Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

)

查询PGA309供应商

PROGRAMMABLE SENSOR CONDITIONER

PGA309

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

Voltage Output

FEATURES

D COMPLETE BRIDGE SENSOR CONDITIONER

D VOLTAGE OUTPUT: Ratiometric or Absolute

D DIGITAL CAL: No Po tent io meters/ Sen so r Trims

D SENSOR ERROR COMPENSATION

− Span, Offset, and Temperature Drifts

D LOW ERROR, TIME-STABLE

D SENSOR LINEARIZATION CIRCUITRY

D TEMPERATURE SENSE: Internal or External

D CALIBRATION LOOKUP TABLE LOGIC

− Uses External EEPROM (SOT23-5)

D OVER/UNDER-SCALE LIMITING

D SENSOR FAULT DETECTION

D +2.7V TO +5.5V OPERATION

D −40°C to +125°C OPERATION

D SMALL TSSOP-16 PACKAGE

APPLICATIONS

D BRIDGE SENSORS

D REMOTE 4-20mA TRANSMITTERS

D STRAIN, LOAD, AND WEIGH SCALES

D AUTOMOTIVE SENSORS

EVALUATION TOOLS

D HARDWARE DESIGNER’S KIT (PGA309EVM)

− Temperature Eval of PGA309 + Sensor

− Full Programming of PGA309

− Sensor Compensation Analysis Tool

P

psi

0

50

No nlinear

Bridge

Transducer

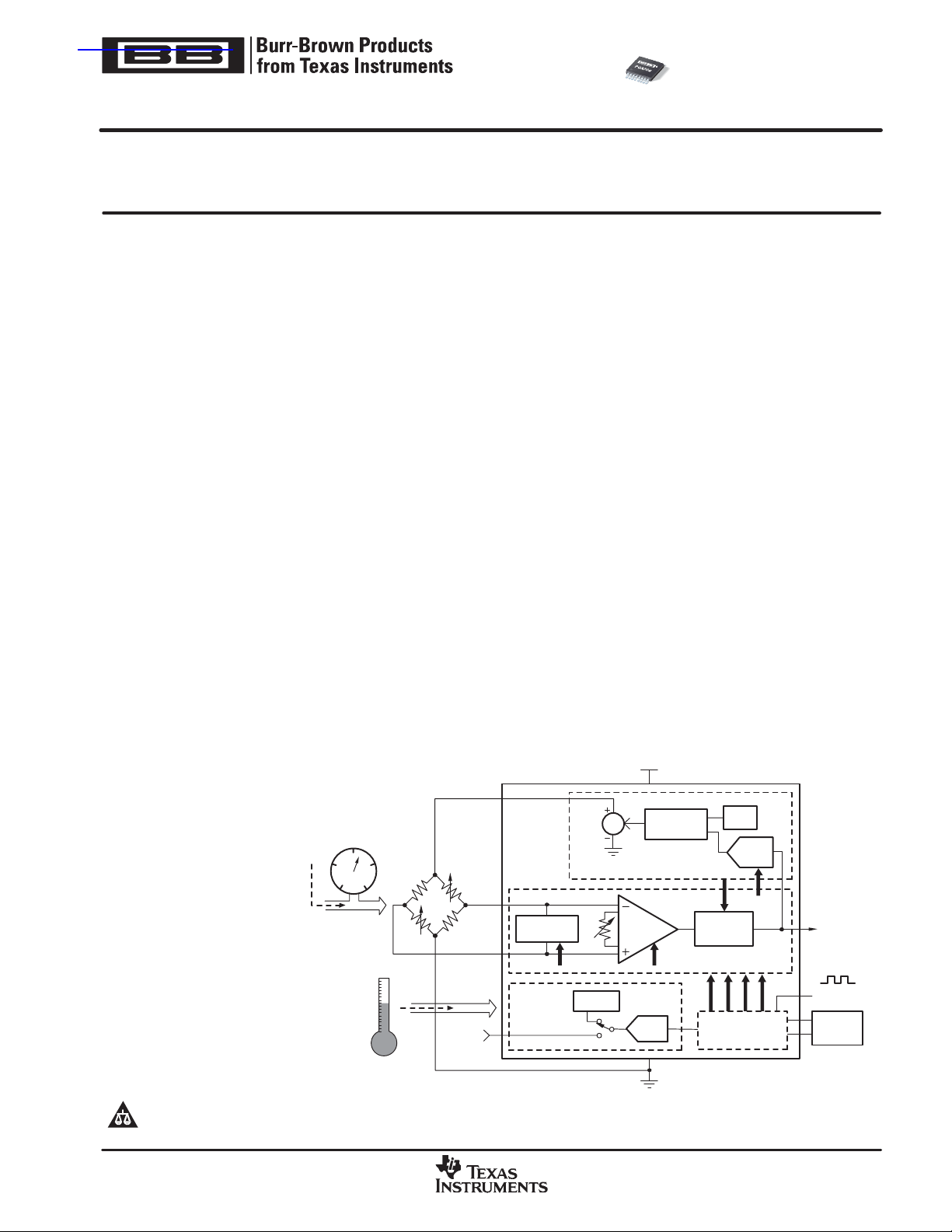

DESCRIPTION

The PGA309 is a programmable a nalog s ignal c onditioner

designed for bridge sensors. The analog signal path amplifies the sensor signal and provides digital calibration for

zero, span, zero drift, span drift, and sensor linearization

errors with a ppl ie d s tress ( pre ssure , strain, e tc.). The calibration is done via a One-Wire digital serial interfac e or

through a Two-Wire industry-standard connection. The

calibration paramet ers are stored in external nonvolatile

memory (typically SOT23-5) to eliminate manual trimming

and achieve long-term st ability.

The all-analog signal path contains a 2x2 input m ultiplexer (mux), auto-zero programmable-gain instrum entation

amplifier, linearization circuit, voltage refer ence, internal

oscillator, control logic, and an output amplifier. Programmable level shifting compens ates for sensor DC offsets.

The core of the PGA309 is the precision, low-drift, no 1/f

noise Front-End PGA (Programmable Gain Amplifier).

The overall gain of the Front-End PGA + Output Amplifier

can be adjusted from 2.7V/V to 1152V/V. The polarity of

the inputs can be switched through the input mux to accommodate sens ors with unknown polarity output. The

Fault Monit or cir cuit detects and signals sens or burnout,

overload, and syst em fault condit ions .

For deta iled applic at ion infor ma tion, s ee t he PGA309

User’s Gui de (SBO U024), avai lable for dow nload at

www.ti.c om .

V

PGA309

EXC

Analog Sensor Linearization

V

S

Linearization

Circuit

Ref

Lin DAC

Fault

Monitor

+125_ C

Digital

T

−40_C

semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

! !

Ext Temp

www.ti.com

Temperature

Compensation

ExtTemp

Auto−Zero

PGA

IntTemp

Temp

ADC

Copyright 2003−2004, Texas Instruments Incorporated

Over/Under

Scale Limiter

AnalogSignalConditioning

Control Register

Interface Circuitry

Linear

V

OUT

DigitalCal

EEPROM

(SOT23−5

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

www.ti.com

(1)

−0.3V to VSA +0.3V. . . . . . . . . . . . . . . . . . . . .

(1)

TEMPERATURE

+7.0V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±150mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFIED

RANGE

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

PACKAGE/ORDERING INFORMATION

PACKAGE

PRODUCT PACKAGE−LEAD

PGA309 TSSOP-16 PW −40°C to +125°C PGA309

(1)

For the most current package and ordering information, refer to our web site at www.ti.com.

DRAWING

ABSOLUTE MAXIMUM RATINGS

Over operating free-air temperature range unless otherwise noted.

Supply Voltage, VSD, V

Input Voltage, V

Input Current, VFB, V

Input Current ±10mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Current Limit 50mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Temperature Range −60°C to +150°C. . . . . . . . . . . . . . . . . . . . . . . .

Operating Temperature Range −55°C to +150°C. . . . . . . . . . . . . . . . . . . . . .

Junction Temperature +150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead Temperature (soldering, 10s) +300°C. . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD Protection (Human Body Model) 4kV. . . . . . . . . . . . . . . . . . . . . . . . . . .

(1)

Stresses above these ratings may cause permanent damage.

IN1

, V

SD

IN2

OUT

(2)

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only , an d

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(2)

Input terminals are diode-clamped to the power-supply rails.

Input signals that can swing more than 0.5V beyond the supply

rails should be current limited to 10mA or less.

PACKAGE

MARKING

ORDERING

NUMBER

PGA309AIPWR Tape and Reel, 2500

PGA309AIPWT Tape and Reel, 250

TRANSPORT MEDIA,

QUANTITY

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

2

"#$%

www.ti.com

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

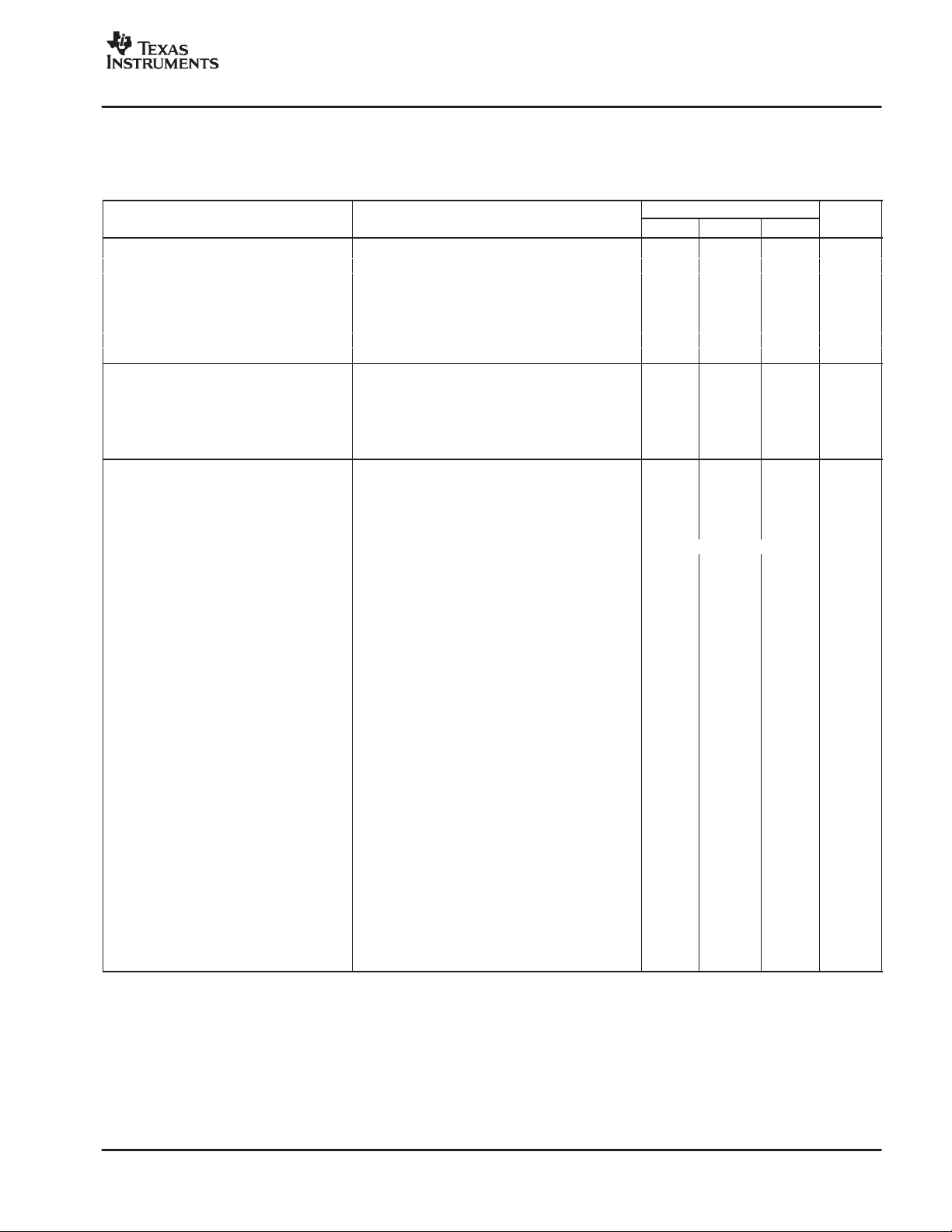

ELECTRICAL CHARACTERISTICS

BOLDFACE limits apply over the specified temperature range: TA = −40°C to +125°C

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

FRONT-END PGA + OUTPUT AMPLIFIER

V

V

V

V

V

External Sensor Output Sensitivity VSA = VSD = V

FRONT-END PGA

Auto-Zero Internal Frequency 7 kHz

Offset Voltage (RTI)

Linear Input Voltage Range

Input Bias Current 0.1 1.5 nA

Input Impedance: Differential 30 || 6 GΩ || pF

Input Impedance: Common-Mode 50 || 20 GΩ || pF

Input Voltage Noise 0.1Hz to 10Hz, GF = 128 4 µV

PGA Gain

Output Voltage Range 0.05 to VSA − 0.1 V

Bandwidth Gain = 4 400 kHz

COARSE OFFSET ADJUST

(RTI OF FRONT-END PGA)

Range ±(14)(V

Resolution ±14 steps, 4-Bit + Sign 4 mV

FINE OFFSET ADJUST (ZERO DAC)

(RTO of the Front-End PGA)

Programming Range 0 V

Output Range 0.1 VSA−0.1 V

Resolution 65,536 steps, 16-Bit DAC 73 µV

Integral Nonlinearity 20 LSB

Differential Nonlinearity 0.5 LSB

Gain Error 0.1 %

Gain Error Drift 10 ppm/°C

Offset 5 mV

Offset Drift 10 µV/°C

OUTPUT FINE GAIN ADJUST (GAIN DAC)

Range 0.33 to 1 V/V

Resolution 65,536 steps, 16-Bit DAC 10 µV/V

Integral NonLinearity 20 LSB

Differential NonLinearity 0.5 LSB

Differential Signal Gain Range

OUT/VIN

Slew Rate 0.5 V/µs

OUT

Settling Time (0.01%) V

OUT

Settling Time (0.01%) V

OUT

Nonlinearity 0.002 %FSR

OUT

(2)

vs Temperature +0.2 µV/°C

vs Supply Voltage, V

vs Common-Mode Voltage GF = Front-End PGA Gain 1500/GF6000/G

Gain Range Steps 4, 8, 16, 23.27, 32, 42.67, 64, 128 4 to 128 V/V

Initial Gain Error GF = 4 to 42 0.2 ±1 %

vs Temperature 10 ppm/°C

vs Temperature 0.004 %/°C

SA

SUPPLY ANALOG

(1)

(3)

(2)

, VSD = V

SUPPLY DIGITAL

Front-End PGA Gains: 4, 8, 16, 23.27, 32, 42.67, 64, 128

Output Amplifier Gains: 2, 2.4, 3, 3.6, 4.5, 6, 9

OUT/VIN

OUT/VIN

Fine Gain Adjust = 1

Differential Gain = 8, RL = 5kΩ || 200pF 6 µs

Differential Gain = 191, RL = 5kΩ || 200pF 4.1 µs

Coarse Offset Adjust Disabled ±3 ±50 µV

; VSA must equal VSD), GNDD = GNDA = 0, and V

= +5V 1 to 245 mV/V

EXC

GF = 64 0.25 ±1.2 %

GF = 128 0.3 ±1.6 %

Gain = 128 60 kHz

)(0.00085) ±56 ±59.5 ±64 mV

REF

= REFIN/REF

REF

PGA309

8 to 1152 V/V

±2 µV/V

0.2 VSA−1.5 V

REF

OUT

µV/V

F

= +5V ,

PP

V

3

"#$%

www.ti.com

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

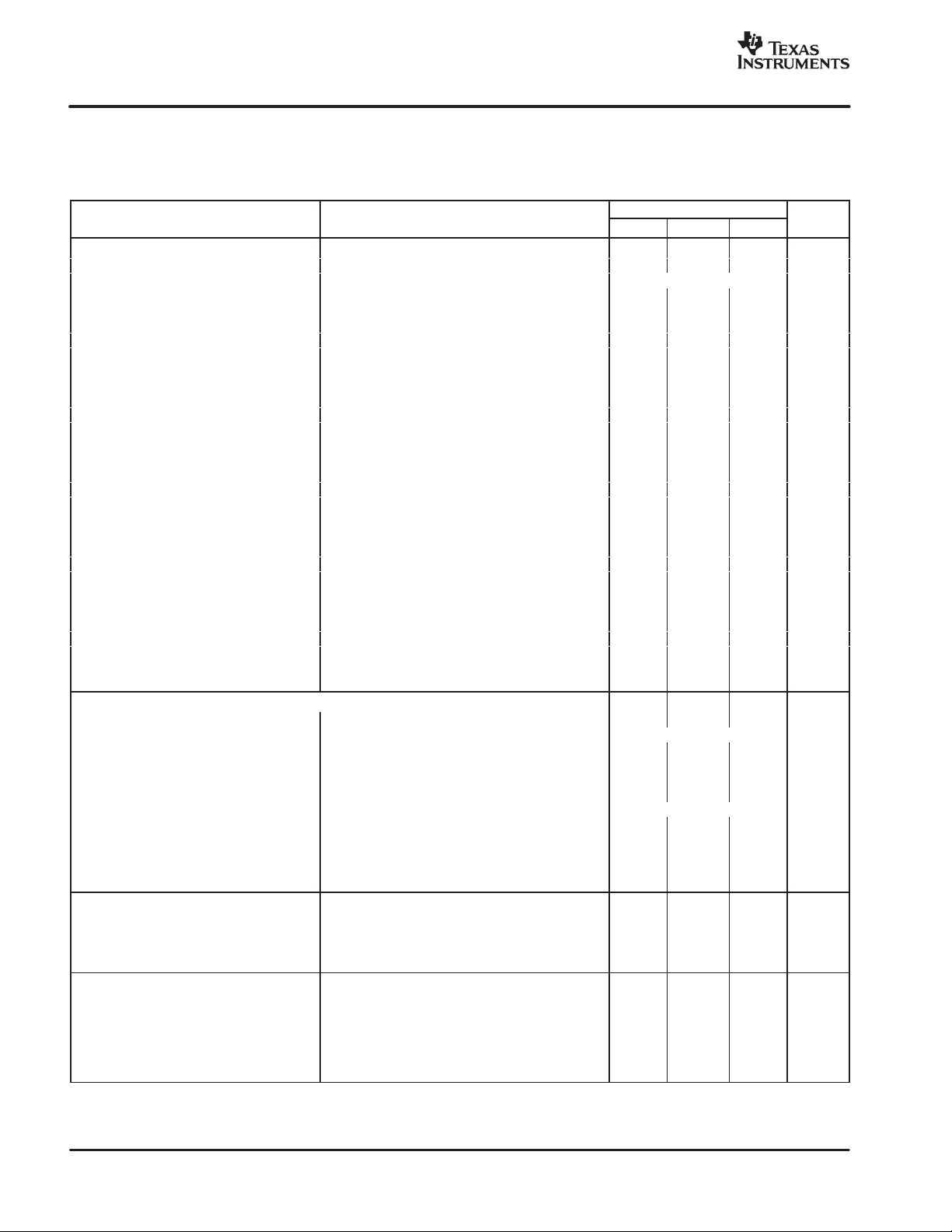

ELECTRICAL CHARACTERISTICS (continued)

BOLDFACE limits apply over the specified temperature range: TA = −40°C to +125°C

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

PARAMETER UNITSMAXTYPMINCONDITIONS

OUTPUT AMPLIFIER

Offset Voltage (RTI of Output Amplifier)

vs Temperature 5 µV/°C

vs Supply Voltage, V

Common-Mode Input Range 0 VSA−1.5 V

Input Bias Current 100 pA

Amplifier Internal Gain

Gain Range Steps 2, 2.4, 3, 3.6, 4.5, 6, 9 2 to 9 V/V

Initial Gain Error 2, 2.4, 3.6 0.25 ±1 %

vs Temperature 2, 2.4, 3.6 5 ppm/°C

Output Voltage Range

Open Loop Gain 115 dB

Gain-Bandwidth Product 2 MHz

Phase Margin Gain = 2, CL = 200pF 45 Degrees

Output Resistance AC Small-Signal, Open-Loop, f = 1MHz, IO = 0 675 Ω

OVER- AND UNDER-SCALE LIMITS (V

Over-Scale Thresholds Ratio of V

Over-Scale Comparator Offset +6 +60 +114 mV

Over-Scale Comparator Offset Drift +0.37 mV/°C

Under-Scale Thresholds Ratio of V

Under-Scale Comparator Offset −7 −50 +93 mV

Under-Scale Comparator Offset Drift −0.15 mV/°C

FAULT MONITOR CIRCUIT

INP_HI, INN_HI Comparator Threshold See Note 5 VSA−1.2 or V

INP_LO, INN_LO Comparator Threshold 40 100 mV

A1SAT_HI, A2SAT_HI Comparator Threshold VSA−0.12 V

A1SAT_LO, A2SAT_LO Comparator Threshold VSA−0.12 V

A3_VCM Comparator Threshold VSA−1.2 V

Comparator Hysteresis 20 mV

SA

(4)

SUPPLY ANALOG

(2)

, VSD = V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

Ratio of V

SUPPLY DIGITAL

, Register 5—Bits D5, D4, D3 = ‘000’ 0.9708

REF

, Register 5—Bits D5, D4, D3 = ‘001’ 0.9610

REF

, Register 5—Bits D5, D4, D3 = ‘010’ 0.9394

REF

, Register 5—Bits D5, D4, D3 = ‘011’ 0.9160

REF

, Register 5—Bits D5, D4, D3 = ‘100’ 0.9102

REF

, Register 5—Bits D5, D4, D3 = ‘101’ 0.7324

REF

, Register 5—Bits D5, D4, D3 = ‘110’ 0.5528

REF

, Register 5—Bits D2, D1, D0 = ‘111’ 0.0605

REF

, Register 5—Bits D2, D1, D0 = ‘110’ 0.0547

REF

, Register 5—Bits D2, D1, D0 = ‘101’ 0.0507

REF

, Register 5—Bits D2, D1, D0 = ‘100’ 0.0449

REF

, Register 5—Bits D2, D1, D0 = ‘011’ 0.0391

REF

, Register 5—Bits D2, D1, D0 = ‘010’ 0.0352

REF

, Register 5—Bits D2, D1, D0 = ‘001’ 0.0293

REF

, Register 5—Bits D2, D1, D0 = ‘000’ 0.0254

REF

; VSA must equal VSD), GNDD = GNDA = 0, and V

4.5 0.3 ±1.2 %

6 0.4 ±1.5 %

9 0.6 ±2.0 %

4.5 5 ppm/°C

6 15 ppm/°C

9 30 ppm/°C

RL = 10kΩ 0.1 4.9 V

= 4.096)

REF

= REFIN/REF

REF

PGA309

3 mV

30 µV/V

−0.1 V

EXC

OUT

= +5V ,

4

"#$%

www.ti.com

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

ELECTRICAL CHARACTERISTICS (continued)

BOLDFACE limits apply over the specified temperature range: TA = −40°C to +125°C

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

PARAMETER UNITSMAXTYPMINCONDITIONS

INTERNAL VOLTAGE REFERENCE

V

REF1

V

Drift vs Temperature +10 ppm/°C

REF1

V

REF2

V

Drift vs Temperature +10 ppm/°C

REF2

Input Current REFIN/REF

Output Current REFIN/REF

OUT

OUT

TEMPERATURE SENSE CIRCUITRY (ADC)

Internal Temperature Measurement Register 6, Bit D9 = 1

Accuracy ±2 °C

Resolution 12-Bit + Sign, Two’s Complement Data Format ±0.0625 °C

Temperature Measurement Range −55 +150 °C

Conversion Rate R1, R0 = ‘11’, 12-Bi t + Sign Resolu tion 24 ms

TEMPERATURE ADC

External Temperature Mode Temp PGA + Temp ADC

Gain Range Steps G

Analog Input Voltage Range GND−0.2 VSA+0.2 V

Temperature ADC Internal REF (2.048V) Register 6, Bit D8 = 1

Full-Scale Input Voltage (+Input) − (−Input) ±2.048/G

Differential Input Impedance 2.8/G

Common-Mode Input Impedance G

Resolution R1, R0 = ‘00’, ADC2X = ‘0’, Conversion Time = 8ms 11 Bits + Sign

Integral Nonlinearity 0.004 %

Offset Error G

Offset Drift G

Offset vs V

SA

Gain Error 0.05 0.50 %

Gain Error Drift 5 50 ppm/°C

Noise All Gains < 1 LSB

Gain vs V

Common-Mode Rejection At DC and G

SA

, VSD = V

SUPPLY DIGITAL

; VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

OUT

PGA309

Register 3, Bit D9 = 1 2.46 2.5 2.53 V

Register 3, Bit D9 = 0 4.0 4.096 4.14 V

Internal V

VSA > 2.7V for V

VSA > 4.3V for V

Disabled 100 µA

REF

= 2.5V 1 mA

REF

= 4.096V 1 mA

REF

= 1, 2, 4, 8 1 to 8 V/V

PGA

PGA

= 1 3.5 MΩ

PGA

G

= 2 3.5 MΩ

PGA

G

= 4 1.8 MΩ

PGA

G

= 8 0.9 MΩ

PGA

PGA

MΩ

R1, R0 = ‘01’, ADC2X = ‘0’, Conversion Time = 32ms 13 Bits + Sign

R1, R0 = ‘10’, ADC2X = ‘0’, Conversion Time = 64ms 14 Bits + Sign

R1, R0 = ‘11’, ADC2X = ‘0’, Conversion Time = 128ms 15 Bits + Sign

= 1 1.2 mV

PGA

G

= 2 0.7 mV

PGA

G

= 4 0.5 mV

PGA

G

= 8 0.4 mV

PGA

= 1 1.2 µV/°C

PGA

G

= 2 0.6 µV/°C

PGA

G

= 4 0.3 µV/°C

PGA

G

= 8 0.3 µV/°C

PGA

G

= 1 800 µV/V

PGA

G

= 2 400 µV/V

PGA

G

= 4 200 µV/V

PGA

G

= 8 150 µV/V

PGA

80 ppm/V

= 8 105 dB

At DC and G

PGA

= 1 100 dB

PGA

= +5V ,

V

5

"#$%

www.ti.com

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

ELECTRICAL CHARACTERISTICS (continued)

BOLDFACE limits apply over the specified temperature range: TA = −40°C to +125°C

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

PARAMETER UNITSMAXTYPMINCONDITIONS

TEMPERATURE ADC (CONTINUED)

Temp ADC Ext. REF (V

Full-Scale Input Voltage (+Input) − (−Input) ±V

REFT

= V

REF

, V

, or VSA) Register 6, Bit D8 = 0

EXC

Differential Input Impedance 2.4/G

Common-Mode Input Impedance G

Resolution R1, R0 = ‘00’, ADC2X = ‘0’, Conversion Time = 6ms 11 Bits + Sign

Integral Nonlinearity 0.01 %

Offset Error G

Offset Drift G

Gain Error −0.2 %

Gain Error Drift 2 ppm/°C

Gain vs V

Common-Mode Rejection At DC and G

External Temperature Current Excitation I

Current Excitation 5.8 7 8 µA

SA

TEMP

Temperature Drift 5 nA/°C

Voltage Compliance VSA−1.2 V

LINEARIZATION ADJUST AND EXCITATION VOLTAGE (V

Range 0 Register 3, Bit D11 = 0

Linearization DAC Range With Respect to V

Linearization DAC Resolution ±127 Steps, 7-Bit + Sign 1.307 mV/V

V

Gain With Respect to V

EXC

Gain Error Drift 25 ppm/°C

Range 1 Register 3, Bit D11 = 1

Linearization DAC Range With Respect to V

Linearization DAC Resolution ±127 Steps, 7-Bit + Sign 0.9764 mV/V

V

Gain With Respect to V

EXC

Gain Error Drift 25 ppm/°C

V

Range Upper Limit I

EXC

I

EXC SHORT

DIGITAL INTERFACE

Two-Wire Compatible Bus Speed 1 400 kHz

One-Wire Serial Speed Baud Rate 4.8K 38.4K Bits/s

Maximum Lookup Table Size

(6)

Two-Wire Data Rate PGA309 to EEPROM (SCL frequency) 65 kHz

LOGIC LEVELS

Input Levels (SDA, SCL, PRG, TEST) Low 0.2 • V

(SDA, SCL, PRG, TEST) High 0.7 • V

(SDA, SCL) Hysteresis 0.1 • V

Pull-Up Current Source (SDA, SCL) 55 85 125 µA

Pull-Down Current Source (TEST) 15 25 40 µA

Output LOW Level (SDA, SCL, PRG) Open Drain, I

, VSD = V

SUPPLY DIGITAL

; VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

OUT

PGA309

REFT/GPGA

= 1 8 MΩ

PGA

G

= 2 8 MΩ

PGA

G

= 4 8 MΩ

PGA

G

= 8 8 MΩ

PGA

PGA

R1, R0 = ‘01’, ADC2X = ‘0’, Conversion Time = 24ms 13 Bits + S ign

R1, R0 = ‘10’, ADC2X = ‘0’, Conversion Time = 50ms 14 Bits + S ign

R1, R0 = ‘11’, ADC2X = ‘0’, Conversion Time = 100ms 15 Bits + Sign

= 1 2.5 mV

PGA

G

= 2 1.25 mV

PGA

G

= 4 0.7 mV

PGA

G

= 8 0.3 mV

PGA

= 1 1.5 µV/°C

PGA

G

= 2 1.0 µV/°C

PGA

G

= 4 0.7 µV/°C

PGA

G

= 8 0.6 µV/°C

PGA

80 ppm/V

= 8 100 dB

At DC and G

PGA

= 1 85 dB

PGA

Register 6, Bit D11 = 1

)

EXC

−0.166 to +0.166 V/V

0.83 V/V

−0.124 to +0.124 V/V

0.52 V/V

Short-Circuit V

EXC

FB

REF

FB

REF

= 5mA VSA − 0.5 V

Output Current 50 mA

EXC

17 x 3 x 16 Bits

SD

SD

SD

= 5mA 0.4 V

SINK

= +5V ,

V

MΩ

V

V

V

6

"#$%

www.ti.com

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

ELECTRICAL CHARACTERISTICS (continued)

BOLDFACE limits apply over the specified temperature range: TA = −40°C to +125°C

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

PARAMETER UNITSMAXTYPMINCONDITIONS

POWER SUPPL Y

VSA, V

SD

ISA + ISD, Quiescent Current VSA = VSD = +5V, without Bridge Load 1.2 1.6 mA

POWER-ON RESET

Power-Up Threshold VSA Rising 2.2 2.7 V

Power-Down Threshold VSA Falling 1.7 V

TEMPERATURE RANGE

Specified Performance −40 +125 °C

Operational − Degraded Performance −55 +150 °C

(1)

PGA309 total dif ferential gain from i nput ( V

(2)

RTI = referred to input. RTO = referred to output.

(3)

Linear input range is the allowed min/max voltage on the V

common-mode and differential voltage is dependent upon gain and offset settings. Refer to the Gain Scaling section for more information.

(4)

Unless limited by over/under-scale setting.

(5)

When V

selector circuit uses V

monitoring in conditions where V

(6)

Lookup Table allows multislope compensation over temperature. Lookup Table has access to 17 calibration points consisting of 3 adjustment

is enabled, a minimum reference selector circuit becomes the reference for the comparator threshold. This minimum reference

EXC

EXC

SUPPLY ANALOG

− 100mV and VSA − 1.2V and compares the V

might be higher or lower than the input CMR of the PGA input amplifier relative to VSA.

EXC

values (Tx, Temperature, ZMx, Zero DAC, GMx, Gain DAC) that are stored in 16-bit data format (17x3x16 = Lookup Table size).

IN1−VIN2

, VSD = V

SUPPLY DIGITAL

) to output ( V

IN1

OUT

and V

; VSA must equal VSD), GNDD = GNDA = 0, and V

2.7 5.5 V

). V

/ (V

OUT

IN1−VIN2

pins for the input PGA to continue to operate in a linear region. The allowed

IN2

pin to the lower of the two references. This ensures accurate fault

INX

) = ( Front-End P GA gain) ( Output Amplifier gain) ( Gain D AC).

REF

PGA309

= REFIN/REF

OUT

= +5V ,

7

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

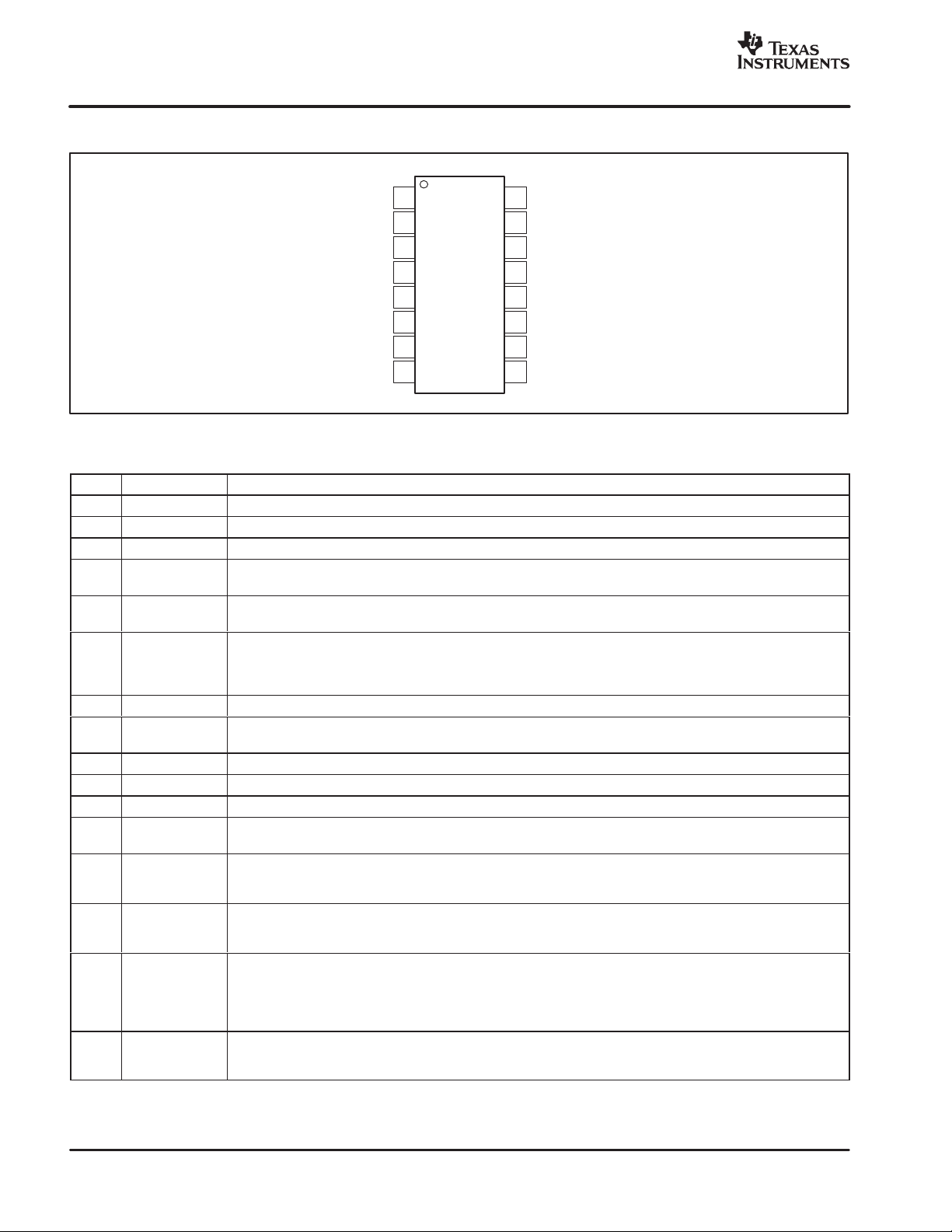

PIN CONFIGURATION

www.ti.com

Top View

V

GND

V

V

V

V

V

V

EXC

OUT

1

2

A

3

SA

4

IN1

IN2

FB

PGA309

5

6

7

8

SJ

16

15

14

13

12

11

10

9

REFIN/REF

TEMP

IN

SDA

SCL

PRG

GND

D

V

SD

TEST

OUT

PIN DESCRIPTION

PIN

NAME DESCRIPTION

1 V

EXC

2 GND

3 V

4 V

5 V

6 V

7 V

8 V

A

SA

IN1

IN2

FB

OUT

SJ

9 TEST Test/External Controller Mode pin. Pull to GNDD in normal mode.

10 V

SD

11 GND

D

12 PRG Single-wire interface program pin. UART-type interface for digital calibration of the PGA309 over a single wire. Can be

13 SCL Clock input/output for Two-Wire, industry-standard compatible interface for reading and writing digital calibration and

14 SDA Data input/output for Two-Wire, industry-standard compatible interface for reading and writing digital calibration and

15 TEMP

16 REFIN/REF

IN

OUT

Bridge sensor excitation. Connect to bridge if linearization and/or internal reference for bridge excitation is to be used.

Analog ground. Connect to analog ground return path for VSA. Should be same as GNDD.

Analog voltage supply. Connect to analog voltage supply. To be within 200mV of VSD.

Signal input voltage 1. Connect to + or – output of sensor bridge. Internal multiplexer can change connection internally to

Front-End PGA.

Signal input voltage 2. Connect to + or – output of sensor bridge. Internal multiplexer can change connection internally to

Front-End PGA.

V

feedback pin. Voltage feedback sense point for over/under-scale limit circuitry. When internal gain set resistors for the

OUT

output amplifier are used, this is also the voltage feedback sense point for the output amplifier. VFB in combination with V

allows for ease of external filter and protection circuits without degrading the PGA309 V

connected to either V

or the point of feedback for V

OUT

, if external protection is used.

OUT

accuracy. VFB must always be

OUT

Analog output voltage of conditioned sensor.

Output amplifier summing junction. Use for output amplifier compensation when driving large capacitive loads

(> 100pF) and/or for using external gain setting resistors for the output amplifier.

Digital voltage supply. Connect to digital voltage supply. To be within 200mV of VSA.

Digital ground. Connect to digital ground return path for VSD. Should be same as GNDA.

connected to V

for a three-lead (VS, GND, V

OUT

) digitally-programmable sensor assembly.

OUT

configuration from external EEPROM. Can also communicate directly to the registers in the PGA309 through the Two-Wire,

industry-standard compatible interface.

configuration from external EEPROM. Can also communicate directly to the registers in the PGA309 through the Two-Wire,

industry-standard compatible interface.

External temperature signal input. PGA309 can be configured to read a bridge current sense resistor as an indicator of bridge

temperature, or an external temperature sensing device such as diode junction, RTD, or thermistor. This input can be internally

gained by 1, 2, 4, or 8. In addition, this input can be read differentially with respect to V

V

. There is also an internal, register-selectable, 7µA current source (I

REF

thermistor, or diode excitation source.

) that can be connected to TEMPIN as an RTD,

TEMP

GNDA

, V

, or the internal/external

EXC

Reference input/output pin. As an output, the internal reference (selectable as 2.5V or 4.096V) is available for system use on

this pin. As an input, the internal reference may be disabled and an external reference can then be applied as the reference for

the PGA309.

TSSOP

SJ

8

www.ti.com

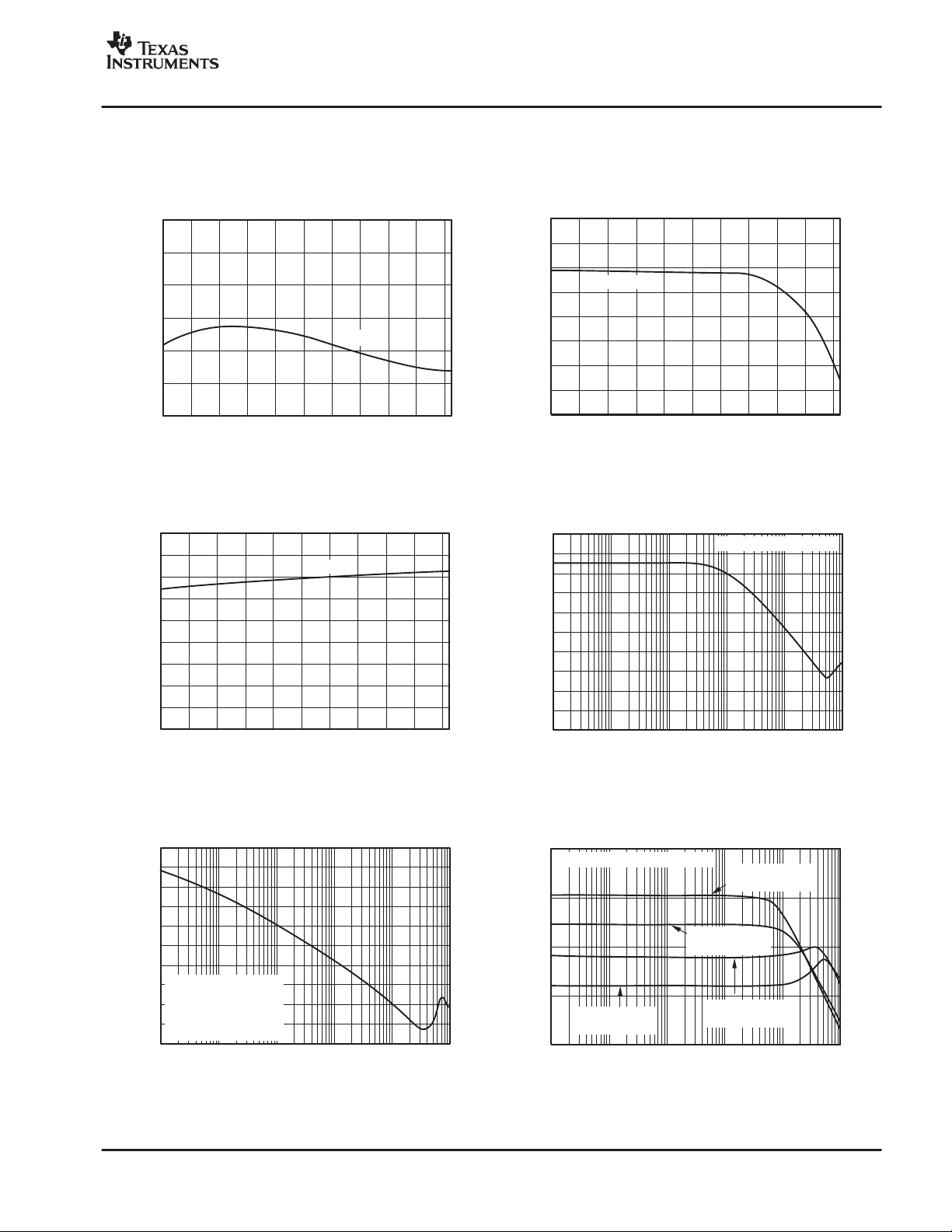

V

vs TEMPERATURE

IBCURRENT vs TEMPERATURE

I

CURRENT vs TEMPERATURE

COMMON−MODE REJECTION RATIO vs FREQUENCY

POWER−SUPPLY REJECTION RATIO vs FREQUENCY

CLOSED−LOOP GAIN vs FREQUENCY

TYPICAL CHARACTERISTICS

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

, VSD = V

SUPPLY DIGITAL

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

, VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

"#$%

= +5V ,

OUT

(V)

V

REF

4.090

4.085

4.080

4.075

4.070

4.065

4.060

−55−35−

9

8

7

6

A)

µ

5

(

4

TEMP

I

3

2

1

0

−55−35−

REF

Average

15 5 25 45 65 85 105 125 145

Temperature (_C)

TEMP

Average

15 5 25 45 65 85 105 125 145

Temperature (_C)

1.0

0.5

0

−

(nA)

−

B

I

−

−

−

−

0.5

1.0

1.5

2.0

2.5

3.0

−55−35−

Average,nA

15 5 25 45 65 85 105 125 145

Temperature (_C)

70

60

RTO of Front−End PGA

50

40

30

20

10

CMRR (dB)

0

−

10

−

20

−

30

10 100 1k 10k 100k 1M

Frequency (Hz)

90

80

70

60

50

40

PSRR (dB)

30

Small−Signal

20

V

and V

=2.5V

EXT

OUT

Enabled

−

10

0

10

REF

V

REF

PSRR at V

10 100 1k 10k 100k 1M

Frequency (Hz)

80

G

= Output Amplifer Gain

OUTAMP

60

40

G

OUTAMP

G

FRONT

G

OUTAMP

G

FRONT

=9V/V

= 32V/V

=9V/V

= 128V/V

Gain (dB)

20

G

OUTAMP

G

FRONT

=2V/V

=8V/V

G

OUTAMP

G

FRONT

=2V/V

=32V/V

0

10 100 1k 10k 100k 1M

Frequency (Hz)

9

"#$%

V

SWINGTORAILvsI

IQvs TEMPERATURE

TEMPERATURE ADC ERROR (INTERNAL MODE)

TEMPERATURE ADC ERROR (EXTERNAL MODES)

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

TYPICAL CHARACTERISTICS (Cont.)

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

, VSD = V

SUPPLY DIGITAL

, VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

www.ti.com

OUT

= +5V ,

V

S

V

S

V

S

V

S

V

S

C)

_

Temp ADC Error(

V

S

−

0.1

−

0.2

−

0.3

−

0.4

−

0.5

0.5

0.4

0.3

0.2

0.1

0

0.4

0.2

0

−

0.2

−

0.4

−

0.6

−

0.8

−

1.0

−

1.2

−55−35−

0

OUT

VS=2.7V

LOAD

VS=5V

VS=5V

VS=2.7V

5 10152025

I

(mA)

LOAD

15 5 25 45 65 85 105 125 145

Actual Die Temperature (_C)

1.6

1.4

1.2

All Blocks Enabled

1.0

0.8

(mA)

Q

I

0.6

Ref, Exc, and ADC Disabled

0.4

0.2

0

−55−35−

15 5 25 45 65 85 105 125 145

Temperature (_C)

0.4

0.3

0.2

Reg 6 = 0433h

V

= 2.5VInternal

REF

15−Bit+ Sign

Reg6 = 0503h

V

REF

(Temp ADC Internal)

15−Bit + Sign

0.1

0

−

TotalError (% ofFS)

−

−

−

Reg 6 = 0430h

0.1

V

= 2.5V Internal

REF

0.2

0.3

11−Bit + Sign

Reg 6 = 0403h

V

=5VExternal

REF

15−Bit + Sign

0.4

−

100−80−60−40−20 0 20 40 60 80 100

Input Signal(% FS of V

REF

)

=2.048V

V

NOISE

REF

(0.1Hz TO 10Hz)

V/div

µ

50

Measured After Bandpass Filter

0.1Hz Second−Order High−Pass

10Hz Fourth−Order Low−Pass

1s/div

10

V

REF

= 4.096V

(0.1Hz TO 10Hz PEAK−TO−PEAK NOISE)

=+61mV

V

IN

CLK_CFG= 00 (default)

1mV/div

Measured After Bandpass Filter

0.1Hz Second−Order High−Pass

10Hz Fourth−Order Low−Pass

V

NOISE

OUT

Coarse Offset =−59mV

1s/div

G=1152

www.ti.com

LARGE−SIGNAL STEP RESPONSE

LARGE−SIGNAL STEP RESPONSE

SMALL−SIGNAL STEP RESPONSE

SMALL−SIGNAL STEP RESPONSE

CAPACITIVE LOAD DRIVE

OVERVOLTAGE RECOVERY

TYPICAL CHARACTERISTICS (Cont.)

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

, VSD = V

SUPPLY DIGITAL

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

, VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

"#$%

= +5V ,

OUT

Gain = 8

(500mV/div)

OUT

V

Time (10µs/div)

(500mV/div)

OUT

V

Time (10µs/div)

Gain = 8

(50mV/div)

OUT

V

(50mV/div)

OUT

V

Gain = 1152

Gain = 256

Time (10µs/div)

25

G

20

s)

µ

15

G

=9V/V

OUTAMP

10

0.5% Settling Time (

5

G

0

0 500 1000 1500 2000 2500

C

(pF)

LOAD

OUTAMP

OUTAMP

=2V/V

=3.6V/V

Time (10µs/div)

V

OUT

(1V/div)

OUT

V

IN

(200mV/div),V

IN

V

Time (100µs/div)

11

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

TYPICAL CHARACTERISTICS (Cont.)

TA = +25°C, VSA = VSD = +5V (VSA = V

unless otherwise noted.

SUPPLY ANALOG

, VSD = V

SUPPLY DIGITAL

, VSA must equal VSD), GNDD = GNDA = 0, and V

= REFIN/REF

REF

www.ti.com

OUT

= +5V ,

120

100

80

(dB)

60

OL

A

40

20

0

OPEN−LOOP GAIN/PHASE vs FREQUENCY

110100

OUTPUT AMPLIFIER

10k 100k 1M 10M0.1

1k

Frequency (Hz)

Error (LSB)

−

−

−

20

15

10

−

10

15

20

5

0

5

CL=100pF

=4.7k

R

L

45

Ω

0

−

45

)

_

−

90

Phase (

−

135

−

180

−

225

GAIN DAC TYPICAL ERROR vs CODE

Code (LSB)

20

15

10

5

0

Error(LSB)

−

5

−

10

−

15

−

20

ZERO DAC TYPICAL ERROR vs CODE

Unit 2

Unit 1

7000010000 20000 30000 4 0000 60000500000

Code (LSB)

7000010000 20000 30000 4 0000 60000500000

12

www.ti.com

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

FUNCTIONAL DESCRIPTION

The PGA309 is a programmable analog signal

conditioner designed for resistive bridge sensor

applications. It is a complete signal conditioner with

bridge excitation, initial span and offset adjustment,

temperature adjustment of span and offset,

internal/external temperature measurement capability,

output over-scale and under-scale limiting, fault

detection, and digital calibration. The PGA309, in a

calibrated sensor module, can reduce errors to the level

approaching the bridge sensor repeatability. Figure 1

shows a block diagram of the PGA309. Following is a

brief overview of each major function.

SENSOR ERROR ADJUSTMENT RANGE

The adjustment capability of the PGA309 is

summarized in Table 1.

FSS (full-scale sensitivity) 1mV/V to 245mV/V

Span TC Over ±3300ppmFS/°C

Span TC nonlinearity > 10%

Zero offset ±200%FS

Zero offset TC Over ±3000ppmFS/°C

Zero offset TC nonlinearity > 10%

Sensor impedance Down to 200Ω

(1)

Depends on the temperature sensing scheme

(2)

Combined coarse and fine offset adjust

(3)

Lower impedance possible by using a dropping resistor in series with the

bridge

(2)

Table 1. PGA309 Adjustment Capability

GAIN SCALING

The core of the PGA309 is the precision low-drift and no

1/f noise Front-End PGA. The overall gain of the

Front-End PGA + Output Amplifier can be adjusted

from 2.7V/V to 1152V/V. The polarity of the inputs can

be switched through the 2x2 input mux to accommodate

sensors with unknown polarity output.

The Front-End PGA provides initial coarse signal gain

using a no 1/f noise, auto-zero instrumentation

amplifier. The fine gain adjust is accomplished by the

16-bit attenuating Gain Digital-to-Analog Converter

(Gain DAC). This Gain DAC is controlled by the data in

the Temperature Compensation Lookup Table driven by

the Temperature Analog-to-Digital Converter (Temp

ADC). In order to compensate for second-order and

higher drift nonlinearity, the span drift can be fitted to

(1)

(2)

(3)

piecewise linear curves during calibration with the

coefficients stored in an external nonvolatile EEPROM

lookup table.

Following the fine gain adjust stage is the Output

Amplifier that provides additional programmable gain.

Two key output amplifier connections, VFB and VSJ, are

brought out on the PGA309 for application flexibility.

These connections allow for an accurate conditioned

signal voltage while also providing a means for PGA309

output overvoltage and large capacitive loading for

RFI/EMI filtering required in many end applications.

OFFSET ADJUSTMENT

The sensor offset adjustment is performed in two

stages. The input-referred Coarse Offset Adjust DAC

has approximately a ±60mV offset adjustment range for

a selected V

of 5 V. The fine offset and the offset drift

REF

are canceled by the 16-bit Zero DAC that sums the

signal with the output of the front-end instrumentation

amplifier. Similar to the Gain DAC, the input digital

values of the Zero DAC are controlled by the data in the

Temperature Compensation Lookup Table, stored in

external EEPROM, driven by the Temp ADC. The

programming range of the Zero DAC is 0V to V

REF

with

an output range of 0.1V to VSA − 0.1V.

VOLTAGE REFERENCE

The PGA309 contains a precision low-drift voltage

reference (selectable for 2.5V or 4.096V) that can be

used for external circuitry through the REFIN/REF

OUT

pin. This same reference is used for the Coarse Offset

Adjust DAC, Zero DAC, Over/Under-Scale Limits and

sensor excitation/linearization through the V

EXC

pin.

When the internal reference is disabled, the

REFIN/REF

pin should be connected to an external

OUT

reference or to VSA for ratiometric-scaled systems.

SENSOR EXCITATION AND LINEARIZATION

A dedicated circuit with a 7-bit + sign DAC for sensor

voltage excitation and linearization is provided on the

PGA309. This block scales the reference voltage and

sums it with a portion of the PGA309 output to

compensate the positive or negative bow-shaped

nonlinearity exhibited by many sensors over their

applied pressure range. Sensors not requiring

linearization can be connected directly to the supply

(VSA) or to the V

pin with the Linearization DAC (Lin

EXC

DAC) set to zero.

13

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

www.ti.com

+5V

Bridge

Sensor

R

TEMP

V

TEMP

TEST

EXC

V

IN1

V

IN2

IN

PGA309

Σ

V

OUT

Temp AD C

Signals Mux

2x2 Multiplexer

K

LIN

Internal

Temp Se nse

Coarse

Offset Adjust

V

Front−EndP GA

(Gain 4 to 1 28)

Fault Conditions

Monitoring Circuit

Test Logic

K

REF

Linearization

OS

V

REF

DAC

Temperature ADC

Input Select

Front−End

PGA Out

Fault

Out

V

V

Power−On

Reset

V

FB

V

TEMP

Temperature

SpanTC and OffsetTC A djust Lookup

Table with interp olation

Fine Offset

Fine Gain

Adjust

SD

ADC

Adjust

Gain

DAC

SA

Zero

DAC

REFIN/REF

Interface and Control

OUT

Band−Gap

Volta ge

Reference

Circuitry

Over/Under−

Scale Limits

V

OUT

Fault Out

Output

Amp

Int/Ext

Feedback

Output Coarse

Gain Adjust

(2 to 9)

+5V

SDA

SCL

Two−Wire

EEPROM

(SOT23−5)

PRG

V

OUT FILT

R

ISO

100

R

100

C

F

150pF

Ω

C

L

10nF

FB

Ω

V

OUT

V

FB

V

FB

V

SJ

GND

A

GND

D

Figure 1. Simplified Diagram of the PGA309 in a Typical Configuration.

14

www.ti.com

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

ADC FOR TEMPERATURE SENSING

The temperature sense circuitry drives the

compensation for the sensor span and offset drift.

Either internal or external temperature sensing is

possible. The temperature can be sensed in one of the

following ways:

D Bridge impedance change (excitation current

sense, in the positive or negative part of the bridge),

for sensors with large temperature coefficient of

resistance (TCR > 0.1%/°C).

D On-chip PGA309 temperature, when the chip is

located sufficiently close to the sensor.

D External diode, thermistor, or RTD placed on the

sensor membrane. An internal 7µA current source

may be enabled to excite these types of

temperature sensors.

The temperature signal is digitized by the onboard

Temp ADC. The output of the T emp ADC is used by the

control digital circuit to read the data from the Lookup

Table in an external EEPROM, and set the output of the

Gain DAC and the Zero DAC to the calibrated values as

temperature changes.

An additional function provided through the Temp ADC

is the ability to read the V

ADC input mux. This provides flexibility for a digital

output through either One-Wire or Two-Wire interface,

as well as the possibility for an external microcontroller

to perform real-time custom calibration of the PGA309.

EXTERNAL EEPROM AND TEMPERATURE

COEFFICIENTS

The PGA309 uses an industry-standard Two-Wire

external EEPROM (typically, a SOT23-5 package). A

1k-bit (minimum) EEPROM is needed when using all 17

temperature coefficients. Larger EEPROMs may be

used to provide space for a serial number, lot code, or

other data.

The first part of the external EEPROM contains the

configuration data for the PGA309, with settings for:

pin back through the Temp

OUT

D Register 3—Reference Control and Linearization

D Register 4—PGA Coarse Offset and Gain/Output

Amplifier Gain

D Register 5—PGA Configuration and Over/Under-

Scale Limit

D Register 6—Temp ADC Control

This section of the EEPROM contains its own individual

checksum (Checksum1).

The second part of the external EEPROM contains up

to 17 temperature index values and corresponding

temperature coefficients for the Zero DAC and Gain

DAC adjustments with measured temperature, and

also contains its own checksum (Checksum2).

The PGA309 lookup logic contains a linear interpolation

algorithm for accurate DAC adjustments between

stored temperature indexes. This approach allows for

a piecewise linear temperature compensation of up to

17 temperature indexes and associated temperature

coefficients.

If either Checksum1, Checksum2, or both are incorrect,

the output of the PGA309 is set to high-impedance.

FAULT MONITOR

To detect sensor burnout or a short, a set of four

comparators are connected to the inputs of the

Front-End PGA. If any of the inputs are taken to within

100mV of ground or V

the Front-End PGA, then the corresponding

comparator sets a sensor fault flag that causes the

PGA309 V

or ground, depending upon the alarm configuration

setting (Register 5—PGA Configuration and

Over/Under-Scale Limit). This will be well above the set

Over-Scale Limit level or well below the set

Under-Scale Limit level. The state of the fault condition

can be read in digital form in Register 8—Alarm Status

Register. If the Over/Under-Scale Limit is disabled, the

PGA309 output voltage will still be driven within 100mV

of either V

configuration setting.

There are five other fault detect comparators that help

detect subtle PGA309 front-end violations that could

otherwise result in linear voltages at V

interpreted as valid states. These are especially useful

during factory calibration and setup, and are configured

through Register 5—PGA Configuration and

Over/Under-Scale Limit. Their status can also be read

back through Register 8—Alarm Status Register.

OVER-SCALE AND UNDER-SCALE LIMITS

The over-scale and under-scale limit circuitry combined

with the fault monitor circuitry provides a means for

system diagnostics. A typical sensor-conditioned

output may be scaled for 10% to 90% of the system

ADC range for the sensor normal operating range. If the

conditioned pressure sensor is below 4%, it is

considered under-pressure; if over 96%, it is

considered over-pressure.

The PGA309 over/under-scale limit circuit can be

programmed individually for under-scale and

over-scale values that clip or limit the PGA309 output.

From a system diagnostic view, 10% to 90% of ADC

range is normal operation, < 4% is under-pressure, and

> 96% is over-pressure. If the fault detect circuitry is

used, a detected fault will cause the PGA309 output to

be driven to positive or negative saturation. If this fault

to be driven within 100mV of either V

OUT

or ground, depending upon the alarm

SA

or violate the input CMR of

EXC,

that would be

OUT

SA

15

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

www.ti.com

flag is programmed for high, then > 97% ADC range will

be a fault; if programmed for low, then < 3% ADC range

will be a fault. In this configuration, the system software

can be used to distinguish between over- or

under-pressure condition, which indicates an

out-of-control process, or a sensor fault.

POWER-UP AND NORMAL OPERATION

The PGA309 has circuitry to detect when the power

supply is applied to the PGA309, and reset the internal

registers and circuitry to an initial state. This reset also

occurs when the supply is detected to be invalid, so that

the PGA309 is in a known state when the supply

becomes valid again. The rising threshold for this circuit

is typically 2.2V and the falling threshold is typically

1.7V. After the power supply becomes valid, the

PGA309 waits for approximately 25ms and then

attempts to read the configuration data from the

external EEPROM device.

If the EEPROM has the proper flag set in address

locations 0 and 1, then the PGA309 continues reading

the first part of the EEPROM; otherwise, the PGA309

waits for one second before trying again. If the PGA309

detects no response from the EEPROM, the PGA309

waits for one second and tries again; otherwise, the

PGA309 tries to free the bus and waits for 25ms before

trying to read the EEPROM again. If a successful read

of the first part of the EEPROM is accomplished,

(including valid Checksum1 data), the PGA309 triggers

the Temp ADC to measure temperature. For 16-bit

resolution results, the converter takes approximately

125ms to complete a conversion. Once the conversion

is complete, the PGA309 begins reading the Lookup

Table information from the EEPROM (second part) to

calculate the settings for the Gain DAC and Zero DAC.

The PGA309 reads the entire Lookup Table so that it

can determine if the checksum for the Lookup Table

(Checksum2) is correct. Each entry in the Lookup Table

requires approximately 500µs to read from the

EEPROM. Once the checksum is determined to be

valid, the calculated values for the Gain and Zero DACs

are updated into their respective registers, and the

output amplifier is enabled. The PGA309 then begins

looping through this entire procedure, starting with

reading the EEPROM configuration registers from the

first part of the EEPROM, then starting a new

conversion on the Temp ADC, which then triggers

reading the Lookup Table data from the second part of

the EEPROM. This loop continues indefinitely.

DIGITAL INTERFACE

There are two digital interfaces on the PGA309. The

PRG pin uses a One-Wire, UART-compatible interface

with bit rates from 4.8Kbits/s to 38.4Kbits/s. The SDA

and SCL pins together form an industry standard

Two-Wire interface at clock rates from 1kHz to 400kHz.

The external EEPROM uses the Two-Wire interface.

Communication to the PGA309 internal registers, as

well as to the external EEPROM, for programming and

readback can be conducted through either digital

interface.

It is also possible to connect the One-Wire

communication pin, PRG, to the V

pin in true

OUT

three-wire sensor modules and still allow for

programming. In this mode, the PGA309 output

amplifier may be enabled for a set time period and then

disabled again to allow sharing of the PRG pin with the

V

connection. This allows for both digital calibration

OUT

and analog readback during sensor calibration in a

three-wire sensor module.

The Two-Wire interface has timeout mechanisms to

prevent bus lockup from occurring. The Two-Wire

master controller in the PGA309 has a mode that

attempts to free up a stuck-at-zero SDA line by issuing

SCL pulses, even when the bus is not indicated as idle

after a timeout period has expired. The timeout will only

apply when the master portion of the PGA309 is

attempting to initiate a Two-Wire communication.

16

www.ti.com

DETAILED BLOCK DIAGRAM

"#$%

SBOS292A − DECEMBER 2003 − REVISED AUGUST 2004

V

TEMP

TEST

REFIN/REF

OUT

V

V

SA

SD

16 3 10

Linearizationand V

7−Bit + Sign

LinDAC

Temp ADC

Internal REF

Temp Select

Coarse

Offset Adjust

4−Bit + Sign

Gain Adjust

Source

DAC

PGA309

V

Enable

V

EXC

EXC

1

V

SA

I

TEMP

7µA

IN

TEMP

15

V

REF

V

EXC

V

OUT

V

IN2

EXC

I

Enable

TEMP

IN

Temp ADC

Input Mux

Temp ADC Input

Mux Select

PGA Gain Select(1 of 8)

Rangeof 4 to 128

(withPGADiffAmpGain=4)

Input Mux

Control

Σ

Internal

Temp Sense

xG

Temp ADC, PGA

(x1,x2, x4, x8)

V

V

INP

REF

5

V

V

IN1

4

Input Mux

INN

Fault Monitor

Test Logic

9

R

Circuit

15−Bit+ Sign

Temp ADC

V

REF

A2

Auto

Zero

R

G

R

Auto

Zero

EXC

Temp ADC

Ref Mux

REFT

V

FB

Temp ADC

REF Select

x0.83

x0.52

V

REF

V

EXC

V

SA

V

REF

(2.5V or 4.096V)

x0.166

x0.124

V

Control Registers

Alarm Register

Offset TC Adjust and Scan TC Adjust

Look−Up Logic with Interpolation Algorithm

Fine

Offset Adjust

16−Bit

Zero

DAC

4R

R

Front−End

F

F

Front End PGA

A1

R

PGA

Diff Amp

Auto

Zero

R

PGA Output

INT/EXT FB Select

Alarm Register Inputs

Output Gain Select (1 of 7)

Range of 2 to 9

V

Internal Set

Digital Controls

A3

V

SA

POR

V

Internal Set

REF

(2.5V or 4.096V)

REF

Interface and

ControlCircuitry

Fine Gain Adjust

(16−Bit)

16−Bit

Gain

DAC

Bandgap

Reference

R

SET

RGO

V

V

REF

RFO

V

REF

SD

Amplifier

Over−Scale

Limit

3−Bit

DAC

Output

3−Bit

DAC

Under−Scale

Limit

Scale

Limiter

VFBV

OUT

14

13

12

7

6

SDA

SCL

PRG

V

OUT

V

V

FB

SJ

8

112

GNDAGND

D

Figure 2. Detailed Block Diagram

17

PACKAGE OPTION ADDENDUM

www.ti.com

9-Dec-2004

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

PGA309AIPWR ACTIVE TSSOP PW 16 2500 Green (RoHS &

no Sb/Br)

PGA309AIPWT ACTIVE TSSOP PW 16 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - May not be currently available - please check http://www.ti.com/productcontent for the latest availability information and additional

product content details.

None: Not yet available Lead (Pb-Free).

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean "Pb-Free" and in addition, uses package materials that do not contain halogens,

including bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDECindustry standard classifications, and peak solder

temperature.

(2)

Lead/Ball Finish MSL Peak Temp

CU SNPB Level-1-260C-UNLIM

CU SNPB Level-1-260C-UNLIM

(3)

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

MECHANICAL DATA

MTSS001C – JANUARY 1995 – REVISED FEBRUARY 1999

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

1,20 MAX

14

0,30

0,19

8

4,50

4,30

PINS **

7

Seating Plane

0,15

0,05

8

1

A

DIM

14

0,10

6,60

6,20

M

0,10

0,15 NOM

2016

0°–8°

Gage Plane

24

0,25

0,75

0,50

28

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

3,10

2,90

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4040064/F 01/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...