VIOmax

STABLE

25 µV

25°C to 85°C

100 µV

25 µV

55°C to 125°C

100 µV

查询OP27A供应商

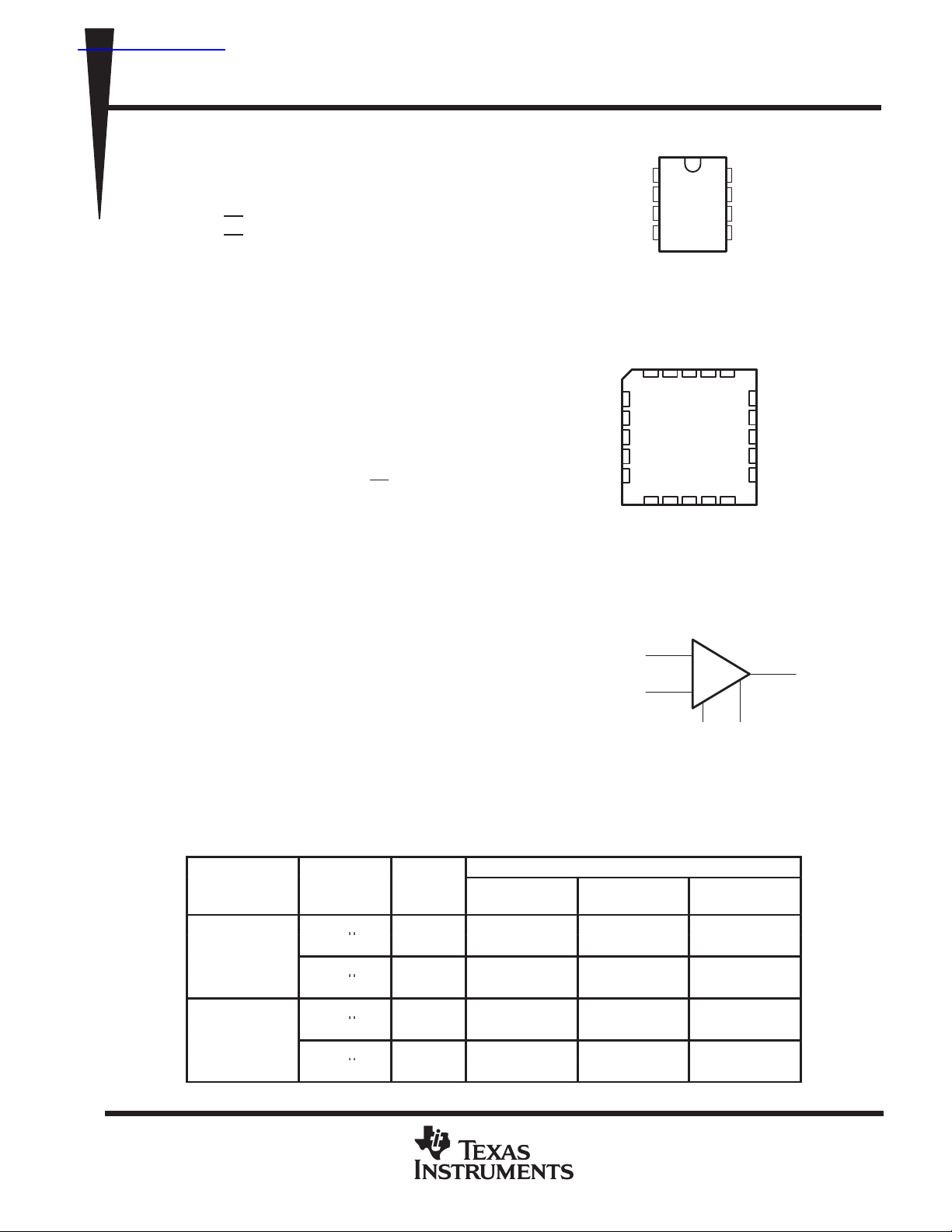

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

• Direct Replacements for PMI and LTC OP27

and OP37 Series

Features of OP27A, OP27C, OP37A, and

OP37C:

• Maximum Equivalent Input Noise Voltage:

3.8 nV/√Hz

5.5 nV/√Hz

at 1 kHz

at 10 kHz

• Very Low Peak-to-Peak Noise Voltage at

0.1 Hz to 10 Hz . . . 80 nV Typ

• Low Input Offset Voltage ...25 µV Max

• High Voltage Amplification ...1 V/µV Min

Feature of OP37 Series:

• Minimum Slew Rate ...11 V/µs

description

The OP27 and OP37 operational amplifiers

combine outstanding noise performance with

excellent precision and high-speed specifications.

The wideband noise is only 3 nV/√Hz

1/f noise corner at 2.7 Hz, low noise is maintained

for all low-frequency applications.

The outstanding characteristics of the OP27 and

OP37 make these devices excellent choices

for low-noise amplifier applications requiring

precision performance and reliability . Additionally ,

the OP37 is free of latch-up in high-gain,

large-capacitive-feedback configurations.

The OP27 series is compensated for unity gain.

The OP37 series is decompensated for increased

bandwidth and slew rate and is stable down to a

gain of 5.

The OP27A, OP27C, OP37A, and OP37C are

characterized for operation over the full military

temperature range of –55°C to 125°C. The

OP27E, OP27G, OP37E, and OP37G are

characterized for operation from – 25°C to 85°C.

T

A

°

–

°

–

°

°

AT 25°C

and with the

JG OR P PACKAGE

(TOP VIEW)

VIO TRIM

V

CC –

NC

1N–

NC

IN+

NC

NC – No internal connection

1

IN–

2

IN +

3

4

FK PACKAGE

(TOP VIEW)

NC

V TRIM

3 2 1 20 19

4

5

6

7

8

910111213

NC

V

IO

NCNCNC

NC

CC –

8

7

6

5

NC

IO

V TRIM

symbol

3

2

+

–

18

VIO TRIM

PLASTIC DIP

IN+

IN –

Pin numbers are for the JG and P packages.

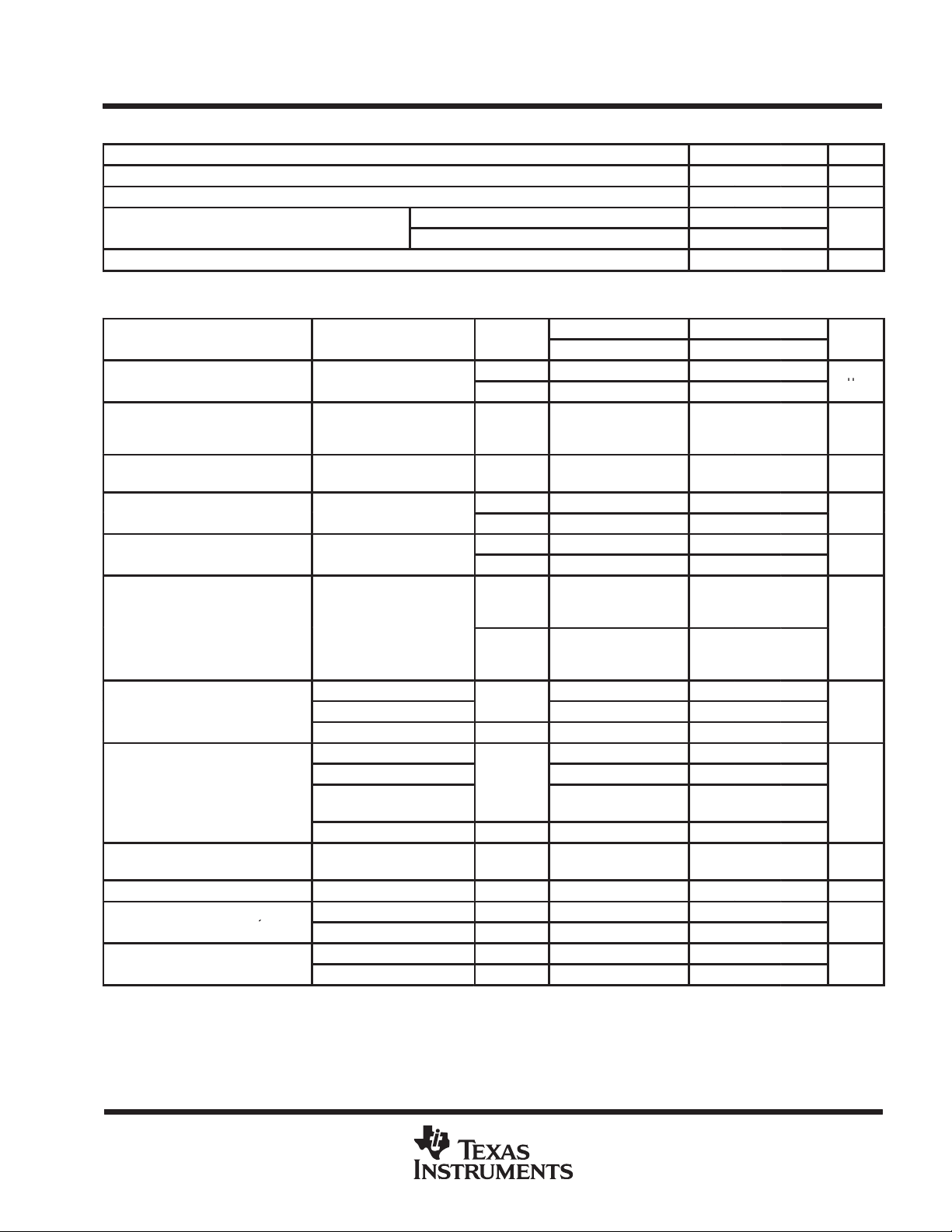

AVAILABLE OPTIONS

PACKAGE

GAIN

1 — — OP27EP

5 — — OP37EP

1 — — OP27GP

5 — — OP37GP

1 OP27AJG OP27AFK —

5 OP37AJG OP37AFK —

1 OP27CJG — —

5 OP37CJG — —

CERAMIC DIP

(JG)

CHIP CARRIER

(FK)

VIO TRIM

V

CC+

OUT

NC

NC

18

V

17

CC+

NC

16

OUT

15

NC

14

(P)

6

OUT

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Copyright 1994, Texas Instruments Incorporated

2–1

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED OPERATIONAL AMPLIFIER

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

V

+

CC

260

750

480 µA

–

OUT

Q46

µA

Q19

Q20

µA

†

C1

Q22

Q24Q23

Q45

340

Q26

CC

V

µA

TRIM

IO

TRIM V

IO

V

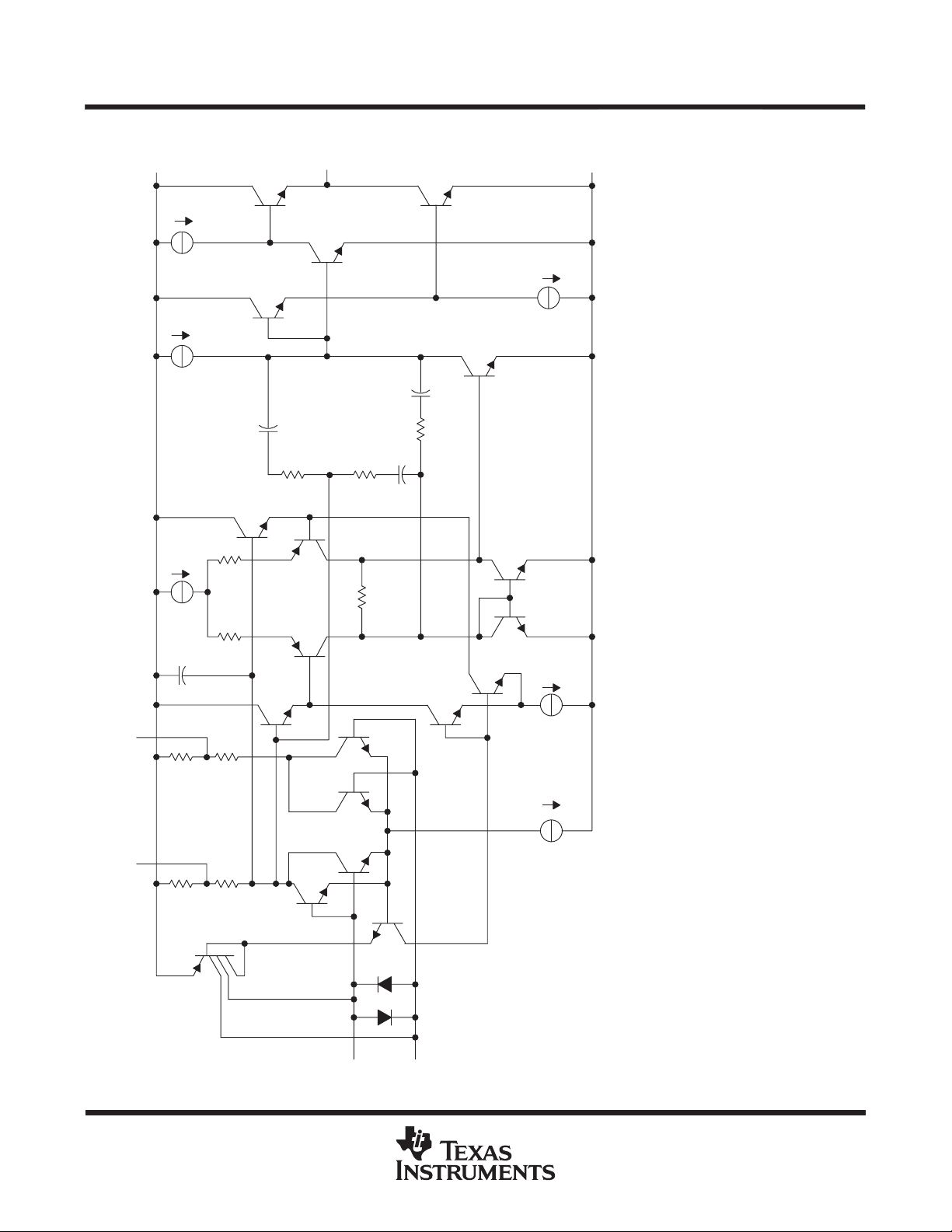

schematic

Q6

Q21

Q1A

Q1B Q2B Q2A

IN +

Q3

IN –

Q27 Q28

Q12

Q11

240 µA 120

µA

C1 = 120 pF for OP27

C1 = 15 pF for OP37

†

2–2

POST OFFICE BOX 655303 DALLAS, TEXAS 75265POST OFFICE BOX 1443 HOUSTON, TEXAS 77251–1443

••

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

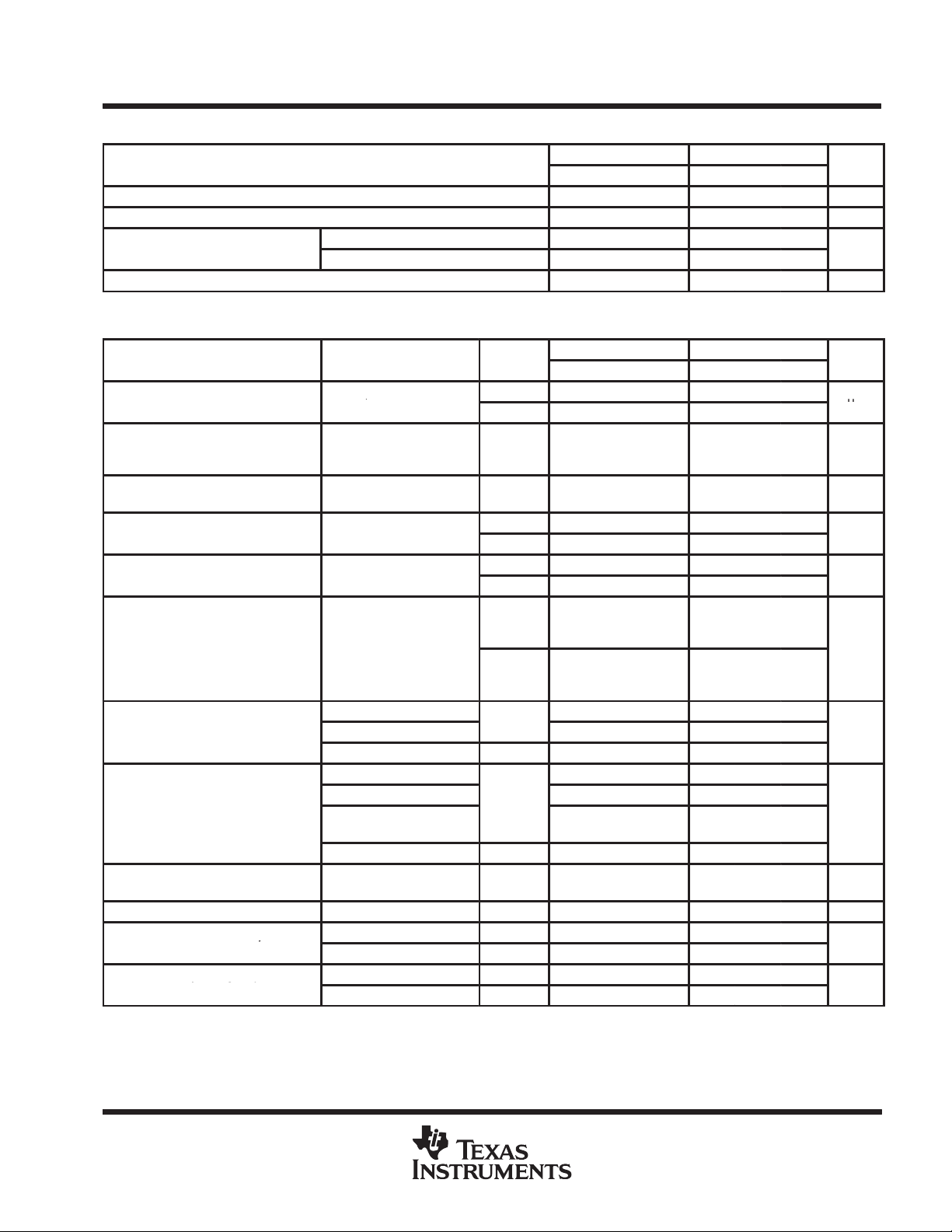

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Supply voltage, V

Input voltage, V

(see Note 1) 22 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC+

(see Note 1) – 22 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC–

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Duration of output short circuit unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input current (see Note 2) ±25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range: OP27A, OP27C, OP37A, OP37C – 55°C to 125°C. . . . . . . . . . . . . . .

OP27E, OP27G, OP37E, OP37G – 25°C to 85°C. . . . . . . . . . . . . . .

Storage temperature range – 65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 60 seconds: JG or FK package 300°C. . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds : P package 260°C. . . . . . . . . . . . . . . . . . . .

NOTES: 1. All voltage values are with respect to the midpoint between V

2. The inputs are protected by back-to-back diodes. Current-limiting resistors are not used in order to achieve low noise. Excessive

input current will flow if a differential input voltage in excess of approximately ± 0.7 V is applied between the inputs unless some

limiting resistance is used.

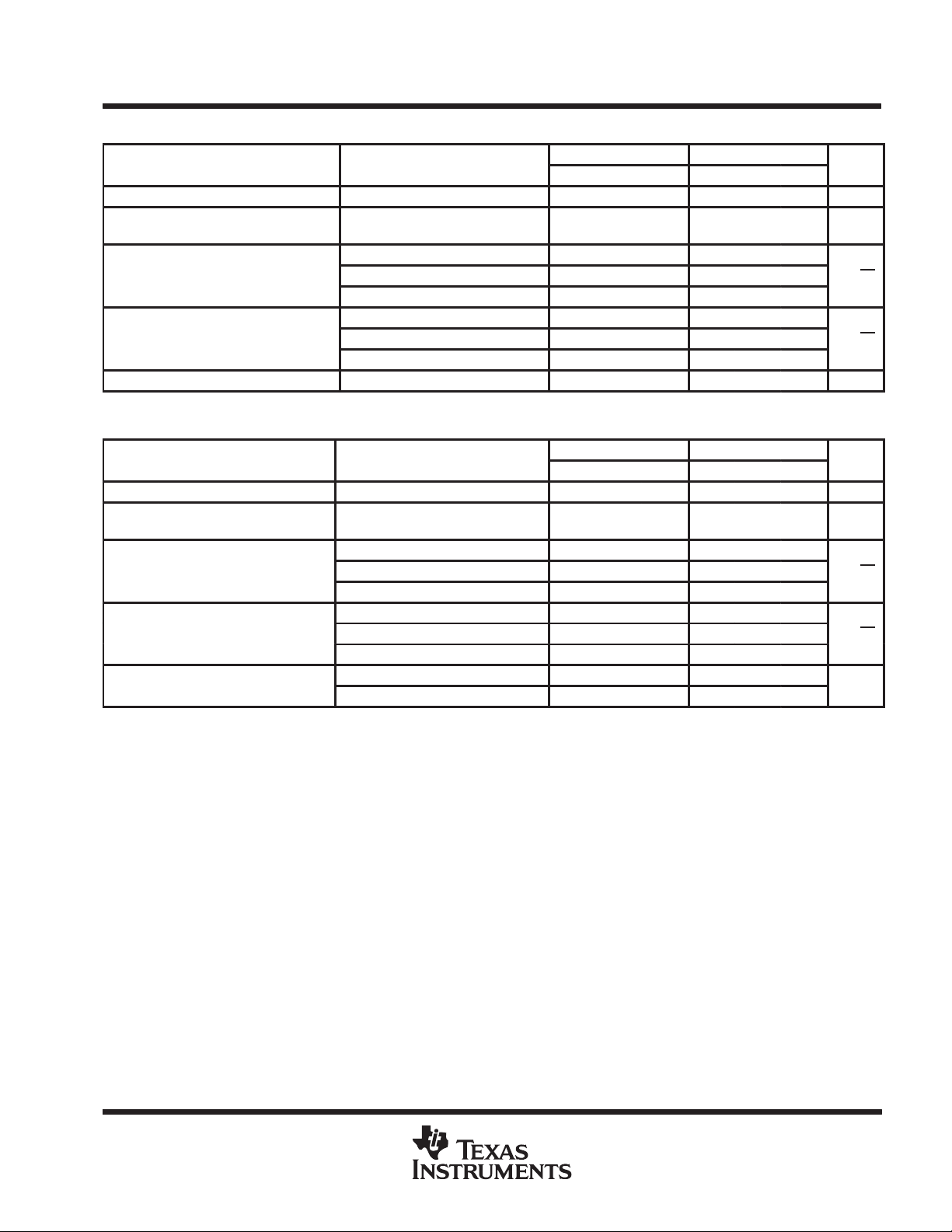

DISSIPATION RATING TABLE

PACKAGE

JG

FK

P

TA ≤ 25°C

POWER RATING

1050 mW

1375 mW

1000 mW

DERATING FACTOR

ABOVE TA = 25°C

8.4 mW/°C

11.0 mW/°C

8.0 mW/°C

CC+

and V

unless otherwise noted.

CC–

TA = 85°C

POWER RATING

546 mW

715 mW

520 mW

TA = 125°C

POWER RATING

210 mW

275 mW

N/A

CC±

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–3

OP27A, OP27C, OP27E, OP27G

UNIT

Common-mode input voltage, V

V

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

O

,

IC

V

IIOInput offset current

V

V

0

nA

IIBInput bias current

V

V

0

nA

V

V

Large-signal differential

CMRR

j

dB

k

ygj

dB

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

recommended operating conditions

OP27A, OP37A OP27C, OP37C

MIN NOM MAX MIN NOM MAX

Supply voltage, V

Supply voltage, V

Operating free-air temperature, T

CC+

CC–

p

V

= ± 15 V, TA = 25°C ± 11 ±11

IC

CC±

V

= ± 15 V, TA = – 55°C to 125°C ±10.3 ±10.2

CC±

A

4 15 22 4 15 22 V

–4 –15 –22 –4 –15 –22 V

–55 125 –55 125 °C

electrical characteristics at specified free-air temperature, V

A

V

p

Average temperature

α

V

A

r

i(CM)

r

o

†

Full range is – 55°C to 125°C.

NOTES: 3. Input offset voltage measurements are performed by automatic test equipment approximately 0.5 seconds after applying power.

coefficient of input

VIO

offset voltage

Long-term drift of input

offset voltage

p

p

Common-mode input

ICR

voltage range

Peak output voltage swing

OM

VD

voltage amplification

Common-mode input

resistance

Output resistance VO = 0, IO = 0 25°C 70 70 Ω

Common-mode rejection

ratio

Supply voltage rejection

SVR

ratio

4. Long-term drift of input offset voltage refers to the average trend line of offset voltage versus time over extended periods after the

first 30 days of operation. Excluding the initial hour of operation, changes in VIO during the first 30 days are typically 2.5 µV

(see Figure 3).

= 0, V

RS = 50 Ω, See Note 3

See Note 4 0.2 1 0.4 2 µV/mo

= 0,

O

= 0,

O

RL ≥ 2 kΩ ±12 ±13.8 ±11.5 ±13.5

RL ≥ 0.6 kΩ

RL ≥ 2 kΩ Full range ±11.5 10.5

RL ≥ 2 kΩ, VO = ±10 V 1000 1800 700 1500

RL ≥ 1 kΩ, VO = ±10 V 800 1500 1500

RL ≥ 0.6 kΩ, VO = ±1 V,

V

= ± 4 V

CC±

RL ≥ 2 kΩ, VO = ±10 V Full range 600 300

VIC = ±11 V 25°C 114 126 100 120

VIC = ±10 V

V

= ±4 V to ±18 V 25°C 100 120 94 118

CC±

V

= ±4.5 V to ±18 V Full range 96 86

CC±

= 0

=

IC

=

IC

25°C 10 25 30 100

Full range 60 300

Full range 0.2 0.6 0.4 1.8 µV/°C

25°C 7 35 12 75

Full range 50 135

25°C ±10 ±40 ±15 ±80

Full range ±60 ±150

25°C

Full range

Full range 110 94

MIN TYP MAX MIN TYP MAX

–11

10.3

–10.3

±10 ±11.5 ±10 ±1 1.5

250 700 200 500

= ±15 V (unless otherwise noted)

CC±

OP27A, OP37A OP27C, OP37C

11

to

to

3 2 GΩ

11

to

–11

10.5

to

–10.5

µ

V

V/mV

2–4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

Common-mode input voltage, V

V

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

O

,

IC

V

IIOInput offset current

V

V

0

nA

IIBInput bias current

V

0

V

0

nA

V

V

Large-signal differential

CMRR

j

dB

k

ygj

dB

recommended operating conditions

Supply voltage, V

Supply voltage, V

Operating free-air temperature, T

CC+

CC –

p

IC

A

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

V

= ±15 V, TA = 25°C ±11

CC±

V

= ±15 V, TA = – 55°C to 125°C ±10.5

CC±

MIN NOM MAX UNIT

4 15 22 V

–4 –15 –22 V

–25 85 °C

electrical characteristics at specified free-air temperature, V

A

V

p

Average temperature

αV

V

A

r

i(CM)

r

o

†

Full range is – 25°C to 85°C.

NOTES: 3. Input offset voltage measurements are performed by automatic test equipment approximately 0.5 seconds after applying power .

coefficient of input

IO

offset voltage

Long-term drift of input

offset voltage

p

p

Common-mode input

ICR

voltage range

Peak output voltage swing

OM

VD

voltage amplification

Common-mode input

resistance

Output resistance VO = 0, IO = 0 25°C 70 70 Ω

Common-mode rejection

ratio

Supply voltage rejection

SVR

ratio

4. Long-term drift of input offset voltage refers to the average trend line of offset voltage versus time over extended periods after the

first 30 days of operation. Excluding the initial hour of operation, changes in VIO during the first 30 days are typically 2.5 µV

(see Figure 3).

= 0, V

RS = 50 Ω, See Note 3

See Note 4 0.2 1 0.4 2 µV/mo

= 0,

O

,

=

O

RL ≥ 2 kΩ ±12 ±13.8 ±11.5 ±13.5

RL ≥ 0.6 kΩ

RL ≥ 2 kΩ Full range ±1 1.5 10.5

RL ≥ 2 kΩ, VO = ±10 V 1000 1800 700 1500

RL ≥ 1 kΩ, VO = ±10 V 800 1500 1500

RL ≥ 0.6 kΩ, VO = ±1 V,

V

= ± 4 V

CC±

RL ≥ 2 kΩ, VO = ± 10 V Full range 600 450

VIC = ±11 V 25°C 114 126 100 120

VIC = ±10 V

V

= ± 4 V to ±18 V 25°C 100 120 94 118

CC±

V

= ± 4.5 V to ±18 V Full range 96 90

CC±

= 0

=

IC

=

IC

25°C 10 25 30 100

Full range 60 220

Full range 0.2 0.6 0.4 1.8 µV/°C

25°C 7 35 12 75

Full range 50 135

25°C ±10 ±40 ±15 ±80

Full range ±60 ±150

25°C

Full range

Full range 110 96

MIN TYP MAX MIN TYP MAX

–11

10.3

–10.3

±10 ±11.5 ±10 ±1 1.5

250 700 200 500

= ±15 V (unless otherwise noted)

±

CC

OP27E, OP37E OP27G, OP37G

11

to

to

3 2 GΩ

11

to

–11

10.5

to

–10.5

µ

V

V/mV

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–5

OP27A, OP27C, OP27E, OP27G

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

voltage

Gain-bandwidth product

MH

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

OP27 operating characteristics over operating free-air temperature range, V

OP27A, OP27E OP27C, OP27G

MIN TYP MAX MIN TYP MAX

SR Slew rate AVD ≥ 1, RL ≥ 2 kΩ 1.7 2.8 1.7 2.8 V/µs

V

N(PP)

V

n

I

n

Peak-to-peak equivalent

input noise voltage

Equivalent input noise voltage

Equivalent input noise current

Gain-bandwidth product f = 100 kHz 5 8 5 8 MHz

f = 0.1 Hz to 10 Hz, RS = 20 Ω,

See Figure 34

f = 10 Hz, RS = 20 Ω 3.5 5.5 3.8 8

f = 30 Hz, RS = 20 Ω

f = 1 kHz, RS = 20 Ω 3 3.8 3.2 4.5

f = 10 Hz, See Figure 35 1.5 4 1.5

f = 30 Hz, See Figure 35

f = 1 kHz, See Figure 35 0.4 0.6 0.4 0.6

0.08 0.18 0.09 0.25 µV

3.1 4.5 3.3 5.6

1 2.3 1

OP37 operating characteristics over operating free-air temperature range, V

OP37A, OP37E OP37C, OP37G

MIN TYP MAX MIN TYP MAX

SR Slew rate AVD ≥ 5, RL ≥ 2 kΩ 11 17 11 17 V/µs

V

N(PP)

V

n

I

n

Peak-to-peak equivalent

input noise voltage

Equivalent input noise

Equivalent input noise current

p

f = 0.1 Hz to 10 Hz, RS = 20 Ω,

See Figure 34

f = 10 Hz, RS = 20 Ω 3.5 5.5 3.8 8

f = 30 Hz, RS = 20 Ω 3.1 4.5 3.3 5.6

f = 1 kHz, RS = 20 Ω 3 3.8 3.2 4.5

f = 10 Hz, See Figure 35 1.5 4 1.5

f = 30 Hz, See Figure 35

f = 1 kHz, See Figure 35 0.4 0.6 0.4 0.6

f = 10 kHz 45 63 45 63

AV ≥ 5, f = 1 MHz 40 40

0.08 0.18 0.09 0.25 µV

1 2.3 1

CC±

CC±

= ±15 V

= ±15 V

nV/√Hz

pA/√Hz

nV/√Hz

pA/√Hz

z

2–6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

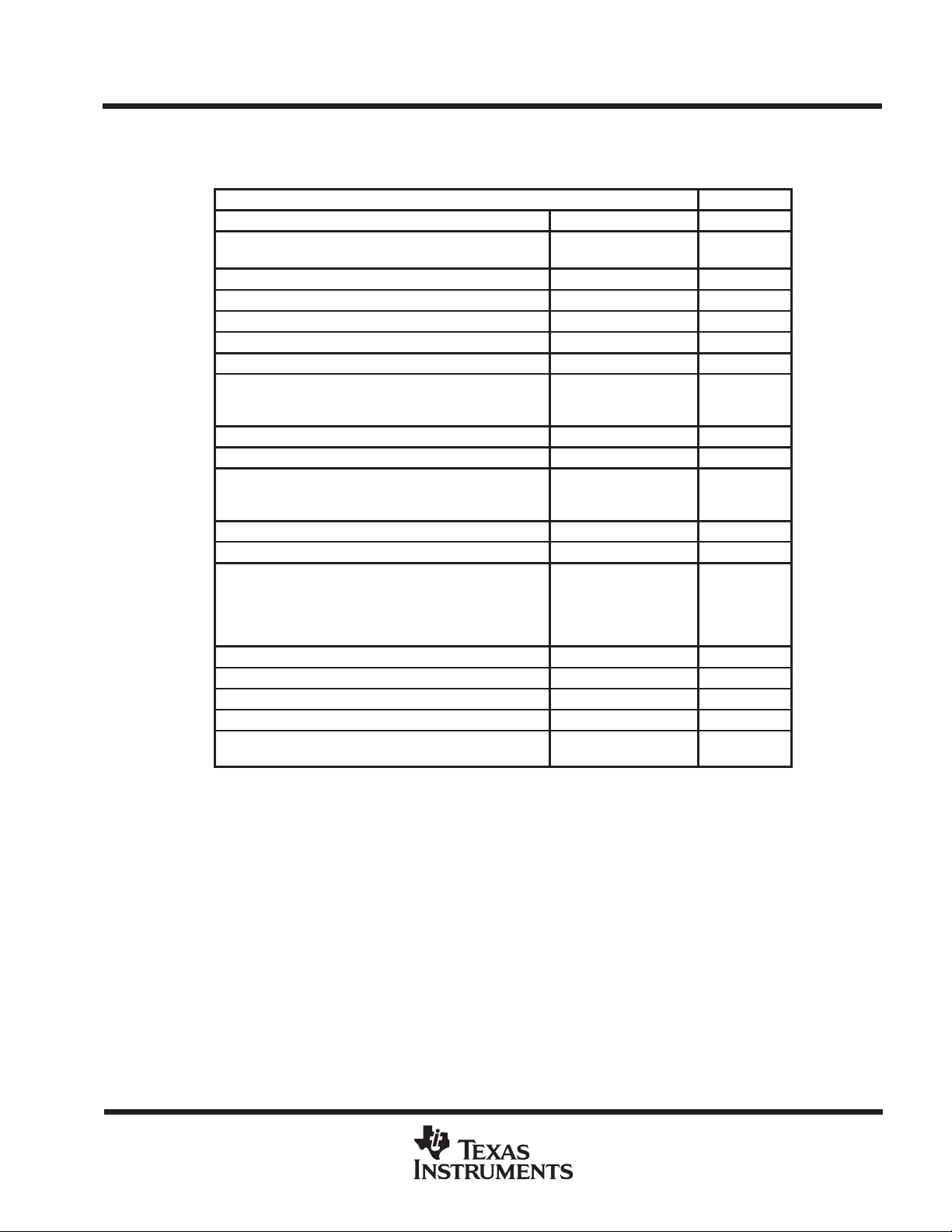

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

V

IO

∆V

I

IO

I

IB

V

ICR

V

OM

V

O(PP)

A

VD

CMRR Common-mode rejection ratio vs Frequency 15

k

SVR

SR Slew rate

φ

m

φ Phase shift vs Frequency 12, 13

V

n

I

n

I

OS

I

CC

Input offset voltage vs Temperature 1

Change in input offset voltage

IO

Input offset current vs Temperature 4

Input bias current vs Temperature 5

Common-mode input voltage range vs Supply voltage 6

Maximum peak output voltage vs Load resistance 7

Maximum peak-to-peak output voltage vs Frequency 8, 9

Differential voltage amplification

Supply voltage rejection ratio vs Frequency 16

Phase margin vs Temperature 20, 21

Equivalent input noise voltage

Equivalent input noise current vs Frequency 27

Gain-bandwidth product vs Temperature 20, 21

Short-circuit output current vs Time 28

Supply current vs Supply voltage 29

Pulse response

vs Time after power on

vs Time (long-term drift)

vs Supply voltage

vs Load resistance

vs Frequency

vs Temperature

vs Supply voltage

vs Load resistance

vs Bandwidth

vs Source resistance

vs Supply voltage

vs Temperature

vs Frequency

Small signal

Large signal

2

3

10

11

12, 13, 14

17

18

19

22

23

24

25

26

30, 32

31, 33

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–7

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

INPUT OFFSET VOLTAGE OF

REPRESENTATIVE INDIVIDUAL UNITS

vs

FREE-AIR TEMPERATURE

100

V

= ±15 V

80

60

µV

40

20

0

– 20

– 40

– Input Offset Voltage – V

IO

– 60

– 80

– 100

– 50 – 25 0 25 50 75 100 125

CC±

OP27C/37C

OP27A/37A

OP27E/37E

OP27G/37G

OP27C/37C

TA – Free-Air T emperature – °C

OP27A/37A

†

WARM-UP CHANGE IN

INPUT OFFSET VOLTAGE

vs

ELAPSED TIME

V

= ±15 V

CC±

TA = 25°C

10

OP27CP/GP

OP37CP/GP

5

OP27AP/EP

– Change in Input Offset Voltage – Vµ

IO

∆V

0

12345

Time After Power On – minutes

OP37AP/EP

Figure 1 Figure 2

LONG-TERM DRIFT OF INPUT OFFSET VOLTAGE OF

REPRESENTATIVE INDIVIDUAL UNITS

6

0.2-µV/mo Trend Line

4

2

0

– 2

– Change in Input Offset Voltage – Vµ

– 4

IO

∆V

0.2-µV/mo Trend Line

– 6

012345678

Time – months

Figure 3

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

2–8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

INPUT OFFSET CURRENT

FREE-AIR TEMPERATURE

50

V

= ±15 V

CC±

40

30

20

– Input Offset Current – nA

IO

I

10

OP27A/E

OP37A/E

0

– 75 – 50 – 25 0 50 75 100 12525

TA – Free-Air Temperature – ° C

TYPICAL CHARACTERISTICS

vs

OP27C/G

OP37C/G

†

INPUT BIAS CURRENT

FREE-AIR TEMPERATURE

± 50

V

= ±15 V

CC±

± 40

± 30

± 20

– Input Bias Current – nA

IB

I

± 10

OP27A/E

OP37A/E

0

– 50 – 25 0 50 75 100 12525

– 75

TA – Free-Air Temperature – ° C

vs

OP27C/G

OP37C/G

Figure 4 Figure 5

COMMON-MODE INPUT VOLTAGE RANGE LIMITS

vs

SUPPLY VOLTAGE

16

TA = –55°C

12

8

4

0

– 4

– 8

– 12

ICR

VICR – Common-Mode Input Voltage Range Limits – V

– 16

V

TA = 25°C

TA = 125°C

TA = – 55°C

TA = 25°C

TA = 125°C

0 ±5 ±10 ±15 ±20

V

– Supply Voltage – V

CC+

MAXIMUM PEAK OUTPUT VOLTAGE

vs

LOAD RESISTANCE

20

VCC ± = ± 15 V

18

TA = 25°C

16

Positive

14

Swing

12

10

8

6

4

– Maximum Peak Output Voltage – VV

OM

2

0

0.1 1 10

RL – Load Resistance – kΩ

Negative

Swing

Figure 6 Figure 7

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–9

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

28

24

20

16

12

8

4

– Maximum Peak-to-Peak Output Voltage – V

OPP

O(PP)

V

0

V

1 k

OP27

MAXIMUM PEAK-TO-PEAK

MAXIMUM PEAK-TO-PEAK

OUTPUT VOLTAGE

vs

FREQUENCY

28

VCC ± = ± 15 V

RL = 1 kΩ

TA = 25°C

10 k 100 k 1 M 10 M

f – Frequency – Hz

24

20

16

12

8

4

– Maximum Peak-to-Peak Output Voltage – V

OPP

O(PP)

V

0

V

10 k

Figure 8 Figure 9

OP37

OUTPUT VOLTAGE

vs

FREQUENCY

VCC ± = ± 15 V

RL = 1 kΩ

TA = 25°C

100 k 1 M 10 M

f – Frequency – Hz

OP27A, OP27E, OP37A, OP37E

LARGE-SIGNAL

DIFFERENTIAL VOLTAGE AMPLIFICATION

vs

TOTAL SUPPLY VOLTAGE

VO = ± 10 V

TA = 25°C

2000

RL = 2 kΩ

1500

RL = 1 kΩ

1000

500

– Differential Voltage Amplification – V/mV

VD

A

0

0 20304050

10

– VCC – – Total Supply Voltage – V

CC+

Figure 10 Figure 11

24002500

2200

2000

1800

1600

1400

1200

1000

– Differential Voltage Amplification – V/mV

VD

A

OP27A, OP27E, OP37A, OP37E

LARGE-SIGNAL

DIFFERENTIAL VOLTAGE AMPLIFICATION

vs

LOAD RESISTANCE

VCC ± = ± 15 V

VO = ± 10 V

TA = 25°C

800

600

400

0.1

110

RL – Load Resistance – kΩV

100

2–10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

OP27

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION AND PHASE SHIFT

vs

FREQUENCY

25

V

CC±

RL = 1 kΩ

TA = 25°C

Phase Shift

– Differential Voltage Amplification – dBA

VD

20

15

10

– 5

– 10

φm = 70°

5

0

A

VD

1

f – Frequency – Hz

10 100

Figure 12 Figure 13

= ±15 V

80°

100°

120°

140°

160°

180°

200°

220°

OP37

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION AND PHASE SHIFT

vs

FREQUENCY

60

50

40

30

20

– Phase Shift

φ

10

– Differential Voltage Amplification – dBA

0

VD

– 10

0.1

Phase Shift

A

VD

1 100

f – Frequency – MHz

V

RL = 1 kΩ

TA = 25°C

φm = 71°

10

CC±

=±15 V

80°

100°

120°

140°

160°

180°

200°

220°

– Phase Shift

φ

OP27A, OP27E, OP37A, OP37E

LARGE-SIGNAL

DIFFERENTIAL VOLTAGE AMPLIFICATION

vs

FREQUENCY

140

V

CC±

120

100

80

60

40

20

– Differential Voltage Amplification – dBA

VD

0

–20

0.1 1 10 100 1 k 10 k 1 M 100 M

f – Frequency – Hz

OP27A/E

RL = 2 kΩ

TA = 25°C

OP37A/E

Figure 14 Figure 15

= ±15 V

OP27A, OP27E, OP37A, OP37E

COMMON-MODE REJECTION RATIO

vs

FREQUENCY

140

120

100

80

OP27A/E

60

CMRR – Common-Mode Rejection Ratio – dB

40

1 k

10 k 100 k 1 M 10 M

f – Frenquency – Hz

V

VIC = ± 10 V

TA = 25°C

OP37A/E

CC±

= ±15 V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–11

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

SUPPLY VOLTAGE REJECTION RATIO

vs

FREQUENCY

160

V

= ±4 V to ±18 V

CC±

TA = 25°C

140

120

100

80

60

40

– Supply Voltage Rejection Ratio – dBk

20

SVR

0

1 10 100 1 k 10 k 100 k 1 M 10 M 100 M – 50 – 25 0 25 50 75 100 125

Negative

Supply

Positive

Supply

f – Frequency – Hz

20

18

16

14

12

10

8

6

SR – Slew Rate – V/µs

4

2

0

†

SLEW RATE

vs

FREE-AIR TEMPERATURE

V

= ±15 V

CC±

RL ≥ 2 kΩ

TA – Free Air Temperature – °C

Figure 16 Figure 17

OP37

(AVD ≥ 5)

OP27

(AVD ≥ 1)

OP37

SLEW RATE

vs

SUPPLY VOLTAGE

20

AVD = 5

RL = 2 kΩ

TA = 25°C

15

µs

10

SR – Slew Rate – V/

5

0

± 3 ± 6 ± 9 ± 12 ± 15 ± 18 ± 21

V

– Supply Voltage – V

CC±

Rise

Fall

Figure 18 Figure 19

OP37

SLEW RATE

vs

LOAD RESISTANCE

19

V

= ±15 V

CC±

AVD = 5

V

= 20 V

O(PP)

TA = 25°C

18

17

SR – Slew Rate – V/µs

16

15

0.1

1 100

f – Frequency – Hz

10

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

2–12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

PHASE MARGIN AND

GAIN-BANDWIDTH PRODUCT

FREE-AIR TEMPERATURE

85°

V

= ±15 V

80°

75°

70°

65°

60°

55°

Φ – Phase Margin

m

φ

50°

45°

40°

35°

CC±

– 75 – 50 – 25 0 50 75 100 12525

TA – Free-Air Temperature – ° C

OP27

vs

φ

m

GBW (f = 100 kHz)

TYPICAL CHARACTERISTICS

GAIN-BANDWIDTH PRODUCT

11

10.6

10.2

9.8

9.4

9

8.6

8.2

7.8

7.4

7

80°

V

75°

70°

65°

60°

55°

50°

Φ – Phase Margin

m

φ

45°

Gain-Bandwidth Product – MHz

40°

35°

30°

CC±

– 50 – 25 0 25 50 75 100 125

†

OP37

PHASE MARGIN AND

vs

FREE-AIR TEMPERATURE

= ±15 V

φ

m

GBW (f = 10 kHz)

TA – Free-Air T emperature – °C

85

80

75

70

65

60

55

Gain-Bandwidth Product – MHz

50

45

40

10

µV

1

0.1

– Equivalent Input Noise Voltage –

n

V

0.01

0.1

Figure 20 Figure 21

EQUIVALENT INPUT NOISE VOLTAGE

vs

BANDWIDTH

V

= ±15 V

CC±

RS = 20 Ω

TA = 25°C

110

Bandwidth – kHz

(0.1 Hz to frequency indicated)

100

TOTAL EQUIVALENT INPUT NOISE VOLTAGE

vs

SOURCE RESISTANCE

100

R1

R2

RS = R1 + R2

Resistor Noise Only

nV/ Hz

10

Total Equivalent Input Noise Voltage –

1

100

V

= ±15 V

CC±

BW = 1 Hz

TA = 25°C

f = 10 Hz

f = 1 kHz

RS – Source Resistance – Ω

–

+

10 k1 k

Figure 22 Figure 23

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–13

OP27A, OP27C, OP27E, OP27G

5

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

OP27A, OP27E, OP37A, OP37E

EQUIVALENT INPUT NOISE VOLTAGE

vs

TOTAL SUPPLY VOLTAGE

20

HzV

nV/

– Equivalent Input Noise Voltage –

RS = 20 Ω

BW = 1 Hz

TA = 25°C

15

10

5

n

0

010203040

V

– V

CC+

CC–

f = 10 Hz

f = 1 kHz

– Total Supply Voltage – V

†

OP27A, OP27E, OP37A, OP37E

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREE-AIR TEMPERATURE

5

V

= ±15 V

CC±

RS = 20 Ω

nV/ Hz

– Equivalent Input Noise Voltage –

n

V

BW = 1 Hz

4

3

2

1

– 50 – 25 0 25 50 75 100 12

TA – Free-Air T emperature – °C

f = 10 Hz

f = 1 kHz

10

9

8

7

nV/ HzV

6

5

4

3

2

– Equivalent Input Noise Voltage –

n

1

Figure 24 Figure 25

OP27A, OP27E, OP37A, OP37E

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREQUENCY

V

CC±

RS = 20 Ω

BW = 1 Hz

TA = 25°C

1/f Corner = 2.7 Hz

1

10 100

f – Frequency – Hz

= ±15 V

1000

EQUIVALENT INPUT NOISE CURRENT

vs

FREQUENCY

10

V

= ±15 V

1

0.1

CC±

BW = 1 Hz

TA = 25°C

10

1/f Corner = 140 Hz

100 1 k

f – Frequency – Hz

HzI

pA/

– Equivalent Input Noise Current –

n

10 k

Figure 26 Figure 27

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

2–14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

SHORT-CIRCUIT OUTPUT CURRENT

vs

ELAPSED TIME

60

V

= ± 15 V

CC±

TA = 25°C

50

I

40

30

20

– Short-Circuit Output Current – mA

OS

OS

I

I

10

012345

OS–

I

OS+

t – Time – minutes

†

SUPPLY CURRENT

vs

TOTAL SUPPLY VOLTAGE

5

4

TA = 125°C

3

– Supply Current – mA

CC

CC

I

I

2

1

515253545

V

CC+

TA = – 55°C

– V

– Total Supply Voltage – V

CC–

TA = 25°C

– Output Voltage – mV

O

V

80

60

40

20

– 20

– 40

– 60

– 80

Figure 28 Figure 29

OP27

VOLTAGE FOLLOWER

VOLTAGE FOLLOWER

SMALL-SIGNAL

PULSE RESPONSE

8

6

4

2

0

V

= ±15 V

CC±

AV = 1

CL = 15 pF

TA = 25°C

0 0.5 1 1.5 2 2.5 3

t – Time – µs

0

– 2

– Output Voltage – V

O

V

– 4

– 6

– 8

PULSE RESPONSE

024681012

OP27

LARGE-SIGNAL

VCC ± = ± 15 V

AV = – 1

TA = 25°C

t – Time – µs

Figure 30 Figure 31

†

Data for temperatures below – 25°C and above 85°C are applicable to the OP27A, OP27C, OP37A, and OP37C only.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–15

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

– Output Voltage – mV

O

V

– 20

– 40

– 60

– 80

80

60

40

20

OP37

VOLTAGE-FOLLOWER

SMALL-SIGNAL PULSE RESPONSE

0

V

= ±15 V

CC±

AV = 5

CL = 15 pF

TA = 25°C

0 0.2 0.4 0.6 0.8 1 1.2

t – Time – µs

Figure 32 Figure 33

8

6

4

2

0

– 2

– Output Voltage – V

O

V

– 4

– 6

– 8

OP37

VOLTAGE-FOLLOWER

LARGE-SIGNAL PULSE RESPONSE

V

= ±15 V

CC±

AV = 5

TA = 25°C

0123456

t – Time – µs

APPLICATION INFORMATION

general

The OP27 and OP37 series devices can be inserted directly onto OP07, OP05, µA725, and SE5534 sockets

with or without removing external compensation or nulling components. In addition, the OP27 and OP37 can

be fitted to µA741 sockets by removing or modifying external nulling components.

noise testing

Figure 34 shows a test circuit for 0.1-Hz to 10-Hz peak-to-peak noise measurement of the OP27 and OP37. The

frequency response of this noise tester indicates that the 0.1-Hz corner is defined by only one zero. Because

the time limit acts as an additional zero to eliminate noise contributions from the frequency band below 0.1 Hz,

the test time to measure 0.1-Hz to 10-Hz noise should not exceed 10 seconds.

Measuring the typical 80-nV peak-to-peak noise performance of the OP27 and OP37 requires the following

special test precautions:

1. The device should be warmed up for at least five minutes. As the operational amplifier warms up, the

offset voltage typically changes 4 µV due to the chip temperature increasing from 10°C to 20°C starting

from the moment the power supplies are turned on. In the 10-s measurement interval, these

temperature-induced effects can easily exceed tens of nanovolts.

2. For similar reasons, the device should be well shielded from air currents to eliminate the possibility of

thermoelectric effects in excess of a few nanovolts, which would invalidate the measurements.

3. Sudden motion in the vicinity of the device should be avoided, as it produces a feedthrough effect that

increases observed noise.

2–16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

APPLICATION INFORMATION

100

90

80

70

60

50

– Differential Voltage Amplification – dB

40

VD

A

30

0.01 0.1 1 10 100

f – Frequency – Hz

0.1 µF

100 kΩ

10 Ω

–

+

OP27/OP37

Device

Under

Test

NOTE: All capacitor values are for nonpolarized capacitors only.

Gain = 50,000

2 kΩ

Voltage

4.7 µF

Figure 34. 0.1-Hz to 10-Hz Peak-to-Peak Noise Test Circuit and Frequency Response

LT1001

+

–

24.3 kΩ

100 kΩ

0.1 µF

4.3 kΩ

2.2 µF

22 µF

Oscilloscope

Rin = 1 MΩ

110 kΩ

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–17

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

APPLICATION INFORMATION

When measuring noise on a large number of units, a noise-voltage density test is recommended. A 10-Hz

noise-voltage density measurement correlates well with a 0.1-Hz to 10-Hz peak-to-peak noise reading since

both results are determined by the white noise and the location of the 1/f corner frequency.

Figure 35 shows a circuit measuring current noise and the formula for calculating current noise.

10kΩ

100 Ω 500 kΩ

500 kΩ

–

+

V

no

In =

[V

no

2

– (130 nV)2]

1 MΩ × 100

1/2

Figure 35. Current Noise Test Circuit and Formula

offset voltage adjustment

The input offset voltage and temperature coefficient of the OP27 and OP37 are permanently trimmed to a low

level at wafer testing. However, if further adjustment of V

as shown in Figure 36 does not degrade the temperature coefficient α

creates an α

of VIO/300 µV/°C. For example, if VIO is adjusted to 300 µV, the change in α

VIO

The adjustment range with a 10-kΩ potentiometer is approximately ±2.5 mV. If a smaller adjustment range is

needed, the sensitivity and resolution of the nulling can be improved by using a smaller potentiometer in

conjunction with fixed resistors. The example in Figure 37 has an approximate null range of ±200 µV.

10 kΩ

15 V

1

2

8

Input

–

3

+

–15 V

7

6

Output

4

Figure 36. Standard Input Offset

Voltage Adjustment

is necessary , using a 10-kΩ nulling potentiometer

IO

Input

. Trimming to a value other than zero

VIO

VIO

4.7 kΩ

1 kΩ

15 V

4.7 kΩ

1

2

3

–15 V

8

7

6

Output

4

is 1 µV/°C.

Figure 37. Input Offset Voltage Adjustment With

Improved Sensitivity

offset voltage and drift

Unless proper care is exercised, thermoelectric effects caused by temperature gradients across dissimilar

metals at the contacts to the input terminals can exceed the inherent temperature coefficient ∝V

amplifier. Air currents should be minimized, package leads should be short, and the two input leads should be

close together and at the same temperature.

2–18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

of the

IO

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

APPLICATION INFORMATION

offset voltage and drift (continued)

The circuit shown in Figure 38 measures offset voltage. This circuit can also be used as the burn-in configuration

for the OP27 and OP37 with the supply voltage increased to 20 V, R1 = R3 = 10 kΩ, R2 = 200 Ω, and

A

= 100.

VD

R1

50 kΩ

15 V

R2

100 Ω

R3

50 kΩ

2

3

–

+

–15 V

7

6

4

VO = 1000 V

IO

NOTE A: Resistors must have low thermoelectric potential.

Figure 38. Test Circuit for Offset Voltage and Offset Voltage

Temperature Coefficient

unity gain buffer applications

The resulting output waveform, when R

is shown in the pulsed-operation diagram in Figure 39.

R

f

–

+

OP27

During the initial (fast-feedthrough-like) portion of the output waveform, the input protection diodes effectively

short the output to the input, and a current, limited only by the output short-circuit protection, is drawn by the

signal generator. When R

≥ 500 Ω, the output is capable of handling the current requirements (load

f

current ≤ 20 mA at 10 V), the amplifier stays in its active mode, and a smooth transition occurs. When

R

> 2 kΩ, a pole is created with Rf and the amplifier’s input capacitance, creating additional phase shift and

f

reducing the phase margin. A small capacitor (20 pF to 50 pF) in parallel with R

≤ 100 Ω and the input is driven with a fast large-signal pulse (> 1 V),

f

2.8 V/µs

Output

Figure 39. Pulsed Operation

eliminates this problem.

f

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

2–19

OP27A, OP27C, OP27E, OP27G

OP37A, OP37C, OP37E, OP37G

LOW-NOISE HIGH-SPEED PRECISION OPERATIONAL AMPLIFIERS

SLOS100B – FEBRUARY 1989 – REVISED AUGUST 1994

APPLICATION INFORMATION

120

100

80

60

40

Noise Voltage – nV

20

0

0246

t – Time – seconds

810

Type S Thermocouples

5.4 µV/°C at 0°C

+

#1

–

+

#2

–

+

#24

–

NOTE A: If 24 channels are multiplexed per second and the output is required to settle to 0.1 % accuracy, the amplifier’s bandwidth cannot be

limited to less than 30 Hz. The peak-to-peak noise contribution of the OP27 will still be only 0.1 1 µV, which is equivalent to an error

of only 0.02°C.

To Gate

Drive

Typical

Multiplexing

FET Switches

Cold-Junction

Circuitry

+

–

AVD = 10,000

+

OP27

–

0.05 µF

High-Quality

Single-Point Ground

Output

100 kΩ

10 Ω

Figure 40. Low-Noise, Multiplexed Thermocouple Amplifier and 0.1-Hz To 10-Hz

Peak-to-Peak Noise Voltage

2–20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...