Page 1

User's Guide

SBAU103 – August 2004

PCM4202EVM User's Guide

This document provides the information needed to set up and operate the

PCM4202EVM evaluation module (EVM). For a more detailed description of the

PCM4202, please refer to the product datasheet available from the Texas Instruments

web site at http://www.ti.com. Additional support documents are listed in the sections of

this guide entitled Related Documentation from Texas Instruments and Additional

Documentation. Throughout this document, the acronym EVM and the phrase

evaluation module are synonymous with the PCM4202EVM. This user's guide includes

setup and configuration instructions, information regarding absolute operating conditions for power supplies and input/output connections, an electrical schematic, PCB

layout drawings, and a bill of materials (BOM) for the EVM.

Contents

1 Introduction ........................................................................................ 3

2 Getting Started ..................................................................................... 7

3 Hardware Description and Configuration .................................................... 8

4 Schematic, PCB Layout, and Bill of Materials ............................................. 13

List of Figures

1 PCM4202 Functional Block Diagram .......................................................... 3

2 PCM4202EVM Functional Block Diagram .................................................... 5

3 DIT (Transmitter) Reset Circuitry ............................................................. 13

4 PCM4202EVM Schematic Diagram ........................................................... 14

5 Top Side Silkscreen ............................................................................. 16

6 Bottom Side Silkscreen ........................................................................ 17

7 Top Layer (Component Side) .................................................................. 18

8 Ground Plane Layer ............................................................................. 19

9 Power Plane Layer .............................................................................. 20

10 Bottom Layer (Solder Side) .................................................................... 21

List of Tables

1 Absolute Operating Conditions ................................................................ 8

2 Audio Data Format Selection ................................................................... 9

3 System Clock Source Selection .............................................................. 10

4 Sampling Mode Selection: PCM Slave Mode Audio Formats .......................... 11

5 Sampling Mode Selection: PCM Master Mode Audio Formats ......................... 11

6 Sampling Mode Selection: DSD Output Mode ............................................. 11

7 Digital High-Pass Filter Configuration ...................................................... 11

PCM4202EVM User's GuideSBAU103 – August 2004 1

Page 2

www.ti.com

8 Digital Interface Transmitter Configuration ................................................ 12

9 Transmitter Master Clock Configuration.................................................... 12

10 Transmitter Output Mode Configuration.................................................... 12

11 PCM4202EVM Bill of Materials ................................................................ 22

PCM4202EVM User's Guide2 SBAU103–August 2004

Page 3

www.ti.com

Delta−Sigma

Modulator

Audio

Serial

Port

Clock

Control

VINR+

VINR

−

LRCK

or DSDBCK

BCK

or DSDL

DATA

or DSDR

CLIPR

CLIPL

Decimation

Filter

Voltage

Reference

NDR

V

REF

R

COM

R

V

COM

L

Voltage

Reference

V

REF

L

GNDL

Delta−Sigma

Modulator

VINL

−

VINL+

Power

V

CC

AGND VDDDGND

HPF

Decimation

Filter

HPF

Reset

Logic

S/M

FMT0

FMT1

HPFD

FS0

FS1

FS2

SCKI

RST

Introduction

1 Introduction

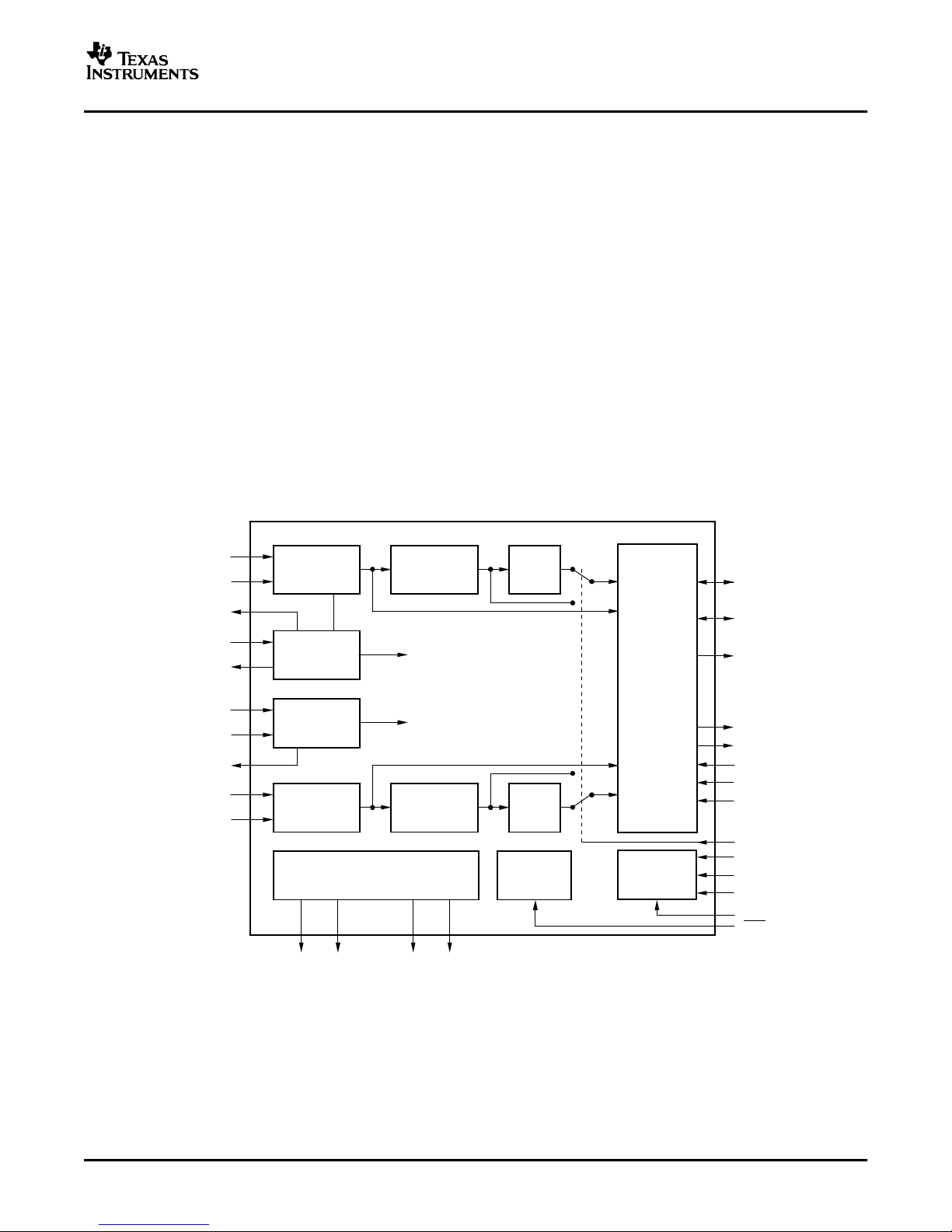

The PCM4202 is a high-performance, two-channel stereo audio analog-to-digital (A/D) converter

designed for use in professional and broadcast audio applications. The PCM4202 features

simultaneous 24-bit linear PCM or 1-bit Direct Stream Digital (DSD) data output for both channels.

Sampling rates up to 216kHz are supported for PCM output formats, while 64x or 128x

oversampled 1-bit data is supported for the DSD output mode. Native support for both PCM and

DSD data formats makes the PCM4202 ideal for use in a variety of audio recording and processing

applications.

The PCM4202 features 1-bit delta-sigma (∆Σ) modulators employing a novel density modulated

dithering scheme, yielding improved dynamic performance. Differential voltage inputs are utilized

for the modulators, providing excellent common-mode rejection. On-chip voltage references are

provided for the modulators, in addition to generating DC common-mode bias voltage outputs for

use with external input circuitry. Linear phase digital decimation filtering is provided for the 24-bit

PCM output, with a minimum stop band attenuation of -100dB for all sampling modes.

The PCM output mode features clipping flag outputs for each channel, as well as a digital high-pass

filter for DC removal. The PCM4202 is configured using dedicated input pins for sampling mode

and audio data format selection, high-pass filter enable/disable, and reset/power-down operation.

A +5V power supply is required for the analog section of the device, while a +3.3V power supply is

required for the digital circuitry. Figure 1 shows the functional block diagram of the PCM4202.

Figure 1. PCM4202 Functional Block Diagram

PCM4202EVM User's GuideSBAU103 – August 2004 3

Page 4

www.ti.com

Introduction

1.1 PCM4204EVM Features

The PCM4202EVM provides a convenient platform for evaluating the performance and functionality

of the PCM4202 product. The primary EVM features include:

• Simple configuration using onboard DIP switches

• Two differential voltage inputs supporting either 3-pin XLR or Balanced TRS connections

• Low-noise input buffer circuits utilizing the OPA1632 fully differential audio amplifier

• Two 75Ω AES3-encoded outputs, supporting operation up to 216kHz sampling rates

• Buffered Audio Serial Port supports a two-channel, 24-bit linear PCM data interface for external

hardware and signal processors. Sampling rates up to 216kHz are supported.

• Two onboard system clock oscillators, operating at 22.5792MHz and 24.576MHz respectively,

supporting standard PCM sampling rates, including 44.1kHz, 48kHz, 88.2kHz, 96kHz, 176.4kHz,

and 192kHz.

• External system clock inputs supporting alternative sampling rates up to 216kHz.

The PCM4202EVM requires +15V, -15V, and +5V analog power supplies. Additionally, a +5V digital

power supply is required, with a +3.3V digital supply being derived onboard using a linear voltage

regulator IC.

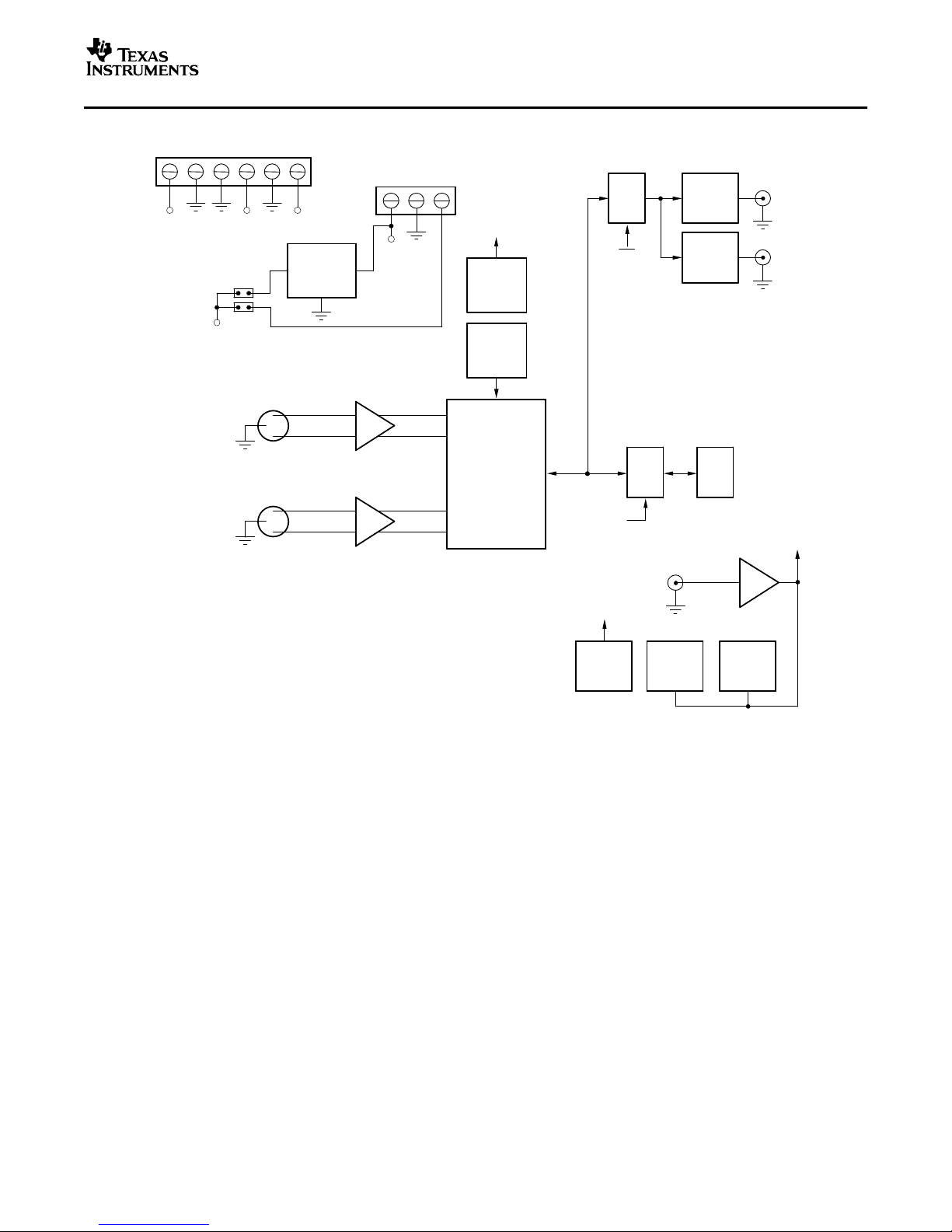

1.2 PCM4202EVM General Description and Functional Block Diagram

The PCM4202EVM provides a complete platform for evaluating the performance and features of

the PCM4202 stereo audio A/D converter. Figure 2 illustrates the functional block diagram for the

evaluation module.

PCM4202EVM User's Guide4 SBAU103 – August 2004

Page 5

www.ti.com

J1

Left Channel

Input

J2

Right Channel

Input

Analog

Input Buffers

OPA1632 x 2

U1

PCM4202

BUF

S/M

PCM Data

Switch

SW1

Switch

SW3

GND

To

DIT Circuitry

J3

+5VA

−

15V+15V

BUF

DIT

U12

DIT4192

J5

AES3 Out #1

Stereo: L + R

Mono: L

HDR

J4

Audio

Serial Port

U6

REG1117

+3.3V

+15

GND

−15GND

+5VA

U13

DIT4192

J6

AES3 Out #2

Stereo: L + R

Mono: R

X1

22.5792M

J7

EXT CLOCK INPUT

Switch

SW5

System

Clock

To

Clock Enables

X2

24.576M

J8

+5VD

+5VD

GND

+3.3VD

+3.3V

JMP3

Introduction

Two differential analog inputs are supported at connectors J1 and J2, corresponding to Left and

Right analog input channels, respectively. These connectors support either 3-pin male XLR or

balanced TRS input plugs. Each of the analog inputs is buffered and filtered using a low noise input

circuit, utilizing a Texas Instruments OPA1632 fully differential amplifier. The output of each buffer

Figure 2. PCM4202EVM Functional Block Diagram

circuit is connected to a corresponding differential input of the PCM4202. The PCM4202 is then

used to convert the analog signal to either a 24-bit linear PCM or 1-bit DSD representation in the

digital domain.

The 24-bit PCM or 1-bit DSD data output is made available at header J4. The 24-bit PCM audio

data is also made available at the AES3 encoded data outputs provided at RCA jacks J5 and J6.

The buffered header is convenient for interfacing to external development hardware or digital signal

processors, while the AES3 encoded outputs may be connected to audio test systems or

commercial audio equipment.

Power is connected to the board at either terminal block J3 for the analog supplies, or at terminal

block J8 for the digital supplies.

PCM4202EVM User's GuideSBAU103 – August 2004 5

Page 6

Introduction

Manual reset circuits are provided for both the PCM4202 (U1) and the AES3 transmitters (U12 and

U13). The ADC RESET switch (SW2) is utilized for resetting the A/D converter, while the DIT

RESET switch (SW4) is utilized for resetting the AES3 transmitters.

The system or master clock for the evaluation module may be generated onboard or by an external

clock source. Oscillators X1 and X2 operate at fixed clock frequencies of 22.5792MHz and

24.576MHz, respectively. The oscillators provide low jitter clock sources for measuring the

performance of the PCM4202 in Master mode operation. Alternatively, an external clock source

may be connected at J7 for Master mode operation, supporting alternate system clock and

sampling frequencies. For Slave mode operation, the system clock is provided from an external

source through header J4 and buffer U9. Switch SW5 provides clock configuration control for the

oscillators and the external clock input at connector J7.

1.3 Related Documentation from Texas Instruments

The following documents provide information regarding Texas Instrument integrated circuits used in

the assembly of the PCM4202EVM. The latest revisions of these documents are available from the

TI web site at http://www.ti.com.

Data Sheet Literature Number

PCM4202 Datasheet SBAS290

DIT4192 Datasheet SBOS229

OPA227 Datasheet SBOS110

OPA1632 Datasheet SBOS286

REG1117 Datasheet SBVS001

SN74AHC08 Datasheet SCLS236

SN74AHC14 Datasheet SCLS238

SN74ALVC245 Datasheet SCES271

SN74LVC1G125 Datasheet SCES223

www.ti.com

1.4 Additional Documentation

The following documents or references provide information regarding selected non-TI components

used in the assembly of the PCM4202EVM. These documents are available from the corresponding

manufacturer.

Document/Reference Manufacturer

SM7745H Series CMOS Oscillators Pletronics ( http://www.pletronics.com )

6 SBAU103–August 2004PCM4202EVM User's Guide

Page 7

www.ti.com

2 Getting Started

This section provides information regarding handling and unpacking the PCM4202EVM, as well as

absolute operating conditions for the unit.

2.1 Electrostatic Discharge Warning

Failure to observe proper ESD handling precautions may result in damage to

EVM components.

Many of the components on the PCM4202EVM are susceptible to damage by electrostatic

discharge (ESD). Customers are advised to observe proper ESD handling procedure when

unpacking and handling the EVM, including the use of a grounded wrist strap at an approved ESD

workstation. Failure to observe ESD handling procedures may result in damage to EVM

components.

2.2 EVM Package Contents

Upon opening the PCM4202EVM package, please check to make sure that the following items are

included:

· One PCM4202EVM

· One printed copy of the PCM4202 product datasheet

· One printed copy of this PCM4202EVM User's Guide

Getting Started

CAUTION

If any of these items are missing, please contact the Texas Instruments Product Information Center

nearest you to inquire about replacements.

2.3 Absolute Operating Conditions

Exceeding the absolute operating conditions may result in damage to the

evaluation module and/or the equipment connected to it.

The user should be aware of the absolute operating conditions for the PCM4202EVM. Table 1

summarizes the critical data points.

CAUTION

SBAU103– August 2004 PCM4202EVM User's Guide 7

Page 8

Hardware Description and Configuration

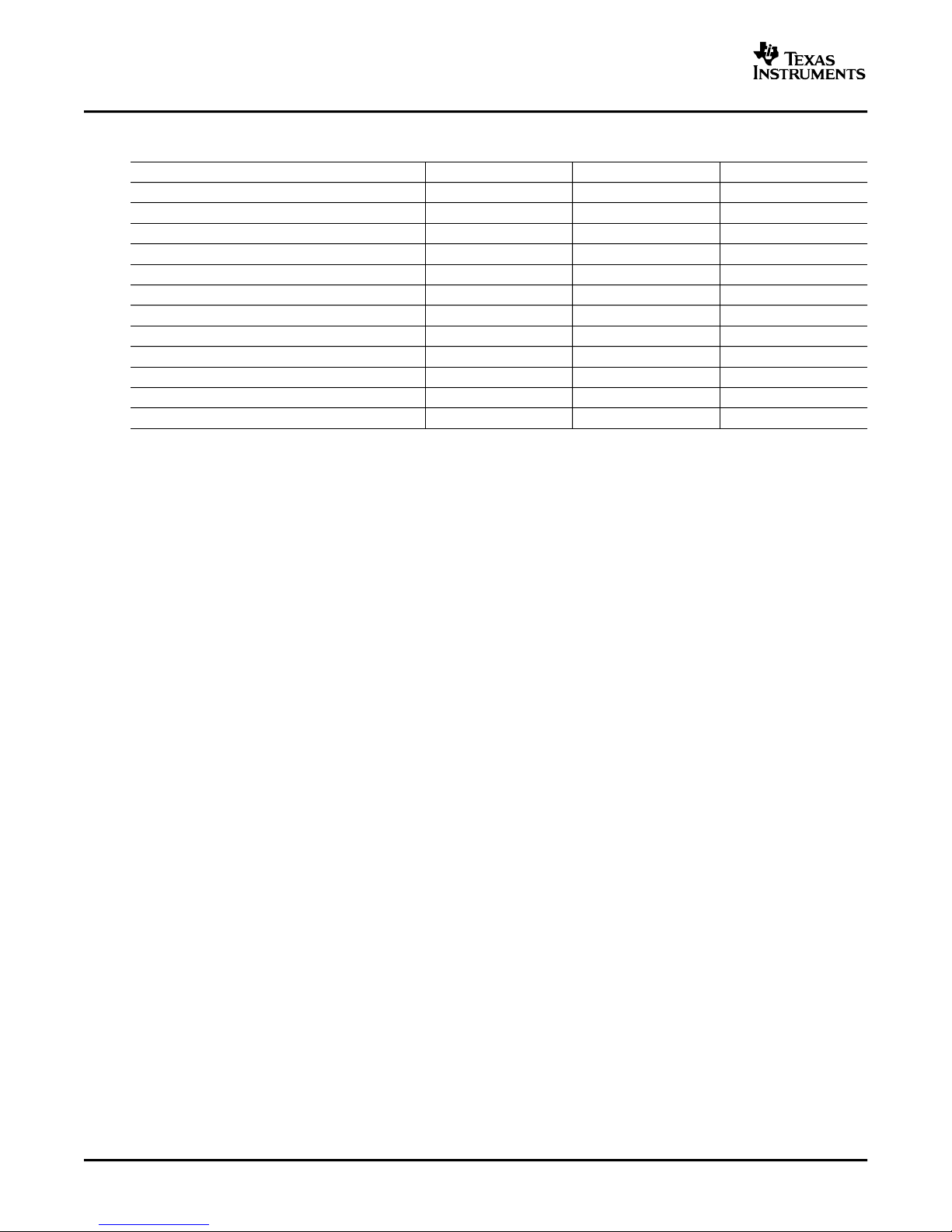

Table 1. Absolute Operating Conditions

Power Supplies

+15V +5.0 +16.0 V

-15V -5.0 -16.0 V

+5VA +4.5 +5.5 V

+5VD +4.5 +5.5 V

EXT +3.3V +3.0 +3.6 V

Audio Serial Port (J4)

VIH, Input High Voltage (VDD= +3.0V to +3.6V) 0.7 x V

VIL, Input Low Voltage (VDD= +3.0V to +3.6V) -0.3 0.3 x V

Analog Inputs (connectors J1 and J2)

Differential Input Voltage, RMS 7.9 V

Differential Input Voltage, Peak-to-Peak 22.3 V

3 Hardware Description and Configuration

This section provides hardware description and configuration information for the PCM4202EVM.

www.ti.com

Min Max Units

DD

VDD+ 0.3 V

DD

V

RMS

PP

3.1 Power Supply Configuration

The PCM4202EVM requires three analog power supplies and one digital power supply for

operation. The analog supplies are connected at terminal block J3, while the digital supply is

connected at terminal block J8.

Analog supplies include +15V and -15V DC for powering the input buffer circuits, as well as +5.0V

DC for powering the analog section of the PCM4202. All supplies should be rated for at least

500mA of output current.

The digital supply requires +5.0V DC and should be rated for at least 500mA of output current. The

+5.0V supply is regulated to +3.3V DC by an onboard Texas Instruments REG1117 linear voltage

regulator (U6), which is used to power the digital section of the PCM4202 and the majority of the

support logic circuitry. The core logic and line driver sections of the AES3 transmitters (U12 and

U13) utilize the +5.0V digital supply directly.

An optional external +3.3V DC digital power supply is supported at terminal block J8. Jumper JMP3

is utilized to select either the onboard voltage regulator (U6) or an external +3.3V power source.

Shorting pins 1 and 2 together using the supplied jumper block selects the onboard +3.3V voltage

regulator. Shorting pins 3 and 4 together will select the external +3.3V supply terminal (EXT

+3.3VD) on terminal block J14. Only one source may be selected at any time.

PCM4202EVM User's Guide8 SBAU103–August 2004

Page 9

www.ti.com

3.2 Analog Inputs

The PCM4202EVM includes two Neutrik combo XLR connectors, which accept either 3-pin male

XLR or ¼-inch TRS phono plugs. The connectors are numbered J1 and J2, corresponding to the

left and right channels, respectively.

The analog inputs can accept up to a 7.9V

then attenuated by a factor of 3.7 by the input buffer circuit, which corresponds to the 6.0V

full-scale differential input voltage for the PCM4202 analog inputs.

The input buffer circuits are each comprised of a single OPA1632 fully differential audio amplifier

and associated passive components. The input buffer provides active attenuation and low pass

filtering for the analog input signal. The OPA1632 outputs are DC level-shifted by approximately

+2.5V using the amplifiers V

the PCM4202 V

L (pin 3) or V

COM

3.3 Audio Data Format Selection

Switch SW1 is used to select the audio data format for the PCM4202. Table 2 summarizes the

available audio data formats for both Slave and Master mode operation and the corresponding

SW1 switch settings.

Hardware Description and Configuration

(or 22.3VPP) differential input signal. This signal is

RMS

IN input (pin 2), which are connected to a buffered version of either

COM

R outputs (pin 26).

COM

PP

Table 2. Audio Data Format Selection

FMT1 FMT0 Audio Data Format (Slave or Master Mode)

LO LO 24-Bit Left Justified PCM Data

LO HI 24-Bit I2S PCM Data

HI LO 24-Bit Right Justified PCM Data

HI HI DSD Output Mode (Master Mode only)

For Slave mode operation, the Audio Serial Port header (connector J4) is utilized to interface to a

Master device, such as a digital signal processor, FPGA, or an audio test system with a

synchronous serial port interface. The system clock (SCKI), bit clock (BCK), and left/right word

clock (LRCK) are generated by the Master device and are used to drive the SCKI (pin 18), BCK

(pin 16), and LRCK (pin 17) inputs of the PCM4202. Serial audio data is output at DATA (pin 15).

Slave mode supports PCM-formatted output data only. DSD output data is available only in

Master mode.

For Master mode, the system clock is provided by one of the sources described in Section 3.4 of

this document. The PCM4202 internally generates the BCK and LRCK clocks, which are then

output to the Audio Serial Port header (connector J4) and the AES3 digital interface transmitters,

which then drive output connectors J5 and J6.

Master mode may also be configured to support 1-bit DSD-formatted audio output data, as shown

in Table 2. For the DSD mode formats, header J4 provides the output interface. The DATA output

functions as the RIght channel DSD output (DSDR), the BCK output servers as the left channel

DSD output (DSDL), and the LRCK output becomes the DSD bit clock (DSDBCK).

PCM4202EVM User's GuideSBAU103– August 2004 9

Page 10

www.ti.com

Hardware Description and Configuration

3.4 System Clock Configuration

Switch SW5 is used to select the system clock source for the PCM4202EVM. Table 3 summarizes

the available clock source options. The onboard oscillators support standard PCM sampling rates in

Master mode, including 44.1kHz, 48kHz, 88.2kHz, 96kHz, 176.4kHz, and 192kHz. The external

clock input (connector J7) may be used to supply alternate system clock frequencies that support

alternative sample rates.

Table 3. System Clock Source Selection

Switch SW5

EXT OSC1 OSC0

LO LO LO External clock input at J7 Master

HI LO LO External clock input at the SCKI pin of header J4 Slave

HI LO HI Oscillator X1, 22.5792MHz Master

HI HI LO Oscillator X2, 22.576MHz Master

3.5 Sampling Mode Selection

The sampling mode of the PCM4202 is selected using switch SW1. Table 4 through Table 6

summarize the available sampling modes for both PCM and DSD output modes.

Single Rate sampling mode is designed for output sampling rates up to 54kHz. The modulator

oversampling rate is set to 128x.

Dual Rate sampling mode is designed for output sampling rates greater than 54kHz and up to

108kHz. The modulator oversampling rate is set to 64x.

Quad Rate sampling mode is designed for output sampling rates greater than 108kHz and up to

216kHz. The modulator oversampling rate is set to 32x.

System Clock Source Used for Master or Slave Mode Operation?

10 PCM4202EVM User's Guide SBAU103 – August 2004

Page 11

www.ti.com

Table 4. Sampling Mode Selection: PCM Slave Mode Audio Formats

FS2 FS1 FS0 Sampling Mode

LO LO LO Single Rate with Clock Auto-Detection

LO LO HI Dual Rate with Clock Auto-Detection

LO HI LO Quad Rate with Clock Auto-Detection

LO HI HI Reserved

HI LO LO Reserved

HI LO HI Reserved

HI HI LO Reserved

HI HI HI Reserved

Table 5. Sampling Mode Selection: PCM Master Mode Audio Formats

FS2 FS1 FS0 Sampling Mode

LO LO LO Single Rate with f

LO LO HI Single Rate with f

LO HI LO Single Rate with f

LO HI HI Single Rate with f

HI LO LO Dual Rate with f

HI LO HI Dual Rate with f

HI HI LO Quad Rate with f

HI HI HI Quad Rate with f

SCKI

SCKI

SCKI

SCKI

SCKI

SCKI

SCKI

SCKI

= 768f

= 512f

= 384f

= 256f

= 384f

= 256f

= 192f

= 128f

Hardware Description and Configuration

S

S

S

S

S

S

S

S

Table 6. Sampling Mode Selection: DSD Output Mode

FS2 FS1 FS0 Sampling Mode

LO LO LO 128fsDSD Output Rate with f

LO LO HI 128fsDSD Output Rate with f

LO HI LO 128fsDSD Output Rate with f

LO HI HI 128fsDSD Output Rate with f

HI LO LO 64fsDSD Output Rate with f

HI LO HI 64fsDSD Output Rate with f

HI HI LO Reserved

HI HI HI Reserved

3.6 Digital High-Pass Filter

The PCM4202 includes a digital high-pass filter function for both channels, designed for removing

the DC component from the digitized signal. The high-pass filter is not available when using the

DSD output mode. The high-pass filter function may be enabled or disabled using the HPFD switch

on SW1. Table 7 summarizes the operation of the HPFD switch.

HPFD Digital High-Pass Filter Function

LO Enabled

HI Disabled

= 768f

SCKI

SCKI

SCKI

SCKI

SCKI

SCKI

= 512f

= 384f

= 256f

= 384f

= 256f

S

S

S

S

S

S

Table 7. Digital High-Pass Filter Configuration

PCM4202EVM User's GuideSBAU103– August 2004 11

Page 12

www.ti.com

Hardware Description and Configuration

3.7 Digital Interface Transmitter Configuration

Two Texas Instruments DIT4192 digital interface transmitters provide AES3-encoded outputs for

the PCM4202EVM. Switch SW3 is utilized to configure the transmitters. The outputs of the

transmitters are available at connectors J5 and J6, which are RCA phono jacks. These outputs are

designed for use with 75Ω coaxial cable connections.

The transmitters are enabled using the DIT switch of SW3. The DIT switch operation is summarized

in Table 8 .

DIT Digital Interface Filter Function

LO Enabled

HI Disabled

The audio data format for the transmitters is hardwired for 24-bit I2S data format. When using the

transmitters, the PCM4202 audio data format must be set to 24-bit I2S, as shown in Table 2 .

Like the PCM4202, the DIT4192 transmitters must be configured for the proper master (or system) clock

frequency. The transmitter master clock is driven by the same source as the PCM4202 system clock, as

described in Section 3.4 of this document. Table 9 summarizes the master clock options for the DIT4192

transmitters using switch SW3.

Table 8. Digital Interface Transmitter Configuration

Table 9. Transmitter Master Clock Configuration

CLK1 CLK0 Transmitter MCLK Frequency

LO LO 128f

LO HI 256f

HI LO 384f

HI HI 512f

S

S

S

S

The DIT4192 transmitters may be operated in either Stereo or Mono mode. In Stereo mode, two channels

of audio data are transmitted at the input sampling frequency. In Mono mode, two consecutive samples of

only one channel are transmitted at one-half the input sampling rate. The Mono mode is useful for

performance testing with fS= 176.4kHz or fS= 192kHz with a system that can only accept only half these

rates. This is the case with the Audio Precision System Two Cascade or Cascade Plus test system, which

was used for factory performance testing of the PCM4202. Mono mode can be used in conjunction with

the Audio Precision Dual BNC digital input mode to test at sampling rates up to 216kHz.

The MONO switch on SW3 is used to enable or disable Mono mode operation. Table 10 summarizes the

operation of the MONO switch.

Table 10. Transmitter Output Mode Configuration

MONO Transmitter Output Mode

LO Stereo Mode

HI Mono Mode

Left and Right channel data are output on both J5 and J6

Left channel data is output on J5

Right channel data is output on J6

PCM4202EVM User's Guide12 SBAU103 – August 2004

Page 13

www.ti.com

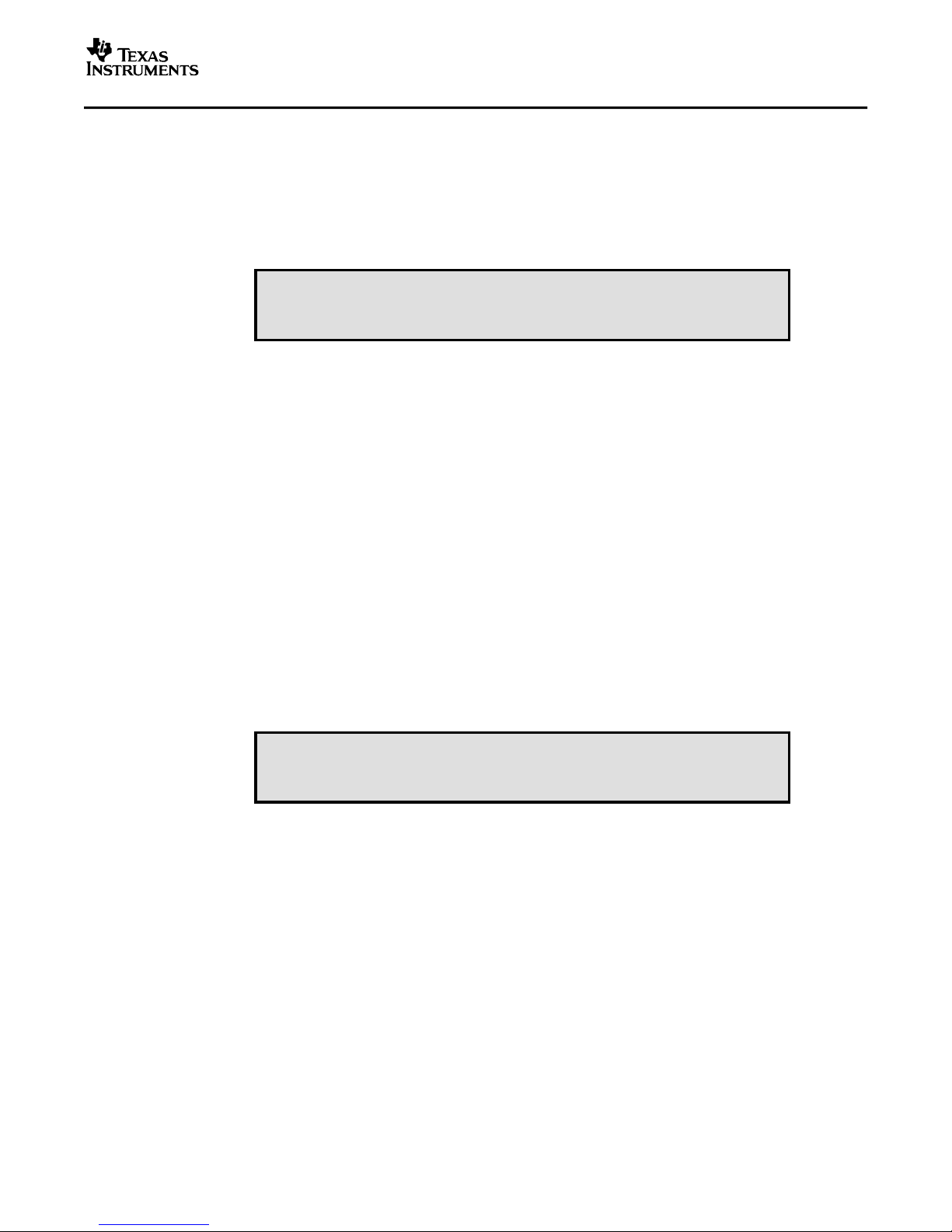

3.8 Reset Operations

The PCM4202EVM includes two reset switches, SW2 and SW4. Both are momentary contact

pushbutton switches that are normally open. SW2 provides the manual reset for the PCM4202

(U1), while switch SW4 provides the manual reset for the two DIT4192 transmitters (U12 and U13).

The PCM4202 may be reset at any time my momentarily pressing and then releasing switch SW2.

This generates a reset pulse and initiates a reset sequence for the device.

For the DIT reset function, the output of the reset circuit is connected to the RST pins of DIT4192

transmitters (U12 and U13). The transmitters may be reset only when the DIT switch of SW3 is set

LO by momentarily pressing and then releasing switch SW4. If the DIT switch is set HI, the output

of the AND gate in the reset circuit is forced low, which will force both transmitters into power-down

mode. The transmitter reset circuit is shown in Figure 3.

SW4

N.O.

+3.3V

From DIT

Schematic, PCB Layout, and Bill of Materials

U7

U8

To RST of

U12 and U13

Figure 3. DIT (Transmitter) Reset Circuitry

4 Schematic, PCB Layout, and Bill of Materials

This section provides the electrical schematic and physical layout information for the

PCM4202EVM. The bill of materials is included as a component reference.

Board layouts are not to scale. These figures are intended to show how the board is

laid out; they are not intended to be used for manufacturing PCM4202EVM PCBs.

4.1 Schematic

The electrical schematic for the PCM4202EVM is shown in Figure 4. The components shown in the

schematic are listed in Table 11 for reference.

NOTE

PCM4202EVM User's GuideSBAU103– August 2004 13

Page 14

www.ti.com

Schematic, PCB Layout, and Bill of Materials

PCM4202EVM User's Guide14 SBAU103 – August 2004

Figure 4. PCM4202EVM Schematic Diagram

Page 15

www.ti.com

4.2 PCB Layout

Schematic, PCB Layout, and Bill of Materials

The PCM4202EVM is a 4-layer printed circuit board with the following layer structure:

• Layer 1: Top (Component Side)

• Layer 2: Ground Plane

• Layer 3: Power

• Layer 4: Bottom (Solder Side)

The ground plane doubles as a heat sink for the PCM4202 PowerPAD package. Refer to the

product datasheet for more information on the purpose and application of the PowerPAD

connection.

Figure 5 through Figure 10 show the top side silk screen, along with the top, ground plane, power,

and bottom layers of the printed circuit board.

PCM4202EVM User's GuideSBAU103 – August 2004 15

Page 16

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 5. Top Side Silkscreen

SBAU103 – August 200416 PCM4202EVM User's Guide

Page 17

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 6. Bottom Side Silkscreen

17SBAU103 – August 2004 PCM4202EVM User's Guide

Page 18

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 7. Top Layer (Component Side)

SBAU103 – August 200418 PCM4202EVM User's Guide

Page 19

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 8. Ground Plane Layer

19SBAU103 – August 2004 PCM4202EVM User's Guide

Page 20

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 9. Power Plane Layer

SBAU103 – August 200420 PCM4202EVM User's Guide

Page 21

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Figure 10. Bottom Layer (Solder Side)

PCM4202EVM User's GuideSBAU103 – August 2004 21

Page 22

Schematic, PCB Layout, and Bill of Materials

4.3 Bill of Materials

The Bill of Materials, listing the components used in the assembly of the PCM4202EVM, is shown

in Table 11.

Table 11. PCM4202EVM Bill of Materials

www.ti.com

ITEM VALUE Ref Des BOARD MFR PART NUMBER DESCRIPTION

1 100pF C45-C48 4 Kemet C0603C101J5GACTU Chip Capacitor, C0G Ceramic, 100pF

2 1nF C31-C34 4 Kemet C0805C102J3GAC Chip Capacitor, C0G Ceramic, 1nF

3 2.7nF C49, C50 2 Kemet C0805C272J3GAC Chip Capacitor, C0G Ceramic, 2.7nF

4 0.01µF C5-C7, 17 Kemet C0603C103J5RACTU Chip Capacitor, X7R Ceramic, 0.01µF

C10-C17, ±5%, 50WV, Size = 0603

C19-C24

5 0.1µF C51-C70 20 Kemet C0603C104J4RACTU Chip Capacitor, X7R Ceramic, 0.1µF

6 10µF C35-C44 10 Kemet T494C106K025AS Chip Capacitor, Low ESR Tantalum,

7 33µF C71-C78 8 Kemet T494B336K010AS Chip Capacitor, Low ESR Tantalum,

8 100µF C8, C9, 5 Panasonic EEV-FK1E101XP Capacitor, SMT Aluminum Electrolytic,

C18, C25, 100µF ±20%, 25WV

C26

9 D1, D2 2 Lumex SML-LX1206IC-TR Red LED, Surface Mount, Size = 1206

10 J1, J2 2 Neutrik NCJ6FI Combo Connector, Female XLR and

11 J3 1 Weidmuller 9967720000 3.5mm PCB Terminal Block, 6 poles

12 J4 1 Samtec TSW-105-07-G-D Terminal Strip, 10-pin (5x2)

13 J5, J6 2 CUI Stack RJC-041 RCA Phono Jack, Black Shell

14 J7 1 Kings Electronics KC-79-274-M06 BNC Connector, Female, PC Mount

15 J8 1 Weidmuller 169968000 3.5mm PCB Terminal Block, 3 poles

16 JMP1, 2 Samtec TSW-102-07-G-S Terminal Strip, 2-pin (2x1)

JMP2

17 JMP3 1 Samtec TSW-102-07-G-D Terminal Strip, 4-pin (2x2)

18 0 R1-R8 8 Panasonic ERJ-6EY0R00V Chip Resistor, 0W, Shunt, Size = 0805

19 40.2 R20-R23 4 Panasonic ERJ-6EN-F40R2V Chip Resistor, Thick Film, 1% Toler-

20 75 R15 1 Panasonic ERJ-6ENF75R0V Chip Resistor, Thick Film, 1% Toler-

21 121 R28, R29 2 Panasonic ERJ-6ENF1210V Chip Resistor, Thick Film, 1% Toler-

22 150 R30, R31 2 Panasonic ERJ-6ENF1500V Chip Resistor, Thick Film, 1% Toler-

23 270 R16-R19 4 Panasonic ERA-6YEB271V Chip Resistor, Metal Film, 0.1% Toler-

24 475 R26, R27 2 Panasonic ERJ-6ENF4750V Chip Resistor, Thick Film, 1% Toler-

25 1K R9-R14 6 Panasonic ERA-6YEB102V Chip Resistor, Metal Film, 0.1% Toler-

26 10K R24, R25 2 Panasonic ERJ-6ENF1002V Chip Resistor, Thick Film, 1% Toler-

27 100 RN2, RN4 2 CTS 742C083101J Thick Film Chip Resistor Array, 100W,

QTY PER MFR

±5%, 50WV, Size = 0603

±5%, 25WV, Size = 0805

±5%, 25WV, Size = 0805

±5%, 16WV, Size = 0603

10µF ±10%, 25WV, Size = C

33µF ±10%, 10WV, Size = B

TRS, Vertical PC Mount

ance, 40.2W, 1/10W, Size = 0805

ance, 75W, 1/10W, Size = 0805

ance, 121W, 1/10W, Size = 0805

ance, 150W, 1/10W, Size = 0805

ance, 270W, 1/10W, Size = 0805

ance, 475W, 1/10W, Size = 0805

ance, 1kW, 1/10W, Size = 0805

ance, 10kW, 1/10W, Size = 0805

8-Terminal, 4 Resistors, Isolated

PCM4202EVM User's Guide22 SBAU103– August 2004

Page 23

www.ti.com

Schematic, PCB Layout, and Bill of Materials

Table

11.

PCM4202EVM

QTY PER MFR

ITEM VALUE Ref Des BOARD MFR PART NUMBER DESCRIPTION

28 10K RN1, RN3, 3 CTS 742C163103J Thick Film Chip Resistor Array, 10kΩ,

RN5 16-Terminal, 8 Resistors, Isolated

29 SW1 1 ITT Industries/ TDA08H0SK1 DIP Switch, 8 Element, Half-Pitch, Sur-

C&K face-Mount, Tape Sealed

30 SW2, SW4 2 Omron B3S-1000 Momentary Tact Switch, SMT without

31 SW3, SW5 2 ITT Industries/ TDA04H0SK1 DIP Switch, 4 Element, Half-Pitch, Sur-

C&K face-Mount, Tape Sealed

32 U1 1 Texas PCM4202DB Stereo Audio A/D Converter

Instruments

33 U2, U4 2 Texas OPA1632DGN Fully-Differential Audio Amplifier

Instruments

34 U3, U5 2 Texas OPA227UA Precision Operational Amplifier

Instruments

35 U7 1 Texas SN74AHC14DBR Hex Schmitt-Trigger Inverters

Instruments

36 U8 1 Texas SN74AHC08DBR Quad 2-Input Positive AND Gates

Instruments

37 U9-U11 3 Texas SN74ALVC245PW Octal Bus Transceiver with Tri-State

Instruments Outputs

38 U12, U13 2 Texas DIT4192IPW 192kHz Digital Audio Transmitter

Instruments

39 U14 1 Texas SN74LVC1G125DBV Single Non-Inverting Buffer with

Instruments Tri-State Output

40 U6 1 Texas REG1117-3.3 Linear Voltage Regulator, +3.3V

Instruments

41 TP1-TP6 6 Keystone 5006 PCB Test Point, Compact, Through-hole

Electronics

42 X1 1 Pletronics SM7745HSW- +3.3V Surface-Mount Clock Oscillator,

43 X2 1 Pletronics SM7745HSW-24.576M +3.3V Surface-Mount Clock Oscillator,

44 3 Samtec SNT-100-BK-G-H Shorting Blocks

42 4 3M Bumpon SJ-5003 Self-Adhesive Rubber Feet

Bill

of

Materials

(continued)

Ground Terminal

22.5792M CMOS Output with Active High Enable,

22.5792MHz±50ppm

CMOS Output with Active High Enable,

24.576MHz±50ppm

PCM4202EVM User's GuideSBAU103 – August 2004 23

Page 24

www.ti.com

Schematic, PCB Layout, and Bill of Materials

This equipment is intended for use in a laboratory test environment only. It generates, uses, and can radiate radio frequency

energy and has not been tested for compliance with the limits of computing devices pursuant to subpart J of part 15 of FCC rules,

which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which case the user at his own expense will be required to

take whatever measures may be required to correct this interference.

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY

and is not considered by TI to be fit for commercial use. As such, the goods being provided may not be complete in terms of

required design-, marketing-, and/or manufacturing-related protective considerations, including product safety measures typically

found in the end product incorporating the goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User's Guide, the kit may be returned within 30 days

from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER

TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods. Please be aware that the products received may not be regulatory compliant

or agency certified (FCC, UL, CE, etc.). Due to the open construction of the product, it is the user's responsibility to take any and

all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE Liable to the other FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of

patents or services described herein.

Please read the EVM User's Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM User's Guide prior to

handling the product. This notice contains important safety information about temperatures and voltages. For further safety

concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warnings

EVM IMPORTANT NOTICE

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM with the operating conditions specified within Table 1 of this document.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are

questions concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the

EVM. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load

specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 37°C. The EVM is designed to

operate properly with certain components above 60°C as long as the input and output ranges are maintained. These components

include but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of

devices can be identified using the EVM schematic located in the EVM User's Guide. When placing measurement probes near

these devices during operation, please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2004, Texas Instruments Incorporated

PCM4202EVM User's Guide24 SBAU103 – August 2004

Page 25

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...