations for the build envelope from desired voxel

resolution are:

Envelope Width = (Desired Voxel Size) * sqrt(2) * (Number of Columns) (1)

Envelope Height = (Desired Voxel Size) * sqrt(2) * (Number of Rows) / 2 (2)

The same formulas above can be used to calculate the voxel resolution from a desired build envelope.

Keep in mind that the build envelope width/height will always respect the 16:10 aspect ratio of the

DLP4500 DMD.

Once the build envelope has been determined, the focal distance for the projector can be calculated using

the throw ratio of the LightCrafter 4500 light engine:

58

DLP®3D Printer Design Considerations DLPU025–September 2014

Figure 5-2. Bottom-Up Build Method

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 59

www.ti.com

Focal Distance = (Envelope Width) * (Throw Ratio) (3)

The focal distance is shorter than the standard LightCrafter 4500 minimum focus distance of 0.5 meters.

The minimum focus distance of the light engine is reduced by placing a shim 1 millimeter thick between

the light engine case and the projection optics. Drawings for the shim can be found in the TIDA-00293

design files installed in Section 2.3.

5.2.4 Build Platform

The z-layer build resolution is driven by the design of the build platform. The build platform is physically

placed by a translation stage that consists of a carriage on a screw drive that is driven by a stepper motor

in the DLP 3D Printer design. The lead screw has a pitch of 1 millimeter per revolution. The stepper motor

has 200 full steps per revolution leading to a z-layer resolution of 5 micrometers per step without microstepping the motor. Other translation stages/motor combinations can be used with the design but would

require rebuilding the microcontroller code from source with the new parameters.

5.2.5 Mechanical Structure

The mechanical structure of the DLP 3D Printer is designed for rigidity during operation of the print cycle.

The only requirement of the mechanical structure is maintaing the proper orientation of the build platform

to the projected image and resin vat. The build platform should travel precisely on the axis normal to the

projected image, and not interfere with the resin vat. The top-down build method requires the entire build

envelope to be filled with resin at the time of printing. Drawings for the mechanical structure can be found

in the TIDA-00293 design file path: ..\Design Files\Mechanical Structure\ installed in Section 2.3.

Hardware Design

5.3 Microcontroller Firmware Design

The microcontroller firmware design section describes the firmware state machine used to synchronize

image exposure and motor control that runs on an MSP430. DLP 3D Printer Firmware source is provided

in the TIDA-00293 design files at ../TIDA-00293_DLP_3D_Printer-1.0/DLP_3D_Printer_Firmware/. See

Section 3.2 for detailed instructions on how to import, and build, the firmware from source.

5.3.1 State Machine

The state machine contains 4 states for the entire print process: Idle, Start Print, Sequence Print, Finish

Print.

5.3.1.1 Idle State

The printer initializes and immediately enters the idle state at start up. The idle state contains no

commands but contains a check to see if the incoming command buffer is full. If the command buffer is

full, a print sequence is pending, and the buffer is parsed. Parsing the buffer will switch the state to Start

Print if the print command is valid.

5.3.1.2 Start Print State

The start print state is used to lower the platform into the reservoir and prompt the user to fill the vat with

resin. At this point the user interfaces with the front panel to determine which state the machine enters

next. If the next button is pressed, the machine transitions to the sequence print state. If the back button is

pressed, the machine transitions to the finish print state and raises the build platform out of the vat.

5.3.1.3 Sequence Print State

The sequence print state updates the LCD with layer completion numbers and handles synchronizing

motor movements with layer exposures. During the sequence print state, a 1 millisecond timer interrupt is

enabled to check the front panel buttons for user input. If the user presses the back button, the machine

will stop and wait for the print to be resumed or cancelled. If the print is cancelled -- or the entire print

sequence is completed -- the current layer will be printed and the machine will transition to the finish print

state.

DLPU025–September 2014 DLP®3D Printer Design Considerations

Submit Documentation Feedback

59

Copyright © 2014, Texas Instruments Incorporated

Page 60

Microcontroller Firmware Design

5.3.1.4 Finish Print State

The finish print state raises the platform and model from the vat and prompts the user to remove the

model. The machine waits in this state until the user interacts with the front panel to indicate the model

has been removed. The following state is always the Idle state.

5.3.2 Communications With The PC

Communications between the PC and the microcontroller use the UART 8N1 protocol at 9600 baud rate.

The UART control registers on both the PC and the microcontroller are set to handle 8 data bits, NO parity

bit, and 1 stop bit. A receive interrupt is enabled in the microcontroller which stores incoming 1-byte chars

into a circular buffer in the microcontroller. The circular buffer is 16 chars in size to encompass the entire

16-byte print command. The printer commands are described in the microcontroller source code provided

in the TIDA-00293 design files at ../TIDA-00293_DLP_3D_Printer-

1.0/DLP_3D_Printer_GUI/DLP_3D_Printer_source/dlp3dprinter.cpp

5.3.3 Motor Drive Functionality

Two functions are written to interface with the DRV8825 motor drive IC on the microcontroller board. The

first function jogs the motor in one direction until the limit switch has been hit, then disables the motor. The

second function steps the motor in a certain direction by a specified number of steps. The limit switches

are also monitored during the stepping function to ensure the motor and the carriage are not driven

against the translation stage end points.

5.3.4 LCD Interface

The microcontroller interfaces with an HD44780 to control a 20×4 character LCD on the front panel. The

functionality of the interface module is reduced to the few commands necessary for basic LCD operation.

The interface library supports initializing the controller in one or two line mode, clearing the display, writing

strings to the display, writing individual characters to the display, and returning the cursor to the home

position. The HD44780 is a 5-V logic level device, and as such, requires a logic level translation board to

convert the MSP430 3.3-V logic. A schematic of the logic level translation board can be found in the TIDA00293 design files.

www.ti.com

5.4 DLP 3D Printer GUI Design

The DLP 3D Printer has a light weight GUI for users to set the basic printing parameters and indicate

where the image layers are contained. DLP 3D Printer GUI source is provided in the TIDA-00293 design

files at ../TIDA-00293_DLP_3D_Printer-1.0/DLP_3D_Printer_GUI/DLP_3D_Printer_source/. See

Section 4.4 for detailed instructions on how to build the GUI from source.

5.4.1 DLP Structured Light SDK

The DLP 3D Printer GUI is built upon the DLP Structured Light SDK which contains many convenient

functions for interfacing with the LightCrafter 4500. These functions include image manipulation and

processing, LightCrafter 4500 firmware creation, LightCrafter 4500 pattern sequence creation, LightCrafter

4500 firmware programming and LightCrafter parameter settings.

5.4.2 Multithreading

Where the DLP Structured Light SDK does not automatically handle multithreading, the DLP 3D Printer

GUI implements it. A thread of execution is spawned for firmware creation and programming in order to

keep the GUI responsive. The child thread cannot be avoided without the GUI appearing as if it has frozen

to the user. The parent thread monitors for concurrency by checking a volatile boolean buffer to determine

if the child thread is still running.

60

DLP®3D Printer Design Considerations DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 61

www.ti.com

5.4.3 Qt Design Environment

The DLP 3D Printer GUI is built using the Qt project framework. The GUI is dependent on the framework

for handling printing parameters from the user, however the DLP Structured Light SDK is not dependent

on the Qt framework. This allows a programmer to take the LightCrafter 4500 firmware creation function

and port it to another framework or make a simple console application from it. The only dependency of the

DLP Structured Light SDK is on the OpenCV libraries.

DLP 3D Printer GUI Design

DLPU025–September 2014 DLP®3D Printer Design Considerations

Submit Documentation Feedback

61

Copyright © 2014, Texas Instruments Incorporated

Page 62

6.1 General Troubleshooting Steps

This chapter details the troubleshooting steps for common problems encountered by users.

• Problem: The LightCrafter 4500 projector will not connect to the DLP 3D Printer GUI.

Solution: Make sure the LightCrafter 4500 GUI is not running on the PC and the LightCrafter 4500 is

connected to the PC. Reset the LightCrafter 4500.

• Problem: The FTDI TTL-232R-3V3 will not connect to the DLP 3D Printer GUI.

Solution: Make sure the cable is connected to the PC and the FTDI D2XX drivers are installed as

shown in Section 2.2. Wait for the FTDI device to enumerate on the USB and try printing again.

• Problem: The print process does not start after the DLP 3D Printer GUI indicates that the upload is

complete.

Solution: The communications between the PC and microcontroller may not be properly connected.

Check the connection of the TTL-232R-3V3 pins to the microcontroller board. Reset the DLP 3D

Printer by cycling the DC power and try printing again from the GUI.

Chapter 6

DLPU025–September 2014

Troubleshooting

62

Troubleshooting DLPU025–September 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 63

IMPORTANT NOTICE