Page 1

User's Guide

SLAU658–March 2016

PGA411-Q1 EVM User's Guide

The PGA411-Q1 EVM allows users to evaluate the functionality of the PGA411-Q1 device. This user’s

guide describes both the hardware platform containing a sample PGA411-Q1 device, and the graphical

user interface (GUI) software used to configure the functionality and diagnostics on the PGA411-Q1

resolver-to-digital interface IC. In addition to evaluating the PGA411-Q1 device, the other objective of this

board is to display in the GUI the position (angle) or velocity readings from a resolver sensor.

This document also includes the EVM schematics, bill of materials, and PCB layout.

NOTE: Texas Instruments recommends using the PGA411-Q1 EVM user's guide (this document)

after reading and following the steps listed in the PGA411-Q1 Evaluation Module Quick Start

Guide. To download this guide, go to the product folder: www.ti.com/product/PGA411-Q1.

Contents

1 Introduction ................................................................................................................... 3

2 Setup and Operation ........................................................................................................ 3

2.1 Required Equipment for Device Evaluation ..................................................................... 3

2.2 Initial EVM Setup ................................................................................................... 3

2.3 GUI Software ........................................................................................................ 7

3 EVM Evaluation Examples................................................................................................ 16

3.1 EVM Checks for Proper Operation.............................................................................. 16

4 Schematics, Bill of Materials, and Layout............................................................................... 20

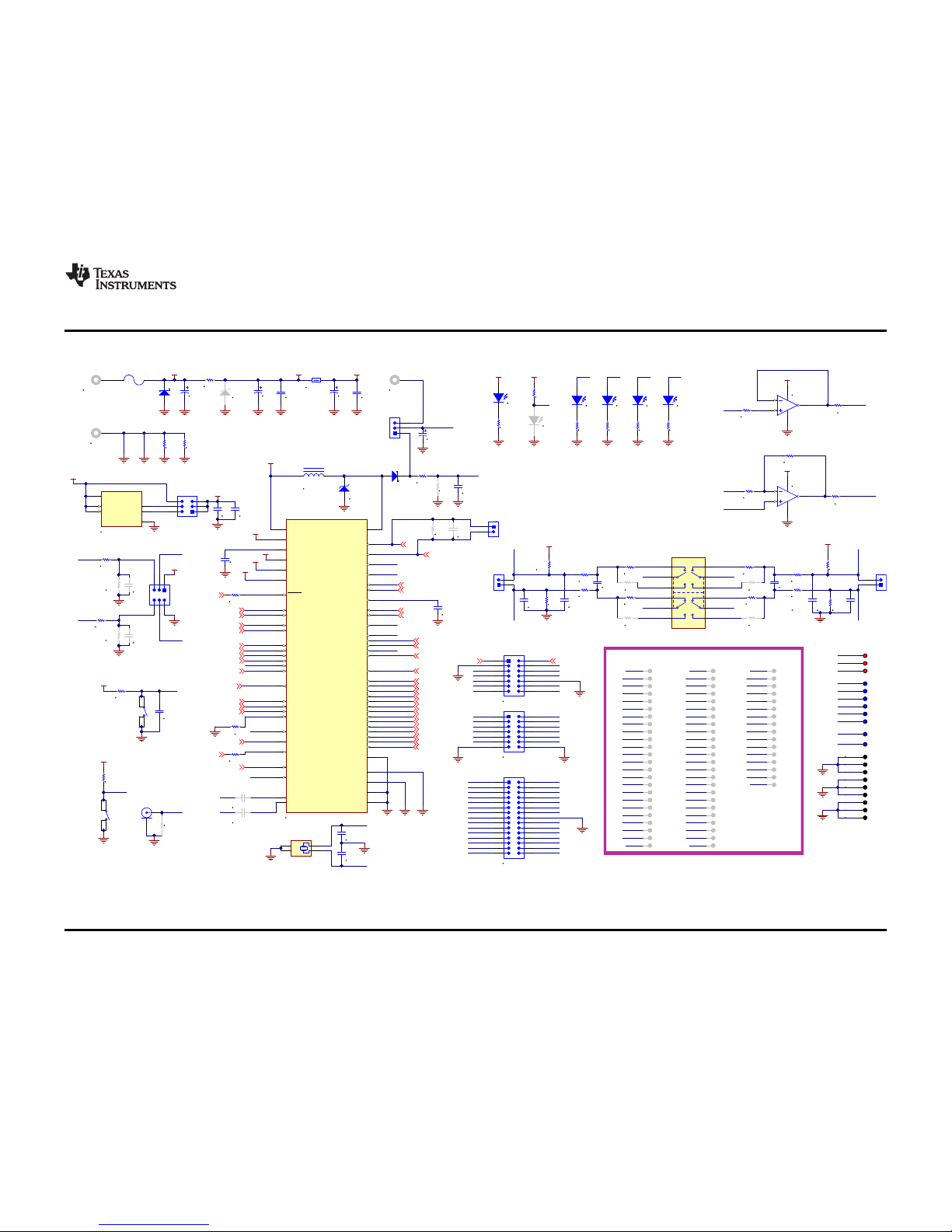

4.1 Schematics......................................................................................................... 21

4.2 Bill of Materials .................................................................................................... 23

4.3 Layout and Component Placement............................................................................. 27

1 PGA411-Q1 EVM Block Diagram.......................................................................................... 3

2 PGA411-Q1 EVM............................................................................................................ 4

3 PGA411-Q1 GUI Block Diagram........................................................................................... 5

4 PGA411-Q1 Device Startup Failed........................................................................................ 5

5 GUI PGA41x-Q1 EVM Main Screen ...................................................................................... 8

6 Device-State Status and Selection ........................................................................................ 8

7 Pin Configuration Screen ................................................................................................... 9

8 Memory Map................................................................................................................ 11

9 Bit Selection................................................................................................................. 11

10 Hex Selection (REG)....................................................................................................... 11

11 Search Box and Register Descriptions.................................................................................. 12

12 Data Monitor ................................................................................................................ 13

13 DEMO Screen .............................................................................................................. 14

14 Fault Status ................................................................................................................. 15

15 FAULTRES Change in Block Diagram .................................................................................. 16

16 FAULTRES Change in Pin Configuration Tab ......................................................................... 17

MSP430, E2E are trademarks of Texas Instruments.

Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

SLAU658–March 2016

Submit Documentation Feedback

List of Figures

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

1

Page 2

www.ti.com

17 Test Points for Exciter Outputs and Common Mode Voltage ........................................................ 18

18 OE1-OE2 Differential Output from the Exciter.......................................................................... 19

19 DEV_OVUV Register Bits Relevant to Exciter Amplifier Gain........................................................ 19

20 Exciter Amplifier Gain Change Using Memory Map ................................................................... 20

21 OE1-OE2 Differential Output from the Exciter With Updated Gain .................................................. 20

22 EVM Schematic............................................................................................................. 21

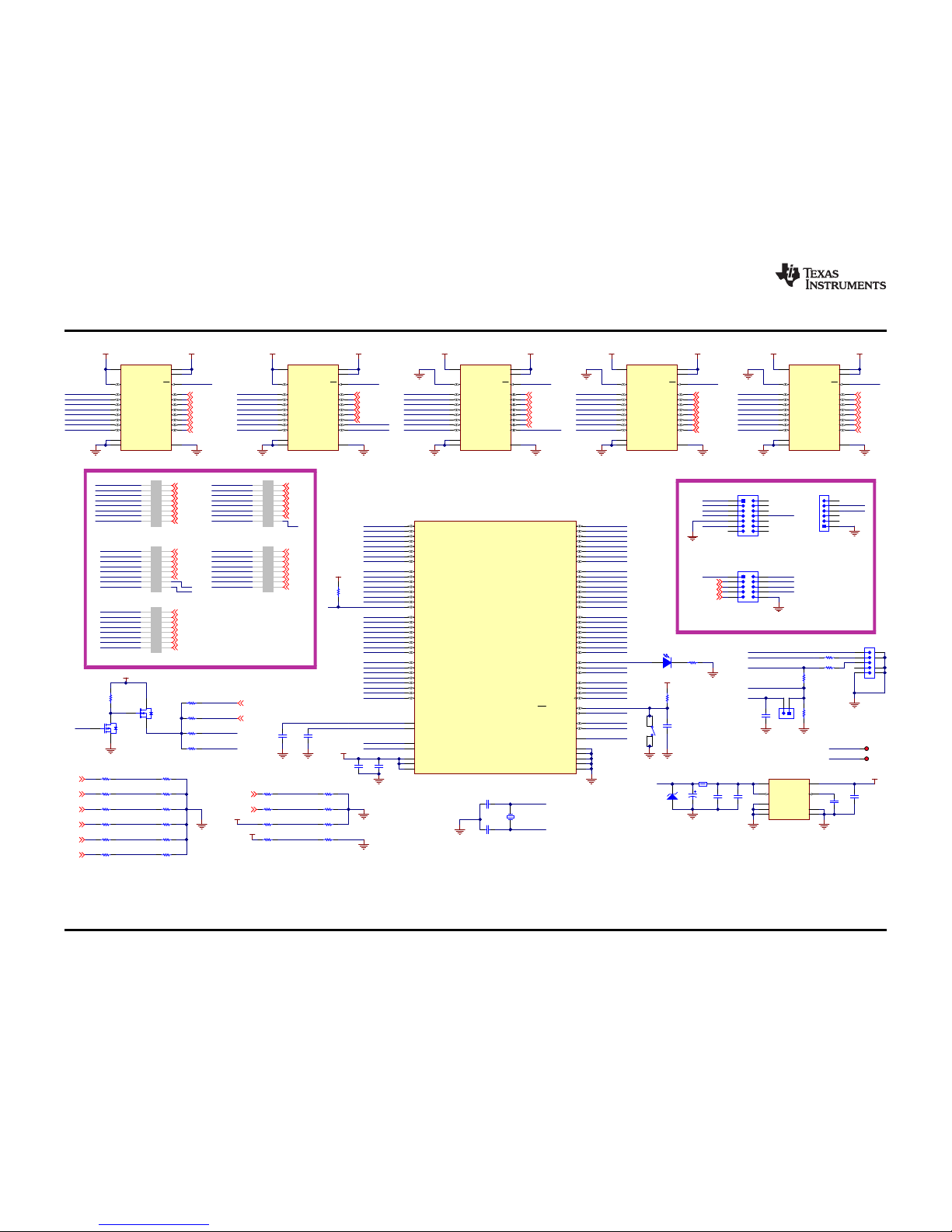

23 Schematic—Digital Interface.............................................................................................. 22

24 Top-Side Layout............................................................................................................ 27

25 Bottom-Side Layout ........................................................................................................ 27

List of Tables

1 Description of EVM Switches .............................................................................................. 6

2 Description of EVM Jumpers............................................................................................... 6

3 BOM.......................................................................................................................... 23

2

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 3

PGA411-Q1

USB

SINE

SPI <4>

PGA411-Q1 EVM

J7

5-V

V

IO

J6

EXCITER

J4

20-MHz XTAL

5 V

FAULT

FAULTRES

Data<N>

PGA411-Q1

GUI

From

Resolver

RESET

To

Resolver

COSINE

MSP430

www.ti.com

1 Introduction

The PGA411-Q1 evaluation module (EVM) is a board designed for the evaluation of the PGA411-Q1

resolver-to-digital interface IC from Texas Instruments. The PGA411-Q1 EVM incorporates all required

circuitry and components with the following features:

• PGA411-Q1 resolver-to-digital interface with power supply & amp

• Texas Instruments' MSP430™ microcontroller used for controlling the PGA411-Q1 device through the

I/O pins and a SPI port in addition to receiving digital data in different formats

• Voltage LDO regulator, TI's TLV716P, to provide configurable VIOvoltages (3.3 V or 1.8 V)

• Voltage LDO regulator, TI's TPS735, for the 3.3-V MSP430

• Circuitry for interfacing general resolver sensors

• 20-MHz XTAL as PGA411-Q1 single reference clock

• Multiple test points for main analog and digital signals

• UART, JTAG, and USB connectors

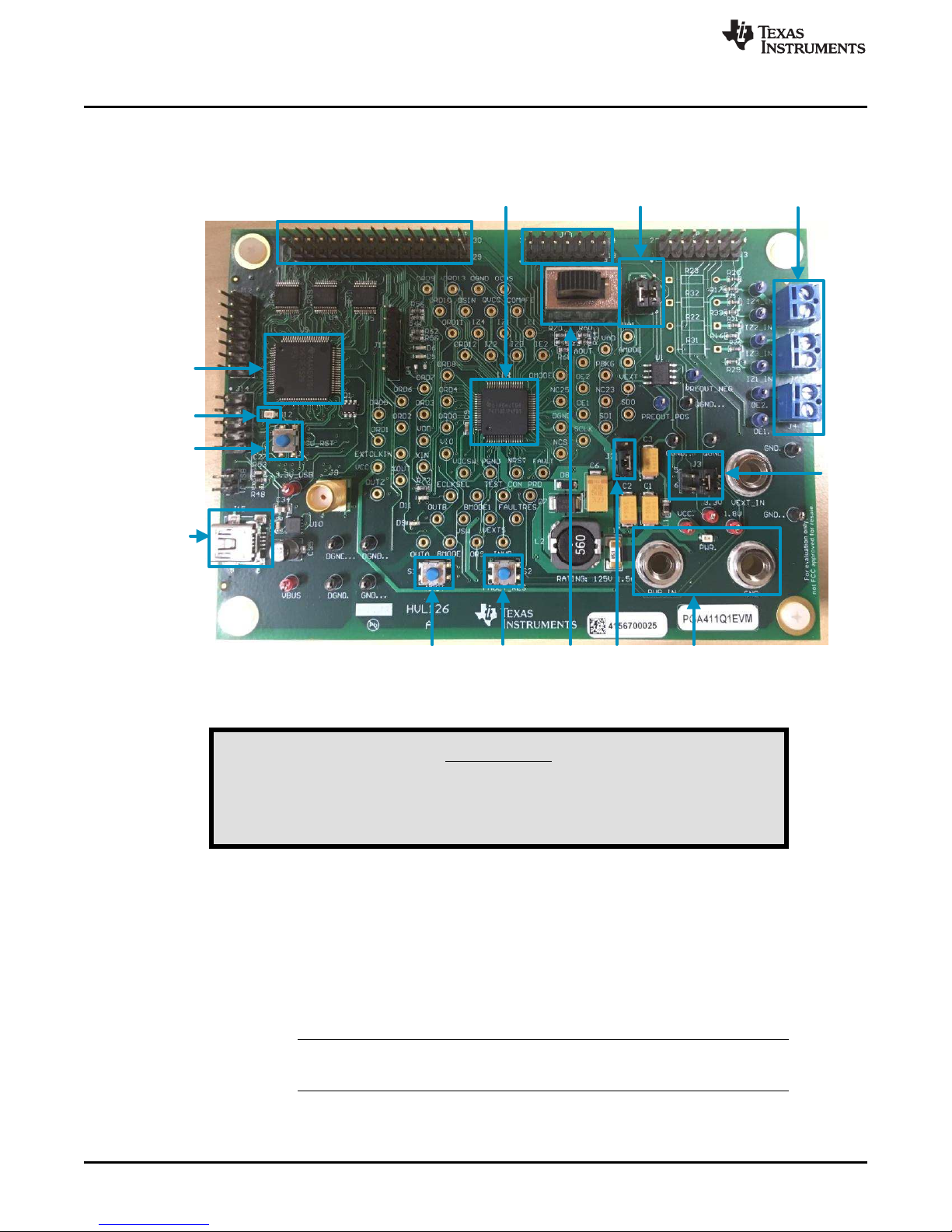

Figure 1 shows the PGA411-Q1 EVM architecture, where the key components and blocks previously listed

can be identified.

Introduction

2 Setup and Operation

2.1 Required Equipment for Device Evaluation

The following elements are required for proper operation and to receive consistent results with this user's

guide:

• A single power supply that is capable of 5-V operation and a minimum current of 0.5 A

• A computer with Windows®XP or Windows 7 and .net Framework 4.0 or later

• The PGA411-Q1 GUI

• A resolver sensor connected to the correct ports. Refer to the resolver data sheet for more information.

2.2 Initial EVM Setup

2.2.1 Installing Graphical User Interface Software

Before the PGA411-Q1 device can be evaluated the GUI software must be available on a host computer.

Run the GUI installer and place the executable file in a convenient location (Desktop or c:\Texas

Instruments EVM\) and double click to run the application.

To download the PGA411-Q1 GUI go to www.ti.com/product/PGA411-Q1.

SLAU658–March 2016

Submit Documentation Feedback

Figure 1. PGA411-Q1 EVM Block Diagram

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

3

Page 4

NRST

(S3)

FAULT_RES

(S2)

MCU_RST (S4)

USB

(J15)

5-V

DC

J2

(1-2)

J3

(3-4)

J10

J5

(3-5, 4-6)

J7

Resolver Sensor

Connections

J6

J4

J11

1

2

S1

PGA411-Q1

MSP430

LED USB_RDY

(D12)

Setup and Operation

2.2.2 Set-Up Instructions

For set-up instructions, refer to Figure 2.

www.ti.com

Figure 2. PGA411-Q1 EVM

This EVM contains components that are sensitive to Electrostatic

Discharge (ESD). Use proper laboratory techniques and equipment

WARNING

to minimize the chance of an ESD or EOS event.

Step 1. Set up EVM jumpers as follows:

• Confirm the J3 jumper settings (3-4) for 3.3-V VIO. This step is required for proper

operation with the MSP430 device.

• Confirm the J5 jumper settings (3-5 and 4-6) to connect the exciter outputs (OEx pins) to

the IEx input pins. The tracking loop inside the PGA411-Q1 device must sense the

exciter outputs.

• Confirm that the J2 jumper is present to connect the internal boost supply to the supply

input of the integrated exciter amplifier (VEXT).

NOTE: Using the integrated boost supply for the exciter amplifier is strongly

recommended.

Step 2. Apply the 5-V supply to the banana connectors for VCCand GND.

4

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 5

Reset

www.ti.com

Setup and Operation

Step 3. Connect the USB cable to the EVM and to the PC.

NOTE: Power, as described in Step 2, must be applied before connecting the USB.

Step 4. Verify that the LED USB_RDY (D12) is on, ensuring a good connection. If it is blinking or off,

unplug and replug the USB cable, and press the MCU reset, MCU_RST (S4).

Step 5. Launch the PGA411-Q1 GUI.

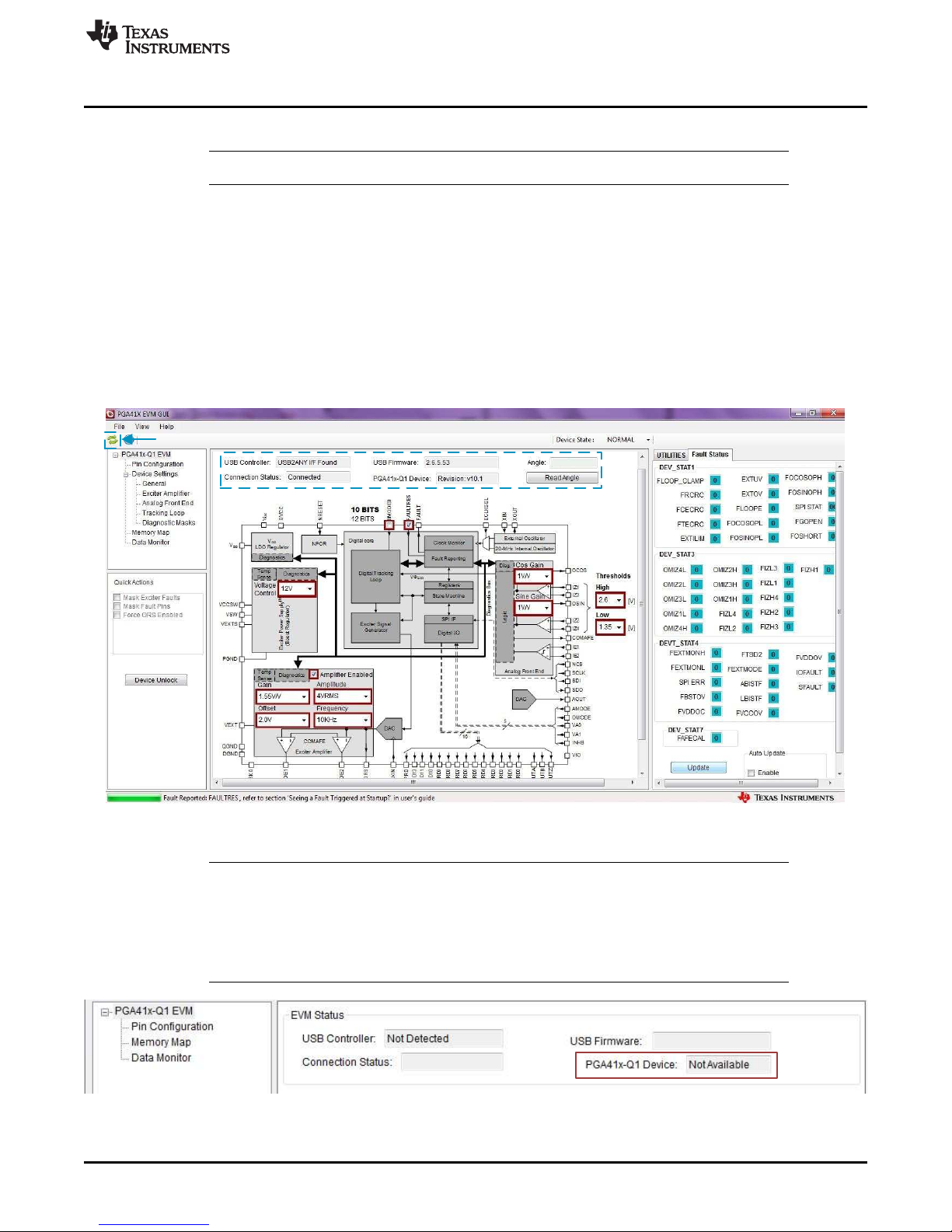

Step 6. Wait a few seconds after the GUI welcome screen appears. The first view should be of a

block diagram which is a high level representation of the PGA411-Q1 resolver-to-digital

interface and contains interactive features. The red boxes indicate controls that can be used

to configure internal blocks inside the PGA411-Q1 device.

If the connection is successful, the Connection Status field displays Connected and a revision number

is displayed in the PGA411-Q1 Device field as shown in Figure 3. If the connection process failed,

press the S4 switch on the EVM and then press the Reset button in the upper left corner of the GUI

(see Figure 3) to restart the connection.

NOTE: Follow the start-up procedure carefully and ensure that board connections are correct. The

power must be applied before the USB cable is plugged in. The USB_RDY LED close to the

MSP430 controller should remain on continuously after connecting the USB cable and

should not blink. If the device does not power up properly, the EVM status field in the GUI

will display: PGA41x-Q1 Device: Not Available as shown in Figure 4. If this occurs, turn off

the 5-V power supply, unplug the USB cable, and go back to Step 2.

Figure 4. PGA411-Q1 Device Startup Failed

SLAU658–March 2016

Submit Documentation Feedback

Figure 3. PGA411-Q1 GUI Block Diagram

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

5

Page 6

Setup and Operation

2.2.2.1 EVM Switches and Jumpers Settings

Refer to Figure 2 for the locations of the switches and jumpers on the PGA411-Q1 EVM.

Table 1 lists the descriptions of the EVM switches. Table 2 lists the descriptions of the EVM jumpers.

Table 1. Description of EVM Switches

Switch (SW) Description

0: This position is the default and selects the prepopulated IZx resistive divider

S1 Voltage divider

S2 Fault reset

S3 Device reset This switch pulls the NRST pin low. This action resets the PGA411-Q1 device.

S4 MSP430 BSL This switch resets the MSP430 microcontroller. The firmware is reloaded.

(30 kΩ / 30 kΩ).

1: This position selects the user-populated IZx resistive divider (30 kΩ / external

resistor value).

This switch pulls the FAULTRES pin low when pressed. When this switch is

pressed and then released, all faults from the PGA411 device are cleared.

Table 2. Description of EVM Jumpers

Jumper No. Function State Description

J2 VEXT Jumper

J3 VIO SELECT

J4 OEx Terminal

J5 OEx to IEx

J6 COS IZx terminal

J7 SIN IZx terminal

J10 Analog Connector — Header for analog signals

J11 Digital Connector — Header for digital signals

J15 USB Connector — Connector for USB cable

Open Disconnect VEXT from boost output

Closed (Default) Connect VEXT to boost output

1-2 Do not use

3-4 (Default) VIO = 3.3 V

5-6

Pin 1 Exciter output 1 to resolver (OE1)

Pin 2 Exciter output 2 to resolver (OE2)

3-5 (Default) Connect OE1 to IE1 through voltage divider

4-6 (Default) Connect OE2 to IE2 through voltage divider

All other combinations Do not use

Pin 1 Input to IZ1 external filter

Pin 2 Input to IZ3 external filter

Pin 1 Input to IZ2 external filter

Pin 2 Input to IZ4 external filter

VIO = VCC (5 V), Do not use with current EVM

version. This mode is to interface PGA411-Q1

device with external microcontrollers.

www.ti.com

6

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 7

www.ti.com

2.3 GUI Software

2.3.1 PGA41x-Q1 GUI Main Screen

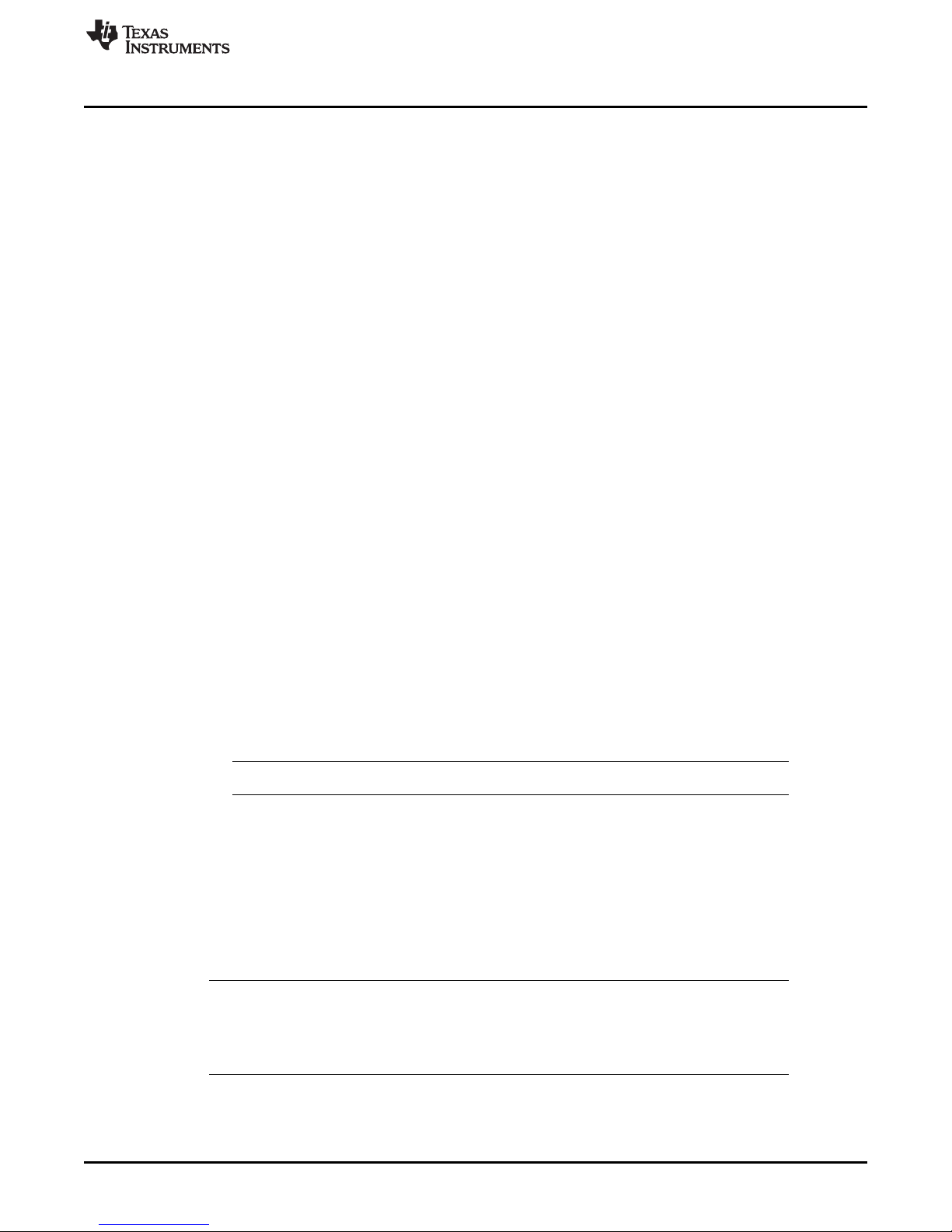

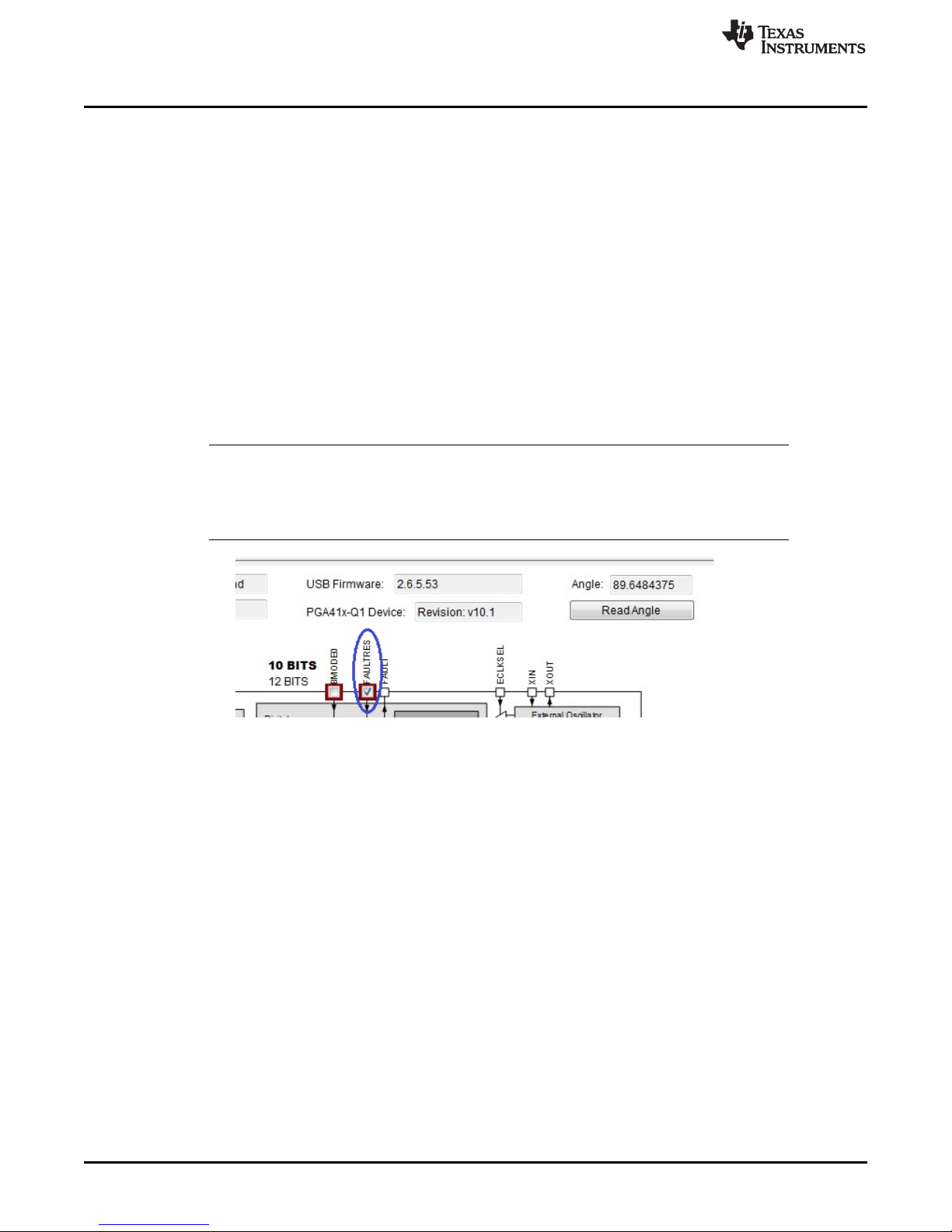

Figure 5 shows the default starting screen of the PGA41x-Q1 GUI. If the EVM is connected properly, the

screen should display the values that follow for the EVM Status fields, as described in Step 5 in

Section 2.2.2:

• USB Controller: USB2ANY I/F Found

• USB Firmware: 2.6.5.53 (this value is designed for Revision B of the EVM)

• Connection Status: Connected

• PGA41x-Q1 Device: Revision: v10.1

The default GUI view is the block diagram of the PGA411-Q1 resolver-to-digital interface IC and contains

interactive features. All boxes in red, as shown in Figure 5, are controls that can be configured. These

boxes indicate the default values of the PGA411-Q1 device after power on. The configurable elements in

this block diagram include:

• Internal boost voltage control

– Boost output voltage from 10 to 17 V

• Exciter amplifier

– Exciter frequency (10 to 20 kHz)

– Exciter amplitude (4 V

– Exciter amplifier gain (1.15 to 1.9 V/V )

– Common-mode offset (0.5 to 2 V)

Use a scope probe on the test points next to exciter connection, J4, to view changes to these

blocks instantaneously. The optimum values depend on the characteristics of the resolver sensor

that is used.

• Analog front end (AFE)

– COS gain and SIN gain from 0.75 to 3.5 V/V.

– Diagnostic values for detection thresholds on the AFE amplifiers. These values include both the

high and low thresholds.

The optimum AFE settings depend on the signal levels from the resolver outputs (sine and cosine).

Observe these signals on the test points next to the J6 and J7 jumpers when configuring the AFE.

RMS

or 7 V

RMS

Setup and Operation

(1)

)

NOTE: Both gains must match to achieve better accuracy on the angle estimation.

• Read Angle button

When pressed, the angle (in degrees) is displayed, if the resolver sensor is rotated and read again, the

value should update.

• BMODE0 which is the control bit for 10-bit and 12-bit modes

Higher precision is achieved by changing the resolution from 10 bits to 12 bits by checking the

BMODE0 box. The new angle reading should have more digits of precision.

• Control bit for the FAULTRES pin

To ignore faults, ensure that the FAULTRES pin is set to low. To set this pin low, uncheck the box.

NOTE: Toggling the FAULTRES pin with a fault condition still present causes the PGA411-Q1

device to go into normal operation, which may cause damage to the PGA411-Q1 device.

This is most likely to occur with high current short circuits on the exciter amplifier.

Ignoring the faults is only recommended for initial evaluation.

(1)

This version is the latest at the time this user guide was generated.

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

7

Page 8

Setup and Operation

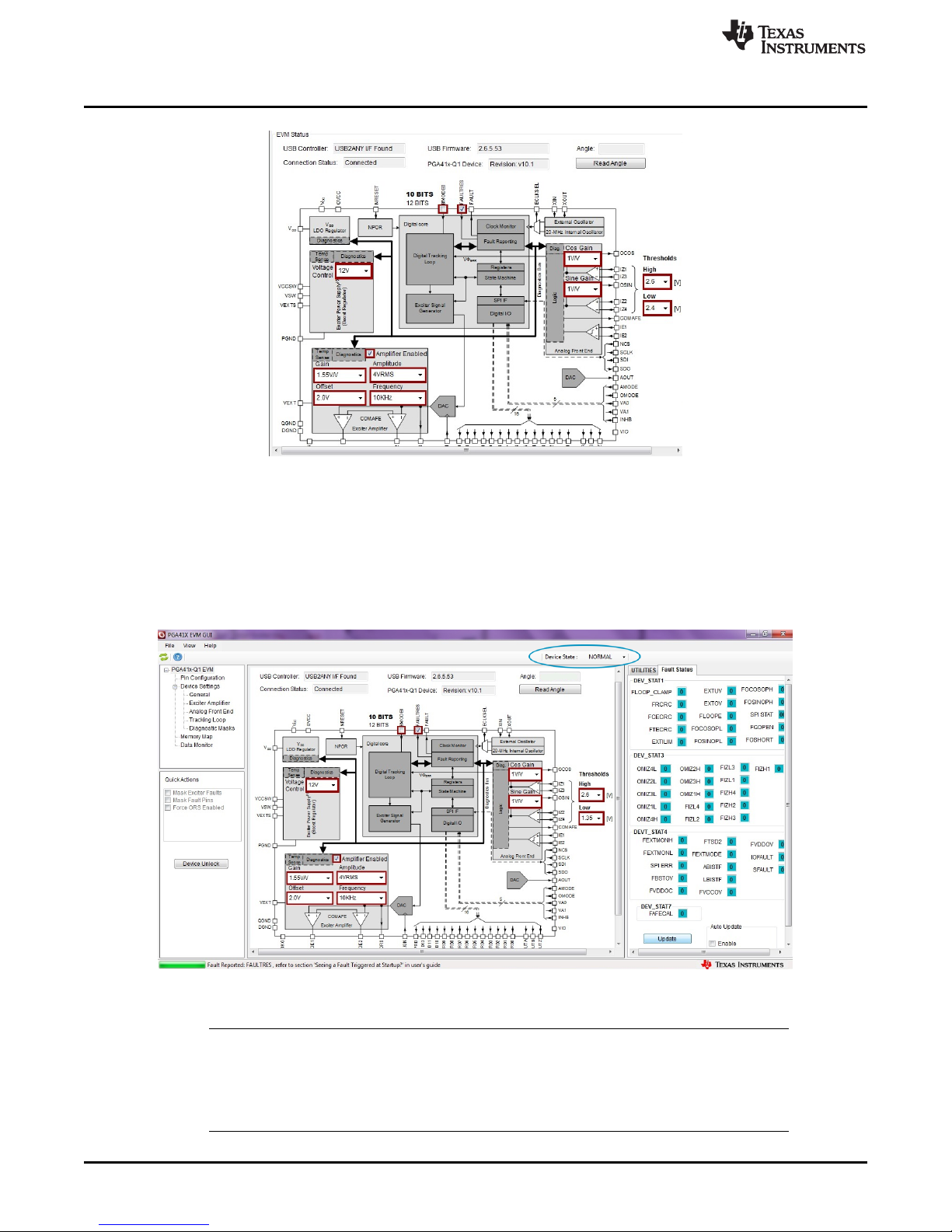

2.3.2 Device State

The Device State menu (see Figure 6) supports two device states: NORMAL and DIAGNOSTICS. This

menu displays the current device state. Click on the down arrow for the dropdown menu to select a new

state. This menu always displays the current device state, therefore serving as a confirmation that the

device transitioned to the new state correctly.

www.ti.com

Figure 5. GUI PGA41x-Q1 EVM Main Screen

Figure 6. Device-State Status and Selection

NOTE: The data sheet includes a detailed description on why and how to change between these

states. Some of the controls in the PGA411-Q1 GUI interactive block diagram change states,

from NORMAL to DIAGNOSTIC in a hidden manner to make the configuration changes (for

example, changing the exciter sine-wave amplitude from 4 V

for more details.

8

PGA411-Q1 EVM User's Guide

RMS

Copyright © 2016, Texas Instruments Incorporated

to 7 V

). See Section 2.3.4

RMS

Submit Documentation Feedback

SLAU658–March 2016

Page 9

www.ti.com

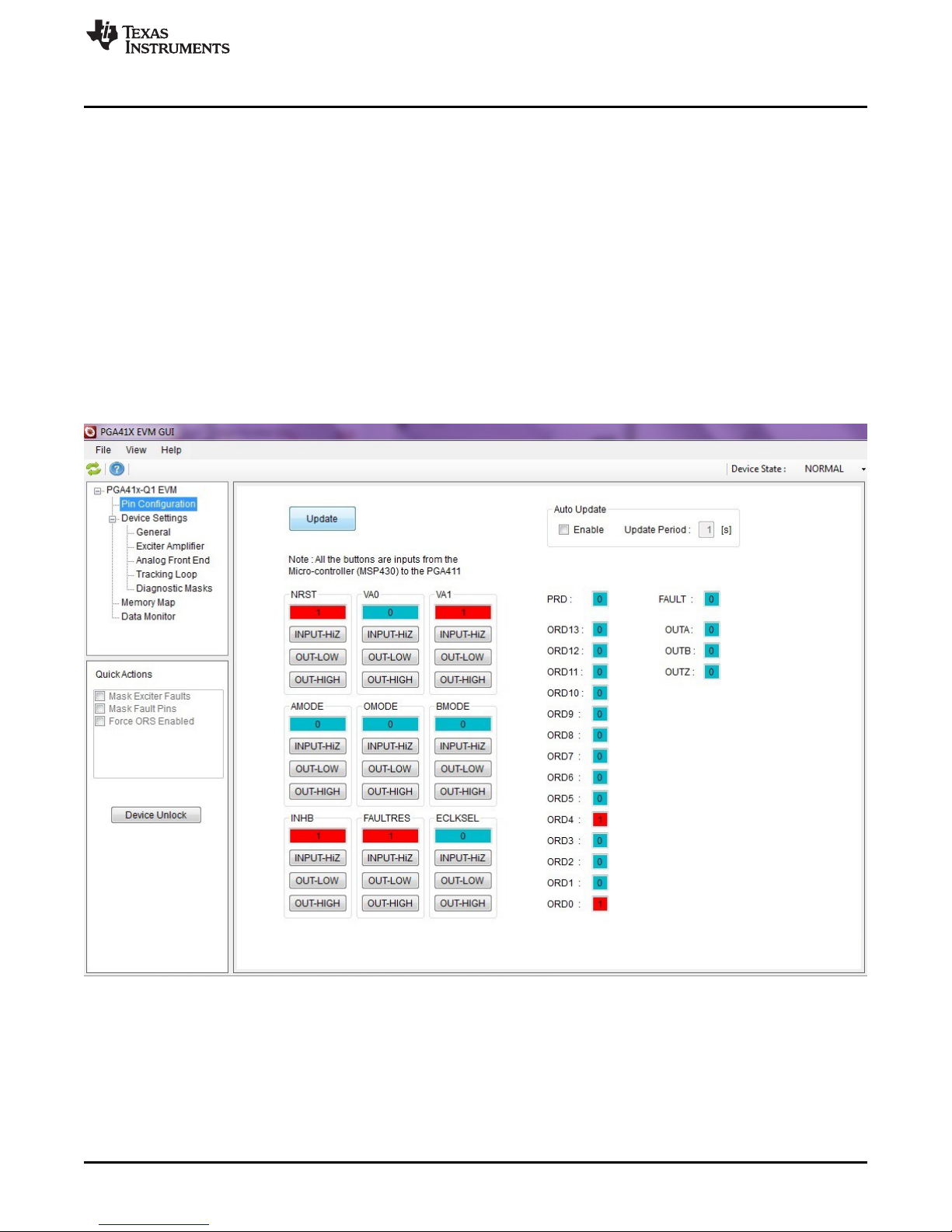

2.3.3 Pin Configuration and Fault Register Status

The Pin Configuration window (see Figure 7) displays the current status of the digital input and output

pins. The input pins of the PGA411-Q1 device are shown in Figure 7 on the left-side (below the Update

button) in the GUI, where the low or high values will be driven by the MSP430. Select the status of the

nine digital-input pins by clicking on the appropriate button (INPUT-HiZ, OUT-LOW, or OUT-HIGH). The

MSP430 device then switches the connected I/O pin to the selected value.

The output pins of the PGA411-Q1 device are displayed to the right of the group of input pins. This section

displays the current status of the output pins with logic low equal to 0 and logic high equal to 1. For

example if the FAULT pin changes to HIGH the GUI displays a 1 in the field which is then highlighted in

red.

The Fault Status tab on the right-side of the Pin Configuration window displays the current status of the

device registers which report any fault in the system. The following sections provide more details on the

fault status registers.

The display updates each time the Update button is pressed. To automatically update this page, check the

Enable box under the Auto Update section and select an update period in 1-s increments.

Setup and Operation

SLAU658–March 2016

Submit Documentation Feedback

Figure 7. Pin Configuration Screen

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

9

Page 10

Setup and Operation

2.3.4 Memory Map

The memory map is used to read and write to all of the device registers. The Memory Map window (see

Figure 8) includes the register name, hex value for all 16 bits, and individual bit values.

A change to a register value occurs in one of two ways. The first way is bit by bit. To change a register

value in this way, click in the text field of the bit number that will change. If this text field displays a 0, click

the text field to toggle the value to 1 (see Figure 9). To update more bits, repeat the procedure. The

second way to update a bit is with the hex value. Click on the hex value under the REG column (see

Figure 10) and type the new HEX value.

In each case, after updating the register values the row should become highlighted in yellow, which

indicates that the change has not yet been programmed to the PGA411-Q1 device.

To program the new register values into the device, click on the Write Selected button to updated only the

highlighted registers. Click on the Write All buttons to modify all registers at one time.

NOTE: The device must be in diagnostics mode to write to the majority of registers. Refer to the

PGA411-Q1 data sheet for the entire list of registers.

The primary buttons at the bottom of this window are defined as follows:

Read Selected —After selecting the register by clicking on the register name while holding the CTRL key

for multiple selection, use this button to read all of the selected registers.

Write Selected —After selecting the register by clicking on the register name while holding the CTRL key

for multiple selection, use this button to write to all of the selected registers.

www.ti.com

Read All —Use this button to read all of the registers and to update the register values in the table.

Write All —Use this button to write the current values listed in the table to all of the registers, including

those that were not modified.

ZERO GRID —Use this button to set all registers to zero.

DESELECT GRID —Use this button to remove all selections from the grid.

SAVE GRID —Use this button to save the contents of the grid to a text file. This option is useful for

reusing register settings that were predefined.

LOAD GRID —Use this button to load the grid with the contents of a text file.

10

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 11

www.ti.com

Setup and Operation

Figure 8. Memory Map

Figure 9. Bit Selection Figure 10. Hex Selection (REG)

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

11

Page 12

Setup and Operation

2.3.4.1 Search Box and Register Descriptions on UTILITIES Tab

The bottom of the GUI includes a useful tool to search the contents of each register. For example, to find

the register that sets the exciter amplifier mode to 7 V

, type 7V in the Search Registers text field and

RMS

click on the Search button. Next, a list of all registers that include any description containing the keyword

7V displays below the search box.

Click on the corresponding register value inside the memory map to view the register description on the

UTILITIES tab on the right-hand side of the GUI. If DEV_PHASE_REG is selected, the UTILITIES tab

displays that bits 11-10 set the exciter mode (EXTMODE). The value for 7 V

In the same UTILITIES tab, the bottom-section of the tab includes a numeric base converter with hex,

decimal, and binary modes.

is 01. Refer to Figure 11.

RMS

www.ti.com

Figure 11. Search Box and Register Descriptions

12

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 13

www.ti.com

2.3.5 Data Monitor

The Data Monitor window (see Figure 12) plots the output angle or velocity information and provides

access to a Demo mode that shows the angle and velocity in an instrument cluster display. The fields and

buttons on this window are described as follows:

Data Capture Source — This field selects between SPI register read, USB, or UART burst reading.

NOTE: The UART mode requires additional hardware setup which is not included in the

Data Monitor — Use this field to select either the angle or velocity to plot.

Resolution — Use this field to select the resolution to export the data as.

Record Length — Use this field to select the number of data samples to plot on the graph.

Loop — If checked, when the graph fills up, selecting this checkbox clears the current graph and begin a

new graph.

RUN — This button starts reading the angle or velocity data.

Clear Plot — This button clears the plot.

Export Data — This button exports the data to a .txt file in comma separated value (CSV) format.

Setup and Operation

EVM package. For evaluation purposes, the UART mode is not required.

NOTE: The GUI was designed to support three modes of reading data from the PGA411-Q1

device. The collected samples could have some non-linearity when using the GUI to

read the angle registers. If a delay occurs in the waveform on the Data Monitor

window when reading the angle value, the delay is because of SPI. The EVM can

support faster data capture by omitting the USB-to-SPI circuit (using MSP430) and

connecting the controller directly to the digital pins available on the board. For

evaluation purposes, TI recommends using SPI.

SLAU658–March 2016

Submit Documentation Feedback

Figure 12. Data Monitor

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

13

Page 14

Setup and Operation

Demo — Use this button to access the high resolution instrument cluster Display for instantaneous angle

and velocity display. Click on the ESC button on the keyboard to exit this mode. Refer to Figure 13.

www.ti.com

Figure 13. DEMO Screen

NOTE: The velocity resolution is limited to 500 rpm.

To properly read the velocity, calibrate the system by clicking the Calibrate button. For

detailed information, refer to Troubleshooting Guide for PGA411-Q1 (SLAA687).

If the fault sign appears in the demo mode (in the form of a warning sign), refer to

Section 2.3.6 to clear the faults.

NOTE: Unlocking the EEPROM device functionality found under the general tab is not currently

available in the current version of the PGA411-Q1 EVM GUI. This functionality will be added

in a future version.

14

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 15

www.ti.com

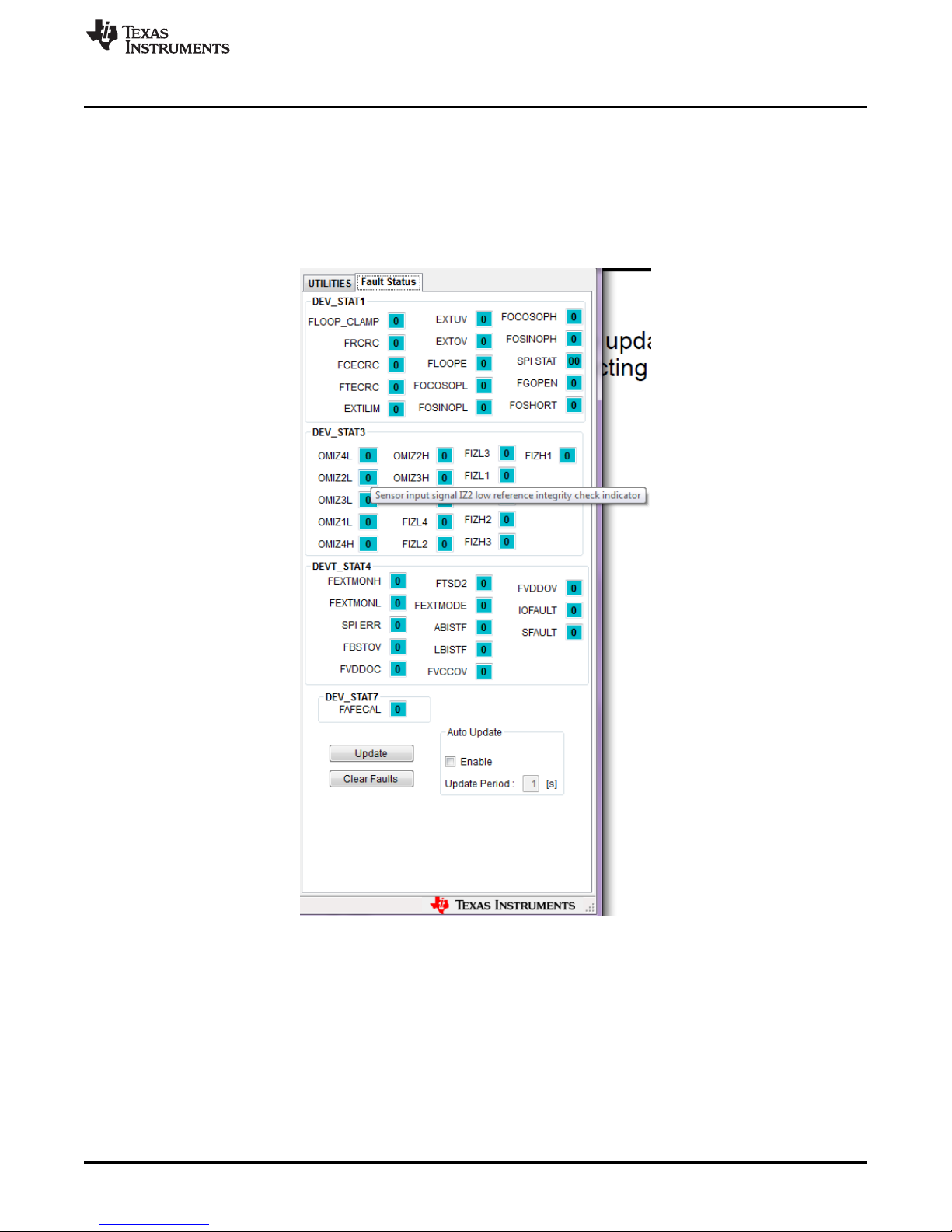

2.3.6 Fault Status

The Fault Status tab (see Figure 14) displays the status of the PGA411-Q1 fault bits. Click the Update

button to refresh the display the current fault status. This tab can be configured to automatically update by

selecting the Enable checkbox in the Auto Update section and setting the update period in 1-s increments.

The PGA411-Q1 device detects a fault in the system when any bit or group of bits displays a 1 and the

color of the text field changes to red. Placing the mouse cursor on top of the status bit displays a text box

with information on the fault, as shown in Figure 14.

Setup and Operation

NOTE: Make sure the FAULTRES pin is HIGH to view the faults (see Section 2.3.1).

If the auto update option is enabled, only the SFAULT may appear because faults are

cleared when read. The SFAULT gives the state of the fault pin.

SLAU658–March 2016

Submit Documentation Feedback

Figure 14. Fault Status

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

15

Page 16

EVM Evaluation Examples

3 EVM Evaluation Examples

3.1 EVM Checks for Proper Operation

3.1.1 Fault Triggered at Startup

The resolver setup may trigger faults because of specific requirements on voltage or current. To

understand the primary cause, ignore the faults and continue with the initial evaluation.

If a fault appears when the GUI is first executed after properly connecting the device EVM as

recommended in Section 2.2.2, the PGA411-Q1 device can be set to ignore the faults. Setting the device

to ignore these faults can occur in two different ways:

• Using the PGA411-Q1 block diagram

Set the FAULTRES pin to low by unchecking the box in the block diagram as shown in Figure 15.

• Using the Pin Configuration tab

Set the FAULTRES bit low by clicking the OUT-LOW button as shown in Figure 16. This setting allows

for further evaluation of the resolver EVM.

NOTE: Toggling the FAULTRES pin with a fault condition still present causes the PGA411-Q1

device to go into normal operation, which may cause damage to the PGA411-Q1 device.

This is most likely to occur with high current short circuits on the exciter amplifier.

Ignoring the faults is only recommended for initial evaluation.

www.ti.com

Figure 15. FAULTRES Change in Block Diagram

16

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 17

www.ti.com

EVM Evaluation Examples

Figure 16. FAULTRES Change in Pin Configuration Tab

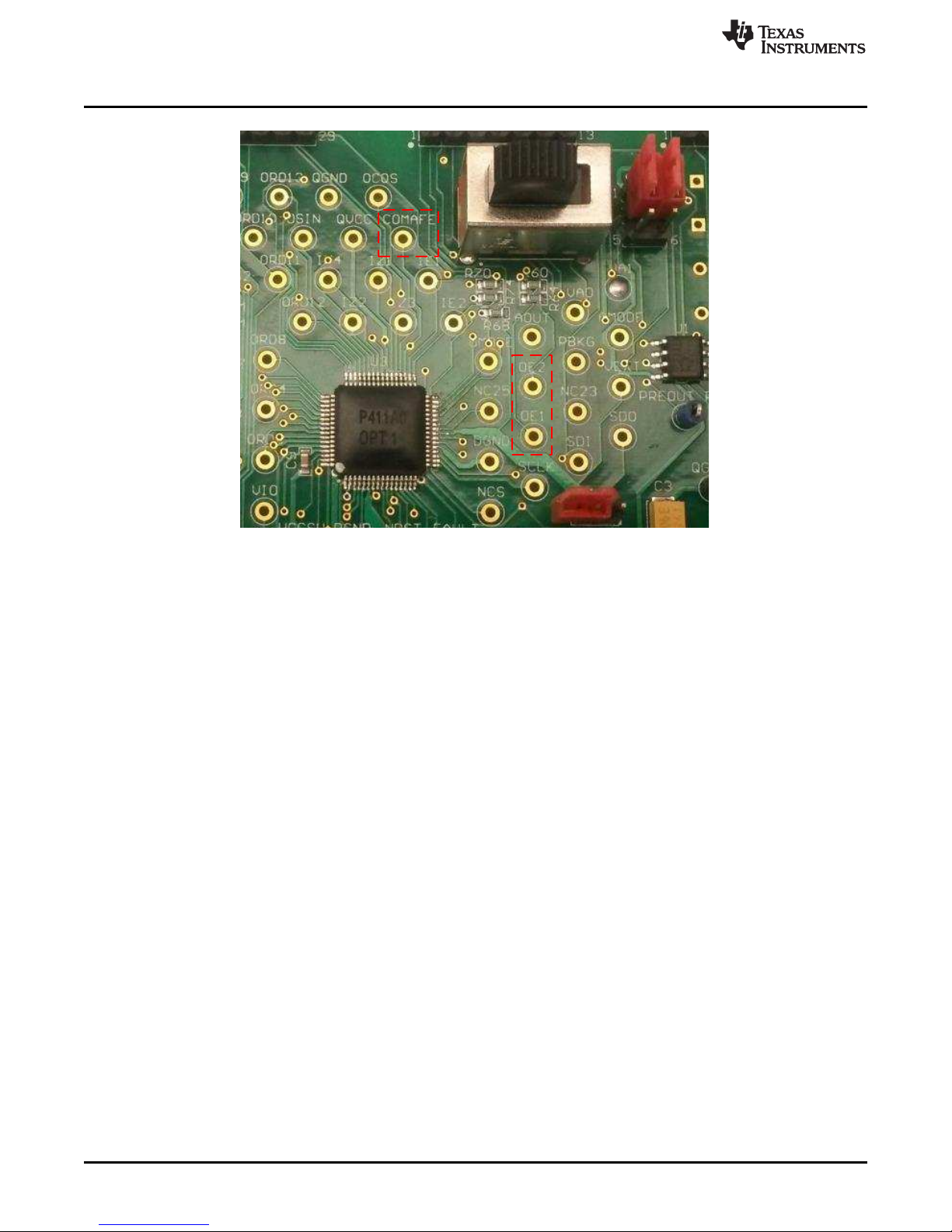

3.1.2 Changing Exciter Signal Pre-Amplifier Gain

Changing the exciter amplifier gain can occur using the PGA411-Q1 block diagram as explained in

Section 2.3.1; however, this section focuses on same procedure using the Memory Map tab which is more

descriptive of how a controller interfaces with the PGA411-Q1 device for this type of operation.

In the preamplifier block, the amplification level of the exciter signal can be adjusted while the common

mode voltage is defined by the voltage at the COMAFE pin (typically 2.5 V). The preamplifier gain is

selectable though the EXTOUT_GL[15:12] bits in the DEV_OVUV1 register and affects both the

preamplifier ORS output and power amplifier output. For more information, refer to the PGA411-Q1 data

sheet, SLASE76.

Step 1. In the GUI, select the Memory Map tab. This section is the primary form of control for the

device registers. For the bit definitions, see the PGA411-Q1 data sheet. The Information box

on the right-side of the window also displays the bit definitions.

Step 2. Change the state of the device to DIAGNOSTICS mode. Refer to Figure 19 and

Section 2.3.2.

Step 3. Probe pins COMAFE to check the 2.5-V pin voltage and use a differential probe on the OE1

and OE2 pins. Figure 17 shows these test-point locations on the board.

OE1 —OE1 is the positive output of the exciter amplifier.

OE2 —OE2 is the negative output of the exciter amplifier.

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

17

Page 18

EVM Evaluation Examples

Figure 17. Test Points for Exciter Outputs and Common Mode Voltage

www.ti.com

18

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 19

www.ti.com

EVM Evaluation Examples

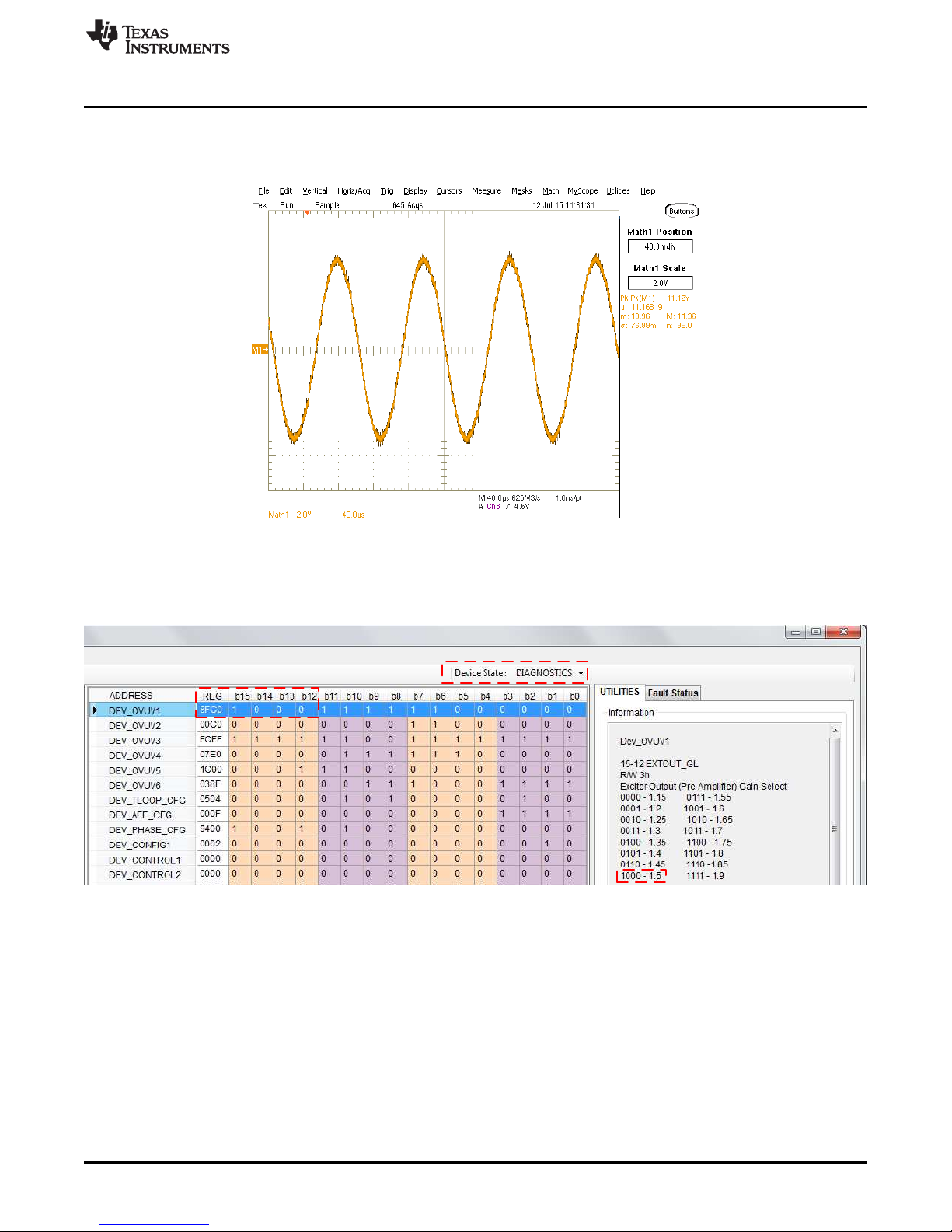

Step 4. Connect the scope probe to OE1 and compare this waveform to the one shown in Figure 18.

In this waveform, the peak-to-peak voltage of the differential voltage output of the exciter is

11.12 VPP.

Figure 18. OE1-OE2 Differential Output from the Exciter

Step 5. Click on the DEV_OVUV1 address inside the register map as shown in Figure 19. Text

should appear in the Information box on the UTILITIES tab. This box displays information

regarding the bits in the DEV_OVUV1 address.

Figure 19. DEV_OVUV Register

Bits Relevant to Exciter Amplifier Gain

Step 6. Click the b14 and b13 bits to change the value inside the cell. To change the exciter

preamplifier gain from 1.5 V/V to 1.85 V/V, update the value of bits b15 through b12 to 1110

and write this register to the PGA411-Q1 device using the Write Selected button as explained

in Section 2.3.4.1. New bit values appear as shown in Figure 20.

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

19

Page 20

Schematics, Bill of Materials, and Layout

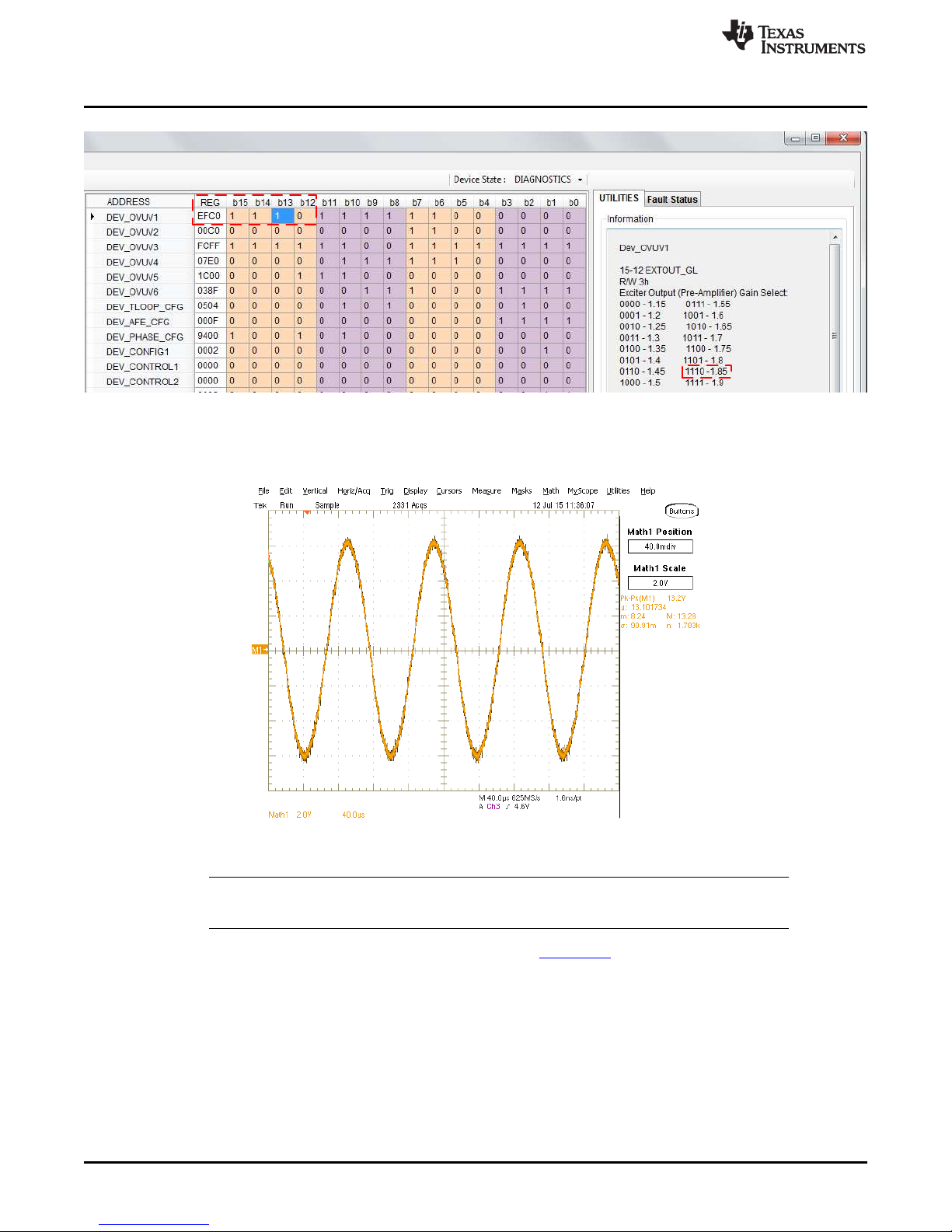

Figure 20. Exciter Amplifier Gain Change Using Memory Map

Step 7. As shown in Figure 21, the amplitude of the waveform increased to approximately 13 V which

corresponds with the new programmed gain of the exciter amplifier.

www.ti.com

Figure 21. OE1-OE2 Differential Output from the Exciter With Updated Gain

NOTE: This example provides a step-by-step guide on how to change key parameters on the

PGA411-Q1 device using the memory map functionality.

For support questions, go to TI's E2E™ online community, e2e.ti.com.

4 Schematics, Bill of Materials, and Layout

This section provides a detailed description of the schematic, bill of materials (BOM), and layout.

20

PGA411-Q1 EVM User's Guide

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLAU658–March 2016

Page 21

ORD9

48

FAULTRES

14

ORD12

45

NCS

17

IZ4

42

SDO

20

QVCC

39

NC

23

OE2

26

OMODE

29

VA1

32

COMAFE

35

PRD

15

FAULT

16

ORD11

46

ORD10

47

OSIN

43

ORD13

44

DGND

21

OE1

22

QGND

40

IZ2

41

IZ3

37

IZ1

38

NC

25

AMODE

28

VA0

31

AOUT

30

IE1

34

OCOS

36

PBKG

27

IE2

33

TEST

11

PGND

8

BMODE0

5

OUTB

2

INHB

13

SCLK

18

SDI

19

VEXT

24

RESET

12

ORS

9

VSW

6

BMODE1

7

ECLKSEL

3

OUTA

1

VEXTS

10

VCCSW

4

ORD8

49

ORD7

50

ORD6

51

ORD5

52

ORD4

53

ORD3

54

ORD2

55

ORD1

56

ORD0

57

OUTZ

64

EXTCLKIN

59

XOUT

63

VIO

61

XIN

62

VCC

60

VDD

58

PAD

65

U3

PGA411PAP

56uH

L2

20V

D8

PGND

J4 OEx

QGND

OE1

4.99k

R34

DNP

QGND

40.2k

R33

OE2

PGND

ORD0

ORD1

ORD2

ORD3

ORD4

ORD5

ORD6

ORD7

ORD8

ORD9

ORD10

ORD11

ORD12

ORD13

PRD

OUTZ

OUTB

OUTA

NCS

SCLK

SDI

SDO

EXTCLKIN

FAULT

AMODE

OMODE

INHB

ECLKSEL

VA0

VA1

VCC

VIO

VIO

OE2

OE1

1

34

2

G

G

Y1

GND

GND

XOUT

XIN

XIN

XOUT

15pF

C24

15pF

C25

C22

DNP

DNP

C23

DNP

DNP

VCC

GND

VEXT

J17

PWR_IN

PGND

J19

GND

GND PGND QGNDDGND

0R90

R10

GND GND QGND QGND

1000 ohm

L1

QVCC

QVCC

QGND DGND

C14

DNP

DNP

C20

DNP

DNP

1.2k

R4

FAULT

OCOS

COMAFE

OSIN

AOUT

ORS

0.1µF

C11

4.99k

R24

DNP

40.2k

R15

C10

DNP

DNP

R14

DNP

DNP

VOUT1

1

VOUT2

2

GND

3

EN2

4

VIN

5

EN1

6

U2

TLV7163318PDPQR

GND

12

34

56

J3

VCCSW

VIO

1µF

C8

DGND

0.1µF

C9

3.3V

1.8V

1

2

3

4

S3

VIO

GND

10k

R37

0.01µF

C21

NRST

TEST_CON

FAULTRES

Green

1

2

D3

VCC

GND

1.2k

R3

0

R36

DGND

10.0k

R11

10.0k

R12

ORS

COMAFE

10.0k

R2

ORS

QGND

QGND

QVCC

QVCC

0

R13

0

R1

PREOUT_NEG

PREOUT_POS

2

1

5

3

4

6 7

8

9

10

11

12

S1

30.0k

R26

J6

470pF

C12

QVCC

1000pF

C17

1000pF

C18

470pF

C13

20.0k

R30

30.0k

R28

30.0k

R19

30.0k

R21

30.0k

R18

30.0k

R20

30.0k

R27

30.0k

R25

IZ3

IZ1 IZ2

IZ4

QGND

QVCC

1000pF

C16

1000pF

C15

20.0k

R29

J7

R22

DNP

DNP

R31

DNP

DNP

R32

DNP

DNP

R23

DNP

DNP

0.01µF

C19

QGND

J9

R35

DNP

DNP

DGND

EXTCLKIN

QGND

QVCC

IE1

IE2

IE1

IE2

Yellow

1

2

D5

DGND

1.2k

R5

AMODE

Yellow

1

2

D6

DGND

1.2k

R6

OMODE

Yellow

1

2

D9

DGND

1.2k

R7

BMODE

Yellow

1

2

D11

DGND

1.2k

R8

ECLKSEL

1 2

3 4

5 6

7 8

9 10

11 12

13 14

J8

PEC07DAAN

DGND

COMAFE

IZ3_IN

IZ1_IN

IZ4_IN

IZ2_IN

IZ1_IN

IZ3_IN

IZ2_IN

IZ4_IN

PREOUT_POS

PREOUT_NEG

IE1

IE2

To Emulate Board

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15

17

19

21

23

25

27

29

16

18

20

22

24

26

28

30

J11

15x2 Header

ORD0

ORD1

ORD2

ORD3

ORD4

ORD5

ORD6

ORD7

ORD8

ORD9

ORD10

ORD11

PRD

VA0

VA1

OUTA

OUTB

OUTZ

NCS

SCLK

SDI

SDO

INHB

FAULTRES

FAULT

ECLKSEL

AMODE

OMODE

BMODE

DGND

1 2

3 4

5 6

7 8

9 10

11 12

13 14

J10

PEC07DAAN

OE1

OE2

AOUT

OCOS

OSIN

COMAFE

QGND

TP49DNP

TP50DNP

TP51DNP

TP52DNP

TP53DNP

TP54DNP

TP55DNP

TP56DNP

ORD8

ORD7

ORD6

ORD5

ORD4

ORD3

ORD2

ORD1

TP57DNP

TP58DNP

TP59DNP

TP60DNP

TP61DNP

TP62DNP

TP63DNP

TP64DNP

ORD0

EXTCLKIN

VCC

VIO

XIN

XOUT

OUTZ

TP25DNP

TP26DNP

TP27DNP

TP28DNP

TP29DNP

TP30DNP

TP31DNP

TP32DNP

OE2

PGND

AMODE

OMODE

AOUT

VA0

VA1

TP33DNP

TP34DNP

TP35DNP

TP36DNP

TP37DNP

TP38DNP

TP39DNP

TP40DNP

IE2

IE1

COMAFE

OCOS

IZ3

IZ1

QVCC

QGND

TP41DNP

TP42DNP

TP43DNP

TP44DNP

TP45DNP

TP46DNP

TP47DNP

TP48DNP

IZ2

IZ4

OSIN

ORD13

ORD12

ORD11

ORD10

ORD9

TP1DNP

TP2DNP

TP3DNP

TP4DNP

TP5DNP

TP6DNP

TP7DNP

TP8DNP

OUTA

OUTB

ECLKSEL

VCCSW

BMODE

PGND

TP9DNP

TP10DNP

TP11DNP

TP12DNP

TP13DNP

TP14DNP

TP15DNP

TP16DNP

ORS

VEXTS

TEST_CON

NRST

INHB

FAULTRES

PRD

FAULT

TP17DNP

TP18DNP

TP19DNP

TP20DNP

TP21DNP

TP22DNP

TP23DNP

TP24DNP

NCS

SCLK

SDI

SDO

DGND

OE1

VEXT

PIN TestPoints. *** DNP- Placeholders for VIAs Only ***

PIN 1

PIN 24

PIN 25

PIN 48

PIN 49

PIN 64

TP65

VCC

QGND

GND

TEST_CON

NRST

VCC

3.3V

1.8V

VEXT

VCC

TP66

3.3V

TP67

1.8V

TP68

TP69

TP70

TP71

IZ3_IN

IZ1_IN

IZ2_IN

IZ4_IN

TP74

PREOUT_POS

TP75

PREOUT_NEG

TP76

GND.

TP77

GND..

TP78

GND...

TP79

QGND.

TP80

QGND..

TP81

QGND...

TP82

DGND.

TP83

DGND..

TP84

DGND...

GND

QGND

DGND

12345

6

J5

IZ1

IZ3

OE1

OE2

BMODE

AMODE

BMODE

OMODE

FAULT

EXTCLKIN

SDO

SDI

SCLK

NCS

IE2

IE1

VA1

VA0

NRST

OE1

OE2

IZ1

IZ3

OUTA

OUTB

OUTZ

PRD

ORD0

ORD1

ORD2

ORD3

ORD4

ORD5

ORD6

ORD7

ORD8

ORD9

ORD10

ORD11

ORD12

ORD13

INHB

FAULTRES

ECLKSEL

VDD

VSW

NC25

NC23

NC23

NC25

VDD

BMODE1 BMODE1

VSW

GPIO1/I2C(SCL)GPIO0/I2C(SDA)

*DNP Position 1-2

VEXTS

TP72

OE1

TP73

OE2

0

R76

R77

DNP

DNP

0.1µF

C7

PGNDPGND

VEXTS

IZ4

IZ4

IZ2

IZ2

VIO

10k

R38

DGND

1

2

D4

Red

DNP

5

6

7

B

V+

V-

8

4

U1B

OPA2313IDR

2

3

1

A

V+

V-

8

4

U1A

OPA2313IDR

1.0k

R79

FAULTRES_1

DGND

1

2

3

4

S2

1.0k

R78

NRST_1

D1

GND

0.1µF

C5

10µF

C3

0.1µF

C4

10µF

C1

10µF

C2

VEXT

D7

1

2

3

J2

PGND

10µF

C6

J18

VEXT_IN

VCCSW

0

R80

D2

DNP

DNP

GND

VCCSW

4.75V - 5.25V

F1

49.9k

R16

49.9k

R17

QGND

www.ti.com

Schematics, Bill of Materials, and Layout

21

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

4.1 Schematics

Figure 22. EVM Schematic

Page 22

DGND

OUT

1

N/C

2

NR/FB

3

GND

4

EN

5

N/C

6

N/C

7

IN

8

PAD

9

U10

TPS73533DRB

DGND

VBUS

5.6V

D10

SMBJ5339B-TP

22µF

C35

50 ohm

L3

1µF

C32

DGND

0.01µF

C36

2.2µF

C34

2

3

4

1

5

J15

1734035-2

P6.4/CB4/A4

1

P6.5/CB5/A5

2

P6.6/CB6/A6

3

P6.7/CB7/A7

4

P7.0/CB8/A12

5

P7.1/CB9/A13

6

P7.2/CB10/A14

7

P7.3/CB11/A15

8

P5.0/A8/VREF+/VEREF+

9

P5.1/A9/VREF-/VEREF-

10

AVCC1

11

P5.4/XIN

12

P5.5/XOUT

13

AVSS1

14

P8.0

15

P8.1

16

P8.2

17

DVCC1

18

DVSS1

19

VCORE

20

P1.0/TA0CLK/ACLK

21

P1.1/TA0.0

22

P1.2/TA0.1

23

P1.3/TA0.2

24

P1.4/TA0.3

25

P1.5/TA0.4

26

P1.6/TA1CLK/CBOUT

27

P1.7/TA1.0

28

P2.0/TA1.1

29

P2.1/TA1.2

30

P2.2/TA2CLK/SMCLK

31

P2.3/TA2.0

32

P2.4/TA2.1

33

P2.5/TA2.2

34

P2.6/RTCCLK/DMAE0

35

P2.7/UCB0STE/UCA0CLK

36

P3.0/UCB0SIMO/UCB0SDA

37

P3.1/UCB0SOMI/UCB0SCL

38

P3.2/UCB0CLK/UCA0STE

39

P3.3/UCA0TXD/UCA0SIMO

40

P3.4/UCA0RXD/UCA0SOMI

41

P3.5/TB0.5

42

P3.6/TB0.6

43

P3.7/TB0OUTH/SVMOUT

44

P4.0/PM_UCB1STE/PM_UCA1CLK

45

P4.1/PM_UCB1SIMO/PM_UCB1SDA

46

P4.2/PM_UCB1SOMI/PM_UCB1SCL

47

P4.3/PM_UCB1CLK/PM_UCA1STE

48

DVSS2

49

DVCC2

50

P4.4/PM_UCA1TXD/PM_UCA1SIMO

51

P4.5/PM_UCA1RXD/PM_UCA1SOMI

52

P4.6/PM_NONE

53

P4.7/PM_NONE

54

P5.6/TB0.0

55

P5.7/TB0.1

56

P7.4/TB0.2

57

P7.5/TB0.3

58

P7.6/TB0.4

59

P7.7/TB0CLK/MCLK

60

VSSU

61

PU.0/DP

62

PUR

63

PU.1/DM

64

VBUS

65

VUSB

66

V18

67

AVSS2

68

P5.2/XT2IN

69

P5.3/XT2OUT

70

TEST/SBWTCK

71

PJ.0/TDO

72

PJ.1/TDI/TCLK

73

PJ.2/TMS

74

PJ.3/TCK

75

RST/NMI/SBWTDIO

76

P6.0/CB0/A0

77

P6.1/CB1/A1

78

P6.2/CB2/A2

79

P6.3/CB3/A3

80

U9

MSP430F5529IPN

NCS_MCU

SDABRD

SCLBRD

I2CPU

SCLK_MCU

GPIO0/I2C(SDA)

GPIO1/I2C(SCL)

SDI_MCU

SDO_MCU

EXT5V_EN

EXT5V_FAULT

EXT3.3V_EN

EXT3.3V_FAULT

DP

DM

PUR

VBUS

VUSB

33k

R50

DGND

VBUS

33

R46

DM

DGND

DP

PUR

DGND

220pF

C28

OUTA_MCU

ECLKSEL_MCU

FAULTRES_MCU

VA0_MCU

VA1_MCU

BMODE_MCU

1

2

24MHz

Y2

30pF

C37

30pF

C38

XT2IN

XT2OUT

XT2IN

XT2OUT

UART_TX

UART_RX

0.1µF

C30

0.1µF

C31

0.47µF

C29

0.1µF

C33

1.5k

R48

1.2M

R53

DGND

33

R47

VUSB

DGND

220pF

C27

DGNDDGND

TDO

TDI

TMS

TCK

TEST

DGND

3.3V_MCU

3.3V_MCU

3.3V_MCU

MCU_RST

DGND

ORD_0_MCU

ORD_1_MCU

ORD_2_MCU

OUTB_MCU

ORD_5_MCU

OUTZ_MCU

ORD_3_MCU

ORD_4_MCU

ORD_7_MCU

ORD_8_MCU

ORD_6_MCU

ORD_9_MCU

ORD_11_MCU

ORD_10_MCU

ORD_13_MCU

ORD_12_MCU

NRST_MCU

FAULT_MCU

AMODE_MCU

OMODE_MCU

INHB_MCU

EXTCLKIN_MCU

PRD_MCU

IZ1_ATT

IZ2_ATT

IZ3_ATT

IZ4_ATT

IE1_ATT

IE2_ATT

OE1_ATT

OE2_ATT

VEXT_ATT

VIO_ATT

Green

1 2

D12

1.2k

R45

DGND

NRST_1

ECLKSEL

FAULTRES_1

BMODE

OMODE

AMODE

NCS

NRST_MCU

ECLKSEL_MCU

FAULTRES_MCU

BMODE_MCU

AMODE_MCU

OMODE_MCU

NCS_MCU

VIO3.3V_MCU

DGND DGND

SCLK

VA0

VA1

INHB

SCLK_MCU

VA0_MCU

VA1_MCU

INHB_MCU

VCCA

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

GND

11

GND12GND

13

B8

14

B7

15

B6

16

B5

17

B4

18

B3

19

B2

20

B1

21

OE

22

VCCB

23

VCCB

24

U5

SN74LVC8T245DGVR

VIO3.3V_MCU

DGND DGND

3.3V_MCU VIO

PRD

EXTCLKIN

ORD_5_MCU

ORD_3_MCU

ORD_4_MCU

PRD_MCU

EXTCLKIN_MCU

DGND DGND

3.3V_MCU VIO3.3V_MCU VIO

FAULT

OUTA

OUTB

FAULT_MCU

OUTA_MCU

OUTB_MCU

ORD_11_MCU

ORD_10_MCU

ORD_13_MCU

ORD_12_MCU

OUTZ

ORD_0_MCU

ORD_1_MCU

ORD_2_MCU

ORD_7_MCU

ORD_8_MCU

ORD_6_MCU

ORD_9_MCU

OUTZ_MCU

DGND DGND DGND DGND

DGND

5

4

1

2

3

6

J13

PEC06SAAN

DGND

UART_TX

UART_RX

1 2

3 4

5 6

7 8

9 10

11 12

13 14

J12

PEC07DAAN

TDO

TDI

TMS

TCK TEST

MCU_RST

DO NOT POPULATE

VBUS

GPIO0/I2C(SDA)

GPIO1/I2C(SCL)

I2CPU

3.3V_MCU

LSHIFT_NEN

LSHIFT_NEN LSHIFT_NEN LSHIFT_NEN LSHIFT_NEN LSHIFT_NENDGND

VCCA

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

GND

11

GND12GND

13

B8

14

B7

15

B6

16

B5

17

B4

18

B3

19

B2

20

B1

21

OE

22

VCCB

23

VCCB

24

U4

SN74LVC8T245DGVR

VCCA

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

GND

11

GND12GND

13

B8

14

B7

15

B6

16

B5

17

B4

18

B3

19

B2

20

B1

21

OE

22

VCCB

23

VCCB

24

U6

SN74LVC8T245DGVR

VCCA

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

GND

11

GND12GND

13

B8

14

B7

15

B6

16

B5

17

B4

18

B3

19

B2

20

B1

21

OE

22

VCCB

23

VCCB

24

U7

SN74LVC8T245DGVR

VCCA

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

GND

11

GND12GND

13

B8

14

B7

15

B6

16

B5

17

B4

18

B3

19

B2

20

B1

21

OE

22

VCCB

23

VCCB

24

U8

SN74LVC8T245DGVR

DGND DGND

1

2

3

4

5

6

78910

11

12

13

14

15

16

33

R39

EXB-2HV330JV

DNP

NRST_MCU

ECLKSEL_MCU

FAULTRES_MCU

BMODE_MCU

AMODE_MCU

OMODE_MCU

NCS_MCU

NRST_1

ECLKSEL

FAULTRES_1

BMODE

OMODE

AMODE

NCS

1

2

3

4

5

6

78910

11

12

13

14

15

16

33

R41

EXB-2HV330JV

DNP

SCLK_MCU

VA0_MCU

VA1_MCU

INHB_MCU

SCLK

VA0

VA1

INHB

1

2

3

4

5

6

78910

11

12

13

14

15

16

33

R40

EXB-2HV330JV

DNP

ORD_5_MCU

ORD_3_MCU

ORD_4_MCU

PRD_MCU

EXTCLKIN_MCU

PRD

EXTCLKIN

1

2

3

4

5

6

78910

11

12

13

14

15

16

33

R42

EXB-2HV330JV

DNP

FAULT_MCU

OUTA_MCU

OUTB_MCU

ORD_11_MCU

ORD_10_MCU

ORD_13_MCU

ORD_12_MCU

FAULT

OUTA

OUTB

ORD_0_MCU

ORD_1_MCU

ORD_2_MCU

ORD_7_MCU

ORD_8_MCU

ORD_6_MCU

ORD_9_MCU

OUTZ_MCU

1

2

3

4

5

6

78910

11

12

13

14

15

16

33

R43

EXB-2HV330JV

DNP

OUTZ

DO NOT POPULATE

PLACE UNDER RESPECTIVE SN74LVC8T245DGVR

EXT5V_EN

EXT5V_FAULTEXT3.3V_EN

EXT3.3V_FAULT

PORT74

PORT76 PORT75

PORT77

1

6

5

Q1A

FDC6333C

4

3

2

Q1B

FDC6333C

100k

R49

DGND

SDABRD

SCLBRD

IZ1_ATT

IZ2_ATT

IZ3_ATT

IZ4_ATT

IE1_ATT

IE2_ATT

OE1_ATT

OE2_ATT

VEXT_ATT

VIO_ATT

200k

R56

200k

R58

200k

R62

200k

R66

200k

R70

200k

R74

200k

R72

300k

R57

300k

R59

300k

R63

300k

R67

300k

R71

300k

R75

300k

R73

4.7k

R54

4.7k

R55

4.7k

R51

4.7k

R52

GPIO0/I2C(SDA)

QGND

IZ1

IZ3

IZ2

IZ4

IE1

IE2

QGND

PGND

200k

R60

200k

R64

200k

R68

40.2k

R69

40.2k

R65

40.2k

R61

OE1

OE2

VIO

VEXT

EXT5V_EN

PORT74

PORT76

EXT3.3V_EN

EXT5V_FAULT

EXT3.3V_FAULT

PORT75

PORT77

A7_1

A8_1

B7_1

B8_1 A8_2 B8_2

A7_1

A8_1 B7_1

B8_1

A8_2

B8_2

SCLBRD

PORT75

PORT77

PORT74

P82_MCU

1 2

3 4

5 6

7 8

9 10

J14

PEC05DAAN

DGND

PORT76

GPIO1/I2C(SCL)

SDABRD

3.3V_MCU

P82_MCU

TP86

3.3V_MCU

SDO

SDO_MCU

SDI

SDI_MCU

ORD0

ORD1

ORD2

ORD6

ORD7

ORD8

ORD9

ORD10

ORD11

ORD12

ORD13

ORD3

ORD4

ORD5

3.3V_MCU

4.7k

R44

SDI_MCU

SDI

SDO_MCU

SDO

ORD3

ORD4

ORD5

ORD10

ORD11

ORD12

ORD13

ORD0

ORD1

ORD2

ORD6

ORD7

ORD8

ORD9

1

2

3

4

S4

1

2

J1

DGND

2200pF

C26

TP85

VBUS

Schematics, Bill of Materials, and Layout

www.ti.com

22

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

Figure 23. Schematic—Digital Interface

Page 23

www.ti.com

Schematics, Bill of Materials, and Layout

23

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

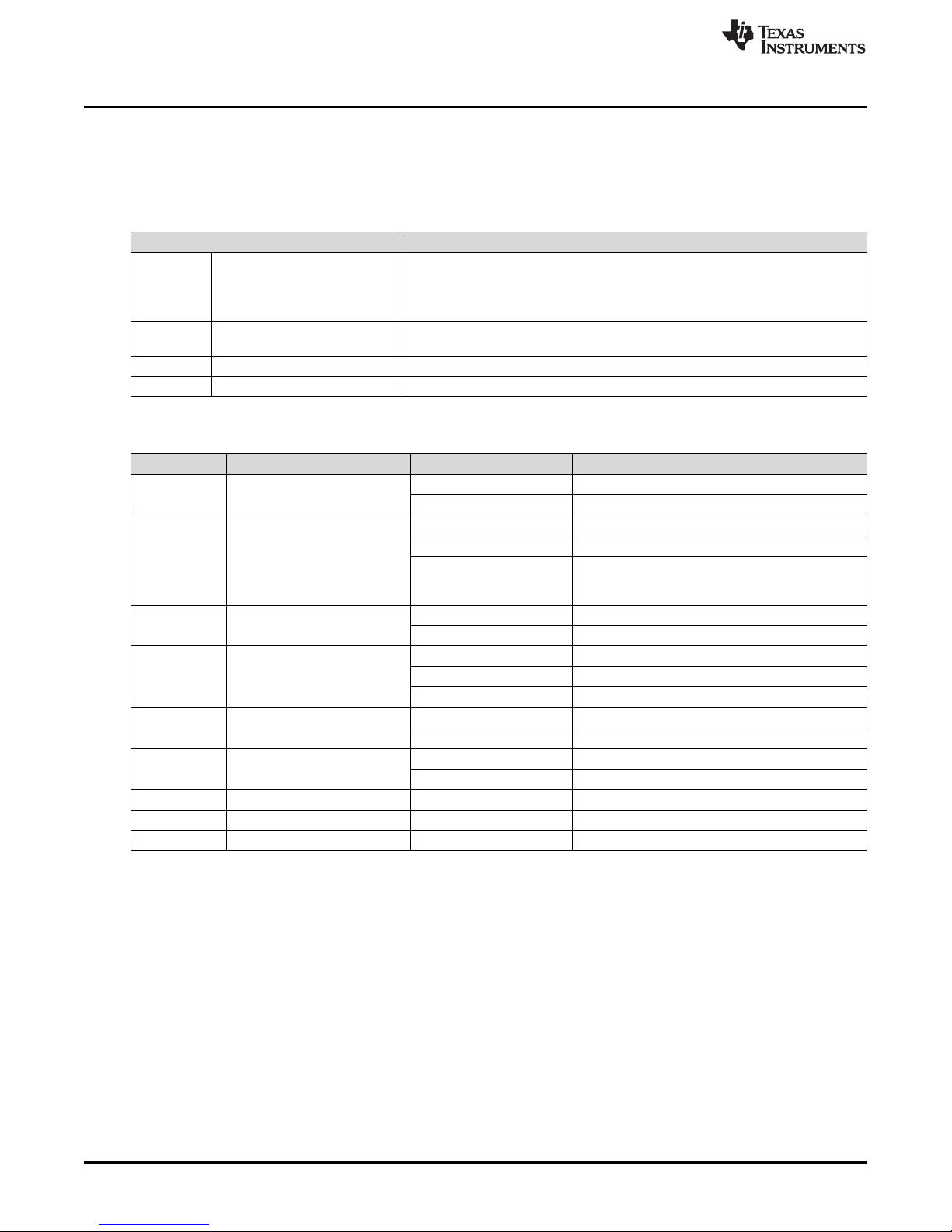

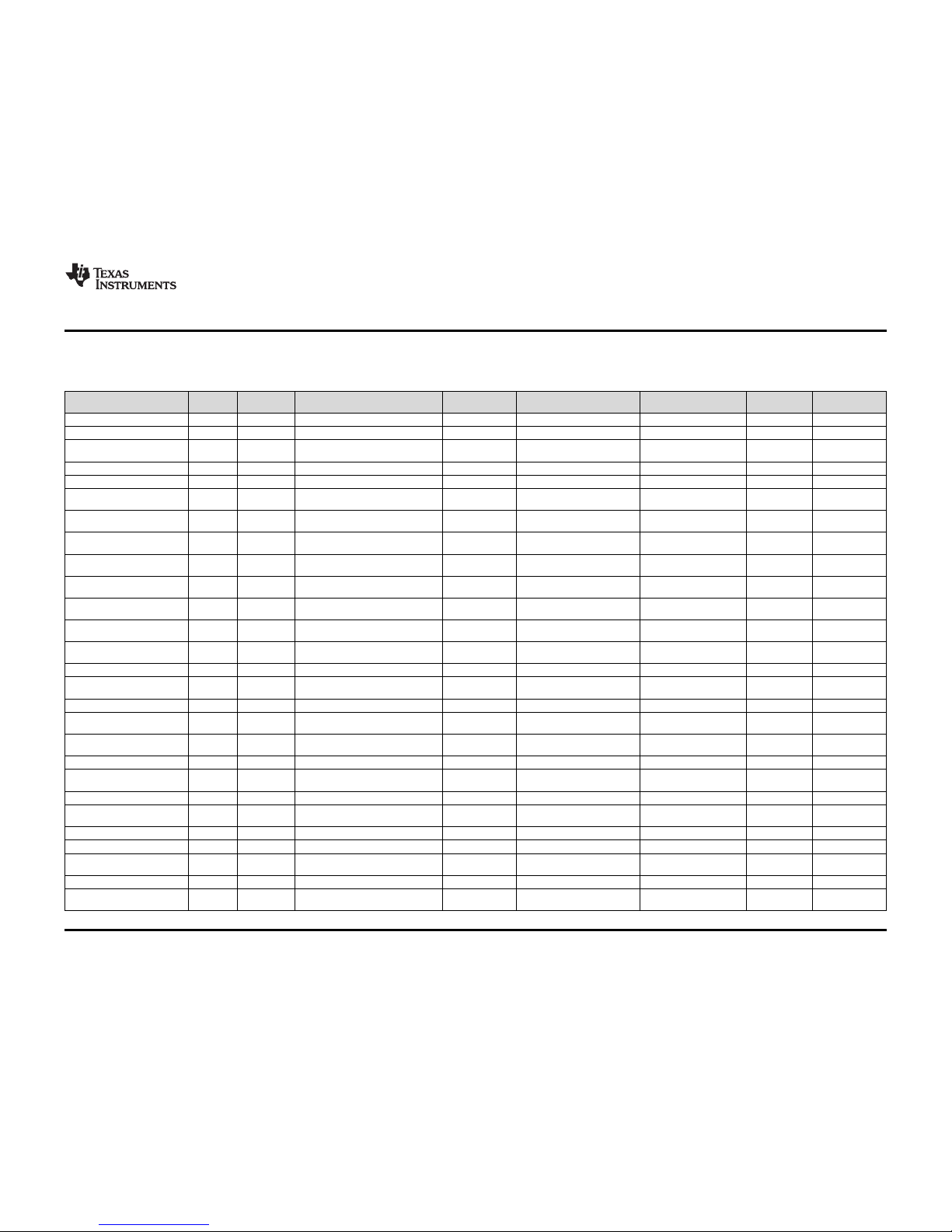

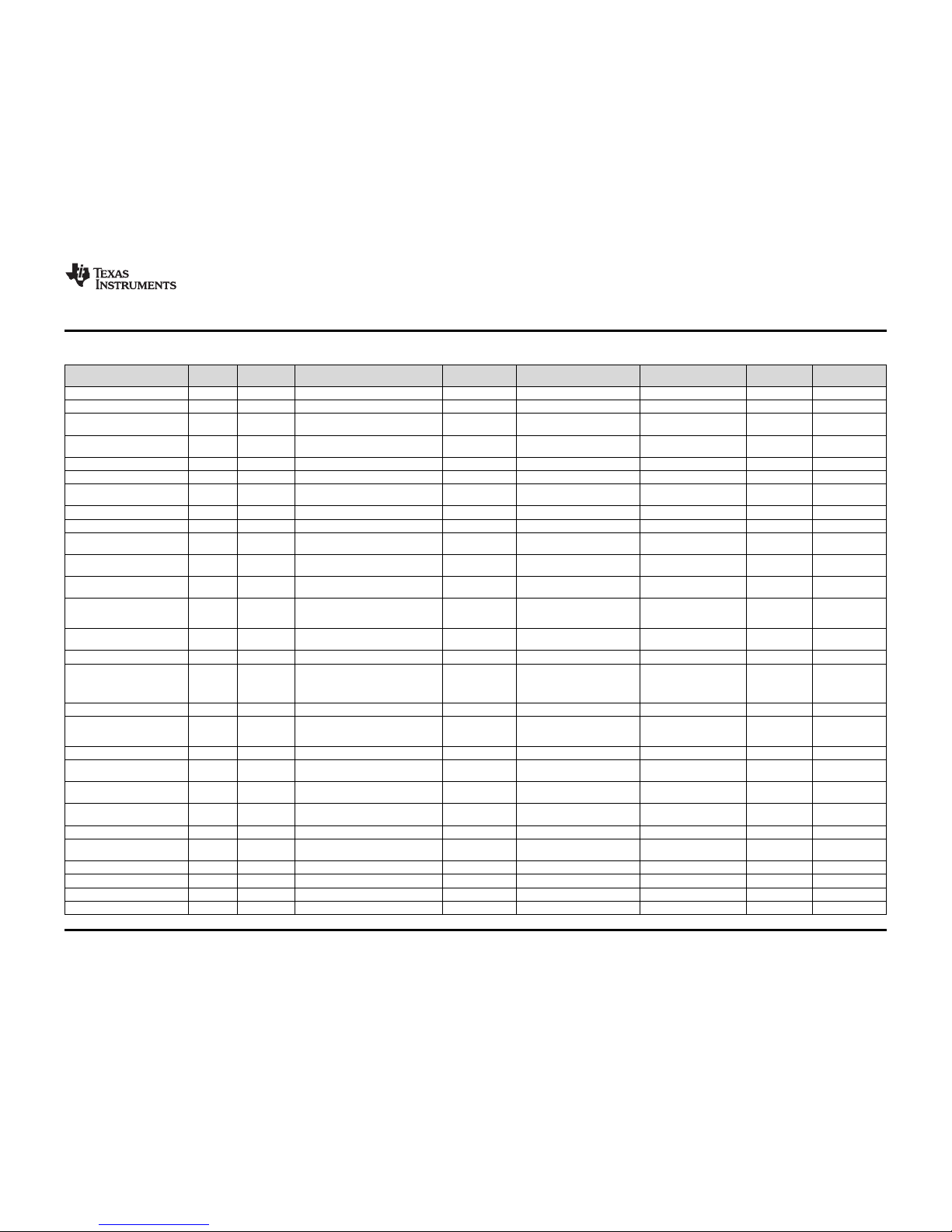

4.2 Bill of Materials

Table 3. BOM

Designator Quantity Value Description Package Reference Part Number Manufacturer

Alternate Part

Number

Alternate

Manufacturer

!PCB1 1 Printed Circuit Board HVL126 Any - C1, C2, C3 3 10µF CAP, TA, 10 µF, 25 V, ±10%, 0.3 Ω, SMD 6032-28 TPSC106K025R0300 AVX

C4, C5, C7, C9, C11 5 0.1µF

CAP, CERM, 0.1 µF, 50 V, ±10%, X7R,

0603

0603 C0603C104K5RACTU Kemet

C6 1 10µF CAP, TA, 10 µF, 50 V, ±10%, 0.3 Ω, SMD 7343-43 T495X106K050ATE300 Kemet

C8 1 1µF CAP, CERM, 1 µF, 25 V, ±10%, X5R, 0805 0805 08053D105KAT2A AVX

C12, C13 2 470pF

CAP, CERM, 470 pF, 50 V, ±5%,

C0G/NP0, 0603

0603 06035A471JAT2A AVX

C15, C16, C17, C18 4 1000pF

CAP, CERM, 1000 pF, 50 V, ±10%,

C0G/NP0, 0603

0603 06035A102KAT2A AVX

C19, C21 2 0.01µF

CAP, CERM, 0.01 µF, 25 V, ±5%,

C0G/NP0, 0603

0603 C0603H103J3GACTU Kemet

C24, C25 2 15pF

CAP, CERM, 15 pF, 50 V, ±5%, C0G/NP0,

0603

0603 C0603C150J5GACTU Kemet

C26 1 2200pF

CAP, CERM, 2200 pF, 25 V, ±10%, X7R,

0603

0603 GRM188R71E222KA01D MuRata

C27, C28 2 220pF

CAP, CERM, 220 pF, 50 V, ±5%,

C0G/NP0, 0603

0603 GRM1885C1H221JA01D MuRata

C29 1 0.47µF

CAP, CERM, 0.47 µF, 16 V, ±10%, X7R,

0603

0603 C0603C474K4RACTU Kemet

C30, C31, C33 3 0.1µF

CAP, CERM, 0.1 µF, 16 V, ±10%, X7R,

0603

0603 C0603C104K4RACTU Kemet

C32 1 1µF CAP, CERM, 1 µF, 16 V, ±10%, X7R, 0805 0805 C2012X7R1C105K TDK

C34 1 2.2µF

CAP, CERM, 2.2 µF, 10 V, ±10%, X7R,

0805

0805 C0805C225K8RACTU Kemet

C35 1 22µF CAP, AL, 22 µF, 10 V, ±20%, 1.35 Ω, SMD SMTRadial B EEE-FK1A220R Panasonic

C36 1 0.01µF

CAP, CERM, 0.01 µF, 16 V, ±10%, X7R,

0603

0603 GRM188R71C103KA01D MuRata

C37, C38 2 30pF

CAP, CERM, 30 pF, 50 V, ±5%, C0G/NP0,

0603

0603 GRM1885C1H300JA01D MuRata

D1 1 30V Diode, Schottky, 30 V, 1 A, SMA SMA B130L-13-F Diodes Inc.

D3, D12 2 Green LED, Green, SMD

LED,

2.3x1.4x1.5mm

LP M67K-D2G1-25-Z OSRAM

D4 1 Super Red LED, Super Red, SMD 2.2x1.3x1.4mm VLMS20J2L1-GS08 Vishay-Semiconductor

D5, D6, D9, D11 4 Yellow LED, Yellow, SMD

LED,

1.3x0.65x0.8mm

LY L29K-J1K2-26-Z OSRAM

D7 1 60V Diode, Schottky, 60V, 2A, SMB SMB MBRS260T3G ON Semiconductor

D8 1 20V Diode, Zener, 20V, 500 mW, SOD-123 SOD-123 MMSZ4707-V Vishay-Semiconductor

D10 1 5.6V Diode, Zener, 5.6 V, 5 W, SMB SMB SMBJ5339B-TP

Micro Commercial

Components

F1 1 Fuse, 1.5 A, 125 V, SMD SloBlo452 045201.5 Littelfuse

H1, H2, H3, H4 4

Machine Screw, Round, #4-40 x 1/4, Nylon,

Philips panhead

Screw NY PMS 440 0025 PH B&F Fastener Supply - -

Page 24

Schematics, Bill of Materials, and Layout

www.ti.com

24

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

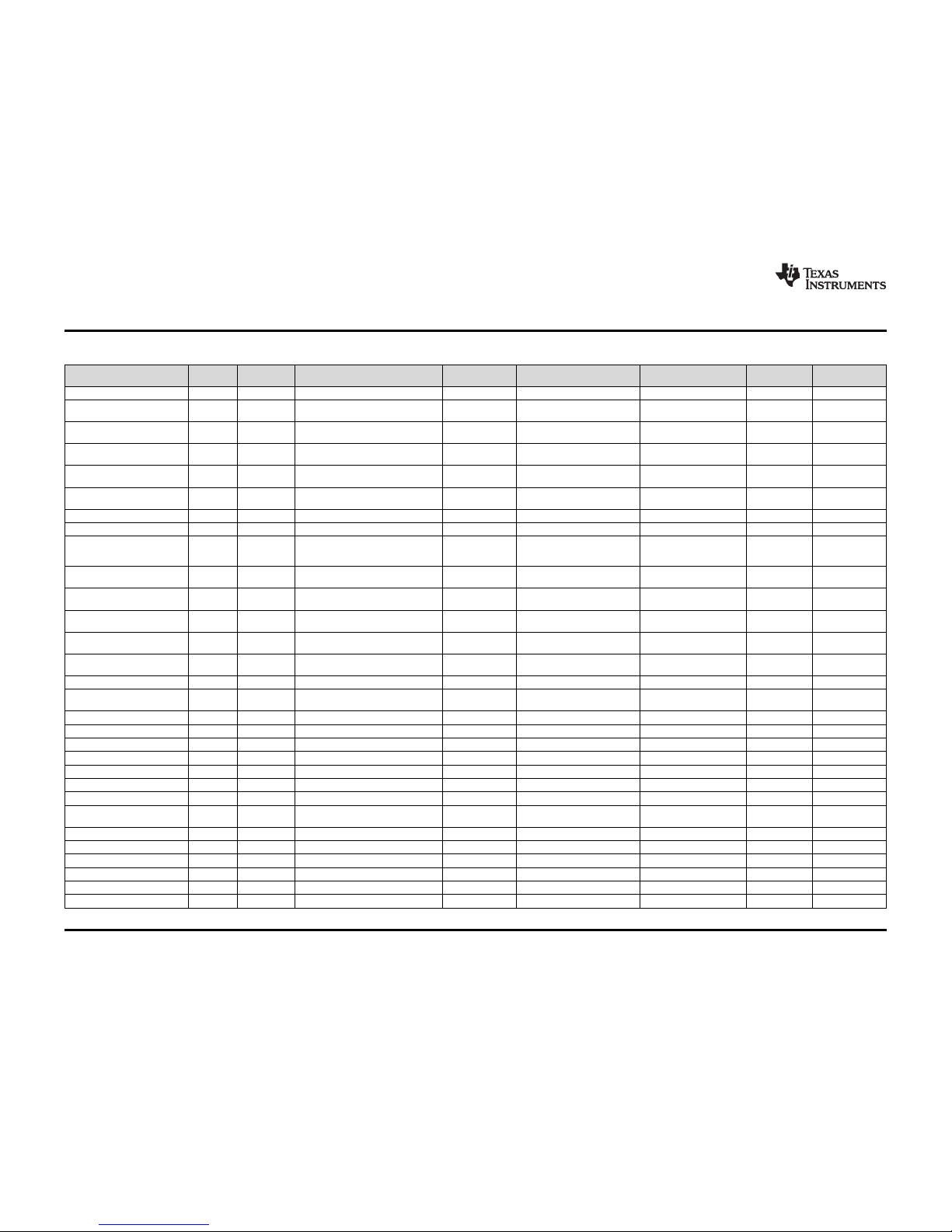

Table 3. BOM (continued)

Designator Quantity Value Description Package Reference Part Number Manufacturer

Alternate Part

Number

Alternate

Manufacturer

H5, H6, H7, H8 4 Standoff, Hex, 0.5"L #4-40 Nylon Standoff 1902C Keystone - J1 1 Header, 100mil, 2x1, Tin, TH

Header, 2x1,

100mil, TH

5-146278-2 TE Connectivity

J2 1 Header, 100mil, 3x1, Tin, TH

Header, 3x1,

100mil, TH

5-146278-3 TE Connectivity

J3, J5 2 Header, 100mil, 3x2, Tin, TH

Header, 100mil,

3x2, TH

5-146254-3 TE Connectivity

J4, J6, J7 3

Terminal Block, 6A, 3.5mm Pitch, 2-Pos,

TH

7.0x8.2x6.5mm ED555/2DS On-Shore Technology

J8, J10, J12 3 Header, 100mil, 7x2, Tin, TH

Header, 7x2,

100mil, Tin

PEC07DAAN Sullins Connector Solutions

J9 1 Connector, SMA Jack, Vertical, Gold, SMD SMA 142-0711-201 Emerson Network Power

J11 1 Header, 100mil, 15x2, Gold, TH 15x 2 Header MTSW-115-22-G-D-315 Samtec

J13 1 Header, 100mil, 6x1, Tin, TH

TH, 6-Leads, Body

608x100mil, Pitch

100mil

PEC06SAAN Sullins Connector Solutions

J14 1 Header, 100mil, 5x2, Tin, TH

Header, 5x2,

100mil, Tin

PEC05DAAN Sullins Connector Solutions

J15 1

Connector, Receptacle, Mini-USB Type B,

R/A, Top Mount SMT

USB Mini Type B 1734035-2 TE Connectivity

J17, J18, J19 3

Standard Banana Jack, Uninsulated,

5.5mm

Keystone_575-4 575-4 Keystone

L1 1 1000 Ω

Ferrite Bead, 1000 Ω at 100 MHz, 0.3 A,

0805

0805 BK2125HS102-T Taiyo Yuden

L2 1 56µH

Inductor, Shielded Drum Core, Ferrite,

56µH, 2A, 0.101 Ω, SMD

10x5x10mm 7447714560 Wurth Elektronik eiSos

L3 1 50 Ω Ferrite Bead, 50 Ω at 100MHz, 6A, 1206 1206 HI1206T500R-10 Laird-Signal Integrity Products

LBL1 1

Thermal Transfer Printable Labels, 0.650"

W x 0.200" H - 10,000 per roll

PCB Label 0.650"H

x 0.200"W

THT-14-423-10 Brady - -

Q1 1 30V MOSFET, N/P-CH, 30 V, 2.5 A, SSOT-6 SSOT-6 FDC6333C Fairchild Semiconductor None

R1, R13, R36, R76 4 0 RES, 0, 5%, 0.1 W, 0603 0603 RC0603JR-070RL Yageo America

R2, R11, R12 3 10.0k RES,10.0 k, 0.1%, 0.1 W, 0603 0603 RT0603BRD0710KL Yageo America

R3, R4, R5, R6, R7, R8, R45 7 1.2k RES, 1.2 k, 5%, 0.1 W, 0603 0603 RC0603JR-071K2L Yageo America

R9, R10 2 0 RES, 0, 5%, 0.333 W, 0805 0805 CRCW08050000Z0EAHP Vishay-Dale

R15, R33, R61, R65, R69 5 40.2k RES, 40.2 k, 0.1%, 0.1 W, 0603 0603 RT0603BRD0740K2L Yageo America

R16, R17 2 49.9k RES, 49.9 k, 1%, 0.1 W, 0603 0603 RC0603FR-0749K9L Yageo America

R18, R19, R20, R21, R25, R26,

R27, R28

8 30.0k RES, 30.0 k, 1%, 0.1 W, 0603 0603 RC0603FR-0730KL Yageo America

R29, R30 2 20.0k RES, 20.0 k, 0.1%, 0.1 W, 0603 0603 RT0603BRD0720KL Yageo America

R37, R38 2 10k RES, 10 k, 5%, 0.1 W, 0603 0603 RC0603JR-0710KL Yageo America

R44, R51, R52, R54, R55 5 4.7k RES, 4.7 k, 5%, 0.063 W, 0402 0402 CRCW04024K70JNED Vishay-Dale

R46, R47 2 33 RES, 33, 5%, 0.063 W, 0402 0402 CRCW040233R0JNED Vishay-Dale

R48 1 1.5k RES, 1.5 k, 5%, 0.063 W, 0402 0402 CRCW04021K50JNED Vishay-Dale

R49 1 100k RES, 100 k, 5%, 0.063 W, 0402 0402 CRCW0402100KJNED Vishay-Dale

Page 25

www.ti.com

Schematics, Bill of Materials, and Layout

25

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

Table 3. BOM (continued)

Designator Quantity Value Description Package Reference Part Number Manufacturer

Alternate Part

Number

Alternate

Manufacturer

R50 1 33k RES, 33 k, 5%, 0.063 W, 0402 0402 CRCW040233K0JNED Vishay-Dale

R53 1 1.2Meg RES, 1.2 M, 5%, 0.1 W, 0603 0603 CRCW06031M20JNEA Vishay-Dale

R56, R58, R60, R62, R64, R66,

R68, R70, R72, R74

10 200k RES, 200 k, 0.1%, 0.1 W, 0603 0603 RT0603BRD07200KL Yageo America

R57, R59, R63, R67, R71, R73,

R75

7 300k RES, 300 k, 0.1%, 0.1 W, 0603 0603 RG1608P-304-B-T5 Susumu Co Ltd

R78, R79 2 1.0k RES, 1.0 k, 5%, 0.1 W, 0603 0603 RC0603JR-071KL Yageo America

R80 1 0 RES, 0, 5%, 0.25 W, 1206 1206 RC1206JR-070RL Yageo America

S1 1 Switch, Slide, 4PDT,TH

Switch, 4P2T,

15x18x9.4 mm

1825264-1 TE Connectivity

S2, S3, S4 3 Switch, Tactile, SPST-NO, 0.1A, 16V, SMT 4.93x4.19x6.2 mm 7914G-1-000E Bourns

SH-J2, SH-J3, SH-J5, SH-J5 4 1x2 Shunt, 100mil, Gold plated, Black Shunt 969102-0000-DA 3M SNT-100-BK-G Samtec

TP65, TP66, TP67, TP85, TP86 5 Red Test Point, Miniature, Red, TH

Red Miniature

Testpoint

5000 Keystone

TP68, TP69, TP70, TP71, TP72,

TP73, TP74, TP75

8 Blue Test Point, Miniature, Blue, TH

Blue Miniature

Testpoint

5117 Keystone

TP76, TP77, TP78, TP79, TP80,

TP81, TP82, TP83, TP84

9 Black Test Point, Miniature, Black, TH

Black Miniature

Testpoint

5001 Keystone

U1 1

1-MHz, Micro-Power, Low-Noise, RRIO,1.8V CMOS OPERATIONAL AMPLIFIER

Precision Value Line Series, D0008A

D0008A OPA2313IDR Texas Instruments OPA2313ID Texas Instruments

U2 1

Dual 150mA, Low Iq LDO regulator,

DPQ0006A

DPQ0006A TLV7163318PDPQR Texas Instruments

TLV7163318PDP

QT

Texas Instruments

U3 1 PGA411PAP, PAP0064M PAP0064M PGA411PAP Texas Instruments None

U4, U5, U6, U7, U8 5

8-BIT DUAL-SUPPLY BUS TRANSCEIVER

with CONFIGURABLE VOLTAGE

TRANSLATION AND 3-STATE OUTPUT,

DGV0024A

DGV0024A SN74LVC8T245DGVR Texas Instruments TexasInstruments

U9 1 Mixed Signal MicroController, PN0080A PN0080A MSP430F5529IPN Texas Instruments None

U10 1

500mA, Low Quiescent Current, Ultra-Low

Noise, High PSRR Low-Dropout Linear

Regulator, DRB0008A

DRB0008A TPS73533DRB Texas Instruments None

Y1 1 Crystal, 20.000MHz, 8pF, SMD 3.2x0.75x2.5mm NX3225GA-20MHZ-STD-CRA-1 NDK

Y2 1 Crystal, 24.000MHz, 20pF, SMD

Crystal,

11.4x4.3x3.8mm

ECS-240-20-5PX-TR ECS Inc.

C10 0 0.01µF

CAP, CERM, 0.01 µF, 50 V, ±5%, X7R,

0805

0805 08055C103JAT2A AVX

C14, C20, C22, C23 0 51pF

CAP, CERM, 51 pF, 50 V, ±5%, C0G/NP0,

0603

0603 GRM1885C1H510JA01D MuRata

D2 0 5.1V Diode, Zener, 5.1 V, 500 mW, SOD-123 SOD-123 MMSZ5231B-7-F Diodes Inc.

FID1, FID2, FID3, FID4, FID5, FID6 0

Fiducial mark. There is nothing to buy or

mount.

N/A N/A N/A

R14 0 0 RES, 0, 5%, 0.333 W, 0805 0805 CRCW08050000Z0EAHP Vishay-Dale

R22, R23, R31, R32 0 100 RES, 100, 1%, 0.25 W, TH 1/4W Resistor CMF50100R00FHEB Vishay-Dale

R24, R34 0 4.99k RES, 4.99 k, 0.1%, 0.1 W, 0603 0603 RT0603BRD074K99L Yageo America

R35 0 50 RES,50, 1%, 0.1 W, 0603 0603 CRCW060350R0FKEA Vishay-Dale

Page 26

Schematics, Bill of Materials, and Layout

www.ti.com

26

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

Table 3. BOM (continued)

Designator Quantity Value Description Package Reference Part Number Manufacturer

Alternate Part

Number

Alternate

Manufacturer

R39, R40, R41, R42, R43 0 33

RES, 33, 5%, 0.0625 W, Resistor Array 8x1

Resistor Array - 8x1 EXB-2HV330JV Panasonic

R77 0 0 RES, 0, 5%, 0.1 W, 0603 0603 RC0603JR-070RL Yageo America

TP1, TP2, TP3, TP4, TP5, TP6,

TP7, TP8, TP9, TP10, TP11, TP12,

TP13, TP14, TP15, TP16, TP17,

TP18, TP19, TP20, TP21, TP22,

TP23, TP24, TP25, TP26, TP27,

TP28, TP29, TP30, TP31, TP32,

TP33, TP34, TP35, TP36, TP37,

TP38, TP39, TP40, TP41, TP42,

TP43, TP44, TP45, TP46, TP47,

TP48, TP49, TP50, TP51, TP52,

TP53, TP54, TP55, TP56, TP57,

TP58, TP59, TP60, TP61, TP62,

TP63, TP64

0 Black Test Point, Miniature, Black, TH

Black Miniature

Testpoint

5001 Keystone

Page 27

www.ti.com

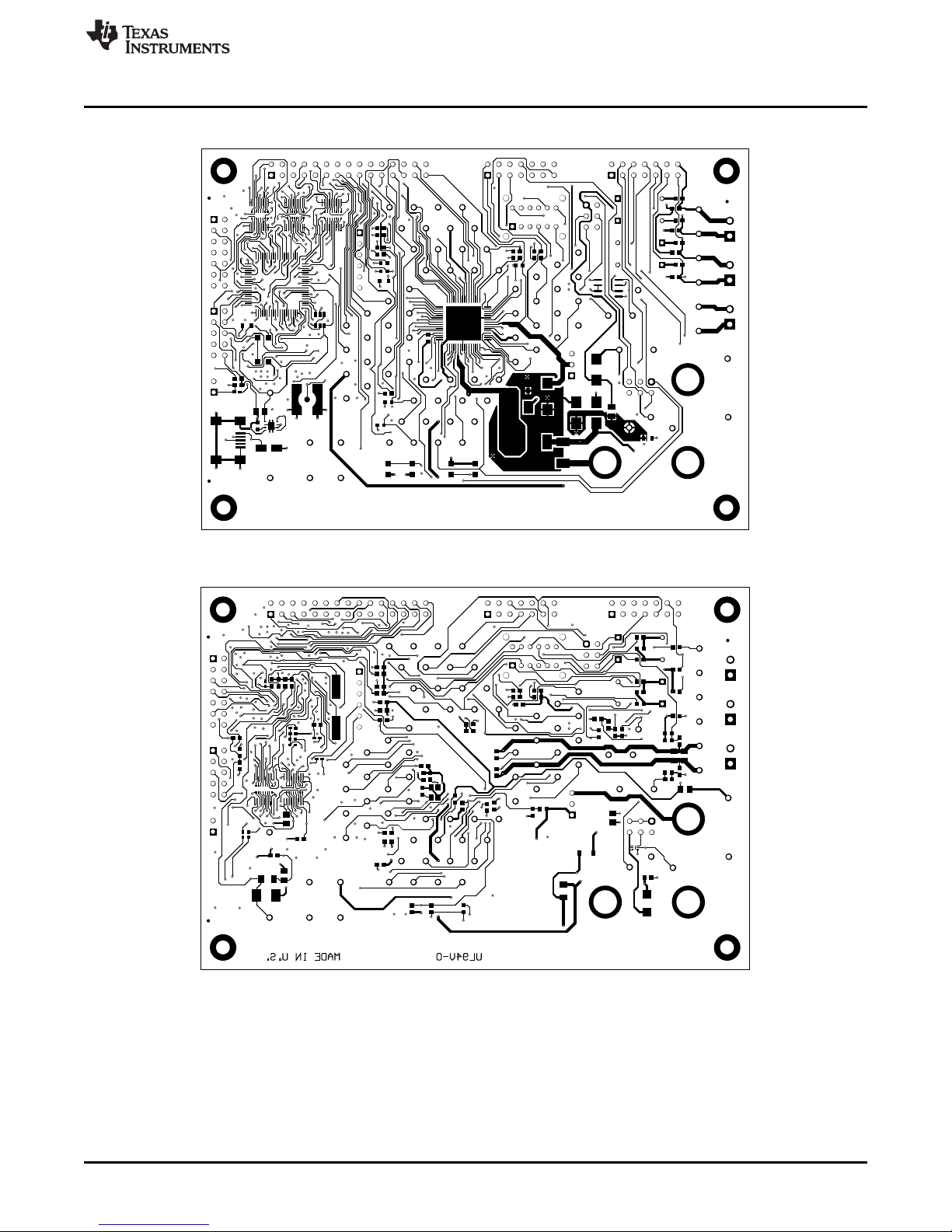

4.3 Layout and Component Placement

Schematics, Bill of Materials, and Layout

Figure 24. Top-Side Layout

Figure 25. Bottom-Side Layout

SLAU658–March 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

PGA411-Q1 EVM User's Guide

27

Page 28

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2016, Texas Instruments Incorporated

Page 29

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

PGA411Q1EVM

Loading...

Loading...